Patents

Literature

707results about How to "Brittle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Method for preparing TC4 titanium alloy ingot casting through electron beam cold bed hearth smelting

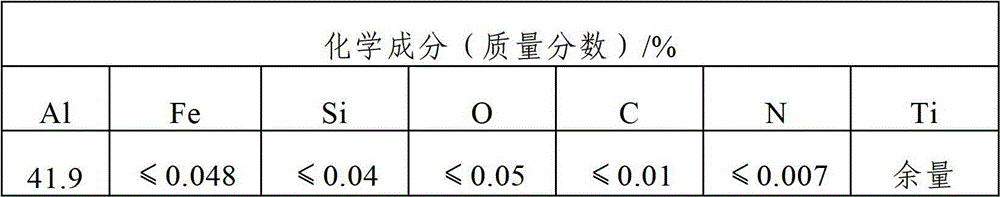

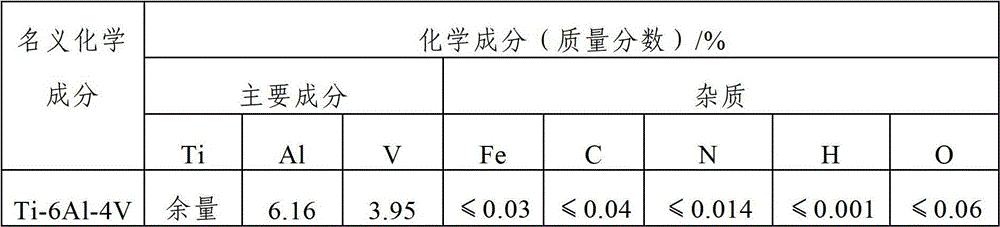

The invention discloses a method for preparing TC4 titanium alloy ingot casting through electron beam cold bed hearth smelting. The method comprises steps as follows: 1, uniformly mixing sponge titanium and aluminum shot, pressing to obtain electrode slabs, and welding to obtain an electrode, then transferring into a vacuum consumable electro-arc furnace to smelt once to obtain Ti-Al intermediate alloy; 2, crushing the Ti-Al intermediate alloy to obtain Ti-Al intermediate alloy particles; and 3, uniformly mixing the sponge titanium, the Al-V intermediate alloy and the Ti-Al intermediate alloy particles, pressing to obtain electrode slabs, and splicing the electrode slabs to obtain the electrode, and then transferring into an electron beam cold bed hearth to smelt once to obtain the TC4 titanium alloy ingot casting. According to the method, the Ti-Al intermediate alloy is used for replacing the aluminum shot, so that volatilization of an Al element is reduced, utilization rates of raw materials are improved, and service efficiency of the electron beam cold bed hearth is improved; the method has stronger advantages of reducing processing cost of a titanium material and improving production efficiency, because the electron beam cold bed hearth is adopted for one-time smelting; and cleanliness of the titanium alloy ingot casting can be improved, so that a high-quality ingot casting can be obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

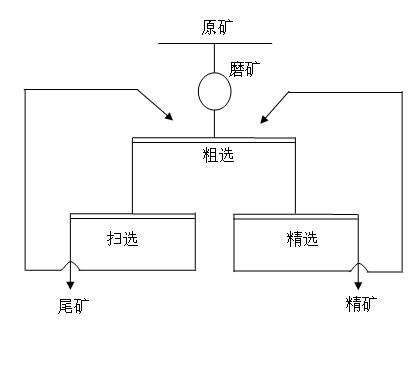

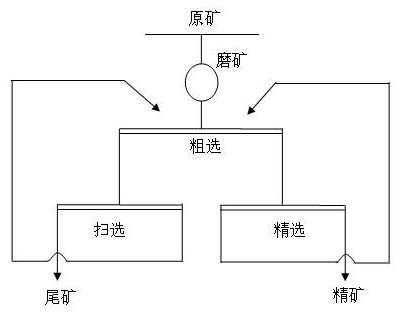

Method for dressing, desilicication and desulfuration of sulfur-containing bauxite

The invention discloses a method for the dressing, desilicication and desulfuration of sulfur-containing bauxite, which relates to a method for the dressing, desilicication and desulfuration of low-quality sulfur-containing bauxite and is characterized in that: a dressing process to mill the sulfur-containing bauxite, regulate the pH to 3 to 6 by using sulfuric acid, add an inhibitor, an activator, a silicate mineral collector and a sulfur-containing gangue collector in turn, stir, perform size mixing and perform flotation; and after flotation, the silicate minerals and sulfur-containing gangue in a major part of the sulfur-containing bauxite are enriched in foam as tailings, and the ore pulp obtained after flotation is used as concentrate. When the method disclosed by the invention is used, the synchronous dressing, desulfuration and desilicication of the sulfur-containing bauxite can be realized quickly. The method has the characteristics of short flow and simple process.

Owner:河南华慧有色工程设计有限公司 +1

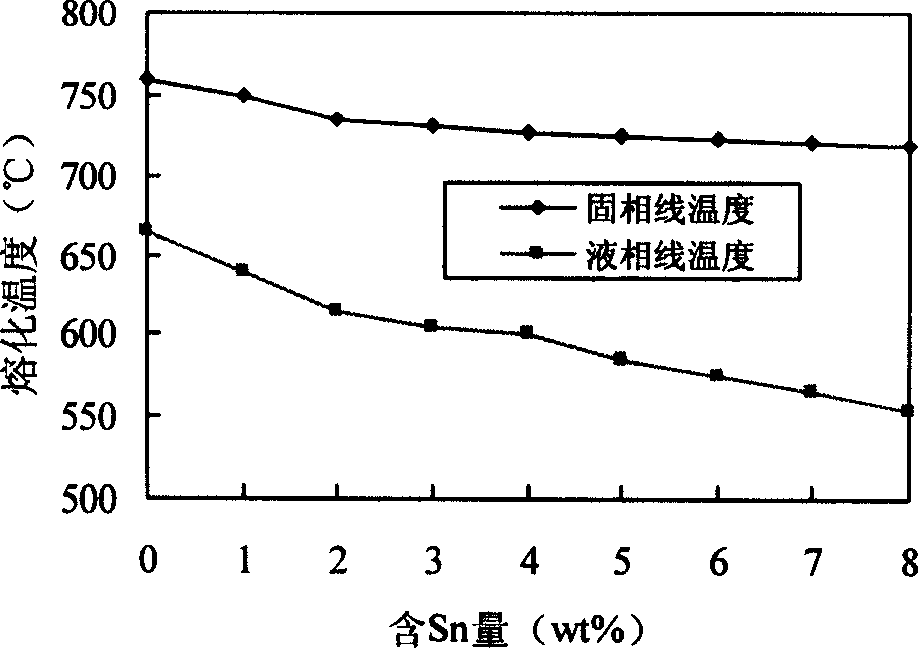

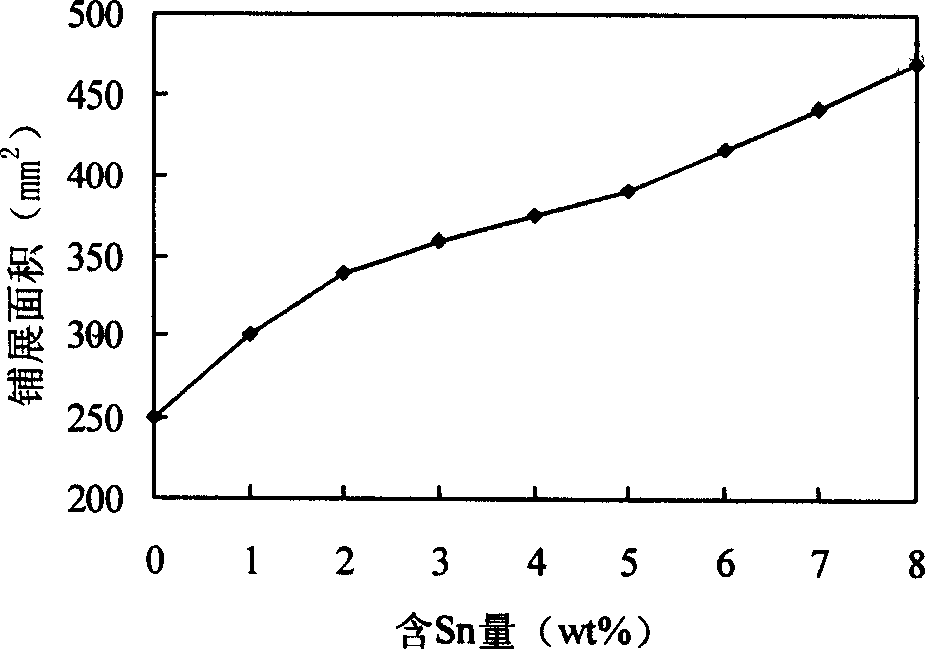

Silver free copper-base brazing filler metal used for braze welding of stainless iron/copper/stainless steel

InactiveCN101693326AImprove liquidityBrittleWelding/cutting media/materialsSoldering mediaWeld seamDissimilar metal

The invention relates to silver free copper-base brazing filler metal used for the braze welding of stainless iron / copper / stainless steel. The brazing filler metal comprises the following element components in percentage by weight: 5.0-7.0 P, 1.0-10 Sn, 0.1-2.0 Si, 0.1-1.0 Zr, 0.05-0.5 La and the balance of Cu. The silver free copper-base brazing filler metal is applied to the high frequency induction pressure braze welding for accomplishing the large area composite braze welding of dissimilar metal, such as stainless iron / copper / stainless steel, by one time, the welding seam shearing strength taub is higher than or equal to 100 MPa, the cost of the brazing filler metal is only one fifth to one fourth of Ag Cu Zn Sn or Ag Cu Zn Sn Cd, and the silver free copper-base brazing filler metal is applicable to the large-scale production of ferromagnetic double-bottom pans.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

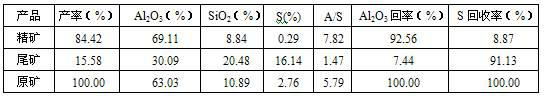

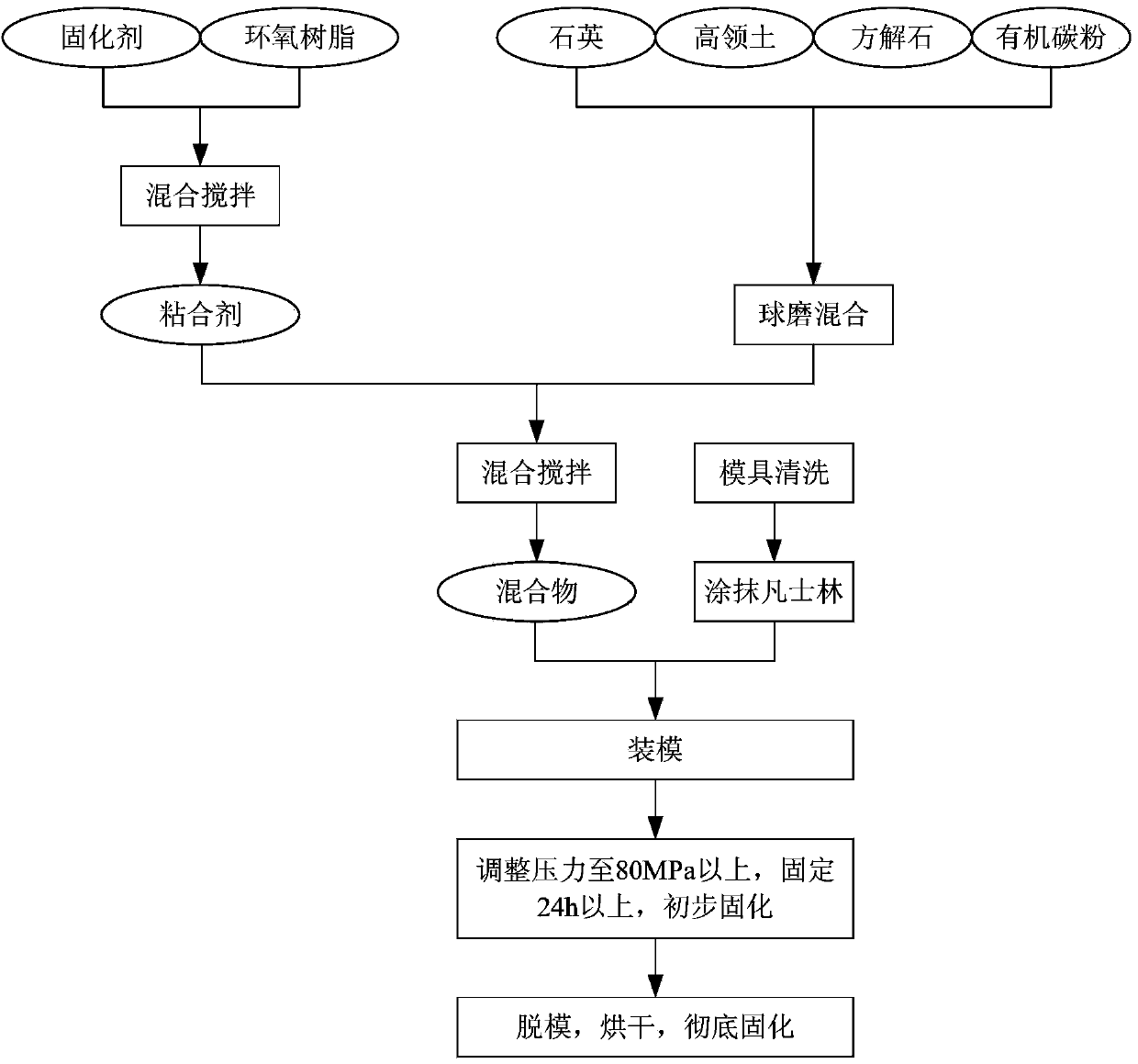

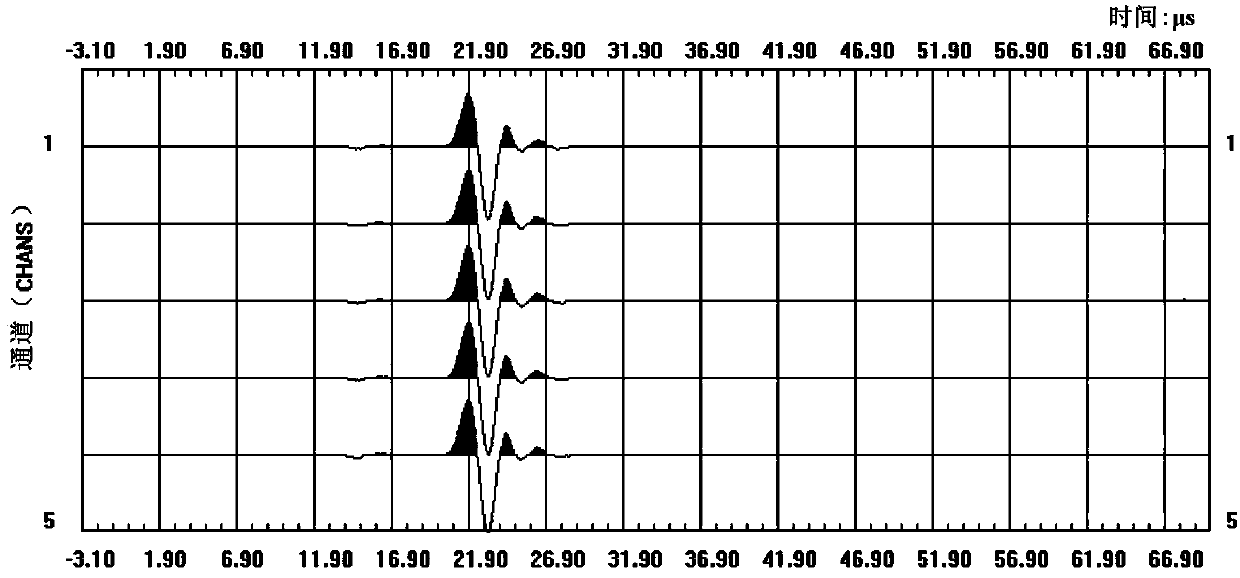

Manual shale physical model and manufacturing method and application thereof

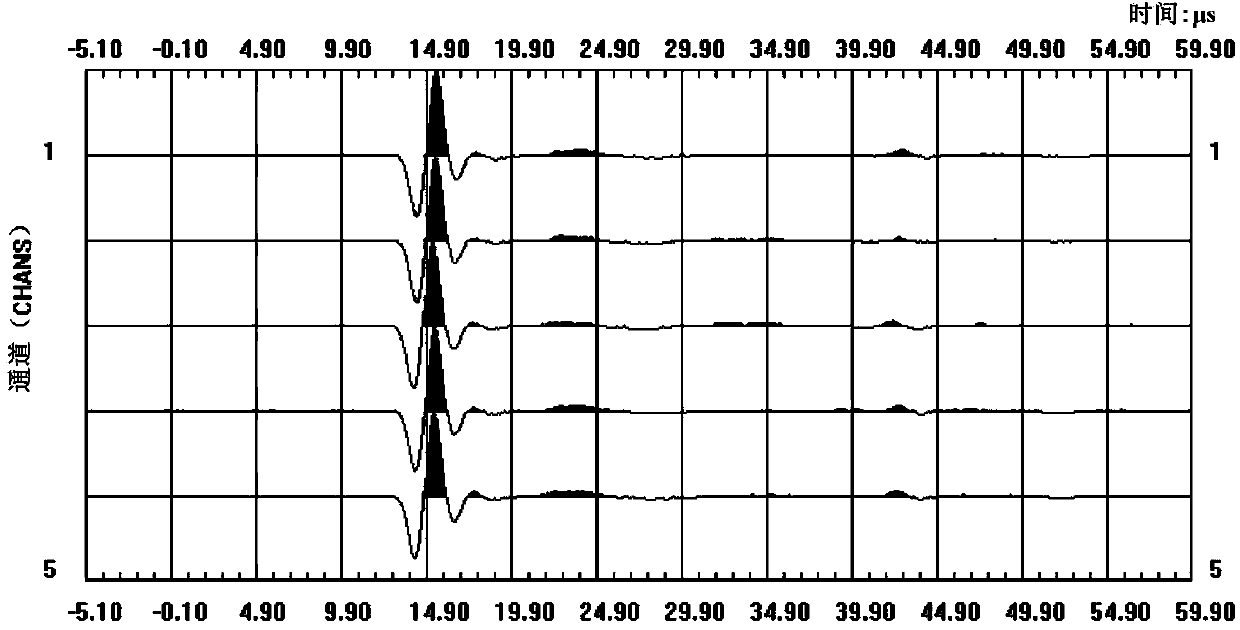

ActiveCN104007463ASignificant shear wave anisotropySignificant longitudinal wave anisotropySeismologyEpoxyPorosity

