Patents

Literature

1758results about How to "Improve low temperature toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-sulfur well mouth valve body welding repair method

ActiveCN107520526AImprove carrying capacityAvoid softening problemsArc welding apparatusWelding/cutting media/materialsCarbon alloyTungsten

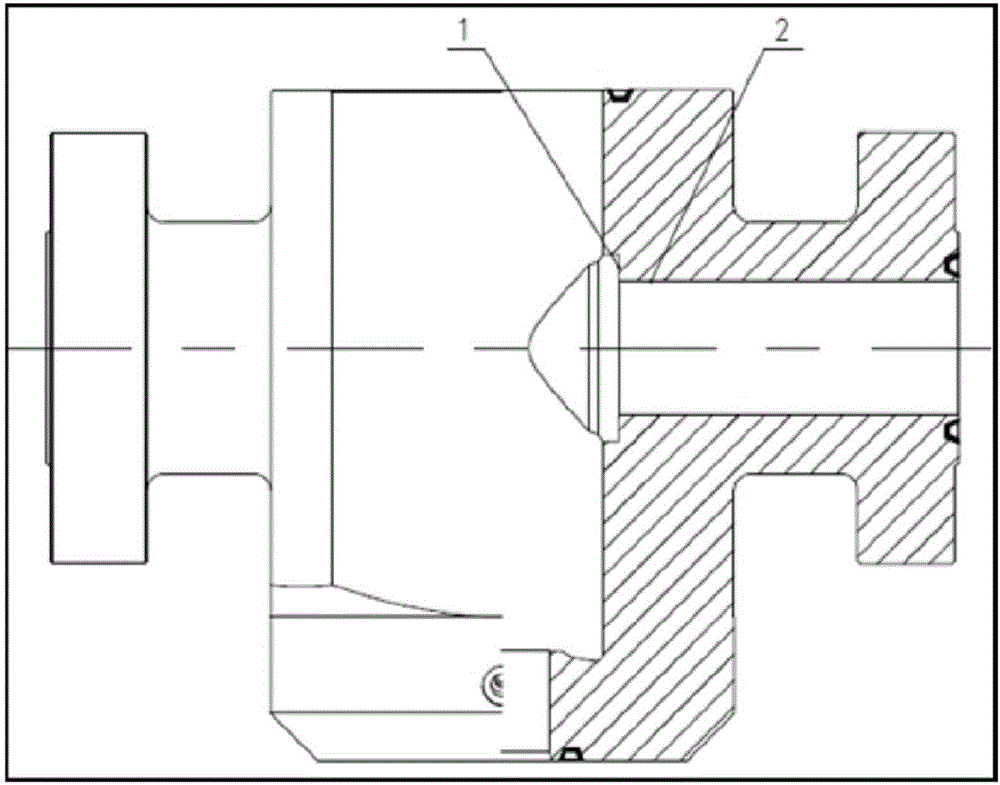

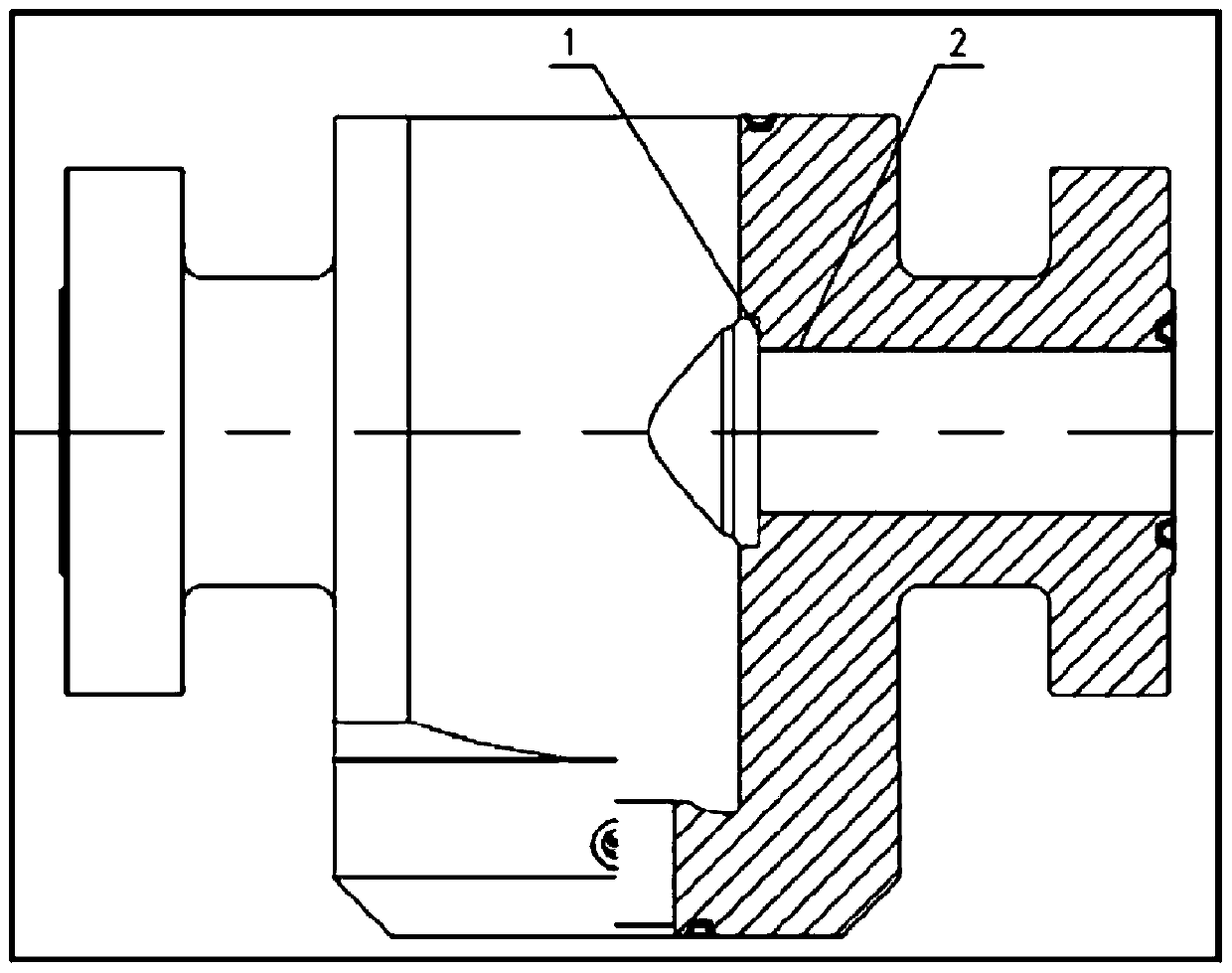

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Weathering steel with yield strength of 550MPa level and manufacturing method thereof

InactiveCN101994064AMeet the requirements of reducing the self-weight of componentsMeet the requirements of self-respectTemperature control deviceSheet steelUltimate tensile strength

