Patents

Literature

62results about How to "Uniform dyeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid dye composition

An acid dye compound is prepared by taking weak acid dye, natural assistant and stabilizer as raw material and mixing to obtain final product. It has higher absorptive rate, better biological degradability and washing fastness.

Owner:DALIAN UNIV OF TECH

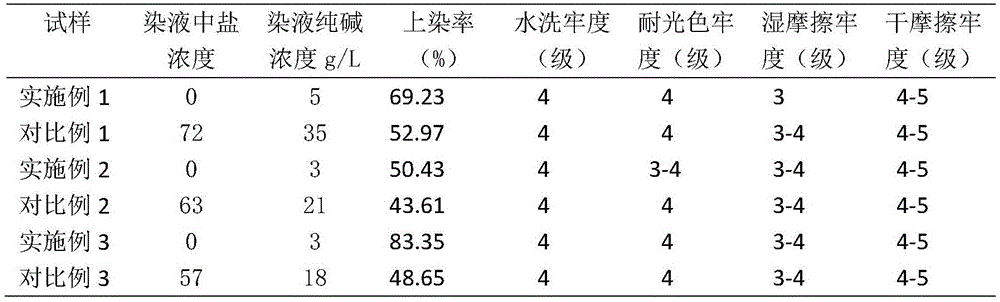

Method for cation modification and salt-free dyeing of cellulose fiber fabric

ActiveCN104233866AImprove permeabilityImprove uniformityDyeing processVegetal fibresRing dyeingSalt free

