Patents

Literature

456results about How to "Improved particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

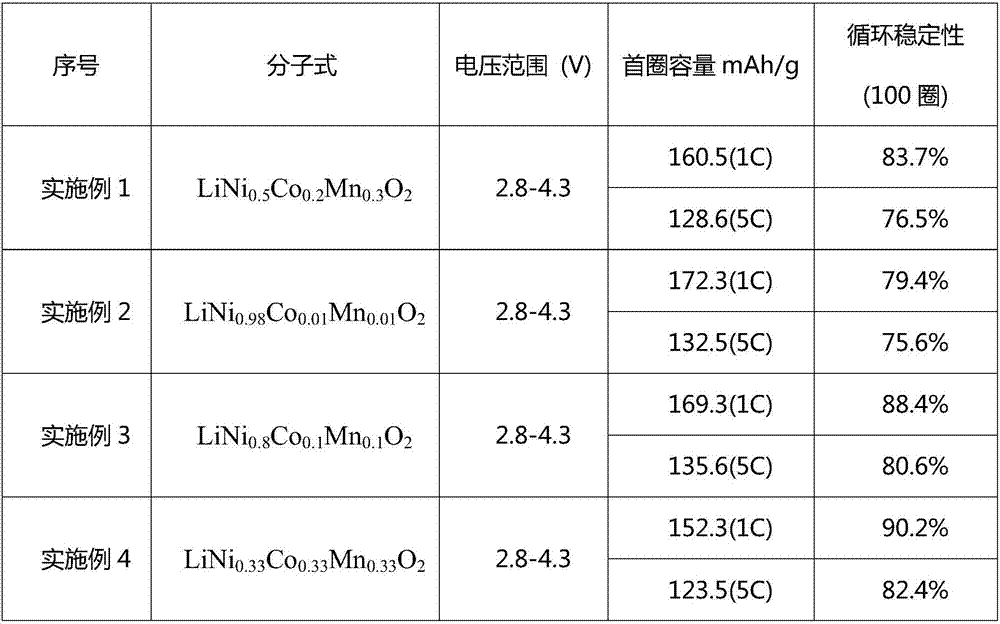

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

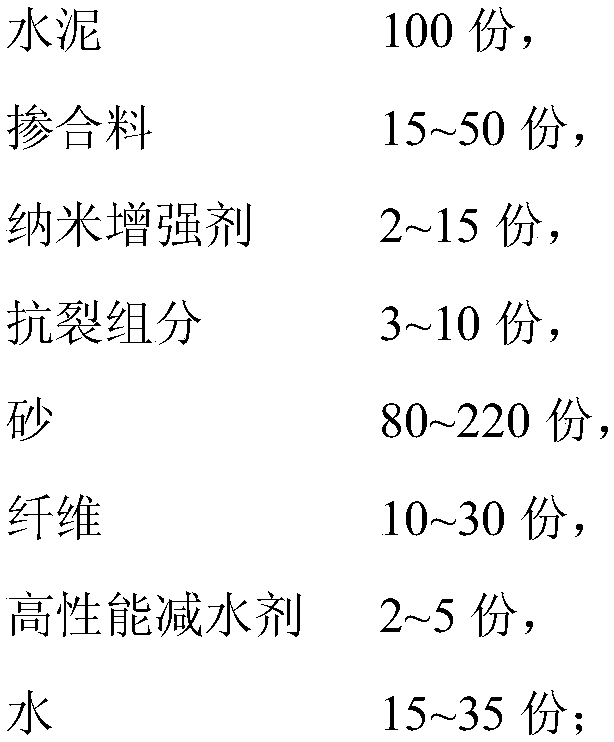

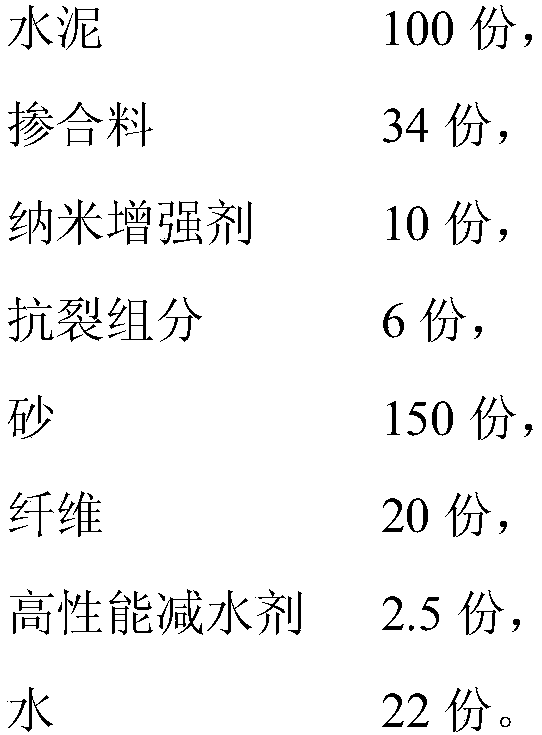

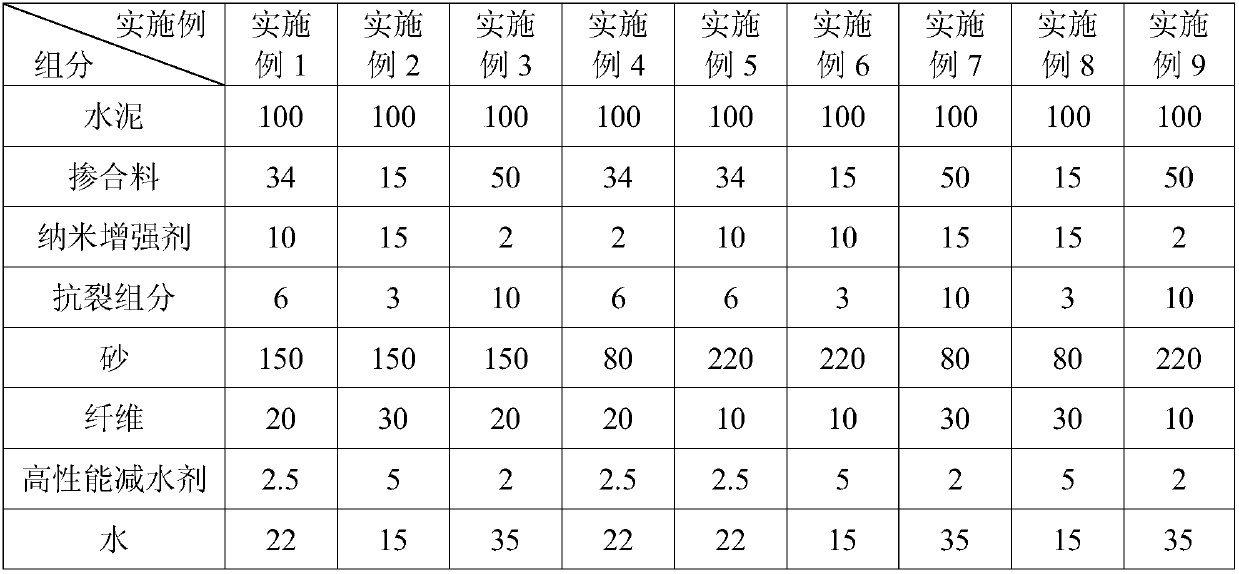

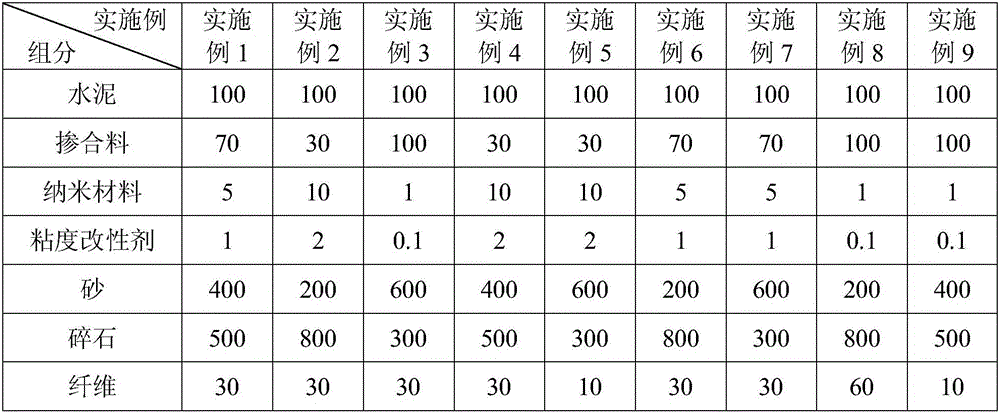

Super-high-performance cement base repairing material and preparing method thereof

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

Carbon black

InactiveUS6290767B1Low structural requirementsReduction in carbon black throughputPigmenting treatmentMaterials sciencePigment

Carbon blacks doped with elements that are not carbon, wherein pairs of carbon atoms have been replaced by iso-electronic pairs of elements or combinations of elements. They can be used as a pigment or filler in rubber, plastics, paints, inks or the like.

Owner:UBS AG

Process for producing titanium dioxide

ActiveUS20070172414A1Direct coolingImproved particle size distributionPigmenting treatmentZirconium compoundsGas phaseLiquid state

This disclosure relates to a process for producing titanium dioxide, comprising: a) providing a quantity of liquid titanium tetrahalide for reacting with an oxygen-containing gas; b) vaporizing a first portion of the liquid titanium tetrahalide and reacting the titanium tetrahalide vapor and the oxygen-containing gas, in a first stage of a reaction zone, the reaction zone temperature ranging from at least about 650° C.—to form a reaction product at least containing titanium dioxide and oxygen-containing gas and passing the reaction product, more typically in the vapor phase, to at least one additional stage of the reaction zone; and c) charging at least one additional portion of the liquid titanium tetrahalide to the at least one additional stage of the reaction zone to cool the titanium dioxide and to react with the oxygen-containing gas to form additional titanium dioxide. This process results in a high conversion to titanium dioxide and formation of titanium dioxide powders having improved particle size and size distribution.

Owner:THE CHEMOURS CO FC LLC

Efficient cellulose nanocrystalline preparing method

ActiveCN105777913AHigh yieldImproved particle size distributionPulp properties modificationWashing/displacing pulp-treating liquorsInorganic saltsCellulose

The invention provides an efficient and quick cellulose nanocrystalline preparing method.According to the method, a cellulose raw material is pretreated with aqueous alkali and then subjected to acidolysis, and inorganic salt containing metal ions is added during acidolysis to serve as a promoter to promote acidolysis reaction.Reaction condition is mild and easy to control, raw materials needed by reaction are simple and easy to obtain, and the method can be widely applied to preparation of cellulose nanocrystalline from various cellulose raw materials.