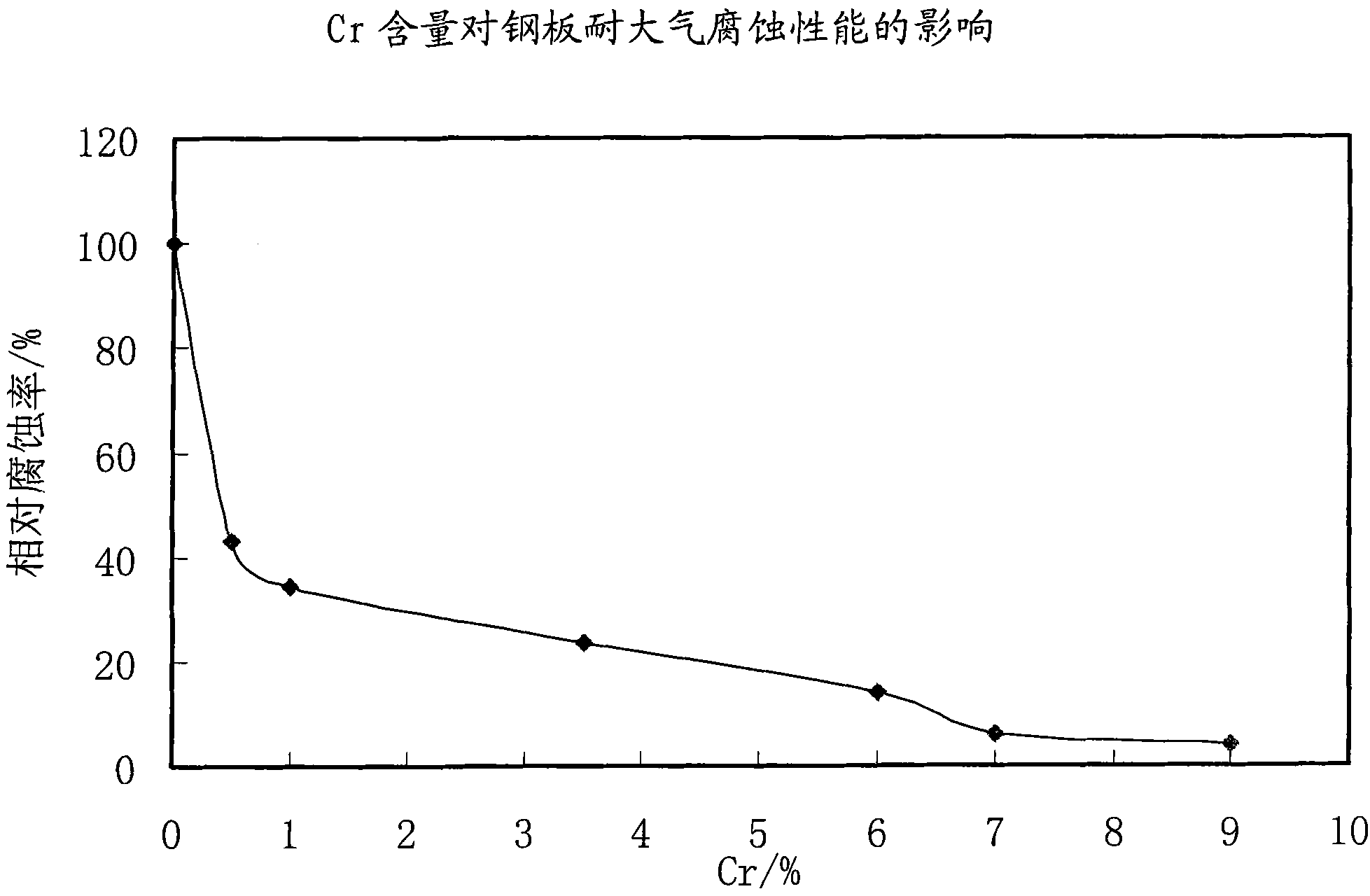

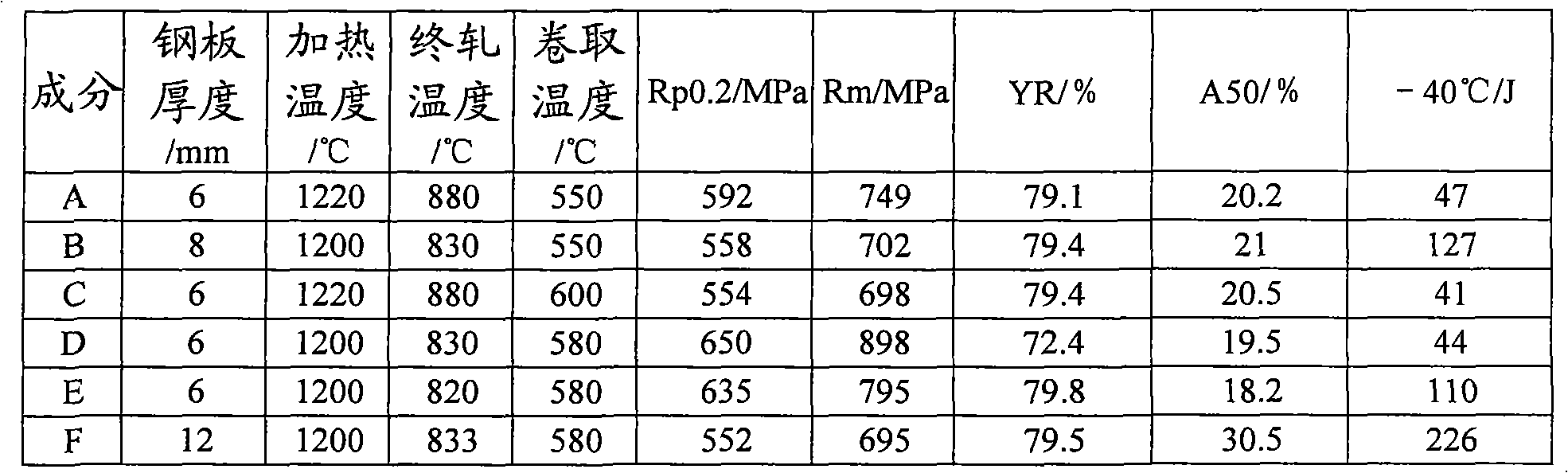

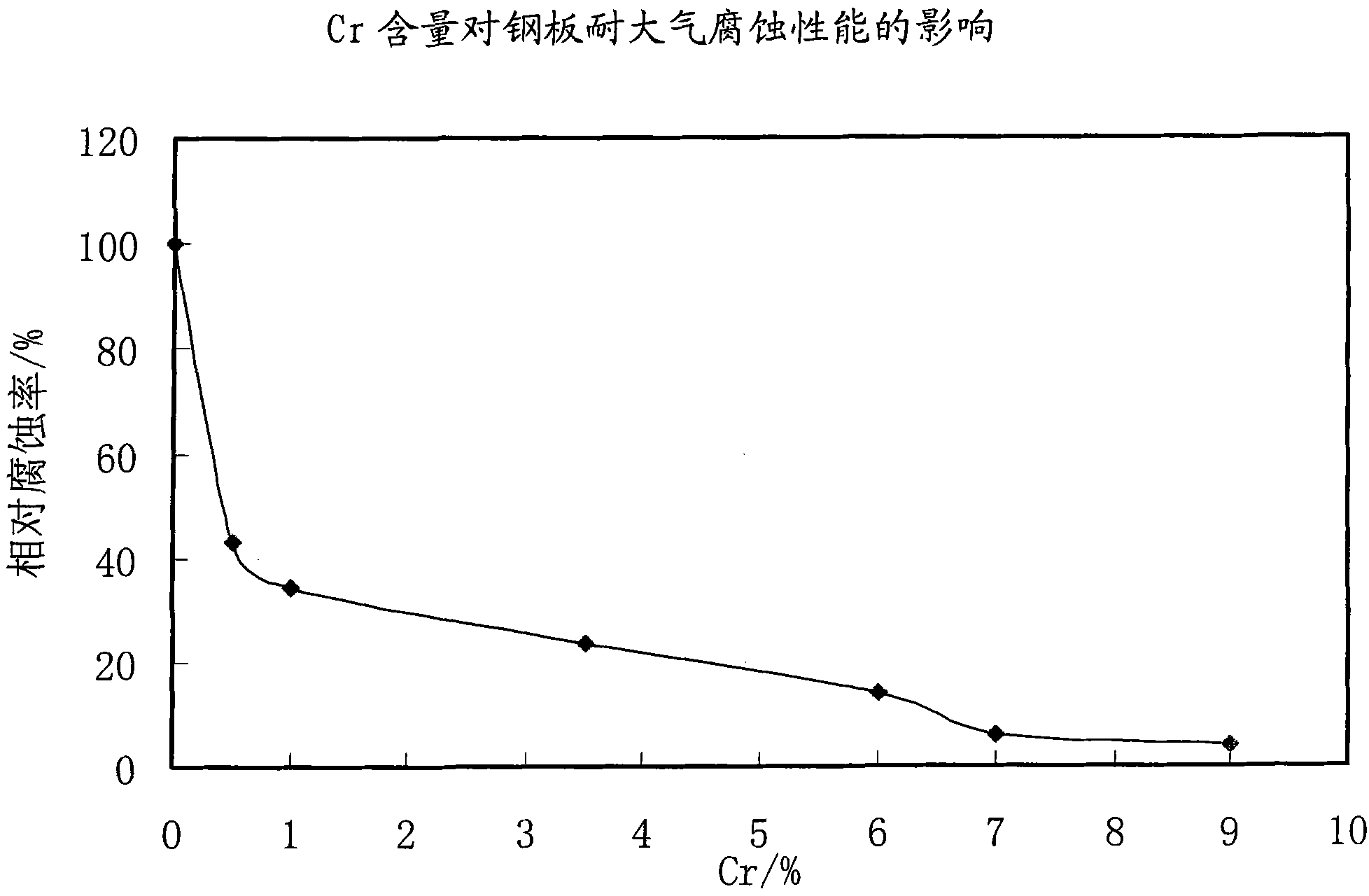

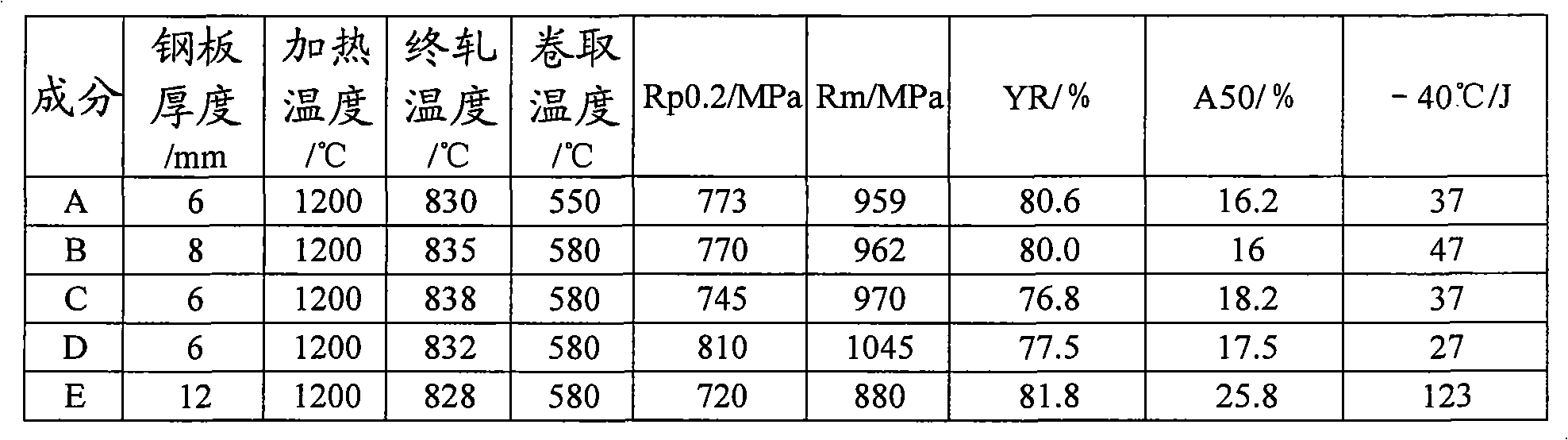

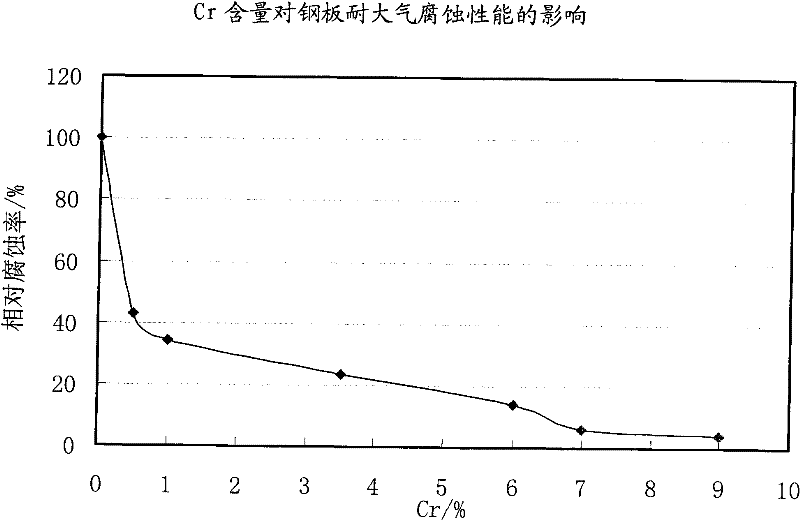

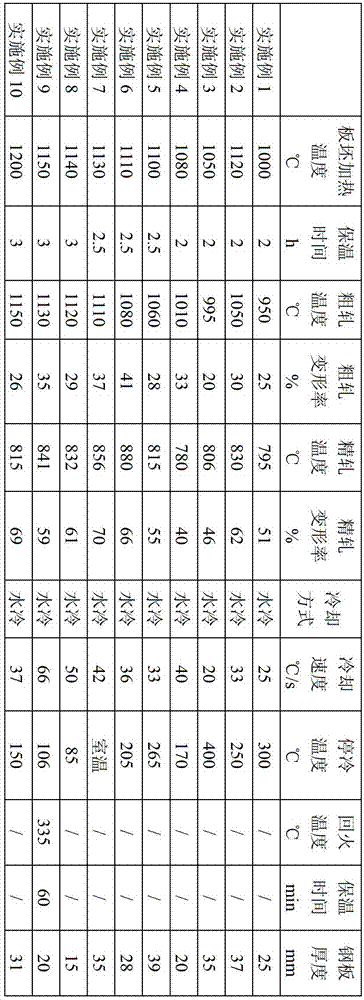

The invention relates to weathering steel with the yield strength of 550MPa level and the advantages of excellent toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components: 0.02 to 0.08wt% of C, 0.15 to 0.55wt% of Si, 0.2 to 1.0wt% of Mn, less than or equal to 0.01wt% of P, less than or equal to 0.006wt% of S, 0.2 to 0.5wt% of Cu, 2.5 to 7.0wt% of Cr, 0.2 to 1.2wt% of Ni, 0.02 to 0.06wt% of Nb, 0.01 to 0.05wt% of Al, less than or equal to 0.05wt% of N, 0.01 to 0.10wt% of Ti and the balance of Fe and the unavoidable impurities. The steel plate made of the steel has the yield strength more than 550MPa and excellent toughness, and the relative corrosion rate is simultaneously reduced by one time on the basis of the traditional weathering steel so as to satisfy the requirement of enhancing the corrosion resistance of the steel for railway vehicles and reach the purposes of prolonging the service duration and reducing the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

Thick steel plate for low temperature use and capable of being welded in superhigh energy and its production process

