Patents

Literature

165results about How to "Increased interfacial shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplasticity sizing agent for carbon fiber and preparation and usage thereof

The invention provides a thermoplasticity sizing agent for a carbon fiber as well as a preparation method and a usage method thereof and relates to solvent sizing agent for a carbon fiber as well as a preparation method and a usage method thereof. According to the invention, the problems that the existing thermoplastic sizing agent is complicate in preparation process and pollutes the environment are solved. The preparation method is as follows: the thermoplastic resin, an organic solvent A and an adjuvant are mixed and stirred uniformly so as to obtain the thermoplastic sizing agent, when being used, the carbon fiber is dipped in the thermoplasticity sixing agent, then fractioning is carried out on the carbon fiber with agent and the treated carbon fiber is dipped in an organic solvent B, and finally the carbon fiber is dried. According to the invention, the wettability of the carbon fiber and the high performance thermoplasticity resin of polyarylether can be improved, the boundary bonding performance of the carbon fiber or the resin matrix composite of thermoplasticity polyarylether can be improved, and the thermoplasticity sizing agent has the advantages that the cost is low, the performance is stable, the utilization is stable and the environment is not polluted. The thermoplasticity sizing agent for the carbon fiber is used for the surface treatment of a carbon fiber material.

Owner:HARBIN INST OF TECH

Process for preparing nano SiO2 modified carbon fiber emulsion pasting agent

ActiveCN1632217AImprove protectionHigh strengthFibre treatmentFibre chemical featuresCarbon fibersEmulsion

A preparation method of a nano-SiO2 modified carbon fiber emulsion sizing agent, which uses nano-SiO2 as a sizing resin modification material, and the modified material, sizing resin, emulsifier, dispersant, organic solvent and particle-free water are prepared in a certain weight ratio Carbon fiber-forming functional emulsion sizing agent. After the carbon fiber is impregnated with a certain concentration of modified sizing agent for an appropriate time, the strength of the carbon fiber increases by up to 8.7%; the interfacial shear strength (IFSS) of the single fiber composite material can reach up to 43.67MPa; ILSS) up to 98.7MPa.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

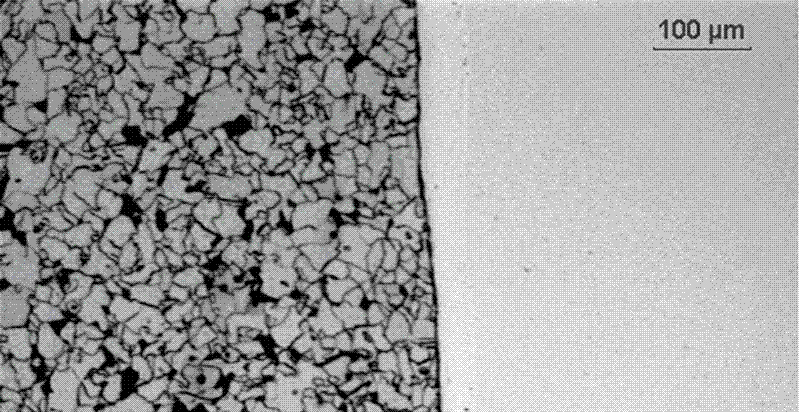

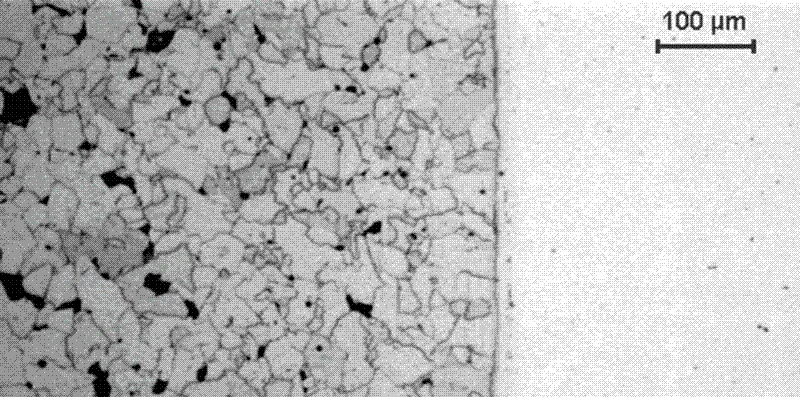

Post-treating method for steel-back aluminium-based semisolid-state clad plate

InactiveCN101117696AIncreased interfacial shear strengthSimple methodRoll mill control devicesMetal rolling arrangementsReduction rateRoom temperature

The present invention discloses a post-processing method for steel-back aluminum-base semisolid composite plates and relates to the post-processing research field of interfacial mechanical characteristic of steel-back aluminum-base semisolid composite plates. At room temperature, a steel-back aluminum-base semisolid composite plate is rolled with the reduction rate of 0.5-1.6 percent on a precision rolling mill, and the difference between shrinkages of the aluminum-base coating and the steel base in the coagulating and cooling process of the composition is redeemed by the difference between the deformation of the aluminum-base coating and the steel base produced in the rolling process, thereby, reducing the additional interfacial stress of the composite plate, simply and conveniently improving the interfacial shear strength of the composite plate, and solving the technical problems of large energy consumption and small increase amplitude of interfacial shear strength in post-processing method of diffusion annealing of aluminum-base semisolid composite plates.

Owner:BEIJING JIAOTONG UNIV

Preparation method of titanium-steel composite plate

InactiveCN101992344ASolve easy oxidationIncreased interfacial shear strengthLaminationLamination apparatusComposite plateVacuum chamber

The invention relates to a preparation method of a composite steel plate, in particular to a preparation method of a titanium-steel composite plate. The preparation method comprises the following steps of: firstly selecting titanium plates and steel plates which have equal width and length and removing rusty layers and oxide layers; then making surfaces of the titanium plates and the steel plates opposite, and completely coinciding to form a combined blank; then sealing up the periphery of the combined blank by taking four titanium plates as side seal plates, and clamping the side seal plates and the combined blank by using a clamp and then putting the side seal plates and the combined blank into a vacuum chamber together; tightly welding all contact seams of the combined blank and the side seal plates, then conveying the combined blank and the side seal plates into a heating furnace together and heating to 600-1200 DEG C, and carrying out heat preservation for 0.1-2h; and finally, conveying the heated combined blank into a rolling mill for rolling to obtain the titanium-steel composite plate with the interface bonding strength of 350MPa. The invention well solves the problem that the interface of the titanium-steel composite plate is oxidized and improves the interface bonding strength of the composite plate, and moreover, argon or brazing filler metal does not need to be added, thereby saving the cost and simplifying the flow of the production process.

Owner:沈阳科安捷材料技术有限公司

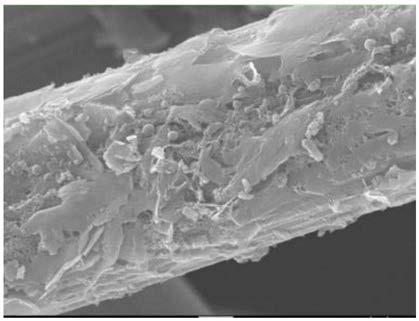

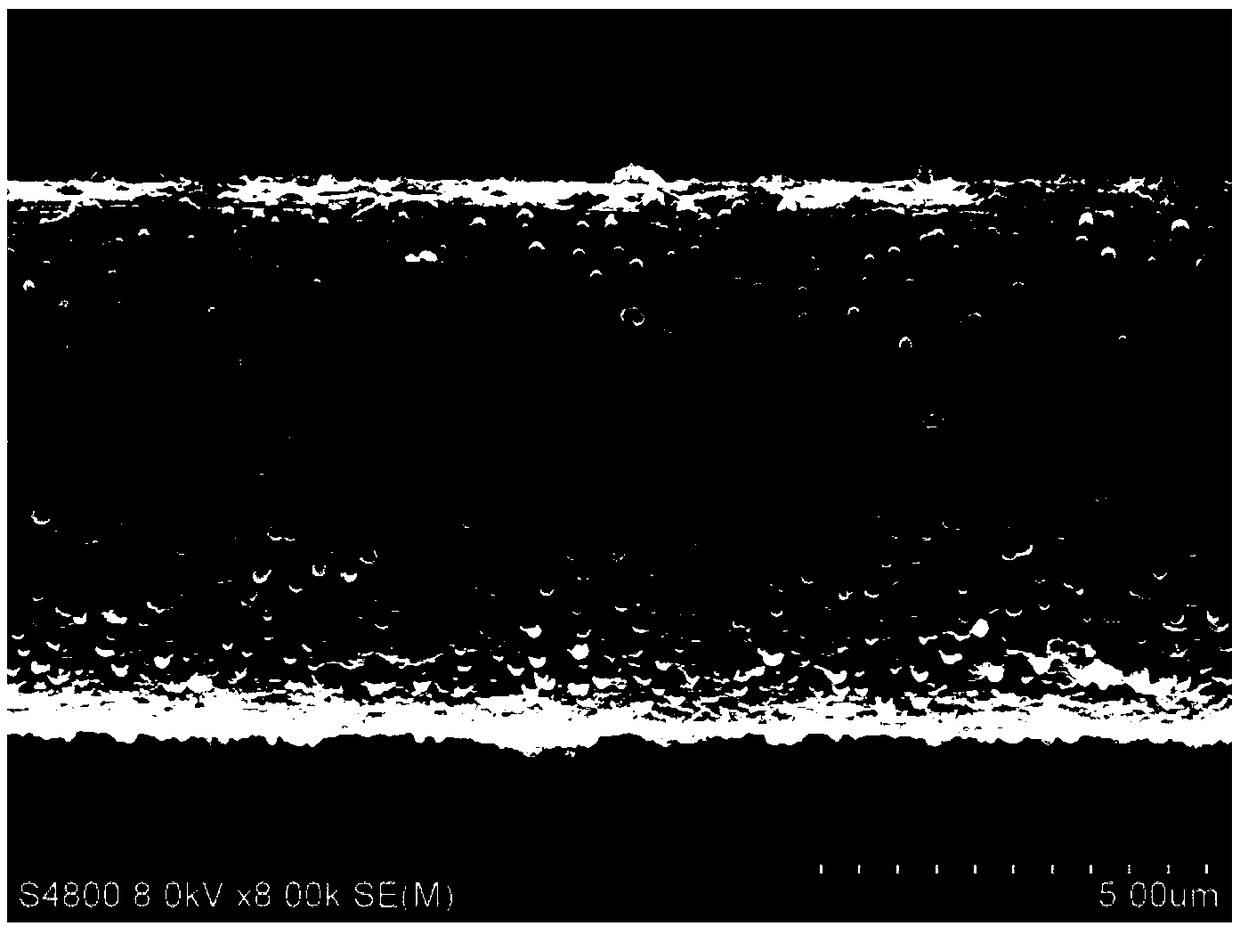

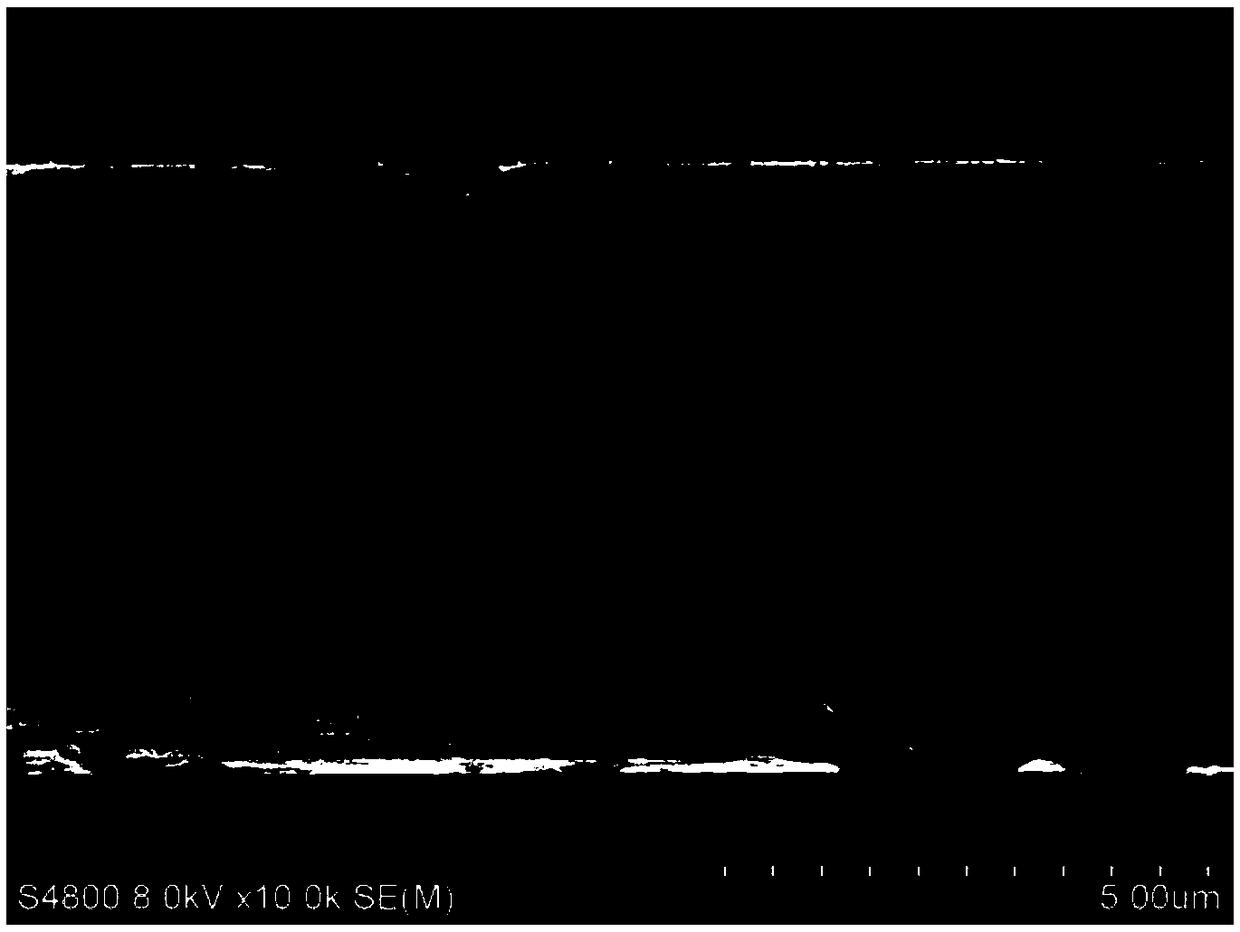

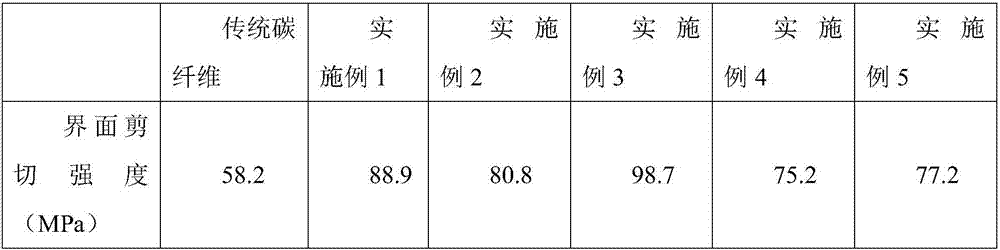

Preparation method of carbon fiber reinforcement grafted by graphene oxide

A preparation method of a carbon fiber reinforcement grafted by graphene oxide relates to a preparation method of a carbon fiber reinforcement grafted by graphene oxide. The invention solves the problems of harsh process conditions, long process period, toxic process, and difficult industrial production for current carbon fiber surface modification methods. The invention adopts a 'grafting' method, and grafts graphene oxide on acidified carbon fiber surfaces through an acylation reaction by using polyamide-amine with a lot of amido active groups; the invention has low cost, is simple, practical, environment-friendly, and nontoxic, and can be completed within a short period. The method particularly comprises the following steps: mixing acidified carbon fibers and a polyamide-amine methanolsolution, reacting to prepare carbon fibers modified by polyamide-amine, adding the prepared carbon fibers in a graphene oxide acetone suspension, mixing, reacting, filtering, drying the precipitatestill the weight is constant. The obtained carbon fiber reinforcement has interfacial shear strength with epoxy resin of up to 79.77-105.50 MPa which is improved.

