Patents

Literature

203results about How to "Shorten firing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature fast-fired ceramic tile and production process thereof

ActiveCN103693942AReduce burning energy consumptionReduce energy consumptionCeramic materials productionClaywaresBrickFiltration

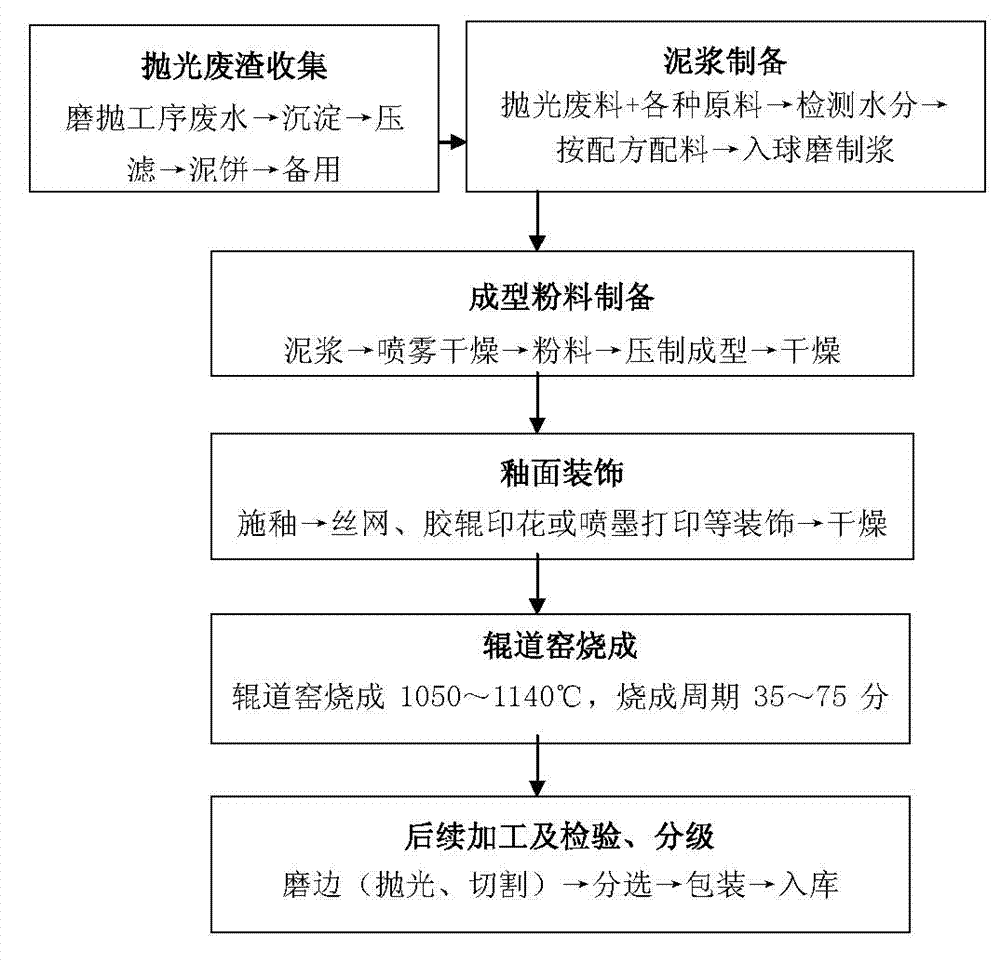

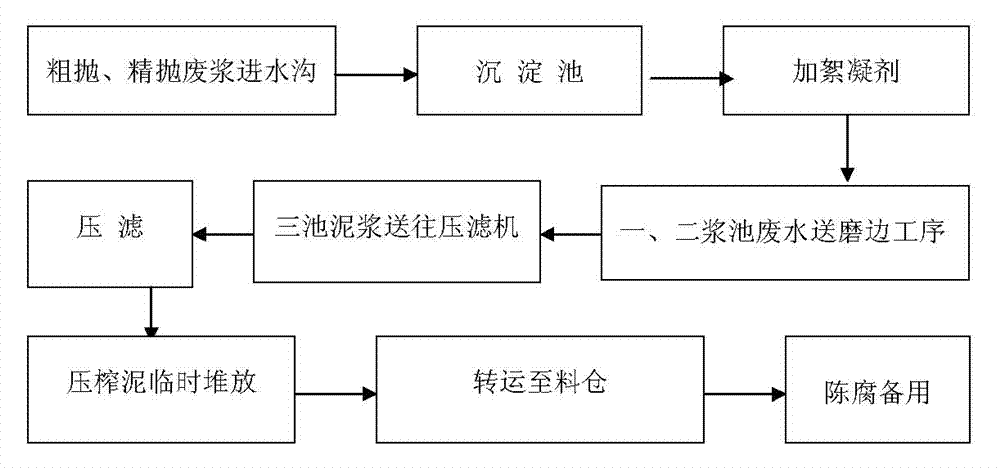

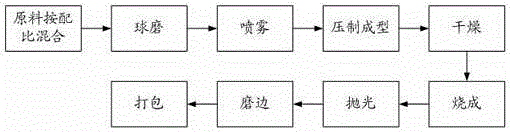

The invention relates to a low-temperature fast-fired ceramic tile and a production process thereof. The blank material of the ceramic tile comprises at least one selected from the group consisting of fine granules produced during grinding and polishing in production of polished tiles, fine granule-containing waste water collected after polishing and a waste polishing material obtained after deposition and press filtration; the blank material of the ceramic tile is composed of, by weight, 48 to 73% of the waste polishing material, 5 to 20% of porcelain sand, 20 to 27% of clay and 2 to 5% of a mineralizer. The production process comprises the following steps: (1) collecting the waste polishing material, carrying out batching according to a formula and then carrying out wet ball milling so as to obtain slurry, wherein the waste polishing material stood for subsequent usage in press filtration and other raw materials are calculated on a dry basis; (2) subjecting the slurry to spray drying so as to obtain powder and carrying out dry-pressing so as to form a ceramic adobe; (3) drying the adobe, glazing the adobe and carrying out surface decoration; and (4) putting a decorated blank into a ceramic roller kiln for firing, wherein fast firing temperature is 1050 to 1140 DEG C, a firing period is 35 to 75 min, and the ceramic tile with a water absorption rate of less than 0.5% is sintered.

Owner:GUANGDONG JIA MEI CERAMIC

Single-layer glazed transmutation brick and preparation method thereof

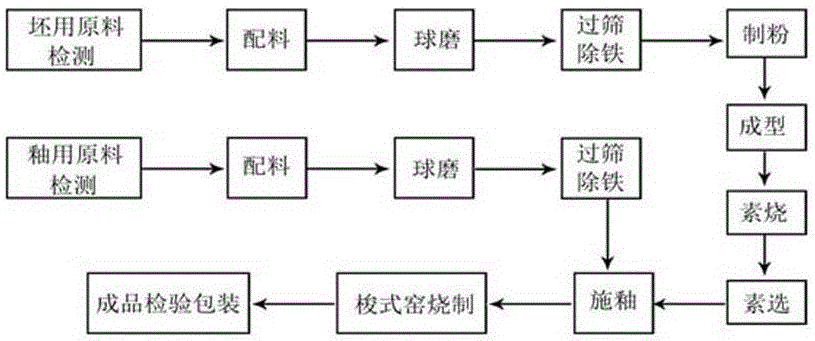

The invention discloses a single-layer glazed transmutation brick and a preparation method thereof and relates to production of architectural ceramic glazed bricks. The method comprises the following steps: (1) preparation of green body slurry; (2) preparation of a glazing material; (3) forming and biscuit firing of a green body; (4) glazing of the green body; (5) firing of the transmutation brick. The glazed green body is fired in a kiln after drying and is subjected to a transmutation reaction through two times of temperature increasing and decreasing, and the single-layer glazed transmutation brick is obtained. The method has the advantages as follows: firstly, the problem about combination of the green body and glaze is solved, the product qualification rate is increased, and the method is suitable for large-scale production; secondly, a ground coat and cover glaze are combined into single glaze layer, a glazing process is simplified, color difference caused by different thickness of the ground coat and the cover glaze is avoided, and the brick can adapt to large-area paving for architectural decoration; thirdly, the firing temperature and firing time for the transmutation glaze are reduced, energy is saved, and consumption is reduced; fourthly, through optimization of a green body formula and a firing process, the brick is magnetized while is not hardened too much, and construction cutting is facilitated.

Owner:JIANGXI GANXIN CRAFT CERAMICS CO LTD

Process for producing super thin ceramic polished brick using ceramic polished waste slag or ceramic waste material

The technological process of producing polished super thin ceramic tile with waste ceramic material includes the following steps: superfine treating the waste ceramic material and other material; drying the superfine powder; forming, baking and polishing. The present invention has the beneficial technological effects of no special requirement on the material, and the superfine processing of the material resulting in fast heat transferring speed in the baking course, short baking period and lowered power consumption. The present invention solves corresponding environment pollution problem.

Owner:毕舒

Technical method for manufacturing ultrathin ceramic bricks

The present invention relates to a process for producing ultrathin ceramic tile, said process includes the following steps: making the raw material for producing ceramic tile undergo the process of ultramicrorefining treatment by means of ultrafniing equipment, drying ultramicrorefined powder body press-moulding the dried powder body, firing and polishing so as to obtain the invented finished product.

