Patents

Literature

50results about How to "Control pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High specific surface area graphene with well-developed mesopores, and preparation method thereof

ActiveCN102992313AImprove permeabilityStrong intercalationGraphenePhosphoric acidPotassium hydroxide

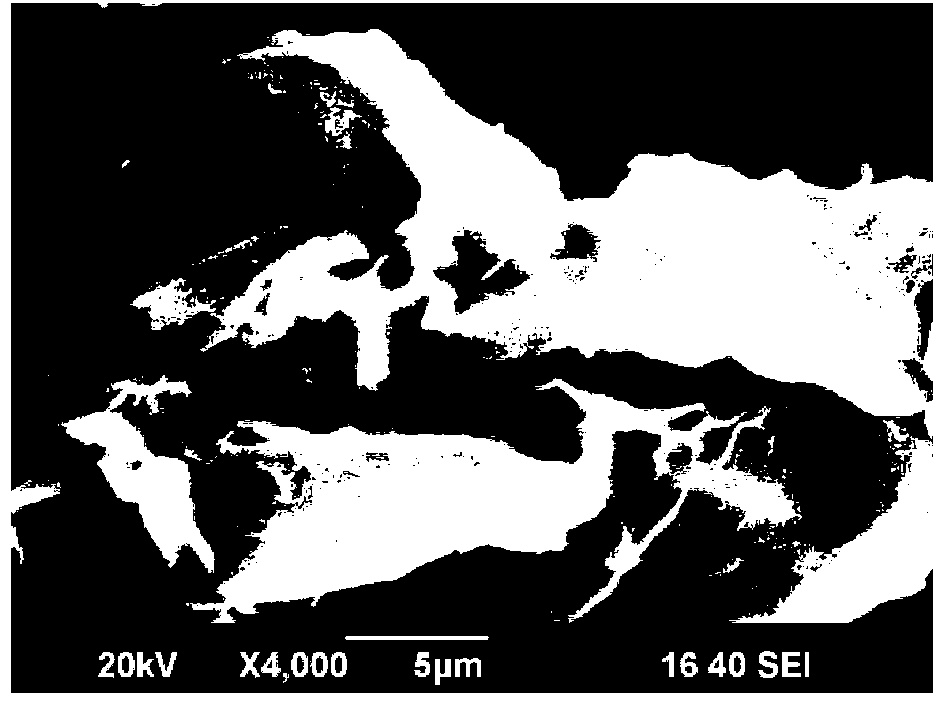

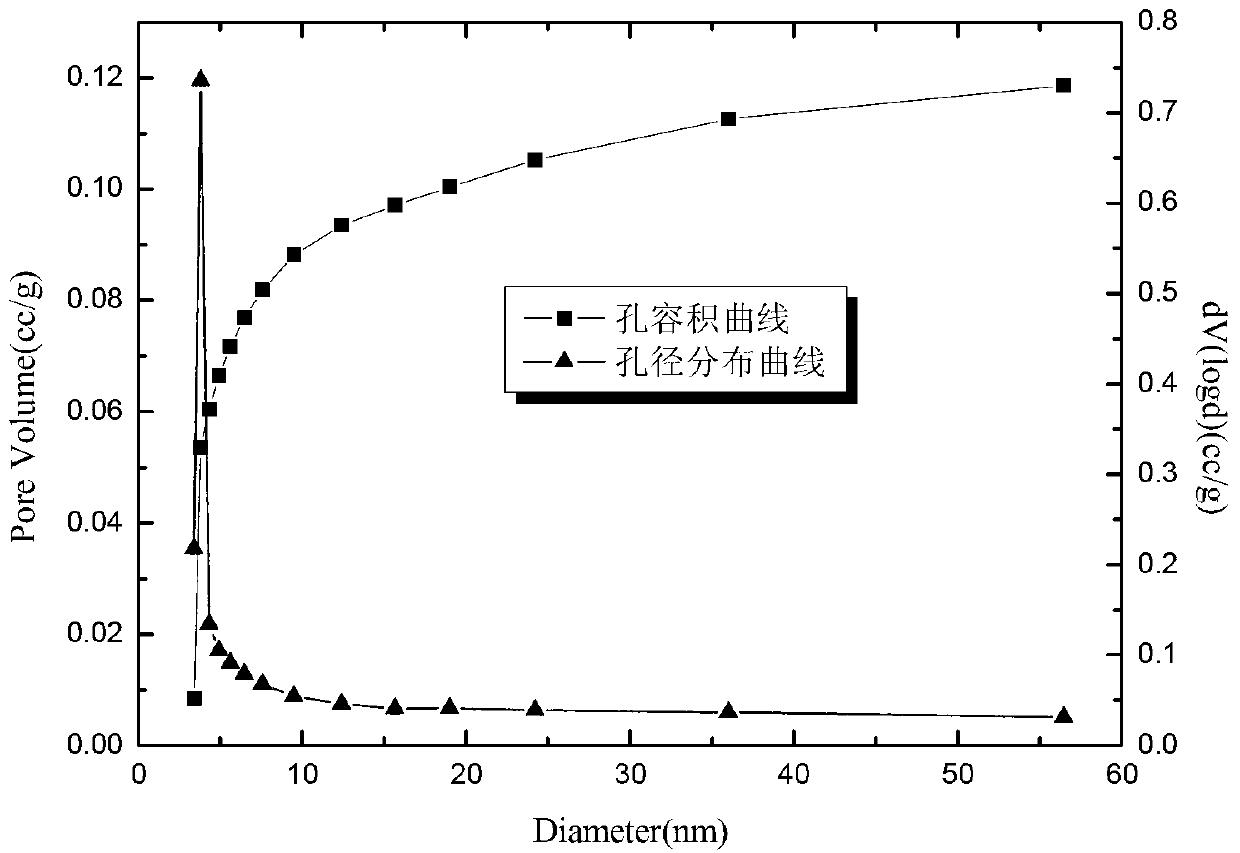

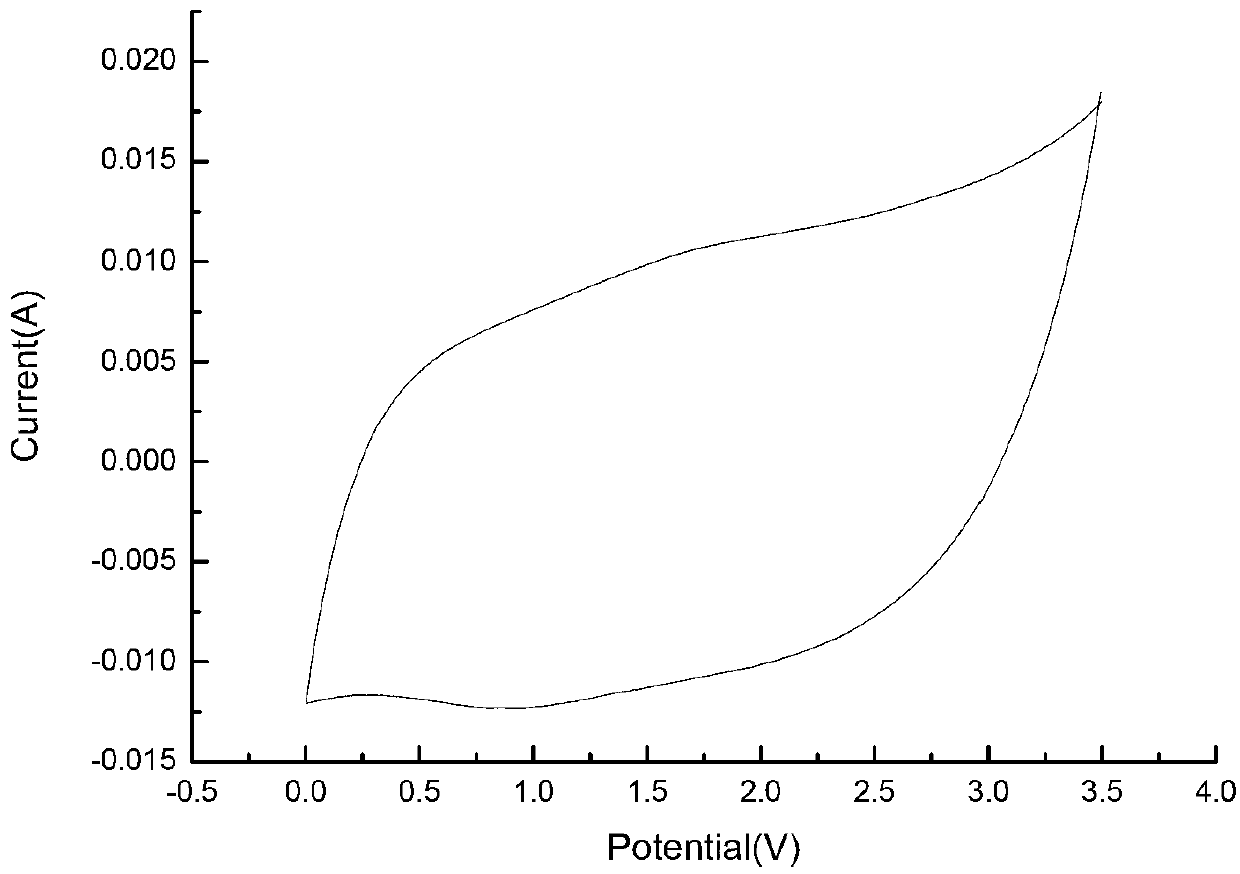

The invention relates to a preparation method of high specific surface area graphene with well-developed mesopores. The method comprises the steps of mixing graphene oxide and an activating agent under a protective atmosphere; passing through an activating gas to active the mixture; and finally obtaining the high specific surface area graphene with the well-developed mesopores through processes of washing, filtering and drying. The activating agent is selected any one from potassium hydroxide, sodium hydroxide, phosphoric acid and zinc chloride or a combination of at least two of the above materials. The method is simple in equipment and low in cost, is safe and reliable, has small pollutions and high production efficiency, and is suitable for large-scale production. The obtained graphene has high specific surface area, and is more suitable for migration of electrolyte ions.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

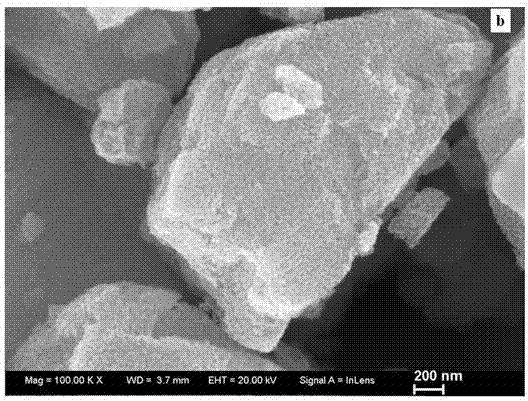

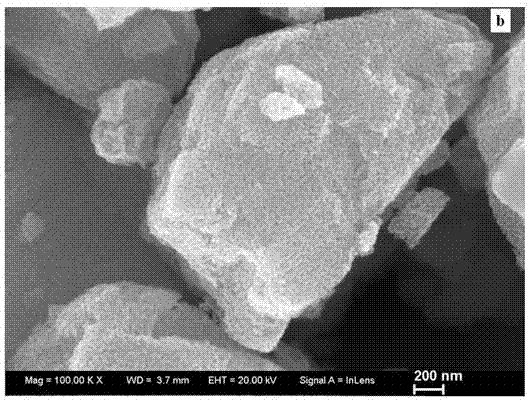

Method for preparing nanometer porous copper powder

The invention discloses a method for preparing nanometer porous copper powder. The method comprises the following steps of: weighing pure copper powder and pure aluminum powder in a ratio of Al-Cu alloy ingredients; adding the pure copper powder, pure aluminum powder and grinding balls into a ball-milling tank, adding a grinding aid, and performing mechanical alloying treatment in a ball-milling machine to obtain Al-Cu alloy powder; and performing dealloying on the obtained Al-Cu alloy powder in alkaline solution, and washing a sample until the sample is neutral to obtain the nanometer porouscopper powder. Precursor alloy is prepared by a mechanical alloying method, and a process is simple; precursor alloy powder has small sizes, so the corrosion time is shortened greatly (within 1 hour generally), and the production efficiency is improved greatly; and the hole size of the prepared nanometer porous copper is only between 15 and 80 nanometers and is reduced greatly, the porous copper is the powdery sample, and a specific surface area is improved greatly.

Owner:UNIV OF JINAN

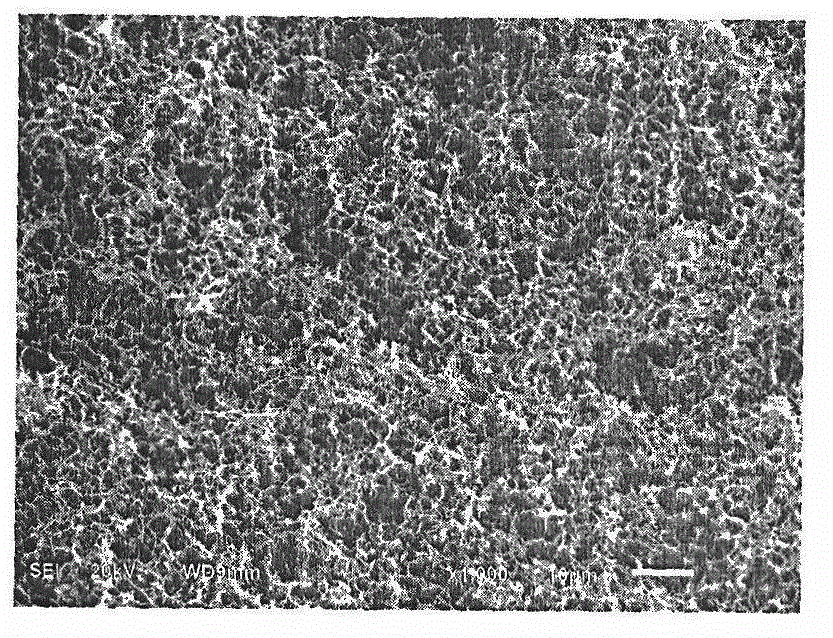

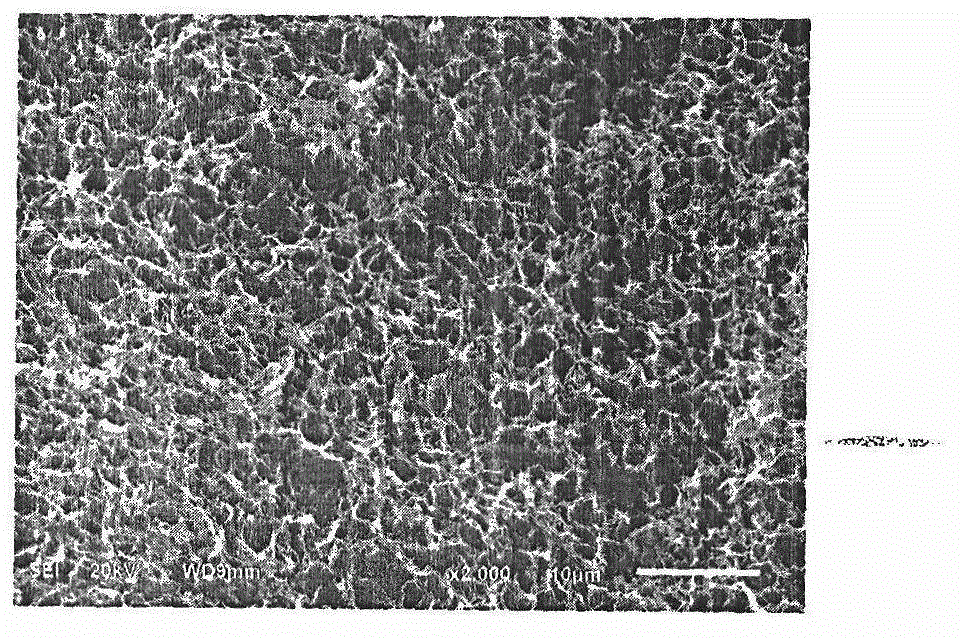

Graphene-based haze-resisting mask filtering material and preparation method thereof

InactiveCN104525107ALarge specific surface areaEffective filteringOther chemical processesDispersed particle filtrationCross-linkHigh absorption

The invention relates to a graphene-based haze-resisting mask filtering material and a preparation method thereof. The material has a three-dimensional graphene sponge structure assembled from graphene oxide. The method and an application comprises the following points: (1) cross-linking agents such as ascorbic acid are added into a graphene oxide water solution; with a hydrothermal reaction, graphene slices are subjected to self assembly, such that porous spongy three-dimensional graphene is obtained; (2) the porous spongy graphene has good mechanical strength, and can be cut into different shapes; (3) the structure of the graphene sponge can be regulated through changing the size of graphene oxide and the addition amount of the cross-linking agents; (4) the porous spongy graphene has high specific surface area and relatively high quantity of surface functional groups; and the porous spongy graphene has high absorption effect and certain bacteria resistance. The preparation process of the graphene absorption material has simple process and low cost. With the method, graphene sponge pore size can be regulated. The graphene sponge can be used as a mask filtering sheet which can effectively filter air pollutants such as PM2.5 particles, and can be used in the fields such as dye and oil dirt absorption.

