Patents

Literature

107results about How to "The composition is uniform and stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

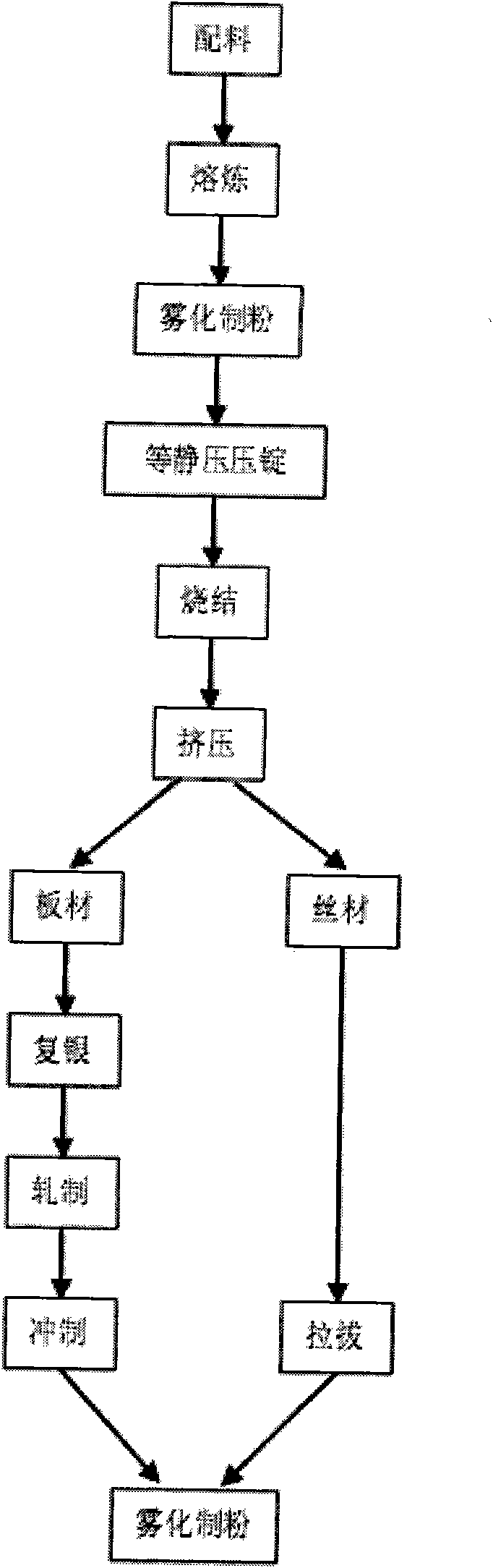

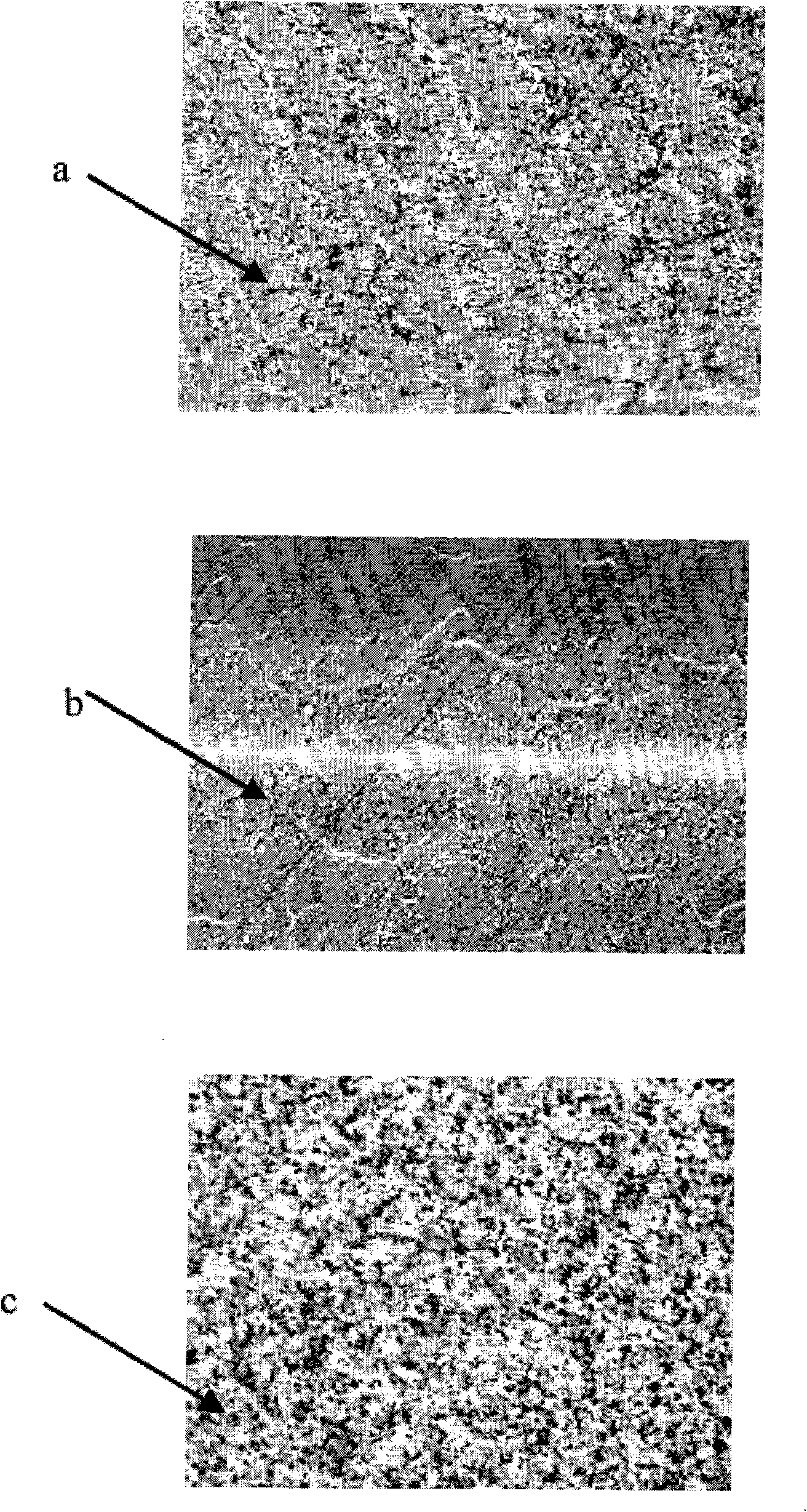

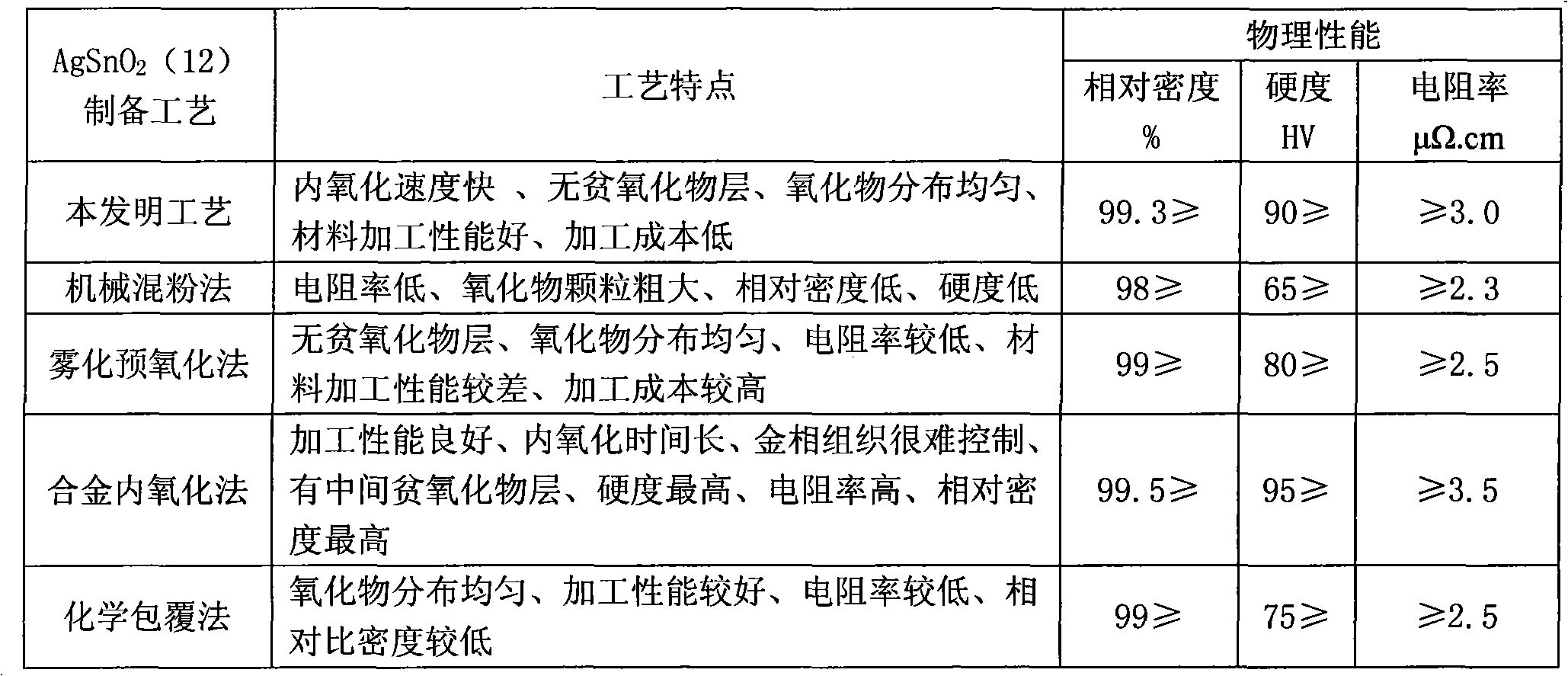

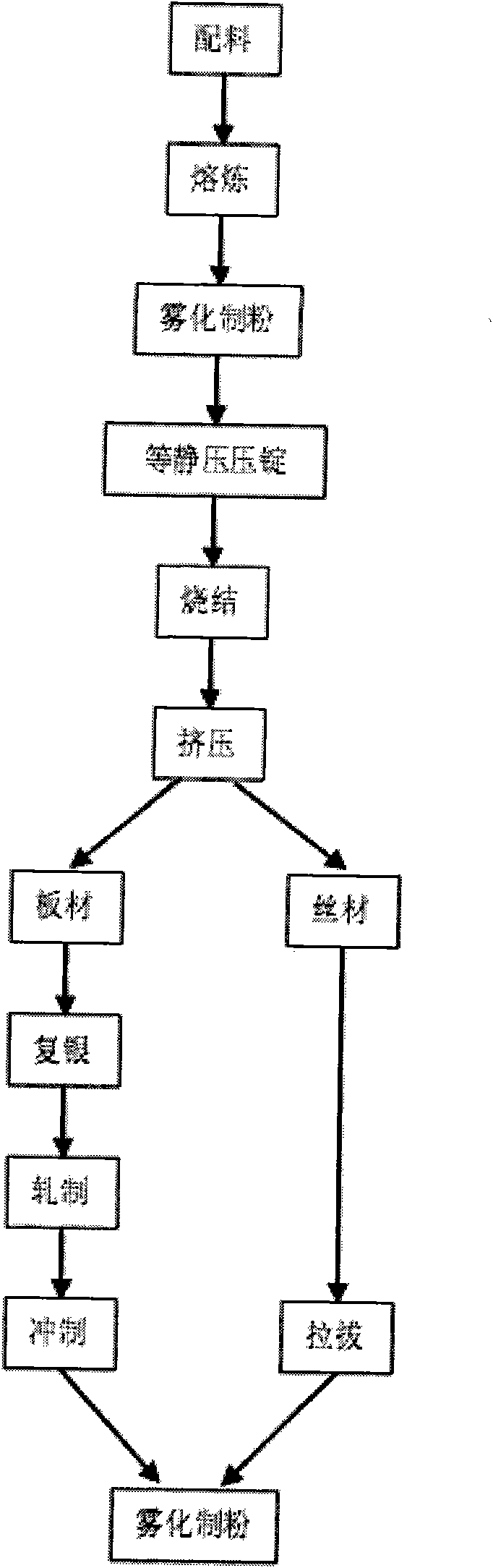

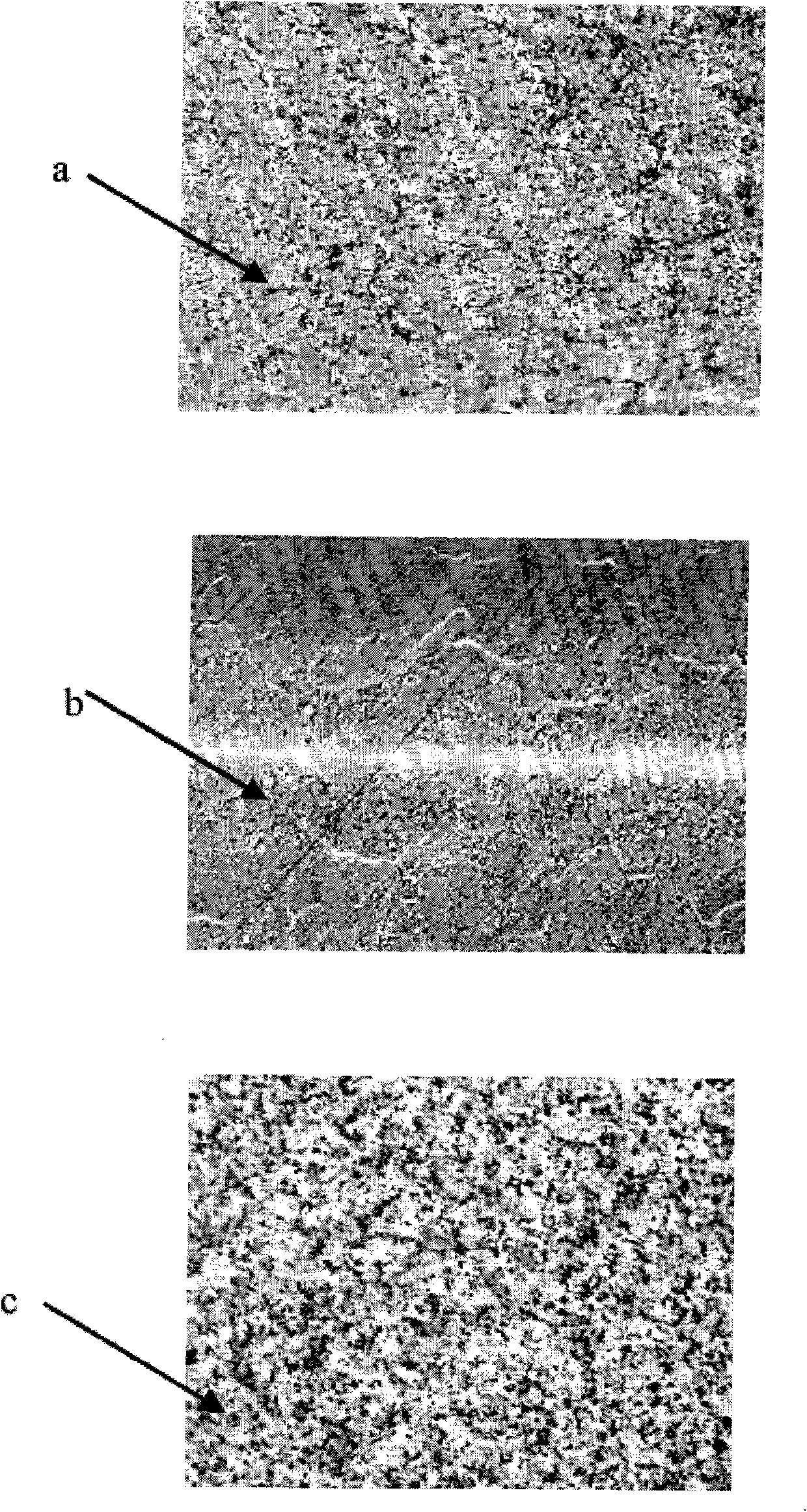

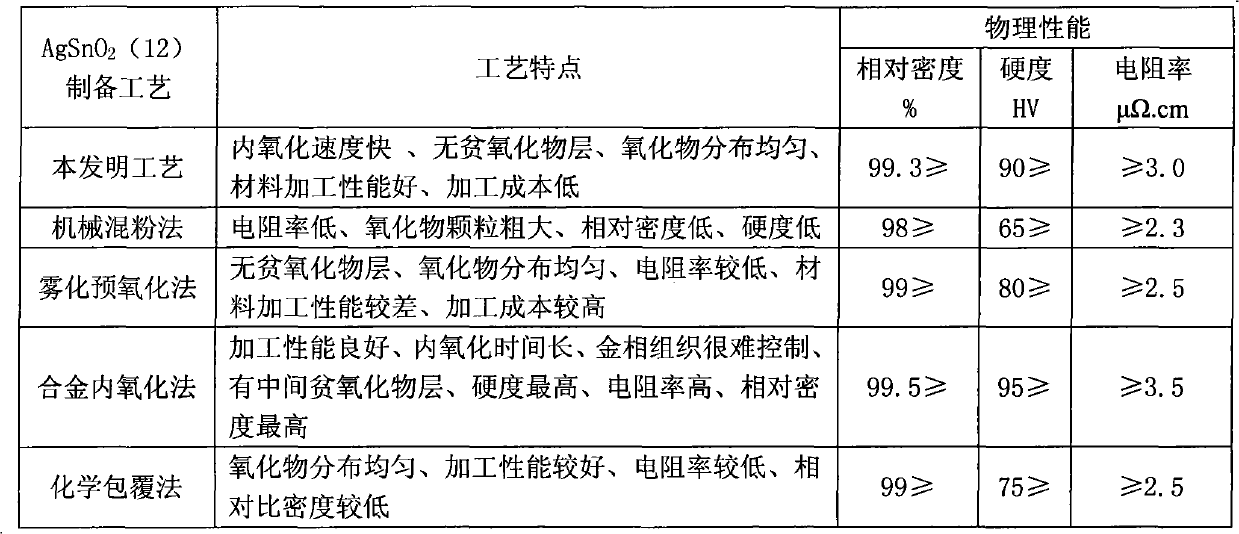

Preparation method for silver tin oxide electrical contact material

The invention discloses a preparation method for a silver tin oxide electrical contact material, which comprises the following steps: by taking a silver ingot, a tin ingot, an indium ingot and an additive ingot as raw materials, atomizing the raw materials to prepare a silver tin alloy powder; ingoting, sintering, extruding and drawing / rolling the silver tin alloy powder to prepare a wire material or a sheet plate or a belt material; and finally, carrying out internal oxidation to prepare the