Patents

Literature

53results about How to "Fully exert the strengthening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

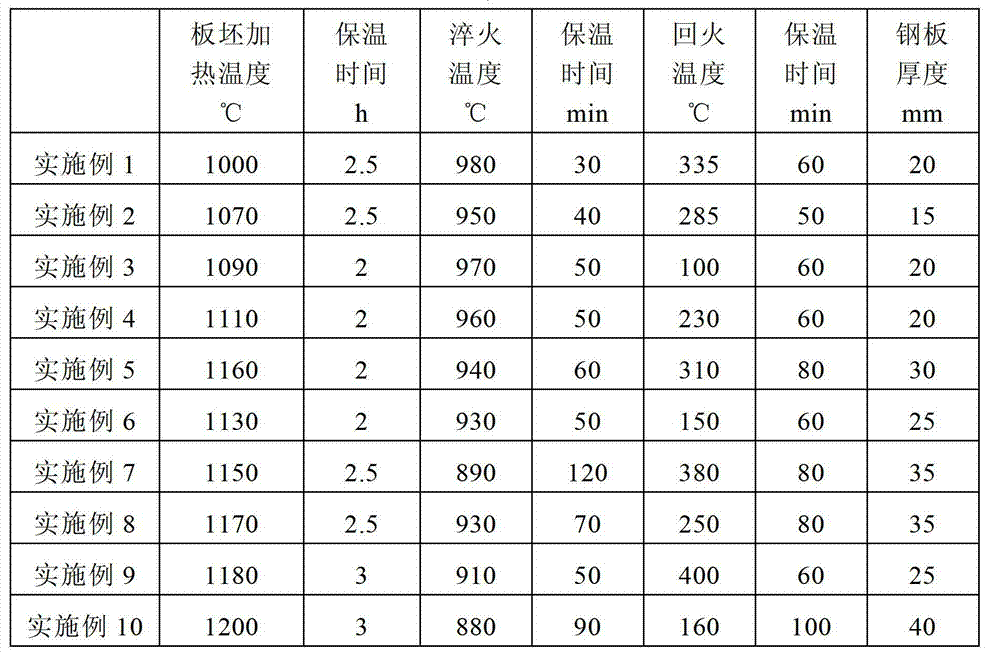

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

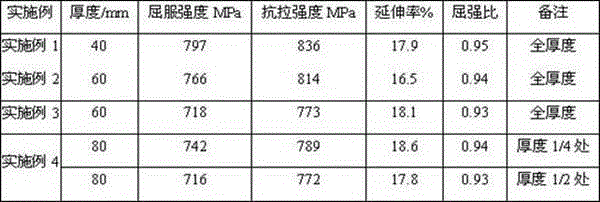

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

Y reinforced Mg-Zn-Y-Zr system magnesium alloy with effective utilization of rare earth element and production method

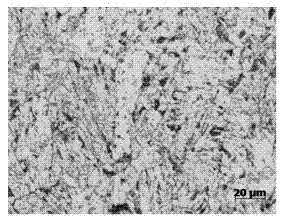

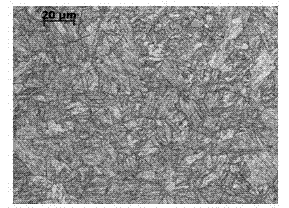

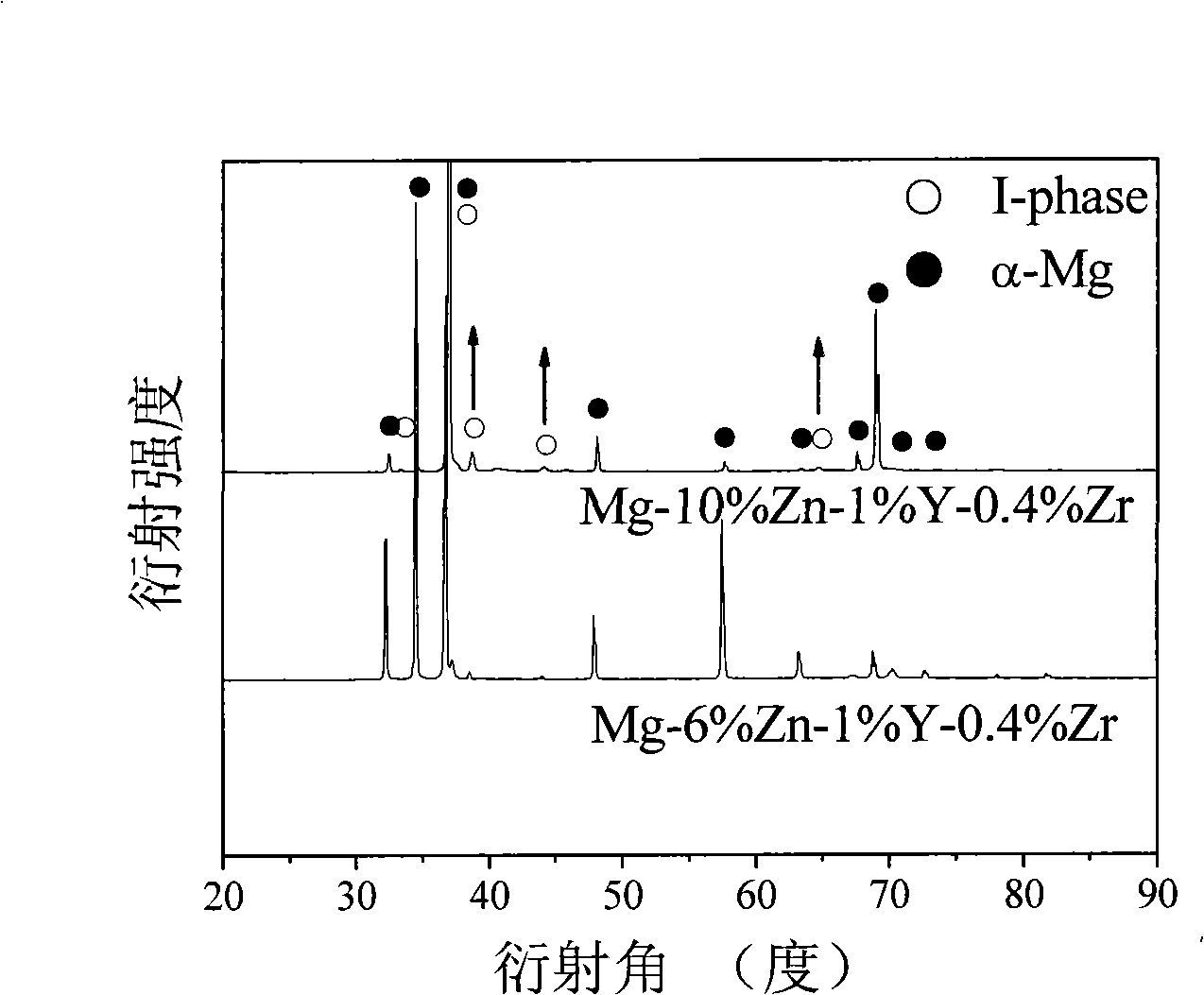

The invention relates to a lanthanon Y which is utilized to strengthen magnesium alloy effectively and a preparation technology thereof, in particular to a quasicrystal phase which is utilized to strengthen Mg-Zn-Y-Zr magnesium alloy and a preparation method thereof, and the problems such as magnesium alloy strengthening, etc. are solved. On the premise of definite Y contents, the volume percentage of the quasicrystal phase which is led into a magnesium alloy matrix to reach the maximum through reasonably choosing the rate between Zn and Y in the alloy (the rate between Zn and Y ranges from 6 to 15), so as to prepare the Mg-Zn-Y-Zr magnesium alloy with low density, high strength and better plasticity. The magnesium alloy material has the components and the contents thereof as follows: the content of zinc (Zn) ranges from 5 to 30 percent; the content of yttrium (Y) ranges from 0.5 to 5 percent; the content of zirconium (Zr) ranges from 0.3 to 0.8 percent, and the others are magnesium (Mg); all the percentage are weight percentage. The magnesium alloy material are processed through alloy melting and subsequent hot extrusion processing and deformed into products, and the operation of the processing technology is simple and convenient. The tensile strength of the material satisfies that Sigma (b) ranges from 290 to 360MPa, the yield stress delta0.2 ranges from 175 to 260MPa, the unit extension Delta ranges from 10 to 18 percent, and the density is 1.84 to 2.73g / cm<3>.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of high plasticity high tenacity super high strength steel plate and its production method

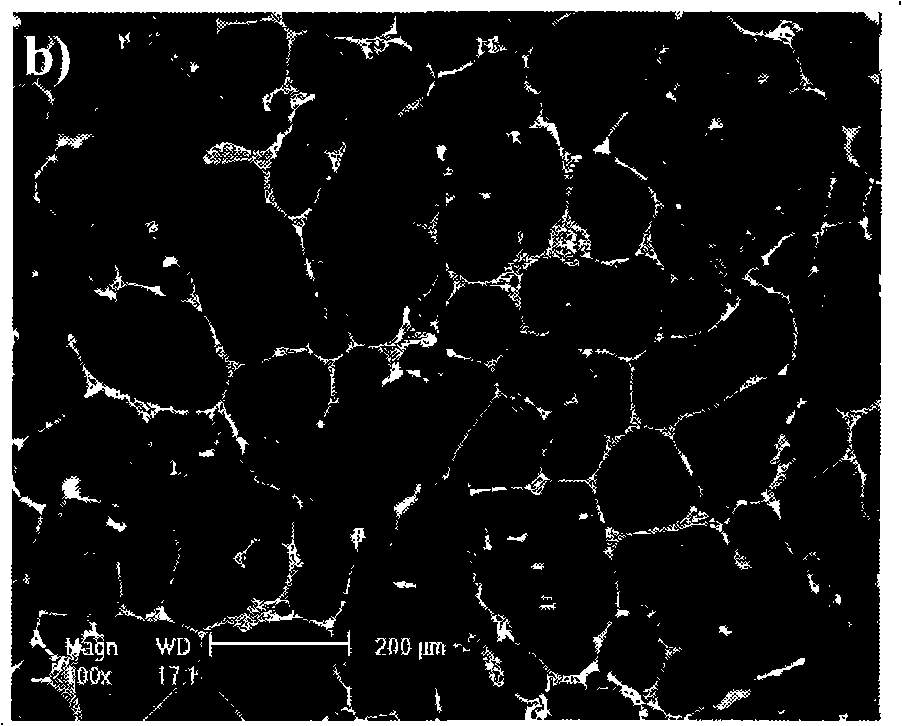

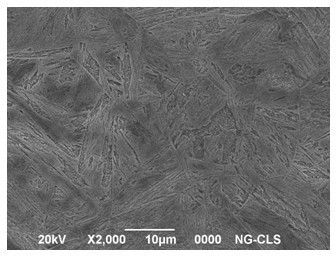

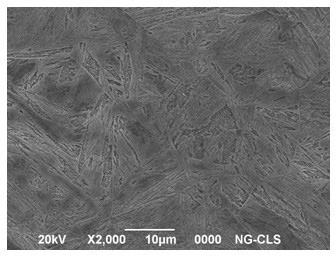

InactiveCN102286695AUniform tissueFully exert the strengthening effectTemperature control deviceHeat treatment process controlTemperingImpurity