Owner:杜茂龙

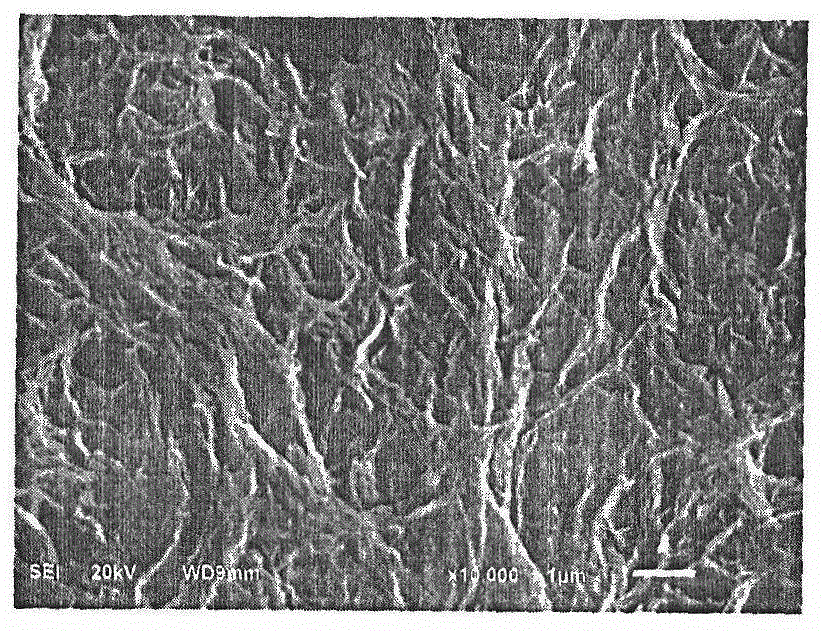

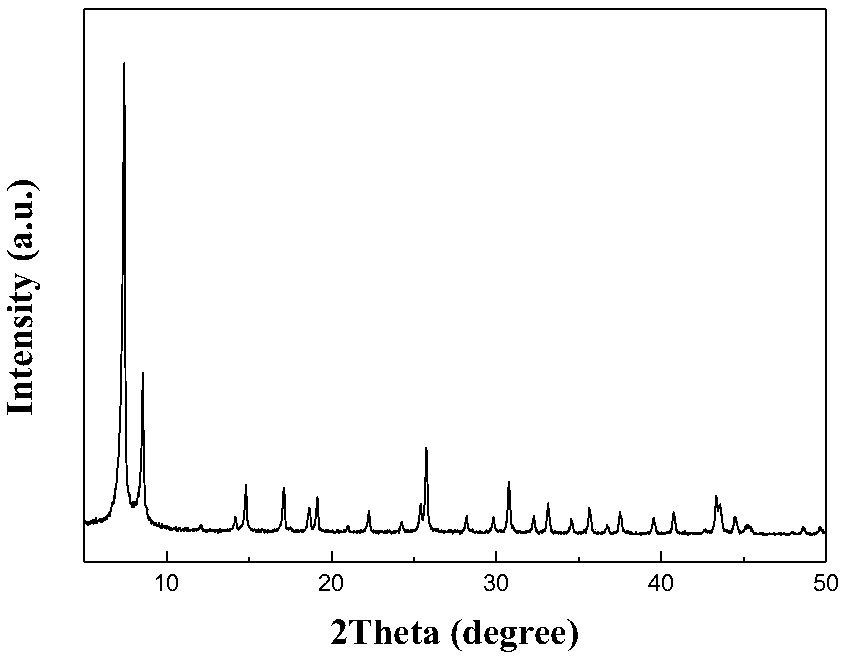

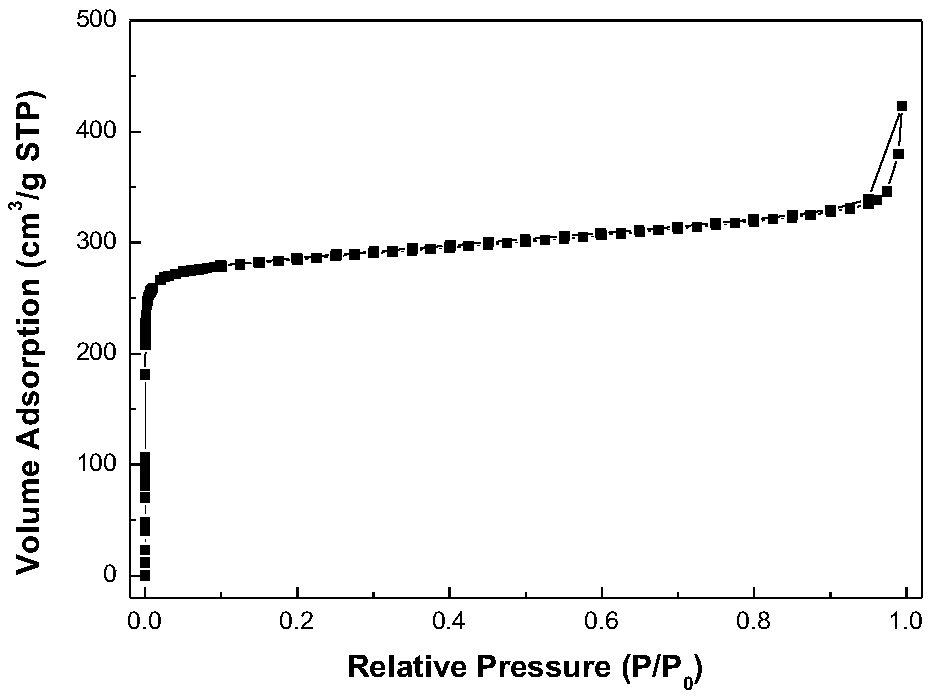

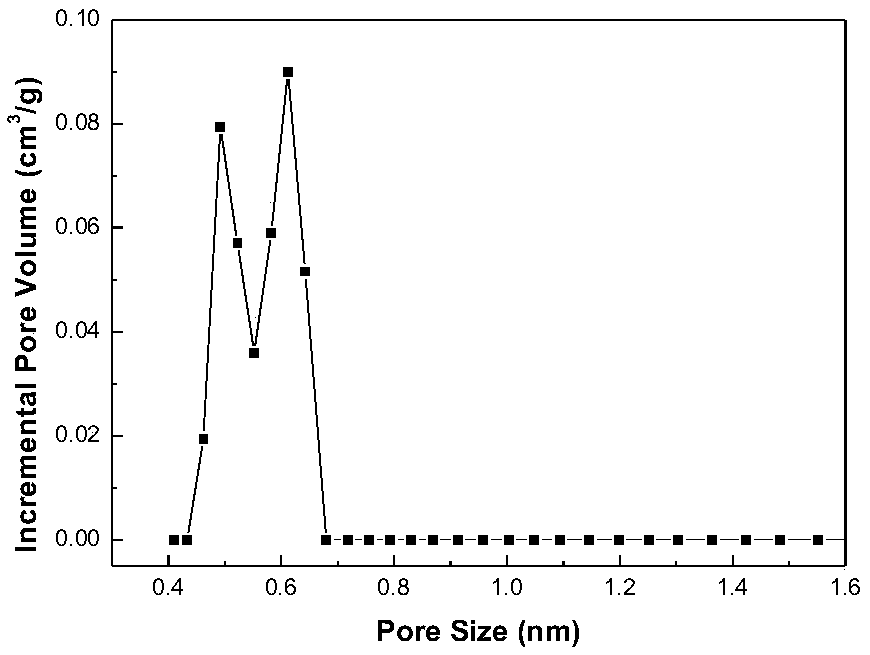

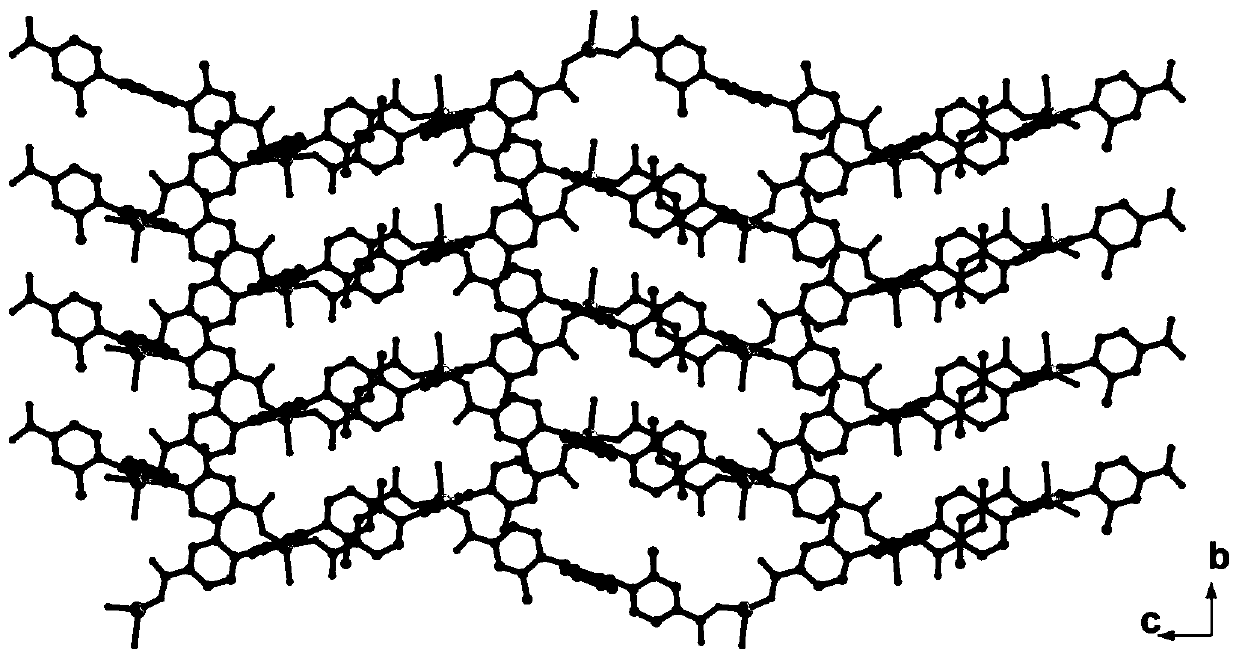

Preparation method for synthesizing metal organic framework UiO-66 adsorbents by aid of mixed ligands

InactiveCN109395698AFacilitated DiffusionImprove adsorption capacityOther chemical processesSorbentMetal-organic framework

The invention provides a preparation method for synthesizing metal organic framework UiO-66 adsorbents by the aid of mixed ligands. The preparation method includes mixing zirconium sources and regulators with one another and then dissolving the zirconium sources and the regulators in solvents to obtain solution A; uniformly dissolving 2-aminoterephthalic acid, terephthalic acid and solvents to obtain mixed ligand solution B; dropwise adding the solution A into the solution B at the constant speed to obtain solution C; injecting the solution C into reaction kettles with polytetrafluoroethylenelinings and carrying out crystallization at the temperatures of 100-160 DEG C for 18-24 h; carrying out reaction, and then carrying out treatment to obtain target products. As proved by XRD (X-ray diffraction) analysis, the obtained products are UiO-66 adsorbent materials. The preparation method for synthesizing the adsorbent materials has the advantages that the preparation method is simple; theUiO-66 adsorbents synthesized by the aid of the mixed ligands are excellent in chemical and thermal stability; the hydrogen adsorption capacity of the metal organic framework UiO-66 adsorbents can beimproved to a great extent, and effective treatment methods and research directions can be provided to hydrogen adsorption separation and storage.