Owner:QINGDAO UNIV OF SCI & TECH

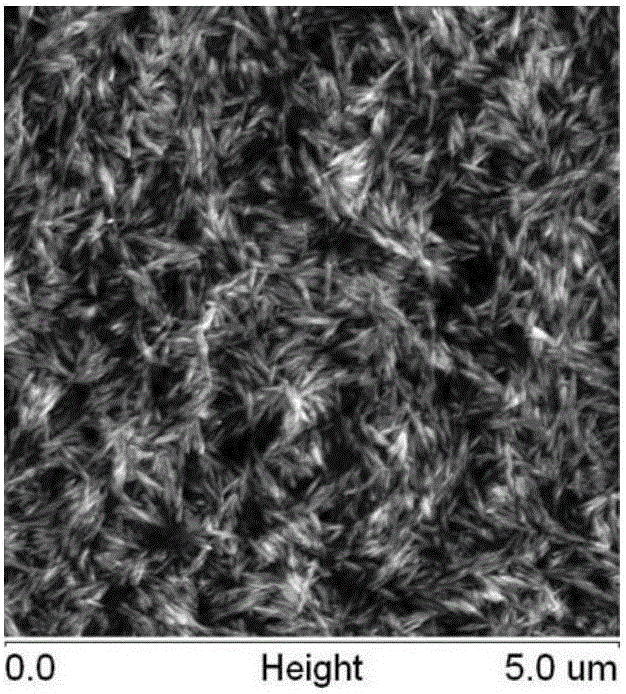

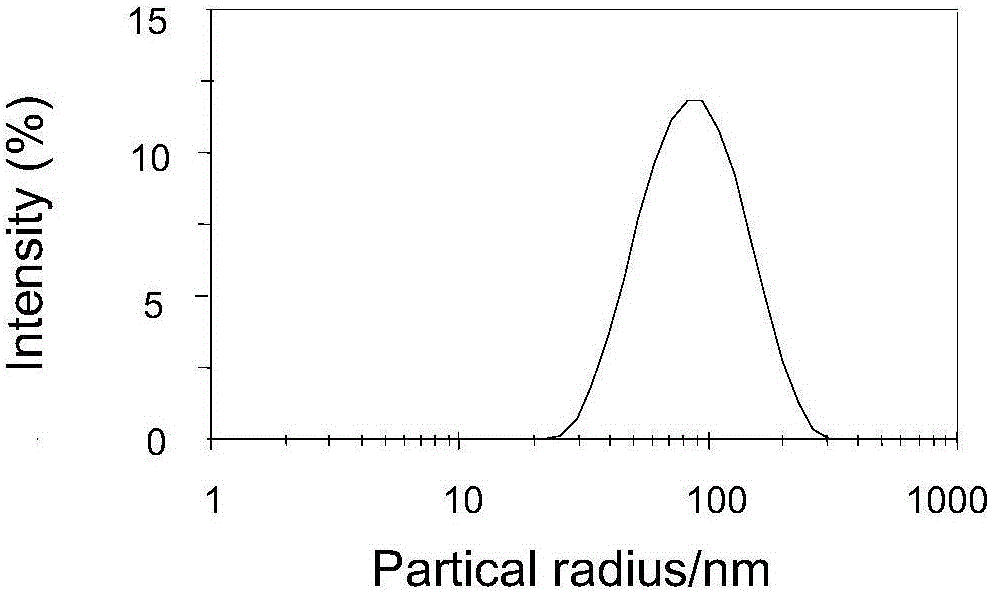

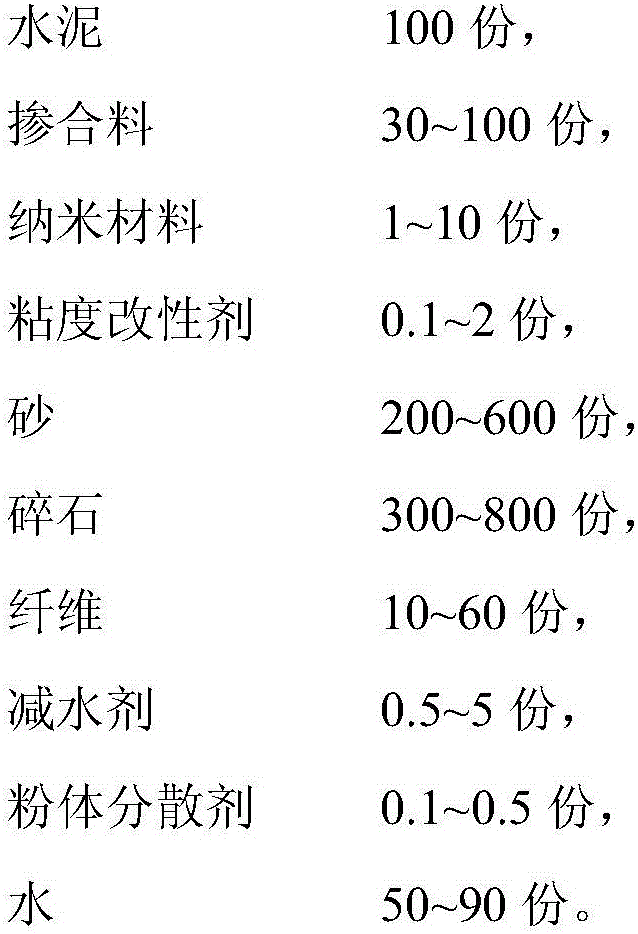

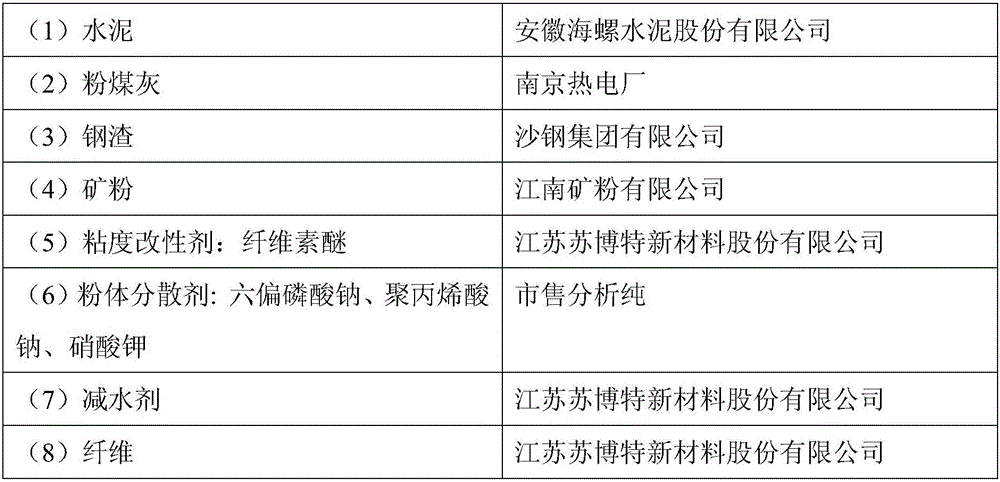

Concrete with common strength and high elastic modulus and preparation method thereof

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

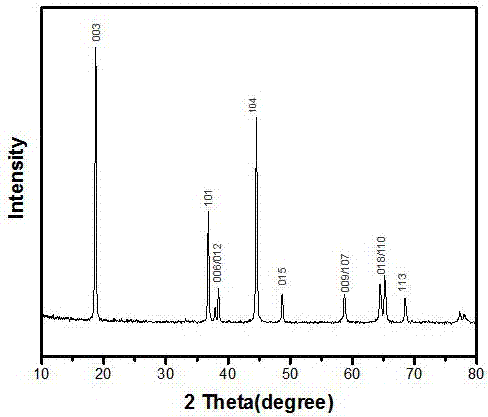

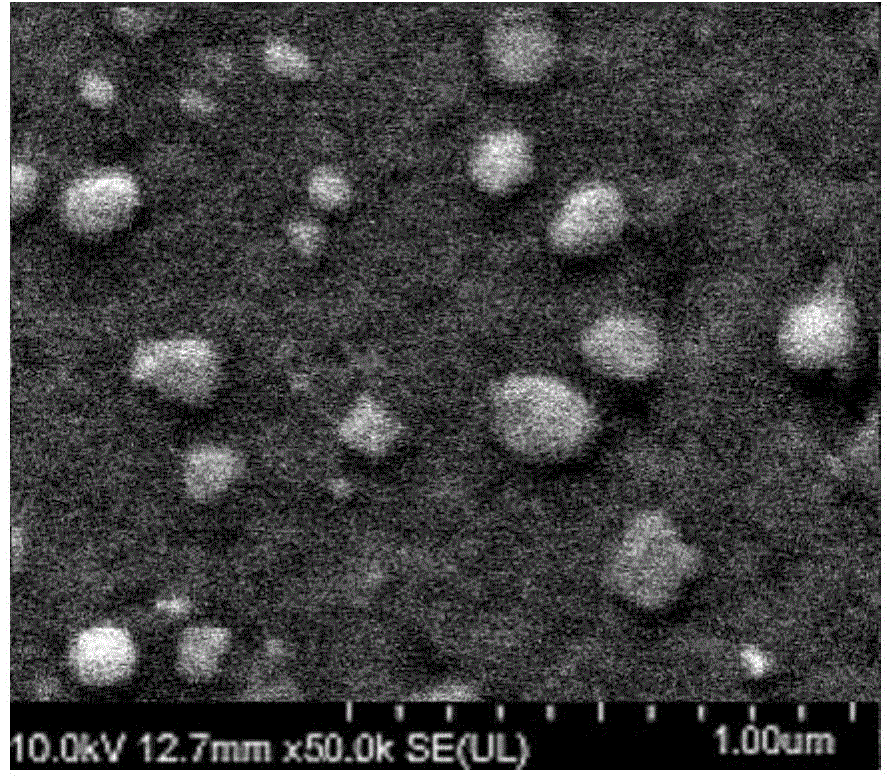

Ternary positive-electrode material prepared by solvothermal method and preparation method thereof

InactiveCN107959022ARegulatory TopographySmall sizeCell electrodesSecondary cellsFiltrationManganese

The invention discloses a ternary positive-electrode material prepared by a solvothermal method and a preparation method thereof. The preparation method includes: dissolving nickel cobalt manganese salt in a solvent, adding a surfactant and hydrolysis auxiliaries, sufficiently stirring, transferring into a reaction kettle, performing solvothermal reaction under certain temperature for 2-24 hours,cooling to room temperature, using a suction filtration method to separate out a nickel cobalt manganese ternary product, washing, drying, and pre-calcining in air to obtain a precursor; grinding andmixing the precursor and a lithium compound, and calcining to obtain the ternary positive-electrode material. The ternary positive-electrode material and the preparation method thereof have the advantages that the ternary oxide precursor prepared by the solvothermal method is small in particle size, uniform in particle distribution and controllable in morphology as compared with a ternary precursor prepared by a conventional precipitation method, so that the finally prepared ternary material is small in granularity, uniform in particle size distribution and controllable in morphology and has excellent electrochemical performance, and the capacity and stability of the prepared ternary material are better than those of a ternary positive-electrode material prepared by the precipitation method.