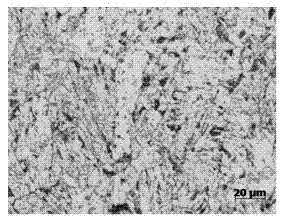

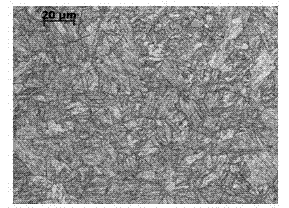

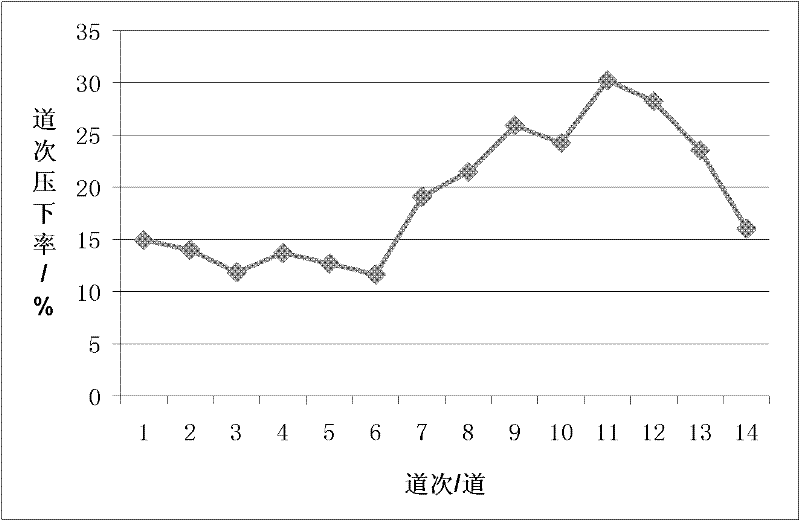

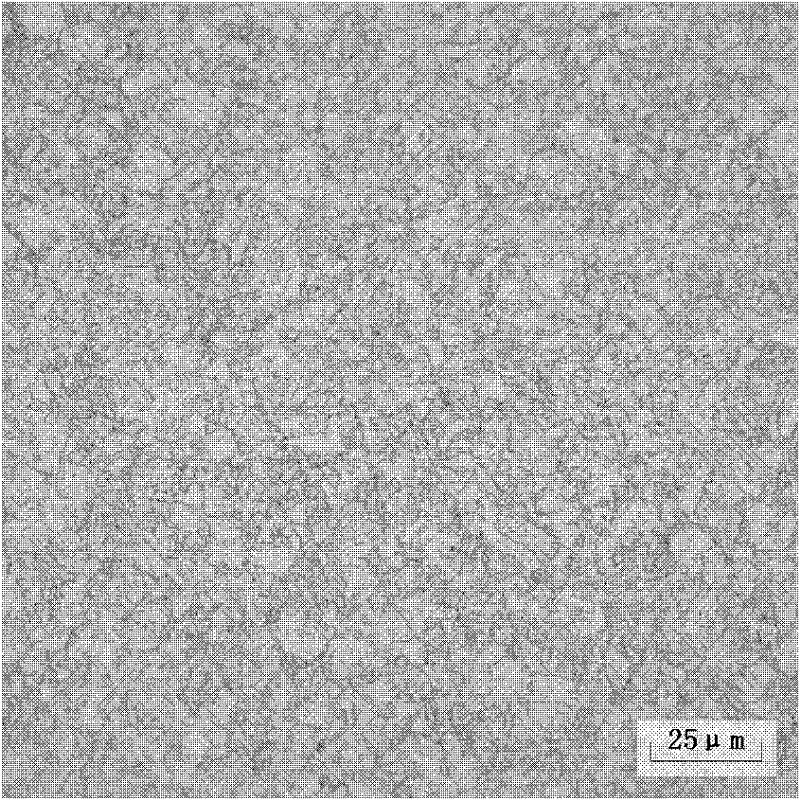

ActiveCN101045976AImprove low temperature toughnessHigh strengthTemperature control deviceHeat treatment process controlSteel platesCrystallite

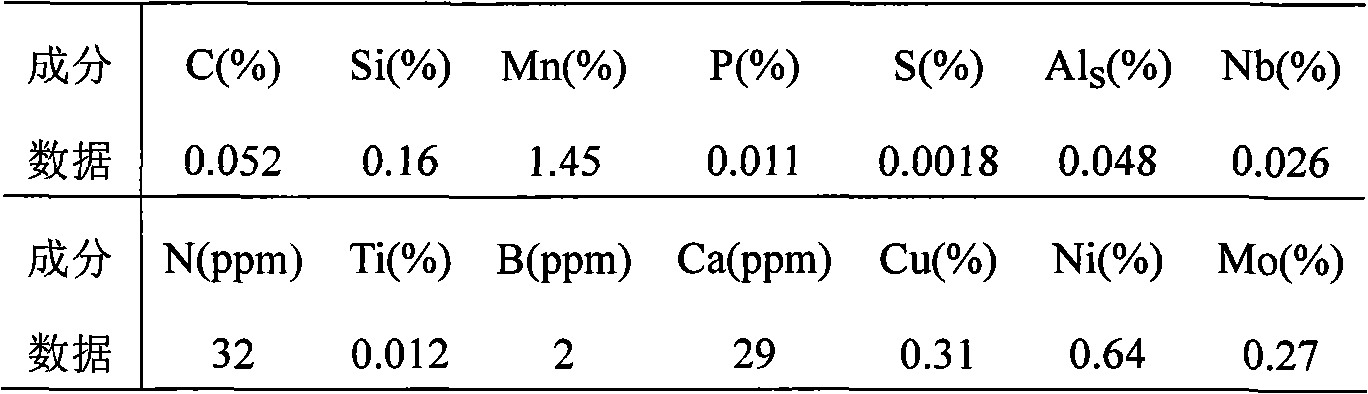

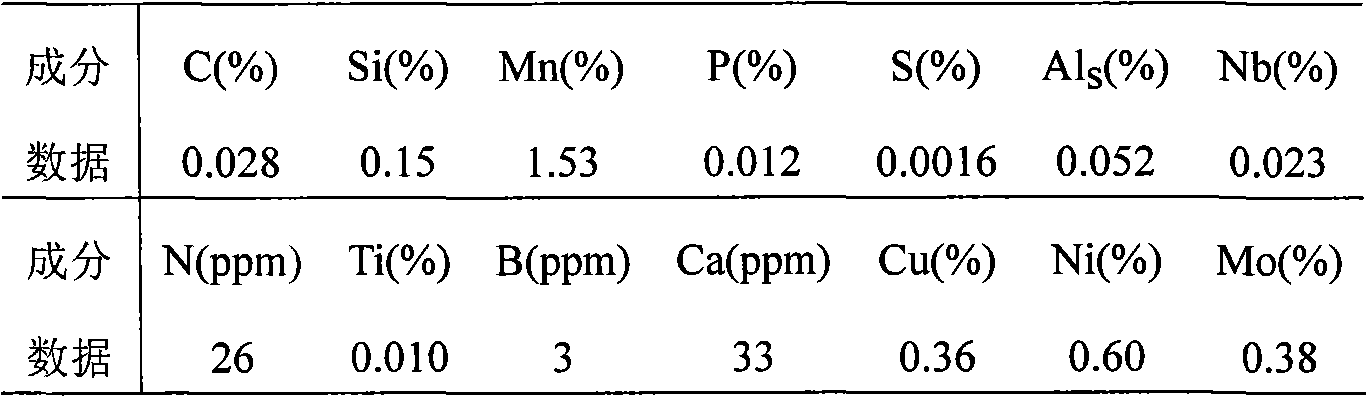

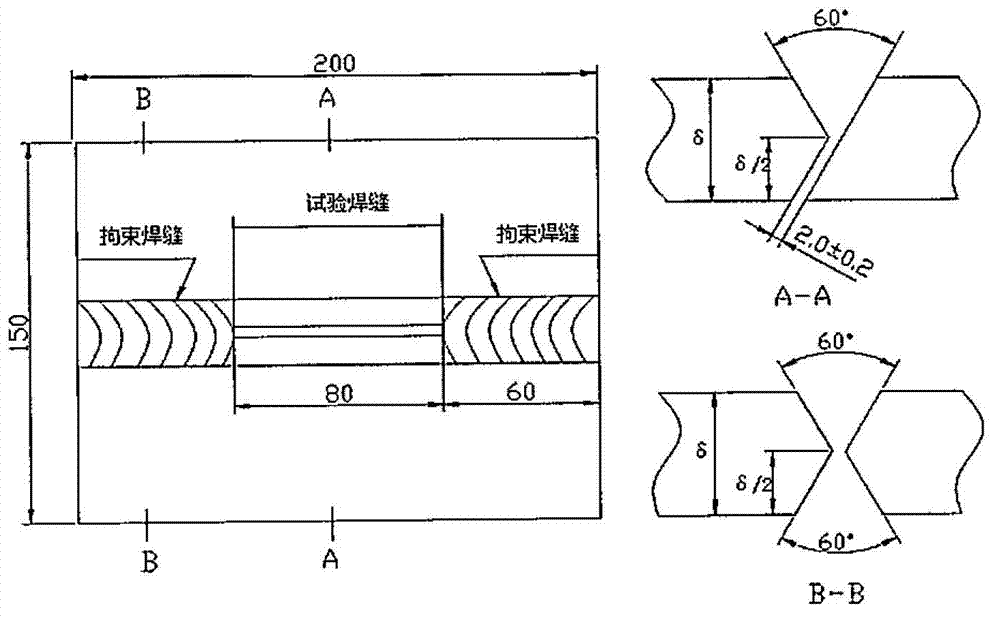

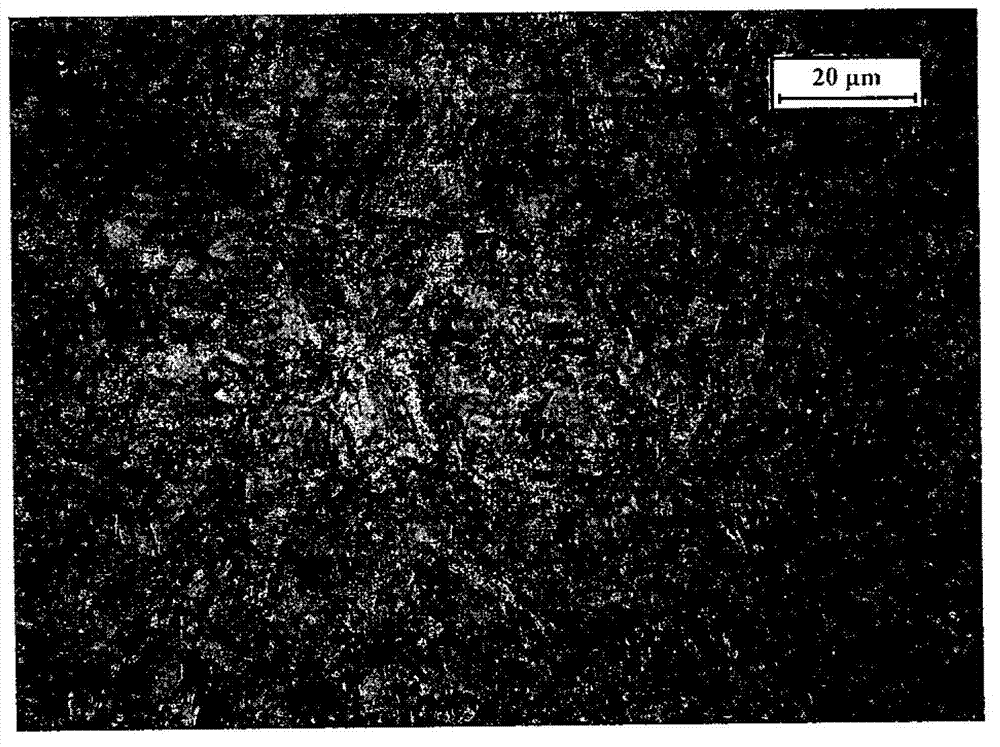

The thick steel plate for low temperature use and capable of being welded in superhigh energy has the material comprising C 0.030-0.050 wt%, Si not more than 0.2 wt%, Mn 1.50-1.80 wt%, P not more than 0.01 wt%, S not more than 0.002 wt%, Nb 0.010-0.020 wt%, Als 0.040-0.060 wt%, Ti 0.008-0.012 wt%, N not more than 0.0035 wt%, Ca 0.001-0.005 wt%, B 0.001-0.003 wt%, and Fe and inevitable impurity for the rest, with Pcm not more than 0.18 wt%. The present invention has low alloy steel as basis, properly raised Als content, C / Mn ratio of 0.020-0.050, Ti-B microalloying, Ca or REM treatment, Ti / N ratio of 3.0-3.5, optimized TMCP treatment, microscopic structure comprising small amount of ferrite and diffused bainite crystal of average crystal grain size below 15 micron, excellent mechanical performance and welding performance, and is especially suitable for being used as high strength ship deck, low temperature pressure container, offshore platform, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-yield ratio, high heat input welding, high-strength and high ductility steel plate and method of manufacture

ActiveCN101289728AIncrease contentSimple processTemperature control deviceAlloy elementOil production

The invention provides a steel plate having low-temperature toughness, high tensile strength and low yield ratio, as well as a method for making the same. By combining simple combination design of alloying elements with optimized TMCP process, the method successfully solves the problem that low-temperature impact toughness and low yield ratio are in mutual conflict and difficult to reconcile in composition design and process design, which reduces the amount of steel material, saves cost, lightens the dead weight of a steel structure, increases stability and safety, and more importantly, improves the safety, stability and seismic damage resistance of the steel structure. The steel plate can be widely applied to large-scale high-rise building structures, bridge structures, offshore oil production platform structures, low temperature pressure vessels and large-scale ship structures.