Owner:HARBIN INST OF TECH

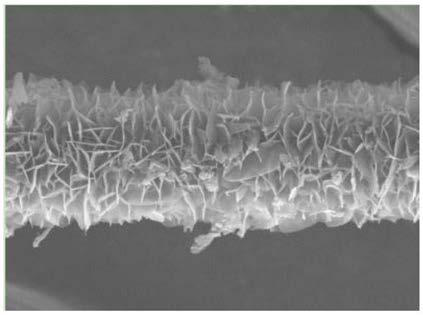

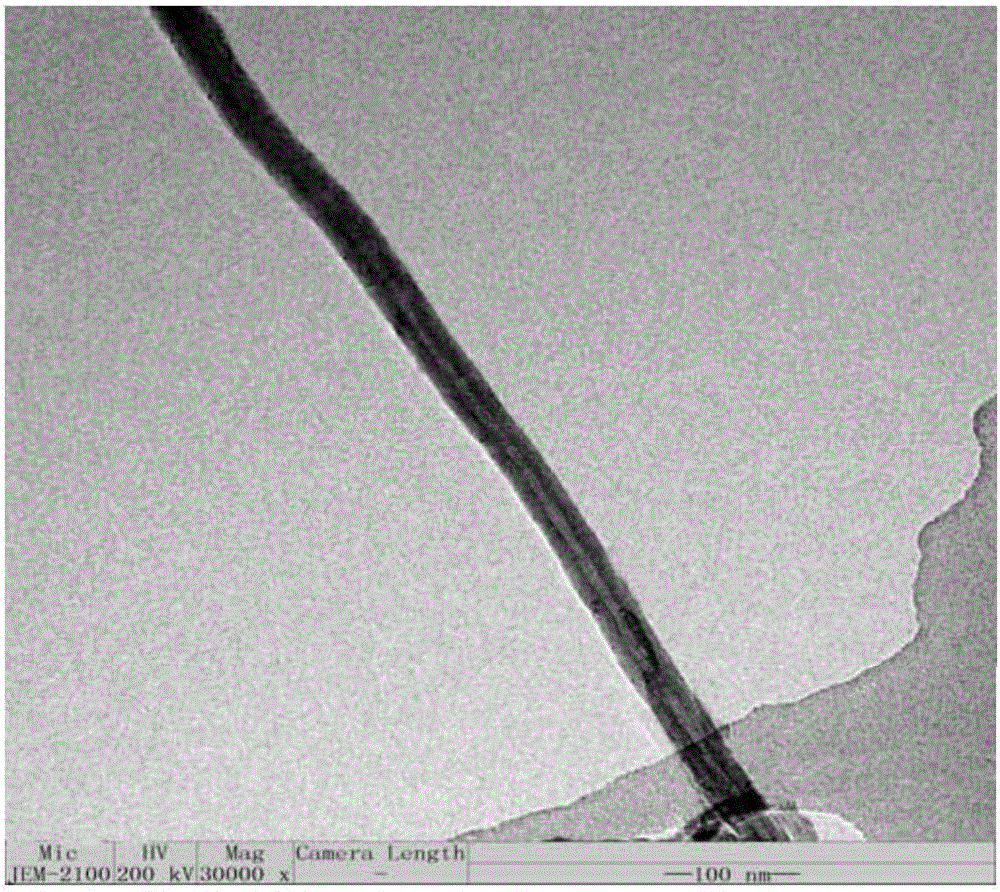

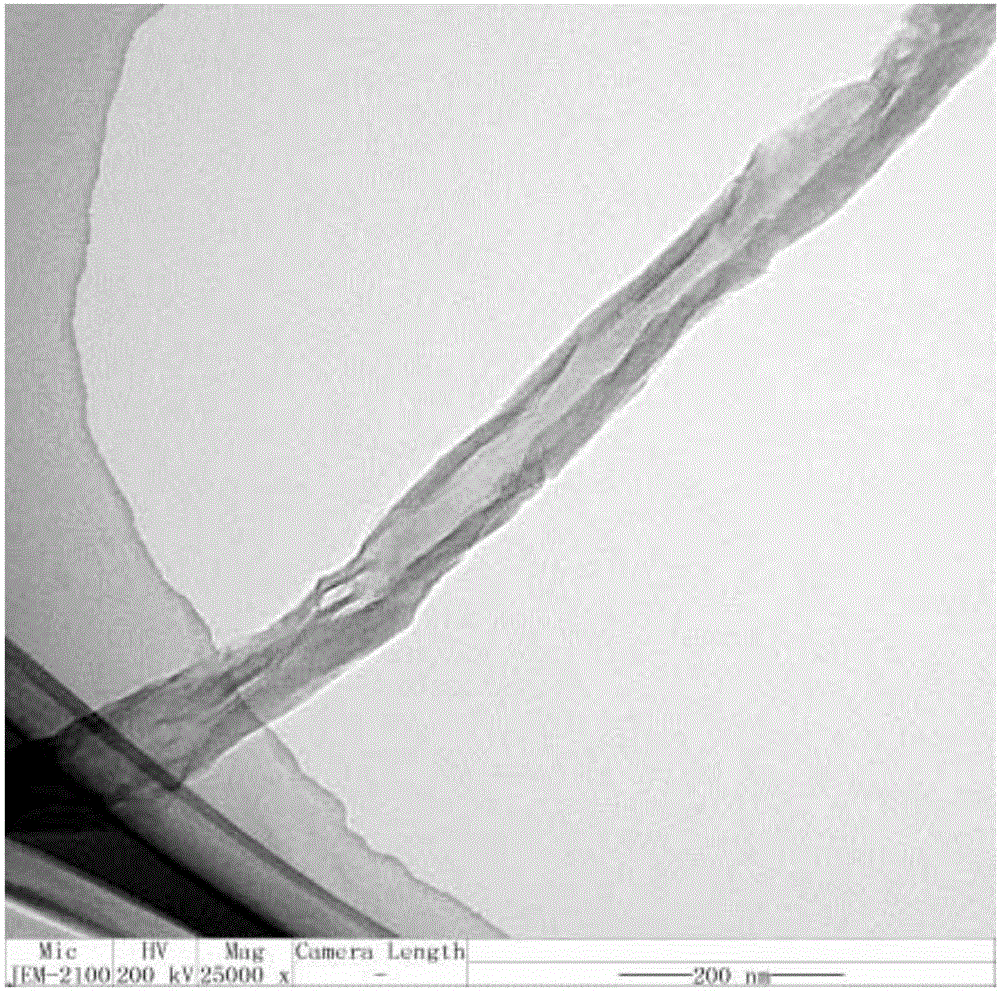

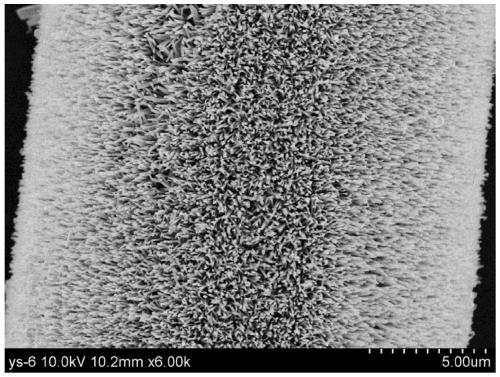

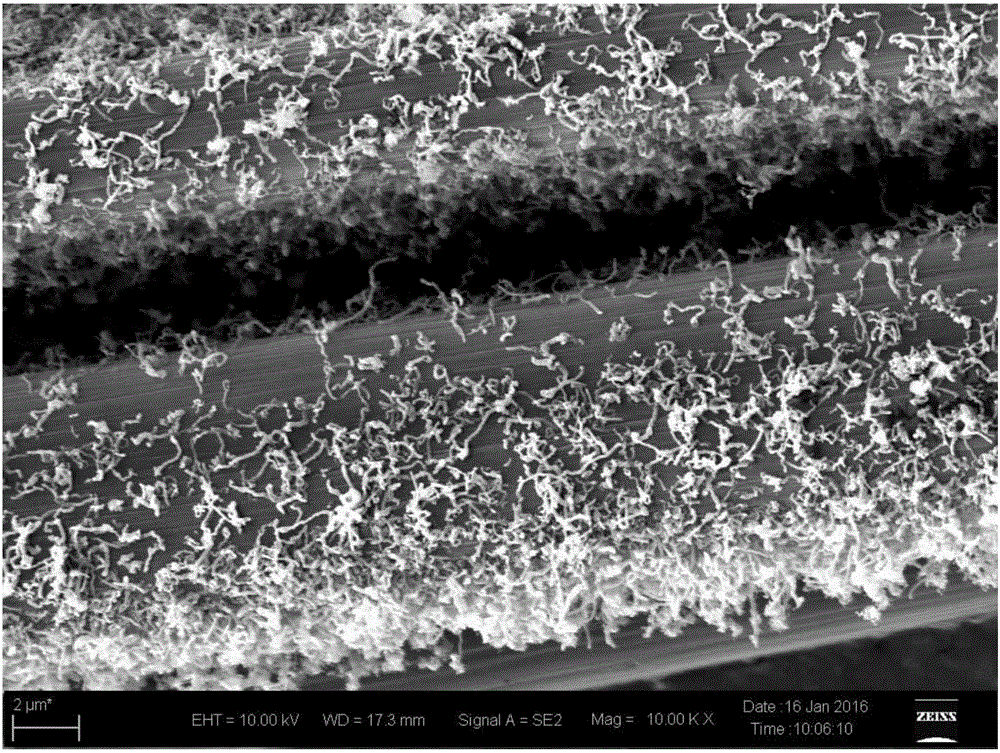

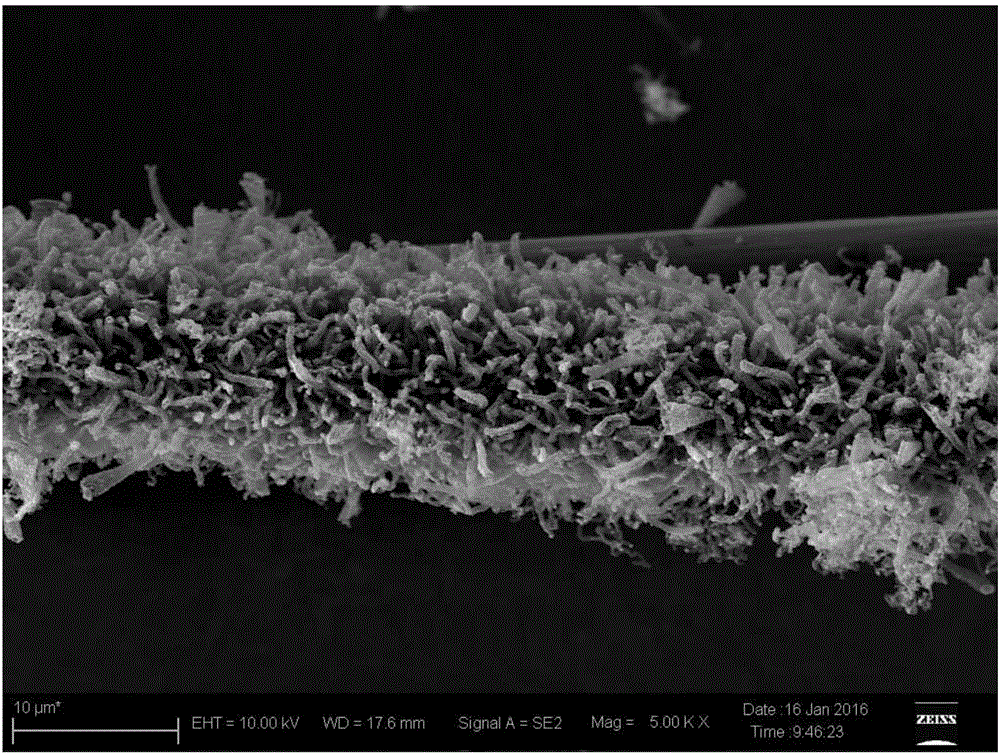

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Carbon nanotube modified emulsion sizing agent, preparation method and applications thereof

InactiveCN104120605AGood dispersionSmall particle sizeFibre treatmentPigment treatment with organosilicon compoundsFiberEpoxy

The invention discloses a carbon nanotube modified emulsion sizing agent, a preparation method and applications thereof, and relates to an emulsion sizing agent, a preparation method and applications thereof. The invention aims to solve the problems that in the prior art the sizing agent is pricy and generates pollution to the environment and the shearing strength is low in the composite material interface after the carbon fiber is processed by the sizing agent. The carbon nanotube modified emulsion sizing agent is composed of the following raw materials in parts by weight: 0.001 to 2 parts of modified carbon nanotube, 50 to 55 parts of epoxy resin emulsion system, 0.001 to 1 part of surfactant, and 45 to 50 parts of deionized water. The preparation method comprises the following steps: (1) preparing an epoxy resin emulsion system; (2) mixing so as to obtain the carbon nanotube modified emulsion sizing agent. The application method comprises the following steps: making carbon fibers go through a solution tank containing the carbon nanotube modified emulsion sizing agent, then scraping the glue on the surface, washing, and drying so as to obtain the sizing agent modified carbon fibers. The invention can obtain a carbon nanotube modified emulsion sizing agent.

Owner:HARBIN INST OF TECH

Method for preventing interface of stainless steel compound plate subjected to vacuum composite rolling from being oxidized

ActiveCN102179405ASolve the problem of elemental diffusionIncreased interfacial shear strengthAuxillary arrangementsMetal rolling arrangementsUltimate tensile strengthVacuum chamber

The invention discloses a method for preventing an interface of a stainless steel compound plate subjected to vacuum composite rolling from being oxidized, and belongs to the technical field of materials. The method comprises the following steps of: (1) performing surface treatment; (2) alternately overlapping a stainless steel plate material and a carbon steel plate material, and separating by using nickel foils to obtain a composite blank; (3) putting between two metal panels to form a clamped composite blank, or welding two composite blanks to form a composite blank-blocker-composite blankcombined structure, and putting between two metal panels to form the clamped composite blank; (4) putting in a vacuum chamber, vacuumizing and welding the peripheries of contact surfaces; (5) heatingand keeping temperature in a resistance furnace to obtain the composite blank subjected to heat treatment; and (6) removing the metal panels, and rolling the composition blank subjected to heat treatment. The method solves the problem of element diffusion of the interface in the process of preparing a stainless steel-carbon steel compound plate, so that the shear strength of the interface is improved by 10-40MPa, and the decarbonization and a chromium-rich layer of the interface are eliminated.