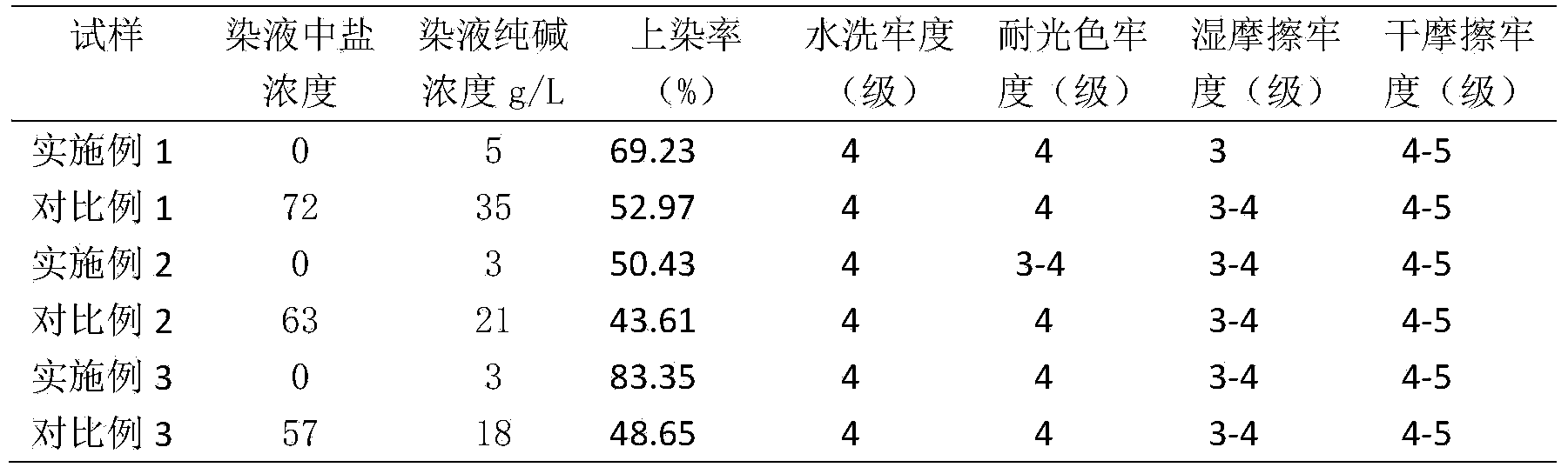

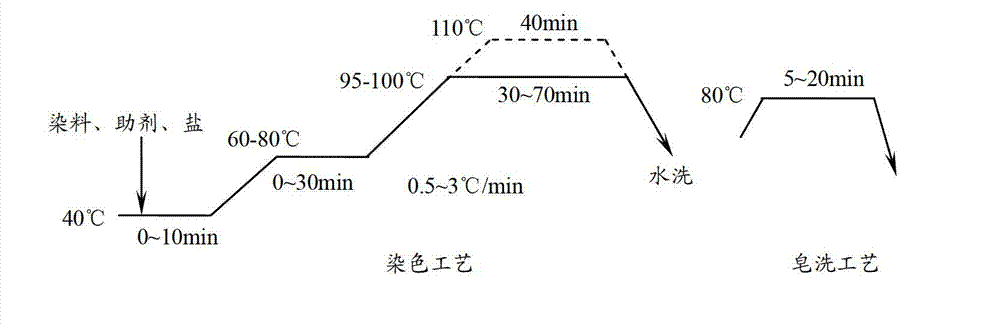

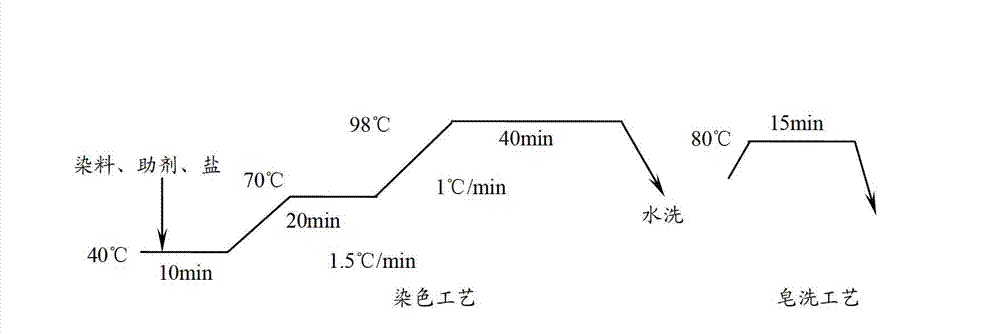

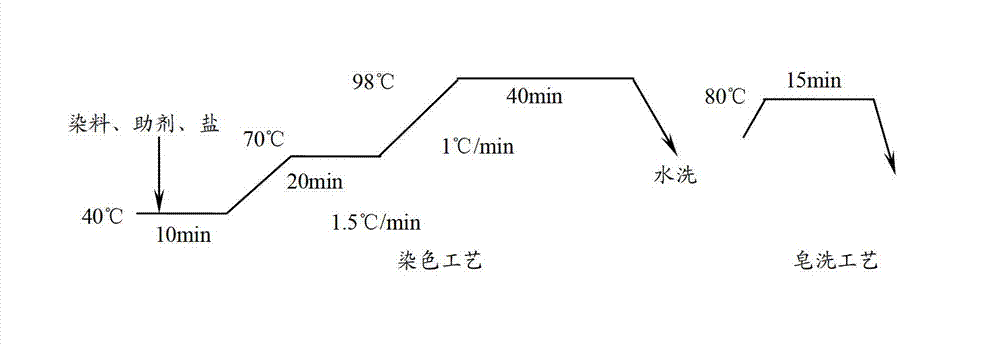

The invention discloses a method for cation modification and salt-free dyeing of a cellulose fiber fabric. The method comprises the steps as follows: preparing a high-polymer cation modifier aqueous solution with soft water, adding the cellulose fiber fabric, then adding NaOH, exerting pressure, heating the solution for a thermostatic reaction, performing cooling and pressure relief, discharging the modifying solution, and performing washing to obtain a cation-modified fabric; placing the cation-modified fabric in a dyeing machine, adding the soft water, sequentially dissolving reactive dye and sodium carbonate with return water, injecting the reactive dye and the sodium carbonate into the dyeing machine, heating the dyeing machine to the dyeing temperature, keeping the temperature, discharging a residual dyeing solution, and dehydrating and drying the fabric after a washing-soaping-washing process to obtain the salt-free low-alkaline dyed fabric. With the adoption of the method, salt-free low-alkali dyeing is realized, the problems of dyeing defects, color sinking and ring dyeing as well as reduction of the color fastness when cellulose fiber fabrics modified by high-polymer cation modifiers are dyed with reactive dyes are solved, a leveling agent is not required to be added during dyeing, the sodium carbonate and the dye can be added into a dyeing vat simultaneously, the sodium carbonate is not required to be added repeatedly during dyeing, and the dyeing operation is simple and easy to control.

Owner:SOUTH CHINA UNIV OF TECH +1

Dye composition for one-bath and one-type based dyeing and dyeing method of dye composition

ActiveCN103044969AReflect the development prospects of energy saving and emission reductionUniform dyeing effectOrganic dyesDyeing processColour fastnessWater saving

The invention provides a dye composition for one-bath and one-type based dyeing and a dye method of the dye composition. The dye composition is used for blending nylon / cotton, nylon / Nien linen and interlacing a fabric. The composite comprises active azo dyes of three or more types and / or transmit metal complex dye compound of three or more types under the ratio of 1:2. The dye composition used in match with the general assistant can successfully and effectively carry out the one-bath and one-type method of light colour, neutral colour, deep colour and even black colour. The dye composition comprises one or more specified active dyes provided by the invention, and one or more metal complex dye under the ratio of 1:2. By adopting the dye composition, the implemented dyeing technology has the following characteristics: the one-bath and one-type method is carried out, so that the operation is simple and convenient, and great reproducibility is realized; the dyeing effects of light colour, neutral colour and deep colour, especially the black colour are provided; great homochromatism of nylon / cotton, and nylon / Nien linen dyeing is provided; and the colour fastness is excellent; and compared with the conventional technology, the dyeing method provided by the invention has the advantages of water saving, energy conservation, time saving, and emission reducing.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