Owner:BAOSHAN IRON & STEEL CO LTD

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

Super-strength high-toughness wear resistant steel plate and production method thereof

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

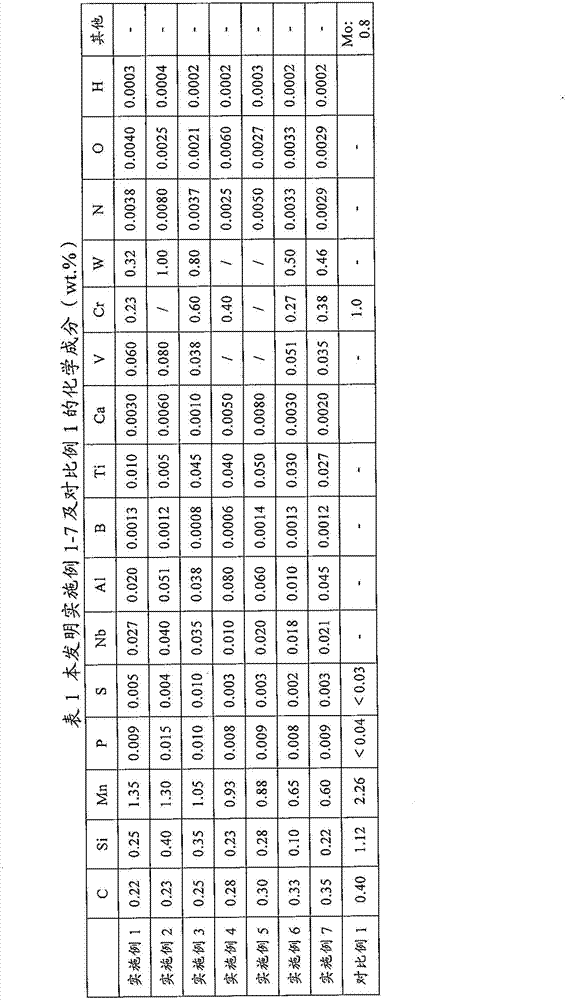

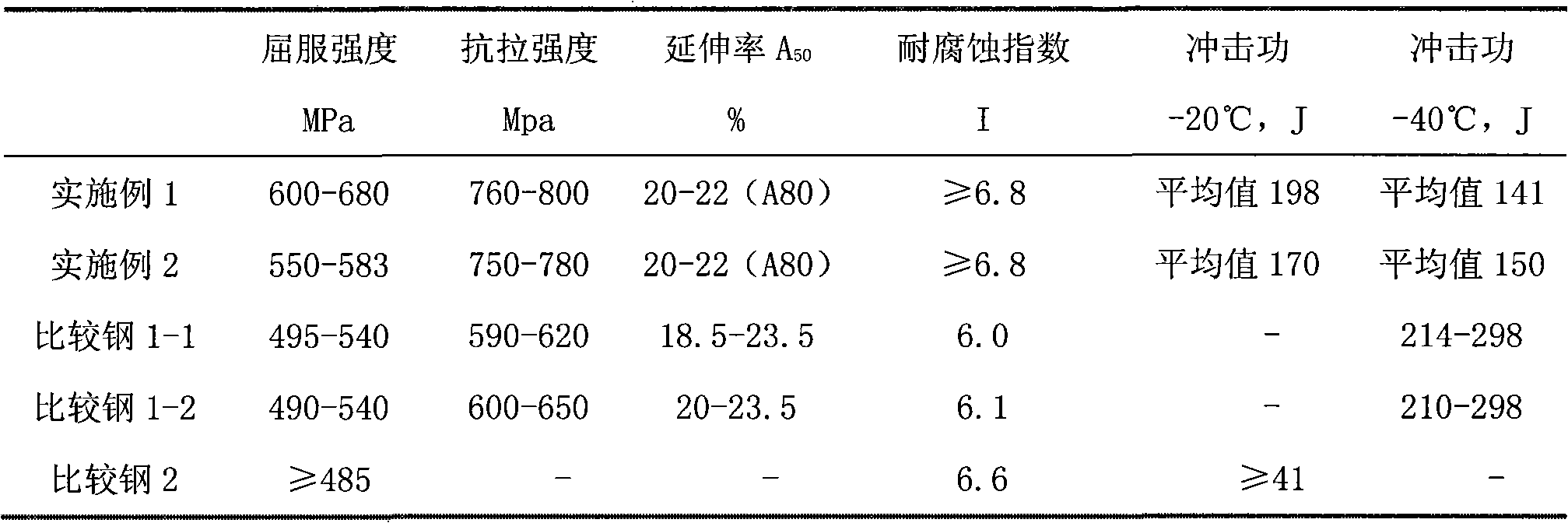

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process

InactiveCN1888120ARaise Strength IndexMeet manufacturing requirementsRoll mill control devicesHeat treatment process controlHeat sensitiveUltimate tensile strength

The present invention discloses one kind of ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process. The ultra-high strength steel consists of C 0.05-0.12 wt%, Si 0.05-0.50 wt%, Mn 1.10-1.70 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Nb 0.025-0.070 wt%, V 0.005-0.080 wt%, Mo 0.20-0.50 wt%, Ni 0.30-0.80 wt%, Ti 0.005-0.025 wt%, Cu 0.25-0.80 wt%, B 0.0005-0.0020 wt%, and Cr 0.10-0.70 wt%, except Fe and inevitable impurities. It has carbon equivalent not lower than 0.65 % and heat sensitive coefficient not lower than 0.30 %. Its making process includes the steps of smelting, desulfurizing molten iron, combined blowing in converter, vacuum treatment, casting into plate blank, etc. It has yield strength not lower than 880 MPa, tensile strength not lower than 980 MPa and V-shaped notch Charpy absorbed-in-fracture energy at -20 deg.c not lower than 100J.