Owner:DALIAN UNIV OF TECH

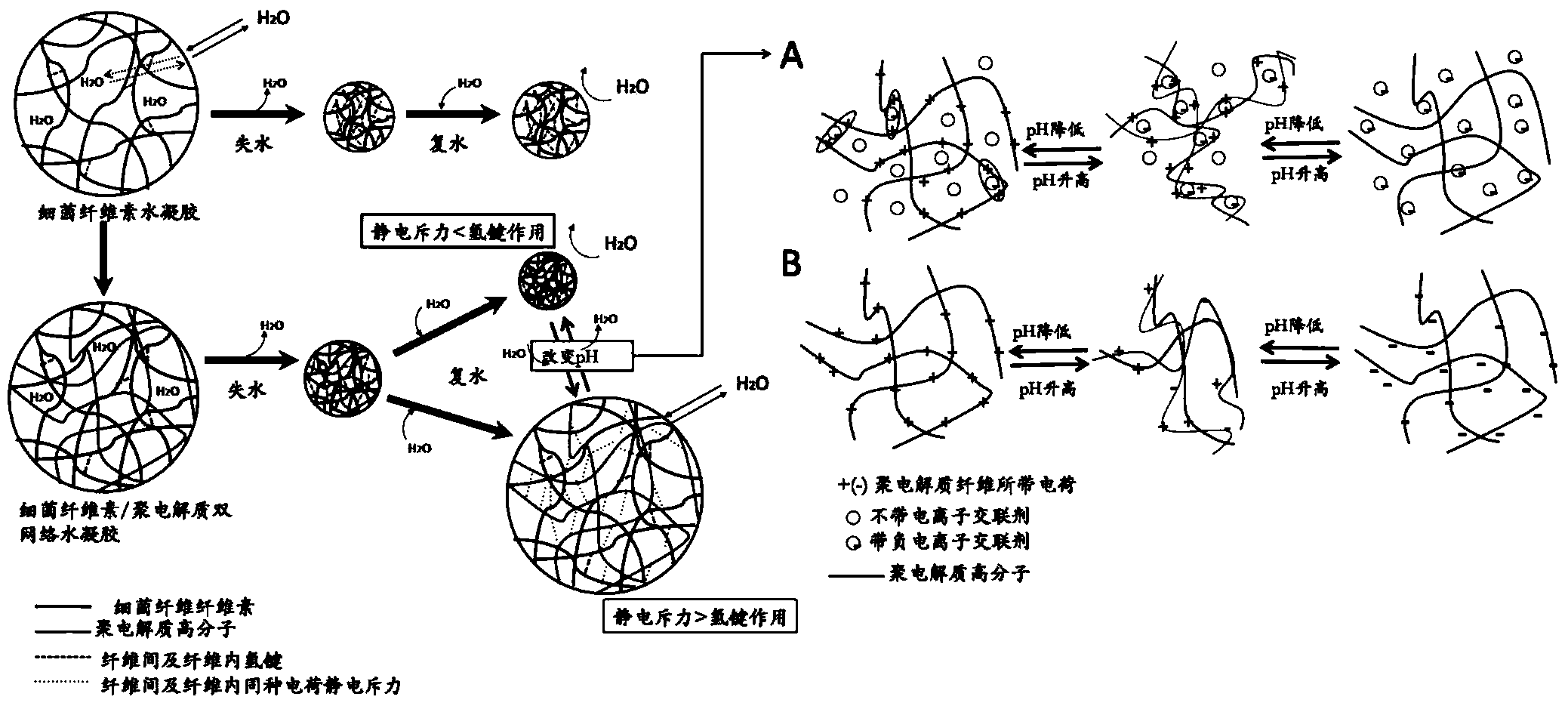

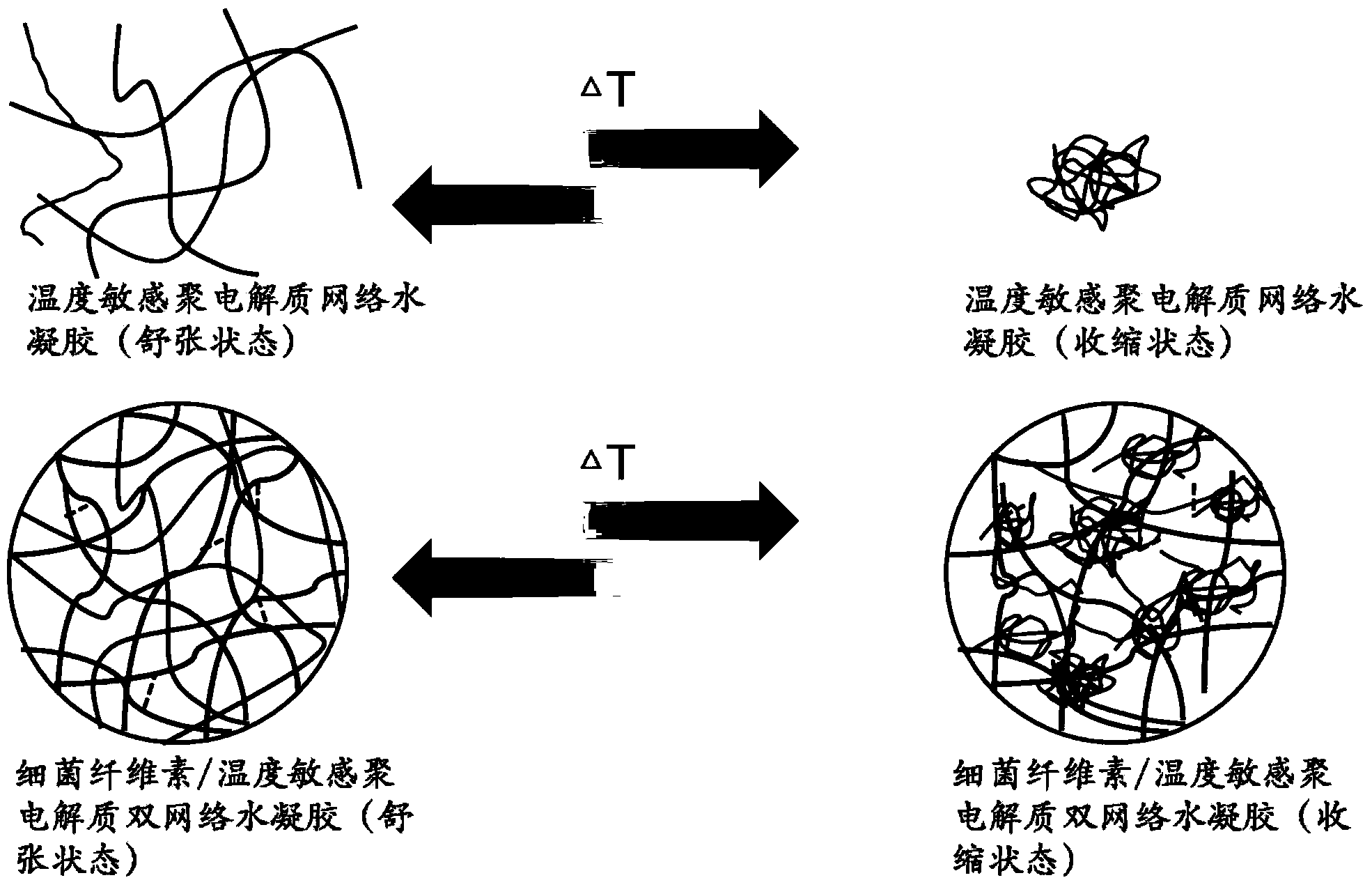

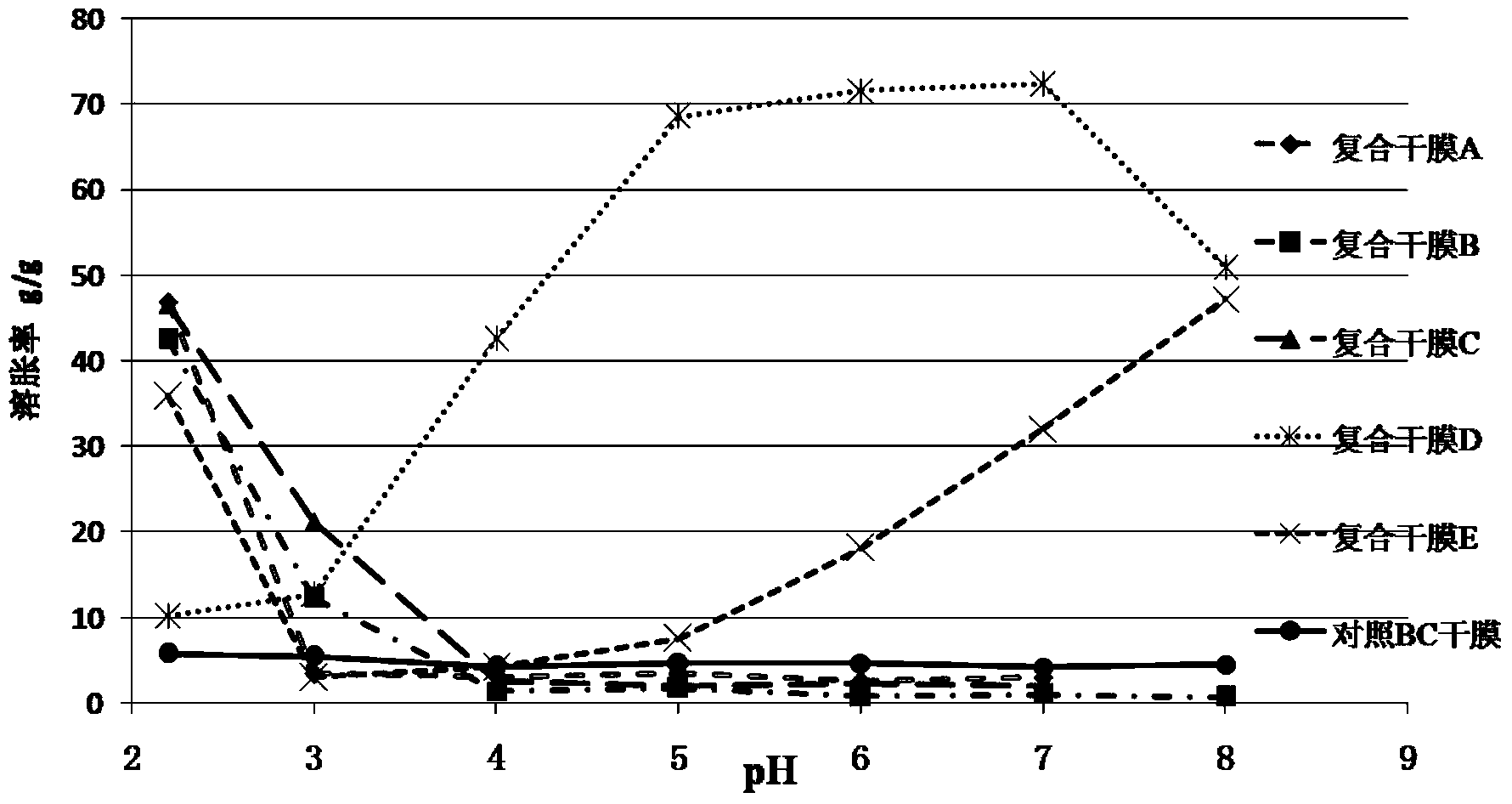

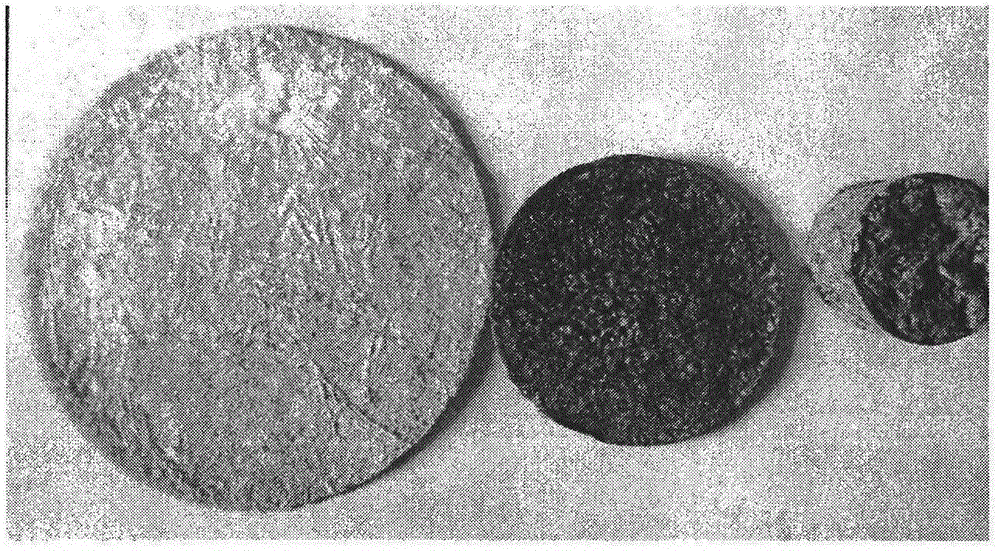

Stimuli-responsive composite material made from bacterial nano cellulose as well as preparation method and application of stimuli-responsive composite material

ActiveCN103665439AHigh strengthGood biocompatibilityPharmaceutical non-active ingredientsAbsorbent padsTemperature responseSwelling capacity

The invention relates to a stimuli-responsive composite material made from bacterial nano cellulose as well as a preparation method and application of the stimuli-responsive composite material. A bacterial nano cellulose base material in a hydrogel state is combined with polyelectrolyte macromolecules in an interpenetrating or semi-interpenetrating manner, and then is wholly or partially dehydrated to obtain the composite material. The composite material is high in rehydration and swelling capacities under the condition of a particular Ph, and keeps the characteristics of low swelling capacity and difficulty in rehydration under the condition of an off-design Ph value. The composite material has the characteristics of temperature response; the pore size of network of the composite material can be controlled, and the penetration rate of solute molecules can be controlled to release a drug in a control manner. Meanwhile, the composite material has the characteristics of high strength, high biocompatibility and the like of the bacterial nano cellulose, and can be applied to smart wound dressings, smart drug carriers, sensors, chemical valves and the like. The composite material has the advantages that the preparation process is simple, the cost is low, and a good application prospect is achieved.

Owner:DONGHUA UNIV

Method of preparing adsorbent of heavy metal ion

InactiveCN1727061AConducive to environmental protectionEasy to operateOther chemical processesSilicon compoundsIonHeavy metals

A process for preparing the adsorbent of heavy metal ions (Hg, Cd, Cu, Cr and Zn) features that the non-ionic polymer as template and the mixture of (MeO)3SiCH2CH2Si(OMe)3 and (MeO)3SiCH2CH2CH2SH are copolymerized in acidic medium to obtain the organic / inorganic hybridized meso-porous material containing-SH adsorbing center. Its advantages are large specific surface area, order artery structure, high stability and high adsorptive power.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Graphene-based air filter material and preparation method thereof

InactiveCN105251268ALarge specific surface areaEffective filteringFiltration separationAir filterFreeze-drying

The invention relates to a graphene-based air filter material and a preparation method thereof, and the material is of a three-dimensional graphene sponge structure assembled by oxidized graphene. The method and application comprise the steps that (1) a thickening agent is added to an oxidized graphene aqueous solution, and pulp is added as a crosslinking agent, so as to obtain porous spongy three-dimensional graphene by using a freeze-drying method; (2) the porous spongy graphene has good mechanical strength and can be freely bent and cut into different shapes; (3) the hole structure of the spongy graphene can be regulated and controlled by changing the size of the oxidized graphene and the quantity of the added crosslinking agent; (4) the porous spongy graphene has a high specific surface area and more surface functional groups and has a strong adsorption effect and certain antibacterial properties. The graphene adsorption material has the advantages of simple preparation process and low cost, the hole size of the spongy graphene can be regulated and controlled, and the graphene adsorption material can be used as the filter material for mask filter discs, filter nets of air conditioners, automobile filters and the like and can be applied to the fields of dye and oil adsorption and the like.

Owner:杜茂龙

Novel lithium ion battery separating membrane and preparation method thereof

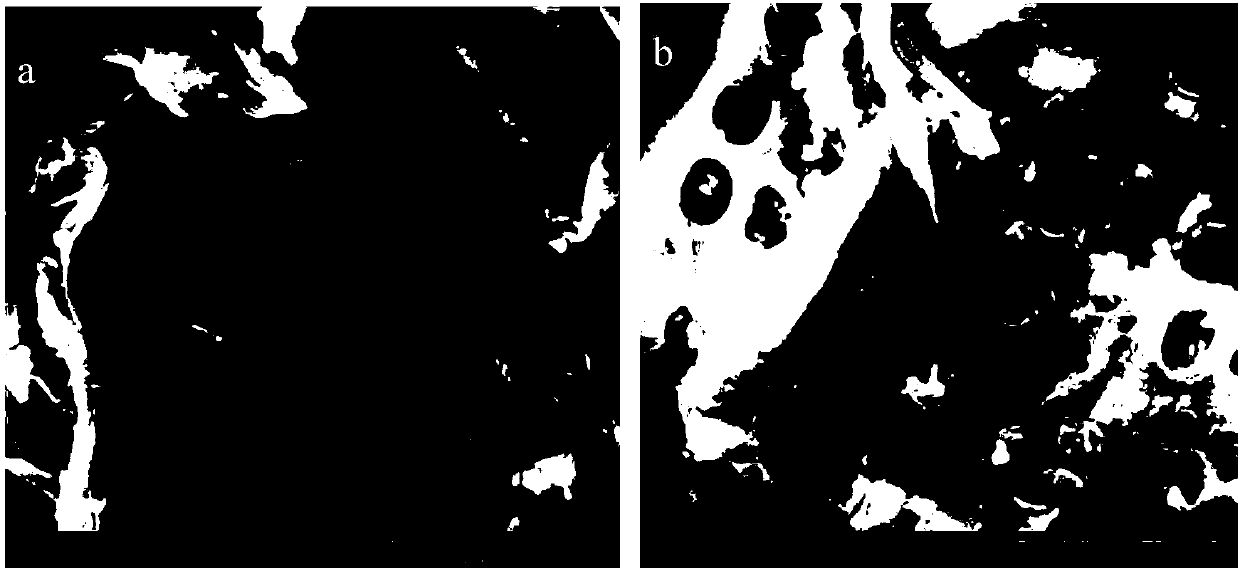

ActiveCN103515562AImprove the performance of pro-retaining fluidUniform thicknessCell component detailsPhysical chemistryCotton fibre

The invention relates to a novel lithium ion battery separating membrane and a preparation method thereof. The separating membrane uses cotton fibers and polypropylene fibers as principal materials and is obtained by wet-method paper-making process. The lithium ion battery separating membrane provided by the invention has the advantages of good lyophilic property, good heat stability, high porosity, uniform pore distribution, small pore size and the like and overcomes the technical defects that the conventional battery separating membrane has poorer lyophilic property, good heat stability and low porosity.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

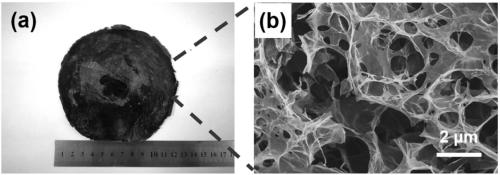

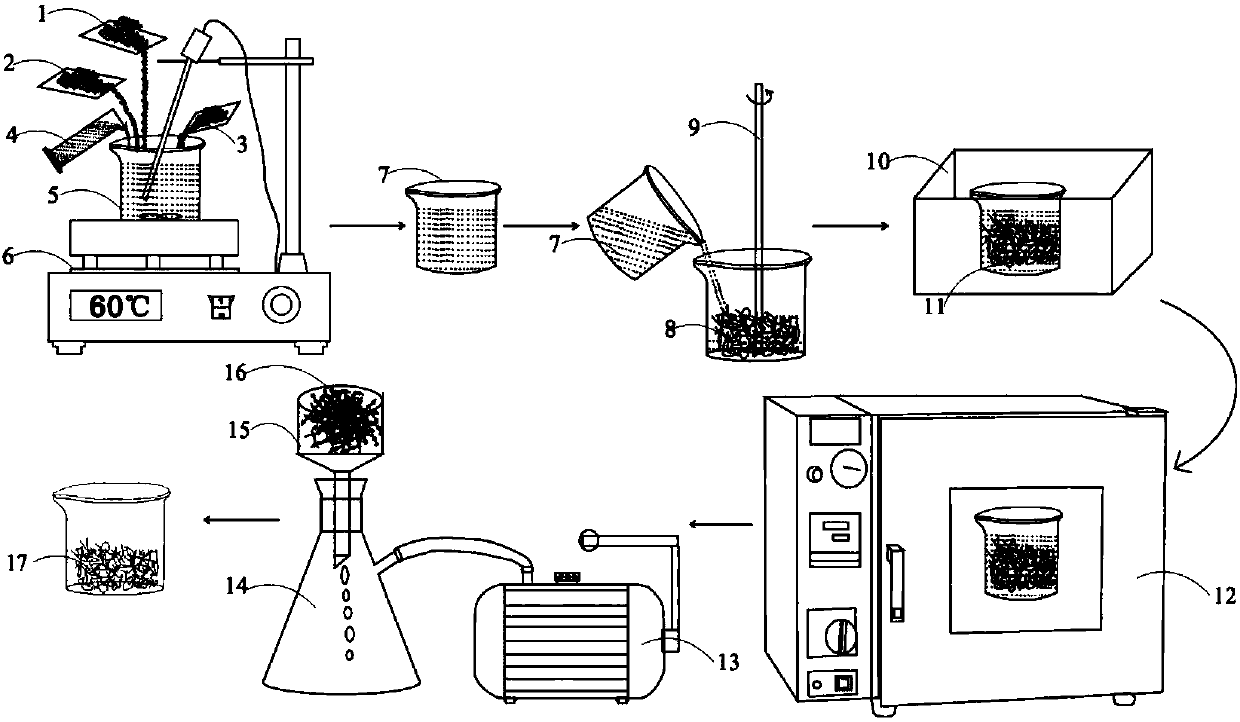

Preparation method of graphene aerogel

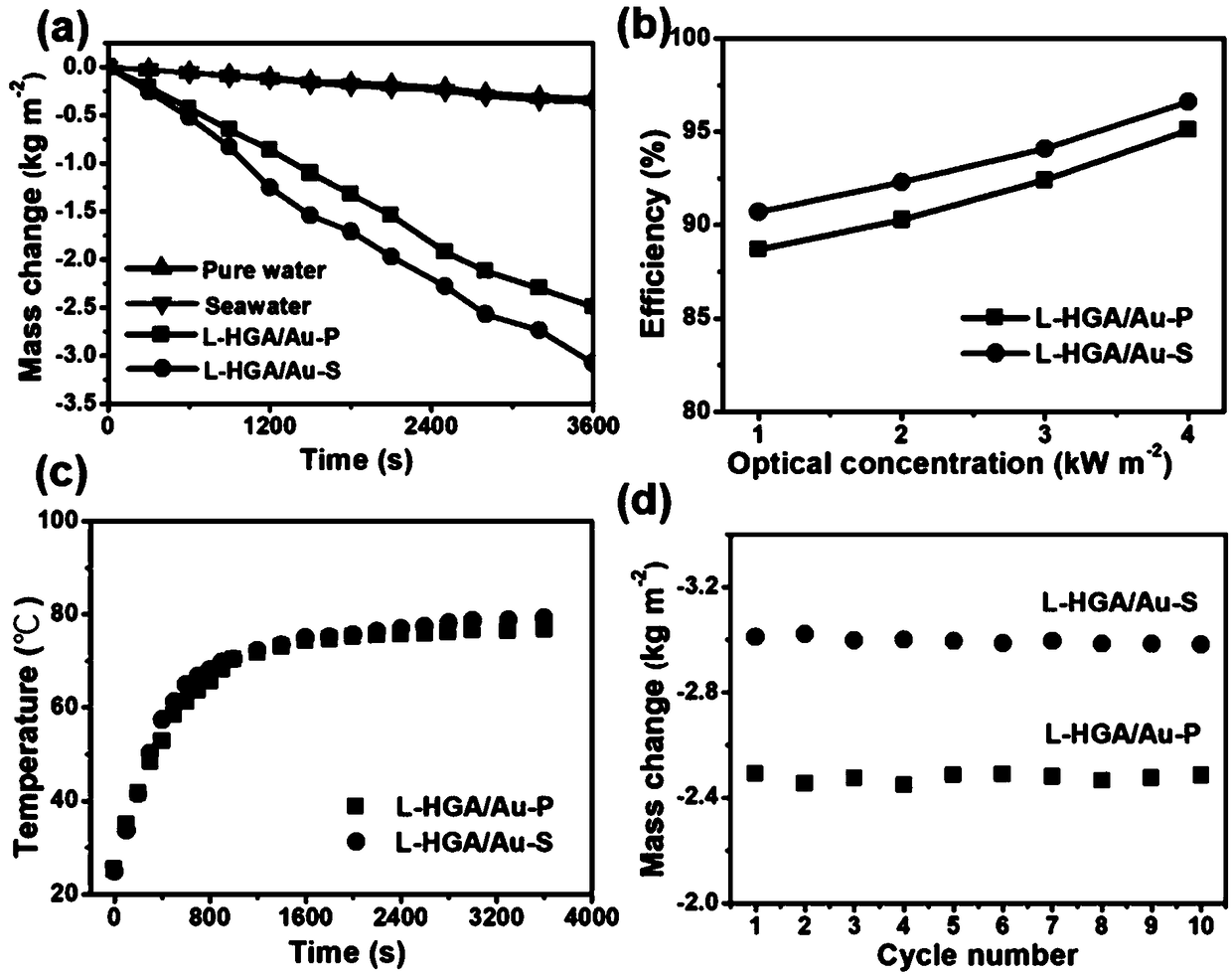

InactiveCN109336093AImprove impactImprove photothermal propertiesGeneral water supply conservationSeawater treatmentCompound aReduction treatment

The invention relates to a preparation method of graphene aerogel. The preparation method comprises the following steps: performing freeze-drying and thermal reduction treatment on a sample obtained by spraying pre-reduction oxidization graphene sol to obtain a graphene aerogel thin film, and adding nano noble metals into the graphene aerogel thin film to prepare the graphene aerogel. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the hydrophilcity and the hydrophobicity of the graphene aerogel are adjusted by compounding a hydrophilic material; the photo-thermal property of the material is further improved by adding the nano noble metals into the graphene aerogel thin film, so that the water evaporation efficiency of sea water or wastewater is promoted.