Owner:毕舒

Low-temperature metal ceramic blinder grinding wheel and production method thereof

InactiveCN103753410ALower sintering temperatureLow costAbrasion apparatusGrinding devicesWaste productGrinding wheel

The invention relates to a low-temperature metal ceramic blinder grinding wheel and a production method thereof. The production method includes the steps of 1, producing low-melting-point ceramic, namely proportionally mixing materials of the low-melting-point ceramic by a dilution method, smelting for 1-3 hours at the temperature of 1200-1300 DEG C, quenching, crushing to 2-5 micrometers by a ball mill, drying, and screening with a 200-mesh screen to obtain the low-melting-point ceramic for use; 2, mixing low-melting-point metal and the low-melting-point ceramic according to a specified proportion, and mixing obtained mixture with abrasive material; 3, forming, namely, weighing required forming material, evenly pouring the forming material into a grinding tool, leveling down, forming by pressing at the temperature of 120-200 DEG C for 30-90 minutes, and releasing; 4, sintering: placing the grinding tool in a program-thermostatic oven, sintering for two hours, and cooling; 5, checking whether waste products are present in the production process or not, so as to obtain the low-temperature metal ceramic blinder grinding wheel. The low-temperature metal ceramic blinder grinding wheel has the advantages that energy resources are saved and sintering fuel cost is reduced.

Owner:威海无缝新材料有限公司

Glaze composition

The invention provides a glaze composition and belongs to the technical field of ceramic products. The glaze composition is prepared from the following raw materials in parts by weight: 7 to 10 parts of Longyan kaolin, 38 to 42 parts of potassium feldspar, 25 to 30 parts of quartz, 18 to 22 parts of wollastonite, 0.5 to 2 parts of bone ash and 1.02 to 2.1 parts of pigment. The glaze provided by the invention has high viscosity and low flowability in a firing process and the defects that the thickness of a glaze surface is not uniform and the color is not uniform, caused by glaze flowing and glaze stacking, are avoided; a firing method of the glaze provided by the invention has a high reduction temperature point and a relatively wide high-temperature firing temperature range; the yield of a product is easy to guarantee; furthermore, a ceramic product fired by the invention has high glaze surface glossiness, pure color, beautiful appearance and long implication.

Owner:JINGDEZHEN CERAMIC INSTITUTE

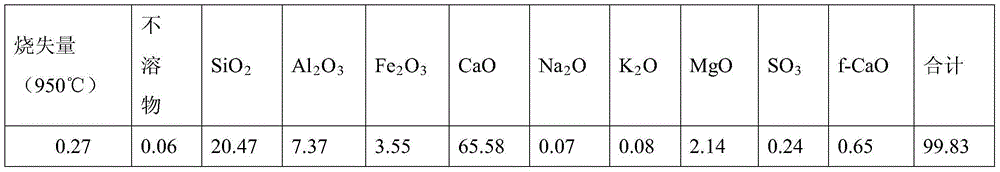

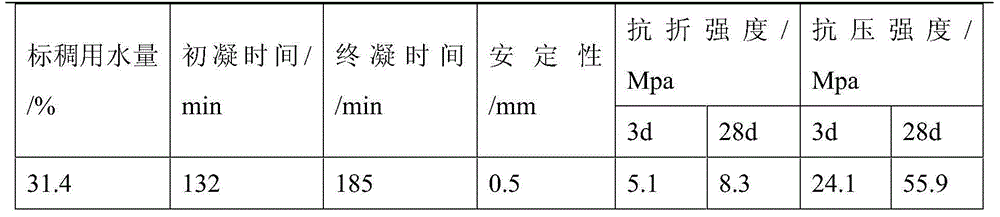

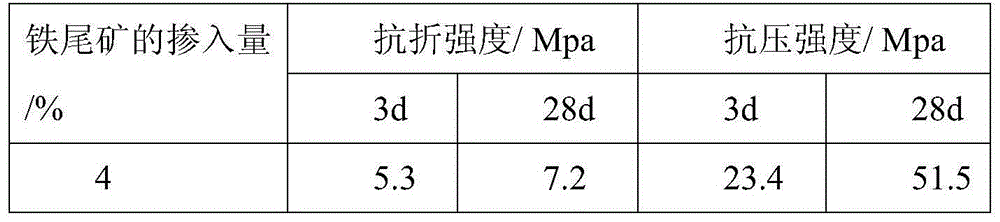

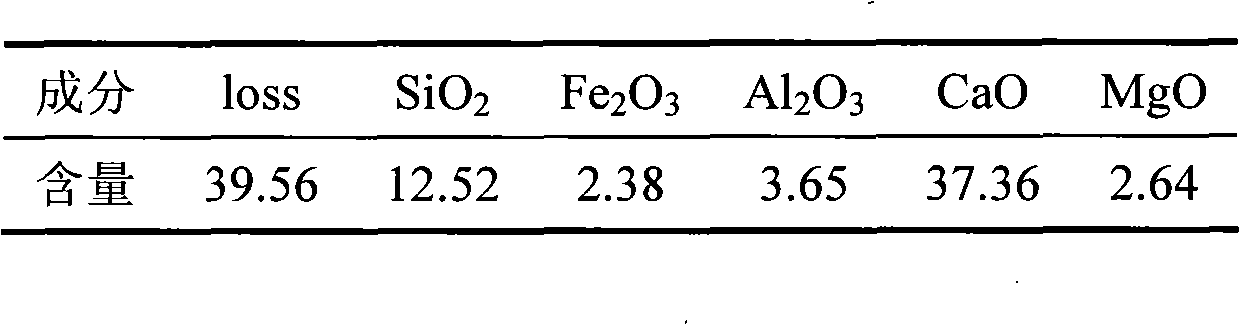

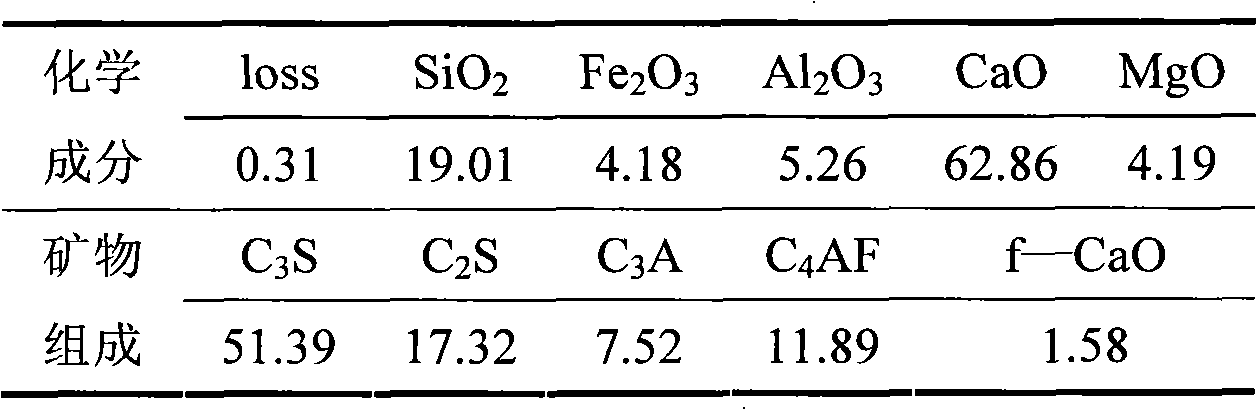

Preparation method for Portland cement with iron tailings

The invention provides a preparation method for Portland cement with iron tailings. The Portland cement comprises at least the following raw materials in percentage by weight: 60-70% of calcium oxide, 12-20% of silicon oxide, 5-20% of the iron tailings and 3-6% of aluminium oxide. The preparation method comprises the following steps: weighing the raw materials according to the mass ratio, and mixing uniformly and fine grinding the weighed raw materials; calcining the fine grinded raw materials in a high-temperature furnace, and drawing out and quenching the calcined raw materials to obtain clinkers; adding the iron tailings to the clinkers, mixing uniformly mixtures of the iron tailings and the clinkers, and fine grinding the mixtures to obtain the Portland cement with the iron tailings, wherein the mass of the added iron tailings is 1-8% of the total mass of the clinkers. The method provided by the invention can effectively use the iron tailings as raw materials for production to prepare the Portland cement with excellent quality, so that the deficiencies in the prior art can be overcome, the use of the iron tailings can be maximized, and the purposes of saving resources, reducing the production cost, protecting environment and the like can be realized.

Owner:北海诚钢矿业股份有限公司

Preparation method of black pottery artware

The purpose of the invention is to provide a preparation method of a black pottery artware. First, blank material yellow clay is selected, and processes of crushing, deposition, mud extruding, and fermentation are carried out on the yellow clay to obtain black pottery mud. Then, moulding processing is carried out on the black pottery raw material, and after the processes of shade drying, shape modification, polishing, painting, engraving, polishing once again and shade drying are carried out on an unburned earthenware body, surface treatment is carried out on the unburned earthenware body. Finally, the unburned earthenware body is put into a kiln special for black pottery sintering to carry out sintering, and the sintering process comprises preheating, heating, cooling, smoke drawing, kiln closing, and kiln moistening. In sintering, both the surface and the interior of the unburned earthenware body of the black pottery artware sintered in the invention can be carbonized uniformly, and present a black color. Fine channels favor the penetration of soot, so that the black pottery artware is pitch black and bright from inside to outside, has a natural, smooth, and non-fading color, and has no peculiar smell of asphalt or impurities. In addition, the preparation method of the invention has short sintering time, and saves both energy and labor.

