Method of granulation by spraying melted nicotinamide

A technology of spray granulation and nicotinamide, which is applied in liquid droplet granulation, organic chemistry, etc., can solve problems such as physical injury of workers, easy moisture absorption of nicotinamide, and dust pollution in workshops, and achieves reduction of screening load, particle size reduction, etc. Good diameter distribution and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

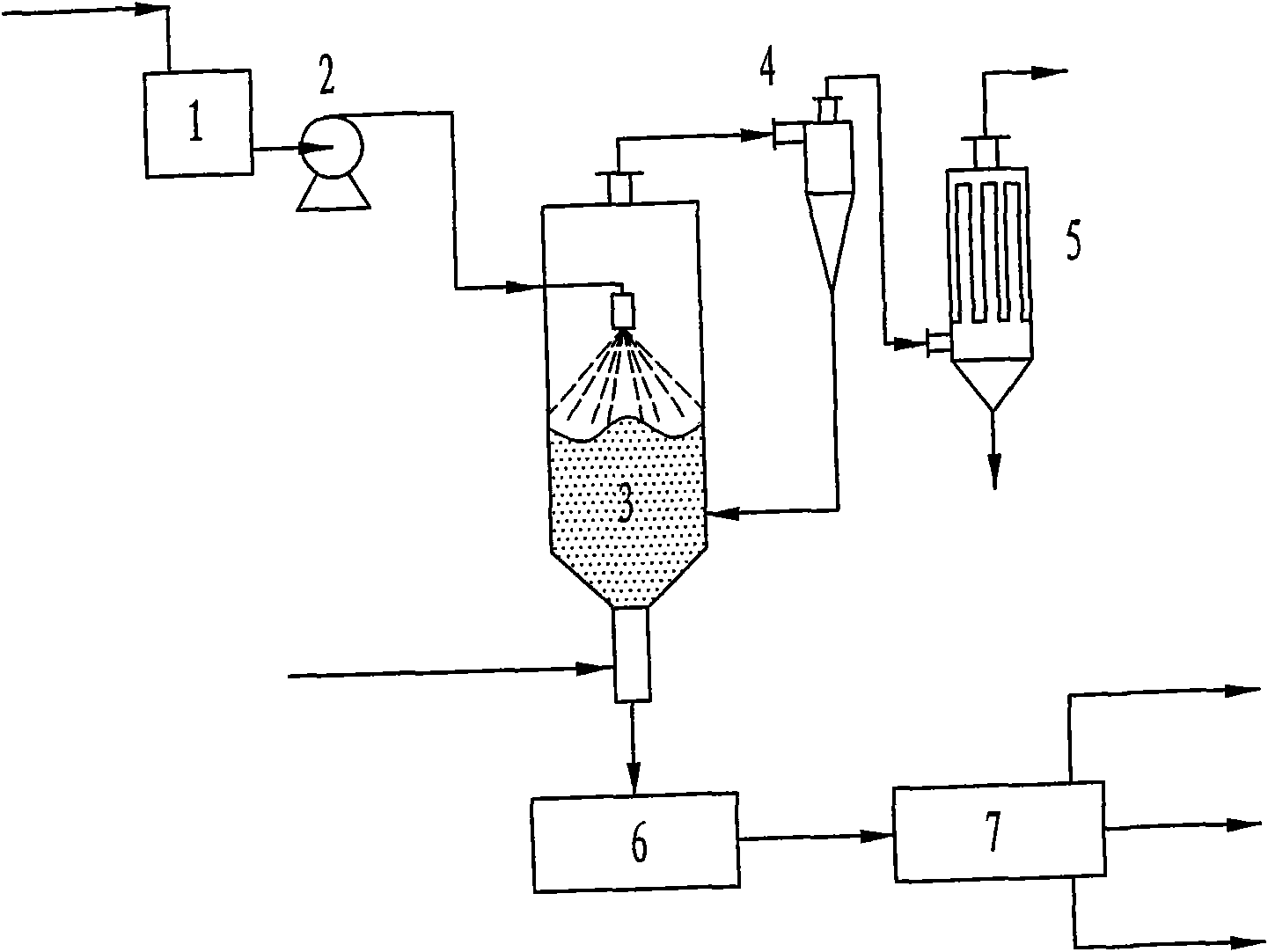

[0015] refer to figure 1 , a method for melt spray granulation of nicotinamide, the method steps comprising:

[0016] The nicotinamide powder is melted in the melting tank (1), the temperature is 140-160°C, and the pressure is normal pressure; the molten nicotinamide is sent to the upper nozzle of the fluidized bed spray granulation tower (3) by the high pressure pump (2) And atomized into droplets, sprayed down into the fluidized bed, the high-temperature droplets in the fluidized bed contact with the low-temperature nicotinamide particles in the fluidized state and the low-temperature air used for fluidization upwards, the droplets adhere to the particles, As the temperature decreases and solidifies, the particle size becomes larger; at the same time, due to the collision and crushing of the fluidized particles, some fine particles will also be entrained and discharged by the upwardly flowing air through the gas outlet pipe at the top of the prilling tower; the discharged ni...

Embodiment 2

[0018] According to the production process steps of Example 1, the production capacity of nicotinamide melt granulation can reach 200 kg / hour, and the product mesh is between 30-80 mesh. The product does not need to be further dried, and can be directly packaged.

[0019] The present invention proposes a nicotinamide melting spray granulation method, which can produce granular nicotinamide with a particle size of 0.2-0.8 mm, which greatly reduces dust pollution and moisture absorption and agglomeration in packaging, storage and transportation, and use occasions. On the one hand, under the premise of not changing the subsequent feed and other production processes, a suitable product particle size distribution ensures good dispersibility of nicotinamide in subsequent downstream products such as feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com