Owner:SOUTH CHINA UNIV OF TECH

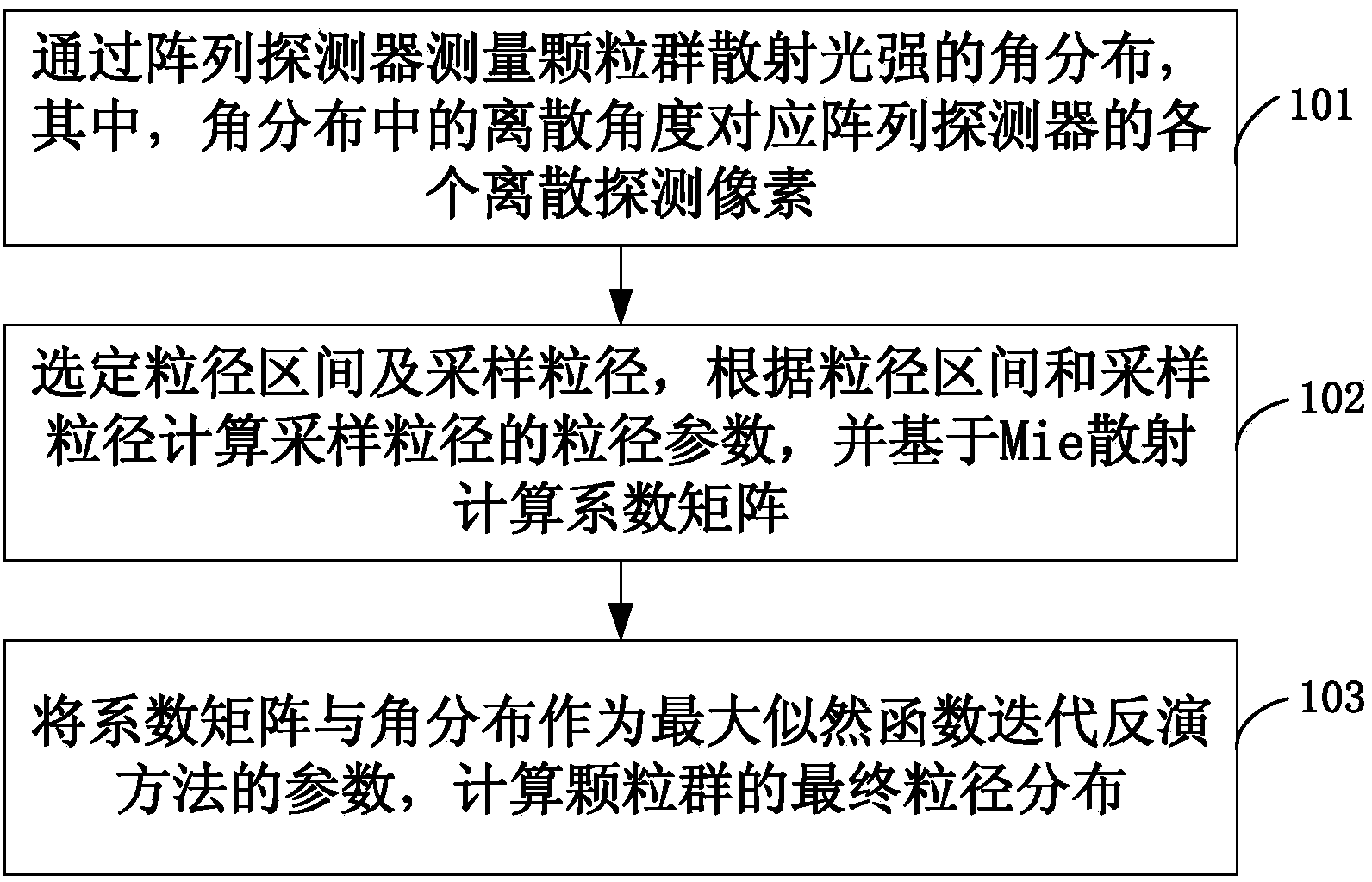

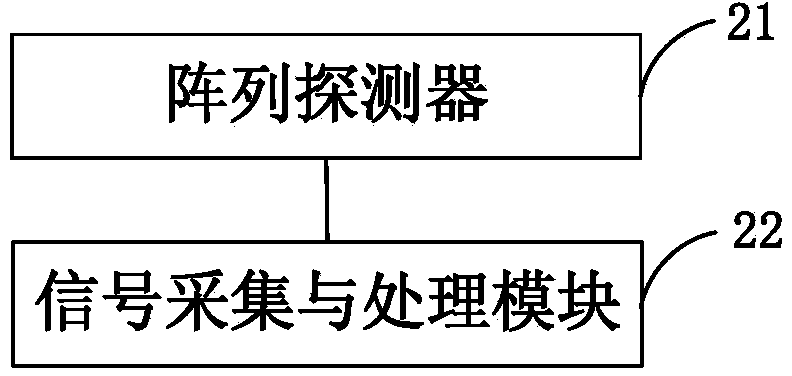

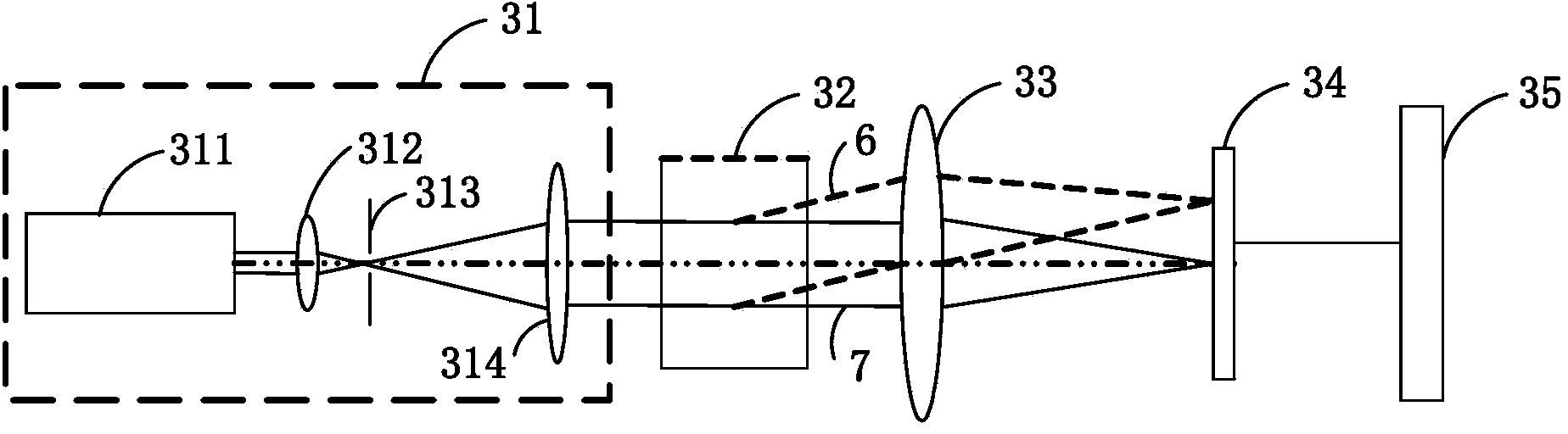

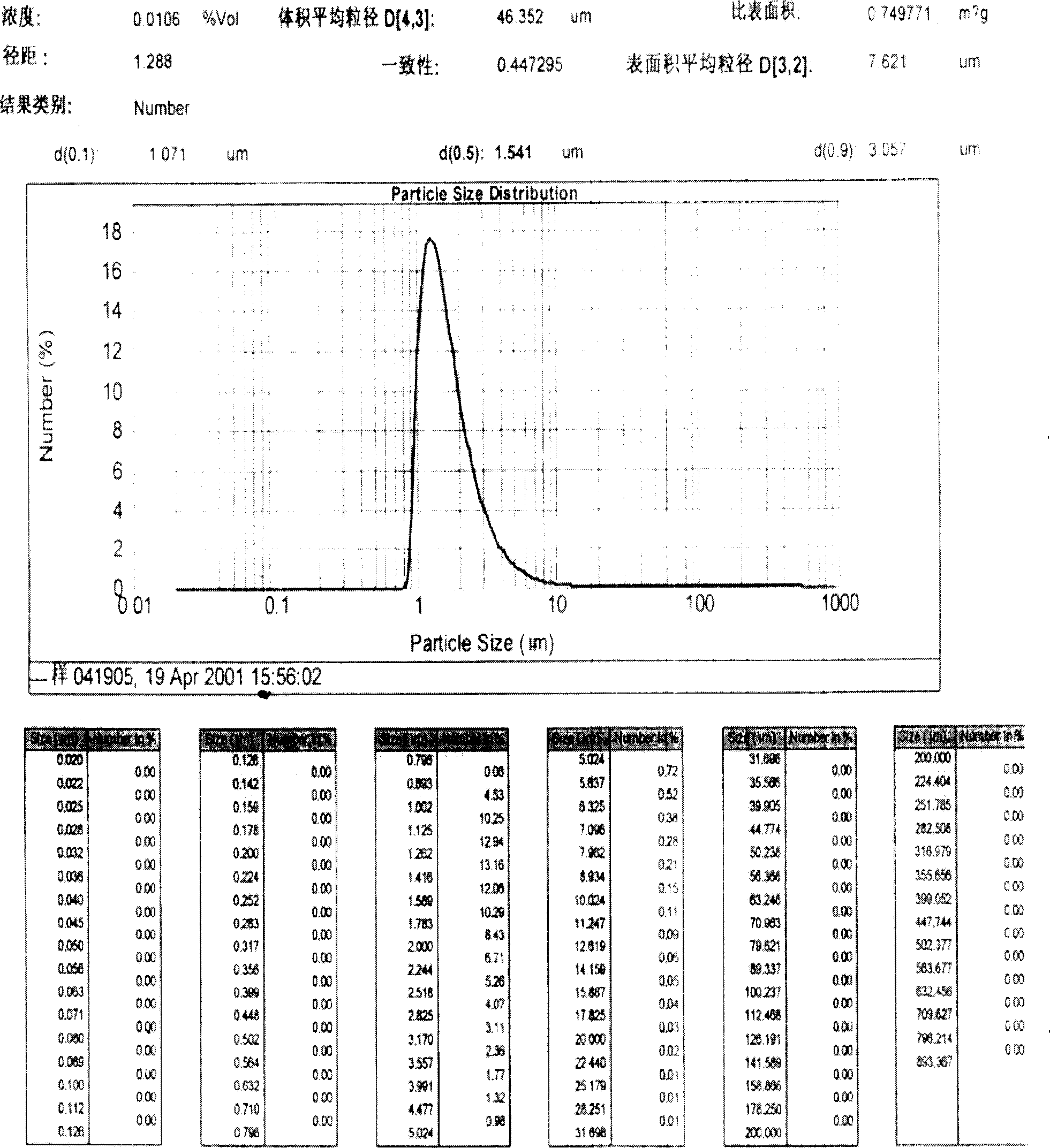

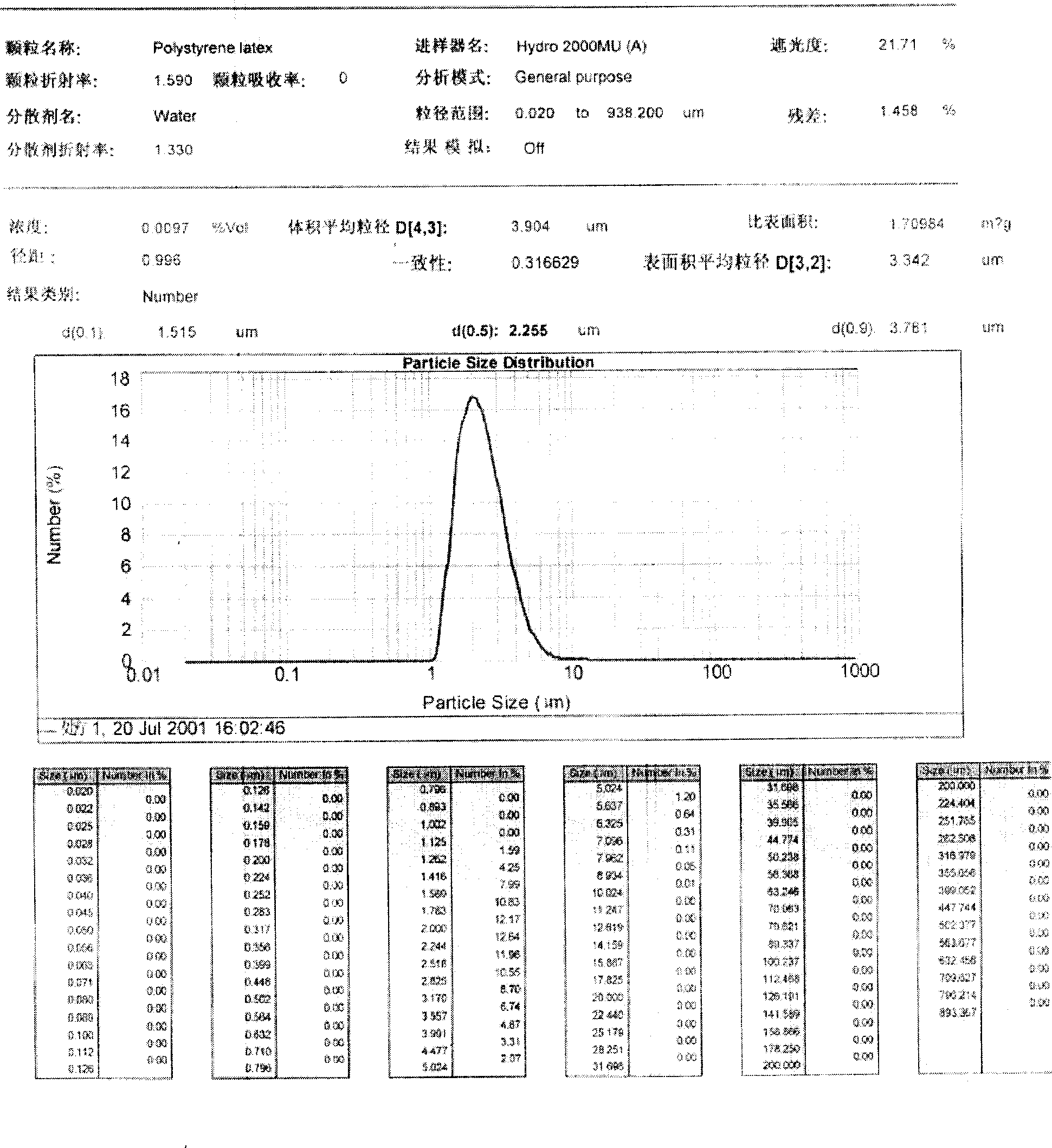

Method for measuring particle size distribution of particles, and apparatus thereof

InactiveCN103983546AAccelerateLower requirementParticle size analysisSignal-to-noise ratio (imaging)Computational physics

The invention provides a method for measuring the particle size distribution of particles, and an apparatus thereof. The method for measuring the particle size distribution of particles comprises the following steps: measuring the angular distribution of the scattering light intensities of a particle group through an array detector, wherein discrete angles in the angular distribution correspond to all discrete detection pixels of the array detector; selecting a particle size interval and a sampling particle size, calculating the particle size parameter of the sampling particle size according to the particle size interval and the sampling particle size, and calculating a coefficient matrix based on a Mie scatterometer; and calculating the final particle size distribution of the particle group by using the coefficient matrix and the angular distribution as parameters of a maximum likelihood iterative inversion process. The inversion calculation of the particle size distribution of measured data with a low signal-to-noise ratio can be accurately realized in the invention.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

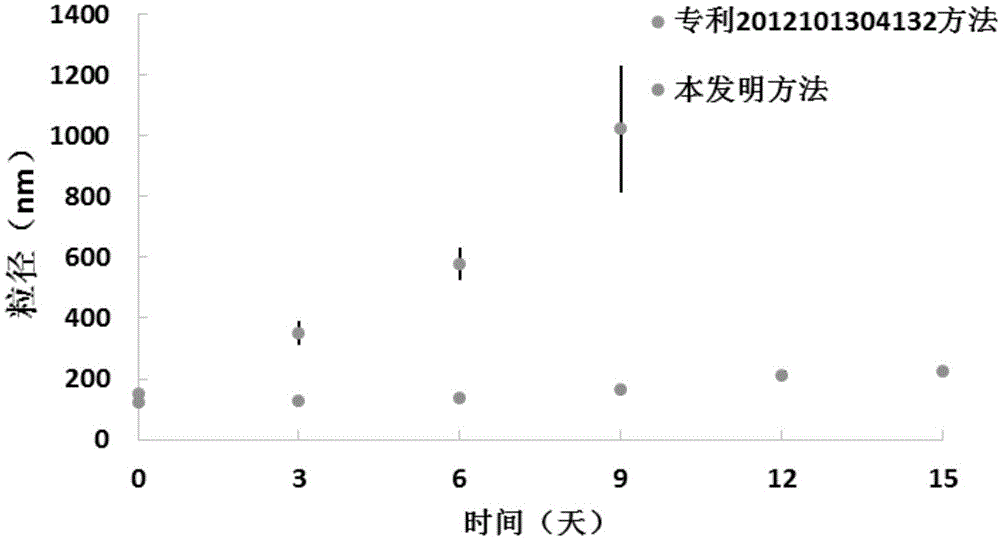

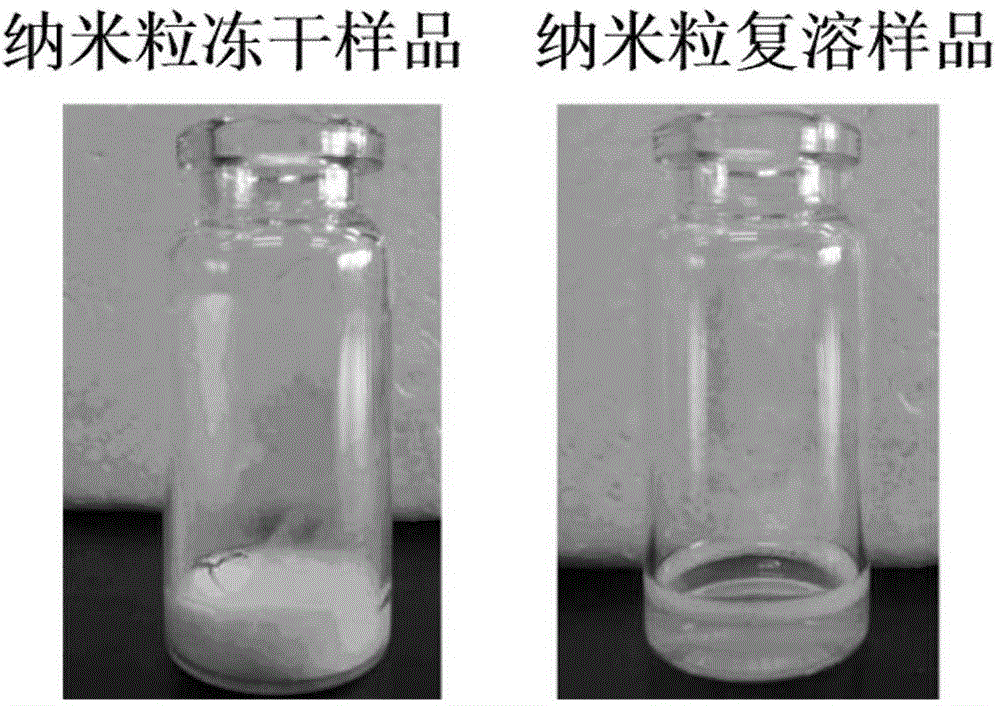

Preparation method of tinib drug alhumin nano preparation used for injection

InactiveCN105616361ASmall particle sizeEvenly distributedPowder deliveryOrganic active ingredientsLaboratory scaleFreeze-drying

The invention belongs to the field of medicinal preparation, and relates to a preparation method of a tinib drug alhumin nano preparation used for injection. According to the preparation method, a tinib drug is dissolved in an oil phase; a mixture is prepared from the oil phase and a human serum albumin water phase; the mixture is delivered into a high pressure homogenizer for high shearing so as to obtain a nano preparation; organic solvents are removed via thin film evaporation; and a finished product is obtained via freeze drying. A solubilizer, an oil stabilizing agent, and a pH adjusting agent are added so as to ensure the stability of the nano particles, relatively small particle size, and narrow particle size distribution. Reproducibility of the preparation method is excellent; content of the tinib drug in the nano particles can be increased; corresponding sets of apparatus from laboratory scale to large-scale production scale of the adopted technologies are available; and industrial production application prospect is promising.

