Preparation method and application of acellular collagen matrix membrane

A collagen matrix and decellularization technology, applied in the field of preparation of acellular collagen matrix membrane, can solve the problems of destroying the biocompatibility of collagen membrane, affecting the biological effect of collagen membrane, easy residue of detergents and enzymes, etc. Barrier function and space maintenance function, avoid biocompatibility damage, promote cell adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

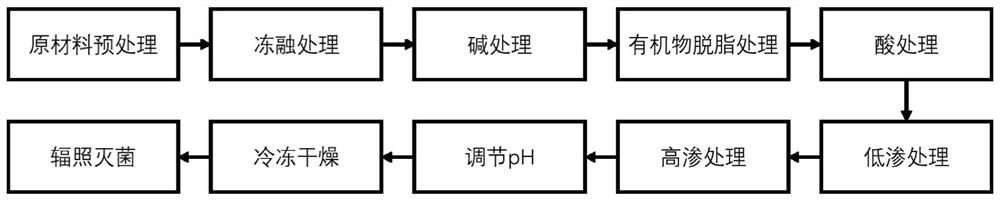

[0050] A preparation method of decellularized collagen matrix membrane, such as figure 1 shown, including the following steps:

[0051] S1. Take the pig peritoneum, pretreat the pig peritoneum, wash the blood stains with pure water first, use scissors without tension to remove as much fat and muscle tissue as possible, keep the biofilm thickness of about 0.5mm-2mm, and remove the biofilm Cut the film into 30mm×30mm size, soak it in pure water for 12 hours, and obtain the first intermediate product—biofilm, which is ready for use;

[0052] S2,

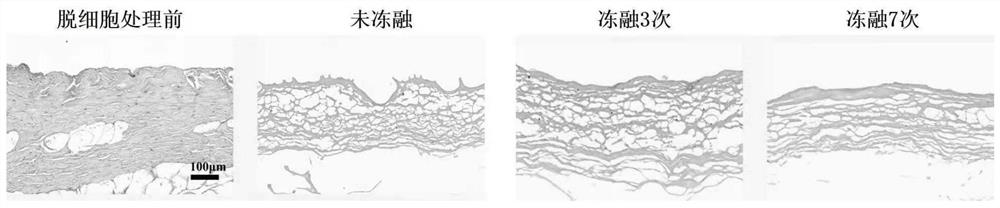

[0053] S2-1, repeated freeze-thaw treatment

[0054] Soak the biofilm obtained in step S1 in liquid nitrogen at -80°C, the volume ratio of biofilm to liquid nitrogen is 1:10, let it stand for 5 minutes, and melt it in flowing pure water at 25°C for 10 minutes, repeat 3 times; Wash with water, soak in pure water for 15 minutes, repeat 5 times;

[0055] S2-2. Alkali treatment

[0056] Soak the biofilm after S2-1 treatment in 2g / L sod...

Embodiment 2

[0073] A preparation method of decellularized collagen matrix membrane, such as figure 1 shown, including the following steps:

[0074] S1. Take the pig peritoneum, pretreat the pig peritoneum, wash the blood stains with pure water first, use scissors without tension to remove as much fat and muscle tissue as possible, keep the biofilm thickness of about 0.5mm-2mm, and remove the biofilm Cut the film into 30mm×30mm size, soak it in pure water for 12 hours, and obtain the first intermediate product—biofilm, which is ready for use;

[0075] S2,

[0076] S2-1, repeated freeze-thaw treatment

[0077] Soak the biofilm obtained in step S1 in liquid nitrogen at -80°C, the volume ratio of biofilm to liquid nitrogen is 1:10, let it stand for 5 minutes, and melt it in flowing pure water at 25°C for 10 minutes, repeat 7 times; Wash with water, soak in pure water for 15 minutes, repeat 5 times;

[0078] S2-2. Alkali treatment

[0079] Soak the biofilm after S2-1 treatment in 2g / L sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com