Owner:SHANGHAI JIAO TONG UNIV

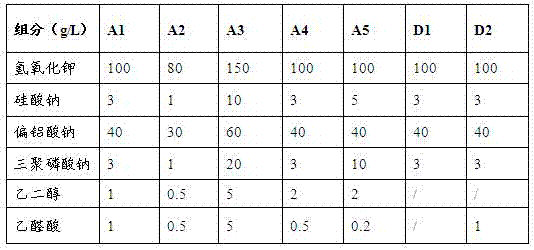

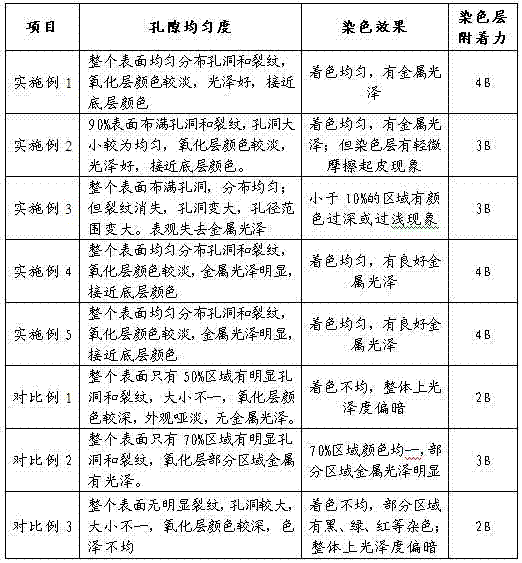

Magnesium alloy anodizing solution, preparing method and anodizing method for magnesium alloy

The invention relates to a magnesium alloy anodizing solution. The anodizing solution is an aqueous solution containing hydroxide, silicate, meta-aluminate, phosphate, ethylene glycol and glyoxylic acid. The invention further provides a preparing method for the magnesium alloy anodizing solution and an anodizing method for the magnesium alloy with the adoption of the magnesium alloy anodizing solution. According to the provided magnesium alloy anodizing solution, sizes of pores in an oxidation film can be effectively reduced, uniformity of the pores is improved, and the dyeing effect of the rear section is improved accordingly.

Owner:BYD CO LTD

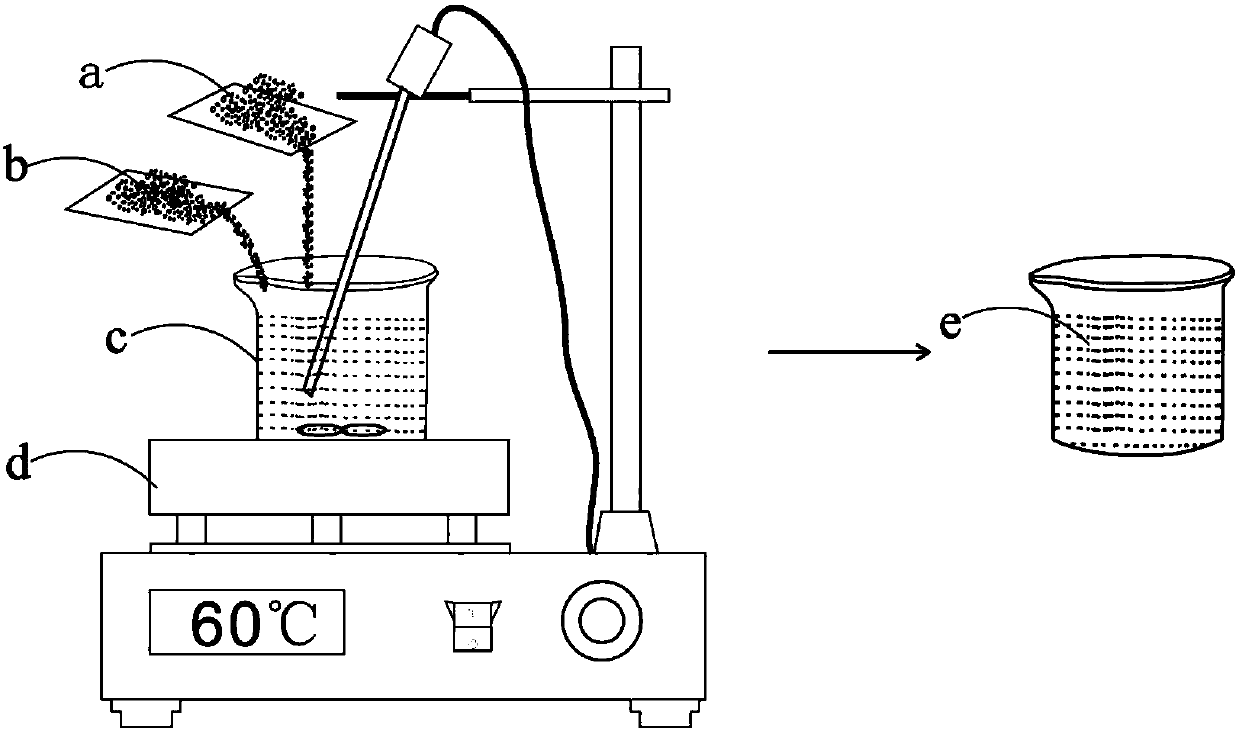

Modified wood fibre phase change energy storage material and preparation method thereof

InactiveCN107739445AControl pore sizeTo achieve the purpose of reamingHeat-exchange elementsChemical treatmentFatty acid

The invention discloses a modified wood fibre phase change energy storage material and a preparation method thereof. According to the modified wood fibre phase change energy storage material and the preparation method thereof, the pore diameters of wood fibres can be adjusted and controlled effectively, besides, porous structures of the wood fibres are improved, and the compatibility of the wood fibres and a phase change material is improved. The modified wood fibres are taken as a loading matrix of the phase change energy storage material; more phase change materials can be remained through the actions of hydrogen bonds, capillary force, intermolecular force and the like of the modified wood fibres, so that the enthalpy of phase change is improved; the modified wood fibres are combined with a fatty acid eutectic mixture, so that the requirement on low-temperature energy storage can be met; moreover, the phase change material prepared by the preparation method is degraded without heatin a phase change temperature range, which shows that the thermal stability of the modified wood fibre phase change energy storage material is high; and after 100 times of thermal cycle, the phase change material does not leak, which shows that the thermal reliability is high, and the thermal energy storage efficiency is high. The preparation method disclosed by the invention is simple in process;the wood fibres serving as the raw material are wide in source and low in cost; the raw materials do not need to be subjected to chemical treatment, and are environment-friendly and energy-saving, and the modified wood fibre phase change energy storage material has a wide application prospect in the field of solar energy utilization, building energy conservation and the like.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing nickel porous materials based on nickel oxalate and sodium chloride co-mixing reducing method

The invention discloses a method for preparing nickel porous materials based on a nickel oxalate and sodium chloride co-mixing reducing method, relates to a nickel porous material preparing method, and belongs to the technical field of metal porous material preparing. After nickel oxalate powder and sodium chloride powder are subjected to ball grinding and evenly mixed, reducing is conducted, thereducing temperature is 400-450 DEG C, and nickel powder and sodium chloride powder evenly-mixed powder is obtained; then, pressing is conducted at 100 MPa-200 MPa, sintering is conducted at 700-800 DEG C, and a sintered blank with certain strength is obtained; and finally, a water dissolving method is used for removing sodium chloride in the sintered blank, and the nickel porous materials are obtained. The preparing method has environment friendliness, and the prepared porous materials have the characteristics that porosity is high, hole distribution is uniform, and the hole diameter is controllable.

Owner:CENT SOUTH UNIV

Oriented microchannel stent for promoting tissue regeneration and preparation method of stent

InactiveCN113244460ASolve the problem of difficult control of apertureControl pore sizePharmaceutical delivery mechanismTissue regenerationMedicineEngineering

The invention belongs to the technical field of preparation of porous natural polymer scaffolds in the field of tissue engineering, and relates to a preparation method of an oriented micro-channel scaffold for promoting tissue regeneration. The method comprises the following steps: preparing a fiber support skeleton, filling a natural scaffold material, and eluting the fiber support skeleton. The preparation method has the beneficial effects that the pore diameter of the natural polymer stent is controllable, and the pores are communicating, and the problem that the pore diameter of a natural polymer stent material is difficult to control is successfully solved.

Owner:NANKAI UNIV

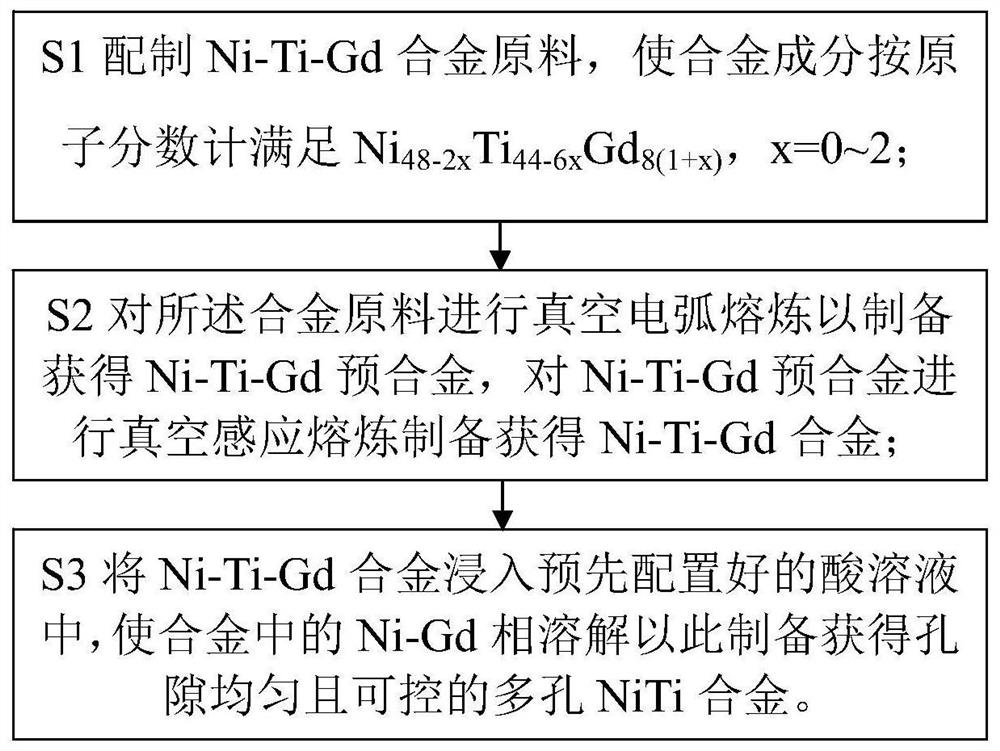

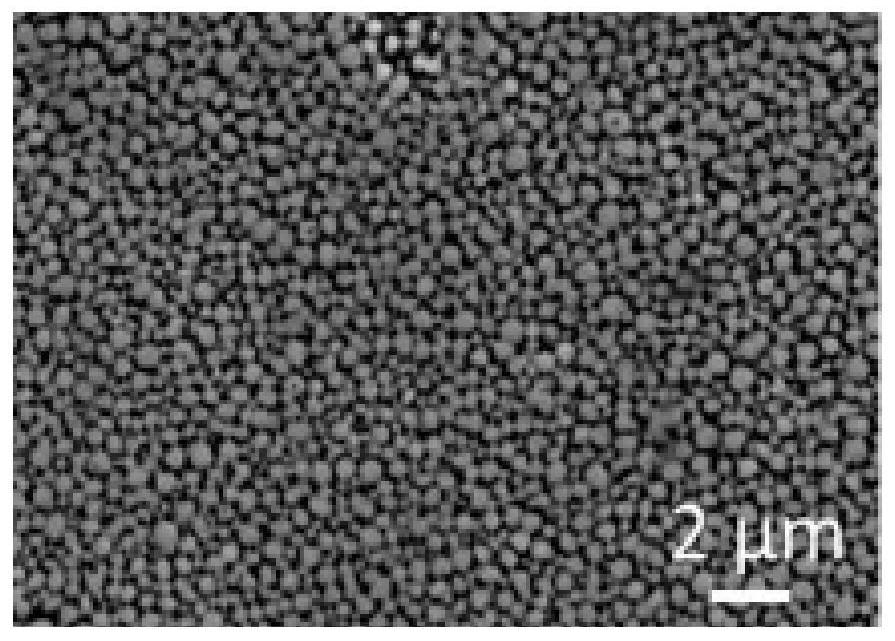

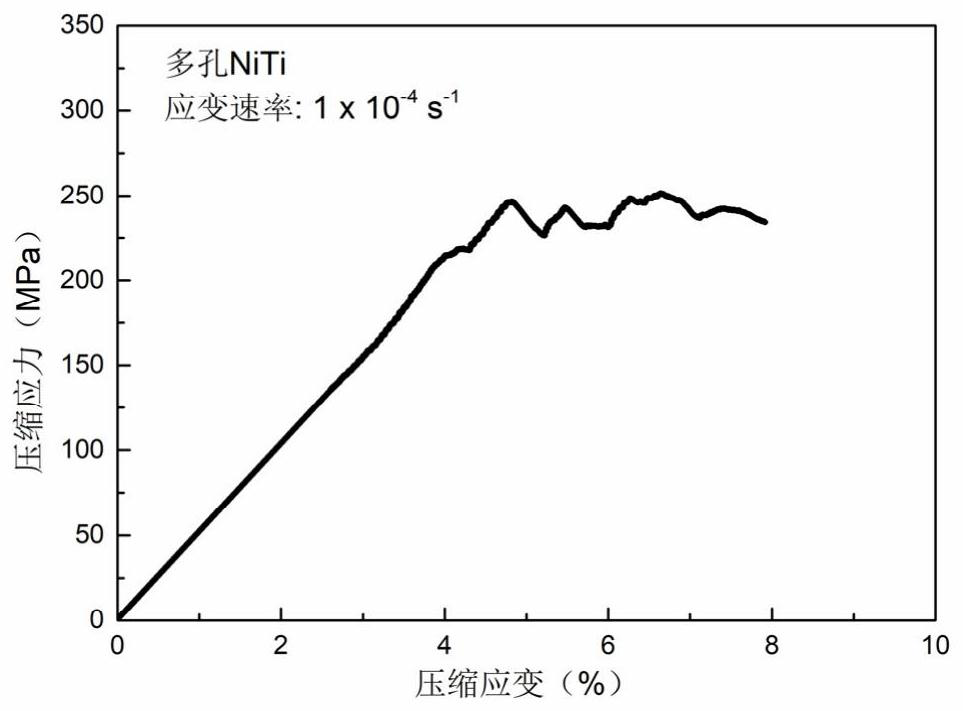

Preparation method for porous NiTi alloy based on selective dissolution and product

The invention belongs to the field of porous alloy preparation, and particularly discloses a preparation method for a porous NiTi alloy based on selective dissolution and a product. The preparation method comprises the following steps: adding a Gd element into a Ni-Ti binary alloy, based on the characteristic that the Gd element can react with the Ni element but not react with the Ti element, onlyNi-Ti and Ni-Gd phases are generated in the alloy, and then removing the Ni-Gd phases based on selective corrosion by using an acid solution to obtain the porous NiTi alloy with uniform and controllable pores. The method can be used for preparing the porous NiTi alloy with small pore size and uniform distribution, and has the advantages of simple and convenient operation process and lower cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Photoinduced liquid film pH step-by-step regulation method for synthesizing mesoporous heteroatomic molecular sieve

ActiveCN108059482AControl pore size distributionControl pore sizeMolecular-sieve silicatesMolecular sieveSolvent