Owner:FUDAN UNIV

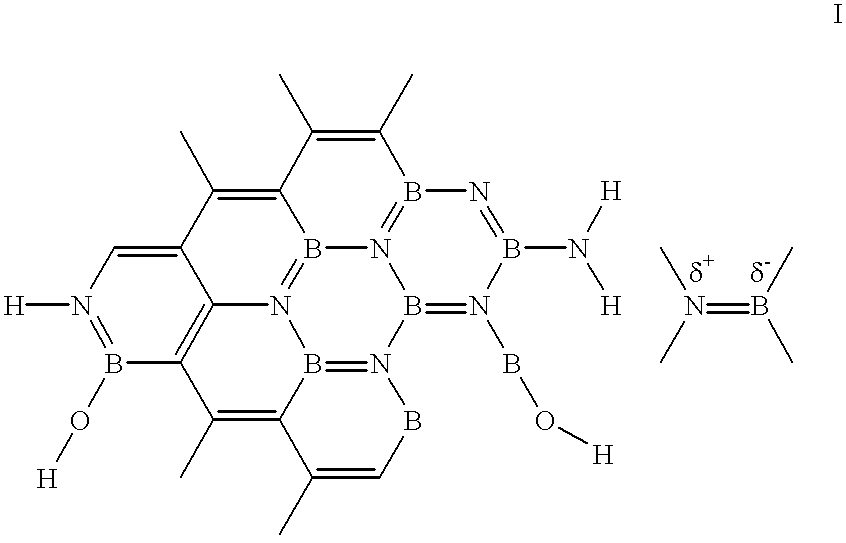

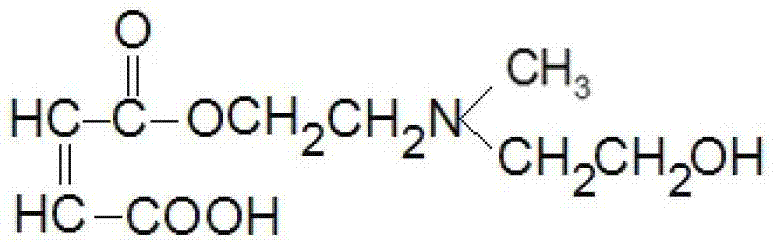

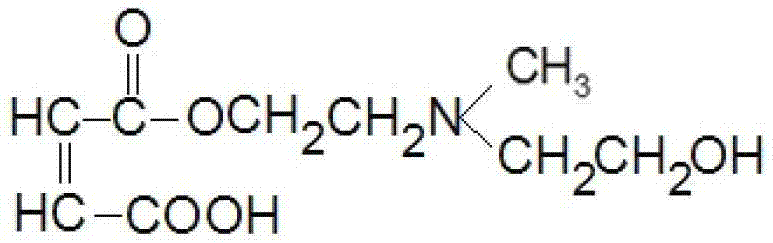

Alcohol amine-carboxylic acid polymer as well as preparation method and application thereof

The invention discloses an alcohol amine-carboxylic acid polymer. The molecular structural formula of the principal component of the alcohol amine-carboxylic acid polymer is as follows: a,b=2-20, and n=20-60. The invention also provides a method for preparing the alcohol amine-carboxylic acid polymer and an application thereof as a cement grinding aid. The alcohol amine-carboxylic acid polymer disclosed by the invention can improve the consistency of cement and a water-reducing agent as the cement grinding aid and has the advantages of outstanding grind aiding effect, excellent general effect, stability in property, low cost, small effective mixing amount and wide application prospect.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

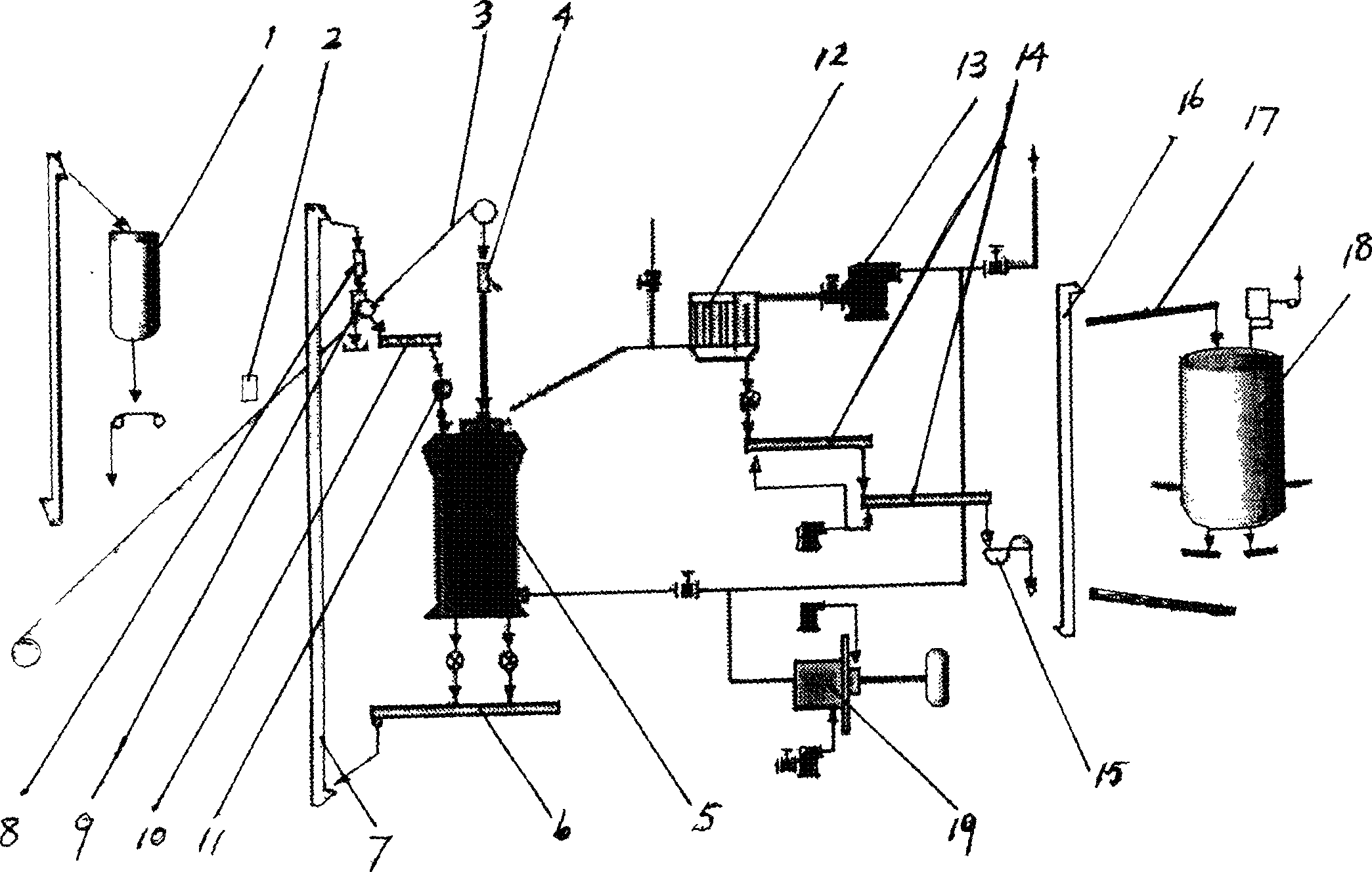

Slow-releasing bFGF-PLGA microball and its prepn and use

InactiveCN1398584AImproved particle size distributionGood conditionPeptide/protein ingredientsSkeletal disorderDiseaseMicrosphere

The present invention provides one kind of slow-releasing basic fibroblast growdth factor (bFGF) microsphere and its preparation and use. The microsphere has coated bFGF as medicine, and matrix of polylactide-co-glycolide (PLGa). The slow-releasing bFGF microsphere is prepared by using PVA or mixed PVA-PEG liquid as dispersing medium and through w / o / wt% re-emulsion and drying process and mechanical stirring. Its freeze dried power has good dispersivity and low organic solvent residue. The present invention can be used for local administration or vein administration of treating fracture, bone defect and other diseases.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Aluminum hydroxide microcapsule coated with melamine-formaldehyde resin and preparation method of aluminum hydroxide microcapsule

InactiveCN104289161AImprove aging resistanceImprove water resistanceMicroballoon preparationMicrocapsule preparationMelamine formaldehyde resinPrepolymer

The invention discloses an aluminum hydroxide microcapsule coated with melamine-formaldehyde resin and a preparation method of the aluminum hydroxide microcapsule. The aluminum hydroxide microcapsule coated with the melamine-formaldehyde resin is prepared from the following components in parts by mass: 10 parts of aluminum hydroxide, 0.3 part of an emulsifying agent and 5-30 parts of a melamine-formaldehyde resin prepolymer. The preparation method comprises the following steps: firstly, preparing the melamine-formaldehyde resin prepolymer; preparing an aluminum hydroxide water suspension solution containing the emulsifying agent; adding the melamine-formaldehyde resin prepolymer into the aluminum hydroxide water suspension solution containing the emulsifying agent; adjusting the pH to 5-5.5 with a citric acid solution with the mass percent concentration of 10% at a room temperature; raising the temperature to 50-80 DEG C and carrying out heat preservation for 2 hours; standing and filtering; washing an obtained filter cake with de-ionized water for 5 times; and drying at 105 DEG C for 5 hours and grinding to obtain the aluminum hydroxide microcapsule coated with the melamine-formaldehyde resin, which has high flame retardant property and good heat stability.

Owner:SHANGHAI INST OF TECH

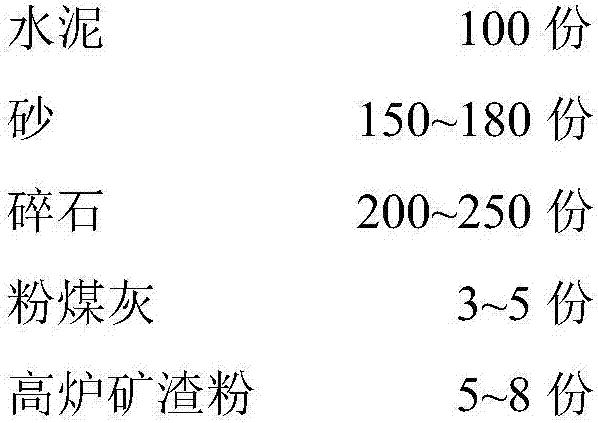

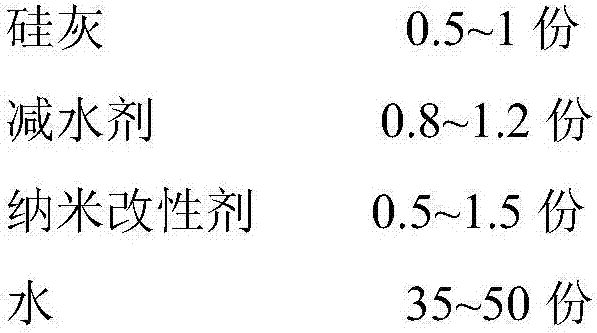

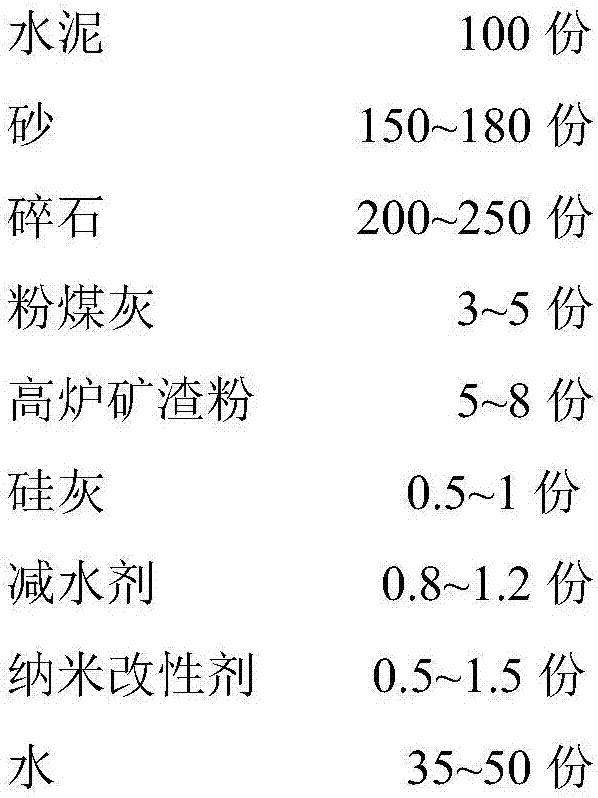

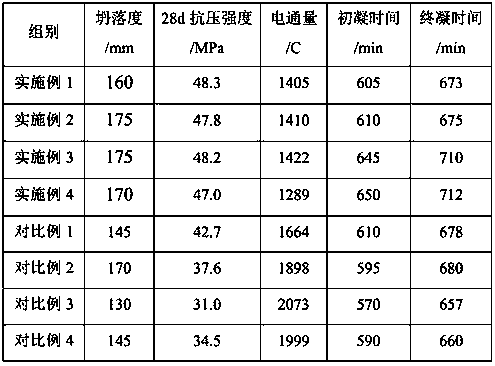

Preparing method of nano-modified high permeability resistant concrete

InactiveCN107032734ATake full advantage of stackingGive full play to the synergistic effectSolid waste managementChipsealSlag

The invention relates to building material engineering, and aims at providing a preparing method of nano-modified high permeability resistant concrete. The preparing method comprises the steps of conducting dry stirring on cement, sand, gravel, fly ash, blast-furnace slag powder and silica fume, and mixing the mixture evenly; mixing a nanometer additive, a water reducing agent and water which accounts for half the weight evenly, and adding the nanometer additive, the water reducing agent and the water which accounts for half the weight into the mixture for stirring; then adding the water which accounts for the other half the weight and continuing to conducting mixing; conducting discharging, and putting the new mixture into molds; conducting maintenance according to a conventional maintenance mode after removing the molds to obtain the nano-modified high permeability resistant concrete. According to the preparing method of the nano-modified high permeability resistant concrete, the limitation of the influence of a single mineral component on the performance of the concrete is solved, through the combination of the multifunctional composition, the effect of function superposition and synergy is achieved, the composite multifunctional composition can effectively optimize the concrete structure grain composition, and by optimizing the internal pore structure of the concrete, the aim of improving the permeability resistance is achieved. The grain composition optimization is conducted on the concrete structure by utilizing the nanometer additive, the high activity and the microcrystal nuclear effect of nano-particles are given full play to at the same time, and the permeability resistance of the concrete structure is improved.

