Patents

Literature

212results about How to "Fast sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

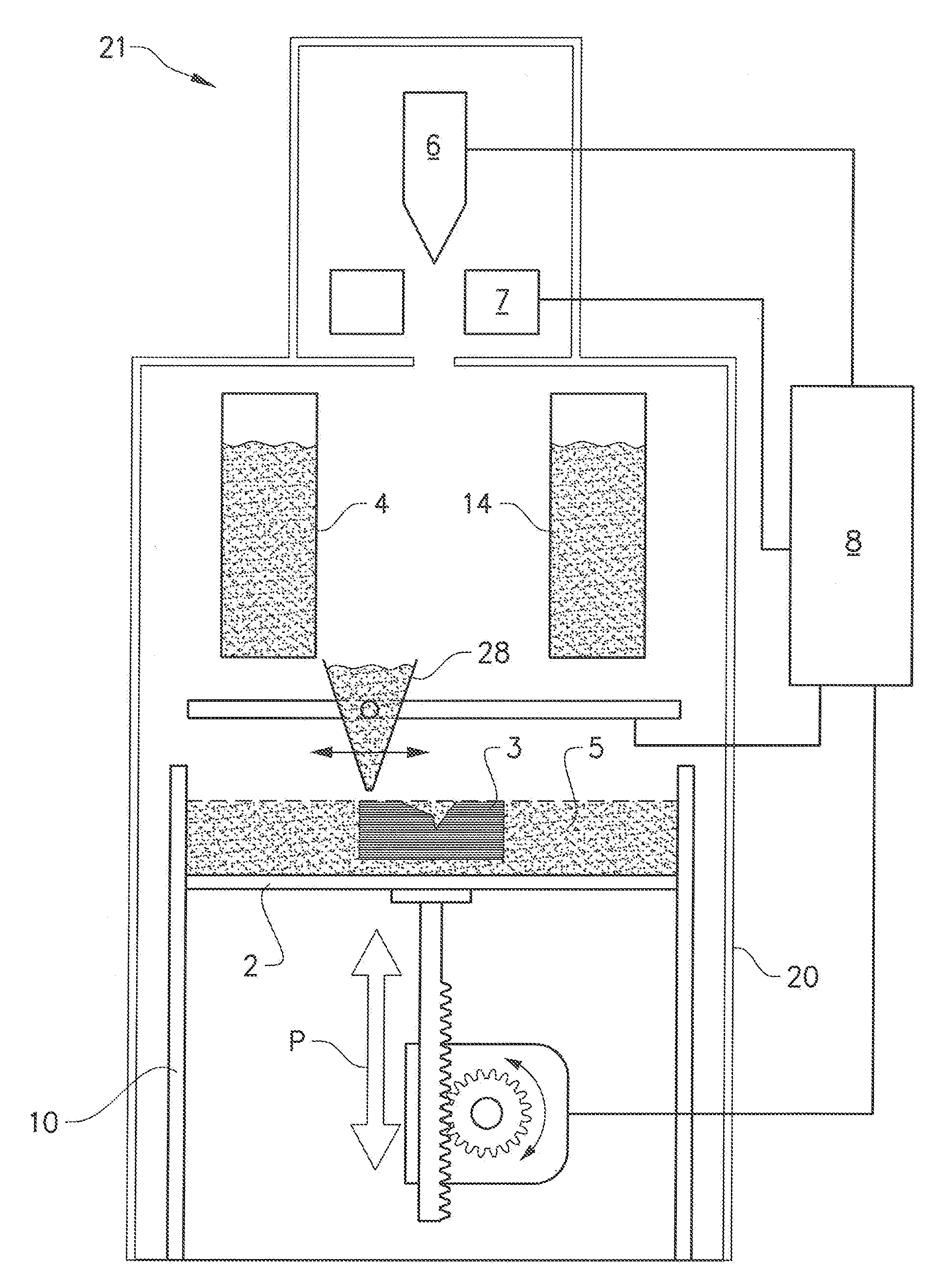

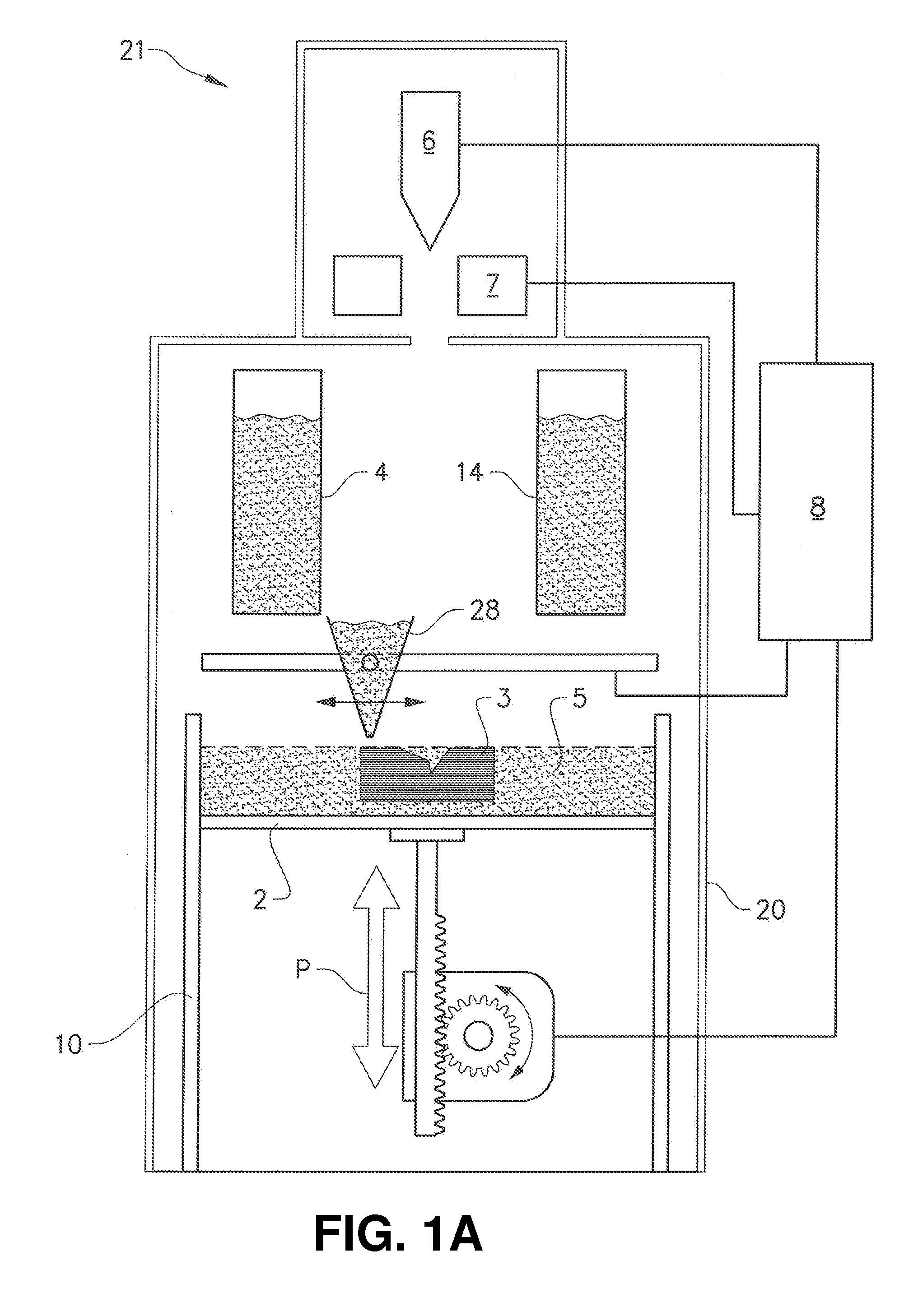

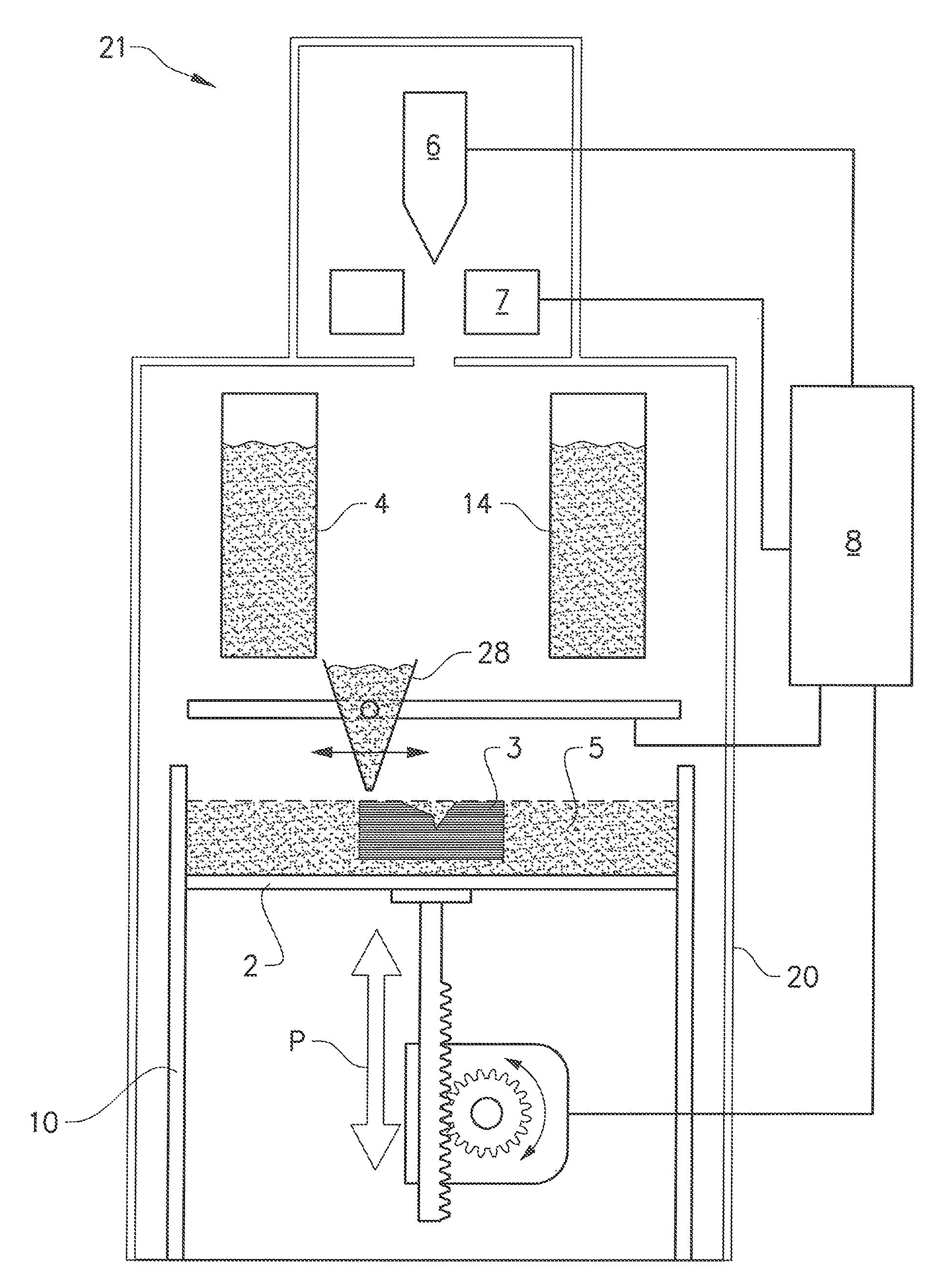

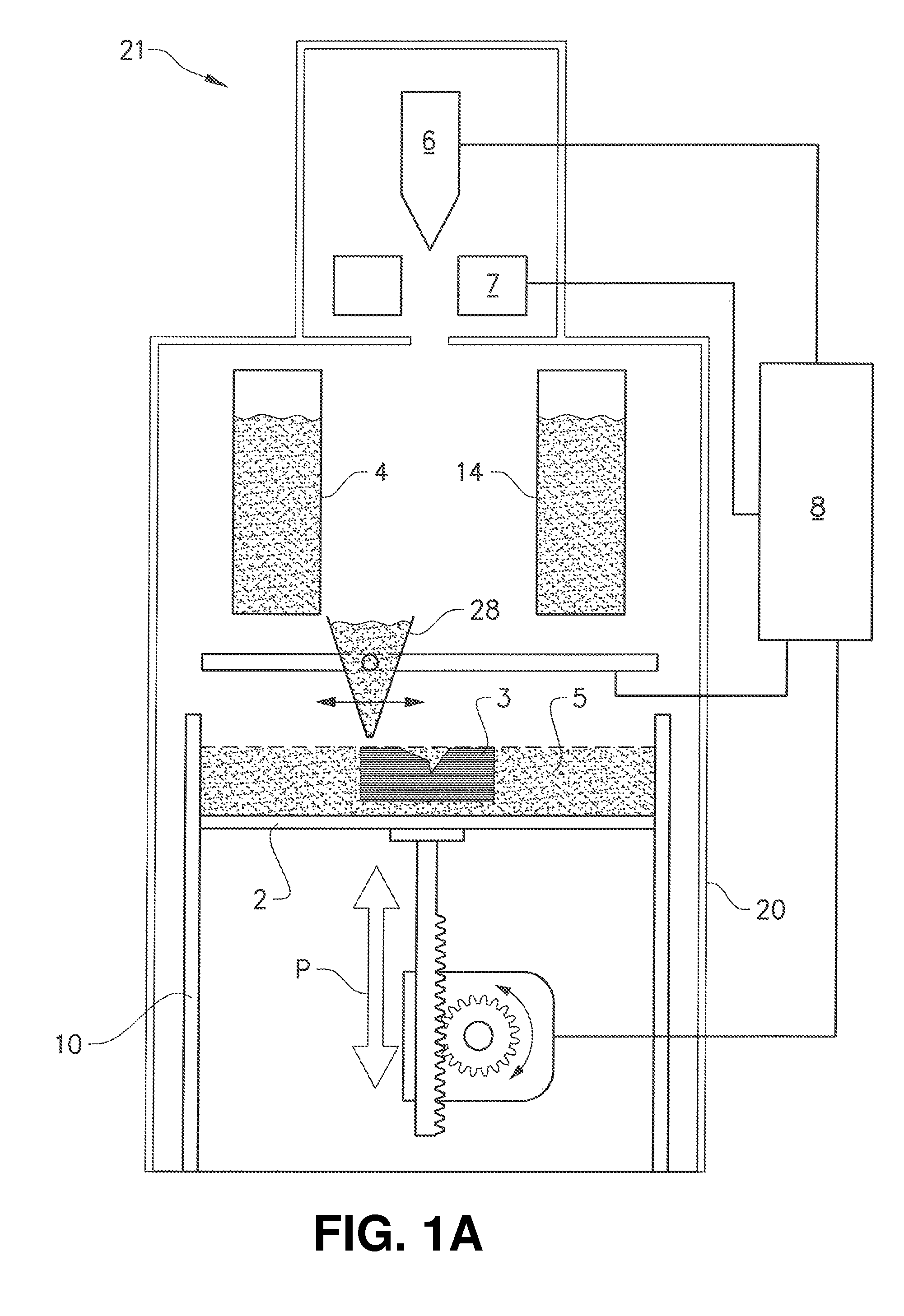

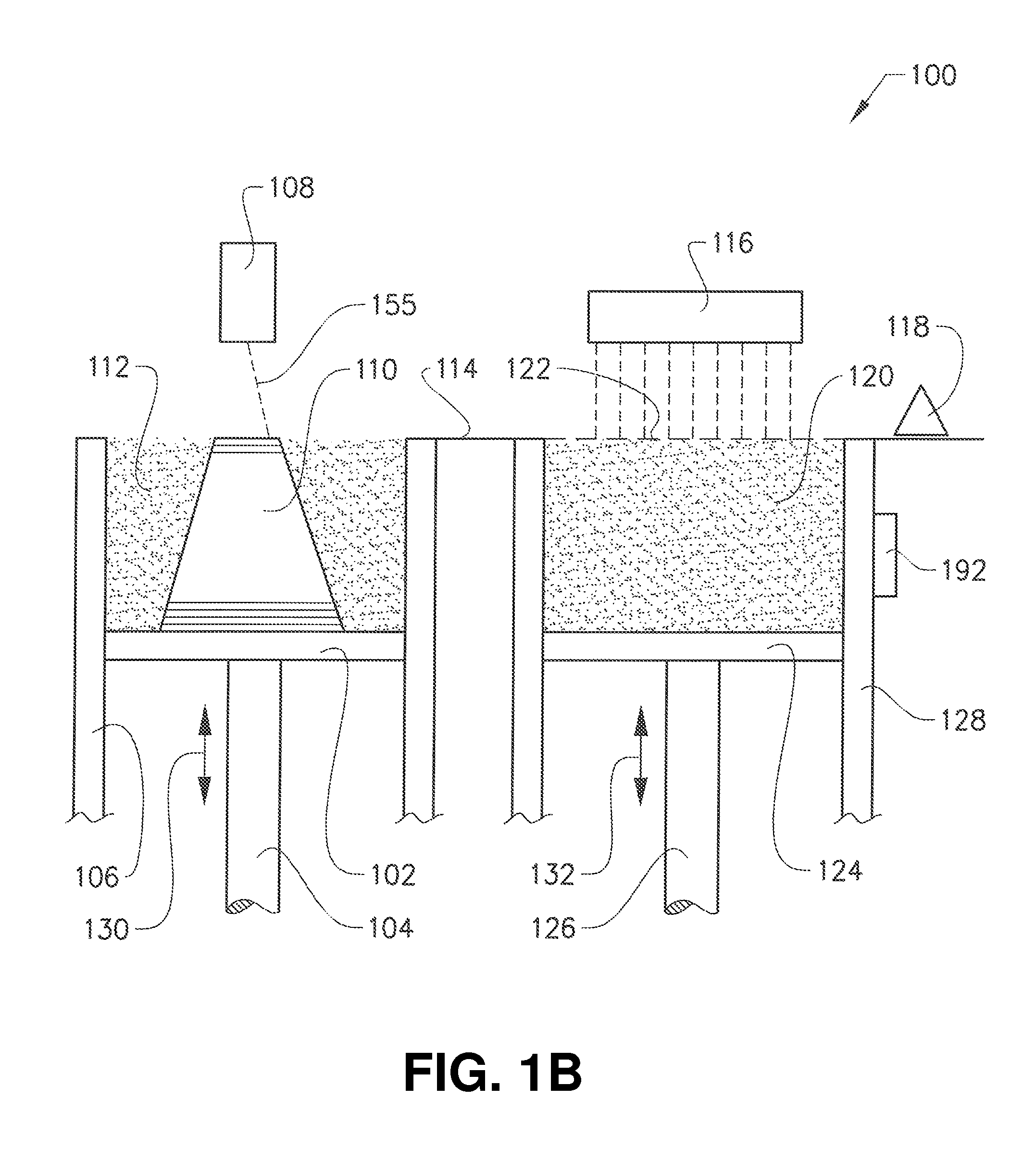

Method and apparatus for additive manufacturing

ActiveUS20140314964A1Improve conductivityReduce probabilityVacuum evaporation coatingPretreated surfacesMetallurgyElectron

Various embodiments provide a method and apparatus for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table in an additive manufacturing machine, which parts corresponds to successive cross sections of the three-dimensional article. The method comprises the steps of: applying a layer of predetermined thickness of powder particles on the work table, applying a coating on at least a portion of the powder particles, which coating is at least partially covering the powder particles, and fusing the powder particles on the work table with an electron beam.

