Patents

Literature

341 results about "Niobium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

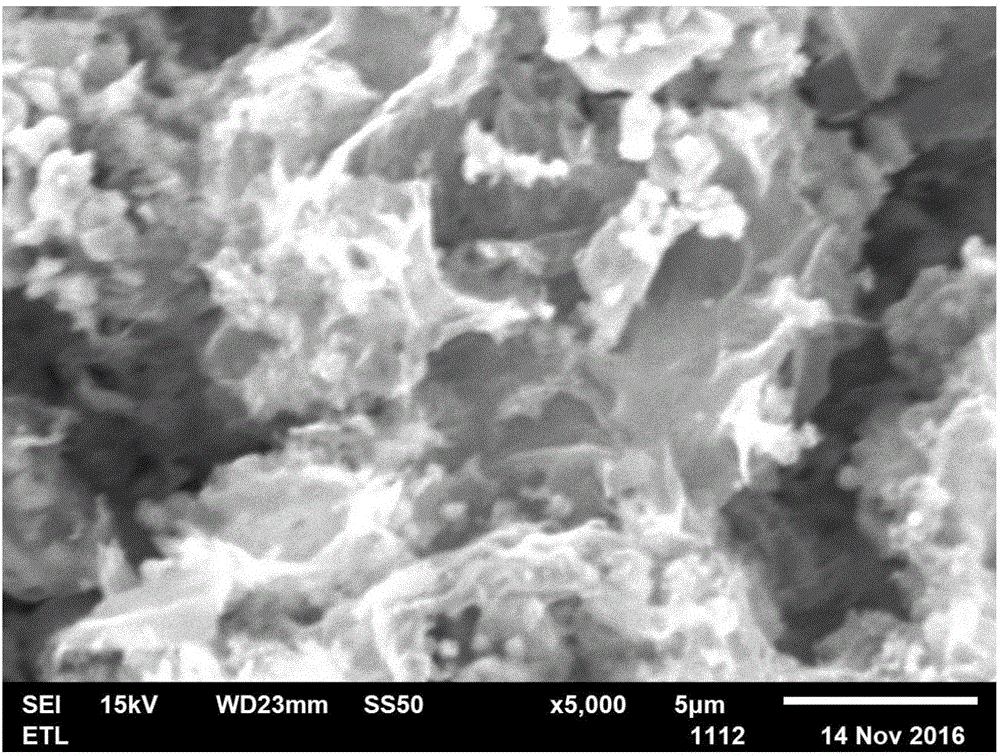

Niobium carbide (NbC and Nb₂C) is an extremely hard refractory ceramic material, commercially used in tool bits for cutting tools. It is usually processed by sintering and is a frequent additive as grain growth inhibitor in cemented carbides. It has the appearance of a brown-gray metallic powder with purple lustre. It is highly corrosion resistant.

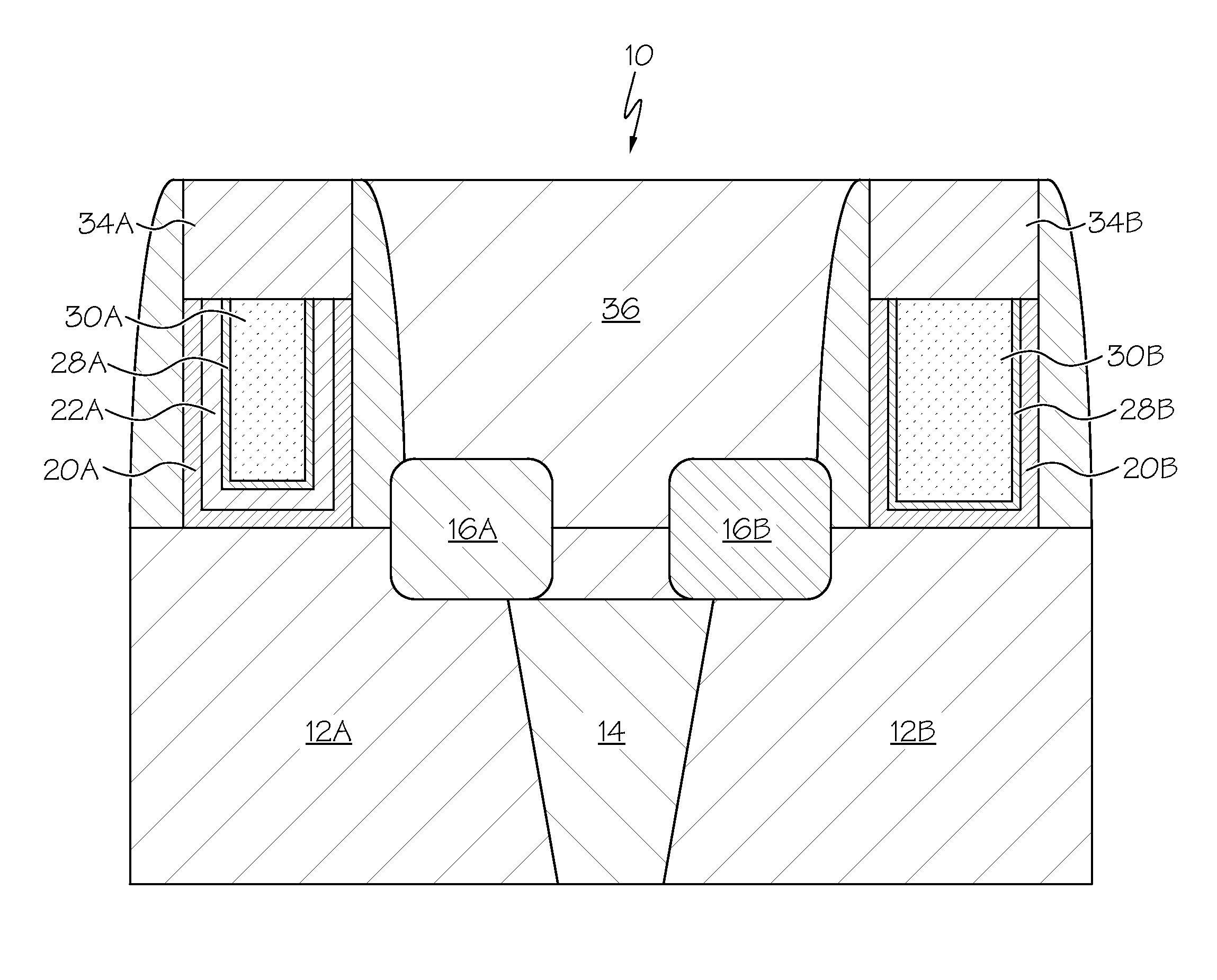

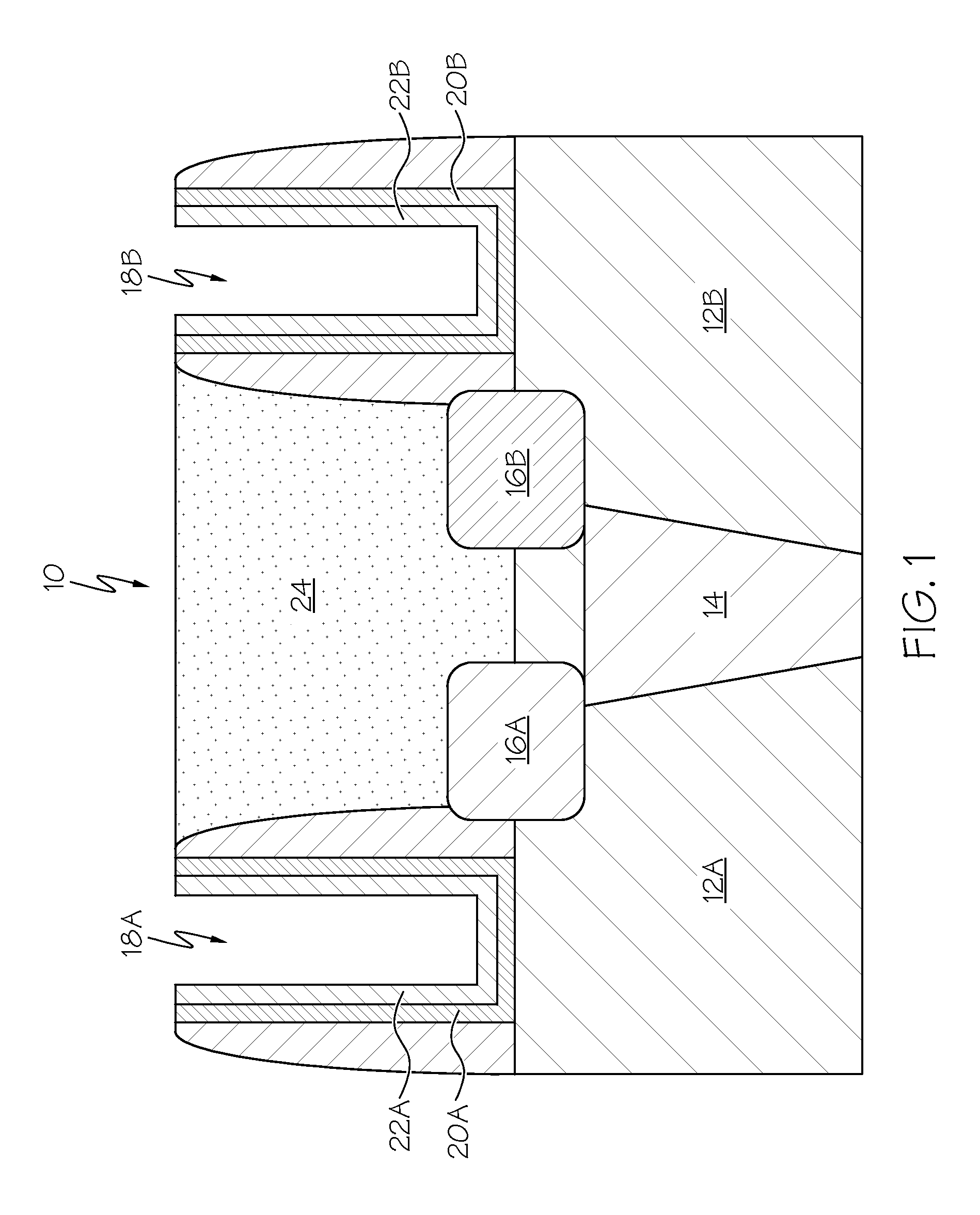

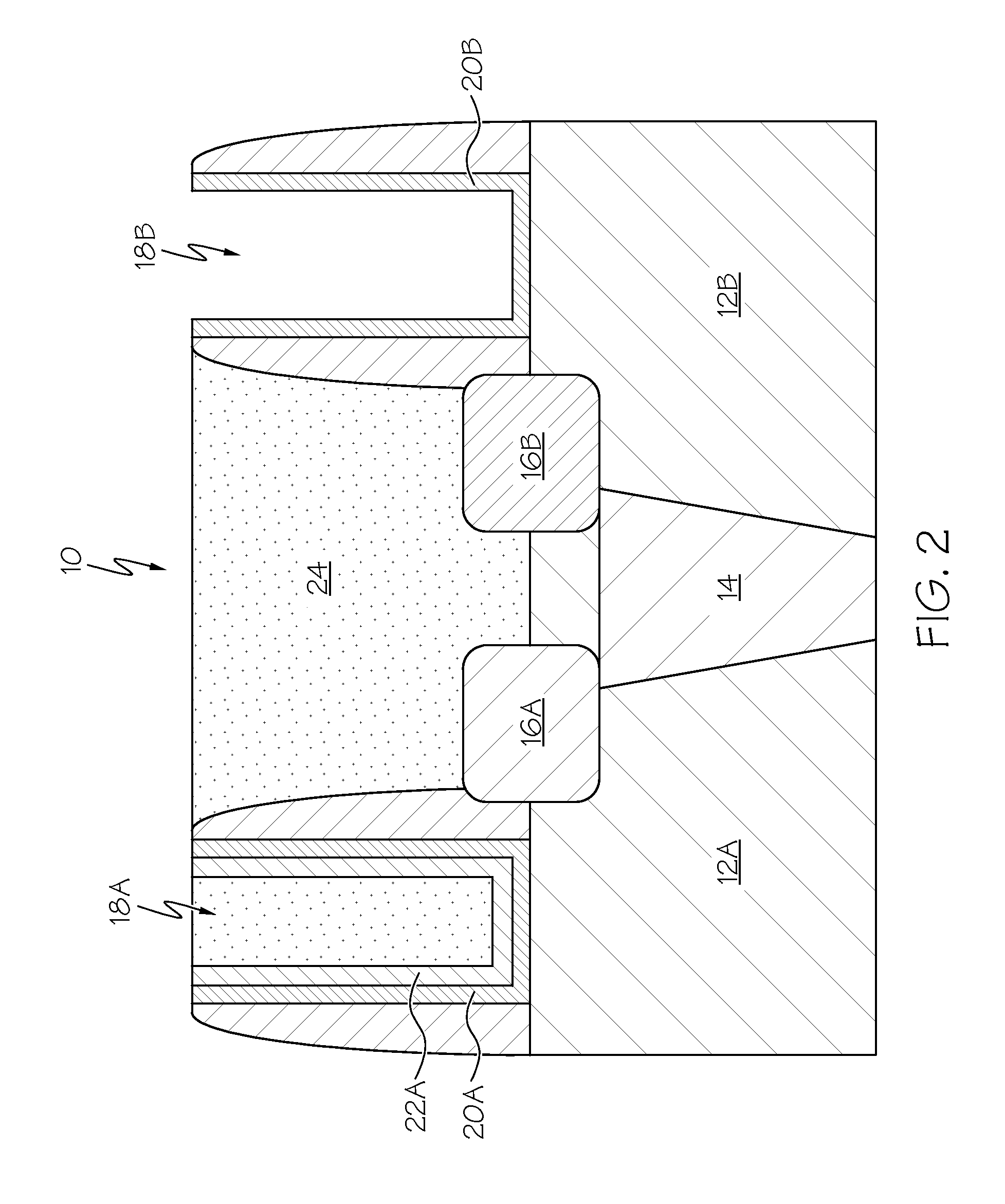

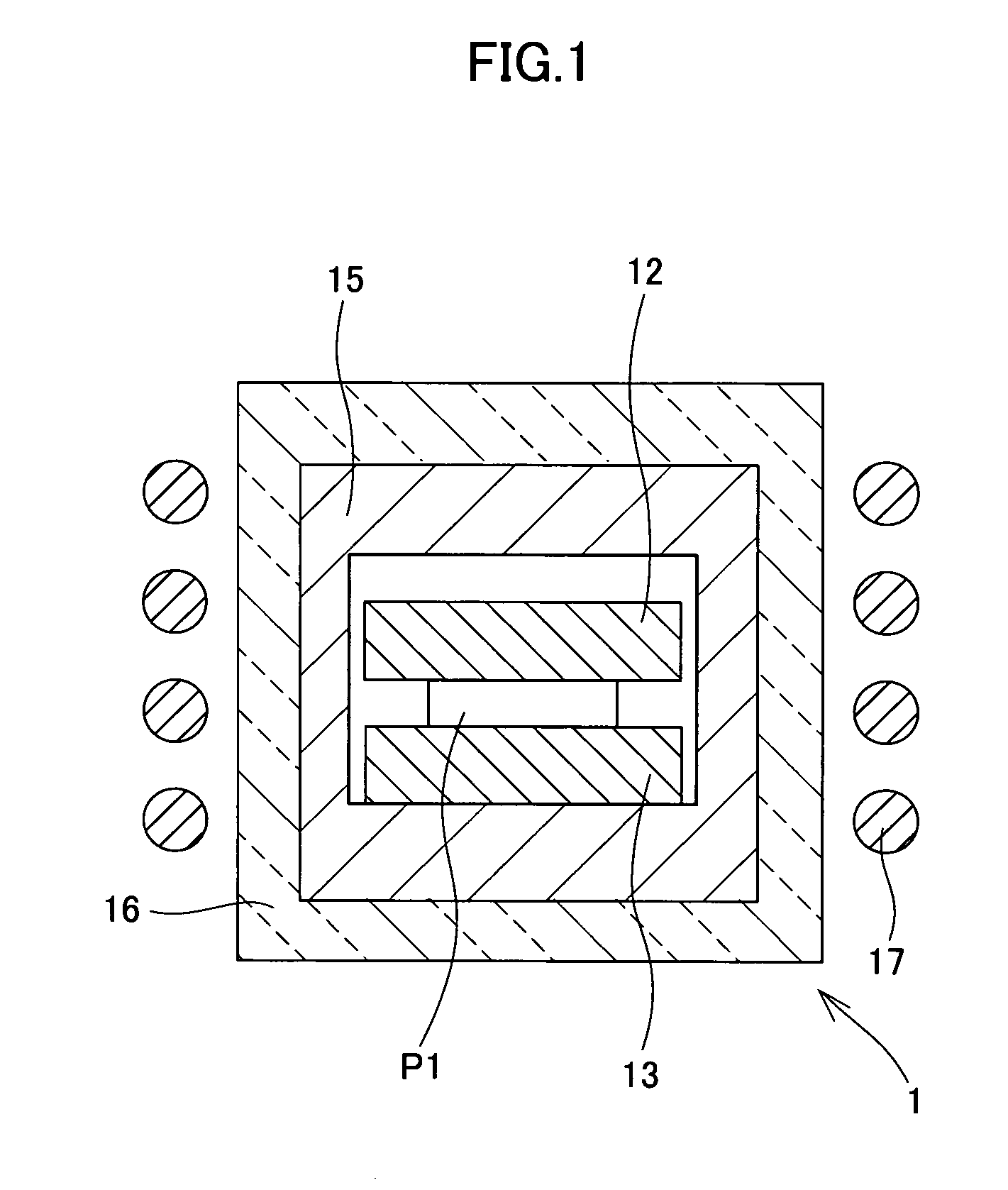

Semiconductor device incorporating a multi-function layer into gate stacks

InactiveUS8859368B2Reduce in quantityReduce complexityTransistorSolid-state devicesWork functionGate stack

Approaches are provided for forming a semiconductor device (e.g., a FET) having a multi-function layer (e.g., niobium carbide (NbC)) that serves as a work function layer and a gate metal layer in gate stacks of solid state applications. By introducing a single layer with multiple functions, total number of layers that needs processing (e.g., recessing) may be decreased. As such, the complexity of device integration and resulting complications may be reduced.