Owner:ZHEJIANG UNIV

High-strength coral aggregate concrete and preparation method thereof

ActiveCN108218350AReduce hydration temperature riseReduce or avoid temperature cracksMetakaolinSeawater

The invention discloses high-strength coral aggregate concrete which is prepared from the following ingredients in parts by weight: 260-350 parts of low-heat marine Portland cement, 35-50 parts of flyash floating beads, 35-50 parts of mineral powder, 8-16 parts of silica fume, 8-16 parts of metakaolin, 2-6 parts of nano silicon dioxide, 2-6 parts of polyaluminum chloride, 550-679 parts of coral reef sand, 890-1000 parts of coral reef and 180-256 parts of seawater. The high-strength coral aggregate concrete has the advantages that the pelagic engineering construction cost is lowered, and environment-friendly and energy-saving requirements of civil engineering are also met.

Owner:CCCC SECOND HARBOR ENG +2

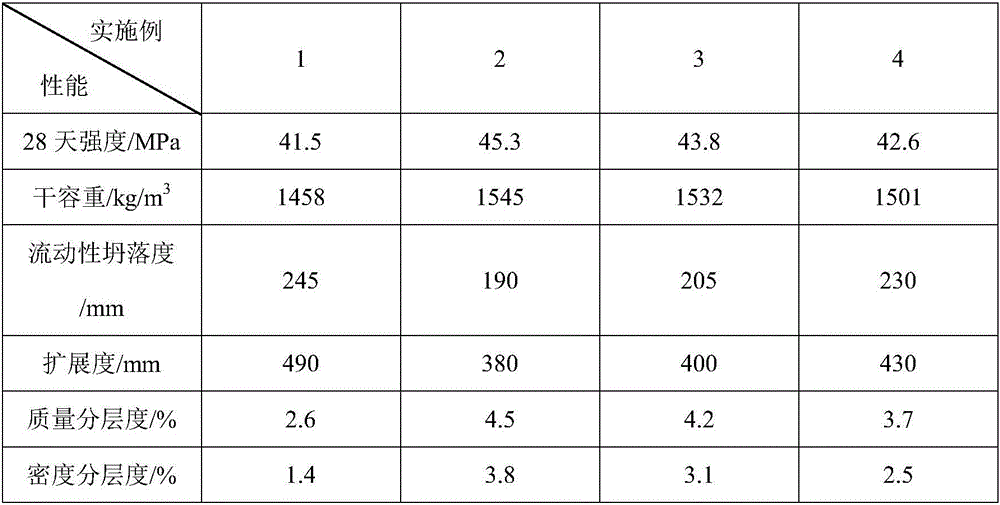

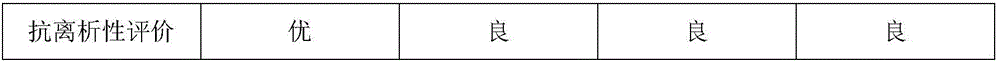

Lightweight aggregate high-performance concrete and preparation method thereof

InactiveCN106830988AImproved particle size distributionGood adhesivenessCeramicwareOperabilityUltimate tensile strength

The invention discloses a lightweight aggregate high-performance concrete and a preparation method thereof. The lightweight aggregate high-performance concrete contains the following raw materials: 180-310 parts of cement, 580-650 parts of ceramsite, 420-500 parts of pottery sand, 0-80 parts of sand regenerated from construction waste, 100-130 parts of coal ash, 100-210 parts of mineral powder, 130-160 parts of water, 4.5-6.5 parts of water reducer, 1-1.5 parts of enhanced modified material and 0.45-0.60 part of anti-separation material. The lightweight aggregate high-performance concrete has the advantages of light unit weight (1450-1550kg / m3), high 28-day strength (40-50MPa), separation resistance, capability of being pumped, slump of 190-250mm, divergence of 400-550mm, no aggregate floating, simple preparation method, high operability and low cost.

Owner:JIANGSU UNIV OF SCI & TECH

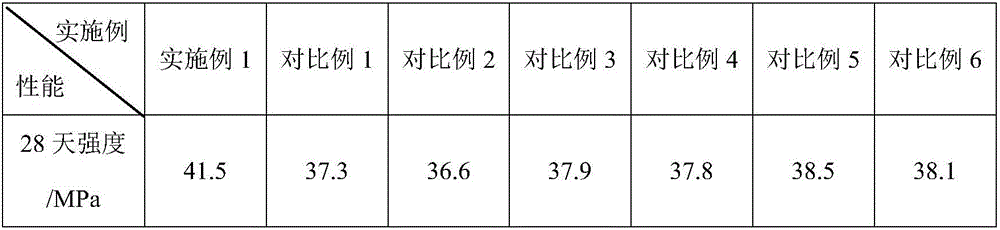

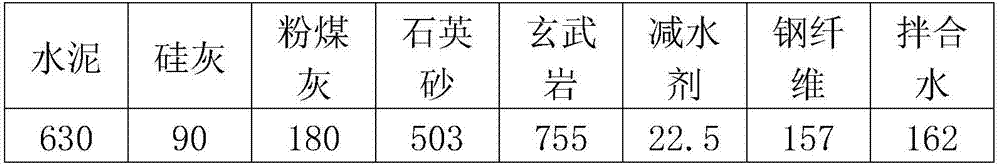

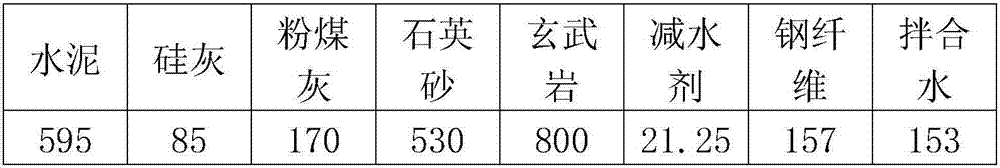

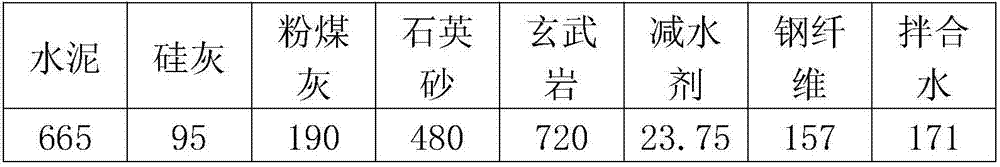

Ultrahigh-performance concrete containing basalt coarse aggregate and preparation method of same

The invention provides ultrahigh-performance concrete containing basalt coarse aggregate and a preparation method thereof. The concrete includes a cementing material, an aggregate, water, a polycarboxylate high-effective water reducer, and steel fibers. The concrete is prepared by mixing the raw materials in specific sequence and performing nature maintenance. In the invention, basalt gravel, as a coarse aggregate, is blended with the ultrahigh-performance concrete, so that shrinkage of the ultrahigh-performance concrete is effectively inhibited; when reduction range of strength is small, production cost of the ultrahigh-performance concrete is greatly reduced. In addition, the maintenance method is simple, so that the preparation method has convenience in practical engineering application.

Owner:WUHAN UNIV

Slow-releasing bFGF-PLA-PEG microball and its prepn and use

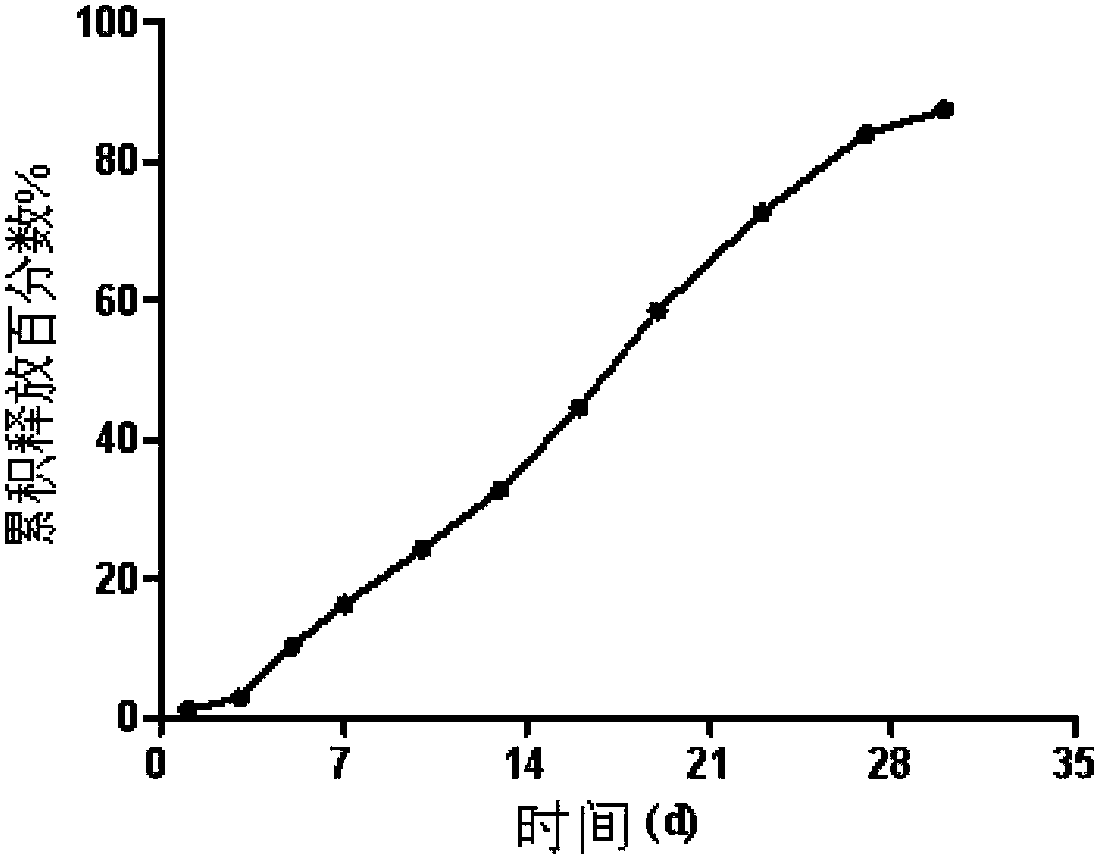

InactiveCN1398585AImproved particle size distributionGood conditionPeptide/protein ingredientsGranular deliveryDiseaseMicrosphere

In the present invention the microsphere has coated bFGF as medicine, and matrix of lactic acid-glycol copolymer (PLA-PEG). The slow-releasing bFGF microsphere is prepared by using PVA-PEG mixed liquid as dispersing medium and through evaporation and mechanical stirring. It has excellent slow-releasing performance of over two-week releasing period. Its freeze dried powder has good dispersivity and low organic solvent residue. The present invention can be used for local administration or vein administration of treating fracture, bone defect and other diseases.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

High-performance lightweight aggregate concrete

InactiveCN101747006AImprove the way of forceImprove mechanical propertiesSolid waste managementSlagExpanded clay aggregate

The invention discloses high-performance lightweight aggregate concrete. The high-performance lightweight aggregate concrete is characterized in that: high-performance porcelain granules are taken as lightweight aggregate; and the high-performance lightweight aggregate concrete is prepared by mixing the following raw materials in proportion: 400 to 430 kg / m<3> of cement, 500 to 570 kg / m<3> of high-performance porcelain granule, 40 to 55 kg / m<3> of fly ash, 40 to 55 kg / m<3> of grounded furnace slag, 540 to 565 kg / m<3> of sand, 180 to 185 kg / m<3> of water and 6 to 10 kg / m<3> of water reducing agent, wherein the performance indexes of the high-performance porcelain granule is that stacking density is less than and equal to 700 kg / m<3>, cylinder pressure strength is greater than and equal to 6.0 MPa, strength mark is greater than and equal to 35 MPa and water absorbing capacity is less than and equal to 1.0 percent. The high-performance lightweight aggregate has the advantages that the strength is high, and workability and pumpability can meet design and construction requirements.