silver tin oxide electrical contact material. The preparation method for the silver tin oxide electrical contact material has the characteristics of uniform and stable contact material components, no conventional internally oxidized central lean oxidation zone, high density, high hardness and the like. The preparation method for the silver tin oxide electrical contact material has a simple process and is suitable for mass production. A prepared silver tin oxide product can be widely used for relays and contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

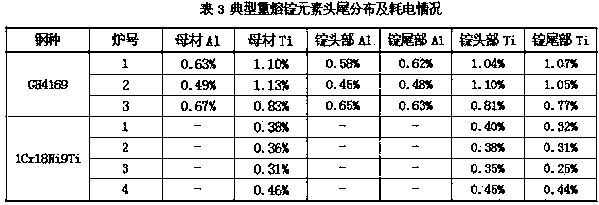

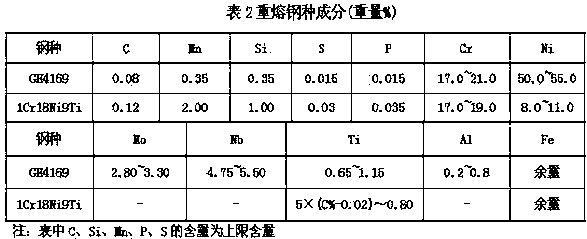

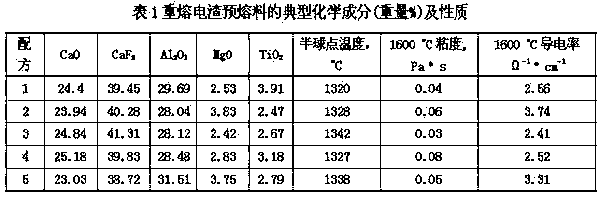

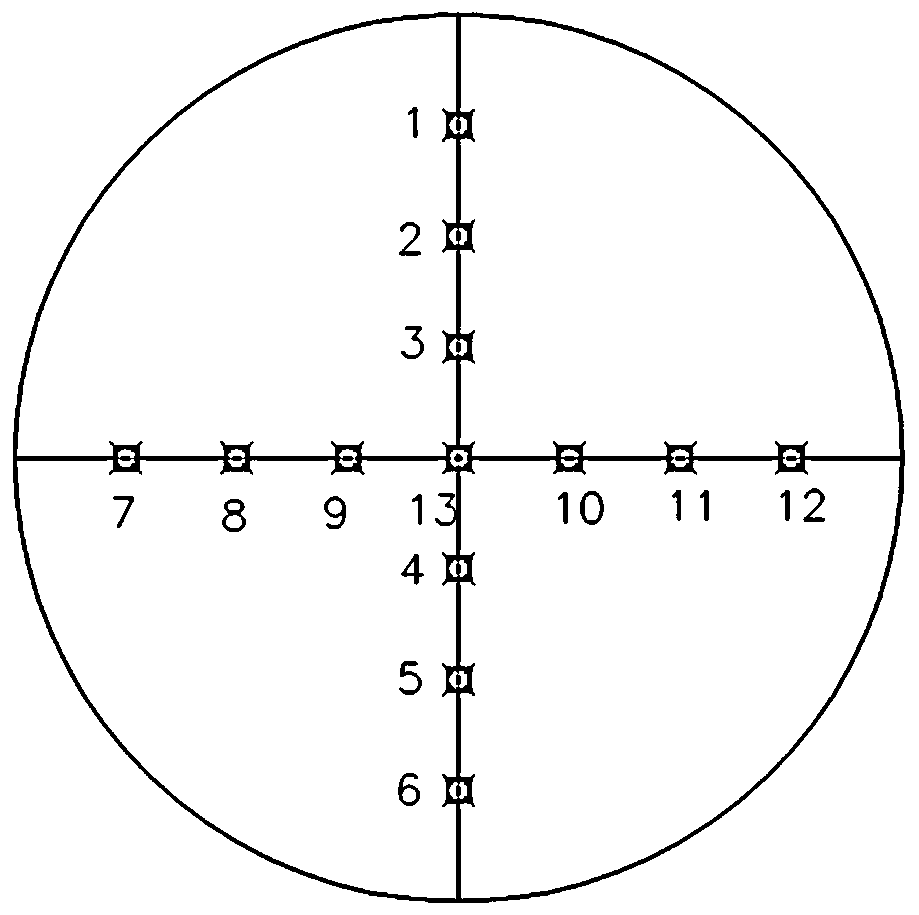

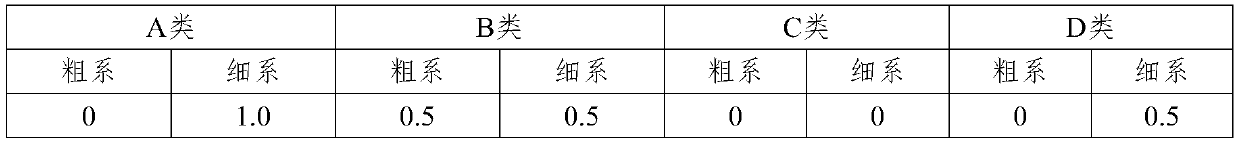

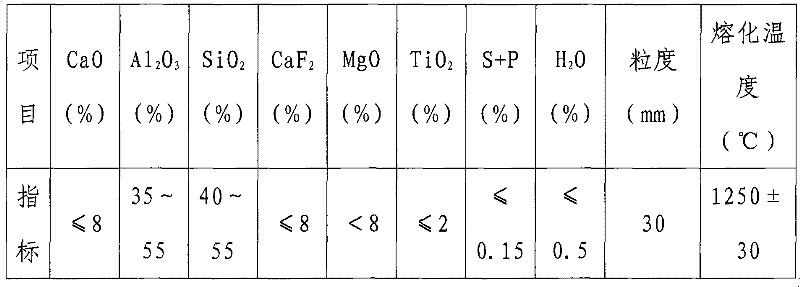

Remelting electroslag premelting material for high alloy steel round billet containing aluminum and titanium and preparation method thereof