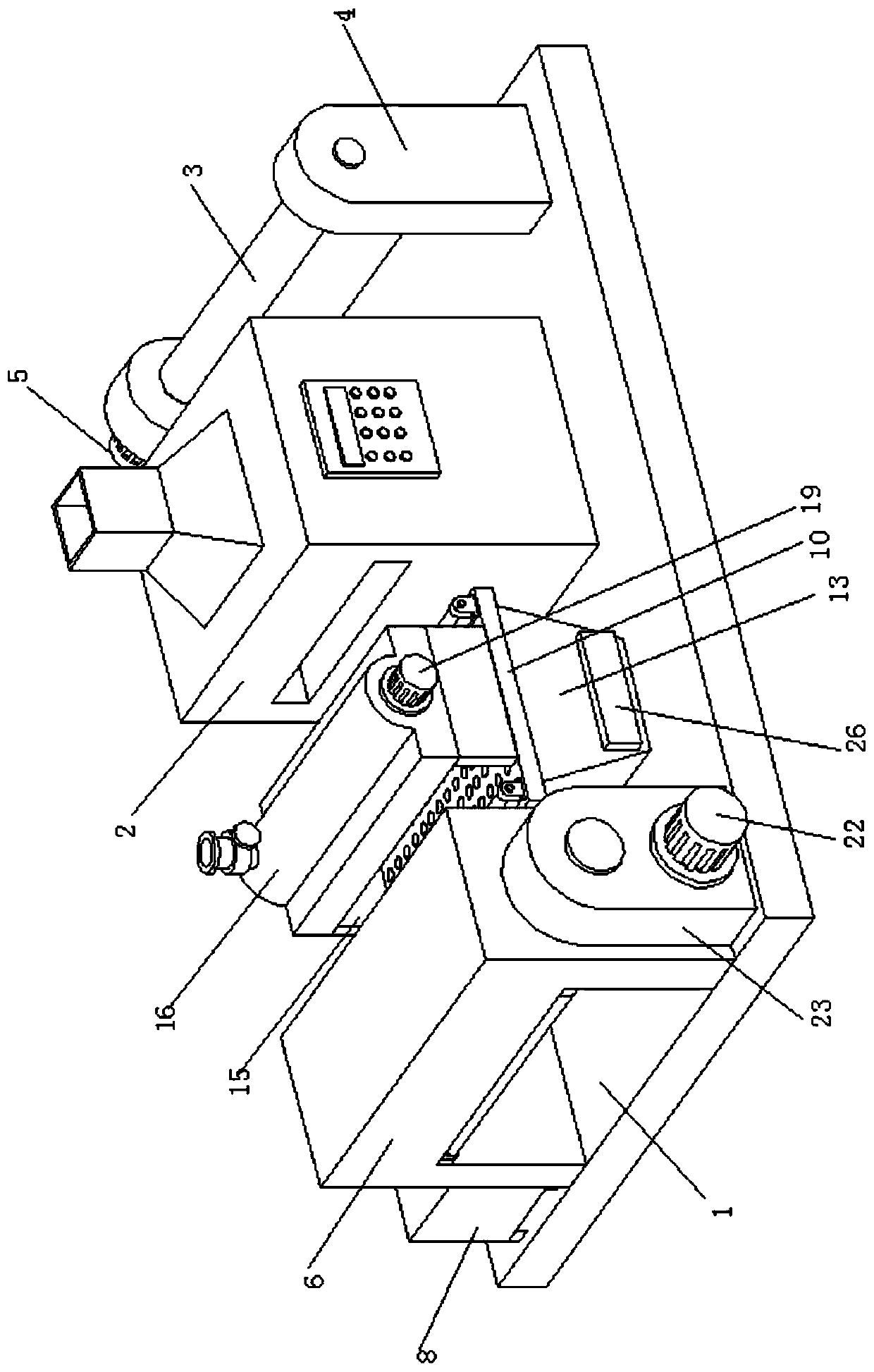

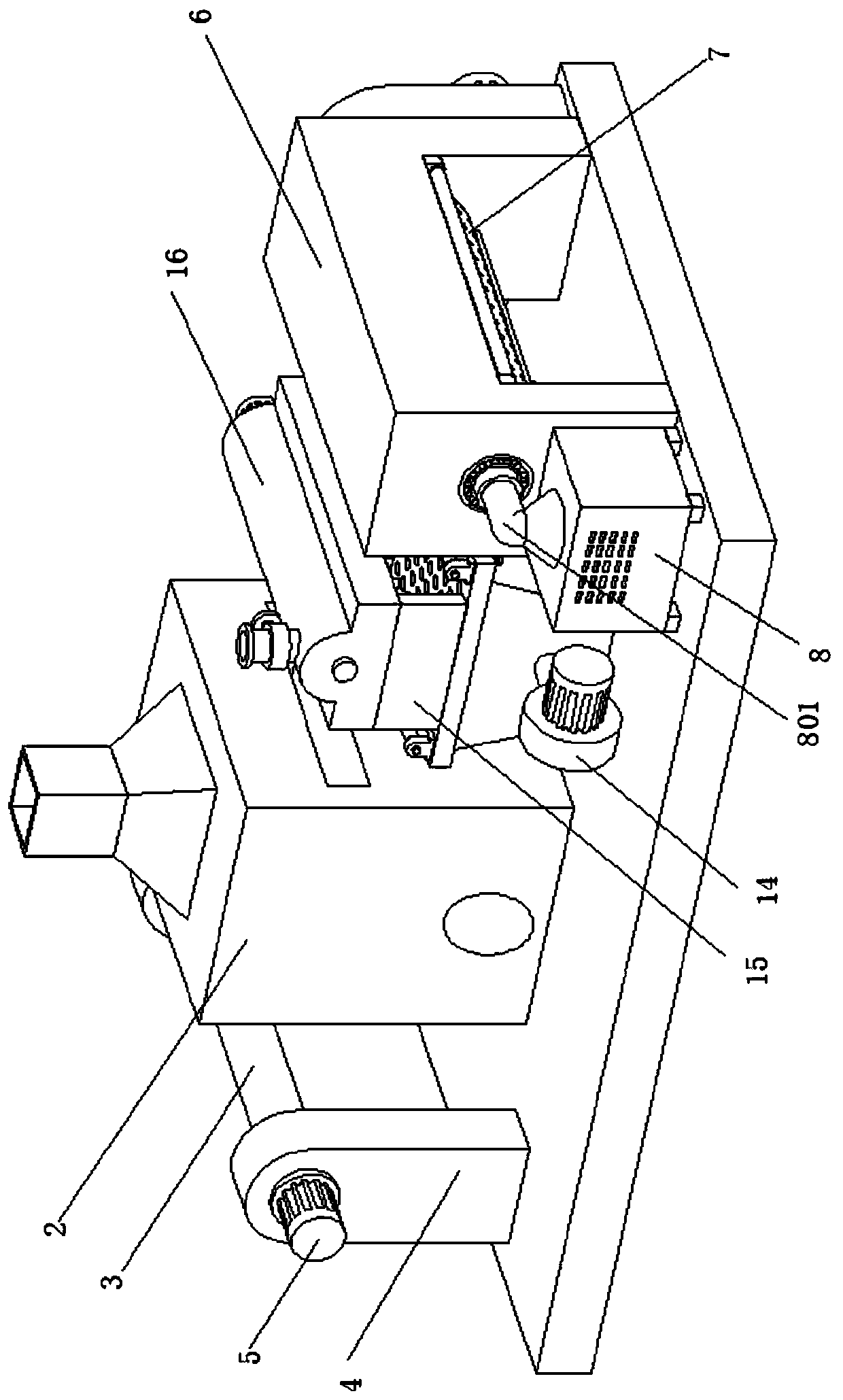

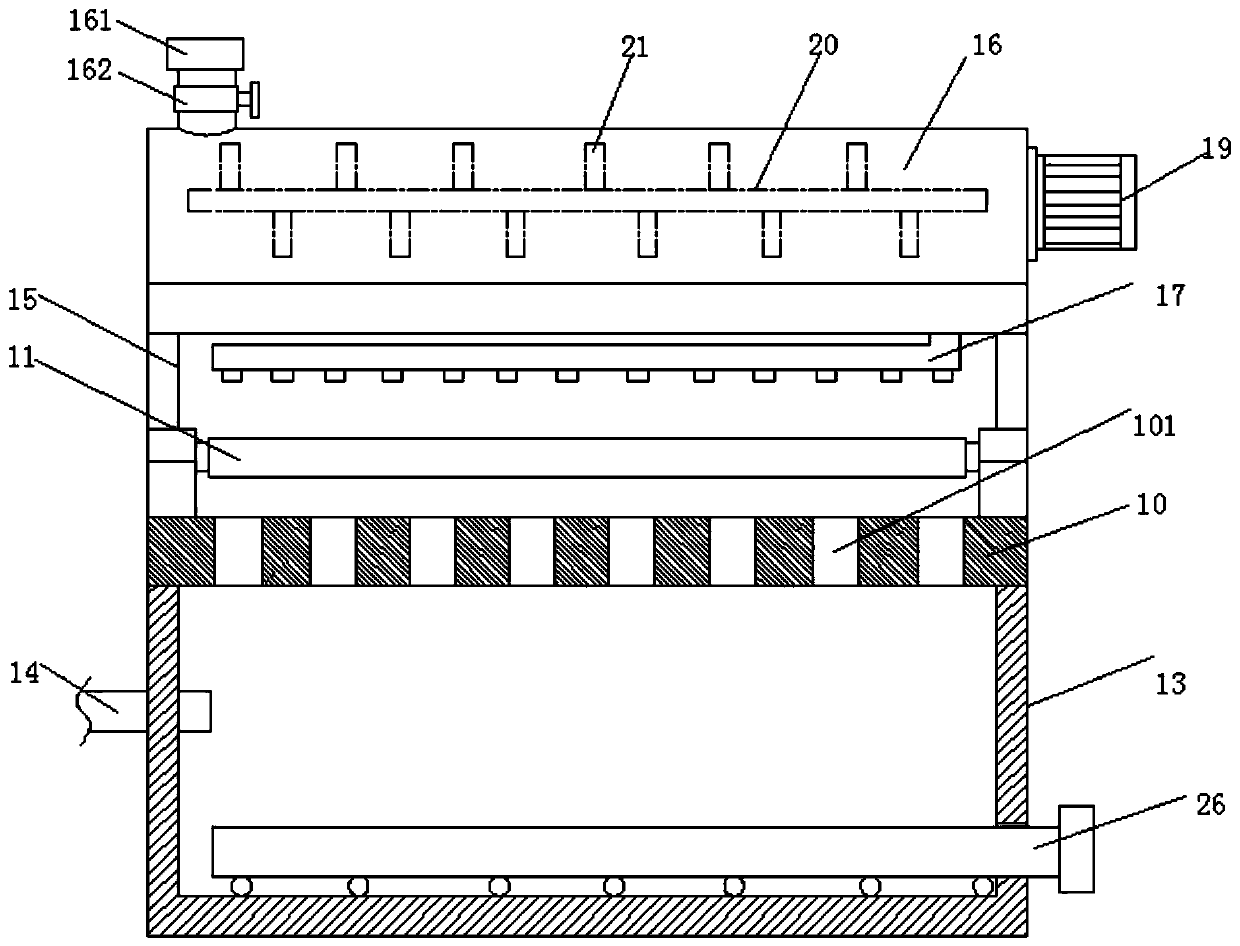

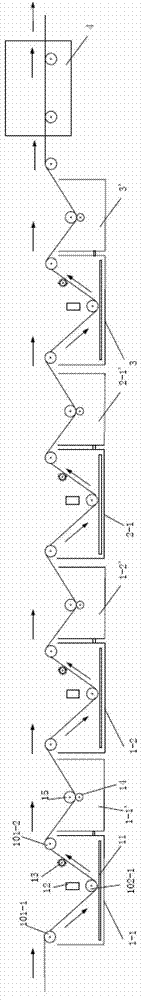

Environment-friendly efficient chemical fiber fabric printing and dyeing equipment and process

ActiveCN111334955AGood dyeing effectReduce steam consumptionTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringDyeing

The invention relates to the technical fields of textile fabric printing and dyeing, in particular to environment-friendly efficient chemical fiber fabric printing and dyeing equipment and process. The environment-friendly efficient chemical fiber fabric printing and dyeing equipment comprises a bottom plate, a drying box and a wind-up roller, wherein two rotating supports are arranged at the right end of the upper surface of the bottom plate; the wind-up roller is rotatably arranged on the two rotating supports; a winding motor is arranged on one rotating support; and an output shaft of the winding motor penetrates through the rotating support to be connected with the end face of the winding roller. When an atomizer sprays, dyes and colors the upper surface of chemical fiber fabric, a negative pressure exhaust fan draws the interior of a case to a negative pressure state, so that a pressure difference is formed between the upper space and the lower space of the chemical fiber fabric,dye liquor sprayed on the chemical fiber fabric accelerates to permeate from the upper surface of the chemical fiber fabric to the lower surface of the chemical fiber fabric under the action of negative pressure, the quality problem caused by large chromatic aberration difference between a spray dyeing surface and a back surface due to poor penetration effect of the chemical fiber fabric in existing fabric printing and dyeing equipment can be effectively solved, and the dyeing effect is excellent.

