Magnesium alloy anodizing solution, preparing method and anodizing method for magnesium alloy

An anodic oxidation and magnesium alloy technology, which is applied in the field of metal surface treatment, can solve the problems of easy peeling of the film layer, uneven pores of the oxide film, uneven coloring, etc., and achieve the effect of not easy to fall off, uniform dyeing effect, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention also provides the preparation method of above-mentioned anodic oxidation solution, comprises adding hydroxide, silicate, metaaluminate, phosphate, glyoxylic acid and ethylene glycol into water, and stirring until dissolving. Preferably, hydroxide, metaaluminate, silicate and phosphate, ethylene glycol and glyoxylic acid are sequentially added into water to dissolve and stirred evenly.

[0017] The invention also provides a method for anodizing the surface of the magnesium alloy. The magnesium alloy is immersed in the above magnesium alloy anodizing solution for anodizing. Preferably, the temperature of the magnesium alloy anodic oxidation solution is 30-40° C., the anodic oxidation current is 3-7A, and the anodic oxidation time is 5-30 min.

[0018] Preferably, the magnesium alloy can be pretreated before anodizing; pretreatment is a commonly used pretreatment method in the field, specifically mechanical removal of oxide layer, ash removal, oil rem...

Embodiment

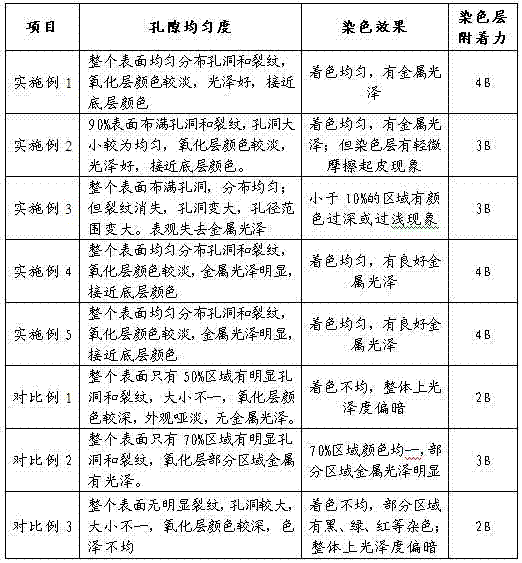

[0021] Example 1-5

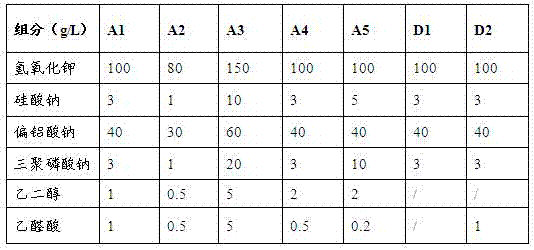

[0022] 1. Preparation of magnesium alloy anodizing solution: Add hydroxide, silicate, metaaluminate, phosphate, ethylene glycol and glyoxylic acid into deionized water. The magnesium alloy anodic oxidation solution A1-A5 was obtained according to the component distribution ratio in Table 1, and the specific dosage of each component is shown in Table 1.

[0023] 2. Pre-treat a 5cm×3cm magnesium alloy sample (brand AZ91D) to remove the oxide layer, remove ash and oil, and wash with water; put the above-mentioned pretreated magnesium alloy sample into the magnesium alloy anodic oxidation in step (1) In the solution, oxidize for 10 minutes at a solution temperature of 35°C and a current of 5A; take out the oxidized magnesium alloy, wash it with water, and dry it to obtain experimental samples Y1-Y5.

[0024] Table 1:

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com