Patents

Literature

51results about How to "To achieve the purpose of continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

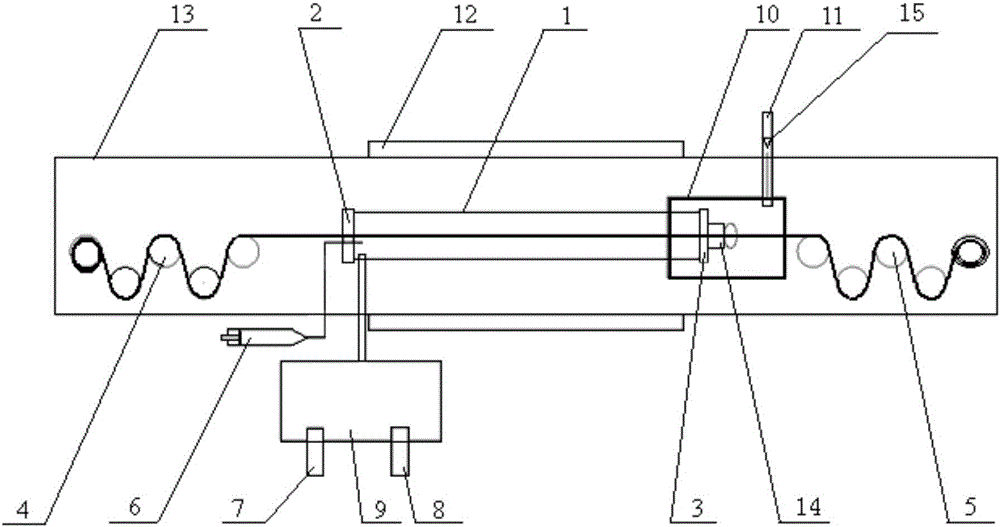

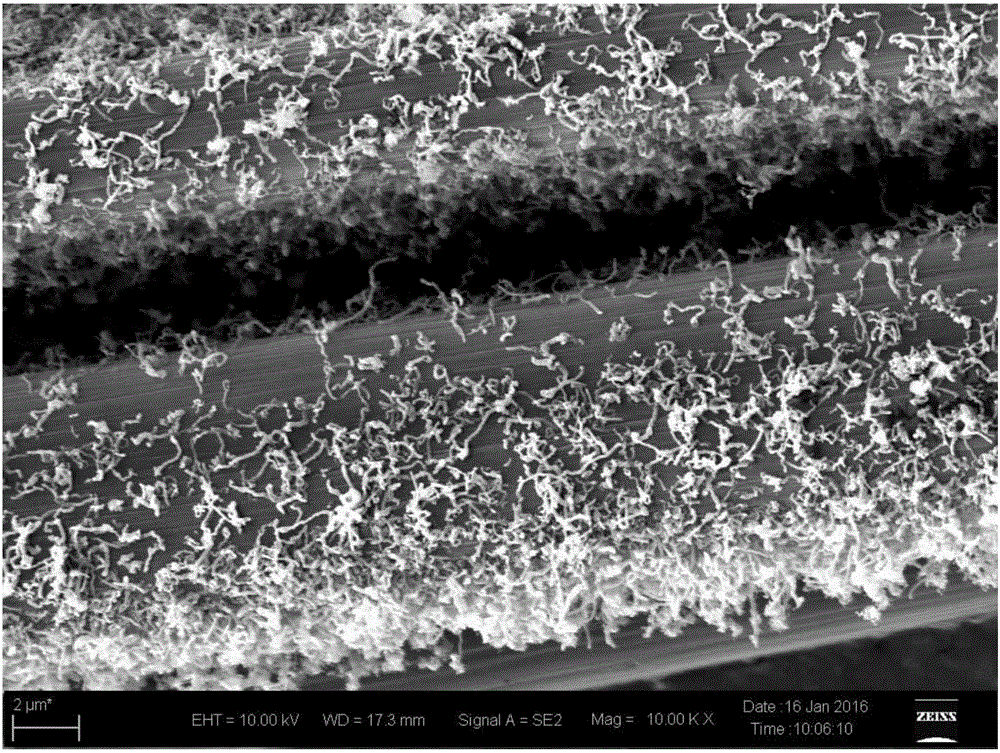

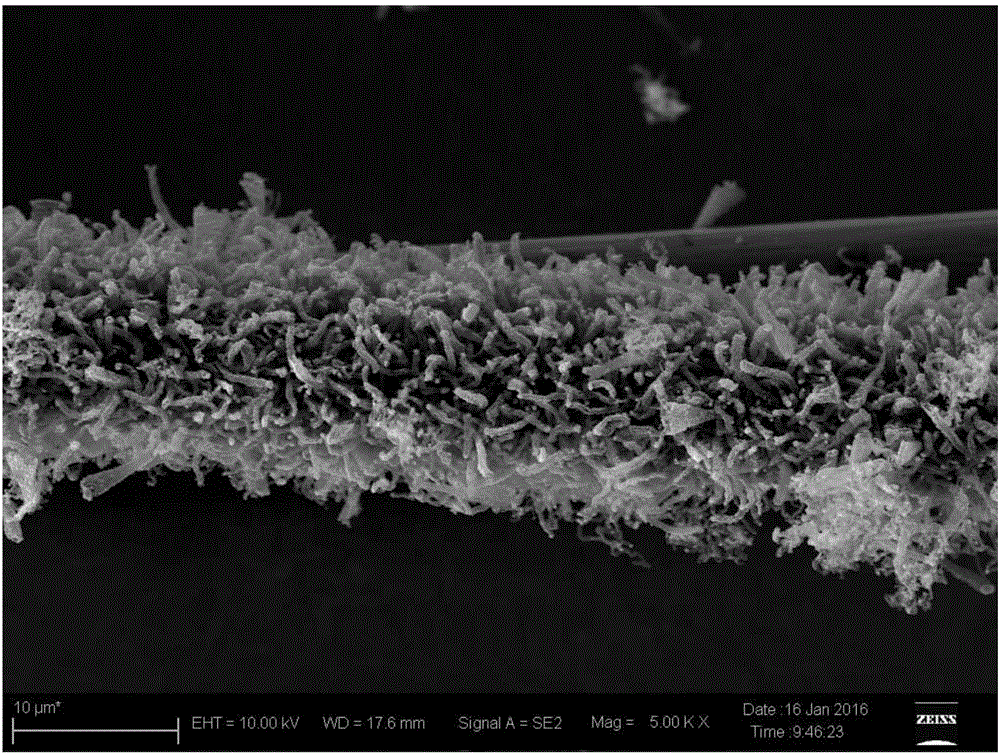

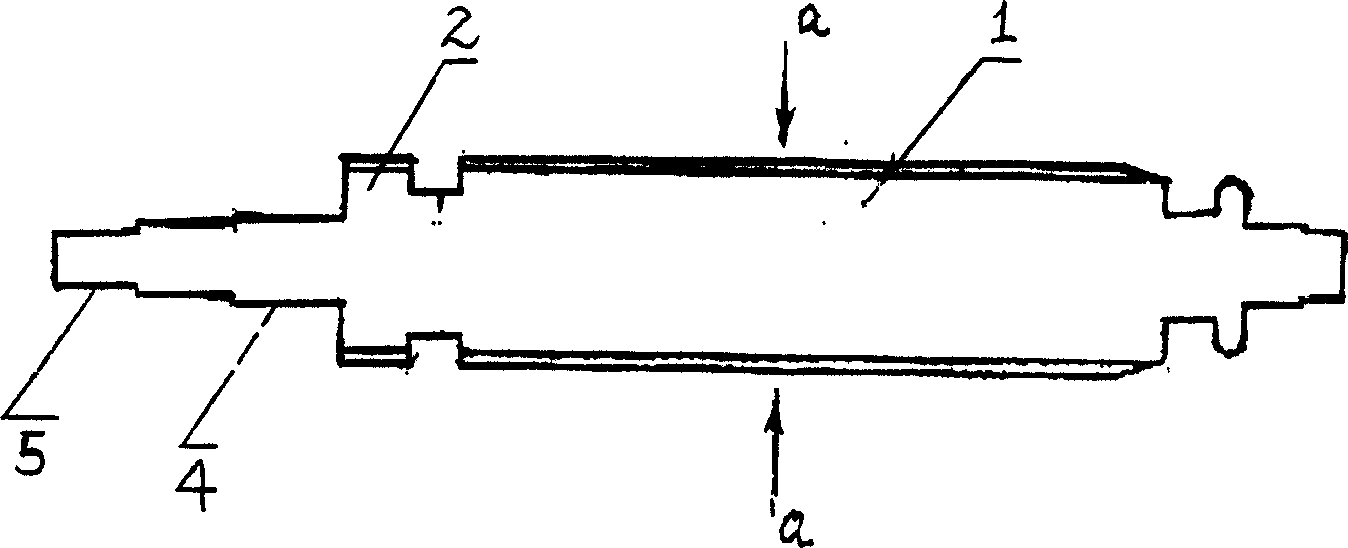

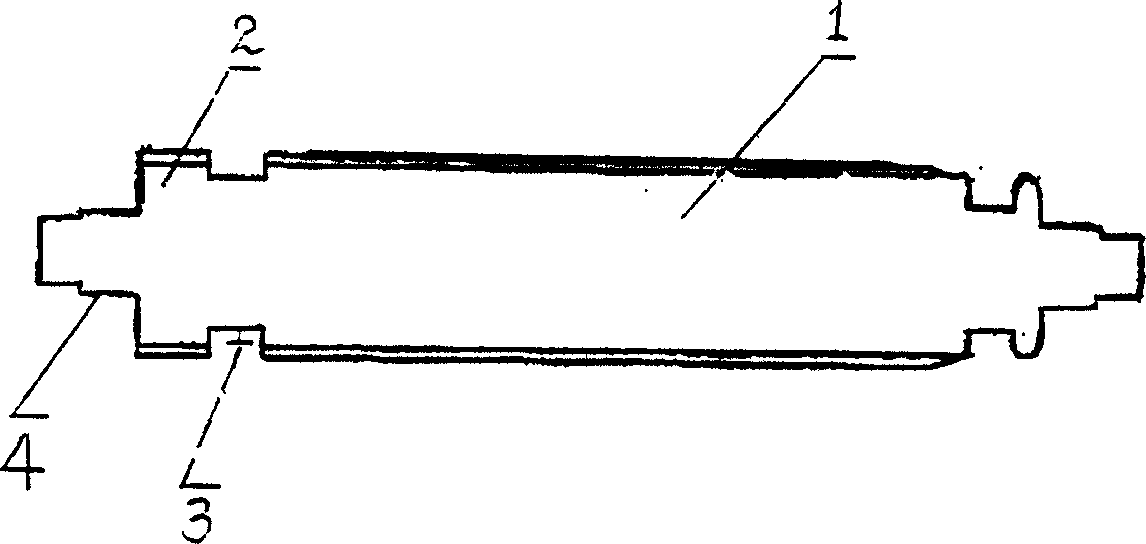

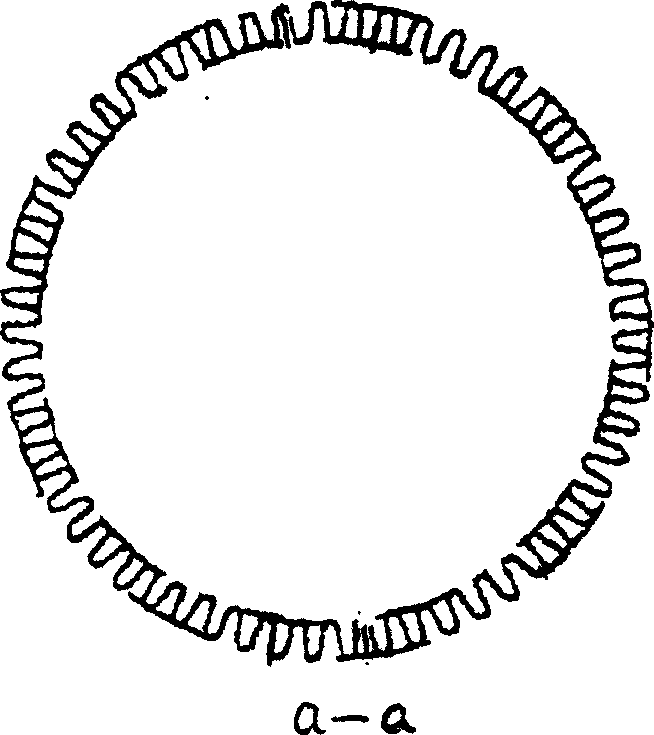

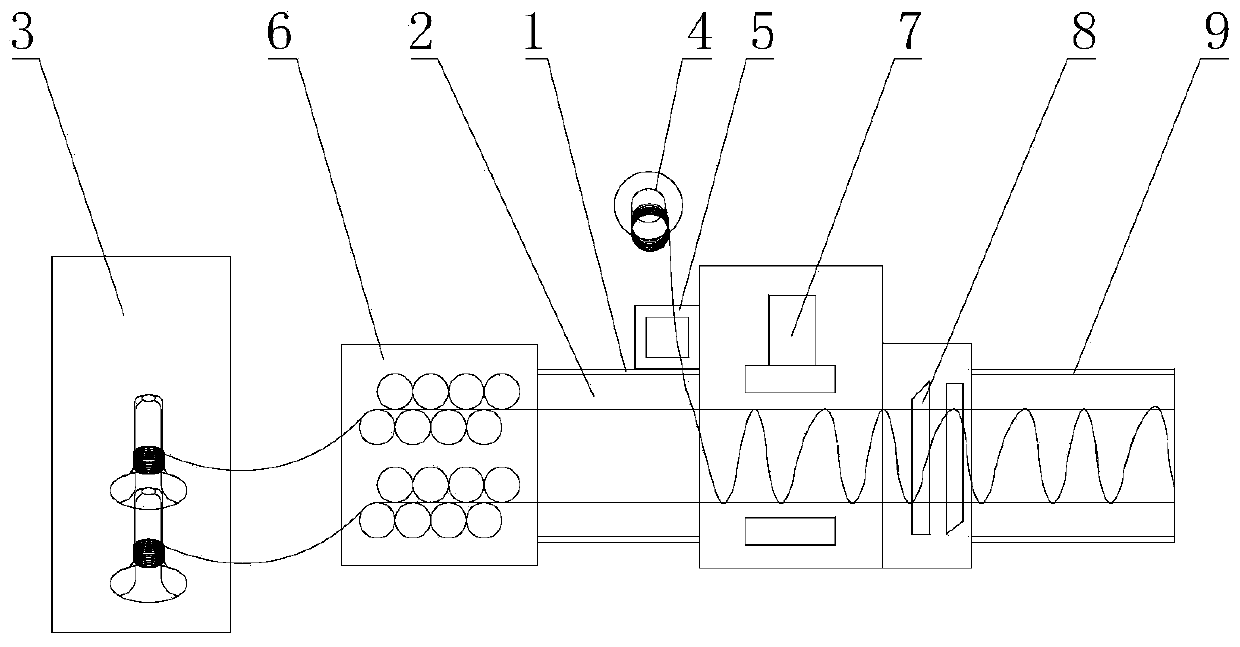

Device and method for preparation of continuous carbon fiber with carbon nanotubes growing on surface

ActiveCN105908491AGuaranteed continuityIncreased interfacial shear strengthCarbon fibresFiberCarbon fibers

Relating to devices and methods for carbon fiber interfacial modification, the invention provides a device and method for preparation of continuous carbon fiber with carbon nanotubes growing on the surface. The invention aims to solve the problem that continuous modified carbon fiber cannot be obtained through existing modification of carbon fiber with carbon nanotubes. The device comprises a quartz tube, a head-end sealing plug, a tail-end sealing plug, front drawing rollers, back drawing rollers, a micro-injection pump, a hydrogen generator, an argon bottle, a gas mixing apparatus, a tail gas treatment device, an exhaust pipe, a heating jacket and a sealed bin. The micro-injection pump and the gas mixing apparatus are both connected to the quartz tube, and the heating jacket is disposed outside the sealed bin. The method consists of: passing a carbon fiber tow through the front drawing rollers, the back drawing rollers and the quartz tube and conducting tensioning, introducing argon into the quartz tube to perform purification, then introducing the mixed gas of hydrogen and argon into the heated quartz tube, then dissolving ferrocene into a solvent and then introducing the product into the quartz tube, and depositing carbon nanotubes on the surface of moving carbon fiber so as to obtain continuous carbon fiber with carbon nanotubes growing on the surface. And the continuous carbon fiber with carbon nanotubes growing on the surface can be used as a reinforcement in composite materials.

