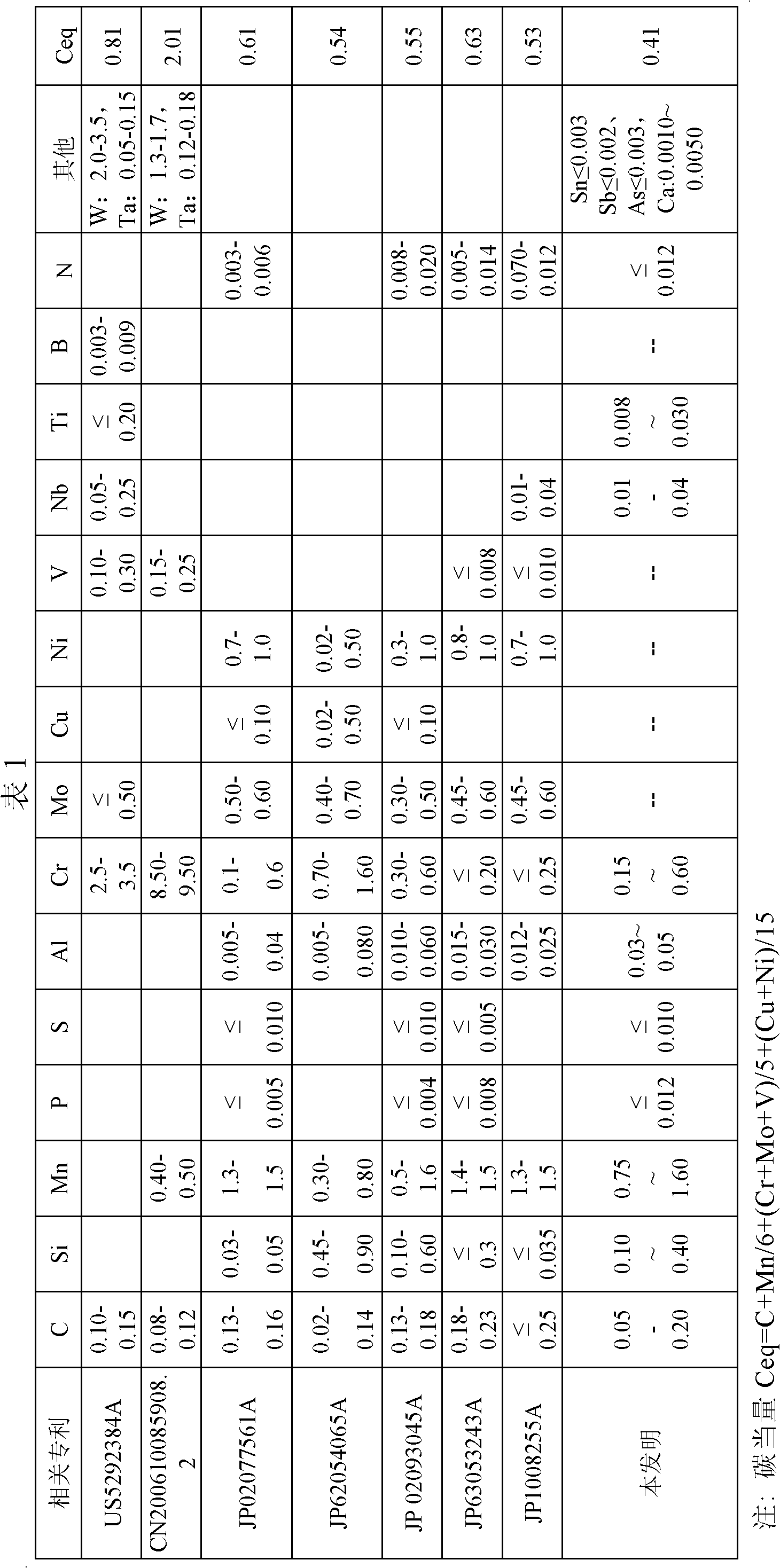

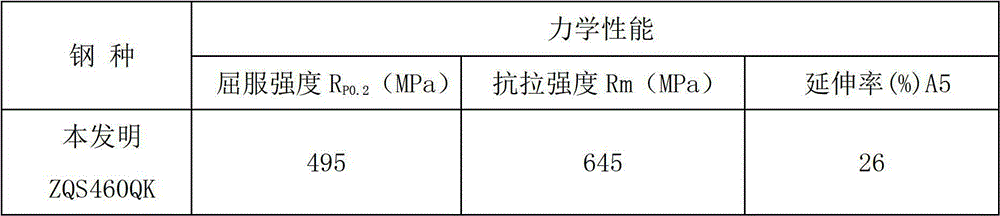

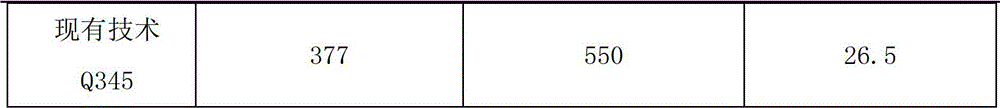

Patents

Literature

221results about How to "Good cold bending performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

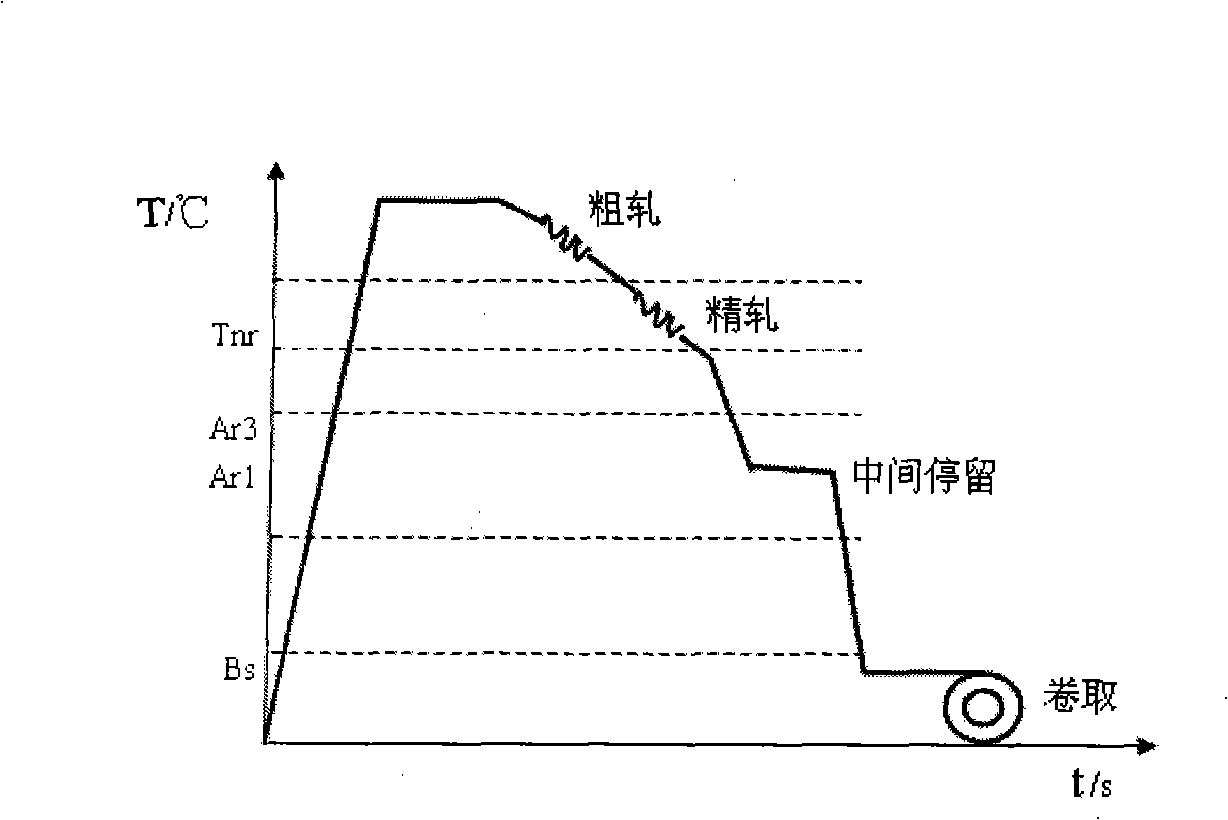

Steel for controlled rolling and controlled cooling platform and production method thereof

ActiveCN101358320AGood cold bending performanceSimple processTemperature control deviceCooling temperatureCost savings