The invention relates to the field of synthesis of a mesoporous heteroatomic molecular sieve film, and discloses a photoinduced liquid film pH step-by-step regulation method for synthesizing a mesoporous heteroatomic molecular sieve. The method comprises uniformly mixing and stirring a transition metal precursor, a silicon source, a template, a photo acid generator (PAG) and a photo base generator(PBG) to obtain a coating solution; uniformly applying the coating solution to a substrate to form a liquid film; performing UV-irradiation with the wavelength being 350-420 nm and the intensity being 10-100% to the liquid film, and performing UV-irradiation with the wavelength being 300-350 nm and the intensity being 10-100% to the liquid film to obtain a template-containing mesoporous heteroatomic molecular sieve film; and performing UV-irradiation with the wavelength being 350 nm and the intensity being 50-100% to the mesoporous heteroatomic molecular sieve film for 60-120 min to remove the template. The method is fast in curing rate, free of solvent, saved in energy, regulatable in reaction time, and controllable in optical parameters. The coating solution is continuously stable in anempty-illumination condition. The method is efficient controllable green technology.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

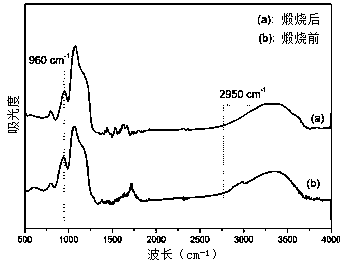

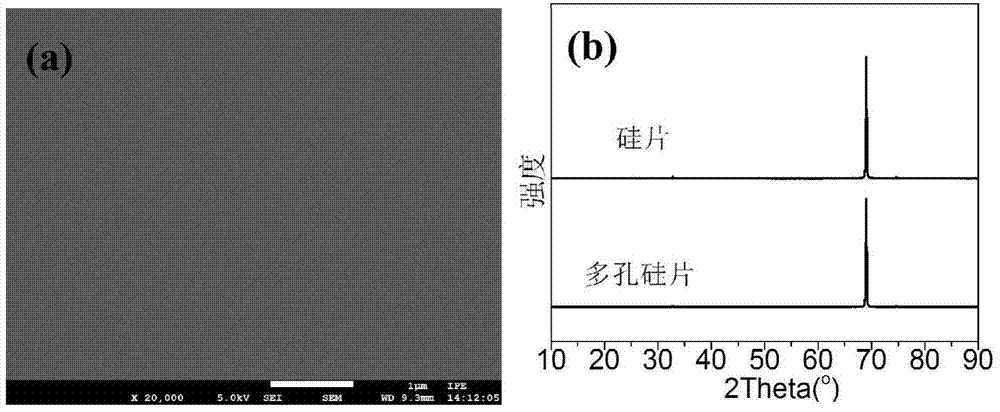

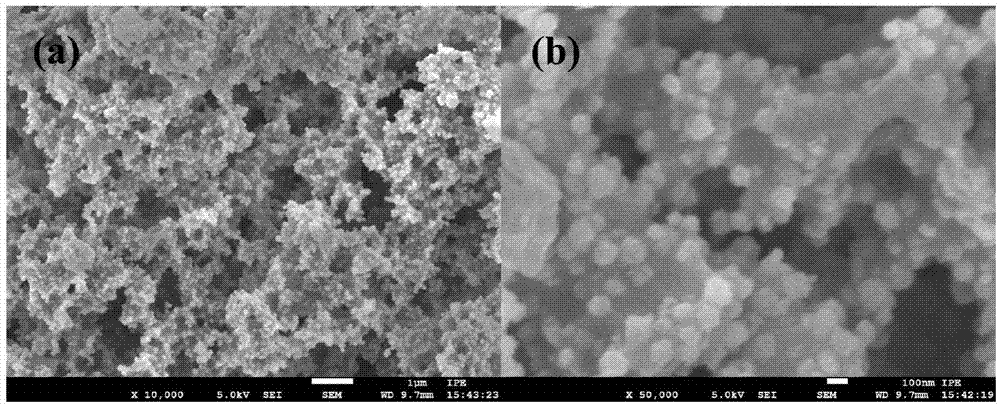

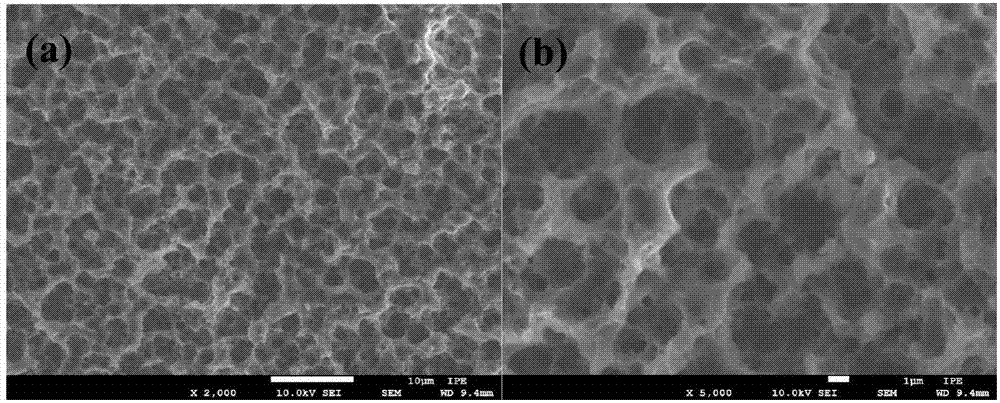

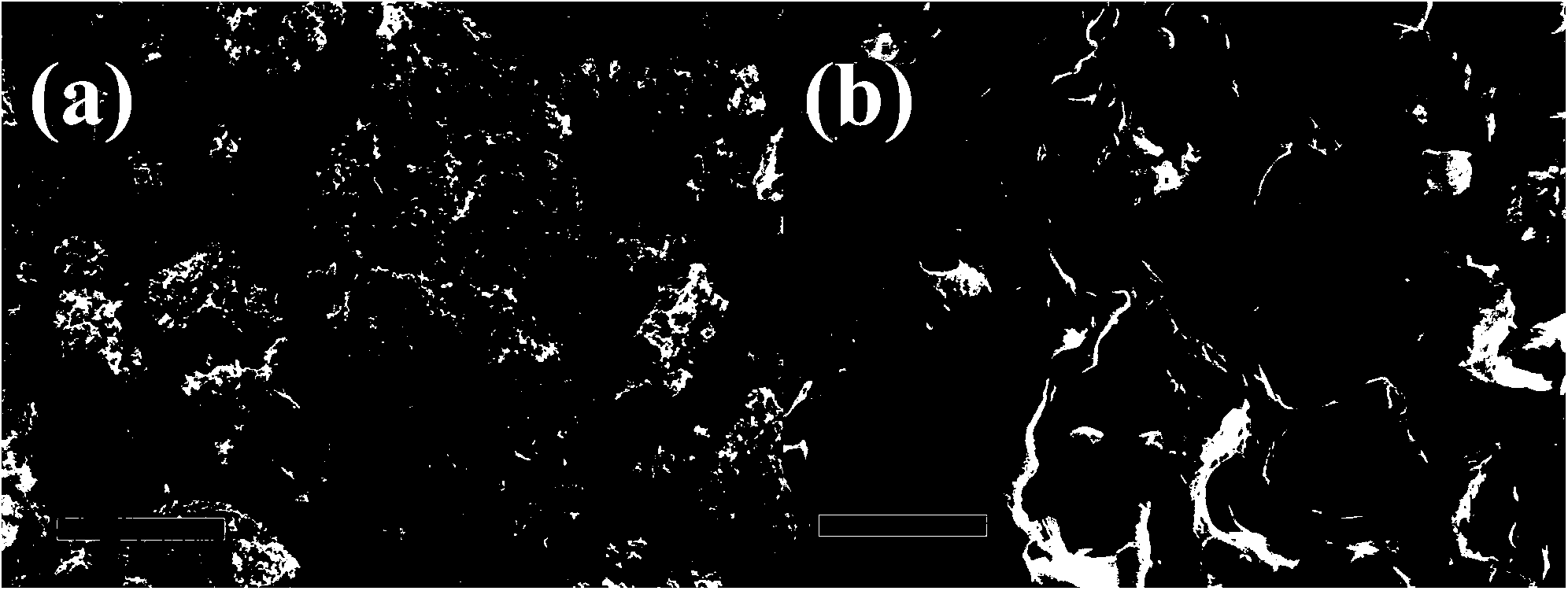

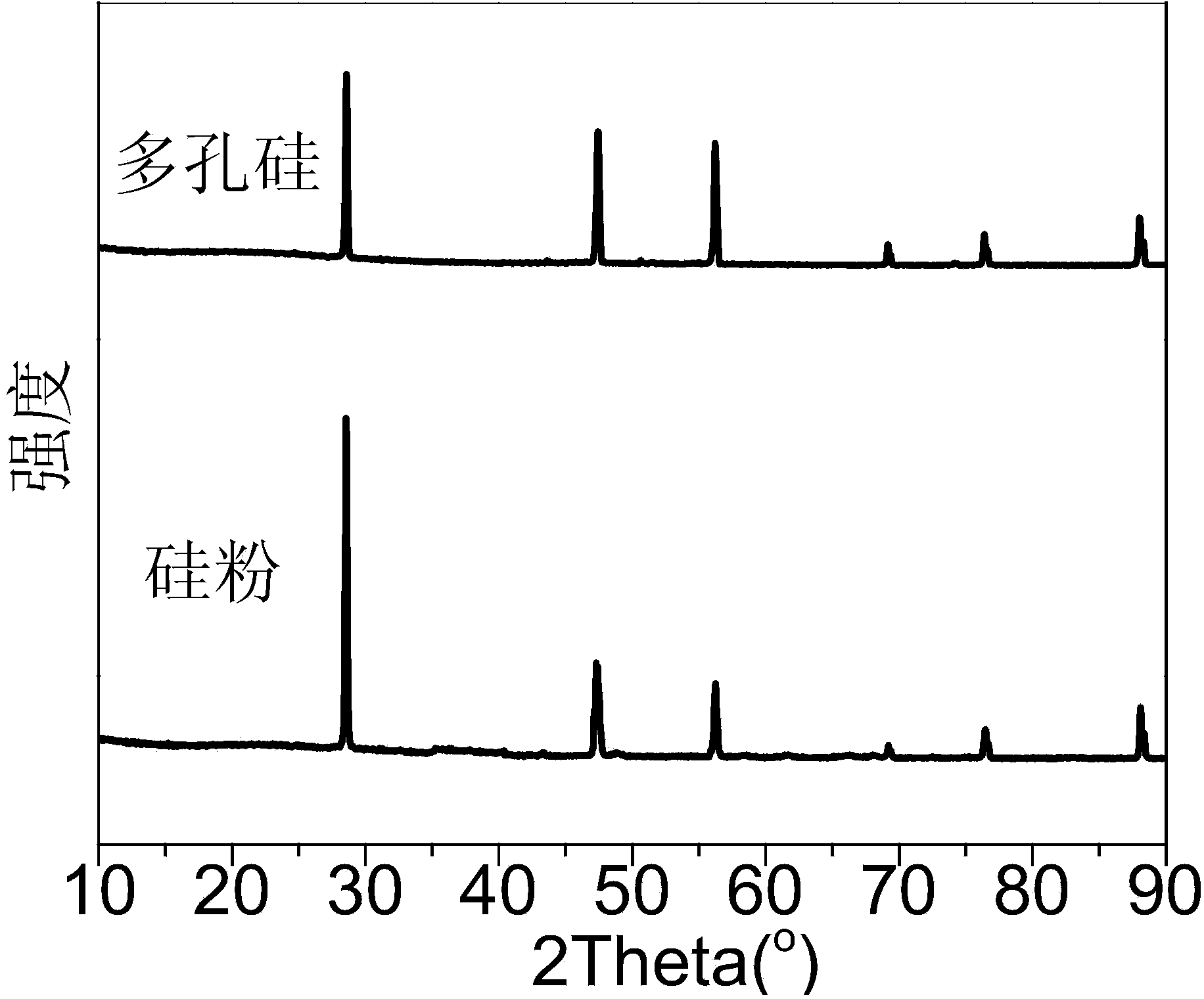

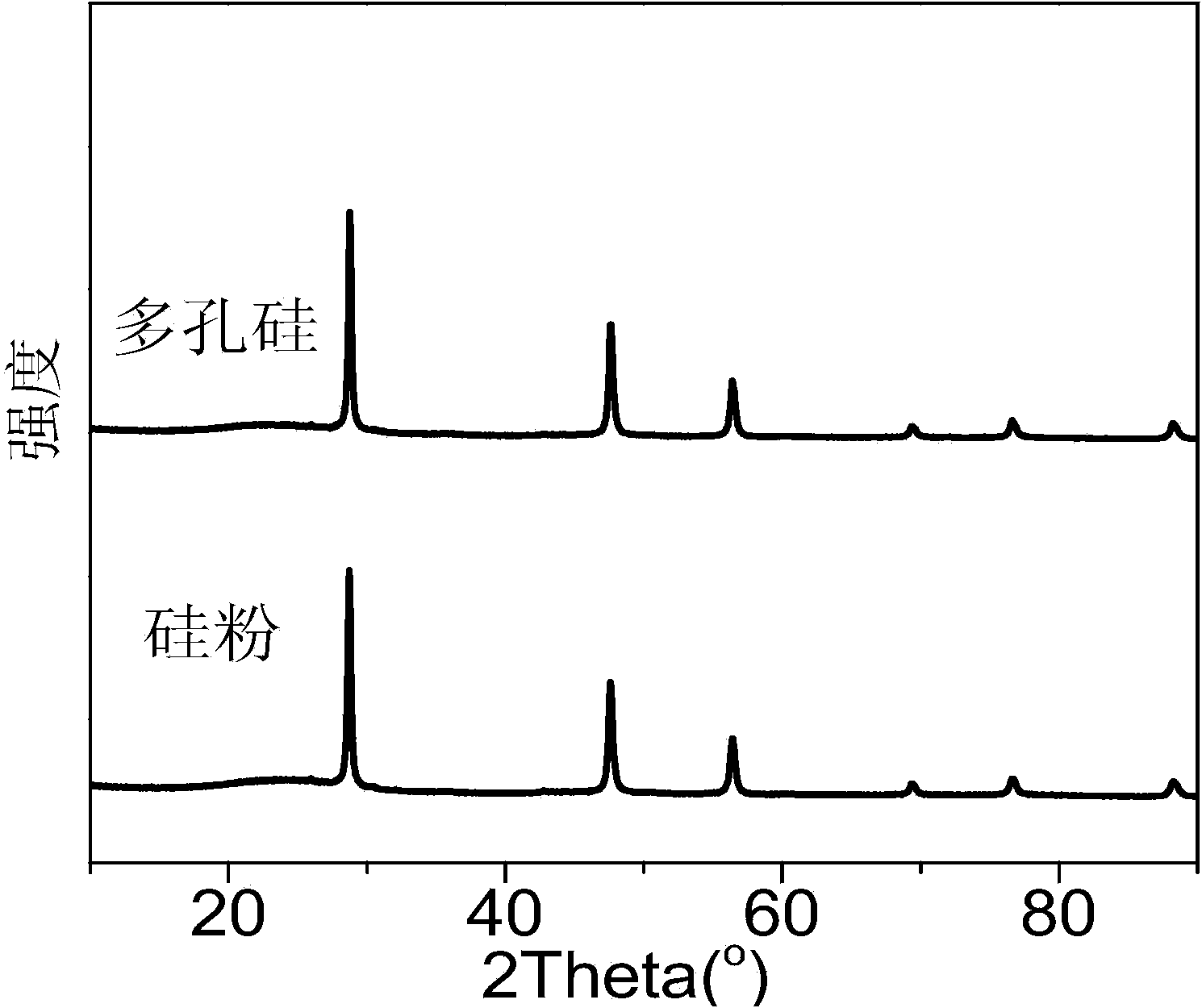

Porous silicon material, preparation method and application thereof

The invention discloses a porous silicon material and its preparation method. The preparation method of the porous silicon material includes: letting a transition metal salt precursor and raw material silicon undergo an in situ catalytic reaction in an organic solvent under certain temperature and pressure and the action of a mineralizing agent, and carrying out pickling and other post-treatment impurity removal processes, thus obtaining the porous silicon material. By adjusting the variety and concentration of the transition metal salt precursor, the organic solvent variety and reaction condition parameters, the pore size, distribution and porosity of the silicon material can be regulated. By means of the method provided by the invention, the porous silicon material that is difficult to obtain by the prior art can be obtained. The porous silicon material prepared by the method has the characteristics of low production cost and simple process, can be prepared in large scale, is suitable for industrial production, and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Aluminum-based composite bearing material with high corrosion resistance

The invention discloses an aluminum-based composite bearing material with high corrosion resistance. The aluminum-based composite bearing material is prepared from the following raw materials in parts by weight: 85-90 parts of aluminum, 5-8 parts of zinc, 3-4 parts of carbon, 1-2 parts of chromium, 0.5-1 part of silicon, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methylcellulose, 1-1.5 parts of graphite, 1.2-2 parts of petroleum asphalt, 1-2 parts of glass fiber, 0.4-0.5 part of titanium nitride and a proper amount of oleic acid. The aluminum-based composite bearing material prepared by the invention can be continuously and efficiently produced in batches; the product is high in yield, high in size accuracy, low in production cost, high in comprehensive mechanical performance, high in abrasion resistance and corrosion resistance, high in bearing capability, high in fatigue resistance and worthy to popularize.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