Owner:苏兆起

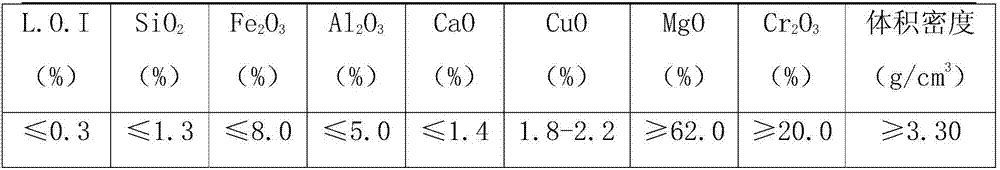

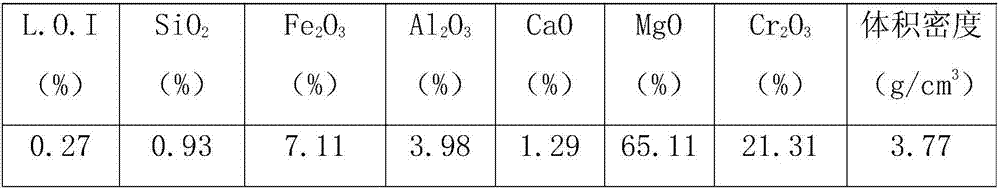

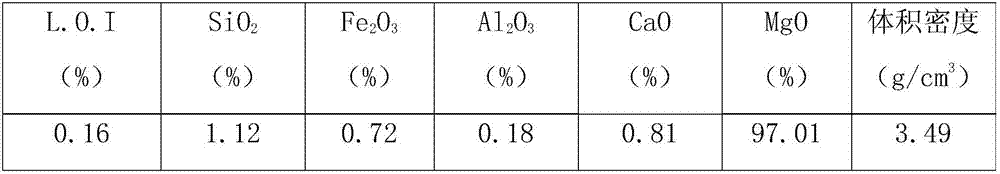

Copper composite high-performance magnesia-chrome brick and manufacturing method thereof

The invention belongs to the technical field of refractory materials, especially refractory materials for nonferrous smelting, and especially relates a copper composite high-performance magnesia-chrome brick and a manufacturing method thereof. The brick comprises 1-10 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 3-5 mm, 10-35 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 1-3 mm, 10-25 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 0.088-1 mm, 1-5 wt% of fused magnesia-chrome sands with the particle size being 3-5 mm, 1-15 wt% of fused magnesia-chrome sands with the particle size being 1-3 mm, 2-13 wt% of fused magnesia-chrome sands with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia-chrome sands with the particle size being not more than 0.088 mm, 1-5 wt% of fused magnesia with the particle size being 3-5 mm, 1-15 wt% of fused magnesia with the particle size being 1-3 mm, 2-13 wt% of fused magnesia with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia with the particle size being not more than 0.088 mm, 2-10 wt% of chromium concentrate with the particle size being not more than 0.088 mm, 1-6 wt% of a composite additive and 3-5 wt% of an (externally added) binder. Magnesia-chrome brick wastes generated by the nonferrous smelting can be fully used reasonably and effectively in the invention.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

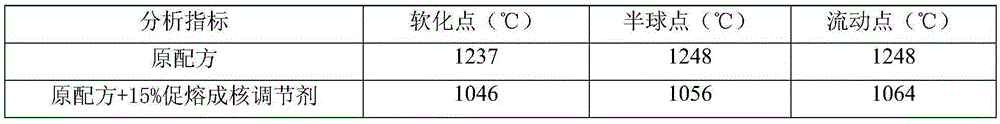

Microcrystalline material fluxing nucleating agent and preparation method thereof

InactiveCN105417950AGuaranteed mutual coordinationLower melting temperatureGlass shaping apparatusSulfurBoron

The invention relates to a microcrystalline material fluxing nucleating agent, which is composed of a base mineral raw material and a regulator mineral raw material. Specifically, the base mineral raw material accounts for 50%-80% of the total mass of the nucleating agent, the regulator mineral raw material accounts for 20%-50% of the total mass of the nucleating agent, and the sum of the two is 100%. The regulator mineral raw material comprises chambersite, manganese boron and sulfur stone, and other mineral raw materials. The composite microcrystalline material fusion promoting nucleating regulating agent prepared by the method provided by the invention can greatly reduce the firing temperature of traditional ceramic glazes, glaze materials or novel microcrystalline ceramics by 100DEG C-200DEG C, and reduce the melting temperature of microcrystalline glass or traditional glass raw materials by 150DEG C-200DEG C.

Owner:HEBEI UNIV OF TECH

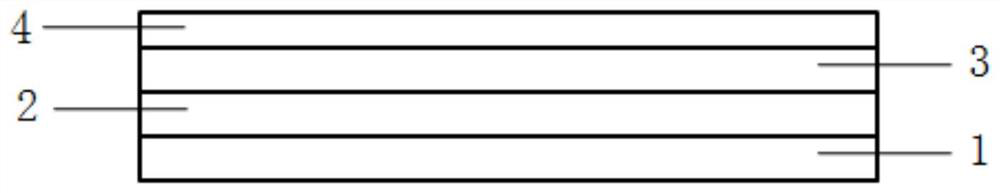

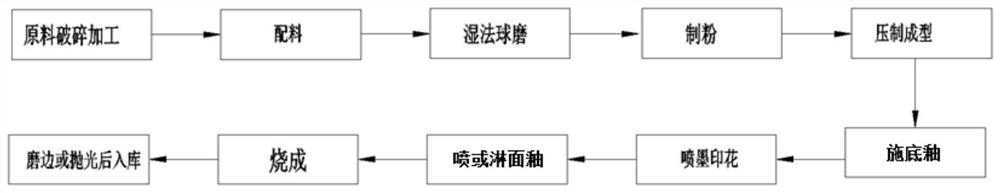

Ceramic rock plate prepared from wollastonite tailings through ultralow-temperature fast firing and manufacturing method of ceramic rock plate

InactiveCN114163213AHigh whitenessReduce intensityCeramic materials productionClaywaresWollastonitePotassium feldspar

The invention discloses a ceramic rock plate prepared from wollastonite tailings through ultralow-temperature fast firing and a manufacturing method, the ceramic rock plate comprises a green body, and the green body comprises the following raw material components in parts by weight: 25-45 parts of wollastonite tailings, 10-50 parts of clay, 5-15 parts of potassium feldspar and albite, 10-20 parts of quartz, 0-5 parts of zirconium silicate, 2-10 parts of a mineralizing agent, 0-1.0 part of a dispergator and 0-1.0 part of a reinforcing agent. According to the invention, the wollastonite tailings are introduced into the formula of the ceramic rock plate blank, so that an ultralow-temperature fast firing process with the firing temperature of 1000-1100 DEG C and the firing period of 35-50 minutes can be realized, and the firing temperature and the firing time are greatly reduced; the high-proportion wollastonite tailings are introduced into the formula of the ceramic rock plate blank, so that the whiteness of the blank can be improved and reaches 50 degrees or above, and the ceramic rock plate blank can be well applied to development and production of various rock plate products; in addition, the wollastonite tailings are introduced to replace a large amount of expensive mud and sand raw materials, so that the production cost of the ceramic rock plate product is reduced.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +1

Light-weight high-temperature mullite refractory brick prepared from pulverized fuel ash

The invention discloses a light-weight high-temperature mullite refractory brick prepared from pulverized fuel ash. The light-weight high-temperature mullite refractory brick comprises the following raw materials: 40-50% of pulverized fuel ash, 25-35% of clay, 10-20% of aluminite powder, 7-8% of coal gangue, 1-2% of polystyrene, and 0.5-1.5% of saw dust. The light-weight high-temperature mullite refractory brick is prepared through the following steps: (1) weighing pulverized fuel ash, clay, aluminite powder, coal gangue, polystyrene and saw dust according to the proportion of the raw materials formulations; (2) grinding weighed coal gangue into powder, and mixing, adding water into, stirring the raw materials formulations into slurry, wherein the water addition is 23-25%; (3) placing the slurry as a product into a die to be subjected to compression moulding; (4) sending the compressed green body to a dry kiln to be dried, wherein the temperature is 100-150 DEG C, and the water content is 2-7%; (5) sending the dried green body in a tunnel kiln, and calcining for 38-42 minutes at the high temperature of 1,200-1,400 DEG C; and (6) cutting the calcined green body to form a finished product. The mullite refractory brick is energy-saving and is high in heat preservation efficiency.

Owner:SHUOZHOU SHUOXIANG CERAMICS

Porcelain grey tile without carburization and sintering method thereof

InactiveCN102826833ASave clay resourcesNo crackingCeramic materials productionClaywaresMulti materialDrying time

A porcelain grey tile without carburization and a sintering method thereof. Bauxite, purple sand, clay, and gas stove coal cinder are mixed, added with water to prepare a green body, and then the porcelain grey tile without carburization is sintered under a certain temperature condition. According to the invention, a mixture of multiple materials is used instead of pure clay for sintering, which saves clay resources; the green body does not crack when a lot of water is lost within a short period, which greatly shortens the drying time of the green body; during high temperature sintering, carbon particles are generated in raw coal reactions of generator gas and gas stove coal cinder, and colorize the inner and outer sides of the green body, which omits the colorization and color preservation processes in the prior art, shortens the process flow, increases the sintering efficiency, and saves energy.