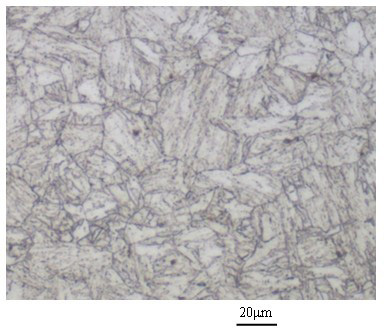

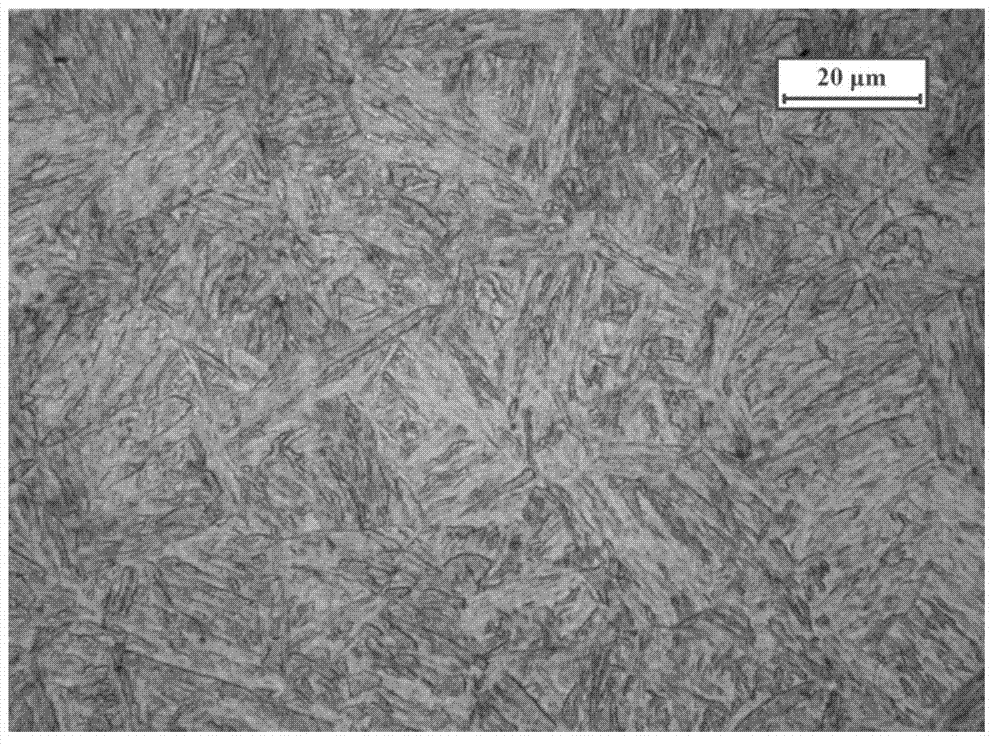

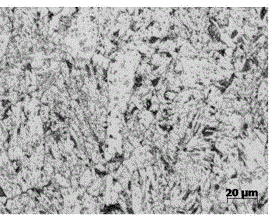

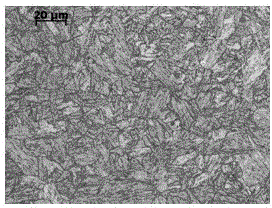

The invention discloses a high-plasticity, high-toughness, ultra-high-strength steel plate and a manufacturing method thereof. The chemical composition of the high-strength steel plate is calculated by weight percentage, C: 0.14-0.18%, Si: 0.10-0.30%, Mn: 0.80-1.30%, P : ≤0.015%, S: ≤0.005%, Nb: 0.010~0.050%, Ti: 0.006~0.020%, V: 0.020~0.060%, Cr: 0.30~0.60%, Mo: 0.20~0.80%, the balance is Fe and unavoidable impurities. Manufacturing method: Smelting in a converter. Through the TMCP process, followed by quenching and tempering treatment. The microstructure of the high ductility, high toughness and ultra-high strength steel plate obtained is tempered sorbite, the lamellar spacing is fine, and the original austenite grains are uniform and fine. It has the characteristics of stable production process, strong operability, low cost and high performance.

Owner:NANJING IRON & STEEL CO LTD

Low-compression ratio super-strength steel plate for ocean engineering and manufacturing method thereof

InactiveCN102691018AHigh strengthImprove plasticityHeat treatment process controlSolderabilityUltimate tensile strength

The invention discloses a low-compression ratio super-strength steel plate for ocean engineering and a manufacturing method thereof. The super-strength steel plate for ocean engineering comprises the following chemical components in percentage by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 1.60-1.80% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0080% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.90-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.40% of Cu, 0.40-0.60% of Mo, and the balance of Fe and inevitable impurities. The laboratory smelting, trial rolling on a rolling mill, TMCP (thermal mechanical control processing) technology and thermal refining are sequentially performed, thus the super strength, high toughness, weldability and manufacturability of the super-strength steel plate for ocean engineering are realized.

Owner:NANJING IRON & STEEL CO LTD

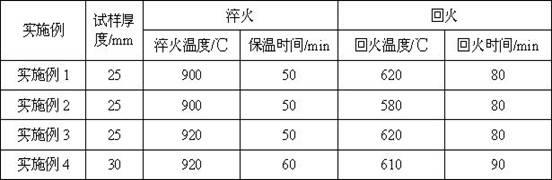

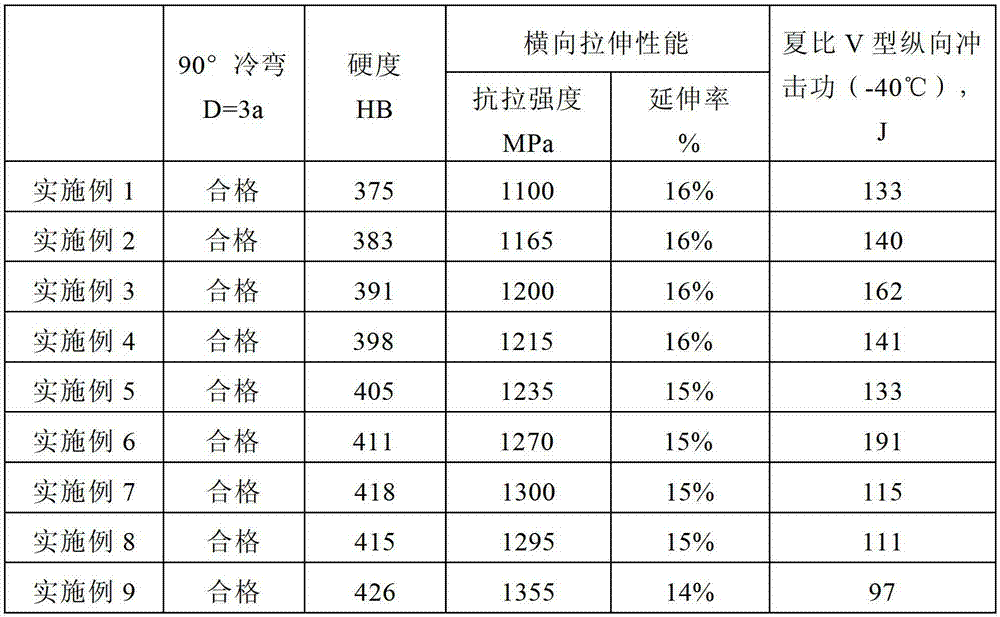

HB360-level wear-resistant steel plate and preparation method thereof

The invention discloses an HB360-level wear-resistant steel plate and a preparation method thereof. The HB360-level wear-resistant steel plate comprises the following components in percentage by weight: 0.08%-0.20% of C, 0.10%-1.00% of Si, 1.00%-2.00% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 1.20% of Cr, not more than 0.80% of Mo, not more than 1.00% of Ni, not more than 0.080% of Nb, 0.010%-0.100% of Al, 0.0005%-0.0040% of B, 0.005%-0.050% of Ti, 0.0010%-0.0080% of Ca, not more than 0.080% of N, not more than 0.0080% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein (Cr / 5+Mn / 6+50B) is not less than 0.20% and not more than 0.55%, (Mo / 3+Ni / 5+2Nb) is not less than 0.02% and not more than 0.45%, (Al+Ti) is not less than 0.01% and not more than 0.13%. The tensile strength of the steel plate is 1100MPa-1400MPa, the elongation of the steel plate is 14%-16%, the Brinell hardness of the steel plate is 360HB-440HB, the Charpy longitudinalV-shaped longidutional impact power at -40 DEG C is 80J-120J. The steel plate obtained by the components through each thermal treatment process is high in strength hardness, good in flexibility, easy to weld, excellent in mechanical machining performances and suitable for easy-wearing components in various mechanical devices.