Owner:武钢集团有限公司

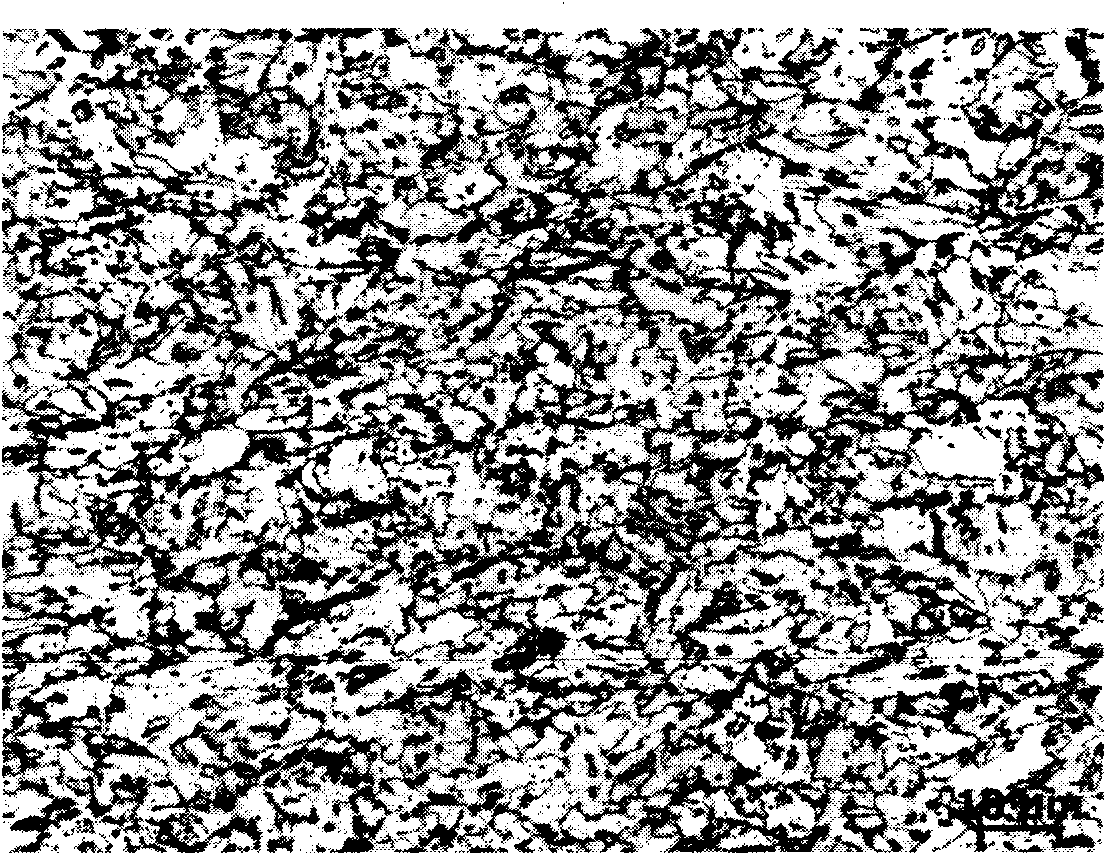

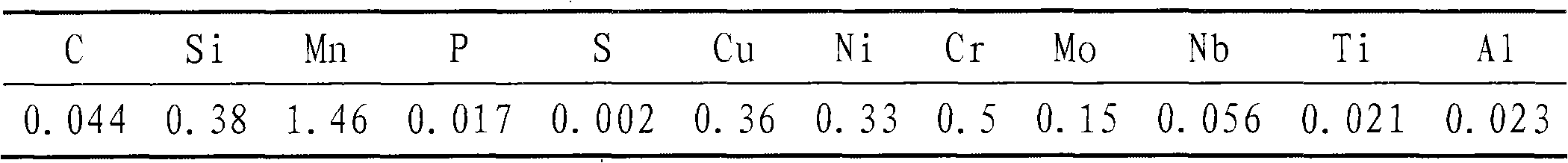

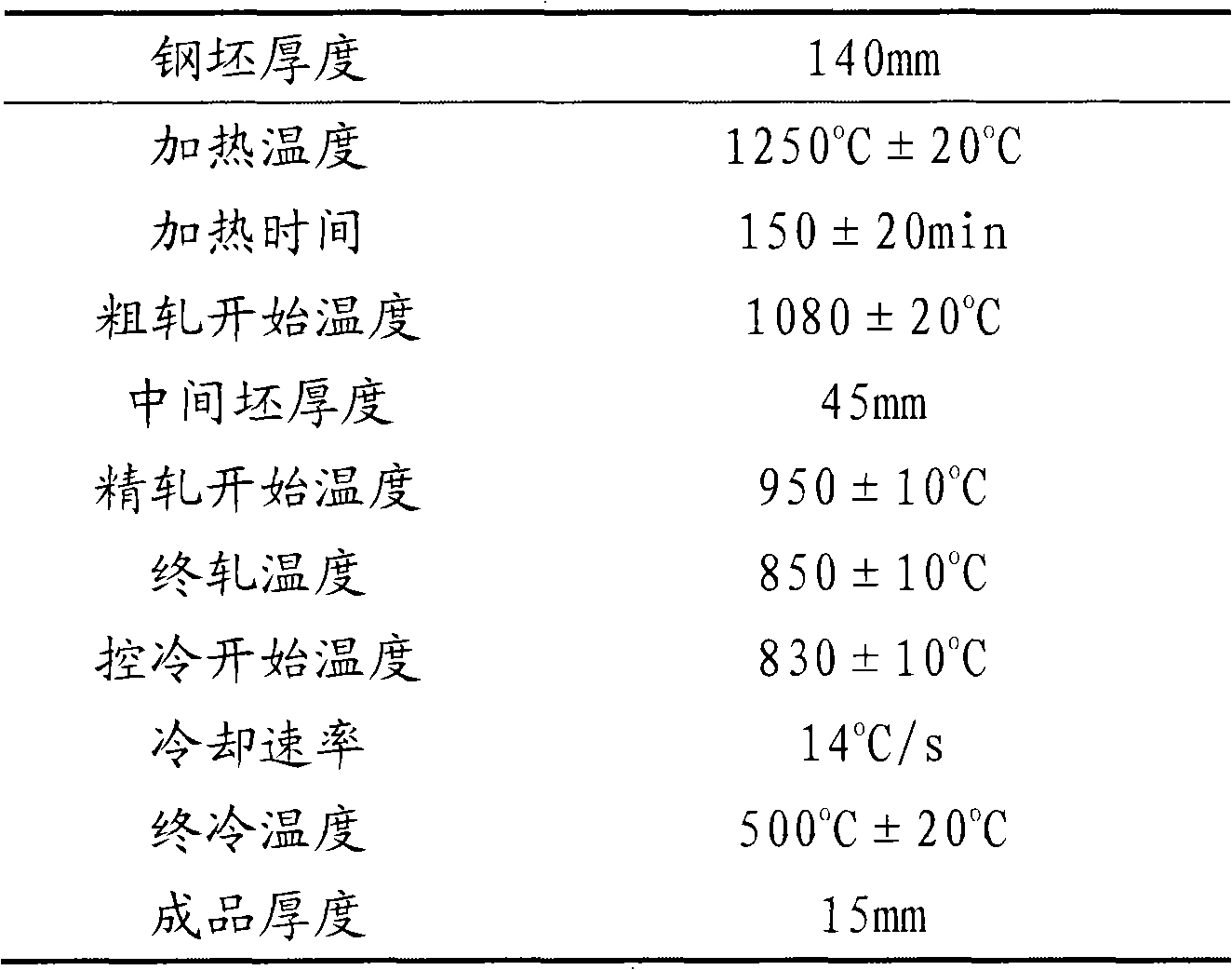

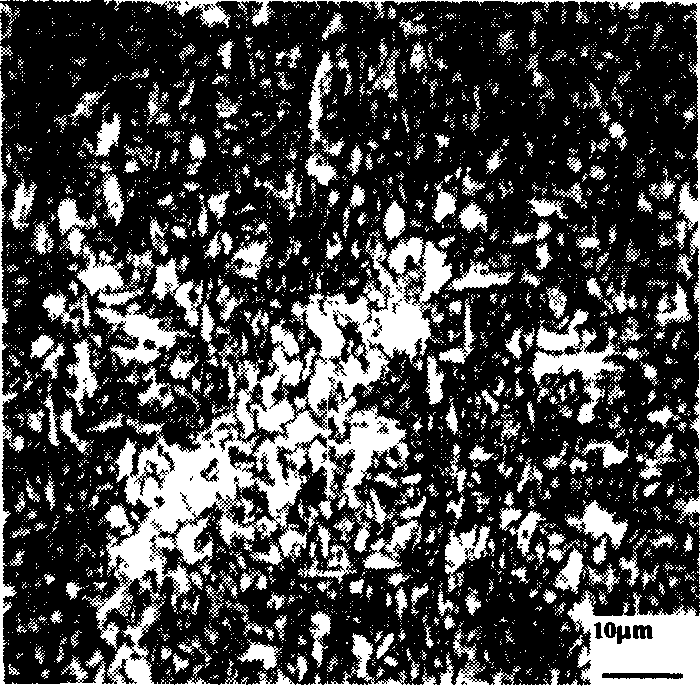

Hot rolled weatherproof bridge steel with yield strength of 500 MPa level and manufacturing method thereof

The invention relates to a hot rolled weatherproof bridge steel with yield strength of 500 MPa level and a preparation process thereof. The weatherproof bridge steel comprises the following chemical components in percentage by weight: 0.03-0.08% of C, no more than 0.5% of Si, 1.0-1.5% of Mn, no more than 0.015% of P, no more than 0.01% of S, 0.3-0.6% of Cu, 0.20-0.50% of Ni, 0.40-1.0% of Cr, 0.15-0.35% of Mo, 0.03-0.08% of Nb, no more than 0.04% of Ti, no more than 0.04% of Als and balance Fe and impurities, and the weatherproof bridge steel is mainly prepared by a control rolling and cooling process. The weatherproof bridge steel has the advantages of simple composition, low cost, yield strength more than 500 MPa, favorable low-temperature tenacity, weldability and weatherability, convenient preparation process and high controllability. The preparation method can be widely used in the production field of various bridge steels.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

InactiveCN101660108AThe ingredients are designed to be simpleObvious effectManufacturing convertersSimple componentHigh intensity

The invention relates to a non-quenched acicular structure high strength low yield ratio weathering resistant steel and a production method thereof. The steel comprises components by weight percent: basic components: 0.03-0.08% of C, 0.30-0.60% of Si, 1.30-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cu, 0.20-0.50% of Ni, 0.40-0.80% of Cr, 0.10-0.40% of Mo, 0.030-0.080% of Nb and less than or equal to 0.04% of Ti; optional components are two or more in less than or equal to 0.04% of AlS and less than or equal to 0.40kg / t steel of RE or less than or equal to 0.005% of Ca; and the rest of Fe and impurities. Welding cold crack is low in susceptibility coefficient and high in corrosion resisting index. The steel has simple components as wellas excellent moldability, weatherability, weldability and low temperature toughness; meanwhile, the preparation technique is simple, heat treatment is not needed, the production period is short, and the production cost is low.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Superhigh strength thick steel plate capable of large-line energy welding and its manufacturing method

ActiveCN1676656AReduce manufacturing costGood welding performanceHigh intensityUltimate tensile strength

This is a super intensive thick steel board which can be welded with jug line power. It contains 0.01-0.06%C, 0.10-0.50%Si, 1.00 -1.40%Mn, 0.010-0.050%Nb, 0.040-0.090%V, 0.60-1.00%Cu, 0.20-0.50%Cr, 0.20-0.50%Mo, 0.50-0.80%Ni, 5ppm-30ppmB, 0.005-0.020%Ti, 0.040-0.070%Als, and remained Fe and inevitable impurity: 0.065<=(%Cu*%V)<=0.085. The producing method includes: casting technique, slab heating, hot rolling, which is asynchronous rolling in austenite non-crystallized area, strain relaxation and direct cooling by quenching. This invention associates well the steel board's high intensity, high ductility and good weldability. It decreases the quantity of alloying agent and reduces the cost for steel board's production. It can as well improve the low-temperature flexibil ity and welability of the steel board, as it realizes welding with jug line power. As a result, it needs no pre-heating to weld steel board above 0 degree Centigrade.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh-strength atmospheric-corrosion resistant steel

The invention discloses a hyperstrength atmospheric corrosion-tolerant steel, which comprises the following parts: 0.01-0.07% C, 0.25-0.50% Si, 1.60-2.00% Mn, not more than 0.018% P, not more than 0.008% S, 0.20-0.50% Cu, 0.40-0.75% Cr, 0.25-0.60% Ni, 0.03-0.08% Nb, 0.10-0.40% Mo, not more than 0.02 Ti, not more than 0.035% Als, not more than 0.003% B and Fe and impurity.

Owner:武钢集团有限公司

Submerged arc welding flux material used for high grade pipe line steel

InactiveCN100999043AHigh strengthGood stress corrosionArc welding apparatusWelding/cutting media/materialsChemical compositionMetallurgy

The present invention provides a welding flux material for submerged arc welding for welding high-grade line pipe steel and other structure steel. Its chemical composition includes (by wt%) 15%-25% of CaF2, 15%-25% of MgO, 15%-20% of Al2O3, 5%-10% of MnO, 5%-10% of TiO2, 10%-15% of SiO2, 5%-10% of CaO, 1.0%-2.5% of Na2O, 1.5%-3.0% of B2O3, 0.2%-0.4% of Re(Mg) and 3%-5% of ZrO2. Said welding flux material can be prepared by adopting sintering process. Besides, said invention also provides its application method.

Owner:XIAN UNIV OF TECH

Weathering steel with yield strength of more than 700MPa and manufacturing method thereof

InactiveCN101994063AMeet the requirements of reducing the self-weight of componentsGood atmospheric corrosion resistanceTemperature control deviceSheet steelUltimate tensile strength

The invention relates to Cr-containing weathering steel with the yield strength of more than 700MPa, good toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components in percentage by weight: 0.02 to 0.10 percent of C, 0.1 to 0.4 percent of Si, 0.3 to 1.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.006 percent of S, 0.2 to 0.5 percent of Cu, 2.5 to 10 percent of Cr, 0.2 to 1.0 percent of Ni, 0.02 to 0.06 percent of Nb, 0.01 to 0.05 percent of Al, less than or equal to 0.005 percent of N, 0.02 to 0.10 percent of Ti and the balance of Fe and inevitable impurities. A steel plate made of the steel has the yield strength of more than 700MPa and good toughness; meanwhile, the relative corrosion rate of the steel is reduced by one time compared with that of the conventional weathering steel, so the steel meets the requirement of improving the corrosion resistance of steel for railway vehicles and fulfils the aims of prolonging the service life and reducing maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Austenitic stainless steel welding wire and welding structure

ActiveUS20060243719A1Improve corrosion resistanceIncreased durabilityWelding/cutting media/materialsSoldering mediaAusteniteMaterials science

