(HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of high-entropy ceramic powder and high-entropy ceramic blocks

A technology of ceramic powder and ceramic powder, which is applied in the field of preparation of high-entropy compound materials, can solve problems such as the inability to realize the preparation of bulk ceramics and limit the application of high-entropy carbide ceramics, and achieve the effect of fine grain size and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of (HfTaZrTiNb)C high-entropy bulk ceramic powder, the specific steps and process parameters are as follows:

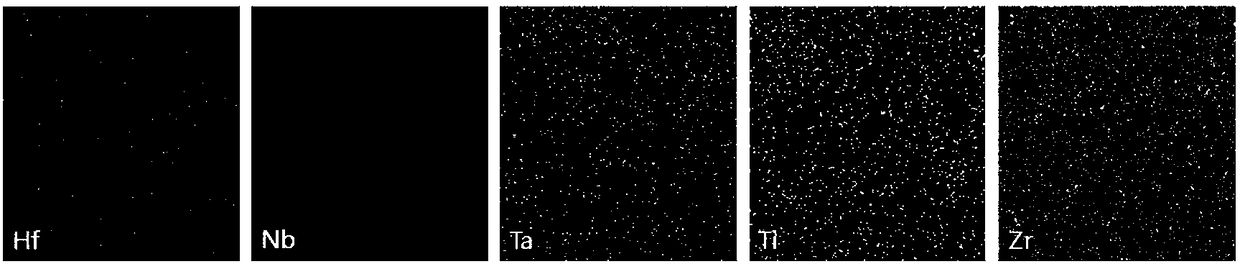

[0028] Step 1. Preparation of amorphous ceramic powder: Weigh five powders of TaC, HaC, NbC, TiC, and ZrC in equimolar ratios in a glove box filled with argon, add a small amount of stearic acid, and put the powder into In the cemented carbide tank, the selected ball-to-material ratio is 9:1, the rotational speed is 550r / min, every 1h of ball milling is intermittent for 5min, and a total of 8h of ball milling is obtained to obtain an amorphous ceramic mixture with uniform composition;

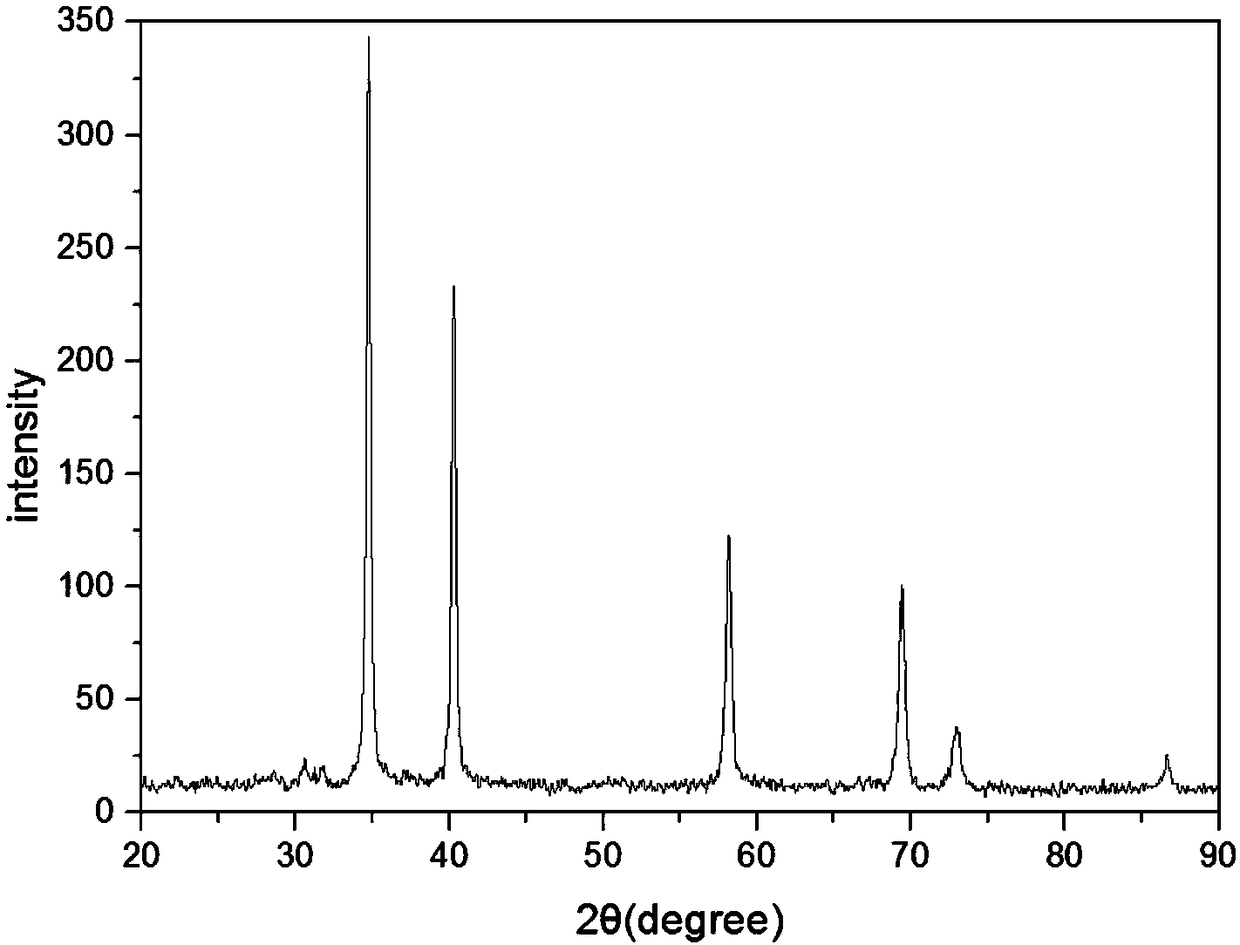

[0029] Step 2. Preparation of high-entropy ceramic powder: heat-treat the ceramic powder obtained in step 1 at 1400° C. for 6 hours to obtain (HfTaZrTiNb)C crystalline high-entropy ceramic powder.

Embodiment 2

[0031] The amorphous ceramic powder in Example 1 is prepared into a high-entropy ceramic block: the amorphous ceramic powder is packed into a graphite mold in a glove box, and the graphite mold is sealed, and then the mold is placed in a discharge Sintering is carried out in a plasma furnace to obtain (HfTaZrTiNb)C bulk ceramics.

Embodiment 3

[0033] Prepare the high-entropy ceramic powder obtained in step 2 of Example 1 into a high-entropy ceramic block: put the high-entropy ceramic powder into a graphite mold in a glove box, seal the graphite mold, and then place the mold in Sintering is carried out in a discharge plasma furnace to obtain (HfTaZrTiNb)C bulk ceramics.

[0034] The sintering process of described embodiment 2 and embodiment 3 is as follows:

[0035] Sintering equipment: spark plasma sintering furnace

[0036] Heating method: AC pulse current

[0037] Sintering temperature: 1700°C

[0038] Sintering time: 7min

[0039] Sintering pressure: 30MPa

[0040] Heating rate: 75°C / min

[0041] The average grain size of the sintered (HfTaZrTiNb)C high-entropy ceramics is 5um, the weight gain after 10h oxidation is 13%, and the KIC is 4.5MPa.m 1 / 2 , compared with the performance of ceramics prepared from five kinds of raw material powders, the oxidation resistance and KIC of (HfTaZrTiNb)C high-entropy cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com