Owner:ARCAM AB

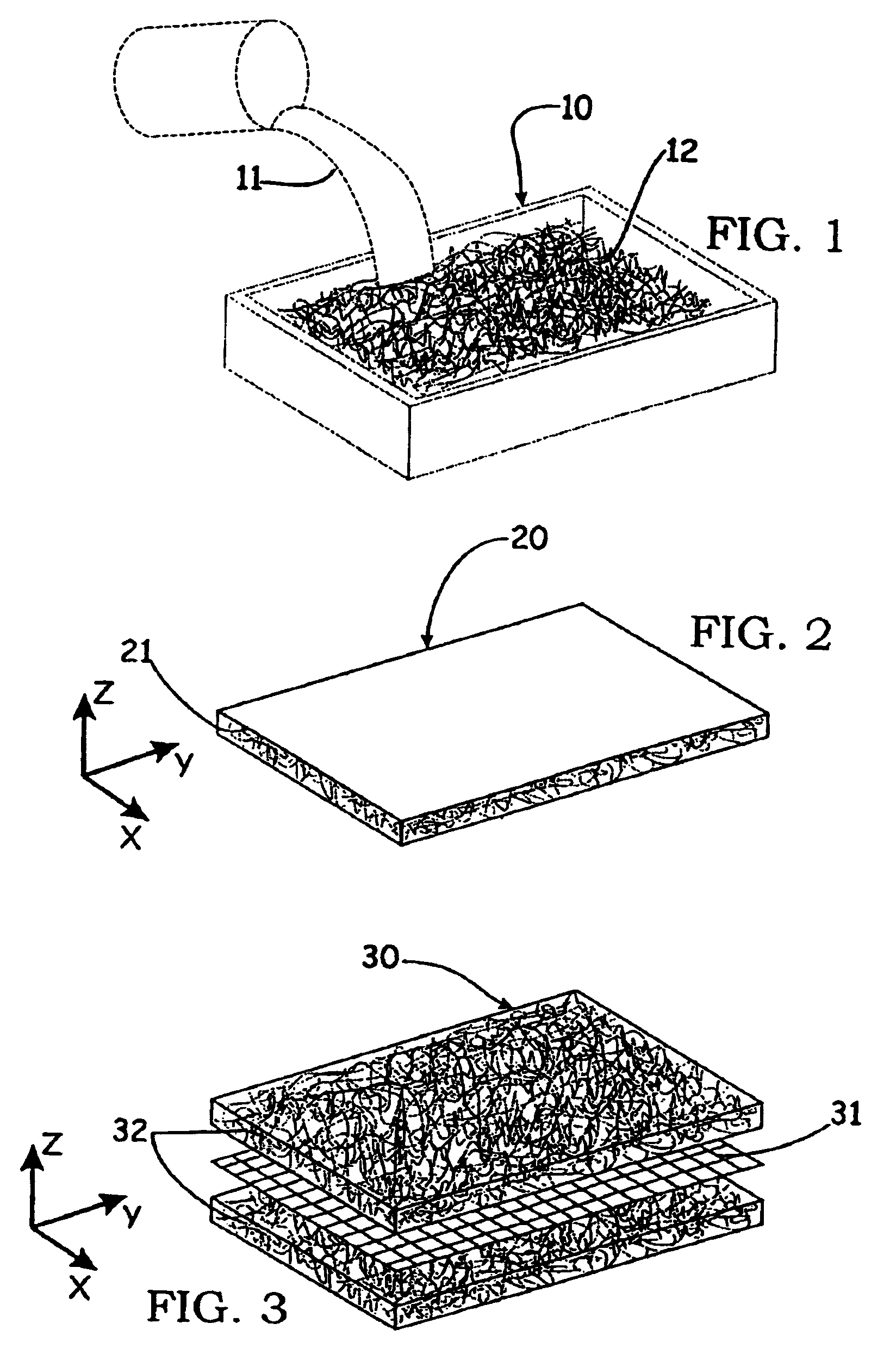

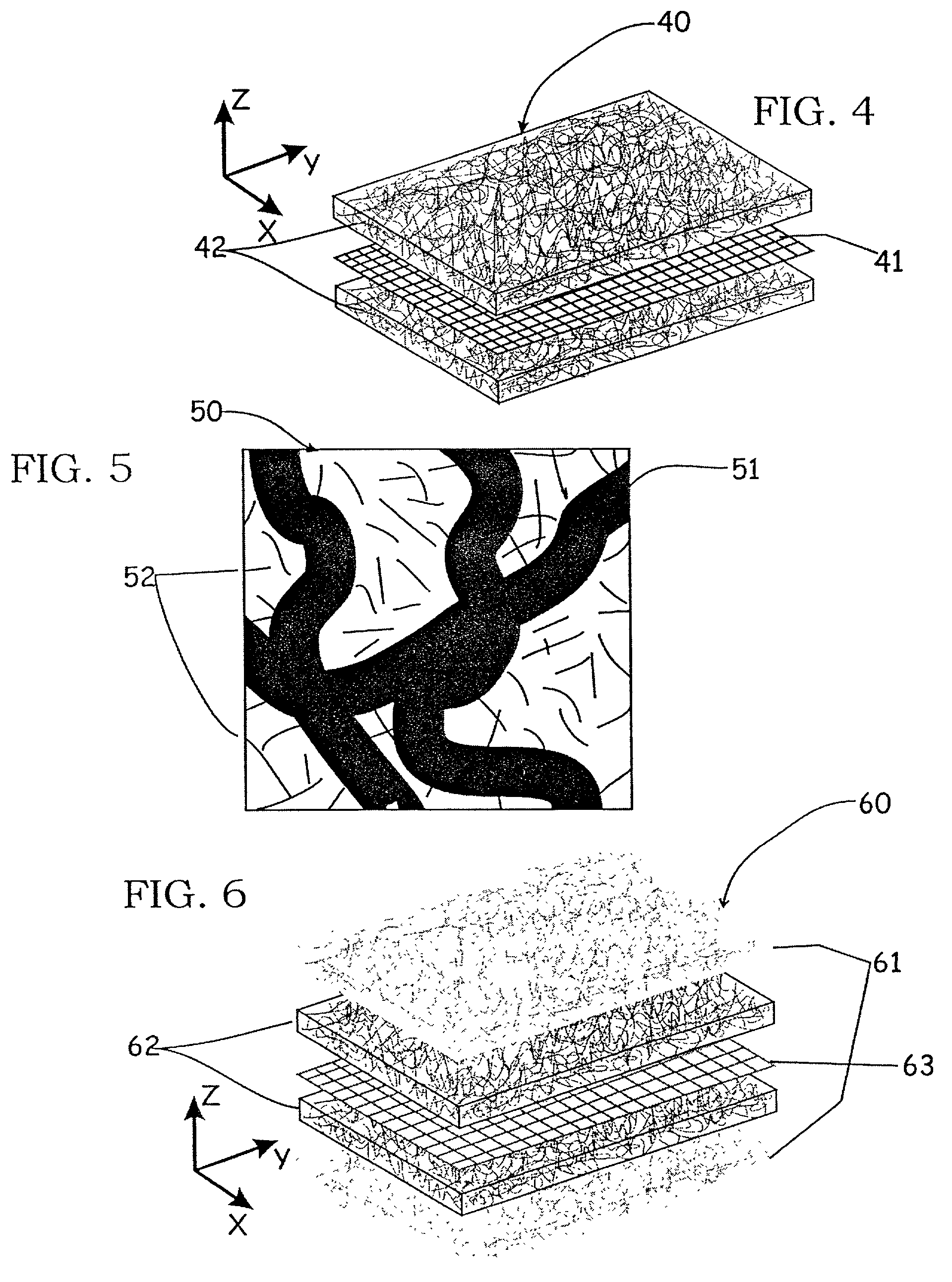

Aerogel composite with fibrous batting

InactiveUS7078359B2Improve thermal efficiencyMinimized volumeShielding materialsCeilingsUltrasound attenuationPliability

Aerogel composite materials having a lofty fibrous batting reinforcement preferably in combination with one or both of individual short randomly oriented microfibers and conductive layers exhibit improved performance in one or all of flexibility, drape, durability, resistance to sintering, x-y thermal conductivity, x-y electrical conductivity, RFI-EMI attenuation, and / or burn-through resistance.

Owner:ASPEN AEROGELS INC

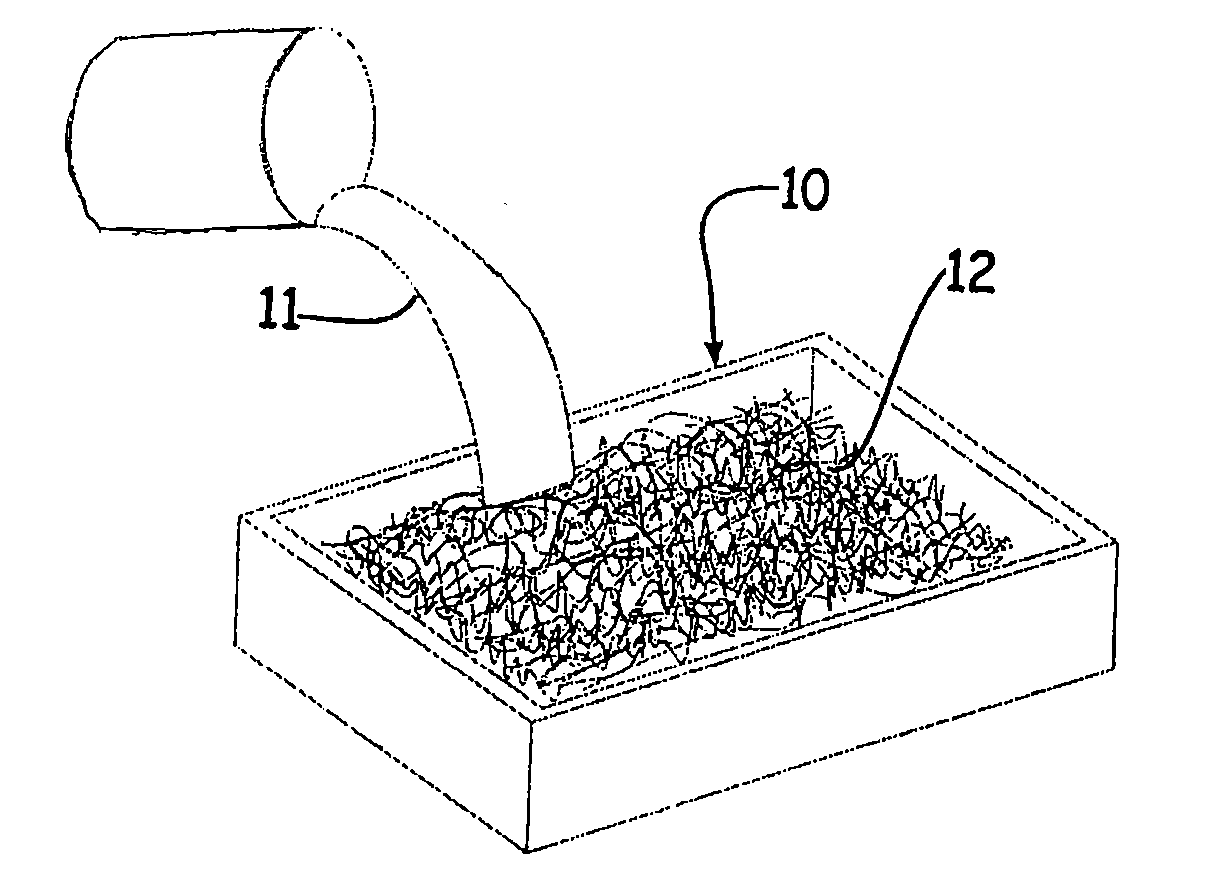

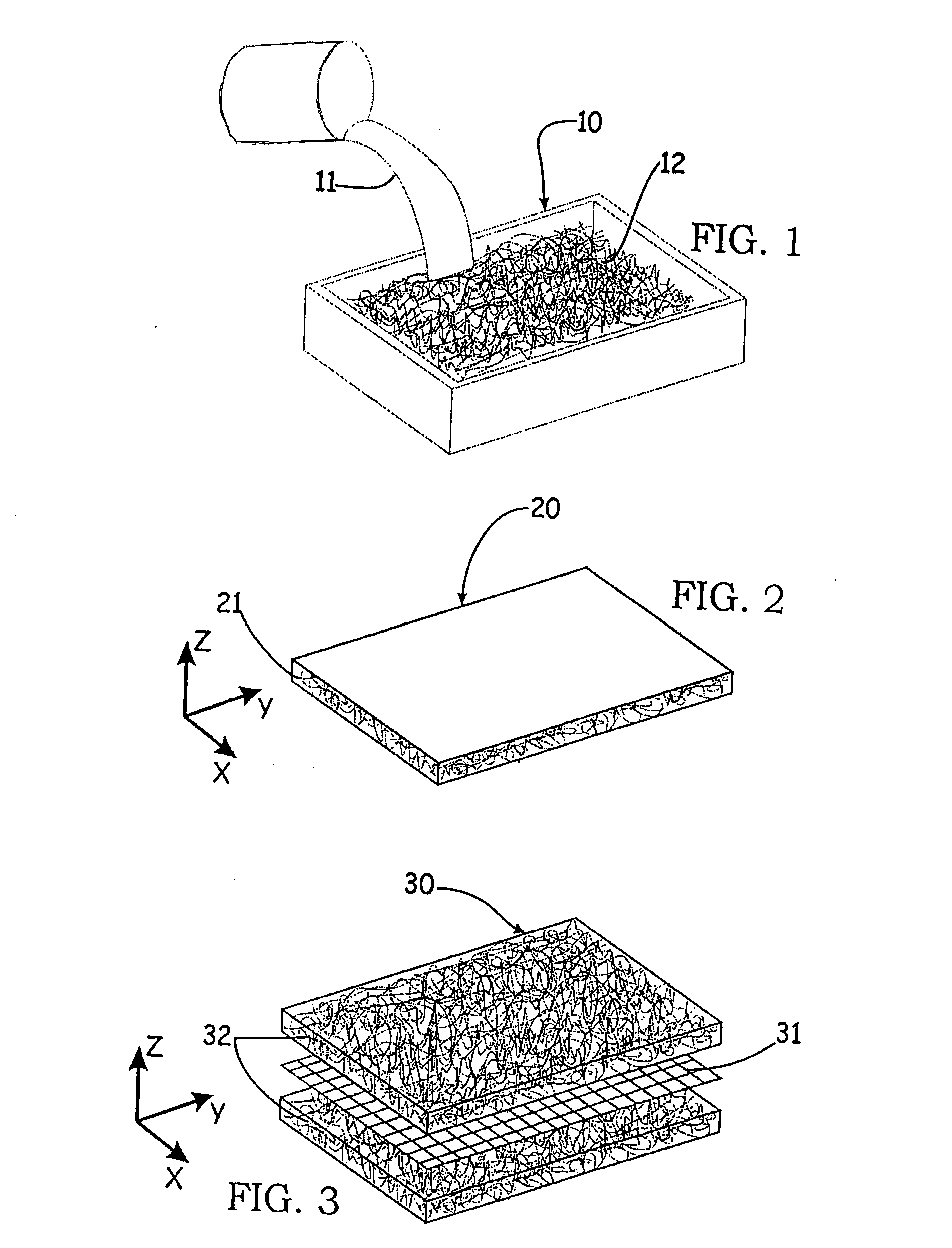

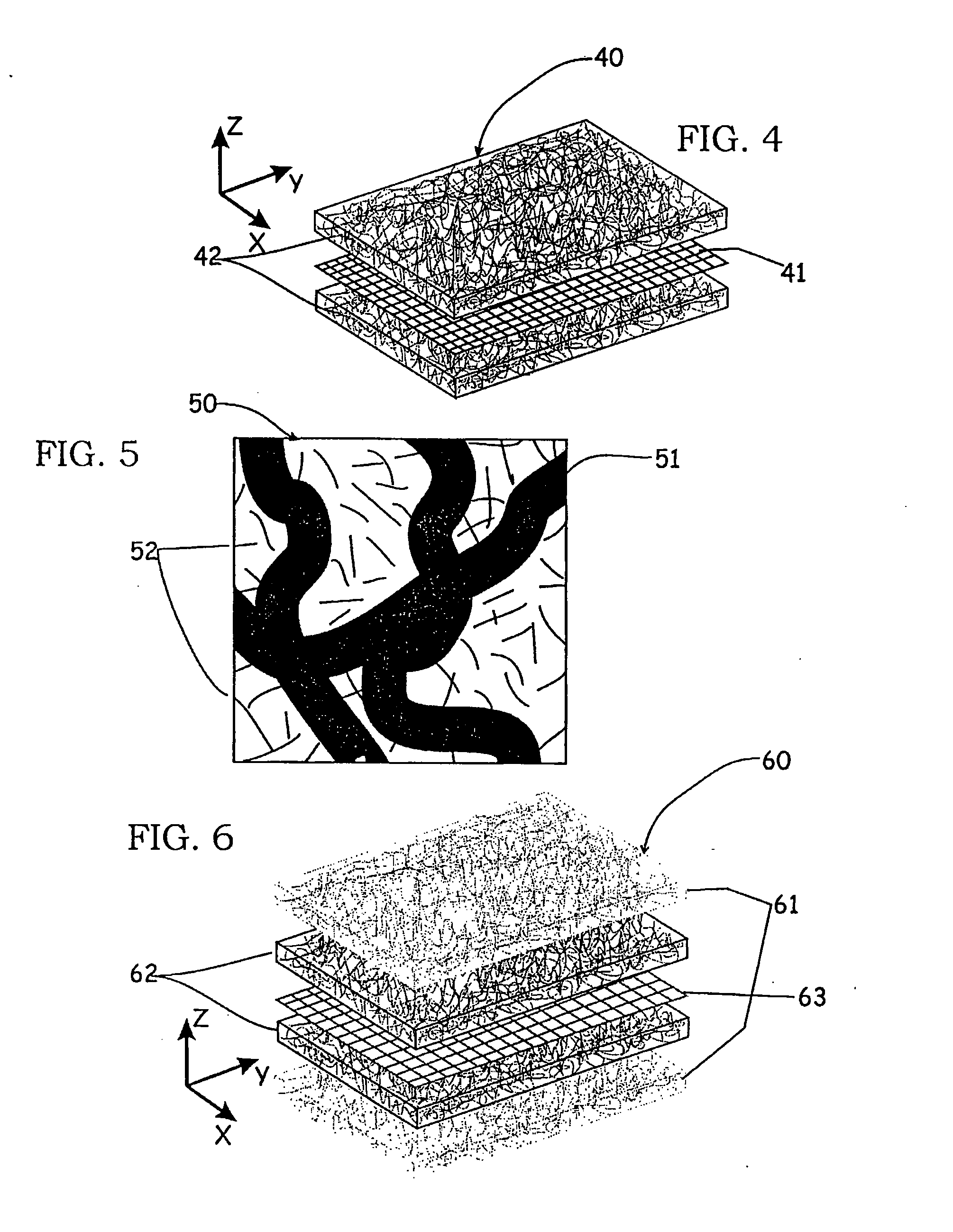

Method and apparatus for additive manufacturing

ActiveUS9550207B2Improve conductivityReduce probabilityAdditive manufacturing apparatusTransportation and packagingPowder bedEngineering

Various embodiments provide a method and apparatus for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table in an additive manufacturing machine, which parts corresponds to successive cross sections of the three-dimensional article. The method comprises the steps of: applying a layer of predetermined thickness of powder particles on the work table, applying a coating on at least a portion of the powder particles, which coating is at least partially covering the powder particles, and fusing the powder particles on the work table with an electron beam.