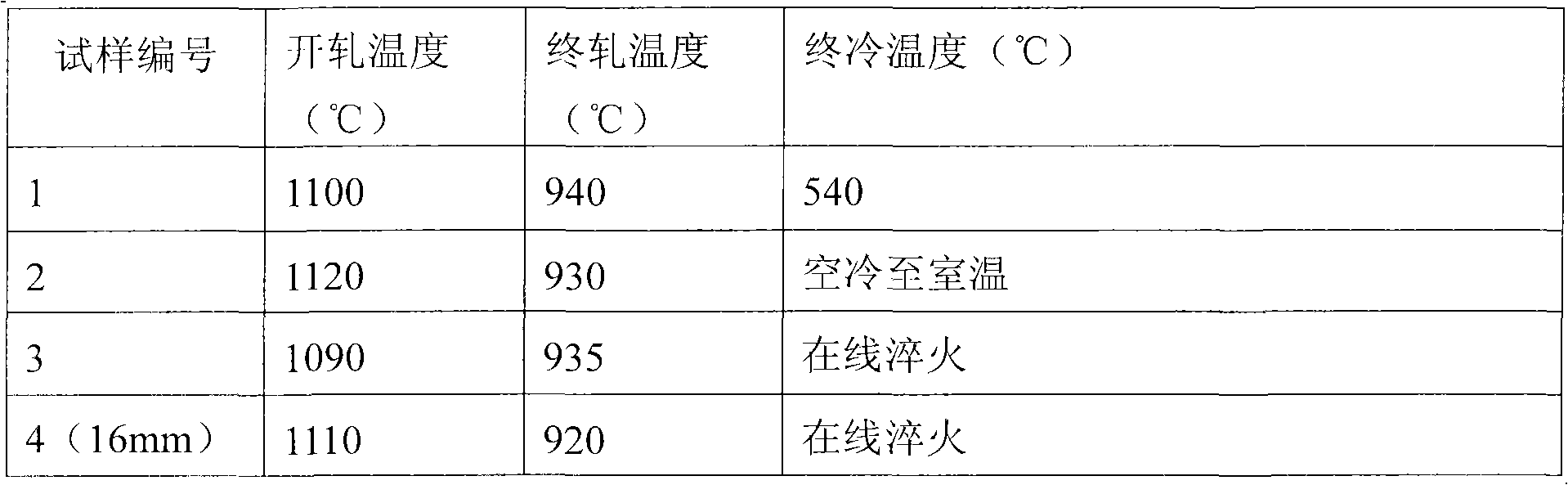

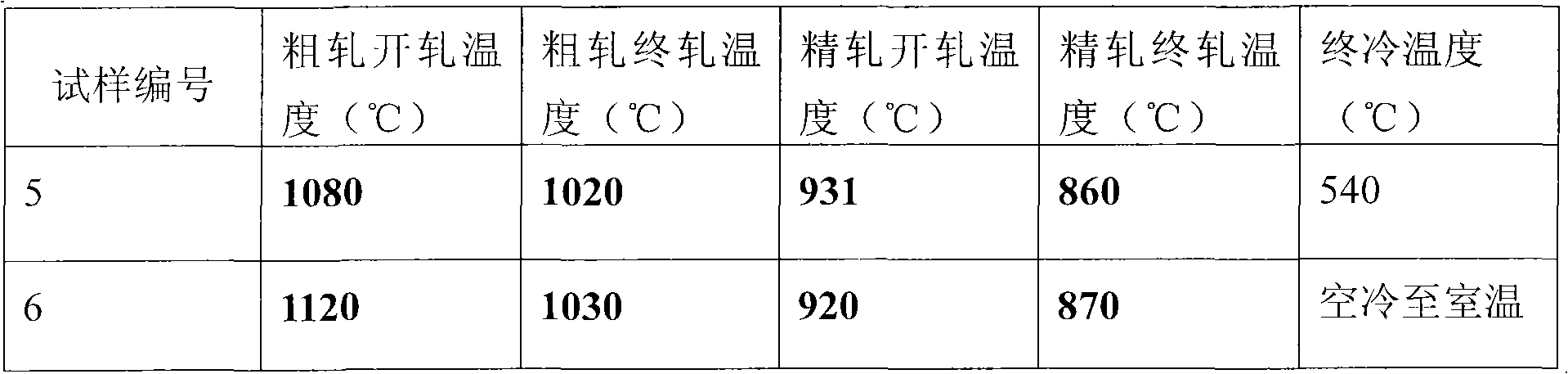

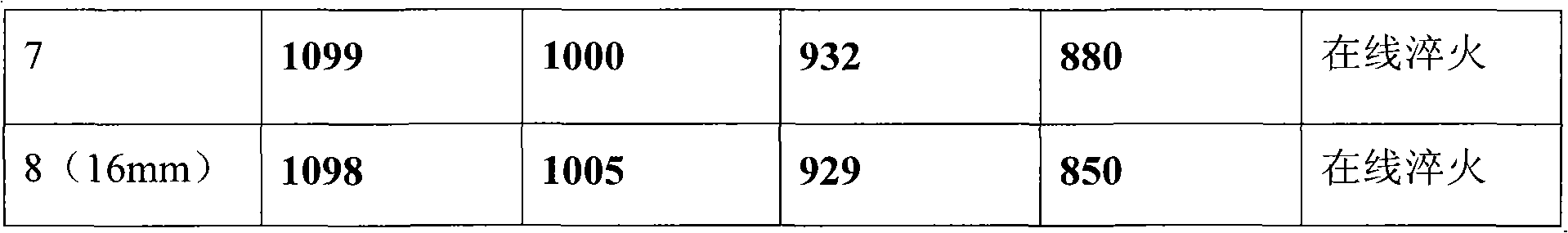

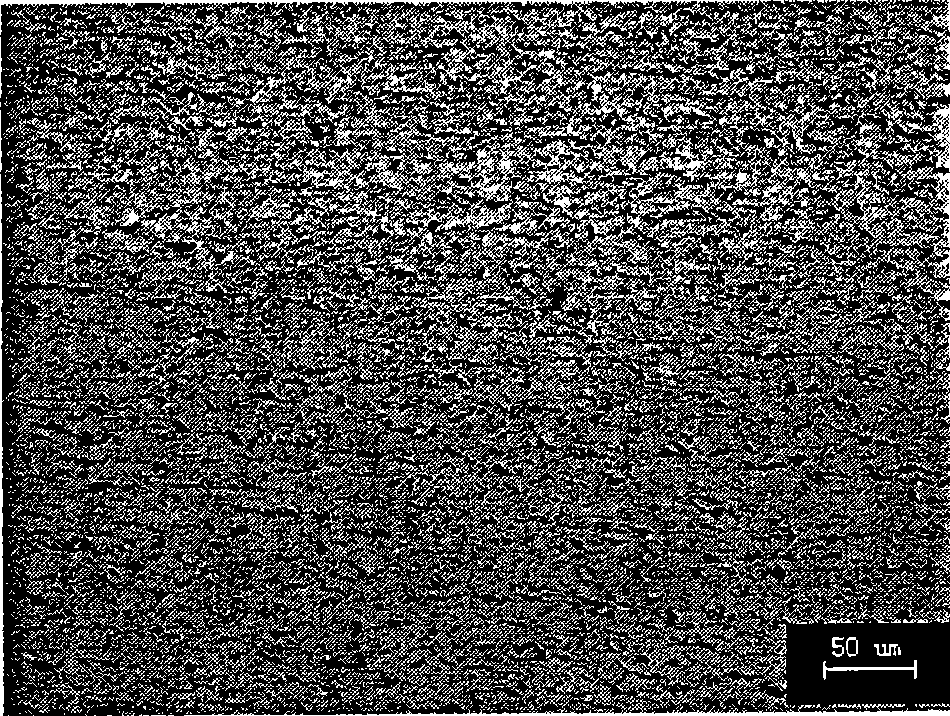

The invention relates to steel used for controlled rolling and cooling offshore platform, and a production method thereof. The invention belongs to the technical field of low-alloy high-strength steel. The steel was produced through slab continuous casting and TMCP processes after steel making and refining. The components of the slab are as follows: 0.05 percent to 0.09 percent of C, 1.20 percent to 1.60 percent of Mn, 0.20 percent to 0.50 percent of Si, 0.03 percent to 0.05 percent of Nb, 0.010 percent to 0.020 percent of Ti, 0.03 percent to 0.06 percent of V, equal to or less than 0.005 percent of S, 0.020 percent to 0.040 percent of Als, equal to or less than 0.015 percent of P, and the rest are Fe and impurities. Molten steel which is smelt by the component is cast into the slab which is 220mm to 250mm thick; the ingot is put into a slap heating furnace to be heated and rolled when being discharged. The initial billet temperature for rough rolling is 1060 DEG C to 1160 DEG C, the initial billet temperature for fine rolling is 840 DEG C to 940 DEG C, and the finishing temperature is 780 DEG C to 820 DEG C; the thickness of the rolled steel sheet is 10mm to 60mm. The starting cooling temperature is 760 DEG C to 810 DEG C; the finishing cooling temperature is 550 DEG C to 650 DEG C; the cooling speed is 10 DEG C / s to 17 DEG C / s. The production method has the advantages of simplified procedures and cost saving.

Owner:SHOUGANG CORPORATION

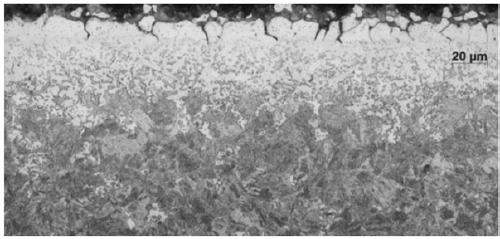

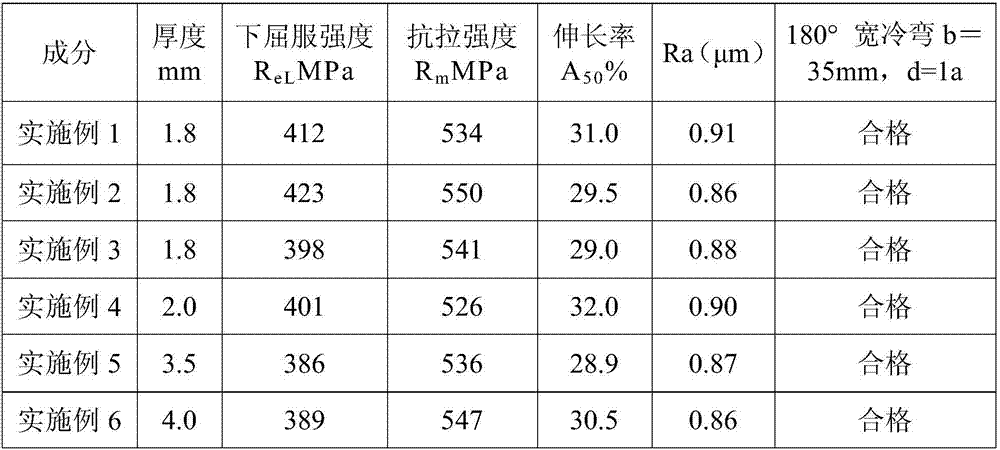

Zinc-plated hot-formed steel plate or steel strip with excellent cold bending performance and manufacturing method thereof

InactiveCN109371325AGood cold bending performanceHot-dipping/immersion processesSheet steelAustenite grain

The invention discloses a zinc-plated hot-formed steel plate or steel strip with excellent cold bending performance and a manufacturing method thereof. The zinc-plated hot-formed steel plate or steelstrip comprises a base plate with a surface decarburization layer thickness of 20 [mu]m or below and a zinc coating with an adhesion amount of 10-100 g / m<2> on the base plate. The constituent weight percentage of the base plate is C: 0.1-0.8%, Si: 0.05-2.0%, Mn: 0.5-3.0%, P: <=0.1%, S: <=0.05%, Al: <=0.1%, N: <=0.01%, and the balance Fe and unavoidable impurities. The average size of original austenite grains of the base plate is 15 [mu]m or below. The hot-formed steel plate or steel strip has a continuous and complete coating, no cracks extending to the base plate and excellent cold bending performance on the basis of meeting the conditions that the tensile strength of the base plate after hot-forming is 1500 MPa and the elongation after breaking is 5%.

Owner:BAOSHAN IRON & STEEL CO LTD

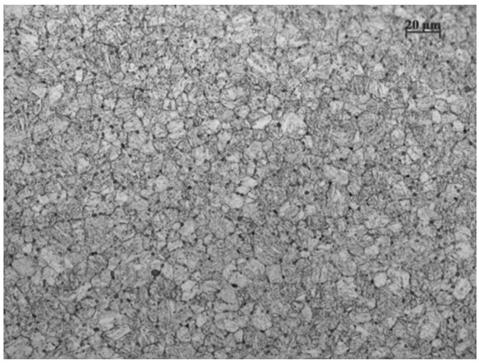

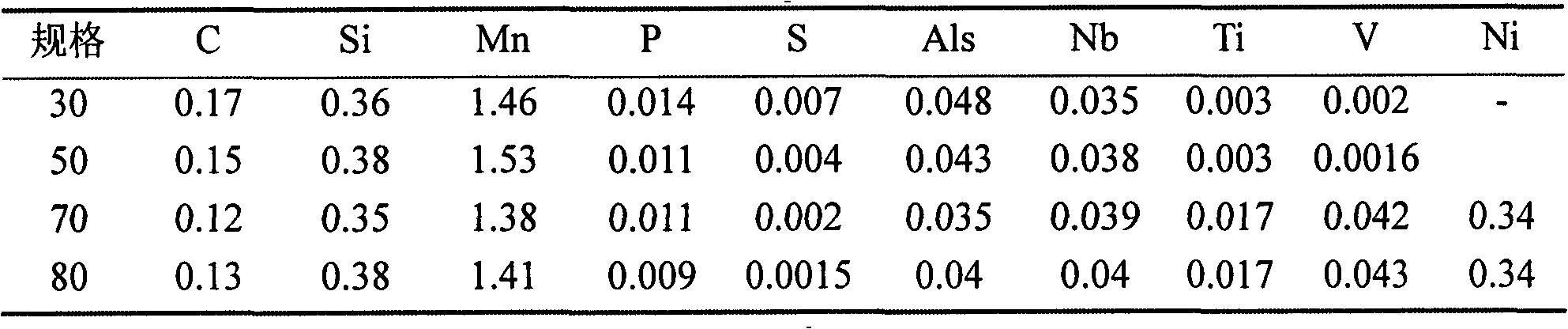

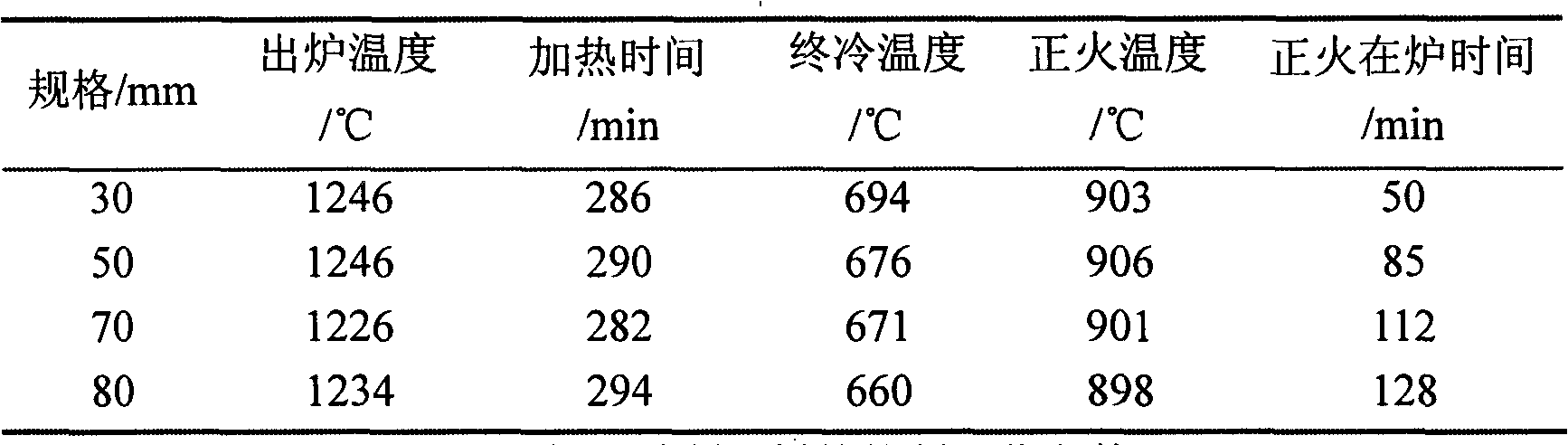

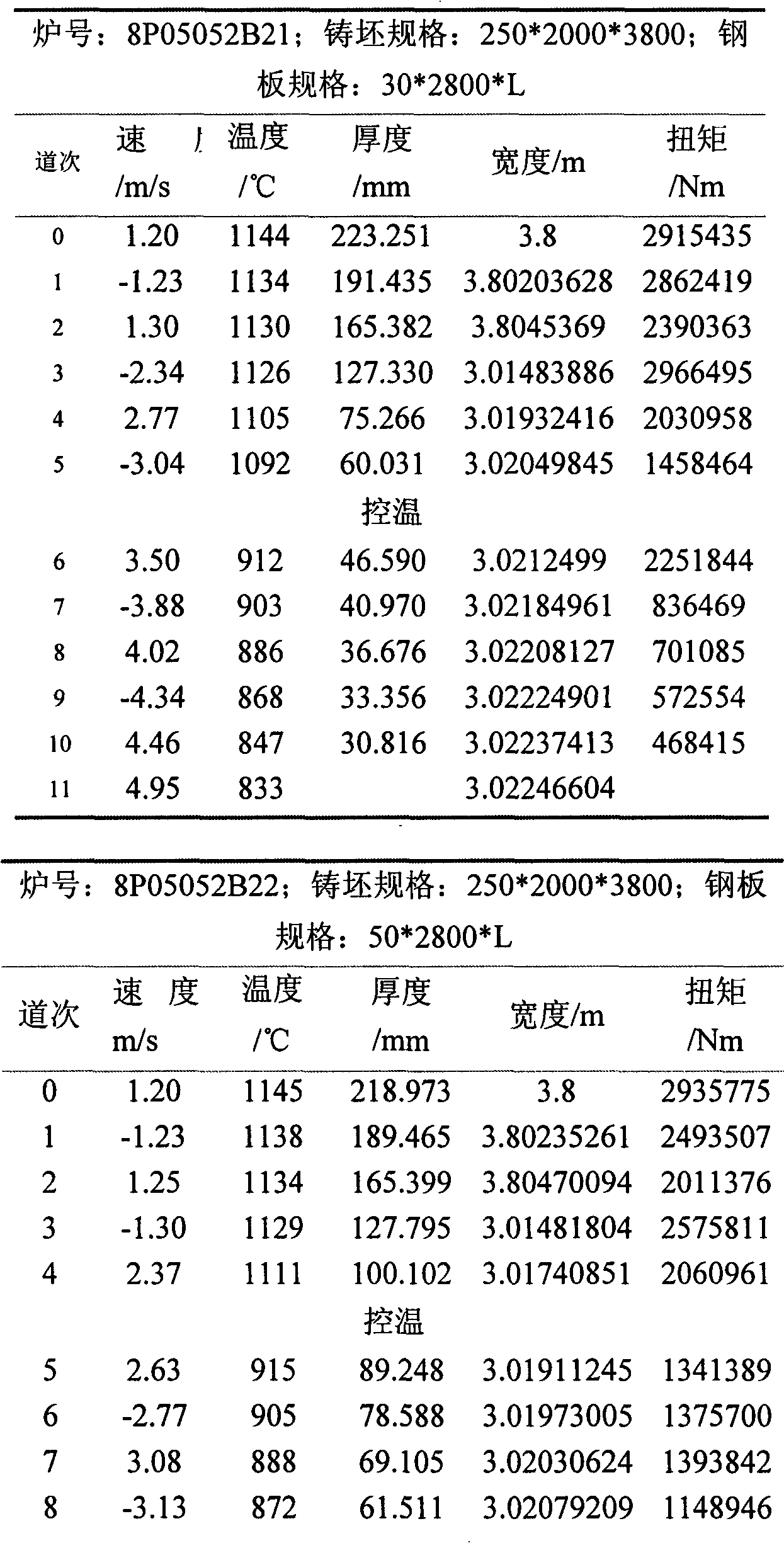

Steel for 36kg-grade ocean platform and production method thereof

The invention relates to steel for a 36kg-grade ocean platform and a production method thereof, belonging to the technical field of a ship body and structural steel for oceanographic engineering. A steel plate with thickness of 5-50mm comprises the following chemical components: 0.14-0.18 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, 0.02-0.05 percent of Nb, less than or equal to 0.005 percent of S, less than or equal to 0.015 percent of P, 0.020-0.04 percent of Als, and the balance of Fe and inevitable impurities; a steel plate with the thickness of 50-80mm comprises the following chemical components: 0.12-0.18 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, 0.02-0.05 percent of Nb, 0.02-0.06 percent of V, 0.010-0.020 percent of Ti, 0.10-0.40 percent of Ni, less than or equal to 0.005 percent of S, less than or equal to 0.015 percent of P, 0.020-0.04 percent of Als, and the balance of Fe and inevitable impurities; and in addition, the sum of Nb, V and Ti is less than or equal to 0.12 percent. The production method has the advantages of low production cost, uniform and stable comprehensive performance and good cold bending property.

