Graphene composite titanium dioxide photocatalyst capable of magnetic separation and recovery, and preparation method thereof

A graphene composite, magnetic graphene technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor properties, no graphene conductive properties, stability, etc., and achieve strong magnetic properties. , The preparation process is simple and feasible, and the properties are stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the graphene composite titanium dioxide photocatalyst that can be magnetically separated and recovered comprises the following steps:

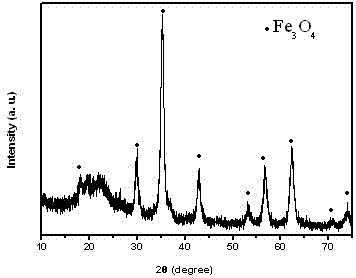

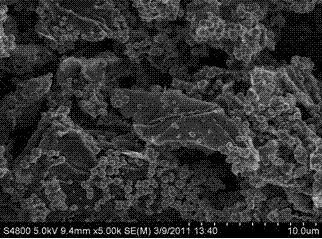

[0022] 1) Disperse 10-100mg graphene oxide in alcohol solvent, ultrasonically treat for 0.5-2 hours, add 0.2-1.0g ferric salt, stir for 1-2 hours, add 1-5g reducing agent and 1-5g surface active agent, stirred for 0.5 to 1 hour, mixed evenly, transferred to a stainless steel reaction kettle, reacted at 100 to 200°C for 10 to 24 hours, rinsed with ethanol and centrifuged, dried in vacuum at 50°C to obtain magnetic graphene powder;

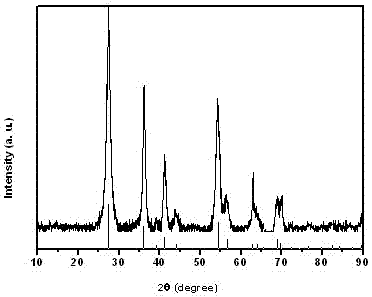

[0023] 2) Add 1-10ml of titanium compound dropwise into the mixed solution of reducing alcohol and acid with a volume ratio of 1:1-1:10, stir until clear, add water to a total volume of 20-80ml, and stir for 0.5 ~1 hour, transfer to a stainless steel reaction kettle for hydrothermal reaction at 80-200°C for 0.5-24 hours, rinse with deionized water and centrifuge, add ethanol and mix ...

Embodiment 1

[0027] 1) Disperse 10mg of graphene oxide in alcohol solvent, sonicate for 0.5 hours, add 0.2g of ferric sulfate, stir for 1 hour, add 1g of sodium acetate and 1g of polyvinyl alcohol, stir for 0.5 hours, mix well, transfer to a stainless steel reactor , reacted at 100°C for 10 hours, rinsed with ethanol and centrifuged, and dried in vacuum at 50°C to obtain magnetic graphene powder;

[0028] 2) Add 1ml of butyl titanate dropwise to a mixed solution of ethanol and hydrochloric acid with a volume ratio of 1:1, stir until clear, add water to a total volume of 20ml, stir for 0.5 hours, transfer to a stainless steel reaction kettle at 80 Hydrothermal reaction at ℃ for 0.5 hours, rinse with deionized water and centrifuge, add ethanol and mix to obtain rutile titanium dioxide sol;

[0029] 3) The magnetic graphene was impregnated in the rutile-type titania sol, stirred for 0.5 hours, and dried to powder by rotary evaporation to obtain a titania-supported magnetic graphene composite ...

Embodiment 2

[0031] 1) Disperse 100mg of graphene oxide in alcohol solvent, sonicate for 2 hours, add 1.0g of ferric chloride, stir for 2 hours, add 5g of potassium acetate and 5g of polyethylene glycol, stir for 1 hour, mix well, transfer to stainless steel In the reaction kettle, react at 200°C for 24 hours, rinse with ethanol and centrifuge, and dry in vacuum at 50°C to obtain magnetic graphene powder;

[0032] 2) Add 10ml of titanium chloride dropwise to the mixed solution of propanol and sulfuric acid with a volume ratio of 1:10, stir until clear, add water to a total volume of 80ml, stir for 1 hour, transfer to a stainless steel reaction kettle at 200°C Hydrothermal reaction at high temperature for 24 hours, rinse with deionized water and centrifuge, add ethanol and mix to obtain rutile titanium dioxide sol;

[0033] 3) The magnetic graphene was impregnated in the rutile-type titania sol, stirred for 2 hours, and dried to powder by rotary evaporation to obtain a titania-supported magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com