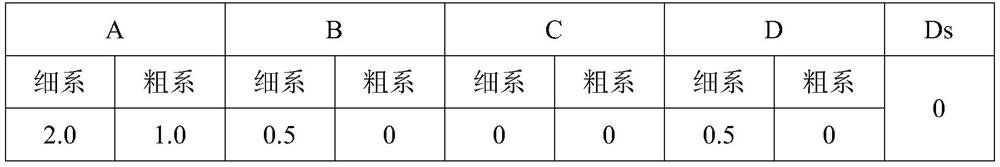

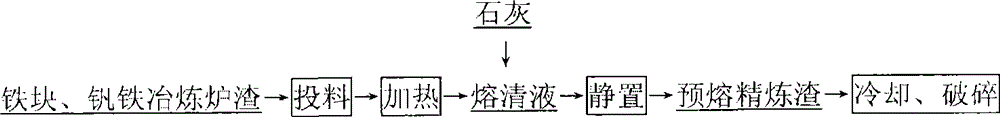

InactiveCN103725895AThe composition is uniform and stableLow melting point of slagPremeltingIngot casting

The invention discloses a remelting electroslag premelting material for a high alloy steel round billet containing aluminum and titanium and a preparation method thereof. The remelting electroslag premelting material is prepared from the following components in parts by weight: 20-25 parts of CaO, 28-32 parts of Al2O3, 40-45 parts of CaF2, 2-4 parts of MgO, 2.5-4 parts of TiO2, less than 1.5 parts of SiO2, and less than 0.3 part of FeO. The remelting electroslag premelting material has uniform and stable components, the time for melting slag charge is shortened, the degree of environment contamination is lowered, power consumption is lowered, the oxidation of alloy elements such as Al and Ti is reduced, alloy elements are uniformly distributed in electroslag ingots, the surface quality of an ingot casting is good, and the interior thereof is qualified.

Owner:CHONGQING UNIV

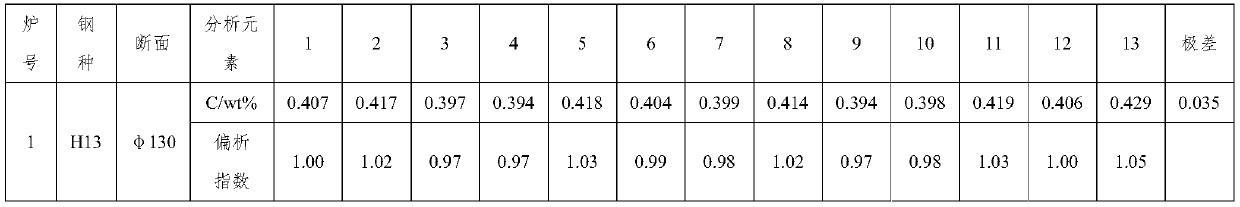

H13 die steel and production method thereof

The invention belongs to the technical field of die steel and particularly relates to H13 die steel and a production method of the H13 die steel. The H13 die steel comprises chemical components including, by weight, 0.32%-0.45% of C, 0.80%-1.20% of Si, 0.20%-0.50% of Mn, 4.75%-5.50% of Cr, 1.10%-1.75 of Mo, 0.80%-1.20 of V, not larger than 0.25% of Cu, not larger than 0.25% of Ni, larger than andequal to the sum of 2.726 C and 0.183 Si and smaller than or equal to the sum of 3.283 C and 0.179 Si of the sum of Mo, Nb and Ti and the balance Fe and inevitable impurities. By the adoption of the H13 die steel and the production method, the content of harmful elements in the steel is strictly controlled, the content of inclusions in the steel is reduced through a reasonable refining process, and it is ensured that the die steel has good cleanliness; with large compression ratio rolling, the compression ratio is larger than or equal to 15, and the internal structure of an H13 rolled materialis dense; and the transverse and longitudinal unnotched impact of the steel are both larger than or equal to 280 J, and the ratio of the transverse unnotched impact energy to the longitudinal unnotched impact energy is larger than 0.8.

Owner:SHANDONG IRON & STEEL CO LTD

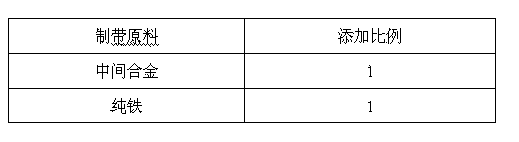

Preparation method of rare earth-iron intermediate alloy for low-oxygen rare earth steel

The invention discloses a preparation method of a rare earth-iron intermediate alloy for low-oxygen rare earth steel. The preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel comprises the steps that a vacuum smelting furnace is adopted, and rare earth metal and pure iron are placed in a crucible of the vacuum furnace at the mass ratio of 1-5:5-9; vacuumizing is conducted on the vacuum furnace until the pressure of the vacuum furnace is below 20 Pa, inert gas is fed for shielding, and the process of high-temperature melting-refining and electromagnetic stirring alloying is executed, wherein the high-temperature melting temperature is 1000-1500 DEG C, the temperature of the refining process is 1400-1500 DEG C, and the time is 5-15 minutes; molten metal is poured into an ingot mold, and then the rare earth-iron intermediate alloy is obtained. By the adoption of the preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel, the rare earth yield can be significantly improved, the content of the rare earth in the steel can be accurately controlled, the adding cost of the rare earth is reduced, and the plasticity, the low-temperature impact toughness, the thickness-direction property and the corrosion resistance of the steel are improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Multi-element nitralloy cored wire and application method thereof in reinforcing treatment technique of Q620D steel

The invention discloses a multi-element nitralloy cored wire and an application method thereof in a reinforcing treatment technique of Q620D steel and belongs to the technical field of alloy material application. A wire core of the multi-element nitralloy cored wire comprises 15.5-24.9% of N, 27-48% of V, 18-32% of Si, 0.3-4% of Nb, 0.05-3% of Mn, 0.3-4.5% of B, 0.8-7.0% of Ti, 0.1-5.0% of Cr, 0-1.4% of C, 0-0.10% of P, 0-0.10% of S, and the balance Fe and trace impurities. According to the multi-element nitralloy cored wire and the application method thereof in the reinforcing treatment technique of the Q620D steel, multi-element nitralloy with the most proper components is designed and selected; beneficial elements are added, so that N is transferred to V, B and Nb easily, the V, B and Nb and N are combined easily, and positive correlation functions are achieved for steel performance reinforcement; the requirements of a microalloying reinforcing technique of the Q620D steel are completely meet, and the reinforcing effect of the multi-element nitralloy cored wire is brought into full play.