Owner:SHOUGANG CORPORATION

Low-yield-ratio high-tenacity steel plate and manufacture method thereof

ActiveCN103014554AGood cold bending performanceRoll force/gap control deviceTemperature control deviceReduction rateYield ratio

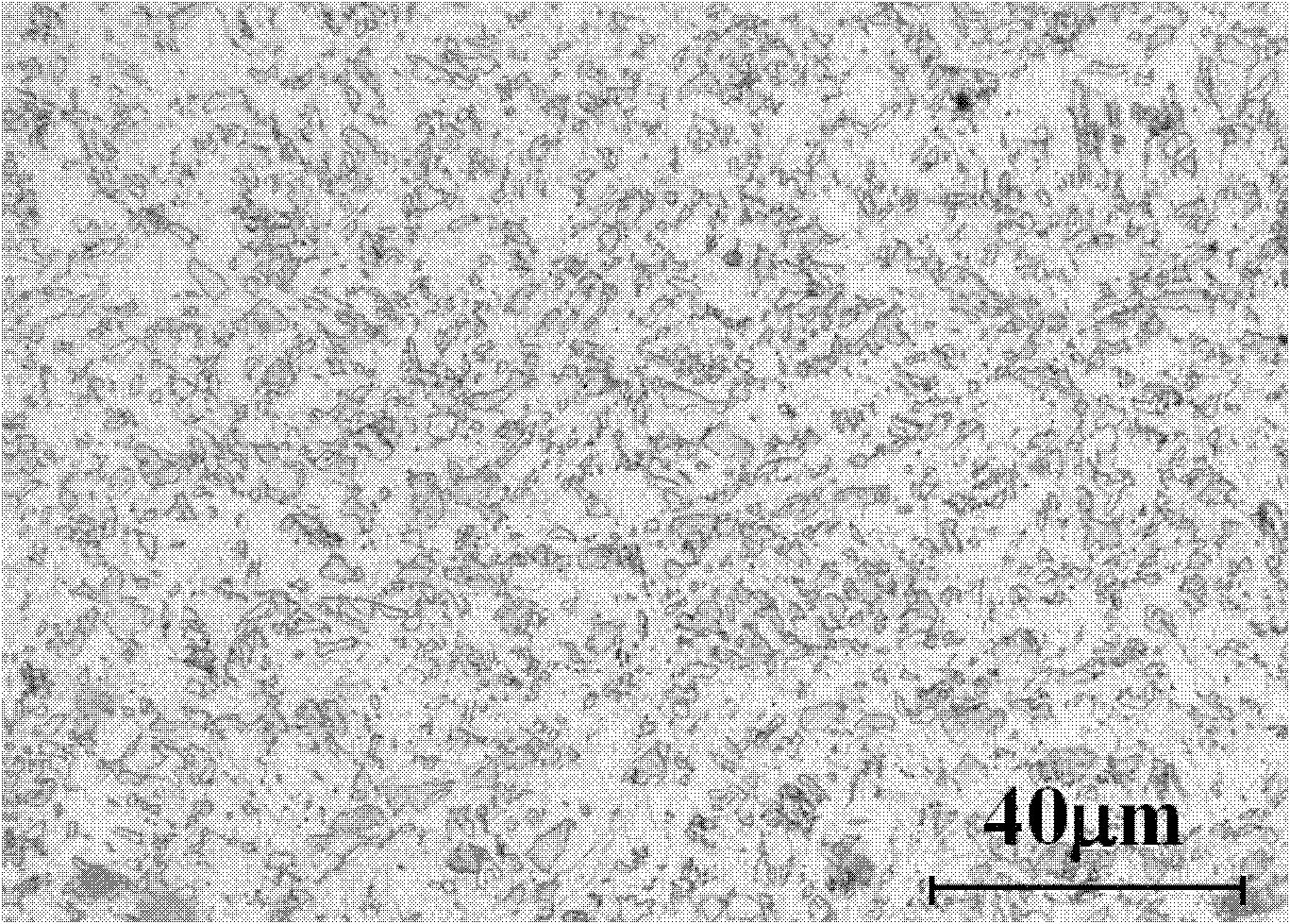

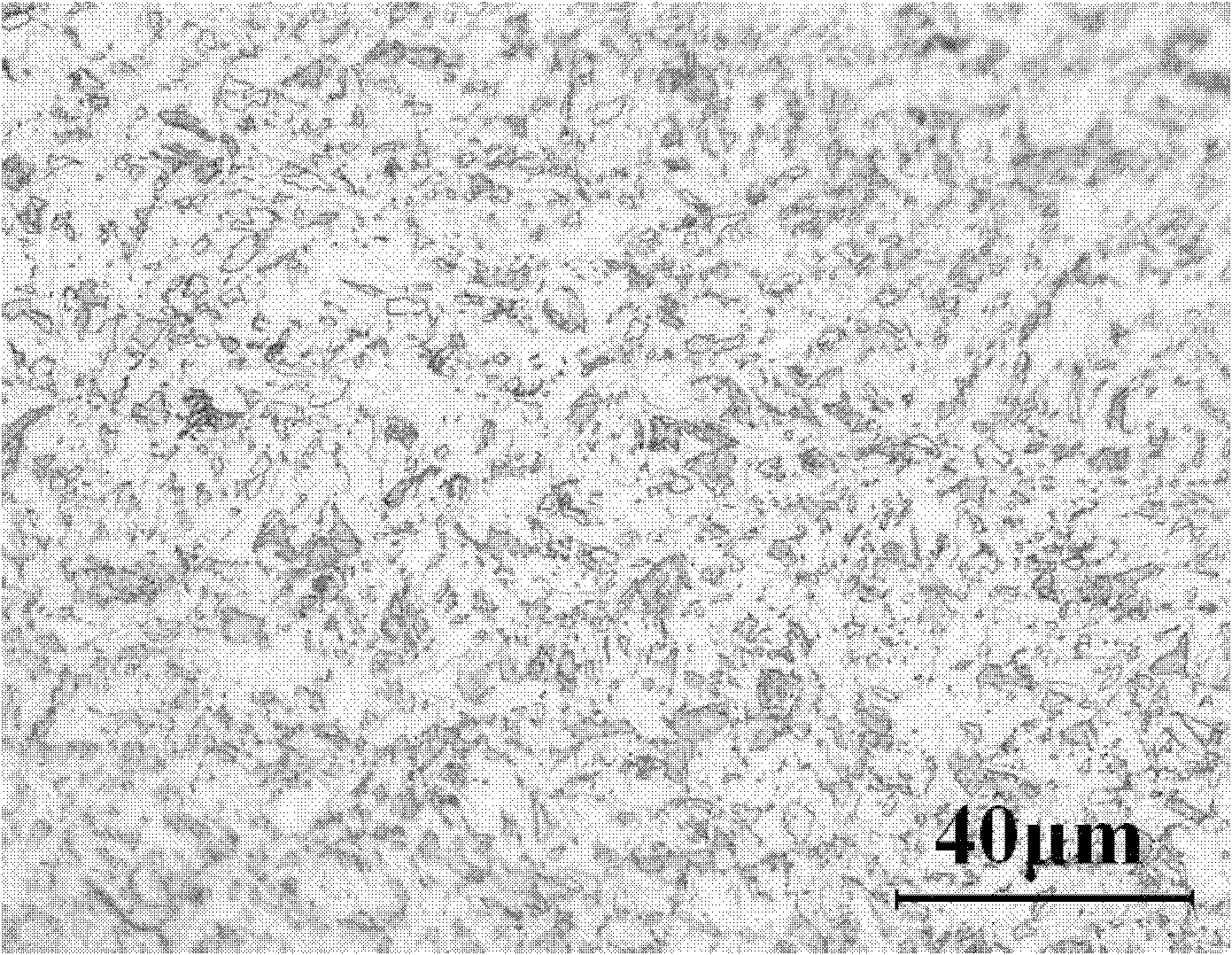

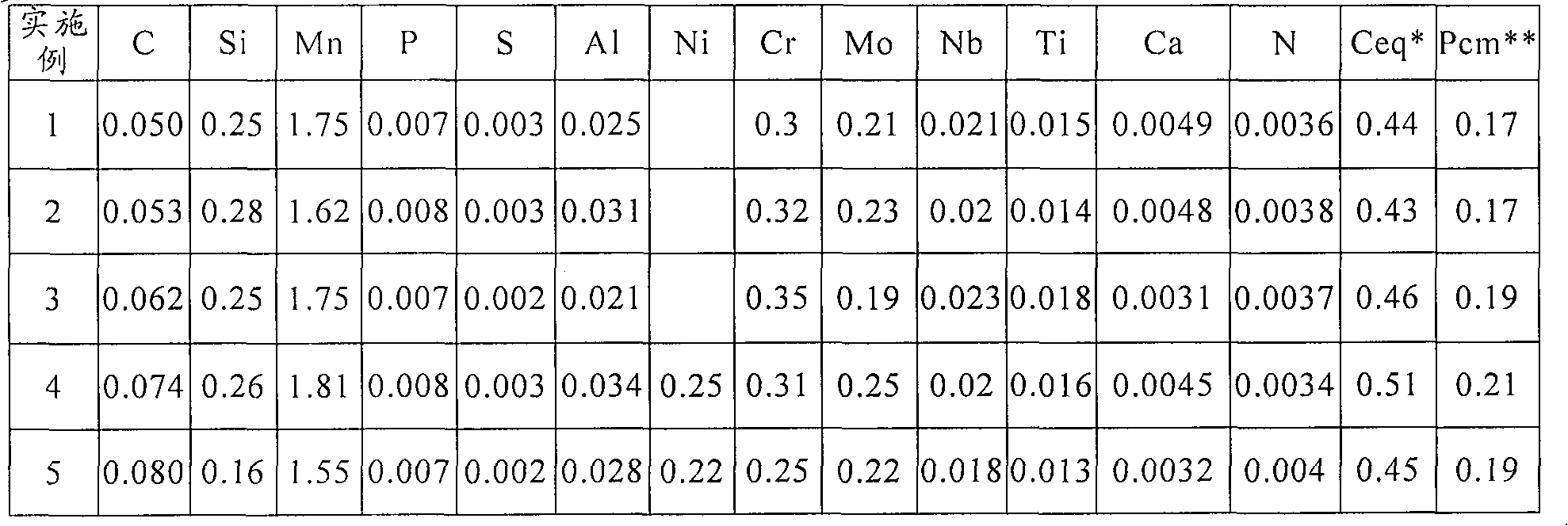

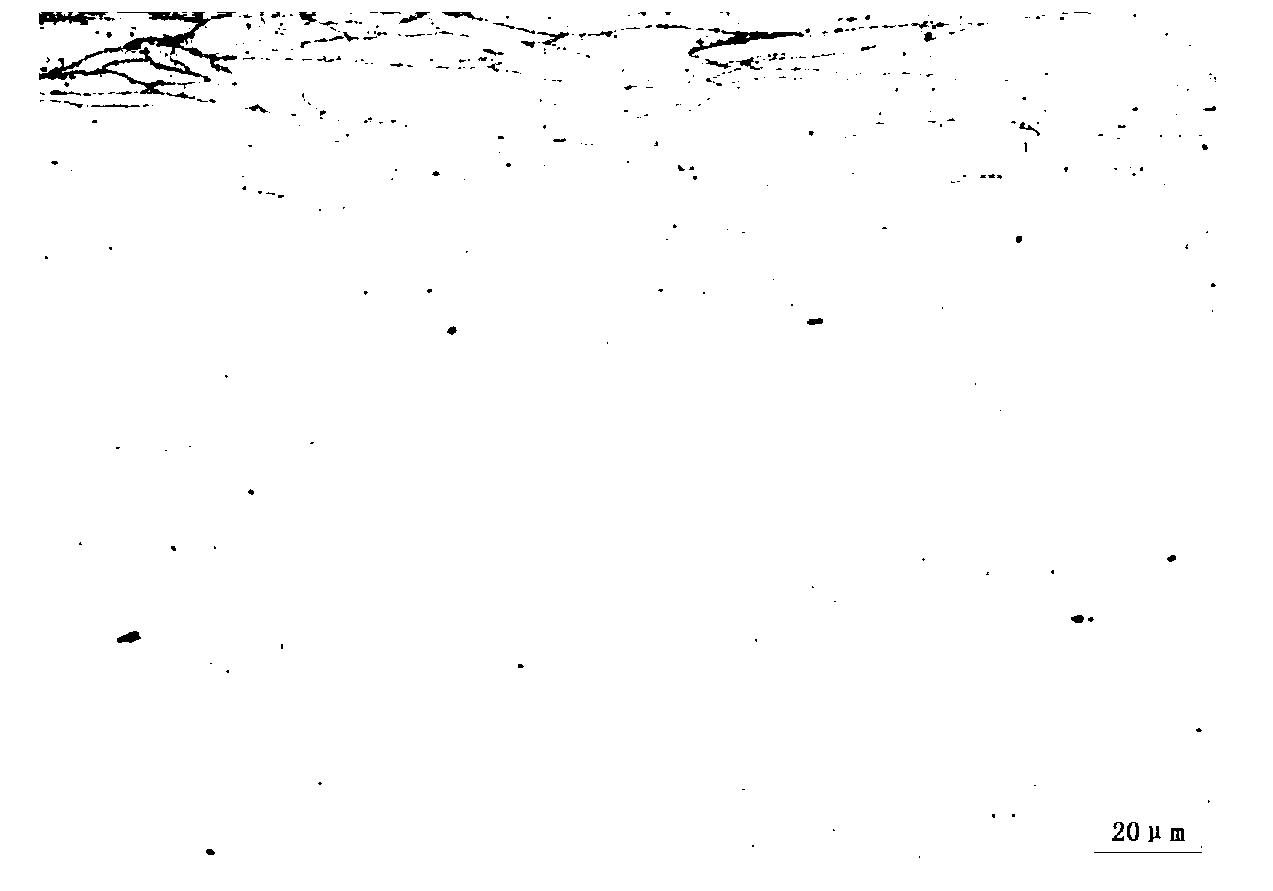

The invention relates to a low-yield-ratio high-tenacity steel plate. The steel plate comprises the following chemical constituents in percentage by weight: 0.05 to 0.08 percent of C, 0.15 to 0.30 percent of Si, 1.55 to 1.85 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.005 percent of S, 0.015 to 0.04 percent of Al, 0.015 to 0.025 percent of Nb, 0.01 to 0.02 percent of Ti, 0.20 to 0.40 percent of Cr, 0.20 to 0.30 percent of Mo, smaller than or equal to 0.006 percent of N, smaller than or equal to 0.004 percent of O, smaller than or equal to 0.005 percent of Ca, smaller than or equal to 0.40 percent of Ni, and the balance of iron and inevitable impurities, wherein Ca / s is larger than or equal to 1.5. The steel plate is manufactured through the following method: heating a continuous casting or steel billet at 1150 to 1220 DEG C and performing multi-pass rolling, wherein the total reduction rate is larger than or equal to 80 percent, and the finish rolling temperature is larger than or equal to 850 DEG C; performing rapid water cooling on a rolled steel plate at the speed of 15 to 50 DEG C / s to a temperature range from Bs-60 DEG C to Bs-100 DEG C, and then performing air cooling for 5 to 60 seconds; and heating the cooled steel plate in an on-line induction heating furnace to Bs plus 20 DEG C at the speed of 1 to 10 DEG C / s, tempering for 40 to 60 seconds, then discharging from the furnace and performing air cooling. The thickness of the steel plate is 10 to 25mm, the yield strength is larger than or equal to 500MPa, the yield ratio is smaller than or equal to 0.75, the ductility A50 is larger than or equal to 20 percent, and Akv at minus 60 DEG C is larger than or equal to 200J.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength steel plate and method for producing the same