Owner:NINGBO UNIV

Instantly grinding scoria micro powder and process for manufacturing the same

InactiveCN1482090AIncrease productivityReduce energy consumptionSolid waste managementChemical compositionMetallurgy

The vertically ground mineral residue fine powder has the chemical composition of CaO 39.0-40.0 wt%, Al2O3 13.0-16.0 wt%, SiO2 32.0-35.0 wt%, MgO 2-10 wt%, and small amount of MnO, TiO2, T-Fe, T-S, P2O5, Na2O, K2O, L.O.I and I.R. It is crushed fully, has specific surface area greater than 400 sq m / kg, and over 90 % of it has grain size less than 30 microns. The production process includes material conveyance, once iron elimination, grinding and storing. The vertically ground mineral residue fine powder can raise the comprehensive performance of concrete with it, and the vertical grinding process has high production efficiency, low power consumption and low production cost.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

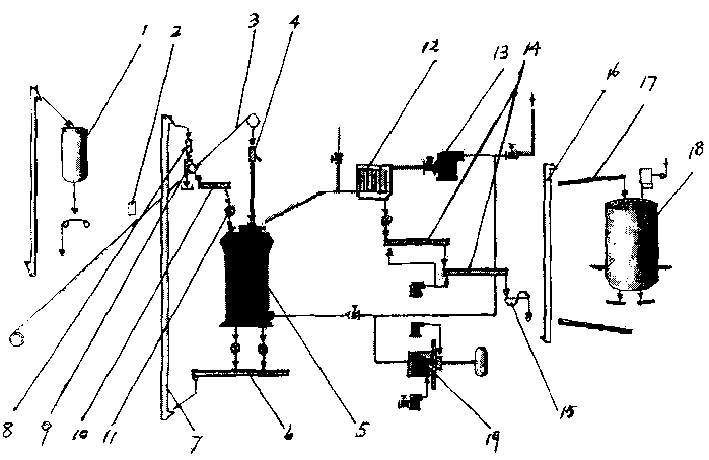

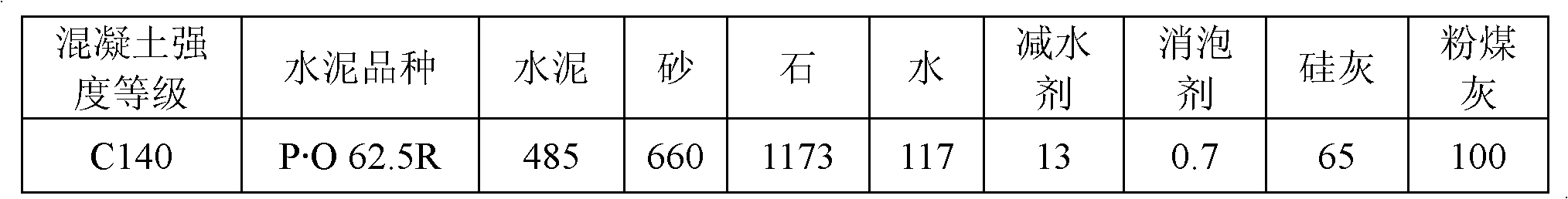

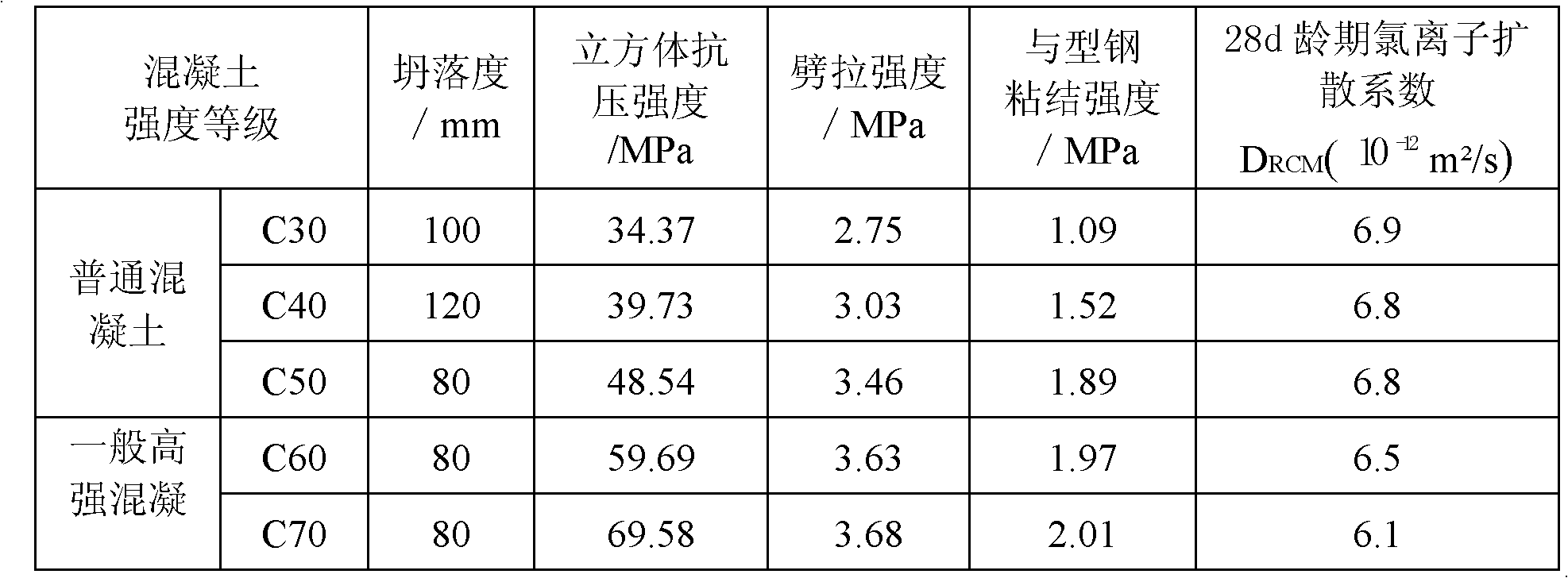

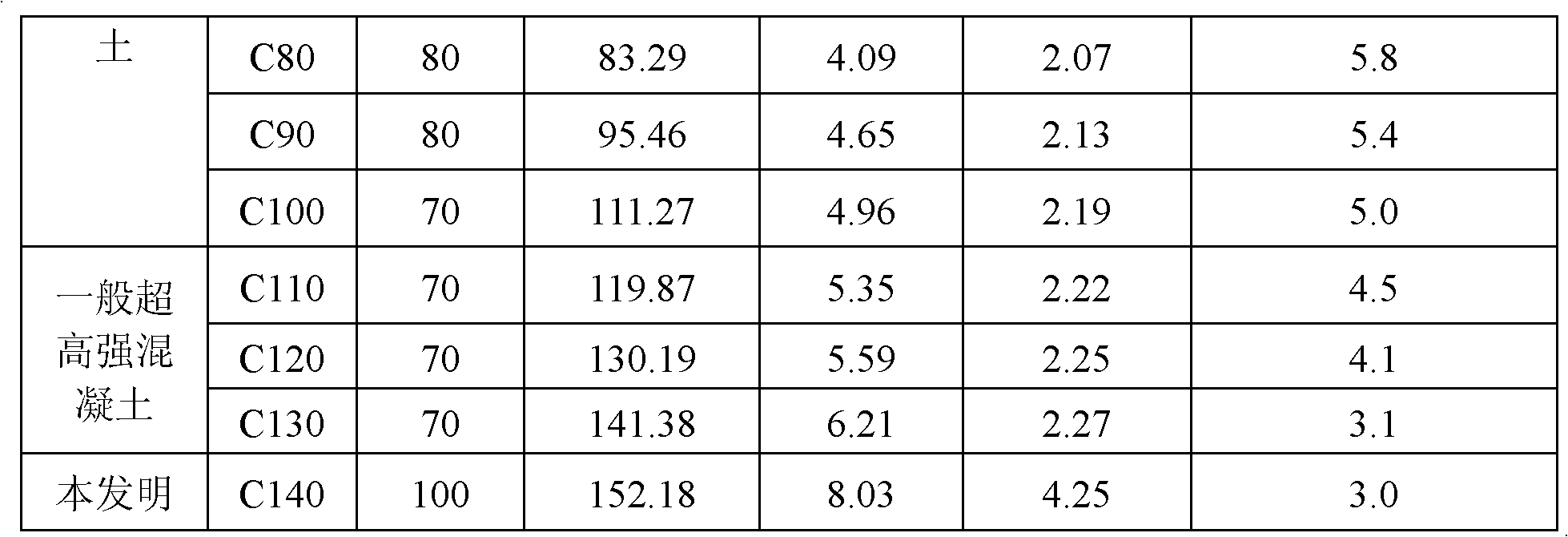

Concrete with strength grade of C140 used for profile steel-concrete composite structure

InactiveCN101913815AIncreased durabilityHigh Strength and DurabilitySolid waste managementCarrying capacityNatural state

The invention discloses concrete with strength grade of C140 used for a profile steel-concrete composite structure. The concrete is characterized by being prepared from cement, fine aggregate, coarse aggregate, water, a water reducing agent, an antifoaming agent, siliceous dust, coal ash(kg / m<3>) in a mixing proportion of 485:660:1,173:117:13:0.7:65:100. A preparation method of the concrete comprises the following steps of: adding the fine aggregate and the water in an amount of which is a half based on the total weight of the used water into a forced mixer according to the weight proportion in turn; uniformly stirring for 1 to 2 minutes; adding the coarse aggregate into the mixer; uniformly stirring for 2 to 4 minutes; adding the cement, the siliceous dust and the coal ash into the mixer; uniformly stirring for 2 to 3 minutes; adding the water reducing agent, the antifoaming agent and the rest water into the mixer; uniformly stirring for 2 to 5 minutes; and discharging to obtain a concrete mixture. The concrete can obviously improve the adhesive property between profile steel and the concrete in a natural state, effectively exert respective capacity and cooperative work performance of both materials, greatly improve the carrying capacity and performance of members, and improve the durability, high volume stability and economy of the members.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Copper tailing composite mineral mixed material and preparation method thereof

ActiveCN108117292AHigh activityImprove hydration crystal structureSodium metasilicateMixed materials

The invention provides a copper tailing composite mineral mixed material which is prepared from the following raw materials in parts by mass: 25-50 parts of grinded copper tailings, 40-60 parts of coal ash, 0.4-1 part of an active activator and 0-35 parts of an active mineral mixed material, wherein the active activator is a mixture consisting of more than any three of calcium oxide, sodium metasilicate, sodium sulfate, sodium thiosulfate or sodium tripolyphosphate. By adopting the copper tailing composite mineral mixed material provided by the invention, high-cost raw materials such as coal ash are massively replaced by the copper tailings, high-value recycling of the copper tailings is achieved, environment protection can be facilitated, the cost of the mixed material is reduced, the mixed material has ideal activity as a whole, early-stage hydration crystallization structures and products of cement concrete are improved, and good late-stage strength is achieved. The invention further provides a method for preparing a premixed concrete mineral mixed material from copper tailings.