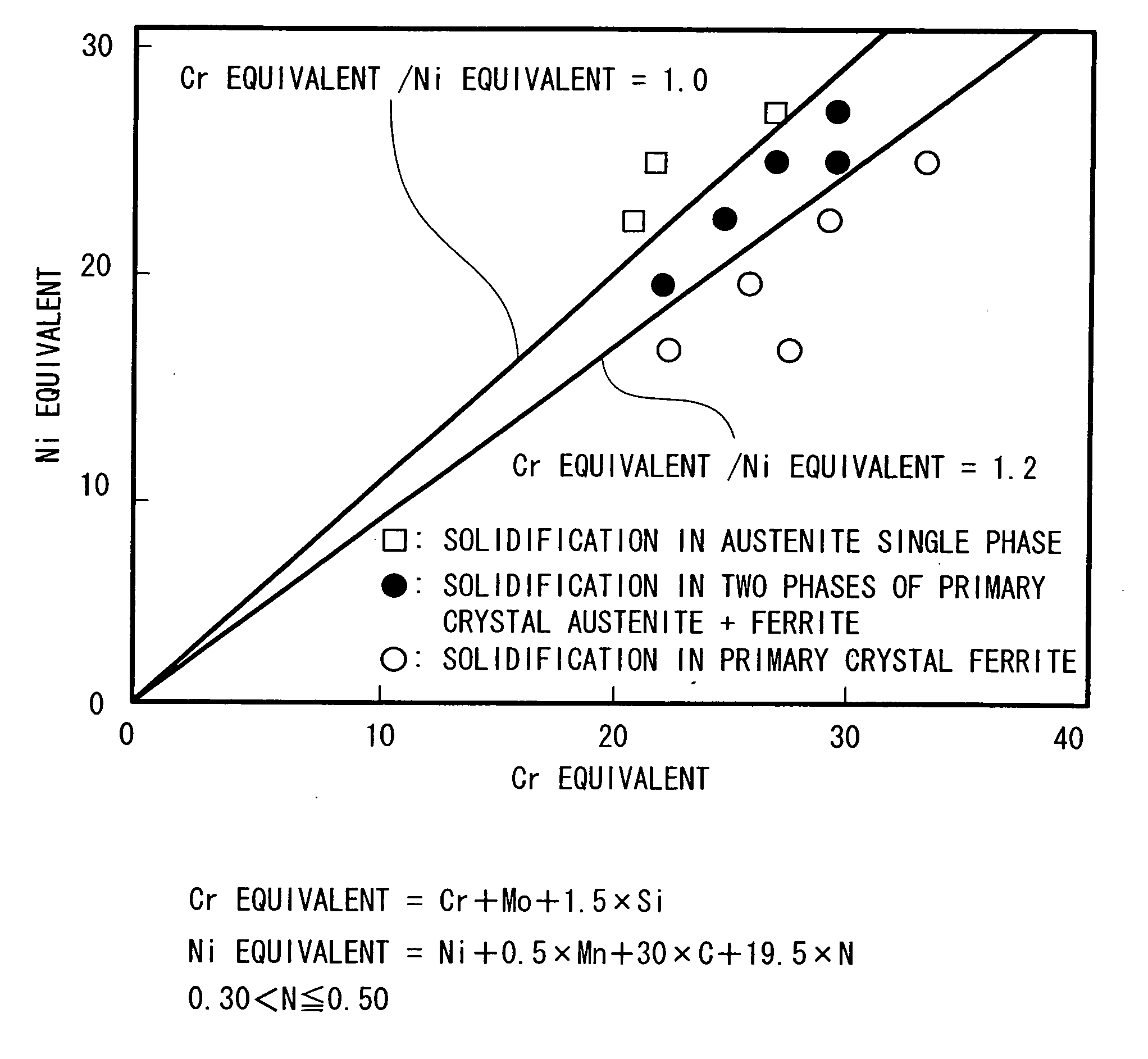

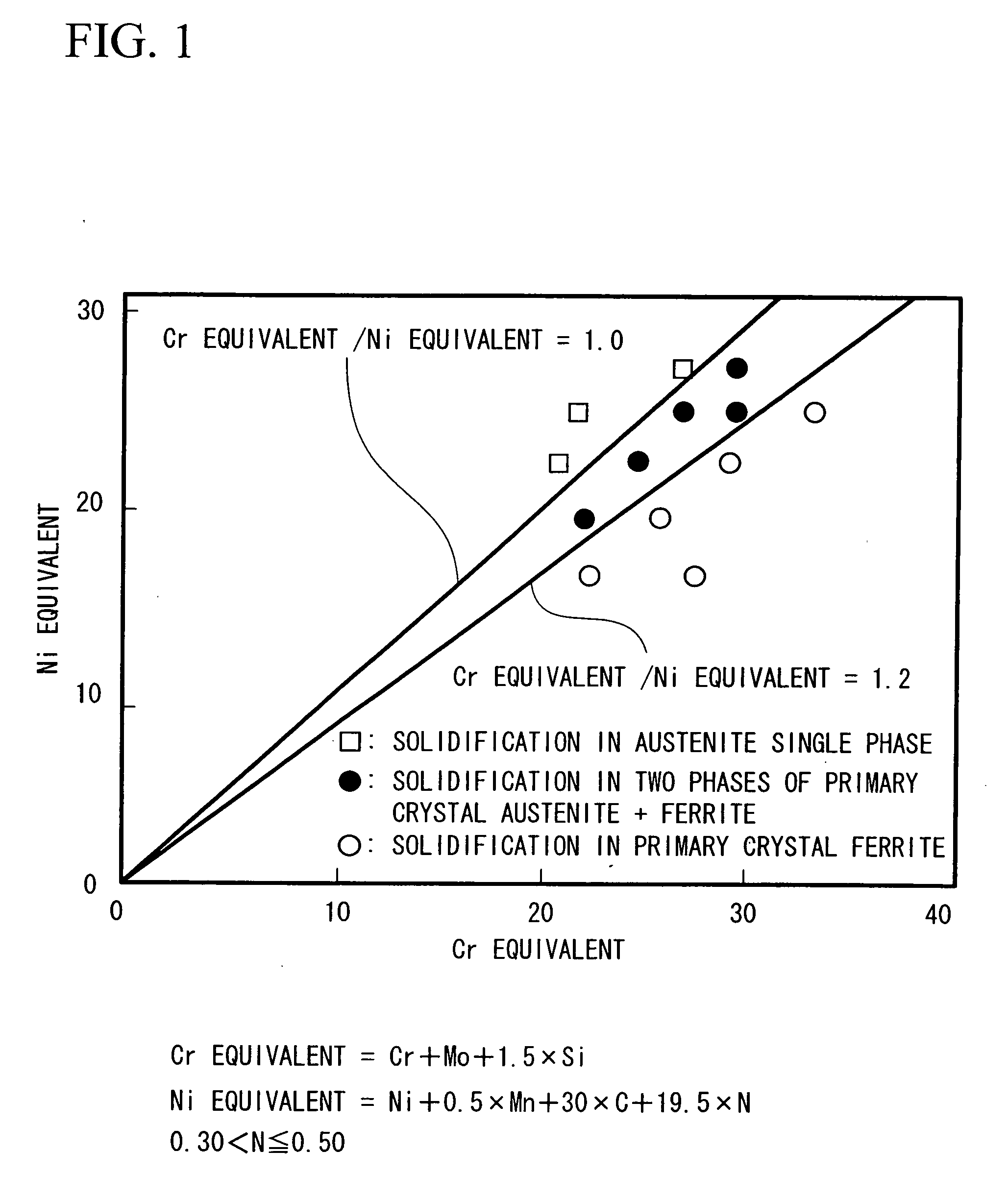

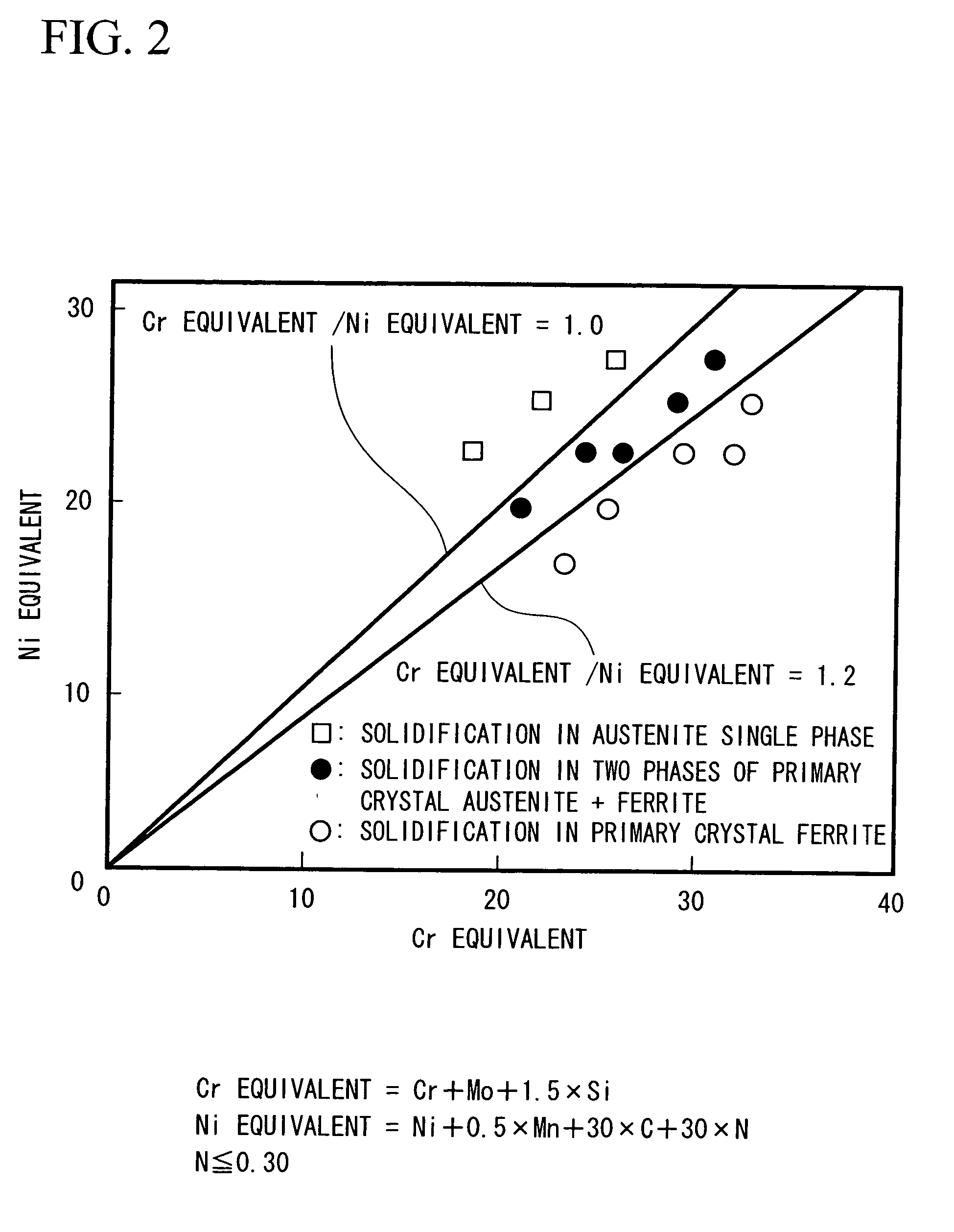

A welding wire for austenitic stainless steel welding contains, in percent by mass, C: 0.005 through 0.05%, Si: 0.1 through 1.0%, Mn: 1.0 through 3.5%, Cr: 25.0 through 28.0%, Ni: 16.0 through 23.9%, Mo: 1.6 through 3.0%, Cu: 0.1 through 0.5%, Al: 0.001 through 0.02%, and N: more than 0.30 through 0.50%, limiting 0 to 0.03% or less, P to 0.03% or less, and S to 0.005% or less, and having a ratio of a Cr equivalent to Ni equivalent (Cr equivalent / Ni equivalent) within a range between 0.85 and 1.2 and a PI value of 35 or more, the remainder being iron and unavoidable impurities.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Corrosion resisting steel and corrosion resisting oil well pipe having high corrosion resistance to carbon dioxide gas

InactiveUS6248187B1Excellent in resistance to corrosionHigh strengthMartensiteUltimate tensile strength