The invention relates to a 110Kg level high tensile steel plate with the yield strength not less than 960MPa. The steel plate comprises the following chemical components by weight percentage: 0.14 to 0.18 percent of C, 0.20 to 0.50 percent of Si, 0.90 to 1.30 of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.70 to 0.10 percent of Ni, 0.04 to 0.08 percent of V, 0.020 to 0.060 percent of Nb, 0.020 to 0.060 percent of Al, 0.30 to 0.80 percent of Cr, 0.30 to 0.60 percent of Mo, 0.010 to 0.030 percent of Ti, 0.0010 to 0.0030 percent of B, and the balance being Fe and inevitable impurities. Through the reasonable design of alloy components and mainly the control on quenching and tempering process, the thickness of the obtained steel plate can reach 80mm. The steel plate has high yield strength, high welding performance, high cold bending performance, good low temperature toughness, good steel plate profile, and excellent comprehensive performance. The steel plate can be widely applied to the manufacturing of engineering machinery and has bright application prospect.

Owner:WUYANG IRON & STEEL

Ultra high-strength high titanium steel plate with yield strength of 960 MPa and preparing method of same

The invention relates to an ultra high-strength high titanium steel plate with yield strength of 960 Mpa and a preparing method of the same. The steel plate is composed of following components: C 0.06 to 0.09%, Si 0.10 to 0.50%, Mn 1.00 to 1.60%, P smaller than 0.015%, S smaller than 0.005%, Cr 0.20 to 0.50%, Mo 0.15 to 0.30 %, Nb 0.02 to 0.05%, Ti 0.06 to 0.20%, B 0.0005 to 0.003%, Cu not larger than 0.10%, Al 0.01 to 0.05%, N smaller than 0.005%, O smaller than 0.003%, Ni 0 to 0.30%, and the rest is Fe and unavoidable impurities. The preparing method comprises smelting and casting, continuous casting billet heating, two-stage rolling and a tempering treatment. The ultra high-strength high titanium steel plate has a good toughness and a good cold bending performance.

Owner:NANJING IRON & STEEL CO LTD +1

X70 pipeline steel hot rolled coil and manufacture method thereof

The invention relates to an X70 pipeline steel hot rolled coil and a manufacture method thereof. The coil comprises the following ingredients in percentage by weight: 0.02 to 0.05 percent of C, 0.10 to 0.30 percent of Si, 1.00 to 1.40 percent of Mn, at most 0.015 percent of P, at most 0.002 percent of S, 0.015 to 0.05 percent of Alt, 0.05 to 0.08 percent of Nb, 0.02 to 0.035 percent of V, 0.01 to 0.02 percent of Ti, 0.10 to 0.50 percent of Cr, at most 0.006 percent of Ca, 0.10 to 0.30 percent of Ni and 0.10 to 0.30 percent of Cu. The manufacture method is mainly characterized in that a, the laser fused (LF) refining is carried out outside a furnace: desulfurization is carried out until the weight percent of S is less than or equal to 0.0015 percent; b, the RH refining is carried out outside the furnace: Ca-Si lines are added before the vacuum smelting and steel outlet; c, the continuous casting temperature is 1553+ / -15DEG C; d, the continuous casting pulling speed is higher than or equal to 1.0 m / min; e, the plate blank heating temperature is lower than or equal to 1200 DEG C; f, the rough rolling terminating temperature is 930 to 1030 DEG C; g, the finish rolling terminating temperature is 780 to 850 DEG C; h, the steel band coiling temperature is 450 to 580 DEG C; and l, the cooling speed of the layer flow cooling is higher than or equal to 5 DEG C / s. The X70 pipeline steel hot rolled coil simultaneously meets the requirements of high toughness and hydrogen sulphide corrosion resistance of X70 pipeline steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Thick plate for ultra-high strength hull structure and production method thereof

InactiveCN102286701AGood cold bending performanceImprove performanceTemperature control deviceChemical compositionHull structure

The invention discloses a thick plate for an ultra-high-strength hull structure. The mass percentage of the chemical composition of the thick plate is: C: 0.05-0.10%, Si: 0.1-0.55%, Mn: 1.0-1.6%, Nb: 0.02-0.05 %, Ti: 0.007-0.02%, Als: 0.020-0.050%, the balance is Fe and unavoidable impurities; among them, P<0.015%, S<0.005%, O<0.0020%, N<0.0045% in unavoidable impurities , H<0.0002%. The present invention produces ultra-high-strength hull structure thick plates through low-carbon, low-phosphorus, ultra-low-sulfur and TMCP processes under the condition of a 3500-steel rolling mill. It has good comprehensive performance and good cold-bending performance, and is a high-quality hull Structural steel.

Owner:NANJING IRON & STEEL CO LTD +1

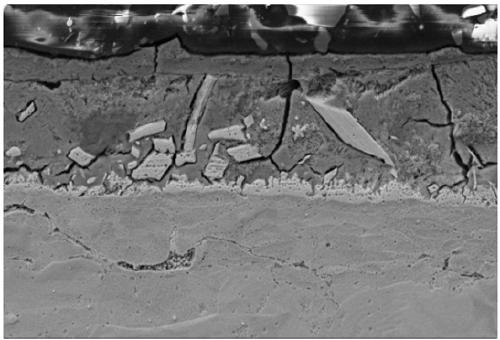

High-toughness hot-formed steel with tensile strength higher than or equal to 1800 MPa grade and production method thereof

InactiveCN110306123AImproved cold bending performanceTissue components are evenly distributedAlloy elementSmelting

The invention discloses a high-toughness hot-formed steel with tensile strength higher than or equal to the 1800 MPa grade and a production method thereof, and belongs to the technical field of metallurgy. The high-toughness hot-formed steel with the tensile strength higher than or equal to the 1800 MPa grade comprises components including, by mass, 0.29%-0.35% of C, not larger than 0.5% of Si, 0.5%-1.5% of Mn, not larger than 0.020% of P, not larger than 0.010% of S, not larger than 0.50% of Cr, 0.01%-0.06% of Al, 0.01%-0.06% of Nb, 0.01%-0.06% of V, not larger than 0.5% of Mo and the balanceFe and inevitable impurities. The high-toughness hot-formed steel is produced by the following processes including smelting, blank casting, hot rolling, cold rolling, annealing and hot forming. According to the high-toughness hot-formed steel and the production method, specific component alloy elements are added, the specific production processes are used in cooperation, and therefore the manufactured steel has the tensile strength higher than or equal to the 1800 MPa and has high toughness and high cold bending property.

Owner:MAANSHAN IRON & STEEL CO LTD

Submerged arc welding method of bridge steel of different intensity scale

InactiveCN101337301AImprove toughnessImprove securityArc welding apparatusWelding/cutting media/materialsSheet steelIntensity scaling

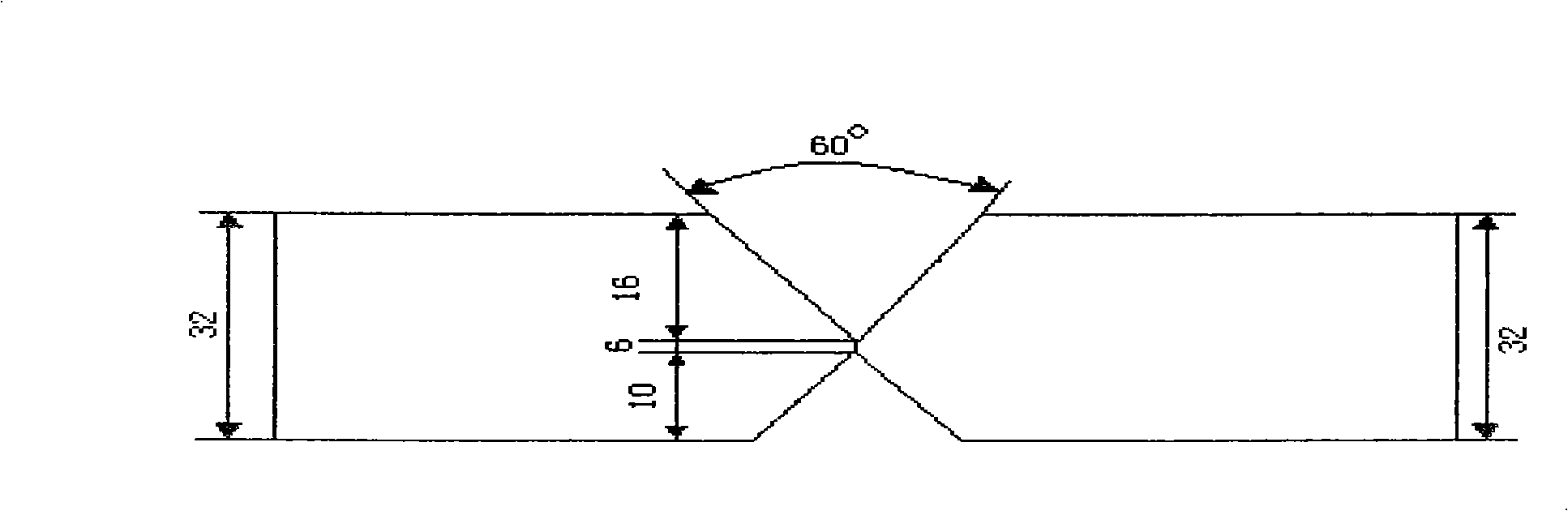

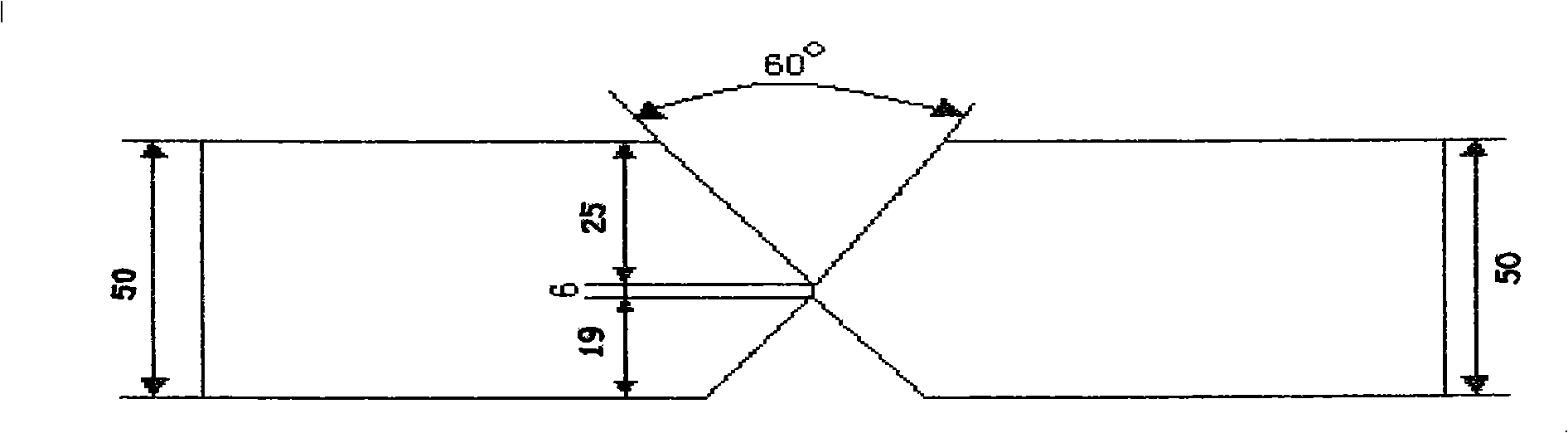

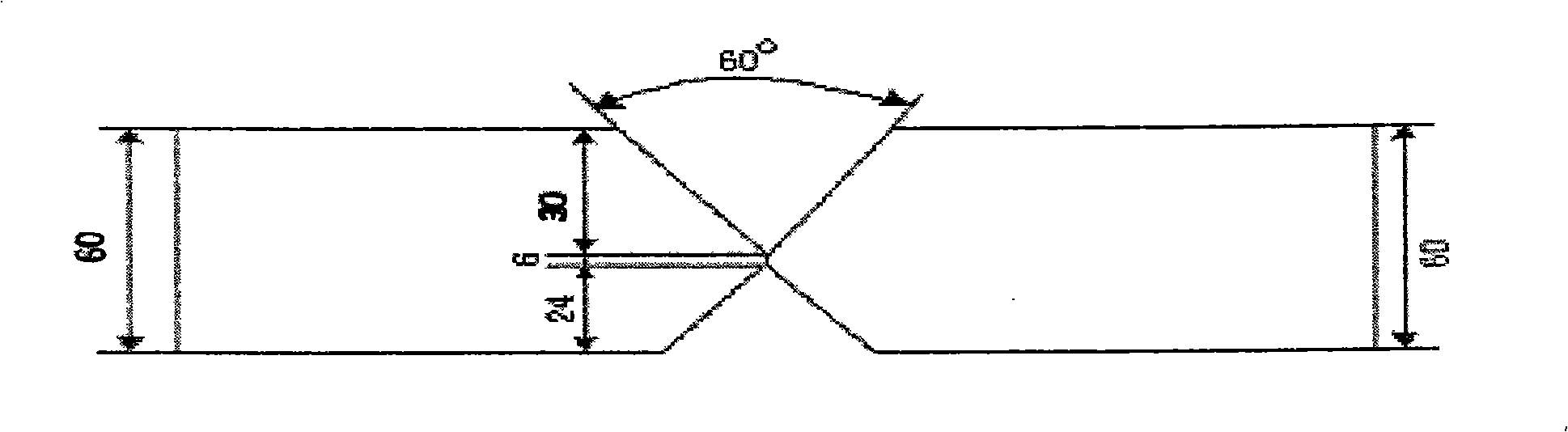

The invention discloses a hidden arc welding method for bridge steel at different levels of strength, which adopts two steel types with different tensile strengths, namely 510-550MPa and 570-650MPa as the subject of hidden arc welding; an X-type asymmetric divided edge is adopted as the divided edge of hidden arc welding; the adopted steel types are 14MnNbq steel and WNQ5709 steel; the yield strength ReL of the 14MnNb steel is 370-415MPa, the tensile strength Rm thereof is 510-550MPa, the unit extension A thereof is 20-35%, and the -40 DEG C AKV impact energy thereof is 120-290J; the yield strength Rel of the WNQ570 steel is 420-560MPa, the tensile strength Rm thereof is 570-650MPa, the unit extension A thereof is 18-27%, and the -40 DEG C AKV impact energy thereof is 120-270J; the thickness of steel plates is 32-60mm; the angle of the divided edge is 60 DEG; and the length of the truncated edge is 6mm. The hidden arc welding method meet the requirements for using the key hidden arc welding technique to manufacture dissimilar steel joints with a novel bridge structure of large-span, heavy-duty, high-speed, high-strength and high-tenacity. The joints made through hidden arc welding have good tensile strength and cold-bending performance; the impact energy of the three areas of the joint reaches a high level; and the joints have relatively high impact tenacity reserve and safety margin.