Owner:HARBIN INST OF TECH

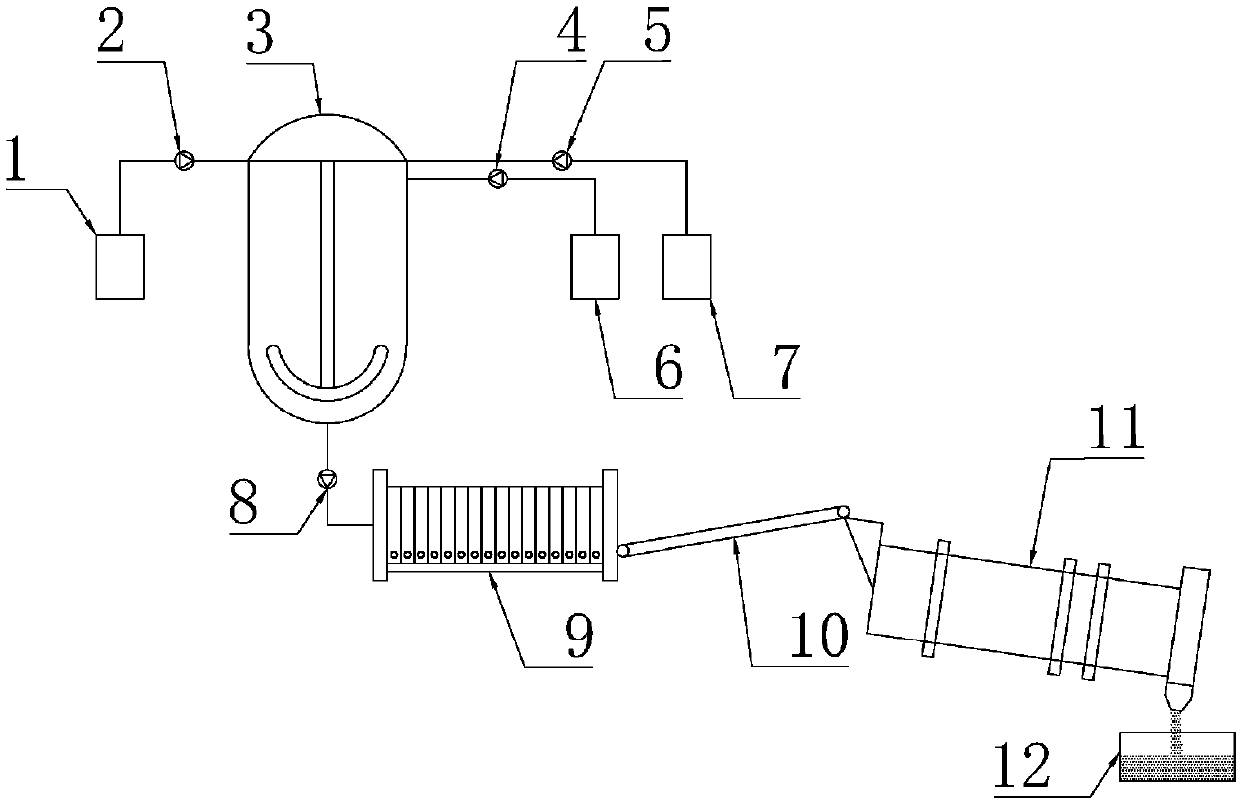

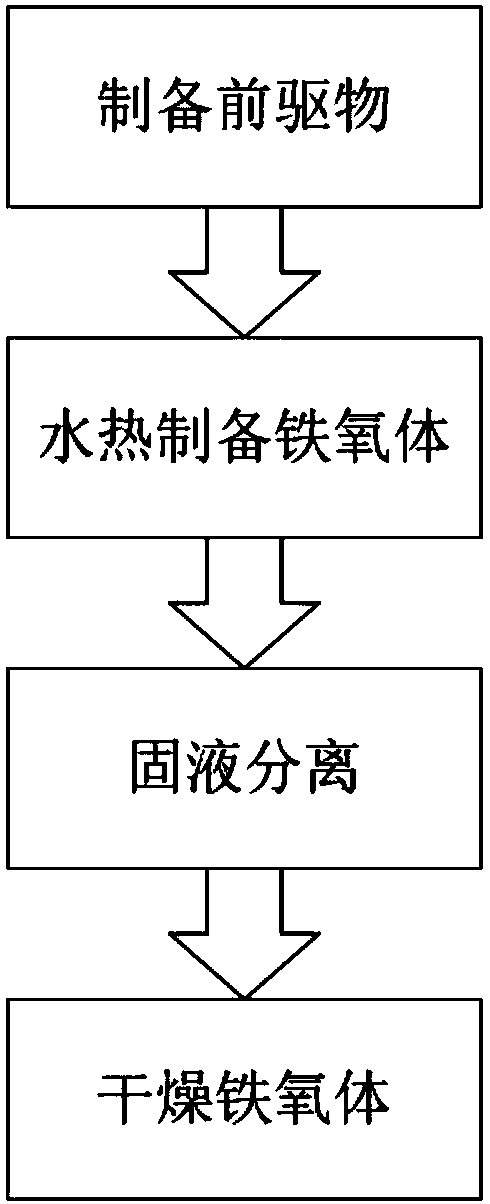

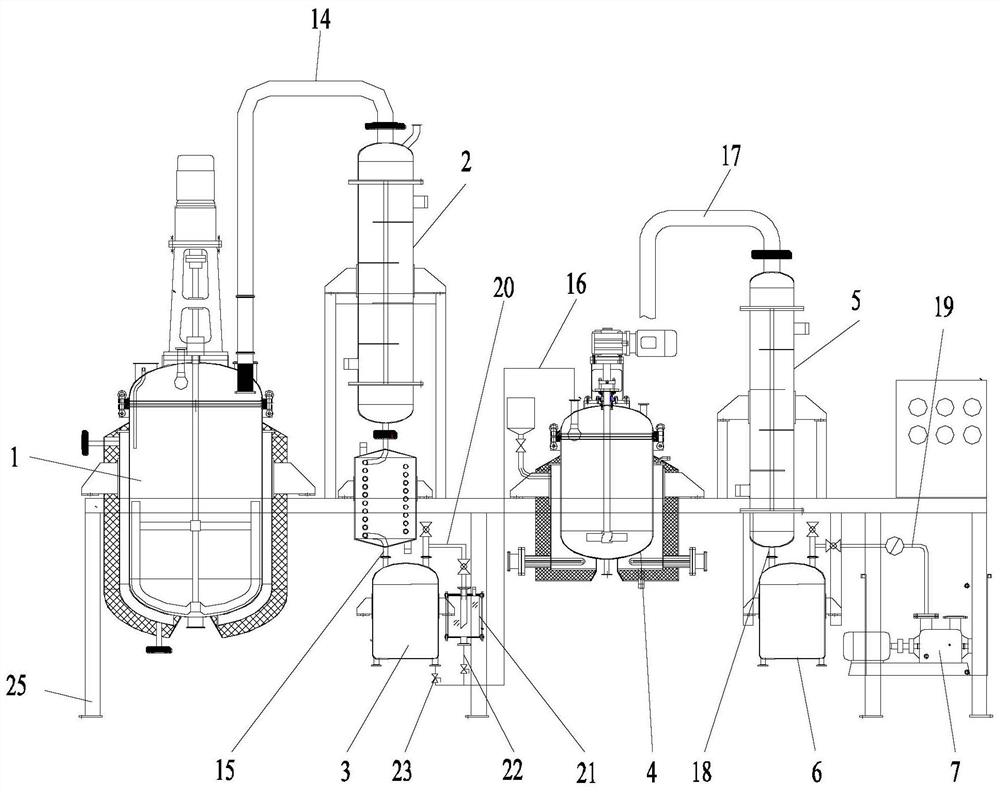

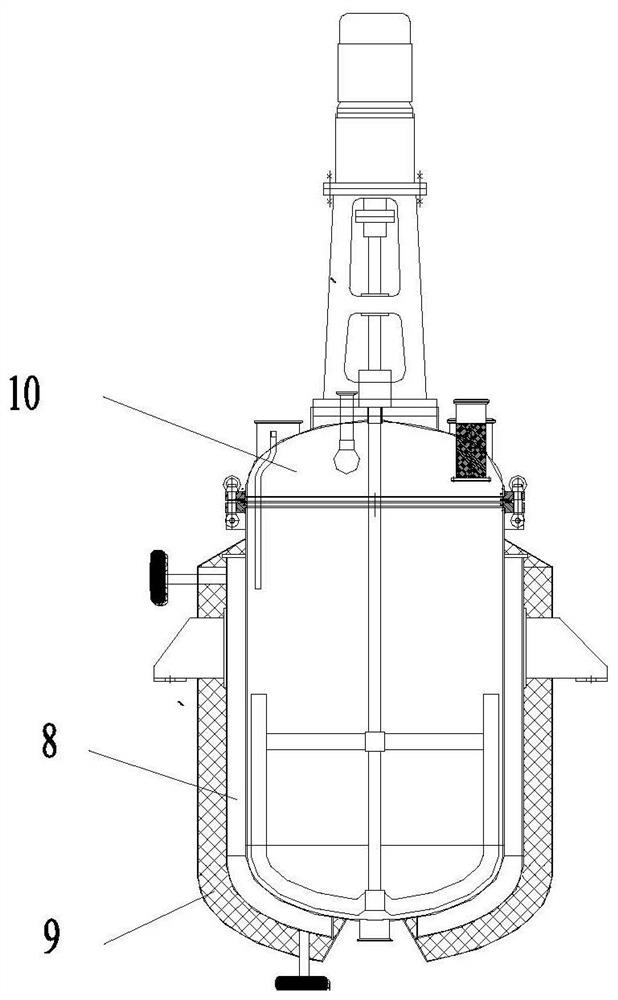

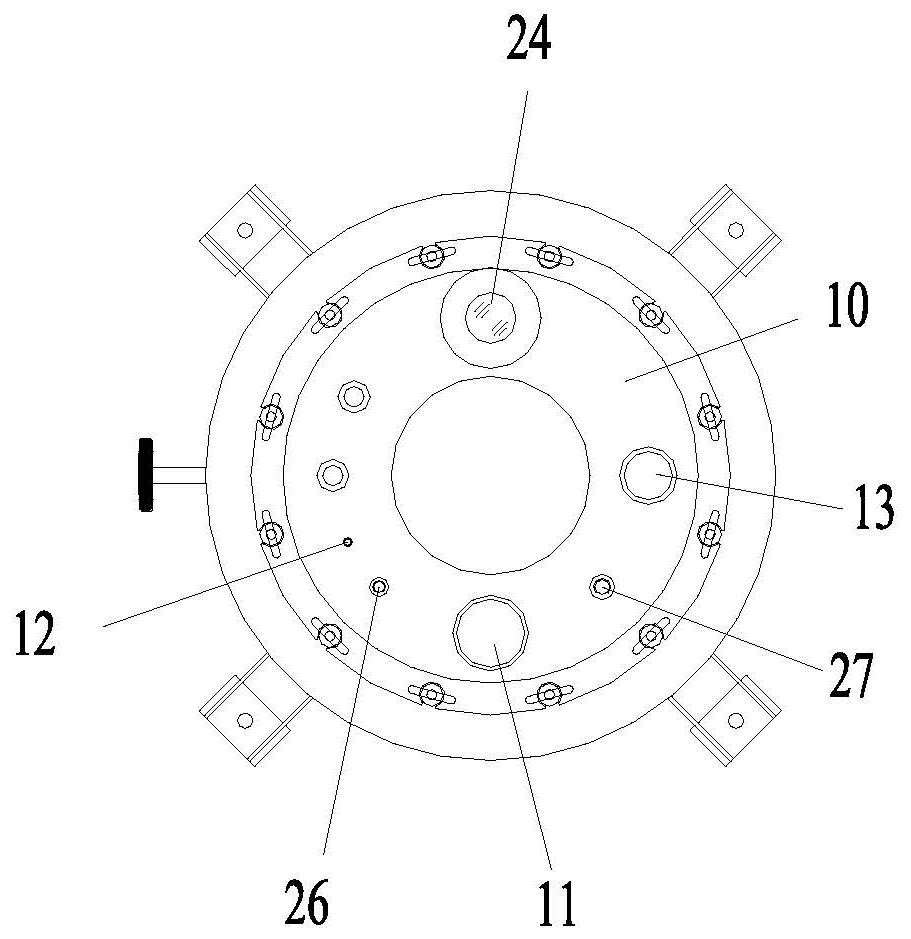

System and method for preparing magnesium-zinc ferrite from acid pickling sludge and acid pickling waste liquor

PendingCN107673409ARealize reduction disposalIncrease added valueMaterial nanotechnologyIron compoundsWater storage tankSludge

The invention discloses a system and a method for preparing a magnesium-zinc ferrite from acid pickling sludge and acid pickling waste liquor and belongs to the field of recycling of hazardous waste.The system comprises a water storage tank, a water pump, a ferrite hydrothermal preparation device, a first charging pump, a second charging pump, an acid storage tank, an alkali storage tank, a discharging pump, a solid-liquid separation and filter-pressing device, a ferrite drying device and a ferrite collecting device, wherein the water storage tank, the acid storage tank and the alkali storagetank are connected with the ferrite hydrothermal preparation device through the water pump, the first charging pump and the second charging pump respectively; a discharge port of the ferrite hydrothermal preparation device is connected with the solid-liquid separation and filter-pressing device through the discharging pump; the solid-liquid separation and filter-pressing device is connected withthe ferrite drying device. The method for preparing the magnesium-zinc ferrite from the acid pickling sludge and the acid pickling waste liquor comprises steps of precursor preparation, hydrothermal preparation of the ferrite, solid-liquid separation and ferrite drying. The acid pickling sludge and the acid pickling waste liquor are co-processed in a recycling manner for preparing the magnesium-zinc ferrite.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Macro preparation method of tobacco thermal reaction spice

ActiveCN112375626AHigh bulk densityLarge reaction dosageTobacco preparationBiofuelsDistillationProcess engineering

The invention discloses a macro preparation method of tobacco thermal reaction spice. The macro preparation method comprises two procedures of extraction and concentration, and comprises the followingsteps: granulating tobacco powder serving as a raw material to obtain tobacco particles, performing destructive distillation extraction on the tobacco particles under the protection of nitrogen, andperforming reduced pressure distillation and concentration on the obtained extract to obtain the tobacco thermal reaction spice. The adopted tobacco particles are large in stacking density, the reaction feeding amount is large, and the yield of the extracted thermal reaction spice is high.

Owner:CHINA TOBACCO ANHUI IND CO LTD

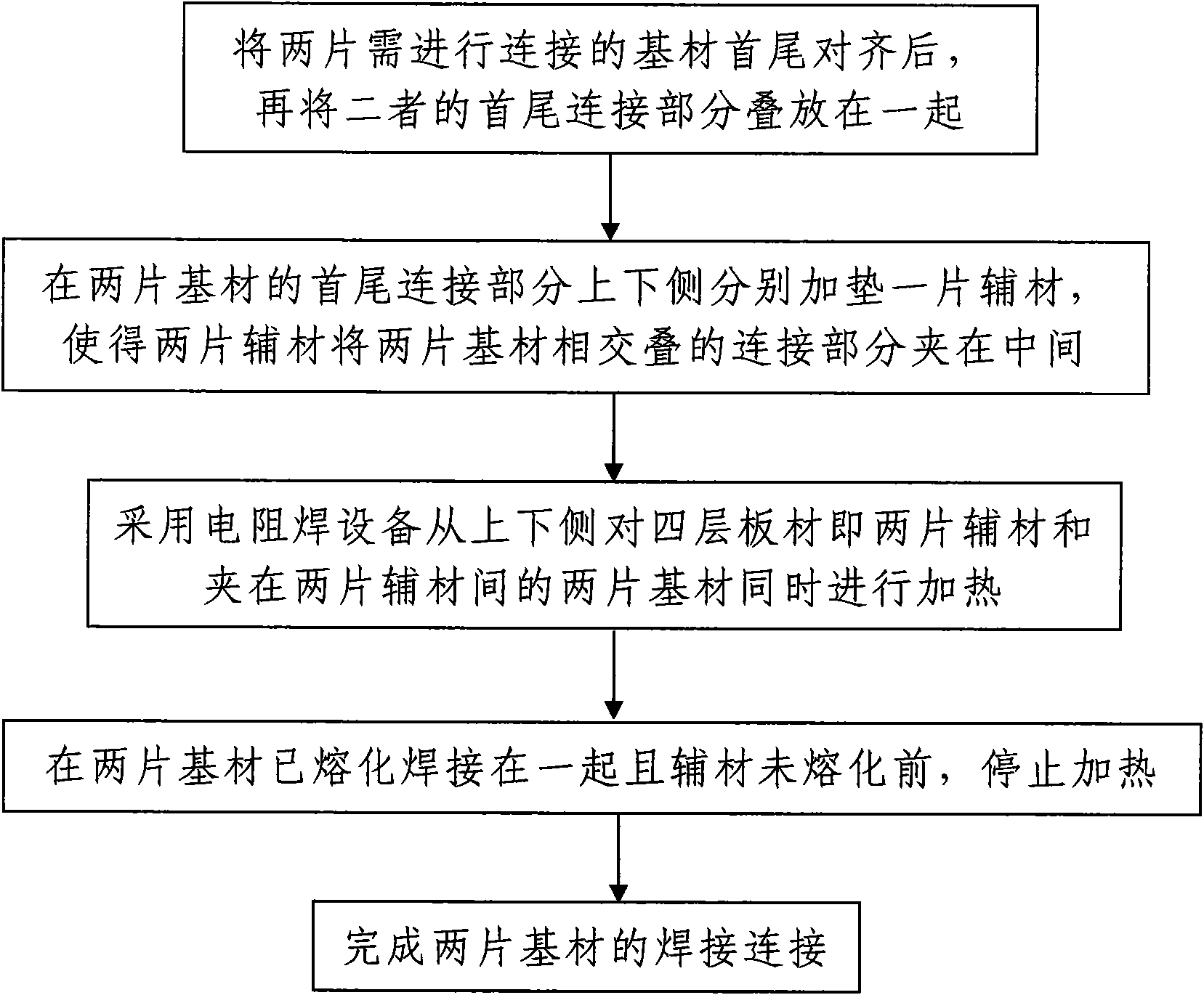

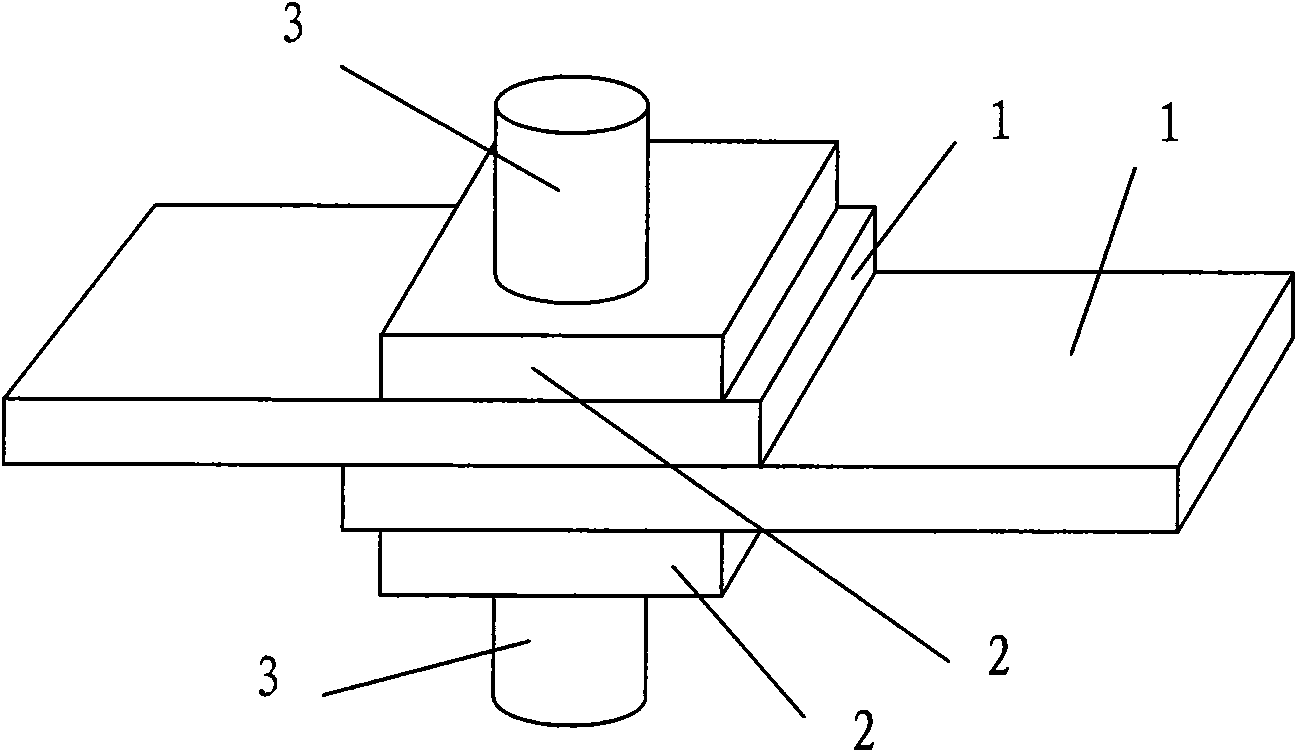

Novel process for welding copper strip and aluminum strip

InactiveCN101590564AInnovative designReasonable designWelding/soldering/cutting articlesMetal working apparatusProduction lineElectric resistance welding

The invention discloses a novel process for welding a copper strip and an aluminum strip, which comprises the following steps: firstly, aligning two copper strip materials or aluminum strip materials required to be connected, namely the heads and the tails of base materials, and then overlapping the joint parts of the heads and the tails of the two base materials; secondly, underlaying an auxiliary welding plate, namely an auxiliary material to the upper side and the lower side of the overlapped joint parts of the heads and the tails of the two base materials respectively so that the two auxiliary materials clamp the overlapped joint parts of the heads and the tails of the two base materials in the middle; and thirdly, heating the two auxiliary materials and the two base materials clamped between the two auxiliary materials at the same time from the upper side and the lower side by adopting an electric resistance welding device, and before the two base materials are melted and welded together and the auxiliary materials are not melted, stopping heating to finish the welded connection of the two base materials. The process has the advantages of novel and reasonable design, simple and convenient use and operation, high production efficiency, low manufacturing cost, good welding effect and reliable connection, and can effectively solve the problem of production line continuous production in the prior production process of the copper and aluminum strip materials.

