Device and method for preparation of continuous carbon fiber with carbon nanotubes growing on surface

A carbon nanotube and surface growth technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problem that carbon nanotubes cannot be modified carbon fiber, and achieve the effects of low cost, continuity and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

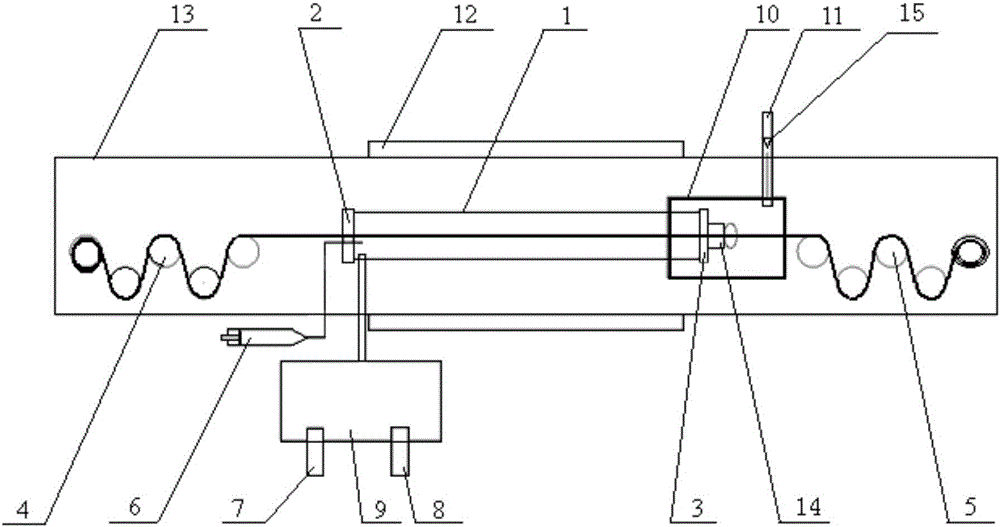

[0016] Embodiment 1: The device for preparing continuous carbon fibers with carbon nanotubes grown on the surface of this embodiment,

[0017] Including quartz tube 1, head sealing plug 2, tail sealing plug 3, front drafting roller 4, rear drafting roller 5, micro injection pump 6, hydrogen generator 7, argon gas bottle 8, gas mixing device 9, exhaust gas Processing device 10, exhaust pipe 11, heating jacket 12 and sealing chamber 13; Head end sealing plug 2 and tail end sealing plug 3 are all provided with wire holes, and the two ends of quartz tube 1 are respectively sealed with head end sealing plug 2 and The tail end sealing plug 3 is plugged, the tail of the quartz tube 1 is in the exhaust gas treatment device 10, the quartz tube 1, multiple front drafting rollers 4, multiple rear drafting rollers 5 and the exhaust gas treatment device 10 are all arranged in the sealing chamber 13 Inside, the front drafting roller 4 is located in front of the head end sealing plug 2, the ...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the device for preparing continuous carbon fibers with carbon nanotubes grown on the surface also includes a gas filter 14 arranged in the tail gas treatment device 10, and the gas filter 14 is connected to the tail gas. On the end sealing plug 3, the others are the same as in the first embodiment.

[0019] The gas filter 14 of this embodiment can remove carbon deposits.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the device for preparing continuous carbon nanotubes on the surface of continuous carbon fibers also includes a one-way valve 15 arranged in the exhaust pipe 11 . Others are the same as in the first or second embodiment.

[0021] The one-way valve 15 in this embodiment can ensure the one-way flow of gas and prevent outside air from entering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com