The invention provides a manual shale physical model and a manufacturing method and application of the manual shale physical model. The manufacturing method of the manual shale physical model includes the first step of mixing adhesives and stone powder evenly, wherein the adhesives are epoxy resin adhesives, the stone powder comprises 10%-70% of quart, 10%-80% of kaoline, 4%-25% of organic carbon powder and 3%-10% of calcite, and the use amount of the adhesives is 5%-35% of the total mass of the stone powder, the second step of filling a mould with mixtures of the adhesives and the stone powder, placing and fixing the mould on a pressure gauge horizontally, adjusting the perpendicular pressure intensity to 80-300 MPa, fixedly placing the mould for more than 24 hours for preliminary solidifying, and the third step of demoulding, drying a shale sample subjected to preliminary solidifying at the temperature ranging from 30 DEG C to 50 DEGC and obtaining the manual shale physical model. The obtained manual shale physical model is compact, has specific porosity and density, has anisotropic characteristics, has transverse isotropic characteristics and can provide a reliable basis for comparison and verification of research results of actual shale reservoir strata.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

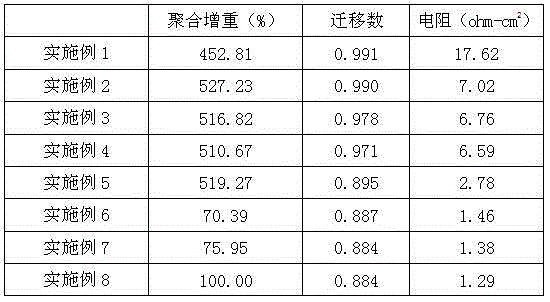

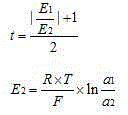

Method for preparing homogeneous phase ion exchange membrane

InactiveCN104610558AImprove surface propertiesImprove hydrophilicitySemi-permeable membranesCation exchanger materialsCross-linkFunctional monomer

The invention discloses a method for preparing a homogeneous phase ion exchange membrane. The method comprises the following steps: (1) blending a functional monomer, a cross-linking agent and an initiator into a uniform solution, thereby obtaining a membrane liquid; (2) soaking a substrate into the membrane liquid to impregnate, taking out the substrate, and clamping between two thin clamps, thereby forming a composite body; (3) enabling the initiator to initialize polymerization reaction on the composite body at 60-120 DEG C, and peeling off the two thin clamps, thereby obtaining a polymerized membrane; (4) putting the polymerized membrane into a chlorosulfonic acid chloroform solution for sulfonation treatment, after the sulfonation treatment, soaking in a NaCl solution, after being soaked, washing with water, and drying, thereby obtaining a Na type cation exchange membrane, or putting the polymerized membrane into a trimethylamine solution, performing amination treatment at 20-40 DEG C, after the amination treatment, soaking in the NaCl solution, after being soaked, washing with water, and drying, thereby obtaining a Cl type anion exchange membrane. The cation exchange membrane prepared by using the method is low in surface resistance, high in transference number and relatively high in selectivity.

Owner:SHANDONG TIANWEI MEMBRANE TECH

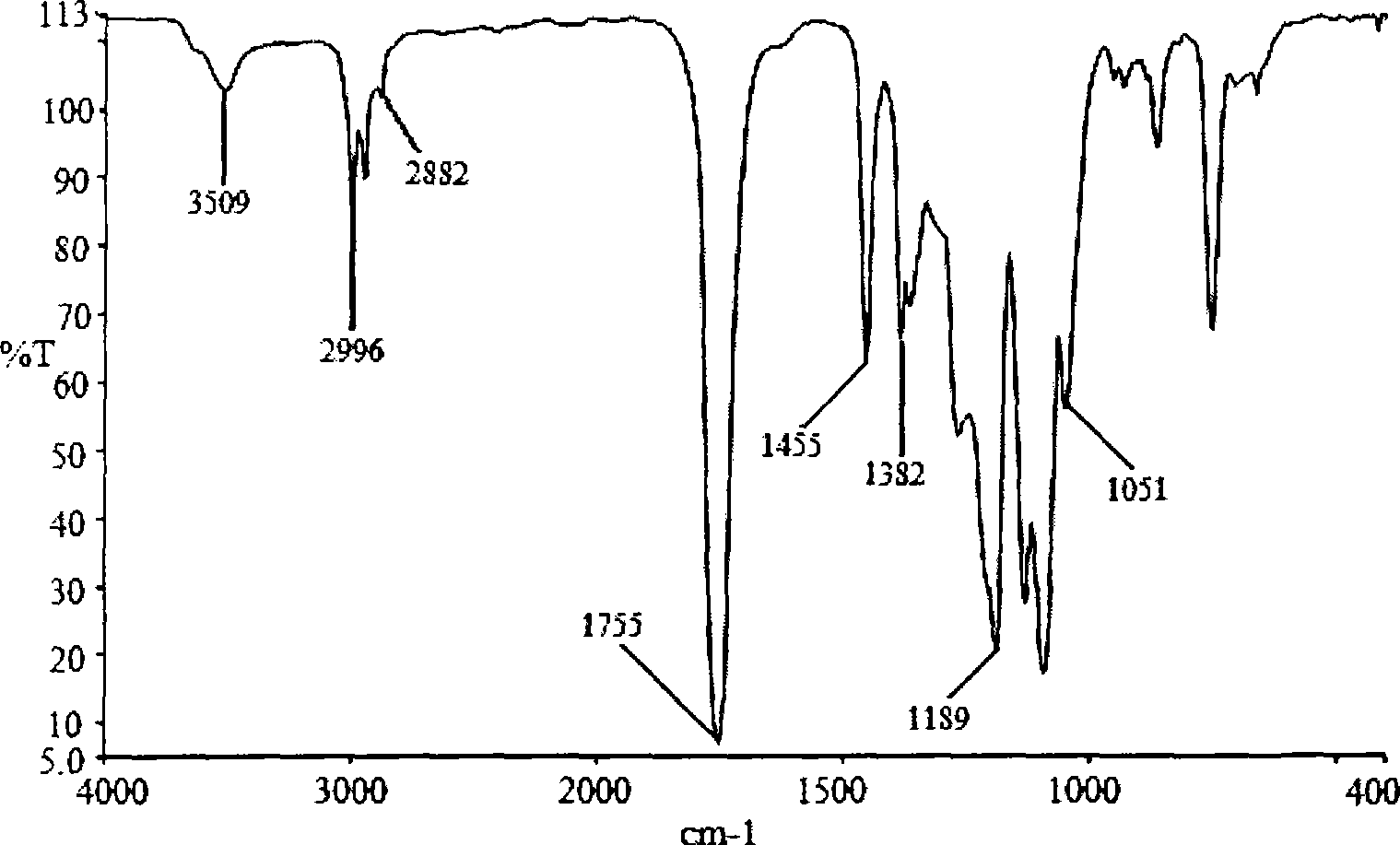

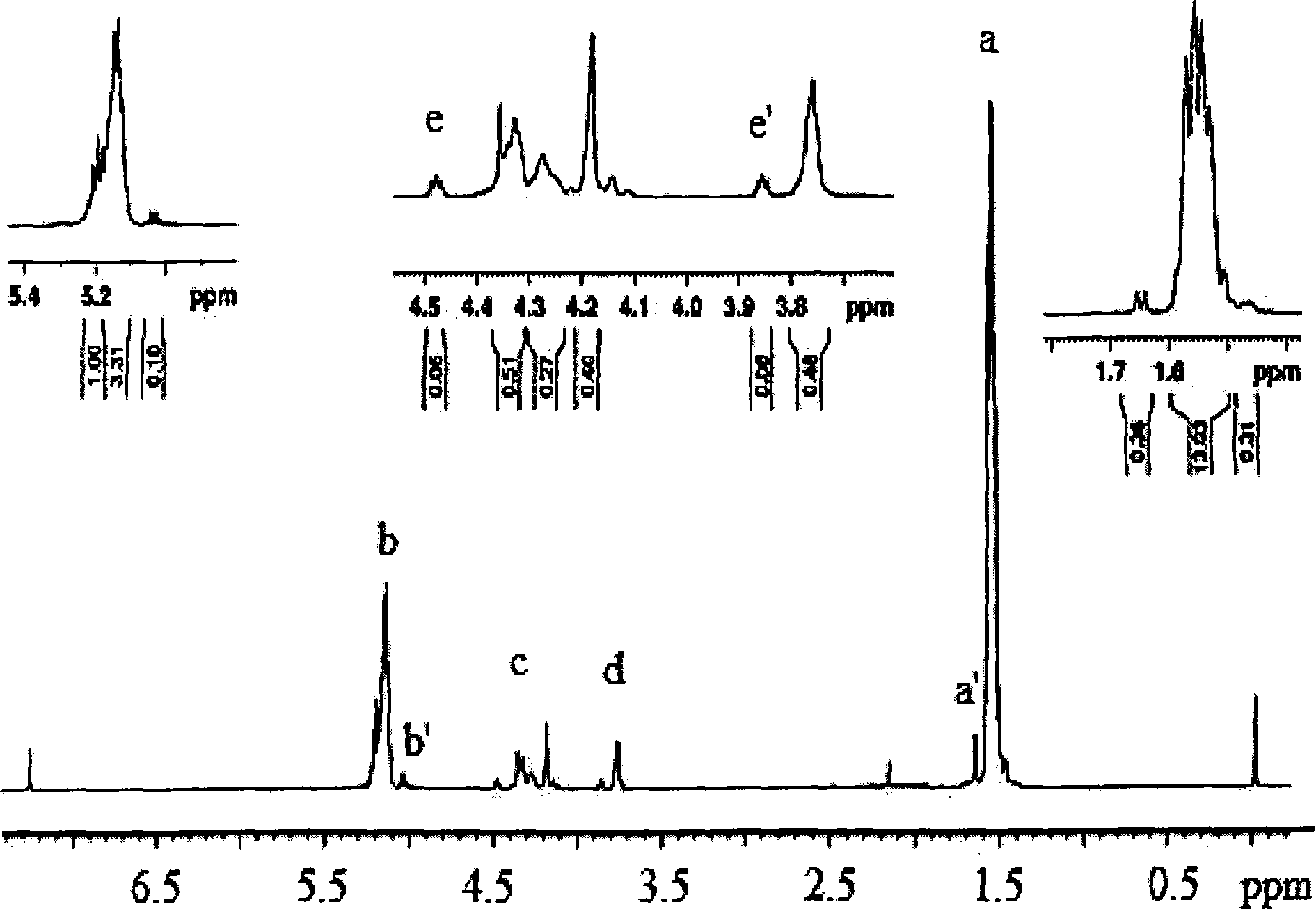

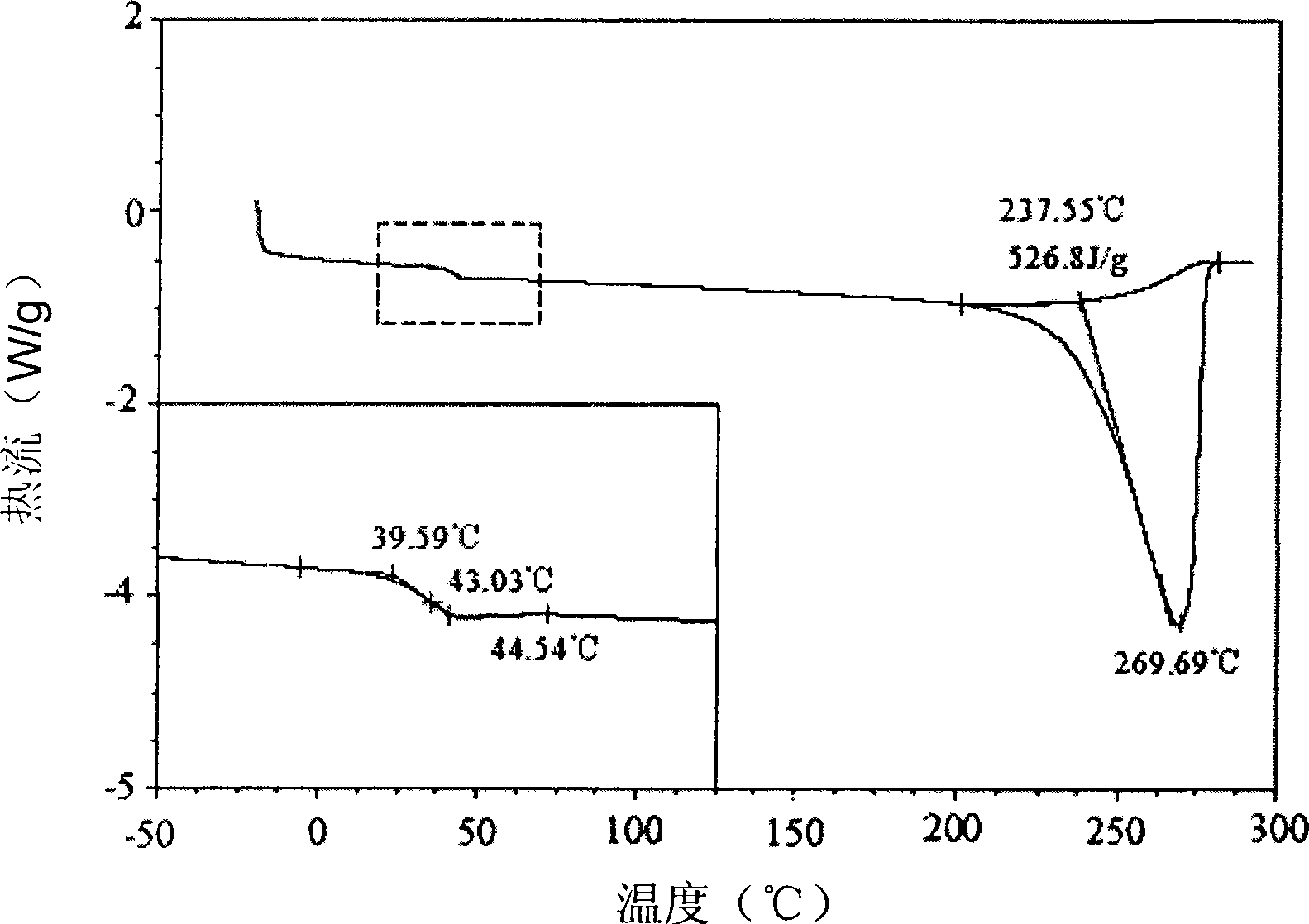

Multi-block polyurethane shape memory high molecule material and preparation method thereof

The invention provides a multi-block polyurethane shape memory polymer material based on lactide and 1, 4-dioxegy cyclohexanone. The polymer material takes hydroxyl terminated poly (lactide-co-1, 4-dioxegy cyclohexanone) as a soft block; a PUU chain segment or uramido chain segment product which is formed by vulcabond and bifunctional micromolecules containing active hydrogen is chosen as a hard block. The temperature of the shape memory is within 20-55 DEG C. The invention further provides the preparation method of the material. The shape memory polymer material based on lactide and 1, 4-dioxegy cyclohexanone provided by the invention integrates good odegradability, biocompatibility, high mechanical strength, flexility and the shape memory performance together. The deformation temperature of the polymer material can be adjusted to be close to human body temperature; therefore, the polymer material is applied to surgical operations or medical appliance implantation materials.

Owner:CHONGQING UNIV +1

A kind of biodegradable composition and preparation method thereof

InactiveCN102295825AImproved hydrolysis resistance and thermal oxygen resistanceFast biodegradationConjugated synthetic polymer artificial filamentsArtifical filament manufactureCopolyesterPolymer chemistry

The invention discloses a biodegradable composition and a preparation method thereof, which consist of a biodegradable homopolyester (A), a biodegradable copolyester (B) and a chain extender (C), the total weight of which is 100 parts by mass Calculated, containing (A+B) is 95.0~99.9 parts and containing C is 0.1~5.0 parts, wherein the ratio of A:B is in the range of 1:9~9:1. The present invention finds that the compounding of biodegradable homopolyester with faster biodegradation rate and biodegradable copolyester with better processability in different proportions can not only endow the composition with proper biodegradation rate, but also improve the composition The physical properties and processing performance can be properly adjusted according to the requirements of different processing and application fields; we also found that by introducing a chain extender with long chain characteristics into the biodegradable resin composition, the combination after chain extension can be avoided It can prevent unnecessary gel phenomenon during processing and improve the heat resistance and stability of the material.