Owner:ARCAM AB

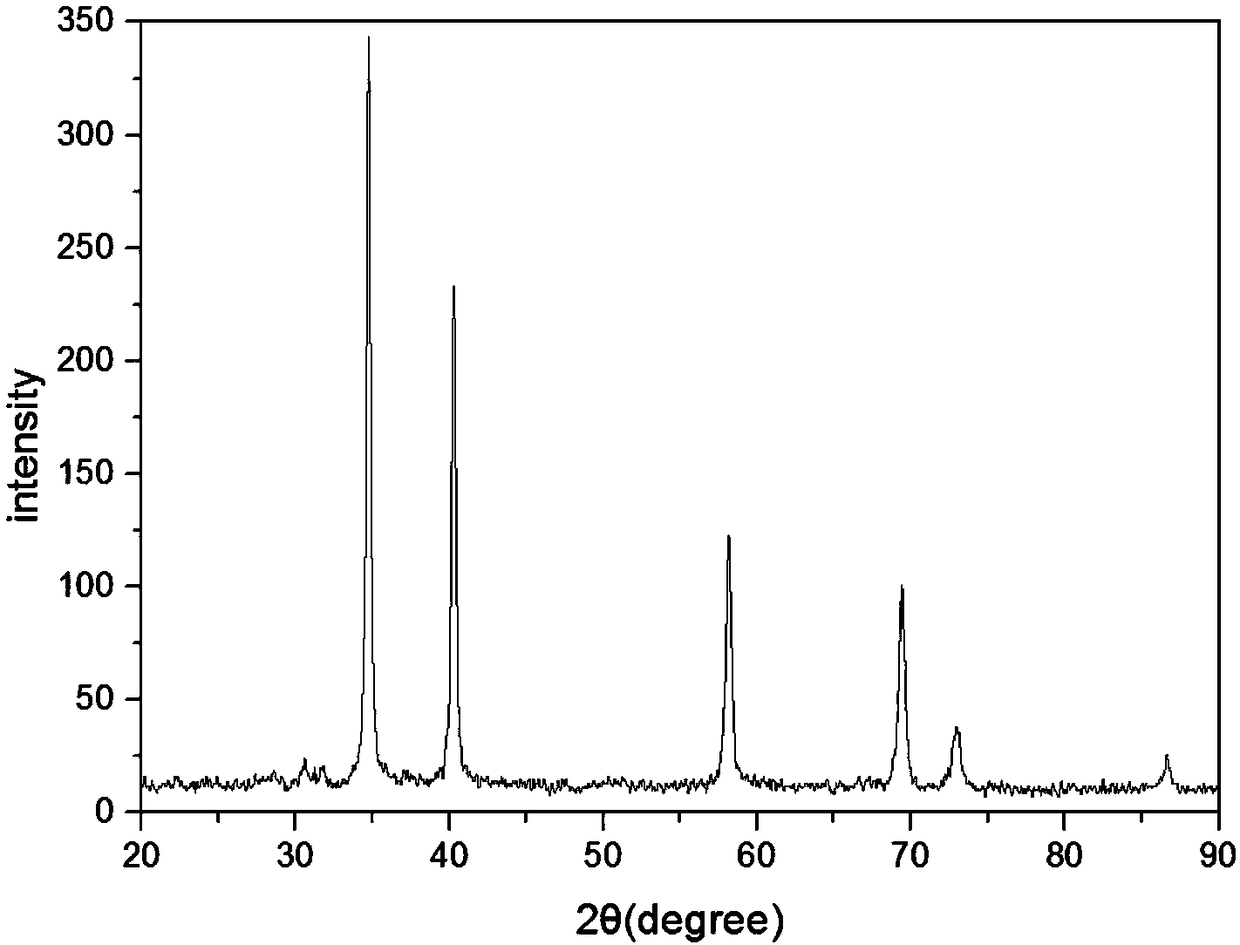

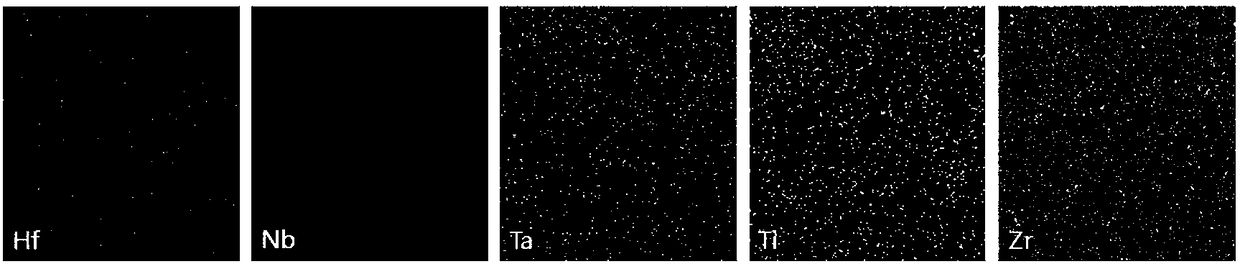

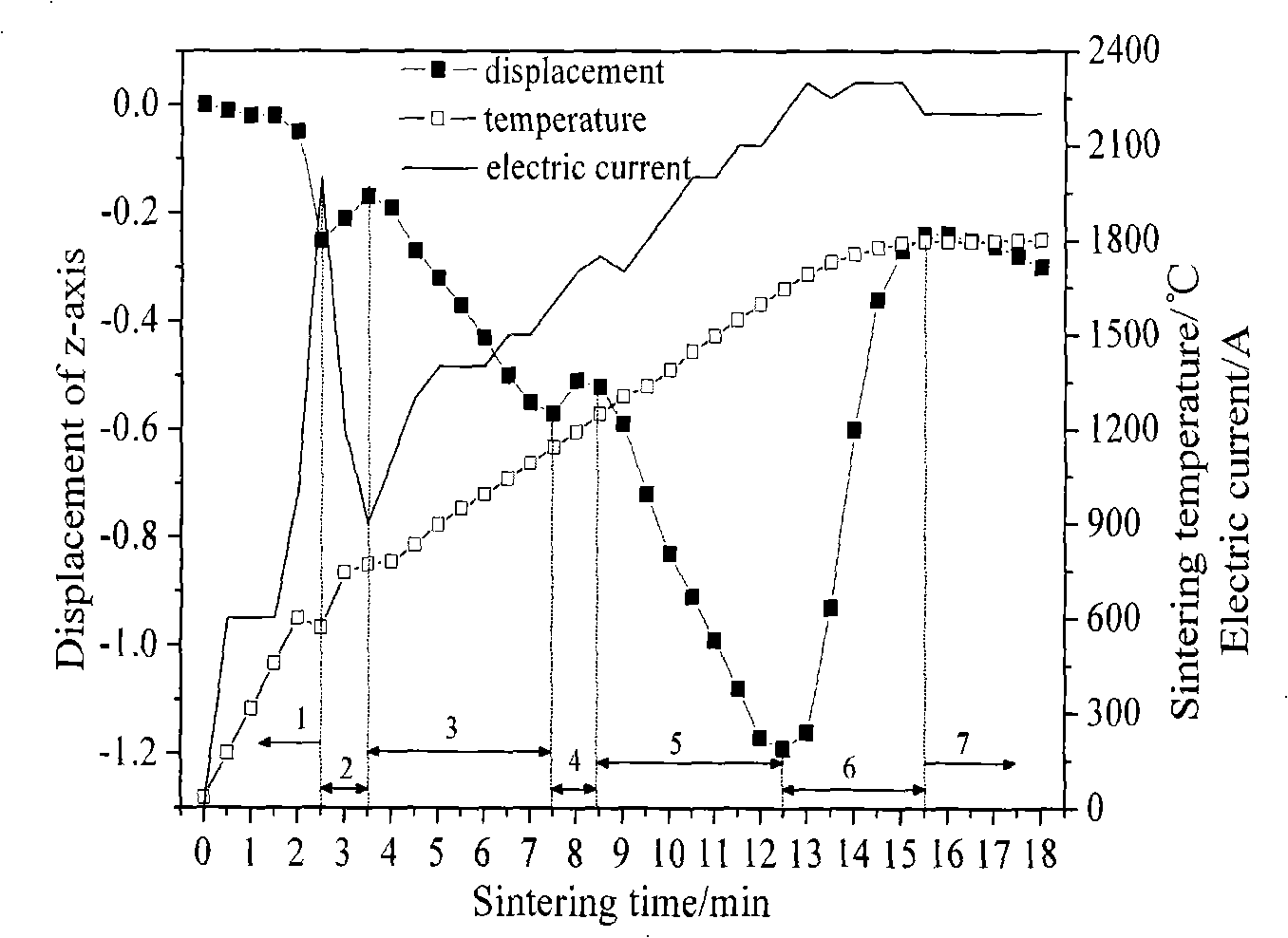

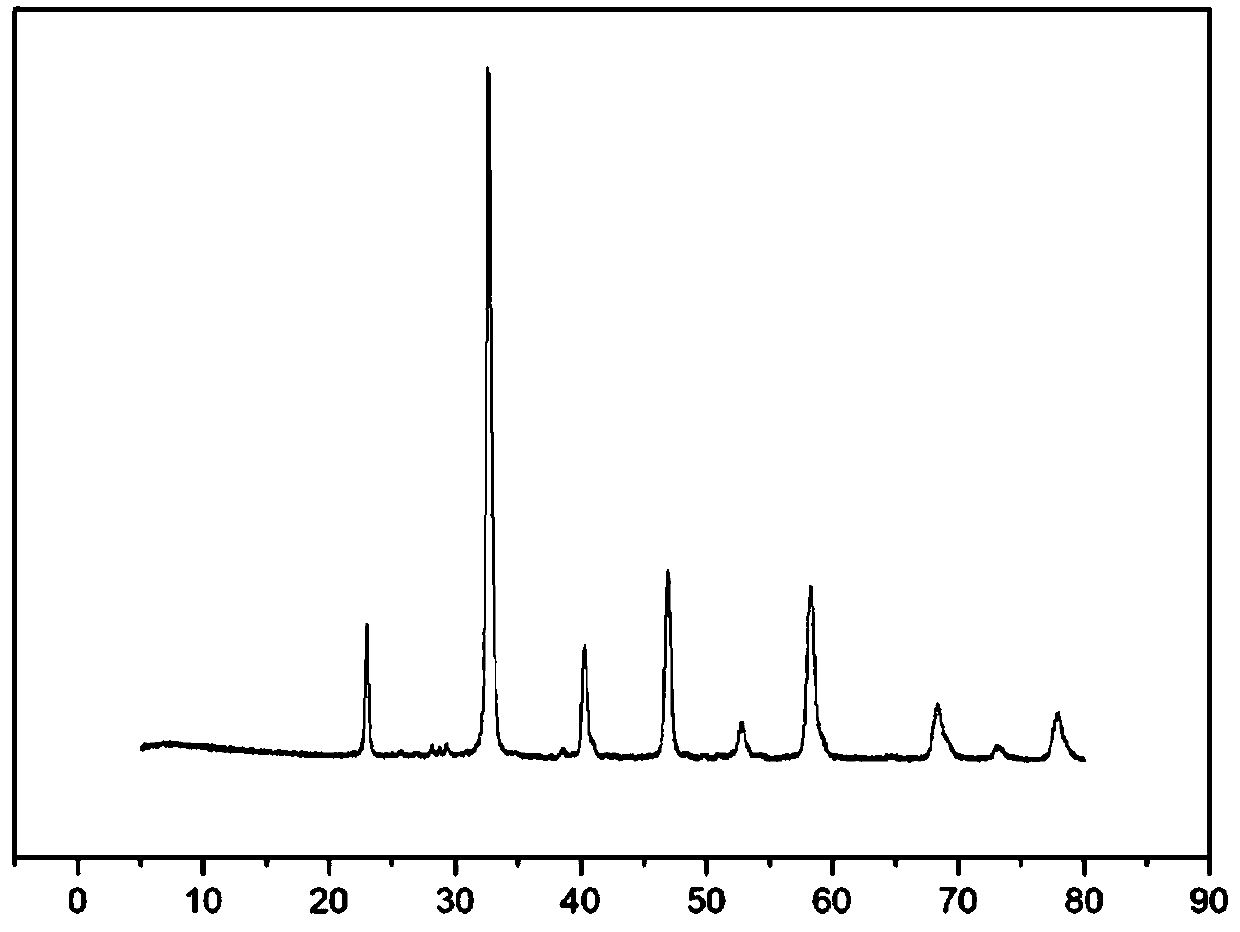

(HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of high-entropy ceramic powder and high-entropy ceramic blocks

The invention relates to (HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of the high-entropy ceramic powder and high-entropy ceramic blocks. Five-face centered cube (FCC) carbonizedpowder is made into ceramic powder through a high-energy ball milling method, then a discharging plasma method is adopted to realize preparation of the high-entropy ceramic blocks, and quick sintering of ceramic within a temperature range of 1700-2350 DEG C can be realized to obtain high-entropy ceramic with single-phase-face centered cube (FCC) structure. The preparation method of (HfTaZrTiNb) Chigh-entropy block ceramic is solved; the high-entropy ceramic with the FCC structure is finally obtained by strictly controlling parameters of a discharging plasma sintering furnace or a hot press furnace and characterizing XRD, so that the ceramic material system is enriched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

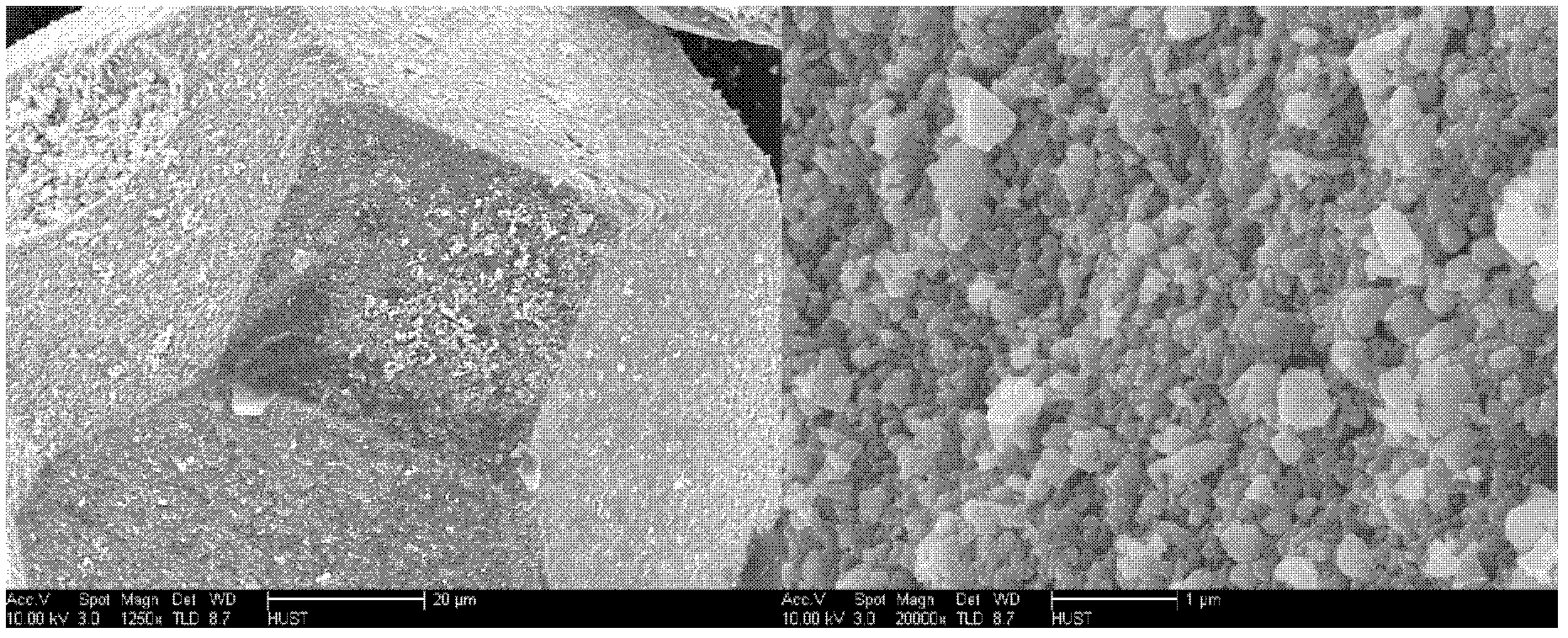

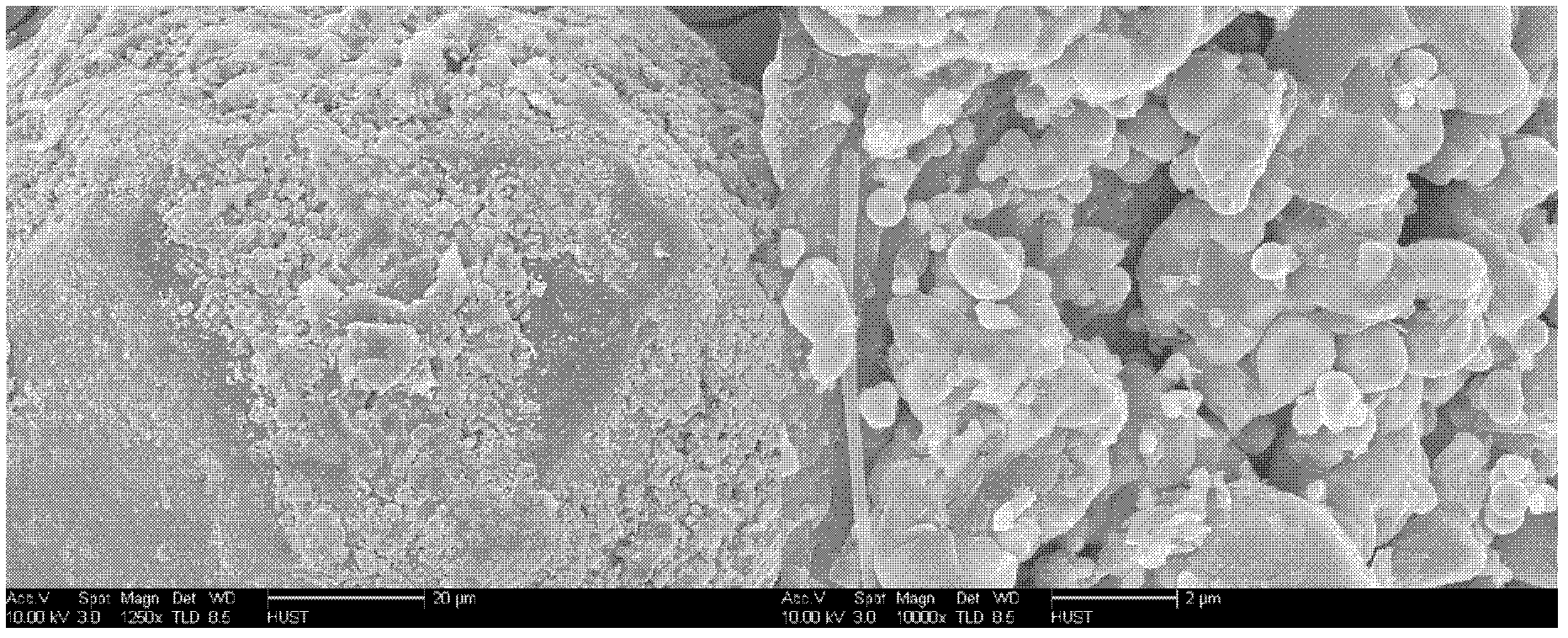

Method for preparing diamond-copper composite material by virtue of metallization of high-temperature blending surface

InactiveCN102383014AImprove wettabilityControllable coefficient of thermal expansionRoom temperatureCarbide

The invention belongs to a preparation technique of a copper-based composite material, and discloses a method for preparing a diamond-copper composite material by virtue of metallization of a surface. The method comprises the following steps of: mixing diamond micropowder with copper powder and powder formed by strong carbide elements, wherein the particle size of diamond is 80-300mu m, the content of the strong carbide elements is 1-10wt%, and the mass fraction of the copper powder is 20%-85%; blending the obtained mixed powder for 10-90 minutes at the temperature of 1050-1150 DEG C, and then cooling along with a furnace; sieving to select the powder with the particle size of 80-300 mu m; mixing the mixed powder with the copper powder again, wherein the mass fraction of the copper powderis 40%-95%; quickly heating the mixed powder material to 850-950 DEG C for sintering at the sintering pressure of 30-50MPa; and then, cooling the obtained product to a room temperature along with thefurnace to obtain the diamond-copper composite material. The method for preparing the diamond-copper composite material has the advantages that the operability of the metallization of the surface of the diamond is strong; the process is simple; the wetting property of a matrix and an enhancer in the prepared diamond-copper composite material is improved greatly; and as an electronic encapsulatingmaterial, the composite material has better comprehensive property, wherein the thermal conductivity is up to 672 W / m.K, the thermal expansion is lower than 7.6 mu m / m. DEG C, and the compactness reaches above 96%.

Owner:HUAZHONG UNIV OF SCI & TECH

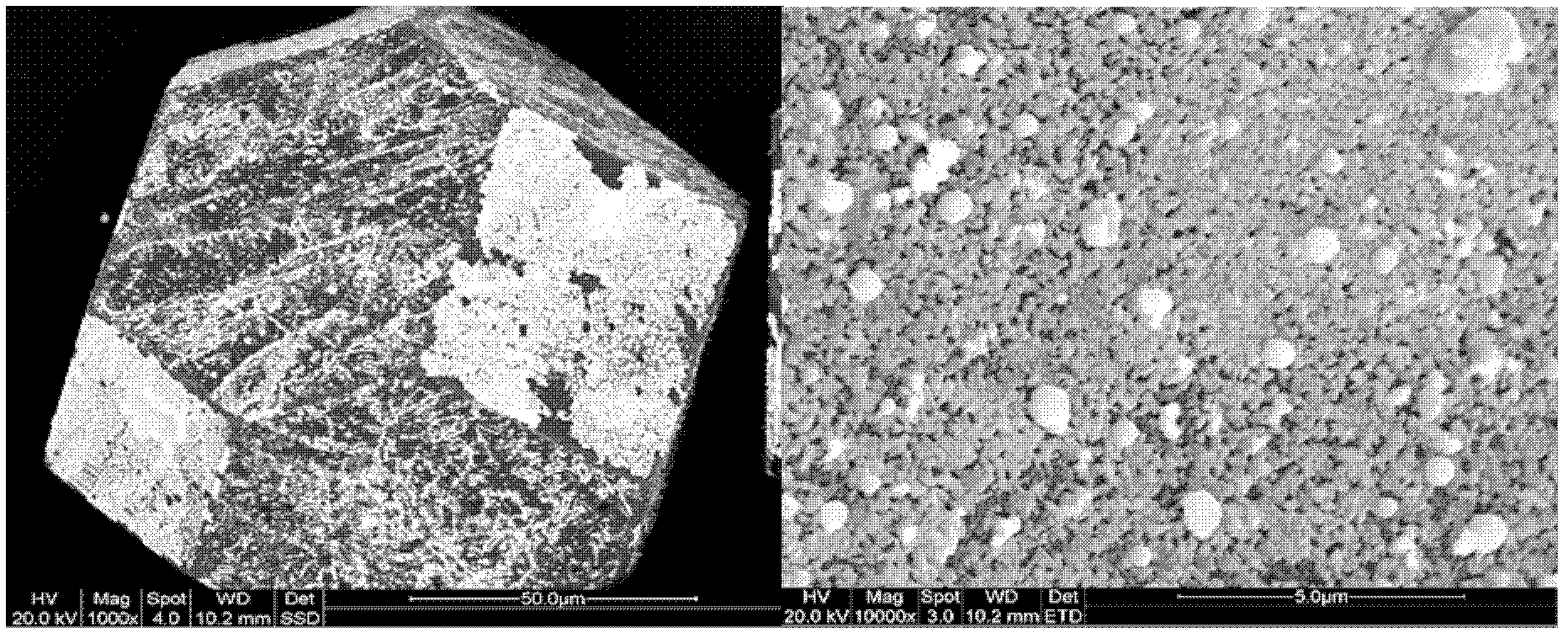

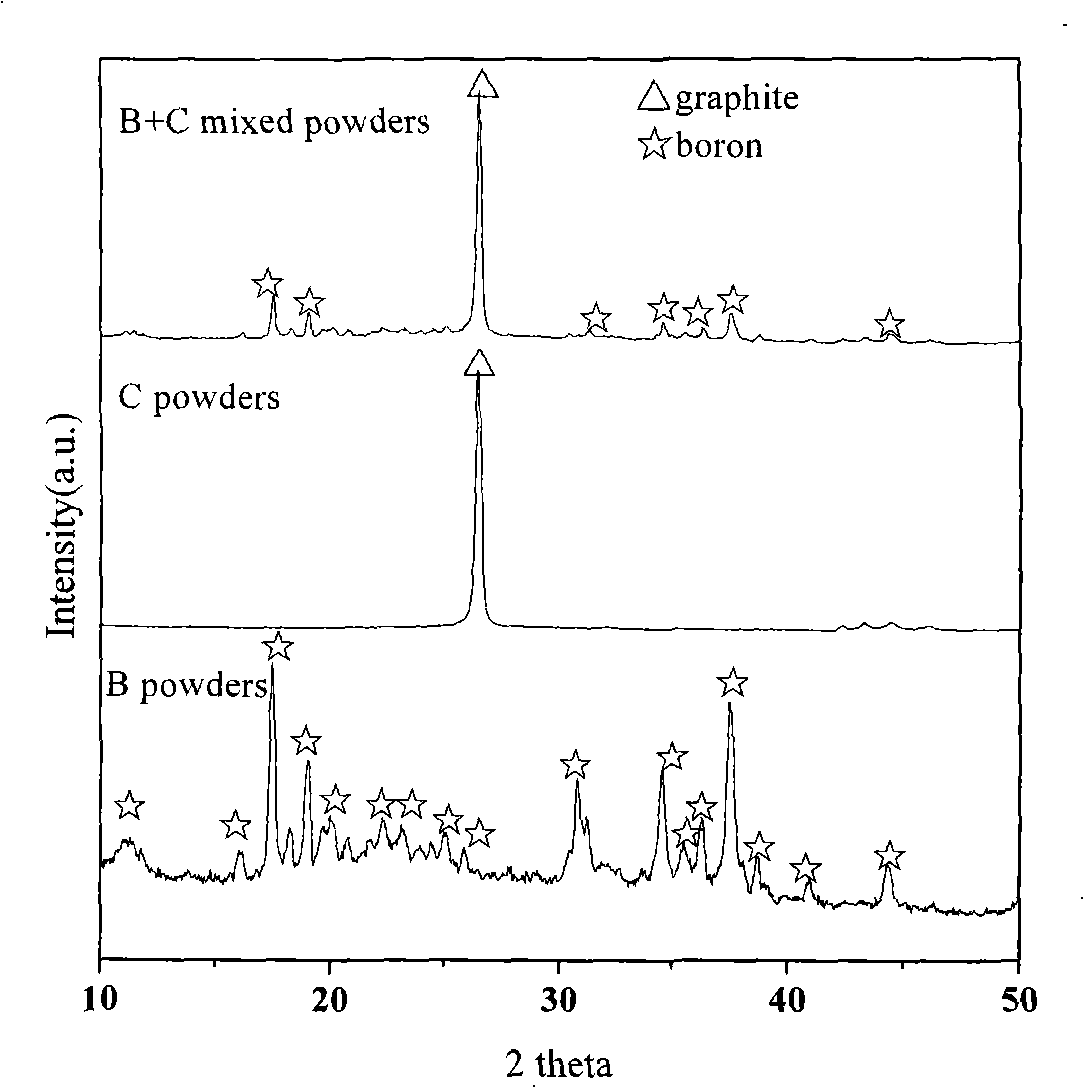

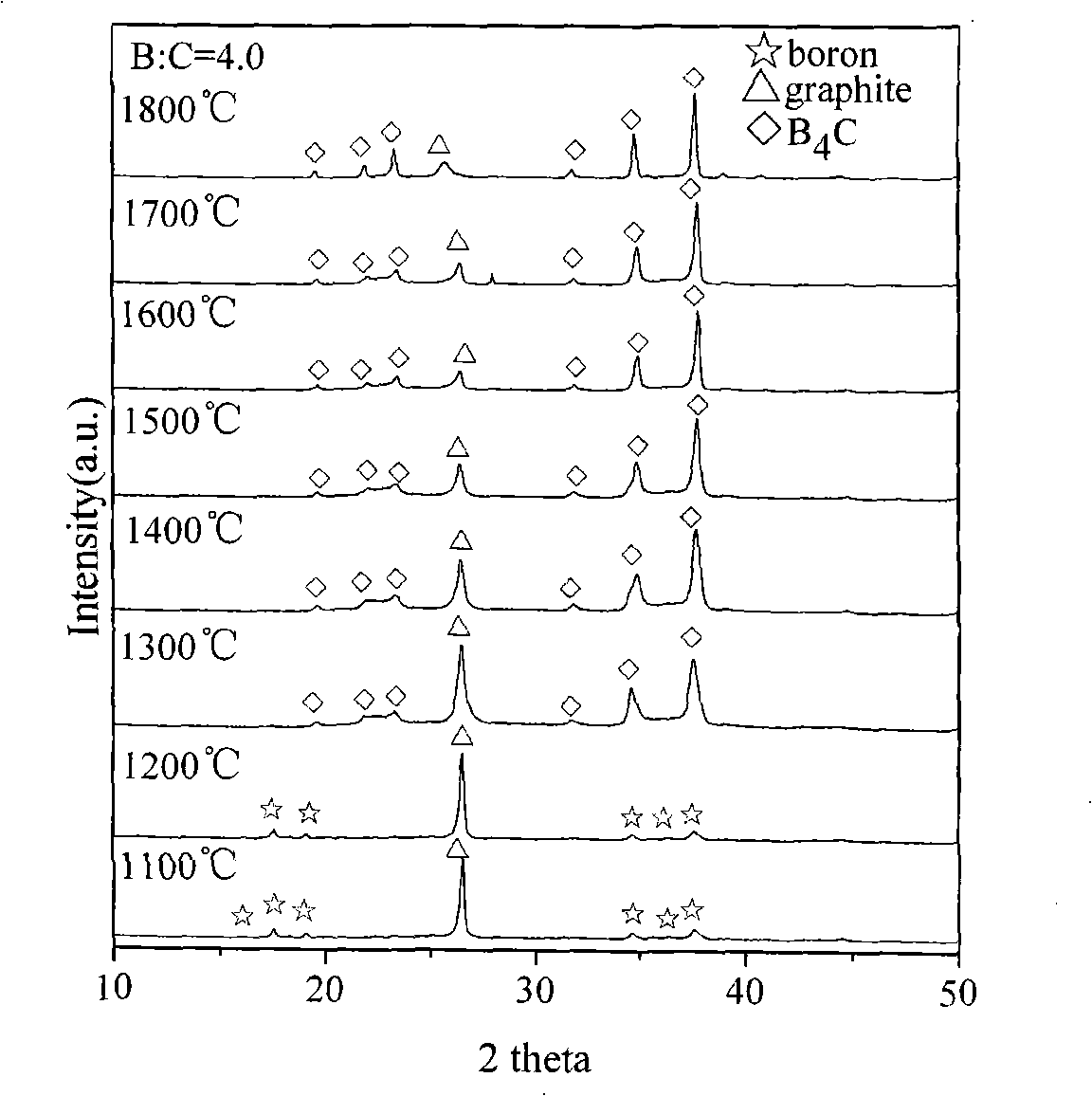

Method for preparing boron carbide ceramic

The present invention relates to a preparation method of boron carbide ceramics. In particular, the preparation method comprises the following steps: first, boron powder and carbon powder are weighed and mixed with the molar ratio of boron and carbon equal to 0.5 to 22.5; secondly, the powder prepared in the first step is arranged in a die and transmitted to discharging plasma sintering equipment for sintering, and the temperature is raised to be between 1300 and 2200 DEG C under the vacuum conditions; thirdly, the die is taken out from the discharging plasma sintering equipment and cooled to be at the room temperature; then the die is drawn away and thus the final product is prepared. In the preparation method, the direct synthesis and densification of boron carbide are completed in one step; the powder is sintered under the vacuum conditions; and the prepared boron carbide ceramics has the advantages of high purity, variety in the ratio of boron and carbon, and high hardness.

