Superfine high-entropy solid solution powder as well as preparation method and application thereof

A technology of solid solution and powder, which is applied in the field of ultrafine high-entropy solid solution powder and its preparation, can solve the problems of difficult preparation of raw material fine powder and large particle size of powder, and achieve small particle size, uniform and stable components, The effect of good particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

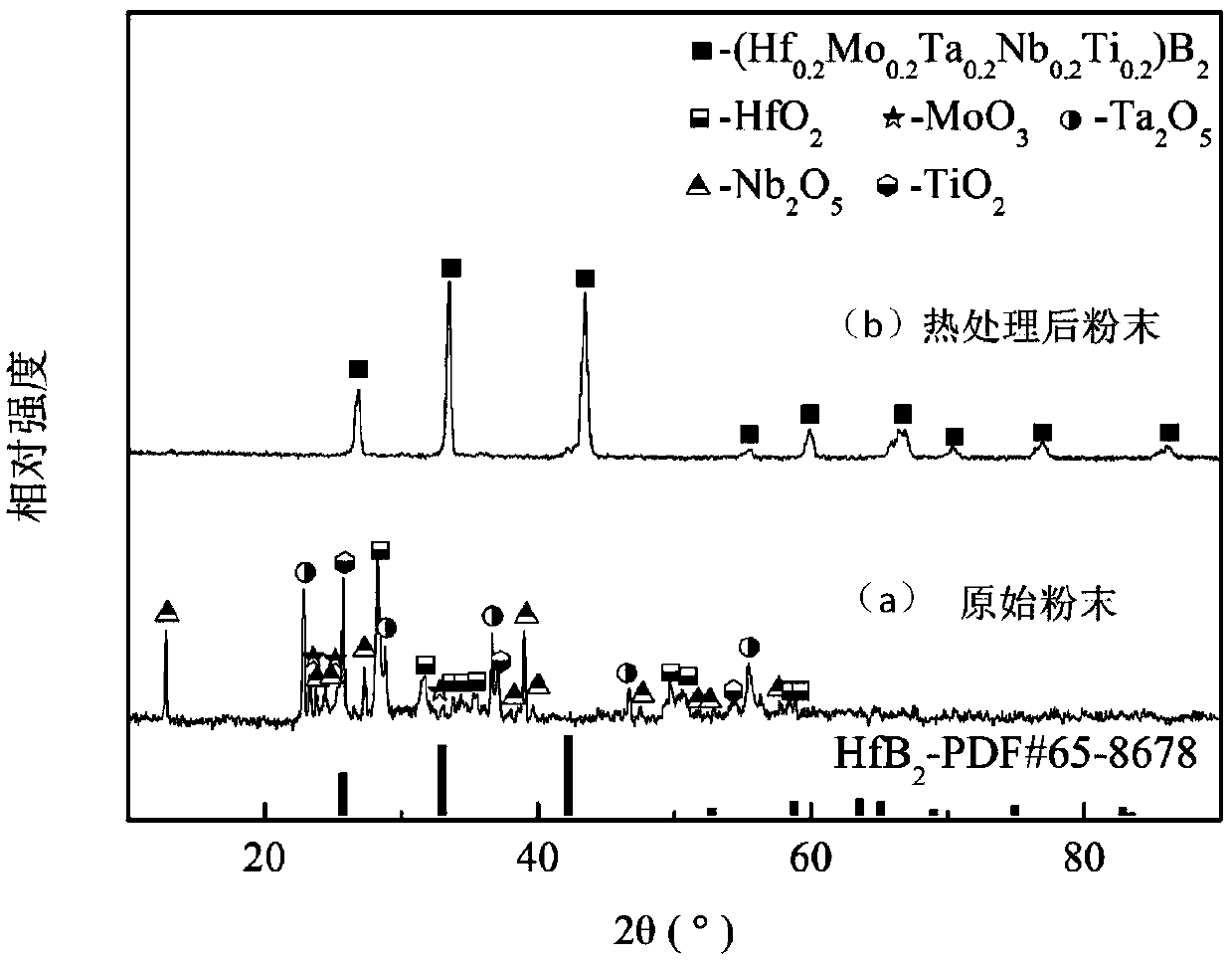

Method used

Image

Examples

Embodiment 1

[0028] 1. With HfO 2 (powder purity 99.9%, particle size 1μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Nb 2 o 5 (powder purity 99.9%, particle size 2μm), TiO 2 (powder purity 99.9%, particle size 1μm) and MoO 3 (The purity of the powder is 99.9%, particle size 1 μm) The powder is proportioned in equal atomic proportions, and mixed with amorphous boron powder (purity 95.6%, particle size 1 μm) according to the excess 10wt% of the above-mentioned oxide mixed total amount according to the metering ratio.

[0029] 2. Amorphous boron powder and HfO 2 , ZrO 2 and TiO 2 The molar ratios are 3.67:1, amorphous boron powder and Nb 2 o 5 The molar ratio is 8.067:1, amorphous boron powder and MoO 3 The molar ratio is 4.4:1. With ethanol as solvent, Si 3 N 4 The ball is the ball milling medium, and it is mixed on a roller ball mill for 24 hours, and the mixed powder is obtained after mixing and drying.

[0030] 3. Put the final green body after the mixed powder molding...

Embodiment 2

[0033] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 2μm), Nb 2 o 5 (powder purity 99.9%, particle size 2μm), TiO 2 (powder purity 99.9%, particle size 2μm) and Ta 2 o 5 (Powder purity 99%, particle size 2 μm) powder powder is mixed with amorphous boron powder (purity 96%, particle size 2 μm) according to the excess 10wt% of the above-mentioned oxide mixed total amount according to the metering ratio.

[0034] 2. Amorphous boron powder and HfO 2 , ZrO 2 and TiO 2 The molar ratio is 3.67:1, amorphous boron powder and Ta 2 o 5 and Nb 2 o 5 The molar ratio is 8.067:1. With ethanol as solvent, Si 3 N 4 The ball is the ball milling medium, and it is mixed on a roller ball mill for 24 hours, and the mixed powder is obtained after mixing and drying.

[0035] 3. Put the molded green body of the mixed powder into a graphite crucible, raise the temperature to 1200°C at a heating rate of 10°C / min and keep it for 1 hour, t...

Embodiment 3

[0038] 1. With HfO 2 (powder purity 99%, particle size 8μm), ZrO 2 (powder purity 99%, particle size 8μm), Cr 2 o 3 (powder purity 99%, particle size 8μm), TiO 2 (powder purity 99%, particle size 5μm) and Ta 2 o 5 (99% of the purity of the powder, 8 μm of particle diameter) powder powder is mixed with amorphous boron powder (96% of purity, 8 μm of particle diameter) according to the excess 10wt% of the above-mentioned oxide mixed total amount according to the metering ratio .

[0039] 2. Amorphous boron powder and HfO 2 , ZrO 2 and TiO 2 The molar ratio is 3.67:1, amorphous boron powder and Ta 2 o 5 The molar ratio of both is 8.067:1, amorphous boron powder and Cr 2 o 3 The molar ratio is 8.8:1. With ethanol as solvent, Si 3 N 4 The ball is the ball milling medium, and it is mixed on a roller ball mill for 24 hours, and the mixed powder is obtained after mixing and drying.

[0040] 3. Put the molded green body of the mixed powder into a graphite crucible, raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com