Owner:马鞍山中科冶金材料科技有限公司

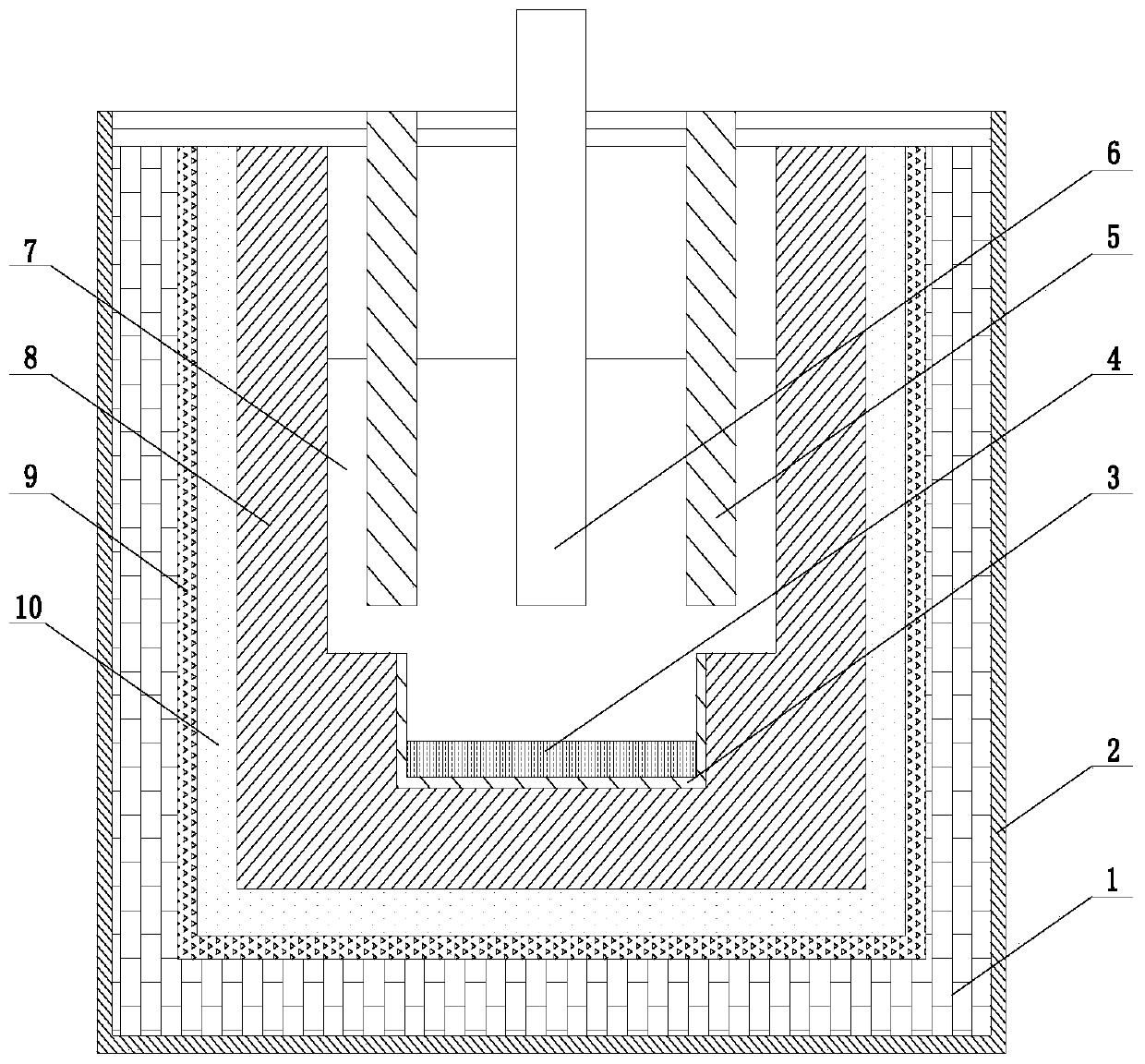

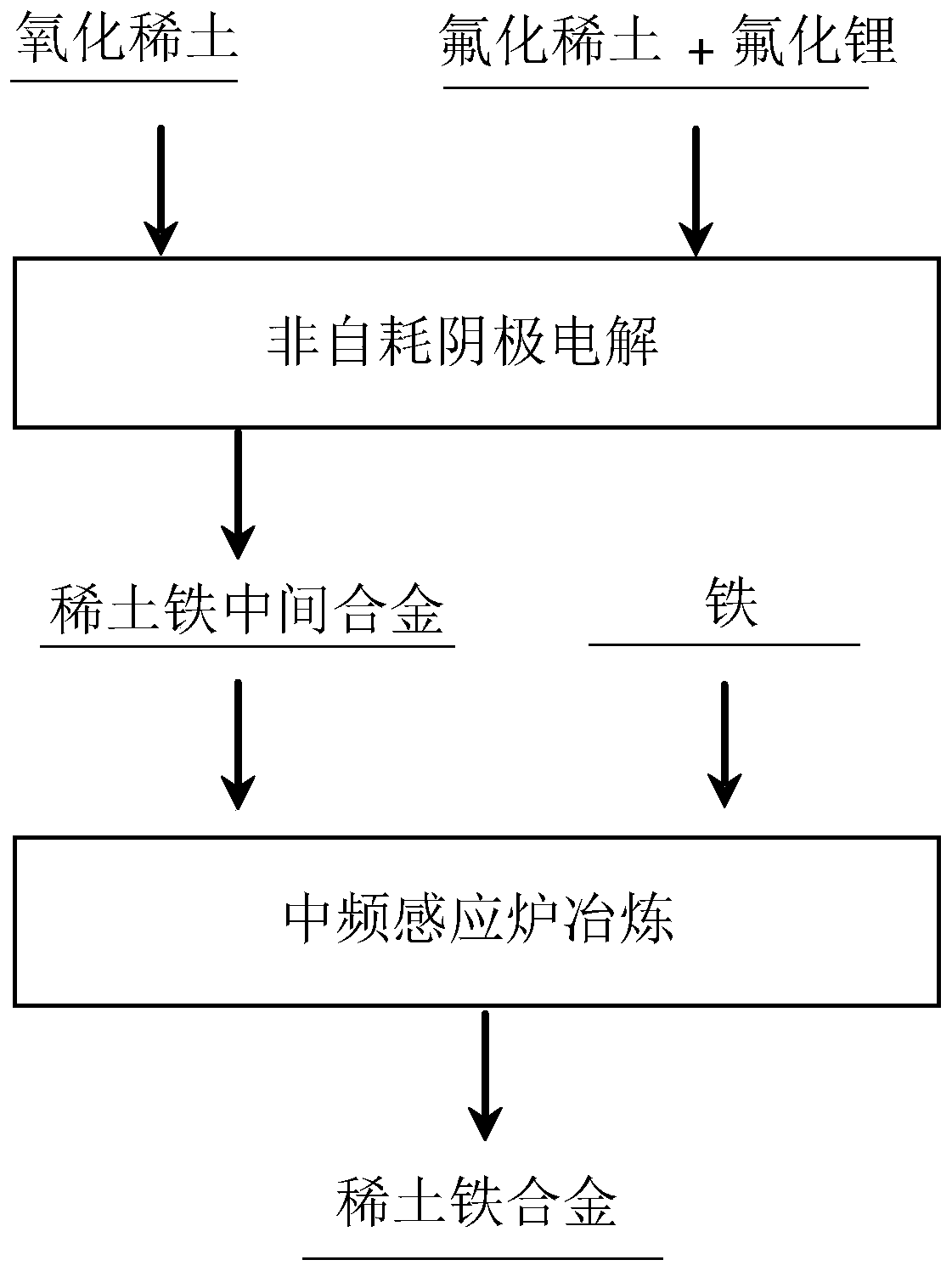

Preparation method of rare earth ferroalloy

ActiveCN111411372AThe composition is uniform and stableReduce segregationInduction furnaceLithium fluoride

The invention discloses a preparation method of a rare earth ferroalloy. The preparation method of the rare earth ferroalloy comprises the steps that a rare earth iron immediate alloy is prepared by non-self-consuming cathode electrolysis; an electrolyte is loaded in an electrolytic cell, a graphite carbon plate is used as an anode, a tungsten or molybdenum material is used as an cathode, and a crucible under the tungsten and molybdenum cathode is used as a receiver; in an electrolyte system of rare earth fluoride and lithium fluoride molten salt, rare earth oxide and iron are used as raw materials, then a direct current is passed for electrolysis, and the rare earth iron immediate alloy is obtained in the receiver; and the rare earth iron immediate alloy and iron are put into the crucibleas the raw materials, and the rare earth iron immediate alloy is further smelted by a melting and mixing method in a medium frequency induction furnace to obtain the rare earth ferroalloy. The rare earth ferroalloy obtained by the preparation method has uniform and stable composition, low impurity element content and close density and melting point to the density and melting point of steel, and the rare earth ferroalloy is easy to be added to the steel; and the rare earth ferroalloy can fundamentally solve the problem of effective addition of rare earth in the steel and can accurately controlthe content of the rare earth in the steel.

Owner:BAOTOU RES INST OF RARE EARTHS +1

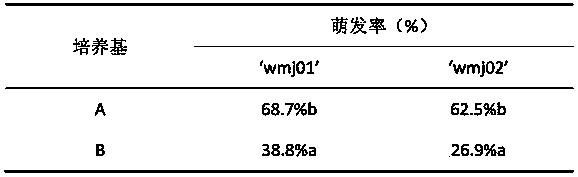

Method for determining pollen viability of watermelon

InactiveCN104178448AThe composition is uniform and stableImprove ventilationPlant cellsMaterial analysisSucrosePollen tube

The invention relates to a method for determining the pollen viability of watermelon, belonging to the technical field of plant. The invention discloses a method for determining the pollen viability of watermelon by using an in-vitro germination method, and the pollen viability of the watermelon can be effectively determined. An in-vitro pollen germination culture medium used comprises the following components of 200g / L sucrose, 10mg / L H3BO3, 800mg / L Ca(NO3)2.4H2O, and 6.5g / L agar. The method comprises the following steps: evenly sowing pollen into the solid culture medium, and culturing at dark conditions 85% relative humidity at 25DEG C; and after four hours, observing the pollen germination and pollen tube growth situations through an optical microscope. The method is simple, completely quantitative, reliable in data, and strong in operability, has higher practical application values, and achieves important significance on the breeding efficiency of watermelons.

Owner:ZHENJIANG SUIHAN AGRI

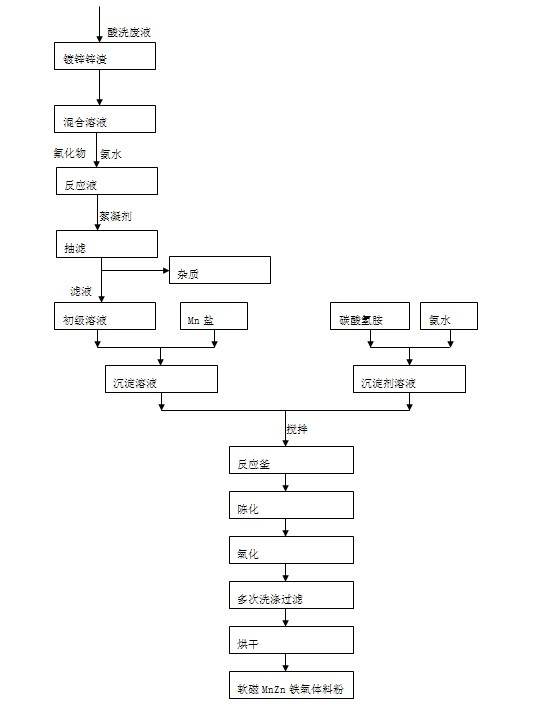

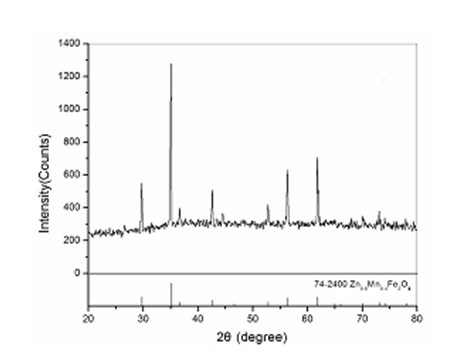

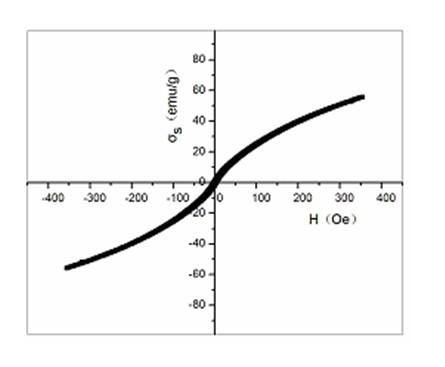

Method for preparing MnZn ferrite material powder from acid washing waste liquid and galvanized zinc slag

The invention discloses a method for preparing MnZn ferrite material powder from acid washing waste liquid and galvanized zinc slag. The method comprises the following steps of: (1) placing the galvanized zinc slag into the acid washing waste liquid to dissolve to obtain mixed solution; (2) adjusting the pH value of the mixed solution to 3 to 6 by using ammonia water, adding fluoride and reacting to obtain reaction solution; (3) adding a flocculating agent into the reaction solution and filtering out precipitate in the mixed solution by a suction filtration method, wherein the filtrate is primary solution; (4) preparing precipitate solution from the primary solution and manganese chloride according to the mole ratio of Fe2O3 to MnO to ZnO of the ferrite components and preparing precipitator solution from ammonium bicarbonate and ammonia water; (5) allowing the precipitate solution and the precipitator solution to enter a reaction kettle to react to obtain slurry; (6) ageing the slurry obtained from the complete reaction; and (7) oxidizing, washing, filtering and drying the aged slurry to obtain MnZn ferrite material powder. The soft magnetic MnZn ferrite material powder has fine granularity, uniform and stable components and high magnetic property.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

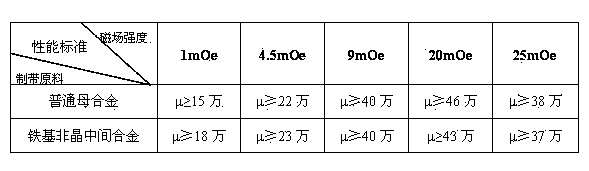

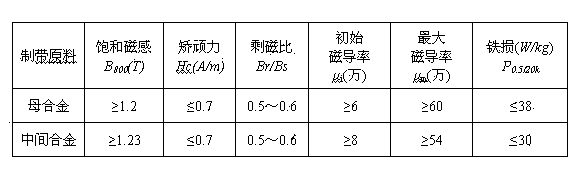

Special intermediate alloy for iron base amorphous nanocrystalline alloy and smelting method thereof

Special intermediate alloy for iron base amorphous nanocrystalline alloy belongs to the field of metallurgy. The alloy comprises the following chemical components: 15.7 wt% of Si, 3.8 wt% of B, 11 wt% of Nb, 2.4 wt% of Cu and the balance of Fe. A smelting method is as below: successively adding industrial pure iron, niobium iron, industrial silicon and electrolytic copper ferroboron into an intermediate frequency smelting furnace; (2) preheating with a small power and heating with high power; (3) completely fusing the raw materials, stirring alternatively with high and low power, at the same time carrying out furnace rocking with small to middle amplitude; and heating to 1400 DEG C and insulating for 5 min; and (4) finally carrying out dedrossing and tapping. The invention solves the problems of raw material burning loss and hard fusion of high-melting-point alloy. The amorphous nanocrystalline alloy strip produced from the intermediate alloy has multiple advantages including uniform composition, good toughness, significantly improved magnetic property and the reduced manufacturing cost.

Owner:太原钢铁(集团)有限公司

Equipment for preparing chromium zirconium copper alloy wire pole by electromagnetic stirring fusion metallurgy

InactiveCN101376165ASimple manufacturing processThe composition is uniform and stableManufacturing technologyCopper alloy

The invention relates to a device for preparing an alloy mast through electromagnetic stirring and melting, wherein the alloy is made from chromium, zirconium and copper. A baffle is arranged in the middle part of a furnace body to divide the furnace body into a melting furnace part and a holding furnace part; the furnace bottom of the melting furnace part is higher than that of the holding furnace part; an electromagnetic stirrer is arranged on the outer side of the melting furnace part, and a melting furnace sensor is arranged at the lower part of the melting furnace part; and a holding furnace sensor is arranged at the lower part of the holding furnace part, and an up-pulling system is arranged above the holding furnace part. Under a non-vacuum condition, the device can realize continuous preparation of the alloy (containing chromium, zirconium and copper) mast which is easily oxidized and difficult in adding element zirconium; the manufacturing technology for the alloy mast is greatly simplified, a product with uniform and stable components can be acquired, the production cost can be reduced, and the device is worthy of promotion.