Owner:GLOBALFOUNDRIES INC

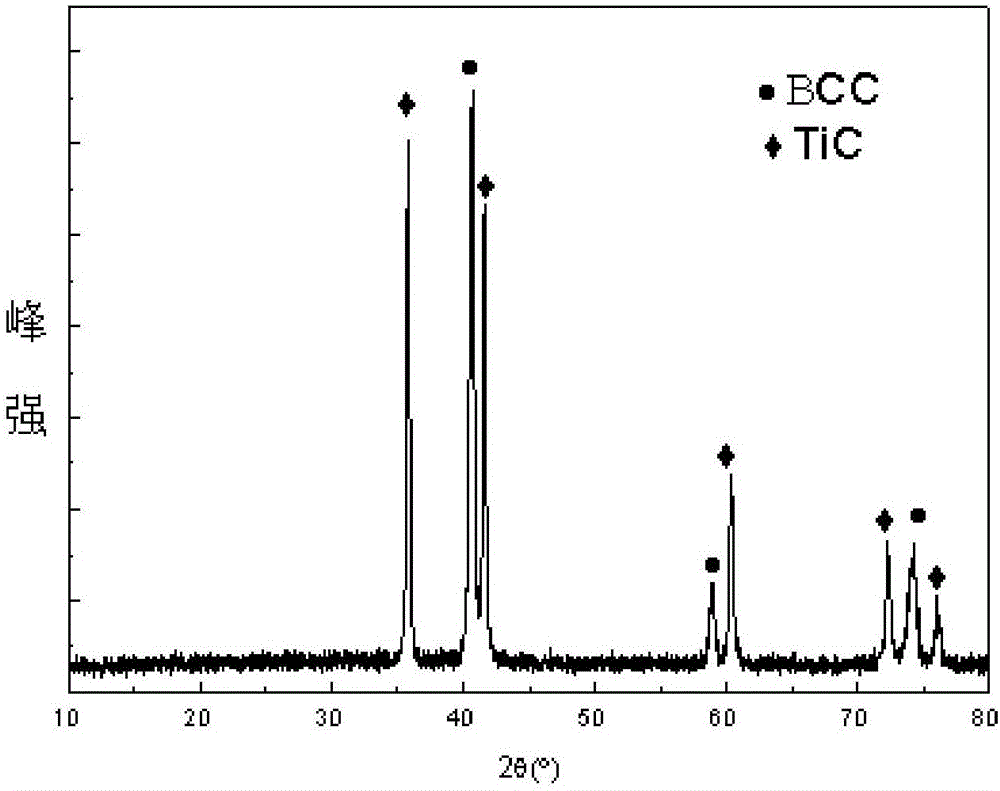

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

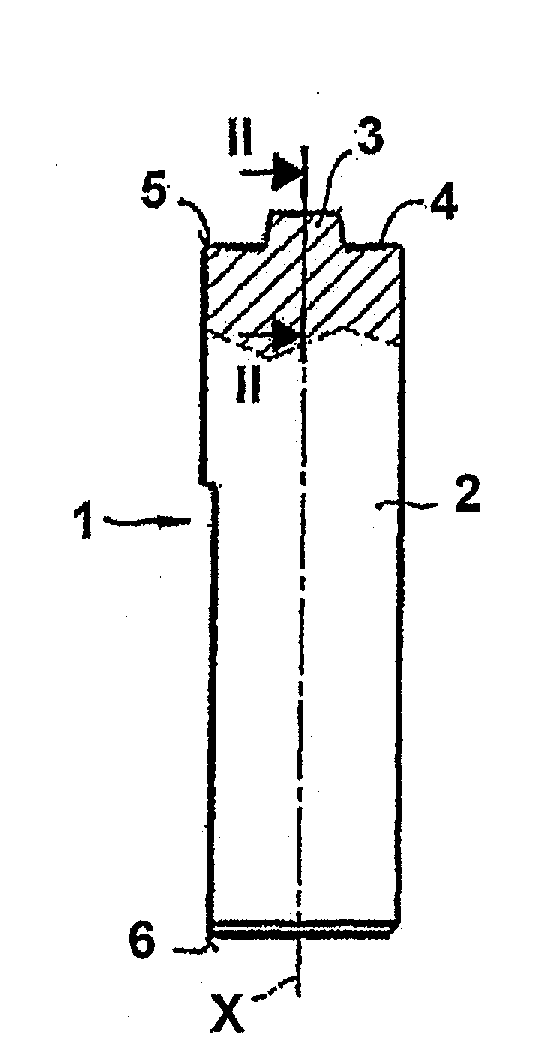

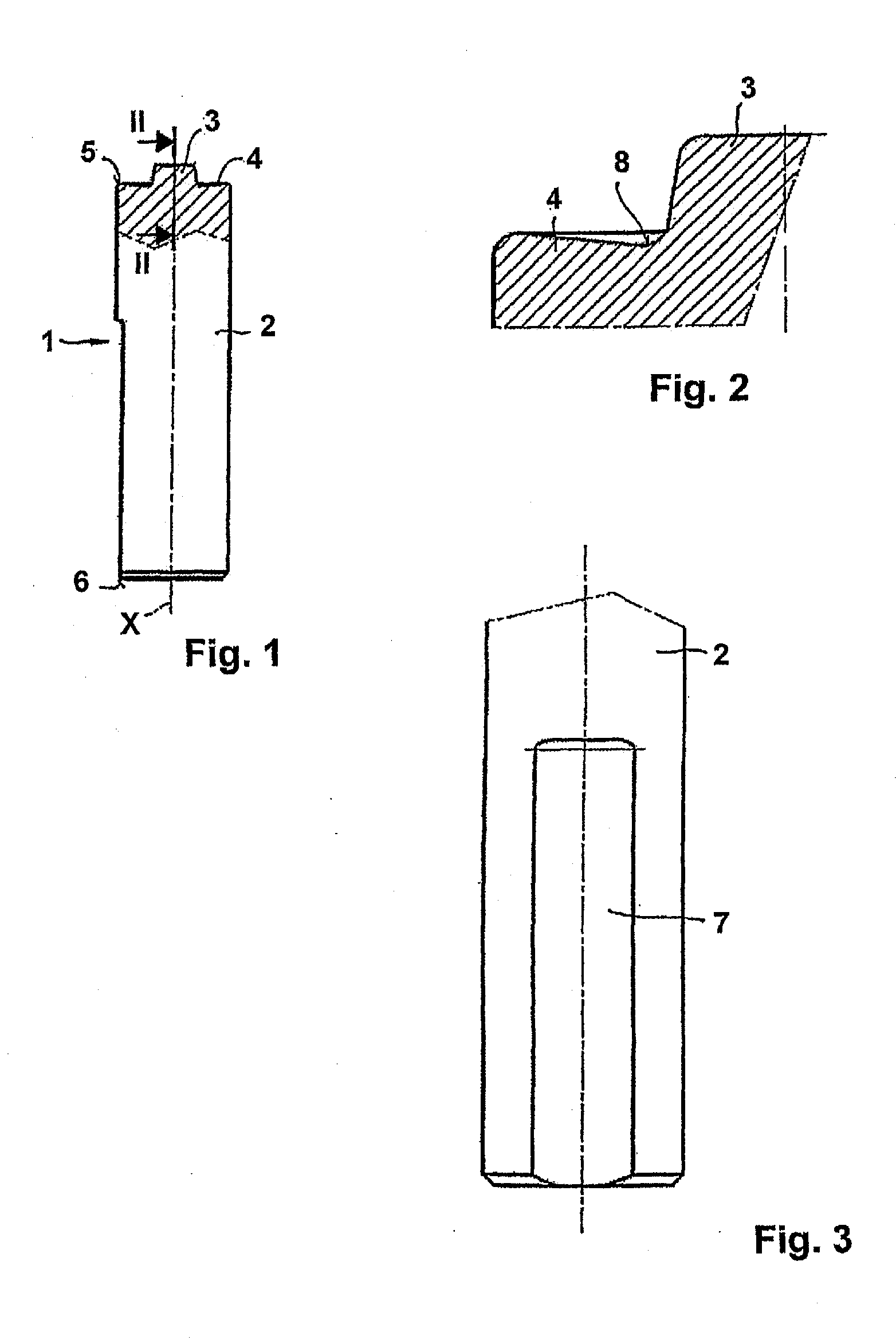

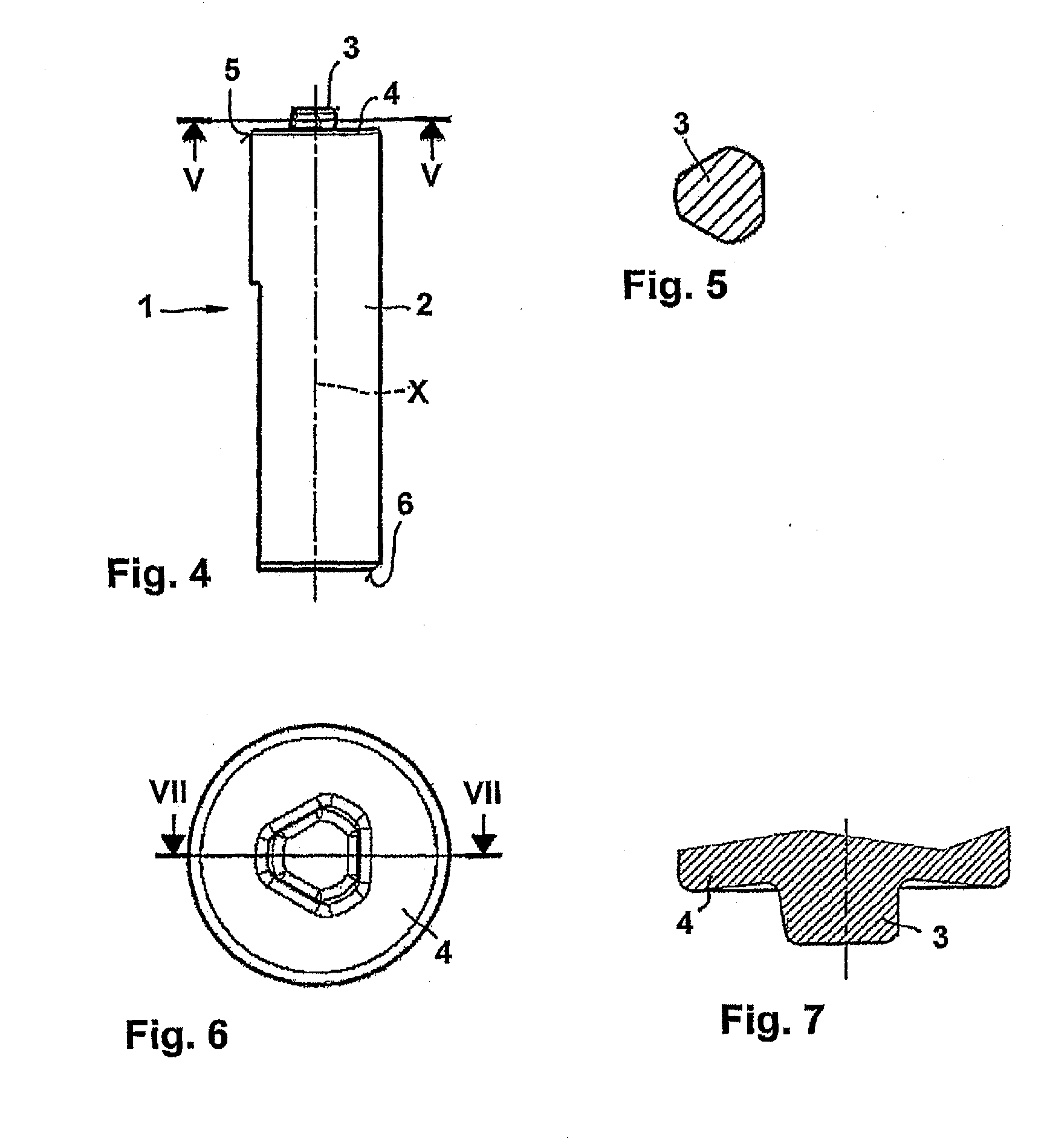

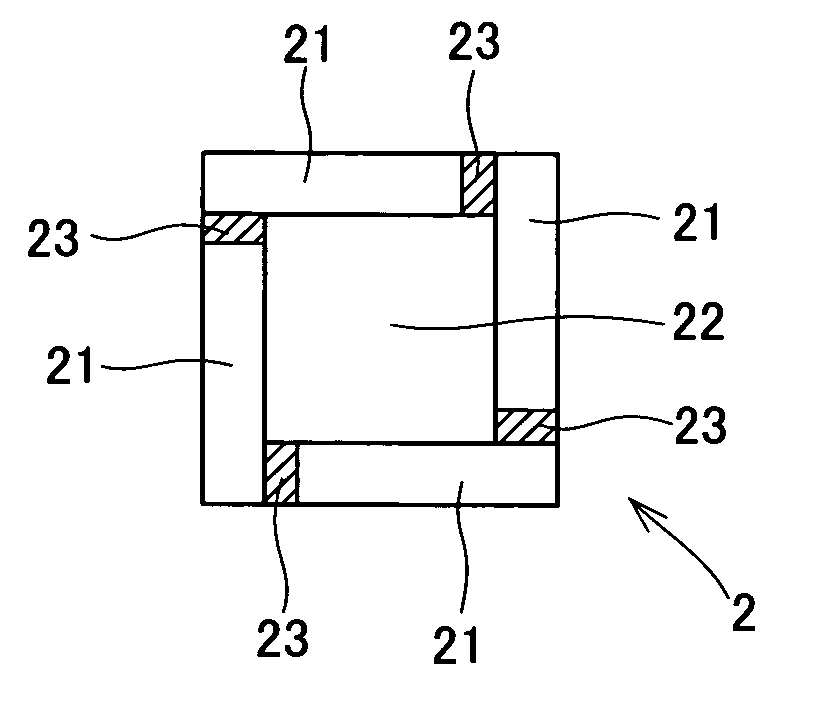

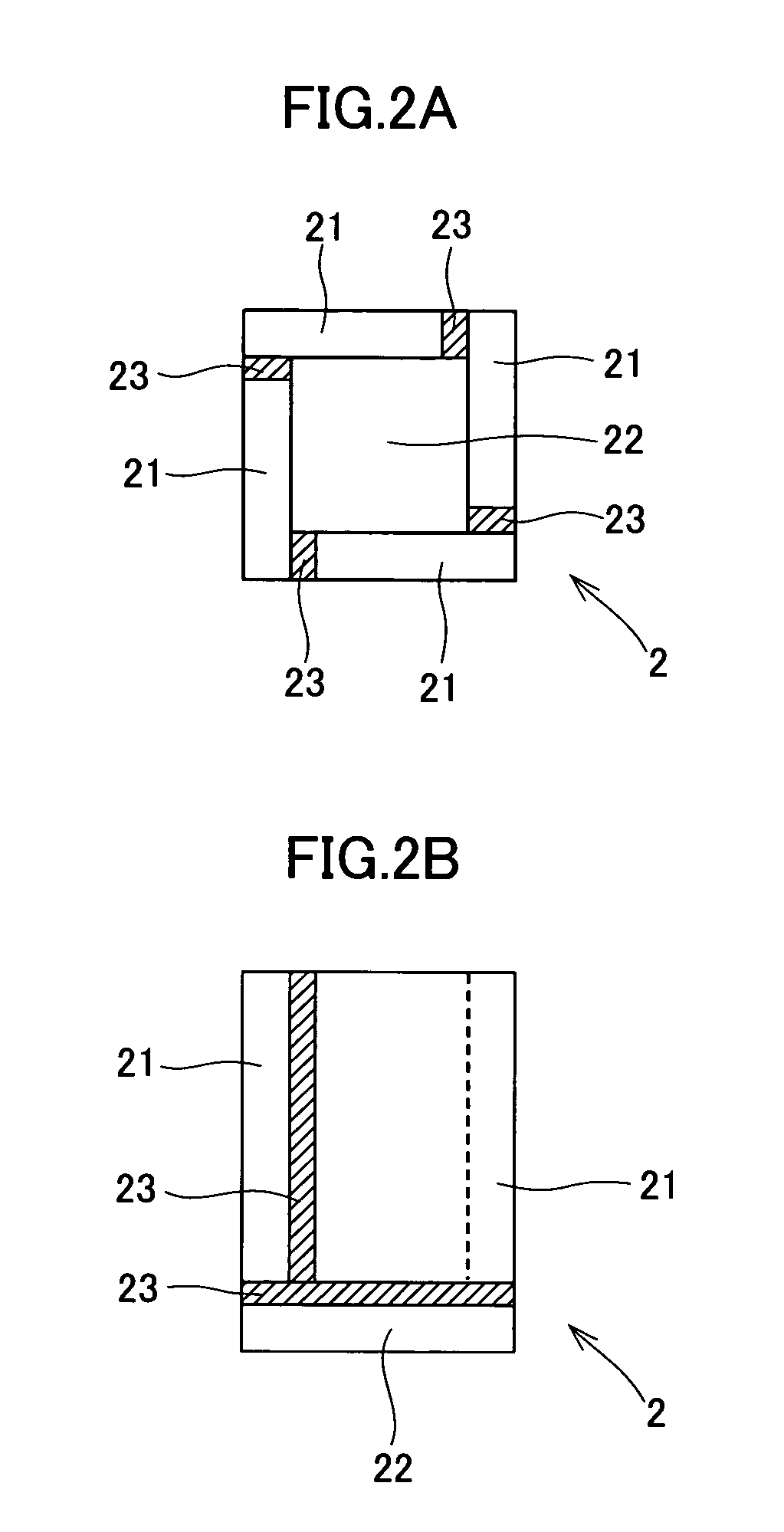

Friction stir welding tool

InactiveUS20100258612A1Easy to useReduce sensitivityWelding/cutting auxillary devicesAuxillary welding devicesHard metalTitanium carbide

The invention relates to a friction stir welding tool (1) with an essentially cylindrical shank (2), which has a peg (3) with a smaller diameter projecting on one end (5) starting from a shoulder region (4) of the shank (2). According to the invention it is provided in order to create a friction stir welding tool (1) for welding steel, that the friction stir welding tool (1), at least in the region of the peg (3) and in the shoulder region (4), is made of a hard metal containing 80% by weight to 98% by weight tungsten carbide with an average grain size of more than 1 μm and up to 20% by weight cobalt as well as optionally a total of up to 18% by weight titanium carbide, tantalum carbide, niobium carbide and / or mixed carbides thereof and at least in one of the referenced regions has a coating of one or more layers.

Owner:BOEHLERIT GMBH & CO KG

Ceramic cladding powder and preparation method thereof

InactiveCN101423398AThere will be no phenomenon of grain aggregation and growthEvenly distributedCeramic coatingTitanium nitride

The invention relates to ceramic coating powder the ceramic phase of which is coated by a metallic phase cobalt or / and a metallic phase nickel. The metallic phase cobalt and the metallic phase nickel are obtained by means of a liquid phase reduction method; and the ceramic phase is at least one of titanium carbonitride, titanium carbide, titanium nitride, tungsten carbide, silicon carbide, niobium carbide, tantalum carbide, aluminum oxide, zirconium oxide, magnesium oxide, boron nitride and silicon nitride. A method for preparing the ceramic coating powder is the liquid phase reduction method to carry out a reduction reaction between cobalt or / and nickel ions in a plating solution to generate the metallic phase cobalt or / and nickel which is deposited on the surface of a ceramic core to form the ceramic coating powder; and the process steps are as follows: (1) pre-treatment of the ceramic powder; (2) preparation of the plating solution; (3) liquid-phase reduction reaction; and (4) plating post treatment.

Owner:SICHUAN UNIV

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

High wear resistance, high toughness titanium carbide base hard alloy capable of welding

A carbonized hard Ti-base alloy with high weldability, anti-wear nature and toughness is prepared proportionally from the hard phase (TiC or the mixture of TiC and WC), adhesive phase chosen from Ni, Co and Fe, Cu and Mn or Mn compound, C, tantalum carbonate and / or niobium carbonate, V or V compound, Cr or Cr compound, and Mo or Mo compound.

Owner:帅进 +1

Enhanced metal ceramic abrasion-resistant composite material and preparation method thereof

The invention discloses an enhanced metal ceramic abrasion-resistant composite material and a preparation method thereof. The composite material is composed of, by mass, 25-35 parts of nano molybdenum carbide, 15-25 parts of nano ceramic powder, 10-15 parts of glass fiber, 5-10 parts of cobalt, 10-15 parts of chrome, 10-15 parts of titanium carbonitride, 1-3 parts of zirconium oxide, 3-5 parts of silicon oxide, 8-10 parts of cerium oxide, 1-3 parts of aluminium oxide, 5-10 parts of niobium carbide, 5-15 parts of silicon carbide, 1-3 parts of vanadium carbide, 4-9 parts of copper, 1-5 parts of titanium powder, 1-5 parts of coupling agents, 1-3 parts of antistatic agents and 1-3 parts of curing agents. The preparation method of the enhanced metal ceramic abrasion-resistant composite material just comprises mixing, drying, sintering and cooling. The metal ceramic composite material has good properties that the bending resistant strength is up to 2500 MPa and the Rockwell hardness is up to 93; in addition, the metal ceramic composite material also has good properties of abrasion resistance and high temperature resistance; the preparation method is simple and feasible and suitable for application and popularization on a large scale.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Ultra-fine hard alloy coated powder and method for preparing same

InactiveCN101186990AReduced tendency to aggregate and growWell mixedLiquid/solution decomposition chemical coatingCarbonizationTitanium carbide

The invention discloses a super-fine cemented carbide coating powder and process of preparation thereof. Super-fine hard-phase carbonization tungsten in the cemented carbide coating powder and other carbides such as titanium carbide, tantalum carbide, niobium carbide, vanadium carbide and / or chromium carbide are composed around by cobalt-phase ultra-fine powder particles. Karl Fischer's mean particle size of the super-fine cemented carbide coating powder is <=1 mu m. The super-fine tungsten carbide of the invention is put into the liquor of water-soluble metal cobalt-salt after being activated and dispersed with other hard-phase of carbide powder, the super-fine carbide powder and other hard-phase of carbide powder are taken as the core, chemical coprecipitation coating is employed in the reaction, and a uniform cobalt carbonate or cobalt hydroxide inhibitory coating is formed on the surface of the tungsten carbide powder and other hard-phase of carbide powder. The coprecipitation coating powder can be made into the super-fine cemented carbide coating powder by filtering, washing, and drying and low temperature reduction. The invention has the advantages of simple technique and low cost, which can take place the existing cemented carbide wet grinding mixture and the preparation method. High quality super-fine cemented carbide can be prepared by utilizing the powder of the invention.