Owner:江西万铜环保材料有限公司

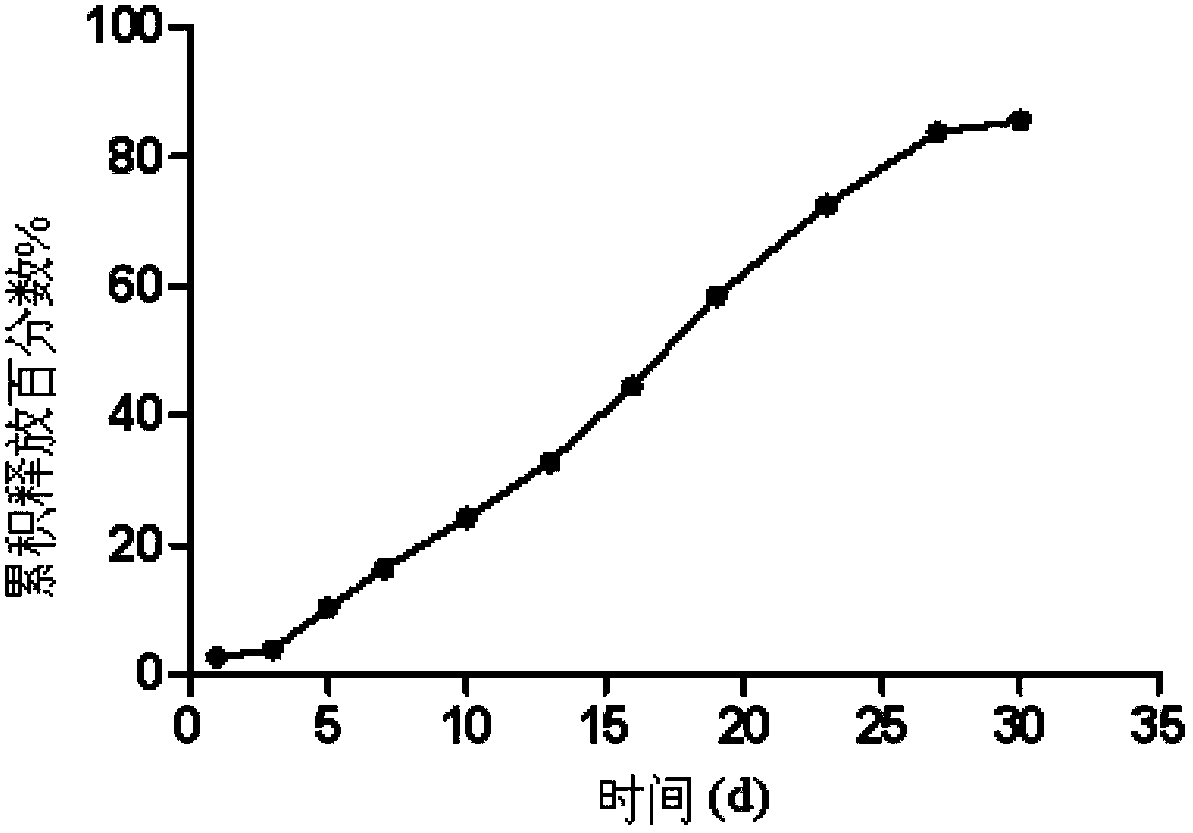

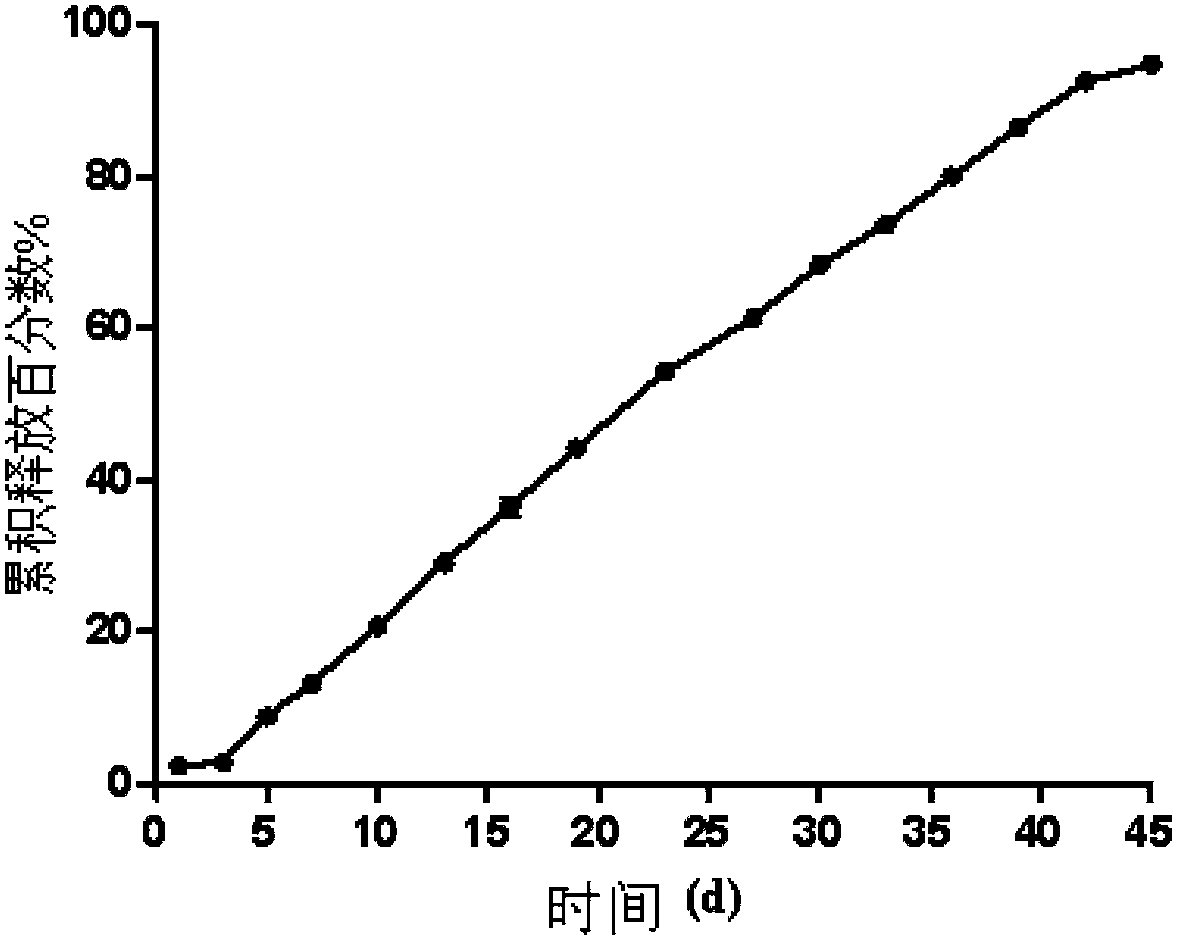

Olanzapine-containing biodegradable microsphere preparation and preparation method thereof

InactiveCN103417492AHigh drug loadingImproved particle size distributionOrganic active ingredientsNervous disorderBiodegradable microspherePharmaceutical drug

The invention discloses an olanzapine-containing biodegradable microsphere preparation and a preparation method thereof. The olanzapine-containing biodegradable microsphere preparation comprises 10-50wt% of olanzapine or its salt, 0.5-20wt% of release adjusting agents and 30-89.5% of PLGA. In the invention, the PLGA having a proper monomer LA:GA ratio is selected as a matrix material, and above one release adjusting agents are added, so the olanzapine loading is improved to above 30%, and the particle size distribution and the in-vitro drug release of microspheres are improved. The utilization of a biodegradable material to encapsulate olanzapine to prepare the microspheres realizes a good slow release effect and the maintenance of an in-vivo relatively-stable drug concentration for above 15-45d or more.

Owner:SHANGHAI MODERN PHARMA ENG INVESTIGATION CENT

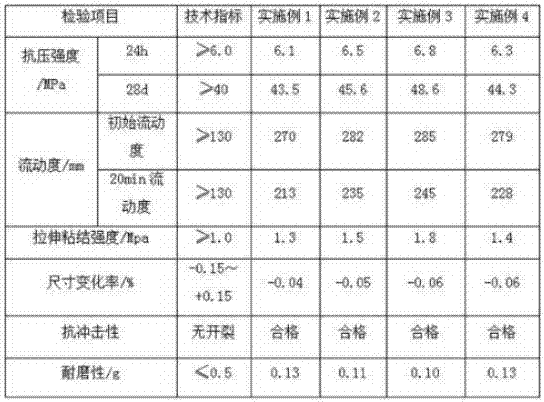

Wear-resisting anti-crack cement-based self-leveling mortar and its production method

The invention relates to a wear-resisting anti-crack cement-based self-leveling mortar and its production method. The wear-resisting anti-crack cement-based self-leveling mortar is characterized by being prepared from, by weight, 20-35 parts of Portland cement, 10-15 parts of aluminate cement, 40-50 parts of aggregate, 10-15 parts of filler, 5-10 parts of mineral admixtures, 0.5-2 parts of redispersible powder, 0.5-1.5 parts of high-efficient reducing agent, 0.5-2 parts of expanding agent, 0.05-0.2 part of shrinkage reducing agent, 0.05-0.2 part of retarder, 0.1-0.3 part of water-retaining agent, 0.05-0.1 part of super plasticizer, 0.05-0.2 part of antifoaming agents. The wear-resisting anti-crack cement-based self-leveling mortar is simple, convenient and fast in construction, and featured by high intensity, good mobility, wear-resistance, good crack resistance, high bonding strength, and excellent construction performance; the wear-resisting anti-crack cement-based self-leveling mortar can automatically and accurately level the ground, and meet the construction purpose of rapid construction and fast use.