Porous silicon material and preparation method thereof

The invention relates to a porous silicon material and a preparation method thereof. The method for preparing the porous silicon material comprises the following steps: carrying out an in-situ catalytic reaction between a silicon material and chloromethane at the temperature of 401 to 800 DEG C in the presence of a solid copper-based catalyst, and preparing the porous silicon material through calcining, acid pickling, alkaline washing and other after-treatment impurity removal technologies, wherein the solid copper-based catalyst comprises one or a mixture of more than two in primary catalysts such as CuOx, CuCl and CuCl2, x is more than or equal to 0 and less than or equal to 1, as well as a small amount of secondary catalysts. Reaction condition parameters are regulated, so that the pore size, pore size distribution and porosity of the silicon material can be regulated. According to the method, a porous silicon material which is difficultly obtained in the patented technology at present is obtained, and important organic silicon monomer chemicals can be obtained. The porous silicon material prepared by the method is uniform in pore size, low in production cost, simple in process and suitable for industrial production and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

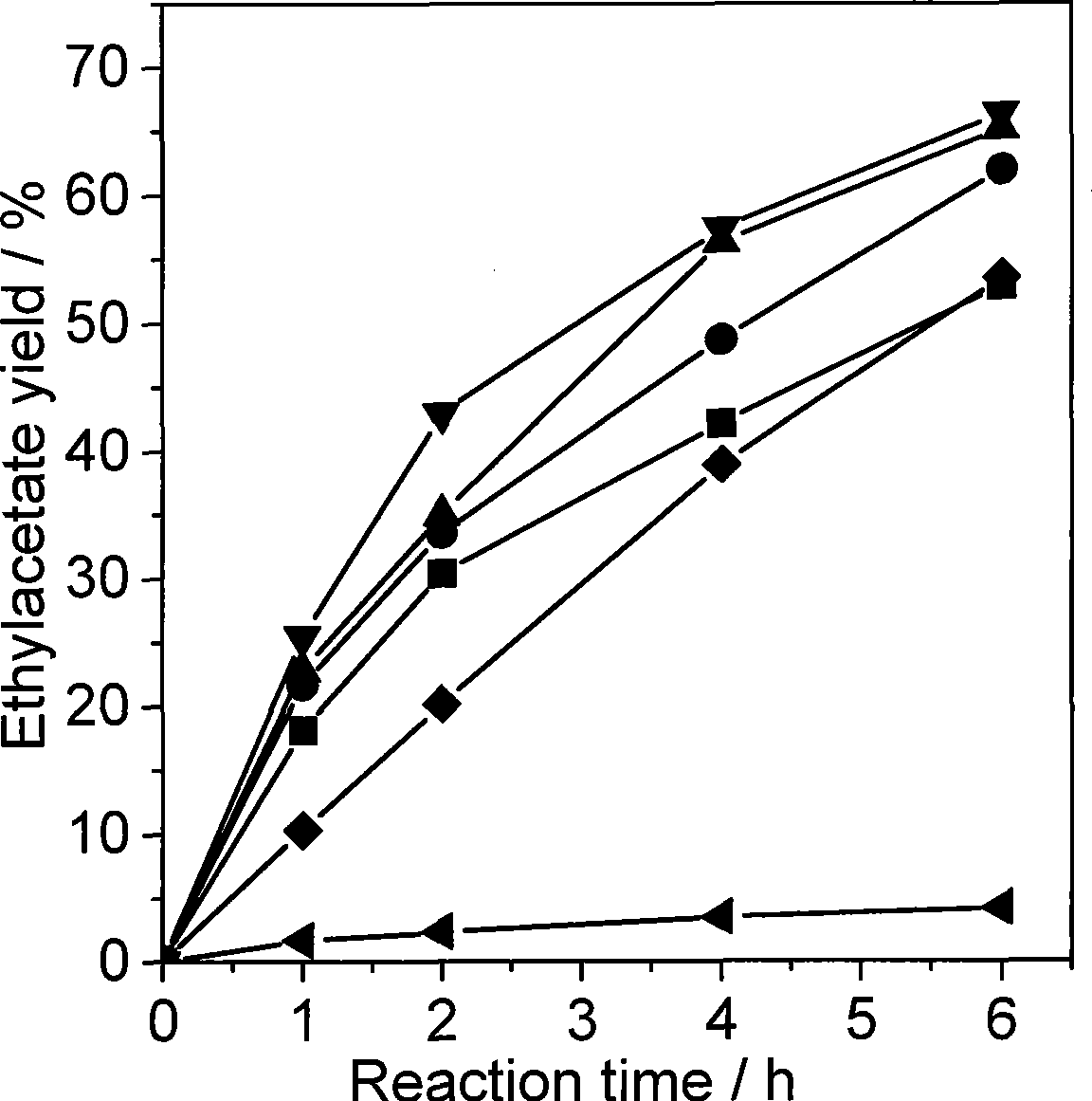

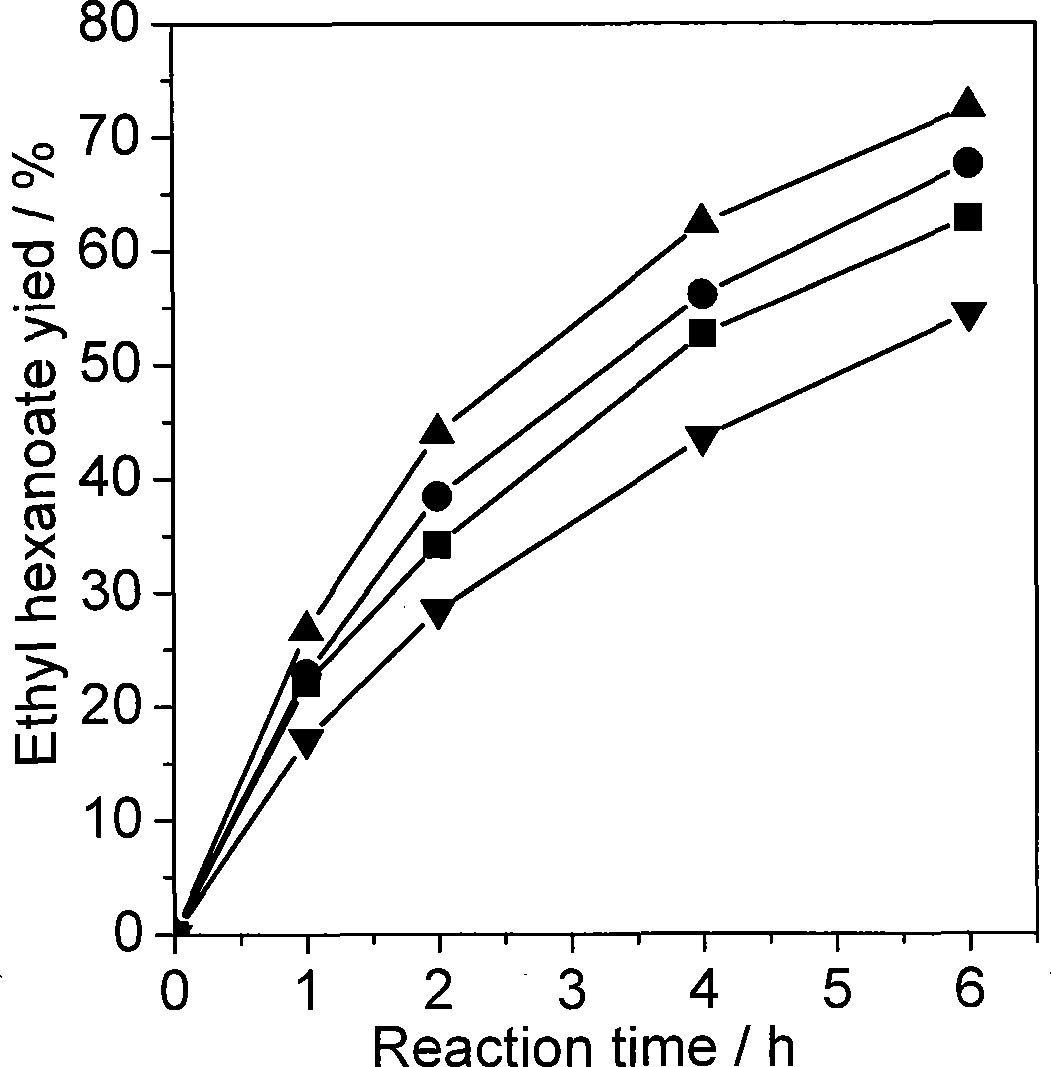

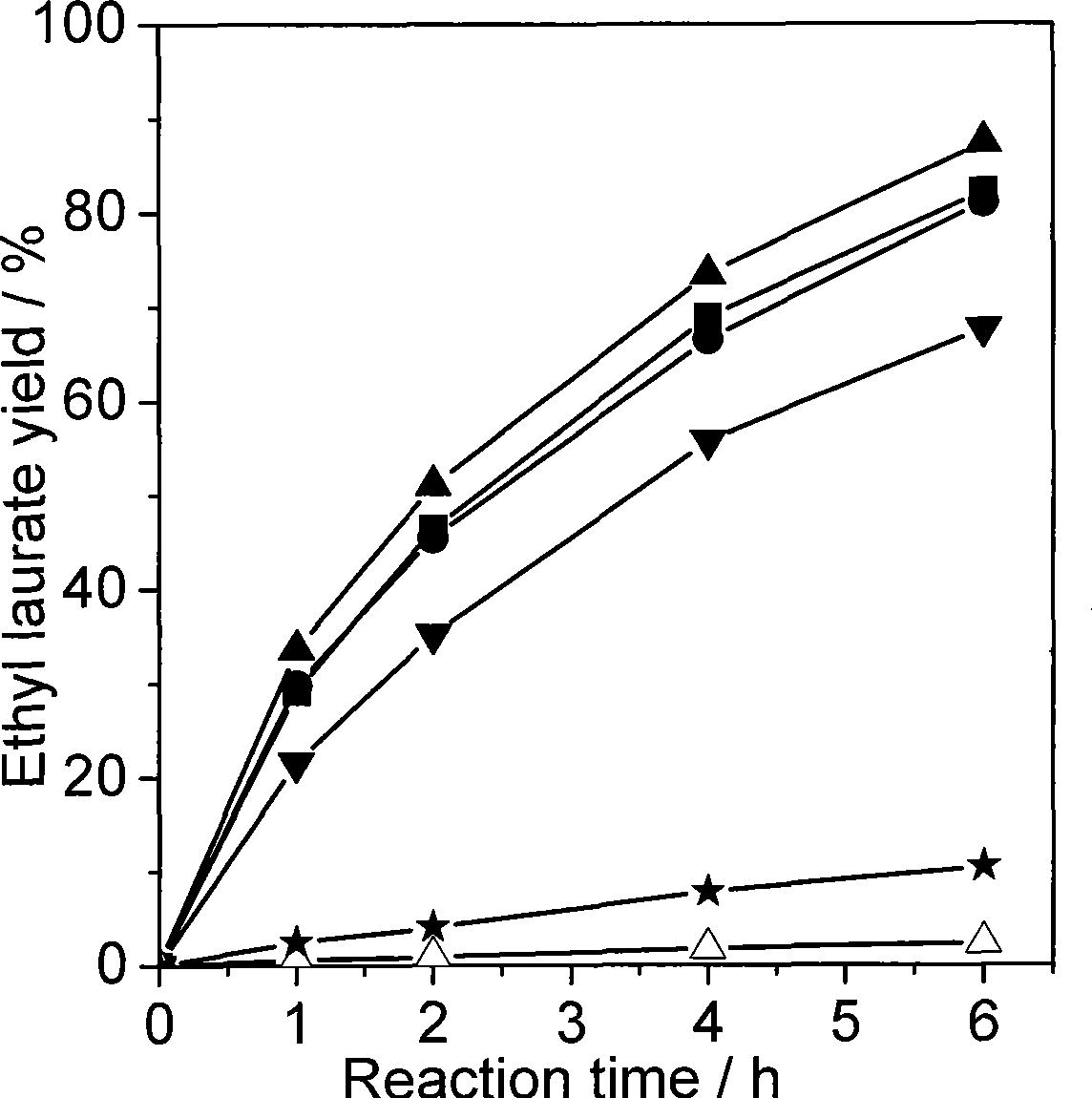

Method for preparing functionalization and hybridization of sulfonic acid material with special structure

The invention provides a method for preparing a sulfonic acid functionalized hybrid material with special structure. In a buffer solution system, a nonionic copolymer as a template agent and (EtO)3SiCH2CH2CH2SSCH2CH2CH2Si(OEt)3 as a mixed silicon source are stirred and crystallized, so as to obtain an organic / inorganic hybrid material with a multistage pore structure. The material synthesized through the method has a special pore path structure, and the acid content of the sulfonic acid functionalized hybrid material which is prepared by use of a simple nitric acid oxidation method and has the multistage pore structure can be adjusted in the range between 0.78 and 0.89 mmol H<+>g<-1>. The oxidized material shows great reaction performance in the esterification of ethanol and the fatty acids with different chain length. The multistage pore structure of the material is beneficial to the diffusion of reactants, and especially shows the unique advantages of the multistage pore structure for the reaction in which macromolecules participate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

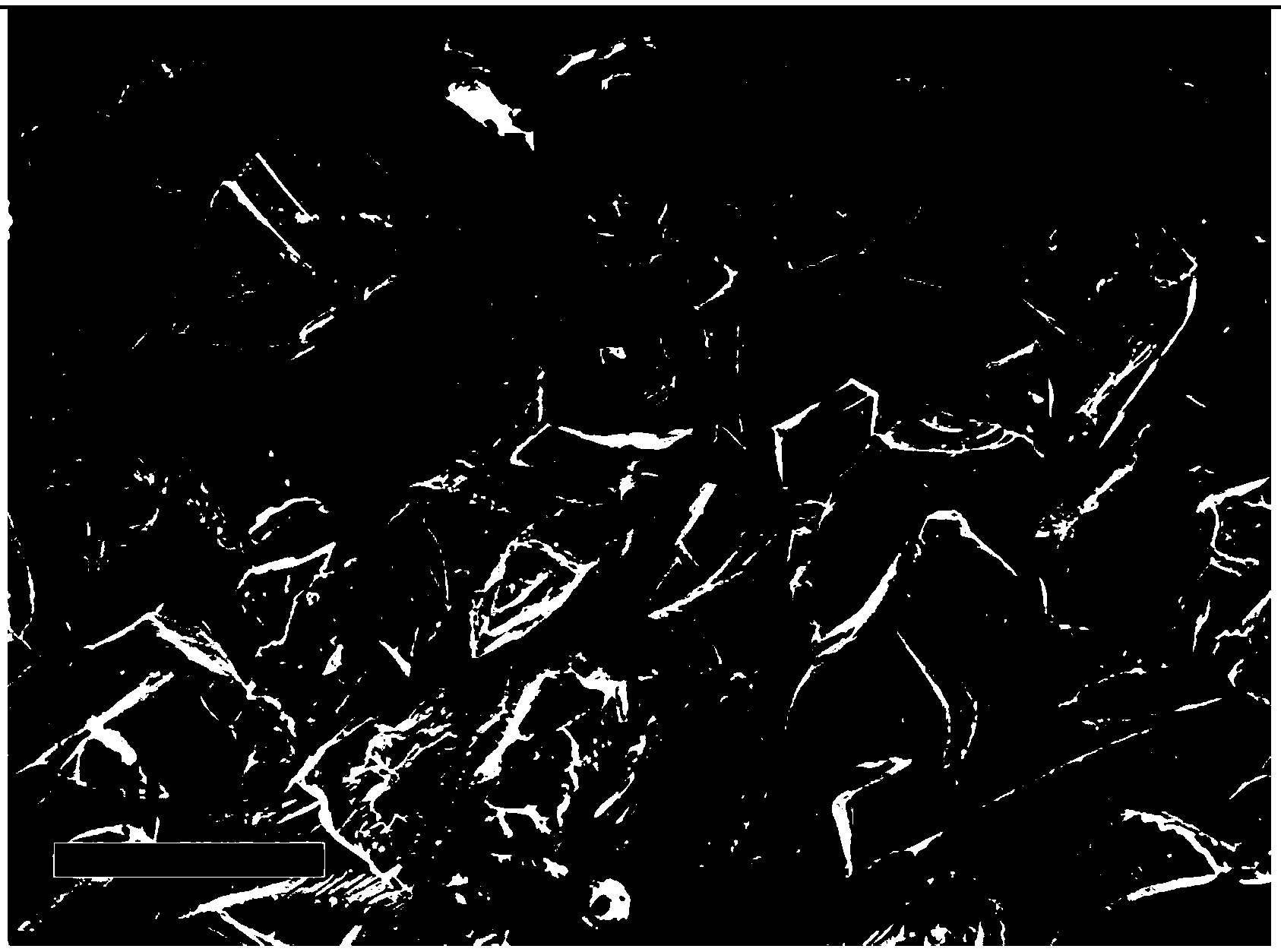

Porous silicon material and preparation method of porous silicon material

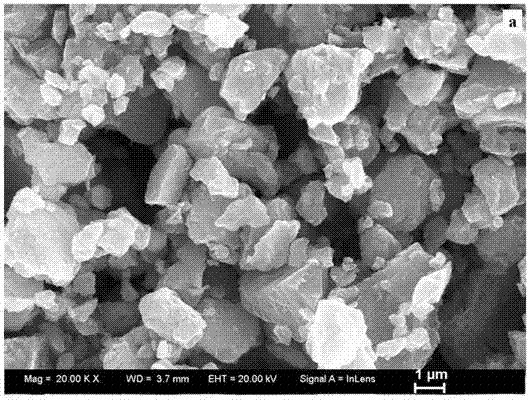

InactiveCN104229804AUniform hole sizeSize fine-tuningSilicon compoundsMetal/metal-oxides/metal-hydroxide catalystsAlcoholCopper