Owner:HENAN YANSHI CLASSICAL GARDENS

Heat pressing burnt carbon brick for lining and hearth of iron smelting blast furnace

ActiveCN1752218AReduce energy consumptionImprove thermal conductivityBlast furnace componentsBlast furnace detailsBrickSilicon oxide

A carbon brick used for the liner and inner box of blast furnace is proportionally prepared from electrically calcined anthracite, natural graphite, artificial graphite, metallic silicon, silicon oxide, aluminium oxide and high-temp asphalt through crushing, grinding, proportional mixing, kneading, loading it in mould, pressing for shaping, electric heating at 800-1100 deg.C while pressing under 30-50 MPa, and conventional trimming. Its advantage is short calcining time.

Owner:河南远洋新材料技术有限公司

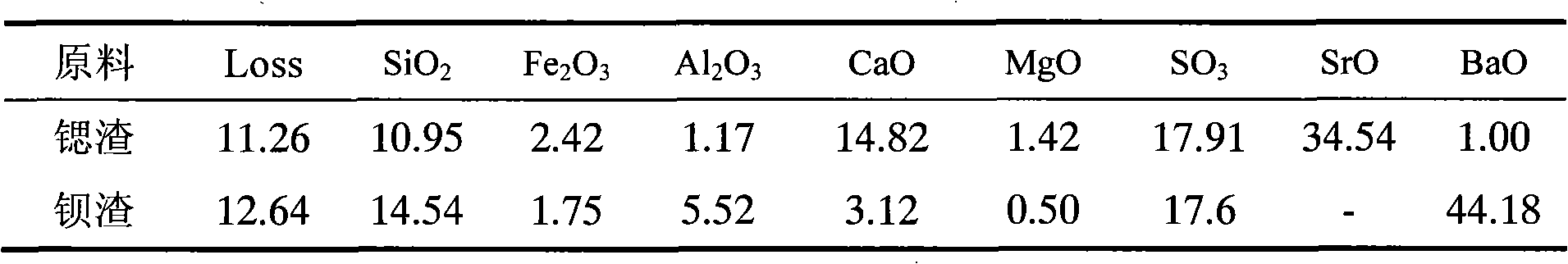

Strontium-barium cement calcination composite mineralizer

The invention relates to a strontium-barium cement calcination composite mineralizer, which is mainly made of strontium slag and barium slag, wherein both the weight percentage of the strontium slag and the weight percentage of the barium slag are 15 to 85 percent; the strontium slag is waste residue for producing strontium carbonate, and the weight percentage of SrO is required to be 25 to 40 percent; and the barium slag is waste residue for producing barium carbonate, and the weight percentage of BaO is required to be 20 to 50 percent. The invention utilizes the strontium slag and the barium slag as raw materials to synthesize the composite mineralizer, and achieves the aims of improving the cement strength, accelerating the hydrating and hardening of cement, improving the yield of kilns, reducing the cement cost, saving energy and resources, and reducing environmental pollution through the activation and mineralization of the composite mineralizer during the calcination of cement clinker.

Owner:UNIV OF JINAN

Method for preparing foamed ceramic by microwave sintering of cobalt smelting waste slag

InactiveCN109553393AMass consumptionSolve environmental problemsCeramic materials productionCeramicwareHigh energySlag

The invention belongs to the technical field of resource utilization of solid wastes, and particularly relates to a method for resource utilization of cobalt smelting waste slag. The invention provides the method for preparing foamed ceramic by microwave sintering of the cobalt smelting waste slag. The method comprises the following steps: carrying out proportioning by using the cobalt smelting waste slag, filler, a liquid phase agent, a plasticizer and a foaming agent, carrying out grinding, mixing, granulating, and mold pressing or mold powder accumulation to prepare a green body; and carrying out microwave sintering to prepare the foamed ceramic. The microwave heating method is adopted, and compared with a conventional electric heating or fuel heating mode, the microwave heating methodhas the advantages that the foaming temperature is greatly reduced, the foaming time is shortened, and therefore energy consumption is greatly reduced. According to the method, the problems of high energy consumption in existing formed ceramic industry and high additional value comprehensive utilization of the cobalt smelting waste slag are solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

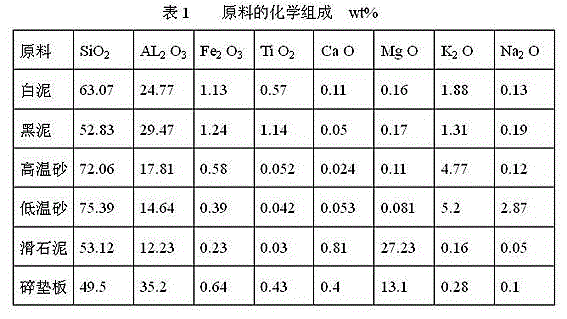

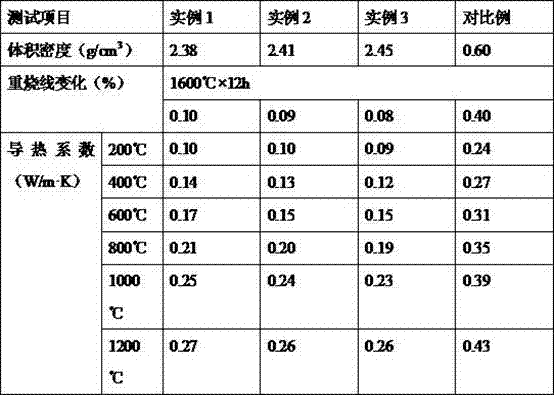

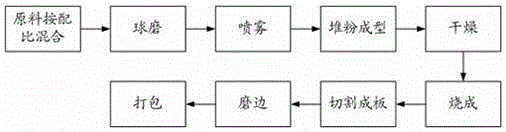

Production method of ultrathin outer wall full-body brick

The invention discloses a production method of an ultrathin outer wall full-body brick, relating to the technical field of architectural ceramics manufacturing. The ultrathin outer wall full-body brick is produced from the following raw materials in percentage by weight: 20% of white mud, 8% of black mud, 6% of high-temperature sand, 40% of low-temperature sand, 8% of talc mud and 18% of broken cushion board. The production method comprises the following steps of: mixing the raw materials, ball-milling the mixture in a ball mill, sieving the slurry, spraying the sieved slurry into powder by using a spray drying tower, and ageing the powder for later use; dry-pressing the powder into a green body with 4.1-4.2 mm in thickness by using a large-tonnage press; and placing the green body on a cushion board through a vacuum absorber, sending the green body placed on the cushion board together with the cushion board into a roller kiln to fire, controlling the firing temperature within the range of 1190 DEG C to 1230 DEG C, and firing the green body for 60 min to obtain the finished product. Compared with the prior art, the breaking strength of the ultrathin outer wall full-body brick is 500 N and meets the requirement that the average breaking strength in the standard Ceramic Thin Brick for Outer Wall is greater than or equal to 350 N.

Owner:岑溪市新建球陶瓷有限公司

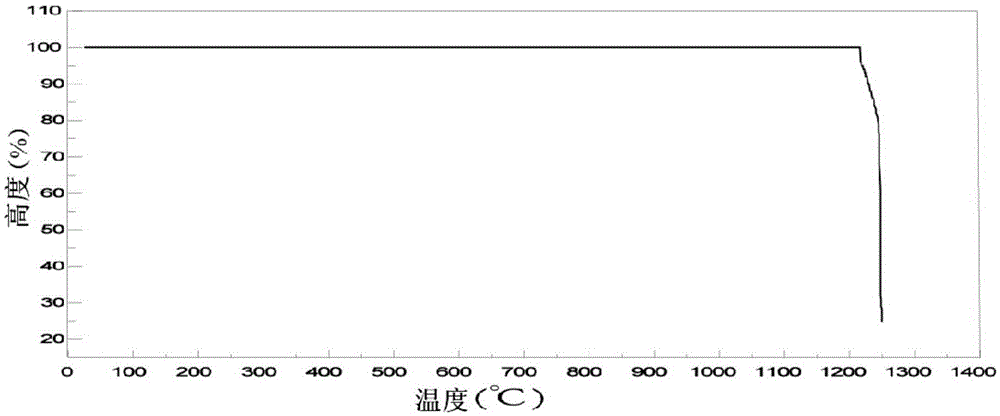

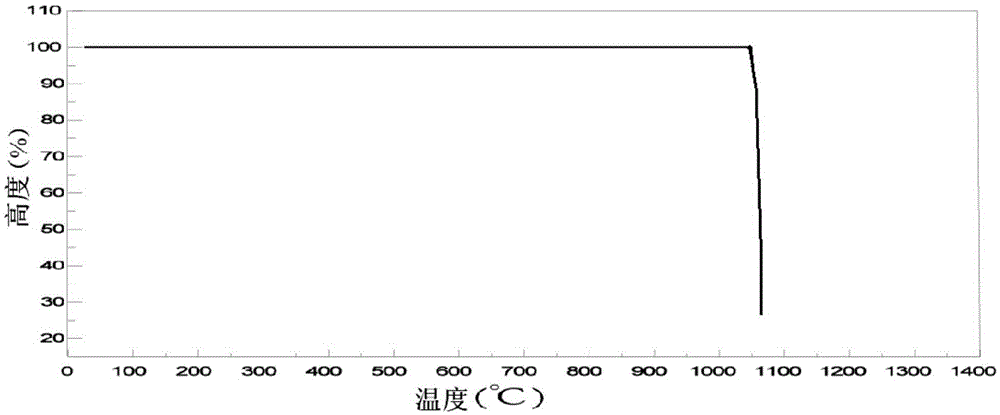

Air brick fired at low temperature by using gel and preparation process thereof

The invention relates to an air brick fired at low temperature by using a gel and a preparation process of the air brick. The raw materials of the air brick include an aggregate and a fine powder, wherein the weight ratio of the aggregate to the fine powder is 6.5:3.5-7:3; the alumina gel fine powder is used as a binding agent; due to the addition of the alumina gel particle having quite high chemical activity into the air brick in the firing process of the air brick at the temperature being lower than 800 DEG C, the air brick body has high strength; the addition of chromium sesquioxide fine powder can effectively improve the capacities of resisting the permeability of molten steel and the erosion by the steel slag in the use process of the air brick, so as to ensure the good application performance of the air brick; and the firing temperature of the air brick provided by the invention is controlled at 500-800 DEG C, but the firing temperature of a traditional air brick is generally higher than 1300 DEG C, and therefore, the cost of the fuel gas can be saved by about 60% and the firing time can be shortened by about 50%.