Owner:张聪聪

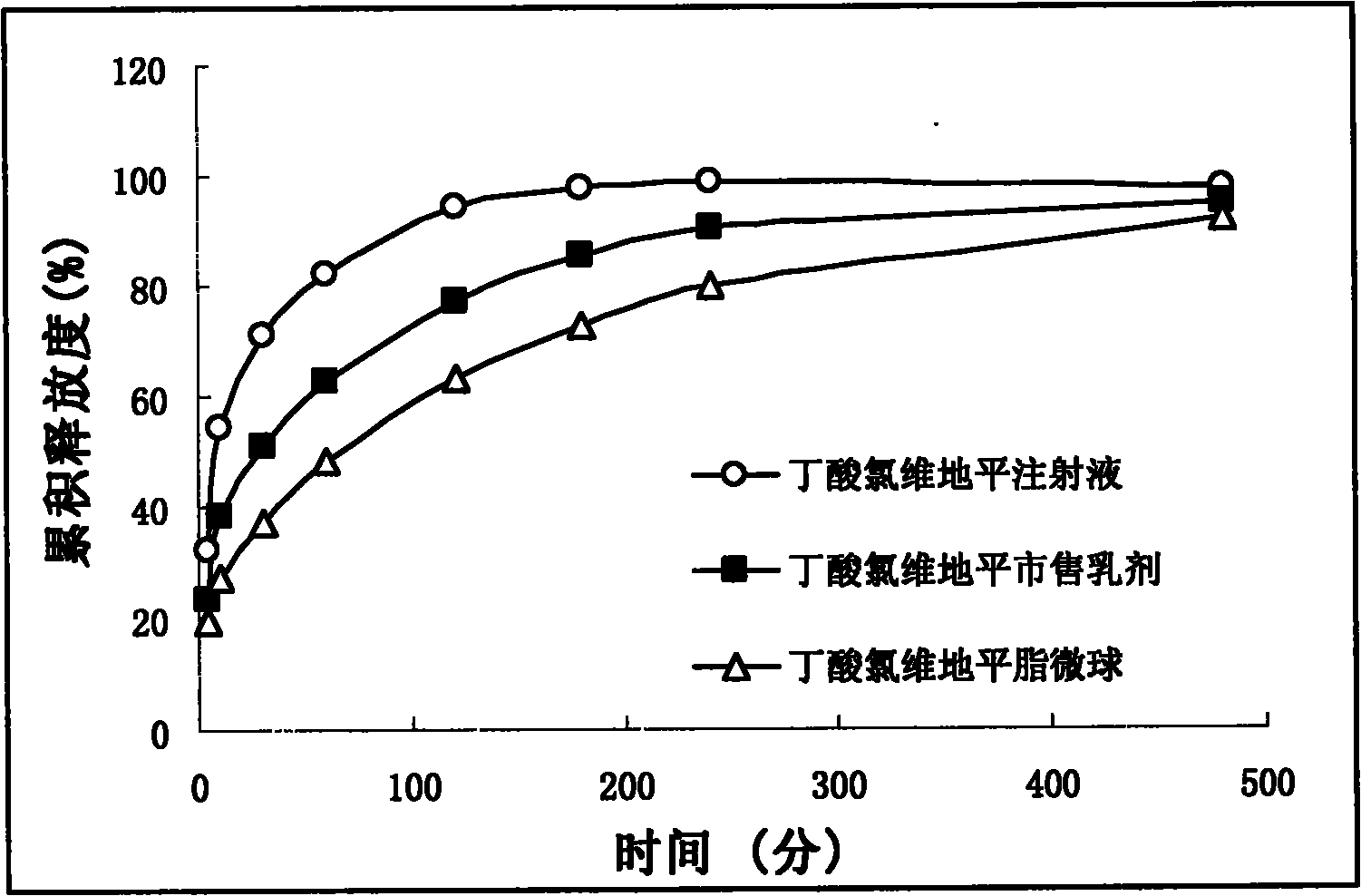

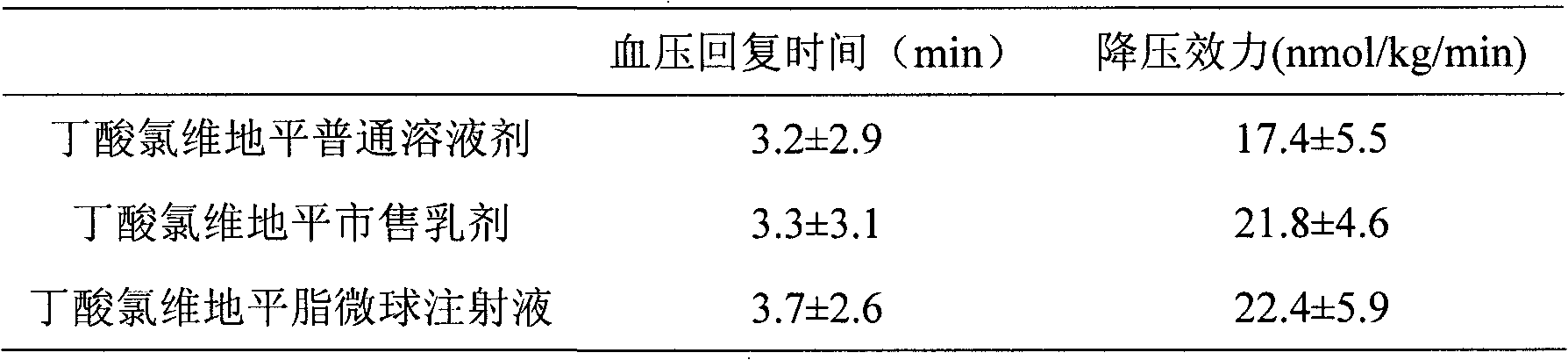

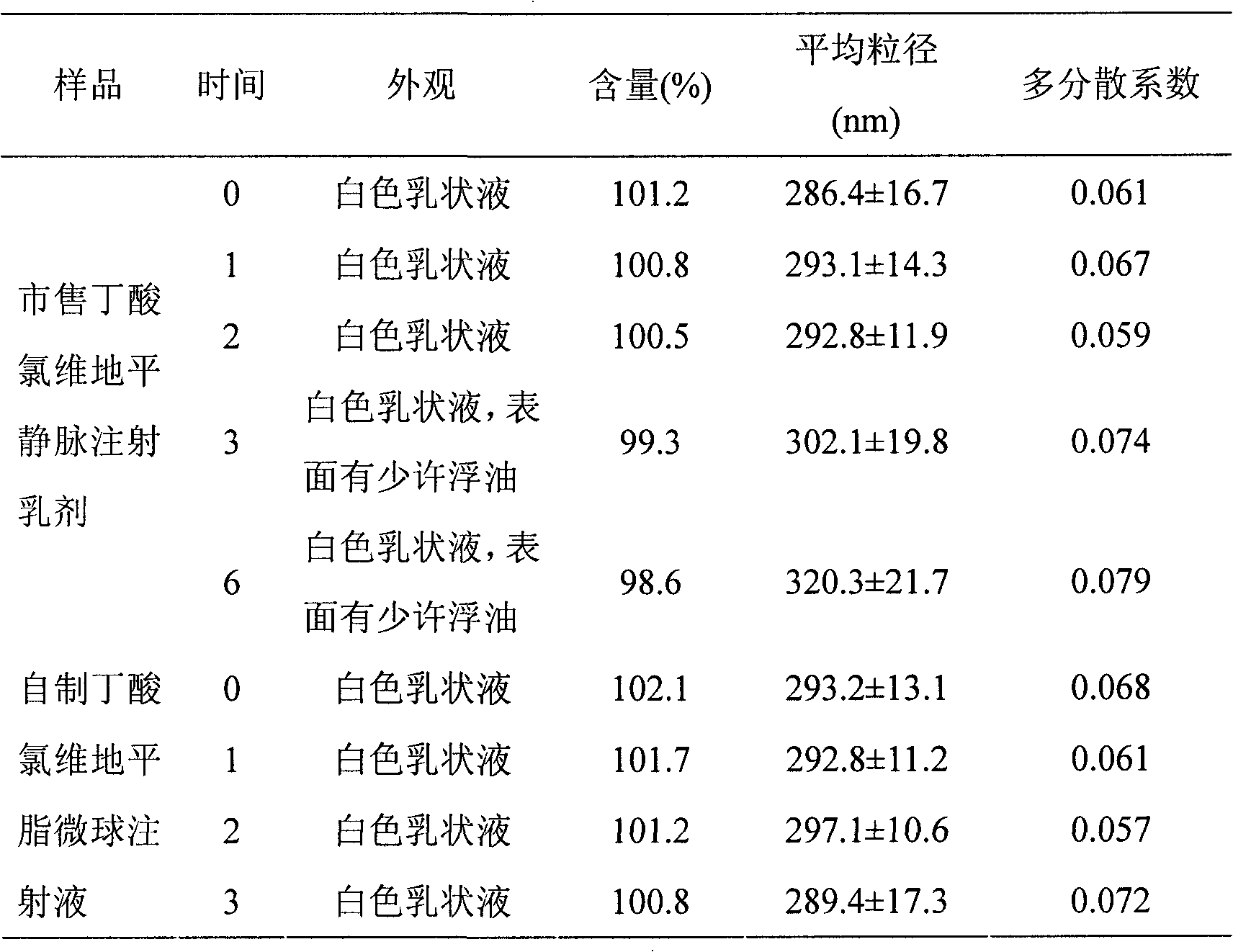

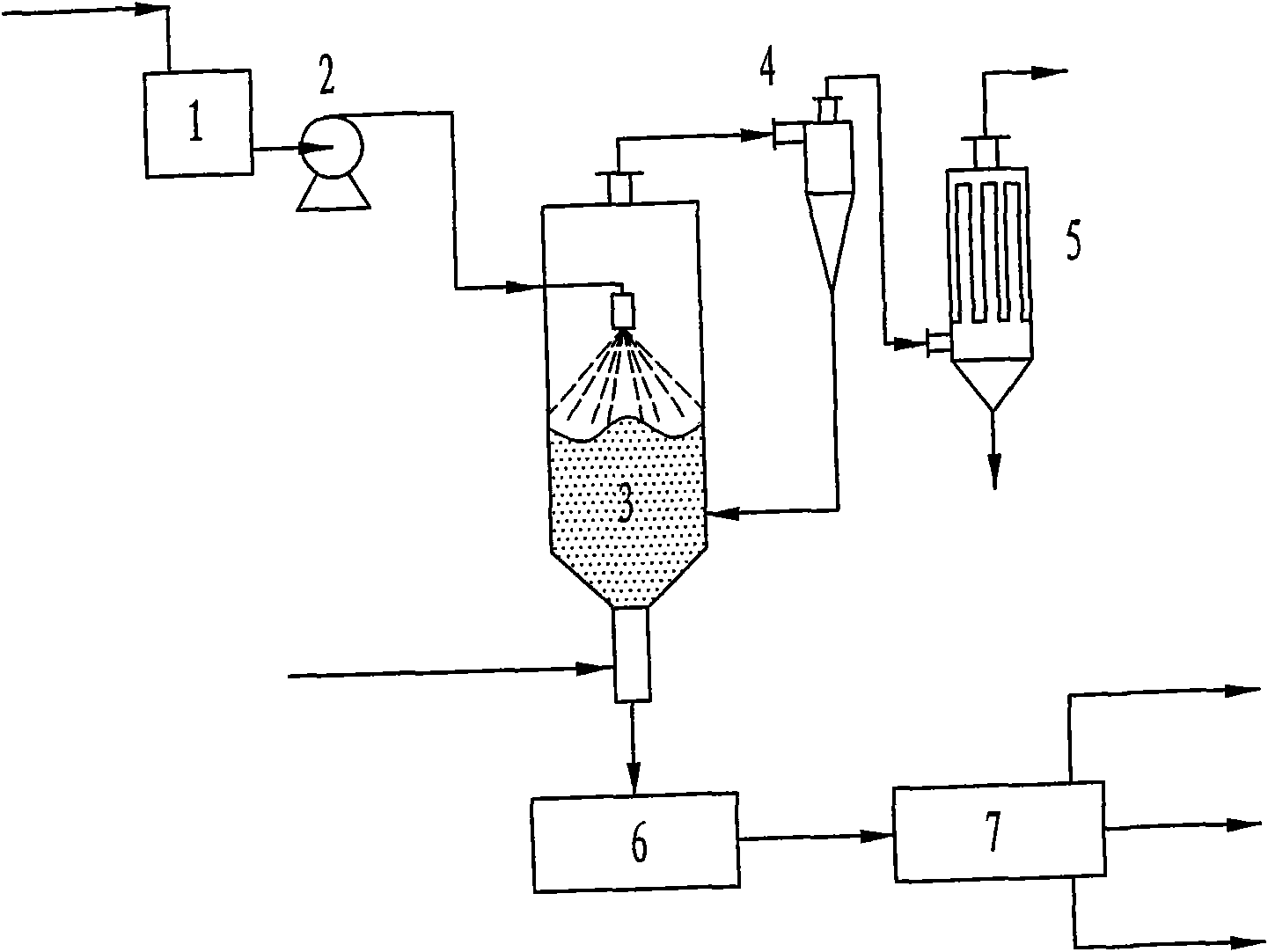

Butyrate clevidipine lipid microsphere injection and preparation method thereof

ActiveCN101780036AImproved particle size distributionControl releaseOrganic active ingredientsSolution deliveryDrugPolyethylene glycol

The invention relates to a lipid microsphere injection of butyrate clevidipine which is a rapid-effect hypotensive medicine and can be intravenously injected and a preparation method thereof. The lipid microsphere injection comprises butyrate clevidipine, oil for injection, an emulsifying agent, polyethylene glycol ester, medical additive and water for injection. The lipid microsphere injection can effectively control the medicine release at the same time of ensuring the curative effect and reduce the occurrence rate of adverse reactions.

Owner:WUHAN WUYAO SCI & TECH

Method of granulation by spraying melted nicotinamide

InactiveCN101569840AGood dispersionGood particle size distributionOrganic chemistryGranulation by liquid drop formationPelletizingSpray nozzle

The invention discloses a method of granulation by spraying melted nicotinamide. The method comprises the following steps: injecting the melted nicotinamide into the spray-granulation tower of a fluidized bed for granulation by a pressure-type spraying nozzle; automatically grading the nicotinamide granules with the granularity being 0.4 to 1.0 mm in the granulation tower by controlling the gas velocity of fluidizing air in the inlet pipe at the lower part of the granulation tower; entering silos through the inlet pipe of the granulation tower of the fluidized bed, and then screening the products within the range of the granularity by a screener; and finally obtaining the nicotinamide granules with the granule size being 0.4 to 1.0 mm. On the one hand, the granular nicotinamide produced by the method of the invention can greatly reduce the dust pollution, moisture absorption and agglomeration occurring to places for packaging, storing, transporting and applying, and on the other hand, the granule sizes of the products are properly distributed so as to ensure the good dispersion of nicotinamide in the following downstream products, such as feed and the like, upon the premise that the following processing technique, such as feed and the like, remains unchanged.

Owner:HANGZHOU SHENGDA PHARMA

Method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with method

The invention relates to a method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with the method. The method for preparing the high-specific-surface-area cotton-shaped super-fine silver powder comprises the following steps of A, preparing a first water solution; B, preparing a second water solution; C, conducting reduction treatment; D, conducting washing; E, conducting drying and sieving, and obtaining the dried finished high-specific-surface-area cotton-shaped super-fine silver powder. According to the silver powder prepared with the method, the specific surface area is over 6.5 m<2> / g, and the burning lose content is smaller than 1.5 after heat treatment is conducted for one hour at the temperature of 538 DEG C. The method for preparing the high-specific-surface-area cotton-shaped super-fine silver powder and the silver powder prepared with the method have the advantages that the method is controlled effectively, the prepared silver powder is high in quality and stable, the production efficiency is high, pollution is avoided, the requirement for environment protection is met, after the silver power is prepared into silver paste, the viscosity and the rheological property of electrocondution slurry are maintained, the conductivity of a silver film obtained by burning the electrocondution slurry is not changed, and the proportion of the silver powder in the electrocondution slurry can be reduced. The silver powder prepared with the method has the outstanding advantages that the particle size distribution range is narrow, the dispersibility is high, the purity is high, and the specific surface area is high and is an ideal material for silver paste for electrodes of electronic components.

Owner:中船黄冈贵金属有限公司

Micro capsule of nano beef essence and its preparation method

InactiveCN1799405AGood particle size distributionUniform particle size distributionFood preparationSolventIsopropylene glycol

The invention discloses a nanometer microcapsule beef perfume compound and the preparing method, the said nanometer microcapsule beef perfume compound is composed of the following components: beef perfume compound of 0.5-1% by weight, chitose of 0.1-0.4% by weight, sodium tripolyphosphate of 0.025-0.075 by weight, glacial acetic acid of 0.15-0.7% by weight and deionized water. The method employs methyl ethylene glycol as solvent, deploying the components according to proportion, then preparing the nanometer microcapsule beef perfume compound under magnetic stirring. The product is characterized by the good distribution of the granular size, uniform granular size, about 250nm, stable scent, better slow releasing property and longer scent retaining time.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

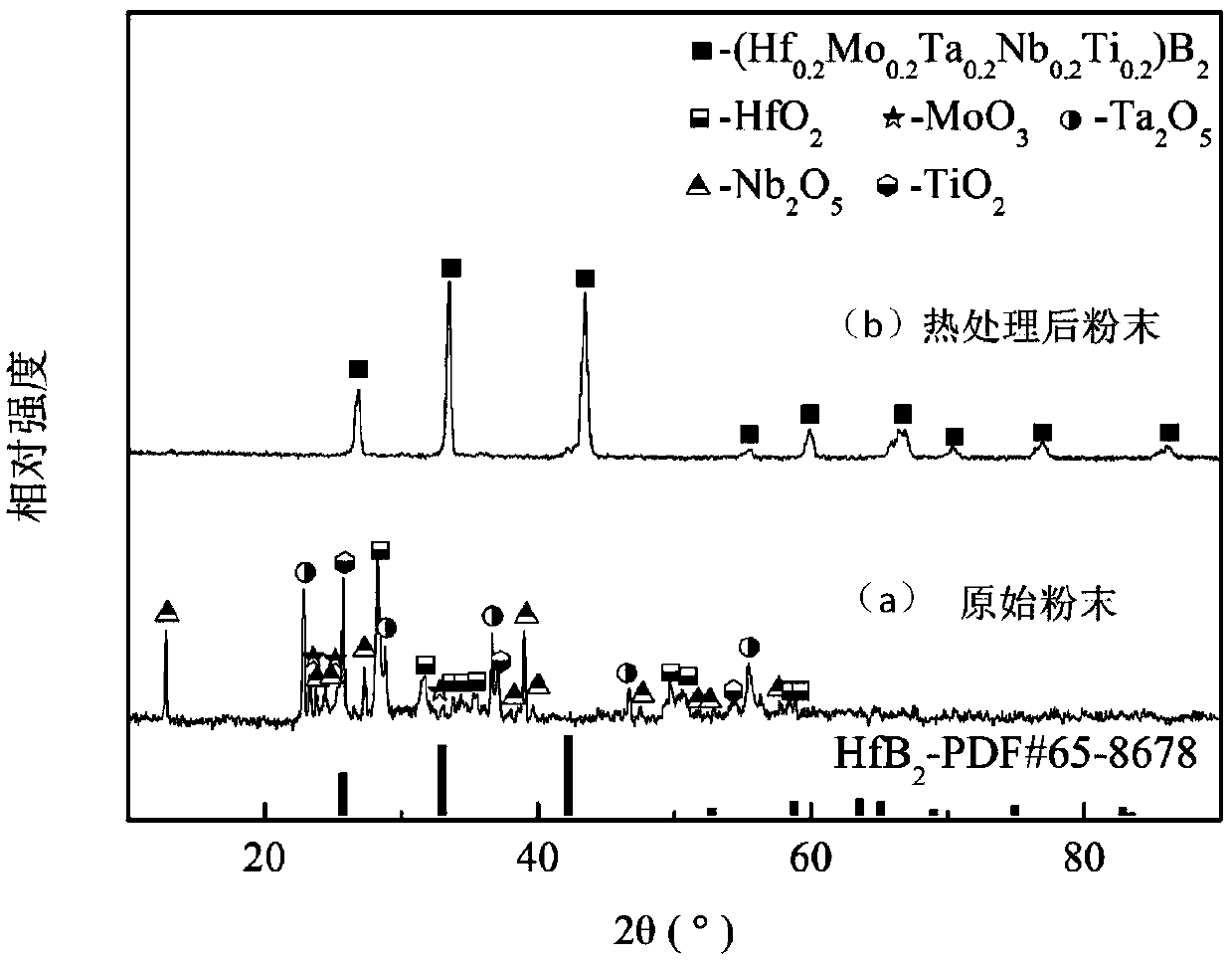

Superfine high-entropy solid solution powder as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials and discloses superfine high-entropy solid solution powder as well as a preparation method and application thereof. The solid solutionpowder is prepared by the steps of with metal oxide and amorphous boron powder as raw material powder, adding a solvent and a ball-milling medium, mixing, drying to obtain mixed powder, carrying outmold pressing on the mixed powder so as to obtain a mixed powder blank, carrying out thermal treatment under a vacuum condition, firstly heating to 800-1200 DEG C, maintaining the temperature for I, heating to 1400-1600 DEG C, maintaining the temperature for II, grinding, and sieving, wherein the oxide is one or more of HfO2, ZrO2, Nb2O5, Ta2O5, Cr2O3, TiO2 or MoO3, and the molar ratios of metal ions in the metal oxide are the same. The solid solution powder has a uniform solid solution phase and further has the advantages of small particle size and uniform and stable components.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com