Owner:绍兴水乡纺织科技有限公司

Coating liquid for tobacco sheet cigarette paper

ActiveCN105040518AIncrease contentProduct quality, safety and stabilityNon-fibrous pulp additionPaper/cardboardMaillard reactionIrritation

The invention discloses a coating liquid for tobacco sheet cigarette paper. The coating liquid is prepared from a toner, a combustion improver and a spice, wherein the toner is prepared by the following steps: (1) adding water to tobacco leaf waste, decocting, extracting, adding saccharomycetes and protease to an extracted liquid for fermentation, concentrating the fermented liquid, adding ethanol, standing, taking a supernatant liquid, recovering the ethanol and carrying out vacuum concentration to form clear paste; and (2) adding hot water, revertose and amino acid to the clear paste, carrying out maillard reaction, ending the reaction, and concentrating a reaction liquid, so as to obtain the coating liquid. According to the coating liquid disclosed by the invention, the wood gas, the offensive odor and the oral irritation of the tobacco sheet cigarette paper can be reduced; the fragrance of the tobacco sheet cigarette paper can be increased; the smoke panel test result is improved; and meanwhile, the cigarette paper can also be dyed by the coating liquid instead of a natural pigment.

Owner:HUBEI CHINA TOBACCO IND

Acid dye mixture with good colourability

InactiveCN102408750AImprove wet fastnessHigh exhaustion rateOrganic dyesDyeing processFiberWastewater

The invention discloses an acid dye mixture with good colourability. The acid dye mixture has the following beneficial effects: as a natural auxiliary is added, the wet fastness of the acid dye after mixing is improved, the fiber handfeel can not be changed and the exhaustion of the dye is substantially improved; the wastewater generated after dyeing can be entirely degraded biologically; and the acid dye mixture is more suitable to dye nylons, silk, leathers, wool, paper, synthetic resins and other substances, simultaneously is quite suitable for various novel fibers and has uniform dyeing effect.

Owner:DAFENG QIANCAI FINE CHEM

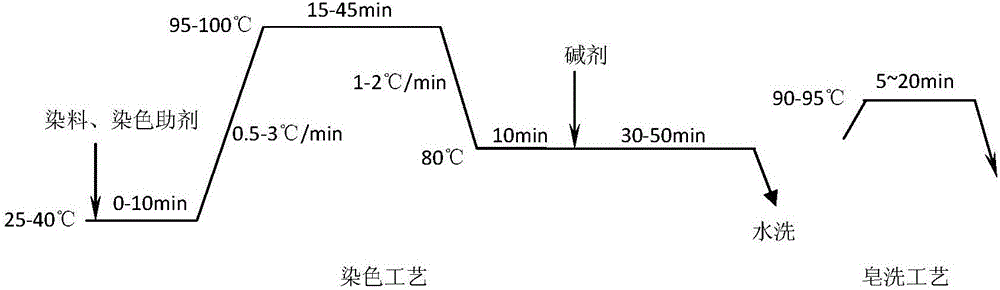

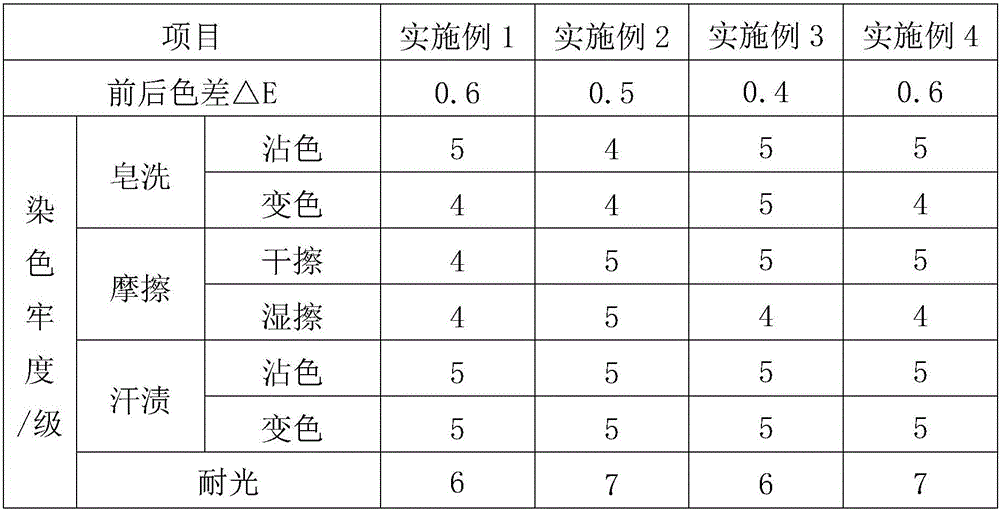

PTT/PET (polytrimethylene terephthalate/polyethylene terephthalate) composite fiber fabric dyeing and finishing process capable of forming crepe feeding

InactiveCN110306310AUniform dyeing effectReduce usageHeating/cooling textile fabricsDry-cleaning apparatus for textilesPolyethylene terephthalatePolyethylene terephthalate glycol