Owner:沈阳科安捷材料技术有限公司

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Method for modifying carbon fibers by dendritic macromoleculars

InactiveCN101709542AUnique rheological propertiesGood groomingPhysical treatmentCarbon fibresFiberEpoxy

The invention provides a method for modifying carbon fibers by dendritic macromoleculars, relating to a method for modifying the carbon fibers and aiming at solving the problem of poor stability due to that only one functional group of organic silicon compound can react with the fiber modified surface so as to limit a membrane in a bidimensional surface. The method comprises the following steps: adding carbon fibers in a strong oxidizing acid, utilizing ultrasonic for processing, heating and refluxing, drying, adding into dendritic macromolecular solution for ultrasonic processing once again, reacting under the temperature of 20-100 DEG C, washing and drying to obtain the carbon fibers modified by the dendritic macromoleculars. The dendritic macromoleculars used in the invention have the advantages of tri-dimensional structure, evenly-distributed and thick outer functional groups, lower viscosity, unique flowing deformation property, good film forming property and favorable modified effect. The epoxy resin composite material prepared by using the carbon fibers modified by the dendritic macromoleculars obtained in the invention has 53.2-55.8MPa of interface shearing strength.

Owner:HARBIN INST OF TECH

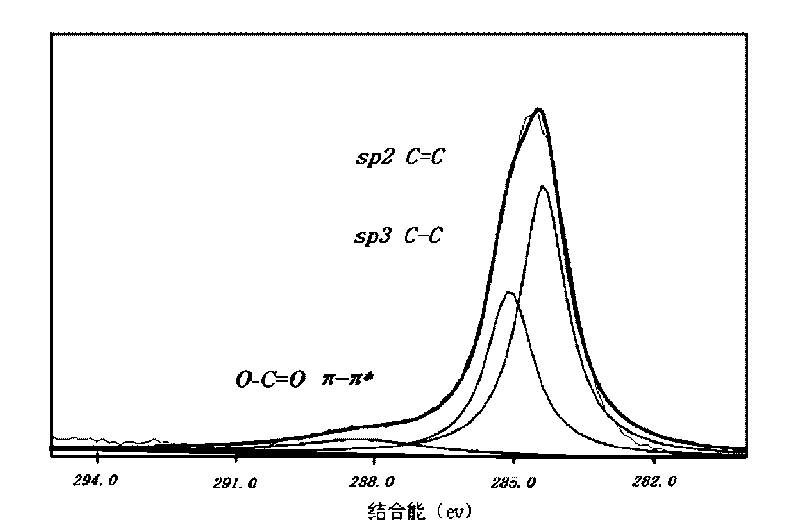

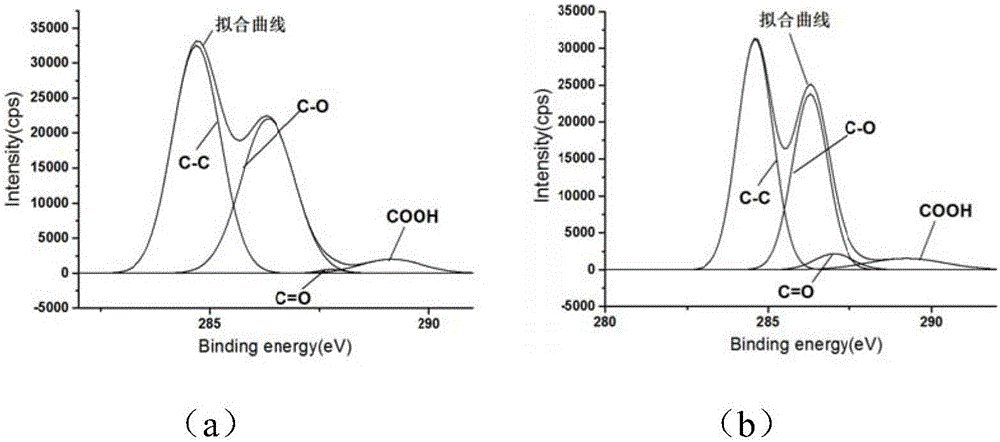

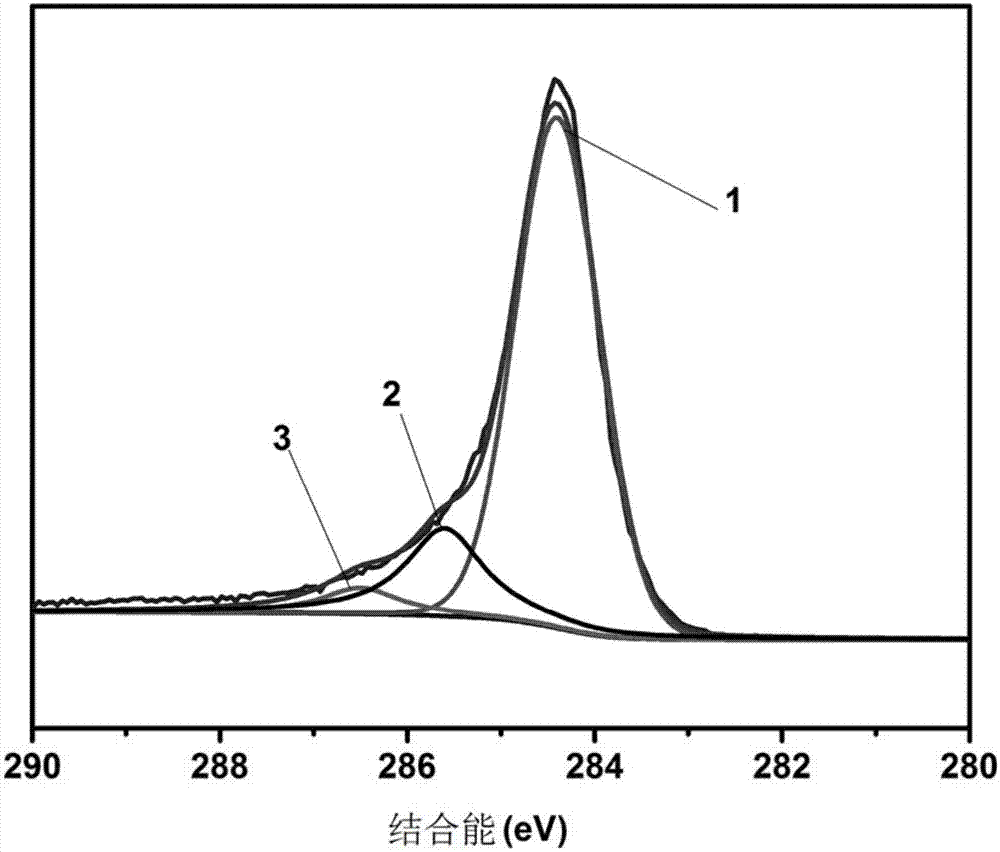

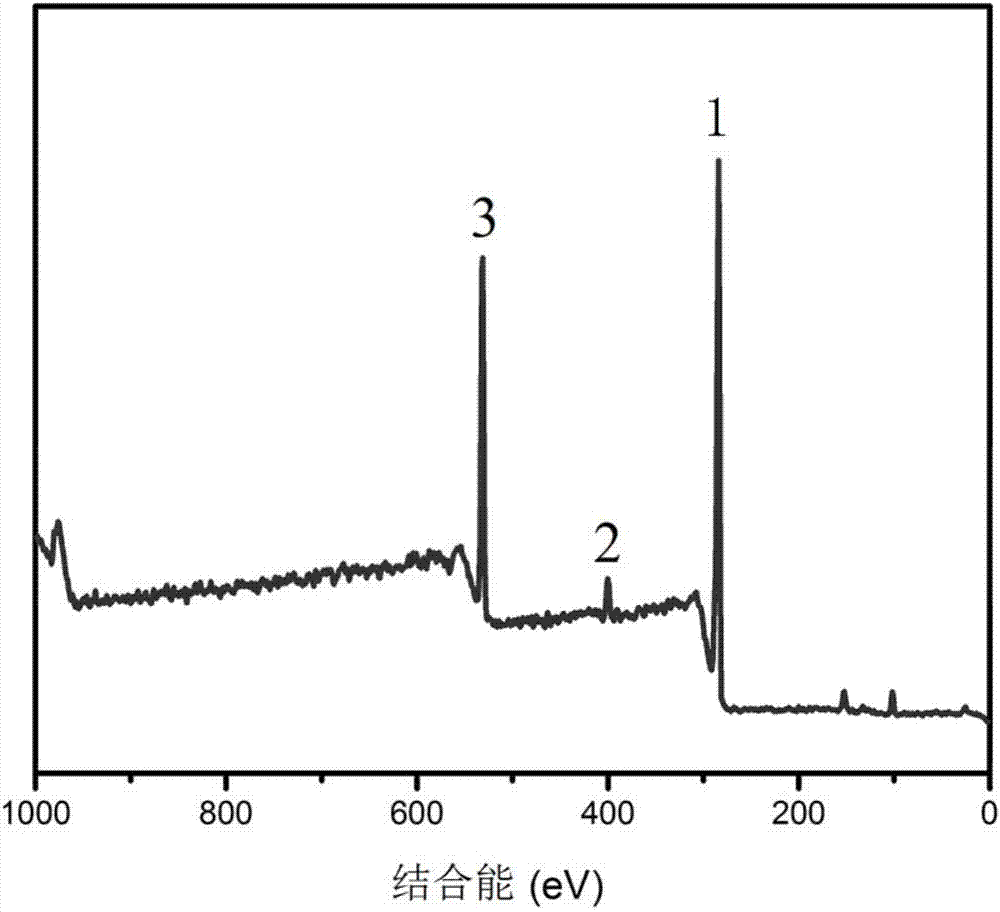

Method for modifying carbon fiber surface by assembly of aromatic fused ring molecules and preparation method of carbon fiber interface reinforced resin matrix composite

The invention provides a method for modifying a carbon fiber surface by assembly of aromatic fused ring molecules and belongs to the technical field of carbon fiber modification. The method comprisesthe following steps: aromatic fused ring dianhydride and diamine are subjected to imidization, and an aromatic fused ring imide molecule assembly liquid is obtained; carbon fibers are soaked in the aromatic fused ring imide molecule assembly liquid, the aromatic fused ring imide molecules are combined with the carbon fibers, and the carbon fibers with surfaces subjected to assembly modification are obtained. Chemical activity of the surfaces of the carbon fibers can be improved with the modification method. The invention further provides a preparation method of a carbon fiber interface reinforced resin matrix composite. The obtained carbon fibers with the surfaces subjected to assembly modification are compositely cured with resin, and the aromatic fused ring molecule assembly-modified carbon fiber interface reinforced resin matrix composite is obtained. The interface reinforced resin matrix composite obtained with the preparation method has good interfacial adhesion strength and interfacial shear strength.

Owner:BEIJING UNIV OF CHEM TECH

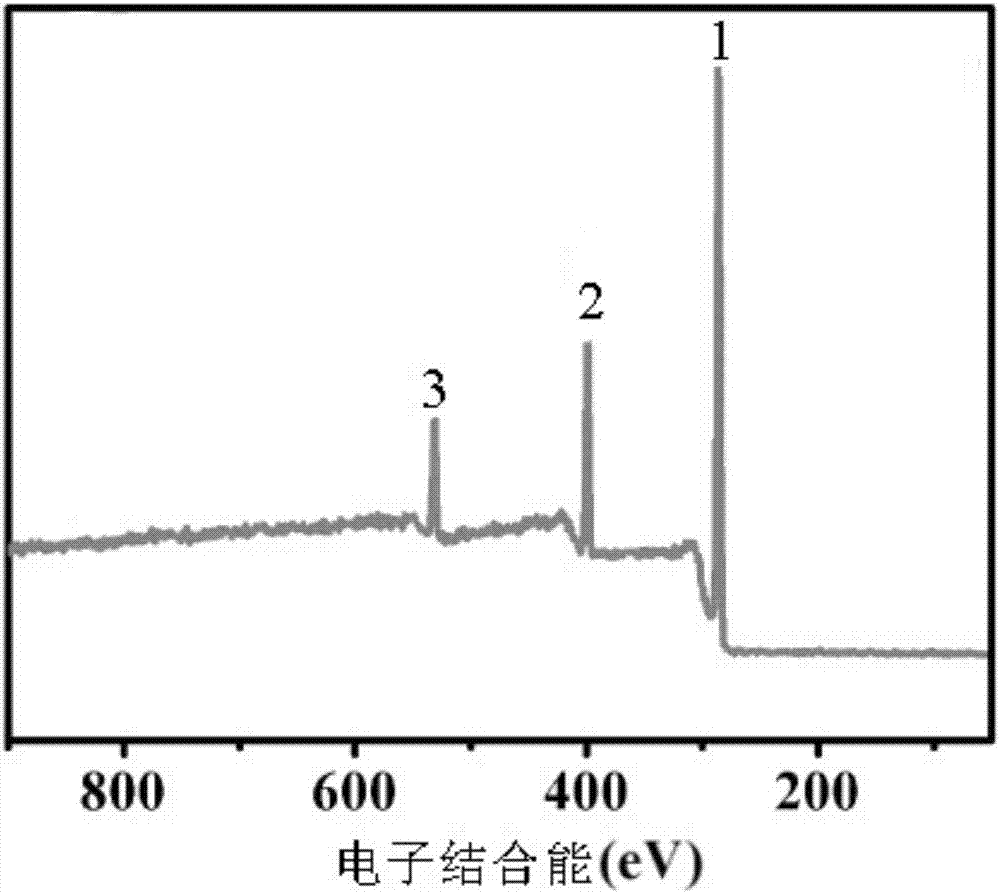

Method for green grafting of polyether amine on carbon fiber surface

ActiveCN107142730AImprove interface performanceThe method steps are simpleCarbon fibresDry-cleaning apparatus for textilesUltimate tensile strengthInterfacial bonding

Relating to a carbon fiber surface grafting method, the invention provides a method for green grafting of polyether amine on a carbon fiber surface. The invention aims to solve the problems of great loss of loaded carbon fiber body strength and low interfacial bonding strength of a carbon fiber composite material in existing carbon fiber surface modification methods. The method includes: 1. cleaning; 2. oxidation; 3. carbon fiber grafting treatment, thus obtaining carbon fiber with a surface grafted with polyether amine, i.e. accomplishing the method for green grafting of polyether amine on the carbon fiber surface. The interfacial shear strength of the carbon fiber with the surface grafted with polyether amine prepared by the method provided by the invention is increased from the 48.8MPa of protofilament to 76.6Mpa-82.3MPa, and is improved by more than 57.4%. The tensile strength of the carbon fiber with the surface grafted with polyether amine prepared by the method provided by the invention is enhanced from 3.80GPa to 3.89Gpa-3.92GPa, and is improved by 2.4%-3.2%. The invention can acquire the method for green grafting of polyether amine on a carbon fiber surface.