Owner:武钢集团有限公司

Ultra high strength ship plate steel and production method thereof

The invention discloses ultra high strength ship plate steel and a production method thereof. A plate blank comprises the following components in percentage by weight: 0.02-0.09 percent of C, 0.1-0.4 percent of Si, 0.5-1.6 percent of Mn, 0.01-0.04 percent of Alt, 0.02-0.05 percent of Nb, 0.008-0.02 percent of Ti, 0.3-0.7 percent of Cr, 0.2-0.5 percent of Mo, 0.5-1 percent of Ni, 0.2-1 percent of Cu, less than 0.013 percent of P, less than 0.005 percent of S, less than 0.0012 percent of O, less than 0.0045 percent of N, less than 0.00015 percent of H and the balance of Fe and inevitable impurities. The production method comprises the following steps of heating the plate blank with the thickness of 220-300 mm before rolling at the temperature of 1250 DEG C; starting rough rolling at the starting temperature of not less than 1100 DEG C; starting finish rolling at the temperature of not more than 910 DEG C, and stopping finish rolling at the temperature of 870-890 DEG C; rolling a steel plate with the thickness of 10-60 mm; rapidly entering ACC to control cooling at the cooling speed of 8-12 DEG C / s after finish rolling; returning red at the temperature of 650-680 DEG C; and tempering for 90-180min at the temperature of 500-680 DEG C. The product has good comprehensive mechanical property.

Owner:NANJING IRON & STEEL CO LTD

Steel for nuclear pressure vessels and manufacturing method thereof

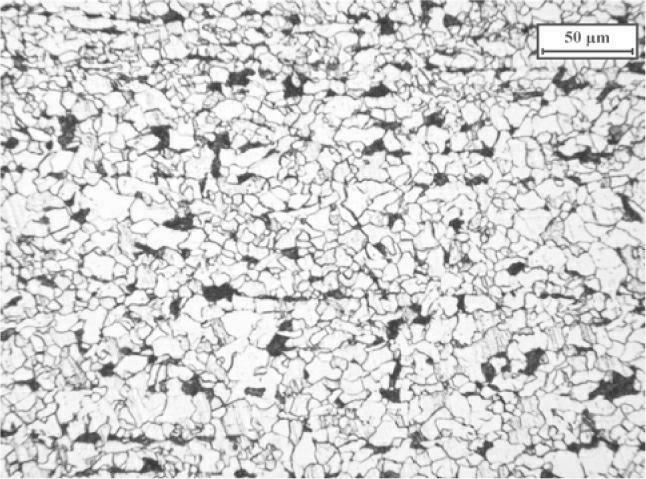

The invention discloses a kind of steel for nuclear pressure vessels and a manufacturing method thereof. The manufacturing method comprises the following steps of: 1) smelting and plate blank casting, wherein the steel comprises the following components in percentage by weight: 0.05-0.20% of C, 0.10-0.40% of Si, 0.75-1.6% of Mn, 0.15-0.6% of Cr, 0.010-0.04% of Nb, 0.008-0.03% of Ti, 0.030-0.050% of Alt, 0.0010-0.0050% of Ca, 0.003-0.012% of N, less than or equal to 0.010% of S, less than or equal to 0.012% of P, less than or equal to 0.003 wt. % of Sn, less than or equal to 0.002% of Sb, less than or equal to 0.003% of As, and the balance of Fe and inevitable impurities, wherein Alt / N is greater than or equal to 2; 2) hot rolling, wherein the heating temperature of a plate blank is 1100-1250 DEG C, the first-stage rolling temperature is 950-1020 DEG C, the first-stage reduction ratio is greater than or equal to 80%, the second-stage rolling temperature is 780-900 DEG C, and the second-stage reduction ratio is greater than or equal to 60%; and 3) cooling and coiling, wherein the cooling speed is 4.0-15 DEG C / s, and the coiling temperature is 590-680 DEG C; and through a controlled rolling and cooling process, the microscopic structure of the obtained steel for nuclear pressure vessels is a fine ferritic and pearlitic structure.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength automobile axle housing material and method for manufacturing axle housing

The invention discloses a high-strength automobile axle housing steel plate material and a method for manufacturing the axle housing. The axle housing is formed by punching and welding a hot continuous rolling steel plate, wherein the hot continuous rolling steel plate comprises the following chemical ingredients in percentage by weight: 0.10 to 0.20 percent of C, 0.20 to 0.60 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.05 percent of Ti, less than or equal to 0.20 percent of V, less than or equal to 0.10 percent of Nb, less than or equal to 0.30 percent of Cr, less than or equal to 0.80 percent of Ni, less than or equal to 0.55 percent of Cu, 0.020 to 0.065 percent of Alt, less than or equal to 0.22 percent of Nb and V and Ti and the balance of Fe and inevitable impurities. The axle housing is high in strength, stamping formability and welding performance; and after the axle housing material is subjected to hot compacting, the problem of the deformation of an axle housing assembly which is subjected to profiling, welding and machining is solved by adjusting parameters of a welding process, welding materials and a process, so that the axle housing is reliable and stable in performance and long in fatigue life.

Owner:SINO TRUK JINAN POWER

High-grade wear-resistant steel plate and production method thereof

InactiveCN101748346AGuaranteed hardenabilitySolve the coarse and uneven grain sizeRoll mill control devicesElectric furnaceWear resistantQuenching

The invention discloses a high-grade wear-resistant steel plate. The steel plate comprises the following components in percentage by mass: less than or equal to 0.26 percent of C, less than or equal to 0.50 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.30 percent of Ni, less than or equal to 1.50 percent of Cr, less than or equal to 0.06 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.03 percent of Ti, less than or equal to 0.50 percent of Mo, less than or equal to 0.08 percent of V, less than or equal to 0.004 percent of B, and the balance of Fe and inevitable impurities. A method for producing the steel plate comprises smelting, casting, heating, rolling, straightening, shot blasting, quenching, heat treatment, cutting and other process steps. The steel plate has the advantages of steel purity, high strength, high hardness, good low temperature toughness, good weldability, good processability, good cold bending property, large steel plate thickness, good plate cut, little noble metal added to the steel plate and low cost. The steel plate can be widely used in the industry of manufacturing mining, engineering, metallurgical and other machinery with broad application prospects.

Owner:WUYANG IRON & STEEL +1

Hot continuous rolling plate strip steel for 510MPa automotive frame and production technology thereof

InactiveCN103451535ARealize reduced productionImprove performanceTemperature control deviceAuto industryStrip steel

The invention belongs to the technical field of steel rolling, and particularly relates to a low cost hot continuous rolling plate strip steel for a 510MPa automotive frame and a production technology thereof. The hot continuous rolling plate strip steel for the automotive frame comprises the following components by weight percent: 0.13-0.18% of C, 0.30-0.50% of Si, 0.75-1.15% of Mn, 0.02-0.06% of Alt, less than or equal to 0.025% of P, less than or equal to 0.008% of S, 0.008-0.025% of Ti, less than or equal to 0.006% of N, the balance of Fe, and inevitable impurities. According to the production technology, by slightly adjusting the content of C and Si, lowering the content of Mn, only adding a small quantity of cheap Ti, and adding no other precious alloy elements, the production cost is remarkably lowered, the production quantity of the type of steel is reduced, the energy is saved, the consumption is lowered, the cost is lowered, and an automotive frame steel with excellent comprehensive properties is obtained, so that the production technology can provide products with high cost performance for the auto industry.

Owner:JIGANG GRP

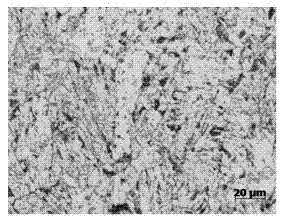

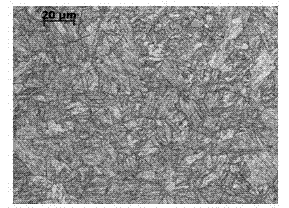

Martensite-ferrite double-phase wear-resisting steel plate and preparing method thereof

The invention provides a martensite-ferrite double-phase wear-resisting steel plate and a preparing method thereof. The martensite-ferrite double-phase wear-resisting steel plate comprises a martensite and ferrite double-phase structure, the volume fraction of the martensite structure is larger than 90%, the hardness of the martensite structure ranges from 480HB to 560HB, and the martensite structure is obtained by preparing C, Si, Mn, P, S, Nb, V, Ti, Mo, Ni, Cr, Al, B, N, Fe and other elements of the specific amount. The martensite-ferrite double-phase wear-resisting steel plate has the higher hardness and meanwhile has the good low-temperature toughness and wear-resisting performance; and manufacturing of mechanical parts under the atrocious environment particularly the condition with the extremely low temperature is facilitated. The preparing method of the martensite-ferrite double-phase wear-resisting steel plate is simple in process, the martensite and ferrite double-phase structure can be obtained, the hardness, the low-temperature toughness and the wear-resisting performance of the martensite and ferrite double-phase structure can be comprehensively improved, and large-scale production is facilitated.

Owner:NORTHEASTERN UNIV +1

Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

InactiveCN102181806AImprove toughnessDoes not reduce weldabilityRoll mill control devicesMetal rolling arrangementsSheet steelIngot

The invention discloses a thick chromium-molybdenum steel plate for hydrogenation equipment, and also discloses a production method of a steel plate. The steel plate comprises the following components by weight percent: 0.12%-0.15% of C, 0.02%-0.07% of Si, 0.50%-0.60% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, 2.35%-2.50% of Cr, 0.95%-1.10% of Mo, 0.012%-0.02% ofNb, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.005% of Sn, less than or equal to 0.016% of As, less than or equal to 0.003% of O, less than or equal to 0.008% of N and less or equal to 0.0002% of H, the balance of Fe and inevitable impurities. For the steel plate, an electroslag remelting technology is adopted,electroslag ingot with the maximum piece weight being 50t is melted, and the maximum thickness of the produced thick chromium-molybdenum steel plate for the hydrogenation equipment can achieve 198mm,and the maximum piece weight of the single-piece finished steel plate can achieve 37.2t by a heating-rolling technology and thermal-processing production equipment of normalizing plus accelerated cooling plus tempering.

Owner:WUYANG IRON & STEEL +1

Method for manufacturing low-cost super-high intensity steel plate with yield strength of over 960 MPa for wide process operation window

ActiveCN101935810ALow costGuaranteed to dissolveTemperature control deviceHeat treatment process controlMetallurgyHigh intensity

The invention relates to a super-high intensity steel plate with yield strength of over 960 MPa. The steel plate comprises the following chemical constituents in percentage by weight: 0.12 to 0.14 percent of C, 0.3 to 0.4 percent of Si, 1.45 to 1.6 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.002 percent of S, 0.02 to 0.04 percent of Al, 0.38 to 0.42 percent of Cr, 0.28 to 0.32 percent of Ni, 0.35 to 0.41 percent of Cu, 0.35 to 0.45 percent of Mo, 0.015 to 0.025 percent of Ti, 0.02 to 0.03 percent of Nb, 0.0012 to 0.002 percent of B, less than or equal to 0.004 percent of N, less than or equal to 0.002 percent of O and the balance of iron and inevitable impurities. Production methods include conventional rolling and thermo-mechanical control process (TMCP) rolling.