The invention provides a porous silicon material and a preparation method of the porous silicon material. The preparation method of the porous silicon material comprises the following steps: carrying out in-situ catalytic reaction on silicon and alcohol at 60-400 DEG C under the action of a solid copper-based catalyst, and preparing the porous silicon material by post-treatment and purification technologies such as burning, and pickling and alkali washing. The porous silicon material prepared by the method is uniform in aperture, and the pore structure, size and porosity of silicon can be regulated and controlled by adjusting reaction parameters. The method is low in production cost, simple in process, easy to operate, clean in preparation process, and suitable for industrial production, and has a wide application prospect. In addition, the process can be combined with an alkoxy silane production process, and the process is expected to achieve double-win of porous silicon material and alkoxy silane production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-aluminum-based composite material applied to automobile bearings

The invention discloses a high-aluminum-based composite material applied to automobile bearings. The high-aluminum-based composite material is prepared from the following raw materials in parts by weight: 85-90 parts of aluminum, 5-8 parts of zinc, 3-4 parts of bismuth, 1-2 parts of magnesium, 0.5-1 part of arsenic, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methylcellulose, 1-1.5 parts of graphite, 1.5-2 parts of benzotriazole, 1-1.2 parts of caprolactam, 0.5-0.7 part of phosphorus pentoxide and a proper amount of oleic acid. The high-aluminum-based composite material is few in holes, excellent in structural stiffness, hardness, fatigue resistance performance and tensile strength performance, free of lead, low pollution to environment and simple in production steps; the production efficiency is improved.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

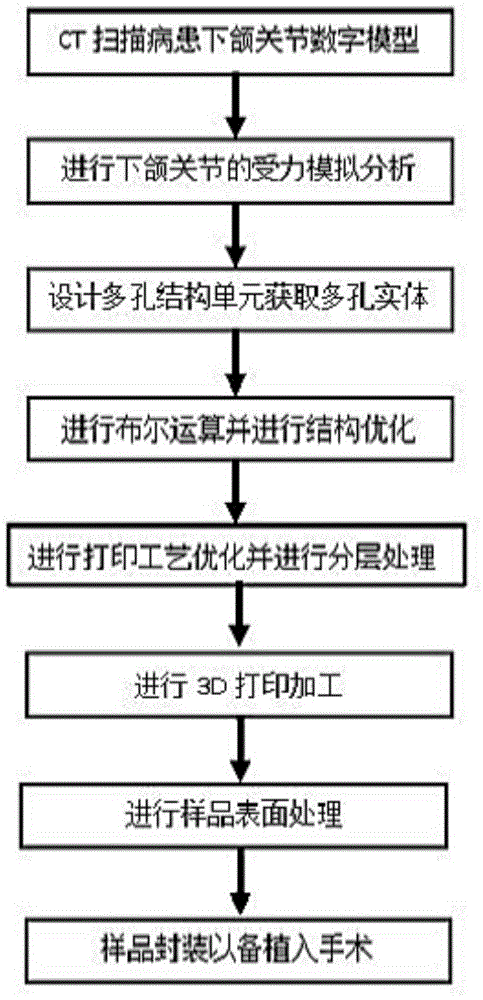

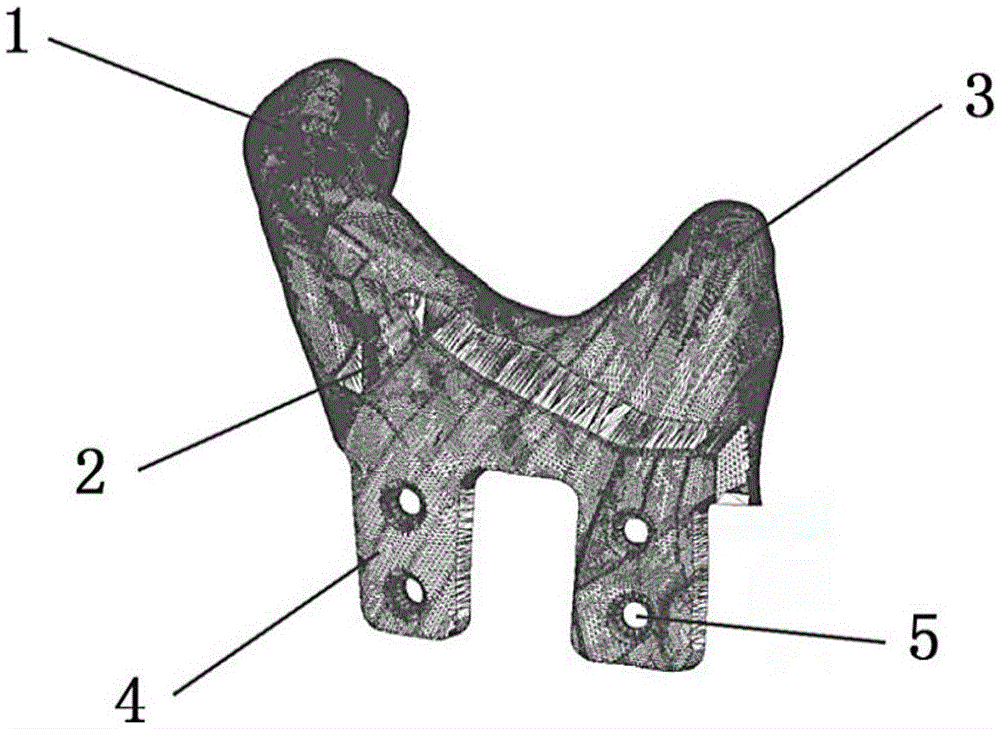

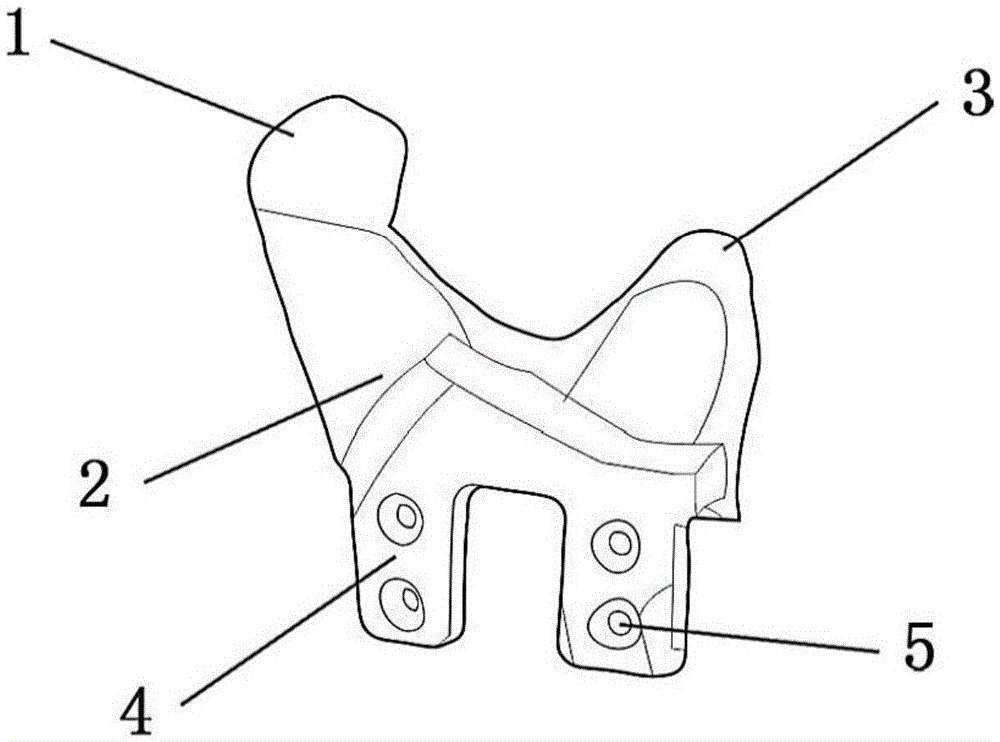

Porous artificial temporal-mandibular joint structure and making method

InactiveCN105616040AGood biocompatibilitySimple structureJoint implantsTissue regenerationStress concentrationPorosity

The invention discloses a porous artificial temporal-mandibular joint structure and a making method.The porous artificial temporal-mandibular joint structure comprises a coracoid, a condyle process, a condyle process neck and titanium plates provided with nail holes.The coracoid protrudes from the front edge of the upper end of the condyle process neck, the condyle process protrudes from the back edge of the upper end of the condyle process neck, and the titanium plates are arranged at the lower end of the condyle process neck.The artificial temporal-mandibular joint is a porous component and is composed of a plurality of mesh units, the mesh units are in hollowed truncated octahedron shapes, the thickness of frames of the mesh units ranges from 200 microns to 300 microns, the apertures of the mesh units range from 500 microns to 1,250 microns, and the porosity of a porous body is 75%-80%.The strength of the porous artificial temporal-mandibular joint structure is similar to that of primary skeleton of a patient, the tenacity of the porous artificial temporal-mandibular joint structure is similar to that of the primary skeleton of the patient, stress concentration generated after implantation can be avoided, and the porous structure can assist peripheral tissues in combination with the artificial temporal-mandibular joint.

Owner:广东健齿生物科技有限公司

Preparation method for high-performance heat conductive copper powder

ActiveCN110394457AIncrease viscosityIncrease profitTransportation and packagingMetal-working apparatusPorosityReduction treatment

The invention discloses a preparation method for high-performance heat conductive copper powder. The preparation method specifically comprises the steps of melting a copper ingot; performing air blowing oxidation on molten copper liquid by using an air compressor; adopting an atomization method to place the copper liquid in a condition of a high pressure of 20 Mpa or above and spray copper powderfrom an annular nozzle; drying the atomized copper powder, and strictly grading the dried copper powder; carrying out oxygen roasting treatment on the atomized copper powder; then carrying out reduction treatment on the powder of all particle size ranges by using a reducing gas at a temperature of 600-800 DEG C; and finally, respectively crushing the oxidized and reduced powder in all particle size ranges to obtain the heat dissipation copper powder with various particle sizes required by the heat conduction industry at the present stage and with controllable porosity and capillary gap size. By means of the preparation method, the viscosity of the copper liquid can be improved through blowing air for oxidation in the molten copper liquid, so that the comprehensive utilization rate of copper powder products obtained by atomizing the copper liquid is improved, and the production cost is greatly saved.

Owner:铜陵鑫佳粉体新材料科技有限公司

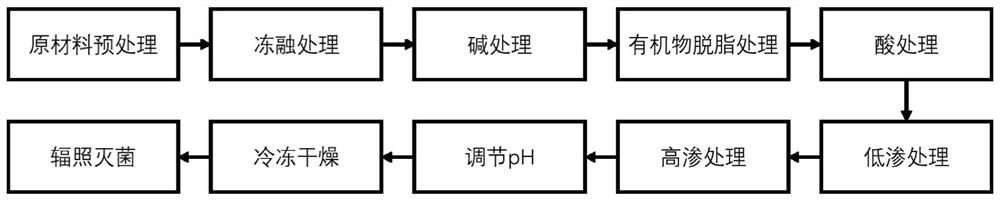

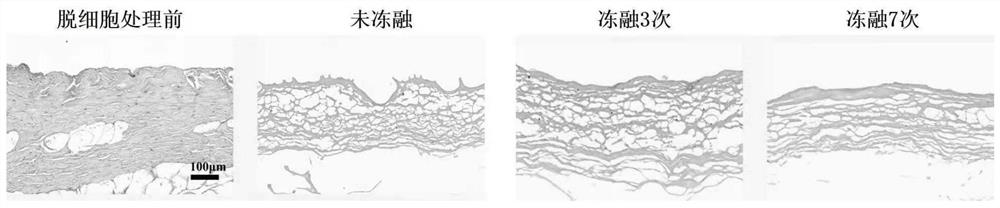

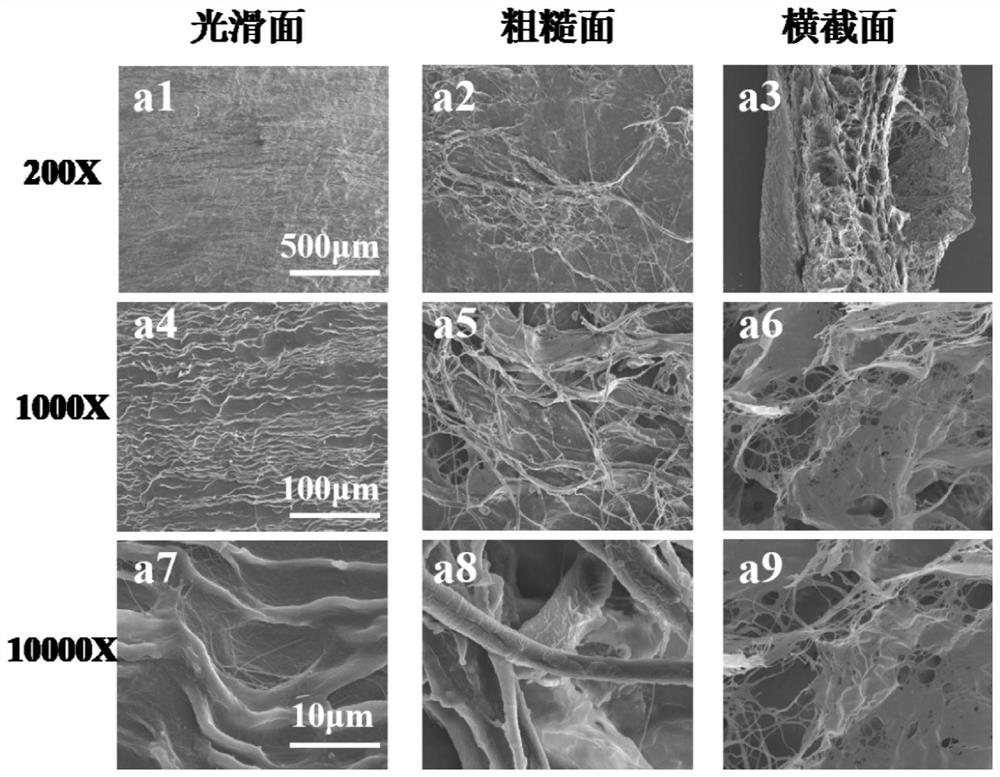

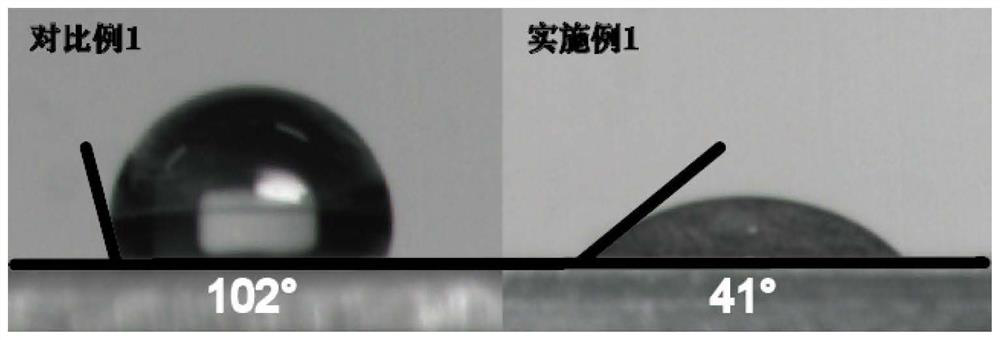

Preparation method and application of acellular collagen matrix membrane

PendingCN114028614AAvoid damagePromote degradationTissue regenerationProsthesisCollagenanBiocompatibility

The invention provides a preparation method of an acellular collagen matrix membrane, and the method comprises the following steps: performing pretreating to obtain a mammalian membrane tissue, and then carrying out repeated freeze-thawing treatment, acid-base treatment, gradient dehydration treatment, organic matter degreasing treatment and hypotonic / hypertonic treatment on the mammalian membrane tissue, thereby effectively removing tissue immunogenicity, retaining an ordered collagen fiber structure, and improving the decellularized collagen matrix membrane; then performing drying and sterilizing to obtain an acellular collagen matrix membrane, wherein the decellularized collagen matrix membrane has excellent flexibility, biocompatibility and soft and hard tissue regeneration promoting performance, has a smooth-surface and rough-surface double-layer bionic structure, can retain a natural three-dimensional pore scaffold structure similar to the tissue, retains a collagen structure, and has good water absorption and thermal denaturation stability; source materials are easy to obtain, the cost is low, the decellularized collagen matrix membrane has a stronger barrier function and a space maintaining function, and the surface appearance, the elastic modulus, the porosity and the pore size of the decellularized collagen matrix membrane can be regulated and controlled through different freeze-thaw treatment modes.