Owner:XIAN MEHAT IND TECH

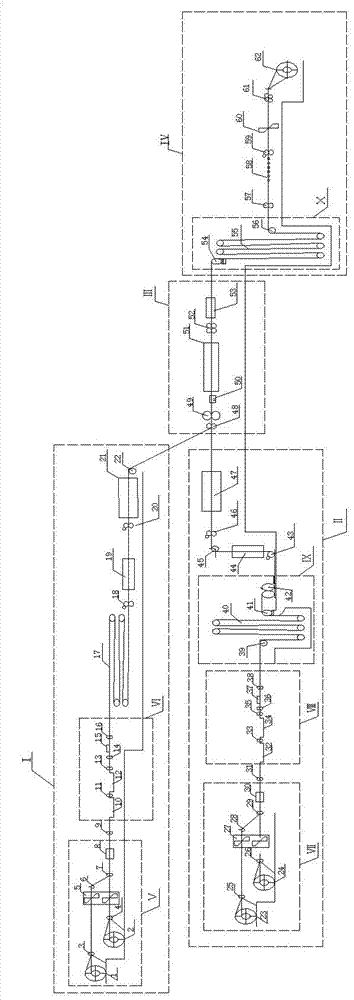

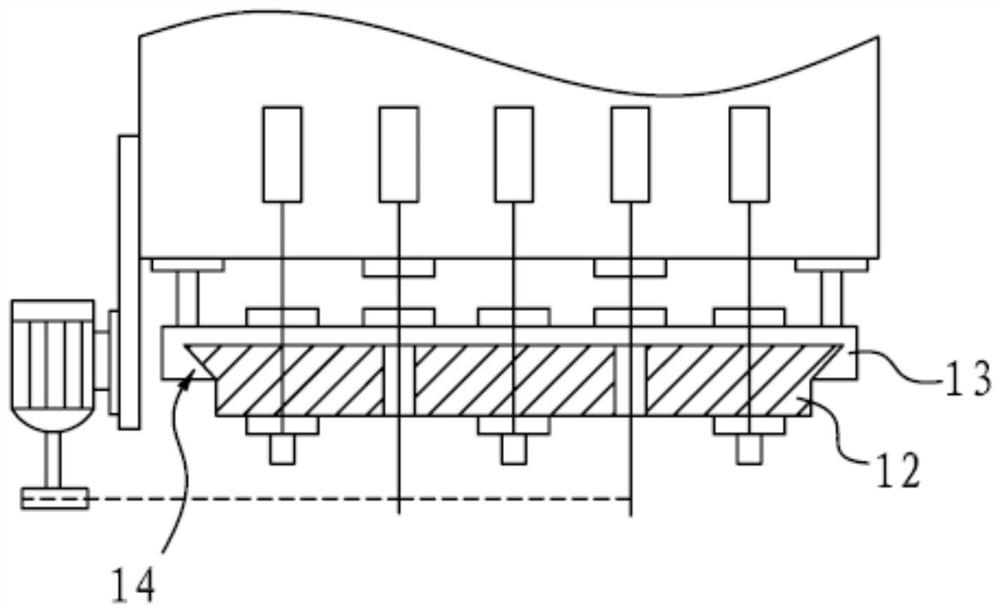

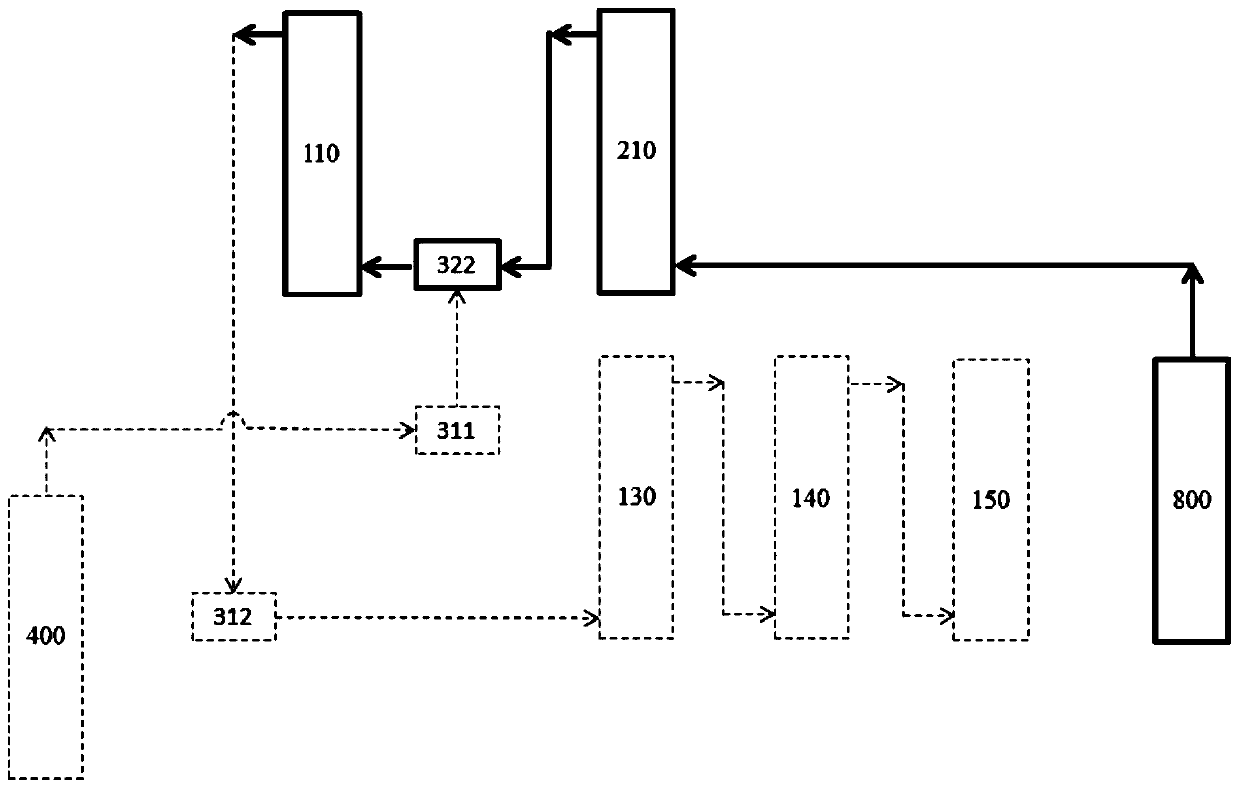

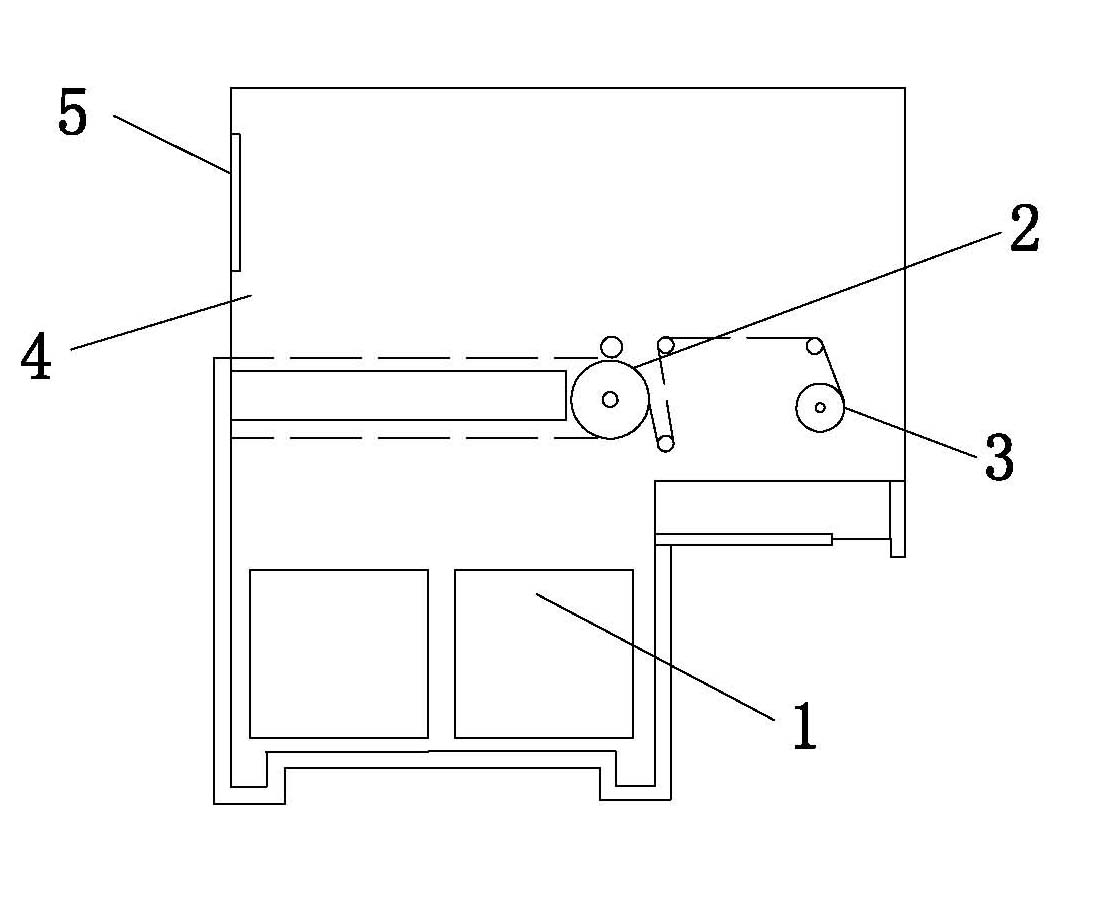

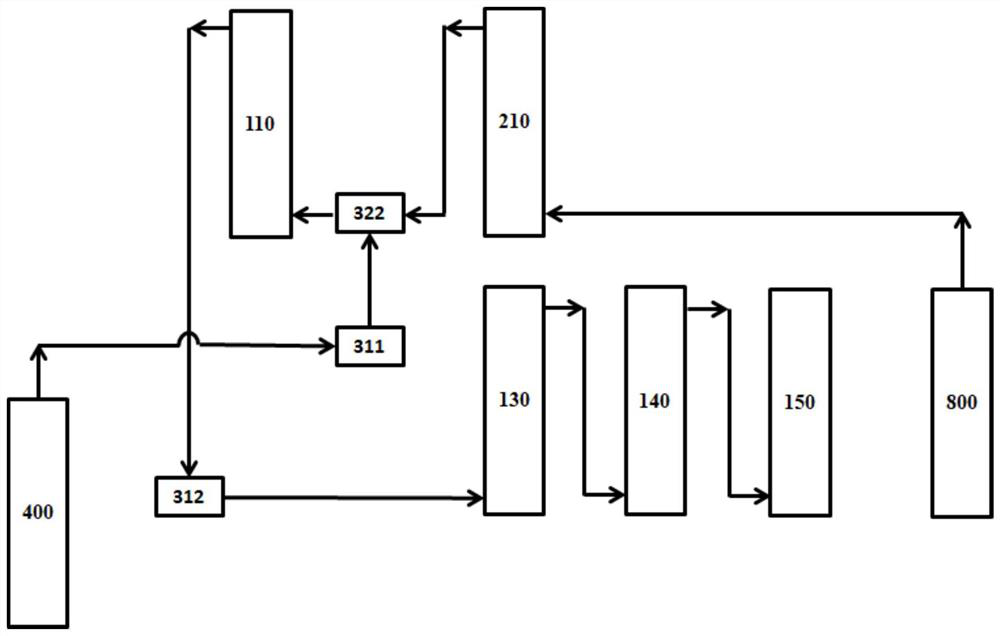

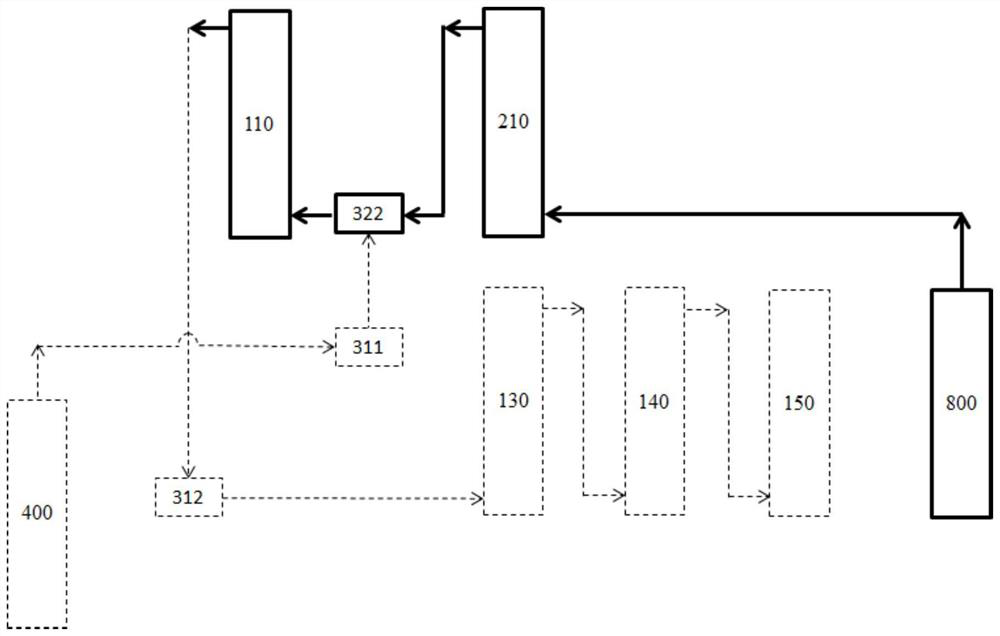

Continuous automatic production device of vibration damping plate and production method

PendingCN107097075AImprove adhesionImprove performanceLamination ancillary operationsLaminationProduction lineSheet steel

The invention belongs to the field of architectural ornament, automobiles and home appliance materials, discloses a continuous automatic production device of a vibration damping plate and a production method, and aims to solve the technical problems that a single plate production line is low in production efficiency, large in alignment tolerance, low in peel strength and unstable in property. The continuous automatic production device comprises an upper-layer steel plate processing unit, a lower-layer steel plate processing unit, a recombination unit and a postprocessing unit. The production method of the vibration damping plate comprises the steps of the upper-layer steel plate processing stage, the lower-layer steel plate processing stage, the two-layer steel plate recombination stage and the processing stage after the recombination. According to the invention, the degree of automation of the technology is high, the yield is high, the technology is stable, the produced product is high in peel strength, the property is excellent, and the purpose of continuous automatic production is realized.

Owner:嘉峪关天源新材料有限责任公司

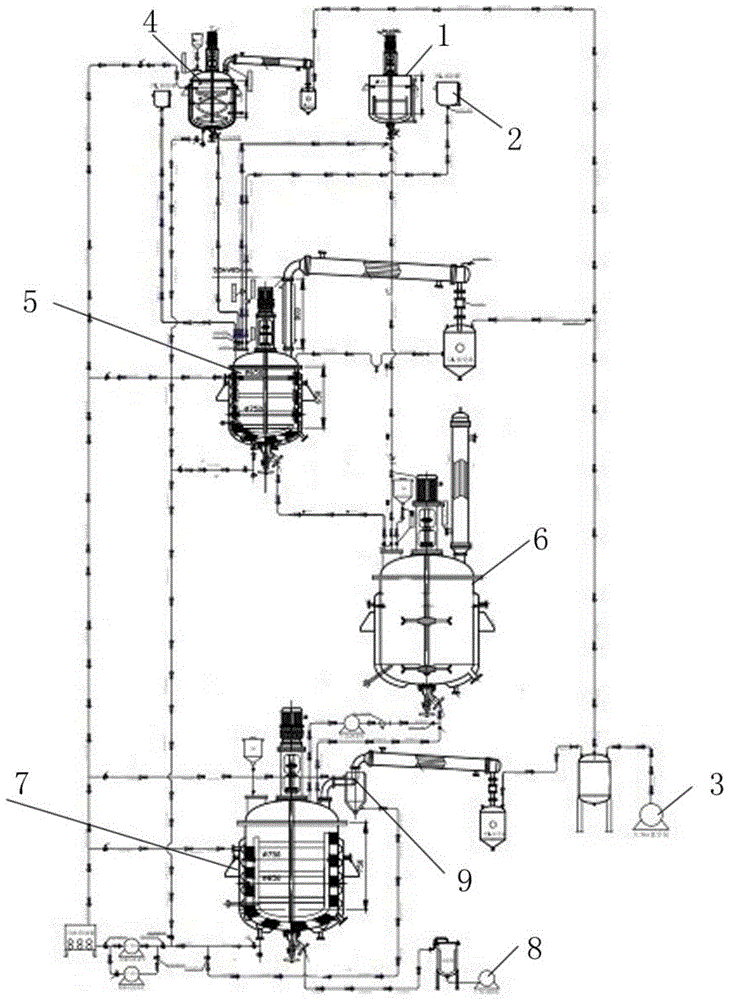

Waterborne polyurethane-acrylate interpenetrating polymer network copolymer emulsion continuous production method and device

The invention discloses a waterborne polyurethane-acrylate interpenetrating polymer network copolymer emulsion continuous production method and device. The method comprises carrying out polyol manufacture or polyol dehydration through a high temperature reactor, putting the product into a prepolymerization reactor, carrying out performed polymer synthesis, hydrophilic chain extension and primary acrylate grafting insertion into the polyurethane performed polymer, transferring the performed polymer into a high-speed dispersion kettle, carrying out neutralization, adding water into the high-speed dispersion kettle, carrying out high-speed dispersion to obtain a uniform dispersion liquid, transferring the dispersion liquid into a solvent removal or polymerization kettle, carrying out secondary chain extension, carrying out reduced pressure removal on the solvent in the dispersion liquid, reducing water in the gaseous solvent through a cyclone separator and carrying out acrylate pre-emulsion-polyurethane copolymerization in an emulsification kettle to obtain a high-quality waterborne polyurethane-acrylate interpenetrating polymer network copolymer emulsion. The method and device greatly reduce labor intensity, reduce material adhesion caused by fault of a pipe device such as a pump, greatly improve production efficiency, reduce a formula material loss and reduce a production cost.