Owner:苏州有色金属研究院有限公司

Micro-alloy reinforcing agent and application and application method thereof

InactiveCN106244770AThe strengthening effect is fully exertedRealize the strengthening effectVanadium nitrideMolten steel

The invention discloses a micro-alloy reinforcing agent and an application and an application method thereof, and belongs to the field of steel metallurgy functional additives. The micro-alloy reinforcing agent comprises the components: 23-66% of Si, 0.1-17.5% of Mn, 11-37% of N, 0-9.6% of Ti, 0-7.3% of Cr, 0.03-5.6% of Al, 0.1-1.9% of C, not more than 0.1% of P, not more than 0.15% of S, and the balance Fe and impurities; the micro-alloy reinforcing agent has good enhancement effect especially on vanadium nitride and ferrovanadium nitride, can be suitable for the needs of different micro-alloy steel types, and can be made into ball blocks with the particle size of 5-45 mm with vanadium nitride, is conveniently added into molten steel in the tapping process, and improves the effective utilization rate of micro-alloy elements; a cored wire can be formed by coating the micro-alloy reinforcing agent and vanadium nitride or ferrovanadium nitride particles together, and is fed into molten steel in a refining process, so as to be convenient for accurate control of some micro-alloy steel processes and performance objectives.

Owner:马鞍山市恒兴耐火炉料厂

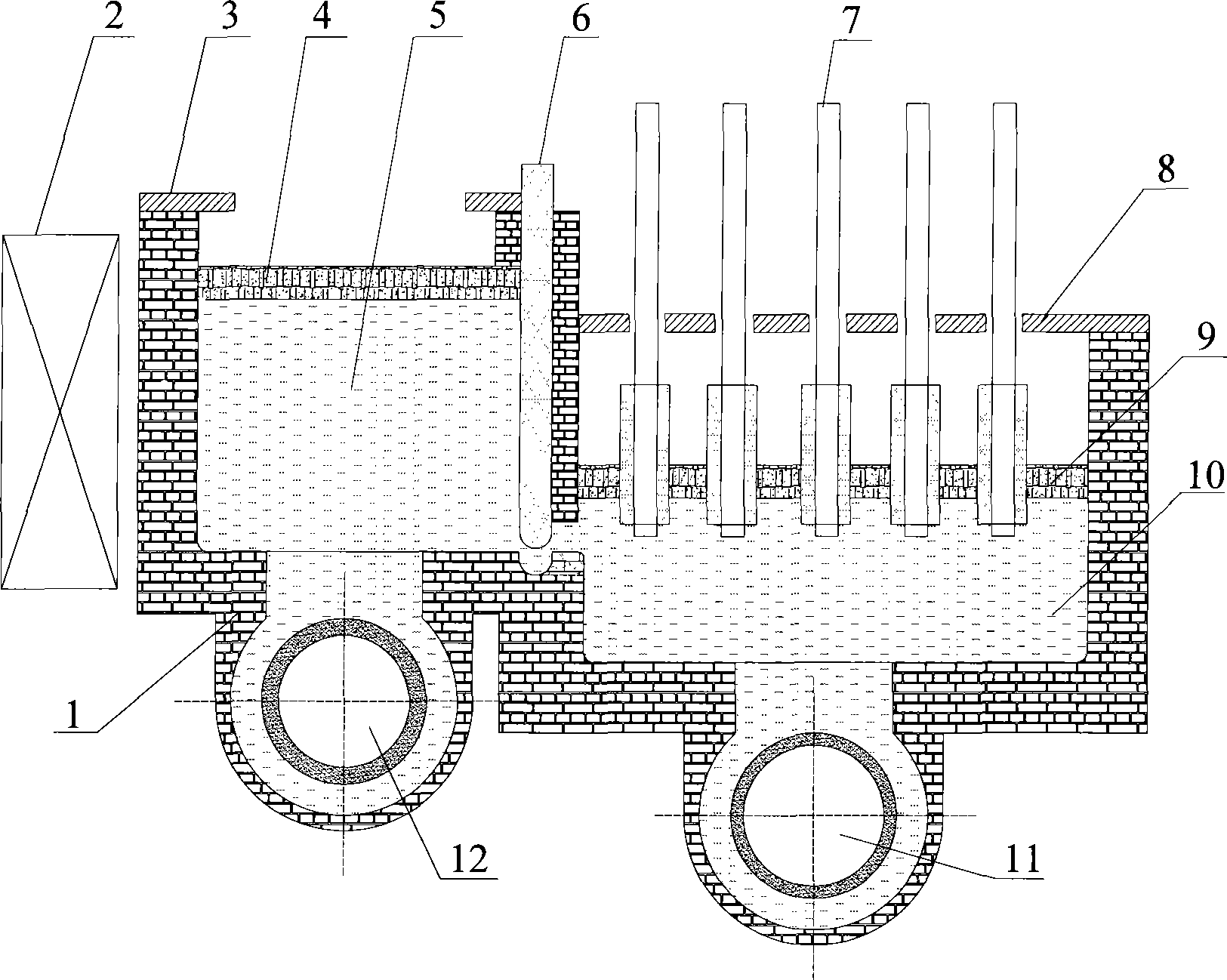

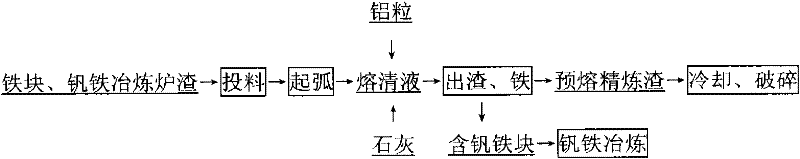

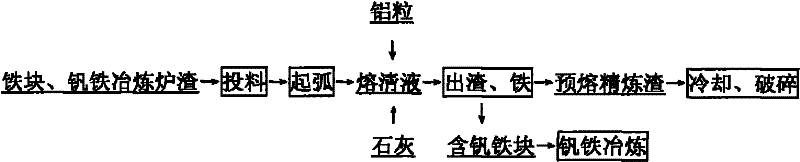

Premelted refining slag and preparation method thereof

The invention provides a premelted refining slag and preparation method thereof. The preparation method comprises the following steps of: adding ferrovanadium slag and arc striking iron to the electric furnace to melt and form a molten bath; adding aluminum to the molten bath to reduce the vanadium oxide in the ferrovanadium slag; adding lime to the molten bath and stirring the bath with inert gases so as to form the slag containing 12Cao.7Al2O3 and / or 3CaO.Al2O3; and separating the slag from the metal liquid in the molten bath to obtain premelted refining slag and metal liquid. The method of the invention can make an effective use of the ferrovanadium slag to obtain premelted refining slag that meets the requirements of metallurgical process like steel making.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

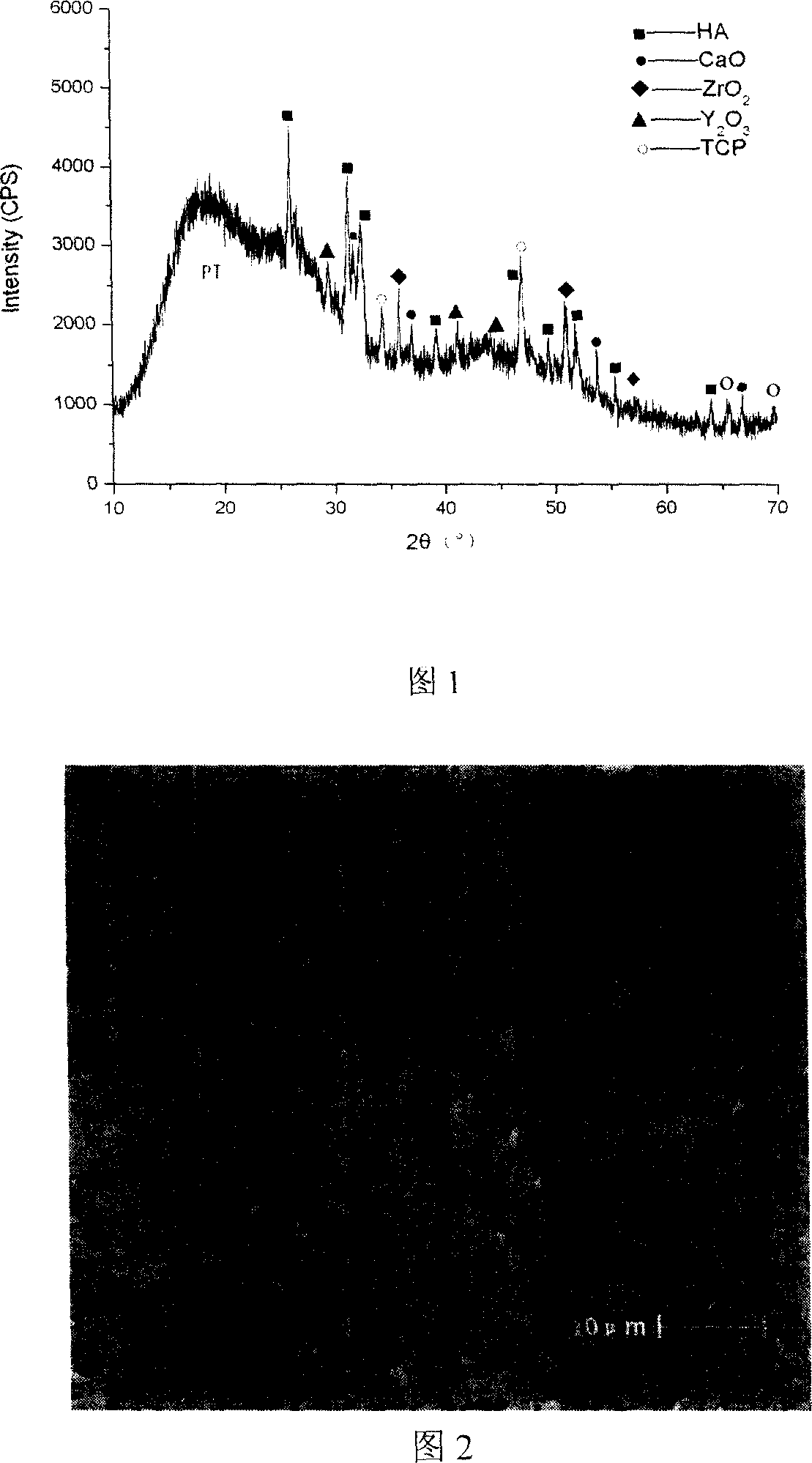

Method for magnetron sputtering preparation of (HAú½Zro#-[2]ú½Y#-[2]O#-[3])/Ti#-[6]Al#-[4]V bio-based composites endosteal implant

InactiveCN1605654AHelp repairHelp rebuildVacuum evaporation coatingSputtering coatingMaterials preparationPorosity

Through the process of composite HA+ZrO2+Y2O3 target material preparation, activation of the Ti2Al4V substrate, setting the composite HA+ZrO2+Y2O3 target and the Ti2Al4V substrate separately in main sputtering chamber and the sample chamber, sputtering under reasonably controlled magnetically controlled sputtering parameters, taking out sample and post-treatment in the sample chamber to obtain the artificial bone implant with composite biological film of composite HA+ZrO2+Y2O3 on the Ti2Al4V substrate. Compared with available prepared technology, the present invention has the advantages of high attachment strength of the composite biological HA+ZrO2+Y2O3 film on the substrate, homogeneous and stable film components without decomposition, capability of gradient varying film, 10-30 % porosity of the film surface favorable to the repairing and re-construction of bone tissue, etc.