Owner:WUHAN UNIV OF TECH

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

Aerogel composite with fibrous batting

InactiveUS20060199455A1Improve thermal efficiencyMinimized volumeShielding materialsNatural cellulose pulp/paperElectrical resistance and conductanceUltrasound attenuation

Owner:ASPEN AEROGELS INC

Nanocrystalline tungsten-based alloy block body material and preparation method thereof

The invention relates to a plastic forming technique and a powder metallurgical technique, in particular to a nano crystal tungsten based alloy block material and a method for preparing the same. The block material comprises the following components in weight percentage: 86 to 88 percent of W, 6.5 to 7.5 percent of Ni, 2.5 to 3.5 percent of Fe, 2 to 4 percent of Mo and 1 to 2 percent of Co. The preparation method comprises the following steps: Fe-Co-Ni and W-Mo after dry mixing are ball milled in advance respectively until the Fe, Co and Ni completely form solid solution, and tungsten phase crystal grain is thinned to below 100nm; the Fe-Co-Ni and W-Mo are subjected to high energy ball milling until the Fe-Co-Ni is evenly distributed around the W-Mo crystal grain; and the discharge plasma rapid sintering is adopted. The nano crystal tungsten based alloy block material has the advantages of reasonable formula, even and thin microstructure, nearly full compact, higher hardness and tensile strength and good specific elongation, and the method for preparing the block material effectively improves the mechanical performances of the sintering material.

Owner:SOUTH CHINA UNIV OF TECH

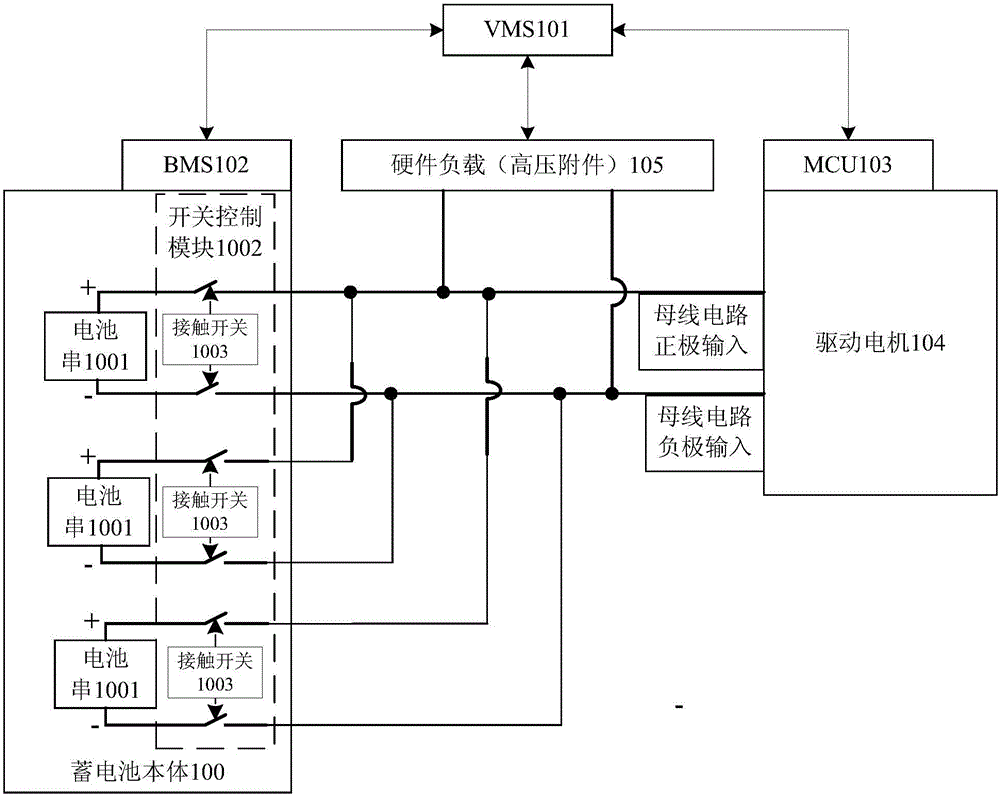

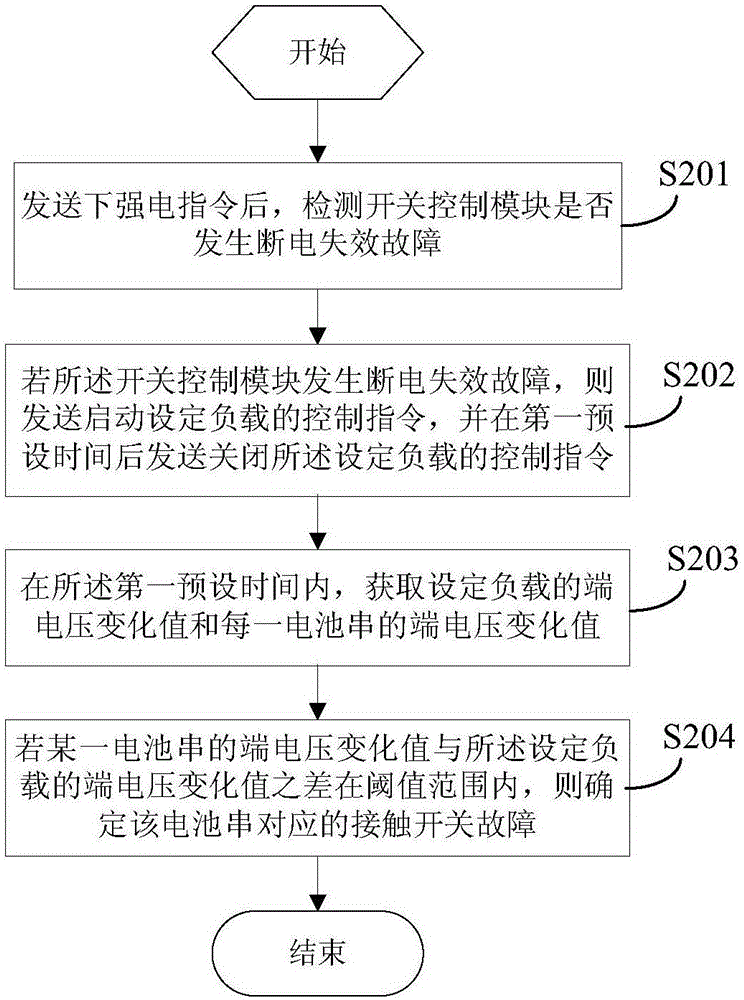

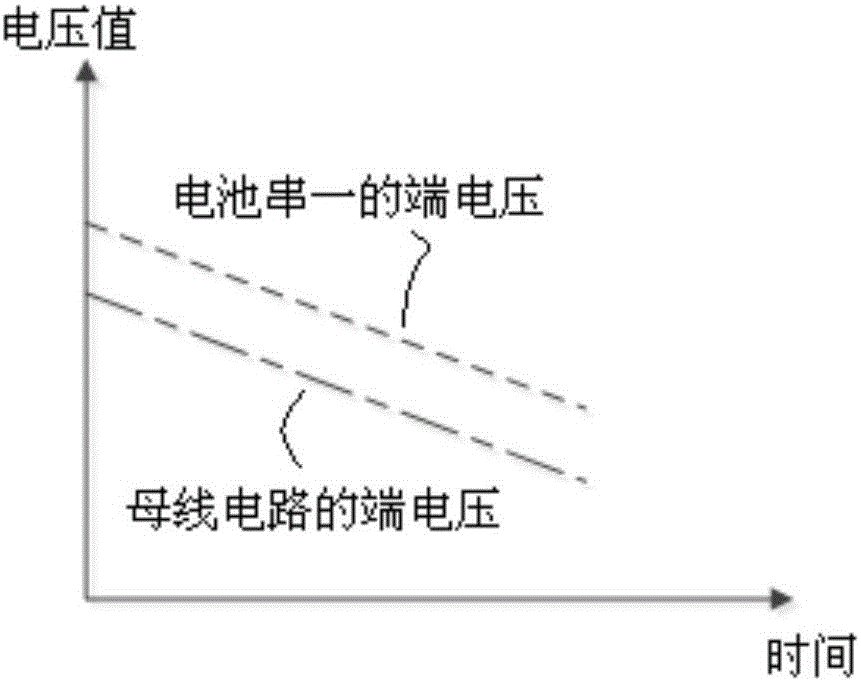

Fault location detection method, fault location detection device, storage battery assembly and motor vehicle

ActiveCN106501711AAccurately determineQuick fixProgramme controlComputer controlLocation detectionElectricity

The embodiment of the invention provides a fault location detection method, a fault location detection device, a storage battery assembly and a motor vehicle. In the scheme, a set load is started and lasts for a first preset time after a power interruption failure is detected to occur in an on-off control module under a strong electricity disconnecting instruction, a terminal voltage variation value of the set load and a terminal voltage variation value of each battery string are acquired within the first preset time, and if the terminal voltage variation value of a certain battery string is consistent with the terminal voltage variation value of the set load, a contact switch corresponding to the battery string is determined to break down. Under the condition of not additionally increasing any sensor, the location of a sintering or adhesion fault and the like can be determined accurately and quickly by using an existing detection component in a motor vehicle power system, so that the maintenance time and the maintenance cost are greatly reduced.

Owner:乐视生态汽车(浙江)有限公司

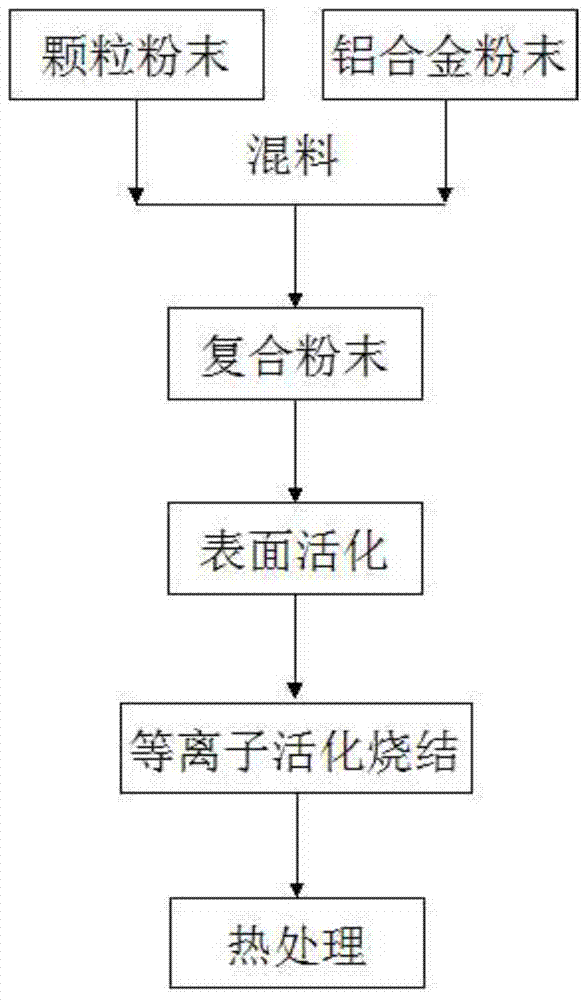

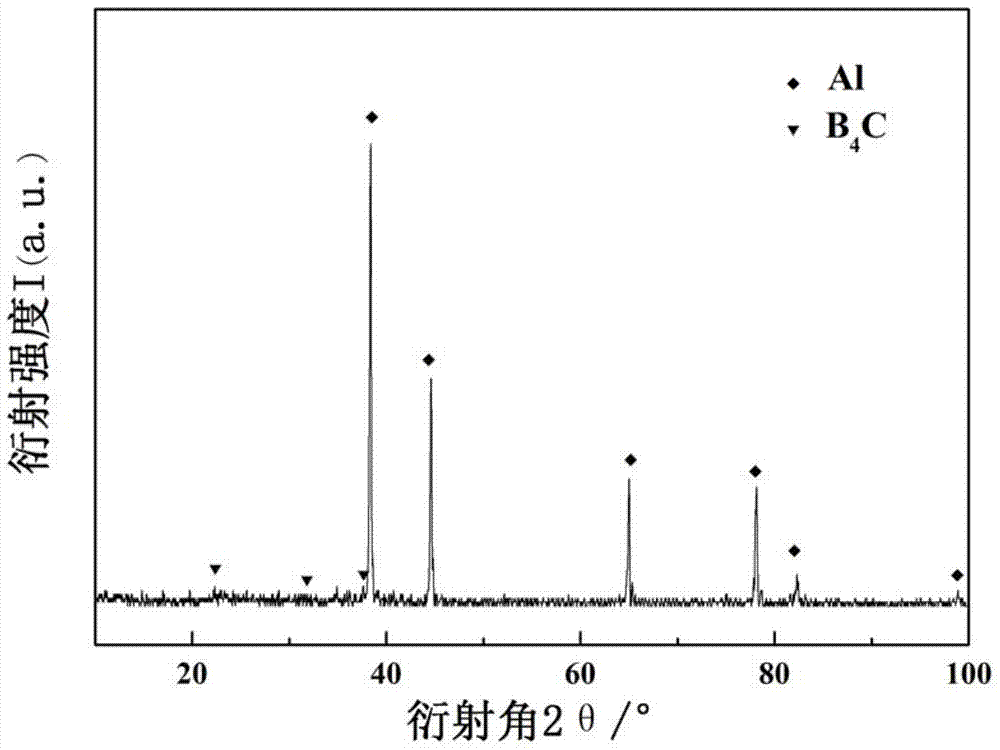

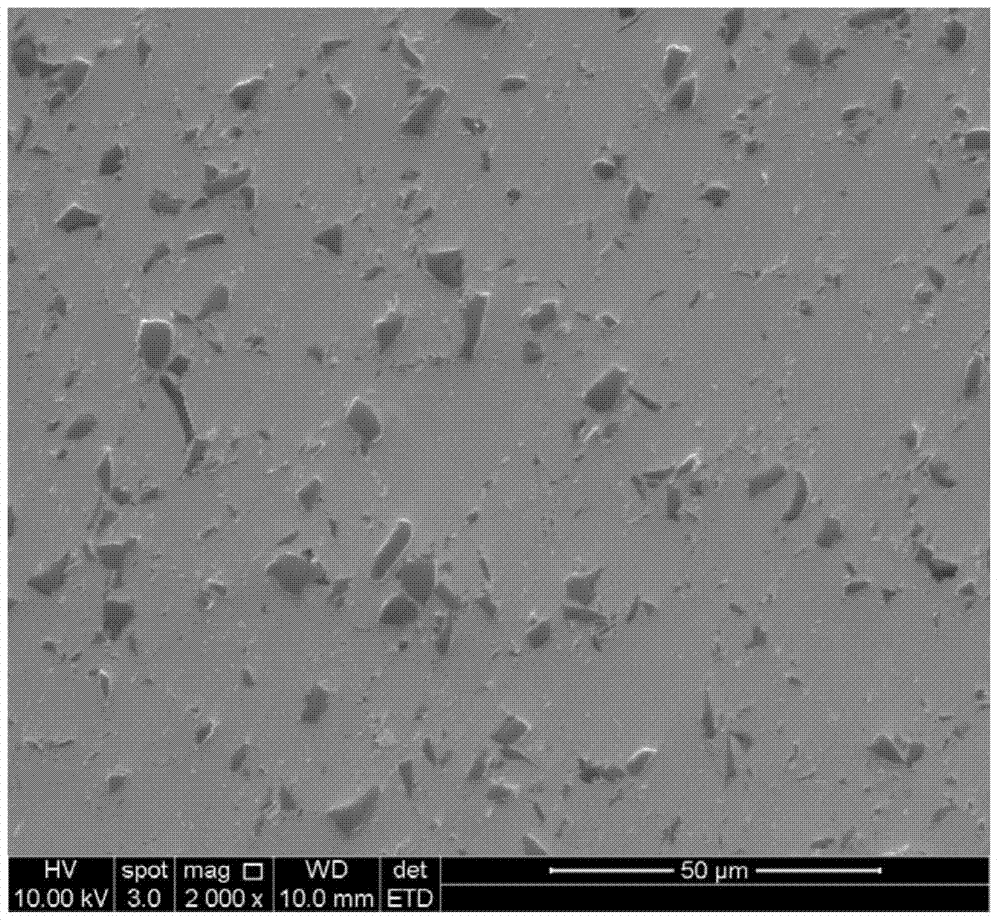

Preparation method of boron carbide particle enhanced aluminum-based composite material

The invention relates to the technical fields of aluminum-based composite materials and preparation thereof, in particular to a boron carbide particle enhanced aluminum-based composite material and a preparation method thereof. According to the composite material, aluminum alloy is used as a matrix; the mass percentage of boron carbide used as a wild phase is 2.5 to 30%; the boron carbide particles are distributed in the matrix uniformly. The specific preparation method comprises the following steps: mixing boron carbide powder and aluminum alloy powder; performing surface activation, plasma activated sintering and heat treatment to prepare a sintering test sample close to full density. The aluminum-based composite material prepared by the method has low sintering temperature, high density, small crystal particles and an excellent mechanical property, is simple to operate and high in controllability, and is a lightweight high-performance aluminum-based composite material.