Owner:广东多正树脂科技有限公司

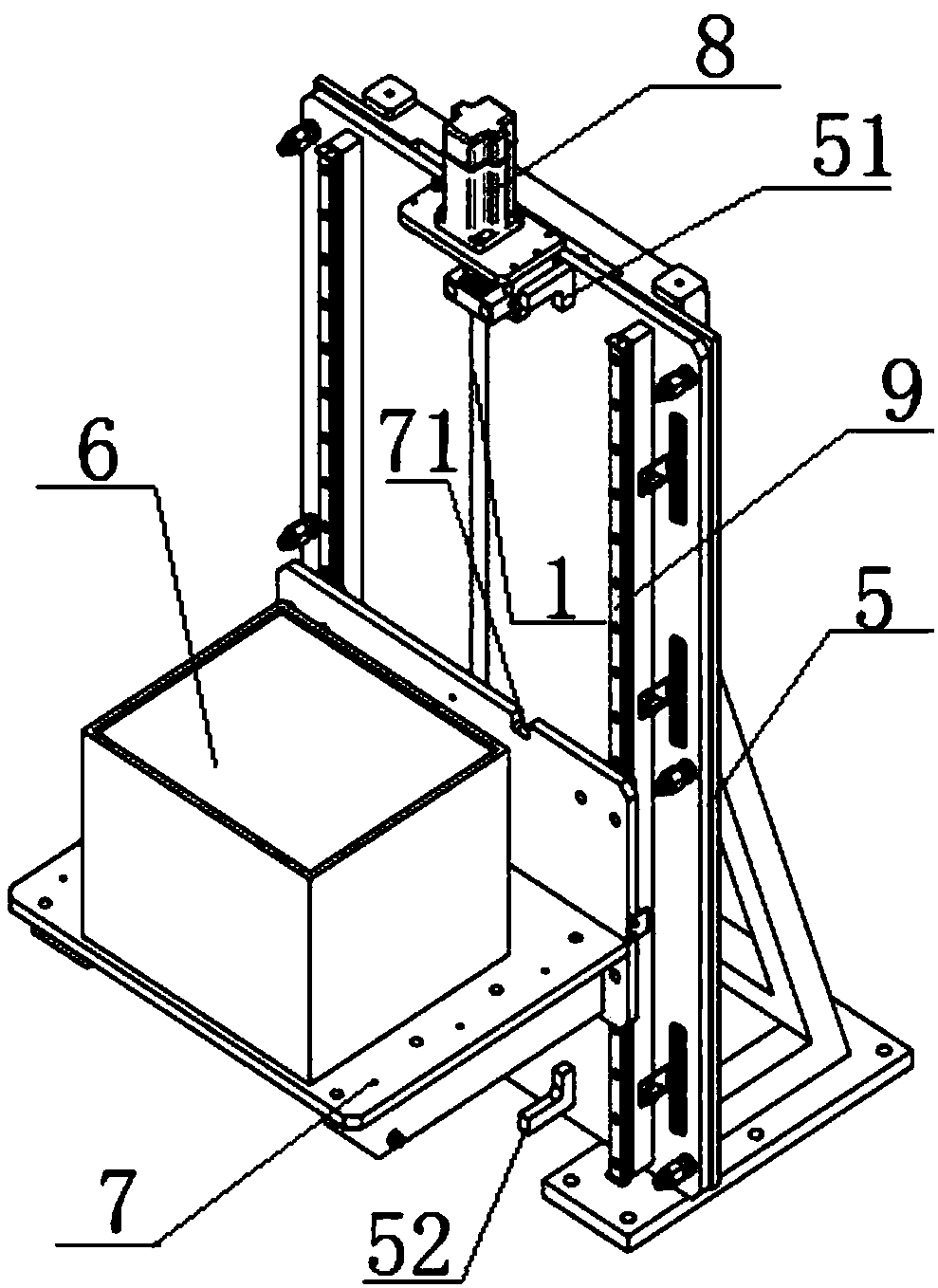

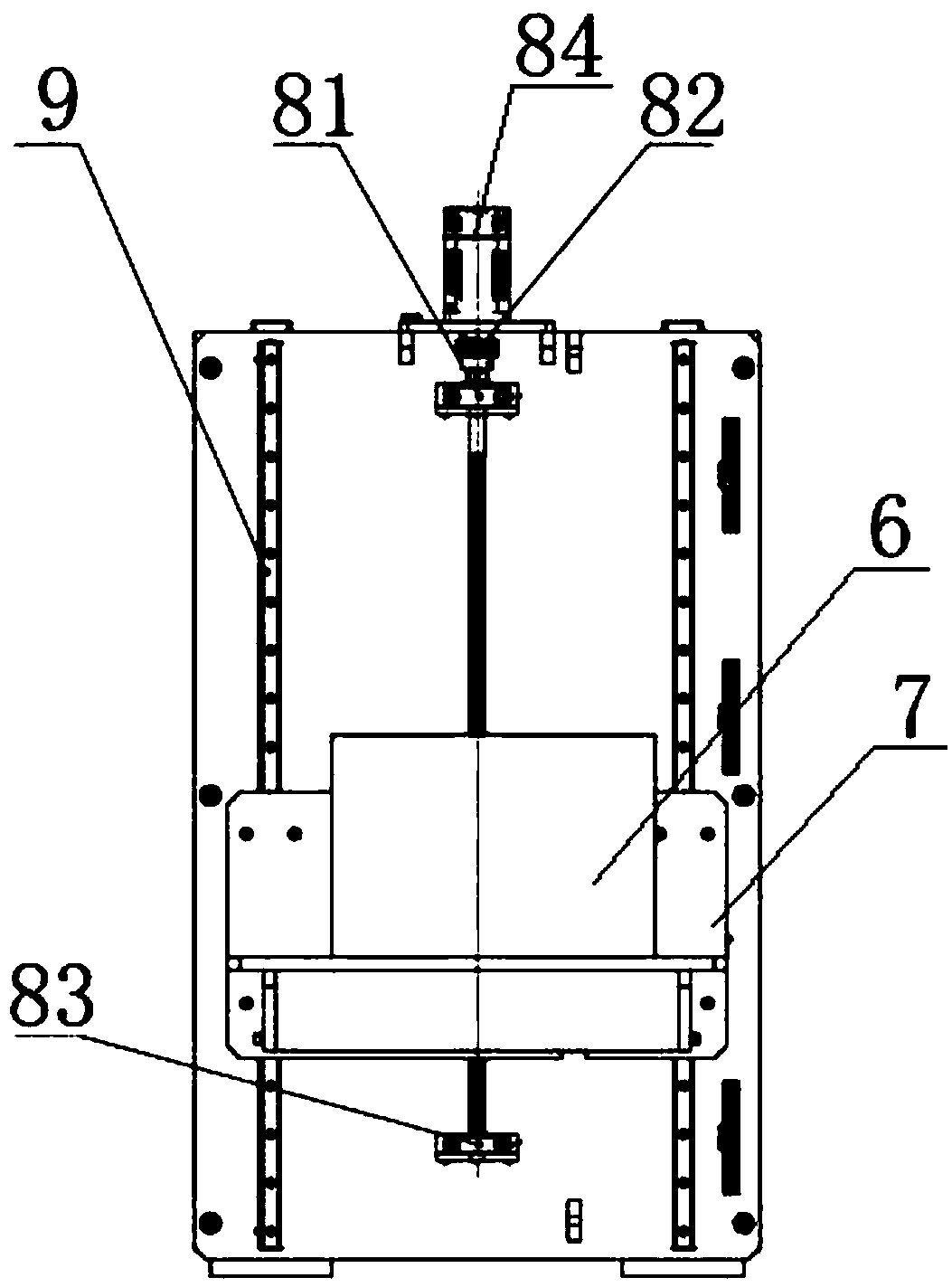

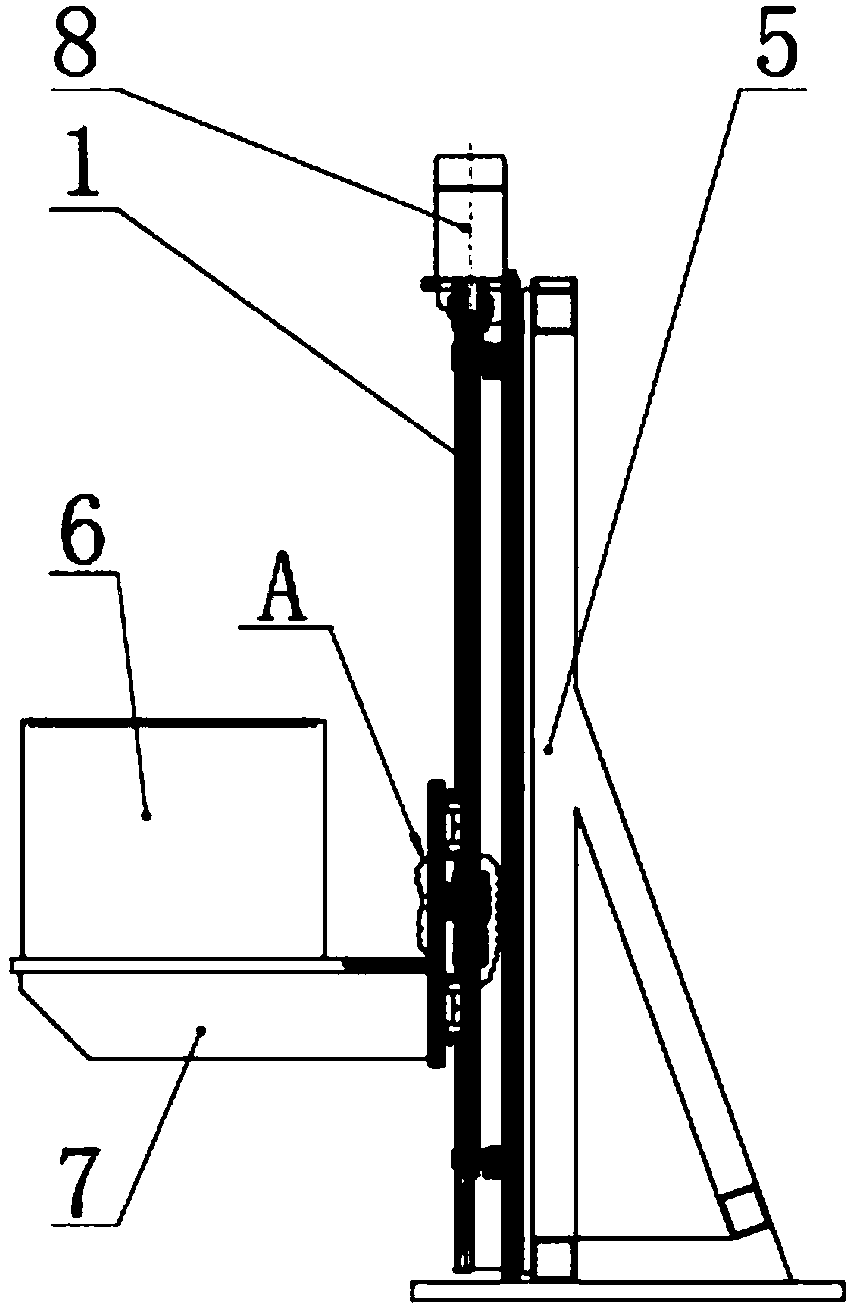

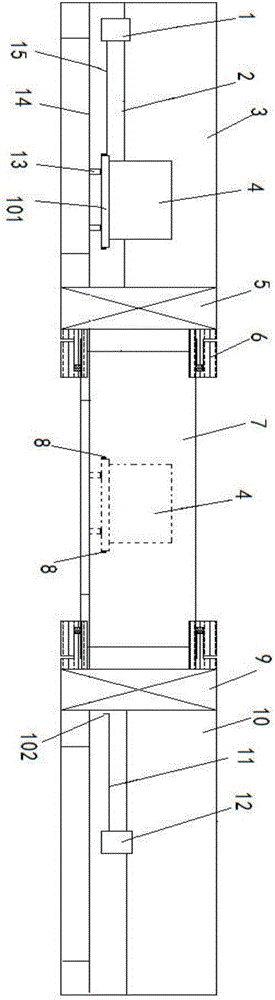

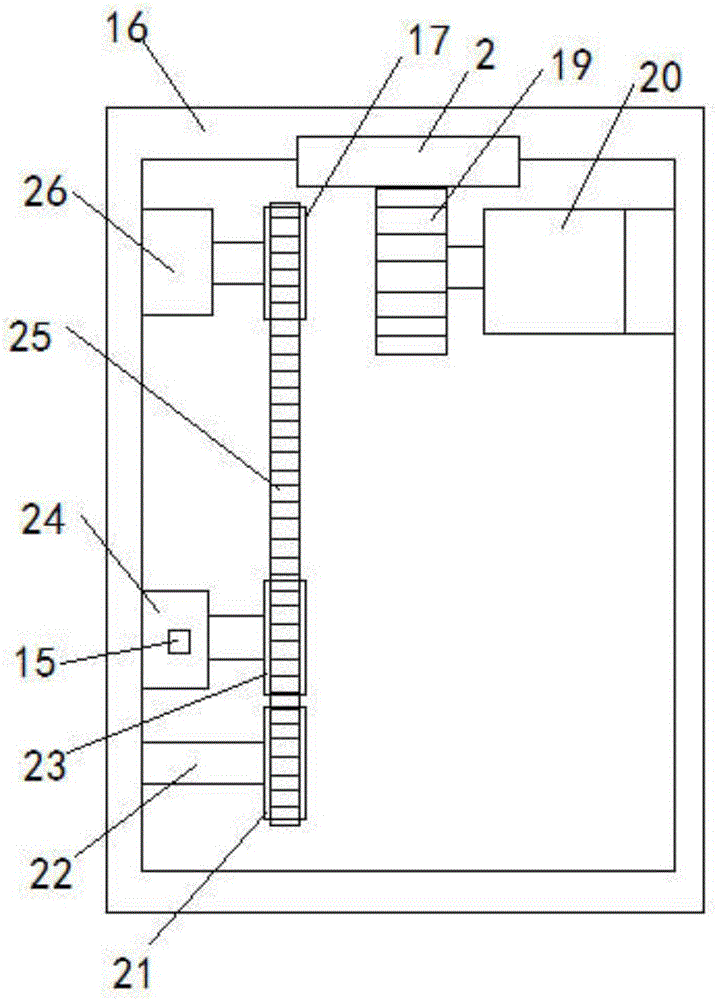

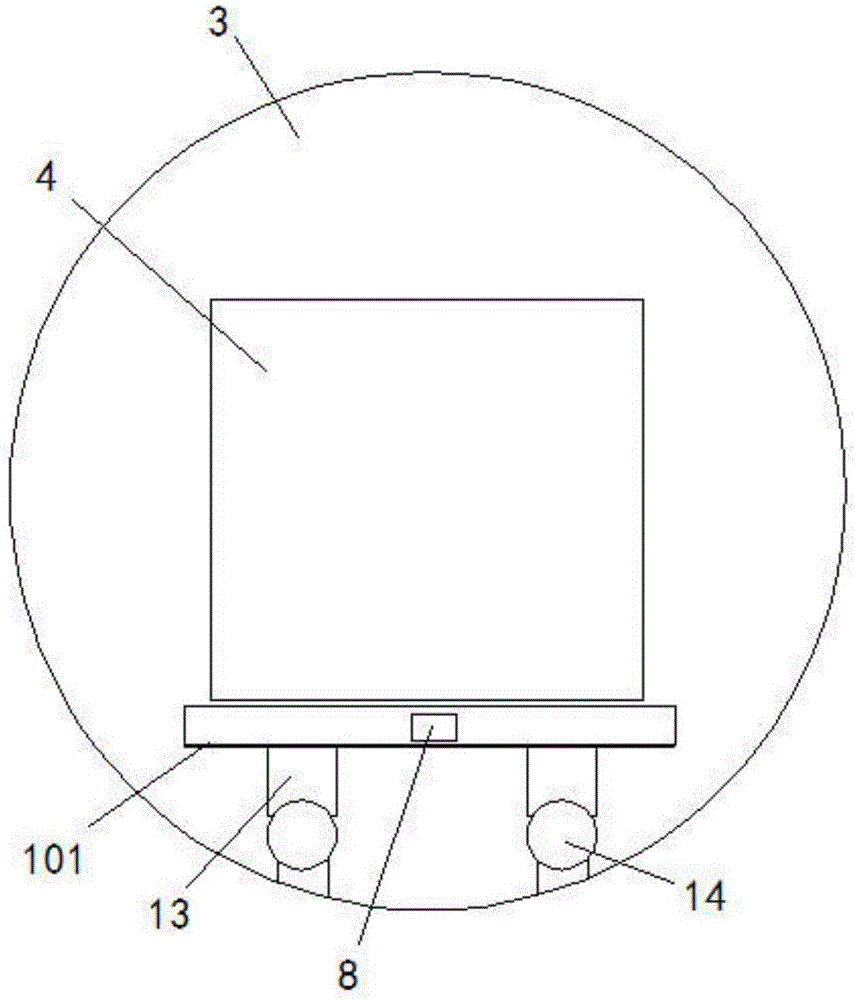

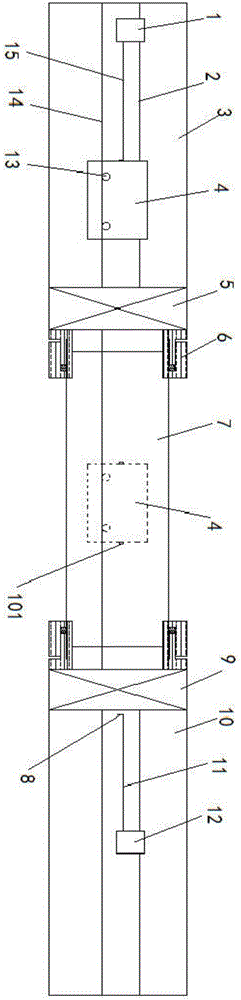

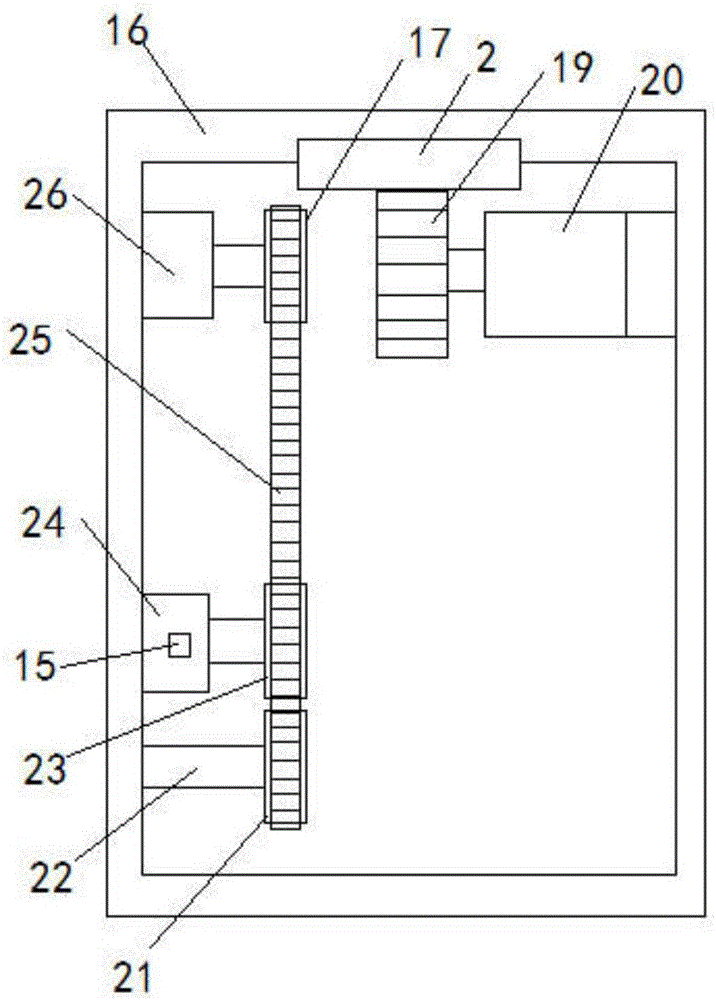

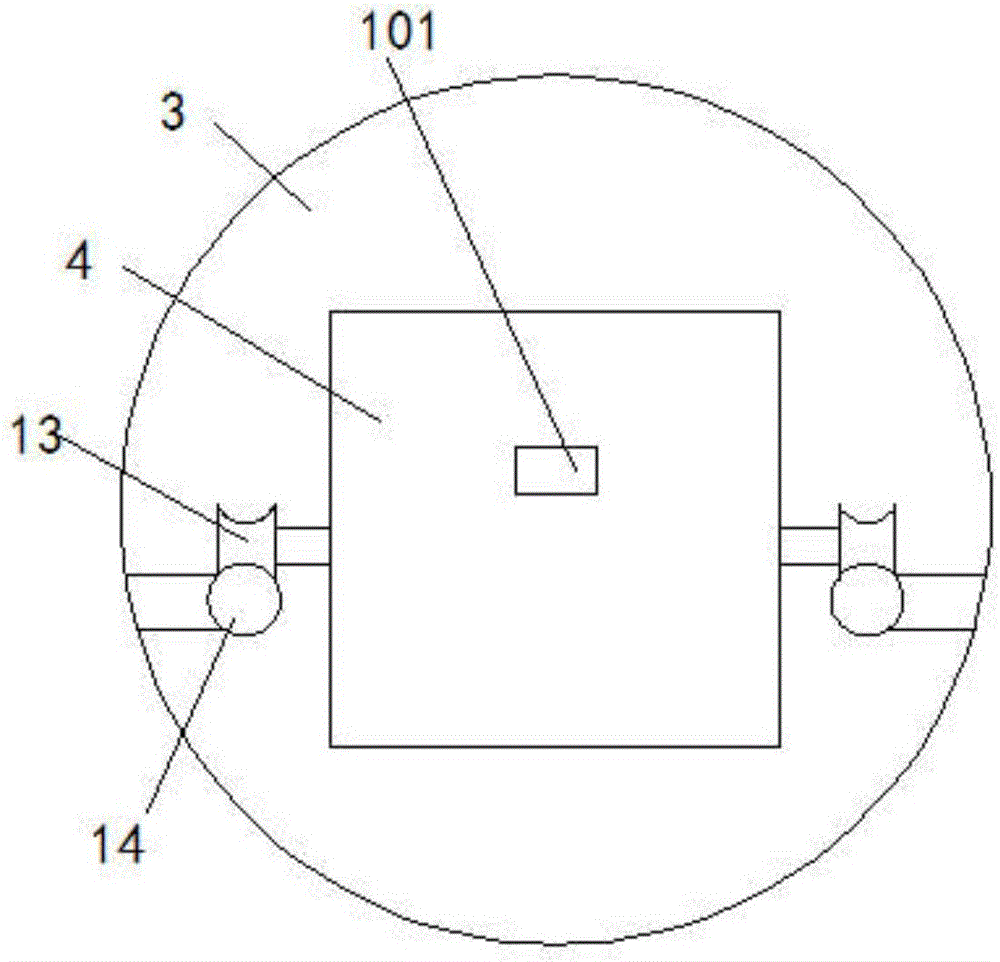

Fall prevention lifting device and fall prevention method thereof

PendingCN108557691AIngenious ideaTo achieve the purpose of continuous productionLifting framesEngineeringWeight-bearing

The invention discloses a fall prevention lifting device and a fall prevention method thereof, and belongs to the technical field of lifting devices. The fall prevention lifting device comprises a rack, a lifting platform and a power mechanism, and further comprises a double-nut screw mechanism, wherein the double-nut screw mechanism comprises a screw rod and a main nut and a sub nut which sequentially sleeve the screw rod, two ends of the screw rod are in transmission connection with the power mechanism, and the power mechanism is fixed to the rack; the main nut is in sleeved connection on anut seat along the outer wall, and the nut seat is fixedly connected with the lifting platform; an interval is reserved between the bottom ends of the main nut and subnut to avoid the load bearing ofthe subnut, so that the main nut holds the weight and the sub nut does nothold the weight. The fall prevention lifting device and the fall prevention method thereof have the advantages that the designis ingenious, and the problems in the prior art are solved that a weight-bearing nut of a screw rod mechanism of the lifting device slips and the production cannot be continuous.