Owner:洛阳利尔功能材料有限公司

Method for preparing yellow phosphorus scrap porous ceramic material

InactiveCN101289331AAchieve reuseReduce manufacturing costCeramic shaping apparatusCeramic materials productionSlagUltimate tensile strength

The invention provides a preparation method of yellow phosphorus slag lacunaris ceramic material, which takes solids waste, yellow phosphorus slag, as the main raw material; charcoal dust is used as a pore-forming agent and is added in a certain amount of bonding agent. The preparation method of the lacunaris ceramic is as follows: the raw materials are mixed evenly and dried at the temperature of 105 DEG C for 30 minutes and then are processed by pressing, baked at the temperature of 1000 to 1400 DEG C and preserved heat to make the lacunaris ceramics. The result shows that the porosity of the sample is 29.03 to 51.46 percent; water absorbing capacity is 20.02 to 39.28 percent; the volume density is 1.15 to 1.89 g / cm<3>; the pressive strength is 2.07 to 9.86 MPa. The lacunaris ceramics has the advantages of good connectedness, even aperture distribution, which makes good use of solids waste and reduces production cost.

Owner:GUIZHOU UNIV

Preparation method for heat-insulating type compact silicon brick

The invention relates to the technical field of a refractory material and specifically relates to a preparation method for a heat-insulating type compact silicon brick. The quartz is modified with peach gum under the effect of microorganisms and the macromolecular monosaccharide decomposed from the peach gum is grafted onto the rock wool surface, so that the adhesiveness of the quartz and the rockwool is promoted; the mineralizing agents, including silicon nitride, ferroferric oxide, calcium oxide and aluminum oxide, are added, so that the transformation of the quartz can be accelerated, thesintering temperature is reduced, the sintering time is shortened, the silicon brick interior is effectively filled, a heat-insulating effect is achieved and the compactness and the heat insulation ofthe silicon brick are promoted; the ethyl orthosilicate, hydrochloric acid, absolute ethyl alcohol and deionized water are mixed and reacted for generating a self-prepared silica sol; a silane coupling agent KH-560 is used for modifying the self-prepared silica sol, so that the silicon dioxide is effectively filled into the silicon brick, the surface property and the reaction activity can be effectively improved, the porosity of the silicon brick can be reduced, the compactness and the heat insulation of the silicon brick can be further promoted and the application prospect is wide.

Owner:陈合华

Manufacturing method of light-permeable ceramic colored glaze

The invention discloses a manufacturing method of light-permeable ceramic colored glaze. The method comprises the steps that A, a ceramic body is prepared; B, the surface of the ceramic body prepared in the step A is colored and glazed. The step A comprises the following substeps of ingredient preparation, ball milling, sieving for iron removal, clay pressing, clay preparation, aging, refining and wet blank forming, drying, washing and renovation, biscuit firing at the temperature of 750-850 DEG C, fine trimming, dry blank forming, and the ceramic body is obtained. The step B comprises the following substeps that 1, raw materials are treated, wherein 65-75% by weight of volcano slime and 25-35% by weight of albite are used as base materials, the base materials and water are poured into a ball mill to be subjected to ball milling for 2+ / -0.1 h, sieving is carried out, and glaze slip is obtained; 2, the ceramic body is evenly coated with the glaze slip in a glaze soaking or glaze spraying or coating mode, and then the ceramic body is dried; 3, the ceramic body coated with the glaze slip is placed into a kiln to be heated to 1280-1350 DEG C, the temperature is kept, and firing is carried out for 0.5-1 h, so that the reddish brown light-permeable ceramic colored glaze is obtained.

Owner:FUJIAN WANQI SANDT CERAMICS CO LTD

Method for preparing high-purity tabular corundum with low energy consumption

InactiveCN102617118AShorten firing timeSave burning energyHydroxypropylmethyl celluloseMethyl cellulose

The invention provides a method for preparing high-purity tabular corundum with low energy consumption. The method comprises the following steps of: adding an additive to industrial alumina powder serving as raw material, wherein the additive is composed of boric acid and aluminum fluoride according to a mass ratio being 0.5-1.5:1 and is used for removing impurities out of alumina powder; mixing and grinding, adding hydroxypropyl methyl cellulose and water and preparing into blank balls; loading the blank balls into a drying chamber at the top of a high-temperature shaft kiln so that the blank balls are dried with hot air pumped out from the bottom of the high-temperature shaft kiln; conveying the dried blank balls into a firing chamber of the high-temperature shaft kiln, keeping the temperature at 1930-1970 DEG C for 40-60 minutes, then cooling to 90-120 DEG C in a cooling chamber and discharging from the shaft kiln; crushing, screening, removing iron and packaging to finally obtain tabular corundum in which mass content of alumina is 99.4-99.6%. The high-purity tabular corundum is fired at a high temperature quickly, the impurity removing effect of the additive is strengthened, the purity of the product is improved, the crystallization of the tabular corundum is promoted, the firing energy consumption is reduced to the greatest extent, and the preparation cost of the tabularcorundum is reduced further.

