Single-layer glazed transmutation brick and preparation method thereof

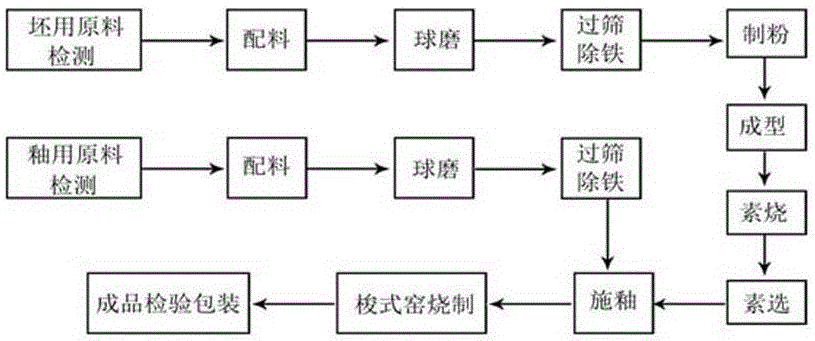

A glazed surface and kiln transformation technology, which is applied to the field of single-layer glazed kiln transformation bricks and their preparation, can solve the problems of high firing temperature, high energy consumption, difficult cutting, etc., so as to improve the qualified rate of products and facilitate construction cutting and firing. The effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of body mud: 35% of pyrophyllite, 15% of wollastonite, 10% of limestone, 10% of Yujiang mud, 15% of Suzhou soil, 8% of magnesia mud and 7% of Ji'an white mud are weighed by weight percentage Put it back into the ball mill, and according to the above materials: ball: water ratio is 1:1.5:0.7 ball mill for 13 hours, the fineness is 250 mesh sieve and the remaining 0.6%;

[0030] (2) Preparation of glazed surface: 20% feldspar, 20% zinc oxide, 8% dolomite, 7% kaolin, 20% quartz, 23% frit and 2% manganese dioxide are weighed into high alumina by weight percentage Lining in the ball mill, and according to the ratio of composite materials: balls: water 1:1.6:0.5, add balls and water together for ball milling for 16 hours, the fineness of ball milling is controlled at 350 mesh, and the sieve allowance is 0.8%, and the balls are milled Put the glaze material into the glaze slurry tank, after stirring, sieving, and iron removal, the specific gravity of the glaze ...

Embodiment 2

[0035] (1) Preparation of body mud: 33% of pyrophyllite, 17% of wollastonite, 8% of limestone, 12% of Yujiang mud, 12% of Suzhou soil, 10% of magnesia mud, and 8% of Ji'an white mud are weighed by weight percentage Put it back into the ball mill, and according to the above materials: ball: water ratio is 1:1.5:0.7 ball mill for 12 hours, the fineness is 250 mesh sieve remaining 0.8%;

[0036] (2) Preparation of glazed surface: 19% feldspar, 21% zinc oxide, 7% dolomite, 7% kaolin, 19% quartz, 25% frit, 1% manganese dioxide, and 1% copper oxide by weight percentage Weigh it into the high-alumina lined ball mill, and according to the ratio of composite materials: balls: water 1:1.6:0.5, add balls and water together for ball milling for 17 hours, the fineness of ball milling is controlled at 350 mesh, and the sieve residue is 0.7% , put the ball-milled glaze material into the glaze slurry tank, after stirring, sieving, and iron removal, the specific gravity of the glaze slurry is ...

Embodiment 3

[0041] (1) Preparation of body mud: 37% of pyrophyllite, 13% of wollastonite, 12% of limestone, 8% of Yujiang mud, 17% of Suzhou soil, 6% of magnesia mud and 7% of Ji'an white mud are weighed by weight percentage Put it back into the ball mill, and according to the above materials: ball: water ratio is 1:1.5:0.7 ball mill for 15 hours, the fineness is 250 mesh sieve and the remaining 0.6%;

[0042] (2) Preparation of glaze surface: feldspar 21%, zinc oxide 19%, dolomite 8%, kaolin 8%, quartz 21%, frit 21%, cobalt oxide 1%, ferric oxide 1% by weight The percentage is weighed into the high-alumina lined ball mill, and according to the ratio of composite materials: balls: water 1:1.6:0.5, balls and water are added together for ball milling for 16 hours. %, put the ball-milled glaze material into the glaze slurry bucket, after stirring, sieving, and iron removal, the specific gravity of the glaze slurry is 1.63 kg / L;

[0043] (3) Green body molding and biscuit firing: put the gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com