Owner:ANHUI GVG NEW MATERIAL CO LTD

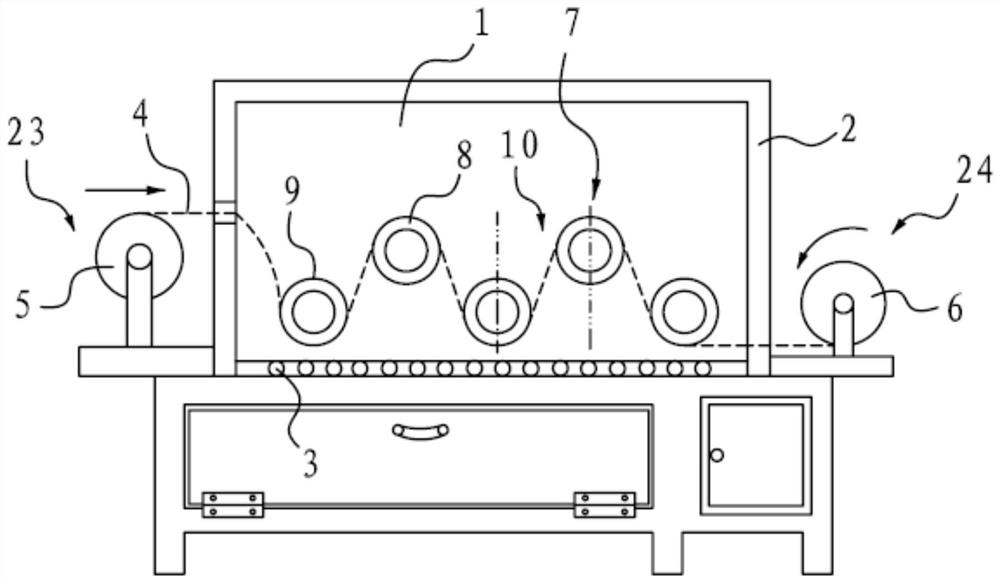

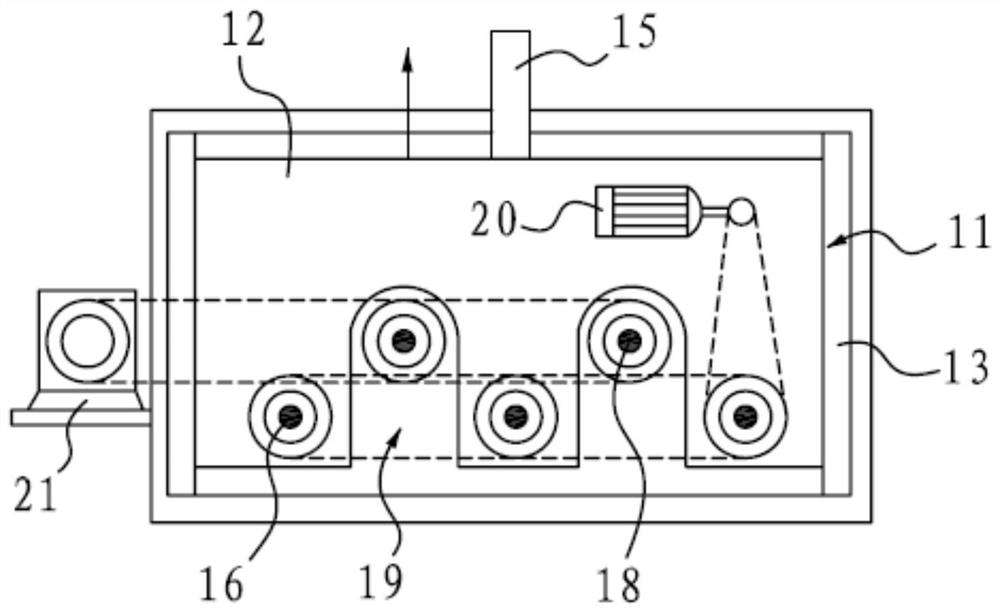

Full-automatic PTFE film/fiber stretching and sintering machine and stretching and sintering method

ActiveCN111941868AResolve the breakAvoid burn hazardFlat articlesTextiles and paperFiberTemperature control

The invention discloses a full-automatic PTFE film / fiber stretching and sintering machine. The full-automatic PTFE film / fiber stretching and sintering machine comprises a box body with a sealed stretching and sintering chamber and a temperature control part, an unwinding device is arranged on one side of the box body, a winding device is arranged on the other side of the box body, in the conveyingdirection of PTFE films / fibers, a plurality of stretching roller assemblies for carrying out constant-force stretching treatment on the PTFE films / fibers and a power mechanism for driving the stretching roller assemblies to rotate at a constant speed are arranged in the stretching and sintering chamber; the full-automatic PTFE film / fiber stretching and sintering machine further comprises a brokenend connecting system which pulls the broken PTFE films / fibers to be sequentially wound on the stretching roller assemblies in a staggered mode and is connected with the winding device when the PTFEfilms / fibers in the stretching and sintering chamber are broken. The invention further discloses a method for stretching and sintering the stretching and sintering machine. By arranging a traction device and a lifting device, the PTFE films / fibers can be sequentially wound on the stretching roller assemblies in a staggered mode again without opening a door, and the problem of breakage of the PTFEfilms / fibers in the stretching and sintering process can be effectively solved.

Owner:QINGDAO UNIV

Process for intermittently polymerizing and continuously producing super high viscosity nylon 6 engineering plastic

The present invention features that through compounding assistant, material throwing substitution, heating to smelt, hydrolysis to open ring at 0.8-1.0 MPa and 250-290 deg.c; releasing pressure inside the reactor, vacuum polymerization for 60-180 deg.c, pressurizing the material into balance tank at 0.3-0.5 MPa and 265-275 deg.c, and discharging continuously from the bottom, nylon-6 engineering plastic with relative viscosity over 5.0 is produced. The method is suitable for producing superhigh viscosity nylon-6 engineering plastic with material caprolactam and its lower polymer.

Owner:夏焕文

Method for producing high-performance high water absorption resin

ActiveCN101143912AIncrease viscosityImprove heating efficiencyAbsorbent padsBandagesUltraviolet lightsPhotochemistry

The invention relates to a production method of high-performance super absorbent resin, which includes six steps. Firstly, with more than fifty mole percent of neutralization rate, acidyl-containing monomer aqueous solution and polymerization initiator stay in a pipeline, so that free radical polymerization reaction occurs to obtain thick prepolymer, and acidyl-containing monomer is selected from acrylic acid or methacrylic acid or 2-allylamine-2-methyl propane sulfonic acid or the compound; secondly, the thick prepolymer is added with long-chain and high-hydrophilic polyepoxy compound and is further converted into gelatiniform solid by utilizing a method of light-starting polymerization; thirdly, the gelatiniform solid is dried by hot wind with a temperature between 100 DEG C and 250 DEG C, smashed and filtered; fourthly, the solid is coated with surface crosslinking agent; fifthly, surface processing is carried out under a temperature between 80 DEG C and 230 DEG C; sixthly, inert inorganic salt powder is added. In the light-starting polymerization, the irradiation of ultraviolet light or infrared is utilized to initiate the prepolymer to be converted into gel.

Owner:FORMOSA PLASTICS CORP

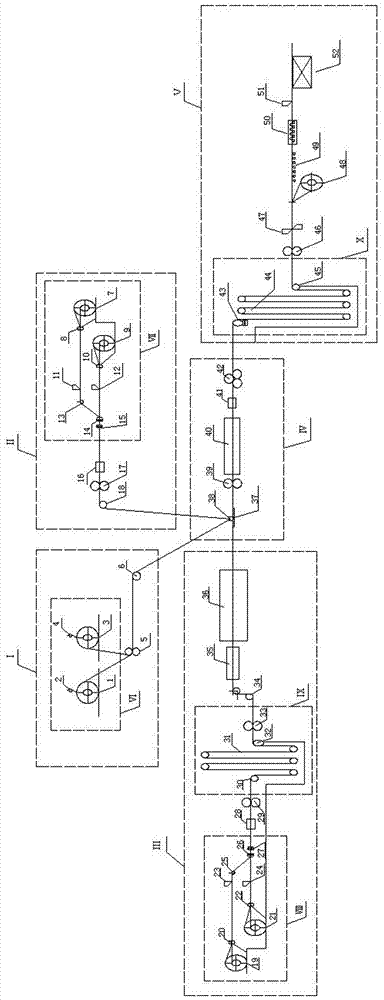

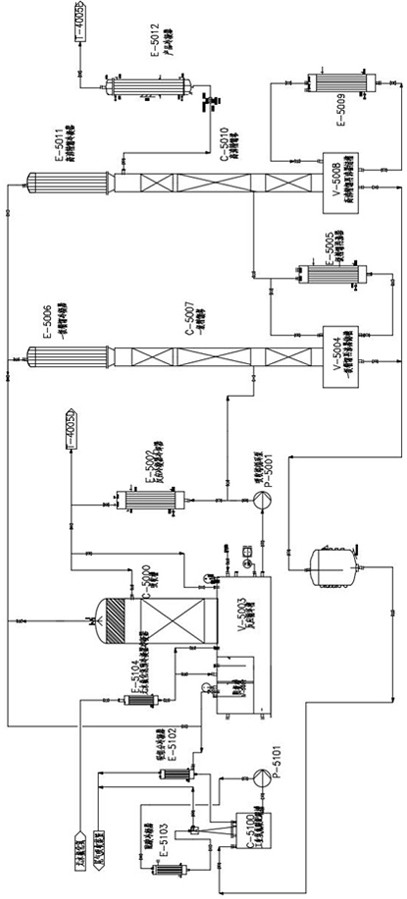

Efficient multifunctional SCF device and integrated multifunctional SCF device

ActiveCN110665253ATo achieve the purpose of continuous productionEfficient extractionChemical/physical/physico-chemical processesSolid solvent extractionControl engineeringProcess engineering

The invention discloses an efficient multifunctional SCF device and an integrated multifunctional SCF device, and relates to the technical field of chemical devices. The efficient multifunctional SCFdevice utilizes the shared tank body concept, and can realize the functions of efficient extraction, fractionation, esterification and the like by simply adjusting the configurations of a control piece assembly and controlling a production path according to production requirements in order to achieve the purpose of continuous production. The integrated multifunctional SCF device can solve the combination problem of an SFF technology, an extraction technology and the like by adjusting the configurations of the control piece assembly in order to achieve the purpose of integration.

Owner:三益创价生物科技(深圳)有限公司 +2

Different-root continuous cultivation method for lianas vegetable

InactiveCN101341833ARenew the root systemShorten the old vineHorticultureHigh survival rateWedge shape

The invention relates to a vegetable framing method, in particular to a continuous farming method of the distinct root seedling of vine vegetables; the method is carried out in a green house; the temperature of the greenhouse is 13 DEG C to 30 DEG C, the humidity is 60 percent to 85 percent and the light time is 8h every day; before grafting, the cultured rootstock seedling is planted at the transposition points 4 days to 5 days in advance; 30cm to 50cm young vine sprouts are selected as grafts; a cutting blade is used to chamfercut from down to top between two sections of very graft, and the depth is 1.5cm to 2.5cm; the cutting blade is used to cut both sides in the middle of the leaves in the second section of the rootstock seedling into sharp wedge shape, the length is consistent with the notch depth of the grafts, and then the two sides are butted and bound with the grafts; one month after the cut is healed, the binding is untied; old vines are cut off from below the grafting cut, pulled up together with old roots and removed outside the greenhouse; the old vines are pulled up after being cut off, plant residue is picked out to receive disinfection, and then organic fertilizer is added in. The seedling grafted through the method has high survival rate, high yield and can realize continuous production.

Owner:马新增

Continuous cultivation method for vertical seedling of lianas vegetables

InactiveCN101341847AShorten the old vineShorten the timeAgriculture gas emission reductionCultivating equipmentsGreenhouseCataphyll

The invention relates to a continuous farming method of the vertical seedlings of vine vegetables; the method is carried out in a green house; the temperature of the greenhouse is 13 DEG C to 30 DEG C, the humidity is 60 percent to 85 percent and the light time is no fewer than 8h every day; when the old vines grow to 10m, 40cm to 60cm young vine sprouts are selected as grafts; meanwhile, 2 to 3 node sprouts are selected to be removed from the base of the leaves by a cutting blade; the base of the leaves is removed; the vines are soaked in rooting powder solution; the organic biological soilless cultured substrate is dug into a valley; riversand is put into the valley; and then the vines are also put into the valley, with the riversand covered on and water sprayed on; finally, the organic biological soilless cultured substrate is covered, and the vines are compacted; after the cutting of the vines is healed and young sprouts grow, the old vines are cut off, pulled up together with old roots, and removed from the valley.

Owner:马新增

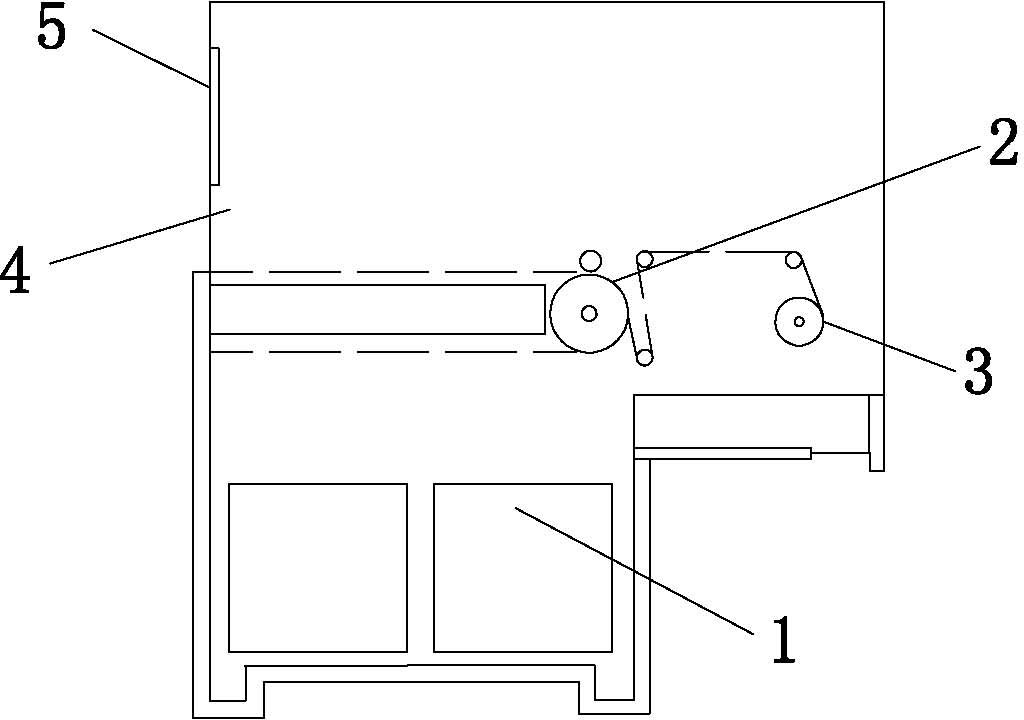

Resin bonded composite board continuous production device and production method

PendingCN106965449AProduction completeImprove performanceFlat articlesComposite slabIndustrial engineering

The invention belongs to the field of elevators, building decoration and household appliance materials, discloses a resin bonded composite board continuous production device and production method and aims to solve the problems that a resin bonded composite board is expensive and limited in application range, the labor cost of a single-board unit for producing the resin bonded composite board is high, continuous production cannot be achieved, and the finished product rate is low. The device comprises a thermoplastic resin film uncoiling unit, an upper-layer steel sheet processing unit, a lower-layer steel sheet processing unit, a composite unit and a post-processing unit. The resin bonded composite board production method includes the steps of an upper-layer steel sheet processing stage, a thermoplastic resin film uncoiling stage, a lower-layer steel sheet processing stage, a two-layer steel sheet composite stage and a composite post-processing stage. By means of the resin bonded composite board continuous production device and production method, the purpose of continuous production of the resin bonded composite board is achieved, the finished product rate is high, the production cost is greatly lowered, the shock reduction and noise reduction effects are better, and the process is simpler.

