Laser cladding metal/ceramic composite coating and preparation technology thereof

A laser cladding and ceramic composite technology, which is applied in metal material coating technology, laser welding equipment, metal processing equipment, etc. Large and other problems, to achieve the effect of improving hardness and wear resistance, not easy to float and sink, and good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

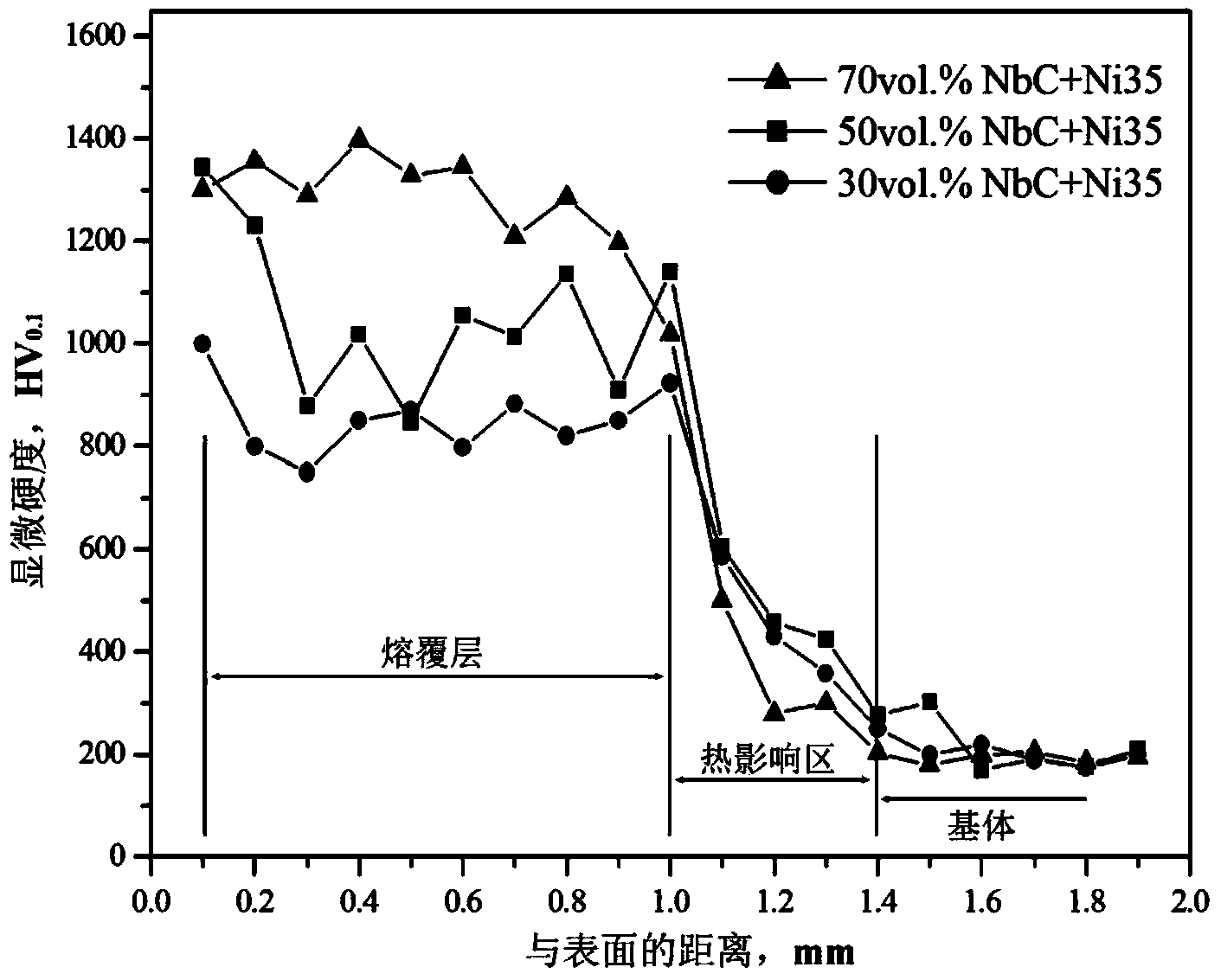

[0045] With Q235 as the base material, the volume fraction of the cladding material used is 50% of Ni35 alloy powder and 50% of large particle NbC. (The volume is calculated by dividing its powder mass by its density)

[0046] 1) Mix the cladding materials evenly in proportion, adjust the mixed powder into a paste with water glass dilution solution, and evenly apply it on the surface of the cleaned sample, control its thickness to 1.2-1.5mm, and dry it;

[0047] 2) Scan the sample with a continuous laser, keep the spot diameter at 4mm, power at 3kW, scan speed at 5mm / s for laser cladding, and protect with side blowing argon.

[0048] The structure observation, hardness and wear resistance analysis of the prepared cladding layer were carried out.

[0049] Observe the microstructure morphology in the middle of the cladding layer, such as Figure 5 As shown, there are both unmelted bulk NbC and precipitated NbC in the cladding layer. The distribution of NbC is relatively uneven...

Embodiment 2

[0055] With Q235 as the base material, the volume fraction of the cladding material used is 70% of Ni35 alloy powder and 30% of large particle NbC.

[0056] 1) Mix the cladding materials evenly in proportion, adjust the mixed powder into a paste with water glass dilution solution, and evenly apply it on the surface of the cleaned sample, control its thickness to 1.2-1.5mm, and dry it;

[0057] 2) Scan the sample with a continuous laser, keep the spot diameter at 4mm, power at 3kW, scan speed at 5mm / s for laser cladding, and protect with side blowing argon.

[0058] The structure observation, hardness and wear resistance analysis of the prepared cladding layer were carried out.

[0059] Observe the microstructure morphology in the middle of the cladding layer, such as Figure 5 As shown, there are both unmelted bulk NbC and precipitated NbC in the cladding layer, and the distribution of the two in the cladding layer is relatively uniform as Figure 5 (c) (d) shown.

[0060] ...

Embodiment 3

[0063] With Q235 as the base material, the volume fraction of the cladding material used is 30% of Ni35 alloy powder and 70% of large particle NbC.

[0064] 1) Mix the cladding materials evenly in proportion, dilute the mixed powder into a paste with water glass dilution solution and apply it evenly on the cleaning surface

[0065] After the sample surface, control its thickness to 1.2 ~ 1.5mm, and dry it;

[0066] 2) Scan the sample with a continuous laser, keep the spot diameter at 4mm, power at 3kW, scan speed at 5mm / s for laser cladding, and protect with side blowing argon.

[0067] The structure observation, hardness and wear resistance analysis of the prepared cladding layer were carried out.

[0068] Observe the microstructure morphology in the middle of the cladding layer, such as Figure 5 As shown, there are a large amount of unmelted bulk NbC in the cladding layer, and a small amount of precipitated NbC, such as Figure 5 (e) (f) shown.

[0069] The hardness dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com