Owner:青岛碳智新材料科技有限公司

Polyether ketone ketone sizing agent and method thereof for sizing and preparing carbon fiber composite

The invention discloses a polyether ketone ketone sizing agent. The polyether ketone ketone sizing agent is prepared by mixing and stirring the following raw materials in parts by weight: 0.1-5 partsof polyether ketone ketone, 20-99.8 parts of sulfuric acid solution and 0.1-5 parts of graphene oxide; the sulfuric acid solution is 90-99% aqueous sulfuric acid solution; the polyether ketone ketoneis low-crystallizing polyether ketone ketone resin; the graphene oxide is graphene oxide powder with average grain size of 300-5000 meshes. The polyether ketone ketone sizing agent is capable of meeting the requirement for processing temperature of PEKK resin and is capable of effectively promoting adhesiveness of the interface between carbon fiber and PEKK substrate. Preparation technology is simple.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

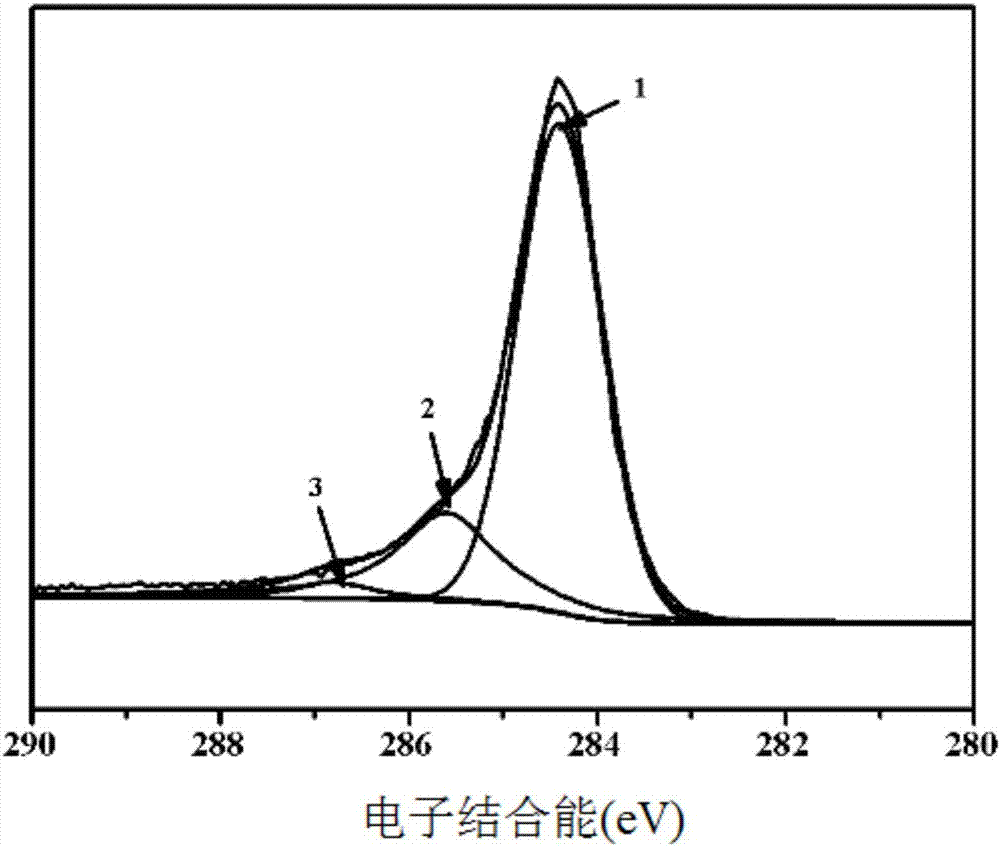

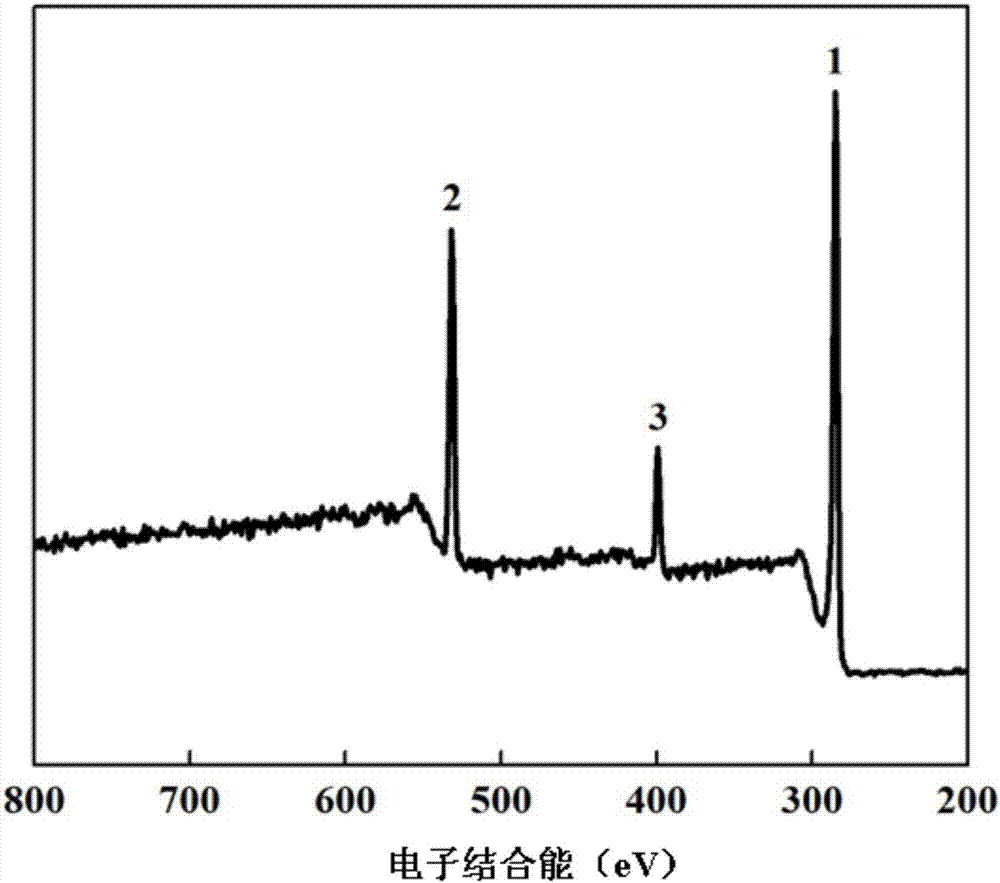

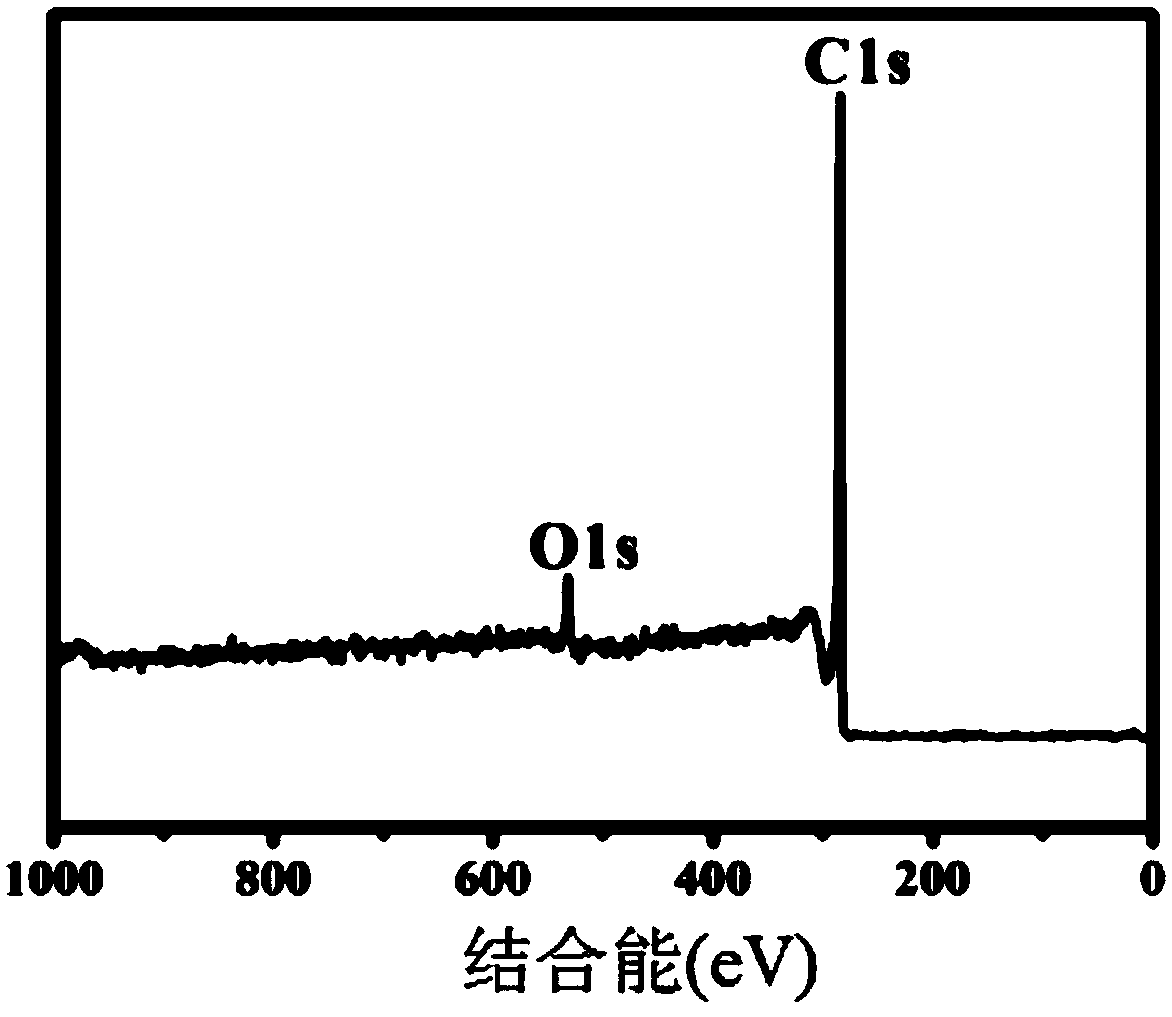

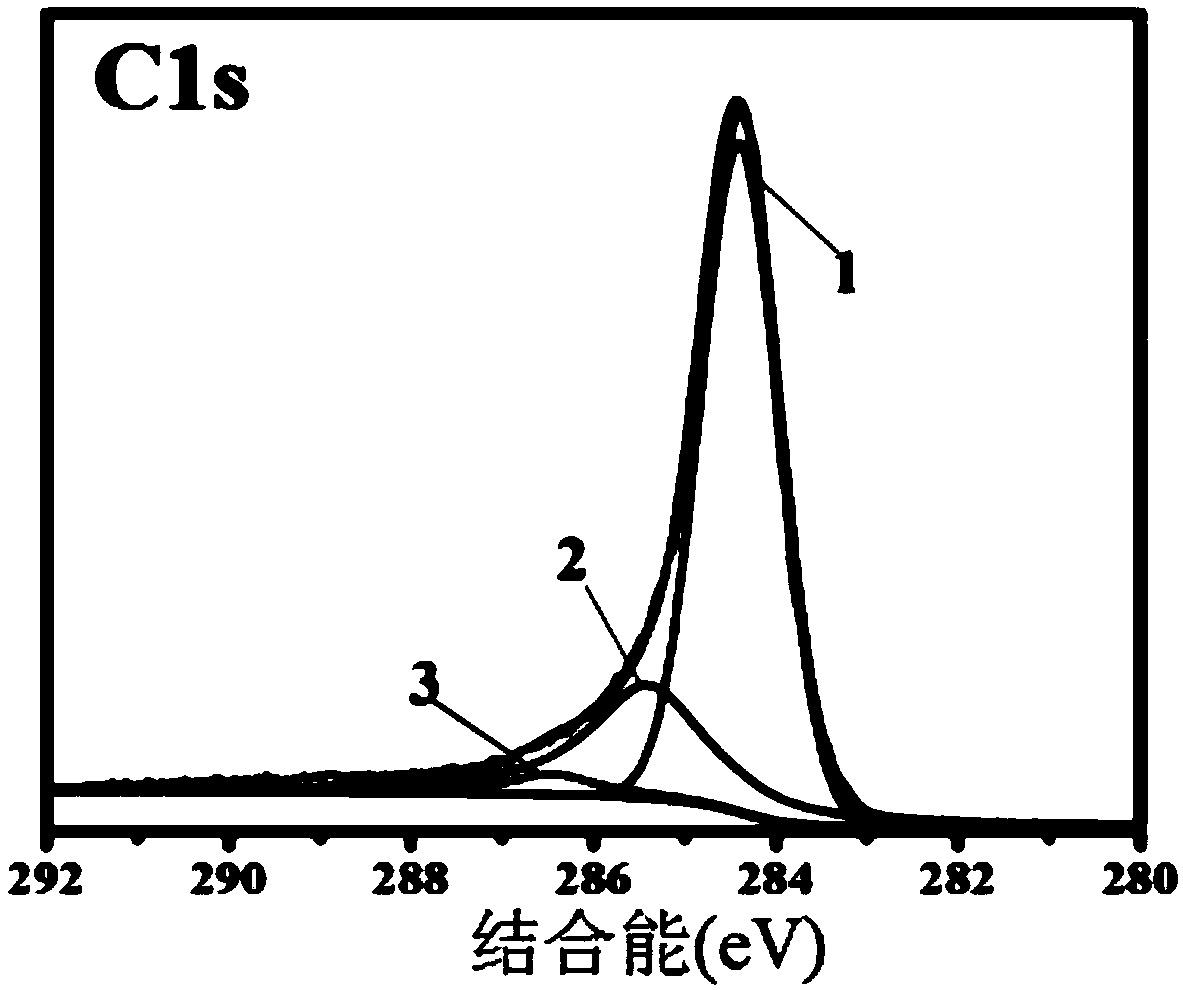

Method for efficiently preparing carbon fiber-grafted polymer

The invention discloses a method for efficiently preparing a carbon fiber-grafted polymer and relates to a carbon fiber surface modifying method. The invention aims to solve the problems of high energy consumption, environment pollution, low grafting degree, serious damage to the main bodies of carbon fibers, and low interfacial strength of the modified carbon fibers of the current carbon fiber modifying method. The method comprises the following steps of 1, extracting the carbon fibers; 2, oxidizing the carbon fibers; and 3, grafting PEI (Polyetherimide) to the carbon fibers to obtain the carbon fiber grafted polyethyleneimine. Content of nitrogen element of the carbon fiber-grafted polyethyleneimine prepared by the method is up to 15.51 to 17.84 percent; compared with the carbon fibers, the carbon fiber-grafted polyethyleneimine prepared by the method is obviously improved in interfacial shear strength, and the interfacial shear strength is improved to 73.7MPa to 89.6MPa from 48.8MPa of the carbon fibers and is improved by 51 to 83.6 percent. An efficient carbon fiber-grafted polymer can be obtained by the method.

Owner:QINGDAO UNIV

Carbon-nanotube-containing glass fiber wetting agent, and preparation method and application thereof

The invention relates to a wetting agent, and a preparation method and application thereof, particularly a carbon-nanotube-containing glass fiber wetting agent, and a preparation method and application thereof. The invention aims to solve the problem that the interface shear strength of the glass fiber composite material is not high after the glass fiber is treated by the existing wetting agent. The carbon-nanotube-containing glass fiber wetting agent is prepared from hydroxylated carbon nanotubes, a surfactant, an antistatic agent, deionized water and an epoxy resin emulsion system. The preparation method comprises the following steps: 1. preparing the carboxylated carbon nanotubes; 2. preparing the hydroxylated carbon nanotubes; 3. preparing the epoxy resin emulsion system; and 4. mixing to obtain the carbon-nanotube-containing glass fiber wetting agent. The application comprises the following steps: wetting the glass fiber with the carbon-nanotube-containing glass fiber wetting agent, spreading, cleaning and drying to obtain the wetting-agent-modified glass fiber. The carbon-nanotube-containing glass fiber wetting agent is mainly used for modifying glass fibers.