Owner:CENT SOUTH UNIV +1

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

Ultrafine cemented carbide coating blade suitable for numerical control machining center and manufacturing method thereof

InactiveCN103801746AHigh hardnessImprove flexural strengthMilling cuttersTurning toolsChromium carbideNumerical control

The invention provides an ultrafine cemented carbide coating blade suitable for a numerical control machining center, the ultrafine cemented carbide coating blade is prepared from the following components by weight: 0.5-2% of tantalum carbide, 0.5-2% of chromium carbide, 0-0.5% of niobium carbide, 6-10% of cobalt and the balance of ultrafine tungsten carbide, and the invention also provides a manufacturing method of the ultrafine cemented carbide coating blade. The manufacturing method of the ultrafine cemented carbide coating blade is low in cost, and the manufactured ultrafine cemented carbide coating blade is excellent in performance, stable in quality, and suitable for the numerical control machining center, satisfies ever-growing market demands of mechanical processing industry of the numerical control machining center, and gradually replaces expensive imported products.

Owner:HUNAN RUIFENG CEMENTED CARBIDE PROD

Hard alloy

The invention discloses a hard alloy, which comprises a hard alloy matrix and further comprises a coating, wherein the hard alloy matrix is composed of metal carbide powder and a metal binder; the coating is coated on the hard alloy matrix; the metal carbide powder mainly comprises the following components in mass percentage: 40-50% of tungsten carbide, 5-10% of vanadium carbide, 3-8% of chromium carbide, 5-9% of titanium carbide, 6-11% of tantalum carbide, and 2-5% of niobium carbide, wherein the metal binder is cobalt the content of which is 12-18%. By means of the manner, the hard alloy disclosed by the invention has the characteristics of being low in cost, high in hardness, intensity, toughness and abrasive resistance, low in wear rate while cutting at high speed, and good in oxidation resistance, heat resistance and chemical stability and is applied to manufacturing cutter materials for high precision processing; in addition, the service life of cutters can be prolonged.

Owner:CHANGSHU LIONY METALS

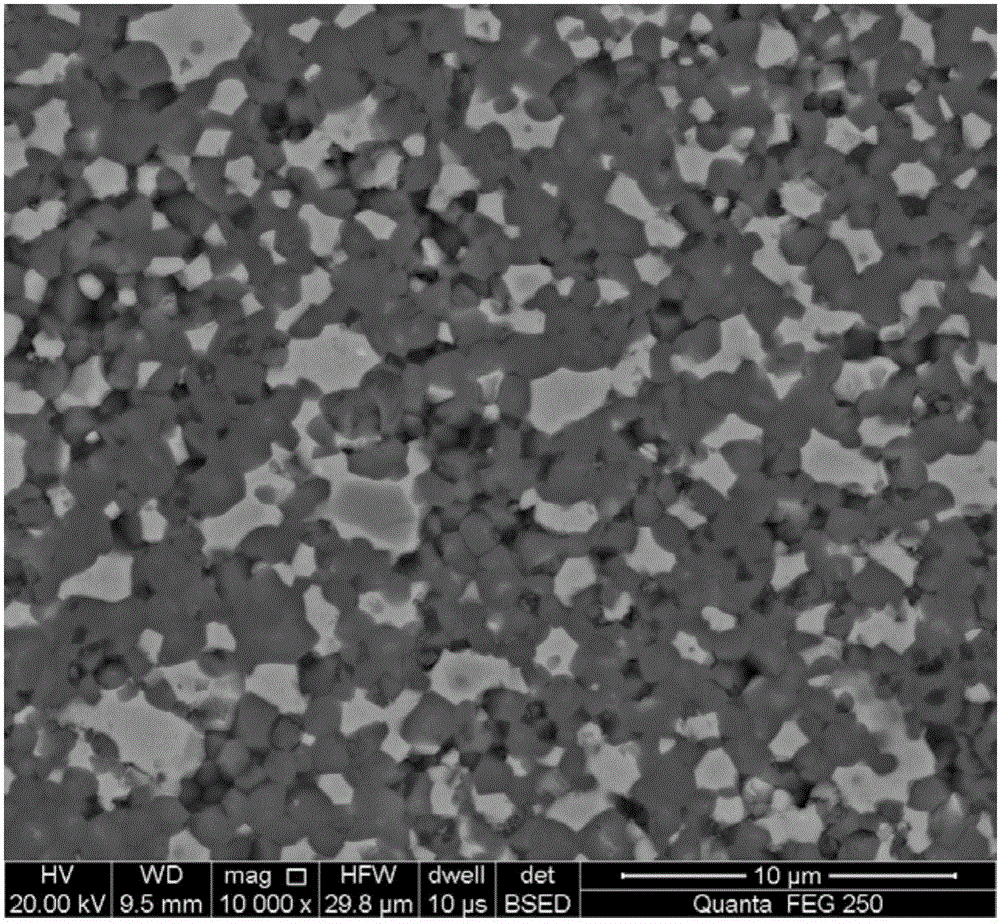

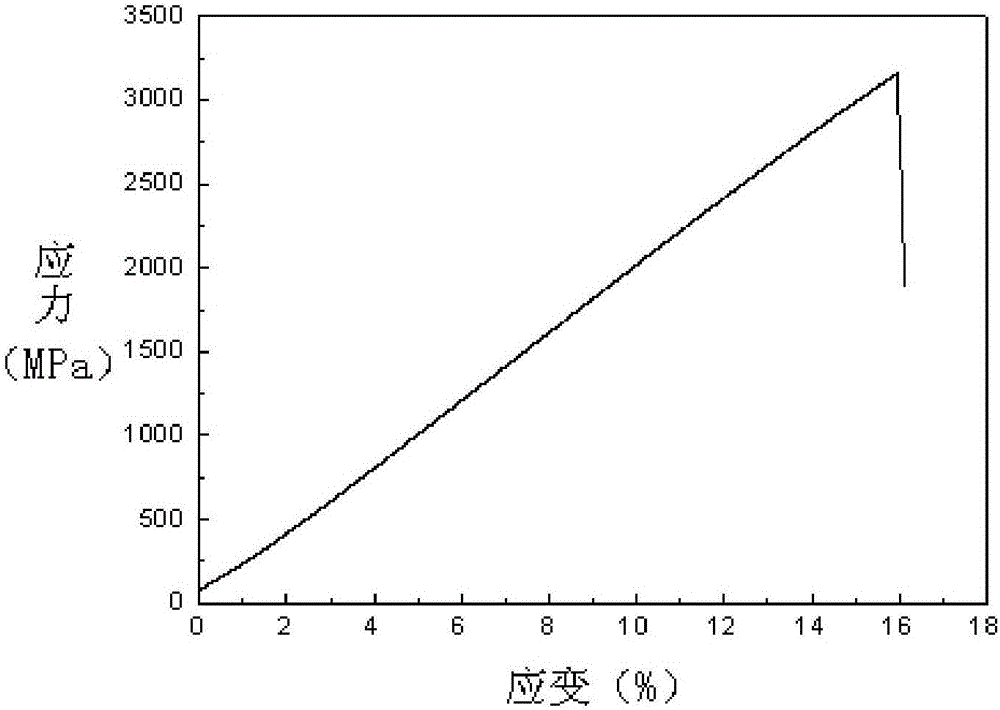

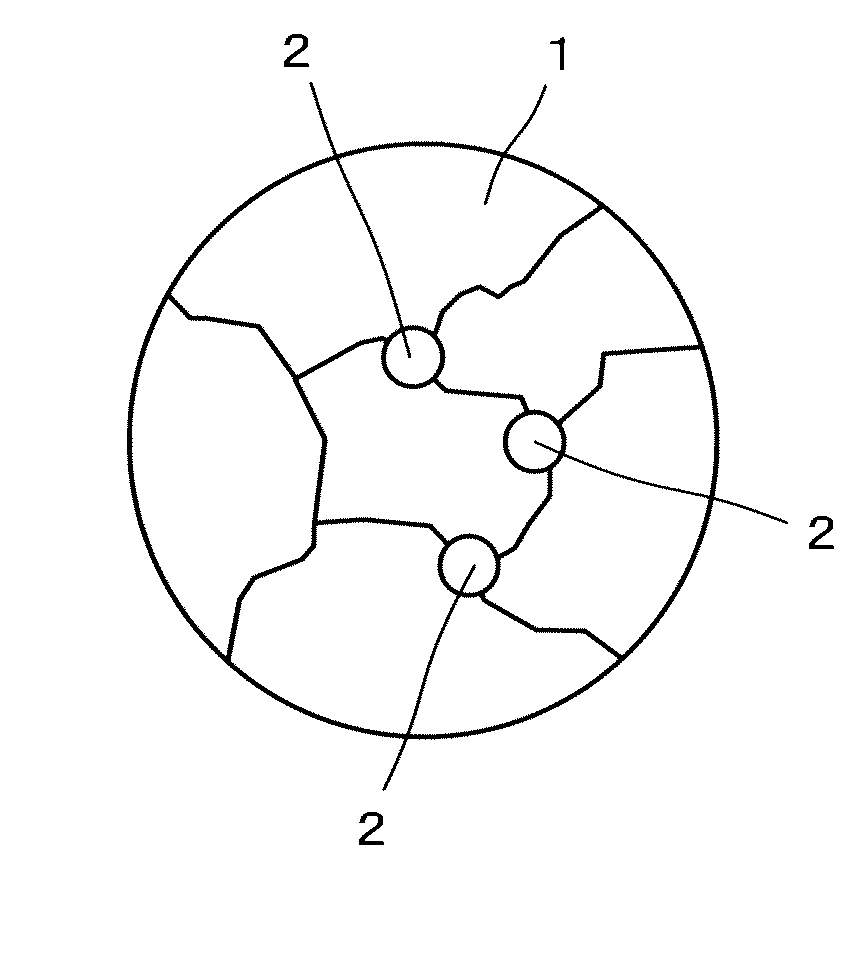

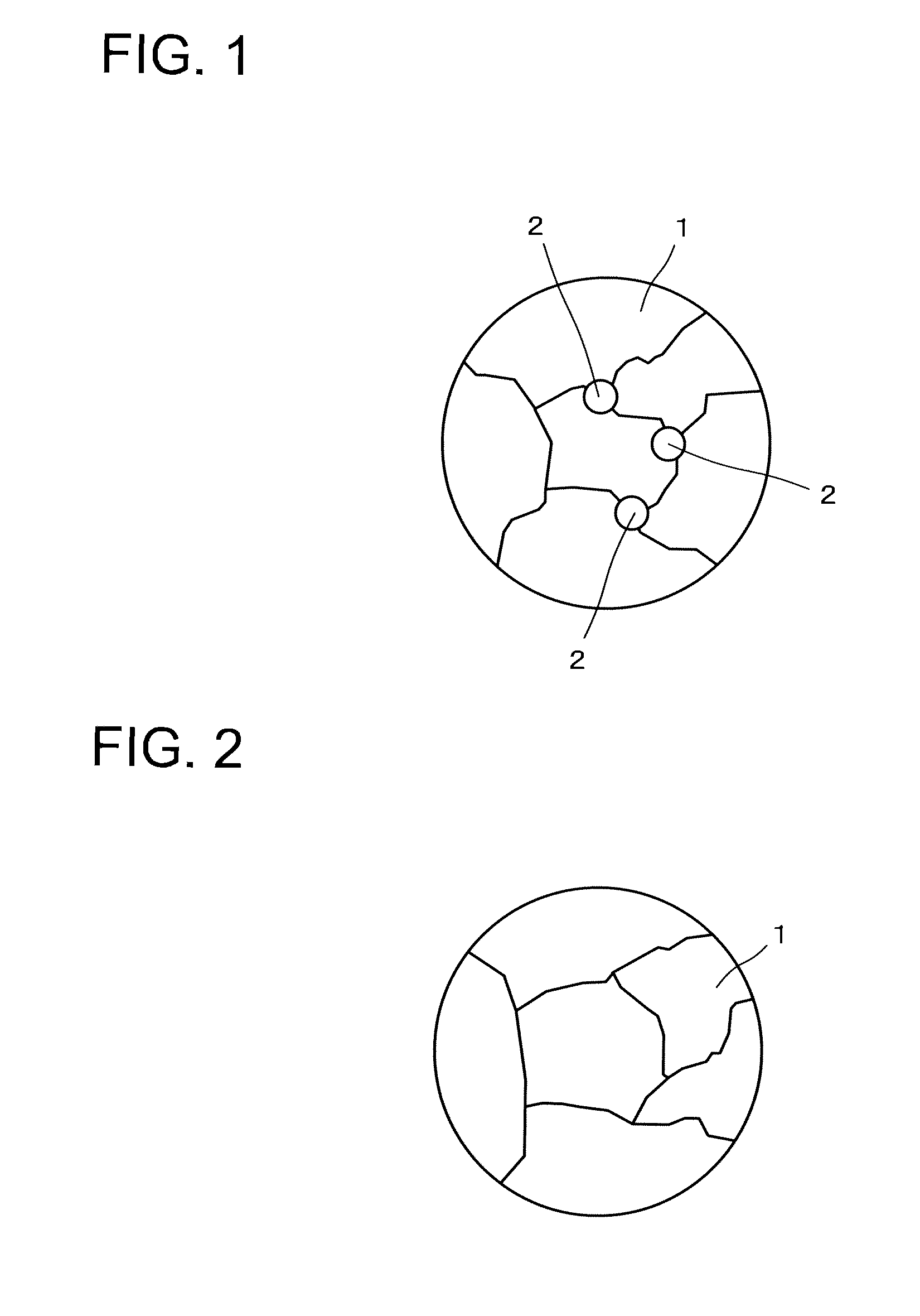

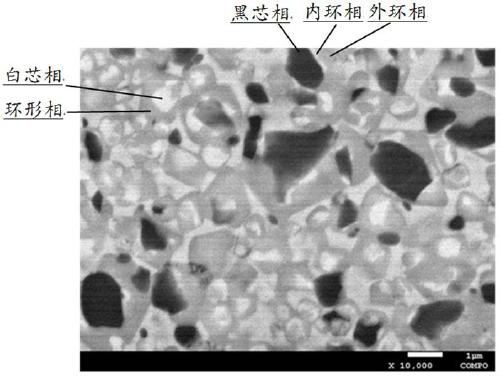

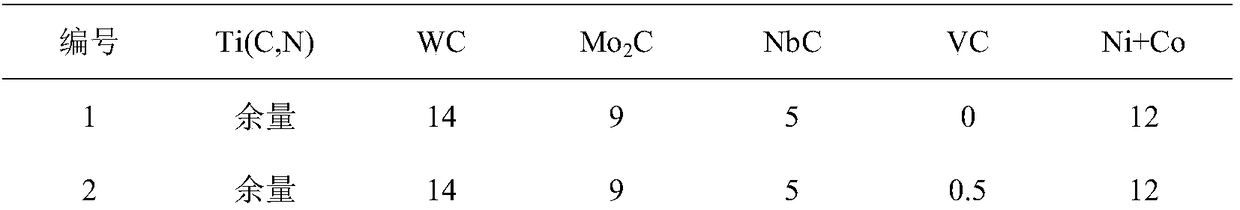

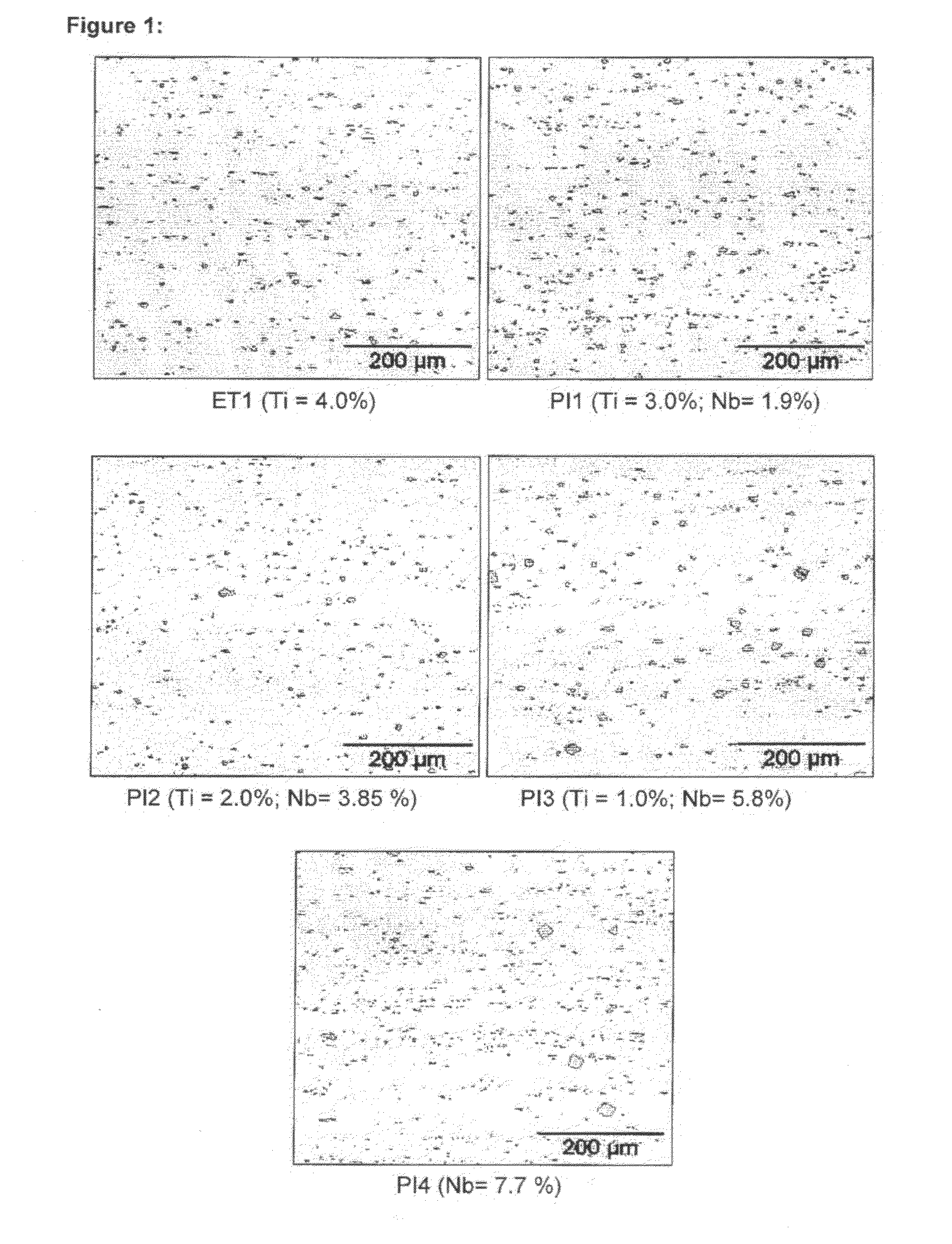

Ti(C,N) base metal ceramic and preparation method thereof

ActiveCN108950342AAdjust machinabilityMachinability satisfactionMilling cuttersWorkpiecesTitanium carbonitrideMolybdenum carbide

The invention discloses Ti(C,N) base metal ceramic and a preparation method thereof. Raw materials of the metal ceramic comprise titanium carbonitride Ti(0.5 of C and 0.5 of N), tungsten carbide WC, molybdenum carbide / molybdenum Mo2C / Mo, niobium carbide NbC, vanadium carbide VC, cobalt Co and nickel Ni powder, wherein the content of NbC ranges from 3 wt% to 15 wt%, the VC content is 0.3-3%, and the VC content changes along with the content of NbC. Hard phases formed by the materials are of two core-ring structures, one structure is a ring-shaped phase structure containing typical black core phases and inner ring phases, or outer ring phases and black core phases, and the other structure is a ring-shaped phase structure containing white core phases. The total credit of the black core phasesin the ring-shaped phase structure containing the black core phases and the inner ring phases, or the outer ring phases and the black core phases is 10-20%, the total credit of the inner ring phasesis 0.5-2%, and the total credit of the white core phases in the ring-shaped structure containing the white core phases is 5-10%. Chemical components of some or all white core phases are different fromthose of the inner ring phases, and the content of the Nb element in some or all white core phases is 30-40 wt% higher than the content of the Nb element in the inner ring phases. The Ti(C,N) base metal ceramic has thermal shock resistant performance and cutting performance.