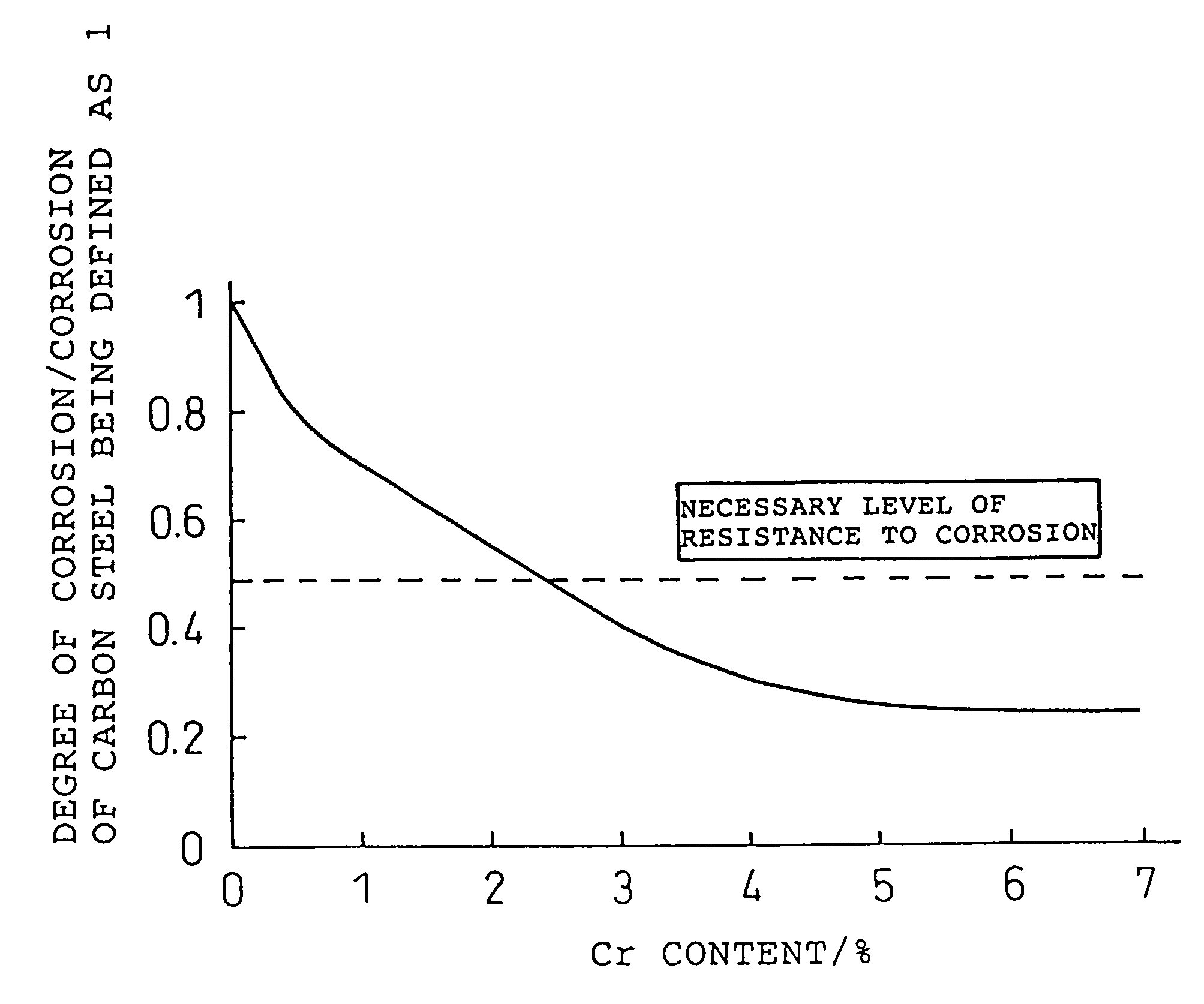

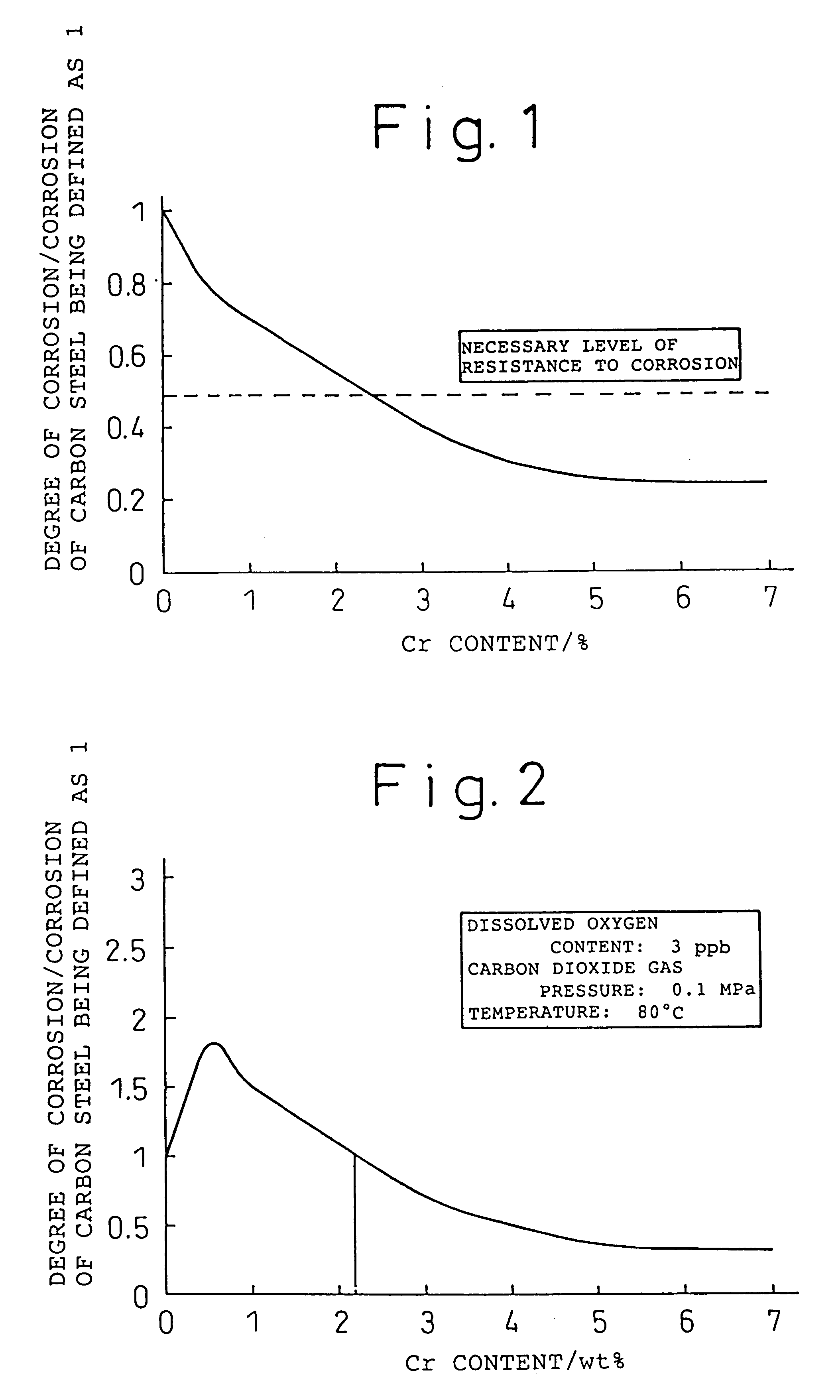

An object of the present invention is to provide a corrosion resistant steel excellent in strength and low temperature toughness as well as resistance to corrosion by carbon dioxide and seawater, and most suitable for oil well steel pipes and line pipes for production and transportation of gas, petroleum, etc. used in the field of energy, or a steel for plants, and corrosion resistant oil well steel pipes. The corrosion resistant steel and the corrosion resistant oil well steel pipes comprise, based on weight, up to 0.30% of C, up to 1.0% of Si, 0.2 to 2.0% of Mn, 2.1 to less than 5.0% of Cr, up to 0.03% of P, up to 0.02% of S, up to 0.10% of Al, up to 0.015% of N, optionally containing Cu, Ni, Mo, Ti, Nb and B, and the balance of Fe and unavoidable impurities, and have a martensitic structure as their metallic structure.

Owner:NIPPON STEEL CORP

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

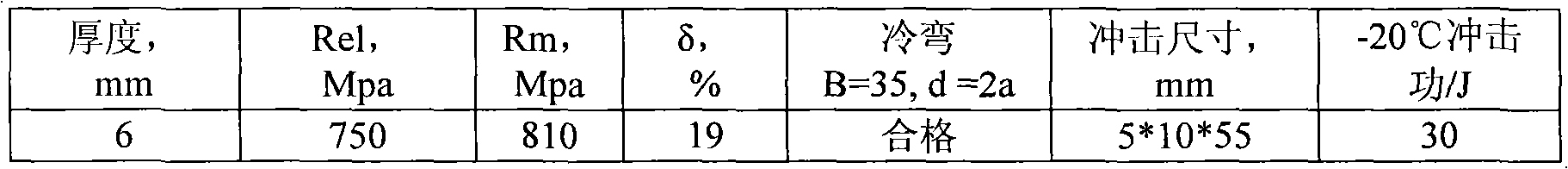

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

Three-layer composite steel plate and manufacturing method thereof

ActiveCN105543649AMeet bulletproof requirementsGood bulletproofMetal layered productsSheet steelSurface layer

The invention discloses a three-layer composite steel plate. The three-layer composite steel plate is provided with a low-hardness layer serving as a middle base layer and a high-hardness layer serving as a surface layer; and the high-hardness layer and the low-hardness layer achieve atom combination through roll cladding, wherein the low-hardness layer is Mn13 steel, the Brinell hardness of the high-hardness layer is larger than 600, and the Brinell hardness of the low-hardness layer is lower than 250. The invention further discloses a manufacturing method for the three-layer composite steel plate. The manufacturing method comprises the steps that (1), a high-hardness layer slab and a low-hardness layer slab are prepared; (2), assembling is carried out, wherein the slab combination face is pretreated, the slab binding face is subject to peripheral welding seal, and the composite slab obtained after welding seal is subject to vacuumizing treatment; (3), heating is carried out; (4), composite rolling is carried out; (5), cooling is carried out; and (6), heat treatment is carried out, wherein the heating temperature of heat treatment ranges from 1050 DEG C to 1100 DEG C, the heating time ranges from 2 min / mm*slab thickness to 3 min / mm*slab thickness, the heated composite plate is subject to water cooling, and the water temperature is smaller than 40 DEG C; and the composite steel plate has the different hardness characteristics.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

Cr-contained weathering steel with excellent toughness and high corrosion resistance

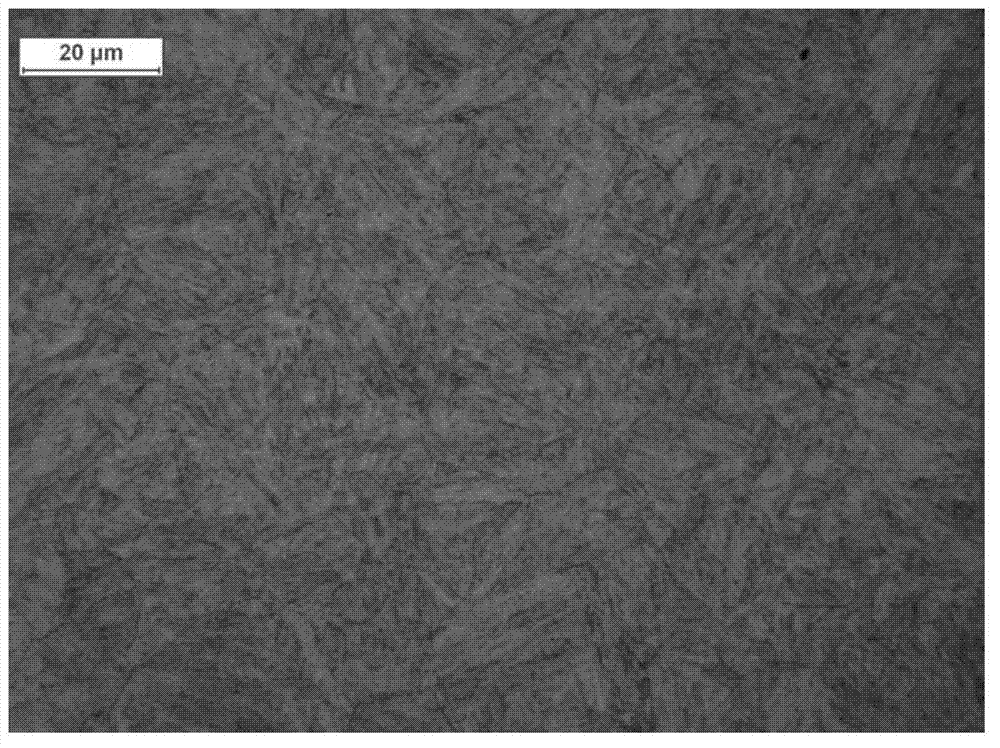

InactiveCN102127717AGood atmospheric corrosion resistanceImprove low temperature toughnessTemperature control deviceToughnessWeathering steel

The invention relates to a Cr-contained weathering steel with high corrosion resistance and a manufacture method thereof. The weathering steel is prepared from the following components in percentage by weight: 0.01-0.06 percent of C, 0.1-0.4 percent of Si, 0.2-0.8 percent of Mn, not more than 0.01 percent of P, not more than 0.006 percent of S, 0.2-0.5 percent of Cu, 2.5-7.0 percent of Cr, 0.2-1.2 percent of Ni, 0.01-0.05 percent of Al, not more than 0.005 percent of N, 0.01-0.10 percent of Ti and the balance of Fe and inevitable impurities. The relative corrosion rate of the weathering steel is decreased twice on the basis of traditional weathering steel and can be served in atmosphere environment; the preferred weathering steel has the yield strength over 460 MPa and excellent toughness, meets the requirement of steel for railway vehicles and achieves the aims of prolonging service length and decreasing maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

High strength low yield ratio welding structure steel and production method thereof

The invention belongs to welded structural steel with high strength and low yield ratio and a production method thereof, aiming at solving the defects that a steel plate or a steel coil with the specification smaller than 25mm can only be produced, the process is long, and the like. The invention adopts the measures that the welded structural steel contains chemical components by weight that: 0.04-0.10 percent of C, 0.60-2.00 percent of Si, 1.50-2.50 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.010 percent of S, 0.20-0.50 percent of Cu, 0.40-0.80 percent of Cr, 0.35-0.80 percent of Ni, 0.0008-0.0030 percent of B, and at least three of the following components: less than or equal to 0.60 percent of Mo, 0.015-0.060 percent of Nb, 0.030-0.120 percent of V, less than or equal to 0.030 percent of Ti, less than or equal to 0.040 percent of Als and less than or equal to 0.010 percent of Zr, and the rest is Fe and unavoidable impurities; and meanwhile, Mn and Cr also need to satisfy the condition that Mn and Cr are equal to 2.20-2.80 percent, and the welding cold crack sensitivity coefficient Pcm is equal to C plus Si / 30 plus (Mn plus Cu plus Cr) / 20 plus Mo / 15 plus Ni / 60 plus V / 10 plus 5B and is less than or equal to 0.30 percent; the production method comprises the following steps of heating a steel billet, rough rolling, finishing rolling, relaxing and laminar cooling, and the laminar cooling comprises the following steps of slow cooling, quick cooling and natural cooling to room temperature.