Owner:KINGFA SCI & TECH CO LTD +2

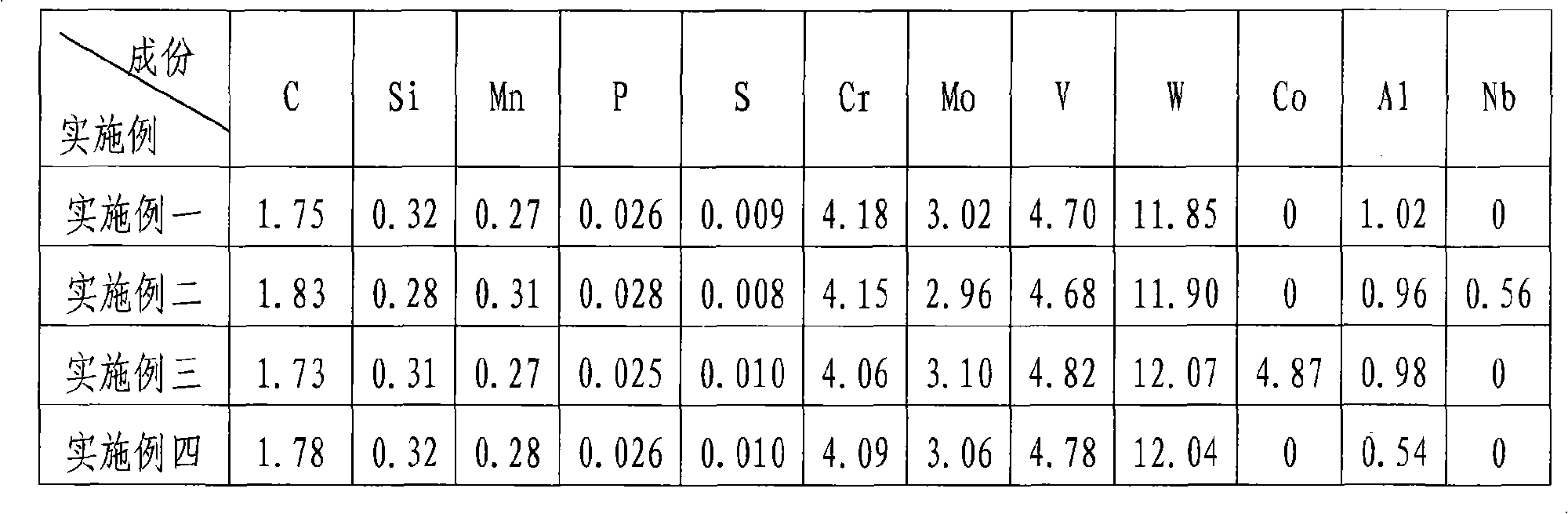

High-hardness high-wear-resistant powder metallurgy high-speed steel

The present invention relates to high-performance high-speed steel, and particularly to a high-hardness high-wear-resistant powder metallurgy high-speed steel which is manufactured according to a power metallurgy method and contains Al. The high-speed steel is composed of C, Si, Cr, Mo, V, W, Nb, Mn, Co, Al, Fe and impurities. The high-speed steel manufactured according to the technical solution has the following advantages: more than 67.5HRC of quenching-tempering hardness, better red hardness and wear resistance, stronger bending strength and lower cost.

Owner:HEYE SPECIAL STEEL

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

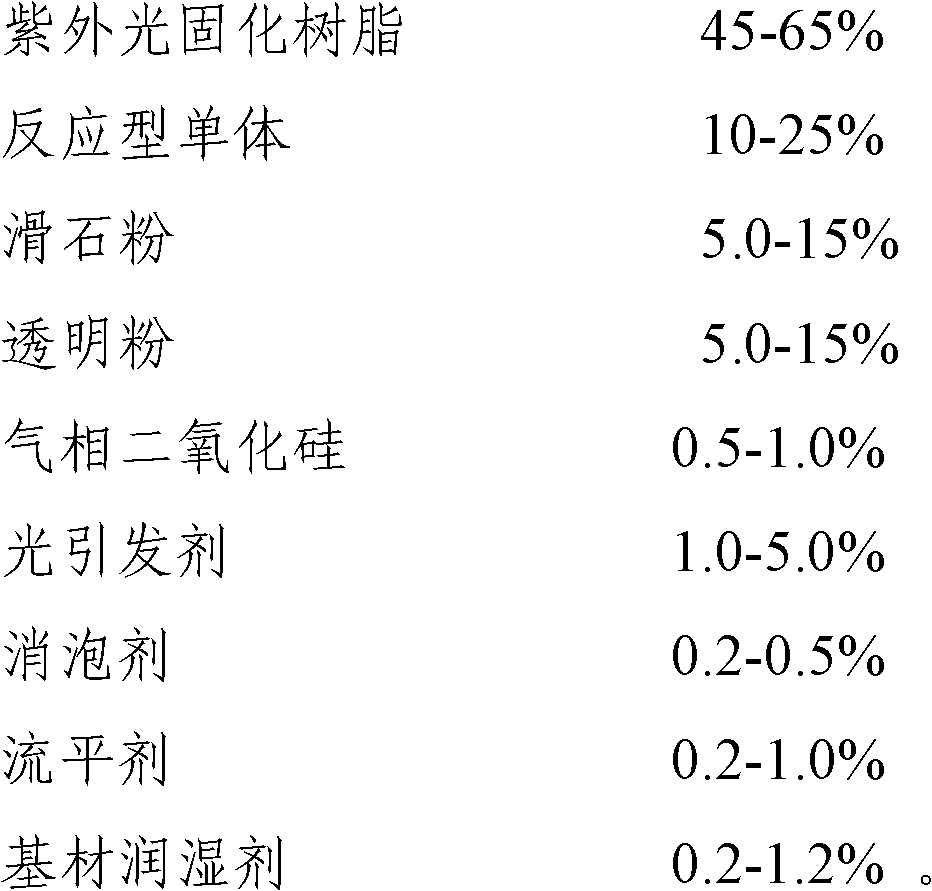

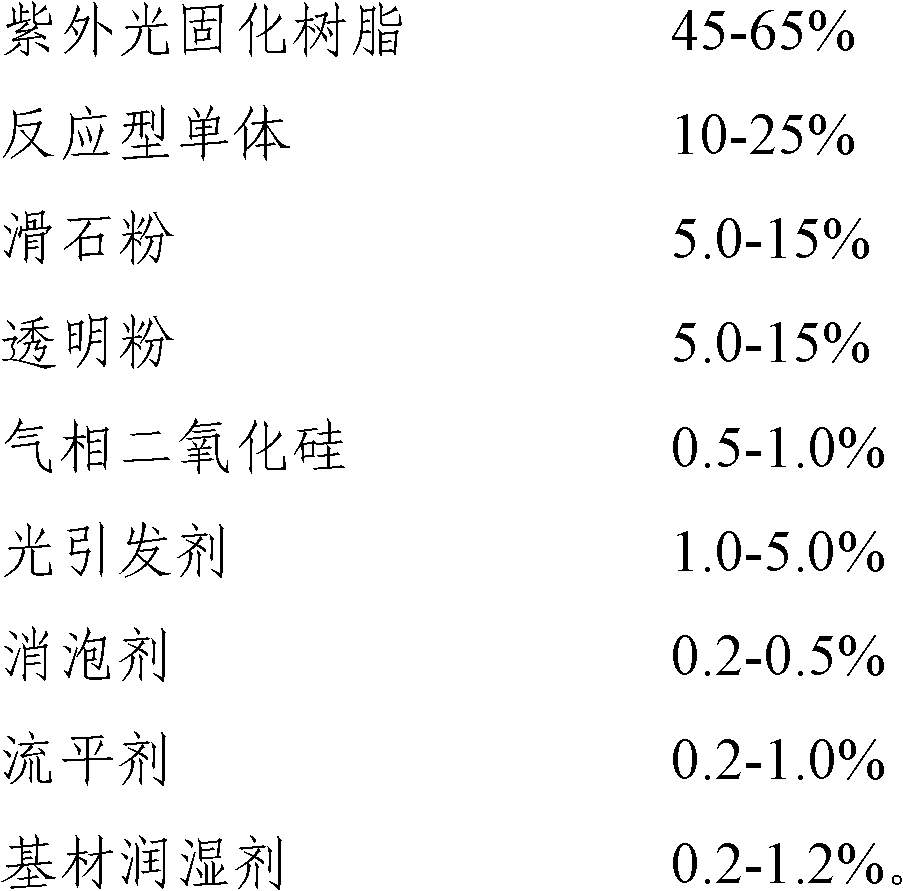

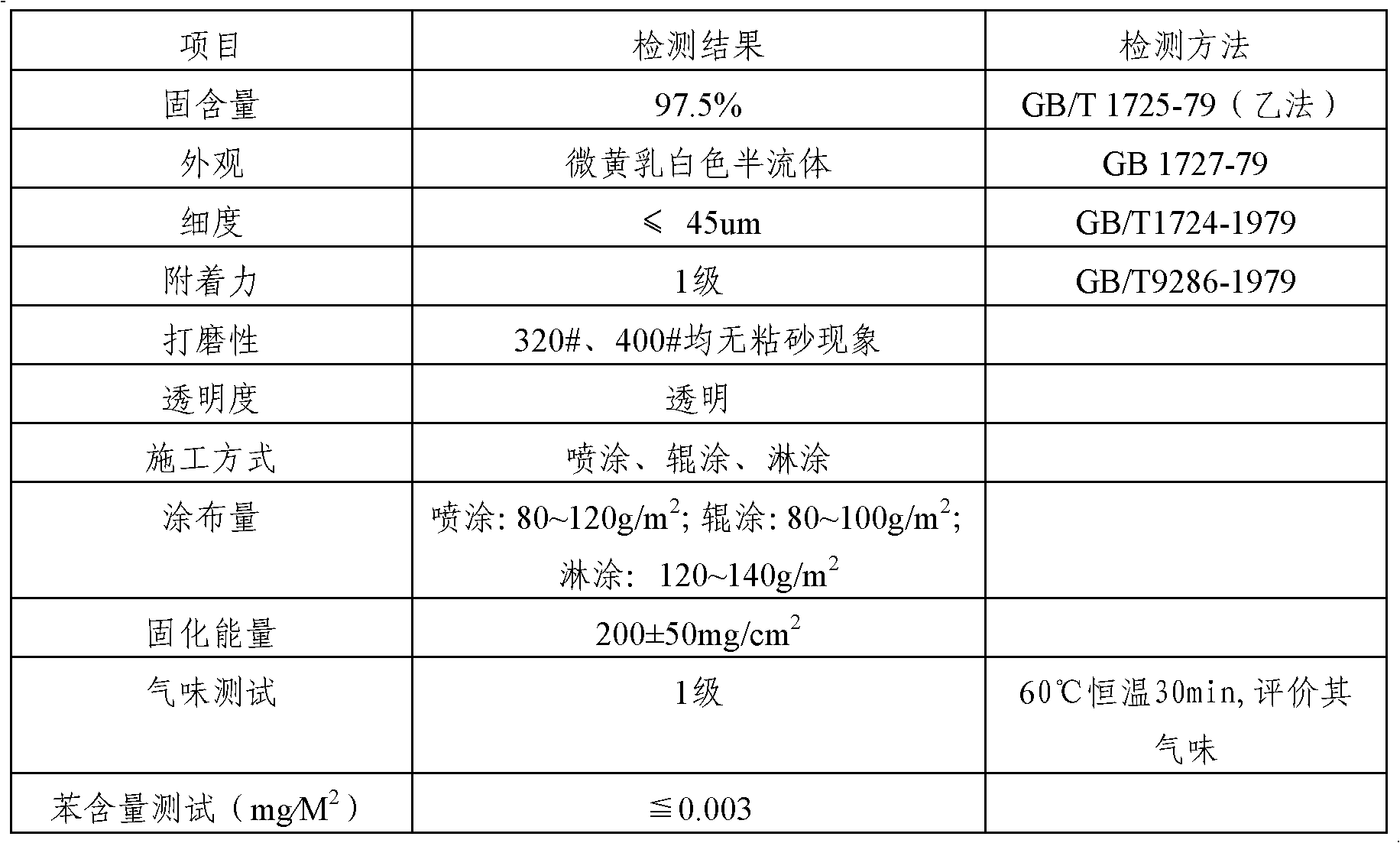

Odorless ultraviolet-curing wood lacquer and preparation method thereof

ActiveCN102352173AEnvironmental protection is goodReduce heavy metal contentEpoxy resin coatingsPolyesterBenzene

The invention relates to an odorless ultraviolet-curing wood lacquer and a preparation method thereof. The wood lacquer is prepared from the following components in percentage by weight: 45-65% of ultraviolet-curing resin, 10-25% of reactive monomer, 5.0-15% of talcum powder, 5.0-15% of transparent powder, 0.5-1.0% of gas-phase silicon dioxide, 1.0-5.0% of photoinitiator, 0.2-0.5% of defoaming agent, 0.2-1.0% of leveling agent and 0.2-1.2% of wetting agent. The odorless ultraviolet-curing wood lacquer does not have irritating odor before and after construction, does not contain benzene, and can be used immediately after construction; and meanwhile, the surface effect and fullness are not inferior to those of nitrocellulose dope, unsaturated paint or polyester paint.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

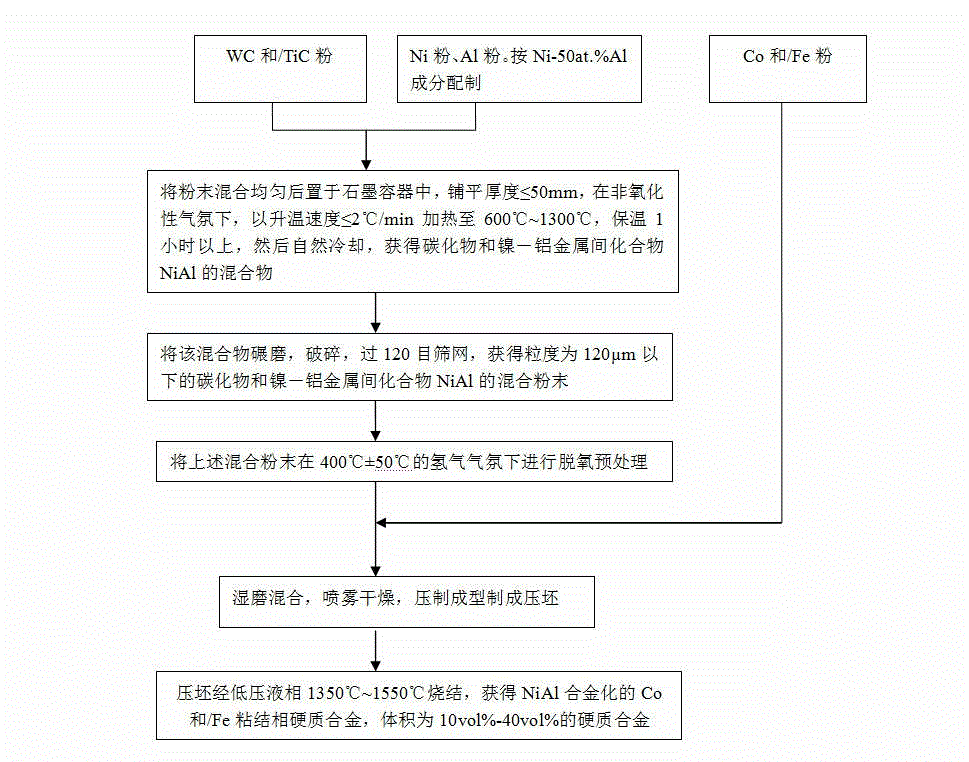

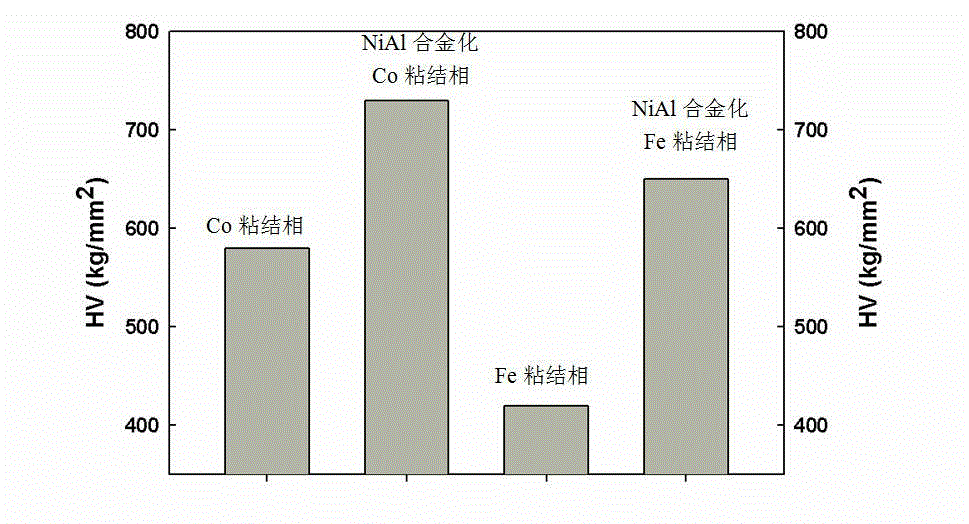

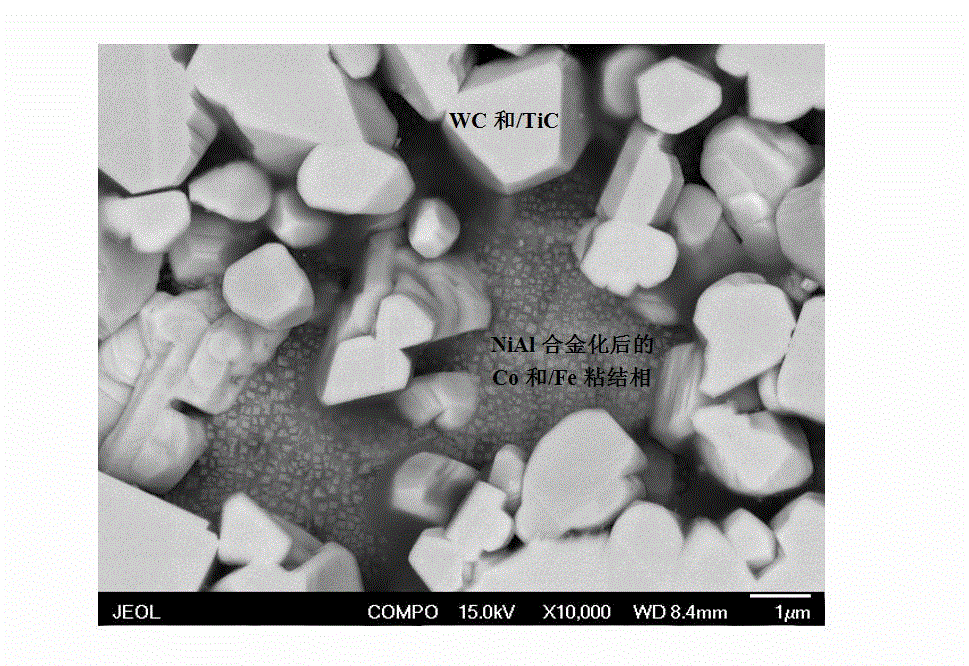

High-temperature-resistant and wear-resistant hard alloy and preparation method thereof