Owner:WUHAN UNIV OF TECH

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

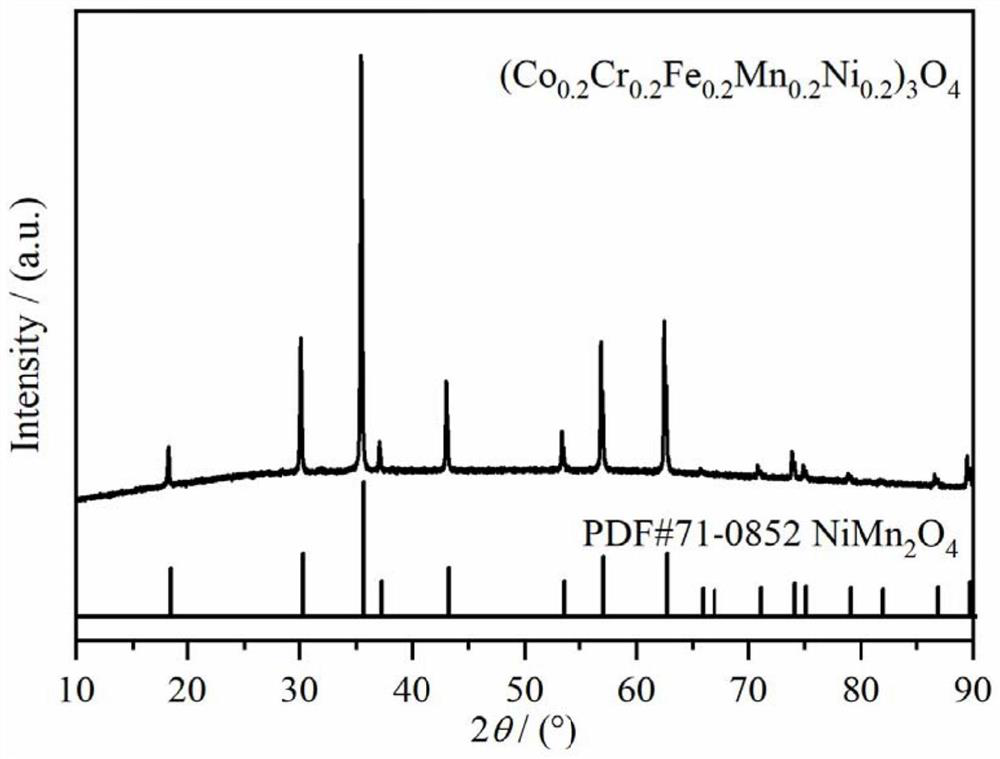

The method for preparing high-entropy oxide ceramic material is simple and low in consumption

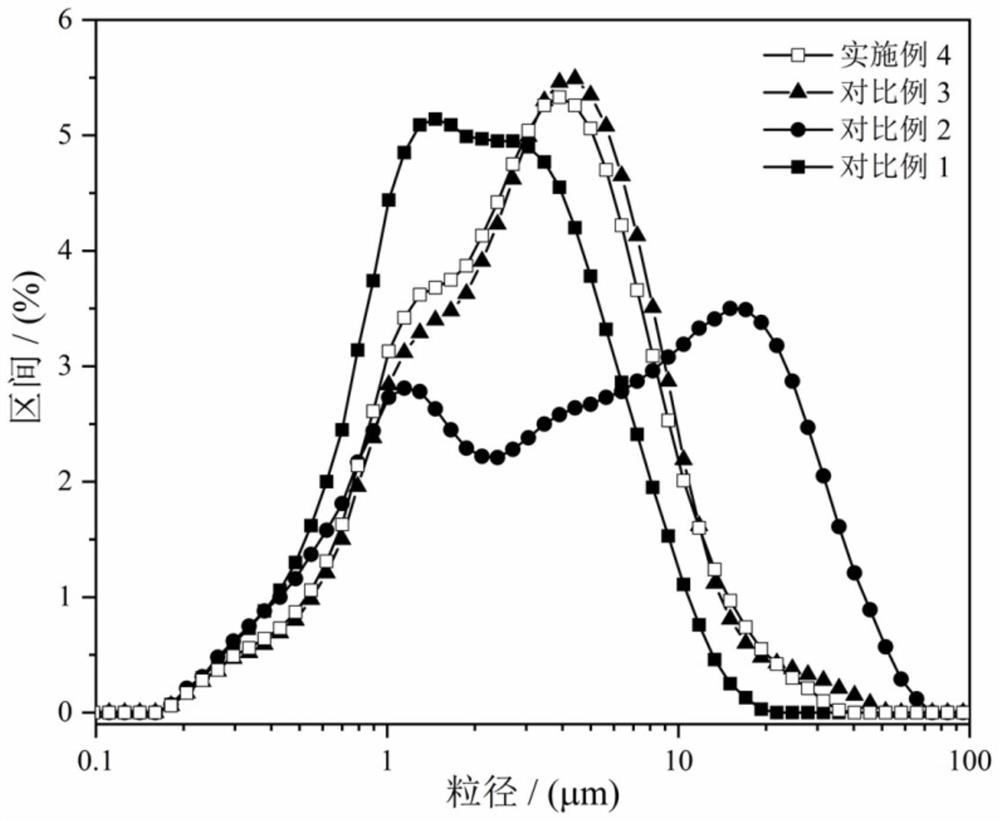

ActiveCN112723862AThe primary particle size is fine and uniformHigh activityOxide ceramicPlasma activation

The invention relates to the technical field of high-entropy ceramic preparation, and discloses a simple and low-consumption method for preparing a high-entropy oxide ceramic material, which comprises the following steps: S1, weighing raw materials: weighing the raw materials required for preparation according to a set ratio; s2, performing particle refinement: adding the raw materials weighed in the step S1 and a dispersing agent into a ball milling tank of a planetary ball mill together for particle refinement grinding to prepare uniformly mixed slurry, then drying the slurry, and grinding again to obtain refined powder; s3, performing spark plasma treatment: performing spark plasma activation on the refined powder obtained in the step S2 to obtain a ceramic raw material; and S4, performing microwave sintering: carrying out microwave sintering on the ceramic raw material obtained in the step S3 to obtain the high-entropy oxide ceramic material.

Owner:TAIYUAN UNIV OF TECH

Doping device for optical fiber preform

ActiveCN102815866AGuaranteed uniformityGuaranteed stabilityGlass making apparatusGas phaseRare earth

The invention provides a doping device for an optical fiber preform. On modified chemical vapor deposition equipment, a required clad material is deposited on an inner wall of a reaction tube by using an improved MCVD method; a gas phase and liquid phase composite doping device is employed to carry out uniform doping of active doping ions and a co-doped agent. For the gas phase doping, a simple-structured and low-cost heater is employed for direct heating; and a dopant is constantly heated by the heater, and is introduced by current-carrying oxygen for doping after vaporization. For the liquid phase doping, a micropore jet doping device is used to carry out direct online doping of a doping solution through an injection device. The composite doping device is used to carry out preparation of a rare earth doped preform, so as to realize synchronous deposition and vitrification of the rare earth doping ions, the co-doped agent and quartz base materials comprising silica and germanium dioxide, avoid dependence on the deposition loose pore structure layer, and increase flexibility of the concentration and the variety of the doping ions.

Owner:武汉长进光子技术股份有限公司

Preparation method of carbon/ceramic composite material

The invention discloses a preparation method of a carbon / ceramic composite material and aims at solving the problems that a traditional preparation method of the carbon / ceramic composite material is long in production cycle, high in cost and the like. The preparation method of a carbon / ceramic composite material comprises four steps of preparing ceramic slurry, grouting, carrying out dehumidification, performing recrystallization and sintering, and the sintering is carried out according to a temperature curve, and compact ceramic matrix coating layers are formed on the surfaces of carbon fibers to prepare the carbon / ceramic composite material. The preparation method of the carbon / ceramic composite material disclosed by the invention can be quickly sintered and is short in preparation cycle, and the bending strength of the prepared carbon / ceramic composite material reaches 130-150 Mpa.

Owner:HUNAN JIUHUA CARBON HI TECH

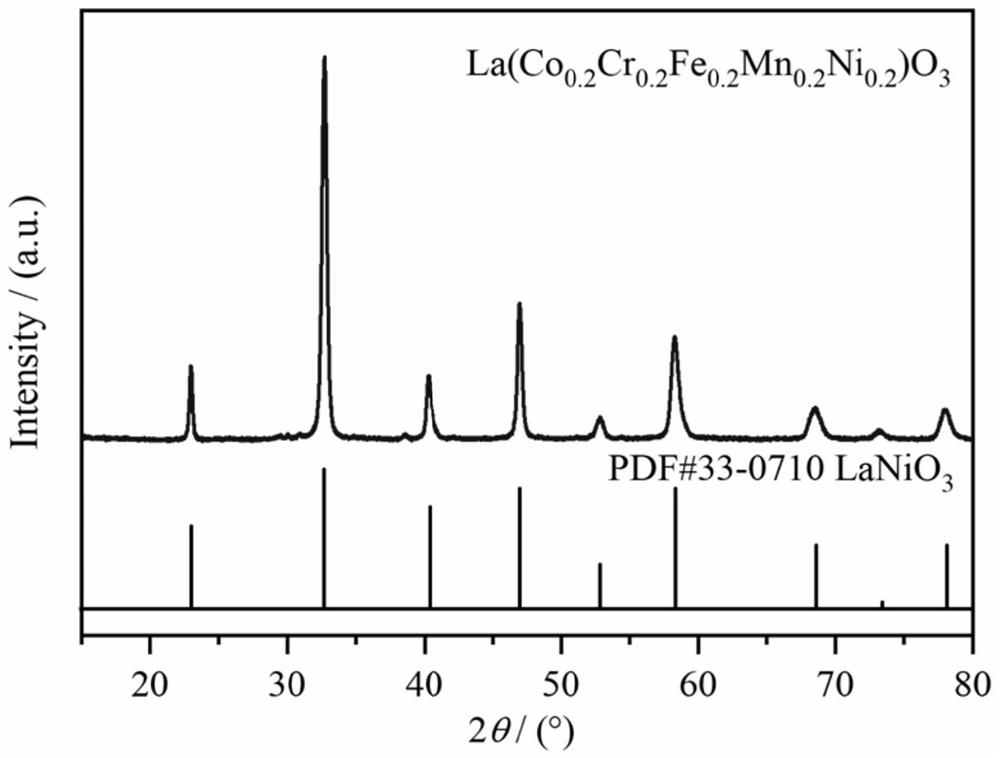

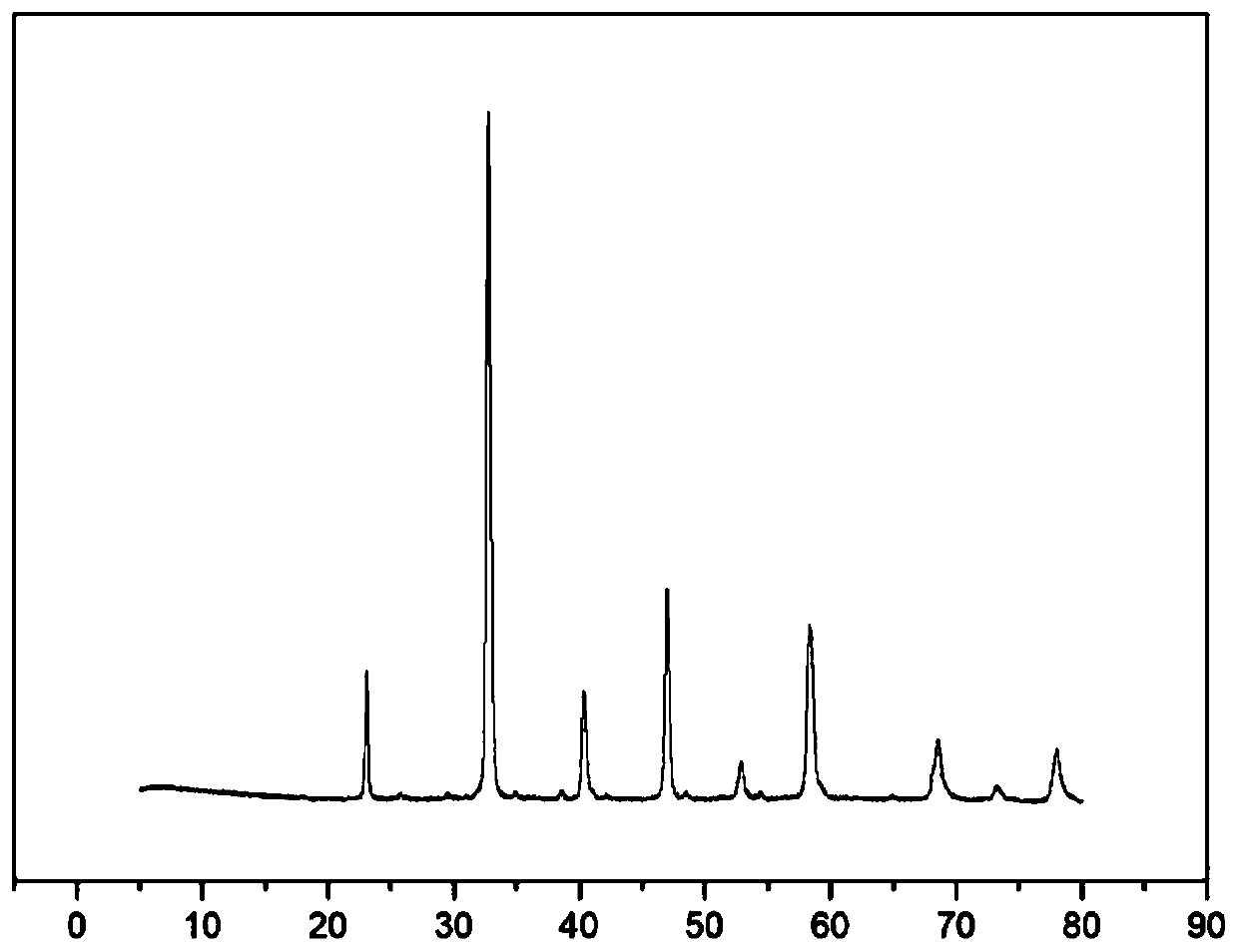

High-entropy ceramic powder and preparation method thereof, and high-entropy ceramic block

The invention relates to the technical field of high-performance ceramics, in particular to high-entropy ceramic powder and a preparation method thereof, and a high-entropy ceramic block. According tothe invention, the high-entropy ceramic powder and the high-entropy ceramic block are prepared by adopting a coprecipitation method; required experimental equipment is simple; operation is easy; large-scale production is facilitated; the sintering temperature of the high-entropy ceramic can be remarkably reduced; rapid sintering of the ceramic is achieved within a temperature range of 1000-1400 DEG C; and the high-entropy ceramic with a perovskite structure is obtained.

Owner:TAIYUAN UNIV OF TECH

Preparation method for porous tungsten bulk material with uniform and controllable pores

The invention discloses a preparation method for a porous tungsten bulk material with uniform and controllable pores. The preparation method is characterized by comprising the following steps of: by taking tungsten powder as a raw material, obtaining spherical tungsten powder through plasma balling treatment and electric vibrating and screening treatment; and then, obtaining the porous tungsten bulk material by discharge plasma sintering. According to the preparation method, the porous tungsten bulk material with uniform and controllable pores is obtained by combining a plasma balling technology, an electric vibrating and screening technology and a discharge plasma sintering technology; the preparation method is simple and liable to realize; the control on pores of the product can be realized by regulating the process parameters, so that the porous tungsten bulk material with porosity of 17%-22.5% and pore size of 2-5 mum; the prepared porous tungsten bulk material can be used for remarkably improving the infiltration performance of the material, so that the launch stability of a barium-tungsten cathode is greatly improved, and the service life of the barium-tungsten cathode is prolonged.

Owner:HEFEI UNIV OF TECH

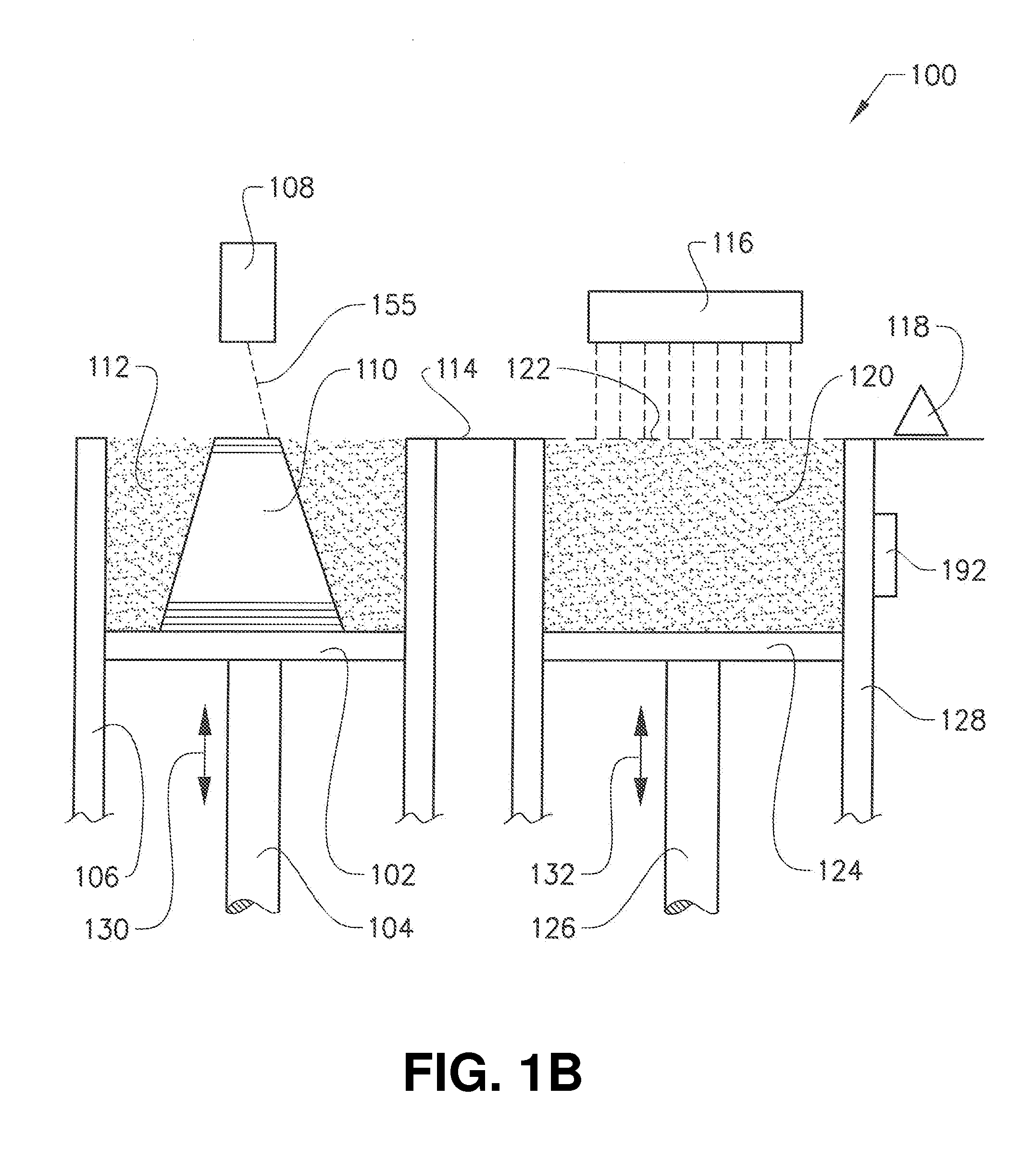

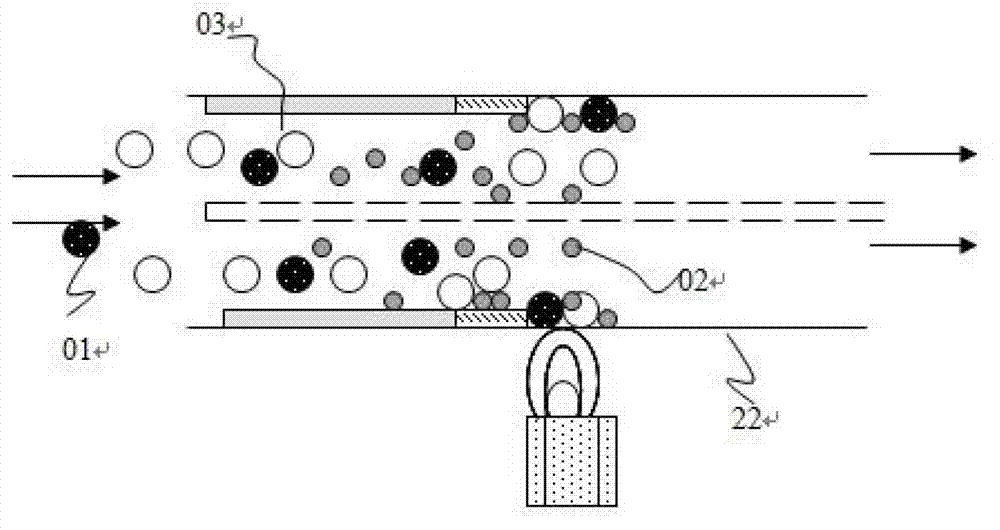

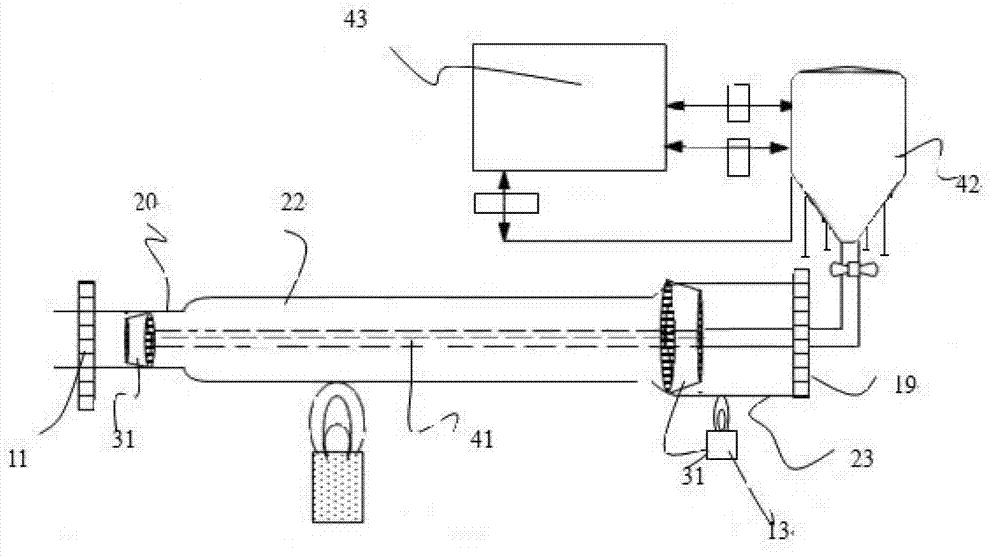

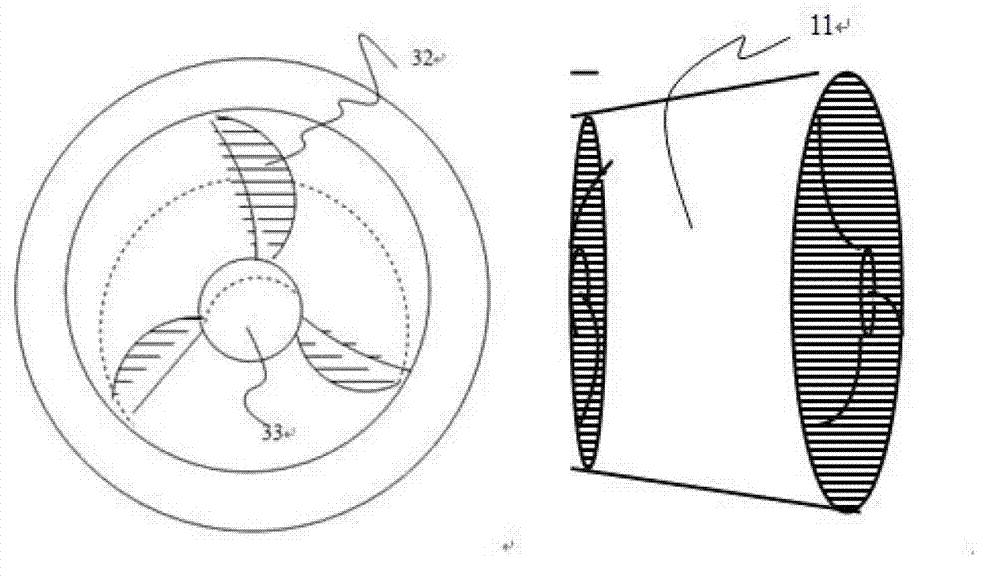

High-throughput preparation device and method for high-silicon aluminum alloy structural gradient material used for packaging

The invention discloses a high-throughput preparation device and method for a high-silicon aluminum alloy structural gradient material used for packaging. The device comprises an upper high-temperature die, outer die moulds, induction coils, a gradient workpiece, cooling water circulating devices, a lower low-temperature die and thermocouples, wherein the upper high-temperature die is used for keeping the inner temperature of the whole die balancing and supplying a certain heat source to atomized powder of the high-silicon aluminum alloy; the outer die moulds are used for positioning two or three kinds of the prepared atomized powder of the gradient high-silicon aluminum alloy; the atomized powder of the high-silicon aluminum alloy is fed based on the sequence that the low-component alloy powder is at the bottom end of each outer die mould, and the high-component aluminum powder is at the top end of each outer die mould; the induction coils can be used as movable induction heating elements for supplying heat to the whole preparation process; the gradient workpiece is used for preparing the gradient material; the cooling water circulating devices can be used for exporting excess heat when the temperature in the preparation process is beyond a set temperature; the temperature of the lower low-temperature die is in contrast to the temperature of the upper high-temperature die, so that temperature gradient can be generated; the thermocouples are used for testing the temperature and controlling the induction heating time, so as to generate the temperature gradient. The alloy prepared by the device and the method is high in density, and the structure is refined, so that the alloy is outstanding in comprehensive performances.