Owner:BAOSHAN IRON & STEEL CO LTD

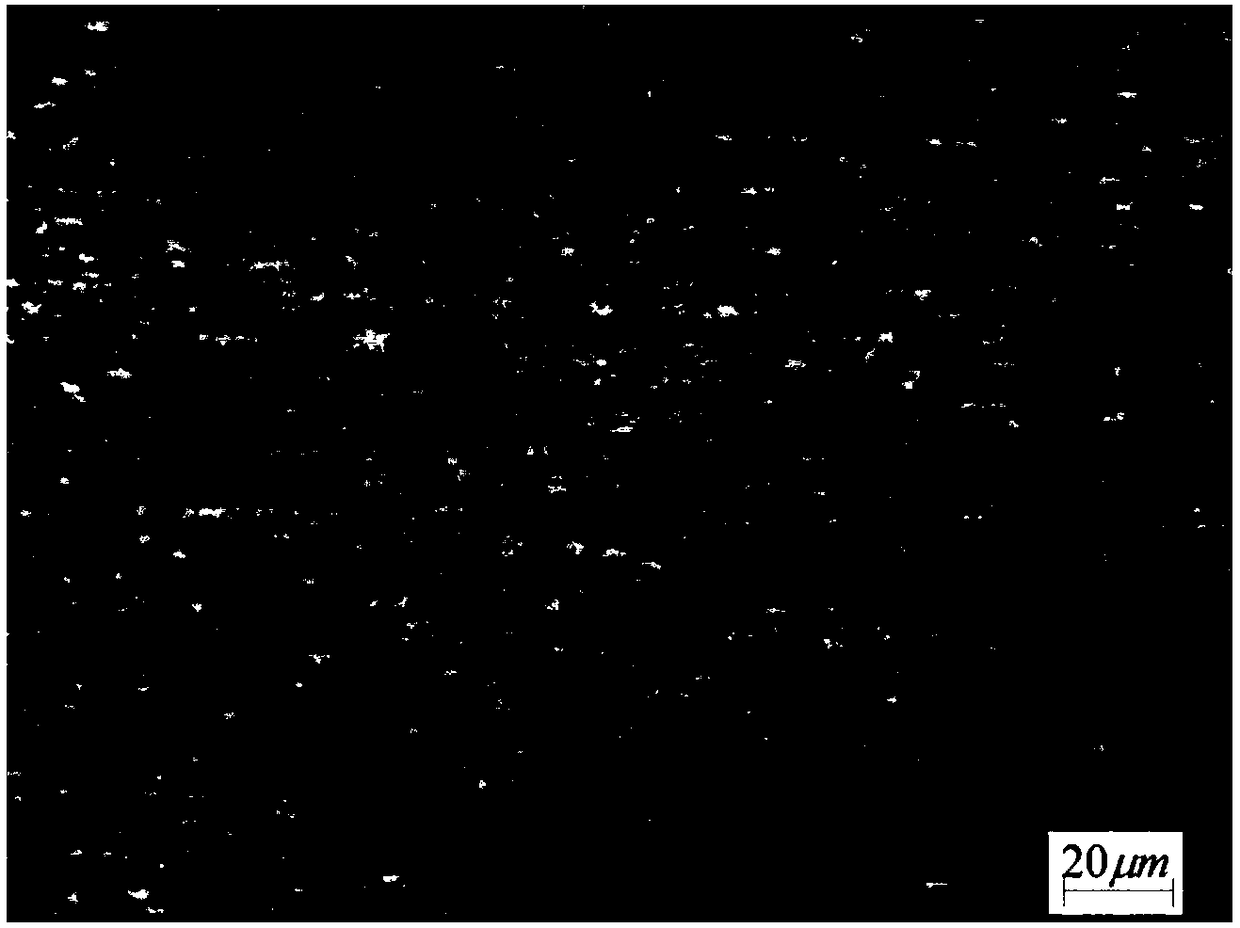

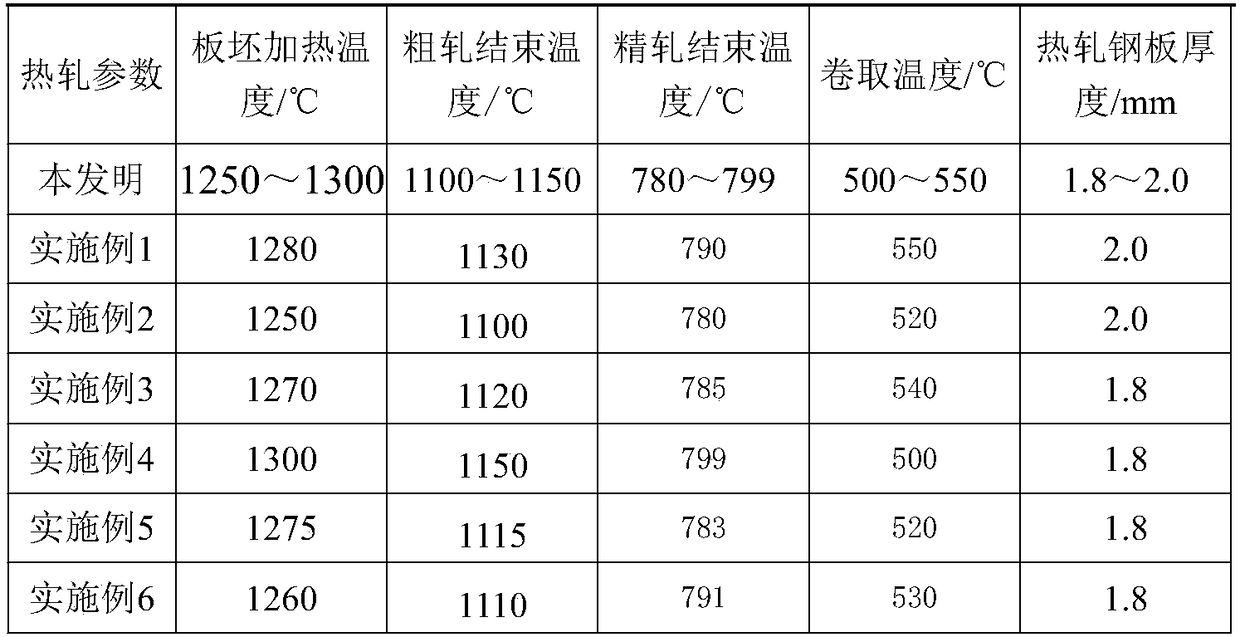

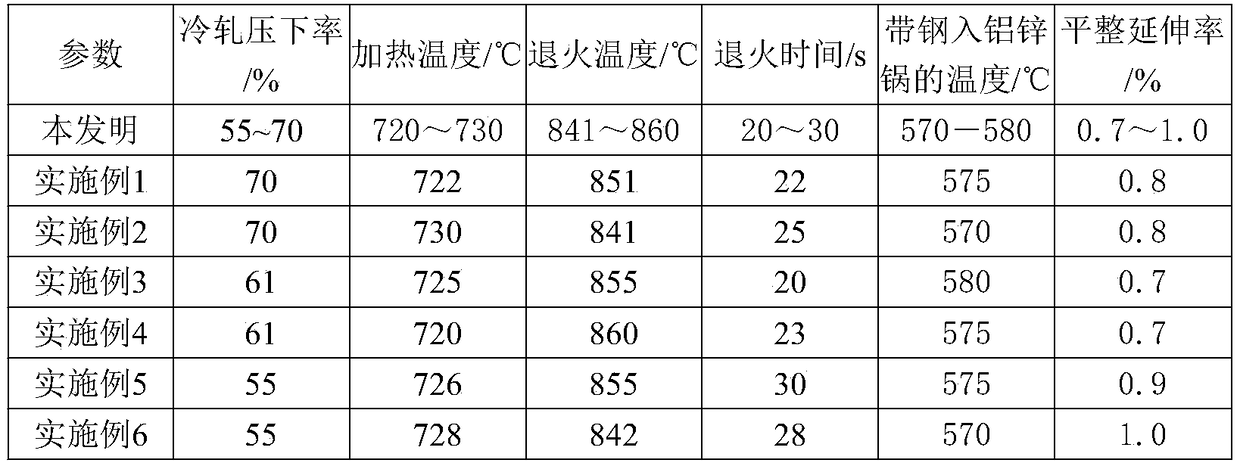

Hot-dipped Al-Zn steel plate with yield strength being 550MPaand manufacturing method thereof

ActiveCN108866428AHigh yield strengthHigh elongationHot-dipping/immersion processesUltimate tensile strengthNiobium carbide

The invention relates to a hot-dipped Al-Zn steel plate with yield strength being 550MPa and a manufacturing method thereof and mainly aims to solve the technical problems in the prior art that a hot-dipped Al-Zn steel plate with yield strength being 550MPa is high in manufacturing cost and low in production efficiency and elongation. According to the hot-dipped Al-Zn steel plate with the yield strength being 550MPa, the base plate of the hot-dipped Al-Zn steel plate comprises the following chemical components in percentage by weight: 0.05%-0.06% of C, 0-0.05% of Si, 1.0%-1.2% of Mn, 0-0.015%of P, 0-0.015% of S, 0.061%-0.080% of Nb and the balanceFe and unavoidable impurities. The metallographic structure of the hot-dipped Al-Zn steel plate is fibrous ferrite, cementite and tiny niobium carbide precipitate; the percentage elongation after fracture of the hot-dipped Al-Zn steel plate with the thickness being 0.60-0.80 mm is 10-18%; and the hot-dipped Al-Zn steel plate is mainly used for components of a construction steel structure.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Moderate-intensity anti-corrosion aluminium alloy material and aluminium alloy rod for cable

The invention discloses a moderate-intensity anti-corrosion aluminium alloy material and an aluminium alloy rod for a cable. The moderate-intensity anti-corrosion aluminium alloy material comprises the components of iron, silicon, magnesium, boron, copper, zinc, rare earth and the balance of aluminium; in a preparation process, an aluminium ingot, aluminum-boron alloy, aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy, aluminum-copper alloy, aluminum-zinc alloy and a magnesium alloy ingot are smelted to form alloy liquid, the alloy liquid is refined and stands by thermal insulation, component regulation is performed, then casting is performed to obtain a cast ingot, and homogenization treatment is performed on the cast ingot to obtain a homogenized cast ingot; the homogenized cast ingot is water-cooled, then hot rolling is performed, and the cast ingot is cooled to be below 100 DEG C to obtain hot rolling aluminum alloy; the hot rolling aluminum alloy is heated, kept warm and then cooled to room temperature, and precipitation heat treatment is performed to obtain the moderate-intensity anti-corrosion aluminium alloy material. The moderate-intensity anti-corrosion aluminium alloy material and the aluminium alloy rod for the cable are high in mechanical strength, good in corrosion resistance and excellent in comprehensive performance.

Owner:ANHUI ELECTRIC GRP SHARES

Method for adjusting and regulating long-periodic structure phase of magnesium alloy

ActiveCN106392044AImprove performanceFully exert the strengthening effectUltrasonic vibrationMagnesium alloy

The invention discloses a method for adjusting and regulating a long-periodic structure phase of magnesium alloy. The method comprises the steps of: firstly preparing Mg-Ni (or Zn)-Y alloy containing LPSO, and then adjusting and regulating form and distribution of a long-periodic structure by applying ultrasonic vibration and pressure in sequence in an alloy solidification process. The alloy preparing and processing comprises the following steps: melting the alloy under protection of mixed gas of N2 and SF6, after temperature reaches 720-730 DEG C, placing a melt in a container in a holding furnace, cooling to a temperature more than a liquidus temperature of the alloy by more than 10-50 DEG C, then performing ultrasonic vibration processing on the melt, lasting for 1-5min, after the vibration is finished, pouring into a preheated die of 200-300 DEG C for extruding to solidify under pressure, wherein an extruding pressure is 50-500 MPa, and pressure holding time is 1-3min. The LPSO phase in the alloy prepared by such method is obviously refined and uniformly distributed, and performances of the alloy are greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