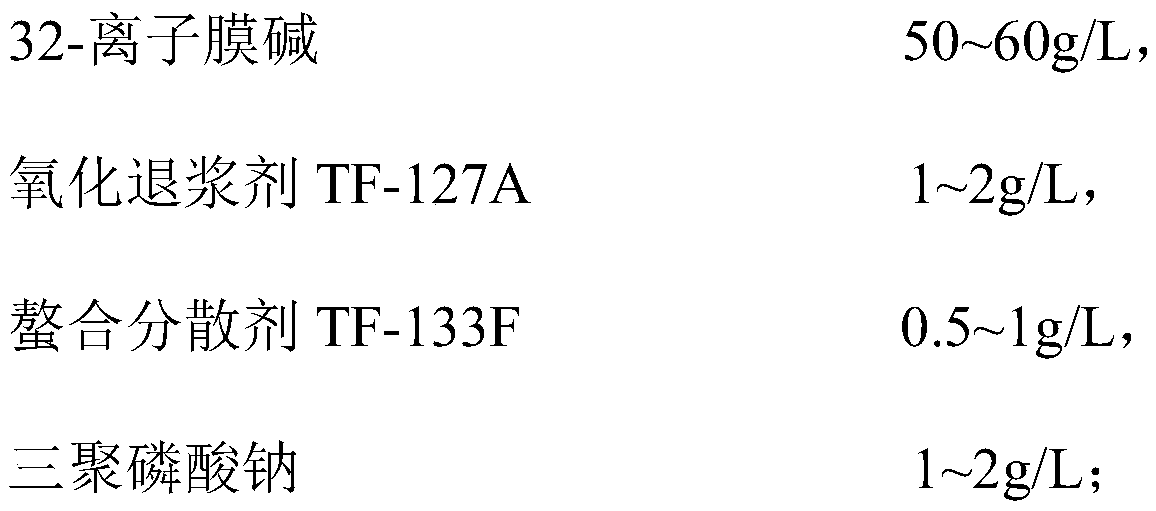

The invention discloses a PTT / PET (polytrimethylene terephthalate / polyethylene terephthalate) composite fiber fabric dyeing and finishing process capable of forming crepe feeding. The dyeing and finishing process includes a pretreating process, a dyeing process and a setting process, and the pretreating process includes a first open width OS desizing process and a second open width OS desizing process. According to the dyeing process, dyeing is implemented by the aid of a high-temperature and high-pressure airflow overflowing dyeing machine, the dyeing process is divided into a dyeing stage and a washing stage, the dyeing machine adopts an airflow mode at the dyeing stage, and the dyeing machine adopts an air-liquid mode at the washing stage. According to the setting process, a dyed gray fabric is set by a setting machine through setting liquid. According to the process, on the premise of ensuring of dyeing quality, a processed fabric can reach flawless, and winding crepe feeding of the fabric is given, so that the fabric has an obvious airflow style and a shape memory function in a weft direction, is good in color repeatability, soft in hand feeling, obvious in elastic force effect and meets clothes using requirements.

Owner:SHENGHONG GRP CO LTD

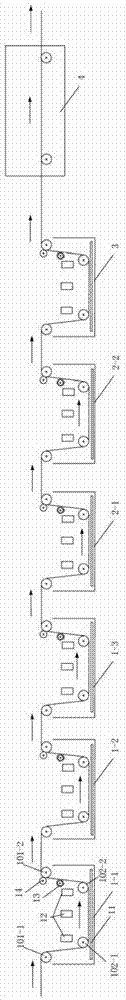

Dyeing process and dyeing apparatus for collagen fiber regenerated leather

ActiveCN103255653BEffective penetrationUniform dyeing effectTextile treatment machine partsDyeing processPolymer scienceCollagen fiber bundle

The invention relates to a dyeing process for collagen fiber regenerated leather. The process successively comprises at least two dyeing treatment, at least one fixation treatment, at least one handfeel modification and drying treatment, wherein dyeing, fixation and handfeel modification are all carried out in an supersonic sound field, so a coloring agent, a fixing agent and a handfeel modifier can effectively penetrate into collagen fiber bundles so as to obtain a more uniform dyeing effect. The concentration of the coloring agent in sequentially used bath liquids increasingly decreases, temperatures of the bath liquids gradually increase, the power of the supersonic sound field increasingly decreases, so bath liquids with high concentration can infiltrate into a leather blank at first, and flooding which is serious in the process of filtration can be eliminated in subsequent dipping in liquids with low concentration; thus, flooding generated in subsequent procedures increasingly decreases, and uniform dyeing of the leather blank is realized. Moreover, surface flooding is eliminated in virtue of a brush of a brush roller in the invention. The invention also relates to a dyeing apparatus capable of realizing continuous uniform dyeing of cloth and leather.

