Steel for nuclear pressure vessels and manufacturing method thereof

A technology for pressure vessels and manufacturing methods, which is applied in the field of steel for nuclear power, and can solve the problems of increasing manufacturing costs, having no economic and social benefits, and increasing the difficulty of material manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with embodiments.

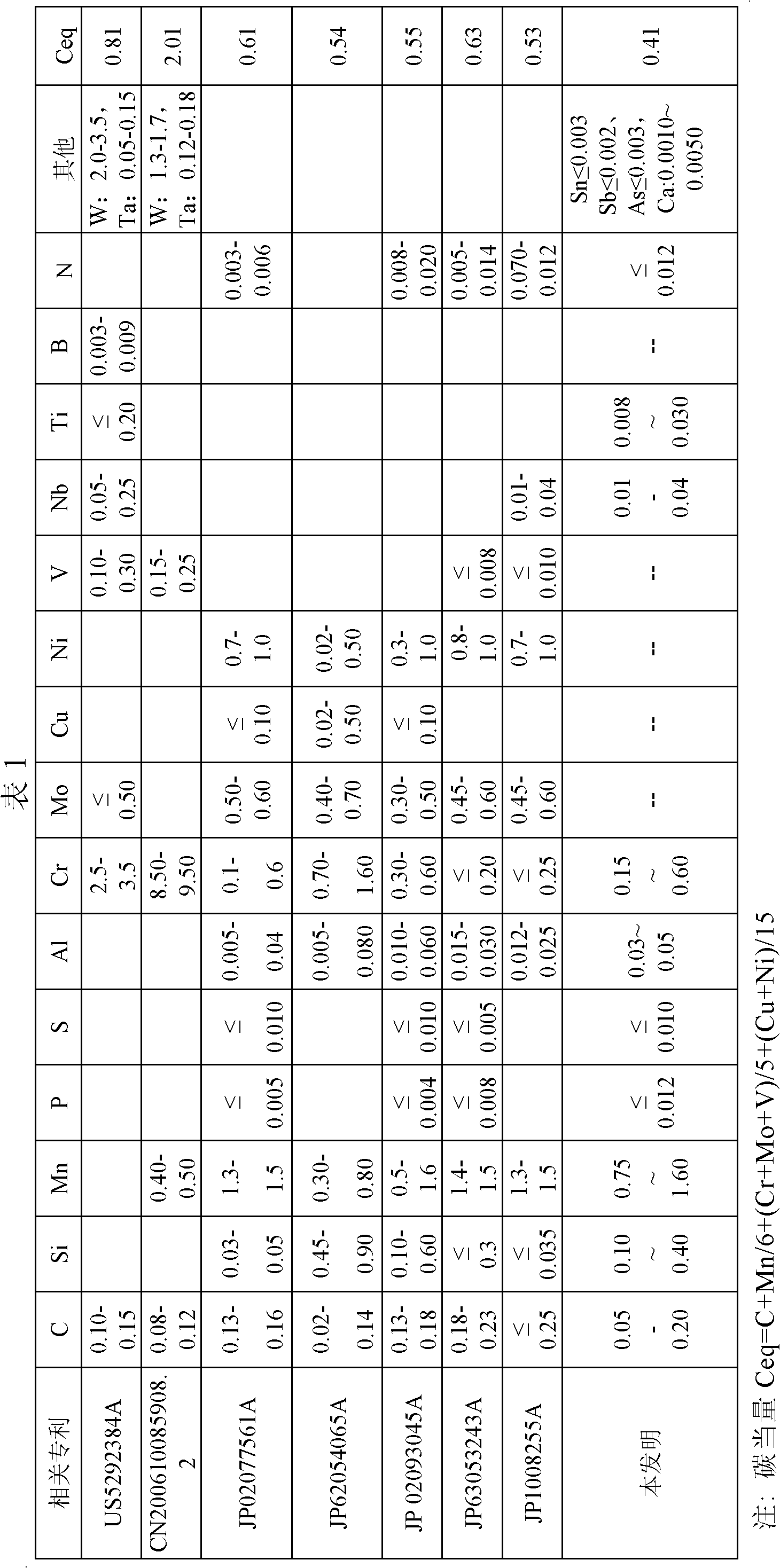

[0060] Table 3 shows the chemical composition of the example steel of the invention, Table 4 shows the process requirements of the example steel of the invention, and Table 5 shows the performance index of the example steel of the invention.

[0061] It can be seen from Table 5 that the yield strength of the steel plates of the present invention are all over 265MPa, the tensile strength is between 440-500MPa, the elongation is over 22%, and they have excellent low-temperature impact performance and stable high-temperature tensile performance.

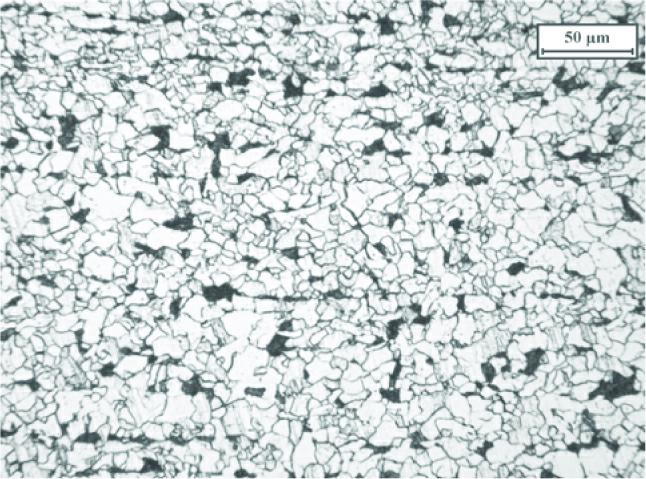

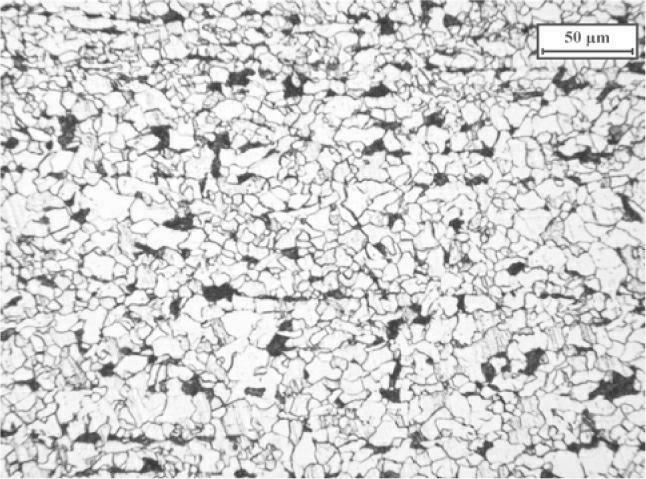

[0062] In summary, the present invention uses C, Mn, and Cr as the main additional elements, and applies Nb and Ti microalloying, combined with the controlled rolling and controlled cooling process of the hot rolling mill, and makes full use of the elements of Nb, Ti and C and N. The relationship is to suppress the growth of austenite grains and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com