Owner:SUZHOU XINHUILIAN SEMICON TECH CO LTD

High-calcium low-iron magnesian dry method ramming mass and its production method

The present invention provides one kind of high calcium low iron magnesia material as refractory ramming material and its preparation process. The present invention has materials including light burnt magnesia powder, light burnt dolomite powder, fused magnesia, superfine fused magnesia powder, iron oxide scale as rolling waste, iron oxide powder as steel making side product, and diesel oil. The present invention has high heat resistance, high load softening performance, high breaking strength, high heat shock performance, high slag corrosion resistance and thin furnace bottom sintered layer. It is especially new steel making process, and can maintain excellent performance at high temperature.

Owner:海城华宇耐火材料有限公司

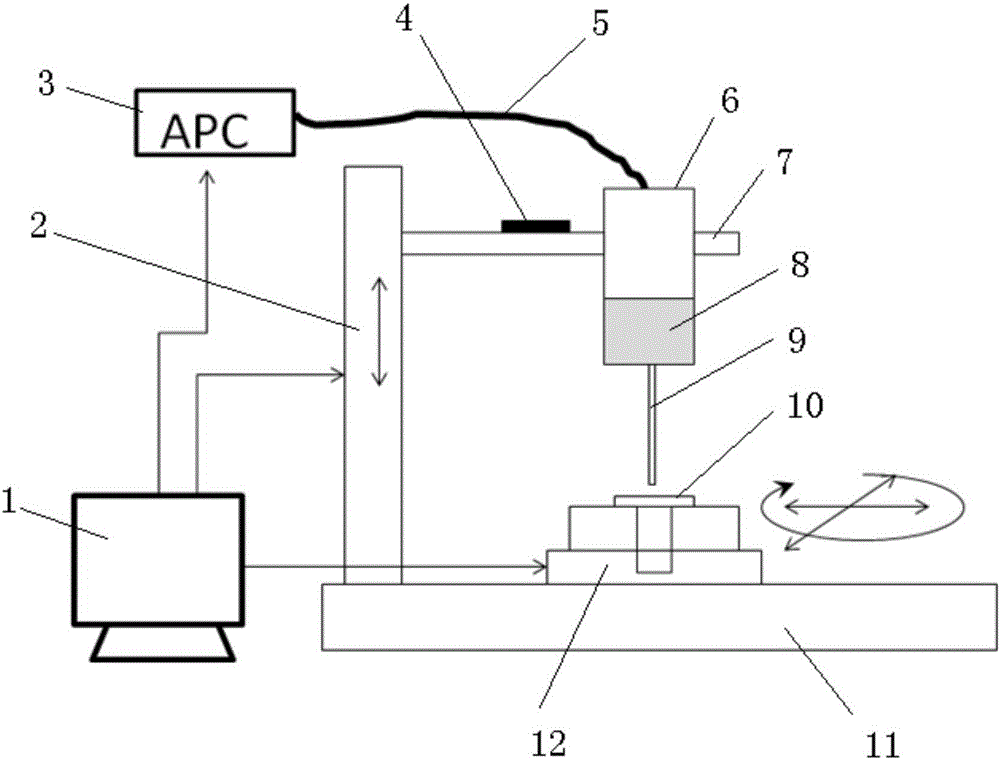

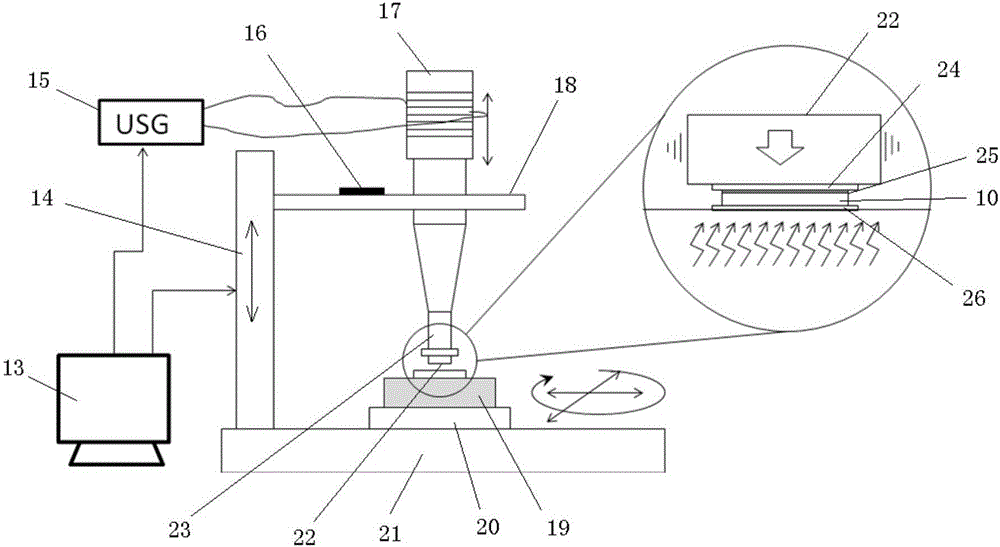

Hot ultrasonic sintering method and device of nano silver/graphene composite ink

ActiveCN106211606AGood electrical conductivityGood mechanical bending resistanceInksConductive pattern formationCvd grapheneSolid-state

The invention discloses a hot ultrasonic sintering method and device of nano silver / graphene composite ink. According to the method, nano silver powder and graphene are dispersed into a mixed organic solvent; the nano silver / graphene composite ink with the mass percent of 0.01%-90% is prepared; the high-viscosity nano silver / graphene composite ink is extruded from a rubber sleeve through air pressure; scribbling is carried out on a flexible substrate through a dispensing head to form the flexible substrate with a conductive circuit; the dried flexible substrate with the conductive circuit is put between two layers of PDMS protective plastic, and pressure is applied to reach a required value of 3-30MPa; the heating temperature is 60-160 DEG C; hot-pressing pre-sintering is carried out under the conditions of 3-30MPa and 60-160 DEG C for 1-10 minutes; hot ultrasonic sintering is carried out under the conditions of 3-30MPa and 60-160 DEG C for 1-10 minutes; solid-state diffusion between nano silver / graphene is achieved through the effects of ultrasound, pressure and temperature; and a flexible circuit with good conductivity and mechanical bending property is prepared.

Owner:CENT SOUTH UNIV

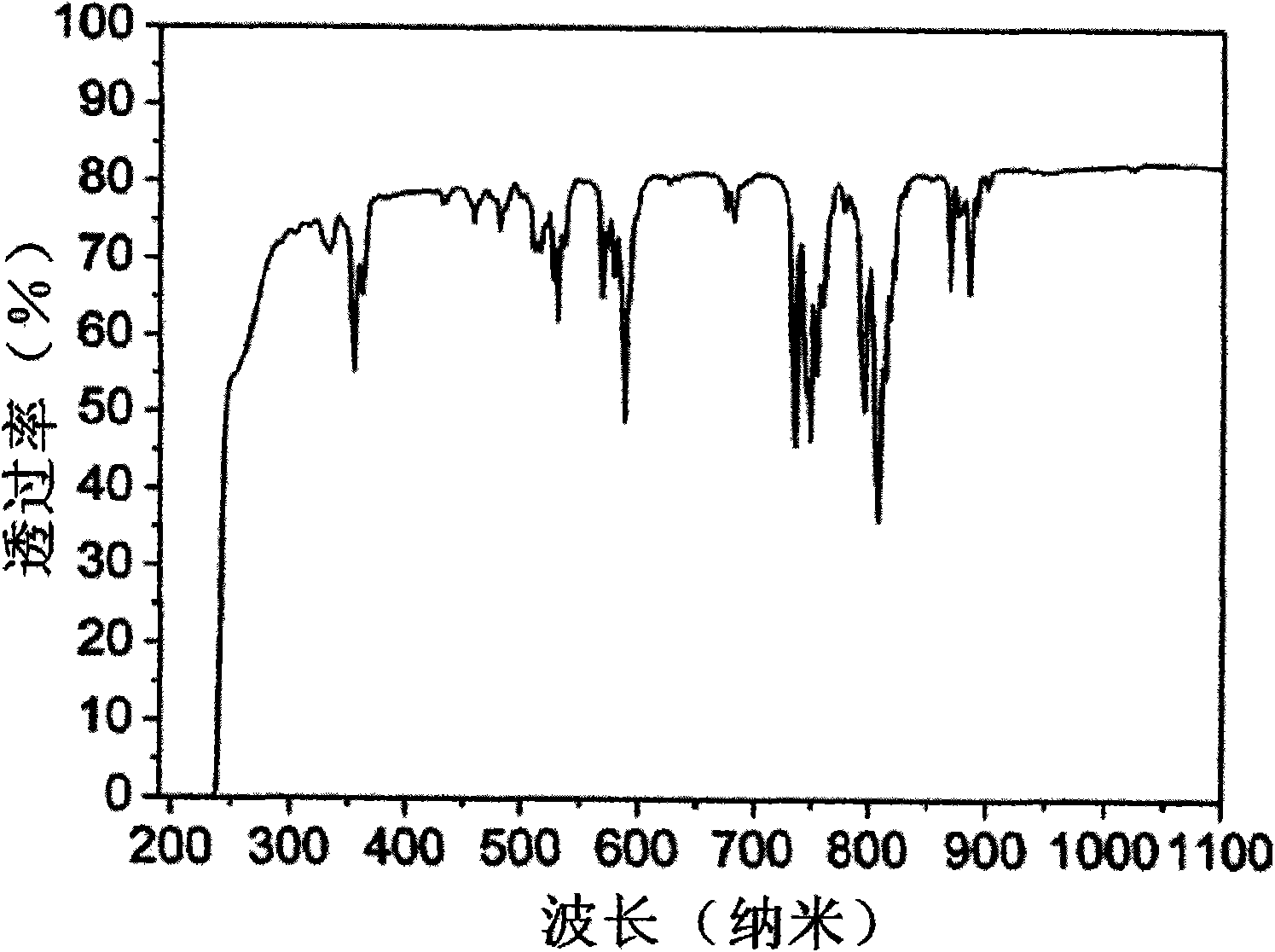

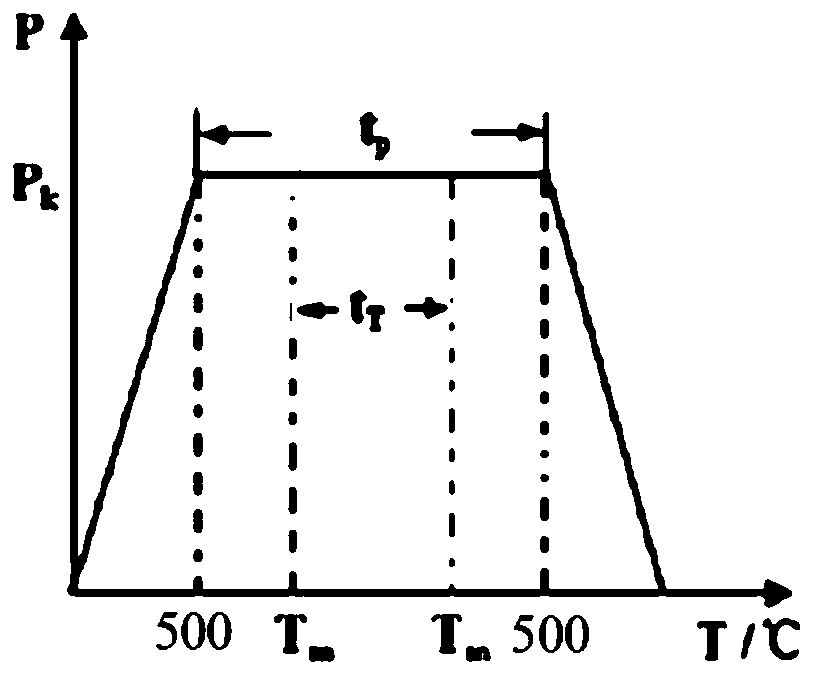

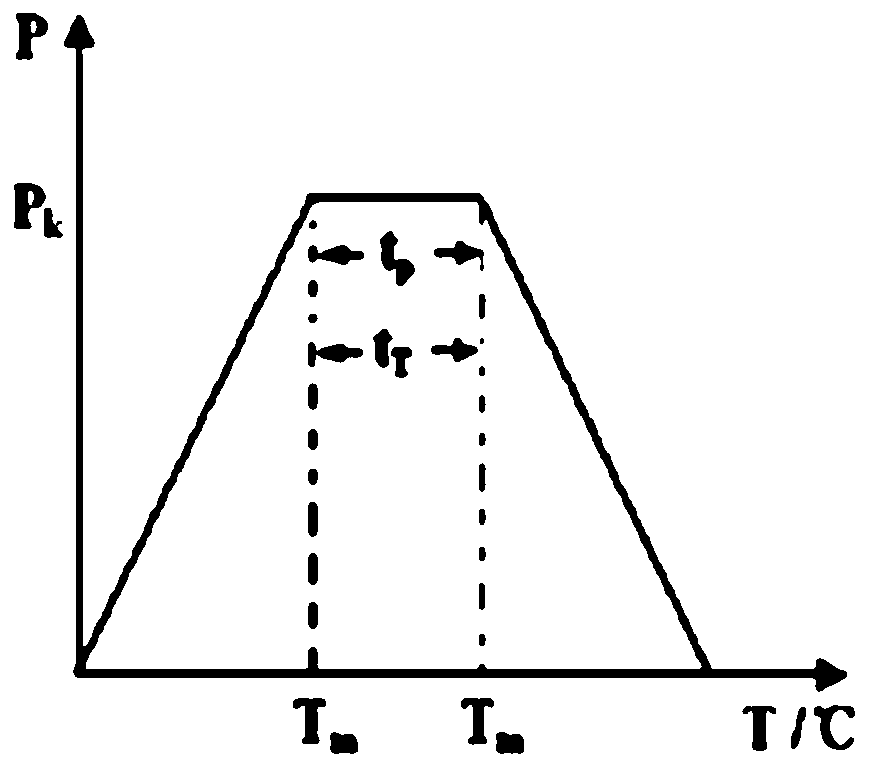

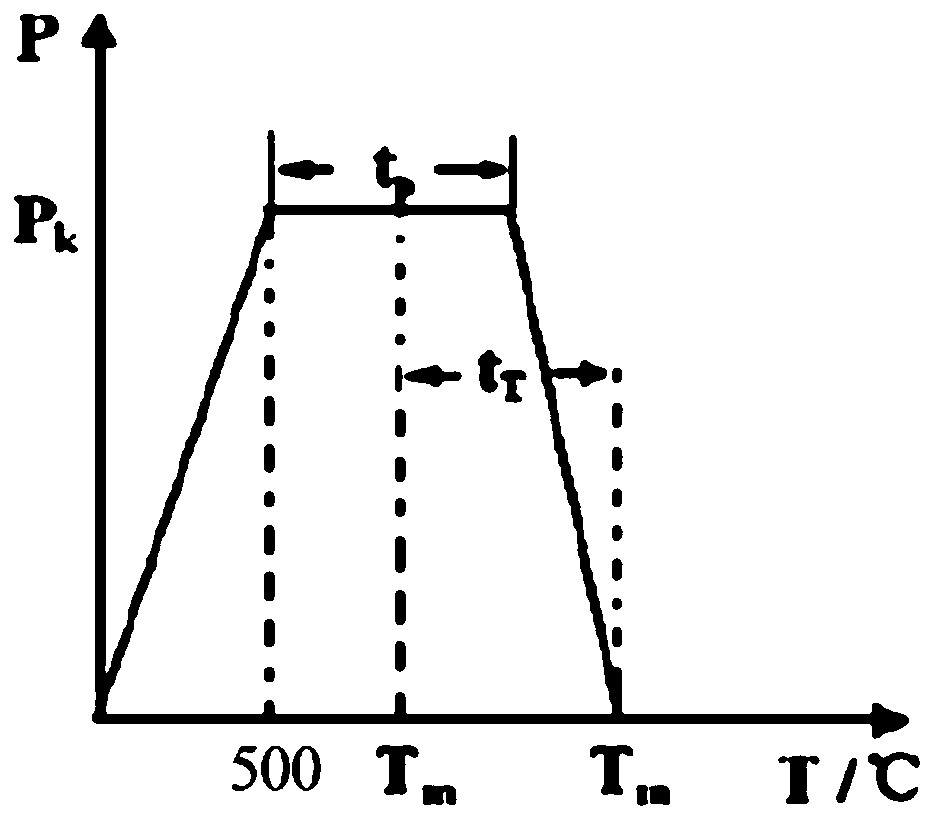

Rapid sintering method for a dental zirconium oxide ceramic

InactiveCN107162603AFast sinteringConsistent sintering effectImpression capsArtificial teethZirconium hydrideMetallurgy

The present invention discloses a rapid sintering method for a dental zirconium oxide ceramic. The rapid sintering method is characterized in that a rapid sintering furnace with a heating rate of 120 DEG C / min and designed by our company is used, a 3% mol Y stabilized zirconium oxide tooth material commonly used in dentistry and a 5% mol Y stabilized zirconium oxide tooth material commonly used in dentistr are used as raw materials, and the sintering method is controlled to adapted to the materials, such that the teeth can achieve the same effect as the effect obtained by using the traditional 7-15 h sintering method commonly used in dentistry after the 3% mol Y stabilized zirconium oxide and the 5% mol Y stabilized zirconium oxide are completely sintered within 0.5-1.5 h, wherein the transparency of the material cannot be reduced.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

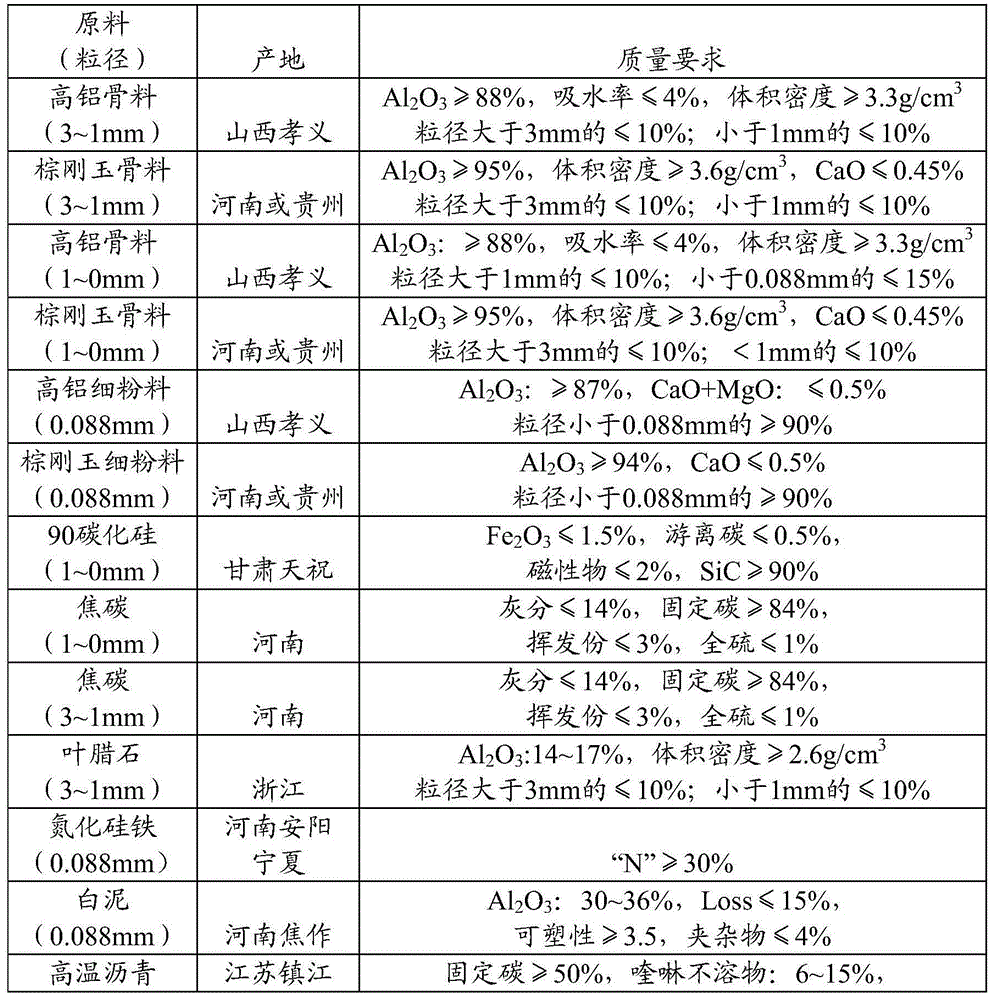

Anhydrous stemming and preparation method thereof

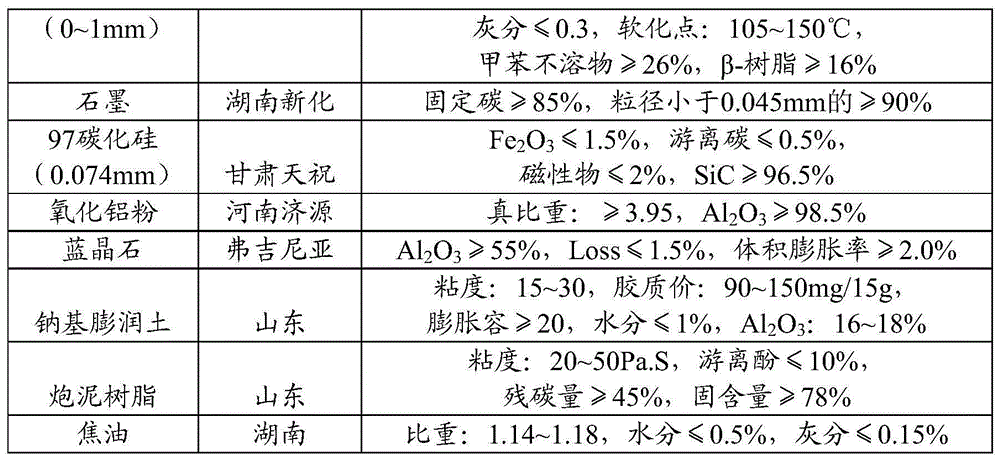

The invention provides anhydrous stemming. The anhydrous stemming comprises the following components by weight percent: 25 to 30 percent of aluminum-containing aggregates, 5 to 10 percent of coke, 15 to 20 percent of silicon carbide, 5 to 10 percent of pyrophyllite, 10 to 20 percent of ferro-silicon nitride, 5 to 10 percent of aluminum-containing aluminum powder, 5 to 10 percent of white mud, 2 to 6 percent of high temperature asphalt, 8 to 15 percent of additives, 2 to 5 percent of sodium-based bentonite and 5 to 15 percent of tar; the particle size of the aluminum-containing aggregate is more than 0.088mm and less than or equal to 3mm; the particle size of the aluminum-containing fine powder is more than 0mm and less than or equal to 0.088mm; and a softening point of the high temperature asphalt is 105 to 150 DEG C. The anhydrous stemming not only can be used as the normal stemming of daily tapping, but also has an effect for repairing the stemming. The invention also provides a preparation method of the anhydrous stemming.