ActiveCN102978499AGuaranteed temperatureEnsure that the temperature of the powder does not exceed the temperatureHydrogen atmosphereWear resistant

The invention discloses a high-temperature-resistant and wear-resistant hard alloy with a NiAl alloying bonding phase. WC and / TiC is used as a hard phase, NiAl alloying Co and / Fe is used as a bonding phase, and the volume ratio of the hard phase to the bonding phase is equal to 10-40%. The preparation method comprises the following steps of: uniformly mixing 0.03-21.04wt% of nickel powder and aluminum powder with carbide powder based on the component proportion of Ni-50at.%Al; placing the mixture in a graphite container to spread out, heating the mixture to 660-1300 DEG C at a non-oxidative atmosphere, preserving heat, and then naturally cooling to obtain a mixture of a carbide and NiAl; grinding, crushing and screening to obtain mixed powder; carrying out deoxidation pretreatment at a hydrogen atmosphere of 400+ / -50 DEG C; carrying out wet grinding on 45.77-96.34wt% of mixed powder and the balance of Co and / Fe powder; carrying out spray-drying on the mixed material subjected to wet grinding and pressing; and sintering a compaction in a liquid phase at low pressure at the temperature of 1350-1550 DEG C to obtain the high-temperature-resistant and wear-resistant hard alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

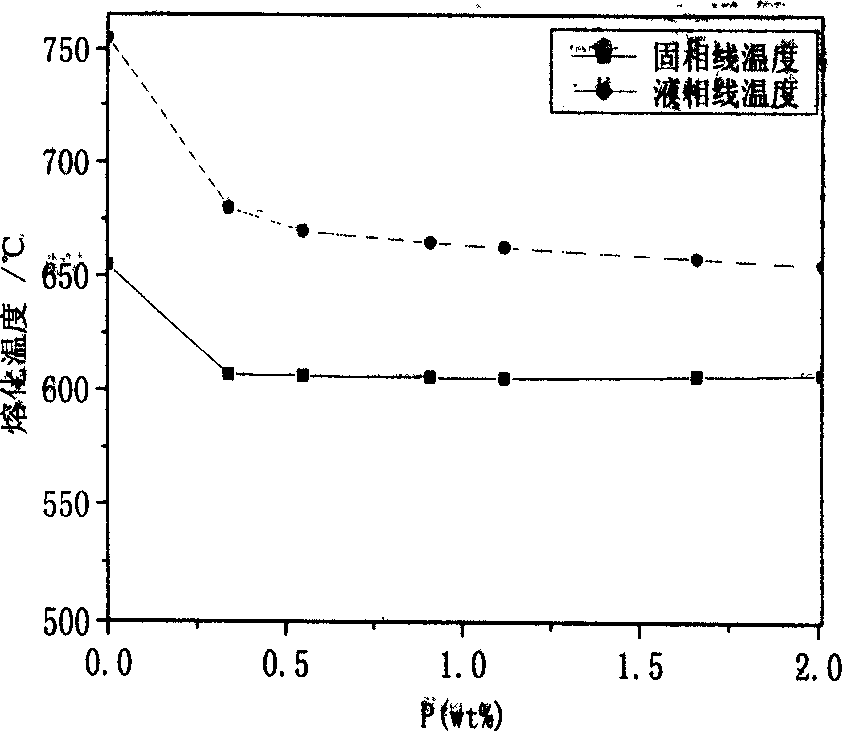

Medium temperature Ag base brazing filler metal and its preparing method

InactiveCN1616182ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCopperFiller metal

The medium temperature silver base brazing filler metal consists of: Ag 29.5-30.5 wt%, Zn 31.5-32.5 wt%, Mn 2.5-3.5 wt%, Sn 2.5-3.5 wt%, P 0.4-0.8 wt% and La 0.2-0.4 wt% except Cu. The preparation process includes the following steps: selecting material, material throwing and smelting, casting, extrusion and drawing. During the step of material throwing and smelting, electrolytic copper and P-Cu alloy are first heated quickly inside furnace for complete melting, covering agent is added, Zn, Cu-Mn alloy are added successively, Ag and Sn-La are added after lowering the temperature, and the temperature is finally raised to 1050-1100 deg.c while stirring before tapping. The product has the features of no harmful elements contained, relatively low cost, short production process, stable quality and raised extrusion and drawing finished product rate.

Owner:HARBIN INST OF TECH

Blast furnace smelting method by using vanadium-titanium two-phase sintering ore

ActiveCN104673951AReduce ironmaking costsImprove utilization factorBlast furnace detailsIronstoneBlast furnace smelting

The invention belongs to the technical field of iron and steel metallurgy, in particular relates to a blast furnace smelting method by using a vanadium-titanium two-phase sintering ore. The blast furnace smelting method by using vanadium-titanium two-phase sintering ore is characterized in that the blast furnace burden structure is as follows: 70-100wt% of vanadium-titanium two-phase sintering ore, 0-30wt% of vanadium titanium magnetite pellet and 0-10wt% of common iron ore, wherein the common iron ore is an iron ore containing no vanadium or titanium. The invention provides the blast furnace smelting method by using vanadium-titanium two-phase sintering ore, and the method is low in cost; vanadium-titanium titanic magnetite for blast furnace smelting is provided by the vanadium-titanium two-phase sintering ore, so as to optimize the blast furnace burden structure, improve the breathability of the blast furnace burden structure and perfect the technical-economic indicator of blast furnace smelting.

Owner:攀钢集团西昌钢钒有限公司

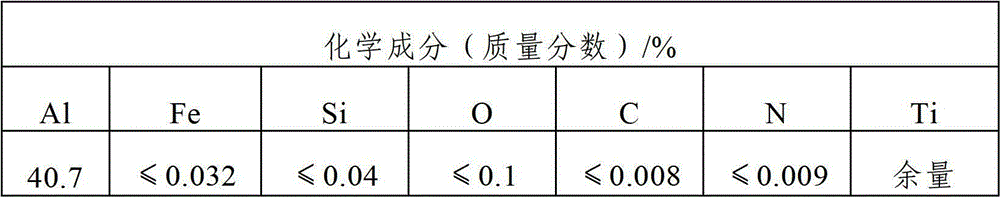

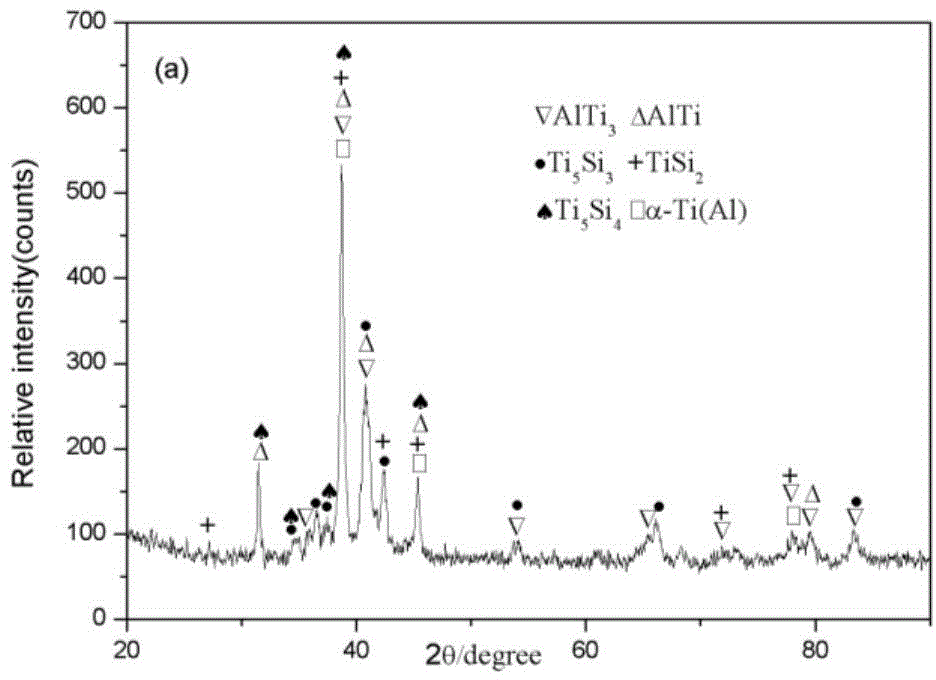

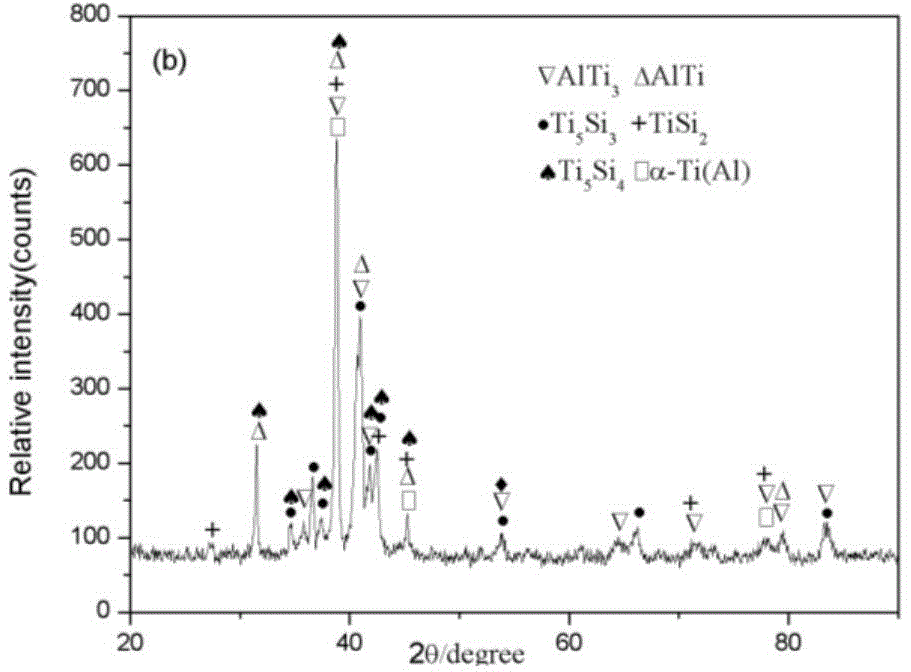

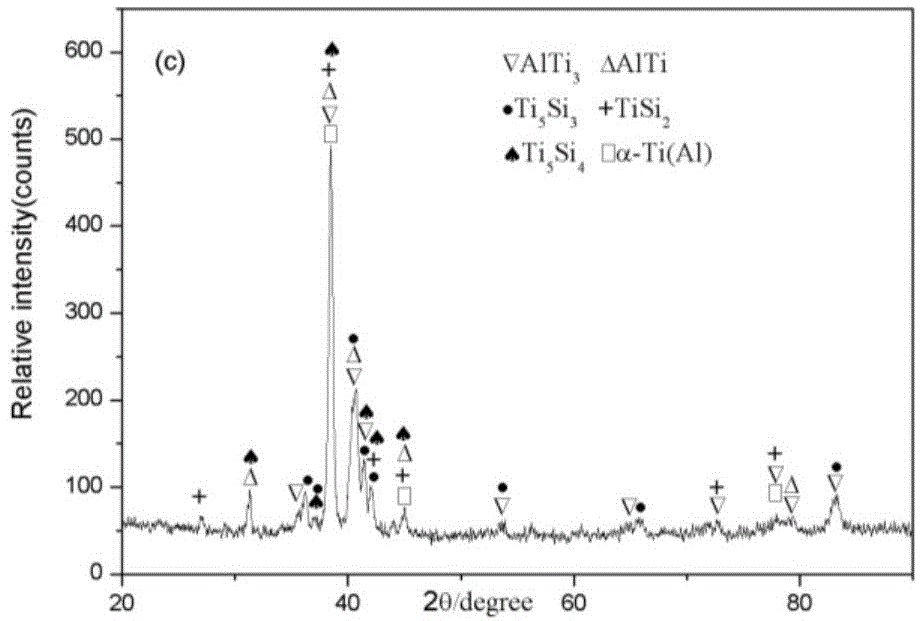

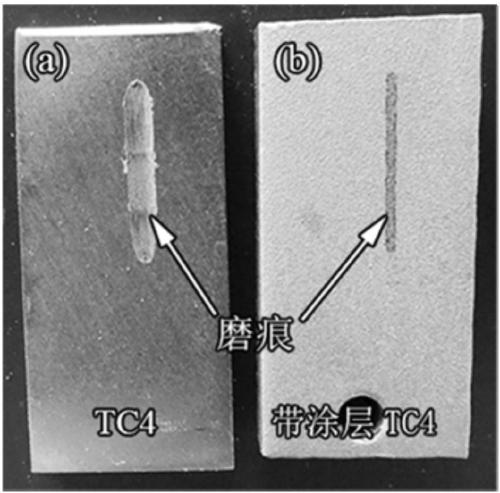

Preparation technology of intermetallic compound based ceramic composite coating on surface of titanium alloy

ActiveCN104152895AHigh hardnessGood metallurgical bondMetallic material coating processesCeramic compositeShielding gas

The invention discloses a preparation technology of an intermetallic compound based ceramic composite coating on the surface of a titanium alloy. The preparation technology comprises the following steps of: (1) uniformly mixing cladding material powder, preparing mixed powder into paste with a water glass solution, uniformly coating the surface of the titanium alloy with the paste with the coating thickness of 0.5-1.0mm, carrying out airing, and (2) carrying out laser cladding on the coating on the surface of the titanium alloy with the laser power of 800-1200W and the laser scanning speed of 2.5-7.5mm / s, and blowing argon for shielding with the shielding gas pressure of 0.2-0.4MPa, wherein a laser spot diameter is fixed at 4mm.The mixed cladding material powder comprises the following ingredients by mass percentage: 25-65% of Ti, 20-60% of Al, 5-30% of Si and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 2-40% of B4C and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 5-40% of TiC, and 0-3% of Y2O3. The composite coating prepared by the technology can significantly increase microhardness of the titanium alloy, improve wear resistance of titanium alloy components, and extend an application scope of titanium alloy spare parts.

Owner:SHANDONG UNIV

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

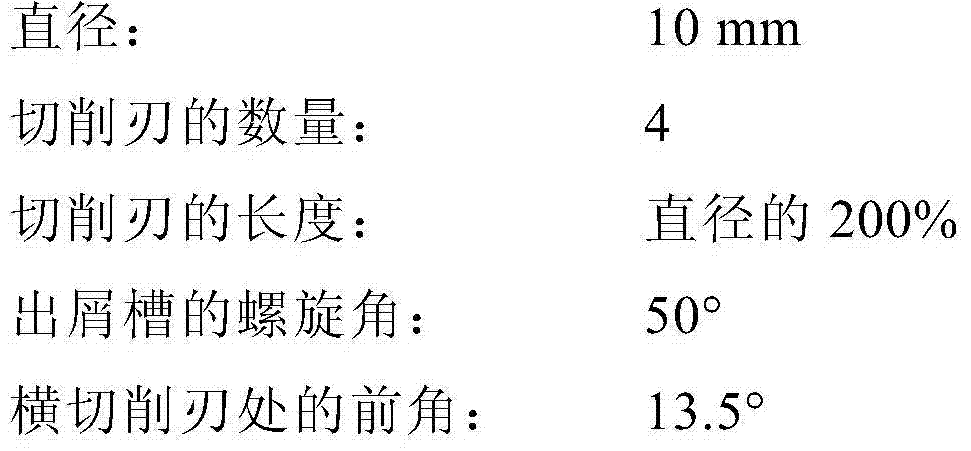

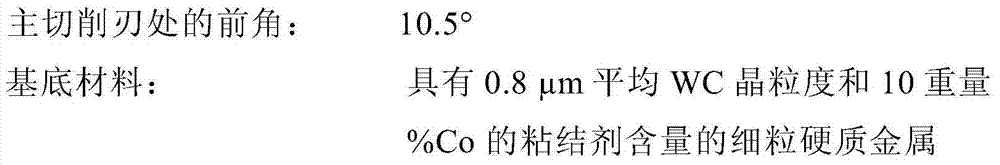

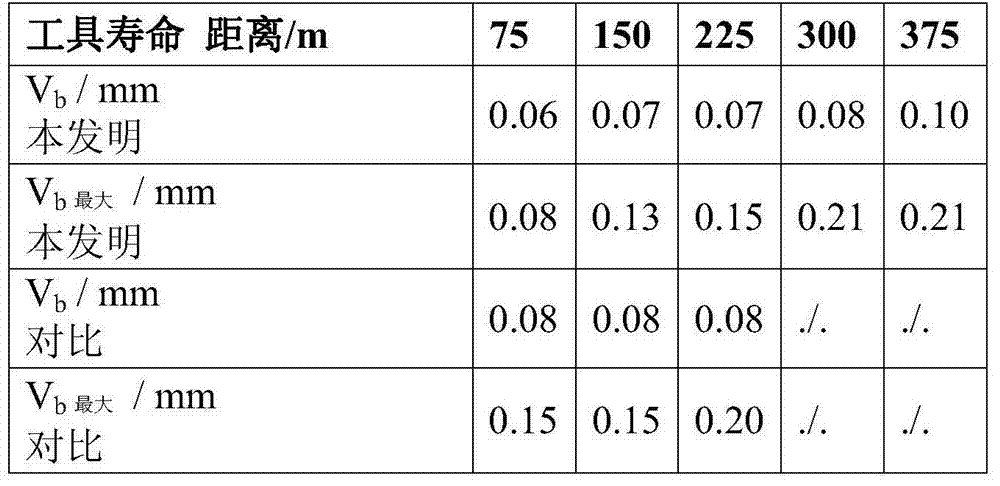

Tialn-coated tool

ActiveCN104520472ASmall sizeReduce crackingMilling cuttersVacuum evaporation coatingPeriodic alternatingWear resistant

A tool with a main body made of hard metal, cermet, ceramic, steel or high-speed steel and a single- or multi-layered wear resistant coating applied thereto in a PVD process, wherein at least one layer of the wear resistant coating is a titanium aluminium nitride layer, TixAlyN where x + y = 1, which can contain, depending on the process used, up to 5 percent by weight of further metals, characterised in that the TixAlyN layer is a multilayer substructure with a plurality of periodically alternating Tix (A)Aly(A)N layers (A), where x(A)+ y(A) = 1 and Tix(B)Aly(B)N layers (B), where x(B) + y(B) = 1, wherein the Al concentration y(B) in layers (B) is at most 70 atomic weight percent (y(B) <= 0.70), and wherein the Al concentration y(B) in layers (B) is 10 to 25 atomic weight percent higher than the Al concentration y(A) in layers (A) (y(B) = (y(A) + 0.10) to (y(A) + 0.25)).