Owner:SHANDONG IRON & STEEL CO LTD +1

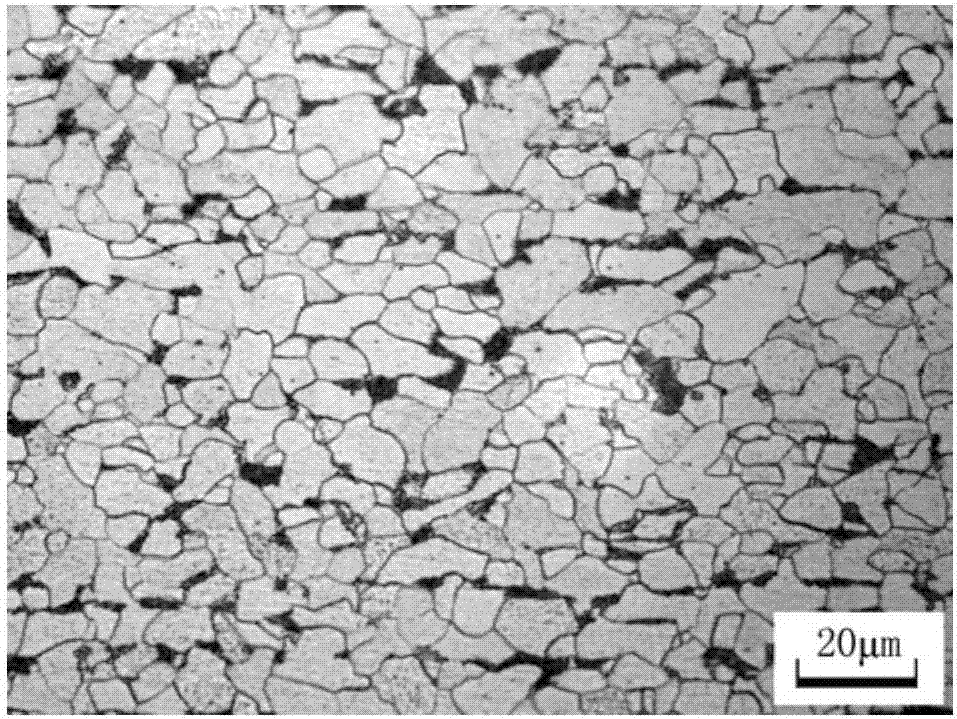

Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

ActiveCN101451216AAvoid formingMeet demanding requirementsTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

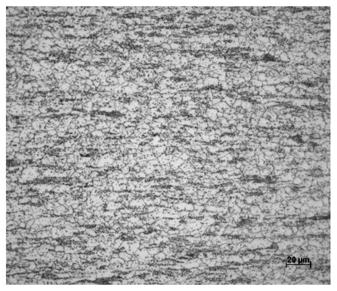

The invention relates to a high strength hot rolled plate and a production process thereof, in particular to a heavy gauge hot rolled steel plate for a roll bending forming high strength steel plate pile and a production process thereof. The invention mainly solves the technical problems of inadequate thickness, and lowcold bending performance and absorbed-in-fracture energy in the prior high strength heavy gauge steel plate. The technical proposal comprises: the heavy gauge hot rolled steel plate for the roll bending forming high strength steel plate pile comprises the following chemical components by weight percentage: 0.08 to 0.15 percent of C, 0.10 to 0.40 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.040 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, and the balance being Fe. The microscopic structures can be fine grain ferrites, and pearlitic structures plus a small amount of bainite structures which are dispersed; the grain size level is 11 to 14; and the banded structure level is less than 0.5. The high strength hot rolled plate is mainly used for producing the steel plate pile.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

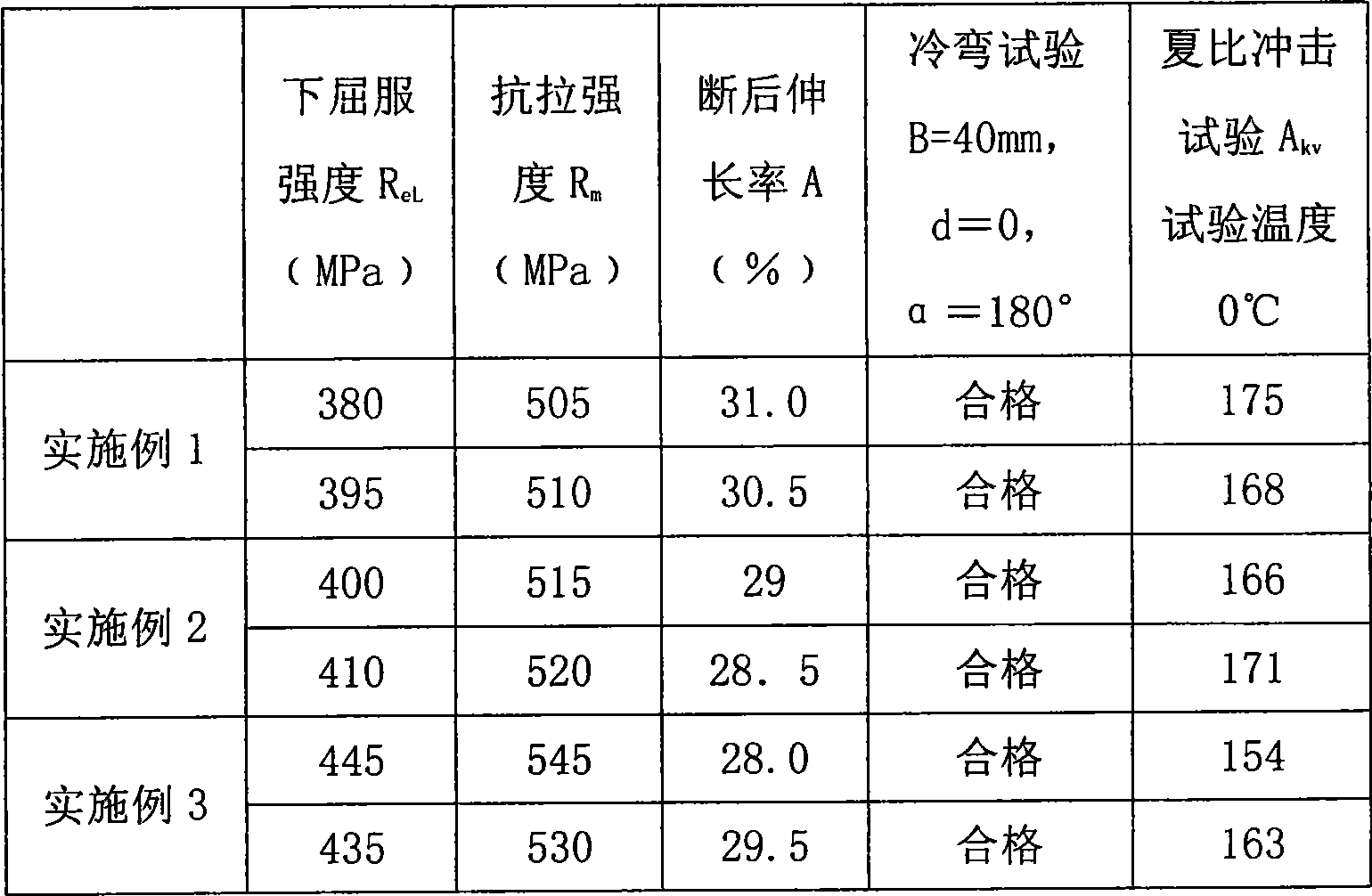

Hot rolled steel plate of 490 MPa level and production method thereof

InactiveCN101935801AGood cold bending performanceGood welding performanceSheet steelRoom temperature

The invention belongs to the technical field of metallurgy, and in particular relates to a micro-niobium alloy hot rolled steel plate of a 490 MPa level and a production method thereof, aiming to solving the first technical problem of providing the hot rolled steel plate of the 490 MPa level with excellent comprehensive performance. The hot rolled steel plate of the 490 MPa level is prepared from the following chemical components in percentage by weight: 0.04-0.11 percent of C, 0.13-0.27 percent of Si, 0.9-1.30 percent of Mn, 0.001-0.007 percent of N, 0-0.027 percent of P, 0-0.017 percent of S, 0.01-0.09 percent of Al, 0.013-0.027 percent of Nb, 0.004-0.012 percent of Ti and the balance of Fe. The hot rolled steel plate of the 490 MPa level, which is provided by the invention, reaches the yield strength not less than 380 MPa, tensile strength not less than 490 MPa, elongation not less than 17 percent and excellent cold bending performance, has favorable room-temperature mechanical performance and process performance and fully accords with the requirements on technical indexes.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

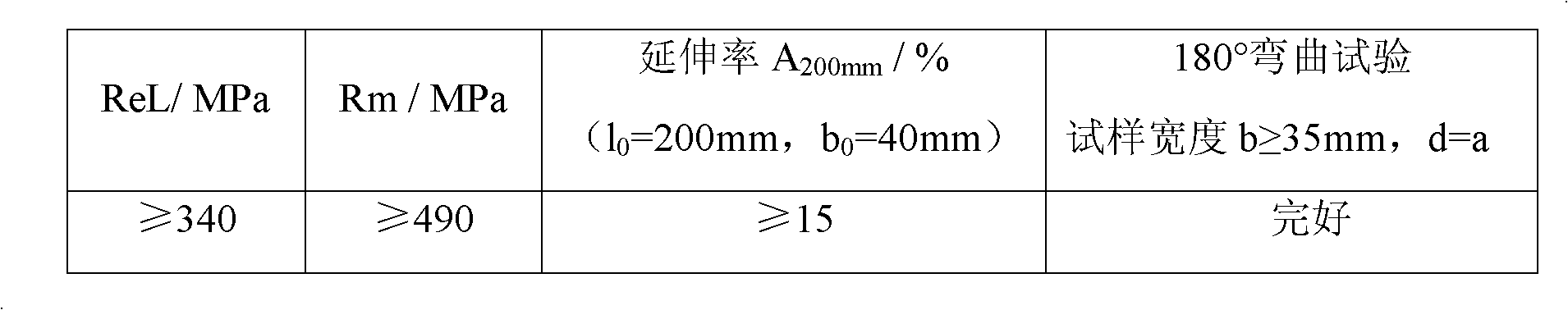

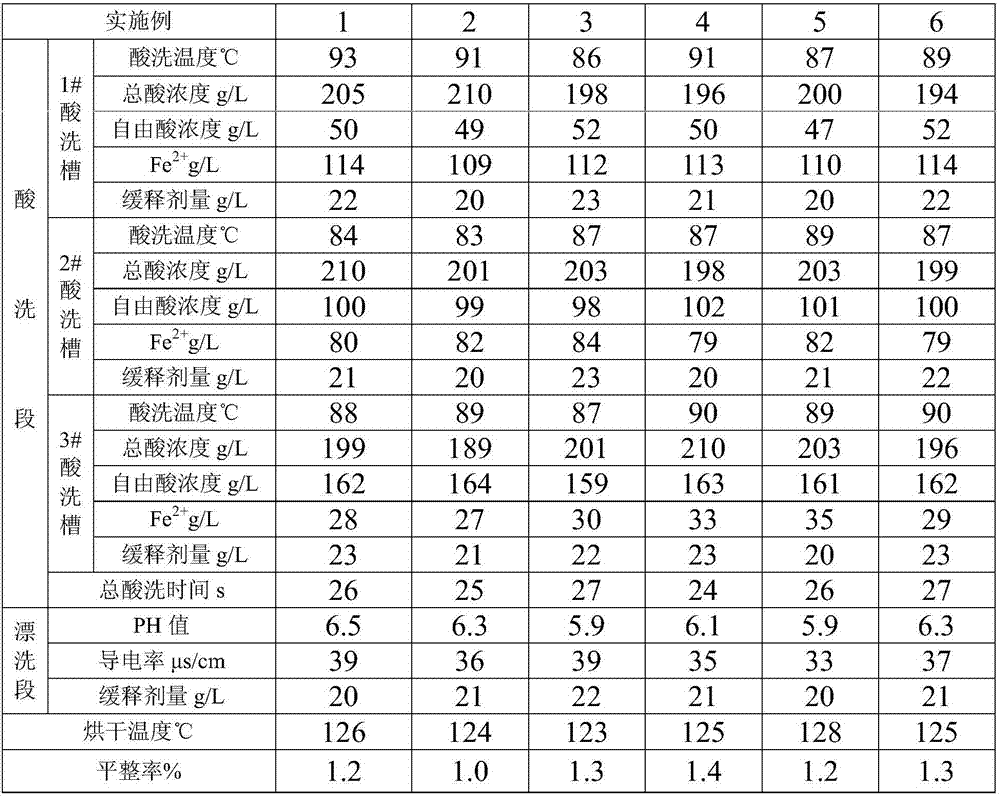

Hot-rolled pickling steel with high surface quality and tensile strength of 490 MPa and manufacturing method for hot-rolled pickling steel

The invention discloses a hot-rolled pickling steel with a high surface quality and a tensile strength of 490 MPa and a manufacturing method. The weight percentages of its chemical components are: C: 0.060-0.080%, Si: 0.100-0.200%, : 1.000~1.250%, P≤0.020%, S≤0.008, Nb: 0.015~0.025%, Als: 0.015~0.040%, Cu≤0.300%, Ni≤0.300%, Cr≤0.300%; the rest is Fe and unavoidable impurity; the method is through hot metal desulfurization, converter smelting, vacuum treatment, continuous casting, shaping, slab heating, hot continuous rolling, laminar cooling, coiling, finishing, pickling process, levelling, coiling, recoiling, Manufactured by oiling and packaging, the hot-rolled pickled steel of the invention has the characteristics of good ductility, cold stamping performance, welding performance and good cold bending performance.

Owner:武汉钢铁有限公司

Hot-rolled polyphase steel plate and method for manufacturing same

ActiveCN101270436AGood extensibilityGood formabilityTemperature control deviceSheet steelYield ratio

The invention provides a hot-rolled multiphase steel plate and a preparation method thereof. The invention has the advantages of the economical, reasonable, environmental-friendly design of steel component, being favorable for effective utilization and recycling of resources, being implemented and controlled easily, the simple and convenient process control, the high strength of steel plate and the good performance of cold bending and welding. The thickness of plate is 2.5 to 6 milimeter, the tensile strength of the hot-rolled steel plate is larger than 1000Megapascal, the yield strength is greater than or equal to 500Megapascal, the yield ratio is low, the minimum yield ratio is equal to 0.51 and the maximum is not higher than 0.80, the elongation A80 i.e. the sample of 80 milimeter of JIS13A standard distance is greater than or equal to 11 percent and the highest value reaches 20 percent, and the longitudinal direction and the transverse direction of cold bending meets the requirement of not cracking when d is equal to 4t. The microstructure is mainly Bainite and Martensite of higher than 90 percent and few ferrite of possible residual Austenite.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-heat treated wire or bar steel for springs

InactiveUS6206984B1Reduce scrollingHigh tensile strengthFurnace typesHeat treatment furnacesBreakage rateRebar

A non-heat treated wire or bar steel for springs which is characterized by having in its as-rolled state a tensile strength of 120-150 kgf / mm2 and a bending breakage rate no higher than 15% when tested according to JIS Z-2248 under the condition of r / d=2.8 where r (mm) denotes the inside radius of the bending curvature and d (mm) denotes the diameter of the as-rolled stock.