Owner:萍乡市黄冠化工有限公司

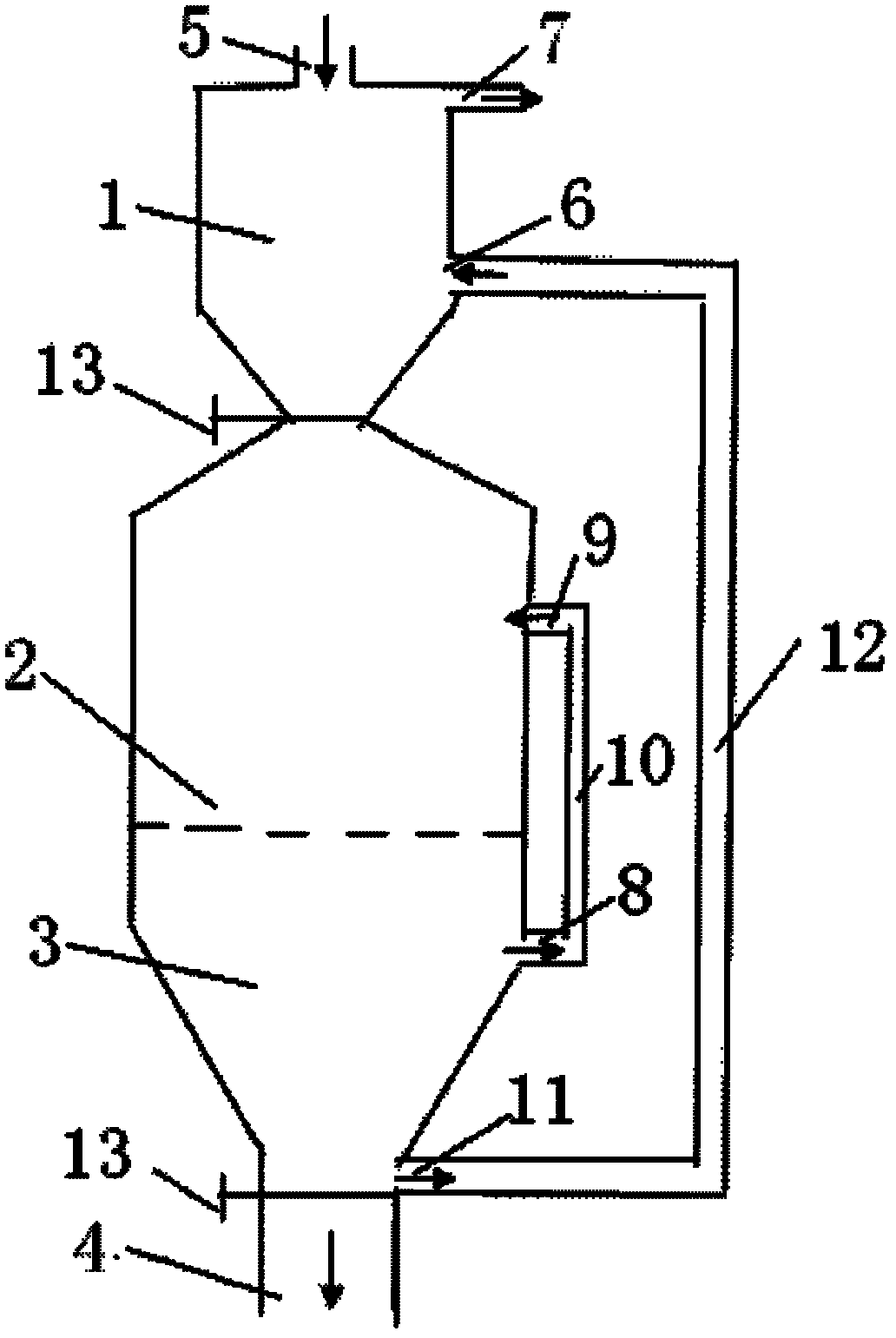

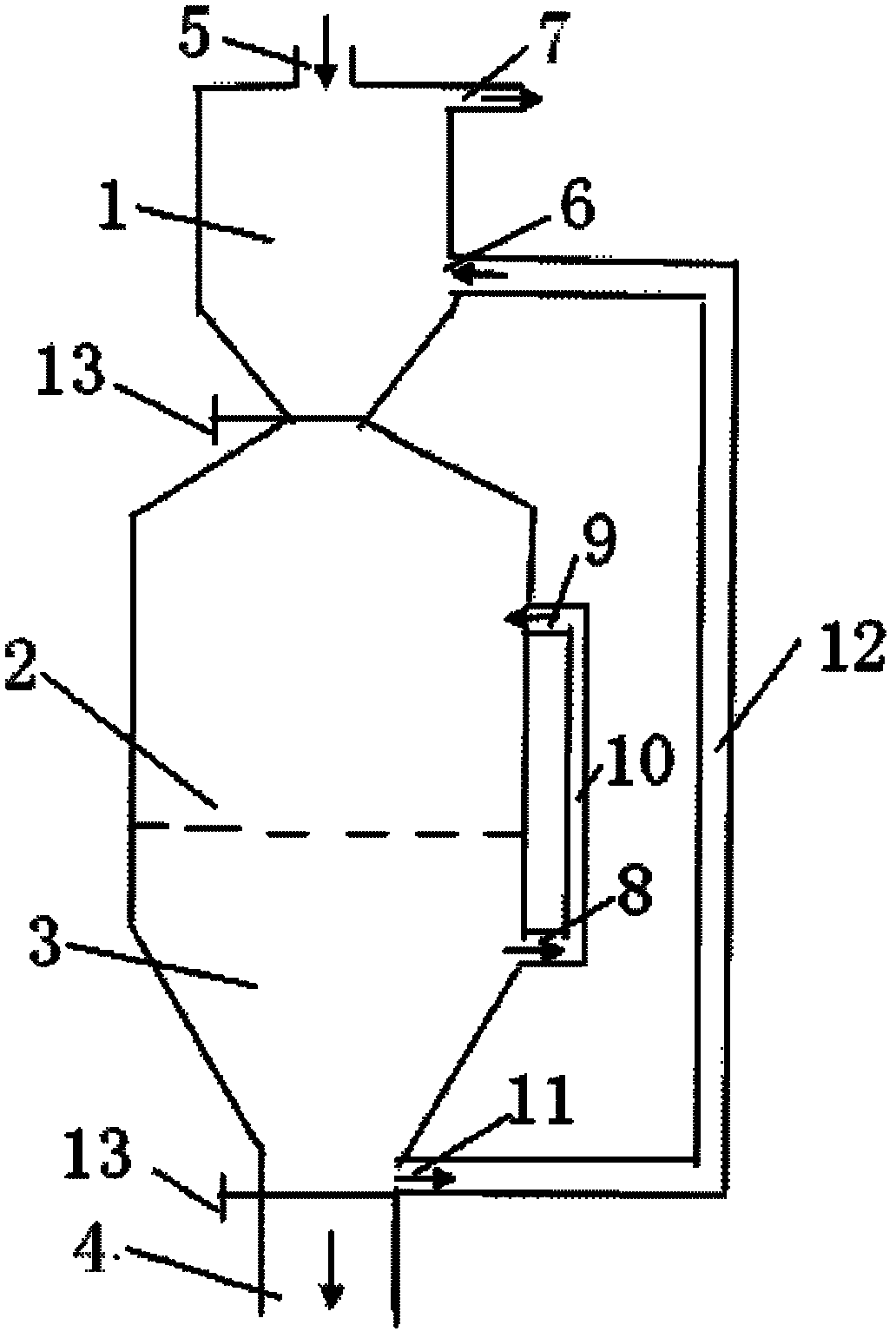

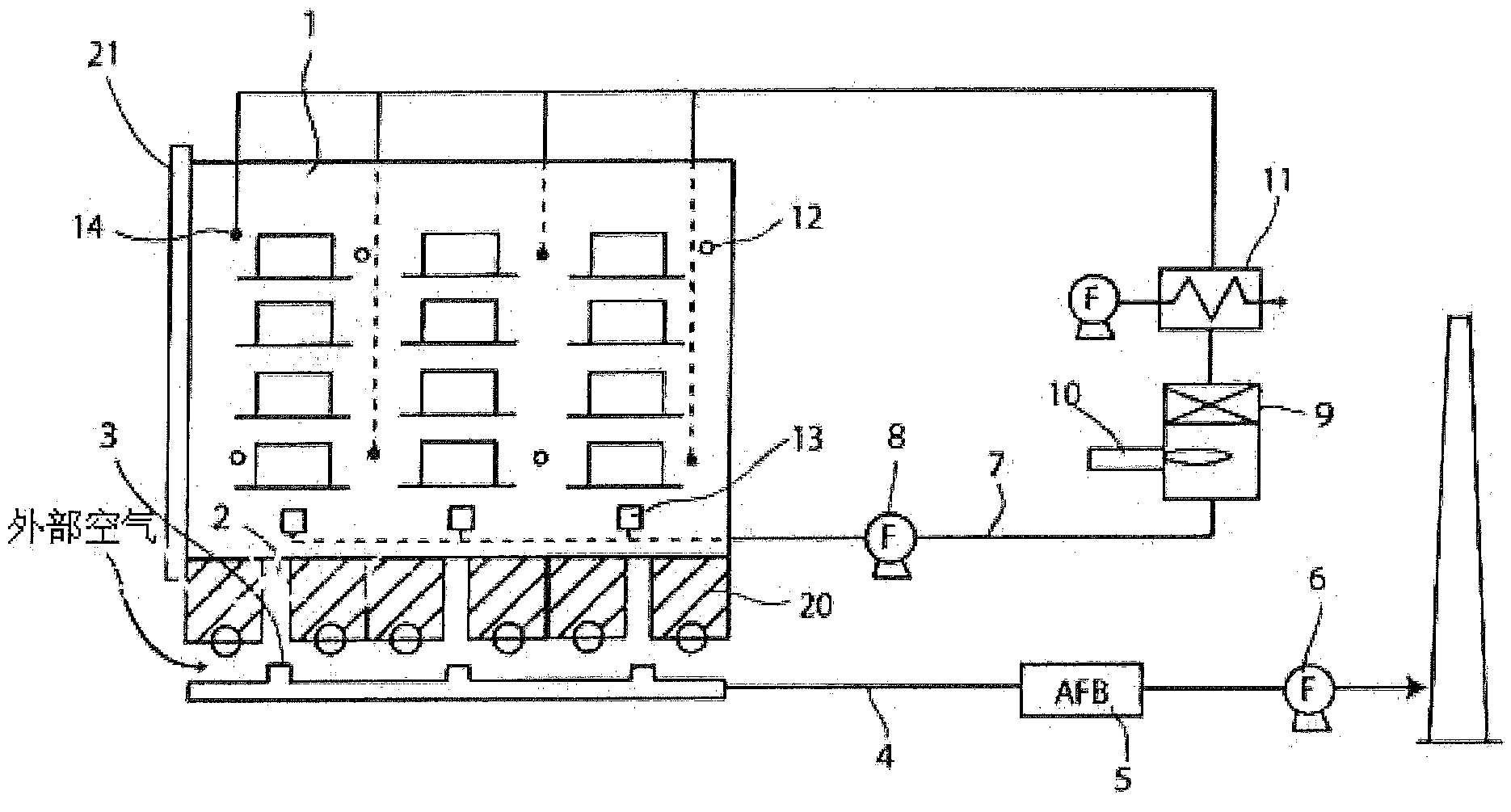

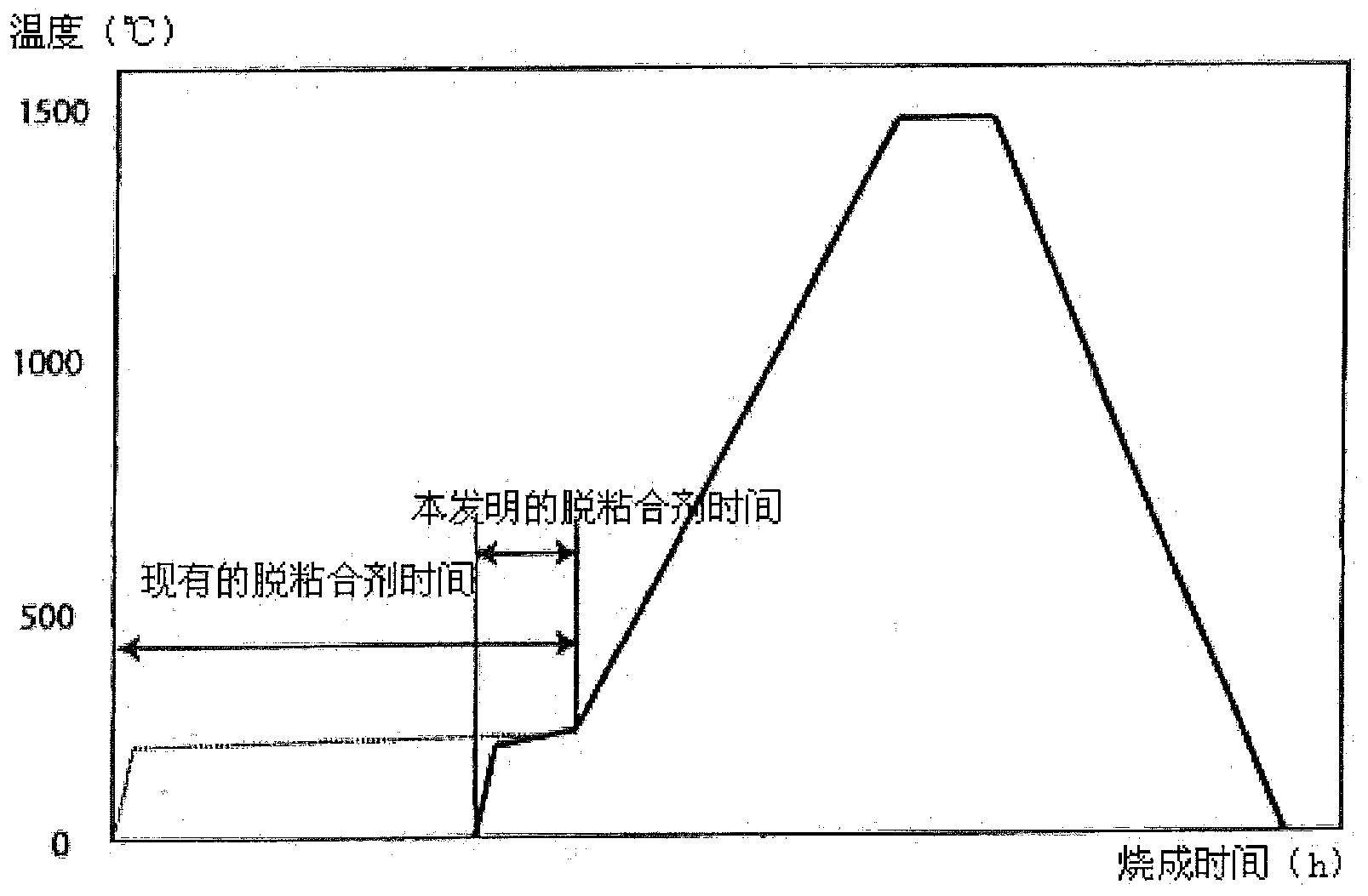

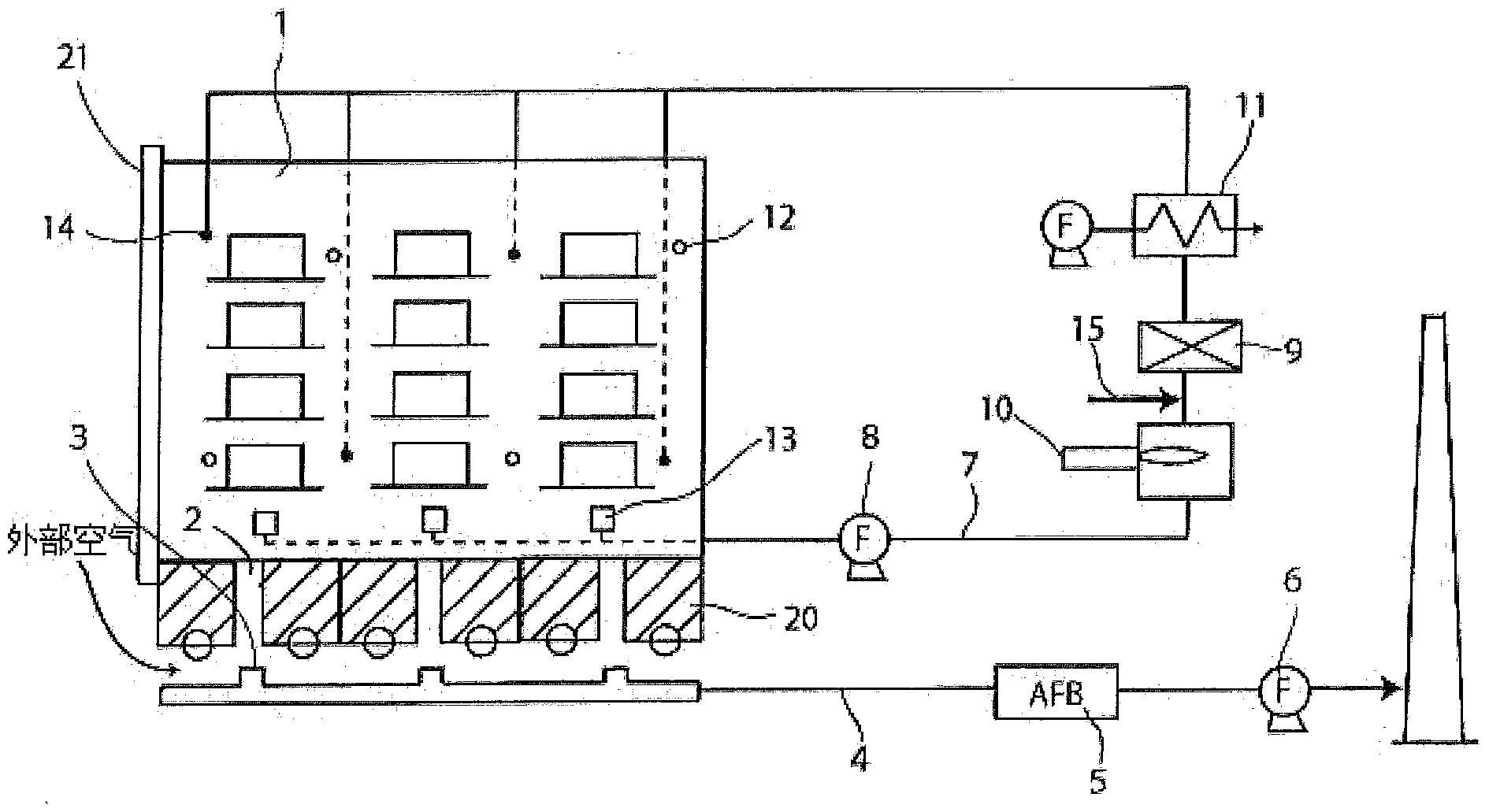

Shuttle kiln for sintering ceramic porous body

ActiveCN103384807AStir wellUniform temperature distributionMaintainance of heating chambersFurnace typesTemperature differenceKiln

Provided is a shuttle kiln capable of sintering a ceramic porous body containing an organic binder at a shorter time than before and without creating cuts caused by the temperature difference between the inside and the outside. This shuttle kiln is suitable for sintering a ceramic porous body containing an organic binder. The shuttle kiln is provided with a gas suction path (4) for sucking the gas in a furnace and discharging said gas via an afterburner (5), and a circulation path (7) for burning an organic binder gas by sucking the gas in the furnace and discharging said gas to the outside of the furnace and for returning the gas back into the furnace.

Owner:NGK INSULATORS LTD

Lithium manganate production method

InactiveCN103618078AIncrease reaction rateIncrease production capacityCell electrodesManganates/permanganatesElectrolysisThermal insulation

The present invention provides a lithium manganate production method, which comprises: taking electrolytic manganese dioxide, trimanganese tetraoxide and lithium carbonate as raw materials, carrying out matching and material mixing according to a molar ratio of Mn to Mn to Li of 5:3:5, and carrying out dry mixing to obtain the completely-mixed raw material; heating the mixed raw material to achieve a temperature of 500-550 DEG C, and carrying out thermal insulation for 1-2 h; briquetting the pre-burnt material, stacking, and firing, wherein a firing temperature is 800-900 DEGC; and carrying out thermal insulation for 3-5 h, and naturally cooling to complete the sintering process so as to obtain the product. According to the present invention, the lithium manganate firing time is shortened, volatilization of the lithium element during the sintering process is reduced, the resources and the material cost are saved, and production capacity is increased.

