Electroplastic rolling method and apparatus for deformable magnesium alloy sheet, band and wire rod

A deformed magnesium alloy, electroplasticity technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of poor quality of hot-rolled products, high cost of cold-rolled processing, and low performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: The incoming material is a fully annealed AZ31 magnesium wire with a diameter of 1.7 mm, which is compared with cold rolling and electroplastic rolling.

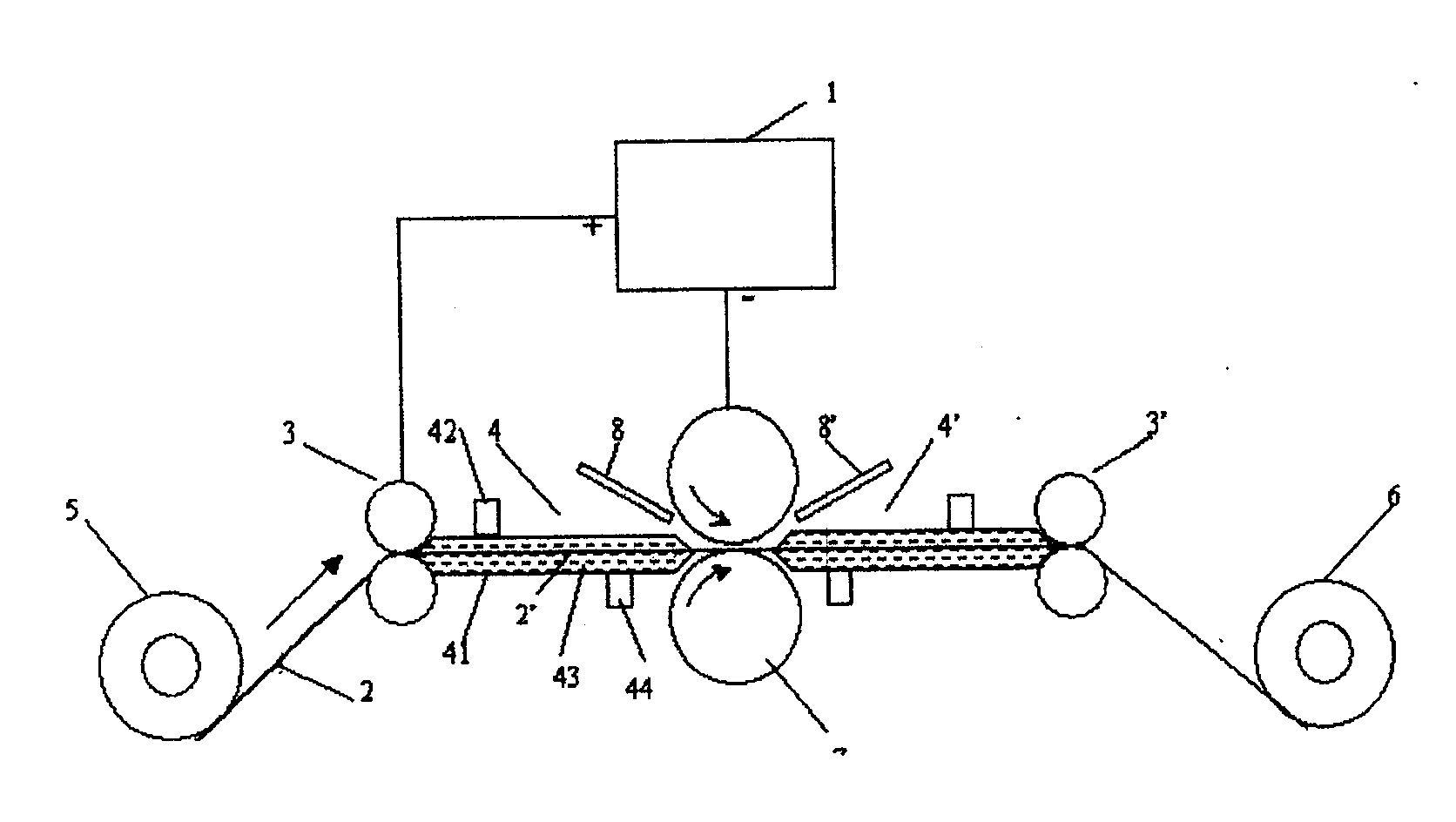

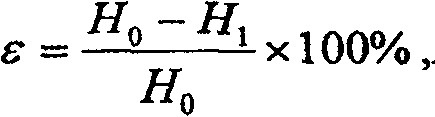

[0024] Refer to electroplastic rolling figure 1 , the tension of the continuous magnesium material 2 is controlled by the unwinding and rewinding device, and the two-roll rolling mill with a work roll diameter of 100 mm is driven to roll at the entrance speed of 3 mpm in the direction of the arrow. The imported magnesium material is introduced into high-energy continuous electric pulses, and the positive and negative poles are respectively conductive wheels 3 (60mm in diameter) and rolls 7 (the distance between the positive and negative poles being 150mm) made of copper-graphite are connected to the electric pulse power supply 1. The electrical section 2' is subjected to forced cooling by cooling device 4, the circulating cooling medium is quenching oil, the cooled oil is pumped through the inlet 42, and th...

Embodiment 2

[0026] Example 2: The incoming material is a fully annealed AZ31 magnesium strip with a thickness of 0.8 mm and a width of 2. mm, compared between electroplastic rolling and cold rolling to a thickness of 0.7 mm.

[0027] The device configuration of the electroplastic rolling process is exactly the same as that of the specific embodiment 1 except that the center distance between the positive and negative electrodes is adjusted to 200 mm. At the same time, the high-energy continuous pulse electrical parameters input at this time are changed to: pulse width 60μs, frequency 400Hz, current density 1500A / mm 2 .

[0028] During the rolling process, the deformation resistance of electroplastic rolling is 17% lower than that of cold rolling (on-line test with a 5-ton pressure sensor), and the comparison of material properties after rolling: the tensile strength of electroplastic rolling samples is 295Mpa, and the elongation is 6.5 %; while the tensile strength of the cold-rolled samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com