Owner:JIANGYIN JUNHUA TEXTILE TECH

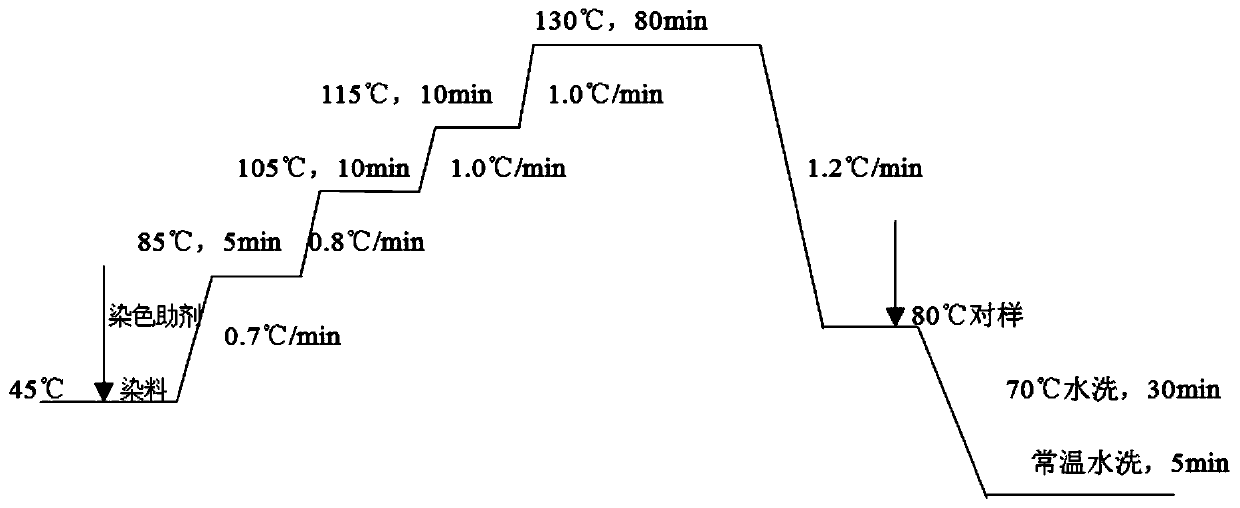

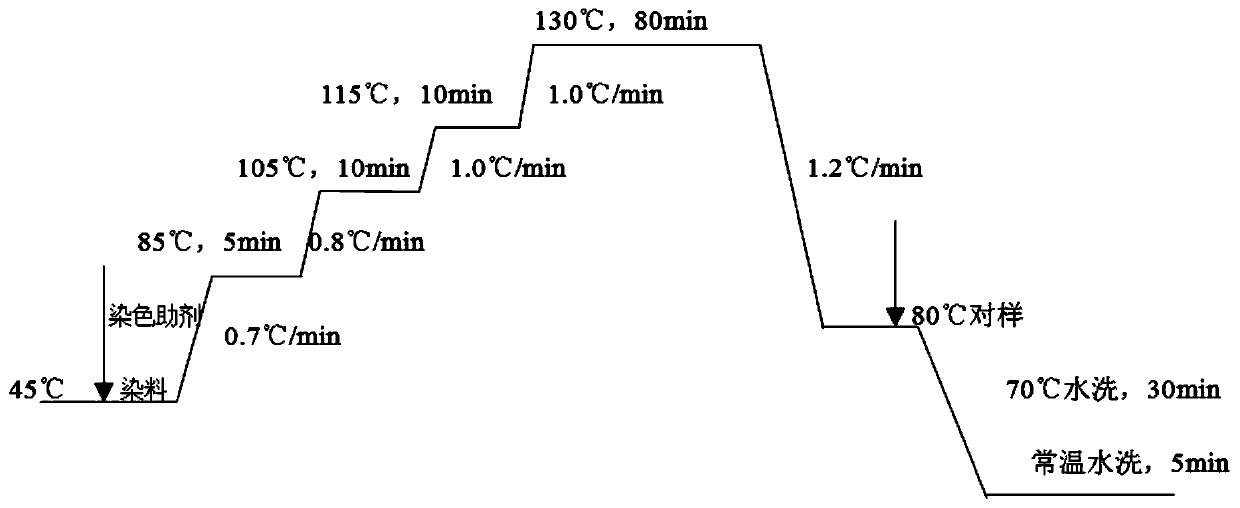

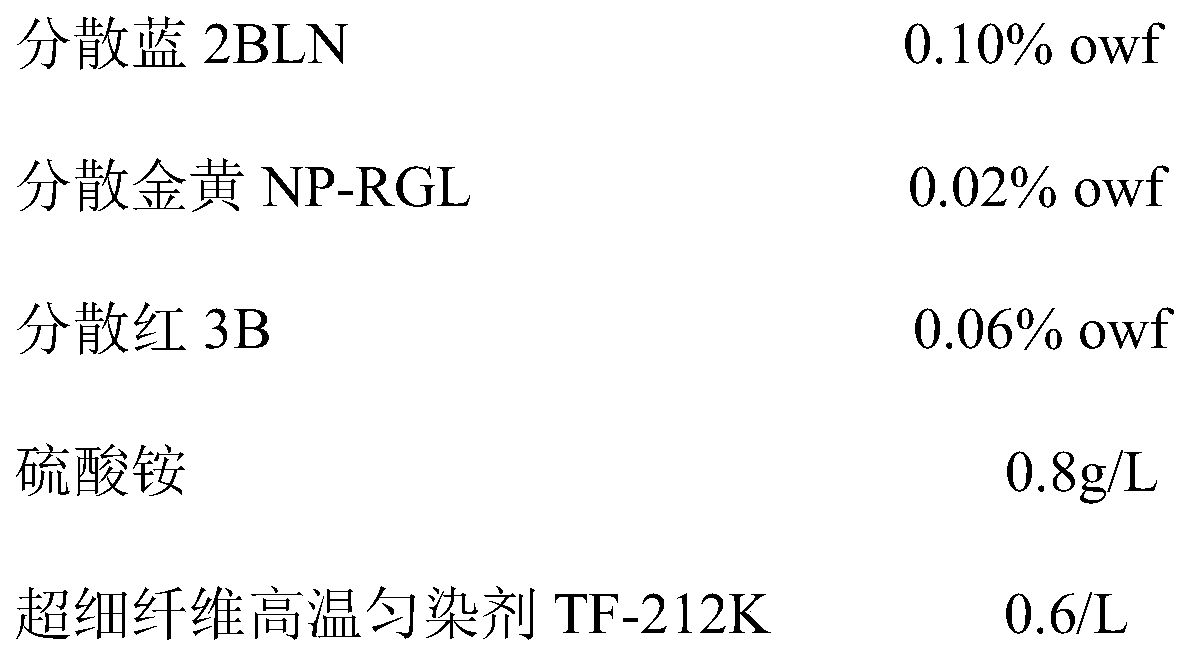

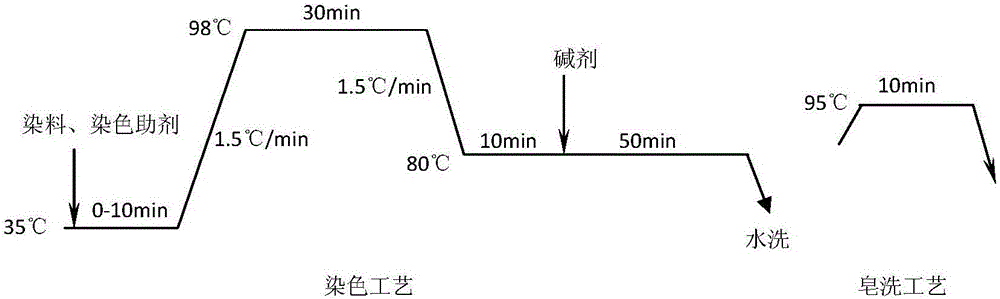

Dyeing process capable of forming PTT/PET composite fiber fabric with crepe feeling

The invention discloses a dyeing process capable of forming a PTT / PET composite fiber fabric with a crepe feeling. According to the dyeing process, an adopted dyeing agent consists of a dyeing assistant and a dye, and the dye is a disperse dye. In the dyeing process, a high-temperature and high-pressure airflow overflow dual-purpose dyeing machine is adopted for dyeing, and when the temperature ofa dyeing cylinder of the dyeing machine reaches 45 DEG C, the dyeing assistant and the disperse dye are separately injected; the dyeing process includes a dyeing stage and a water washing stage; in the dyeing stage, the dyeing machine stays in an airflow mode, and in the water washing stage, the dyeing machine stays in a gas-liquid mode. During dyeing, the temperature of the dyeing cylinder is increased to 85 DEG C at the temperature increase rate of 0.7 DEG C / min, and the temperature is set as the initial dyeing temperature. On the premise of ensuring the dyeing quality, not only can the dyed fabric have no flaws and defects, but also the fabric can be endowed with a zigzag crepe feeling, so that the fabric has an obvious airflow style, good color reproducibility and a soft hand feeling;moreover, the fabric has a shape memory function in the weft direction, the elastic effect is obvious, and the requirements for clothing are met.