Owner:CHINA THREE GORGES UNIV

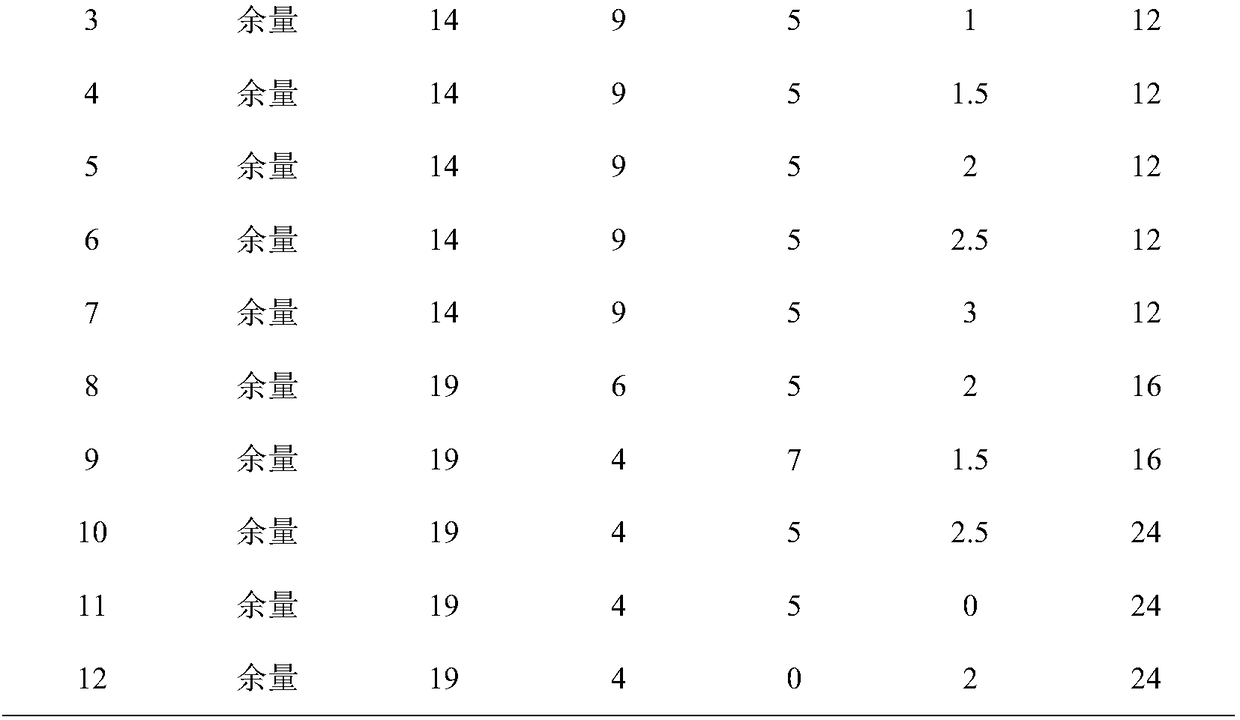

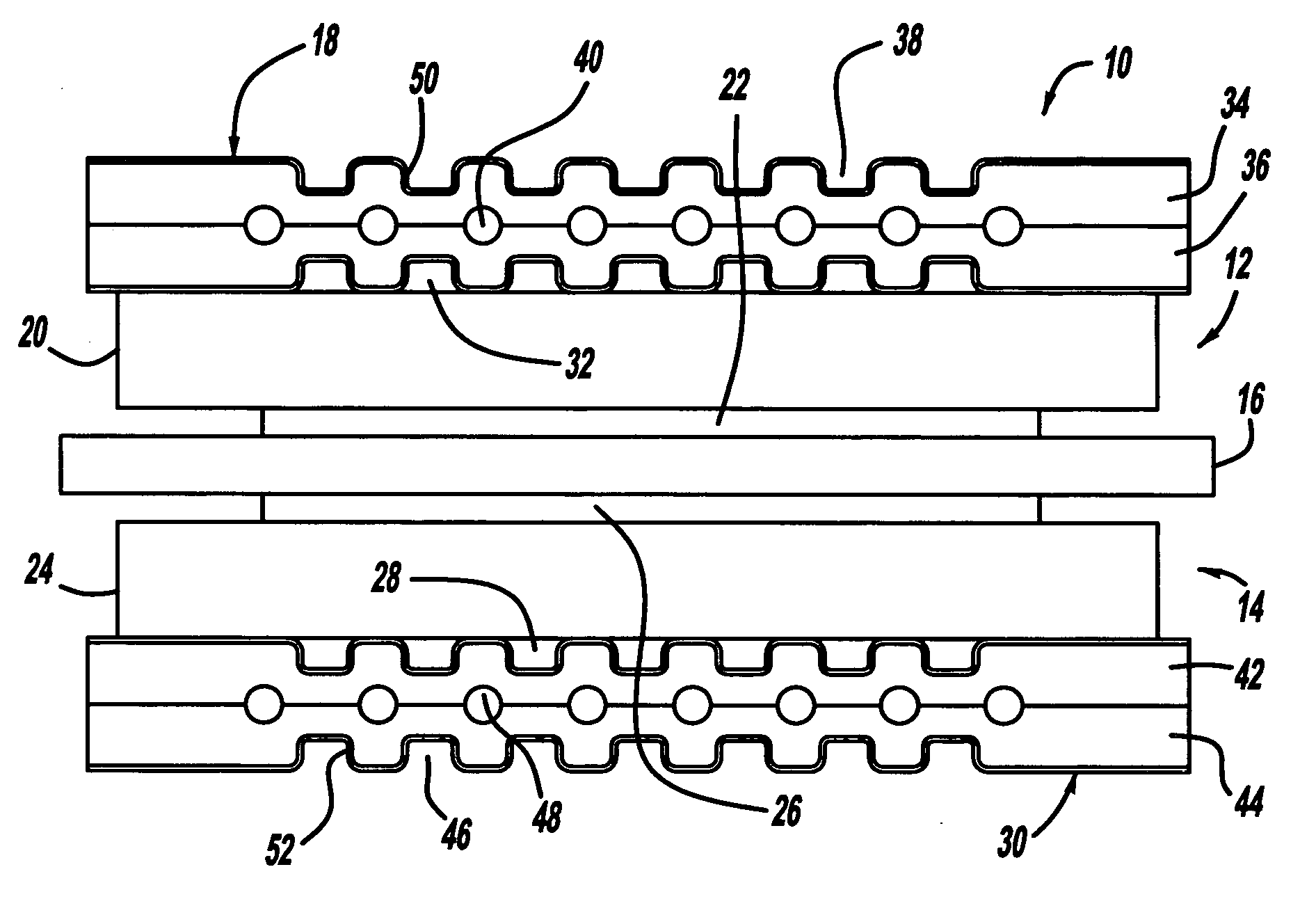

Metallic bipolar plates with high electrochemical stability and improved water management

InactiveUS20070117003A1More hydrophilicStable environmentFuel cells groupingFuel cell auxillariesChromium carbideEtching

A flow field plate or bipolar plate for a fuel cell that includes a carbide coating that makes the bipolar plate conductive, hydrophilic and stable in the fuel cell environment. Suitable carbides include, but are not limited to, chromium carbide, titanium carbide, tantalum carbide, niobium carbide and zirconium carbide. The carbide coating is then polished or textured by a suitable process, such as laser or chemical etching, to provide a surface morphology that makes the coating more hydrophilic, and further reduces the contact resistance on its surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-strength, high-anti-friction hard alloy, and manufacture method and application thereof

Owner:郭庆虎

Preparation method of composite hard alloy used as cutter material

The invention discloses a preparation method of a composite hard alloy used as a cutter material. The composite hard alloy material is prepared from the following components in parts by weight: 35-40 parts of nano titanium carbide, 5-15 parts of nano titanium nitride, 7-9 parts of tungsten carbide, 5-8 parts of niobium carbide, 3-7 parts of silicon carbide, 3-5 parts of cobalt powder, 1-3 parts of yttrium oxide, 1-3 parts of boron carbide and 1-5 parts of copper powder. The method comprises the following steps: preparing materials, preparing carbon-depleted alloy powder, preparing a presintering matrix, carrying out carbonization and carrying out firing step by step. The composite hard alloy prepared by the preparation method has high strength, good toughness and good wear resistance and thermal shock resistance.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

