Method for preparation of Yt-containing TiAl intermetallic compound plate material

A technology of intermetallic compounds and elements, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of difficult deformation, deformation heat processing, difficult to obtain size, etc., to achieve good surface quality and uniform deformation , Improve the effect of rolling deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

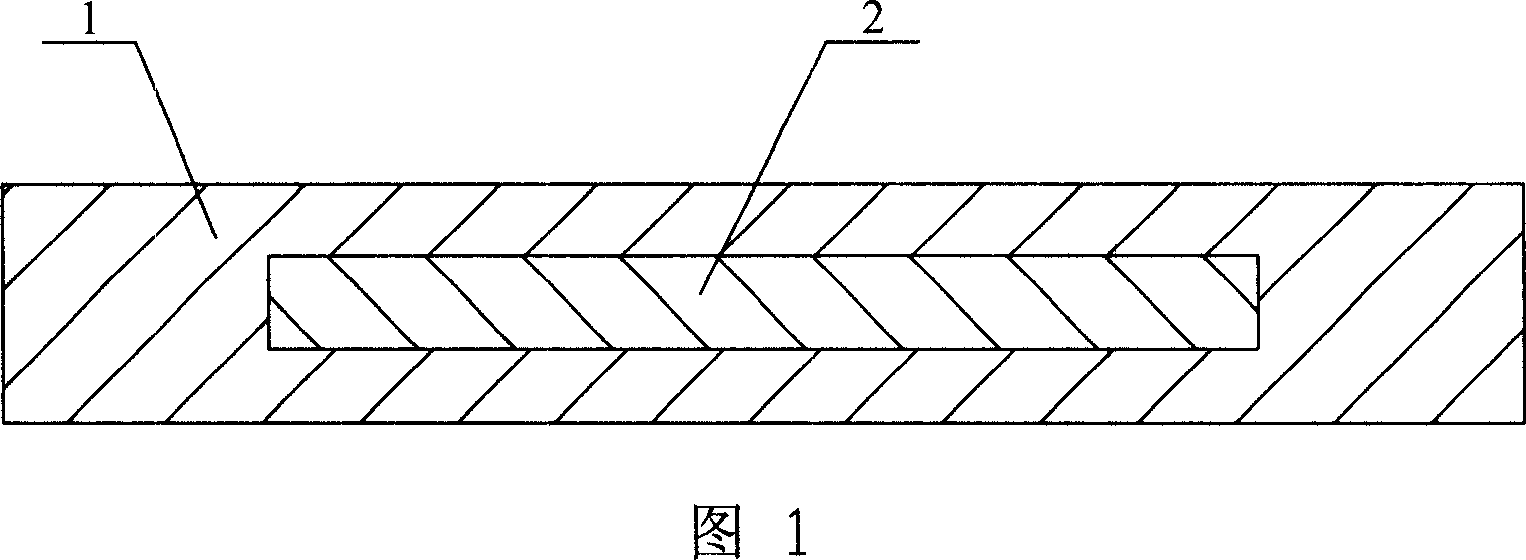

[0012] Specific embodiment one: describe this embodiment in conjunction with Fig. 1, the steps of the preparation method of this embodiment are as follows:

[0013] Step 1, melting and casting the TiAl intermetallic compound ingot containing 0.01-0.6 at.% yttrium element obtained by melting and casting the yttrium content of 0.01-0.6 at.%, the aluminum content of 35-55 at.%, and the titanium content of 44.9-64.4 at.%. The ingot needs to be annealed at 800-1200°C for 10-80 hours, and hot isostatic pressing at 1200-1280°C and 150-250MPa for 3.5-4.5 hours, and then the ingot A square billet cut from the top; or a square billet cut from a TiAl intermetallic compound material containing 0.01 to 0.6 at.% yttrium element obtained through heat treatment, forging or extrusion, etc.;

[0014] Step 2. Select stainless steel, pure titanium or titanium alloy as the sheath material to make a sheath. The thickness of one side of the sheath is 2mm to 30mm. The sheath is divided into upper and...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that it also contains Nb, Cr, Mn, V, Ni, W, Hf, Ta, Mo, Zr, Si, One or more of Y, La, Ce, C, B and other elements, but the total content of elements added is less than 20 at.%.

specific Embodiment approach 3

[0020] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that the Ti-47Al-2Nb-2Mn-0.2Yat.% alloy ingot obtained through the melting and casting process in step 1, with a thickness of 10mm, is cast at 800°C , heat preservation for 48 hours annealing treatment, under the conditions of 1250 ° C and 170 MPa, carry out hot isostatic pressing treatment for 4 hours, and then cut into square billets; Step 3, wrap the square billets in a 304 stainless steel sheath, the thickness of the sheath 6mm; step 4, put it in a heat treatment furnace and heat it to 1050°C, and keep it warm for 30 minutes, then put it on a Φ500×846mm two-roller reversible hot rolling mill, the rolling pressure is 400T, and the rolling speed is 0.5m / s. The amount of deformation in each pass is 10%, and the rolling is carried out by returning to the furnace for 15 minutes between passes. After rolling, return to the furnace, cool to 600°C with the furnace, and then air-cool to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com