Owner:JIANGSU UNIV

Method for preparing alkali cellulose and viscose spinning adhesive from semi-wet slurry

ActiveCN106757461AFully mix and adjustThe composition is uniform and stableArtificial filaments from viscoseCelluloseProduction line

The invention relates to a method for preparing alkali cellulose and viscose spinning adhesive from semi-wet slurry. The preparation method comprises the following steps: mixing, filtering water with a fourdrinier wire, dehumidifying, extruding, grinding, immersing for the first time, squeezing for the first time and grinding, immersing for the second time, squeezing for the second time and grinding, performing belt-type aging, yellowing, carrying out post-dissolving, mixing, filtering and defoaming so as to complete spinning adhesive preparation. According to the preparation method, pumping, drying, slitting and other production links during pulp preparation can be reduced, and the preparation can be completed by twice squeezing and grinding of pulp slush, the process is simple, the process flow becomes smaller, no new squeezing or grinding equipment is required, cost for reforming equipment is greatly reduced, conveying of fluid slurry is greatly reduced, energy consumption is greatly reduced, labor is saved, and technical grafting and transformation on an existing viscose fiber production line can be facilitated.

Owner:山东银鹰化纤有限公司

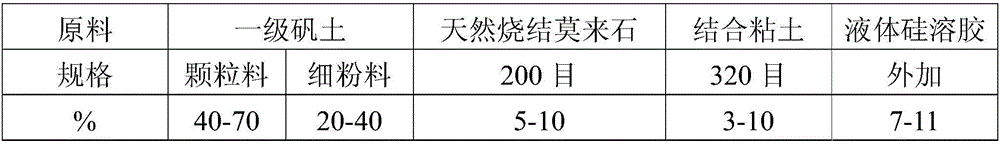

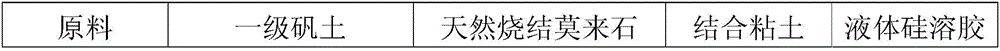

High-quality high-aluminum runner brick as well as preparation method and application thereof

The invention discloses a high-quality high-aluminum runner brick as well as a preparation method and an application thereof. According to the high-quality high-aluminum runner brick, first-grade alumina is taken as aggregate, a proper amount of naturally sintered mullite and binding clay are added to a powdery matrix material, and liquid silica sol is taken as a binding agent. According to the high-quality high-aluminum runner brick, due to the good performance of silica sol, the firing temperature of a product is effectively reduced, the interval range of the firing temperature is increased, and additionally, the physical and chemical indexes of the prepared high-aluminum rubber brick product are superior to those of rubber bricks produced with a conventional binding agent; ingredients of poured quality steel are uniform and stable if the high-quality high-aluminum runner brick is used in mold casting and steel pouring sites, the cleanness is high, and requirements of users are effectively met.

Owner:瑞泰马钢新材料科技有限公司 +1

Aluminum alloy round ingot casting for computer hard disk drive arm and production method of ingot casting

The invention discloses an aluminum alloy round ingot casting for a computer hard disk drive arm. The ingot casting comprises 0.60 to 0.80% of Si, 0.10 to 0.20% of Fe, 0.90 to 1.1% of Mg, 0.10 to 0.30% of Cu, 0.10 to 0.20% of Mn, 0.10 to 0.30% of Cr, smaller than 0.03% of single impurities and the balance Al. The production method comprises the steps that pure aluminum ingot solid cold charge andelectrolytic aluminum liquid are burdened, heating and melting are carried out at the proper temperature, an electromagnetic stirrer is started to rapidly melt the cold charge, temperature uniformityand component uniformity are kept, according to the chemical components in aluminum melt, alloying treatment is carried out, slagging-off is carried out to kept melt clean, high-purity N2 and a refined powder spraying agent are adopted to carry out powder spraying refining, online filtering, slag removal and gas removal are achieved, and through casting production and uniform heating treatment, the aluminum alloy round ingot casting meeting the requirement is produced. The ingot casting is stable and uniform in component, compact in internal structure, smooth and clean in surface, excellent inmechanical performance, and high in product interior cleanness, and the method is an optimal method for producing the aluminum alloy round ingot casting for the computer hard disk drive arm.

Owner:HENAN ZHONGFU ALUMINUM ALLOY

Sintered calcium magnesium silicate refining slag for tire cord steel and preparing method thereof

InactiveCN109439845AImprove qualityLow costProcess efficiency improvementNon-metallic inclusionsSlag

The invention discloses sintered calcium magnesium silicate refining slag for tire cord steel. The slag comprises, by weight percent, 35 to 42% of CaO, 10 to 20% of MgO, 5 to 10% of CaF2, 35 TO 50% ofSiO2, not larger than 2% of Al2O3, and not larger than 4% of other impurities. The invention further provides a preparing method of the sintered calcium magnesium silicate refining slag for tire cordsteel. The form and the number of nonmetallic inclusions in the tire cord steel can be effectively controlled, the nonmetallic inclusions in the steel form low-melting-point plastic composite inclusions, the quality of the steel is improved, and the preparing method of the sintered calcium magnesium silicate refining slag can achieve continuous charging and discharging, simple process, uniform and stable component and low product cost.

Owner:WUHAN RUXING TECH CO LTD

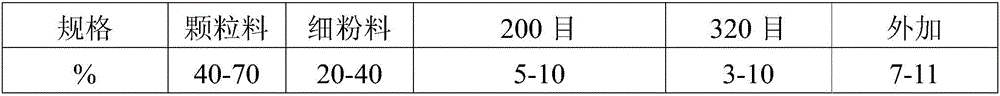

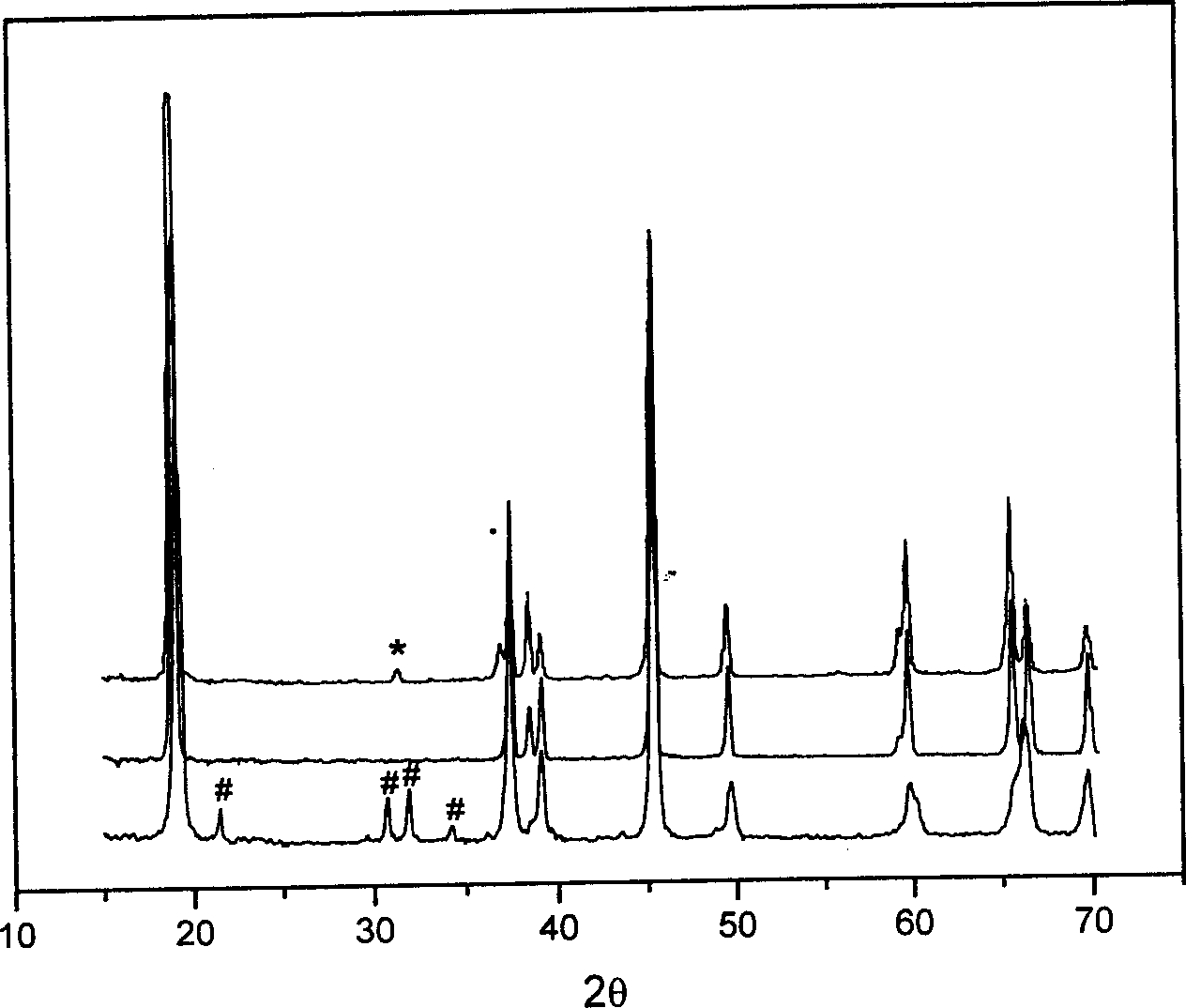

Liquid-phase synthesis of anode material for lithium ion secondary battery

InactiveCN1713420AThe composition is uniform and stableHigh charge and discharge capacityElectrode manufacturing processesPolymer scienceManganese

The method includes following steps: 1) prepares mixing aqueous solution containing cobalt or manganic compounds, lithium compounds and polymer monomer; the mole number ratio of lithium to cobalt is (0.9-1.1):1; the mole number ratio of lithium to manganese is (1~1.1): 2; the volumetric ratio of water to polymer monomer in mixing aqueous solution is (0.2-5): 1; the structure formula of polymer monomer is alkene compound; 2) the mixing aqueous solution is put into the condition under the Y-ray irradiation; Y-ray is used to lead polymerization of polymer monomer in solution and to get macromolecule gel; 3) the gel is processed through drying, thermal decomposition and sintering to form the anode material.

Owner:UNIV OF SCI & TECH OF CHINA

Method for processing waste glass fiber filament powder material

The invention belongs to the technical field of glass fiber recycling and in particular relates to a method for processing a waste glass fiber filament powder material. The method comprises the following steps: firstly, performing soaking treatment on waste glass fiber filaments in a mixed liquid of an alkali and supernate of cement slurry, taking out the soaked waste glass fiber filaments, and performing washing, crushing, drying and powder milling, so as to obtain the waste glass fiber filament powder material. By adopting the method, an impregnating compound on surfaces of the waste glass fiber filaments can be removed, meanwhile, micro cracks on the surface of glass fiber can be increased, the strength of the glass fiber can be degraded, the brittleness of the glass fiber can be improved, and the powder milling effect of the waste glass fiber filaments when being processed into the powder material can be improved; by adopting the method, the waste glass fiber filaments can be efficiently powdered into the powder material, the powder material is uniform and stable in component, and can be mixed with other glass raw materials into a batch which can be fed into a kiln by using a reamer, so that the time and the labor can be saved, and the waste glass fiber filaments can be efficiently repeatedly used; and by adopting the method, the recycling treatment degree of the waste glass fiber filaments of the glass fiber industry can be increased, overstock of waste materials can be avoided, the market purchase cost of cement and alkali liquids is low, and large-scale treatment iseasy.