Owner:嘉峪关天源新材料有限责任公司

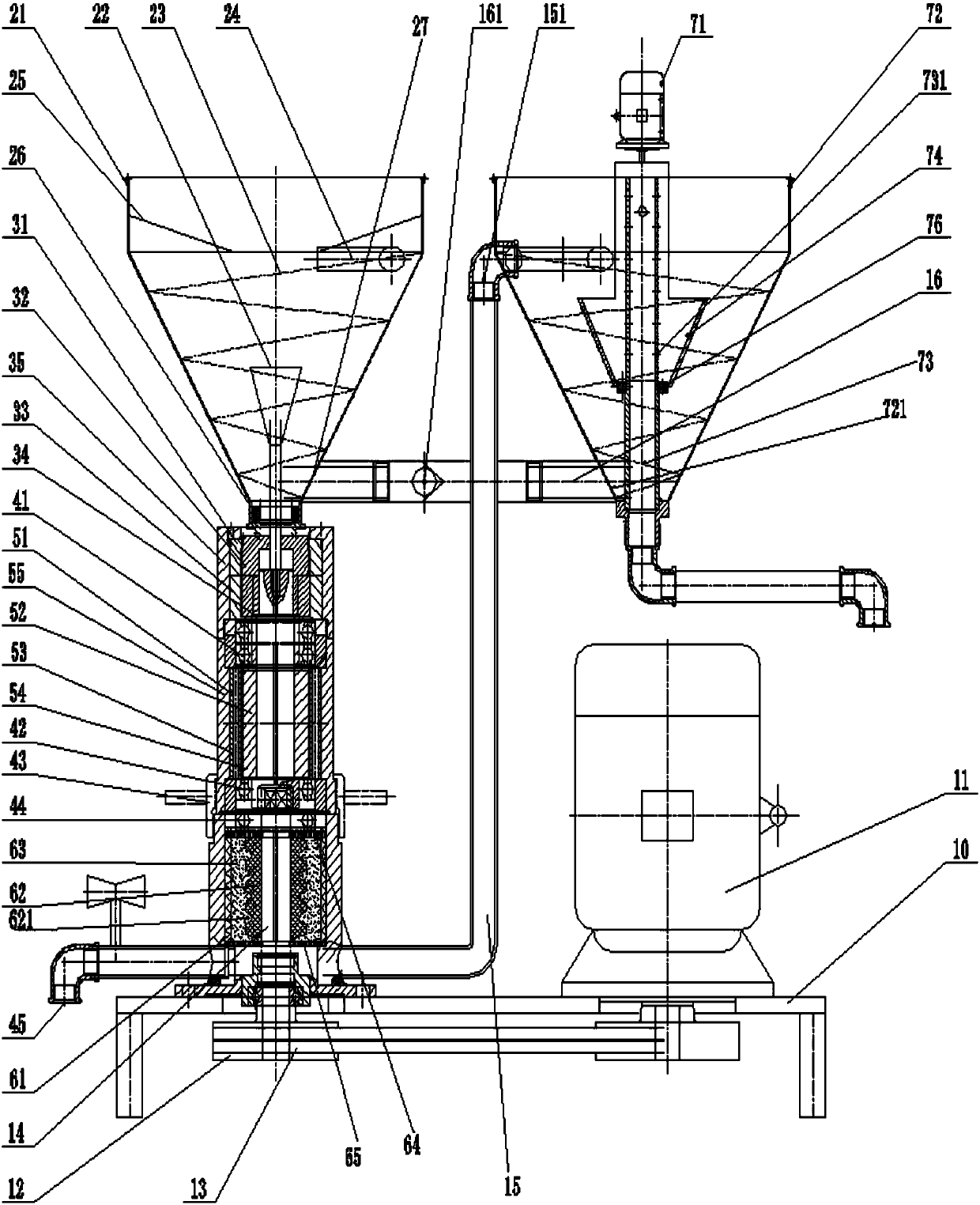

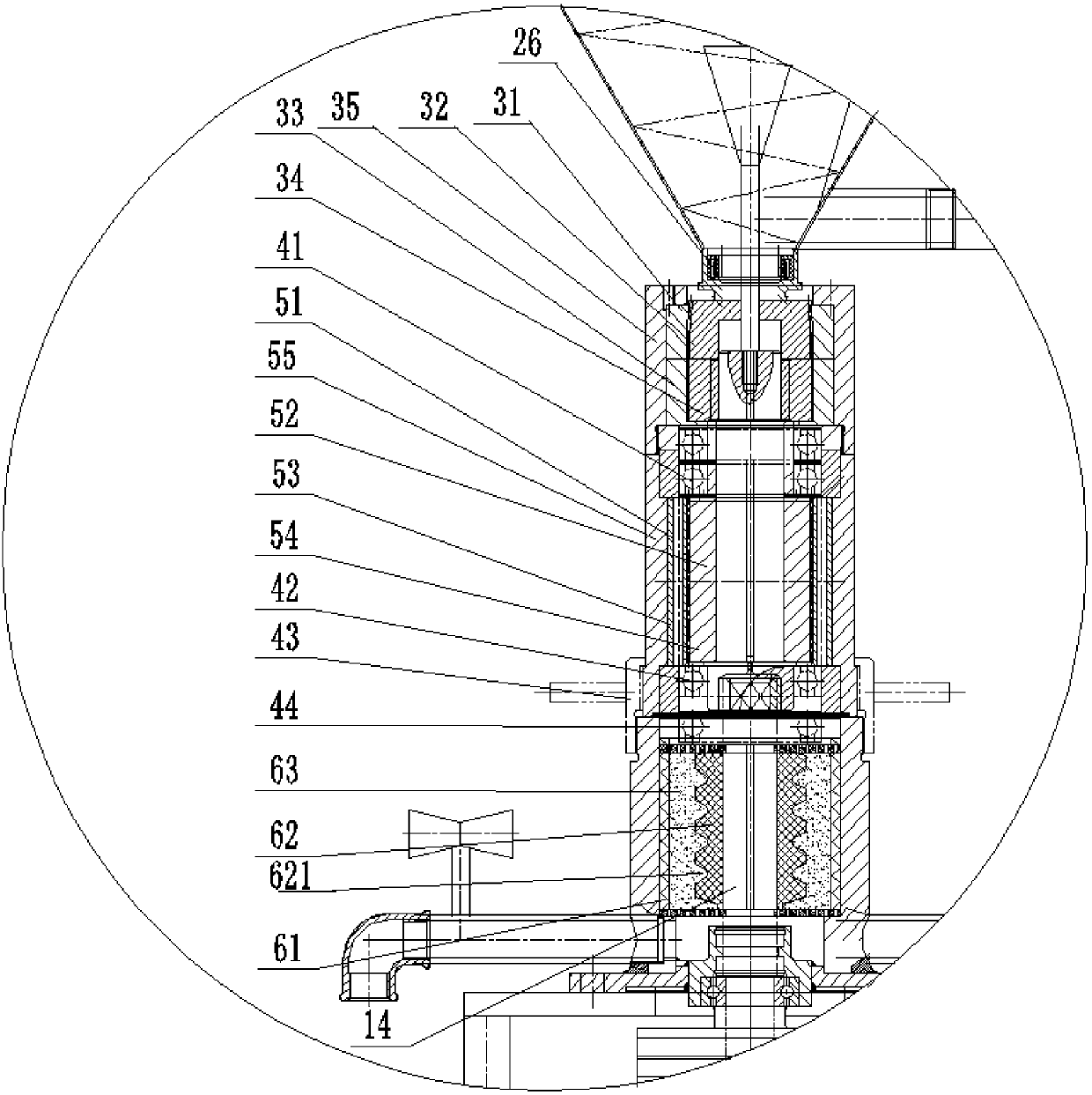

Liquid classifier for colloid mill

PendingCN107824321ATo achieve the purpose of continuous productionGas current separationCocoaElectric machineryColloid mill

The invention discloses a liquid classifier for a colloid mill. The liquid classifier for the colloid mill comprises a classifier shell, a finished product discharge pipe and a classifying mechanism;one end of the finished product discharge pipe is inserted in from the bottom of the classifier shell, and upwards extends; a regrinding flowing outlet is formed in the lower end of the side wall of the classifier shell; the classifying mechanism comprises a speed adjusting motor and a classifier rotating piece; the classifier rotating piece sleeves the finished product discharge pipe; the upper end of the classifier rotating piece is connected with the speed adjusting motor; and the speed adjusting motor can drive the classifier rotating piece to rotate with the finished product discharge pipe as axis. The liquid classifier for the colloid mill uses the classifier rotating piece for rotating materials, so that the materials with different thicknesses generate different speeds for layering; the thicker materials flow back to the colloid mill for continuous grinding from the regrinding flowing outlet; and the materials meeting requirements enter the finished product discharge pipe for discharge from water leakage holes to achieve convenience and speediness.

Owner:韶关市超微磨机设备有限公司 +1

Wire winding shaft

InactiveCN102372191ASimple structureEasy to useFilament handlingWinding machineContinuous production

The invention discloses a wire winding shaft. The wire winding shaft is mounted on a wire winding machine; a wire winding disk is sleeved on the wire winding shaft for winding wire; the edge of the wire winding shaft is of a step shape; and the diameter of the wire winding shaft is gradually increased from top to bottom layer by layer. The wire winding shaft disclosed by the invention has simple structure, and is convenient to use; as the wire winding shaft can directly use the wire winding disks of various apertures, the operator is not required to manually cut wire and replace the wire winding shaft through an operation panel of the wire winding machine, thereby realizing continuous production, saving the production cost and improving the production efficiency.

Owner:JIANGSU BADA CABLE

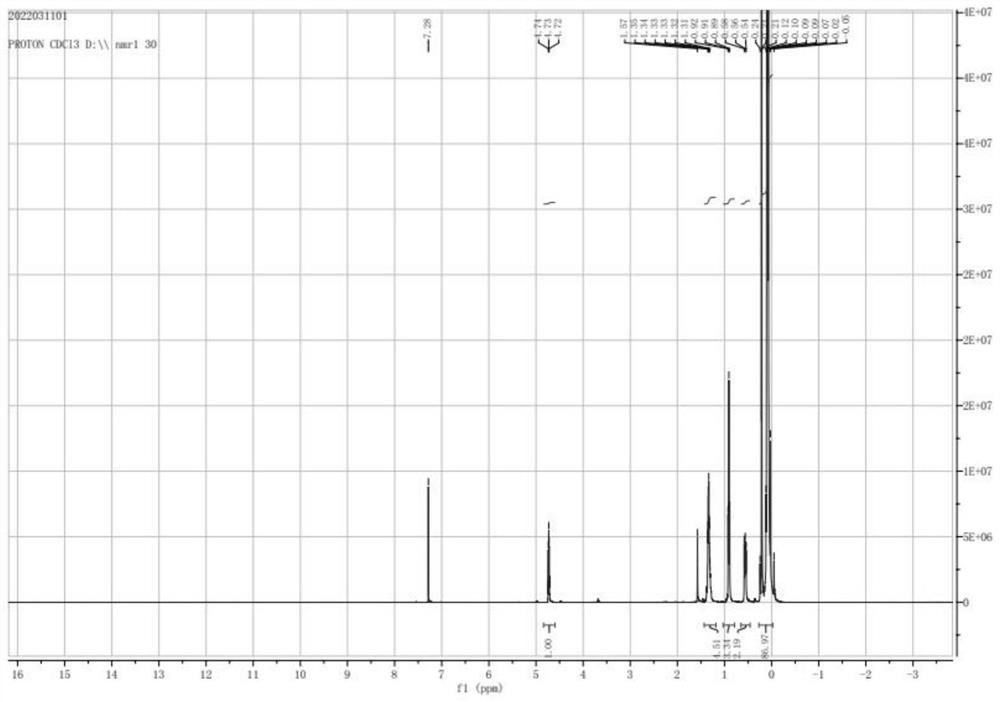

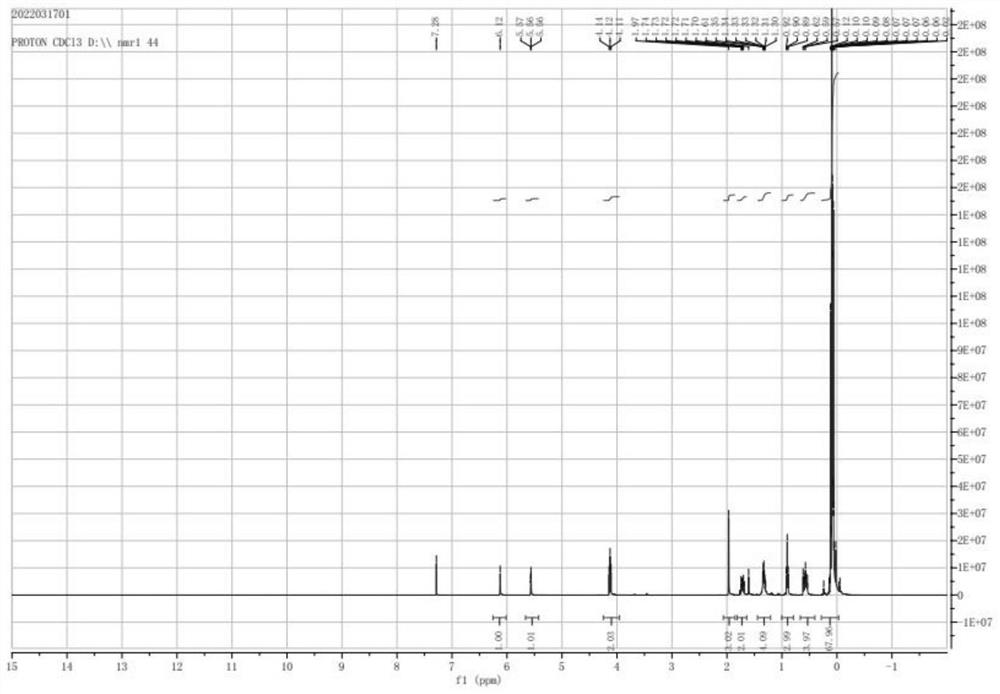

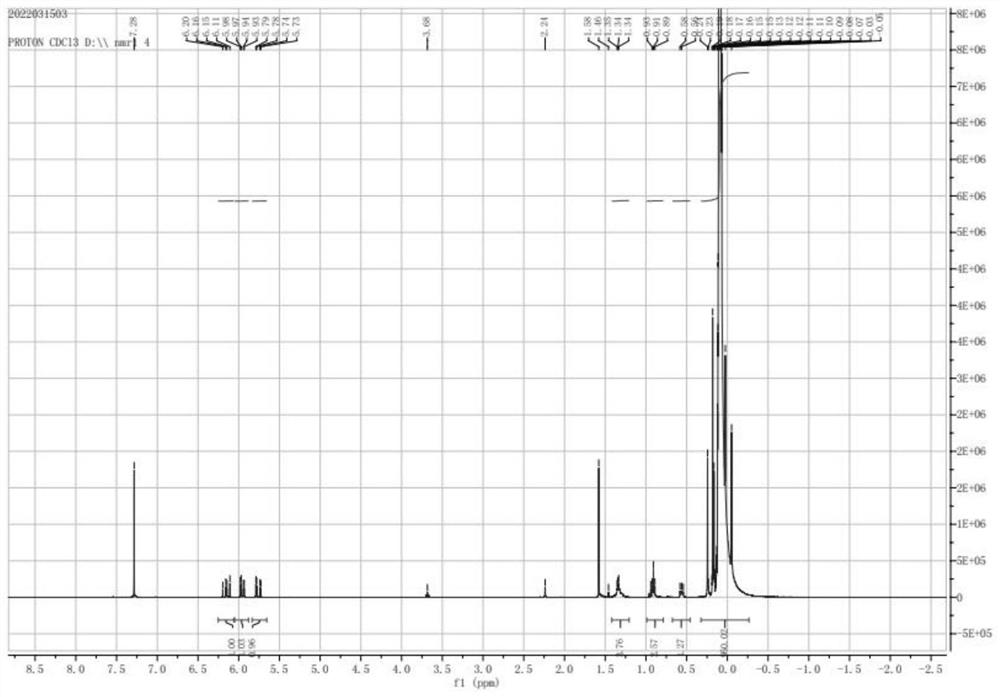

Preparation method of unilateral reaction type functional group terminated silicone oil

PendingCN114854021ANarrow molecular weight distribution widthReduced balance reaction timeEndcappingNitrogen gas

The invention discloses a preparation method of unilateral reaction type functional group end-capped silicone oil, which specifically comprises the following steps: S1, dissolving hexamethylcyclotrisiloxane in THF (tetrahydrofuran) under the protection of nitrogen, setting the flow rate of a metering pump B to be 28.06 g / min, setting the flow rate of a metering pump A to be 4.53 g / min under the protection of 400mL of butyl lithium and nitrogen, simultaneously starting the pumps A and B to pump materials into a premixer and then enter a microchannel reactor, the reaction temperature is set to be 0-5 DEG C, and the mixture enters the reactor through a metering pump C; the preparation method of the unilateral reaction type functional group end-capped silicone oil disclosed by the invention comprises the following steps: carrying out ring-opening polymerization reaction on butyl lithium and hexamethylcyclotrisiloxane cations by using a microchannel reactor, and then reacting with monochlorosilane to generate single-end hydrogen-containing or single-end functional group end-capped silicone oil. The equilibrium reaction time is shortened, the molecular weight distribution width of the silicone oil is reduced, and the high-quality monoreactive functional group terminated silicone oil is obtained.

Owner:希立科高新材料科技(苏州)有限公司

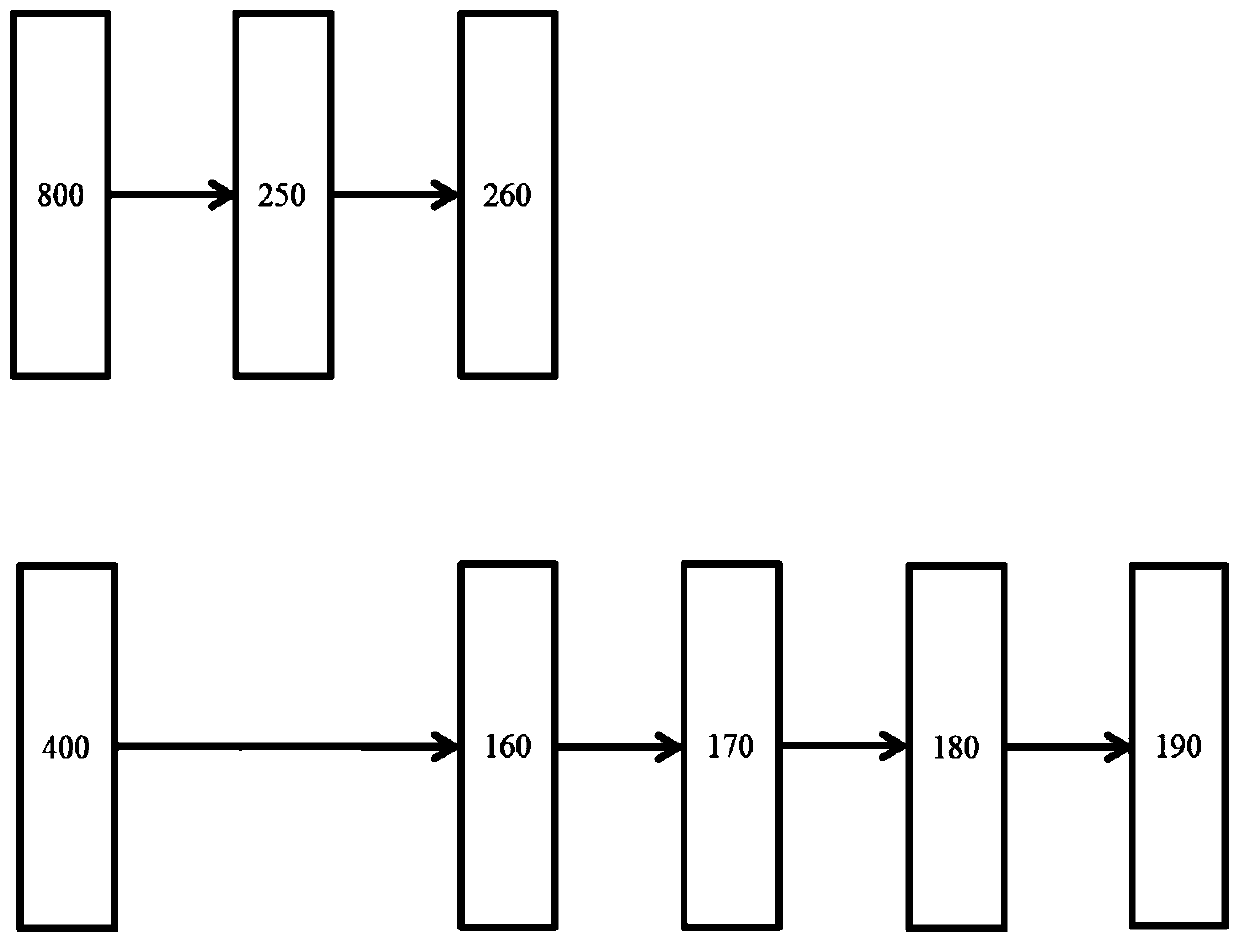

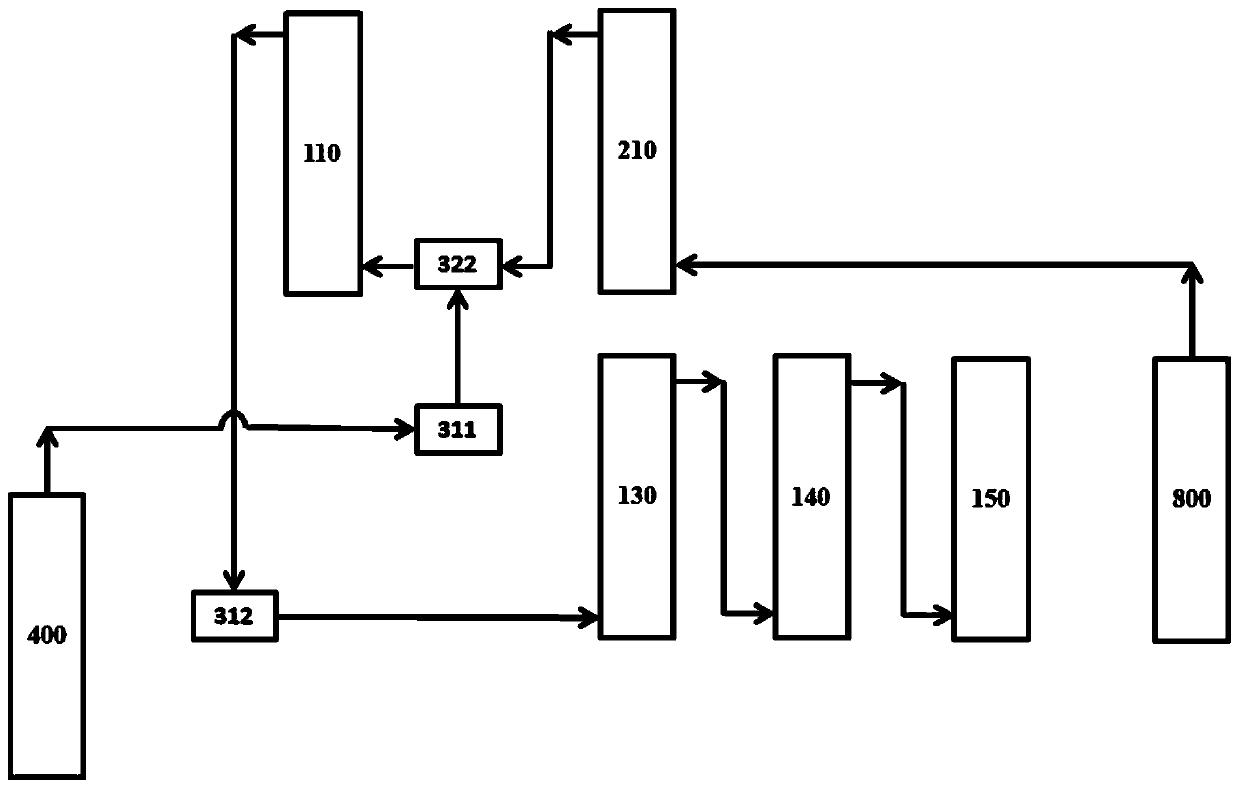

Water-flowing type graphene film preparation device

ActiveCN105970183AAvoid idlingIncrease boat loadChemical vapor deposition coatingCooling chamberWater flow

The invention relates to a water-flowing type graphene film preparation device which comprises a high-temperature technological chamber, a low-temperature cooling chamber A, a low-temperature cooling chamber B and a sample boat, wherein sliding rails are horizontally and fixedly arranged along the bottom inner walls of the low-temperature cooling chamber A, the high-temperature technological chamber and the low-temperature cooling chamber B; a flat car is arranged above the sliding rails and in the low-temperature cooling chamber A; the sample boat is arranged on the flat car; the low-temperature cooling chamber A and the low-temperature cooling chamber B are internally and respectively provided with a boat pushing device A and a boat pushing device B that are consistent in structure; the boat pushing device A and the boat pushing device B are respectively and detachably connected with a sample taking rod A and a sample taking rod B; one end, far from the boat pushing device A, of the sample taking rod A can be driven to be connected with or separated from the flat car by the boat pushing device A; and one end, far from the boat pushing device B, of the sample taking rod B can be driven to be connected with or separated from the flat car by the boat pushing device B. The water-flowing type graphene film preparation device has the benefits that the load capacity of the sample boat is increased and continuous production is realized.

