Method for preparing polypropylene and rice hull powder foamed composite tray

A technology of rice husk powder and polypropylene, which is applied in the field of preparation of polypropylene rice husk powder foamed composite trays, can solve problems such as uneven mixing, and achieve the effects of bright colors, smoother product surfaces, and smoother product surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention comprises the following processing steps:

[0030] 1) According to the weight ratio of the composite material, polypropylene, rice husk powder, and nano-calcium carbonate are used as raw materials, and the rice husk powder is dried at 105°C for 24 hours to obtain dried raw materials for use;

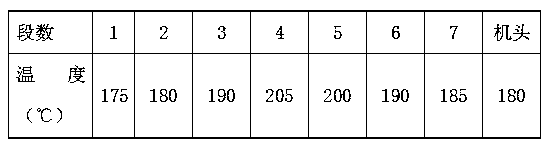

[0031] 2) Preparation of polypropylene / rice husk powder blended particles: first, add rice husk powder, nano-calcium carbonate, and compatibilizer into the high-mixer, stir well and set aside; then add polypropylene, high-density polyethylene, flow aid The agent is mixed uniformly in a high mixer and then used for later use. The above compound is heated, melted, kneaded, sheared and extruded in a twin-screw extruder, and then extruded to granulate, wherein the polypropylene, high density polypropylene Ethylene and flow aid blend are added at the main feeding port of the extruder, and the rice husk powder, nano-calcium carbonate, and ...

Embodiment 1

[0034] Prepare raw materials: 100 parts of polypropylene, 25 parts of high-density polyethylene, 20 parts of 80-mesh rice husk powder, 2.5 parts of nano-calcium carbonate, 5 parts of compatibilizer MAH-g-PP, 4 parts of color masterbatch, foaming agent 1.5 parts of nitrogen dicarboxamide, 0.1 part of nano zinc oxide as a foaming aid, and 1 part of glyceryl stearate as a flow aid.

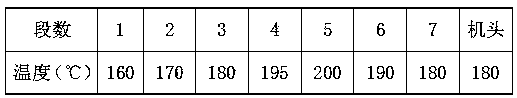

[0035] Add rice husk powder, nano-calcium carbonate, and compatibilizer into the high-mixer, stir evenly and set aside; mix polypropylene, high-density polyethylene, color masterbatch, and flow aid in the high-mixer evenly, and set aside The above-mentioned mixture is heated and melted, kneaded, sheared, extruded in a twin-screw extruder, and then extruded and granulated, wherein the blend of polypropylene, high-density polyethylene, color masterbatch, and flow aid Add at the main feed port of the extruder, and the rice husk powder, nano-calcium carbonate, compatibilizer blend are added at the side f...

Embodiment 2

[0042] Prepare raw materials: 100 parts of polypropylene, 15 parts of high-density polyethylene, 25 parts of 80-mesh rice husk powder, 3 parts of nano-calcium carbonate, 6 parts of compatibilizer titanate coupling agent, 4 parts of color masterbatch, foaming agent 1.5 parts of sodium bicarbonate, 0.1 part of nano zinc oxide as a foaming aid, and 1 part of polyethylene wax as a flow aid.

[0043] Add rice husk powder, nano-calcium carbonate, and compatibilizer into the high-mixer, stir evenly and set aside; mix polypropylene, high-density polyethylene, color masterbatch, and flow aid in the high-mixer evenly, and set aside The above-mentioned mixture is heated and melted, kneaded, sheared, extruded in a twin-screw extruder, and then extruded and granulated, wherein the blend of polypropylene, high-density polyethylene, flow aid, etc. is extruded The main feeding port of the extruder is added, and the rice husk powder, nano-calcium carbonate, and compatibilizer blend are added a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| foaming ratio | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com