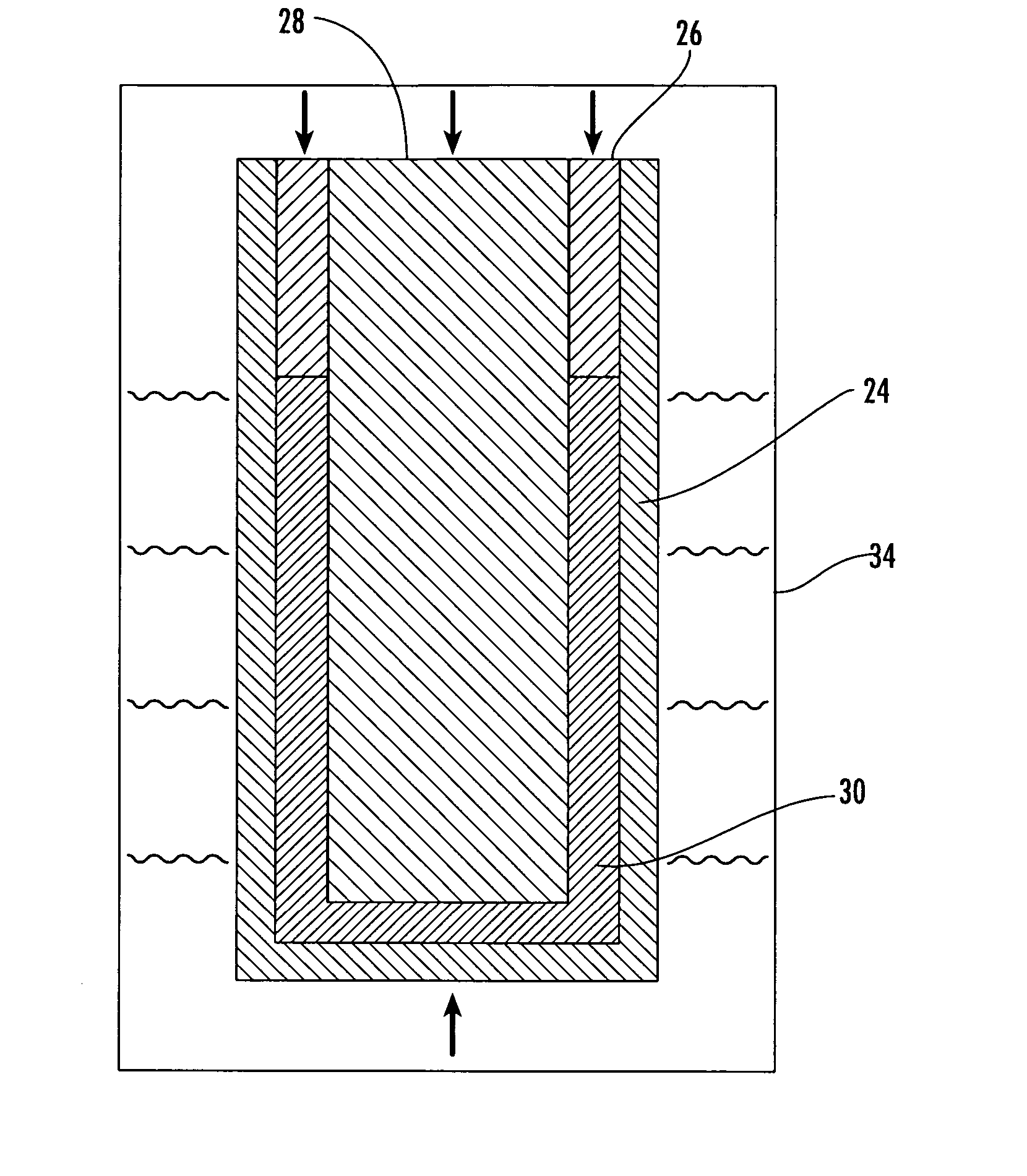

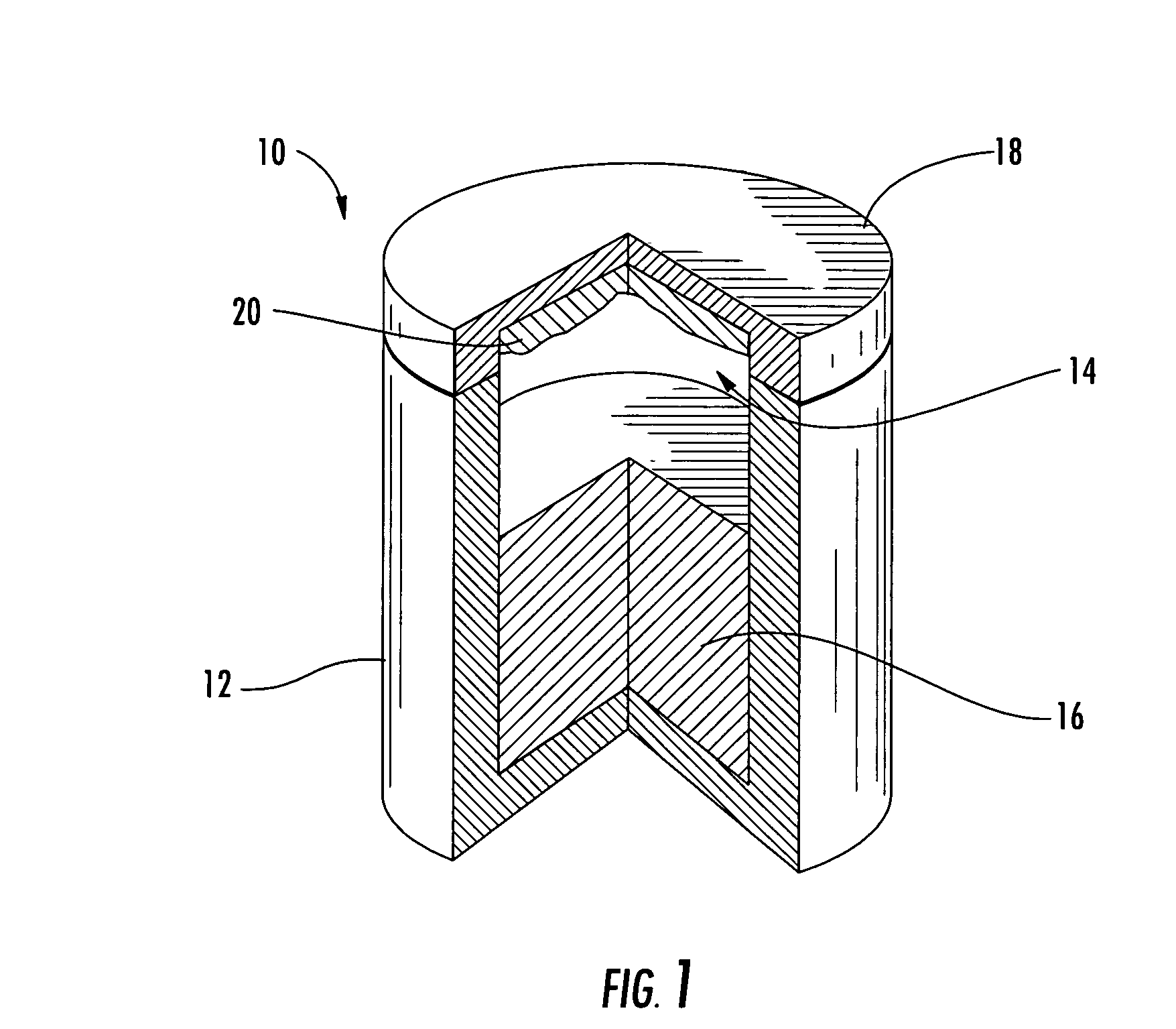

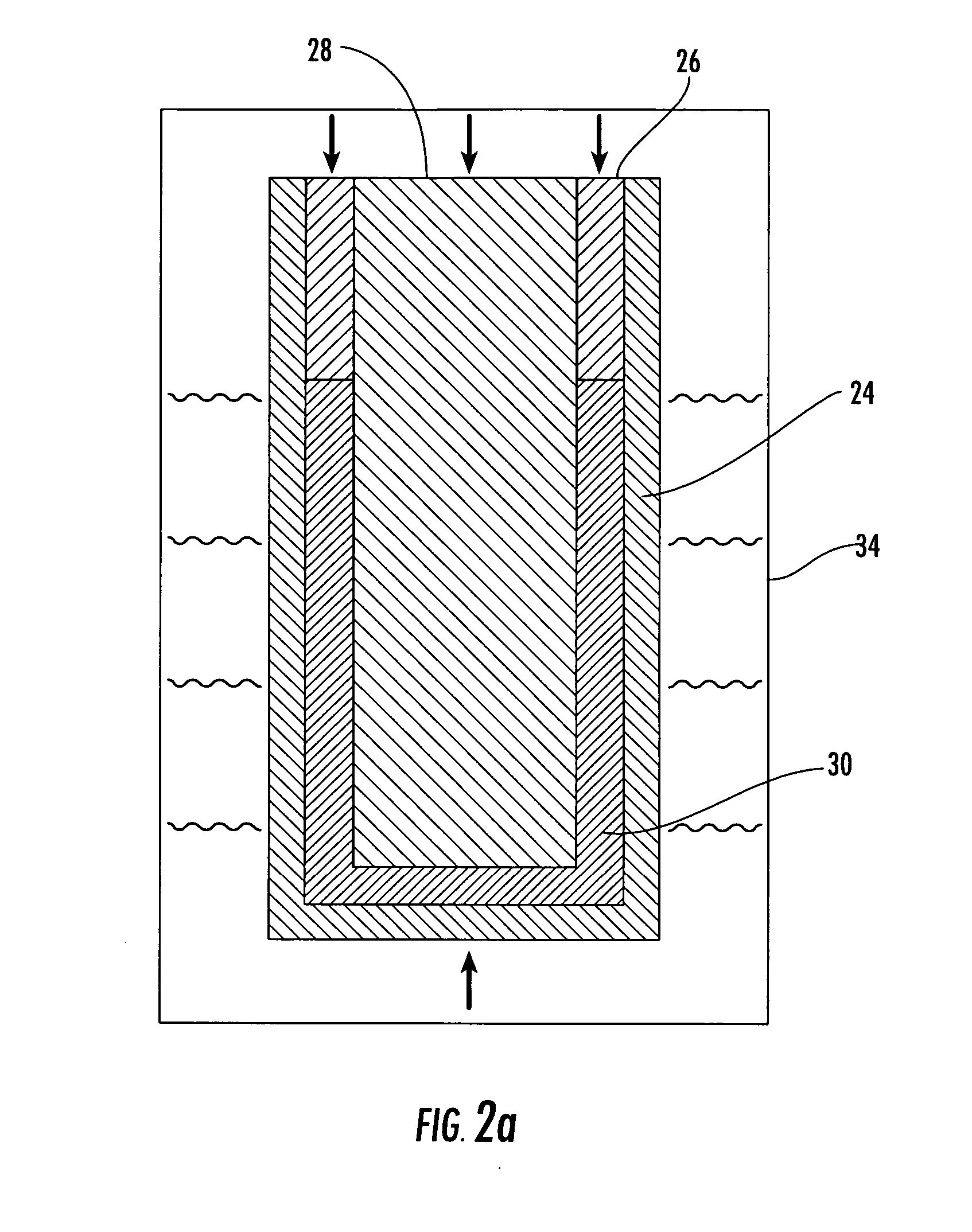

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

Wear resistant alloy for high temprature applications

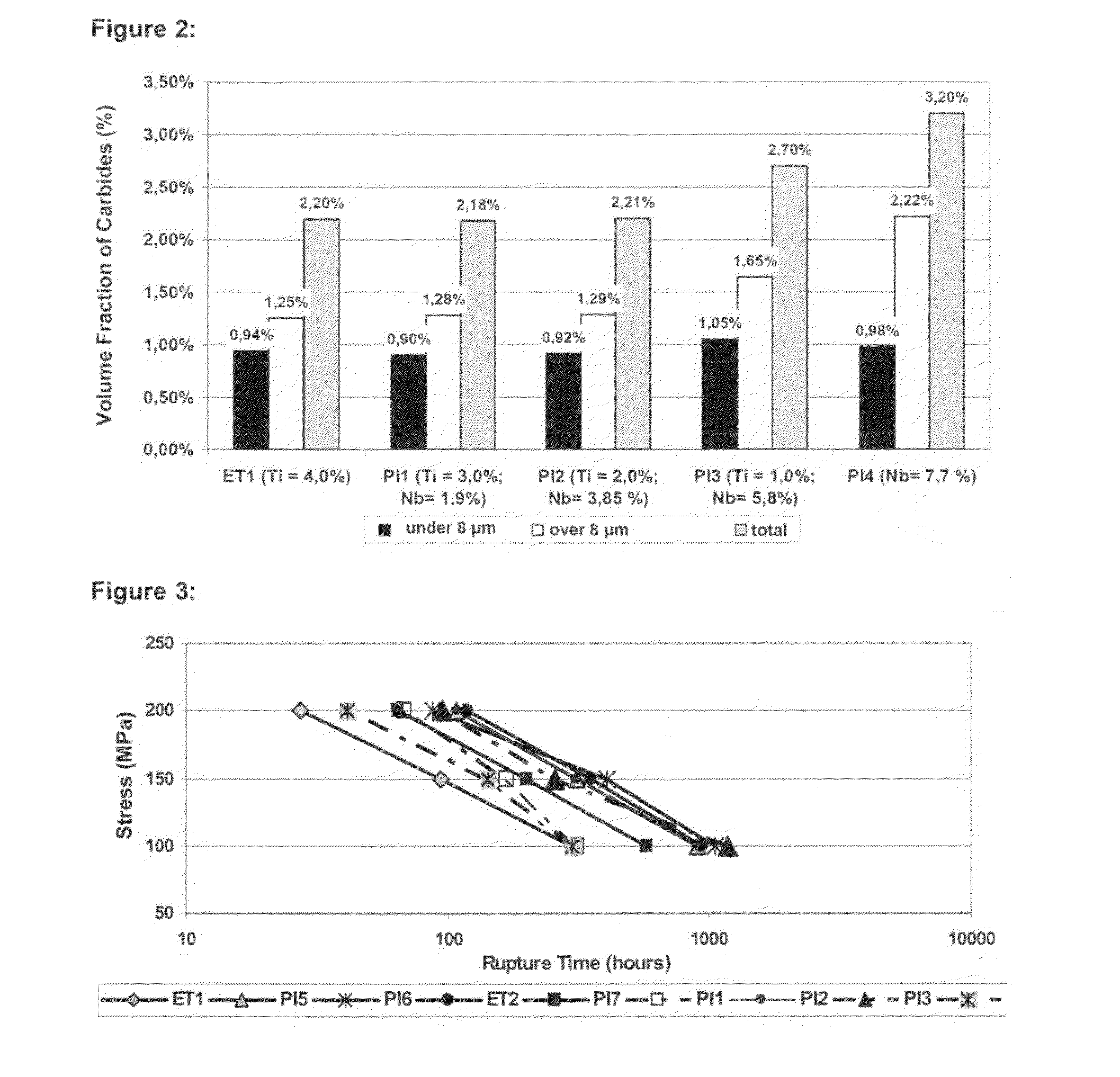

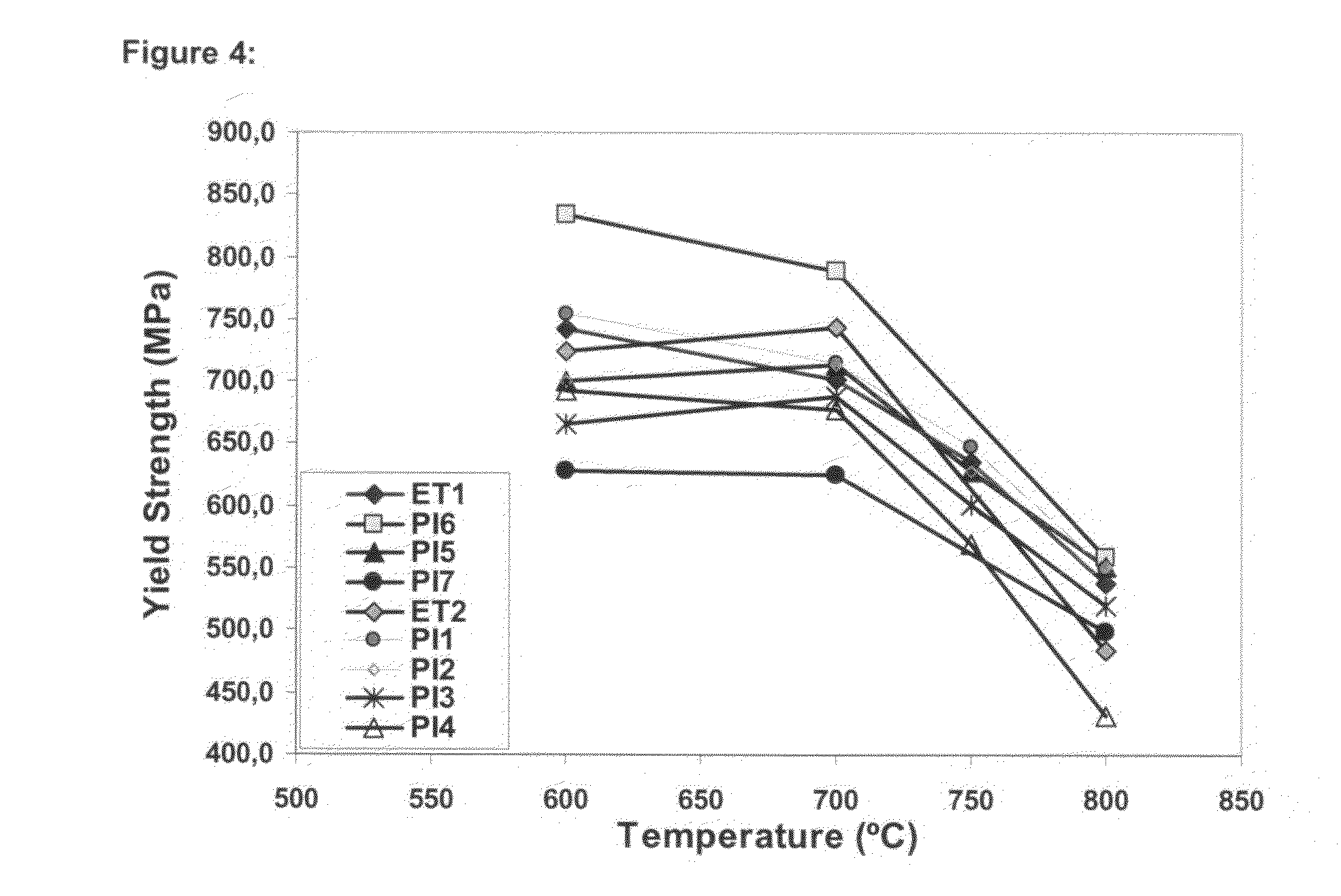

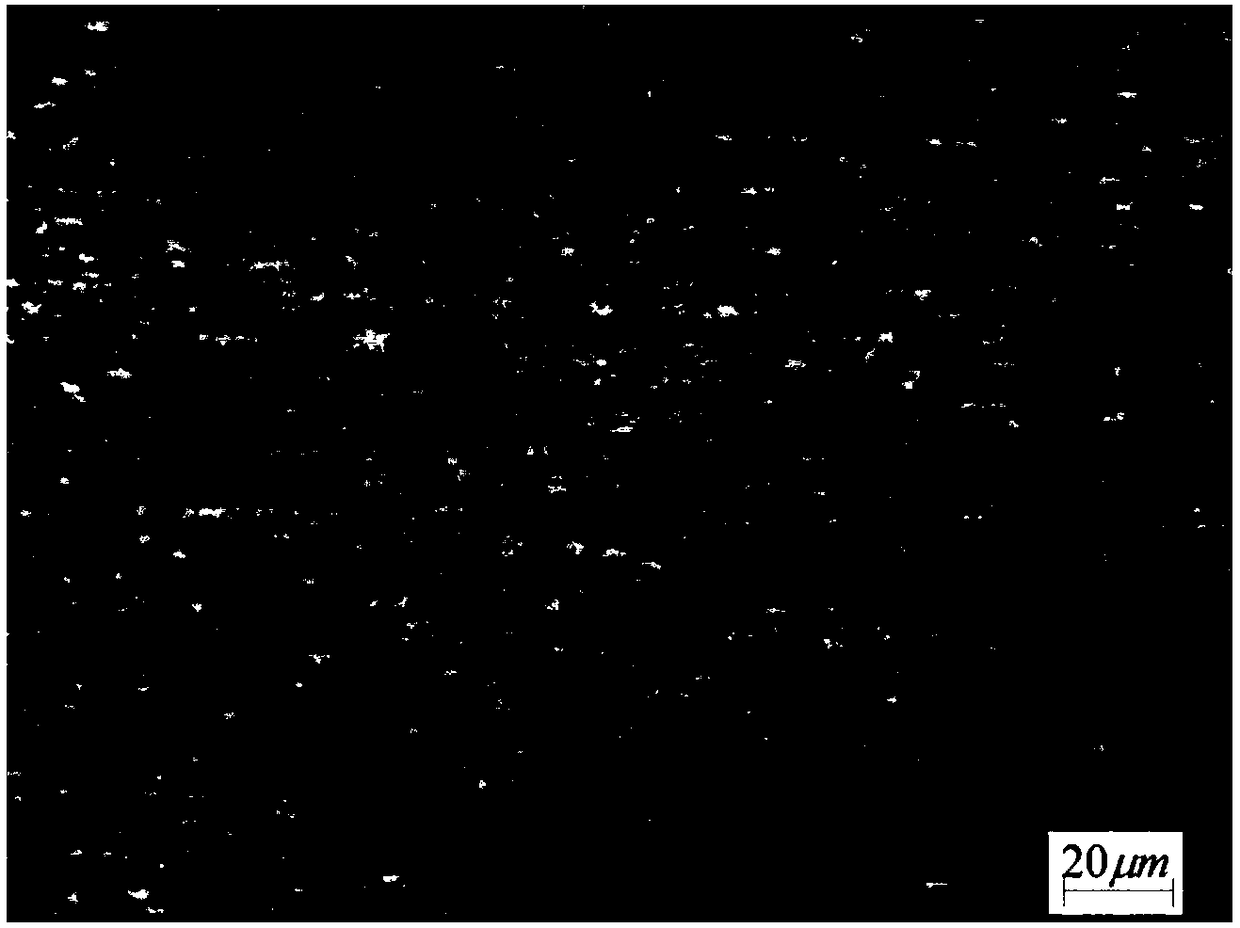

Low cost alloys resistant to mechanical requirements related to high temperatures, resistant to corrosion, resistant to abrasion, with high workability and which meet different requirements in the conditions for application in either exhaust or intake valves for internal combustion engines. The main features of the alloys is the precipitation of Ni3Nb and niobium carbides in its microstructure. In percentage, its mass consists of: 0.15 to 0.50% C, up to 3.0% Mn, up to 1.0% Si, 12.0 to 25.0% Cr, 25.0 to 49.0% Ni, up to 0.50% Mo, up to 0.50% W, up to 0.50% V, 0.50 to 5.0% Cu, 1.85 to 3.0% Al, 1.0 to 4.5% Ti, 3.1 to 8.0% Nb, 0.001 to 0.02% B, 0.001 to 0.10% Zr, up to 2.0% Co, where (Ni+Co) is not higher than 50.0% in mass, nor lower than 25% in mass. The rest is made of iron and impurities inevitable to the Alloy manufacture procedure.