Owner:KOBE STEEL LTD

Large thickness and narrow hardness range wear-resistant steel sheet and preparation method thereof

The invention relates to a large thickness and narrow hardness range wide-resistant steel sheet and a preparation method thereof. The steel sheet comprises the following components: 0.16-0.23% of C, 0.25-0.55% of Si, 0.60-1.00% of Mn, less than or equal to 0.013% of P, less than or equal to 0.003% of S, 0.010-0.030% of Ti, 0.25-0.50% of Ni, 0-0.030% of Nb, 0.40-0.70% of Cr, 0.20-0.50% of Mo, 0.0010-0.0035% of B, 0.010-0.050% of Al, and the balance of Fe and inevitable impurities, wherein the sum of the mass percent of Cr and B meets the following equation: (Cr + B) is greater than or equal to 0.159C + 0.235Mn + 7.282Ti + 0.249Ni or less than or equal to 0.51C + 0.371Mn + 8.147Ti + 0.401Ni. The steel sheet is 40-60 mm in thickness, and meets requirements on hardness at the 1 / 2 sheet thickness.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

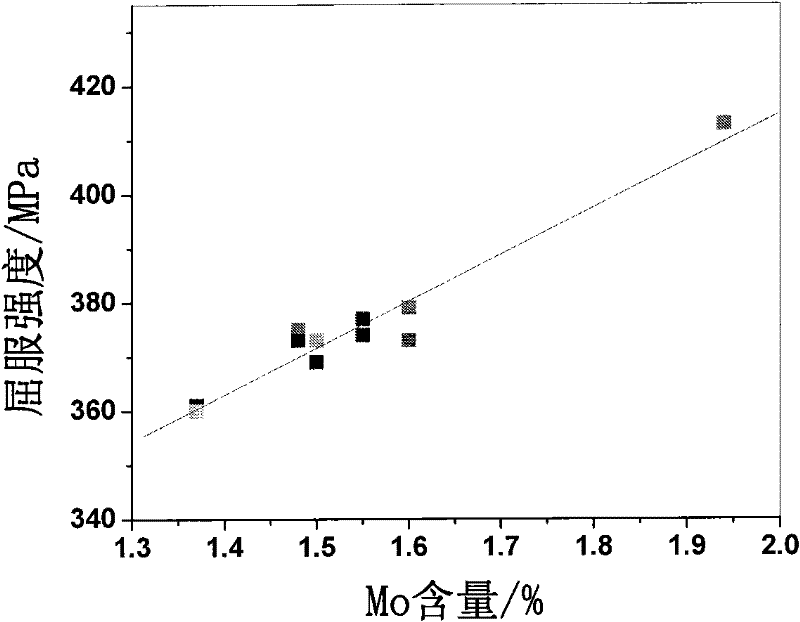

High-performance Cu-containing steel and heat processing process thereof

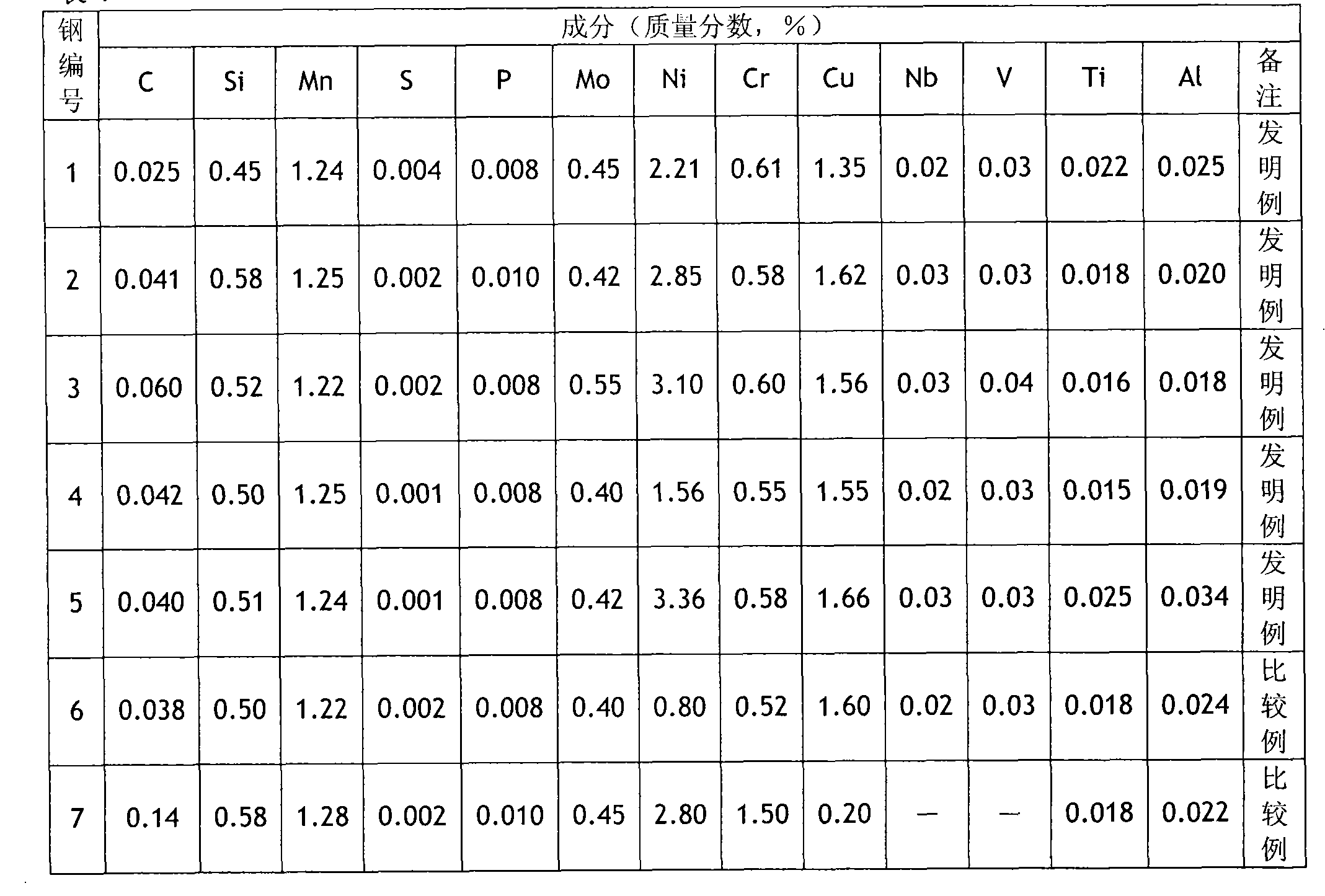

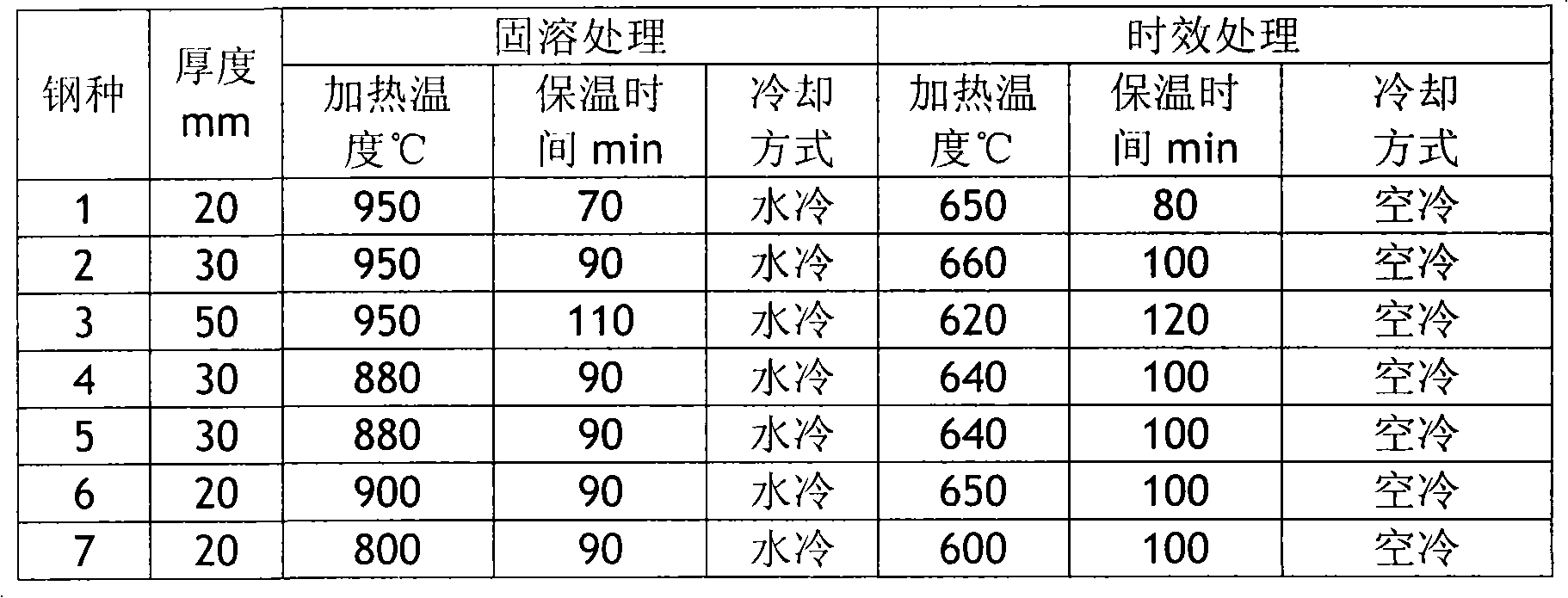

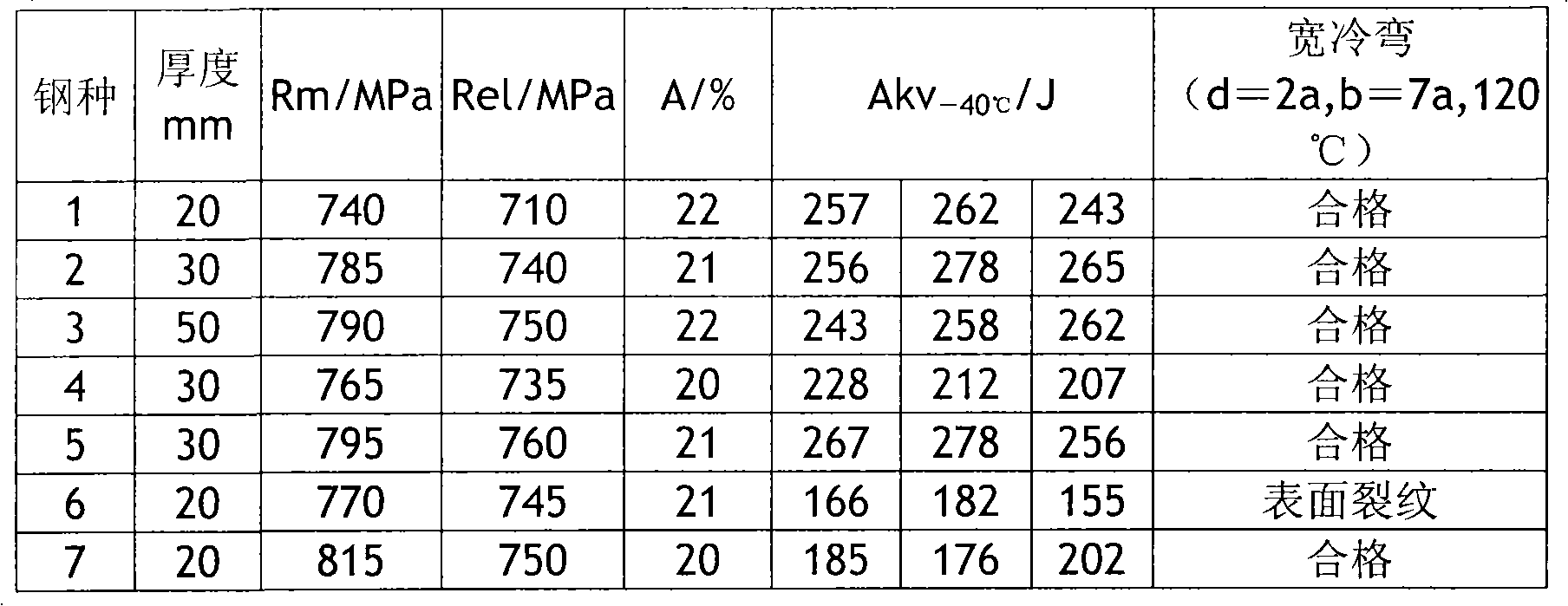

The invention relates to high-performance Cu-containing steel and a heat processing process thereof, and belongs to the technical field of low-alloy and high-strength steel. The high-performance Cu-containing steel comprises the following components in percentage by weight: 0.01 to 0.06 percent of C, 0.10 to 0.60 percent of Si, 0.10 to 1.30 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.008 percent of S, 0.005 to 0.050 percent of Nb, 0.10 to 0.60 percent of Mo, 1.30 to 3.60 percent of Ni, 0.005 to 0.030 percent of Ti, 1.00 to 2.00 percent of Cu, 0.10 to 0.60 percent of Cr, 0.005 to 0.06 percent of V, 0.005 to 0.04 percent of Al and the balance of Fe and inevitable impurities. Simultaneously, the weight ratio of Ni to Cu is 1.00-2.50. The heat processing process of the steel comprises solution treatment at the temperature of between 800 and 950 DEG C and aging treatment at the temperature of between 500 and 700 DEG C. The high-performance Cu-containing steel has the advantages that the yield strength is more than or equal to 690 MPa, the Charpy V-notch impact energy at the temperature of -40 DEG C is more than or equal to 180 joules; and the high-performance Cu-containing steel has the excellent comprehensive mechanical properties and welding performance, and is suitable for steel for ocean shipping, engineering machines, oil platforms and the like.