Owner:HARBIN INST OF TECH

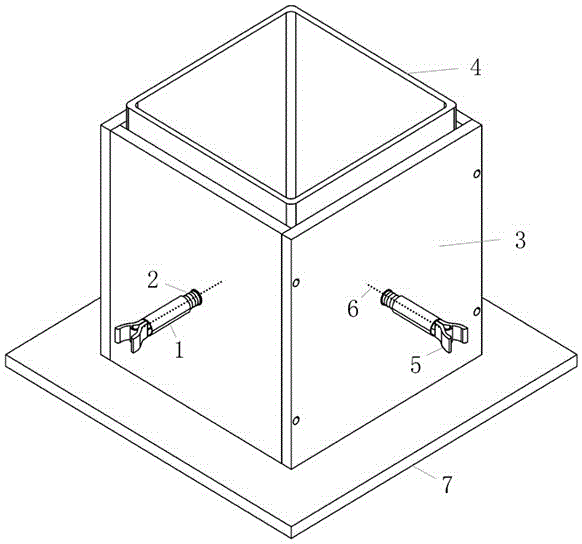

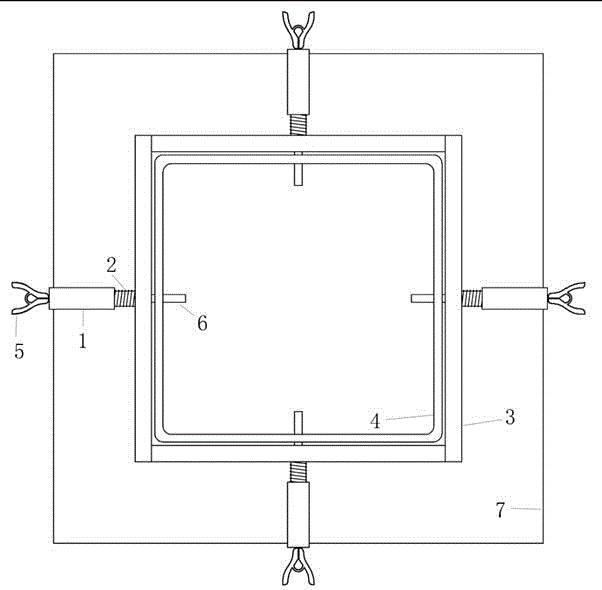

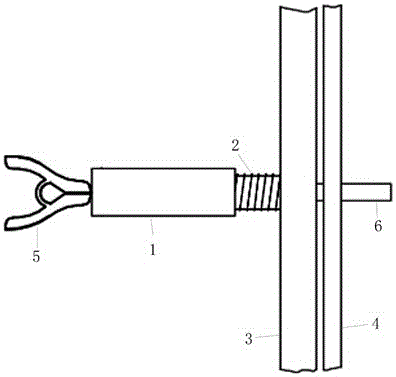

Device and method for testing interfacial shear strength of fiber reinforced thermosetting resin composite materials

InactiveCN105928800AIncreased interfacial shear strengthRealize simultaneous sample preparationMaterial strength using steady shearing forcesSingle fiberResin-Based Composite

The invention relates to a device and method for testing interfacial shear strength of fiber reinforced thermosetting resin composite materials. The device comprises a resin die, support plates, hollow screw rods, sleeves, spring clips, and a bottom support plate; the hollow screw rods and the support plates are connected in rigid connection, the sleeves and the hollow screw rods are connected through internal screw threads, the support plates are vertically placed on the bottom support plates and fixed with screws, the resin die is embedded in the middle part of the support plates and is placed on the bottom support plate, a fiber is introduced to pass through the hollow screw rod and impale a wall of the resin die by a steel needle, a certain length of the fiber is embedded, and the spring clip clamps a free end of the fiber outside the sleeve. The testing method is based on single fiber pull-out technology, and the method comprises the following steps: fibers are embedded into the resin die, and the embedding length is regulated; resin is cast in order to prepare a testing sample; demoulding is carried out for a single fiber pull-out test, and the interfacial shear strength of the composite material is calculated. The device has a simple structure, and can be used for solving difficulties of sample preparation for the single fiber pull-out test of fiber and the like; the interface test method is convenient and rapid to operate.

Owner:TONGJI UNIV

Magnesium/aluminum multi-layer composite material and preparation method thereof

ActiveCN110369709AAchieve high-quality connectionsAchieve densified sinteringTransportation and packagingMetal-working apparatusEconomic benefitsMetal

The invention relates to a powder metallurgy technology, in particular to a magnesium / aluminum multi-layer composite material and a preparation method thereof. The invention aims to solve the problemof bad connection property of magnesium / aluminum dissimilar materials caused by restriction of the prior art; meanwhile, by a compaction and connection integrated forming technology, significant economic benefit is created. The preparation method comprises the following steps: performing laminating and powder paving on aluminum-containing powder and magnesium-containing powder in a mold, heating to 430 to 440 DEG C by a gradient heating mode, controlling the pressure to 20 to 45 MPa and performing spark plasma sintering to further obtain the well-connected magnesium / aluminum multi-layer composite material with a compact base body. The magnesium / aluminum multi-layer material prepared by the method has the advantages of few processes, short time and excellent combination property. The preparation method is suitable for preparation of a series of magnesium / aluminum based composite materials and can be extended to preparation of other dissimilar metal double-layer structure materials withapproximate sintering temperature. The preparation method is simple to operate, easy to control and convenient in industrialized application.

Owner:CENT SOUTH UNIV

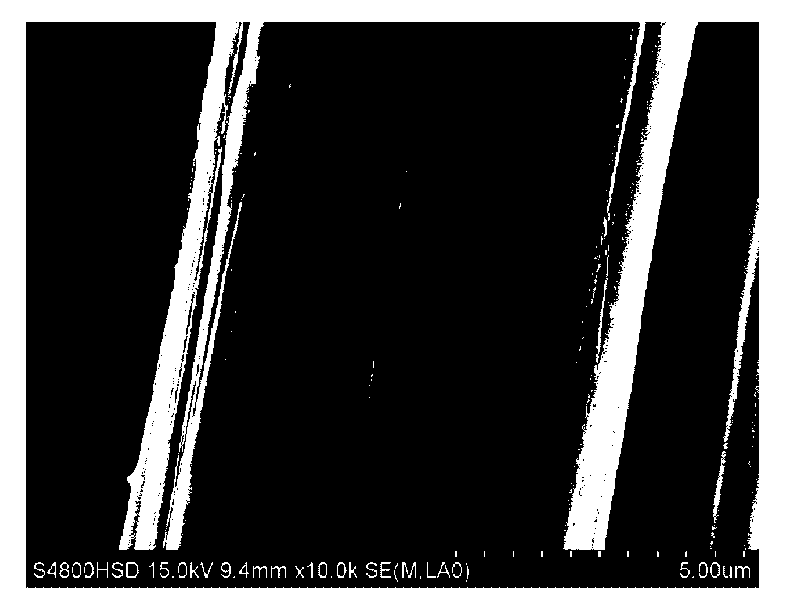

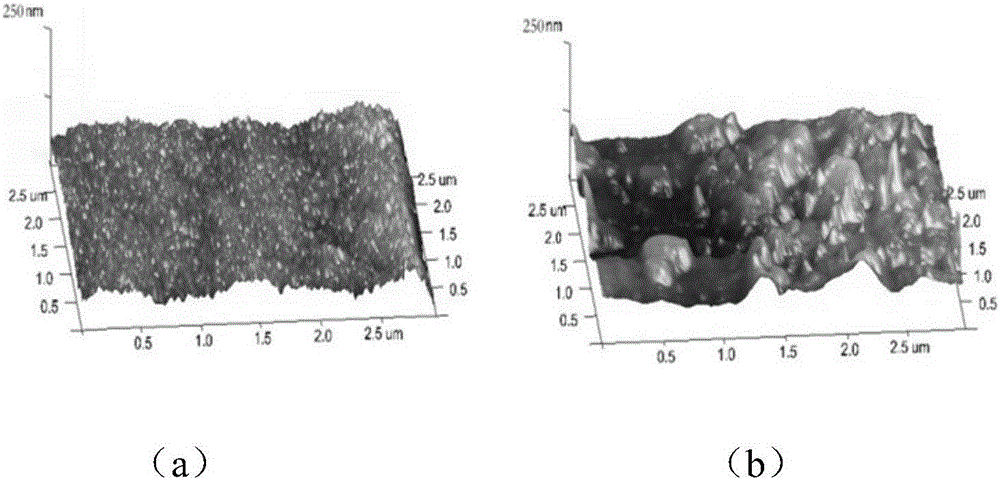

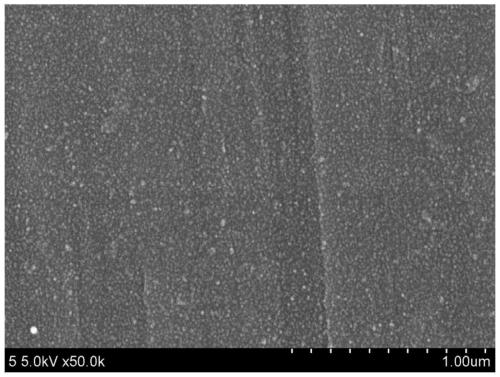

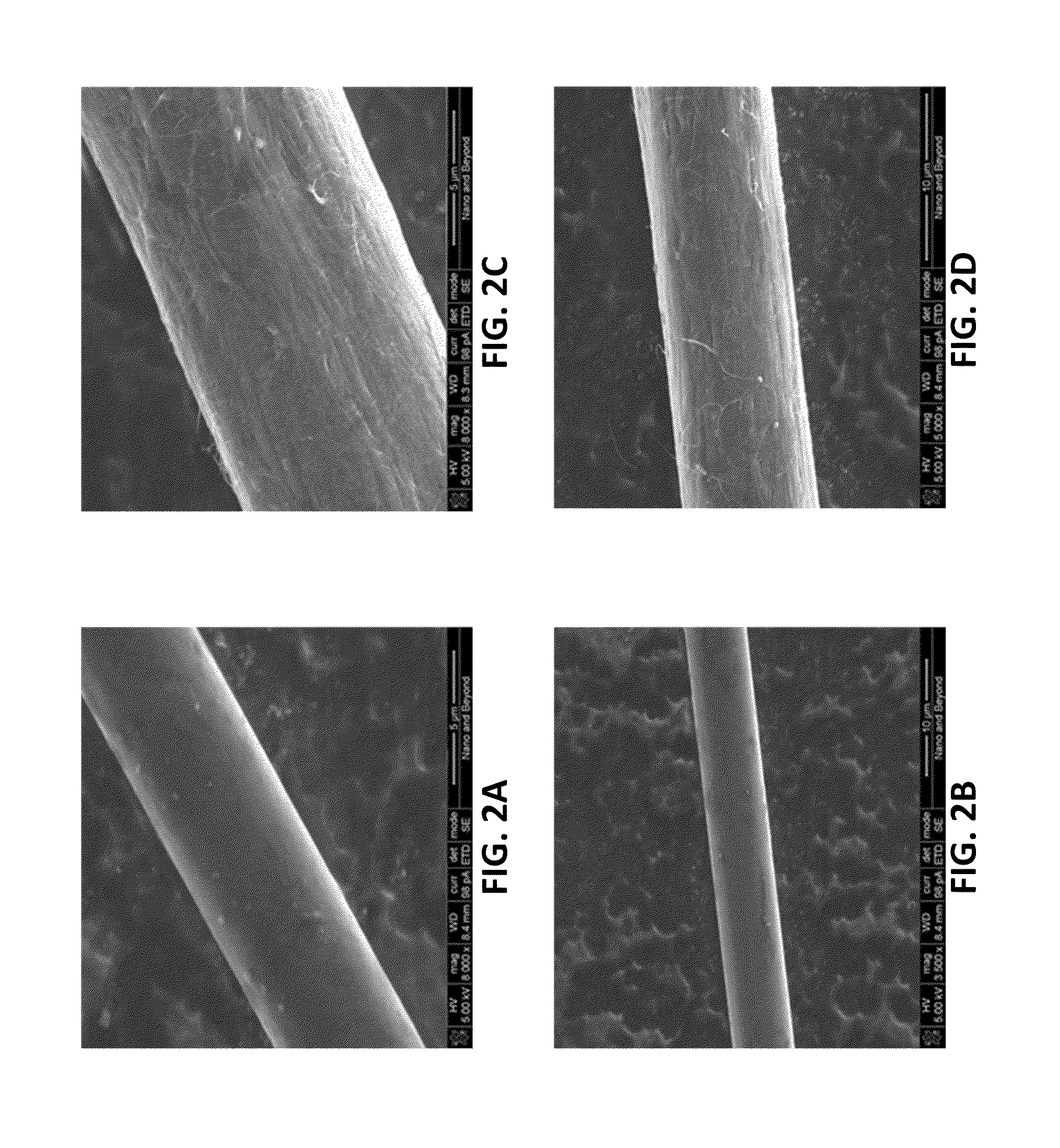

Microwave radiation treatment method and microwave radiation treatment device for improving surface activity of carbon fibers

ActiveCN105887463AImprove interface performanceIncreased interlaminar shear strengthRadio/micro wave fibre treatmentCarbon fibresSurface energyRadiation processing

The invention discloses a microwave radiation treatment method and a microwave radiation treatment device for improving the surface activity of carbon fibers. The microwave radiation treatment method and the microwave radiation treatment device have the advantages that TE10 transverse electric waves are subjected to single-mode transmission in metal rectangular waveguides by the aid of microwave generated in a microwave generator, and the carbon fibers are subjected to radiation treatment by the aid of microwave energy via a flared antenna; the carbon fibers are etched by the microwave, accordingly, the depths of grooves in the surfaces of the carbon fibers can be increased, and the roughness of the surfaces of the carbon fibers can be improved; bonding of single crystals on the surfaces of the carbon fibers is destroyed under the radiation effects of the microwave, accordingly, active carbon atom points can be increased, O / C atomic ratios of the surfaces of the carbon fibers can be increased, and the contents of oxygen-containing active functional groups can be increased; surface energy of the treated carbon fibers can be increased, accordingly, the activity of the carbon fibers can be improved, and the microwave radiation treatment method and the microwave radiation treatment device are favorable for forming excellent interfaces between the carbon fibers and resin matrixes.