Owner:山东硕远新材料有限公司

Method for producing premelting-type calcium aluminate from electrolytic aluminum waste residue

InactiveCN103966453AQuality improvementExtended service lifeChemical industryProcess efficiency improvementAluminateMelting tank

The invention discloses a method for producing premelting-type calcium aluminate from electrolytic aluminum waste residue. The method comprises the following steps of 1, purifying electrolytic aluminum waste residue, 2, mixing the purified electrolytic aluminum waste residue and lime, 3, putting the raw material into a melting furnace and carrying out melting, 4, discharging the melt product into a high temperature-resistant melting tank and carrying out cooling, and 5, crushing the cooled premelting-type calcium aluminate, carrying out screening and carrying out packaging. The method utilizes electrolytic aluminum waste residue and limestone to prepare the premelting-type calcium aluminate, realizes recycle of waste, is environmentally friendly, saves energy, prevents aluminum resource loss, reduces a calcium aluminate cost and reduces environmental pollution. The calcium aluminate produced by the method has the characteristics of less impurity and uniform and stable components, can be used for the refining process of LF, SKF and VHP and can greatly improve molten steel quality and a ladle service life.

Owner:ZHENGZHOU WHALE SPECIAL MATERIALS

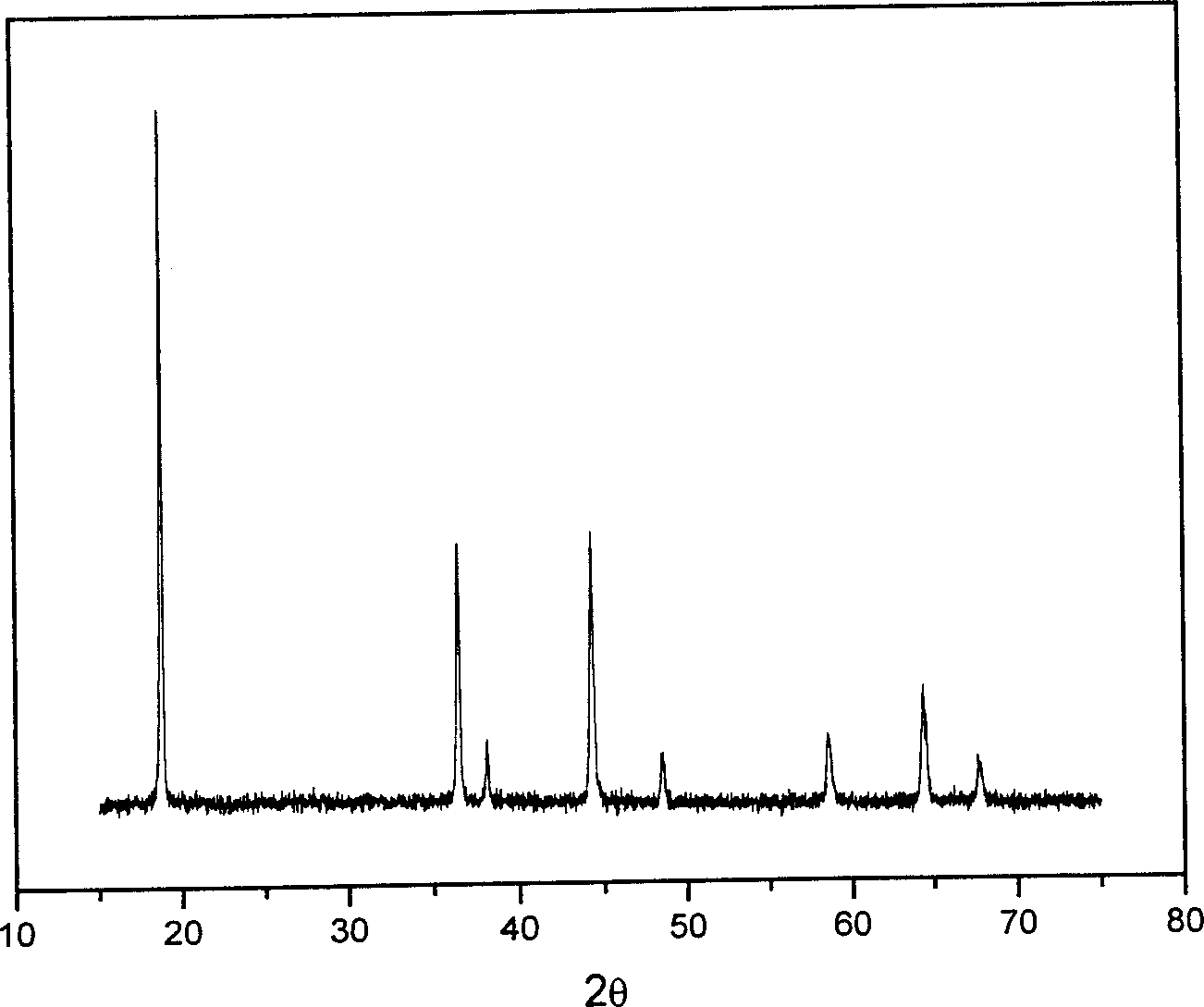

Magnetron sputtering method for preparing HA/YSZ/polyimide bioactive composite material

InactiveCN1995450AHelp repairHelp rebuildVacuum evaporation coatingSputtering coatingSputteringAtmospheric pressure

The invention discloses a making method of biological active composite material of HA / YSZ / polyimide through magnetic control sputtering method, which comprises the following steps: adding 5-40% YSZ powder in the nanometer graded HA powder; making HA / YSZ target material in the vacuum through heat sintering method; cleaning PI base; drying; placing on the base on the carrier of sputtering chamber; extracting the chamber into vacuum; making the pressure below 10-4Pa; activating the surface of PI base surface; placing HA / YSZ target material and PI base in the sputtering chamber; extracting the sputtering chamber into vacuum between 3*10-4 and 5*10-4 Pa; adjusting Ar flow quantity; reducing vacuum degree of sputtering chamber to 2*10-1Pa-1*10-1Pa; adjusting sputtering power to do firing sputter for 6-8h; fetching the sample out of sputtering chamber at 100-200 deg. c; insulating 2-4h; cooling.

Owner:JIANGSU UNIV

Multielement nitralloy cored wire, application of multielement nitralloy cored wire, and production method of HRB500E high-strength aseismic steel

The invention discloses a multielement nitralloy cored wire, an application of the multielement nitralloy cored wire and a production method of HRB500E high-strength aseismic steel, and belongs to the technical field of alloy material applications. A wire core of the multielement nitralloy cored wire comprises the following components (by mass fraction): 17-26% of N, 21-47% of V, 14-35% of Si, 0.6-6.5% of B, 0.3-5.0% of Ti, 0.01-3.0% of Cr, 0-4.5% of Nb, 0.5-8% of Mn, less than or equal to 1.6% of C, less than or equal to 0.10% of P, less than or equal to 0.10% of S, and the balance Fe and unavoidable impurities. With the adoption of multielement nitralloy, sufficient N content can be ensured in a refining process of the HRB500E high-strength aseismic steel, V and B are combined with N(C) fully, and a dissolved precipitation strengthening effect is exerted; in addition, the contents of Si, Mn, Ti, Cr and Nb are adjusted, a best positive correlation strengthening effect is reached; a microalloying technology having least influence factor variable on the steel performance strengthening effect is designed, screened and verified; and the multielement nitralloy cored wire has the advantages that the strengthening effect is most sufficient, the technology stability is good, and a hit rate of the target type of steel is high.

Owner:马鞍山中科冶金材料科技有限公司

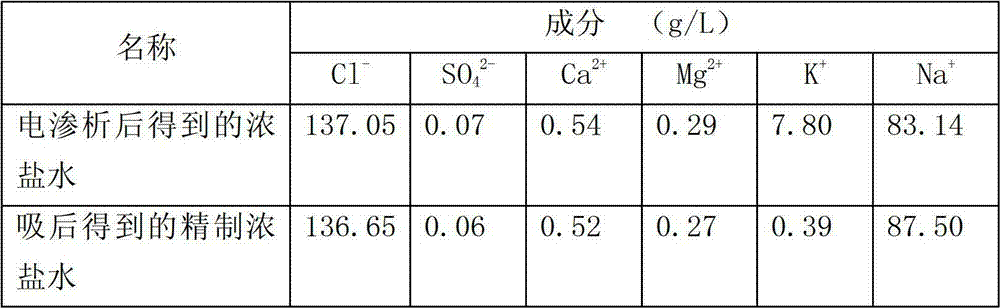

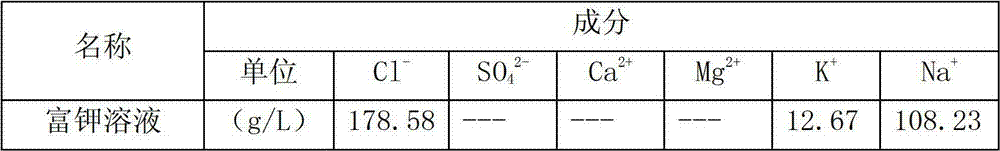

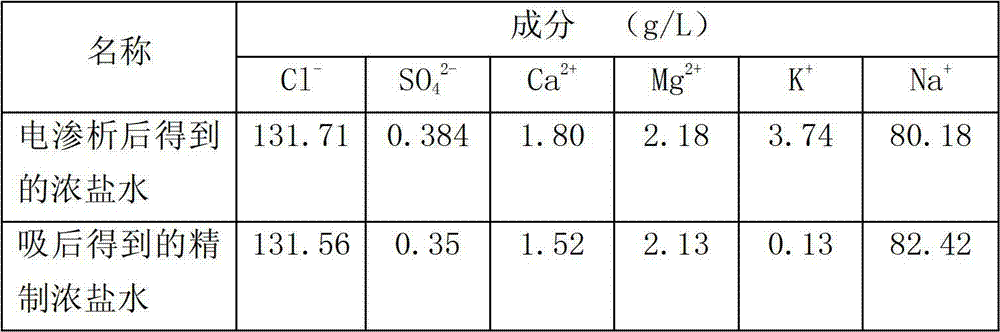

Method for preparing refined strong brine by removing potassium from strong brine

ActiveCN102730722AEfficient removalImprove product qualityAlkali metal chloridesAlkali metal halide purificationSimulated moving bedPotassium ions

The invention provides a method for preparing refined strong brine by removing potassium from strong brine, and relates to a method for removing potassium from strong brine. The method comprises the following steps of: under the temperature of 15-40DEG C, introducing raw material strong brine into an ion exchange column filled with modified zeolite to carry out an adsorbing reaction, adsorbing the raw material strong brine by an analogue moving bed technology till exchange reaction between the potassium ions in the raw material strong brine and the sodium ions on the modified zeolite is completed, and adsorbing to obtain the refined strong brine of which the K<+> content is 0.10g / L-0.39g / L; and eluting potassium ions in the ion exchange column after adsorption in the first step by taking saturated sodium chloride solution as eluant under the temperature of 25-95DEG C, so that the potassium-rich solution of which the potassium ion concentration is 10.23g / L-12.67g / L can be obtained, and the ion exchange column can be recycled after being eluted by the saturated sodium chloride solution. According to the method provided by the invention, the potassium ions in the electrically-dialysed strong brine can be effectively removed, and the qualified brine which meets the requirement of the chlor-alkali industry can be prepared.

Owner:河北八维化工有限公司

Aluminium-silica type refined pre-smelting slag

InactiveCN102344996AThe composition is uniform and stableLower melting temperatureProcess efficiency improvementBrickMetallic foreign material

The present invention discloses an aluminium-silica type refined pre-smelting slag, which is provided for solving the problems of prominent foreign material quality problem and the large fluctuation during a high-grade bearing steel producing process, low continuous casting success rate (only about 30%) during a middle (high) sulfur structure steel producing process, and high unqualified rate of the sulfide. The aluminium-silica type refined pre-smelting slag comprises the following components, by weight, 10.0-30.0% of waste glass, 25.0-45.0% of fly ash, 35.0-55.0% of 65% waste high alumina brick and 1.0-3.0% of a fluxing agent. The aluminium-silica type refined pre-smelting slag has the following advantages that: (1) the slag system is stable, and the slag adjusting process is not required; (2) the level for controling the non-metallic foreign material in the adsorption steel is high; (3) the slag does not agglomerate, the melting and slaggling time is short (less than or equal to 2 minutes); (4) the yield of the sulfur of the middle (high) sulfur structure steel during the later stage sulfur adjusting process is stable; (4) the product does not powder, and the shelf life is more than six months.

