Method for processing waste glass fiber filament powder material

A glass fiber and processing method technology, which is applied to the processing field of glass fiber waste silk powder, can solve the problems of limiting the use amount of glass fiber waste silk, low efficiency of fiber silk powder formation, clogging of dust collection system, etc. Large-scale processing, beneficial to production management, and the effect of increasing the intensity of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Stir the Portland cement according to 25% of the water consumption, form a cement slurry after fully stirring and let it stand for 5 hours, then take its supernatant;

[0036] (2) Soak glass fiber waste silk in a mixed solution composed of NaOH solution and cement slurry supernatant for 13 hours. The mass concentration of NaOH in the mixed solution is 4%, and the soaking temperature is 70°C. After being washed with tap water, it is crushed. The broken glass fiber waste is 2 cm, and it is dried in a drying furnace at 400 °C;

[0037] (3) The dried glass fiber waste enters the pre-mill bin, enters the mill through a continuous feeder, and the ground powder enters the sieving machine, and the qualified powder enters the glass powder homogenization silo , It is required that the particle size of the sieved powder can pass through a 100 mesh sieve.

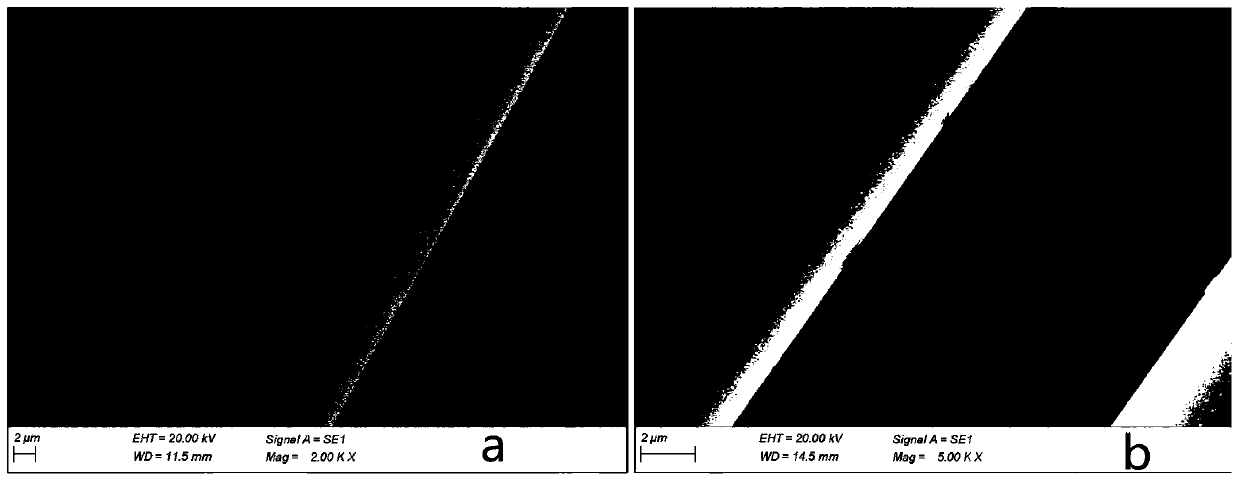

[0038] figure 1 It can be seen that the surface of glass fiber waste silk is smooth before treatment, and microcracks ap...

Embodiment 2

[0040] (1) Stir the slag portland cement according to 22% of the water consumption, form a cement slurry after fully stirring, let it stand for 3 hours, and take its supernatant;

[0041] (2) Soak glass fiber waste in Ca(OH) 2 Solution and cement slurry supernatant were soaked in the mixed solution for 2h, the Ca(OH) in the mixed solution 2 The mass concentration is 1%, the soaking temperature is 30°C, the soaked glass fiber is washed with tap water and crushed, the broken glass fiber waste is 1cm, and it is dried in a drying furnace at 120°C;

[0042] (3) The dried glass fiber waste enters the pre-mill bin, enters the mill through a continuous feeder, and the ground powder enters the sieving machine, and the qualified powder enters the glass powder homogenization silo , It is required that the particle size of the sieved powder can pass through a 100 mesh sieve.

Embodiment 3

[0044] (1) Stir the composite Portland cement according to 28% of the water consumption, form the cement slurry after fully stirring, let it stand for 12 hours, and take its supernatant;

[0045] (2) Soak glass fiber waste silk in a mixed solution composed of KOH solution and cement slurry supernatant for 24 hours. The mass concentration of NaOH in the mixed solution is 15%, and the soaking temperature is 150°C. After being washed with tap water, it is crushed, and the broken glass fiber waste is 3 cm, and it is dried in a drying furnace at 650 °C;

[0046] (3) The dried glass fiber waste enters the pre-mill bin, enters the mill through a continuous feeder, and the ground powder enters the sieving machine, and the qualified powder enters the glass powder homogenization silo , It is required that the particle size of the sieved powder can pass through a 100 mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com