Owner:XI AN JIAOTONG UNIV

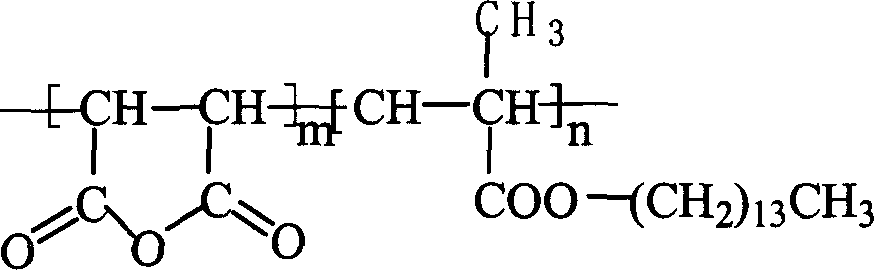

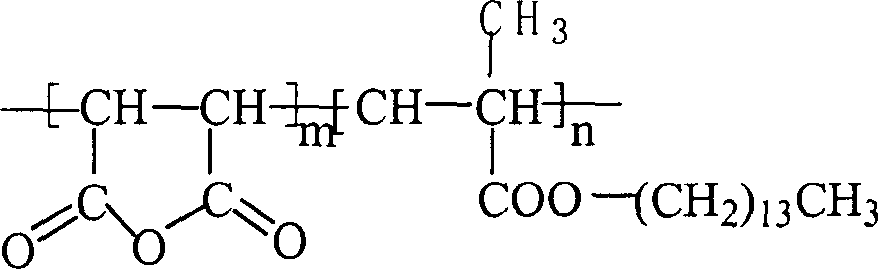

Use of methacrylic acid tetradecyl ester-maleic anhydride copolymer

Owner:TAISHAN FIBERGLASS INC +1

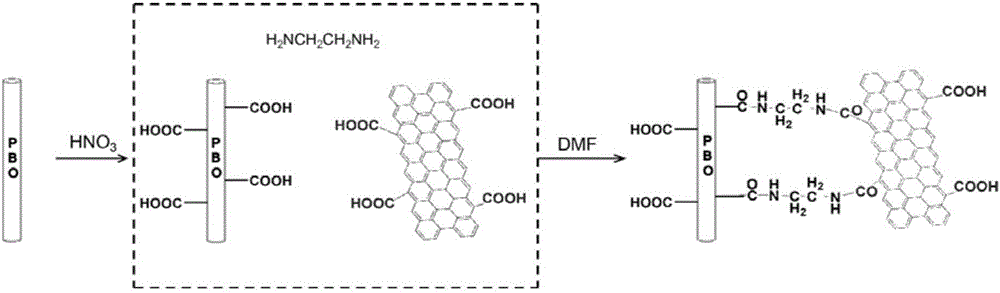

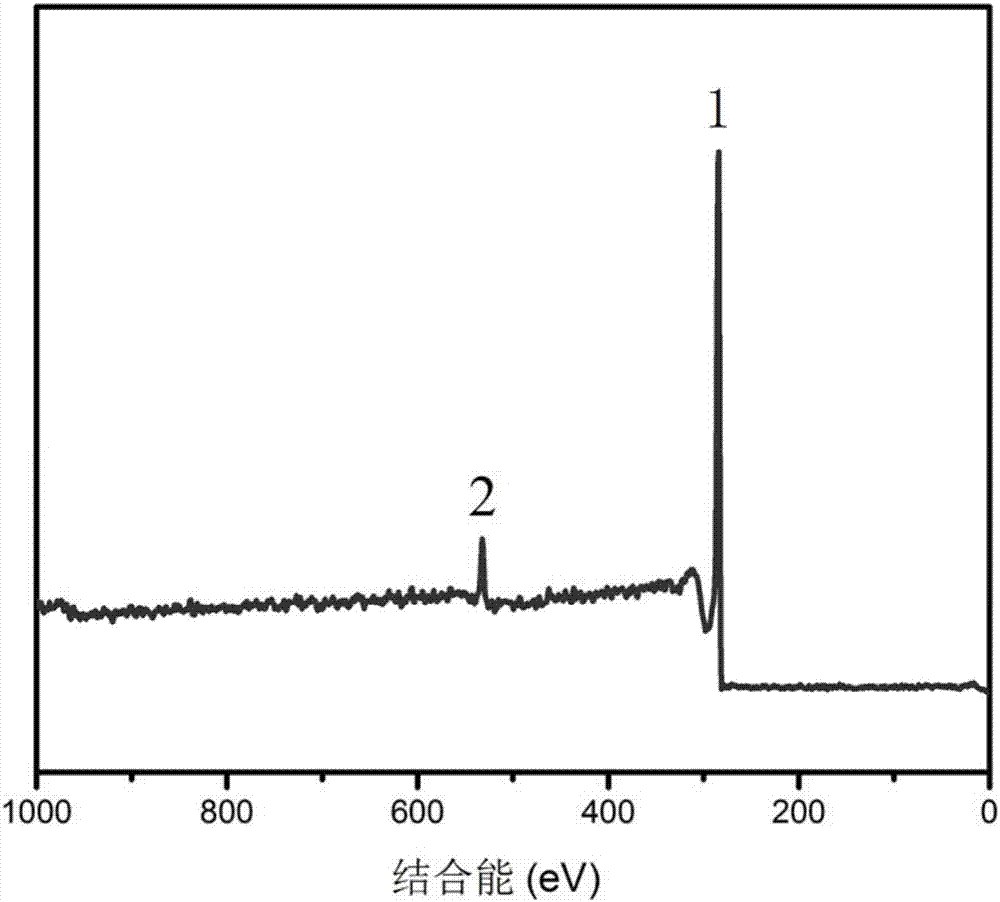

Graphene nanoribbon interface-modified PBO (polyparaphenylene benzobisoxazole) fiber and preparation method thereof

The invention relates to a modification method of a PBO (polyparaphenylene benzobisoxazole) fiber, in particular to a graphene nanoribbon interface-modified PBO fiber and a preparation method thereof, aiming at solving the problem that the existing modification method of the PBO fiber enables the tensile strength of a PBO fiber body to be greatly reduced. The structure of the graphene nanoribbon interface-modified PBO fiber is described in the description. The preparation method comprises the steps of 1, preparing a graphene nanoribbon; 2, treating the graphene nanoribbon by carboxylation; 3, treating the surface of PBO by carboxylation; 4, using the carboxylic graphene nanoribbon interface-modified PBO fiber to obtain the graphene nanoribbon interface-modified PBO fiber. Compared with the untreated PBO fiber, the tensile strength of the modified PBO fiber is only reduced by 5-10 percent; compared with an epoxy resin composite material prepared by the unmodified PBO fiber, the interfacial shear strength of an epoxy resin composite material prepared by the modified PBO fiber is improved by 20-41 percent. The graphene nanoribbon interface-modified PBO fiber can be taken as a reinforcing material for preparing composite materials.

Owner:HARBIN INST OF TECH

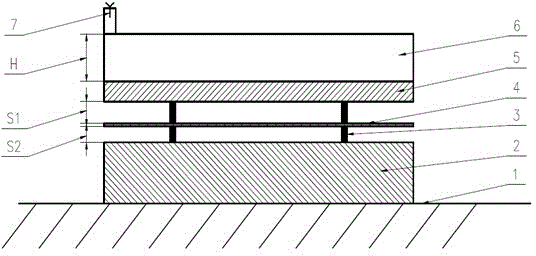

Explosive welding method for improving bonding strength of aluminum-carbon steel composite material

ActiveCN104526150AReduce heat consumptionExtended service lifeWelding/soldering/cutting articlesNon-electric welding apparatusCarbon steelAluminum composites

An explosive welding method for improving the bonding strength of an aluminum-carbon steel composite material comprises the steps of respectively conducting surface polishing on the explosive welding faces of a carbon steel base layer (2), a carbon steel middle thin layer (4) and an aluminum composite layer (5), horizontally arranging the base layer on a foundation (1), arranging the upper end face of the base layer on the carbon steel middle thin layer through supporting of superposed copper pieces (3), forming a separation distance S2 between the middle thin layer and the base layer, arranging the composite layer on the upper end face of the middle thin layer through supporting of the superposed copper pieces, forming a separation distance S1 between the composite layer and the middle thin layer, finally laying explosive (6) with density of 0.5-0.8 g / cm<2> and thickness H on the upper end face of the composite layer and burying detonators (7), wherein the detonation speed is controlled to be 2000-2600 m / s, the composite layer can sequentially bumps the middle thin layer and the base layer through one-time explosive welding, the three-layer integrated aluminum-carbon steel composite material is formed, heat energy consumption is obviously reduced, a melting phenomenon does not occur, and the interface bonding strength is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