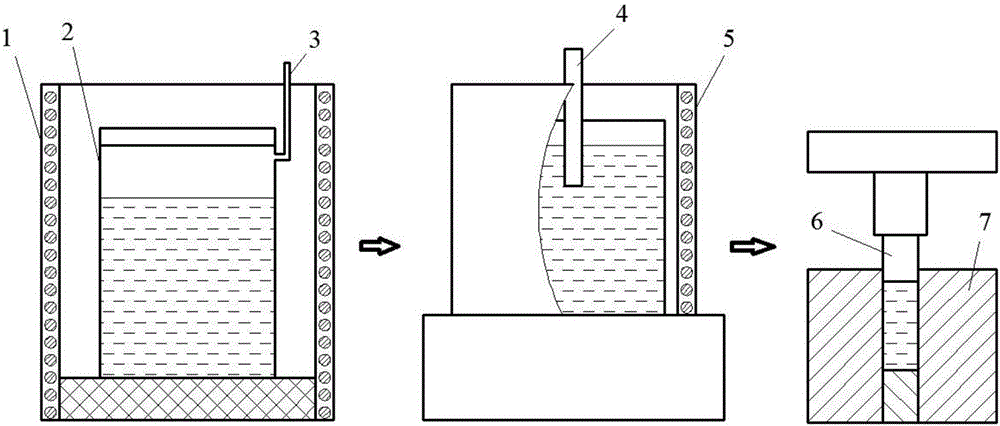

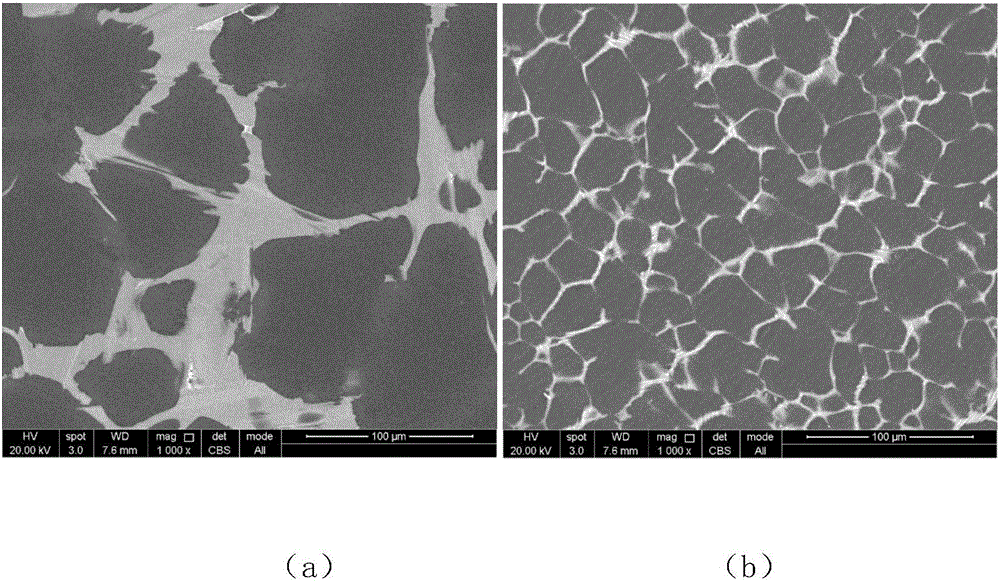

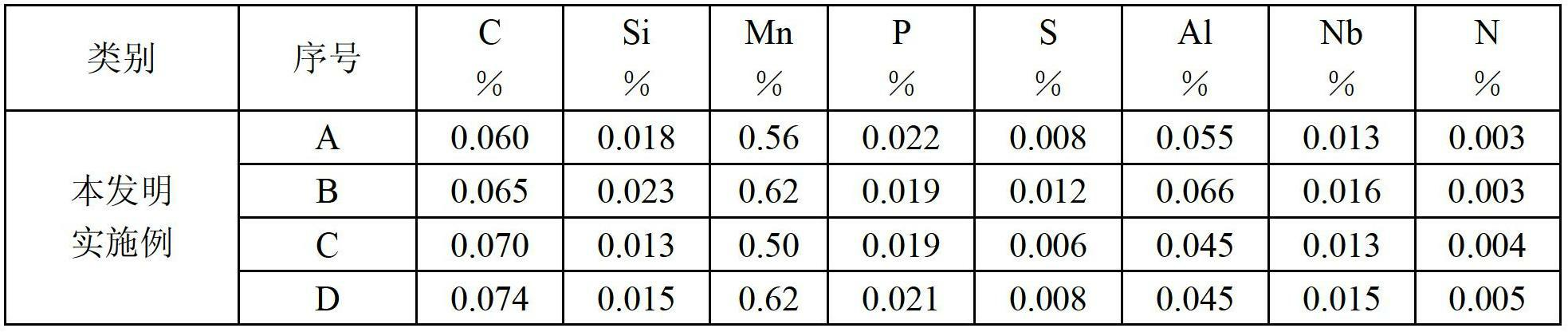

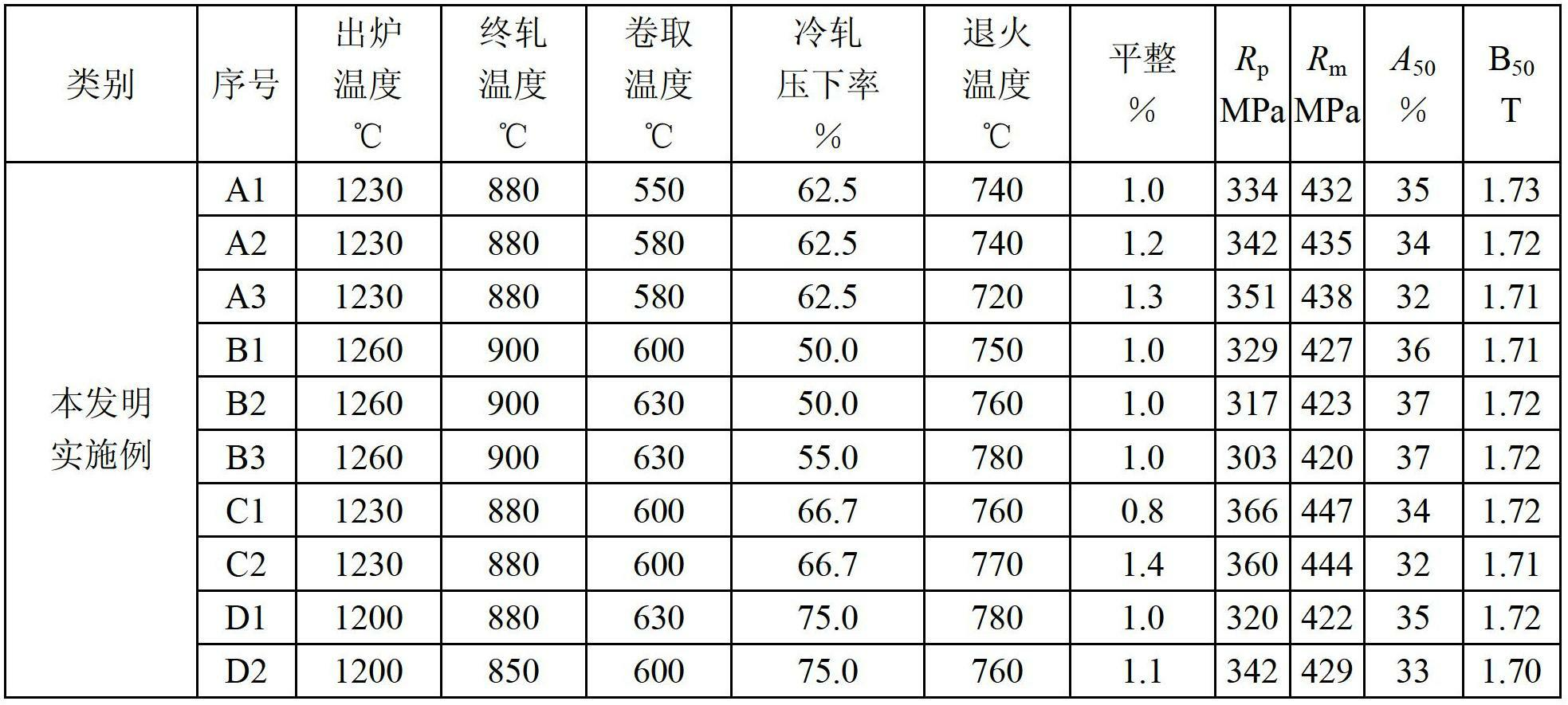

Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

ActiveCN102650016AFully exert the strengthening effectImprove shape qualityRoll mill control devicesMetal rolling arrangementsReduction rateHeating time

The invention discloses a manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel. The manufacturing method comprises the steps as follows: heating a plate blank to be 1200-1260 DEG C and insulating; hotly rolling, wherein the final rolling temperature is 850-900 DEG C, the coiling temperature is 550-630 DEG C and a jet water cooling way is adopted as a cooling way; cooling to be 60-80 DEG C for acid washing, wherein an air cooling way is adopted as the cooling way; coldly rolling, wherein the cold rolling reduction rate is 50-75%; continuously annealing, wherein the temperature of an uniform heating section is 720-780 DEG C and the uniform heating time is 60-200 s; and flattening by a flattening elongation rate of 0.8-1.4% to prepare the 250 MPa cold-rolled magnetic pole steel. The produced magnetic pole steel has lower yield strength ReL of more than 250 MPa and magnetic induction strength B50 of more than 1.70 T, and is suitable for manufacturing a magnetic pole iron core of a rotor body of a large water-wheel generator.

Owner:BAOSHAN IRON & STEEL CO LTD

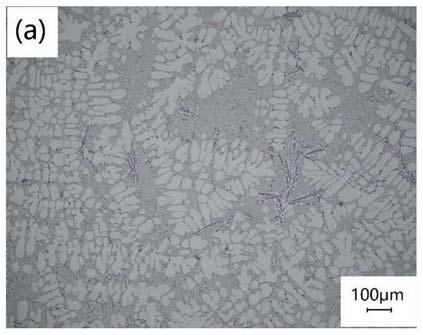

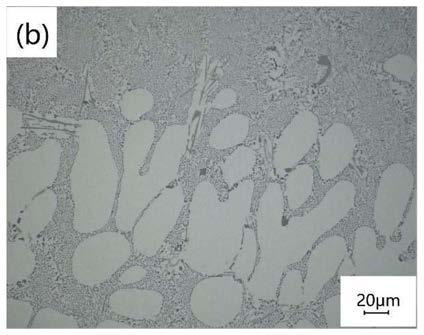

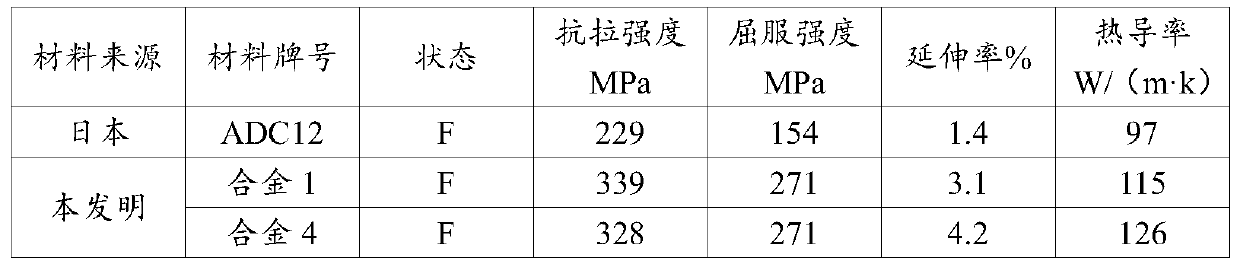

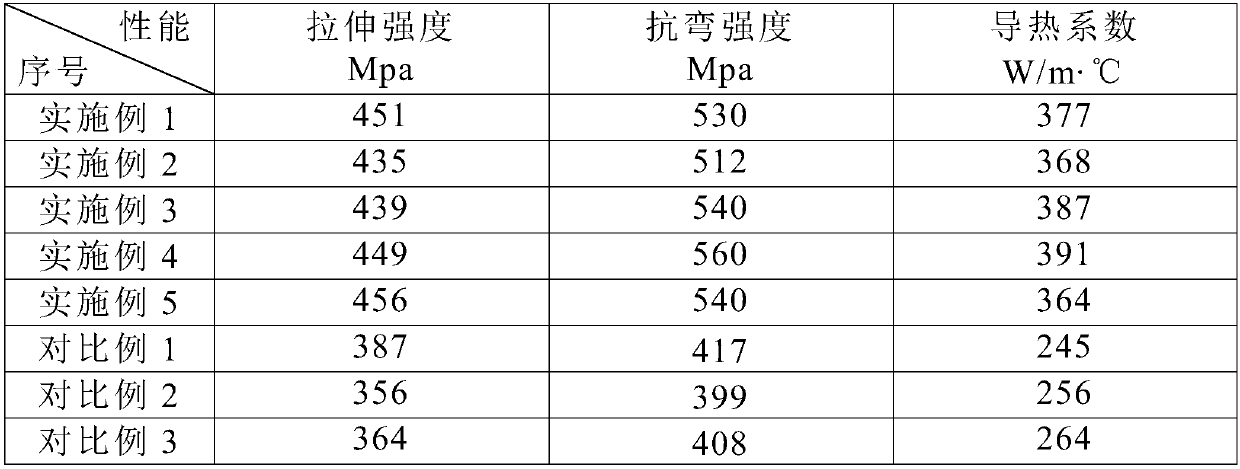

High-toughness heat dissipation aluminum ally material for thin-walled die-casting part and manufacturing method thereof

The invention relates to high-toughness heat dissipation aluminum ally for a thin-walled die-casting part and a manufacturing method of the high-toughness heat dissipation aluminum ally. The high-toughness heat dissipation aluminum ally comprises, by weight, 8.0%-12.6% of Si, 1.0%-2.5% of Mg, 0.2%-0.5% of Cu, 0.2%-0.4% of Fe, 0.001%-0.02% of B, 0.005%-0.1% of Sr, smaller than or equal to 0.01% ofother impurity elements and the balance Al. After a molten aluminum body is manufactured, die-casting production is conducted, the temperature of the molten aluminum body ranges from 680 DEG C to 720DEG C, the die temperature ranges from 150 DEG C to 200 DEG C, and after a casting is taken out, air cooling is conducted for 10-50 seconds, so that the temperature of the casting is reduced to rangefrom 30 DEG C to 50 DEG C. By means of a method of rapid cooling of the thin-walled die-casting part, a large number of the Mg elements, the Si elements, the Cu elements and other elements are kept inan Al substrate in a solid solution mode, and therefore the strength of the alloy is improved, and the elongation of a material is guaranteed. The tensile strength of the obtained material in a die-casting state ranges from 308 MPa to 339 MPa, the yield strength ranges from 253 MPa to 271 MPa, the elongation ranges from 3.1% to 4.2%, and the heat conductivity ranges from 115 W / M*k to 126 W / M*k.

Owner:SUZHOU UNIV

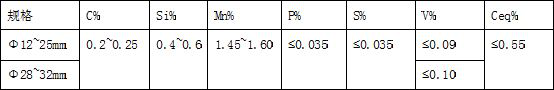

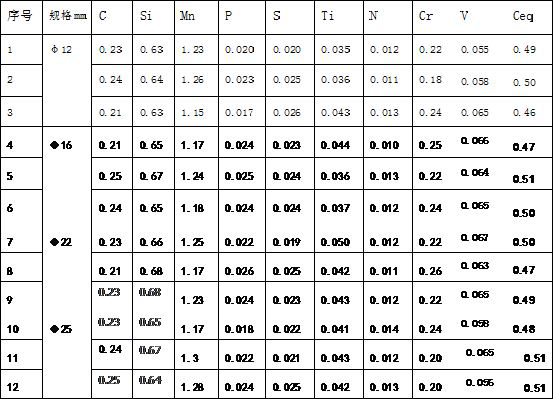

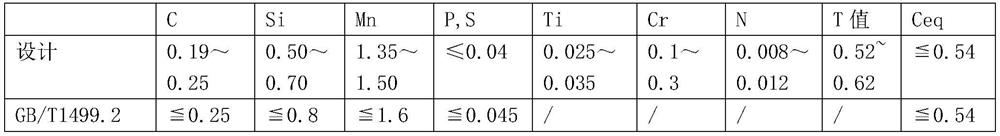

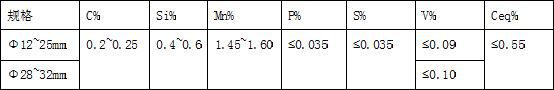

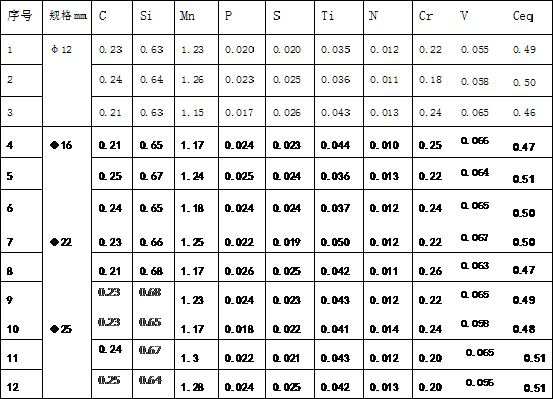

Smelting method for producing HRB500E straight reinforcing steel bar of phi 12-25 mm through microalloying

The invention discloses a smelting method for producing an HRB500E straight reinforcing steel bar of phi 12-25 mm through microalloying. Chemical components of the reinforcing steel bar comprise 0.19%-0.25% of C, 0.60%-0.80% of Si, 1.10%-1.4% of Mn, not larger than 0.04% of S, not larger than 0.04% of P, 0.01%-0.015% of N, 0.03%-0.05% of Ti, 0.05%-0.07% of V, 0.1%-0.3% of Cr, not larger than 1.55% of the sum of the mass percents of Cr and Mn and not larger than 0.54% of Ceq. The smelting method comprises the steps that a pre-deoxidation composite slag washing agent is added in converter tapping, wherein the slag washing agent comprises, by mass percent, 5%-10% of fluorite, 65%-75% of calcium carbide and 15%-25% of limestone; and the pre-deoxidation composite slag washing agent is added after converter tapping is completed, then a silicon manganese alloy, silicon iron and a high-carbon ferrochrome are added in sequence, all the alloys must start to be added when 1 / 3 of tapping is completed, all the alloys are added when 3 / 4 of tapping is completed, a high-nitrogen composite enhancer is added after converter alloy adding is completed, the adding quantity is 0.6-0.8 kg / t, the high-nitrogen composite enhancer comprises 12%-20% of N and 18%-25% of Ti, soft blowing is carried out after ferrotitanium and vanadium nitrogen alloys are added, and the soft blowing effect is that the exposed diameter of broken steel slag molten steel is 100-200 mm.