Owner:CHONGQING GRAPHENE TECH

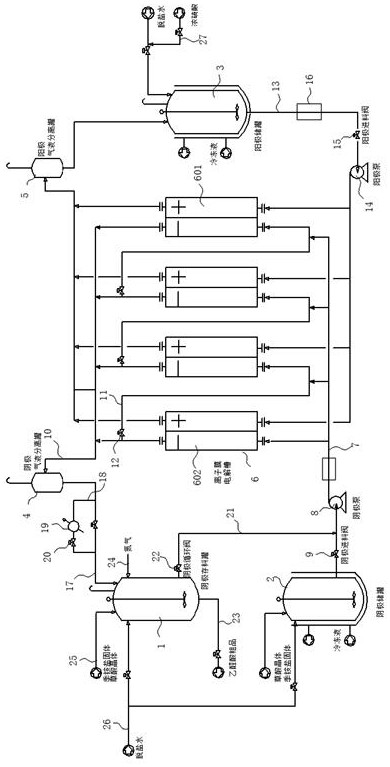

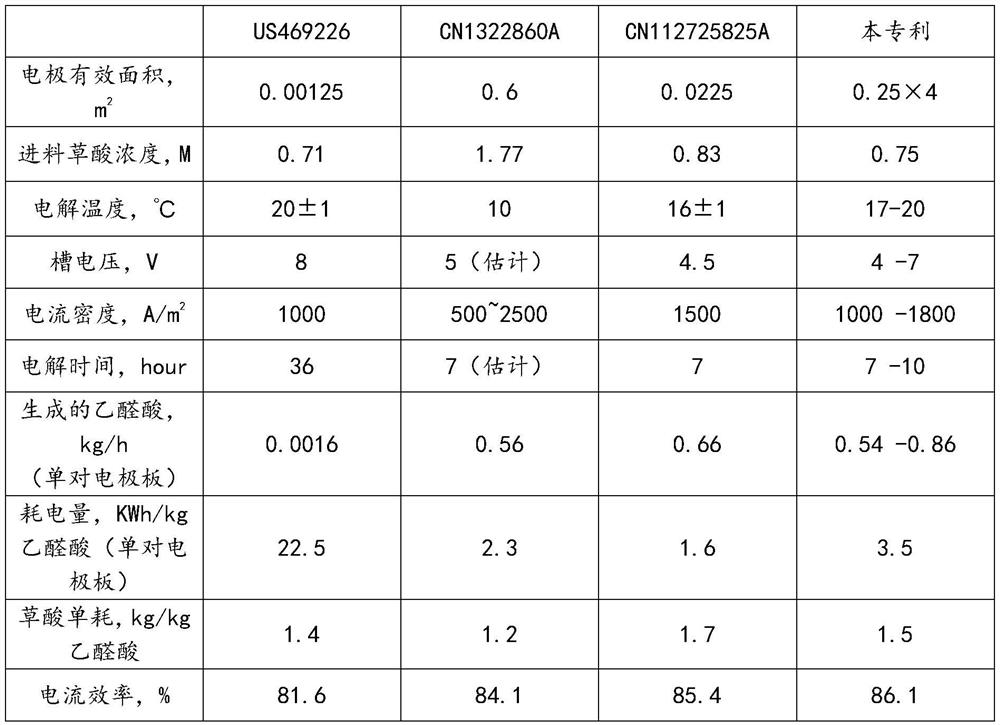

Method for continuously preparing glyoxylic acid through oxalic acid electrolysis

ActiveCN114016059ASimple processLow investment costElectrolysis componentsChemical industryOXALIC ACID DIHYDRATEContinuous operation

The invention discloses a method for continuously preparing glyoxylic acid through oxalic acid electrolysis, which comprises a cathode storage tank, a cathode storage tank, an anode storage tank, a cathode gas-liquid separation tank, an anode gas-liquid separation tank and a plurality of electrolytic cell modules,the electrolytic cell modules are equally divided into anode chambers and cathode chambers, one end of each cathode chamber and the output end of the cathode storage tank are connected with a cathode feeding header pipe, and a cathode pump and a cathode feeding valve are arranged between the two ends of the cathode feeding header pipe. According to the invention, free switching between intermittent operation and continuous operation is realized through switching of connection modes of the plurality of electrolytic cell modules, and the purpose of continuous production is finally achieved: the plurality of electrolytic cell modules are connected in parallel, so that the catholyte is subjected to a rapid circular reaction between the cathode storage tank and the electrolytic cell, and after the concentration of glyoxylic acid in the catholyte reaches a set value, and switching is carried out to a series connection mode, and the circulation is closed to carry out continuous production.

Owner:EAST CHINA ENG SCI & TECH +1

Direct-seeding continuous cultivation method for lianas vegetables in greenhouse

InactiveCN101341848AReduce labor intensityReduce the length of old vinesCultivating equipmentsSoilless cultivationHigh survival rateBiology

The invention relates to a continuous farming method of the direct sown seedlings of vine vegetables; the method is carried out in a green house; the temperature of the greenhouse is 13 DEG C to 30 DEG C, the humidity is 60 percent to 85 percent and the light time is no fewer than 8h every day; the cultured rootstock seedlings are planted at the transposition points in advance; after the seedlings grow into strong seedlings, 30cm to 50cm young vine sprouts are selected as grafts; a cutting blade is used to chamfercut from down to top between two sections of every graft, and the depth is 1.5cm to 2.5cm and the depth is no less than half of the diameter of the young sprouts; the cutting blade is used to cut both sides in the middle of the leaves in the second section of the rootstock seedling into sharp wedge shape, and the length is consistent with the notch depth of the grafts; then the two sides are butted and bound with the grafts; one month after the cut is healed, the binding is untied; old vines are cut off from below the grafting cut, pulled up together with old roots and removed outside the greenhouse; the old vines are pulled up after being cut off, plant residue is picked out to receive disinfection, and then organic fertilizer is added in. The seedling grafted through the method has high survival rate, high yield and can realize continuous production.

Owner:马新增

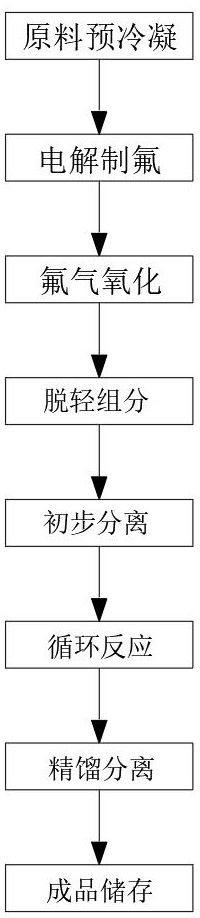

Purification process of high-purity anhydrous hydrogen fluoride

The invention relates to the technical field of purification of anhydrous hydrogen fluoride, in particular to a purification process for high-purity anhydrous hydrogen fluoride. The purification process comprises the following steps: 1, pre-condensation of raw materials; 2, preparation of fluorine by electrolysis; 3, oxidization with fluorine gas; 4, removal of light components; 5, preliminary separation; 6, a circular reaction; 6, a circular reaction; 7, rectification separation; and 8, storage of a finished product. The process has the beneficial effects that by arranging continuous purification equipment, technological process is simple, equipment is few, production cost is low, the purpose of continuous production can be achieved, large-batch production is convenient to achieve, and production and purification efficiency is greatly improved; by arranging separation processes such as electrolysis, the circular reaction and rectification, product separation precision is greatly improved, product purity is greatly improved on the premise of reducing introduced new impurities, and product quality is improved.

Owner:福建瓮福蓝天氟化工有限公司

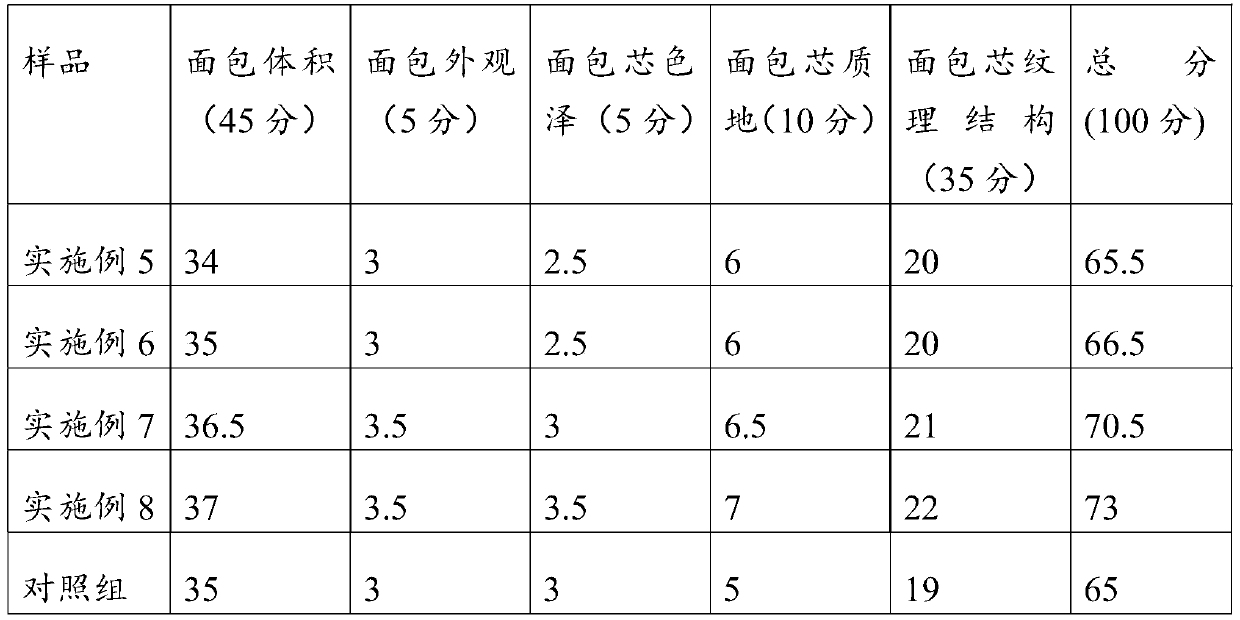

Whole wheat bread improver, whole wheat bread and preparation method of whole wheat bread improver

PendingCN109793030ATargetedImprove qualityDough treatmentPre-baking dough treatmentAlpha-amylaseXylanase

The application discloses a whole wheat bread improver, whole wheat bread and a preparation method of the whole wheat bread improver. The whole wheat bread improver is made from, by weight, 0.05-0.18part of fungal alpha-amylase, 0.40-0.75 part of xylanase, 0.08-0.20 part of glucose oxidase, 10-40 parts of sodium-calcium stearyl lactylate, 0.8-2 parts of vitamin C, and 100-400 parts of wheat gluten. The application also provides whole wheat bread adopting the whole wheat bread improver. The problem of the prior art is solved that a bread improver has no specificity and may cause poor properties, such as small whole wheat bread size, rough interior tissue and dry and hard taste, during making of the whole wheat bread.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

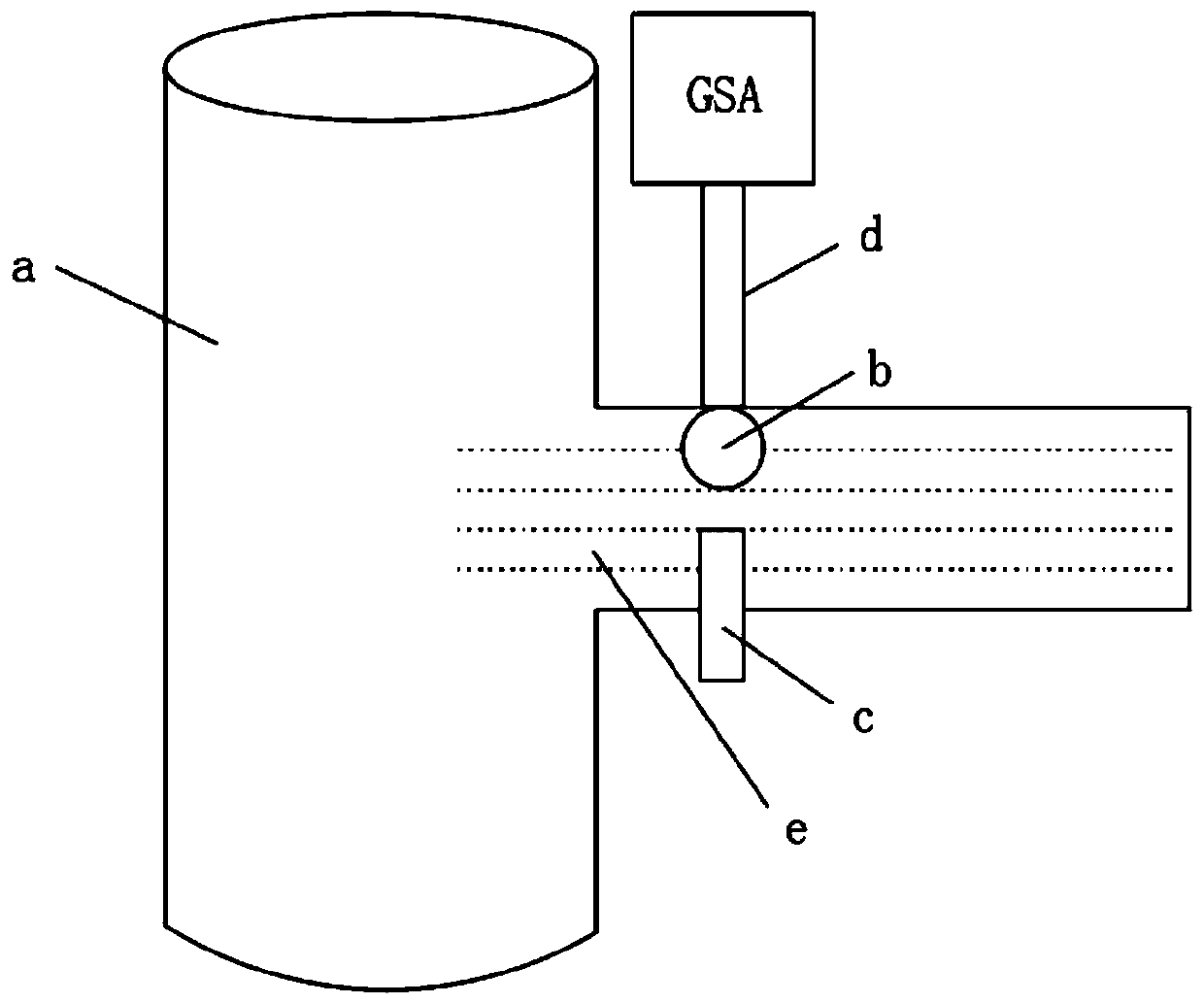

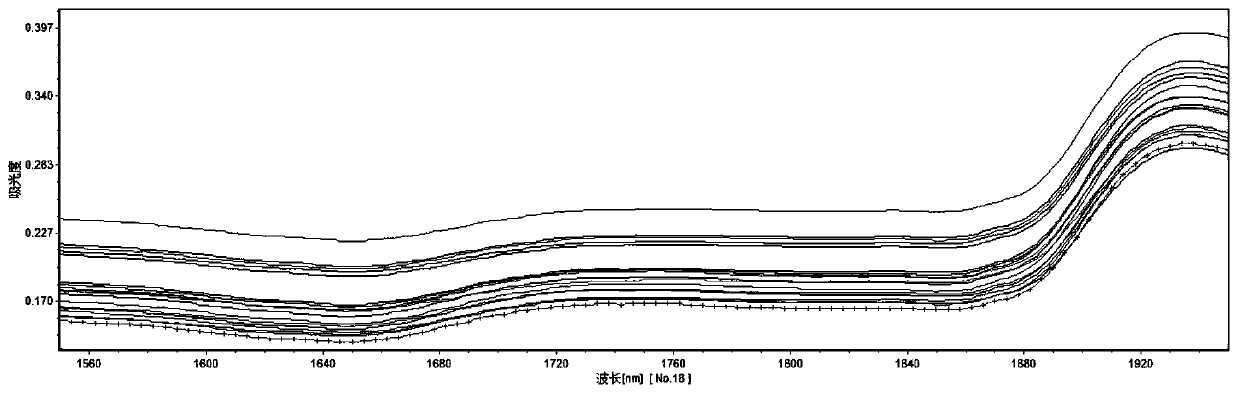

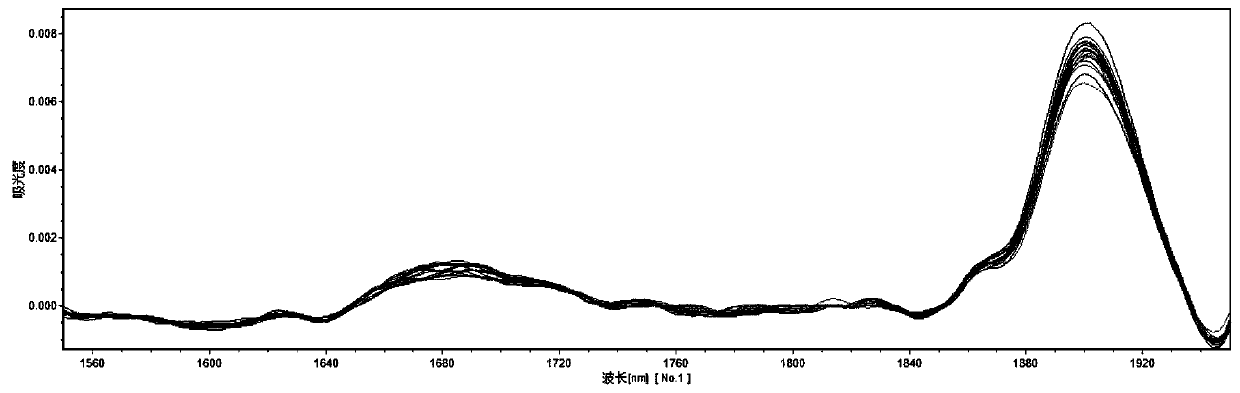

Online detection method for glucoside content in stevioside extracting solution

InactiveCN111077107AImprove detection efficiencyReal-time online detectionMaterial analysis by optical meansPretreatment methodOptical spectrometer

The invention provides an online detection method for the glucoside content in a stevioside extracting solution, and relates to the technical field of glucoside content detection. The online detectionmethod for the glucoside content in a stevioside extracting solution comprises the following steps: S1, establishing a detrending correction pretreatment method; S2, establishing a multiple linear regression modeling method; S3, installing a fluid sample measuring device and a sampling valve of a GSA103 type near-infrared spectrometer at an outlet of a liquid flowing-out pipeline of a macro-porous adsorption tank, immersing the fluid sample measuring device of the instrument in liquid in the pipeline, and fixing the instrument; and S4, setting parameters of the spectrograph, setting the number of scanning times to be 30, setting the number of sampling times to be 20, setting the wavelength scanning range to be 1550-1950 nm, and setting the wavelength increment to be 2 nm. According to theinvention, real-time online detection can be realized, the purpose of continuous production is achieved, information of all samples can be detected, the detection is convenient, and the detection efficiency of the glucoside content is greatly improved; and the detection mode does not need any treatment on the sample, the sample is not damaged, and the detection process is green and environment-friendly.