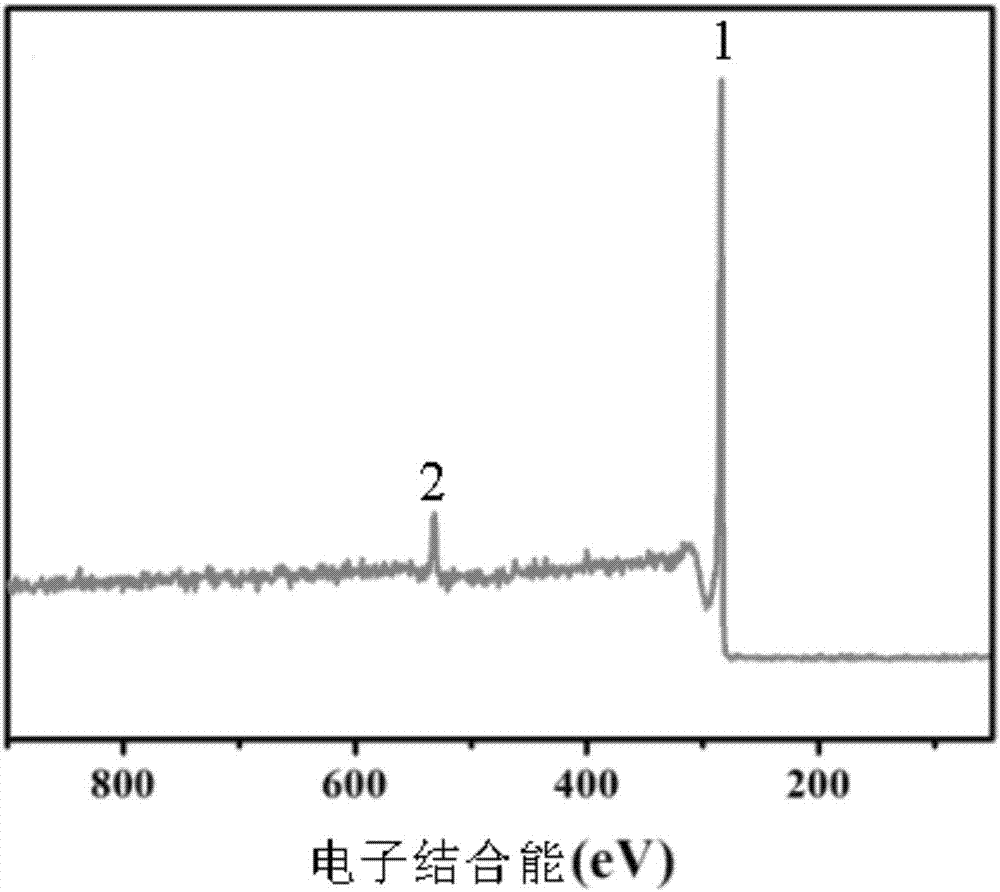

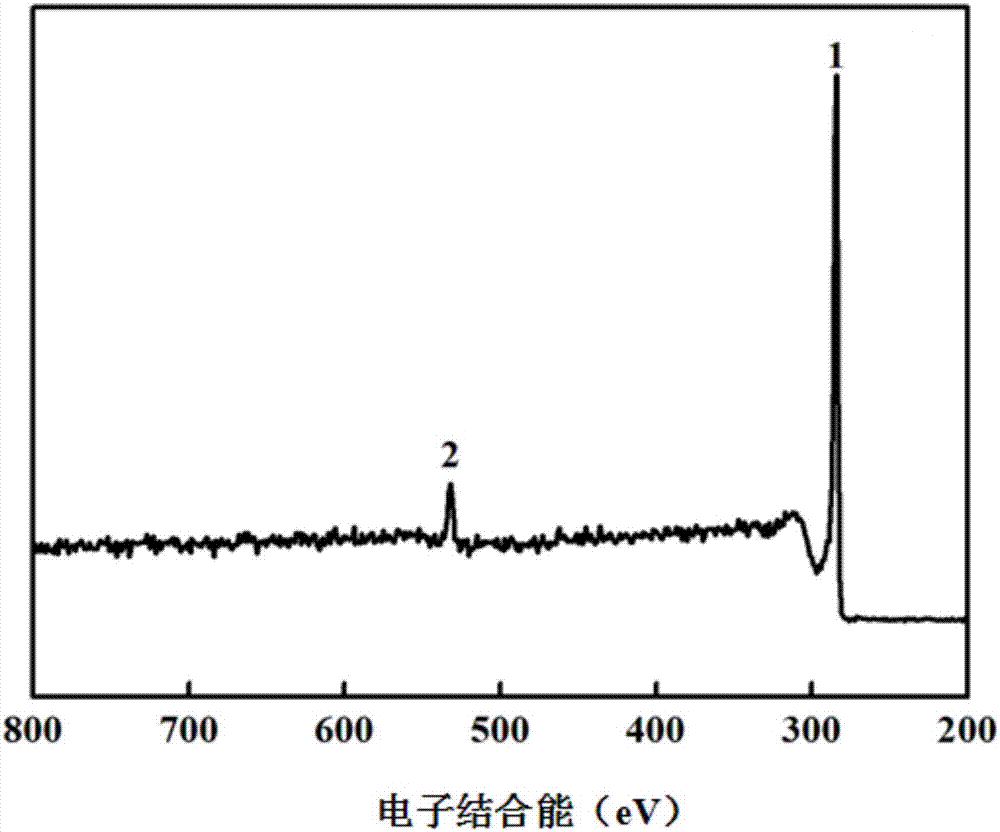

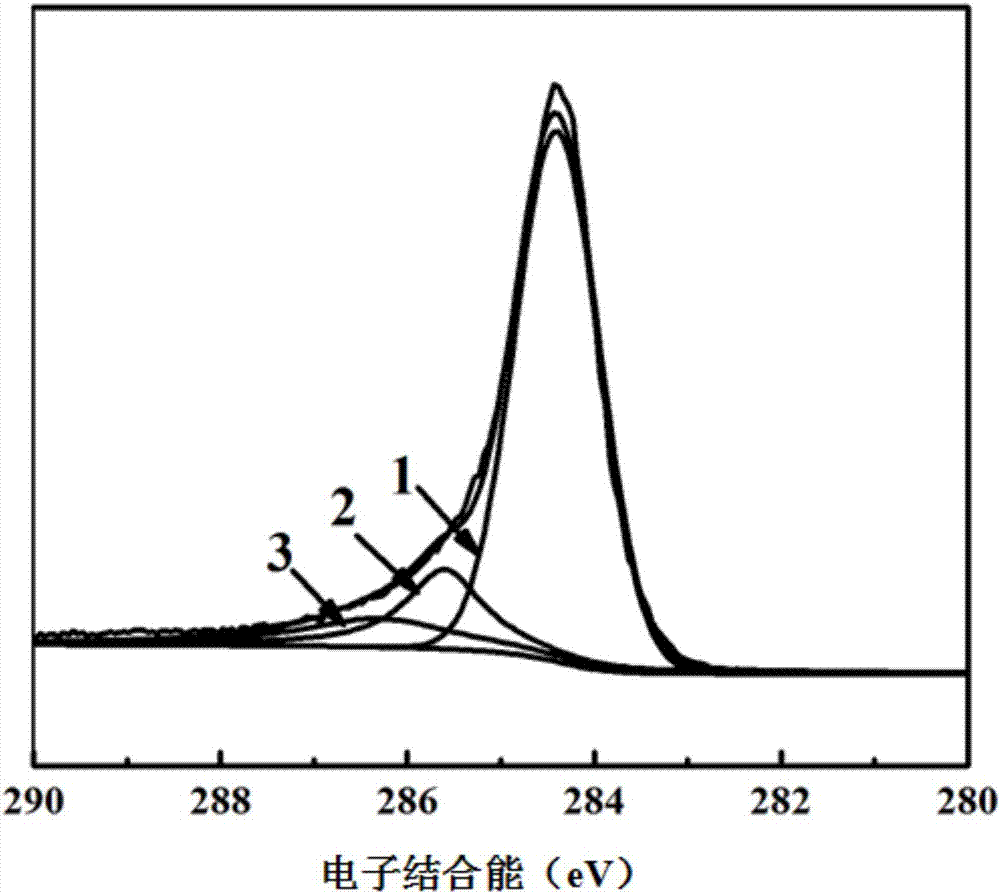

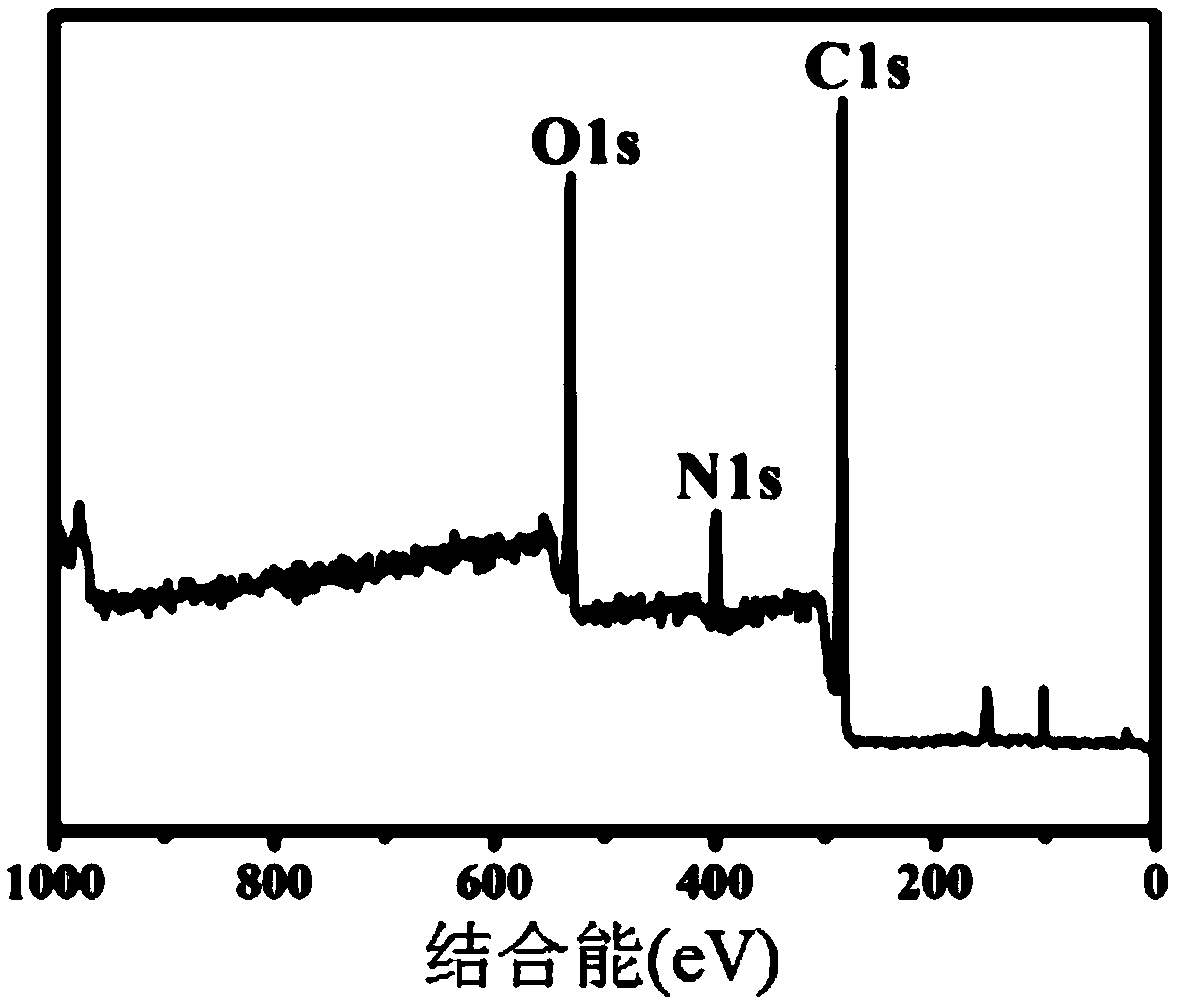

Method for grafting hyperbranched aromatic polyamide to surface of carbon fibers

ActiveCN107313259AImprove application potentialImprove compatibilityCarbon fibresSurface energyPolyamide

The invention discloses a method for grafting hyperbranched aromatic polyamide to the surfaces of carbon fibers and relates to a method for grafting a polymer to the surfaces of the carbon fibers. The invention aims at solving the problem of low interface bonding strength of an existing carbon fiber composite material. The method comprises the following steps: firstly, carrying out extraction treatment on the carbon fibers; secondly, oxidizing; thirdly, carrying out reducing treatment on the carbon fibers; fourthly, carrying out silanization treatment on the carbon fibers; fifthly, preparing a mixture, and heating to obtain the carbon fibers of which the surfaces are grafted with the hyperbranched aromatic polyamide. Compared with untreated carbon fibers, the carbon fibers of which the surfaces are grafted with the hyperbranched aromatic polyamide, prepared by the method disclosed by the invention, have the advantages that the content of N is increased from original 1.11 percent of the untreated carbon fibers to 2.7 to 4 percent, and surface energy is improved by 100.5 percent or above, and the interfacial shear strength is improved by 65 percent. According to the method disclosed by the invention, the carbon fibers of which the surfaces are grafted with the hyperbranched aromatic polyamide can be obtained.

Owner:QINGDAO UNIV

Preparation method of graphene/carbon nano tube-reinforced and toughened carbon fiber composite material

ActiveCN107059403AFew preparation stepsSimple processCarbon fibresGrapheneModified carbonStrong acids

The invention provides a preparation method of a graphene / carbon nano tube-reinforced and toughened carbon fiber composite material. The method comprises the steps of preparing a three-dimensional graphene floccule and a surface-modified carbon nano tube by using a strong acid and a breaker under the action of an oxidizing agent separately; then, carrying out high-speed shear mixing and ultrasonic dispersing processes to obtain a graphene / modified carbon nano tube sizing agent; and preparing the graphene / carbon nano tube-reinforced and toughened carbon fiber composite material through a sizing process. The prepared graphene / carbon nano tube-reinforced and toughened carbon fiber composite material has the characteristics of conductivity and thermal conductivity, high strength, high modulus, rubbing resistance and corrosion resistance of a carbon fiber, the characteristics of the tensile strength, the bending strength and the interfacial shear strength are significantly improved, the cycling processability of the carbon fiber is effectively improved, and the composite material has reinforcing and toughening characteristics.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

Preparation method of nanometer zinc oxide modified aramid fiber

InactiveCN109914094AImprove bonding fastnessImprove adhesionFibre typesEpoxyUltimate tensile strength

The invention relates to aramid fiber with the modified surface. The preparation method of the nanometer zinc oxide modified aramid fiber comprises the steps that the aramid fiber is subjected to surface functionalization, zinc oxide nanometer particles are grafted and grow on the surface of the aramid fiber, and zinc oxide nanowires are grafted and grow on the surface of the aramid fiber. The aramid fiber has the advantages that modification conditions are mild, and the technology is simple; the combining firmness of the nanometer zinc oxide and the aramid fiber is obviously improved; the bonding performance of resin and modified fiber and the ultraviolet-radiation resistance of the fiber is remarkably enhanced. Compared with unmodified aramid fiber, the interface shear strength of epoxyresin and the modified aramid fiber can be increased by 37-61%; after the modified aramid fiber is subjected to ultraviolet radiation testing, the stretching strength retention rate is increased from78.3% to 96.3-97.6%.

Owner:DONGHUA UNIV

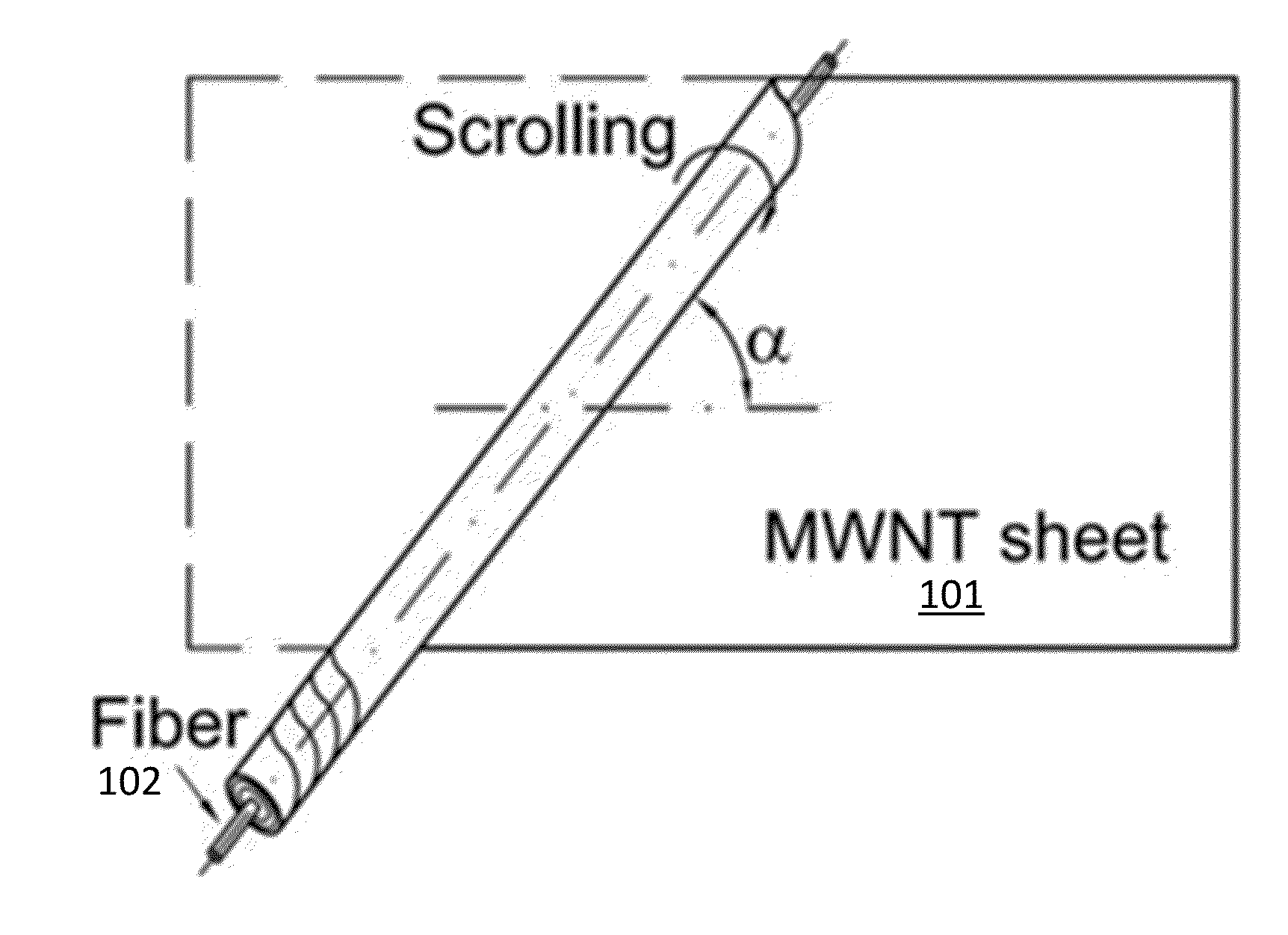

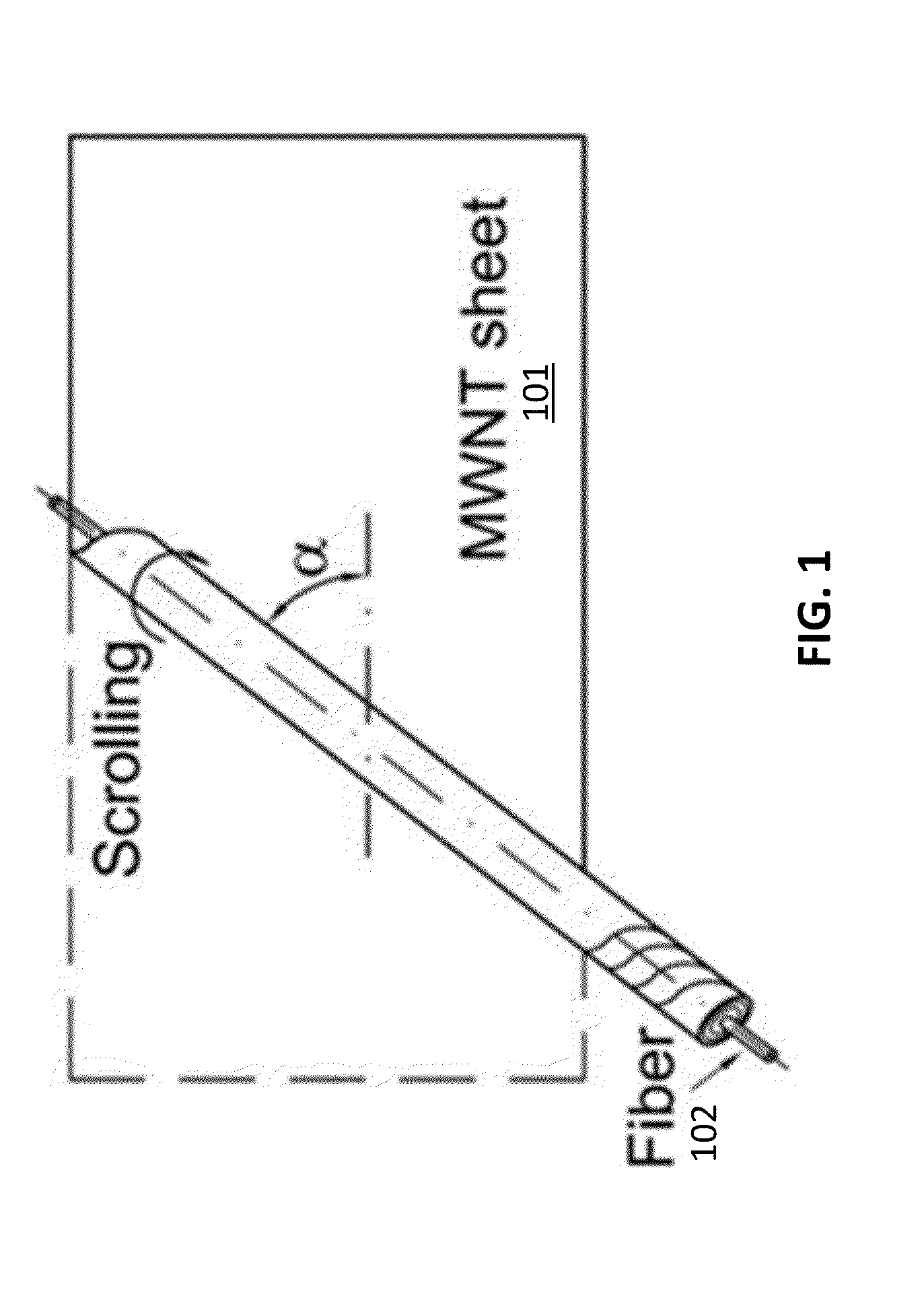

Method of fabricating carbon nanotube sheet scrolled fiber reinforced polymer composites and compositions and uses thereof

A novel method of fabricating carbon nanotube sheet scrolled fiber and fiber tows (carbon, graphite, glass, natural polymer, synthetic polymer, metallic, silicon carbide, Kevlar, etc.) in composites with improved interfacial shear strength, compressive strength, yield strength, stiffness and toughness has been reported. Single or multiple layers of carbon nanotube sheet, with a bias / wrapping angle of 0° and 90°, has been scrolled around single fiber and fibers tows to improve the above mentioned mechanical properties of the matrix surrounding the fiber. Other common methods of growing CNTs directly on the fibers actually damage the fiber surface during the required precursor deposition and CNTs growth process. This demonstrated solid-state method overcomes such known problems. The CNTs sheet scrolled fiber is embedded into the polymer matrix exhibits significant (80%) increase in interfacial shear strength, compressive strength and toughness.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