Owner:XINJIANG BAYI IRON & STEEL

Transgranular-intergranular composite reinforced biological zinc alloy and preparation method thereof

InactiveCN109500396AEvenly distributedFully exert the strengthening effectAdditive manufacturingIncreasing energy efficiencySelective laser meltingNano silicon

The invention relates to a transgranular-intergranular composite reinforced biological zinc alloy and a preparation method thereof, and belongs to the technical field of biological material design andpreparation. The transgranular-intergranular composite reinforced biological zinc alloy is prepared from graphene, nano silicon carbide and a zinc matrix, wherein the graphene is in an onion shape and packaged with nano silicon carbide particles; meanwhile, part of the graphene-packaged nano silicon carbide particles enters zinc crystal particles in an engulfed mode, while other nano silicon carbide particles are subjected to intergranular segregation, so that uniform transgranular-intergranular distribution of nano ceramic particles in the zinc matrix is realized. The preparation method of the transgranular-intergranular composite reinforced biological zinc alloy comprises the steps of batch copious cooling ball milling and selective laser melting. When obtained products are used as implants, bone defects can be well repaired. The transgranular-intergranular composite reinforced biological zinc alloy has reasonable component design, simple and controllable preparation process and excellent product performance.

Owner:CENT SOUTH UNIV

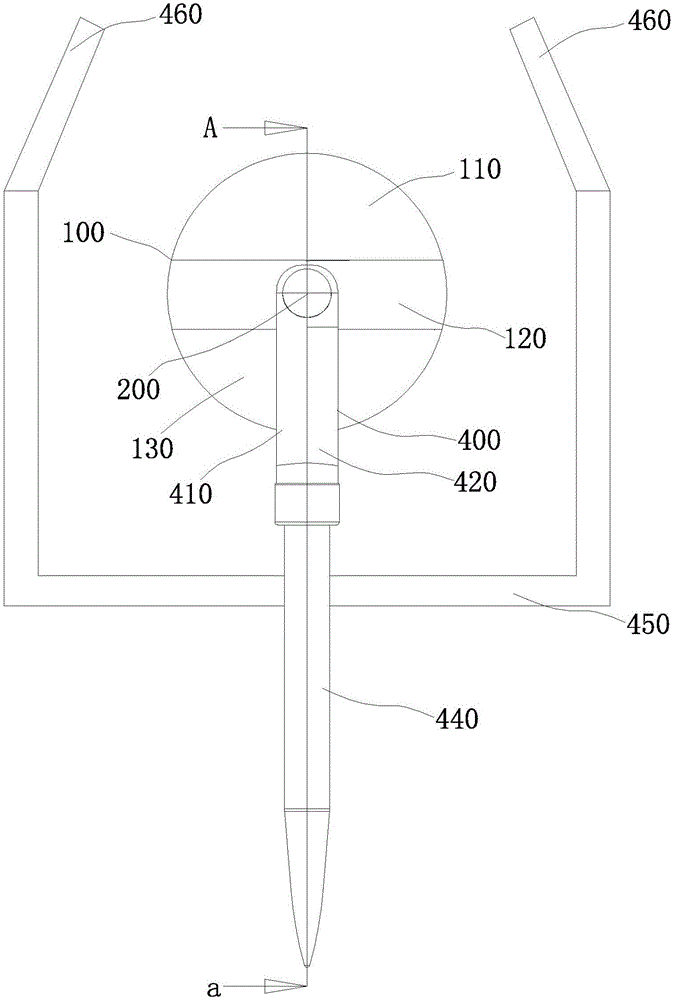

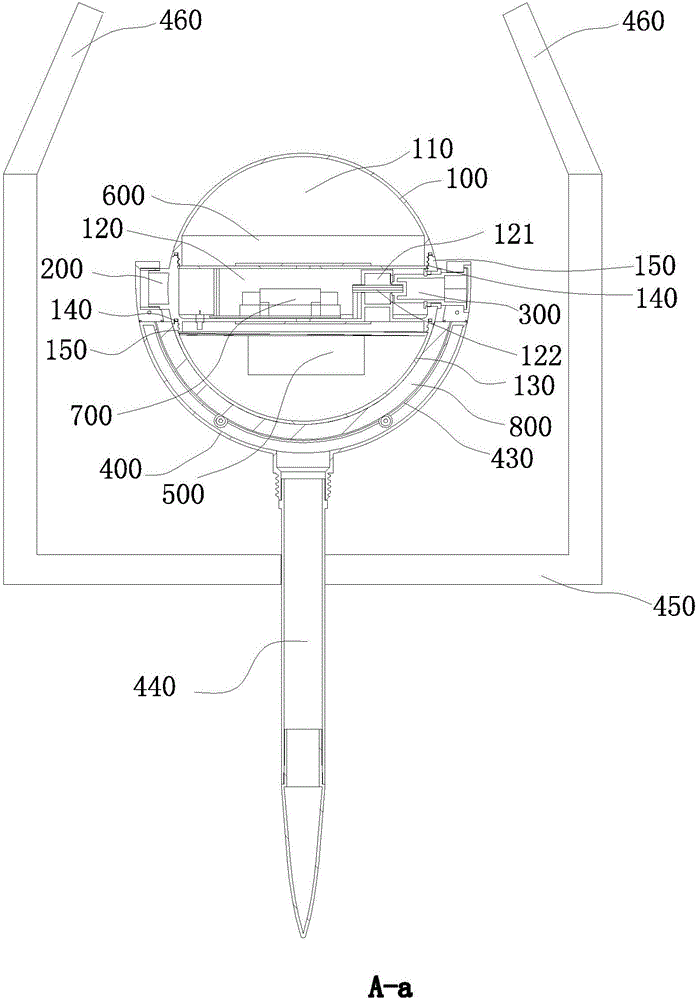

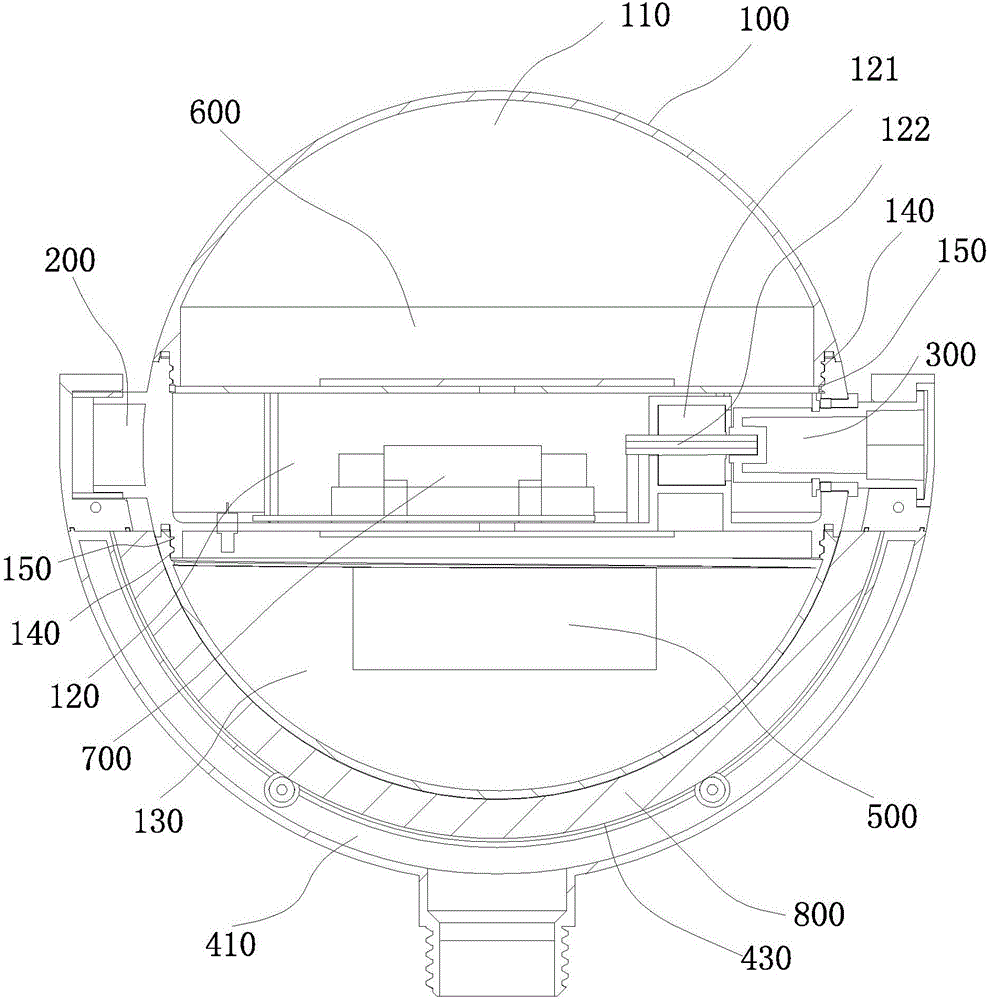

Spherical solar power lamp

InactiveCN106764844AImprove mechanical propertiesHigh strengthLighting support devicesProtective devices for lightingSolar lampElectricity

The invention provides a spherical solar power lamp, comprising a spherical housing, a left shaft, a right shaft, a light source part, a photovoltaic battery plate and a storage battery, wherein the spherical housing comprises an upper hemisphere, a connecting part and a lower hemisphere, the upper hemisphere and the lower hemisphere are respectively connected with two ends of the connecting part; the left shaft is arranged on one side of the connecting part; the right shaft is arranged on the opposite side of the connecting part; the spherical housing is positioned on a U-shaped bracket, the two ends of the U-shaped bracket are respectively connected with the right shaft and the left shaft, the bottom end of the U-shaped bracket is connected with a support bar, the end part of the support bar is provided with branches on which solar panels are fixedly arranged; the light source part is arranged in the lower hemisphere; the photovoltaic battery plate is arranged in the upper hemisphere and is made of brass alloy; and the storage battery is arranged in the connecting part and is respectively electrically connected with the light source part and the photovoltaic battery plate. According to the solar power lamp, the vertical positions of the photovoltaic battery plate and the light source can be conveniently and quickly changed, thereby compromising luminous efficiency and photoelectric conversion efficiency, and prolonging the service life.

Owner:潘云清

Preparation method of high-strength high-conductivity copper-silver alloy wire

InactiveCN105261422AAvoid grain growthMaintain fibrosisCable/conductor manufactureArgon atmosphereHigh intensity

The invention provides a preparation method of a high-strength high-conductivity copper-silver alloy wire. The method comprises the following steps: 1, under the protection of an argon atmosphere, elevating the temperature of a copper-silver alloy ingot to 800-850 DEG C, maintaining the temperature for 4-7h, and performing cooling; and 2, drawing the copper-silver alloy ingot, and performing intermediate thermal treatment of the copper-silver alloy ingot during drawing to obtain the high-strength high-conductivity copper-silver alloy wire with the tensile strength no less than 800MPa and the conductivity no less than 70%IACS. According to the preparation method, time and process of thermal treatment before and during drawing are optimized, thereby fully developing an enforcement effect of a copper-silver alloy material and ensuring whole conductivity of the material. The preparation method has a preferable application prospect.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-strength and corrosion-resisting alloy steel material and preparing technology thereof

InactiveCN108486484AImprove passivation corrosion resistanceEasy to weldProcess efficiency improvementRare-earth elementHigh intensity

The invention discloses a high-strength and corrosion-resisting alloy steel material and a preparing technology thereof. The raw materials and components include 0.21%-0.28% of C, 0.31%-0.43% of Si, 0.09%-0.13% of Mn, 0.21%-0.25% of B, 0.34%-0.42% of Ni, 0.09%-0.17% of Zr, 0.11%-0.15% of Cr, 0.11%-0.13% of Al, 0.07%-0.09% of P, 0.03%-0.04% of S, 0.07%-0.11% of Sb, 0.06%-0.09% of Ti, 0.001%-0.004%of Ca, 0.04%-0.07% of rare earth elements, smaller than or equal to 0.03% of O, smaller than or equal to 0.04% of N, and the balance Fe and inevitable impurities. The steel has good strength and tenacity and has high low-temperature tenacity, the preparing technology is simple, the production cost is relatively low, and the production requirement can be met.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Medium-strength aluminum alloy rod for cables, and production method thereof

ActiveCN104962783AOptimizing Alloy CompositionSimple processMetal/alloy conductorsCable/conductor manufactureSilicon alloyRare earth

The invention discloses a production method of a medium-strength aluminum alloy rod for cables. The method comprises the following steps: melting aluminum ingots, aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy and magnesium ingots to form an alloy liquid, carrying out degassing refining, carrying out heat insulation standing, and casting to obtain cast ingots, wherein the alloy liquid comprises, by mass, 0.30% or less of iron, 0.30-0.50% of silicon, 0.30-0.50% of magnesium, 0.10-0.15% of rare earth, and the balance of aluminum; carrying out water cooling on the obtained cast ingots, carrying out hot rolling, and cooling to obtain a hot-rolled aluminum alloy rod; carrying out solid solution treatment on the hot-rolled aluminum alloy rod to obtain a solid solution treated aluminum alloy rod; and naturally ageing the solid solution treated aluminum alloy rod for 1-2h, and artificially ageing at 150-160DEG C for 3.5-4h to obtain the medium-strength aluminum alloy rod for cables. The invention also discloses the medium-strength aluminum alloy rod for cables.