Owner:VILLARES METALS SA

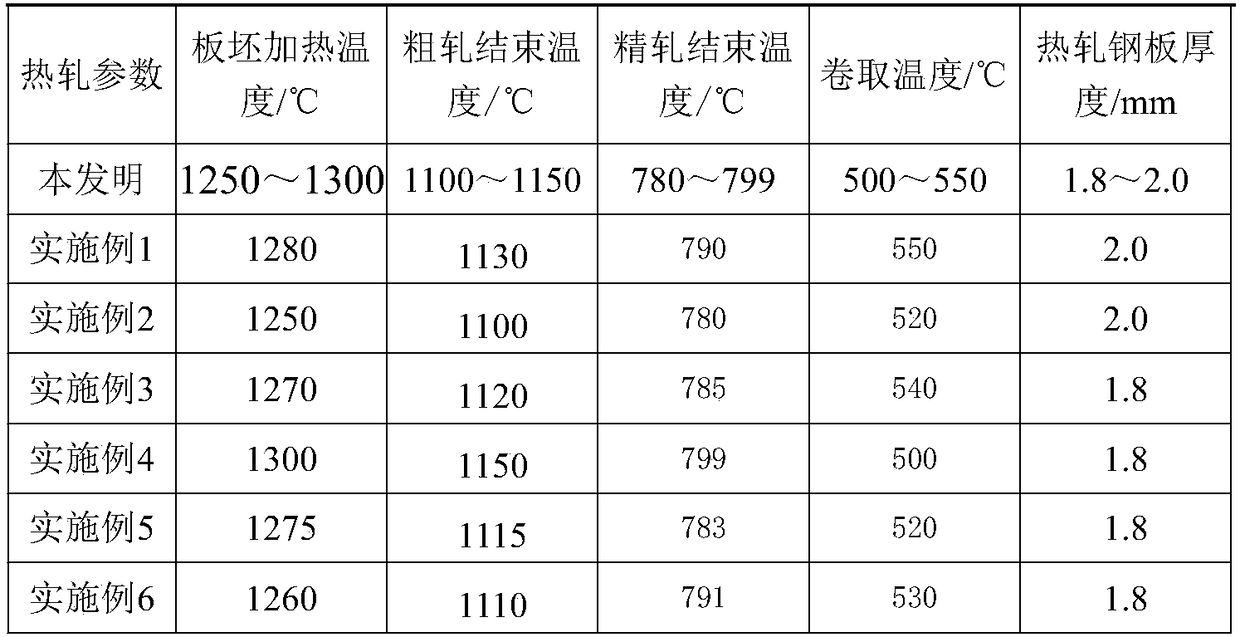

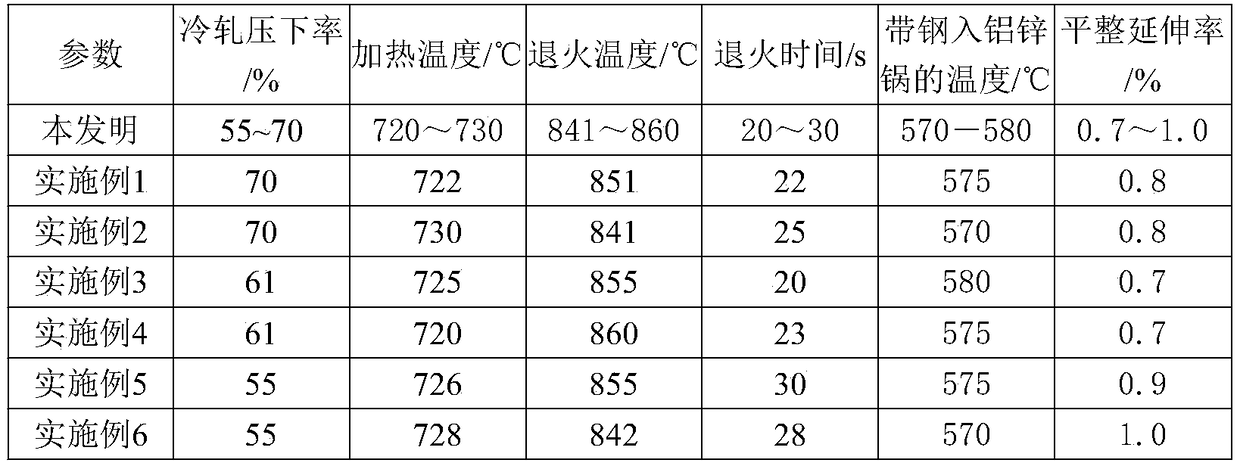

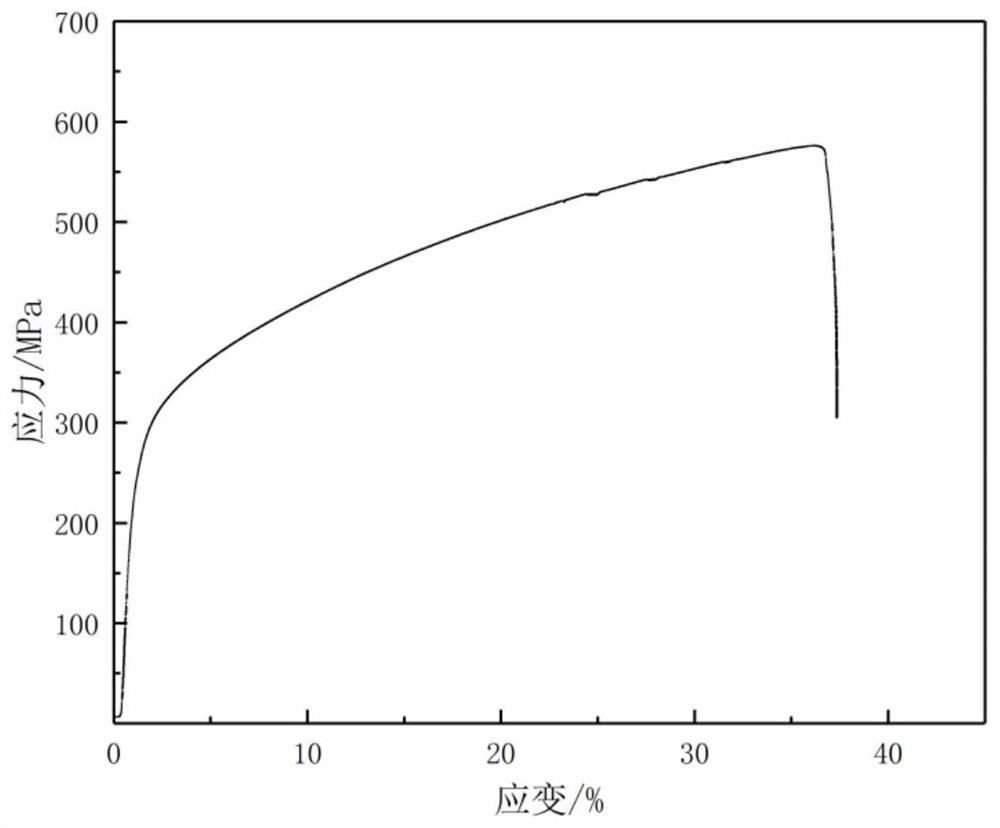

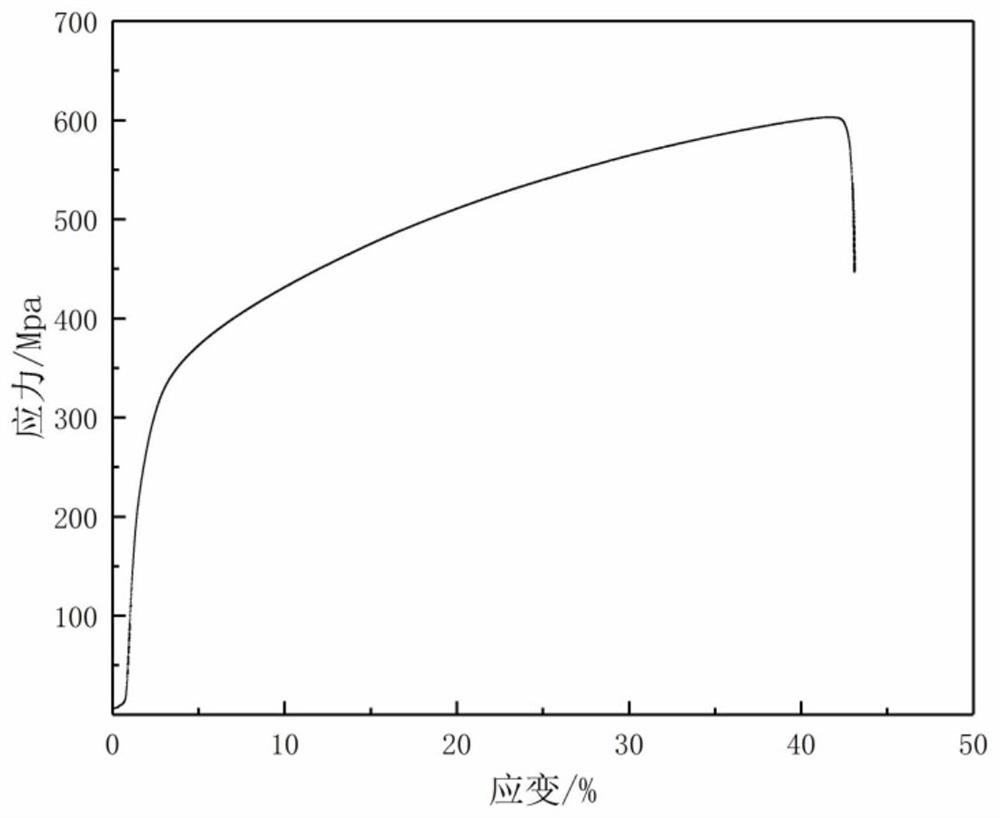

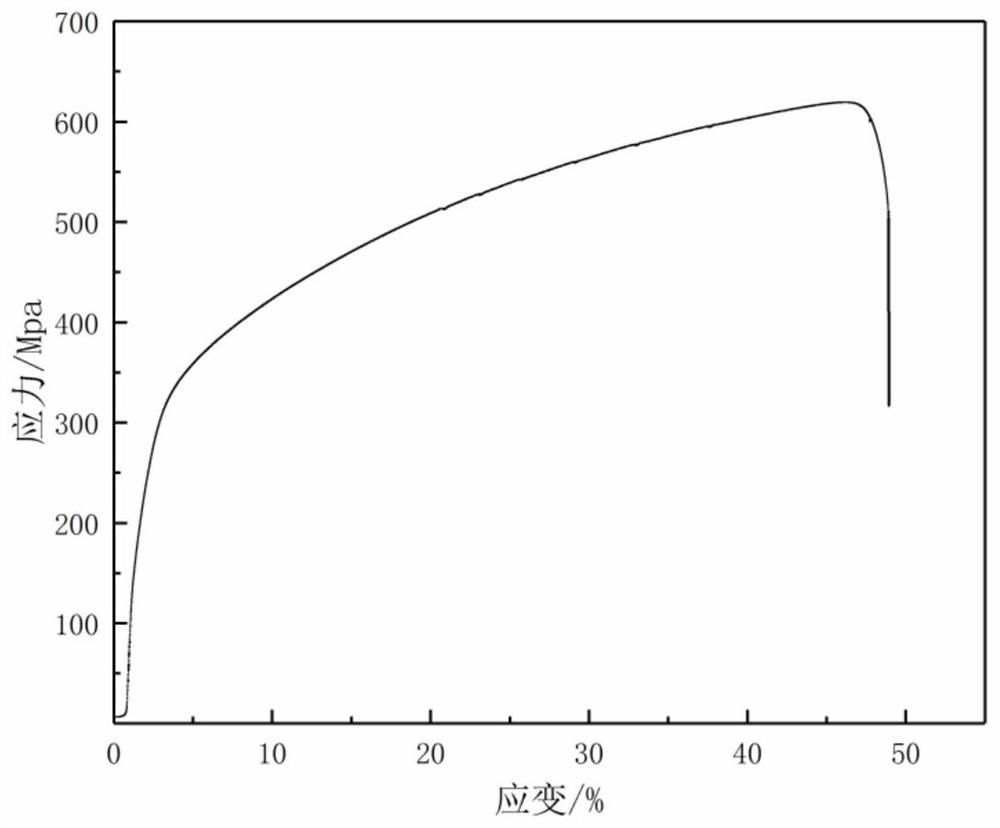

Hot-dipped Al-Zn steel plate with yield strength being 550MPaand manufacturing method thereof

ActiveCN108866428AHigh yield strengthHigh elongationHot-dipping/immersion processesUltimate tensile strengthNiobium carbide

The invention relates to a hot-dipped Al-Zn steel plate with yield strength being 550MPa and a manufacturing method thereof and mainly aims to solve the technical problems in the prior art that a hot-dipped Al-Zn steel plate with yield strength being 550MPa is high in manufacturing cost and low in production efficiency and elongation. According to the hot-dipped Al-Zn steel plate with the yield strength being 550MPa, the base plate of the hot-dipped Al-Zn steel plate comprises the following chemical components in percentage by weight: 0.05%-0.06% of C, 0-0.05% of Si, 1.0%-1.2% of Mn, 0-0.015%of P, 0-0.015% of S, 0.061%-0.080% of Nb and the balanceFe and unavoidable impurities. The metallographic structure of the hot-dipped Al-Zn steel plate is fibrous ferrite, cementite and tiny niobium carbide precipitate; the percentage elongation after fracture of the hot-dipped Al-Zn steel plate with the thickness being 0.60-0.80 mm is 10-18%; and the hot-dipped Al-Zn steel plate is mainly used for components of a construction steel structure.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Metal type flux-cored wire and method of manufacturing austenitic stainless steel structural part

ActiveCN111992923AShort preparation cycleIncrease productivityWelding/cutting media/materialsSoldering mediaManufacturing technologyFerrosilicon

The invention discloses a metal type flux-cored wire. The metal type flux-cored wire is adopted as a raw material, an austenitic stainless steel structural part is manufactured on the basis of an electric arc additive manufacturing technology, and the formed thin-wall structural part has excellent mechanical properties. Flux-cored alloy of the metal type flux-cored wire comprises, by mass percentage, 8% of silicon iron, 18%-22% of manganese powder, 27% of nickel powder, 26% of chromium powder, 4%-8% of molybdenum powder, 1%-3% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder,0.5% of lanthanum oxide, 1% of niobium carbide and the balance iron powder. The sum of the mass percentages of the components is 100%. The austenitic stainless steel thin-wall structural part obtained through additive manufacturing is attractive in appearance and has the excellent mechanical properties. The austenitic stainless steel metal type flux-cored wire for additive manufacturing can be used for additive manufacturing of complex parts in the fields of national defense, energy, petroleum, chemical engineering, aerospace and bioengineering.

Owner:XIAN UNIV OF TECH

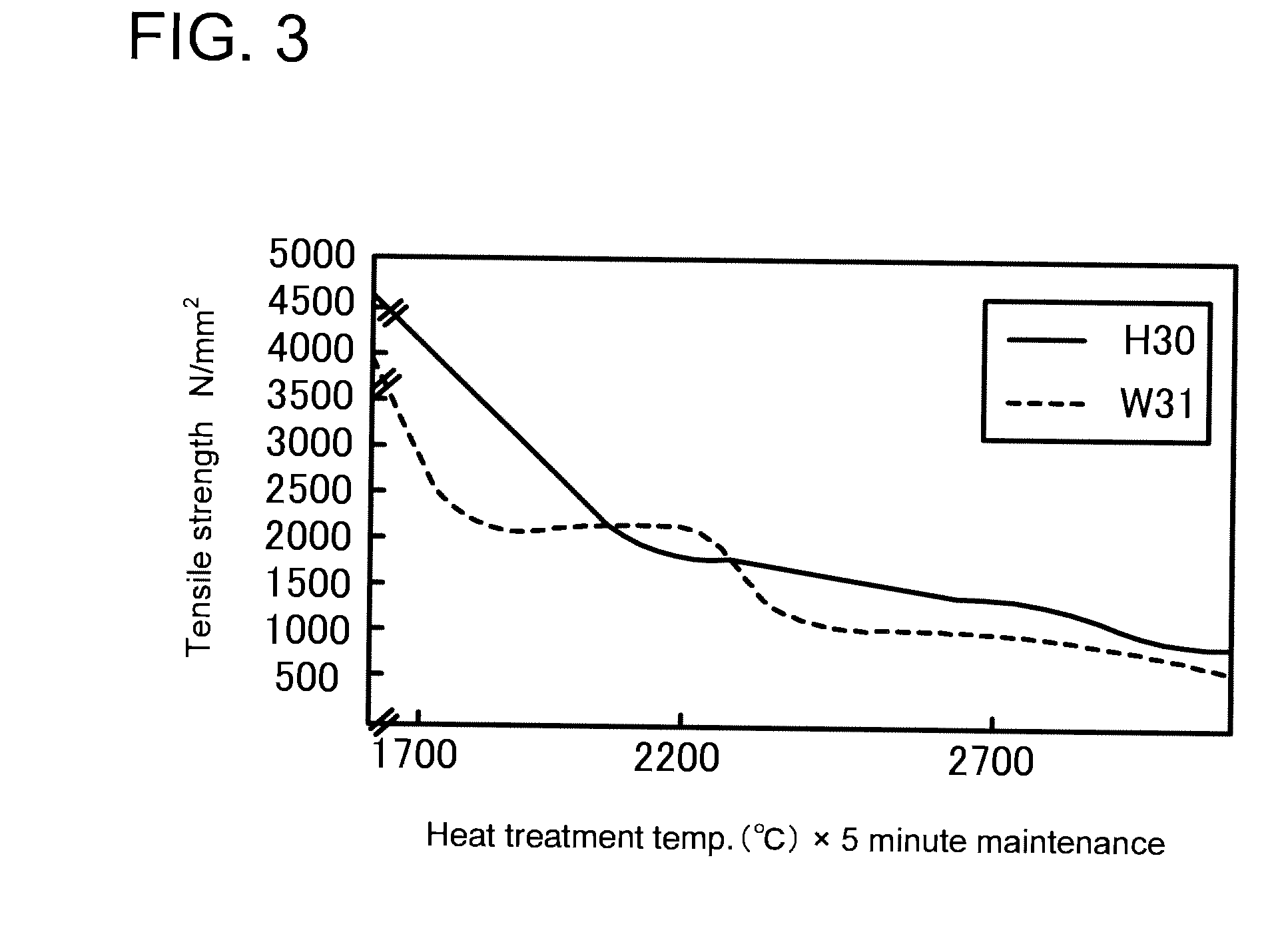

High temperature-resistant article, method for producing the same, and high temperature-resistant adhesive

ActiveUS20100239885A1Low costPolycrystalline material growthPretreated surfacesCarbide coatingAdhesive

A method for producing a high temperature-resistant article comprises an assembling step of foaming an assembly of a first substrate and a second substrate with an adhesive layer interposed therebetween and comprising paste of powder of at least one carbide of niobium carbide, hafnium carbide, tantalum carbide and tungsten carbide; and a bonding step of heating the assembly to bond the first substrate and the second substrate by sintering, thereby obtaining a high temperature-resistant article comprising the assembly after sintering. Moreover, a method for producing a high temperature-resistant article comprises a coating step of coating a slurry comprising powder of at least one carbide of niobium carbide, hafnium carbide, tantalum carbide and tungsten carbide on a surface of a high temperature-resistant substrate; a drying step of drying the substrate after the coating step; and a film-forming step of heating the substrate after the drying step to form a carbide coating film on the surface of the substrate by sintering, thereby obtaining a high temperature-resistant article having the carbide coating film. A high temperature-resistant article of a complicated shape can be easily produced at low costs by these methods.

