Microwave radiation treatment method and microwave radiation treatment device for improving surface activity of carbon fibers

A technology of microwave radiation and surface activity, which is applied in fiber processing, radiation wave/microwave fiber processing, carbon fiber, etc., can solve the problems of complicated processing technology, high energy consumption, and difficult industrial operation, and achieve broad application prospects and low energy consumption. Low, the effect of increasing the interlaminar shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of microwave radiation treatment method that carbon fiber surface activity improves, comprises the following steps:

[0032] Step 1: Extract Toray T300 fiber tow in acetone for 48 hours to remove the sizing agent on the fiber surface.

[0033] Step 2: Sonicate the carbon fiber from which the sizing agent has been removed in deionized water for 1 hour to remove the acetone reagent on the surface of the fiber.

[0034] Step 3: Place the carbon fiber taken out of the deionized water in a vacuum drying oven at 60° C. for 24 hours to dry to ensure that the surface of the carbon fiber is dry to obtain unsized T300 fiber.

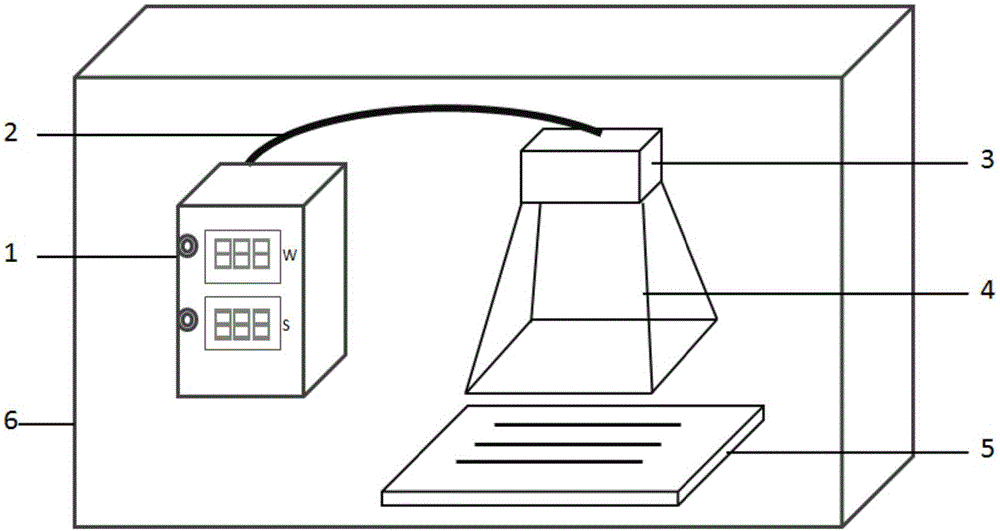

[0035] Step 4: Place the unsized T300 fiber on the non-metallic substrate 5, wherein the dielectric constant of the substrate is 3.9. Adjust the angle of the carbon fiber to ensure that the length direction of the carbon fiber is parallel to the long side of the rectangular waveguide, that is, perpendicular to the direction of the microwave electric...

Embodiment 2

[0038] A kind of microwave radiation treatment method that carbon fiber surface activity improves, comprises the following steps:

[0039] Step 1: Sonicate Toray T700 fiber tow in deionized water for 1 hour to remove impurities on the fiber surface.

[0040] Step 2: The carbon fiber taken out of the deionized water is placed in a vacuum drying oven at 60° C. for 24 hours to dry to ensure that the surface of the carbon fiber is dry.

[0041] Step 3: Place the sized T700 fibers on a non-metallic substrate, where the dielectric constant of the substrate is 3.9. Adjust the angle of the carbon fiber to ensure that the length direction of the carbon fiber is parallel to the long side of the rectangular waveguide of the microwave transmission system, that is, perpendicular to the direction of the microwave electric field.

[0042] Step 4: Use the pulsed electromagnetic wave generated by the magnetron microwave generator to radiate the carbon fiber, determine the size of the rectangu...

Embodiment 3

[0047] A kind of microwave radiation treatment method that carbon fiber surface activity improves, comprises the following steps:

[0048] Step 1: Extract Toray T300 fiber tow in acetone for 48 hours to remove the sizing agent on the fiber surface.

[0049] Step 2: Sonicate the carbon fiber from which the sizing agent has been removed in deionized water for 1 hour to remove the acetone reagent on the surface of the fiber.

[0050] Step 3: Place the carbon fibers taken out of the deionized water in a vacuum drying oven at 60° C. for 24 hours to dry to ensure that the surface of the carbon fibers is dry to obtain unsized T300 fibers.

[0051] Step 4: Place the unsized T300 fiber on the non-metallic substrate 5, wherein the dielectric constant of the substrate is 3.9. Adjust the angle of the carbon fiber to ensure that the length direction of the carbon fiber is parallel to the long side of the rectangular waveguide, that is, perpendicular to the direction of the microwave elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com