Owner:ANHUI ELECTRIC GRP SHARES

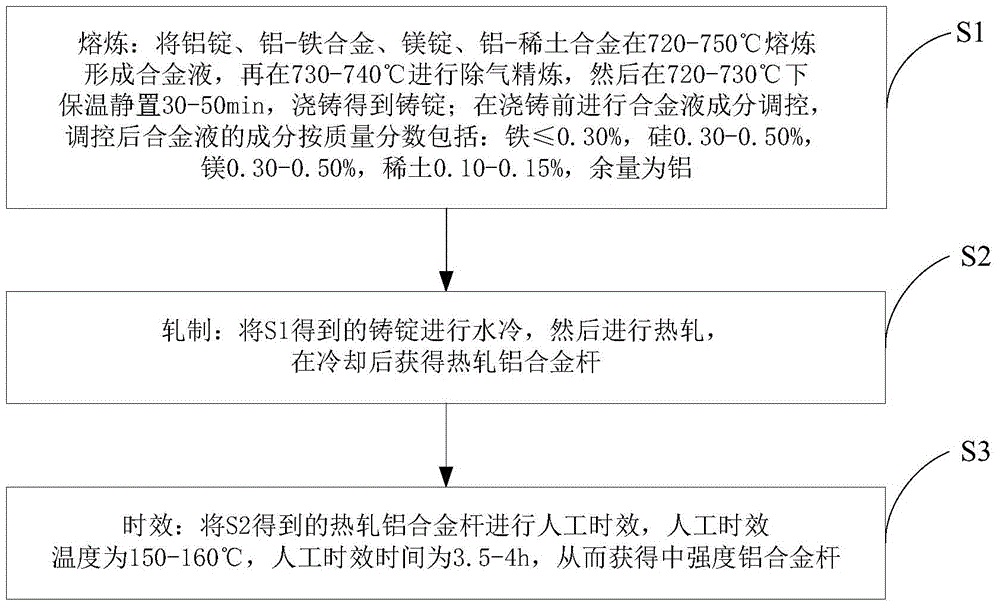

Intermediate-strength aluminium alloy rod and preparation method thereof

The invention discloses a preparation method for an intermediate-strength aluminium alloy rod. The preparation method comprises the following steps: smelting an aluminium ingot, aluminium-silicon alloy, aluminium-iron alloy, a magnesium ingot and aluminium-tombarthite alloy at 720-750 DEG C to form an alloy liquid, then degassing and refining at 730-740 DEG C, then standing at 720-730 DEG C for 30-50 min, and casting to obtain an ingot; adjusting and controlling alloy liquid components before casting, wherein the adjusted and controlled alloy liquid comprises the following components in percentage by weight: smaller than or equal to 0.30% of alloy, 0.30-0.50% of silicon, 0.30-0.50% of magnesium, 0.10-0.15% of tombarthite and the balance of aluminium; performing water cooling on the obtained ingot, then conducting hot rolling, and cooling so as to obtain a hot rolled aluminium alloy rod; conducting artificial aging on the obtained hot rolled aluminium alloy rod, wherein the artificial aging temperature is 150-160 DEG C, and the artificial aging time is 3.5-4 h, so as to obtain the intermediate-strength aluminium alloy rod. The invention further discloses the intermediate-strength aluminium alloy rod obtained by adopting the preparation method for the intermediate-strength aluminium alloy rod.

Owner:ANHUI ELECTRIC GRP SHARES

Heat treatment process of high-strength wear-resistant Al-Si-Cu alloy

The invention belongs to the technical field of nonferrous material manufacturing, and particularly relates to a heat treatment process of high-strength wear-resistant Al-Si-Cu alloy. Through introducing intermediate cold deformation and warm water quenching, and through primary high-temperature processing and two times of annealing processing, a second phase in the alloy is uniformly dispersed and precipitated so as to fully play a role in reinforcement, the quench-cracking tendency of the alloy is effectively inhibited, and the alloy keeps better toughness. The Al-Si-Cu alloy extruded product obtained through treating by utilizing the heat treatment process provided by the invention has the room temperature tensile strength achieving 501MPa or above, the elongation achieving not less than 5 percent, and the average crystallite size achieving 0.020 to 0.035mm, and has an excellent wear-resisting property. Meanwhile, the heat treatment process provided by the invention can be applied in silicon aluminum alloy with the total content of alloy elements achieving not less than 18 weight percent.

Owner:内蒙古蒙东高新集团有限公司 +1

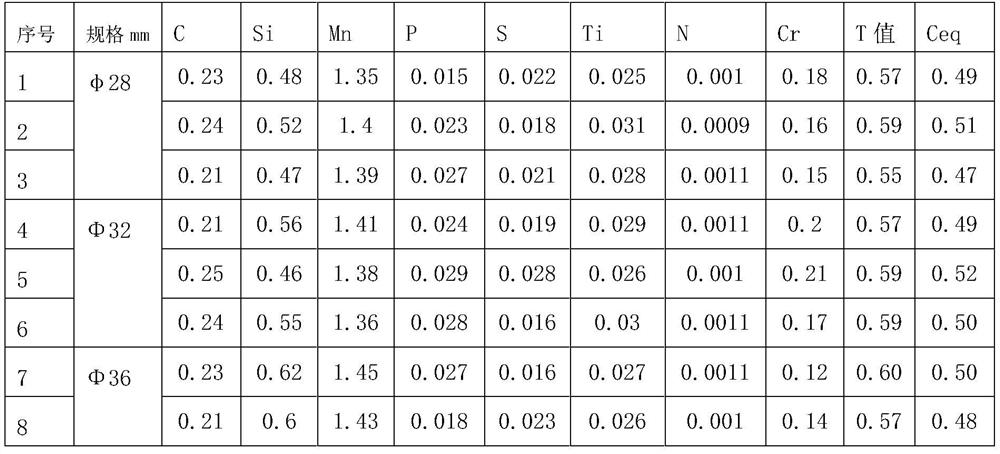

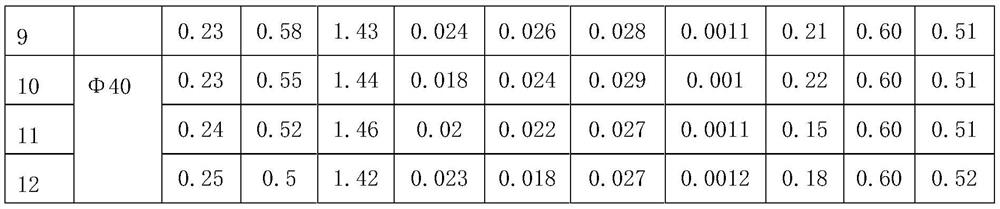

Smelting method of large-specification HRB400E straight reinforcing steel bar with diameter phi of 28-40mm

The invention discloses a smelting method of a large-specification HRB400E straight reinforcing steel bar with the diameter phi of 28-40 mm. The large-specification HRB400E straight reinforcing steel bar comprises the following chemical components in percentage by mass: 0.19-0.25% of C, 0.45-0.65% of Si, 1.30-1.5% of Mn, less than or equal to 0.04% of S, less than or equal to 0.04% of P, 0.008-0.012% of N, 0.025-0.035% of Ti, 0.1-0.25% of Cr and 0.52-0.62% of T value [C + (Si + Mn + Cr) / 6]. The smelting method comprises the following process steps: (1) adding a pre-deoxidized composite slag washing agent after molten steel of steel ladle is seen during converter tapping, wherein the pre-deoxidized composite slag washing agent comprises the following components in percentage by mass: 5-10% of fluorite, 65-75% ofcalcium carbide and 15-25% of limestone; (2) converter tapping is completed, the pre-deoxidation composite slag washing agent is added, then silicon-manganese alloy, silicon iron and high-carbon ferrochrome are added in sequence, the adding amount is set according to component requirements, all the alloys must be added when 1 / 3 of tapping is conducted, and adding of all the alloys is finished when 3 / 4 of tapping is conducted; (3) the steel ladle is conveyed to an argon blowing station through a steel car after tapping is completed, and a high-nitrogen composite enhancer is added according to component requirements; and (4) soft blowing is conducted after ferrotitanium and a high-nitrogen composite enhancer are added.

Owner:XINJIANG BAYI IRON & STEEL

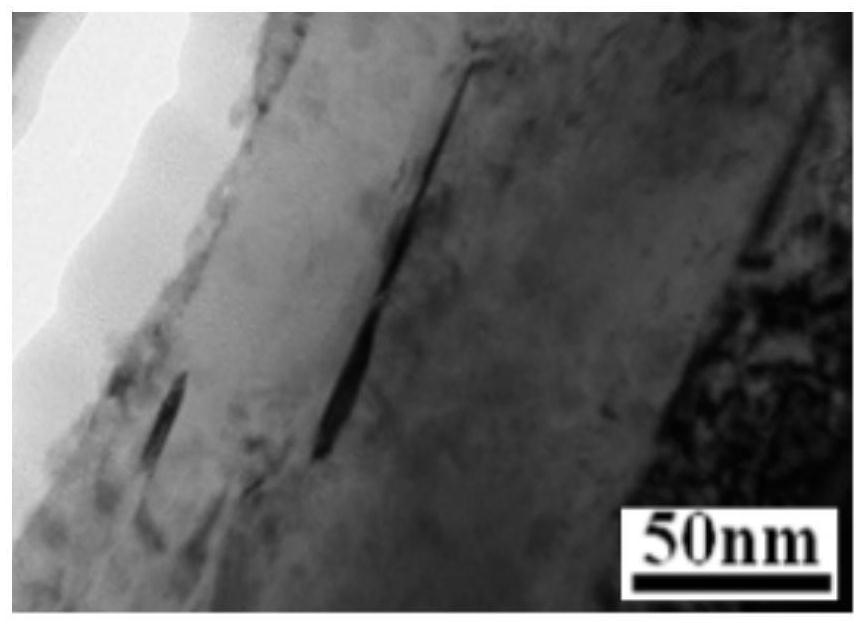

High-strength and high-conductivity copper-silver alloy wire and preparation method thereof

ActiveCN114645153AGuaranteed uniformityEfficient and stable productionApparatus for heat treatmentConductive materialElectrical conductorElectrolysis

According to the high-strength and high-conductivity copper-silver alloy wire and the preparation method thereof, a high-strength and high-conductivity copper-silver alloy takes electrolytic pure copper and high-purity silver (99.99%) as raw materials, and a copper-silver alloy cast ingot is obtained through vacuum magnetic suspension smelting. And the cast ingot is subjected to repeated free forging and final die forging, and the copper-silver alloy round bar is forged. The high-strength and high-conductivity copper-silver alloy wire with the tensile strength not lower than 1 GPa and the conductivity not lower than 80% IACS (International Annealed Copper Standard) is obtained by carrying out continuous drawing on a copper-silver alloy round bar, then carrying out medium-drawing continuous annealing and fine-drawing continuous annealing, finally carrying out continuous drawing, and annealing in a protective atmosphere continuous annealing furnace at the temperature of 150-350 DEG C when the accumulative deformation reaches 90-95%, so as to obtain the high-strength and high-conductivity copper-silver alloy wire with the tensile strength not lower than 1 GPa and the conductivity not lower than 80% IACS (International Annealed Copper Standard). The prepared copper-silver alloy wire has the advantages of being high in strength, good in conductivity, uniform in structure, smooth in surface and the like, the yield is high, and follow-up split charging, wire twisting and the like are facilitated; and the requirements of high-strength and high-conductivity conductor materials in the fields of high-strength magnetic field systems, lead frames and the like can be met.