Owner:TOYOTA CENT RES & DEV LAB INC

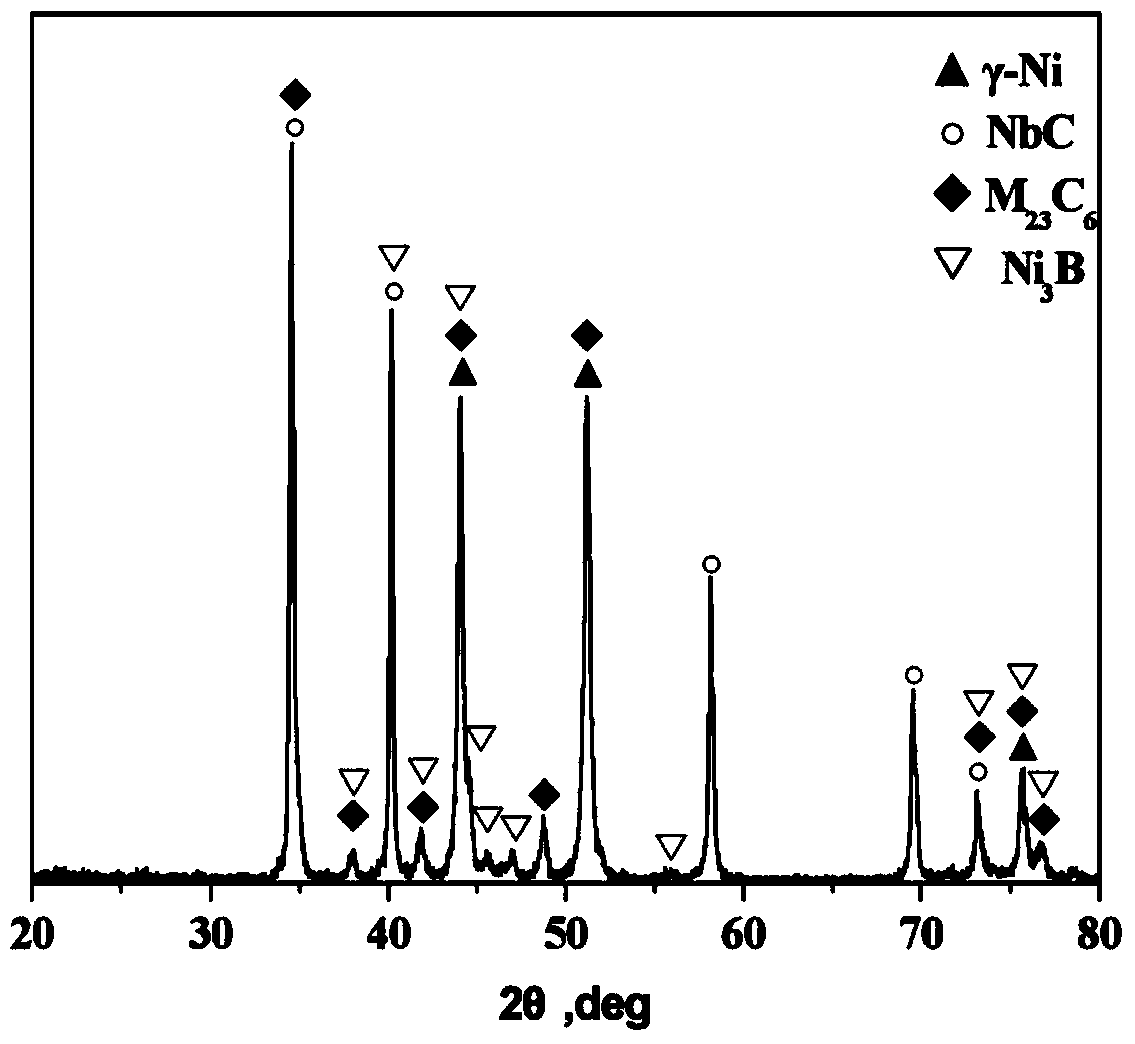

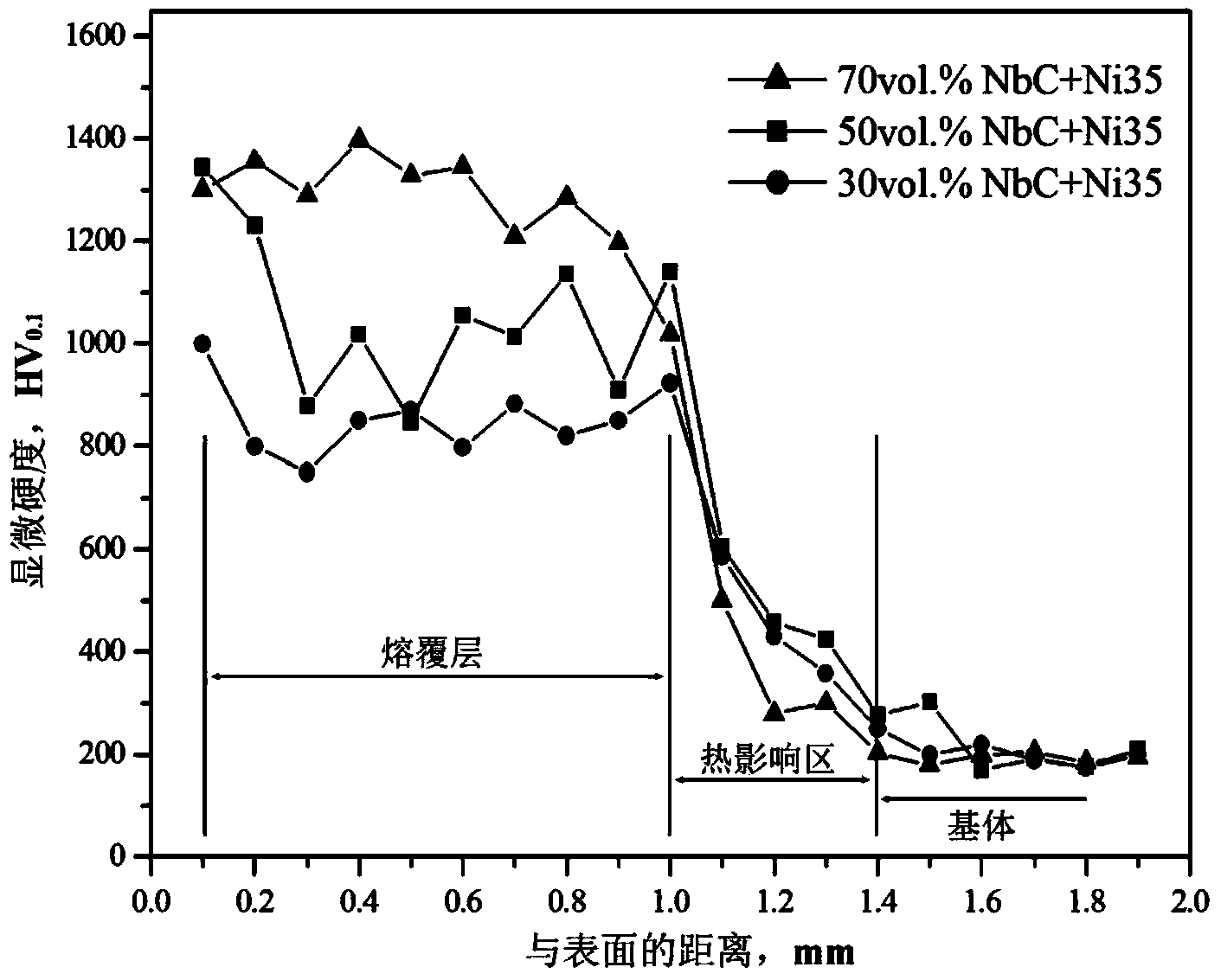

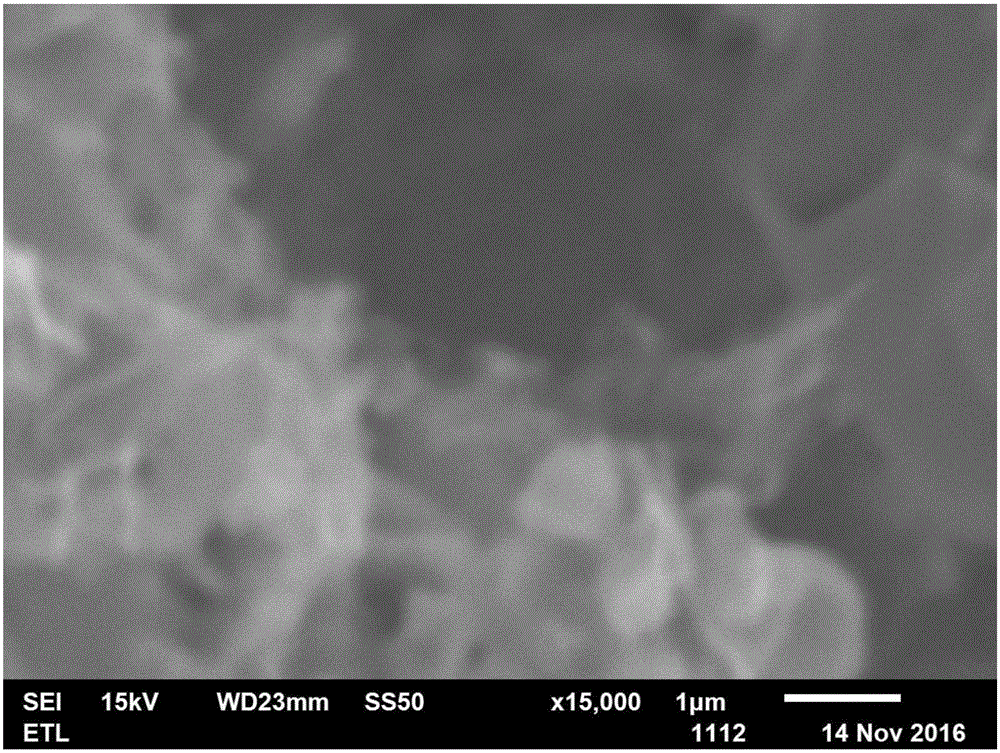

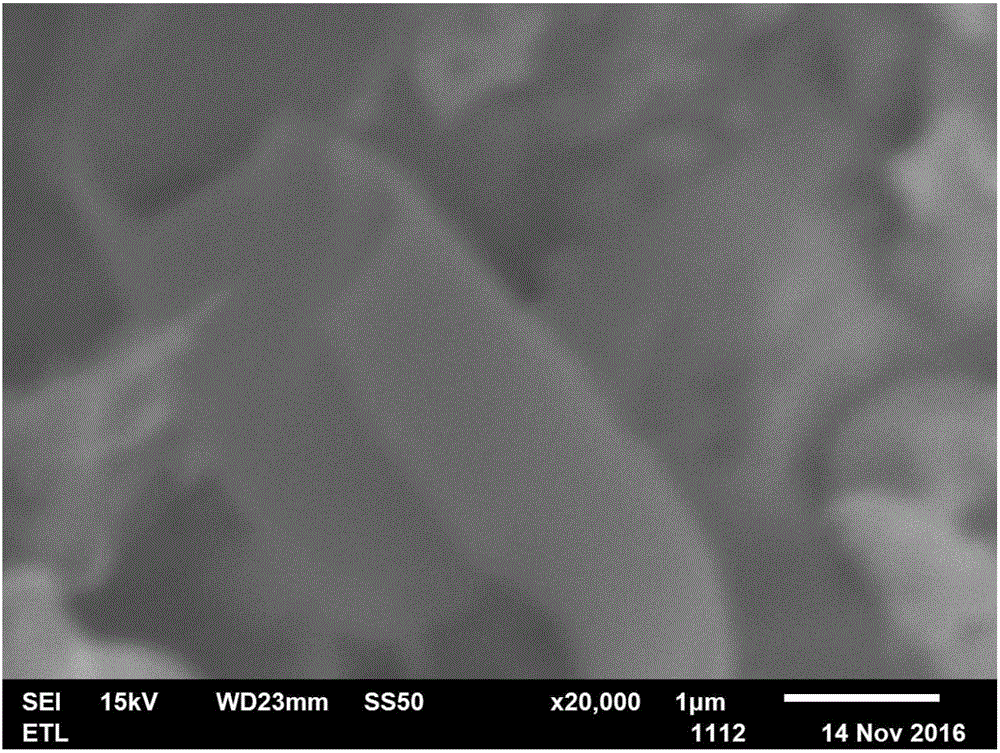

Laser cladding metal/ceramic composite coating and preparation technology thereof

ActiveCN103409749ANo crackImprove lap qualityMetallic material coating processesLaser beam welding apparatusCeramic compositeAlloy

The invention relates to a laser cladding metal / ceramic composite coating and a preparation technology thereof. The laser cladding metal / ceramic composite coating is prepared by carrying out laser cladding on steel as a matrix material as well as Ni35 nickel base alloy powder and large particle niobium carbide NbC as a cladding material, wherein the cladding material is prepared from the components in percentage by weight: 20-80 percent of the Ni35 nickel base alloy powder and 80-20 percent of the large particle niobium carbide NbC. With the adoption of the laser cladding metal / ceramic composite coating, the surface of a cladding layer is smoother without cracks, and the cladding layer is better in the quality of overlap joint, is strong in the rigidity, is smaller in friction coefficient and can bear stronger stress; and a wear mechanism mainly adopts microcosmic spalling together with slight ploughing wear, and shows good anti-dry sliding friction wear resistance.

Owner:SHANDONG UNIV

Metal ceramic composite material and preparation method thereof

The invention relates to a metal ceramic composite material and a preparation method thereof, and belongs to the field of composite materials. The metal ceramic composite material comprises the following raw materials in part by mass: 20-30 parts of nanometer molybdenum carbide, 5-15 parts of cobalt, 8-17 parts of chromium, 5-18 parts of niobium carbide, 1-3 parts of zirconium oxide, 3-13 parts of silicon carbide, 4-9 parts of copper, 10-12 parts of cerium oxide, 1-3 parts of aluminium oxide, and 1-5 parts of titanium powder. The metal ceramic composite material has the advantages that the performance is excellent, the bending strength can reach up to 2500 MPa, and the Rockwell hardness can reach 93; the composite material further has excellent wear resistance and high temperature resistance; the preparation method is simple, feasible, and suitable for large-range popularization and application.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

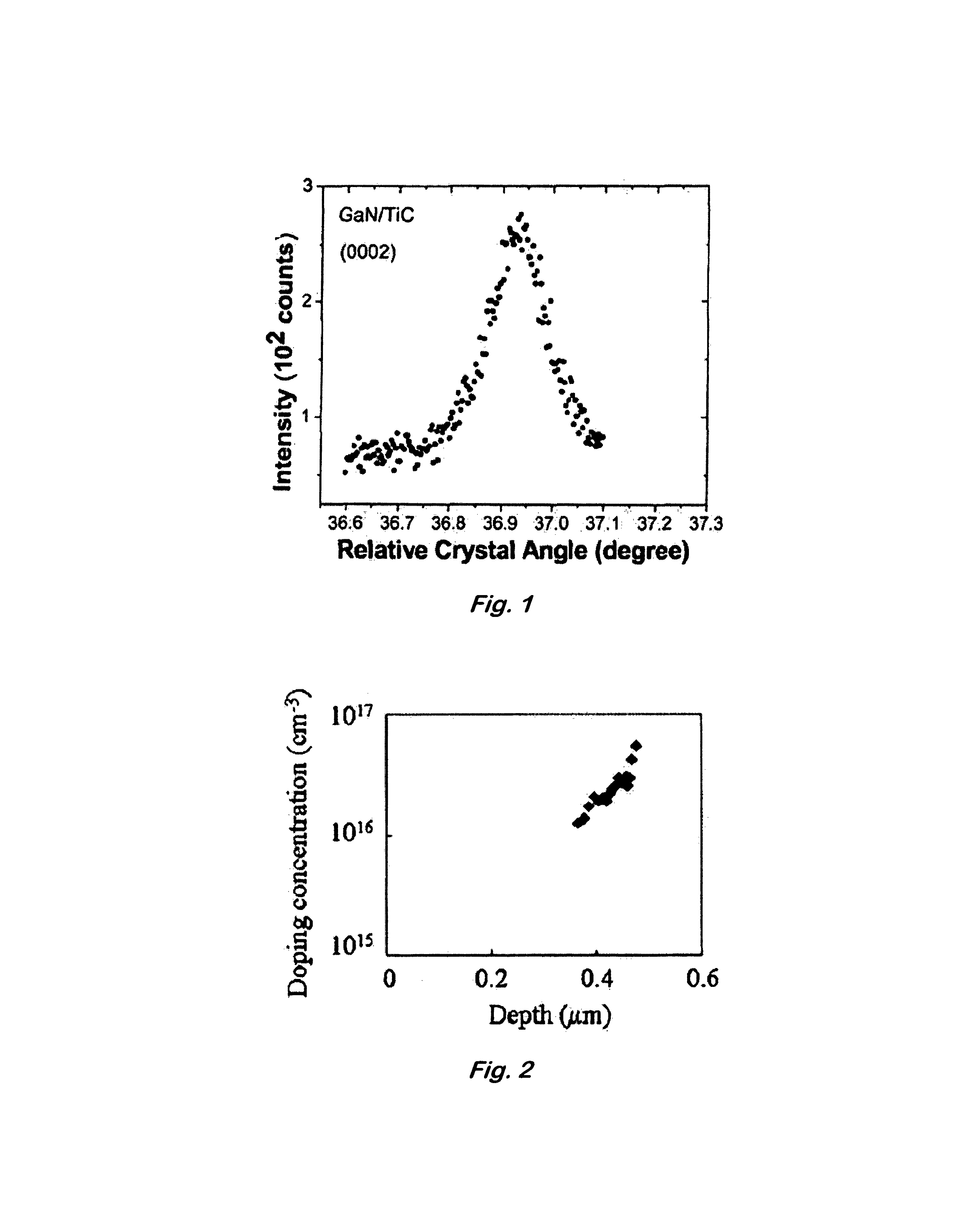

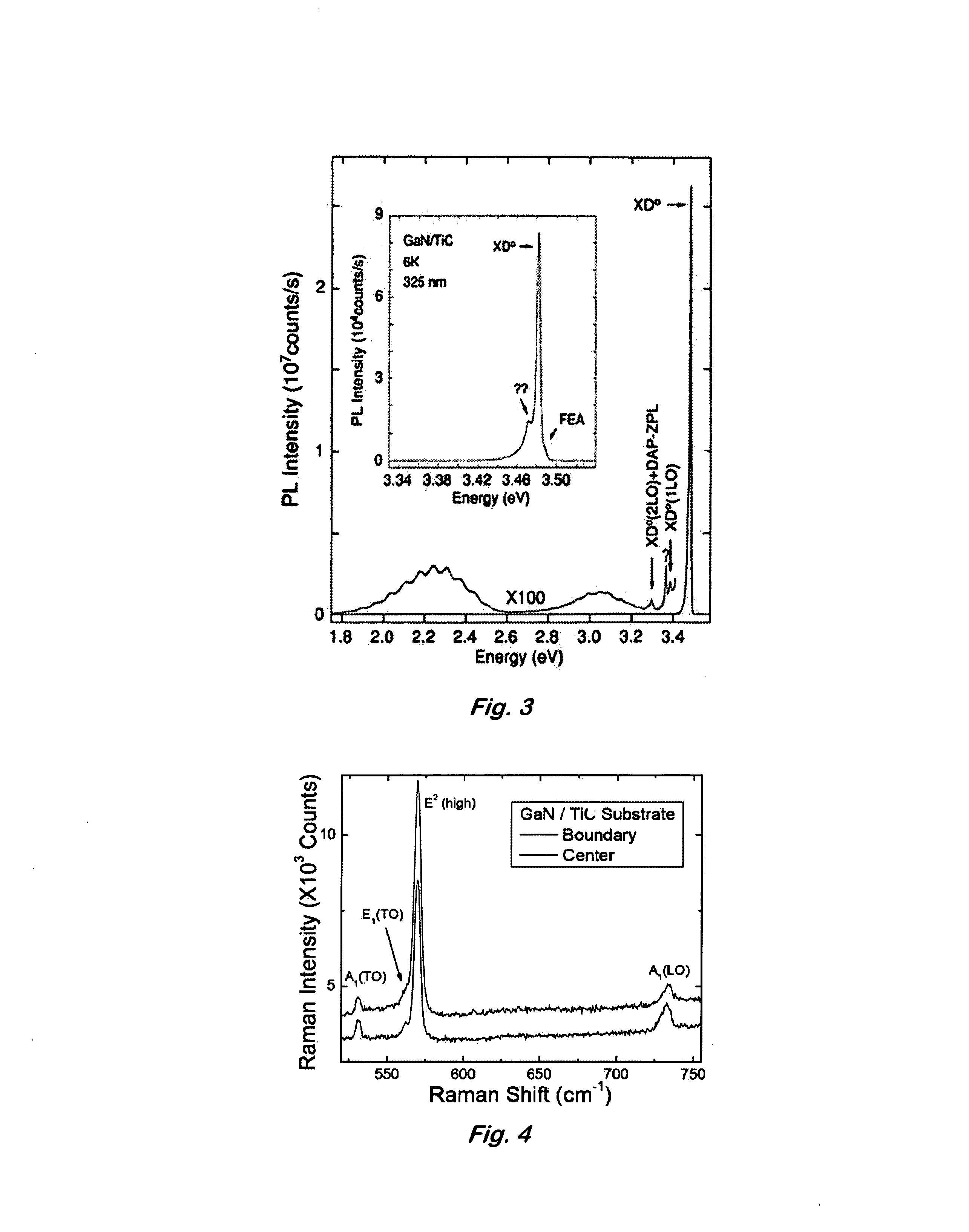

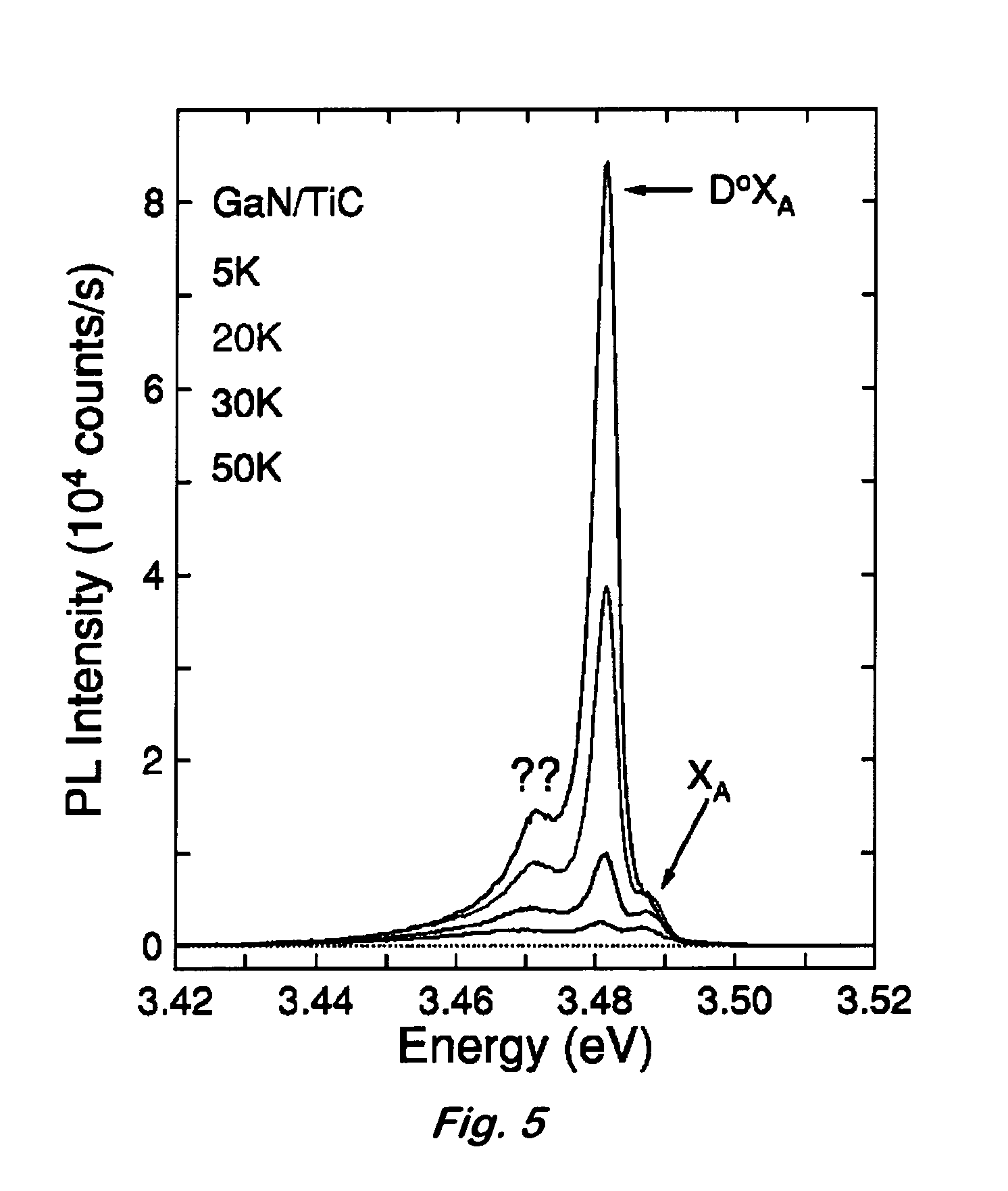

Crystalline III-V nitride films on refractory metal substrates

InactiveUS7482674B1Semiconductor/solid-state device manufacturingSemiconductor devicesHafniumChromium nitride

An article of manufacture having a substrate having a top surface and a first layer on the top surface. The top surface contains titanium carbide, vanadium carbide, zirconium carbide, niobium carbide, hafnium carbide, tantalum carbide, tungsten carbide, chromium nitride, molybdenum nitride, tungsten nitride, titanium nitride, vanadium nitride, zirconium nitride, or a combination thereof. The first layer contains one or more group III-V metal nitrides.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

