Waterborne polyurethane-acrylate interpenetrating polymer network copolymer emulsion continuous production method and device

A technology of urethane acrylate and interpenetrating polymer, which is applied in the field of continuous production method and equipment of water-based urethane acrylate interpenetrating polymer network copolymer emulsion, can solve the mismatch between temperature and flow, deviation of product and formula design, labor intensity It can reduce the number of operators and equipment such as pumps, reduce the frequency of equipment failures, and reduce the labor intensity of personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

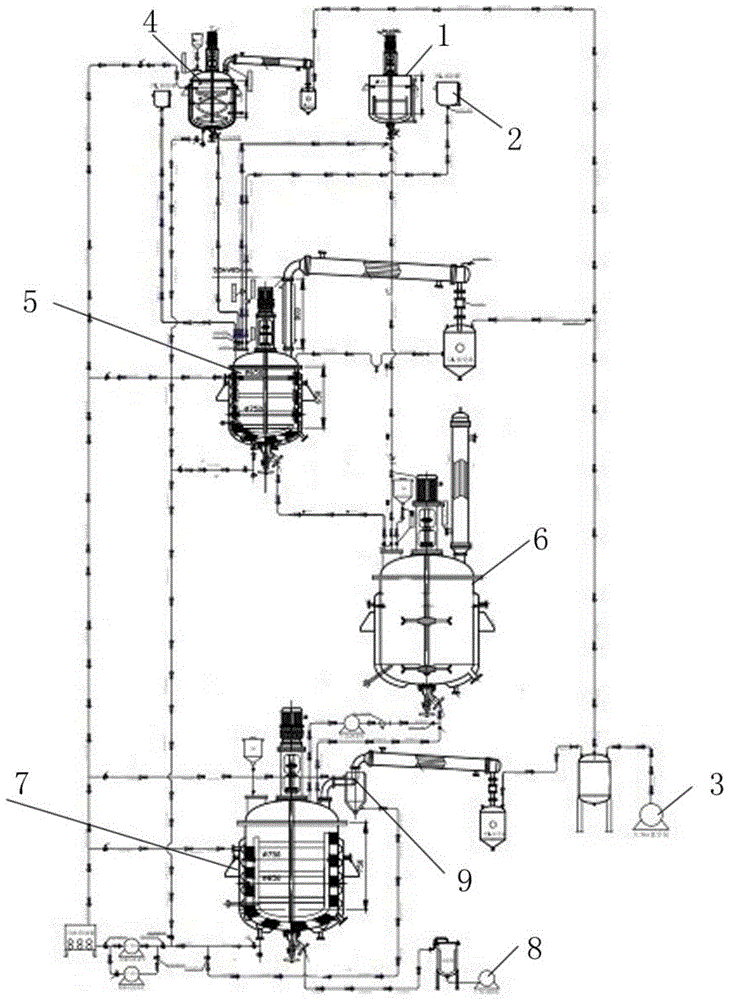

Image

Examples

Embodiment 1

[0024] The continuous production method of aqueous polyurethane acrylate interpenetrating polymer copolymer emulsion, it comprises the steps:

[0025] a. The addition of the following ingredients is calculated by weight. First, put 12 parts of PCL and 86 parts of PBA into the high-temperature kettle, raise the temperature to 120°C, start the vacuum pump, and dehydrate under reduced pressure for 1 hour for later use. Then add 7 parts of HDI and 6 parts of IPDI Add 2 drops of DBTDL to the prepolymerization reactor, open the bottom valve of the high temperature kettle, let the polyol in the high temperature kettle be naturally put into the prepolymerization reactor, draw a vacuum in the prepolymerization reactor, and completely suck the materials in the high temperature kettle into the prepolymerization reactor; again keep the inner temperature of the prepolymerization reactor at 80°C-90°C for prepolymerization for 2 hours, slightly lower the temperature to 70°C-80°C, add 0.2 part...

Embodiment 2

[0029] In this embodiment, it includes the following steps:

[0030] a. The addition of the following ingredients is calculated by weight. First, put 13 parts of PCL and 87 parts of PBA into the high-temperature kettle, raise the temperature to 120°C, start the vacuum pump, and dehydrate under reduced pressure for 1.1 hours for later use. Then add 6 parts of HDI, 5 parts of IPDI Add 2 drops of DBTDL and DBTDL into the prepolymerization reactor, open the bottom valve of the high temperature kettle, let the polyol in the high temperature kettle be naturally put into the prepolymerization reactor, and draw a vacuum in the prepolymerization reactor to completely discharge the materials in the high temperature kettle Inhale into the pre-polymerization reactor; keep the inner temperature of the pre-polymerization reactor at 80°C-90°C for 2.2 hours of pre-polymerization, slightly lower the temperature to 70°C-80°C, add 0.1 parts of TMP, 0.4 parts of BDO, and react for 1.1 hours After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com