Owner:NORTHEASTERN UNIV

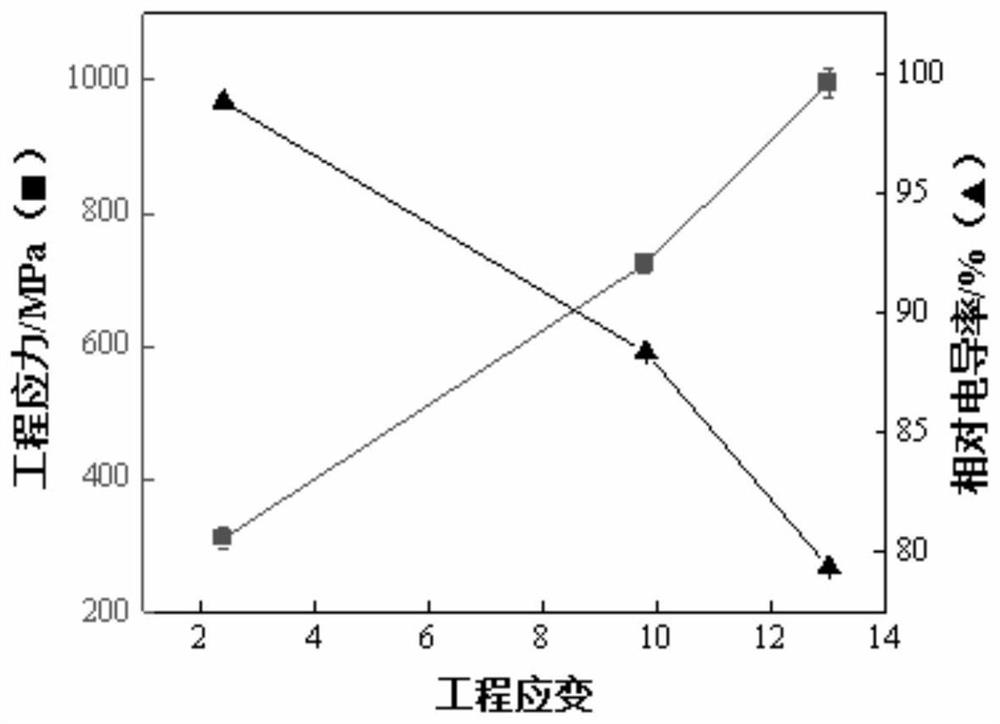

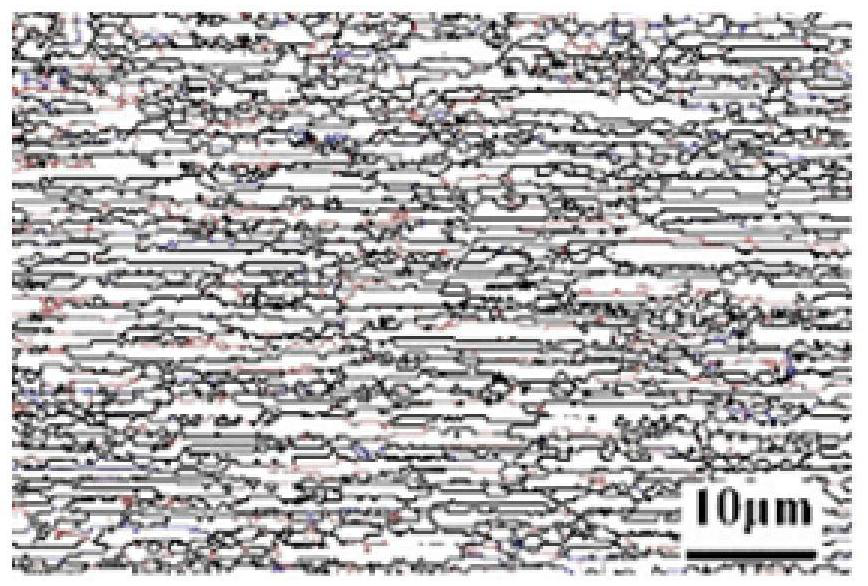

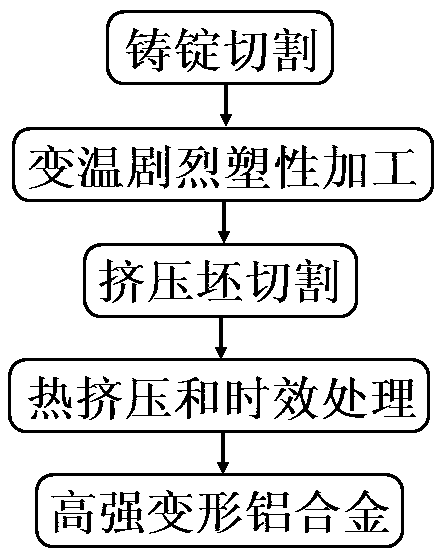

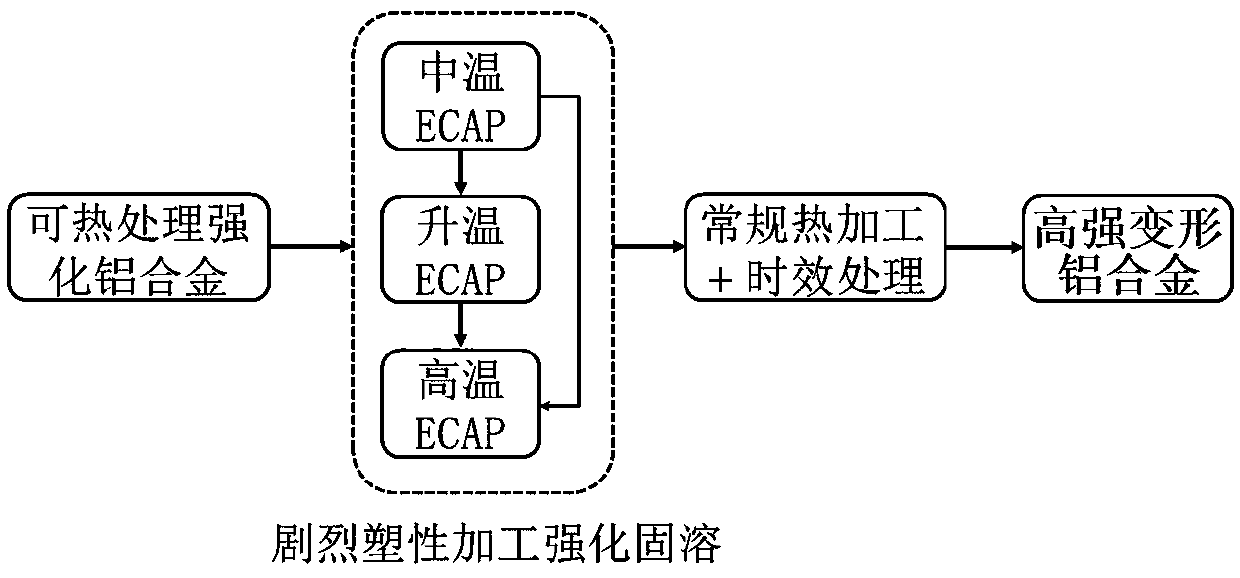

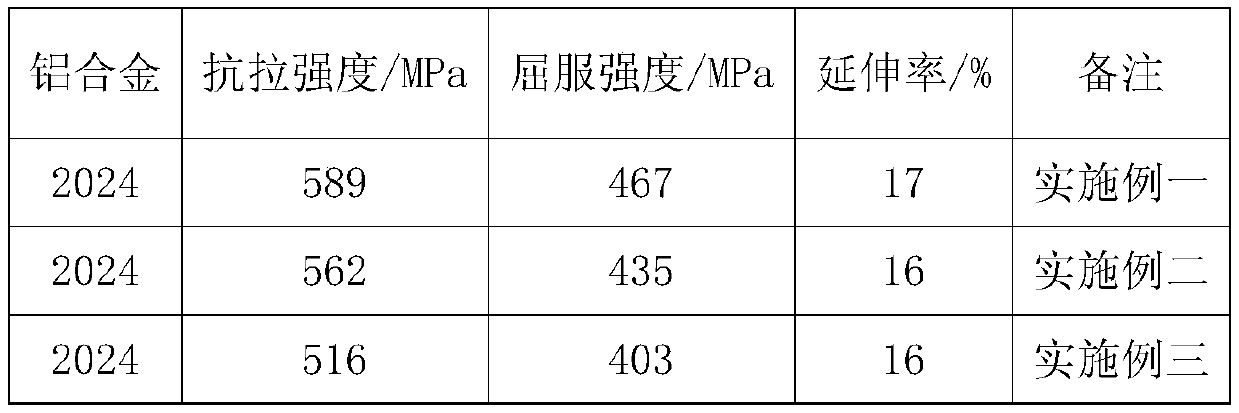

Method for preparing high-strength wrought aluminum alloy based on severe plastic deformation

The invention discloses a method for preparing a high-strength wrought aluminum alloy based on severe plastic deformation. The method comprises the following steps that A, a blank is cut out from an aluminum alloy cast ingot; B, the blank is put into a rotary die equal channel angular pressing die, equal channel angular pressing processing is continuously carried out by adopting multi-temperaturestages of step-by-step temperature rise, strengthened solid solution treatment is realized by using a severe plastic deformation technology, and after completion, water quenching treatment is carriedout so as to obtain a supersaturated solid solution block extrusion billet; and C, an alloy bar with the length direction parallel to the equal-channel angular pressing direction is cut out, and conventional hot extrusion processing and aging treatment are carried out on the alloy bar so as to obtain the high-strength wrought aluminum alloy. According to the method, strengthened solid solution treatment is realized through staged severe plastic deformation of step-by-step temperature rise, a second phase is effectively promoted to dissolve, a single-phase solid solution alloy with fine grain size, high density defects and high supersaturation degree is obtained, then uniform precipitation of a nano precipitation phase is promoted through hot working and aging treatment, and the high-strength wrought aluminum alloy is obtained.

Owner:江苏江南创佳型材有限公司

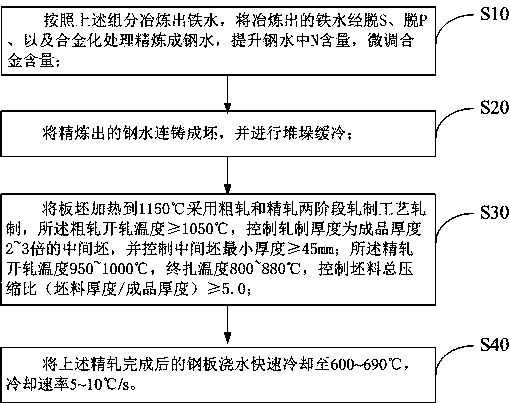

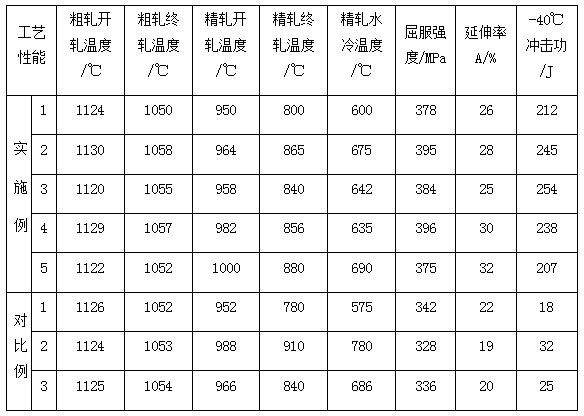

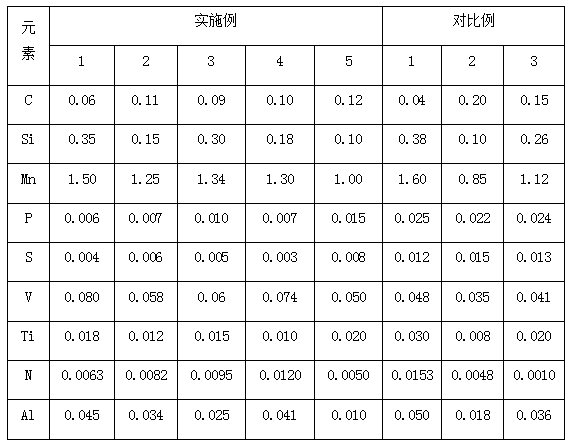

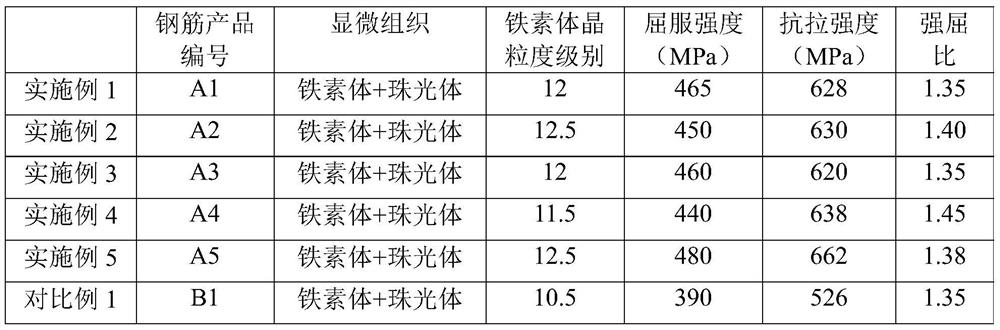

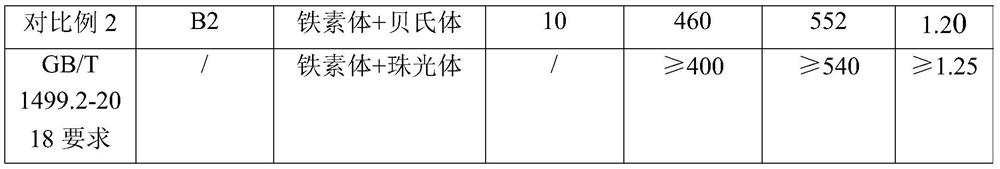

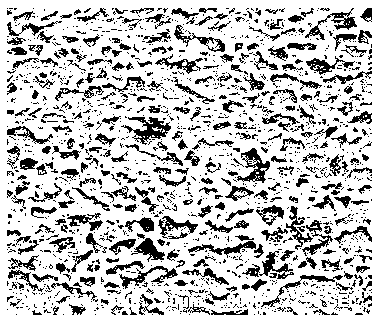

High-nitrogen and low-alloy ship plate steel high in low-temperature toughness and manufacture method thereof