Owner:WALTER AG

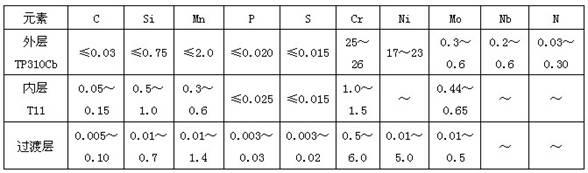

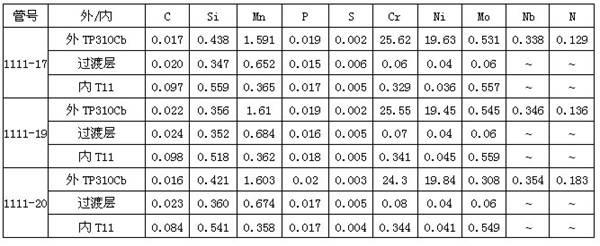

Centrifugally cast TP310Cb/T11 bimetal composite tube blank and method for producing same

InactiveCN102581250ABrittleAvoid ingredients that are out of toleranceStress concentrationHeat resistance

The invention discloses a centrifugally cast TP310Cb / T11 bimetal composite tube blank and a method for producing the same, which belong to the field of casting of tube blanks. The centrifugally cast TP301Cb / T11 bimetal composite tube blank comprises a tube blank inner layer, a tube blank outer layer and a tube blank transitional layer. The method includes controlling components of the inner layer, the outer layer and the transitional layer by means of controlling selection of a tube blank raw material at first; pouring the outer layer; then pouring the transitional layer; and finally pouring the inner layer. The transitional layer is fused with the outer layer, the inner layer is fused with the transitional layer, difference between the components of the outer layer and the components of the outer layer are relieved by the aid of the transitional layer, the purpose of completely fusing is achieved simultaneously, accordingly, interface stress between the inner layer and the outer layer is greatly relieved, stress concentration of interfaces of the inner layer and the outer layer is avoided, and the service life of the centrifugally cast TP310Cb / T11 bimetal composite tube blank is greatly prolonged. Simultaneously, conduction heat resistance of the inner layer and the outer layer is reduced by the aid of metallurgical fusion of the inner layer and the outer layer, and accordingly heat conduction efficiency of a bimetal tube is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

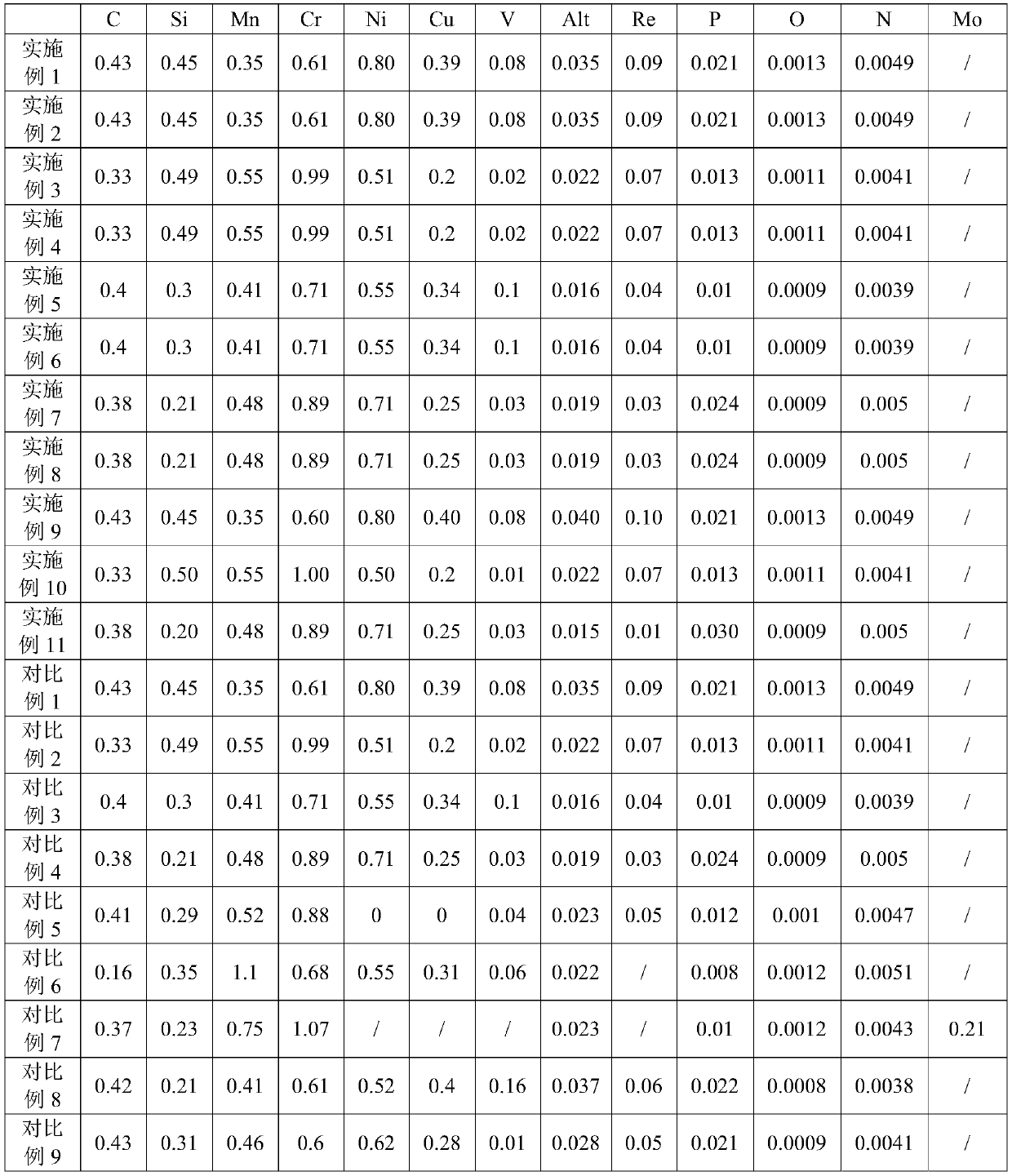

High-weather-resistant cold heading steel for 10.9 grade fastener and production method of high-weather-resistant cold heading steel

ActiveCN110923546AGood weather resistanceStrong adhesionTemperature control deviceFurnace typesChemical compositionWeather resistance

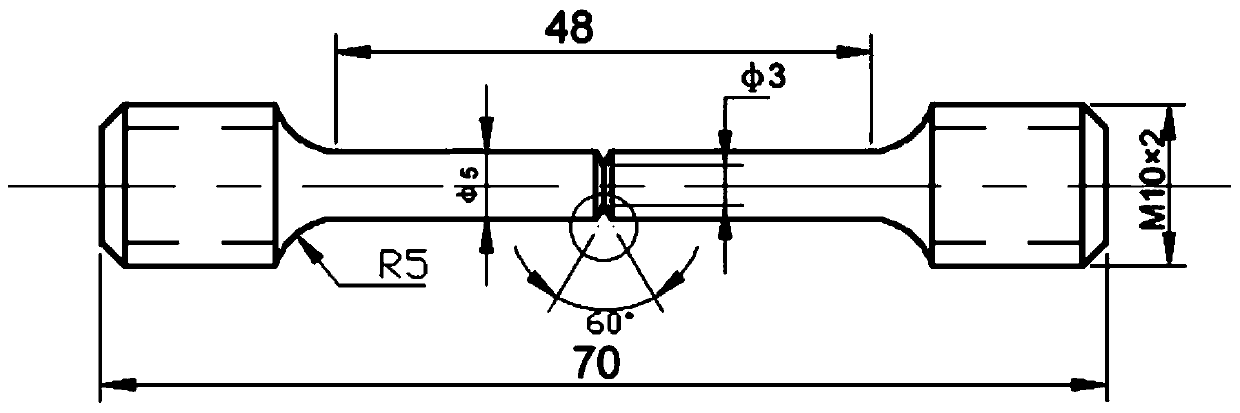

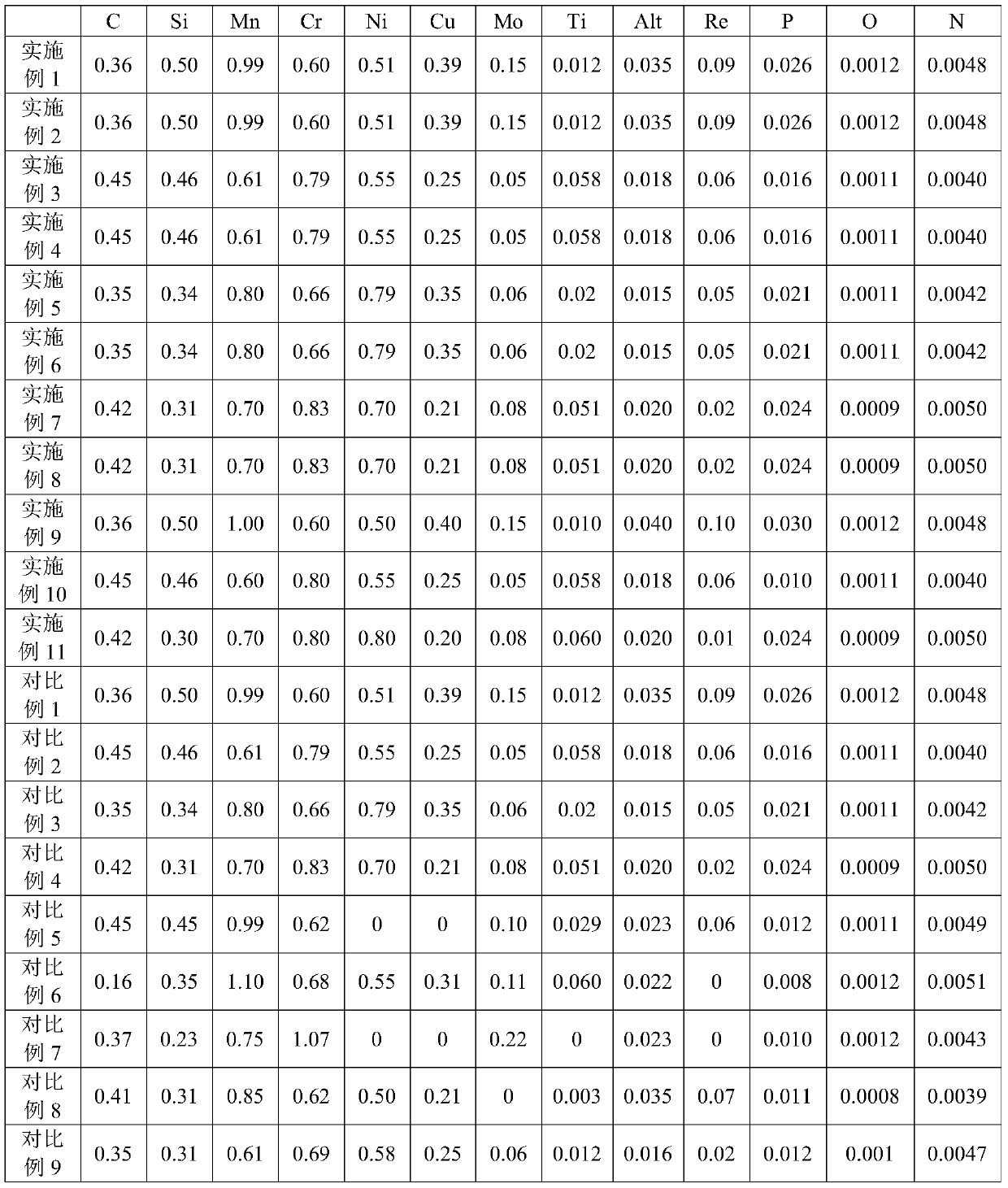

The invention discloses a high-weather-resistant cold heading steel for a 10.9 grade fastener and a production method of the high-weather-resistant cold heading steel, and belongs to the technical field of cold heading steel production. The main chemical composition of the high-weather-resistant cold heading steel comprises, by mass percentage content, 0.33-0.43% of C, 0.20-0.50% of Si, 0.35-0.55%of Mn, 0.60-1.00% of Cr, 0.50-0.80% of Ni, 0.20-0.40% of Cu, 0.01-0.10% of V, 0.015-0.040% of Alt, 0.01-0.10% of Re, 0.010-0.030% of P, no greater than 0.0015% of O, no greater than 0.006% of N and the balance Fe and unavoidable impurities. The tensile strength Rm of the high-weather-resistant cold heading steel is less than or equal to 1040 MPa, the yield strength R<p0.2> is less than or equal to 940 MPa, the post-break elongation A is less than or equal to 9%, the area shrinkage Z is less than or equal to 48%, the yield ratio is less than or equal to 0.9, the requirements of the 10.9 gradefastener steel are met, the high weather resistance is achieved, and the production and use are facilitated.

Owner:MAANSHAN IRON & STEEL CO LTD

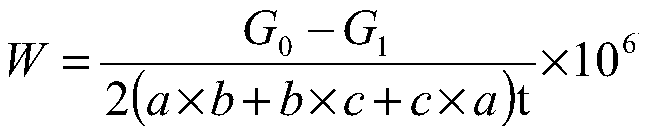

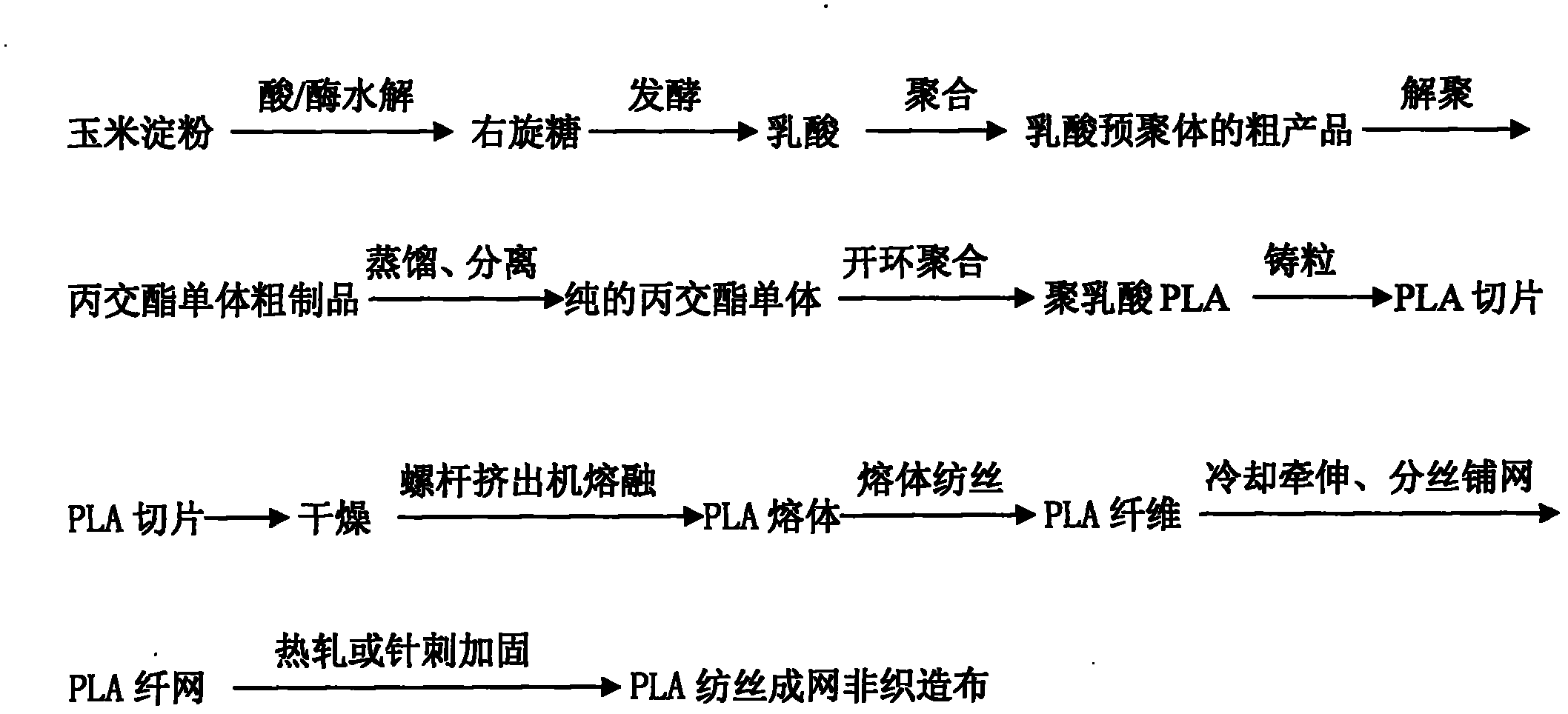

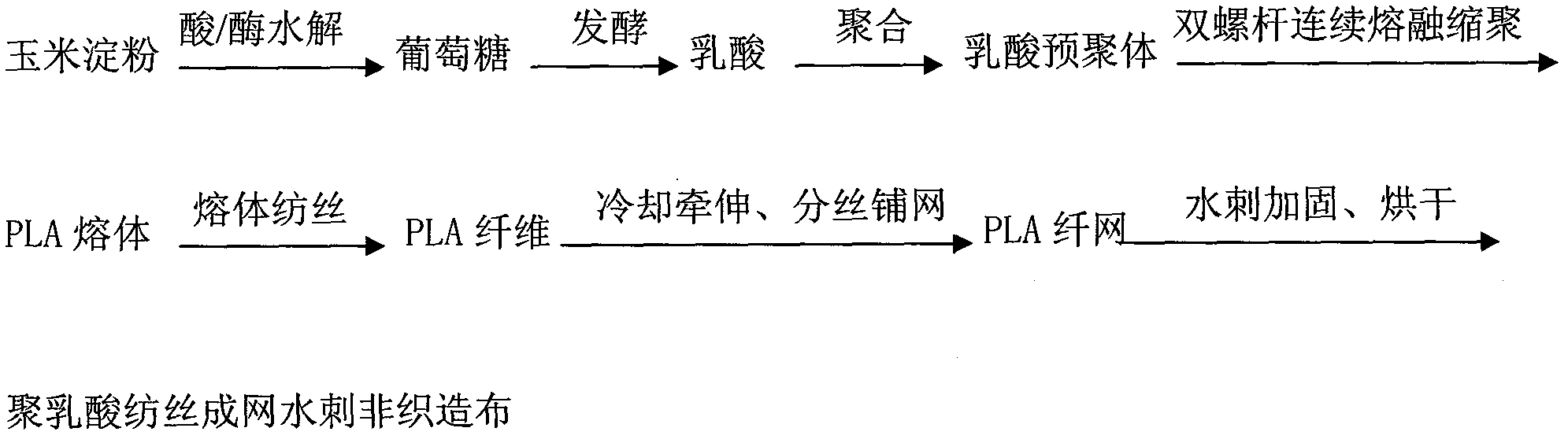

One-step polylactic acid spun-laid spunlace non-woven fabric and manufacturing method of non-woven fabric