Owner:WUXI JEWEL POWER & MATERIALS

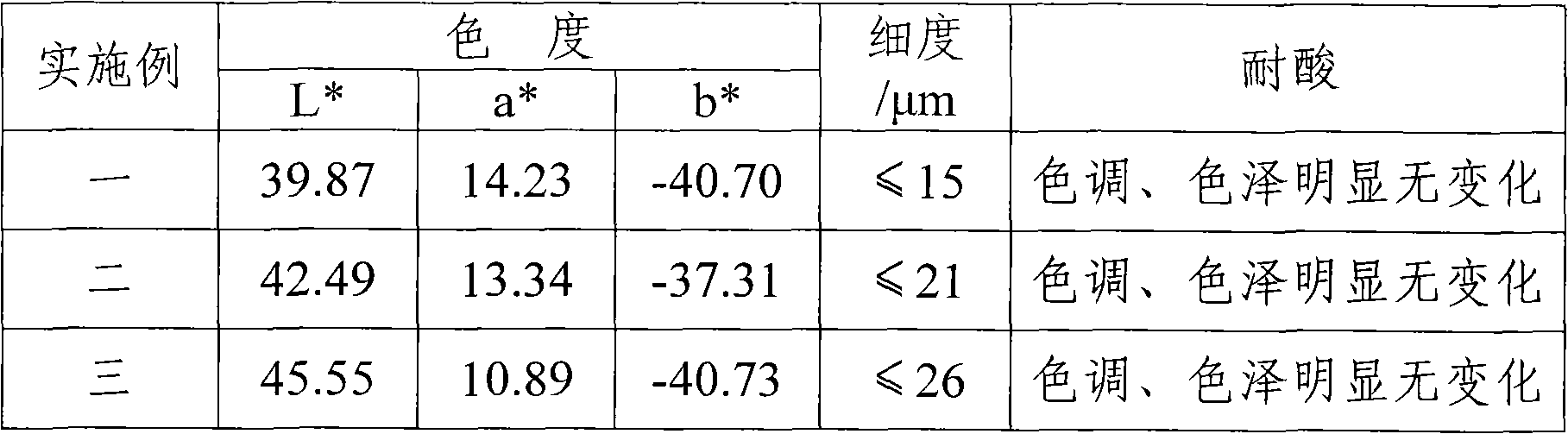

Method for preparing cobalt blue material for decorating ceramic

The invention relates to a method for preparing a cobalt blue material for decorating ceramic. In the method, industrial pure chemical raw materials are adopted; and the method comprises the following steps of: mixing 22 to 45 weight percent of cobalt sesquioxide, 48 to 70 weight percent of aluminum sesquioxide, 0 to 10 weight percent of zinc oxide, 0 to 10 weight percent of magnesium carbonate and 0 to 4 weight percent of chromium sesquioxide; adding 2 to 4 weight percent of boric acid and 6 to 10 weight percent of nucleating agent and uniformly mixing to obtain a reactant; adding acetone in an amount which is 80 percent based on the weight of the reactant; and performing quick ball-milling, drying, baking at the temperature of between 1,100 and 1,200 DEG C, preserving heat, naturally cooling, grinding, cleaning and sieving to obtain the color material. In the method, a large amount of nucleating agent with a small grain size is added into the solid-phase reactant in advance to ensure that crystal simultaneously grows in and on the surface of the reactant, so the grain size of the color material is controlled well, the crystallization completeness is improved, the solid-phase firing temperature is reduced, the firing time is shortened, the acid resistance of the color material is enhanced, and the defects of the conventional solid-phase method for preparing the ceramic color material are overcome.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing corundum abrasive by microwave sintering

InactiveCN107445595AReduce production energy consumptionLower sintering temperatureOther chemical processesMicrowave sinteringEnergy consumption

The invention discloses a method for preparing corundum abrasive by microwave sintering, and belongs to the technical field of abrasive preparation. The corundum abrasive comprises the following raw materials in percentage by weight: 95-98% of Al2O3, 0.5-2.5% of SiO2, 0.5-1% of MgO, 0.2-1% of TiO2, 0.2-1% of MnO2, and 0.1-1% of CuO. The method comprises the following steps: mixing the raw materials; molding; crushing; sieving; grading; performing rubber removing; transferring the rubber-removed blank particles into an SiC crucible; increasing the temperature to reach 1300-1500 DEG C at the rate of 10-20 DEG C per minute; then maintaining the temperature for 5-30min, and performing microwave sintering to obtain the corundum abrasive. With the adoption of the method, energy consumption of the corundum abrasive production can be greatly decreased; in addition, the blank particles are in contact with each other, so that the clearances among the particles are small, the temperature gradient of a sintered body can be reduced, the sintering time is greatly decreased, and as a result, the corundum abrasive sintering quality can be improved.

Owner:河南建筑材料研究设计院有限责任公司

Light insulating brick

ActiveCN105175007AImprove plasticityGuaranteed compressive strengthCeramicwareSpecific gravityPotassium feldspar

The present invention discloses a light insulating brick. The light insulating brick is prepared from the following main raw materials: 50% to 76% of industrial cinder, 6% to 20% of mud, 4% to 20% of potassium feldspar, 4% to 20% of albite, 4% to 20% of quartz and 0 to 15% of polished residues. According to the light insulating brick, the industrial cinder is taken as a main formula body, and the addition is more than 50%; and moreover, the whole sintering time of the light insulating brick is controlled within 4-7 hours. The prepared light insulating brick is rigid in texture, low in specific gravity and high in porosity, and the refractory temperature is over 1000 DEG C, so that conventional fire can be resisted easily; and the light insulating brick is low in heat conductivity and high in compressive strength, and is very suitable for heat insulation of outer walls and indoor heat insulation and sound insulation.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Process for heating foam ceramic

InactiveCN1793051AMeet the process needs of heatingNo pollution in the processCeramicwareHeating timeMicrowave

The invention relates to a heating method for bubble ceramic. According to the method, the bubble ceramic blank is set into the microwave heating device to take heating, under the condition of 300MHz-300GHz, 25-2000 degree centigrade heating time for 30-60 minutes, cooling. The method has simple technology, short producing cycle high production efficiency and high economic benefits.

Owner:长沙隆泰科技有限公司

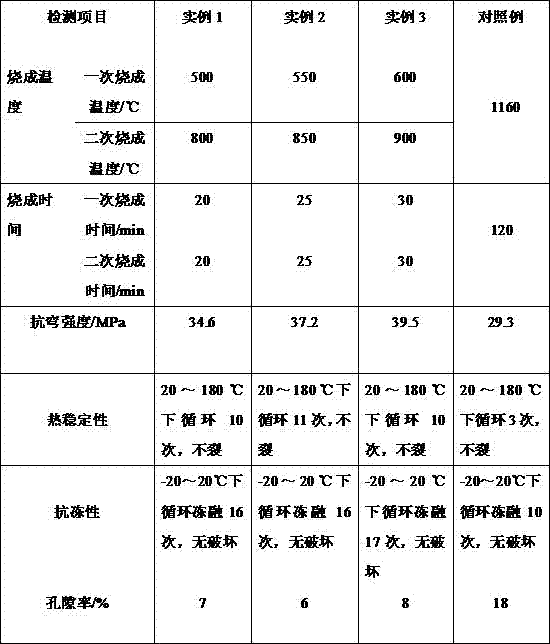

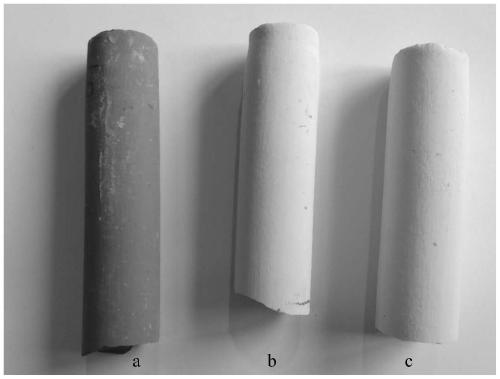

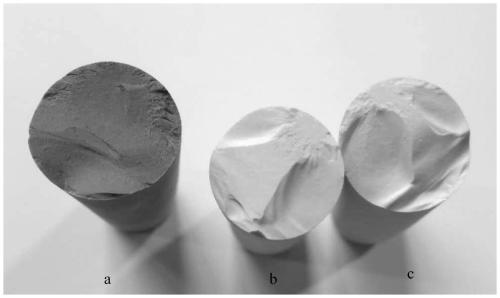

Low-temperature-fired antique glazed tile and its preparation method

InactiveCN107417254ALow melting pointEvenly heatedCeramic materials productionClaywaresFree coolingRoom temperature

The invention discloses a low-temperature-fired antique glazed tile and a preparation method thereof, belonging to the field of building materials. The method comprises the following steps: weighing the raw materials of the low-temperature-fired antique glazed tile, adding water for batch mixing and carrying out aging so as to obtain an aged mixture; compacting the aged mixture to form a blank and carrying out demolding so as to obtain a tile blank; subjecting the tile blank to drying and pre-firing so as to obtain a pre-fired tile blank; then carrying out fumigation, cooling and drying so as to obtain a fumigated tile blank; weighing raw materials for a glaze of the low-temperature-fired antique glazed tile and carrying out batch mixing so as to obtain the glaze; coating the surface of the fumigated tile blank with the obtained glaze and carrying out drying so as to obtain a glazed tile blank; and carrying out heating and heat preservation twice and then carrying out natural cooling to room temperature so as to obtain the low-temperature-fired antique glazed tile. The invention has the beneficial effects that the low-temperature-fired antique glazed tile is low in firing temperature, short in firing time, low in energy consumption, high in product density and good in mechanical properties, has excellent application prospects, and is worthy of promotion and application.

Owner:YUHUAN DEGU NEW MATERIAL TECH CO LTD

Formula for producing post porcelain insulator by using industrial alumina powder instead of high-quality alumina powder by dry method and preparation method and application thereof

The invention relates to a formula for producing a post porcelain insulator by using industrial alumina powder instead of high-quality alumina powder by a dry method and a preparation method and application thereof, and belongs to the technical field of insulators. The formula for producing the post porcelain insulator by using the industrial alumina powder instead of the high-quality alumina powder in the dry method comprises, by weight, 12-16% of the industrial alumina powder, 28-36% of kaolin, 28-36% of flux mineral, 18-22% of elutriation soil, 0.5-3% of an additional mineralizer and 0.15-0.4% of a dispersant, wherein the mineralizer is one or more of barium salt, magnesium salt or talc. By the adoption of the formula for producing the post porcelain insulator by using the industrial alumina powder instead of the high-quality alumina powder by the dry method, the design is simple and scientific; a prepared product has small intensity dispersibility and high intensity; a formed blankis uniform in density and low in internal stress; and meanwhile, the invention provides the simple and convenient preparation method and application.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com