Hot ultrasonic sintering method and device of nano silver/graphene composite ink

A technology of graphene composite and sintering method, which is applied in the direction of ink, application, electrical components, etc., can solve the problems of high sintering temperature, high circuit resistivity, long sintering time, etc., and achieve excellent electrical conductivity and good mechanical bending performance , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

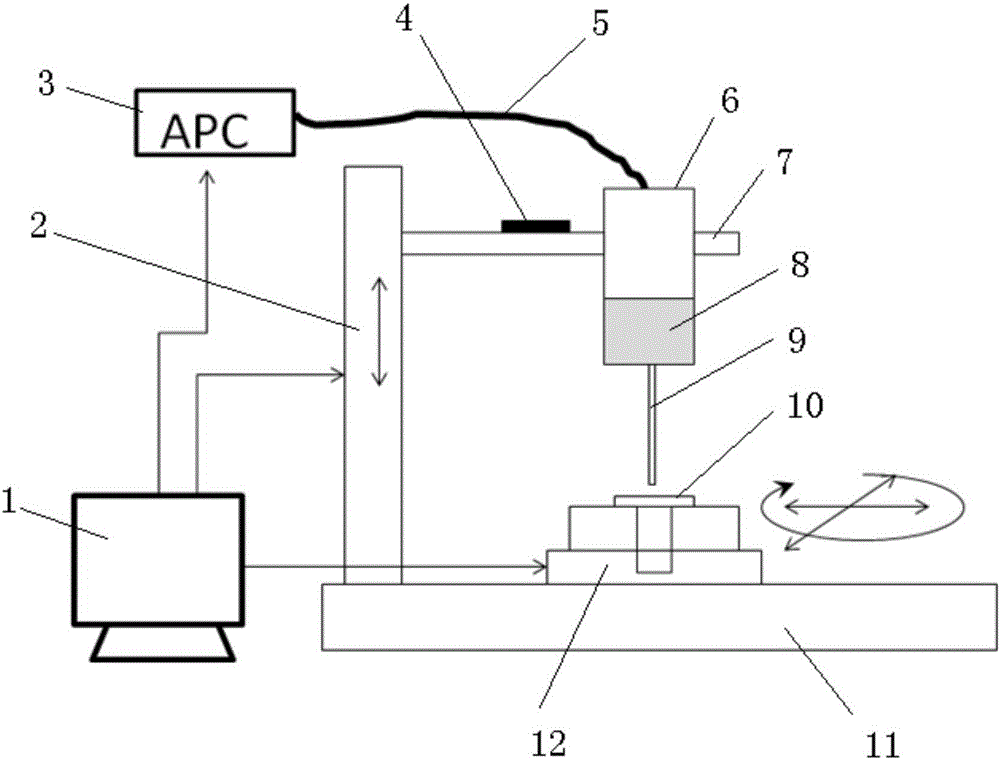

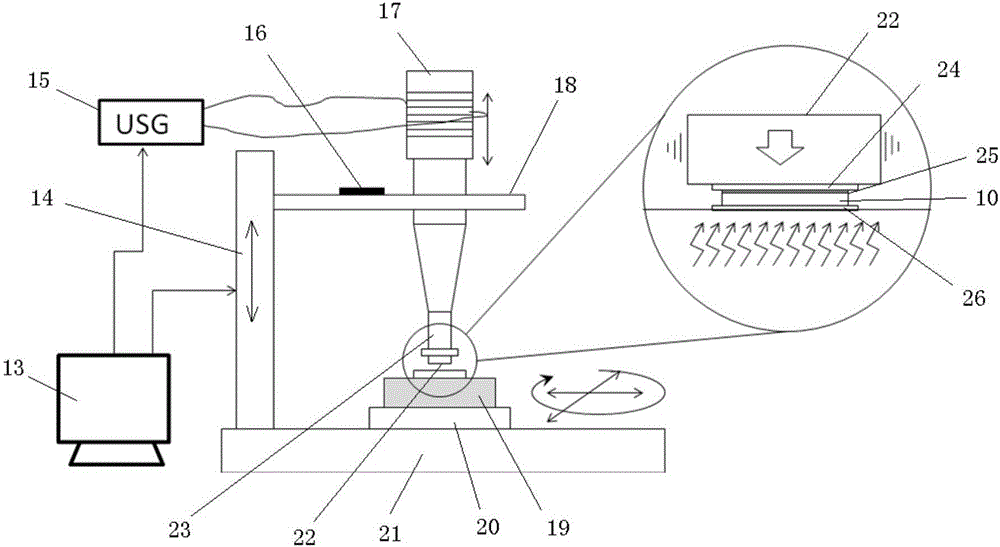

[0038] see figure 1 with figure 2 , the device provided by the invention to realize the thermosonic sintering method of nano-silver / graphene composite ink, including the writing system of nano-silver / graphene composite ink and the thermosonic sintering system of nano-silver / graphene composite ink, nano-silver / graphene The structure of the writing system of the vinyl composite ink is: the writing base 11 is provided with a writing column, an up and down translation platform 2 and a writing movement translation platform 12, and the writing column and the up and down translation platform 2 are provided with a writing fixed bracket 7, and a writing fixed bracket 7 is arranged on the writing base 11. A writing force sensor 4 and a rubber tube 6 are provided. The upper end of the rubber tube 6 is connected to the air pressure controller 3 through the air pipe 5, and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com