InactiveCN102587042AHigh molecular weightReduce crystallinityFilament forming substance formingNon-woven fabricsVitrificationPolymer science

The invention relates to a one-step polylactic acid spun-laid spunlace non-woven fabric and a manufacturing method of the non-woven fabric. The non-woven fabric is prepared from polylactic acid filaments, and the fiber number is in a range of 1-4dtex; the component of the non-woven fabric is crystalline polylactic acid, which has a molecular weight of above 150,000, a melting point of 160-180 DEG C and a glass transition temperature of about 60 DEG C, and is prepared by polymerizing maize starch. The manufacturing method of the non-woven fabric comprises the following steps of: 1, preparing a polylactic acid spun melt, namely, fermenting the maize starch to prepare the polylactic acid, preparing a polylactic acid prepolymer by controlling polymerization conditions with polylactic acid, and preparing the polylactic acid spun melt with a molecular weight of above 150,000 through continuous melt polycondensation by utilizing a double screw; and 2, preparing a polylactic acid spun-bonded spunlace non-woven fabric, namely, spinning the spun melt by a spinning assembly, cooling and drafting by air current, separating and laying, fixing nets by utilizing the spunlace technology, and drying to obtain the polylactic acid spun-laid spunlace non-woven fabric. The polylactic acid spun-laid spunlace non-woven fabric is high in intensity and has the characteristics of good softness, skin affinity, moisture permeability and biodegradability.

Owner:TIANJIN POLYTECHNIC UNIV

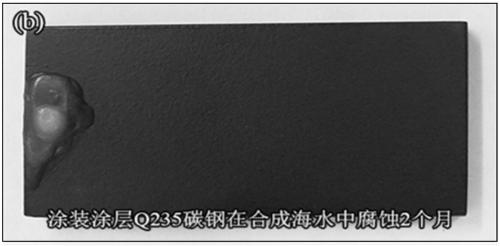

Wear-resistant self-lubricating anticorrosive coating material, preparation method and applications thereof

InactiveCN109836959ASimple preparation processEase of industrial productionAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to a friction-wear-resistant and corrosion-resistant technology of a metal member, particularly to a wear-resistant self-lubricating anticorrosive coating material, a preparationmethod and applications thereof, wherein the wear-resistant self-lubricating anticorrosive coating material comprises, by mass, 5-70 parts of an organosilicon resin, 10-80 parts of an epoxy resin, 2-30 parts of an anticorrosion filler, 3-20 parts of a wear-resistant filler, 5-30 parts of a lubricating filler, 0.5-4 parts of a coating material aid, a curing agent, and 0-80 parts of a diluent, wherein a mass ratio of the curing agent to the epoxy resin is 1:(4-10). The preparation method comprises: preparing a composite filler from the anticorrosion filler, the wear-resistant filler and the self-lubricating filler, preparing a component A from the resin, the composite filler, the coating material aid and the diluent, uniformly mixing the component A and a component B curing agent to preparea coating material, preparing a coating through spray coating, brush costing or dip coating, baking for 2-3 h at a temperature of 150-200 DEG C, and taking out. According to the present invention, the coating material has advantages of excellent wear resistance, excellent self-lubricating performance and excellent corrosion resistance, and can solve the problems of wear and corrosion of metal members in corrosive environments.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

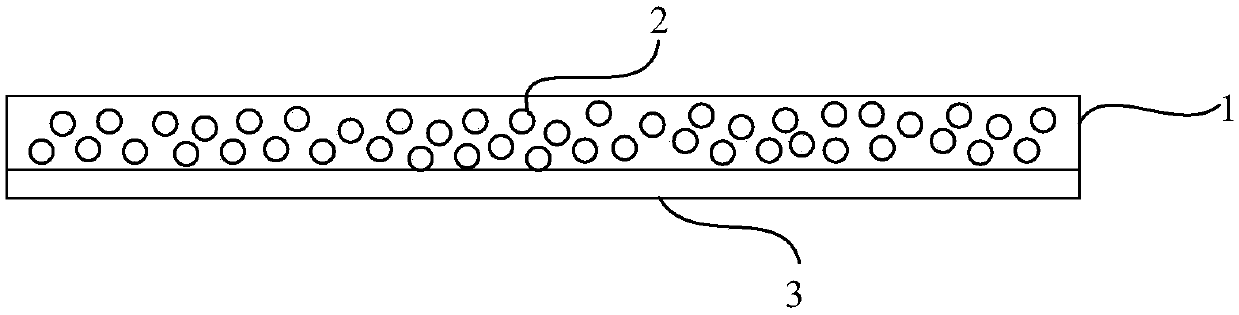

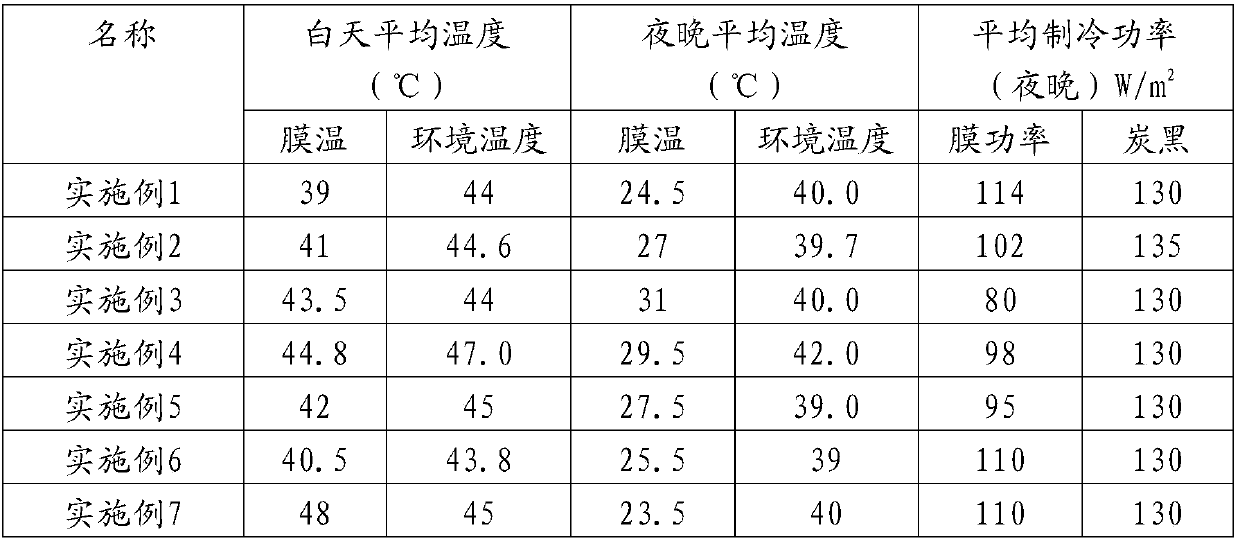

Composite film and preparation method thereof

InactiveCN107936389AGood flexibilityWide range of choicesVacuum evaporation coatingSputtering coatingComposite filmEmissivity

The invention relates to the technical field of radiation refrigeration, in particular to a composite film, a preparation method and application thereof. The preparation method of the composite film has the advantages of simple process, wide material selection and low cost. The obtained composite film has good refrigeration effect and good flexibility at the same time, is suitable for a variety ofapplication scenes, and has a wider application range. The composite film provided by the embodiment of the invention includes a transparent matrix membrane and radiators dispersed in the transparentmatrix membrane. The radiators include first waveband radiators and second waveband radiators, wherein the infrared emission peak of the first waveband radiators is located or covered in a waveband range of 8-10microm, the infrared emission peak of the second waveband radiators is located or covered in a waveband range of 10-13microm, and the average emission rates of the first waveband radiatorsand the second waveband radiators in the infrared radiation waveband are both greater than or equal to 90%, and the average absorption rates in the rest wavebands is less than or equal to 10%. The composite film provided by the embodiment of the invention can be used for preparation of refrigeration materials.

Owner:ENN SCI & TECH DEV

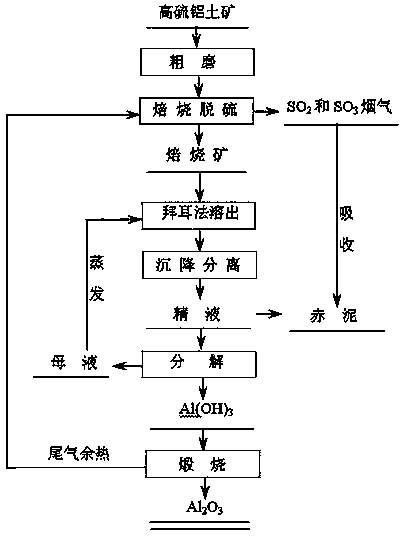

Method for producing alumina by use of high sulfur bauxite

InactiveCN103833056APromote dissolutionReduce energy consumptionAluminium oxides/hydroxidesEnergy consumptionMaterials science

The invention discloses a method for producing alumina by use of high sulfur bauxite, and the method comprises the following steps: carrying out coarse grinding on crushed high sulfur bauxite, roasting the crushed high sulfur bauxite to enable the sulfur content of the ore to be smaller than 0.7%, and then, directly entering an alumina production flow by use of a Bayer process. After the pre-roasting treatment, the leaching performance of the ore is perfected, a better leaching effect can be obtained without fine grinding, and the energy consumption in a fine grinding process of the ore is reduced, so that the method is beneficial to equipment selection in the roasting process and suitable for treating the high sulfur bauxite. The ore in the invention is roasted at a rough particle size, thus helping the overflow of the generated SO2 (or SO3) gas and ensuring a good roasting desulfurization effect; in addition, by adopting the method disclosed by the invention, the energy consumption in the fine grinding process of the ore is reduced, the over burning and dust pollution problems caused by superfine particle size are avoided, the cyclic utilization of energy source is achieved and the desulfurization cost is reduced.

Owner:GUIZHOU UNIV

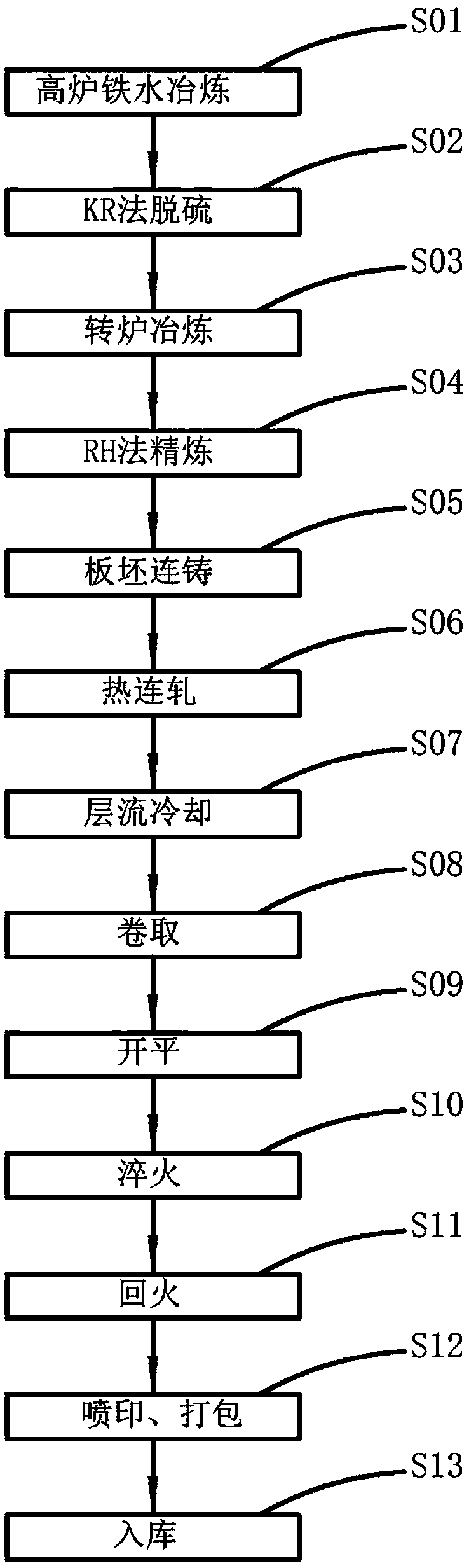

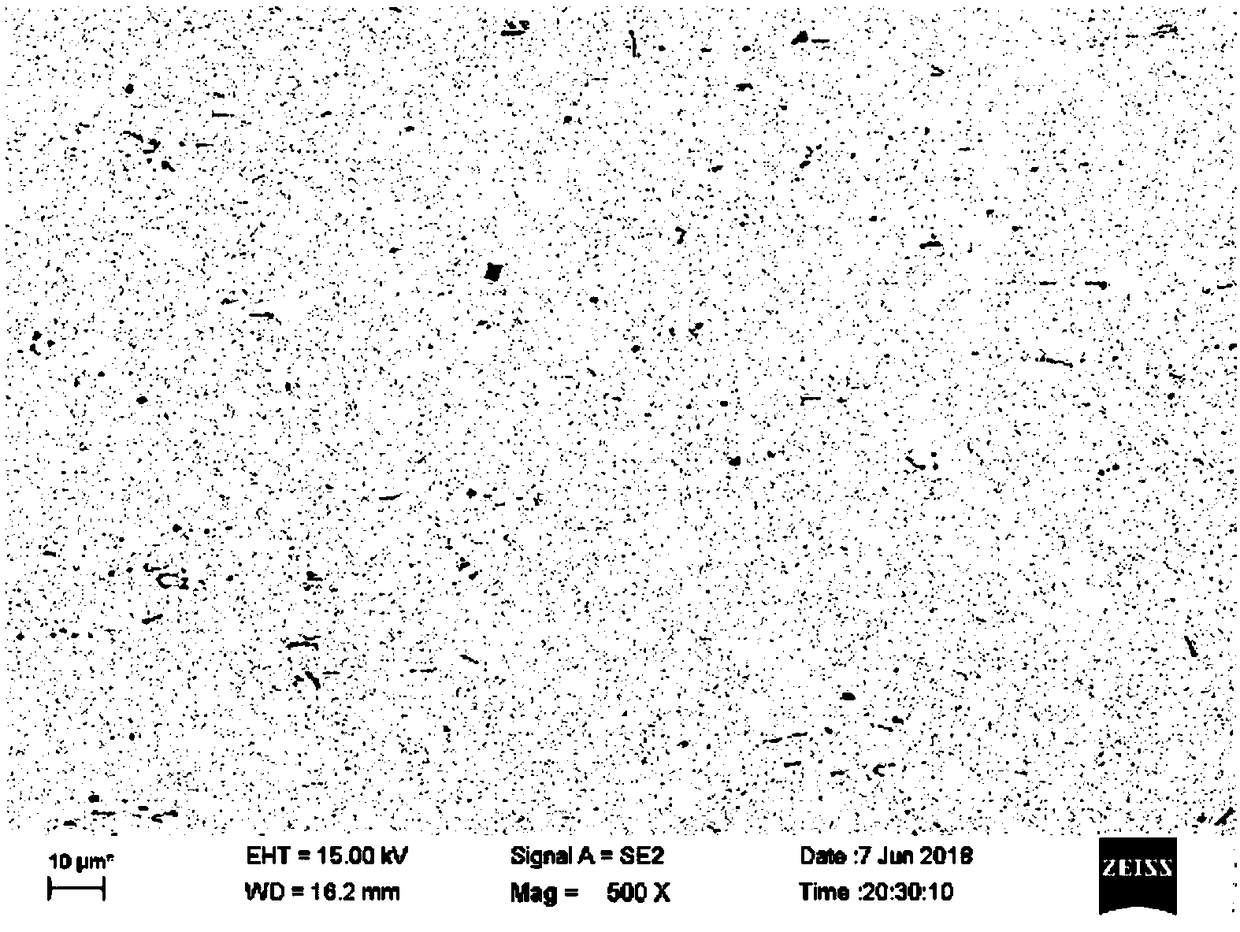

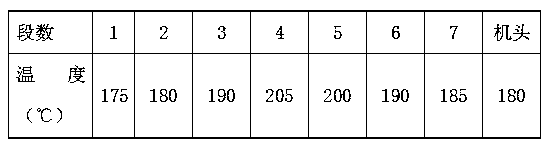

Martensitic wear-resistant steel plate with high wear resistance and manufacturing method thereof

ActiveCN109207853AImproved fine grain strengtheningFine grain strengtheningAustenite grainWear resistant

The invention discloses a martensite wear-resistant steel plate with high wear resistance, belonging to the technical field of steel manufacturing. According to a technical scheme in the invention, the martensite wear-resistant steel plate comprises the following chemical components by weight: 0.32 to 0.38 % of C, 0.02 to 0.30% of Si, 0.8 to 1.0% of Mn, 0.6 to 0.8% of Ti, 0.02 to 0.03% of Nb, 0.15-0.20% of Mo, 0.35-0.45% of Cr, 0.0010-0.0020% of B, no more than 0.003% of S and no more than 0.012% of P, with the balance being Fe and unavoidable impurity elements. In the process of hot continuous rolling in the invention, TiC particles precipitated through continuous casting are gradually fragmented and homogenized along a rolling direction; through rolling fragmentation and solid-state precipitation of nano-sized TiC, most of the micron-sized TiC particles precipitated through continuous casting disappear; and nano-sized TiC can refine original austenite grains and improve ductility andtoughness.