ActiveCN110157986AFully exert the strengthening effectReduce carbon contentSocial benefitsAbsorbed energy

The invention discloses high-nitrogen and low-alloy ship plate steel high in low-temperature toughness and a manufacture method thereof. Components of the high-nitrogen and low-alloy ship plate steelhigh in low-temperature toughness include C, Si, Mn, P, S, V, Ti, Als, N and the balance Fe and impurities, and the content of the component elements mentioned above must simultaneously meet the following relations that V+Ti >=0.070 and (V+Ti) / N >=6.95. According to the manufacture method, combination reinforcement of carbonitride is achieved through the two alloy elements, namely, V and Ti, underthe high N content, and by means of control of the rolling and cooling process, the large amount of carbonitride is formed; the carbon content in the steel is effectively decreased, and the high-strength and high-tenacity ship plate steel is manufactured. The yield strength of steel plates is larger than or equal to 370 MPa, the elongation A is larger than or equal to 25%, and the impact absorbing energy at the temperature of -40 DEG C is larger than or equal to 200 J. The ship plate steel is suitable for constructing ship and ocean engineering steel structures with high requirements for strength and tenacity, is simple in component design, short in technological process and low in production cost, and has good economic benefits and social benefits.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

400MPa-grade titanium microalloyed hot-rolled steel bar and production method thereof

ActiveCN114293095AReduce alloy costSave resourcesProcess efficiency improvementChemical compositionTitanium

The invention relates to the technical field of steel production, in particular to a 400MPa-grade titanium microalloyed hot-rolled steel bar and a production method thereof. Based on the total mass of the 400MPa-grade titanium microalloyed hot-rolled steel bar, the 400MPa-grade titanium microalloyed hot-rolled steel bar comprises the following chemical components in percentage by mass: 0.2-0.25% of C, 0.2-0.8% of Si, 1-1.6% of Mn and 0.01-0.1% of Ti, and the contents of Si, Mn and Ti meet the following relational expression: [Si] + 1.6 [Mn] + 47.3 [Ti]-258.8 [Ti] + 487.9 [Ti] < 5.4. According to the technical scheme, the reasonable matching relation of the alloy elements is limited, the strengthening effect of the alloy elements is brought into full play, the utilization rate of the alloy elements is increased, and meanwhile the product quality performance is guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

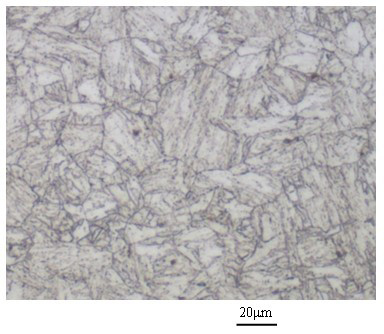

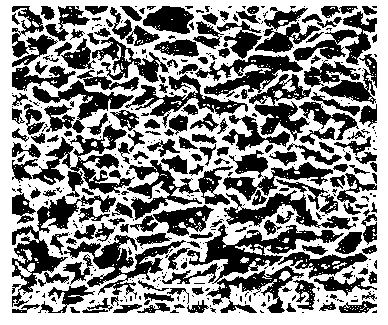

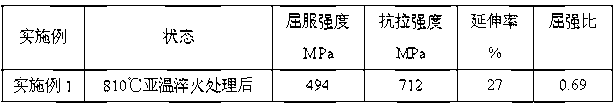

Manufacturing method capable of improving plasticity of pipeline steel plate

InactiveCN103255273AMake up for the low plasticity of steelGuaranteed basic performanceGrain structureUltimate tensile strength

The invention discloses a manufacturing method capable of improving the plasticity of a pipeline steel plate. The manufacturing method comprises the following steps of: reheating the pipeline steel plate at 780 to 830 DEG C, wherein the heat-preserving time is based on 2 min / mm*plate thickness; and performing water quenching or air cooling, wherein the cooling speed is 1 to 20 DEG C / s. The obtained pipeline steel metallographic structure is of a ferrite ultrafine grain structure, so the defect of low plasticity of pure ultrasonic grain steel is overcome. The volume percentage of the crystal grains with the diameter being less than 1 micron is about 50 to 55 percent, the volume percentage of the crystal grains with the diameter being 5 to 10 microns is about 30 to 35 percent, and the volume percentage of the crystal grains with other sizes is about 10 to 15 percent. According to the obtained pipeline steel plate, the yield strength is 450 to 530 MPa, the tensile strength is 670 to 760 MPa, the extension rate is more than or equal to 27 percent, and the yield ratio Rt0.2 / Rm is less than or equal to 0.70. The manufacturing method is stable in production process, high in operability and low cost, and the obtained material has excellent comprehensive performance.

Owner:NANJING IRON & STEEL CO LTD

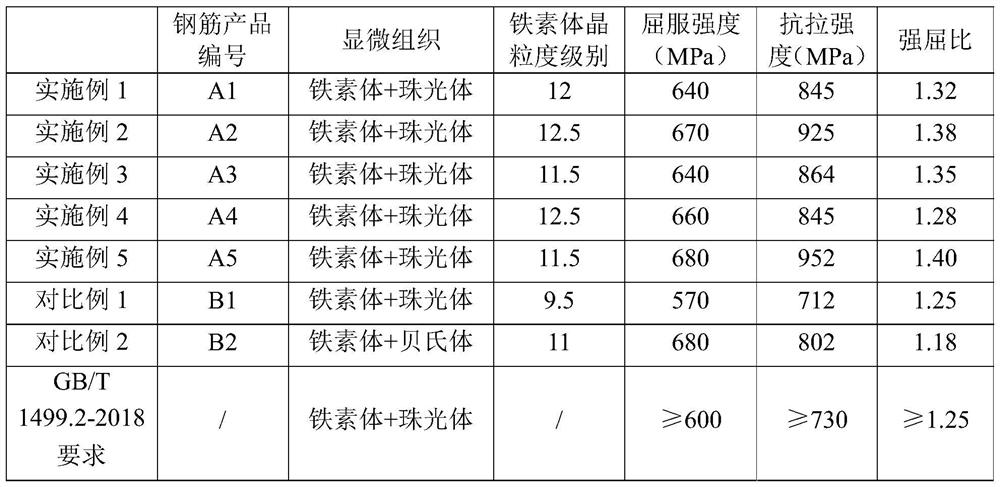

600MPa-grade vanadium-titanium microalloyed hot-rolled steel bar and production method thereof

ActiveCN114293093AReduce alloy costSave resourcesProcess efficiency improvementMetal rolling arrangementsTitaniumRebar

The invention relates to the technical field of steel production, in particular to a 600MPa-grade vanadium-titanium microalloyed hot-rolled steel bar and a production method thereof. Based on the total mass of the 600MPa-grade vanadium-titanium microalloyed hot-rolled steel bar, the 600MPa-grade vanadium-titanium microalloyed hot-rolled steel bar comprises the following chemical components in percentage by mass: 0.2-0.28% of C, 0.2-0.8% of Si, 1-1.6% of Mn, 0.05-0.15% of V and 0.05-0.20% of Ti, the content of Mn and Ti meets the condition that [Mn] + 29.4 [Ti]-169.6 [Ti] + 328.5 [Ti] < 3.0, and the content of V and Ti meets the condition that [V] + [Ti] is greater than 0.15 and less than 0.3. By limiting the reasonable matching relation of the alloy elements, the strengthening effect of the alloy elements is brought into full play, the utilization rate of the alloy elements is increased, and meanwhile the product quality performance is guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

a sink

ActiveCN106756206BFully exert the strengthening effectPerformance maximizationTransportation and packagingMetal-working apparatusMetallurgyMaterials science

Owner:NINGBO OULIN IND CO LTD

An intragranular-intergranular composite-enhanced bio-zinc alloy

InactiveCN109500396BEvenly distributedFully exert the strengthening effectAdditive manufacturingIncreasing energy efficiencyCarbide siliconSelective laser melting

The invention relates to a bio-zinc alloy strengthened by intra- and inter-crystal composites and a preparation method thereof, belonging to the technical field of design and preparation of biomaterials. The biological zinc alloy is composed of graphene, nano-silicon carbide and zinc matrix: the graphene encapsulates nano-silicon carbide particles in the shape of an onion, and at the same time, part of the graphene-encapsulated nano-silicon carbide particles engulfs into the zinc grain, while other The nano-silicon carbide particles segregate between the grains, so that the uniform distribution of the nano-ceramic particles in the zinc matrix and between the grains is realized. Its preparation method is batch cryogenic ball milling + selective laser melting. When the obtained product is used as an implant, it can well repair bone defects. The invention has reasonable component design, simple and controllable preparation process, and the obtained product has excellent performance.

Owner:CENT SOUTH UNIV

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

A medium-strength aluminum alloy rod for cables and its preparation method

ActiveCN104962783BOptimizing Alloy CompositionSimple processMetal/alloy conductorsCable/conductor manufactureSilicon alloyRare earth

The invention discloses a production method of a medium-strength aluminum alloy rod for cables. The method comprises the following steps: melting aluminum ingots, aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy and magnesium ingots to form an alloy liquid, carrying out degassing refining, carrying out heat insulation standing, and casting to obtain cast ingots, wherein the alloy liquid comprises, by mass, 0.30% or less of iron, 0.30-0.50% of silicon, 0.30-0.50% of magnesium, 0.10-0.15% of rare earth, and the balance of aluminum; carrying out water cooling on the obtained cast ingots, carrying out hot rolling, and cooling to obtain a hot-rolled aluminum alloy rod; carrying out solid solution treatment on the hot-rolled aluminum alloy rod to obtain a solid solution treated aluminum alloy rod; and naturally ageing the solid solution treated aluminum alloy rod for 1-2h, and artificially ageing at 150-160DEG C for 3.5-4h to obtain the medium-strength aluminum alloy rod for cables. The invention also discloses the medium-strength aluminum alloy rod for cables.

Owner:ANHUI ELECTRIC GRP SHARES

A smelting method for producing φ12-25mmhrb500e straight bars by microalloying

The invention discloses a smelting method for producing Φ12-25mm HRB500E straight steel bar by microalloying. The chemical composition of the steel bar is: C: 0.19-0.25%, Si: 0.60-0.80%, Mn: 1.10-1.4%, S: ≤0.04%, P: ≤0.04%, N: 0.01~0.015%, Ti: 0.03~0.05%, V: 0.05~0.07%, Cr: 0.1~0.3%, the sum of the mass percentages of Cr+Mn≤1.55% , Ceq≤0.54%; smelting method: add pre-deoxidation composite slag lotion to the converter tapping, the mass percentage composition of the slag lotion is: 5‑10% fluorite, 65‑75% calcium carbide, 15‑25% limestone; converter Add pre-deoxidation composite slag lotion after tapping, and then add silicon-manganese alloy, ferrosilicon, and high-carbon ferrochromium alloy in sequence. All alloys must be added at 1 / 3 of tapping, and all alloys should be added at 3 / 4 of tapping. Finished, the high nitrogen composite strengthener is added after the addition of the converter alloy, the addition amount is 0.6-0.8kg / t, and its composition: N 12-20%, Ti 18-25%, after the titanium-iron and vanadium-nitrogen alloys are added Carry out soft blowing, the soft blowing effect can be as large as 100-200mm in diameter of exposed molten steel after breaking the steel slag.

Owner:XINJIANG BAYI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com