Owner:武钢集团有限公司

Low-alloy high-performance wear-resistant steel plate and manufacturing method thereof

ActiveCN103205627AImprove performanceHigh hardnessFurnace typesQuenching agentsChemical compositionWear resistant

The present invention provides a low-alloy high-performance wear-resistant steel plate and a manufacturing method thereof. The steel plate comprises the following chemical compositions (wt%) of 0.21-0.32% of C, 0.10-0.50% of Si, 0.60-1.60% of Mn, 0.0005-0.0040% of B, 0-1.50% of Cr, 0-0.80% of Mo, 0-1.50% of Ni, 0-0.080% of Nb, 0-0.080% of V, 0-0.060% of Ti, 0.010-0.080% of Al, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0.0004% of H, 0-0.015% of P, and 0-0.010% of S, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, 0.01%<=(Al+Ti)<=0.13%, and the balance is Fe and inevitable impurities. The low-alloy high-performance wear-resistant steel plate manufactured by the above compositions and through a TMCP process has high strength and hardness, good toughness and excellent wear resistance, and is suitable for easy-to-wear parts in various mechanical equipments.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh tough steel with tensile strength of 1100 Mpa and manufacturing method thereof

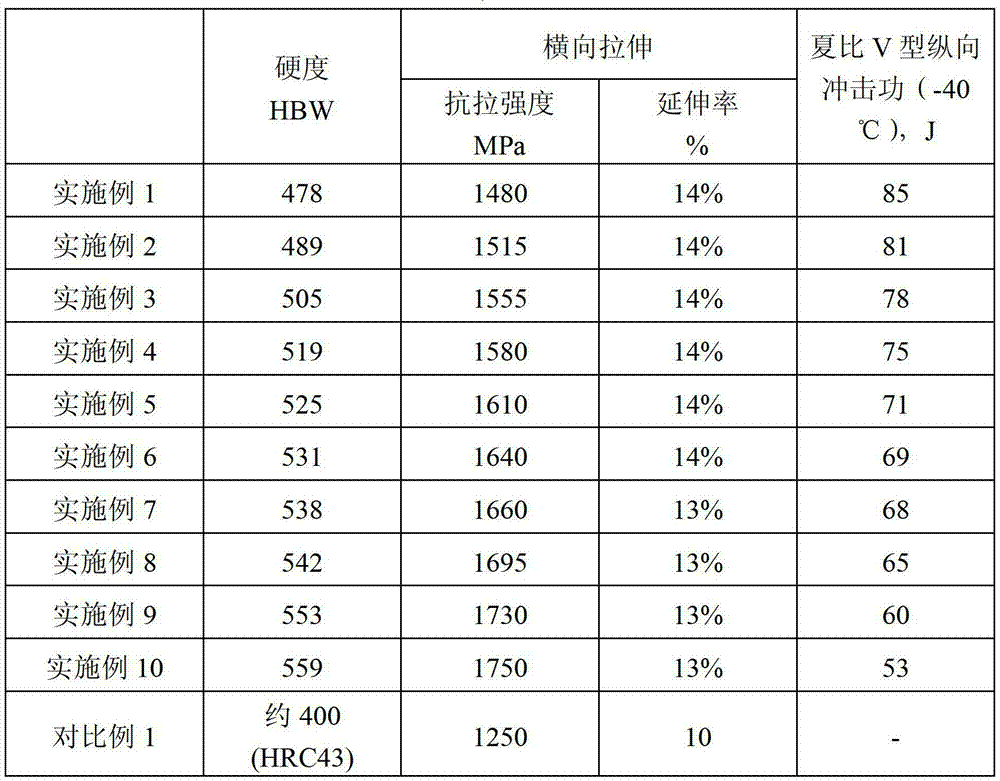

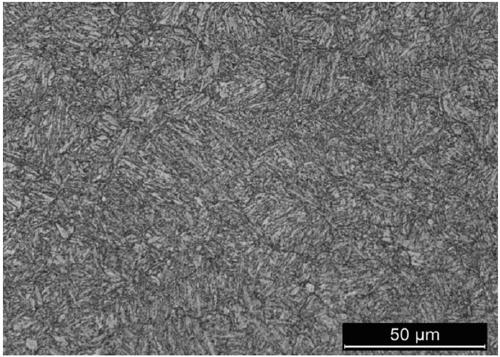

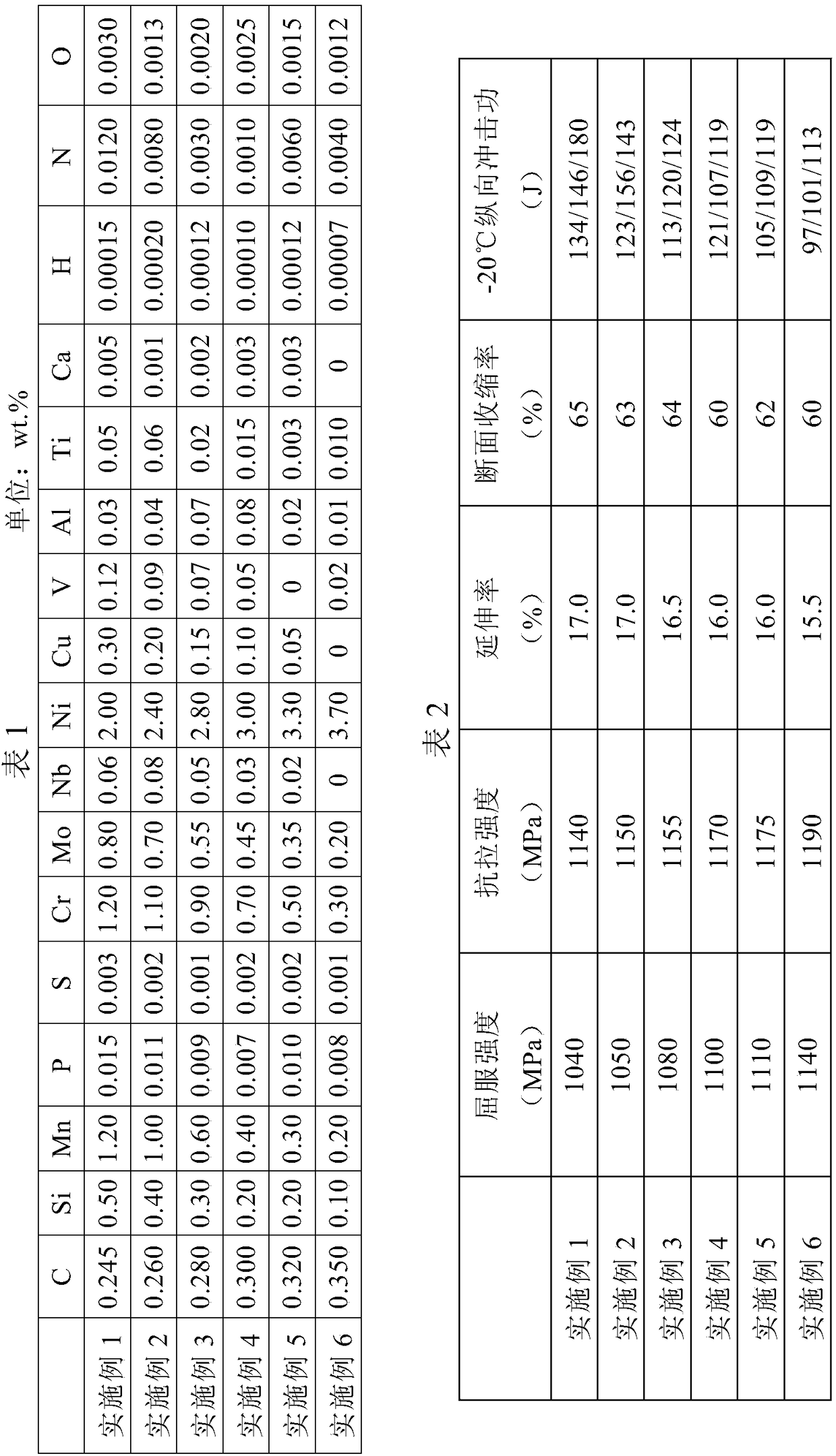

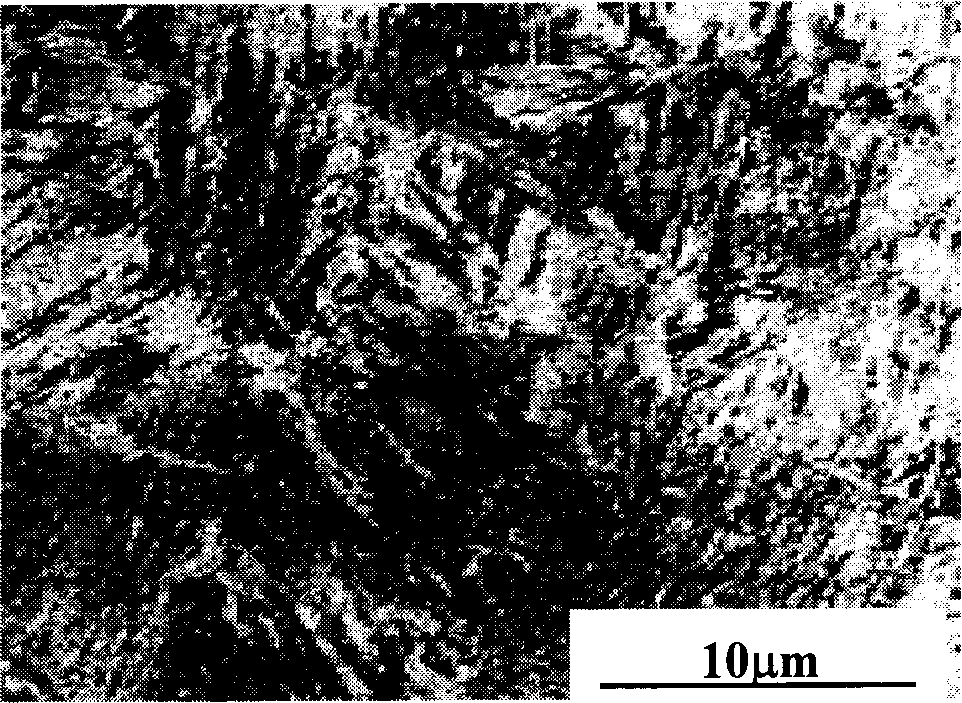

InactiveCN109136737AImprove low temperature impact toughnessImprove tensile propertiesShrinkage rateUltimate tensile strength

The invention discloses ultrahigh tough steel with tensile strength of 1100 Mpa and a manufacturing method thereof. Chemical components of the tough steel comprises, by weight, 0.245-0.350% of C, 0.10-0.50% of Si, 0.20-1.20% of Mn, P less than or equal to 0.015%, S less than or equal to 0.003%, 0.30-1.20% of Cr, 0.20-0.80% of Mo, 2.00-3.70% of Ni, 0-0.30% of Cu, 0-0.08% of Nb, 0-0.12% of V, 0.01-0.08% of Al, 0.003-0.06% of Ti, Ca less than or equal to 0.005%, H less than or equal to 0.002%, N less than or equal to 0.0120%, O less than or equal to 0.0030%, Fe and inevitable impurities. The preparation method adopts quenching plus tempering heat treatment, and tempered martensites plus tempered bainites and residual austenite tissue are obtained. The yield strength of steel is greater than or equal to 900 Mpa, the tensile strength is greater than or equal to 1100 Mpa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 70 J, the elongation rate is greater than or equal to 15%, the shrinkage rate of a fracture surface is greater than or equal to 50%, good strength, low-temperature toughness and plasticity are achieved, and the ultrahigh tough steel can be used for manufacturing high-performance ocean platform mooring cables of R6 grade and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate capable of being welded under large heat input and method for manufacturing the same

ActiveCN1804093AUniform and excellent low temperature toughnessEnsure safetyManufacturing cost reductionMaterials science

The invention provides a thick steel plate for large-thread energy welding, wherein the constituents comprise (by weight percentage) C 0.010-0.020%, Si 0.10-0.30%, Mn 1.80-2.30%, P<=0.010%, S<=0.003%, Nb 0.015-0.030%, Al 0.025-0.050%, Ti 0.010-0.020%, N 0.003-0.006%, REM 0.001-0.005ppm, Mg 0.002-0.006%, B 10-35ppm, and balancing Fe.

Owner:BAOSHAN IRON & STEEL CO LTD

Submerged arc welding wire for steel pipeline

ActiveCN101104229AEasy to implementLow costArc welding apparatusWelding/cutting media/materialsSheet steelWeld seam

The invention relates to a submerged arc welding wire used on a pipeline steel, which is applied in the submerged arc welding of an X80 high steel grade pipeline steel plate used on high-pressure oil and high-pressure gas conveying pipelines. The chemical components comprise (according to weight percent): C 0.02-0.07; Si 0.10-0.30; Mn 1.80-2.50; P is less than 0.010; S is less than 0.010; Cr 0.10- 0.50; Ti 0.05-0.08; Mo 0.20-0.50; B 0.003-0.004; and the rest is Fe. The welding wire is matched with BGSJ101-G flux and other special flux for pipeline steel welding , and then the best strength and toughness of welding seam can be obtained; the tensile strength ob of welded seam metal is more than or equal to 700MPa. Impact energy AkV of the welded seam metal in the minus 20 DEG C is more than or equal to 150J. And thus, the invention is suitable for the submerged arc welding of the X80 high steel grade pipeline steel plate.

Owner:SHOUGANG CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com