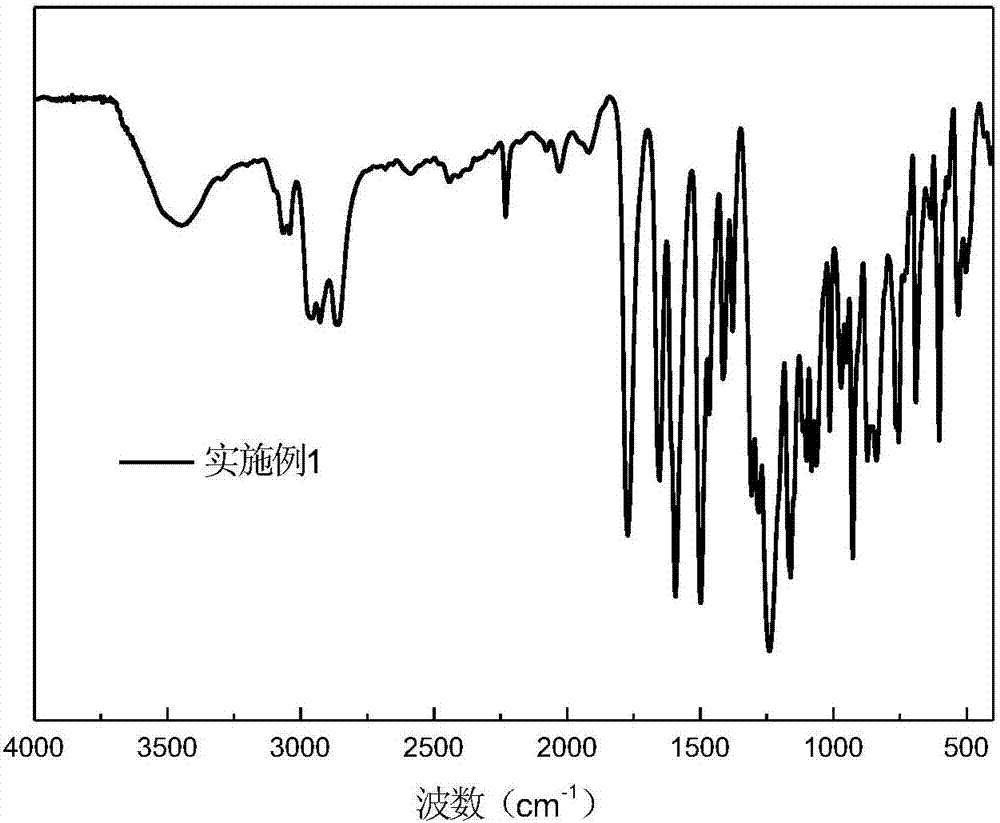

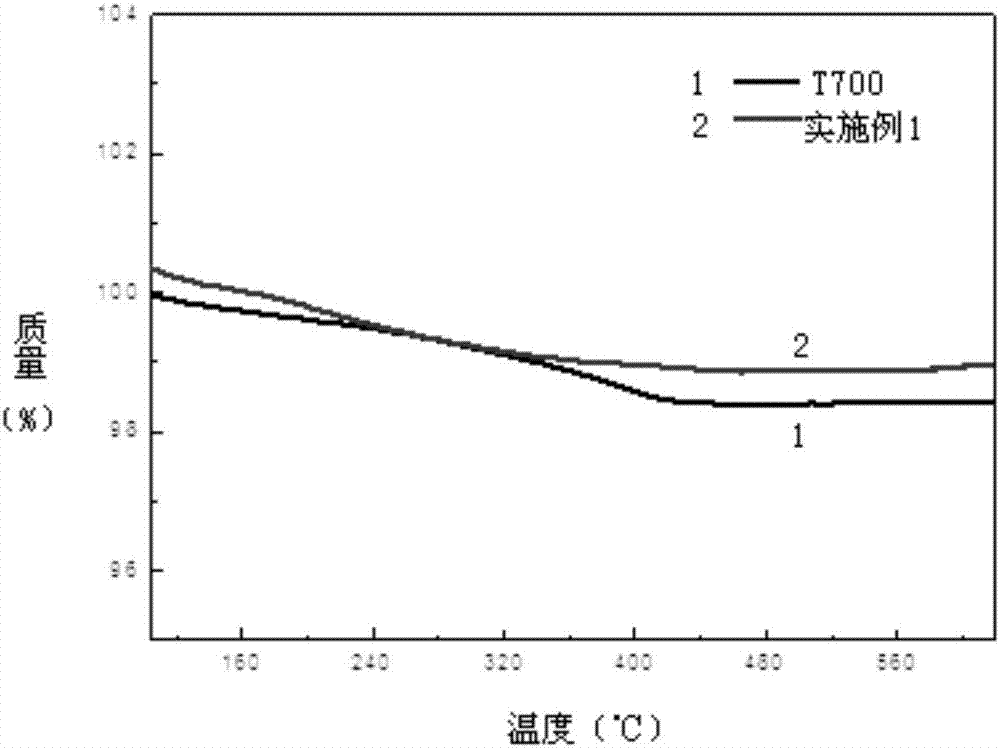

Emulsion type thermoplastic sizing agent for carbon fiber and preparation method of sizing agent

ActiveCN107385918AIncrease surface free energyStable storageCarbon fibresPhenolphthaleinCarbon fibers

The invention firstly provides an emulsion type thermoplastic sizing agent for carbon fiber and a preparation method of the sizing agent and belongs to the technical field of carbon fiber sizing agents. The sizing agent is prepared from components in percentage by mass as follows: 0.1%-2% of thermoplastic resin, 0.05%-2% of an emulsifier, 0.05%-1% of a coupling agent, 0.4%-8% of an organic solvent and 87.0%-99.4% of deionized water, wherein the thermoplastic resin is polyarylether resin adopting a phenolphthalein structure. The invention further provides the preparation method of the emulsion type thermoplastic sizing agent for the carbon fiber. The emulsion type thermoplastic sizing agent is mainly prepared from the polyarylether resin adopting the phenolphthalein structure and having higher temperature tolerance, the sized carbon fiber can be composited with thermoplastic resin with higher thermal resistance for preparation of a composite, an emulsion is stored stably and dispersed uniformly, and the interface shearing strength of the carbon fiber and the thermoplastic resin is remarkably improved.

Owner:芜湖万隆新材料有限公司

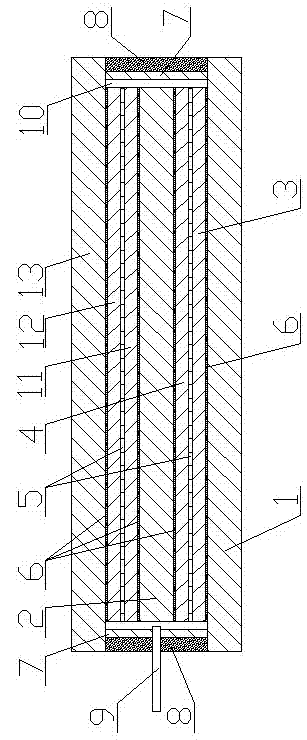

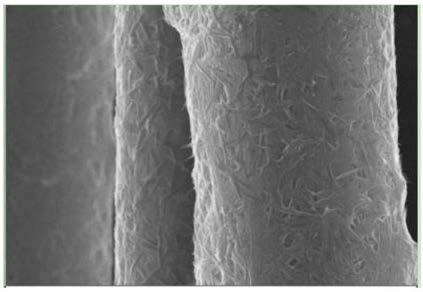

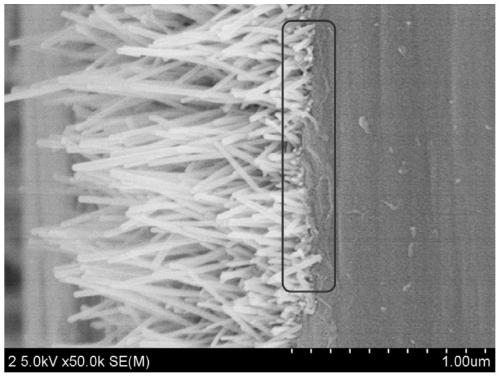

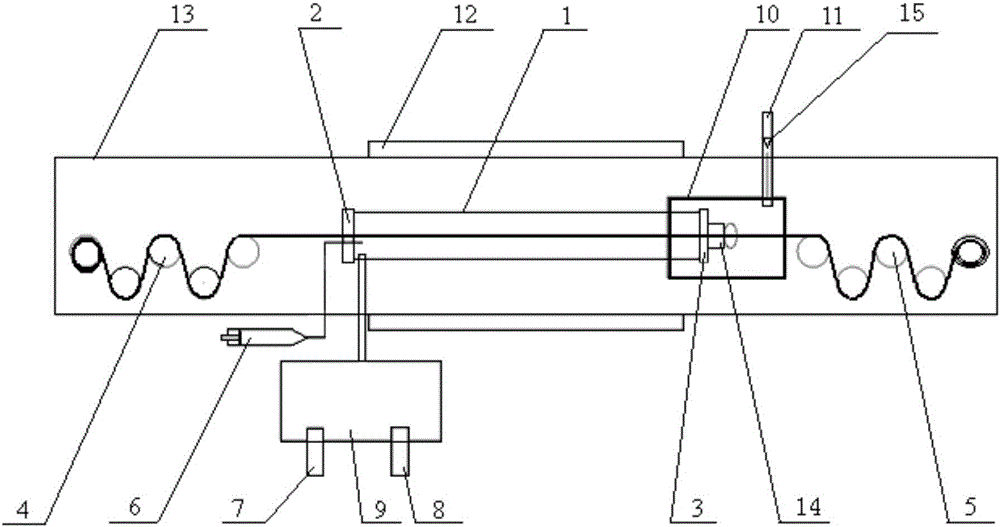

Device and method for preparation of continuous carbon fiber with carbon nanotubes growing on surface

ActiveCN105908491AGuaranteed continuityIncreased interfacial shear strengthCarbon fibresFiberCarbon fibers

Relating to devices and methods for carbon fiber interfacial modification, the invention provides a device and method for preparation of continuous carbon fiber with carbon nanotubes growing on the surface. The invention aims to solve the problem that continuous modified carbon fiber cannot be obtained through existing modification of carbon fiber with carbon nanotubes. The device comprises a quartz tube, a head-end sealing plug, a tail-end sealing plug, front drawing rollers, back drawing rollers, a micro-injection pump, a hydrogen generator, an argon bottle, a gas mixing apparatus, a tail gas treatment device, an exhaust pipe, a heating jacket and a sealed bin. The micro-injection pump and the gas mixing apparatus are both connected to the quartz tube, and the heating jacket is disposed outside the sealed bin. The method consists of: passing a carbon fiber tow through the front drawing rollers, the back drawing rollers and the quartz tube and conducting tensioning, introducing argon into the quartz tube to perform purification, then introducing the mixed gas of hydrogen and argon into the heated quartz tube, then dissolving ferrocene into a solvent and then introducing the product into the quartz tube, and depositing carbon nanotubes on the surface of moving carbon fiber so as to obtain continuous carbon fiber with carbon nanotubes growing on the surface. And the continuous carbon fiber with carbon nanotubes growing on the surface can be used as a reinforcement in composite materials.

Owner:HARBIN INST OF TECH

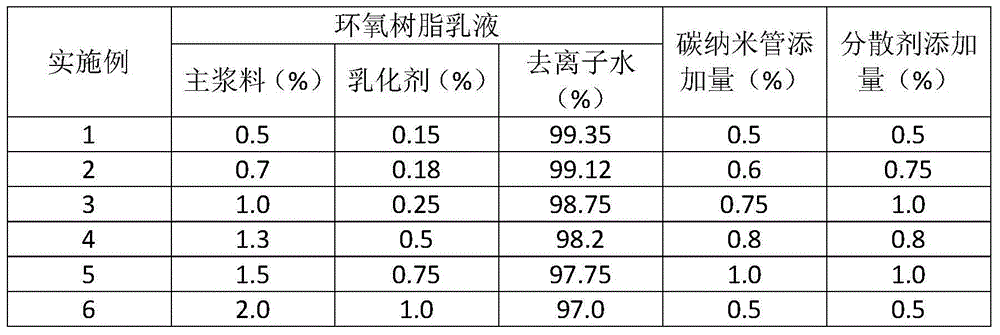

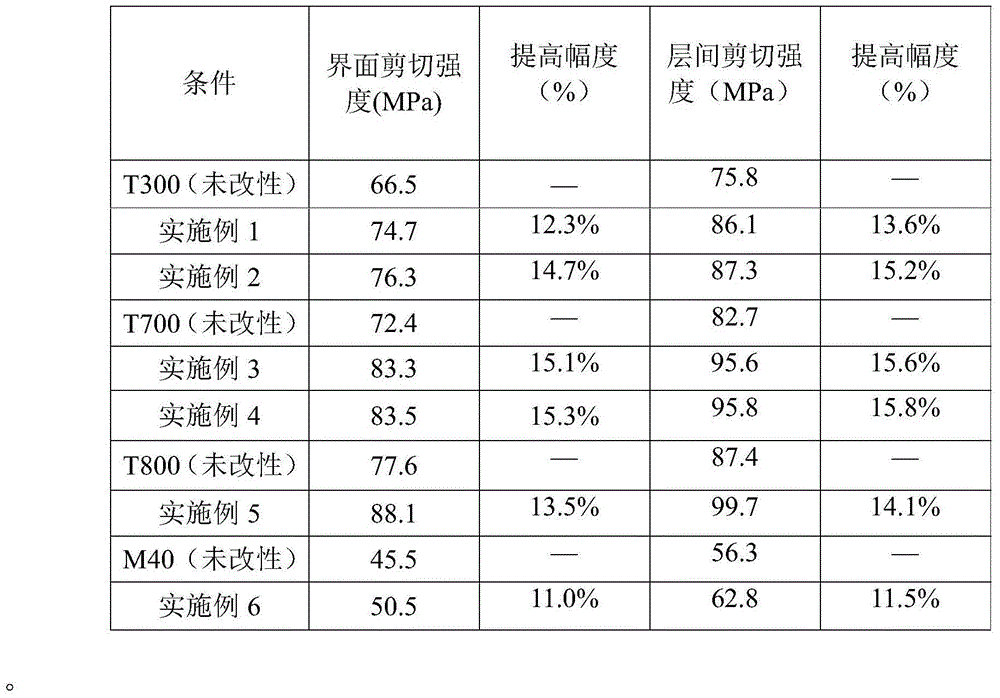

Carbon nanotube modified carbon fiber emulsion sizing agent and preparation method

The invention relates to a carbon nanotube modified carbon fiber emulsion sizing agent. The carbon nanotube modified carbon fiber emulsion sizing agent is prepared by a two-step method, wherein in step 1, an epoxy resin emulsion is prepared from the ingredients in percentage by mass: 0.5-2% of main slurry, 0.15-1.0% of emulsifier and 97-99.35% of deionized water; in step 2, carbon nanotubes are dispersed into the epoxy resin emulsion, wherein the mass percentage of the added carbon nanotubes is 0.5-1.0%, and the mass percentage of an added dispersant is 0.5-1.0%. The carbon nanotube modified carbon fiber emulsion sizing agent has the advantages of being capable of improving the interfacial shear strength and interlayer shear strength of carbon fibers and composite materials thereof and being applicable to industrial application.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Method for grafting hydroxyl terminated hyperbranched polymer to carbon fiber surface

The invention discloses a method for grafting a hydroxyl terminated hyperbranched polymer to a carbon fiber surface, relating to a modification method for a carbon fiber surface. The method is directed to solve the problem that the modification of carbon fibers is restricted by weak interface bonding between the carbon fibers and a resin matrix, complexity of a synthetic process of the hydroxyl terminated hyperbranched polymer, and toxicity of synthetic raw materials. The method comprises the following steps: 1, preparation of a hydroxyl terminated hyperbranched polymer; 2, extraction of carbon fibers; 3, oxidation; and 4, grafting to obtain surface grafted hydroxyl terminated hyperbranched polymer carbon fibers. Since the hydroxyl terminated hyperbranched polymer has a large amount of polar hydroxyl groups and pore structures, after the polymer is grafted to the carbon fiber surface, the wettability and cohesiveness between the carbon fibers and the resin are remarkably improved, which greatly improves the interfacial properties of the composite material, and improves the mechanical properties and thermal stability of the composite material. The invention can obtain a method for grafting a hydroxyl terminated hyperbranched polymer to a carbon fiber surface.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com