Owner:HOSPITAL OF STOMATOLOGY SUN YAT SEN UNIV

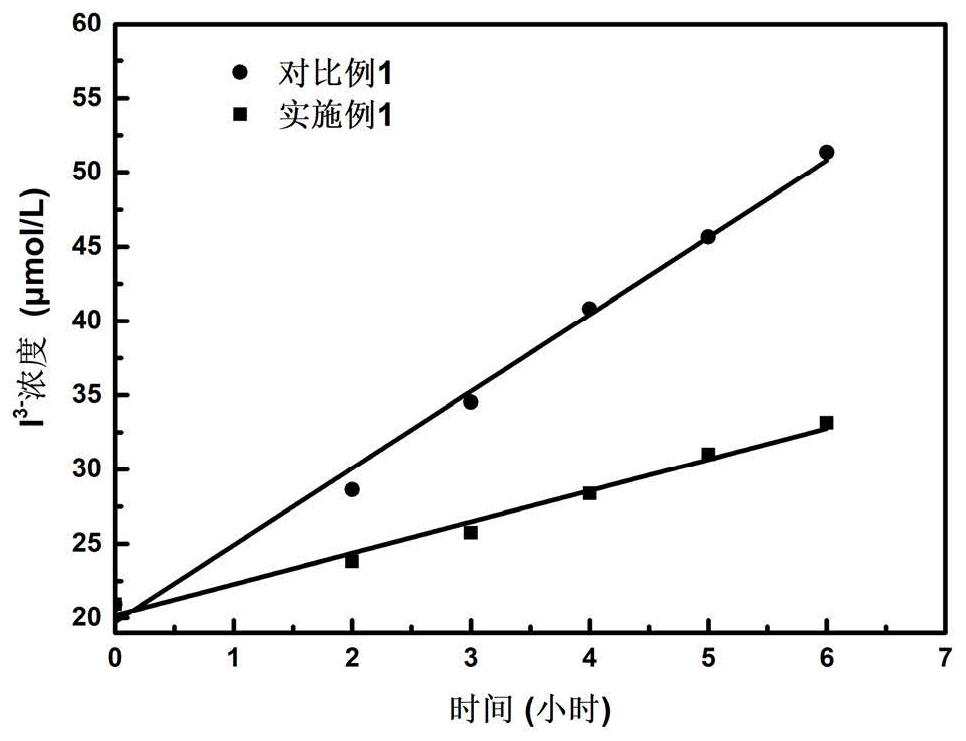

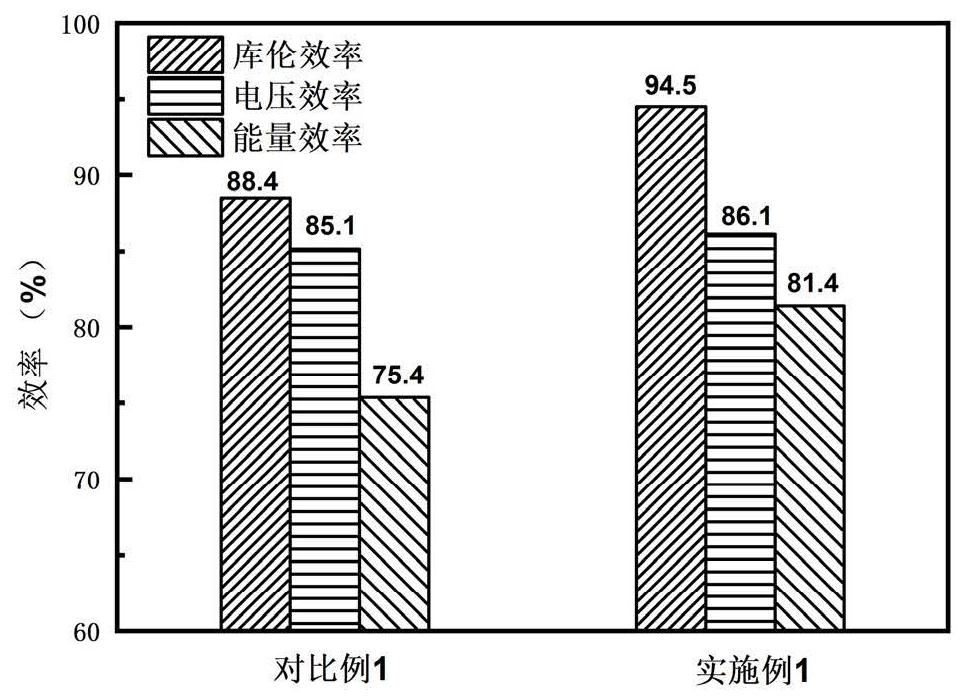

Preparation method and application of metal organic framework compound composite membrane

ActiveCN113861499AEasy to makeProcess environmental protectionFinal product manufactureRegenerative fuel cellsOrganic solventMetal-organic framework

The invention provides a preparation method and application of a metal organic framework compound composite membrane. The method at least comprises the following steps of: (1) transferring a dispersion liquid containing organic polymer resin, a metal source I and an organic solvent to the surface of a porous membrane substrate, and removing the organic solvent to obtain a substrate membrane containing a seed crystal; (2) obtaining a solution containing a metal source II, an organic ligand and an organic solvent; and (3) putting the substrate membrane containing the seed crystal into the solution in the step (2), and carrying out in-situ reaction to obtain the metal organic framework compound composite membrane. The metal organic framework compound is introduced into the surface of the substrate membrane in situ through a seed crystal-secondary growth method, so that the metal organic framework compound composite membrane is formed. The metal organic framework compound composite membrane is simple to prepare, and the process is environment-friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

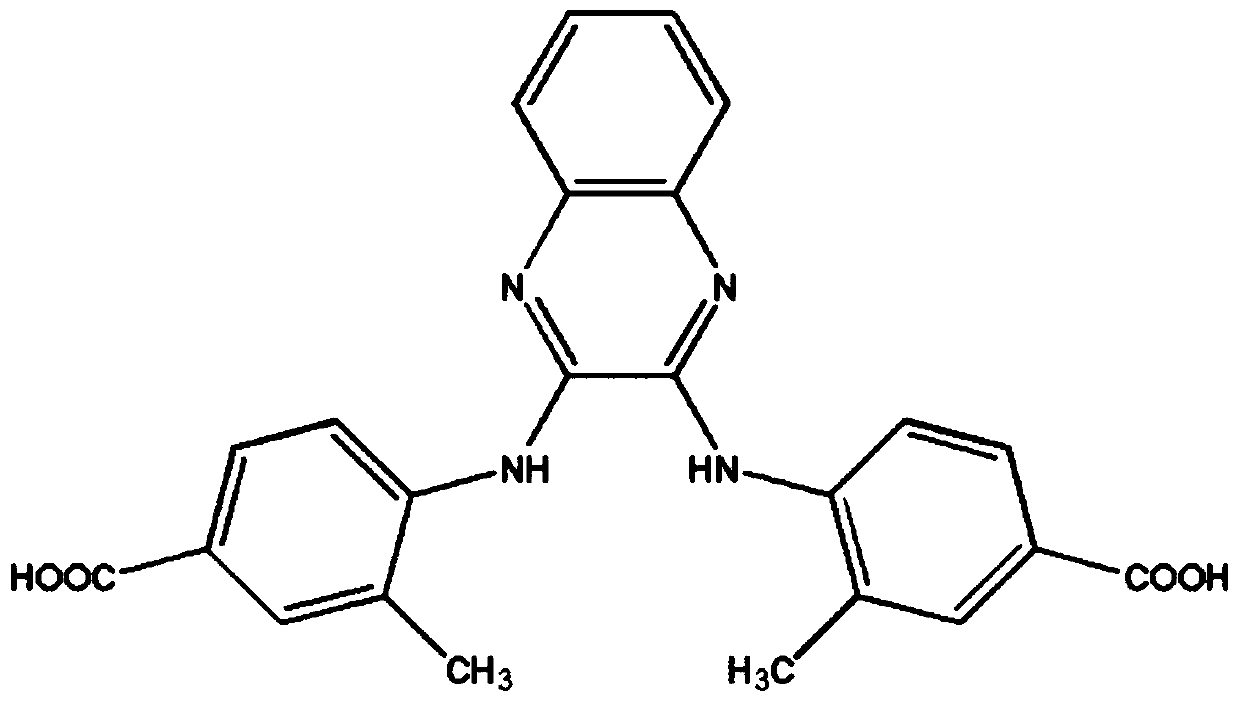

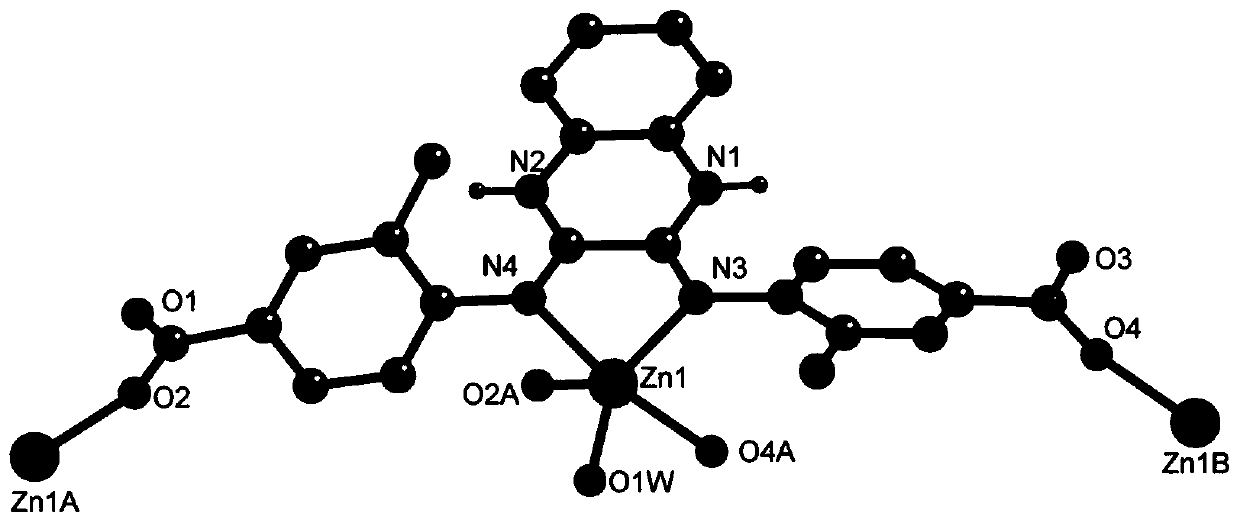

Two-dimensional layered water-stable dye adsorbent and preparation method thereof

ActiveCN111097386AImprove stabilityNovel structureOther chemical processesWater contaminantsQuinoxalineBenzoic acid

The invention provides a two-dimensional layered water-stable dye adsorbent and a preparation method thereof. According to the method, an organic ligand 2, 3-bis (4-amino-3-methylbenzoic acid)-1, 4-quinoxaline (H2QDAB) is used as a raw material. The chemical formula of the obtained compound is [Zn(QDAB)(H2O)].2H2O. Under the solvothermal mild condition, an organic ligand H2QDAB and Zn(NO3)2.6 H2Oare accurately weighed in a mixed solution of DMF and water, and under the condition that NaOH is added, an organic-metal framework crystal is obtained through a thermal reaction. The metal-organic framework material has good water stability, has a good adsorption effect on methyl blue and crystal violet among organic dye molecules, has weak adsorption capacity on rhodamine B and methyl orange, shows a certain selective adsorption effect and can be used for removing organic dye molecules. In addition, due to the unique structural characteristics, the adsorbent is expected to be applied to gasadsorption and separation.

Owner:JIANGSU UNIV

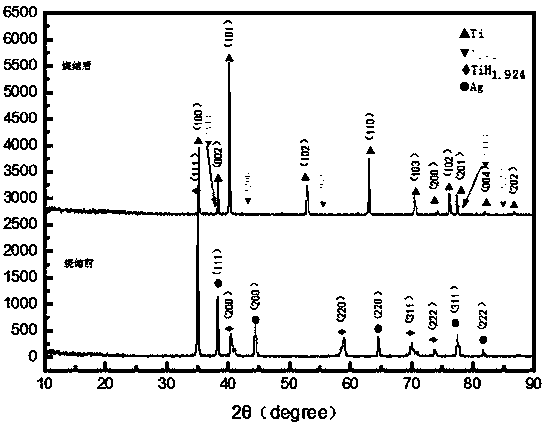

Preparing method of antibacterial porous titanium alloy

InactiveCN111014664AReduce porosityControl pore sizeMaterial nanotechnologyTransportation and packagingAlcoholReaction temperature

The invention discloses a preparing method of an antibacterial porous titanium alloy. The method comprises the steps of carrying out ball milling on raw material powder for standby application; preparing a silver nitrate solution, adding a dispersion agent, and marking a formed solution as a solution A1; preparing a reducing agent solution A2; carrying out water bath heating on the solution A1 andthe solution A2 to a reaction temperature, adding the raw material powder in the solution A1, then, adding a formed solution into the solution A2, adjusting the pH value, keeping the pH value constant, after the reaction, taking out the reaction solution for scattered cleaning, carrying out cleaning separately with deionized water and absolute ethyl alcohol for three times, centrifugally precipitating the processed reaction solution, and finally, performing drying to obtain mixed powder; adding ammonium bicarbonate into the mixed powder for uniform mixing, performing pressing forming on the mixture, and carrying out vacuum sintering, so as to obtain the silver-containing porous titanium alloy. The problems that in the prior art, a process for preparing the porous titanium alloy is complex, and pores of the porous titanium alloy do not have the antibacterial capacity are solved, and the method has the characteristics of being simple in equipment, convenient to operate, high in controllability and the like.

Owner:KUNMING UNIV OF SCI & TECH

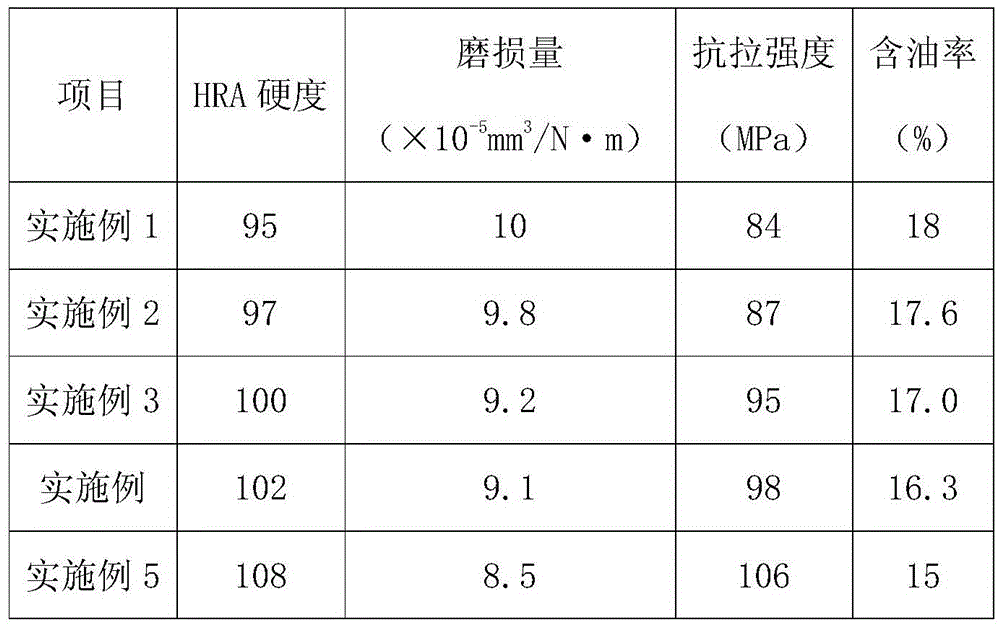

Nanometer silicon nitride bearing material for machinery and preparation method thereof

InactiveCN105665696AGood self-lubricating performanceControl pore sizeTransportation and packagingMetal-working apparatusSodium BentonitePolyvinyl alcohol

The invention discloses a nanometer silicon nitride bearing material for machinery and a preparation method thereof. The material is prepared by the following raw materials in parts by weight: 14-18 parts of nanometer silicon nitride, 58-62 parts of zirconium oxide, 9-13 parts of silicon, 1-2 parts of nickel, 3-4 parts of magnesium, 1.2-1.8 parts of germanium, 5-7 parts of polytetrafluoroethylene powder, 2.8-3.4 parts of polyvinyl alcohol, 0.4-0.8 part of bamboo charcoal powder, 3-5 parts of oleic acid, 0.8-1.2 parts of calcium stearate, 5-7 parts of aluminum oxide, 1.5-2.5 parts of bentonite, and 1.5-2.5 parts of triphenyl phosphate. The pretreatment, the hydraulic molding and the vacuum sintering are performed for the raw materials to obtain a blank; the surface grinding and the deburring treatment are performed; and then, the oil leaching is performed to obtain the material. The prepared bearing material is excellent in wear resistance and mechanical strength, prolongs the service life, and can be widely applied to such heavy mechanical equipment as energy, chemical engineering and ferrous metallurgy.

Owner:桐乡市搏腾贸易有限公司

Aluminum-based composite bearing material high in high-resistance-stability

InactiveCN105369091AImprove plasticityHigh strengthTransportation and packagingMetal-working apparatusHigh resistanceBoron nitride

The invention discloses an aluminum-based composite bearing material high in high-resistance-stability. The aluminum-based composite bearing material is prepared from, by weight, 85-90 parts of aluminum, 5-8 parts of copper, 3-4 parts of molybdenum, 1-2 parts of magnesium, 0.5-1 part of silicon, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methylcellulose, 1-1.5 parts of graphite, 1.5-2 parts of lime putty, 0.4-0.5 part of boron nitride, 1-2 parts of asbestos wool and a proper amount of oleic acid. The material is prepared through a powder metallurgy method, the technique is simple, operation is easy, the material cost is reduced, the material is good in mechanical property and high in high-resistance-stability, the part precision is high, molding is good, and the material is worthy of popularization.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

Aluminum-based composite bearing material high in adhesion resistance

The invention discloses an aluminum-based composite bearing material high in adhesion resistance. The material is prepared from, by weight, 85-90 parts of aluminum, 5-8 parts of silicon, 3-4 parts of copper, 1-2 parts of strontium, 0.5-1 part of manganese, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methylcellulose, 1-1.5 parts of graphite, 1.5-2 parts of quartz powder, 0.4-0.5 part of titanium carbide, 0.8-1 part of coal ash microsphere and a proper amount of oleic acid. The invention provides aluminum-based bearing alloy and a production method thereof, and various requirements for high hardness, high plasticity, high toughness and adhesion resistance of the material are met. The aluminum-based composite bearing material has the prominent characteristics of being simple in production technique, excellent in performance, suitable for industrialized production and the like.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com