Owner:山东金璋隆祥智能科技有限责任公司

Running-form continuous large-scale graphene thin film preparation device

ActiveCN106119806AAvoid idlingIncrease boat loadChemical vapor deposition coatingGrapheneLoad capacity

The invention relates to a running-form continuous large-scale graphene thin film preparation device which comprises a high-temperature process cavity, a low-temperature cooling cavity A, a low-temperature cooling cavity B and a sample boat. Slide rails are horizontally and fixedly arranged along the middles of the two side inner walls of the low-temperature cooling cavity A, the high-temperature process cavity and the low-temperature cooling cavity B correspondingly. Pulley blocks corresponding to the slide rails are rotatably connected to the two sides of the sample boat. The sample boat slides along the slide rails through the pulley blocks on the two sides of the sample boat. A boat push device A and a boat push device B are arranged inside the low-temperature cooling cavity A and the low-temperature cooling cavity B correspondingly, wherein the boat push device A and the boat push device B are of the same structure. A sampling rod A and a sampling rod B are detachably connected to the boat push device A and the boat push device B correspondingly. The end, away from the boat push device A, of the sampling rod A can be driven by the boat push device A to be connected to or disconnected from the sample boat. The end, away from the boat push device B, of the sampling rod B can be driven by the boat push device B to be connected to or disconnected from the sample boat. The running-form continuous large-scale graphene thin film preparation device has the beneficial effects that the load capacity of the sample boat is increased, and continuous production is facilitated.

Owner:CHONGQING GRAPHENE TECH

A high-efficiency multifunctional SCF device and a consistent operation multifunctional SCF device

ActiveCN110665253BTo achieve the purpose of continuous productionEfficient extractionChemical/physical/physico-chemical processesSolid solvent extractionProcess engineeringIndustrial engineering

The invention discloses a high-efficiency multifunctional SCF device and a consistent operation multifunctional SCF device, and relates to the technical field of chemical equipment. The high-efficiency multifunctional SCF device provided by the present invention utilizes the concept of "shared tank body", and can achieve efficient extraction, fractionation, esterification and other functions by simply adjusting the configuration of control components and controlling the production path according to production needs, and achieving continuous purpose of production. The multifunctional SCF device with consistent operation provided by the present invention can solve the problem of combination of SFF technology and extraction technology by adjusting the configuration of the control components, and achieve the goal of consistent operation.

Owner:三益创价生物科技(深圳)有限公司 +2

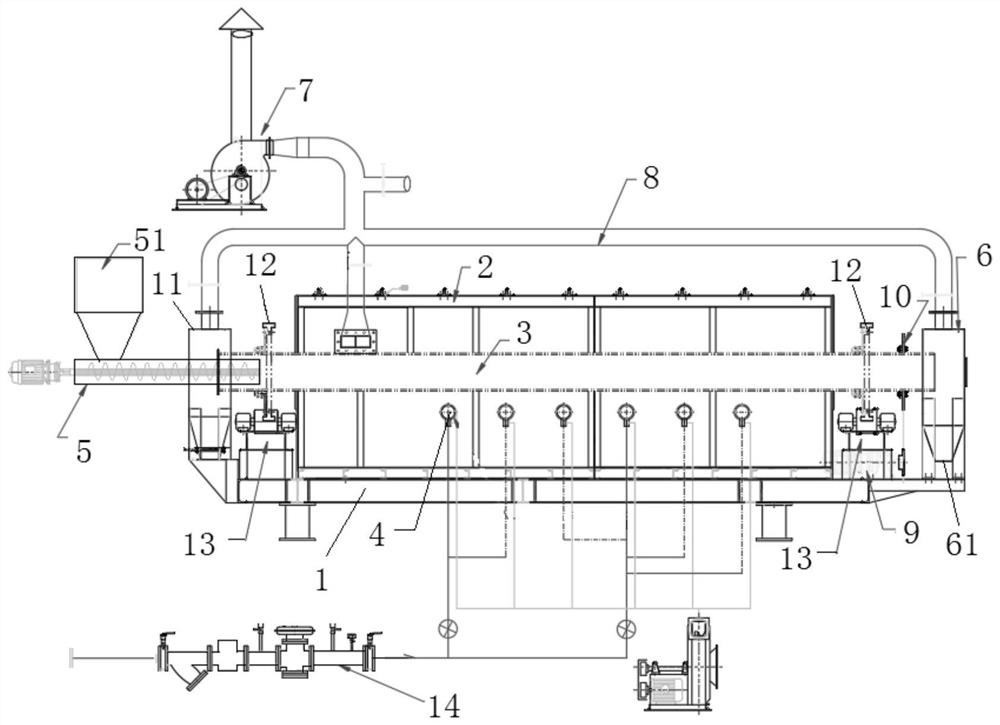

Fuel gas carbonization furnace

InactiveCN111718729AImprove carbonization efficiencyImprove processing efficiencyCombustible gas coke oven heatingStationary retortsCarbonizationProcess engineering

The invention discloses a fuel gas carbonization furnace. The fuel gas carbonization furnace includes a rack, wherein a furnace shell is connected to the rack; a main furnace tube and a gas burner areconnected inside the furnace shell; the gas burner is connected with a gas supply device through a gas pipeline; a feeding device and a discharging box are arranged outside the furnace shell; the feeding device and the discharging box are both connected with the rack; one end of the main furnace tube is connected with the feeding device; the other end of the main furnace tube is connected with the discharging box; the discharging box is provided with a discharging port; the feeding device is provided with a hopper; the rack is further connected with a rotating device; the rotating device is connected with the main furnace tube; the rotating device is used for driving the main furnace tube to rotate; and the discharging box is connected with a smoke exhaust fan through a smoke tube. Continuous production can be effectively realized, the processing time is saved, the processing efficiency of the carbonization furnace is improved, and the service life of the carbonization furnace is greatly prolonged.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

Box type column welding forming machine production line

ActiveCN103990746ATo achieve the purpose of continuous productionIncrease productivityProduction lineMolding machine

The invention discloses a box type column welding forming machine production line. The box type column welding forming machine production line comprises a machine frame. The machine frame is provided with a conveying device used for conveying a first galvanized wire. The discharging end of the conveying device is provided with a shearing device. The shearing device comprises a shearing machine, a control device, a drive device and a spring, wherein the control device is used for controlling the action of the shearing machine, the drive device is used for driving the shearing machine to move, and the spring is used for resetting the shearing machine. The control device can control the shearing machine to perform the shearing action and control the drive device to drive the shearing machine to achieve tracking shearing at the same time. After shearing is completed, the shearing machine is reset through the spring. Due to tracking shearing of the shearing device, it is unnecessary to shut down for waiting shearing in the production process. In this way, the purpose of continuous production is achieved, and production efficiency is enhanced. According to the shearing device, tracking shearing is achieved, it is unnecessary to shut down for waiting shearing in the production process, the purpose of continuous production is achieved, and production efficiency is enhanced.

Owner:ABO BUILDING MATERIAL KUNSHAN CO LTD

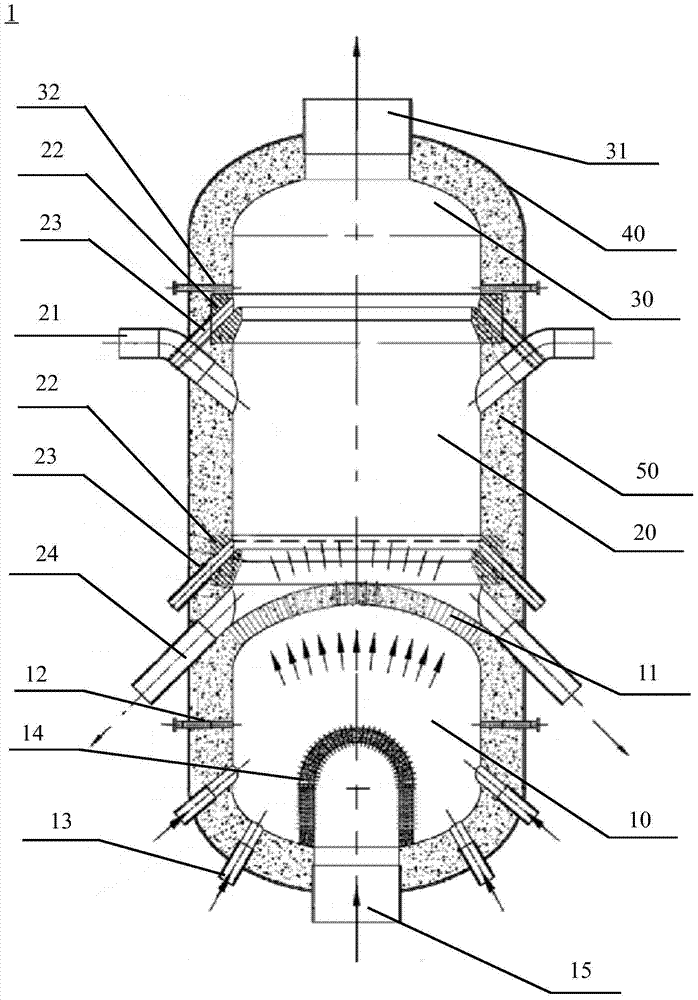

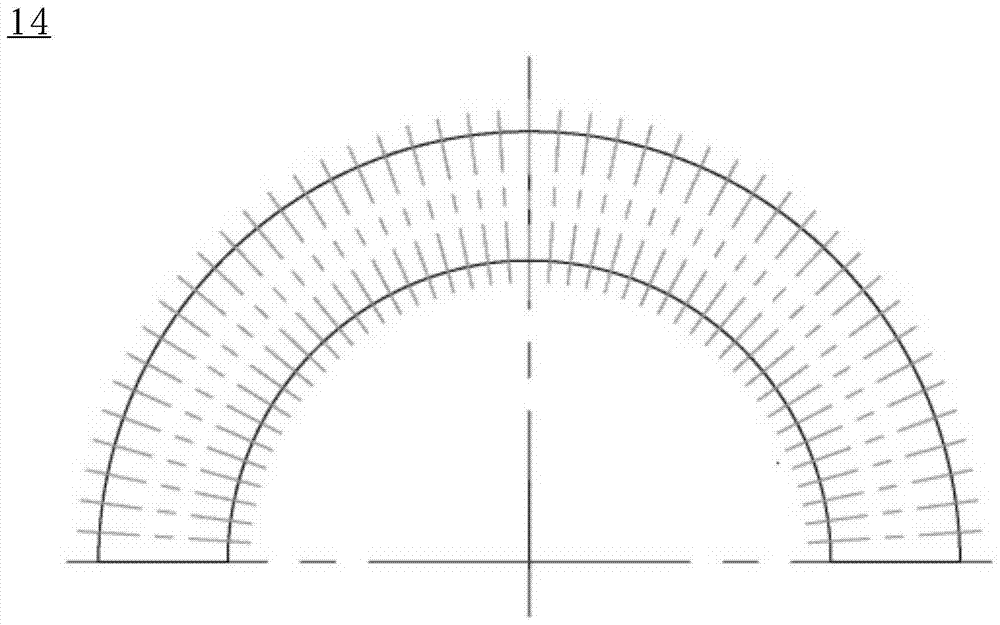

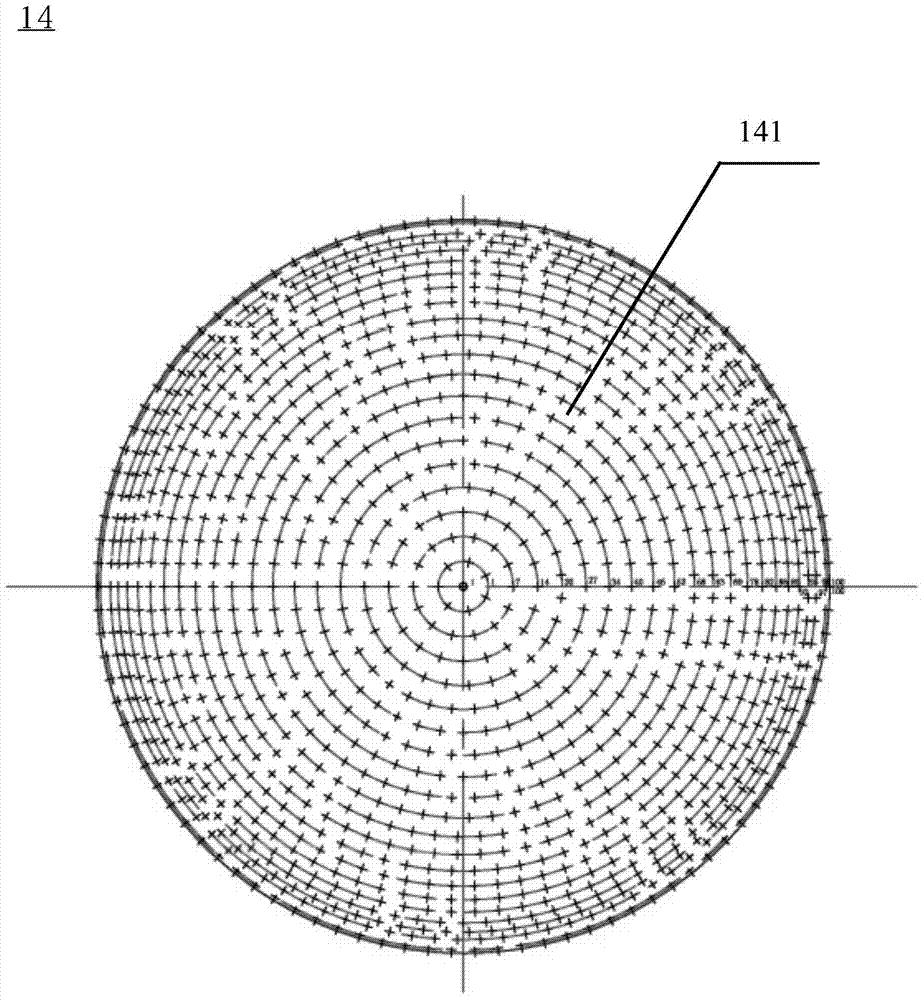

A jet arch for continuous fluidized reactor and aerodynamic fluidization reactor

The present invention relates to a jet arch and a fluidization reactor for continuous fluidization reactors, characterized in that the jet arch is used to separate the fluidization reactor into two sections for fuel combustion and material reaction respectively. Two chambers are arranged in the fluidized reactor, and the surface of the injection arch is provided with at least one elongated jet channel for injecting the combustion gas from the combustion chamber into the reaction chamber at high speed, The overall distribution of the at least one spray channel on the surface of the spray arch is set in such a way that the injected combustion gas has a high flow rate in the central area and a low flow rate in the peripheral area, so that the high-temperature and high-velocity combustion gas transports the material in a suspended state The lift reacts in the reaction chamber, and after the combustion gas is ejected through the injection arch, the outside air is naturally sucked in from the bottom of the combustion chamber, thereby realizing continuous production. The fluidized reactor of the invention has high gas production efficiency and convenient slag discharge, and can realize a one-step high-efficiency and high-temperature fluidized reaction to directly produce P2O5 from ore and then produce phosphoric acid.

Owner:SICHUAN MINGXIN INVESTMENT

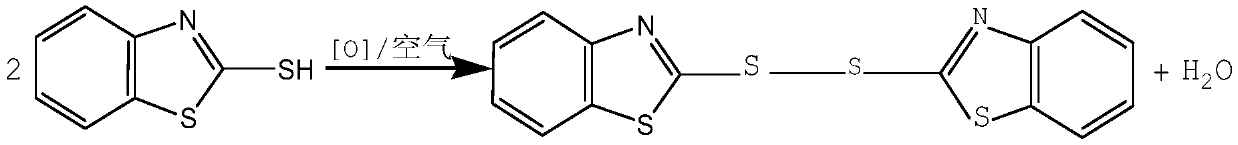

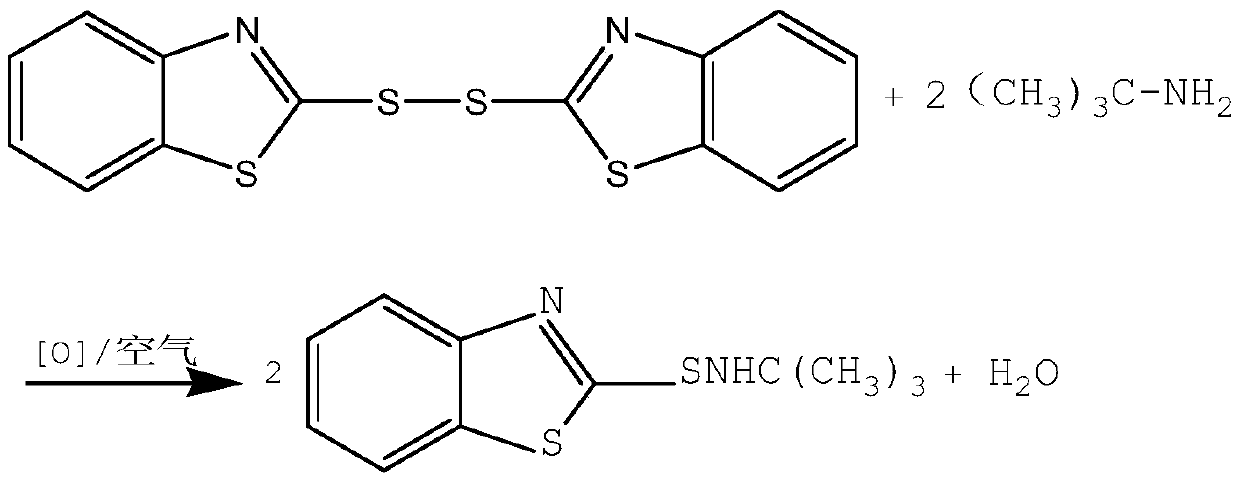

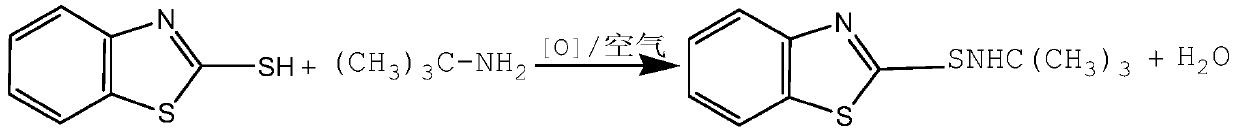

Low-temperature continuous synthesis method of rubber vulcanization accelerator NS

PendingCN110776478AEasy to operateEasy to industrializeOrganic chemistryReaction temperatureAccelerant

The invention provides a low-temperature continuous synthesis method of a rubber vulcanization accelerator NS. The low-temperature continuous synthesis method comprises the following steps: 1, addinga rubber vulcanization accelerator M and a rubber vulcanization accelerator DM into a reaction kettle, adding water, carrying out stirring, and slowly dropwise adding tert-butylamine within 30 min; 2,reducing the temperature of a reaction system in the step 1 to -10 to 40 DEG C, introducing air or compressed air within 10 to 50 min for a reaction, and carrying out sampling to detect the reactionendpoint of the product; and 3, filtering, washing and drying the product obtained in the step 2 to obtain the finished product N-tert-butyl-2-benzothiazole sulfenamide, and recycling mother liquor. According to the method, the lowest reaction temperature can reach -10 DEG C, and reaction time reaches 40-80 min; air / compressed air is used as an oxidizing agent, so production process is safe, and salt-containing wastewater cannot be generated; and the amount of byproducts contained in the mother liquor is low, and the mother liquor can be recycled without treatment of other process steps such as evaporation.

Owner:SHANDONG YANGGU HUATAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com