Owner:CENT IRON & STEEL RES INST

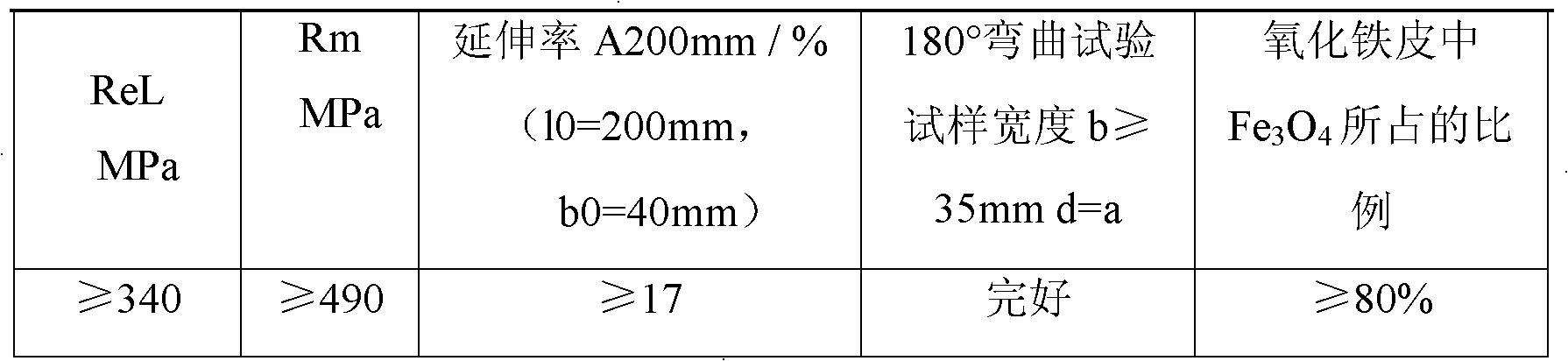

Method for producing 490MPa level acid-washing-free hot rolled steel plate

ActiveCN101935802AGood cold bending performanceGood welding performanceChemical compositionAcid washing

The invention belongs to the technical field of metallurgy, and particularly relates to a method for producing a 490MPa level acid-washing-free hot rolled steel plate. The method comprises the following steps of: heating a continuous casting billet; hot rolling; cooling; reeling, and the like, wherein the billet comprises the following chemical compositions in percentage by weight: 0.04-0.11 percent of C, 0.13-0.27 percent of Si, 0.9-1.30 percent of Mn, 0.001-0.007 percent of N, 0-0.027 percent of P, 0-0.017 percent of S, 0.01-0.09 percent of Al, 0.013-0.027 percent of Nb, 0.004-0.012 percent of Ti and the balance of Fe; the heating temperature of the billet is 1,200-1,240 DEG C, the initial rolling temperature of the hot rolling is 1,120-1,220 DEG C, and the finish rolling temperature is 870-910 DEG C; front-section laminar flow water-cooling after rolling is used by the cooling step; and the temperature of the reeling step is 550-585 DEG C. In the invention, the yield strength of a finished steel band product obtained by the method is larger than or equal to 380MPa, the tensile strength is larger than or equal to 490 MPa, the elongation is larger than or equal to 17 percent, the cold bending property is good, and the proportion of Fe3O4 in an oxidized iron sheet on the surface of the finished product exceeds 80 percent.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

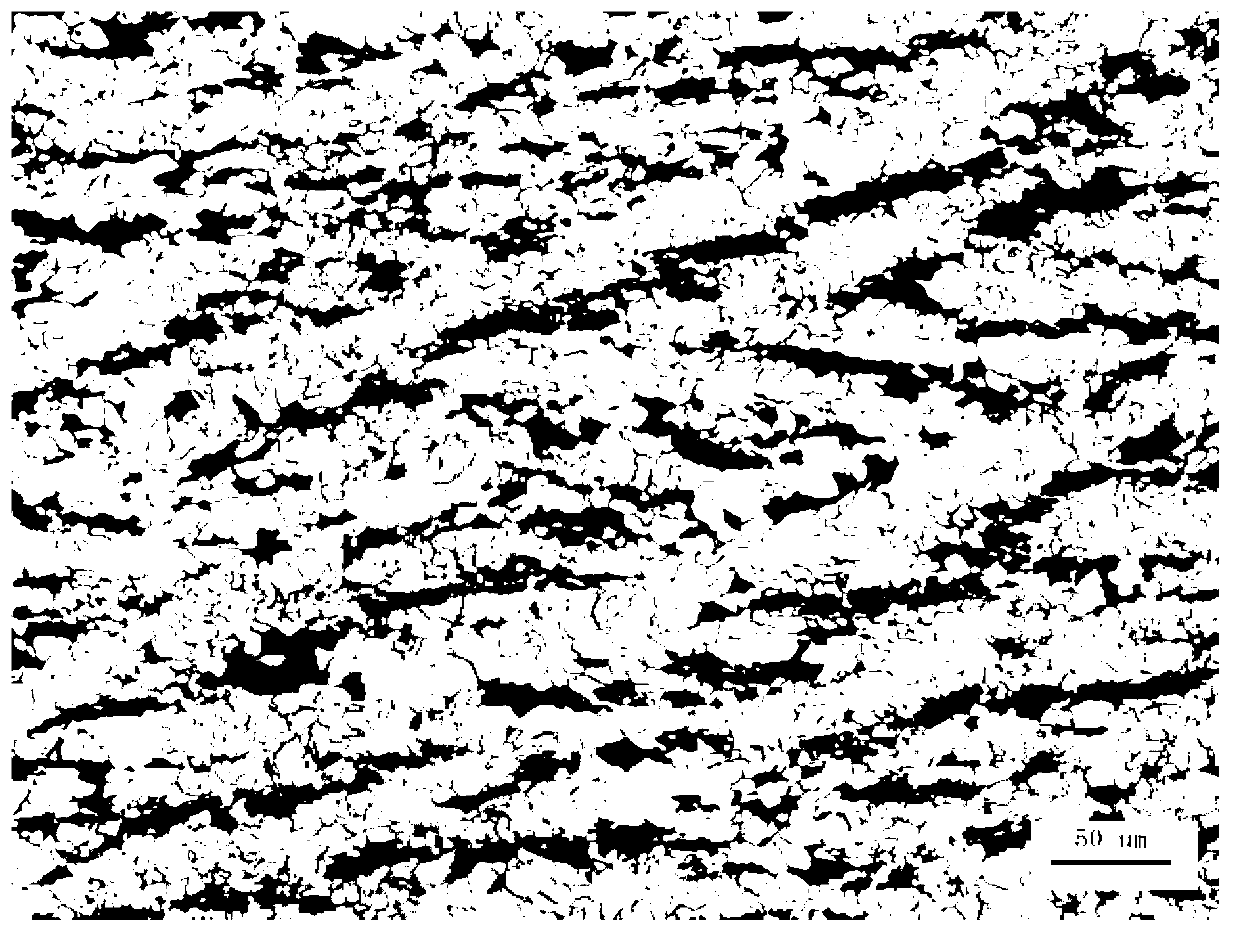

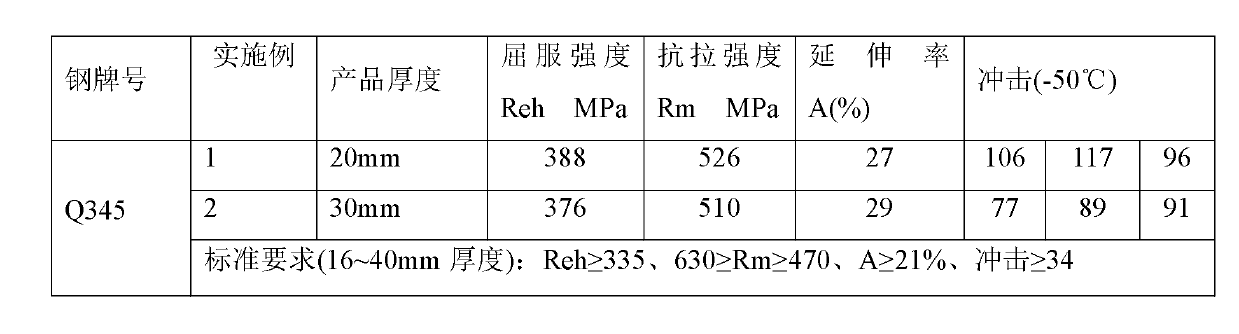

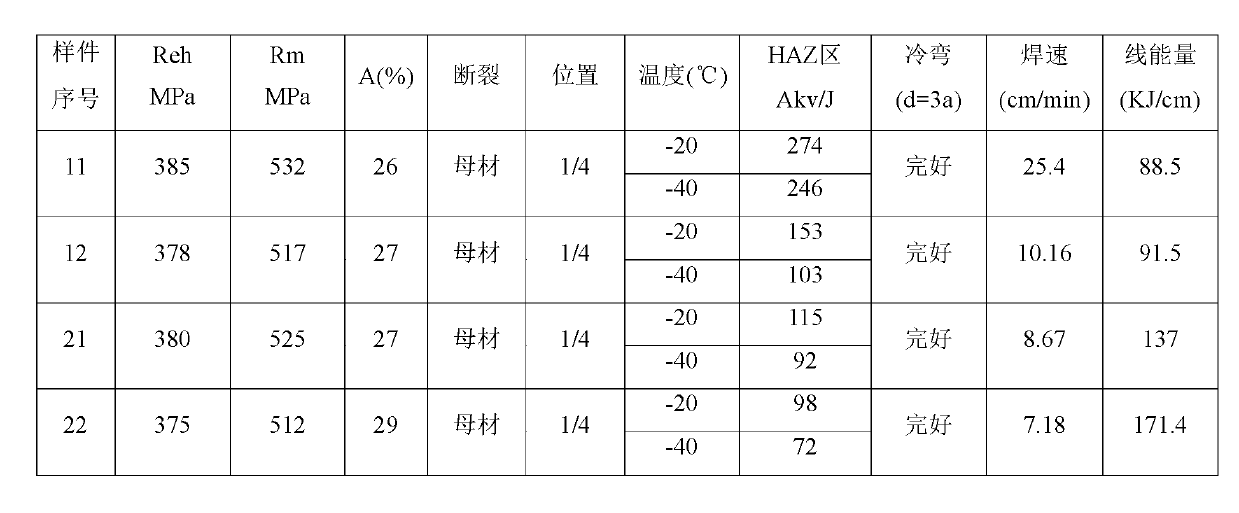

Method for producing high heat input welding Q345-level steel plate

The invention relates to the field of iron and steel products and in particular relates to a method for producing a high heat input welding Q345-level steel plate. The process flow comprises the following steps of: smelting, continuous casting, heating, phosphorous removal, controlled rolling and cooling, thermal straightening, stacking, slow cooling, and cracking off to obtain the finished product. Three key points, such as design of smelting components, controlled rolling and cooling and cooling after final rolling, are controlled, wherein in the design of the smelting components, Ti / (N)is equal to 2.4-3.2. Compared with the prior art, the method has the beneficial effects that according to filed practice, the high heat input welding Q345-level steel plate produced by the method has good performance of a welded joint, the sample fracture occurs on a base metal, and the phenomenon that the welded joint is softened is avoided; along with increase of heat input, lateral impact values in an HAZ area at the temperatures of -20 DEG C and -40 DEG C are reduced; the cold bending performance is good, and the mechanical property and welding performance completely exceed the standard requirements; moreover, the method has the advantages of short production flow, low production cost, suitableness for mass production and the like.

Owner:ANGANG STEEL CO LTD

Ferrite stainless steel for buildings and preparation method thereof

ActiveCN102234738AImprove corrosion resistanceReduce glossTemperature control deviceFurnace typesSheet steelImpurity

The invention discloses ferrite stainless steel for buildings. The ferrite stainless steel comprises the following chemical elements in percentage by mass: less than or equal to 0.015 percent of C, less than or equal to 0.020 percent of N, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.010 percentof S, more than 21.5 percent and less than 23.5 percent of Cr, more than 1.0 percent and less than 3.0 percent of Mo, more than or equal to 0.35 percent and less than or equal to 0.6 percent of Nb, less than or equal to 0.2 percent of Ti and the balance of Fe and other inevitable impurities, wherein (Nb+Ti) is more than or equal to 16(C+N) and less than or equal to 0.6 percent. Correspondingly, the invention further provides a method for preparing the stainless steel for buildings. Compared with the conventional stainless steel for buildings, the ferrite stainless steel has the advantages of excellent corrosion-resistant effect, low surface gloss, good scattered reflection effect, difficulty in deformation of steel plates, low cost and very good application effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

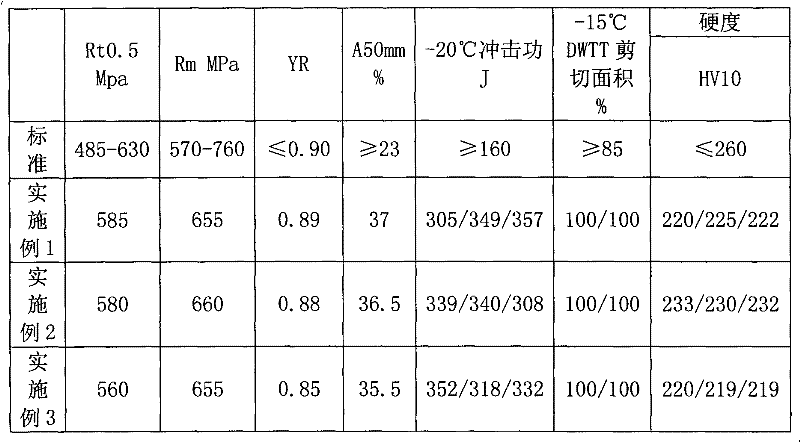

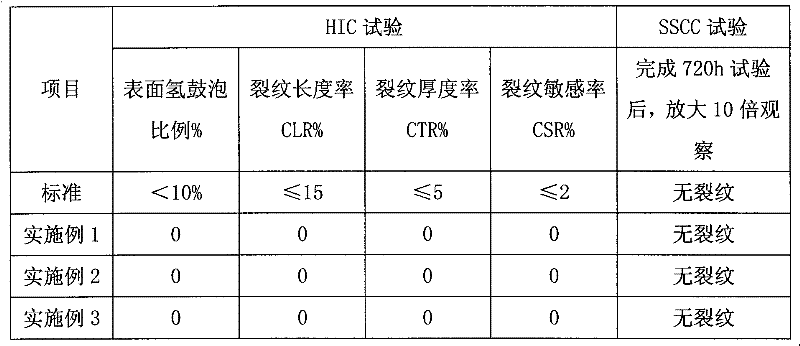

Mobile ocean platform steel with yield ratio not greater than 0.65 and production method thereof

The invention provides mobile ocean platform steel with yield ratio not greater than 0.65. According to the thickness of the finished product of the mobile ocean platform steel, the mobile ocean platform steel being 8 to 50mm in thickness comprises the following components in percentage by weight: 0.08 to 0.12% of C, 0.20 to 0.35% of Si, 1.10 to 1.60% of Mn, not greater than 0.018% of P, not greater than 0.008% of S, 0.10 to 0.20% of Ni, 0.07 to 0.17% of Mo, 0.005 to 0.015% of Ti, 0.015 to 0.035% of Als, and not greater than 0.008% of N; the mobile ocean platform steel being more than 50 to 80mm in thickness comprises the following components in percentage by weight: 0.08 to 0.12% of C, 0.20 to 0.35% of Si, 1.10 to 1.60% of Mn, not greater than 0.010% of P, not greater than 0.004% of S, 0.10 to 0.20% of Ni, 0.10 to 0.20% of Cr, 0.07 to 0.17% of Mo, 0.005 to 0.015% of Ti, 0.015 to 0.035% of Als, and not greater than 0.008% of N. The production method comprises the following steps of: smelting through a converter; continuously casting to obtain a blank; heating the casting blank; roughly rolling; performing finish rolling; cooling; normalizing; performing fog cooling to the steel being not less than 50 to 80mm in thickness. The mobile ocean platform steel has the yield ratio of being not greater than 0.65, is stable in comprehensive performance and outstanding in welding performance, and can completely meet the requirements of the mobile ocean platform steel.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com