Owner:HUNAN XIANGGANG RUITAI TECH

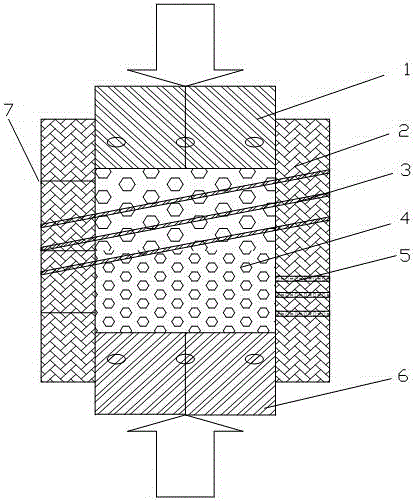

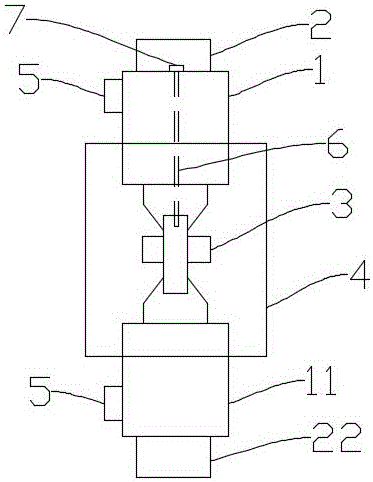

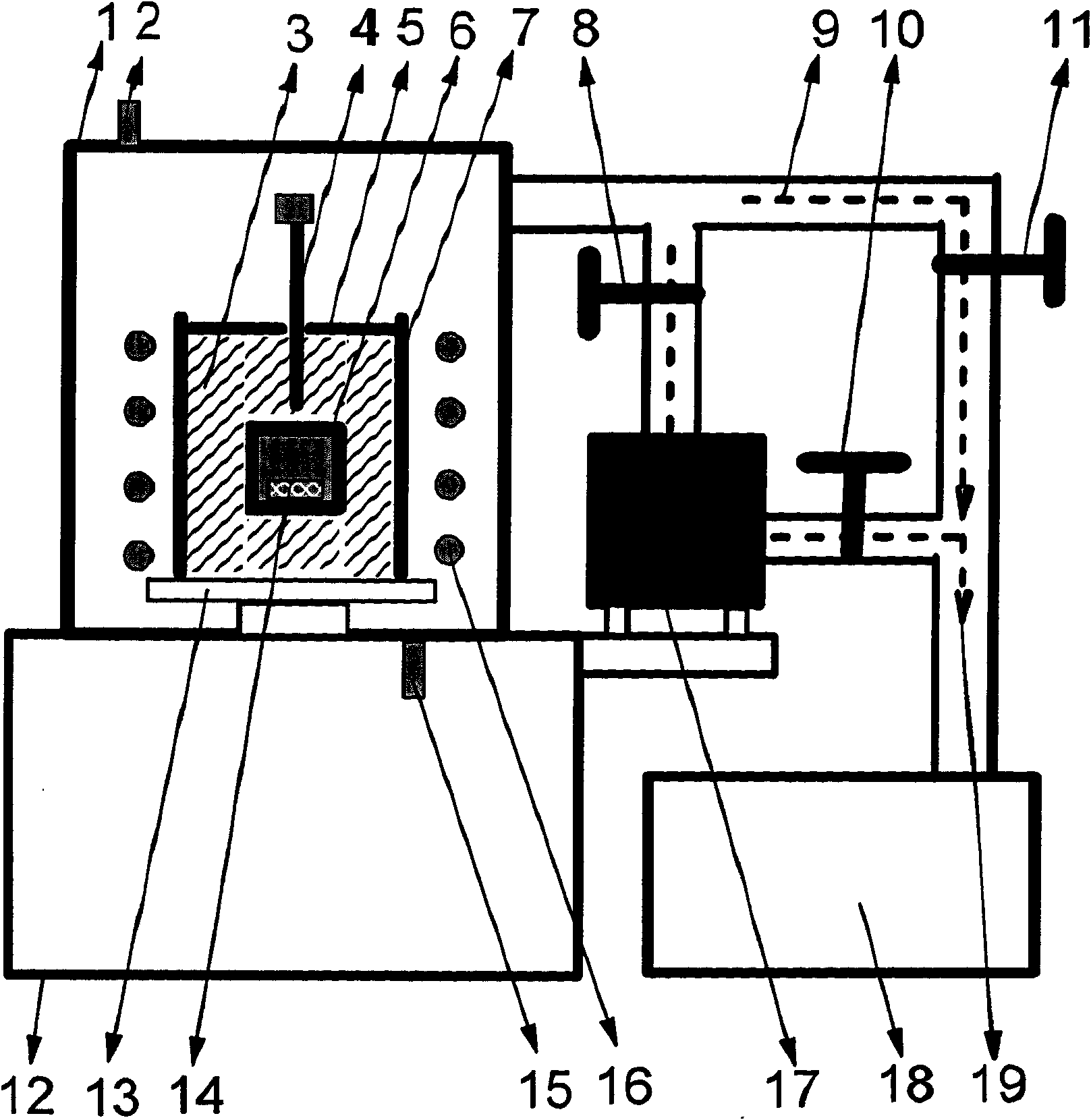

Spark plasma sintering system

The invention discloses a spark plasma sintering system which comprises a sintering furnace and a control system connected with the sintering furnace. The control system comprises a displacement / pressure control system, an atmosphere control system, a vacuum control system and a temperature control system. The sintering furnace comprises a pressurization device and an impulse current generator. The pressurization device comprises an upper pressing head and a lower pressing head which are correspondingly arranged, upper electrodes and lower electrodes which are arranged on the upper sides and the lower sides of both the upper pressing head and the lower pressing head respectively, a sintering die arranged between the upper pressing head and the lower pressing head and a water cooling vacuum chamber arranged on the outer side of the sintering die, and the impulse current generator is connected with the upper electrodes and the lower electrodes. The spark plasma sintering system is good in forming effect, the forming process is controlled accurately, and the product quality is greatly improved.

Owner:浙江晨华科技有限公司

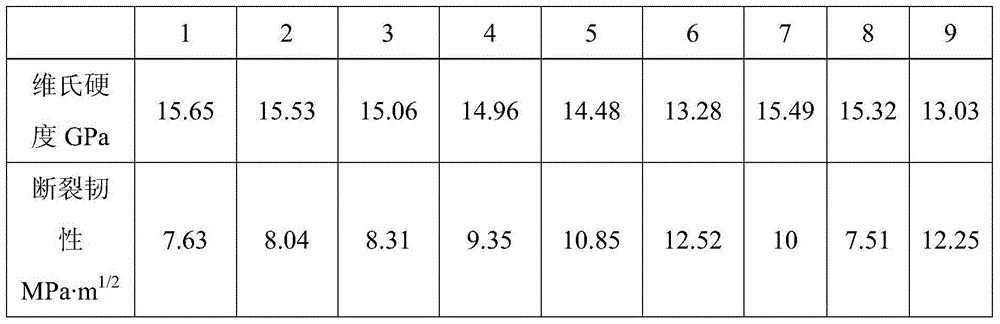

TiCN-base metal ceramic tool material and its microwave sintering process

The invention discloses TiCN-base metal ceramic tool material and its microwave sintering process. The TiCN-base metal ceramic tool material comprises, by weight, 55% to 75% of TiCN, 6% to 24% of Ni, 8% to 15% of WC, and 4% to 15% of Mo2C or Mo4. The 2.45GHz frequency microwave medium is used as a heating source; under the nitrogen atmosphere, the material is sintered. The TiCN-base metal ceramic tool material is higher in compactness, rigidity and breaking tenacity, meets the application requirements and is simple to sinter, high in productivity and low in cost.

Owner:NANJING UNIV OF SCI & TECH

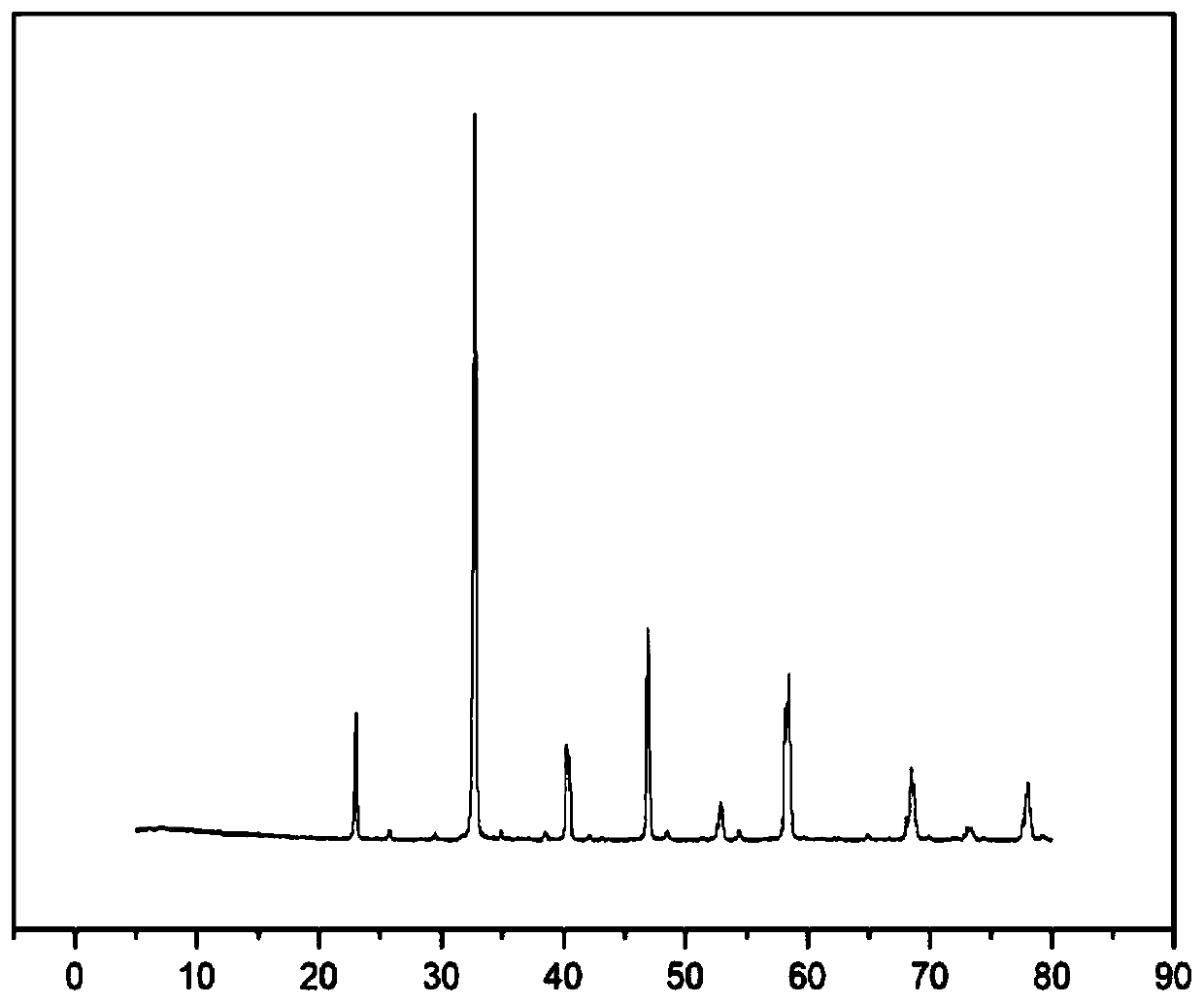

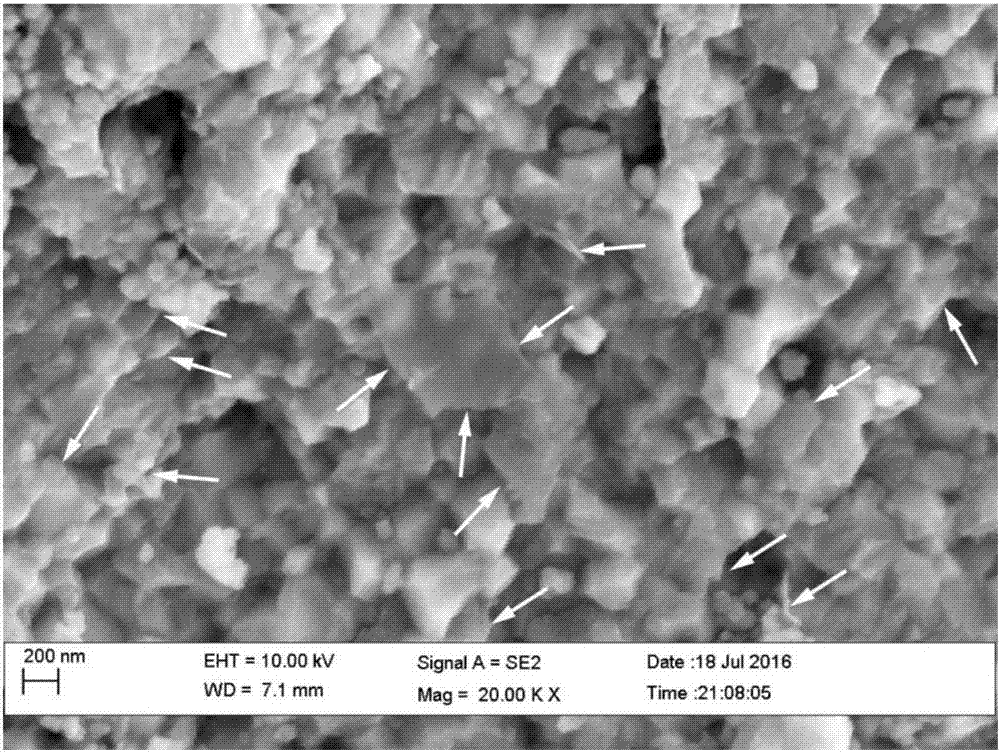

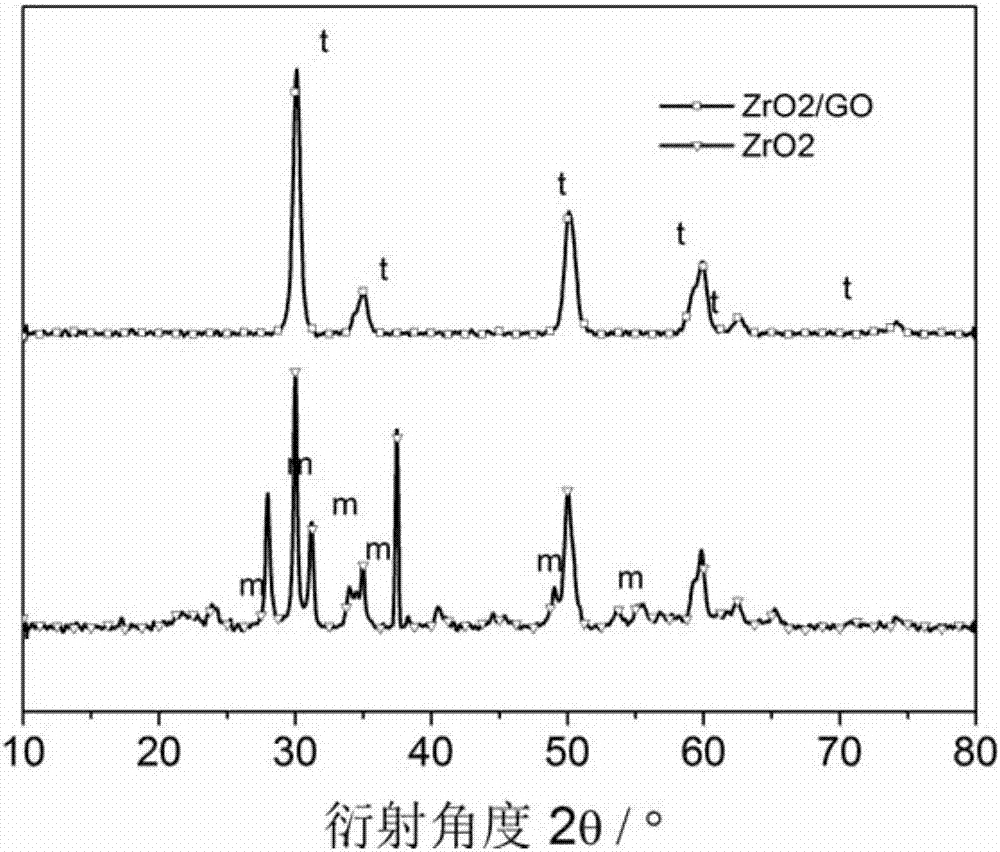

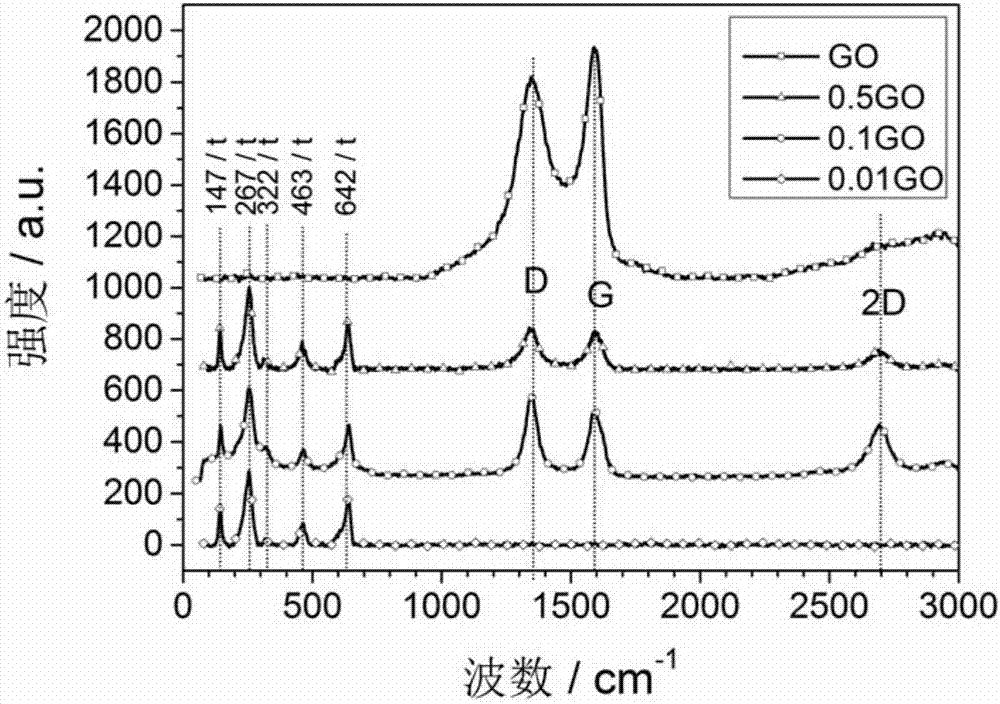

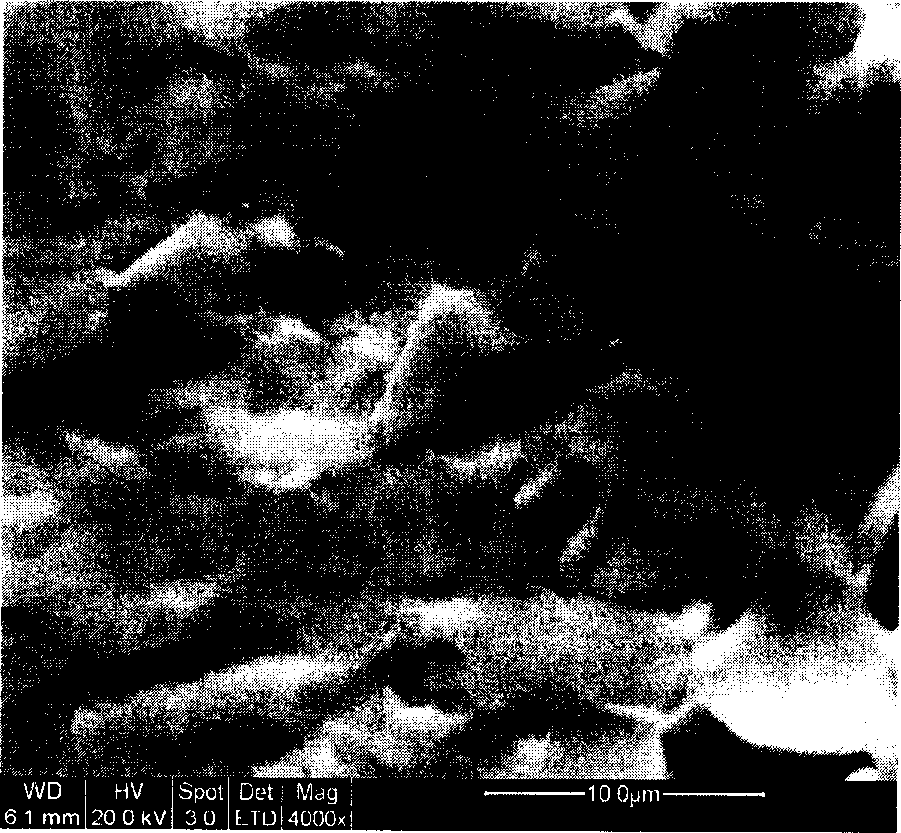

Graphene-zirconium oxide compound material and preparation method of same

The invention discloses a graphene-zirconium oxide compound material and a preparation method of same. The compound powder is prepared with zirconium oxide granulation powder and graphene oxide as raw materials, wherein the zirconium oxide granulation powder accounts for 99.5-99.99% of the total weight of the two components, and the graphene oxide accounts for 0.01-0.5% of the total weight of the two components. The preparation method includes the steps of: 1) dispersing and mixing the raw materials; and 2) sintering the mixture powder. In the method, the character that the graphene oxide can be reduced to form graphene at high temperature is fully considered, and meanwhile, under a high-pressure and high-vacuum atmosphere in the sintering environment, the graphene oxide is reduced in the zirconium oxide substrate in situ. The method has simple operation steps and high production efficiency and improves mechanical performances of zirconium oxide ceramic.