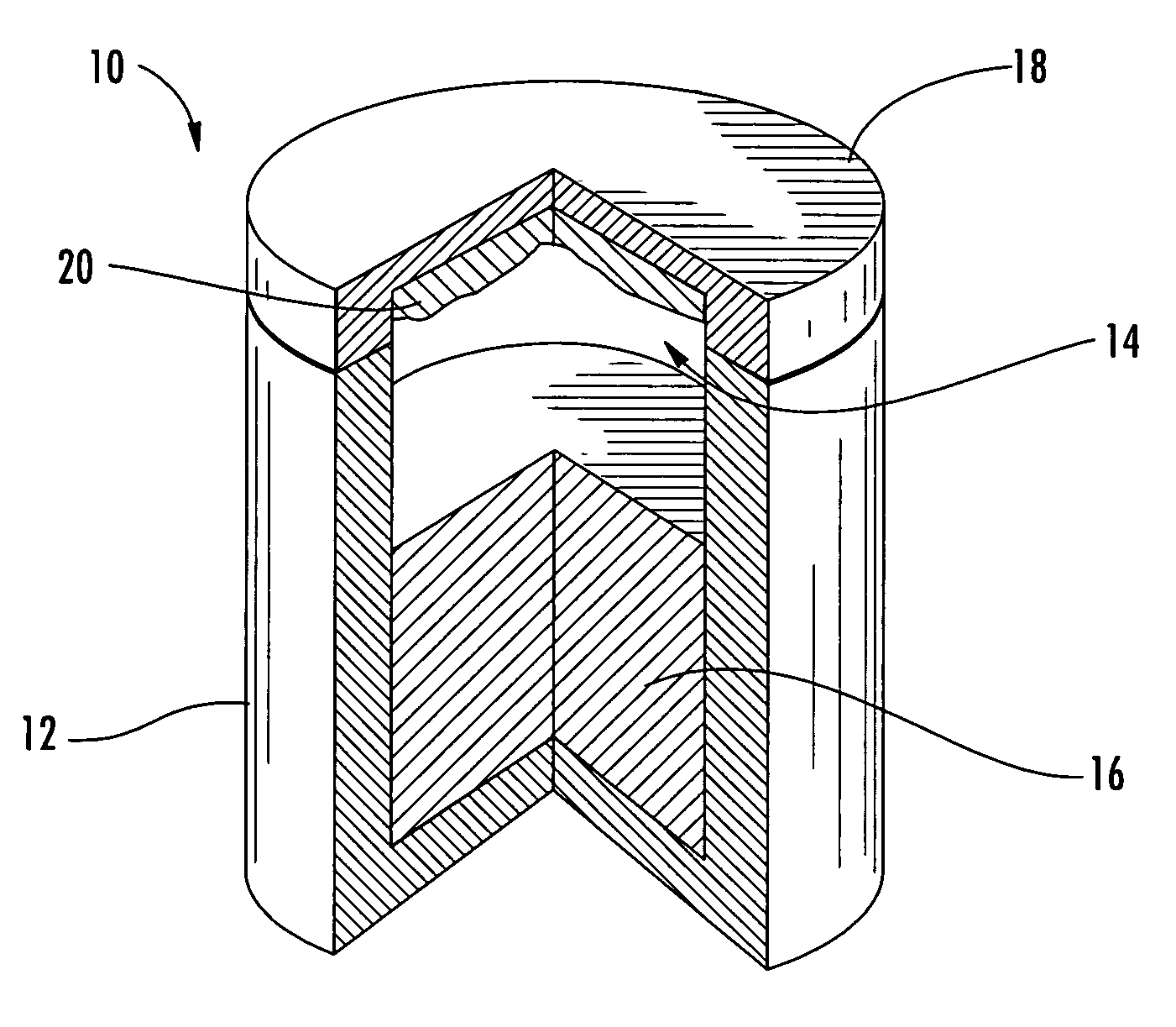

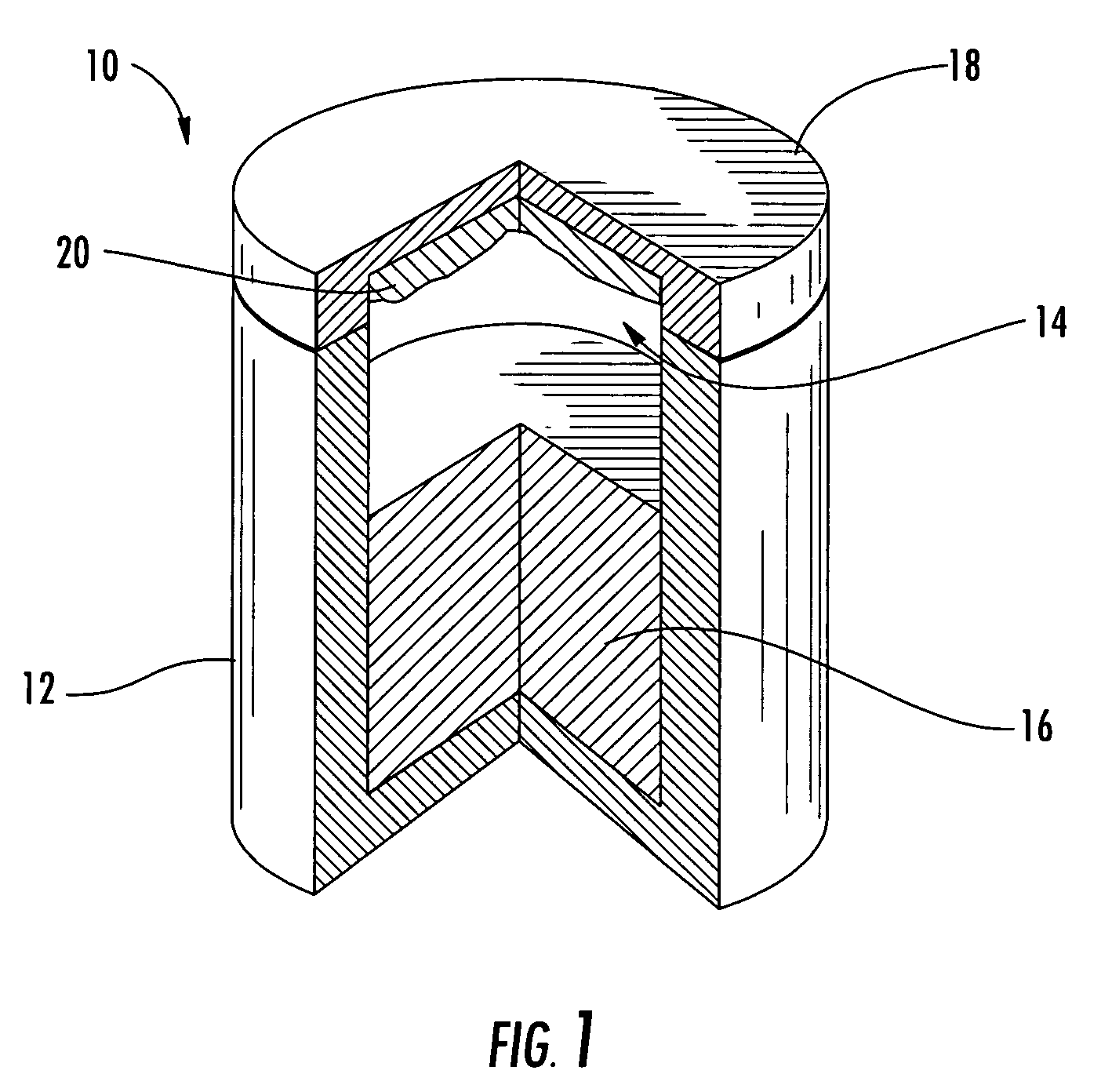

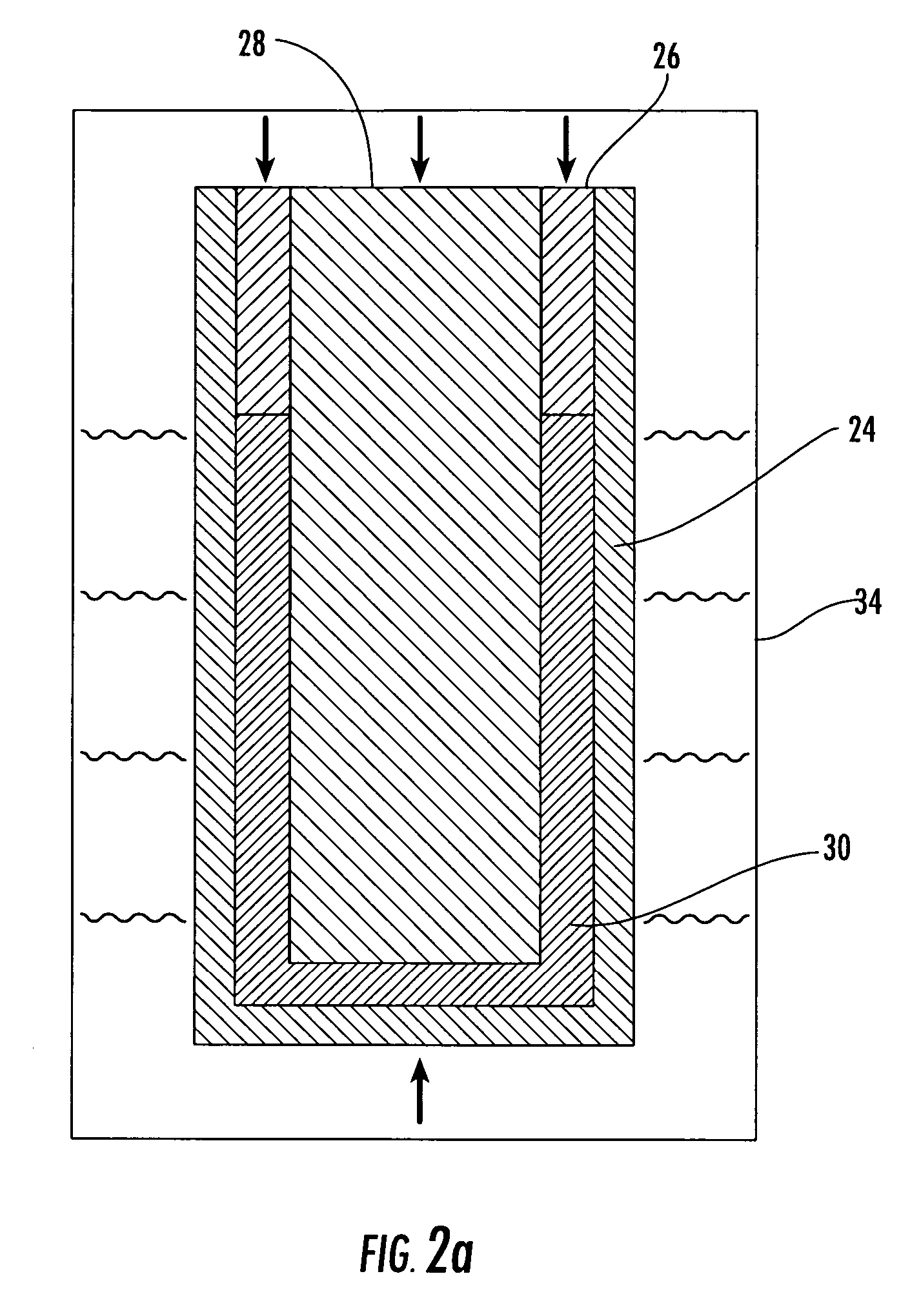

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS7632454B2High utilization yieldPolycrystalline material growthCeramic shaping apparatusPorosityShell molding

The invention provides a method of forming a dense, shaped article, such as a crucible, formed of a refractory material, the method comprising the steps of placing a refractory material having a melting point of at least about 2900° C. in a mold configured to form the powder into an approximation of the desired shape. The mold containing the powder is treated at a temperature and pressure sufficient to form a shape-sustaining molded powder that conforms to the shape of the mold, wherein the treating step involves sintering or isostatic pressing. The shape-sustaining molded powder can be machined into the final desired shap and then sintered at a temperature and for a time sufficient to produce a dense, shaped article having a density of greater than about 90% and very low open porosity. Preferred refractory materials include tantalum carbide and niobium carbide.

Owner:NORTH CAROLINA STATE UNIV +6

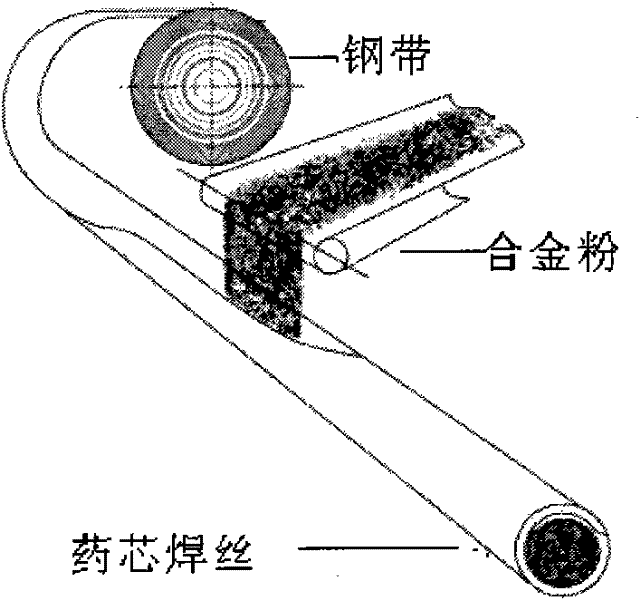

High wear-resistant flux-cored wire for resurfacing welding of spiral reamer of vacuum extruder

The invention provides a flux-cored wire for resurfacing welding of a spiral reamer of a vacuum extruder, belongs to the field of welding materials and aims at solving the problem of prolonging of the spiral reamer of the vacuum extruder. The flux-cored wire for resurfacing welding of the spiral reamer, which is provided by the invention, comprises carbon steel strip-coated metal powder and a small amount of mineral powder. The added power comprises the following substances in percentage by mass: 20-35 percent of niobium carbide, 10-15 percent of ferroboron, 2-5 percent of ferromolybdenum, 5-8 percent of ferromanganese, 2-5 percent of silicoferrite, 2-4 percent of ferrotitanium, 1-3 percent of aedelforsite, 1-3 percent of fluorite (CaF2), 2-4 percent of quartz (SiO2), 1-3 percent of zirconite (ZrO2), 1-3 percent of feldspar, 5-8 percent of natural ruffle (TiO2) and the balance of reduced iron powder. Compared with the prior art, the invention has the advantages of high hardness of a resurfacing welding layer, strong wear resistance, fewer welding slags and no need of cleaning the slags or adding protective gases during welding.

Owner:BEIJING KOOBEN TECH

Nitrogen-doped niobium carbide nanosheets and preparation method thereof

ActiveCN106629728AEasy to operateLow costCarbon compoundsNanotechnologyMetal chlorideRoom temperature

The invention discloses a preparation method of nitrogen-doped niobium carbide nanosheets. The preparation method comprises the following steps: 1) putting Nb2O5, soluble metal chloride or hydrate thereof and C3H6N6 according to an amount ratio of 1: (2-5): (3-6) into a ball mill; 2) performing ball milling in the ball mill; 3) taking out, drying, putting into a fixed tubular atmosphere furnace, and in an inert atmosphere, heating to 900-1200 DEG C at a speed rate of 4-10 DEG C / min; 4) preserving heat for 1-3h, and cooling to room temperature to obtain the nitrogen-doped niobium carbide nanosheets. The invention further discloses the nitrogen-doped niobium carbide nanosheets prepared by the preparation method. According to the preparation method, with low-cost tripolycyanamide as a nitrogen source and a carbon source, the soluble metal chloride or the hydrate thereof as a catalyst and a flux, and the Nb2O5 as a niobium source, the temperature is raised to a specific temperature through temperature programming and a reaction is performed to prepare the nitrogen-doped niobium carbide with a two-dimensional structure; by the preparation method, the operating method is simple, the cost is low and industrialization is easy to implement.

Owner:HUBEI ENG UNIV

Composite hard alloy material and preparation method thereof

The invention discloses a composite hard alloy material and a preparation method thereof. The composite hard alloy material is prepared from the following components in parts by weight: 35-40 parts of nano titanium carbide, 5-15 parts of nano titanium nitride, 7-9 parts of tungsten carbide, 5-8 parts of niobium carbide, 3-7 parts of silicon carbide, 3-5 parts of cobalt powder, 1-3 parts of yttrium oxide, 1-3 parts of aluminium carbide and 1-5 parts of titanium powder. The composite hard alloy material has high strength, good toughness and good wear resistance and thermal shock resistance.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

Highly abrasion-proof columbium carbide-chromium carbide composite surfacing welding rod

InactiveCN1864910AImprove wear resistanceWelding/cutting media/materialsSoldering mediaHigh carbonFerrochrome

The invention relates to a niobium carbide-chromium carbide composite abrasion resistant surfacing welding rod, belonging to the surfacing welding material. Wherein, said solder rod is formed by core and cover, whose mass rate is (35:65)-(40:60); said cover comprises following components in mass percentages that titanium dioxide in 2-6%; marble in 3-9%; ilmenite in 0-8%; fluorite in 3-10%; feldspar in 1-3%; quartz in 0.5-2%; iron oxide red in 1-6%; white niobium in 1-6%; bicarbonate in 0.2-1%; crystaline flake graphite in 0.5-4%; isinglass in 1-4%; medium-carbon ferromanganese in 1-5%; high carbon ferro-chrome in 45-65%; ferrotitanium in 0.2-1%; and niobium carbide in 8-25%. The inventive solder rod can be widely used in abrasion resistant surfacing weld of mechanical element.

Owner:BEIJING UNIV OF TECH

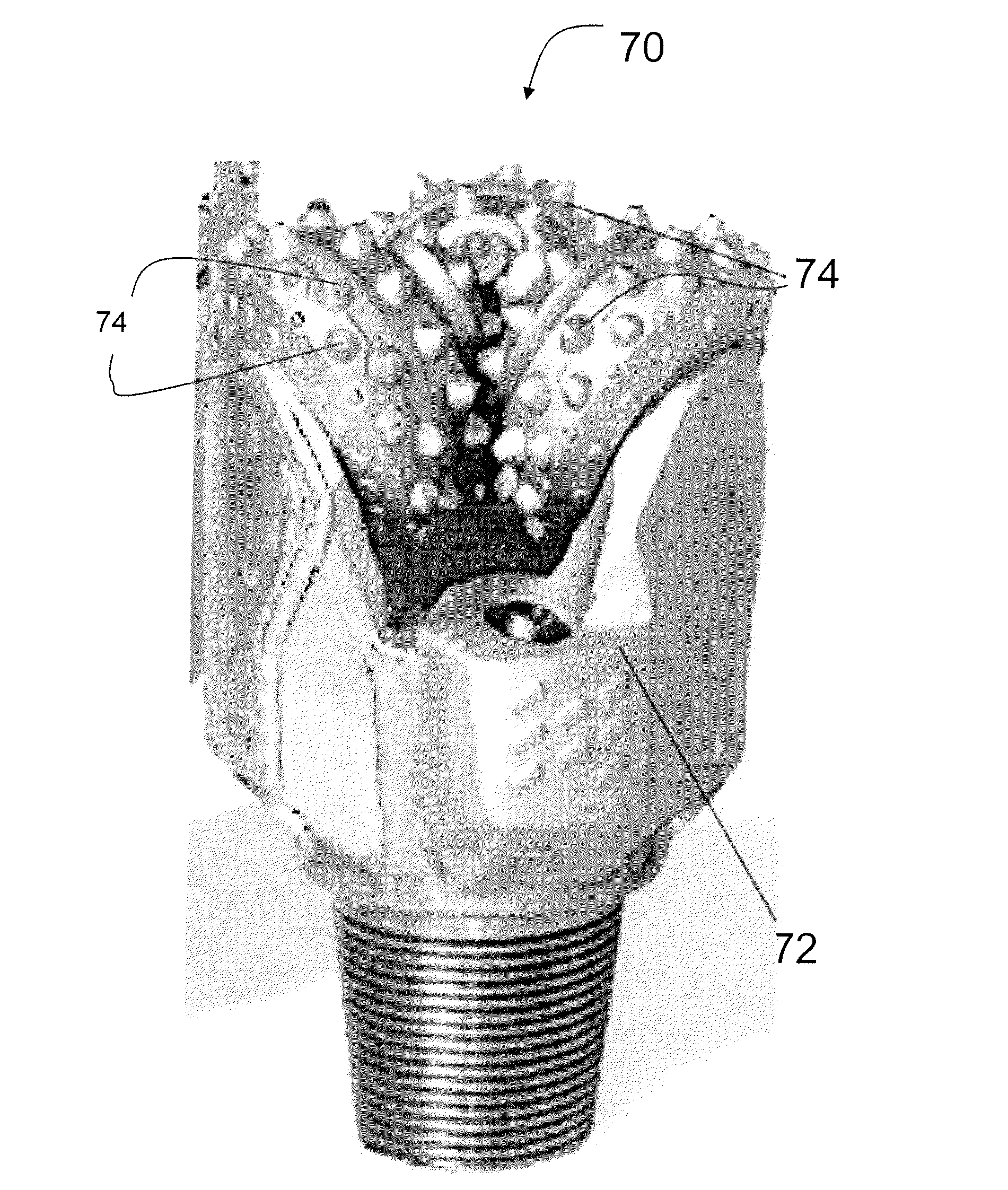

Cutting inserts for earth-boring bits

A cutting insert for an earth-boring bit comprises a cemented carbide material. The cemented carbide material comprises a plurality of tungsten carbide grains, and a plurality of cubic carbide grains comprising at least one of titanium carbide, vanadium carbide, zirconium carbide, hafnium carbide, niobium carbide, tantalum carbide, mixtures thereof, and solid solutions thereof. The cemented carbide material also comprises a binder including at least one of cobalt, a cobalt alloy, nickel, a nickel alloy, iron, and an iron alloy. Embodiments of the cutting inserts are suitable for use on, for example, rotary cone earth-boring bits and fixed cutter earth-boring bits. A hybrid cemented carbide material comprising first regions of cemented carbide based on tungsten carbide and cobalt, dispersed in a continuous region of cemented carbide material comprising cubic carbides also is disclosed and is useful in cutting inserts of earth-boring bits.

Owner:KENNAMETAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com