Method for preparing nanometer porous copper powder

A nanoporous copper and powder technology, applied in the field of preparation of nanomaterials, can solve the problems of long corrosion time, unfavorable high efficiency, large-scale production, etc., and achieve the effects of shortening corrosion time, reducing pore size, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh pure copper and pure aluminum powder (purity ≥ 99.5%, mass ratio) according to the atomic percentage of 32% copper and 68% aluminum, and weigh 30g in total. Adopt zirconia ball mill tank, weigh zirconia balls according to the ball-to-material ratio of 15:1, wherein the mass ratio of the balls with diameters of 10 mm, 6 mm, and 4 mm is 1:1:1, and weigh the grinding aid (stearin acid), its weight is 1% (mass ratio) of the powder.

[0020] (2) Put the powder and balls into the ball mill tank in the order of "ball first, then feed", set the speed of the high-energy ball mill to 300 rpm, stop for 10 minutes every 30 minutes, set the automatic forward and reverse, The ball milling time is 60 hours, and the Al-Cu alloy powder is obtained after the ball milling treatment.

[0021] (3) Prepare a 2M (M=mol / L, the same below) sodium hydroxide aqueous solution with analytical reagents and distilled water, and pass high-purity nitrogen gas for deoxygenation treatmen...

Embodiment 2

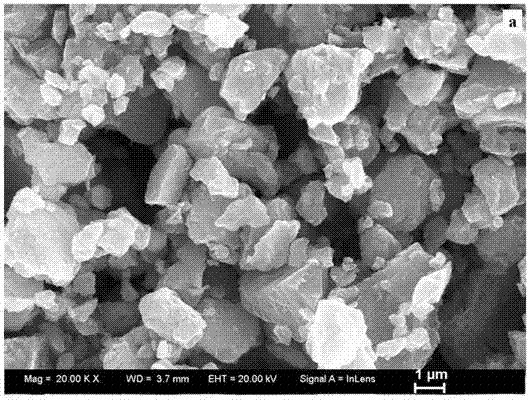

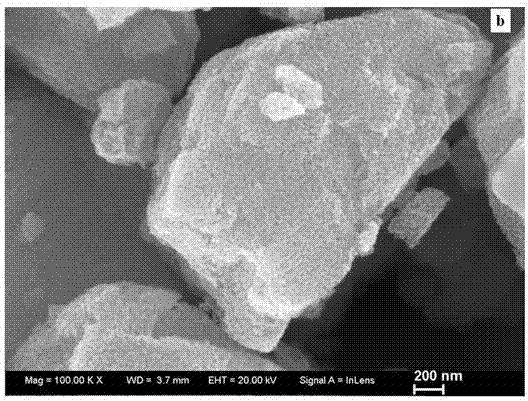

[0024] The accompanying drawing is a scanning electron microscope photo of a nanoporous copper sample obtained after Al-Cu alloy powder (Cu atomic ratio is 33.3%) dealloyed in 2M sodium hydroxide solution. The dealloying temperature is 20°C and the reaction time is 40 minute

[0025] (1) Weigh pure copper and pure aluminum powder (purity ≥ 99.5%, mass ratio) according to the atomic percentage of 33.3% copper and 66.7% aluminum, and weigh 30g in total. Adopt zirconia ball mill tank, weigh zirconia balls according to the ball-to-material ratio of 17:1, wherein the mass ratio of 10 mm, 6 mm, and 4 mm diameter balls is 1:1:1, and weigh the grinding aid (stearin acid), its weight is 1% (mass ratio) of the powder.

[0026] (2) Add the powder and balls into the ball mill tank in the order of "ball first, then feed", set the speed of the high-energy ball mill to 350 rpm, stop for 10 minutes every 30 minutes, and set automatic forward and reverse, The ball milling time was 50 hour...

Embodiment 3

[0030] (1) Weigh pure copper and pure aluminum powder (purity ≥ 99.5%, mass ratio) according to the atomic percentage of 35% copper and 65% aluminum, and weigh 30g in total. Adopt zirconia ball mill pot, weigh zirconia balls according to the ball-to-material ratio of 20:1, wherein the mass ratio of 10 mm, 6 mm, and 4 mm diameter balls is 1:1:1, and weigh the grinding aid (stearin acid), its weight is 1% (mass ratio) of the powder.

[0031] (2) Add the powder and balls into the ball mill tank in the order of "ball first, then feed", set the speed of the high-energy ball mill to 250 rpm, stop for 10 minutes every 30 minutes, and set automatic forward and reverse rotation. The ball milling time is 70 hours, and the Al-Cu alloy powder is obtained after the ball milling treatment.

[0032] (3) Prepare 2.5M sodium hydroxide aqueous solution with analytical reagent and distilled water, and pass through high-purity nitrogen gas for deoxygenation treatment for 15 minutes, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com