Owner:丹东泓辉科大高温材料有限公司

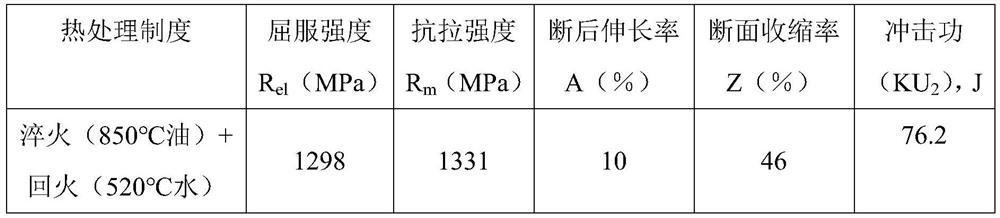

Steel for front axle of medium-sized truck and production method of steel

ActiveCN113201689AStable room temperature impact performanceStability Control RatioMetal rolling arrangementsMetallurgyTruck

The invention discloses steel for a front axle of a medium-sized truck and a production method of the steel. The steel comprises the following chemical components including, by weight, 0.39% to 0.43% of C, 0.20% to 0.37% of Si, 0.65% to 0.80% of Mn, 0.95% to 1.10% of Cr, 0.01% to 0.05% of Mo, 0.02% to 0.03% of Ni, 0.02% to 0.05% of Cu, less than or equal to 0.020% of P, 0.010% to 0.025% of S, 0.010% to 0.040% of Alt and the balance Fe and other inevitable impurities, so that the contents of Mo, Ni and Cu in the steel meet the condition that the sum of Mo, Ni and Cu is more than or equal to the sum of 0.013C, 0.033Mn and 0.034Cr and less than or equal to the sum of 0.018C, 0.026Mn and 0.065 Cr. According to the steel for the front axle of the medium-sized truck and the production method of the steel, the contents of Mo, Ni, Cu and other elements in the steel are accurately controlled, steel grains are refined, the impact toughness of the steel is improved, and the fatigue life of the automobile front axle is prolonged.

Owner:SHANDONG IRON & STEEL CO LTD

Utilization method of ferrovanadium slag and premelted refining slag

The invention provides a utilization method of ferrovanadium slag and premelted refining slag. The utilization method of ferrovanadium slag comprises the following steps of adding ferrovanadium slag to a high-temperature furnace to melt and form a molten bath; adding lime to the molten bath and stirring the bath with inert gases so as to form the slag containing 12Cao.7Al2O3 and / or 3CaO.Al2O3; and cooling the slag to obtain premelted refining slag. The method of the invention can make an effective use of the ferrovanadium slag to obtain premelted refining slag that meets the requirements of metallurgical process like steel making.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Preparation technique of nanoparticle composite material film for welding

The invention relates to the technical field of preforming welding material, and particularly discloses a preparation technique of a nanoparticle composite material film for welding; the technique includes steps of material mixing-vacuum defoamation- curtain coating and film formation-drying and curing-after-treatment. The preparation technique is featured by simple and feasible practice, strong controllability, high efficiency, and low cost; the technique can effectively guarantee the component of the prepared nanoparticle composite material film, uniform and stable dimension, excellent processing performance and high reliability of low-temperature sintering and welding; the preparation technique can be widely applied to the field of preforming welding material.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

Preparation method for silver tin oxide electrical contact material

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

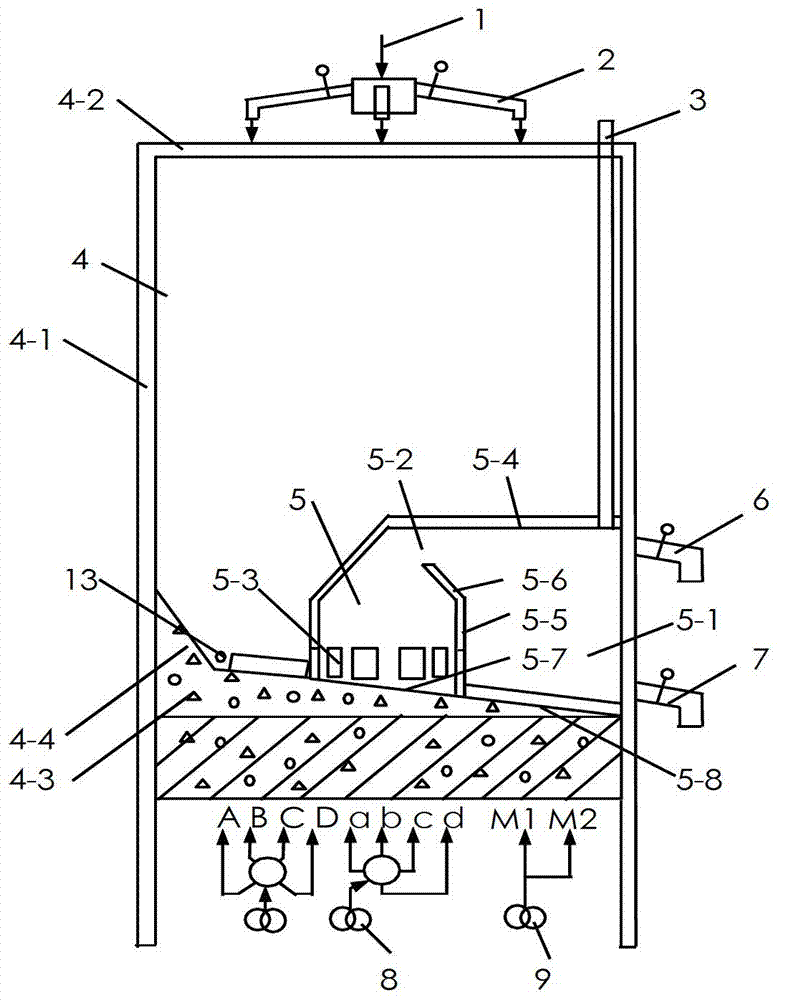

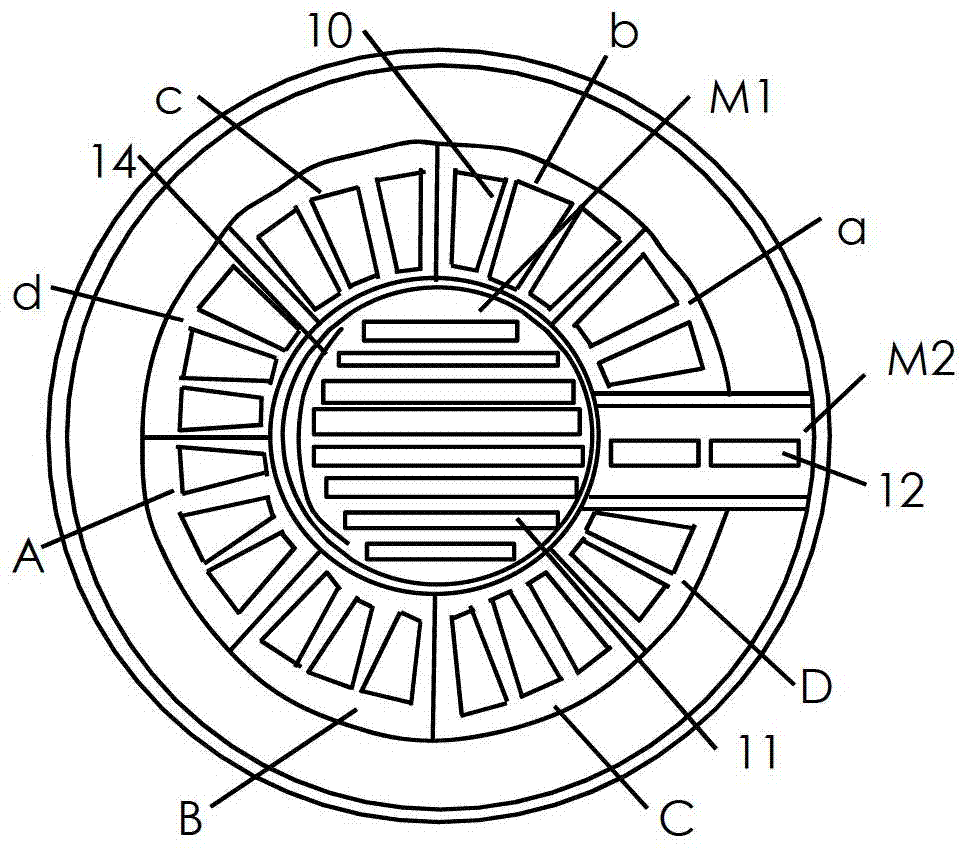

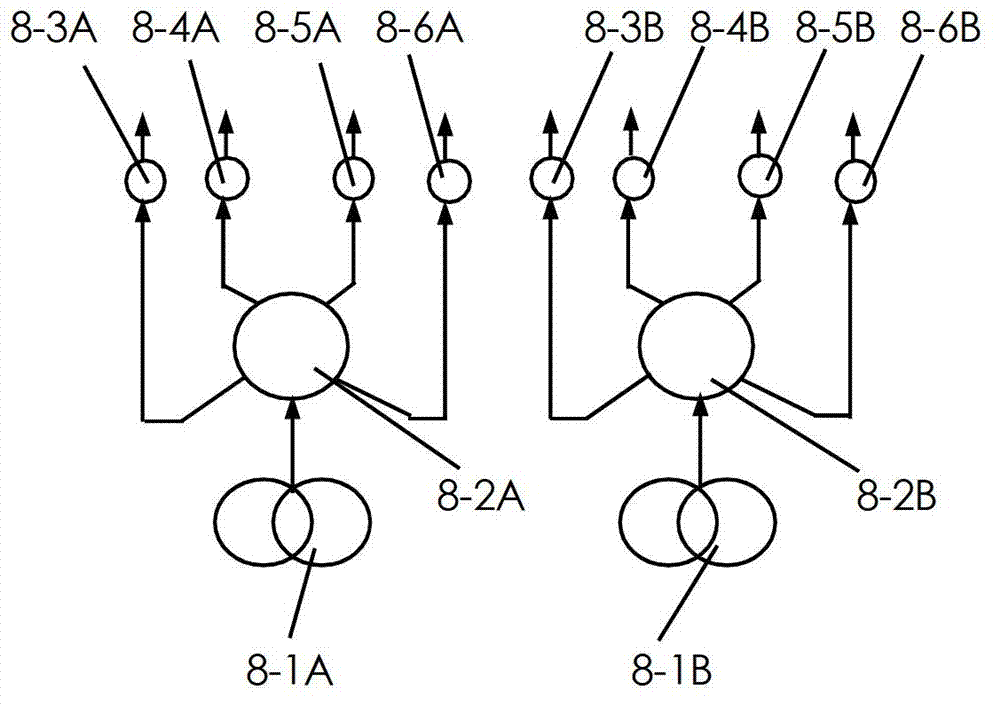

Device and method for homogenizing oil shale powder

ActiveCN103394302AHighlight Substantial ProgressThe composition is uniform and stableTransportation and packagingMixersOil shalePetroleum engineering

The invention discloses a device and a method for homogenizing oil shale powder. The device is characterized by mainly comprising a round bin, and a homogenizing chamber, a discharging chamber, a high-position unloading device, a low-position unloading device, a soft inflation system, a forced inflation system, a plurality of open type inflation boxes and a roots blower which are arranged in the round bin. By using the device, inflation air passing through the inflation boxes enters the oil shale powder in the round bin so as to be uniformly and fully mixed with the oil shale powder; then the mixed oil shale powder is continuously unloaded by the high-position unloading device connected with the round bin; as the device and the method are used, the fluctuation range of the oil content of the oil shale powder can be reduced to be below + / -0.2%, and the homogenizing coefficient can be up to 8-13.

Owner:SHENYANG XINBO IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com