Negative plate, preparation method thereof and lithium battery

A negative electrode, lithium battery technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve battery safety hazards, battery capacity, uneven lithium metal deposition, serious lithium dendrites and other problems, and achieve good results. Cycling performance, inhibition of lithium dendrite generation, and effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

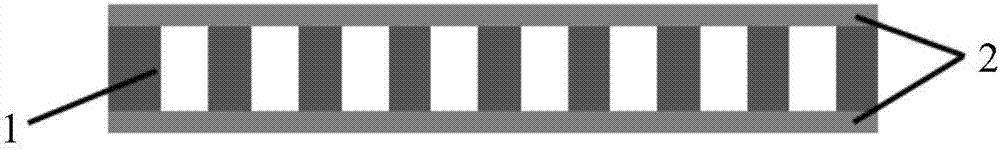

[0047] The PVDF binder dry powder is dissolved in nitrogen methylpyrrolidone (NMP) to form a concentration of 0.1 to 10% PVDF glue, then add graphene to the resulting PVDF glue, stir at a high speed to obtain a uniform graphene slurry, and then Gained slurry covers a 0.5 μm thick graphene layer 2 ( figure 1 ), and dry to remove the solvent to obtain a lithium-free negative electrode sheet.

[0048] The positive electrode sheet is prepared by a conventional method. The positive electrode active material on the positive electrode sheet is lithium iron phosphate. The negative electrode sheet, the lithium iron phosphate positive electrode sheet, and the diaphragm are laminated using a lamination process, and a liquid electrolyte is used to form a lithium battery.

Embodiment 2

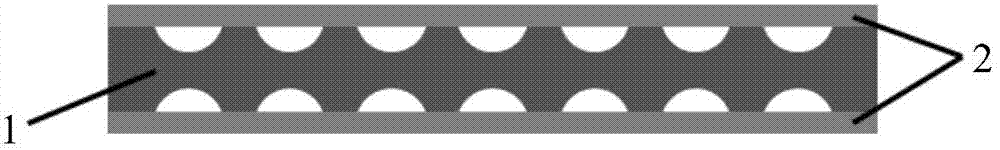

[0052] Dissolve PVDF binder dry powder in nitrogen methyl pyrrolidone (NMP) to form a PVDF glue with a concentration of 0.1-10%, then add conductive carbon black to the obtained PVDF glue, and stir at a high speed to obtain a uniform carbon black slurry. Then the obtained slurry is covered with a 5 μm thick conductive carbon black layer 2 ( figure 2 ), and dry to remove the solvent to obtain a lithium-free negative electrode sheet.

[0053] The positive electrode sheet was prepared by a conventional method. The active material of the positive electrode in this example was lithium cobalt oxide. The negative electrode sheet, lithium cobalt oxide positive electrode sheet, and separator were wound together with a gel electrolyte to make a lithium battery.

Embodiment 3

[0057] Dissolve commercially available acrylic adhesive dry powder in deionized water to form an acrylic adhesive with a concentration of 0.1 to 10%, then add carbon nanotubes to the acrylic adhesive, and stir at high speed to obtain uniform carbon nanotubes. tube slurry, and then the resulting slurry is covered with a 10 μm thick carbon nanotube layer 2 ( figure 2 ), and the lithium-free negative electrode sheet can be obtained after drying to remove the solvent.

[0058] The positive electrode sheet is prepared by a conventional method. The positive electrode active material in this example is a ternary material, and the negative electrode sheet, the ternary positive electrode sheet, and the diaphragm are laminated using a solid electrolyte to form a lithium battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com