Owner:NORTHEASTERN UNIV +2

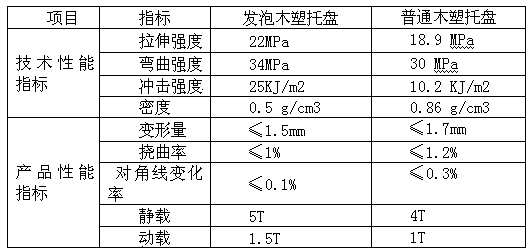

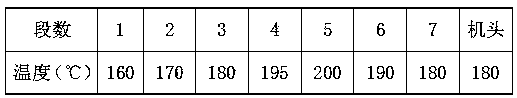

Method for preparing polypropylene and rice hull powder foamed composite tray

The invention provides a method for preparing a polypropylene and rice hull powder foamed composite tray. The tray comprises a tray body, wherein the tray body is formed through blending the following materials in parts by weight and then carrying out injection molding: 90-100 parts of polypropylene, 20-30 parts of rice hull powder, 5-35 parts of high density polyethylene, 2-5 parts of nano calcium carbonate, 4-7 parts of compatibilizer, 0.5-2 parts of foamer, 0.1-0.2 part of foaming auxiliaries, 3-8 parts of color master batch and 0.5-1 part of flow auxiliaries. According to the method, due to a composite material, the problem that polypropylene melt is low in strength and poor in foaming ability is better solved, and the prepared composite material has the advantages of good mechanical properties, light weight, low shrinkage, easiness in processing, uniformity in mixing, recyclability and the like and can meet the use requirements of different industries for trays.

Owner:江苏力达塑料托盘制造有限公司

High weather-resistant cold heading steel for 12.9-grade fasteners and production method thereof

ActiveCN110923545AGood weather resistanceImprove adhesionTemperature control deviceFurnace typesChemical compositionYield ratio

The invention discloses high weather-resistant cold heading steel for 12.9-grade fasteners and a production method thereof, and belongs to the technical field of cold heading steel production. The high weather-resistant cold heading steel comprises the following chemical compositions of, by mass, 0.35%-0.45% of C, 0.30%-0.50% of Si, 0.60%-1.00% of Mn, 0.60%-0.83% of Cr, 0.50%-0.80% of Ni, 0.20%-0.40% of Cu, 0.05%-0.15% of Mo, 0.01%-0.06% of Ti, 0.015%-0.040% of Alt, 0.01%-0.10% of Re, 0.010%-0.030% of P, less than or equal to 0.0015% of O, less than or equal to 0.006% of N, and the balance Feand inevitable impurities. The tensile strength Rm is greater than or equal to 1220 MPa, the yield strength Rp0.2 is greater than or equal to 1100 MPa, the elongation after fracture A is greater thanor equal to 8%, the area shrinkage Z is greater than or equal to 44%, and the yield ratio is greater than or equal to 0.9, so that the performance requirements of the 12.9-grade cold heading steel aremet.

Owner:MAANSHAN IRON & STEEL CO LTD

Composite ceramic material and inner container of electric cooker prepared from composite ceramic material

ActiveCN105084905AExcellent thermal diffusivityImprove heat transfer efficiencyCooking-vessel materialsPtru catalystComposite ceramic

The invention discloses a composite ceramic material and an inner container of an electric cooker prepared from the composite ceramic material. The composite ceramic material is prepared from the following components in parts by weight: 3-8 parts of barium carbonate, 20-35 parts of calcite, 5-10 parts of kaolin, 35-55 parts of silica powder, 3-8 parts of potassium nitrate, 10-15 parts of paraffin, 3-8 parts of sodium carbonate, 7-8 parts of boric acid, 11-15 parts of quartz, 50-75 parts of aluminum nitride powder, 2-3 parts of yttrium oxide and 3-5 parts of lanthanum oxide, wherein the aluminum nitride powder is generated by reacting aluminum oxide powder serving as an aluminum source and carbon black powder in the flowing nitrogen atmosphere at the temperature of 1500-1700 DEG C; calcium oxide is added as a catalyst in the reaction process, and decarbonization is carried out in dry air with the temperature of 700-800 DEG C after the reaction is finished; the mass content of cation impurities in the aluminum oxide powder is lower than or equal to 0.02%, and the mass contents of silicon and iron impurities are respectively lower than 0.001%; and the average particle size of the carbon black powder is 35-40nm, and the specific surface area is smaller than or equal to 90m<2> / g.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

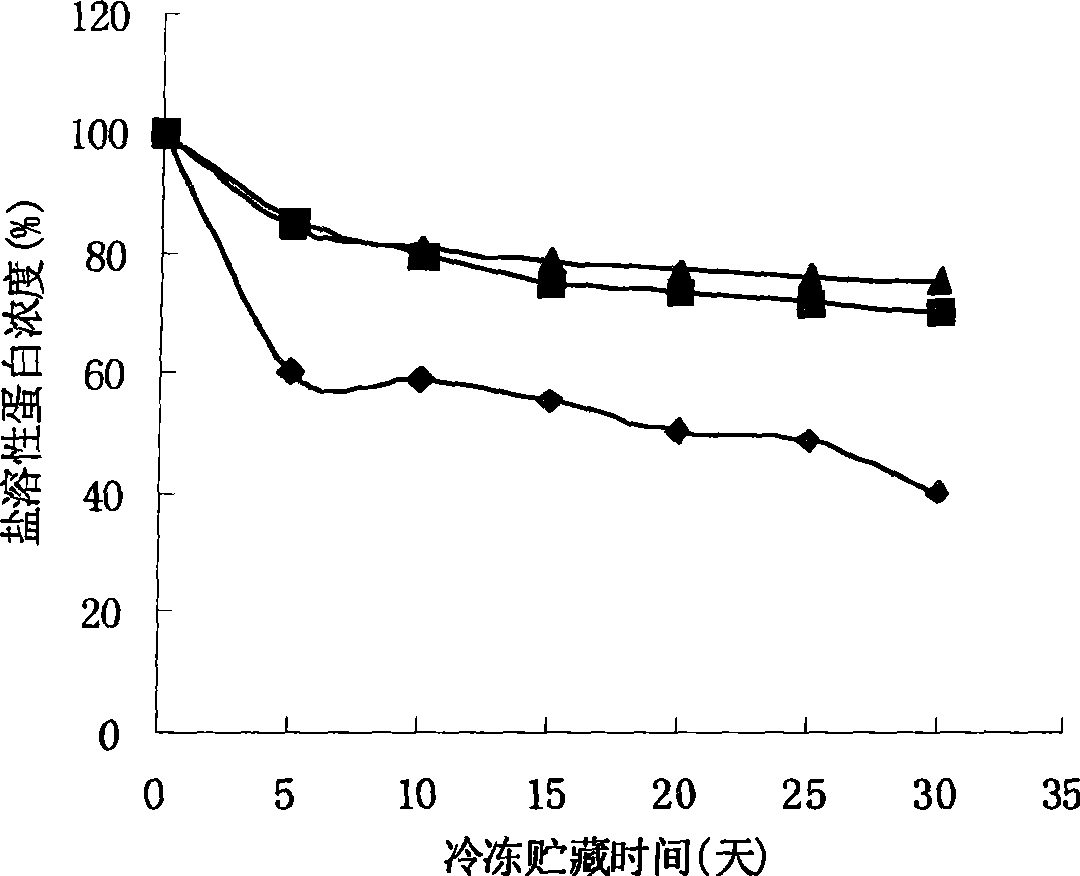

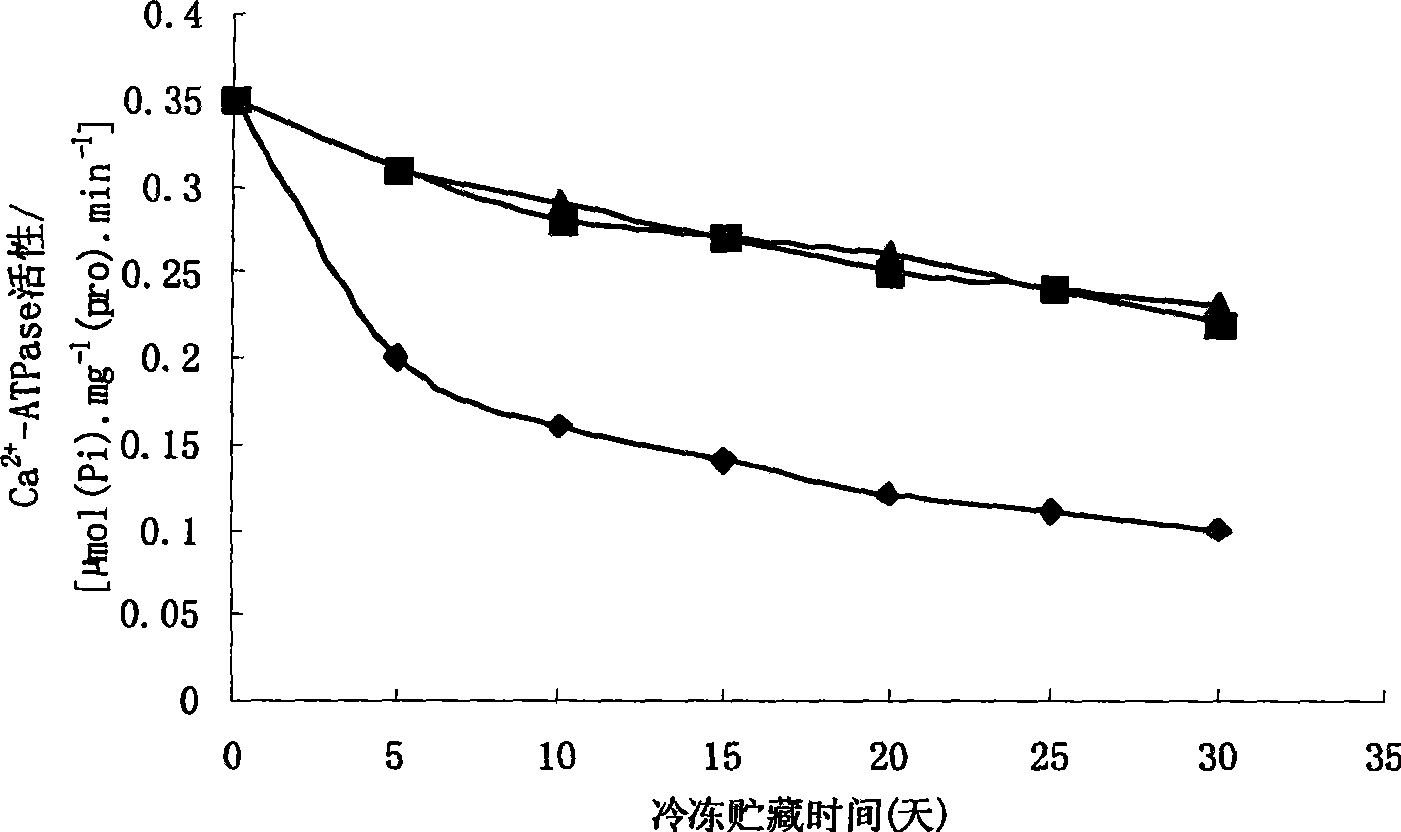

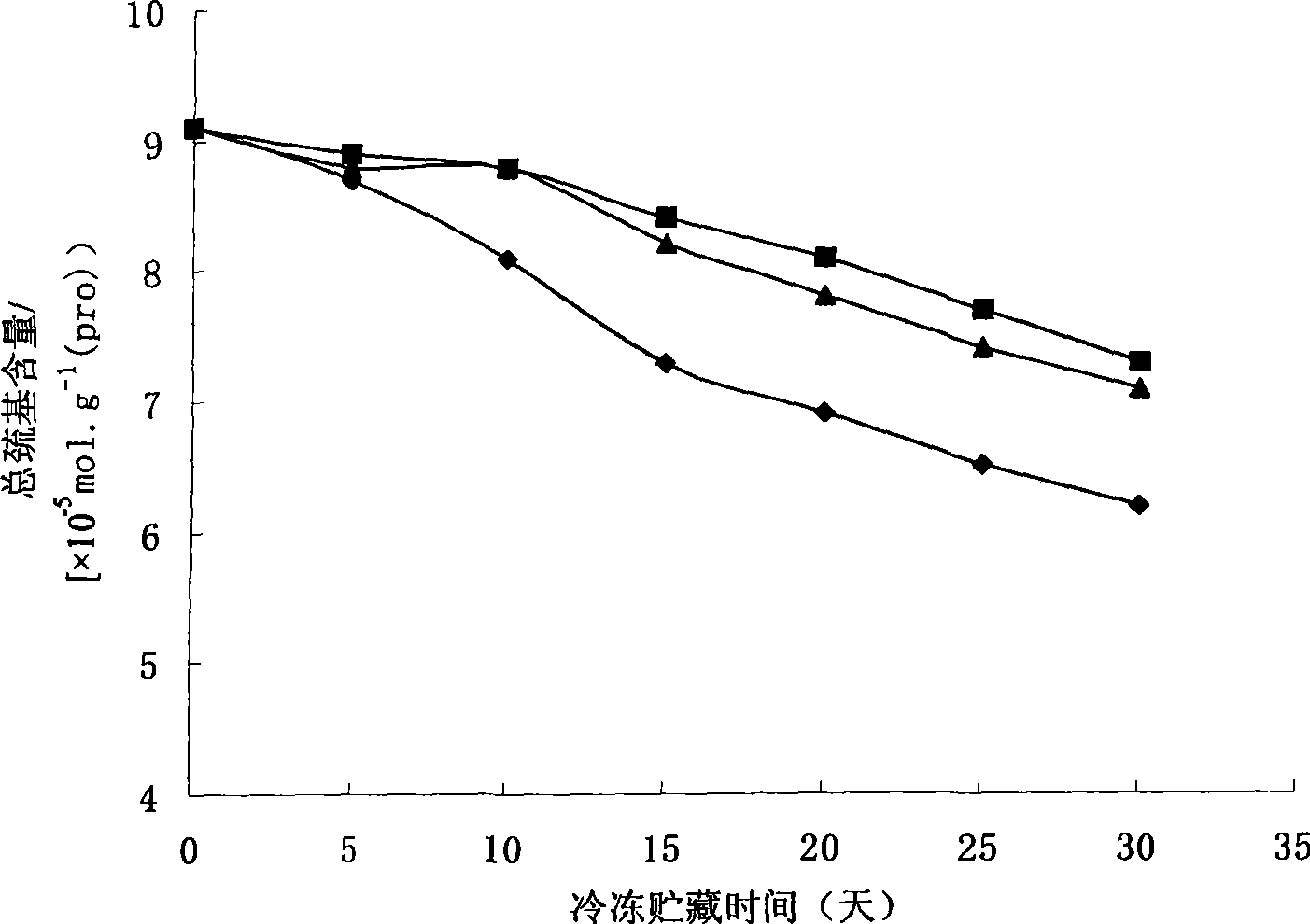

Use of konjac glucomannan in changing fresh-water fish protein frozen denaturation and minced fish meat texture characteristics and minced fish meat water-retention property

InactiveCN101507474AAvoid aggregate denaturationAggregation denaturation preventionFood preparationWater soluble polymersChemistry

The invention relates to a study on konjac glucomannan for modifying fresh water fish protein freeze denaturation and minced fillet texture characteristic as well as minced fillet water binding capacity. The konjac glucomannan is a non-ionic water soluble polymer polyhexose; and in the molecular structure of the non-ionic water soluble polymer polyhexose, the active hydroxide radical -OH or hydrogen bond -H on the D-glucose and the D-mannose cells can prevent the formations of the hydrogen bond, a hydrophobic bond, a disulfide bond and a salt bond among myofibril protein molecules of fish meat in the freeze preservation process so as to generate aggregation and modification, prevent the salt solubility of myofibril proteins from being reduced, the Ca-ATPase from being inactivated, and the content of total hydrosulfide groups and active hydrosulfide groups from being reduced, thereby remarkably improving the freeze denaturation resistance of fresh water fish proteins. Fresh water fish minced fillets are added with the konjac glucomannan so that the breaking strength, the depth of concavity and the gel strength thereof are increased along with the addition of the konjac glucomannan, the water binding capacity of the fresh water fish minced fillets is strengthened, and simultaneously the frangibility of the fresh water fish minced fillets is increased along with the addition and the color of the fresh water fish minced fillets is deepened. Thus, the addition (w / w) of the konjac glucomannan in the fresh water fish minced fillets is advisable to be between 0.8 and 1.2 percent.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