Owner:SOUTH CHINA UNIV OF TECH

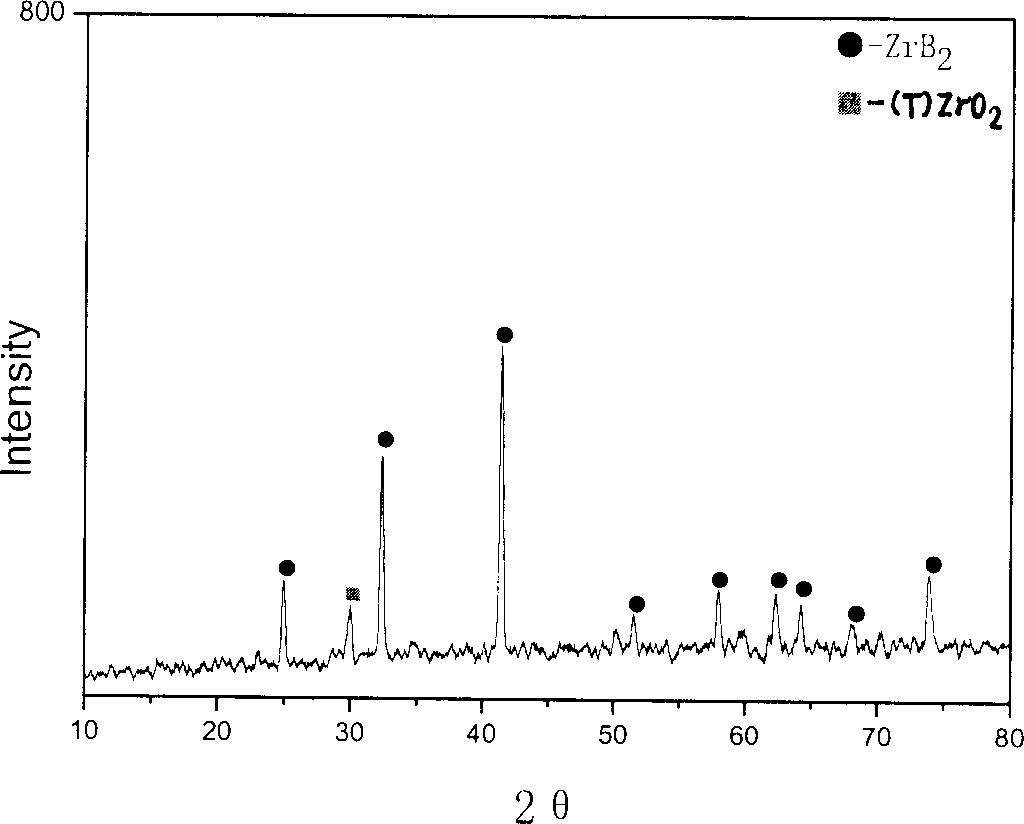

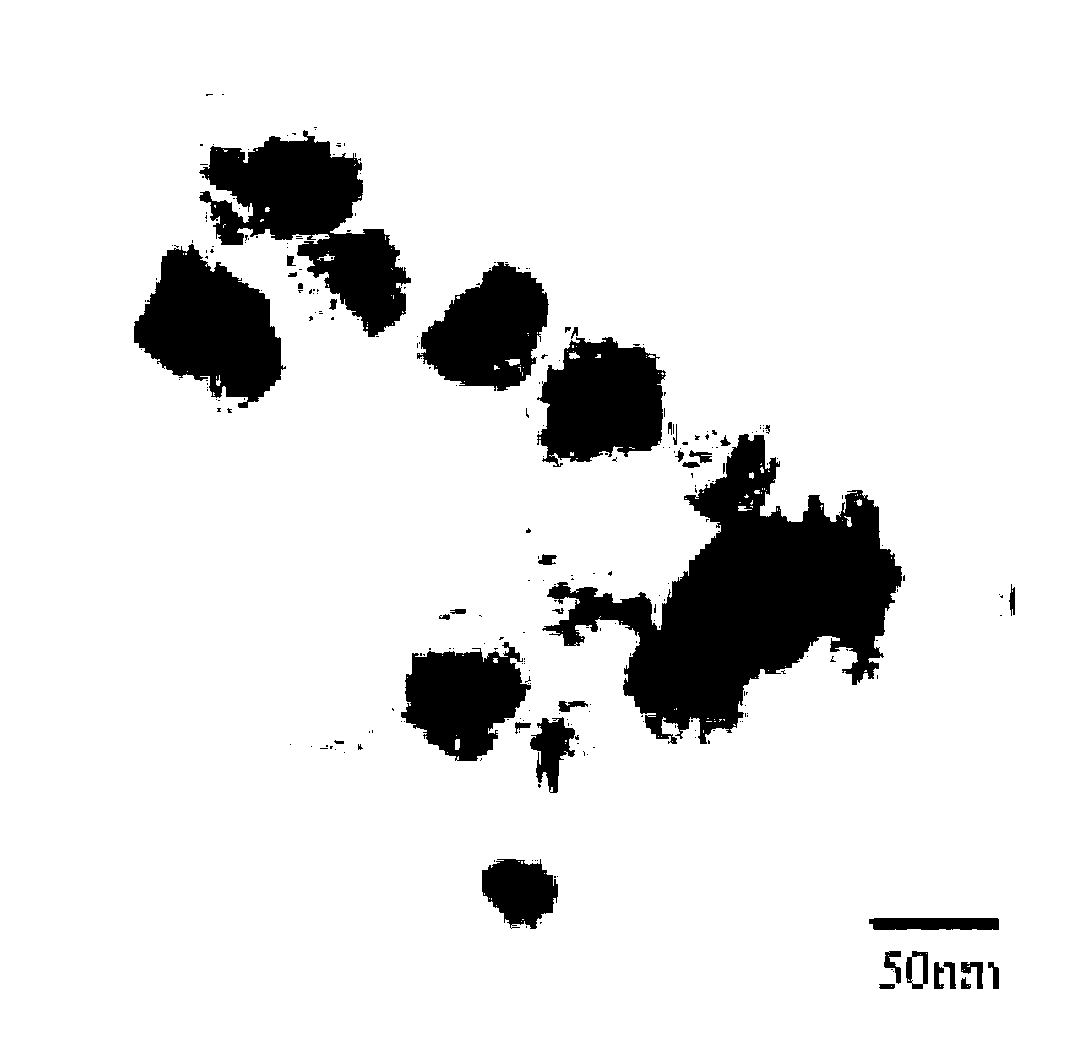

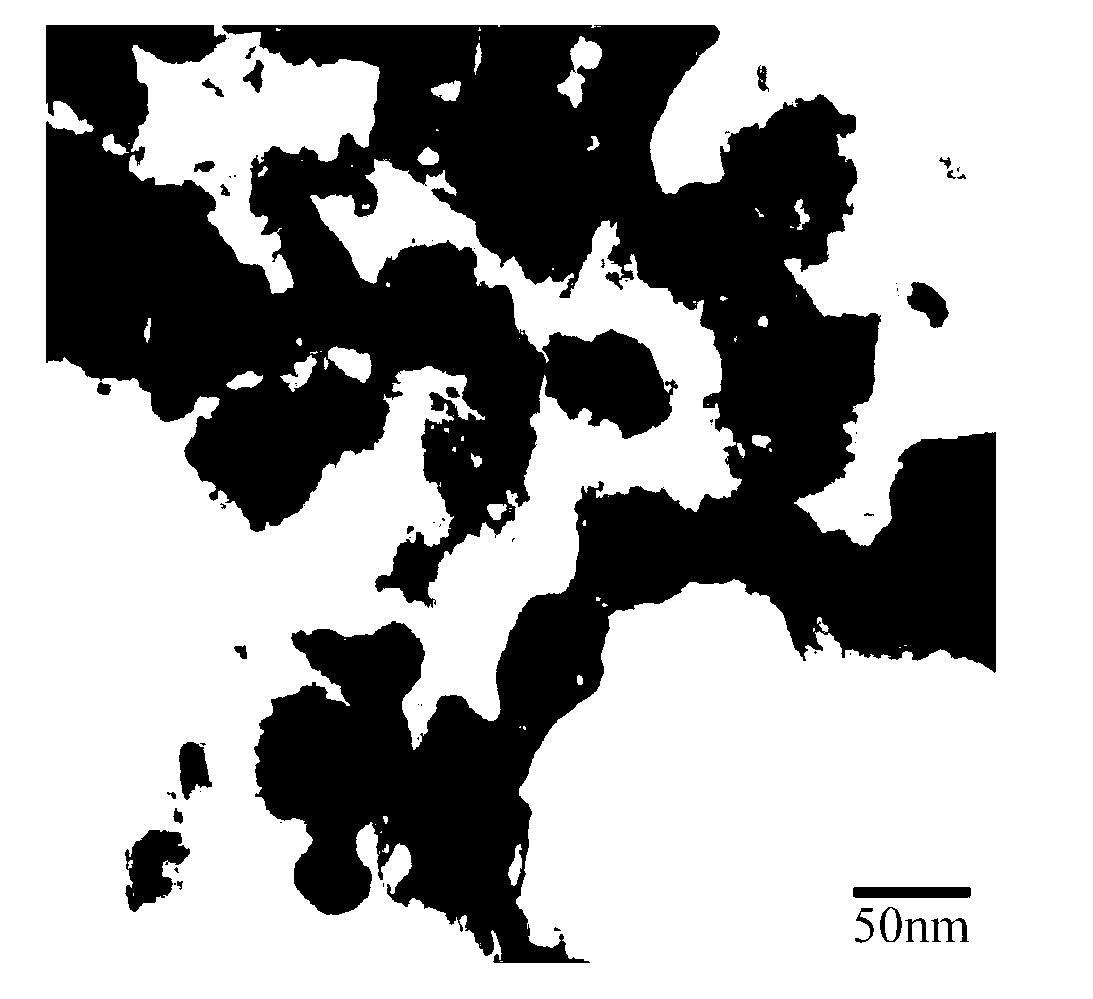

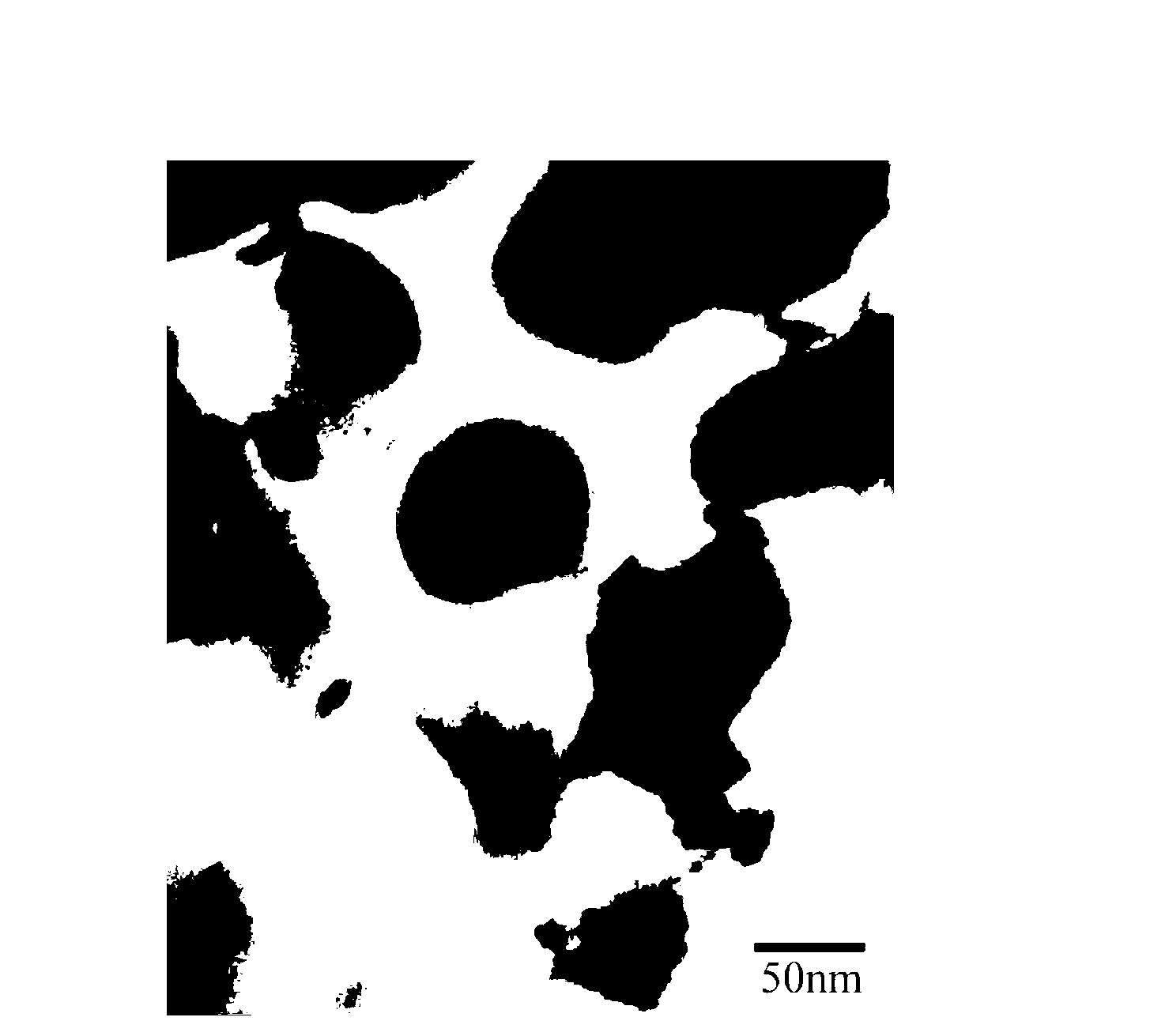

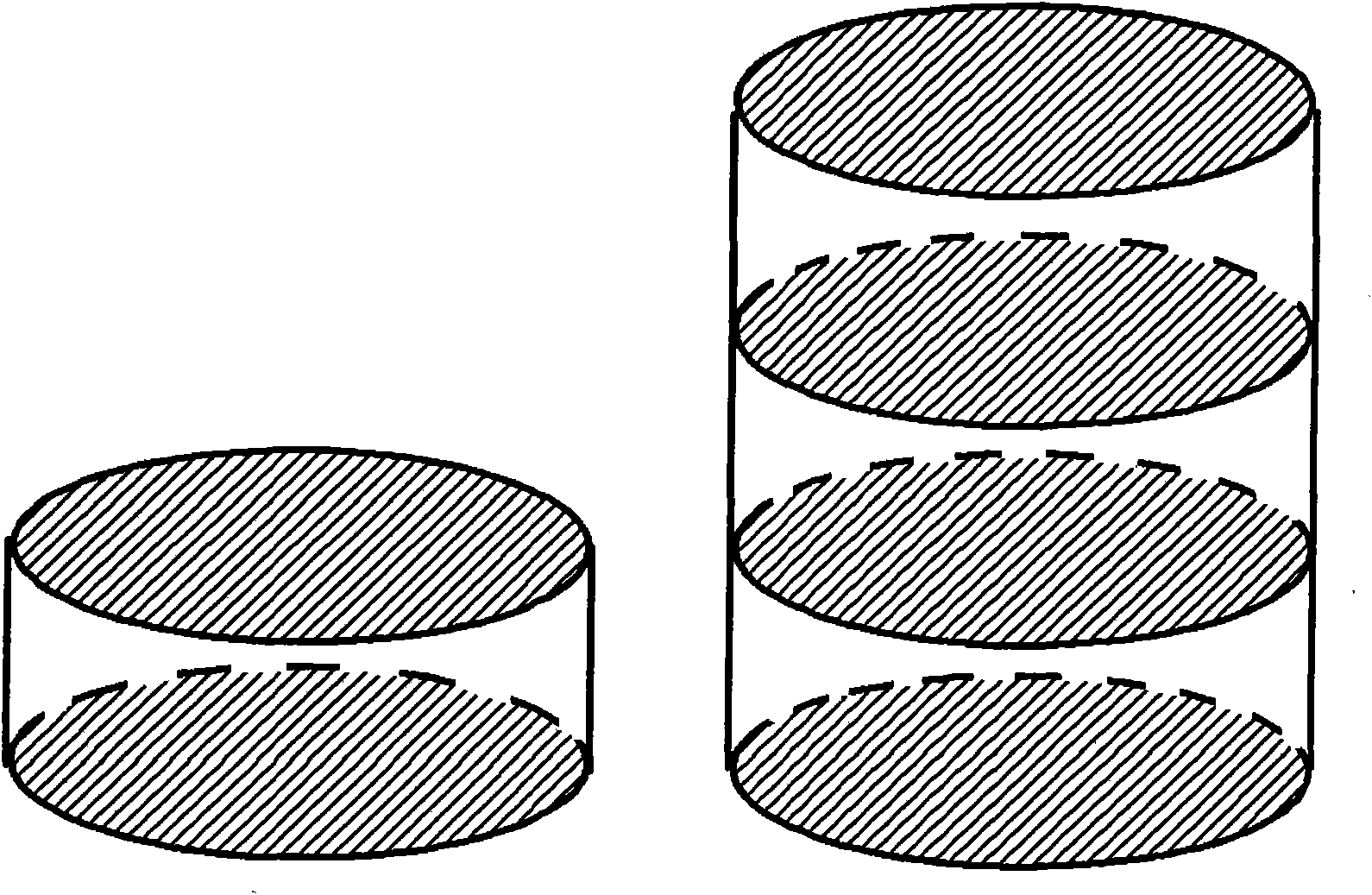

Process for preparing high-density zirconium diboride blocks by spark plasma sintering

InactiveCN1837044ASintered to achieveFast sinteringZirconium compoundsMetal boridesHigh densityAxial pressure

The invention refers to a method for preparation of zirconium diboride block material. The method is about a discharging plasma sinter high-integrity zirconium diboride block material, the character is lies in it includes steps as follows: directly posting coated format ZrB2 in graphite mould, and then putting mould in discharging plasma sintering furnace, applying axial pressure of 10- 50MPa, adopting vacuum condition or interia atmosphere which vacuum degree is less than 10Pa, sintering in sintered temperature of 1600- 2200Deg C, heating-up with rate of 50-500Deg C / min, heat preserving for 1-30min, cooling under 1300Deg C with cooling rate of 10-100Deg C / min, finally furnace cooling to room temperature, getting high degree of compactness zirconium diboride block material. The produced zirconium diboride block materials have high degree of compactness, hardness, high-temperature strength and oxidation resistance capability.

Owner:WUHAN UNIV OF TECH

Manufacturing method of high-precision and high-reliability NTC thermistor chip

The invention discloses a manufacturing method of a high-precision and high-reliability NTC thermistor chip, which comprises the following steps of: 1) weighing corresponding metal oxides according to a chemical formula Mn3-x-y-zNixFeyCozQtO4, mixing, ballmilling, and roasting into thermal sensitive ceramic pre-powder A, 2) uniformly mixing the thermal sensitive ceramic pre-powder A and nano thermal sensitive ceramic pre-powder B into a mixture, preparing the mixture into slurry, 3) filter-pressing and forming the slurry to a green body, drying and isopressing the green body, 4) conducting microwave sintering on the body obtained in Step 3), and 5) slicing an obtained sinter cake, placing an electrode and conducting heat treatment in a shielding gas atmosphere, wherein the mass percent of the B in the mixture is 5-75wt%, and the solid content of the slurry is 70-80wt%. The 1% yield of the prepared chip is improved greatly, and the reliability is also improved obviously.

Owner:GUANGZHOU MAGNET ELECTRICITY

Device for sintering transparent ceramics by induction heating

ActiveCN101551194AReduce the temperatureReduce heat exchangeMuffle furnacesRetort furnacesRheniumGlass cover

A device for sintering transparent ceramics by induction heating comprises a double-layer stainless steel furnace mantle with an intermediate course where cooling water can pass and a bracket supporting the furnace mantle, wherein the upper and lower walls of the furnace mantle are provided with gas ports used when atmosphere sintering, a tray is installed at the center of the bottom of the internal wall of the furnace mantle, a quartz barrel is disposed on the tray, a ceramic sample to be sintered is disposed in a heating element, and the heating element is embedded in a heat insulating material inside the quartz barrel; the quartz barrel is covered with a quartz glass cover with a round hole at the center; an induction coil is installed outside the quartz barrel; one end of a tungsten-rhenium thermoelectric couple is penetrated into the quartz barrel passing through the round hole of the quartz glass cover and is tightly close to the external wall of the heating element; a main gas path is formed by a first baffle valve, a molecular pump, a second baffle valve and a mechanical pump connected gradually at the pumping hole of the upper side of the furnace mantle via pipelines, and pipelines directly communicated with the main gas path between the furnace mantle and the first baffle valve through the third baffle vale by the mechanical pump through the pipelines are gas bypasses.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Tap hole clay for recycled material high blast furnace and preparation method thereof

The invention belongs to the field of blast furnace iron making and particularly relates to tap hole clay for a blast furnace which replaces the conventional dense raw materials and coke powder by recycled materials and a preparation method thereof. The formula of the tap hole clay comprises the following components in percentage by weight: 55 to 70 percent of recycled material, 14 to 23 percent of clay, 2 to 5 percent of asphalt, 2 to 5 percent of sericite and 12 to 16 percent of binding agent. The dense raw materials such as dense corundum, high-alumina aggregate, an SiC raw material and the like and the coke powder are replaced by the recycled materials, so that mineral resources are saved, a large amount of energy is saved, waste discharge can be reduced effectively, the production cost of the tap hole clay is lowered and remarkable economic and social benefits are achieved.

Owner:通化耐博新材料股份有限公司

Method for preparing perovskite type composite oxide high-entropy ceramic through hot pressed sintering

The invention belongs to the field of high-entropy ceramic materials and particularly discloses a method for preparing perovskite type composite oxide high-entropy ceramic through hot pressed sintering. The A position of the perovskite type composite oxide high-entropy ceramic is occupied by Sr, and the B position of the perovskite type composite oxide high-entropy ceramic is composed of Zr, Sn, Ti, Hf elements and any one selected from the group consisting of Nb, Ta, Mn and Tb elements in a nearly equal molar ratio. The Sr(Zr<0.2>Sn<0.2>Ti<0.2>Hf<0.2>M<0.2>)O<3> (wherein M is Nb, Ta, Mn or Tb) composite oxide high-entropy ceramic material is prepared by adopting a hot pressed sintering technology, and the prepared ceramic material is submicron-sized in crystal grain, compact in structure,simple in preparation process and short in period.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com