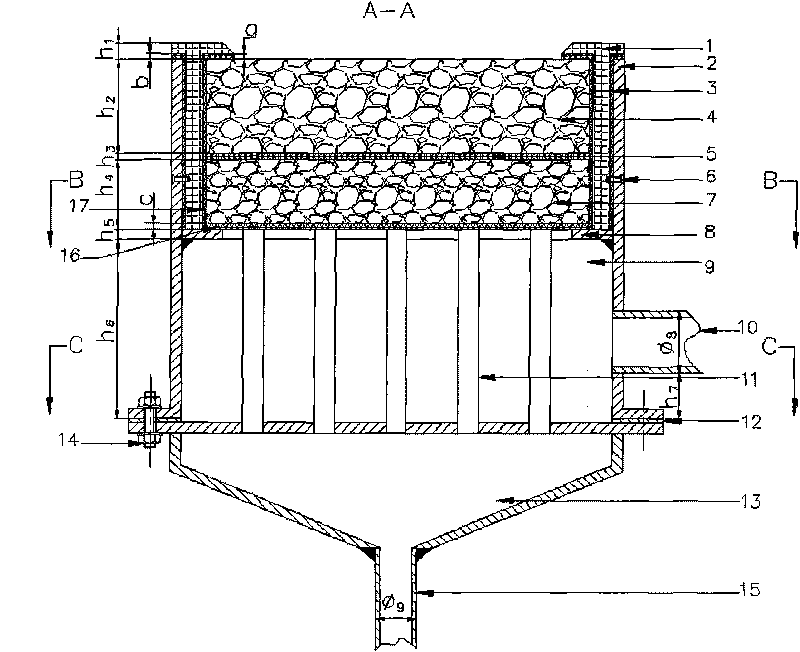

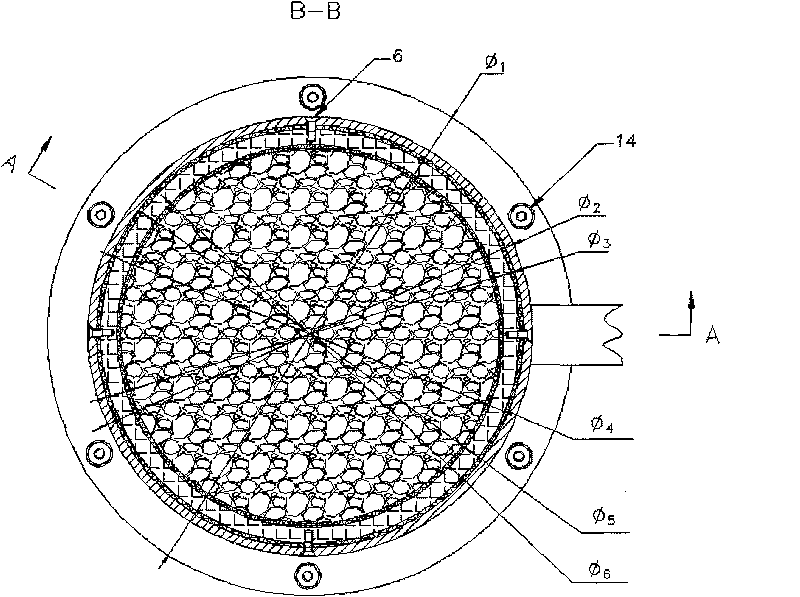

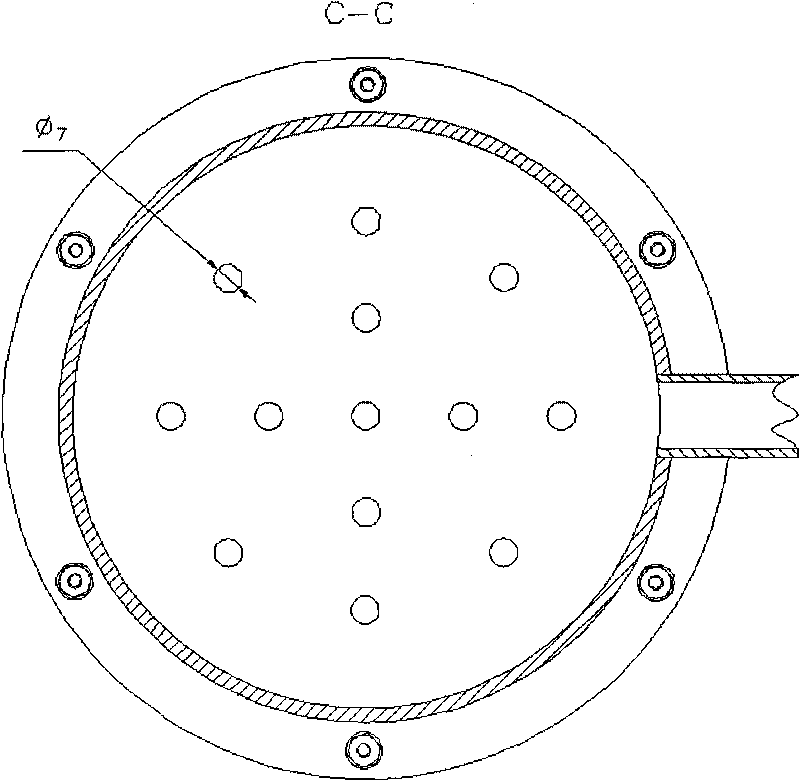

Diffusion type porous medium gas fuel combustor

InactiveCN101737778AUniform density distributionPrevent flashbackGaseous fuel burnerCombustorPorous medium

A diffusion type porous medium gas fuel combustor comprises a shell, an air duct and a fire-resistant casing pipe, the air duct is connected with the shell, the bottom end of the shell is connected with the top plate of a gas flow dividing tank, the shell is internally provided with the fire-resistant casing pipe, a tray and a gas flow dividing tube from top to bottom, the bottom end of the fire-resistant casing pipe is contacted with the tray, the tray is fixed on the shell or the gas flow dividing tube, the bottom end of the gas flow dividing tube is fixed on the top plate of the gas flow dividing tank, and the gas flow dividing tube and the gas flow dividing tank are communicated internally; the fire-resistant casing pipe is provided with macro porous medium, micro porous medium and lower layer metal fiber from top to bottom, and the lower layer metal fiber is connected with the tray and the gas flow dividing tube simultaneously. The inventive diffusion type porous medium gas fuel combustor can be used for efficiently avoiding tempering when combustion intensity is stronger, thus achieving the effects of protecting micro porous medium and saving energy.

Owner:NORTHEASTERN UNIV

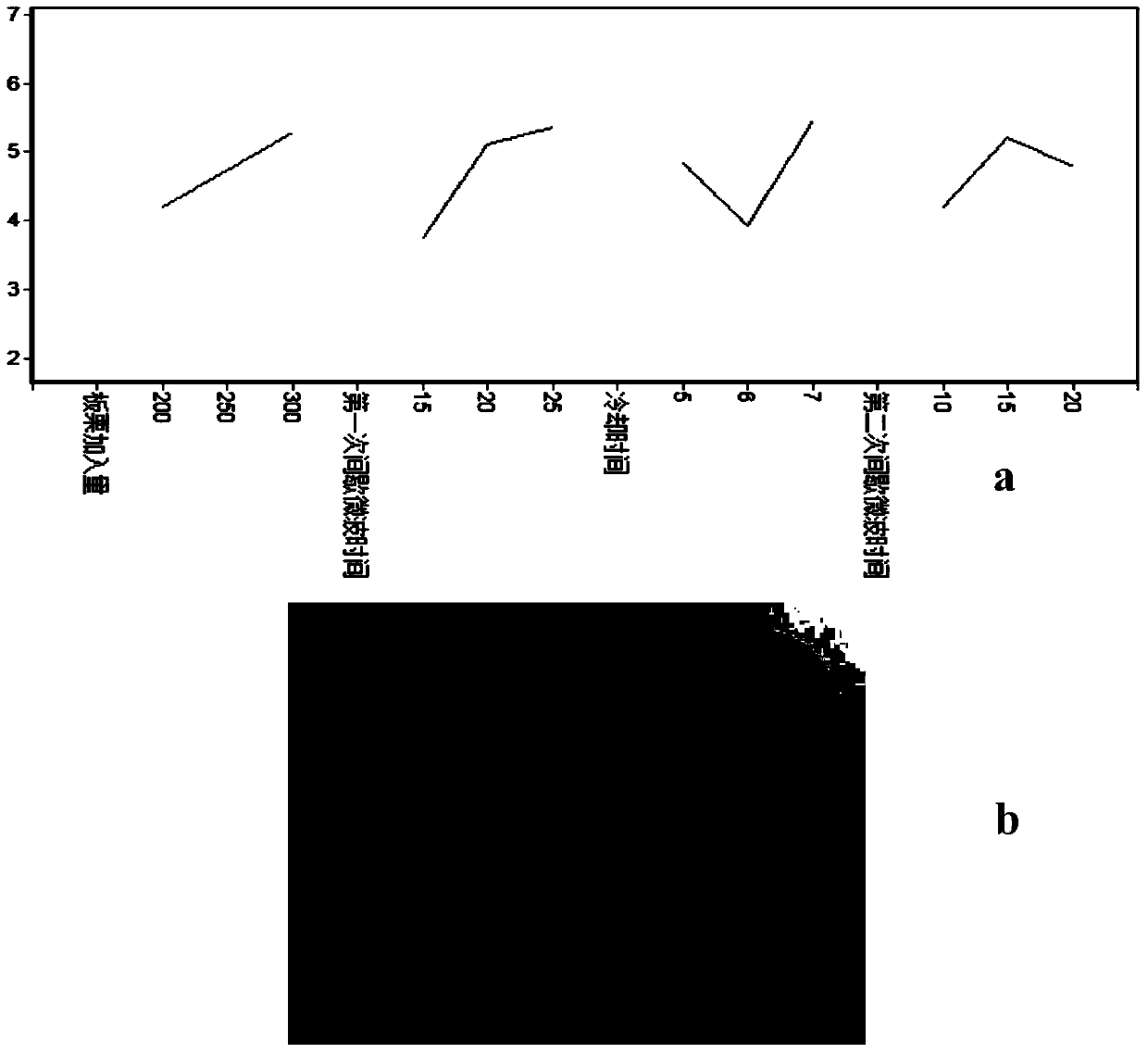

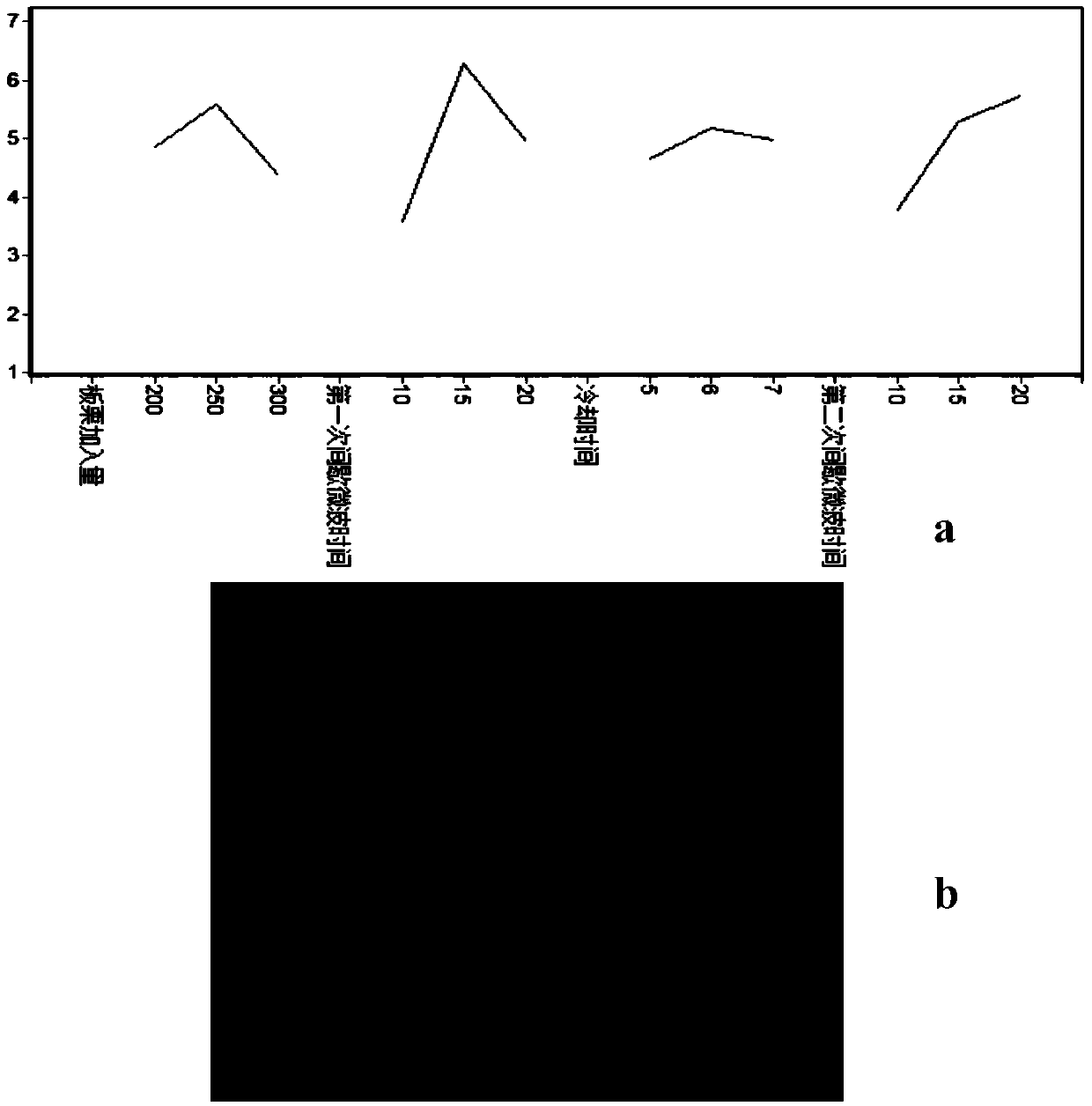

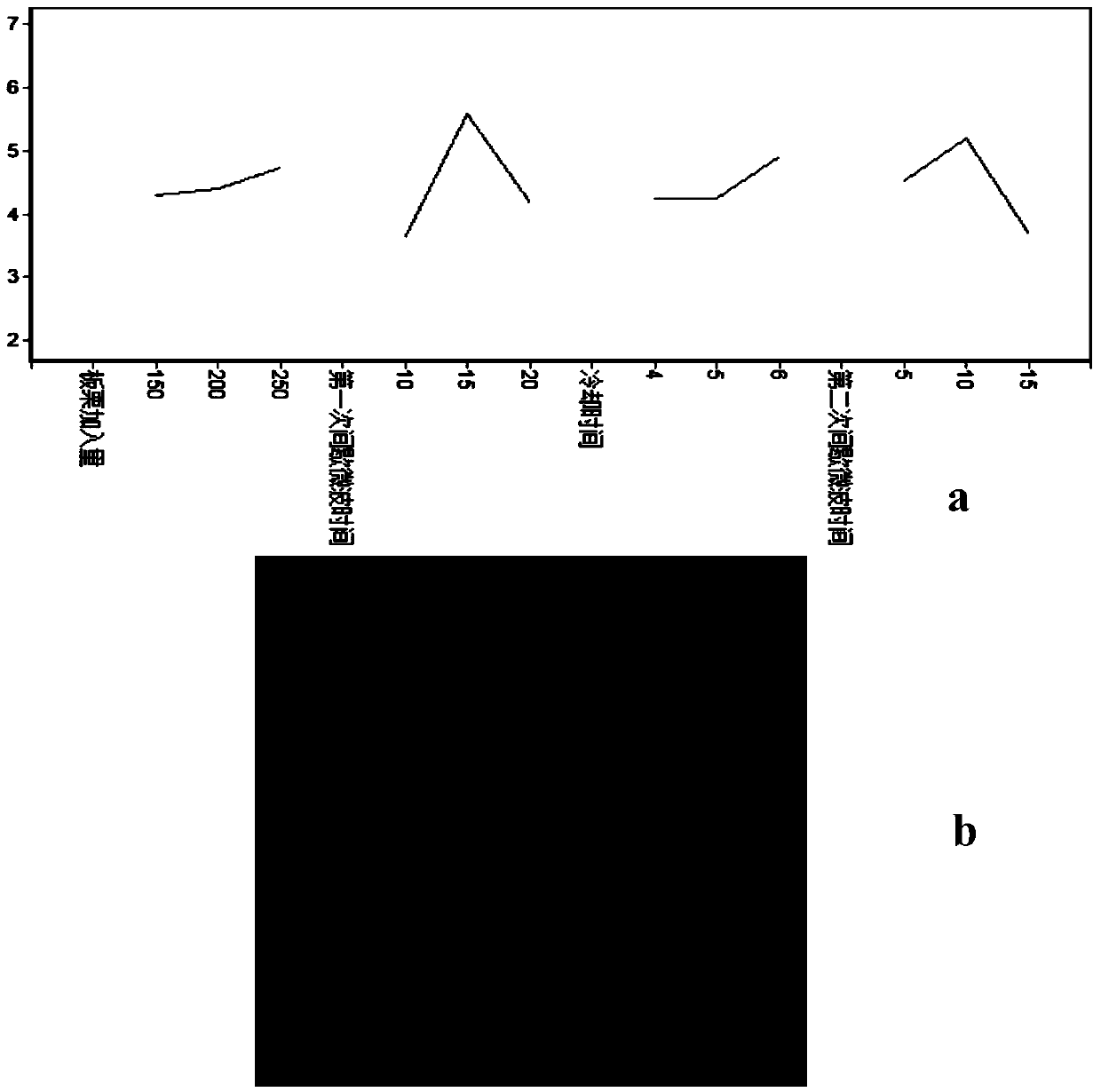

Method for synchronously removing shell and peel of Chinese chestnut through microwaves

The invention discloses a method for synchronously removing the shell and peel of a Chinese chestnut through microwaves. The method comprises the following steps: the shell of the Chinese chestnut is cut, the Chinese chestnut is subjected to microwave processing for the first time, the Chinese chestnut is cooled after the microwave processing for the first time, then, the Chinese chestnut is subjected to microwave processing for the second time, the shell and the peel of the Chinese chestnut are removed after the microwave processing for the second time, and therefore the kernel of the Chinese chestnut is obtained. According to the method for synchronously removing the shell and peel of the Chinese chestnut through the microwaves, the microwaves are used for instantaneous intermittent heating with a high power, as a result, the kernel of the Chinese chestnut shrinks due to dehydration and is separated from the shell and the peel, and the phenomenon that the kernel of the Chinese chestnut is cooked and exploded due to an excessively quick temperature rise in the one-time heating process can be well avoided; meanwhile, the hot Chinese chestnut is cooled for a short time, as a result, water in the shell of the Chinese chestnut is evaporated, brittleness is further improved, and original color and luster, a special flavor and nutrition of the kernel of the Chinese chestnut are guaranteed to the maximum.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com