Owner:SUZHOU XINMIN PRINTING&DYEING CO LTD

Polyester combined-filament yarn and woven or knitted fabric comprising it

InactiveUS20090013662A1Improve tensile propertiesUniform dyeing effectWeft knittingSynthetic resin layered productsPolyethylene terephthalate glycolAlkaline earth metal

A polyester combined-filament yarn having an excellent stretch property and a bathochromic effect, as well as uniformity of apparent dyed color density, comprises two different multifilament components (A) and (B), wherein the multifilament component (A) comprises polyester filaments composed of polyethylene terephthalate (PET) polymer, a metal-containing phosphorus compound (a) and an alkaline earth metal compound (b), and a conjugate multifilament component (B) comprises side-by-side or eccentric core-sheath conjugate polyester filaments composed of two mutually different polyester resins (at least one of which is polytrimethylene terephthalate resin), the mass ratio (A) / (B) of components (A) and (B) is in the range of 80 / 20 to 50 / 50. Woven or knitted fabrics comprising the combined-filament yarn are useful for women's and men's fashion apparel and black formals.

Owner:TEIJIN FRONTIER CO LTD

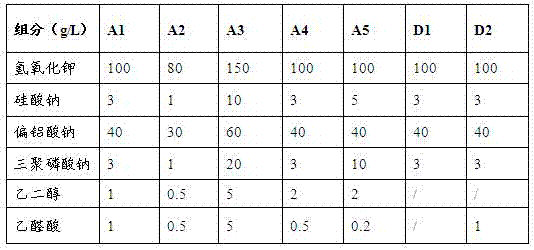

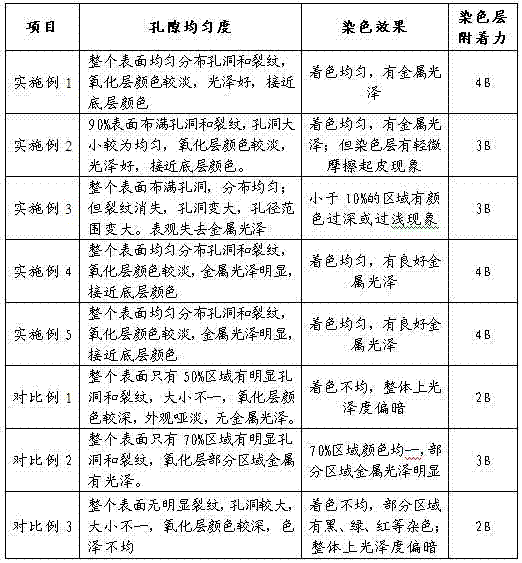

Magnesium alloy anodizing solution, preparing method and anodizing method for magnesium alloy

The invention relates to a magnesium alloy anodizing solution. The anodizing solution is an aqueous solution containing hydroxide, silicate, meta-aluminate, phosphate, ethylene glycol and glyoxylic acid. The invention further provides a preparing method for the magnesium alloy anodizing solution and an anodizing method for the magnesium alloy with the adoption of the magnesium alloy anodizing solution. According to the provided magnesium alloy anodizing solution, sizes of pores in an oxidation film can be effectively reduced, uniformity of the pores is improved, and the dyeing effect of the rear section is improved accordingly.

Owner:BYD CO LTD

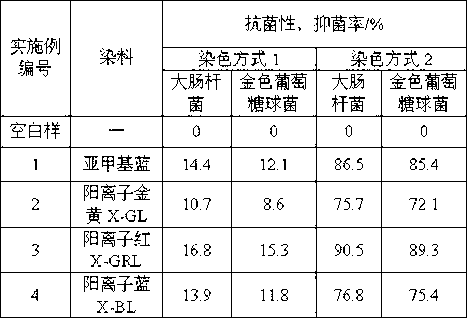

Natural retarding agent for dyeing of cationic dye and using method of natural retarding agent

InactiveCN103321064AConsistent product qualityAntibacterial and Antistatic Antibacterial or AntistaticDyeing processDyeingBenzalkonium chloride solution

The invention discloses a natural retarding agent for dyeing of cationic dye. The natural retarding agent is at least one of chitosan and derivatives thereof, wherein the concentration of the chitosan or the derivatives thereof is 0.1-4g / L. According to the retarding agent, natural chitosan or derivatives thereof, such as carboxymethyl chitosan and hydroxypropyl chitosan with different molecular weights are adopted for dyeing of cationic dye, and the problem that 1227 contains benzalkonium chloride and CTAB (cetyltrimethyl ammonium bromide) has strong fishy smell when a conventional cationic dye is used for dyeing are solved; and the prepared product has the quality consistent with that of a product prepared by adopting a conventional process, and has a certain antibacterial and anti-static performance. The technical scheme disclosed by the invention is simple in process and convenient to operate, does not have special requirement on cationic dye and equipment, and can be applied to large-scale production by utilizing conventional dyeing equipment.

Owner:HENAN INST OF ENG

A kind of oxidative dyeing composition

ActiveCN105596228BSmall color differenceSatisfy dyeing needsCosmetic preparationsHair cosmeticsMethylenedioxyPhenol

The invention relates to an oxidized type dyeing composition. The oxidized type dyeing composition comprises a first agent and a second agent, wherein the first agent contains an oxidation coloring base, a coupling agent and an oxidation retarder; the second agent contains an oxidant; the oxidation coloring base comprises 2,5-diaminotoluene or an addition salt thereof, the coupling agent comprises hydroxyethyl-3,4-methylene dioxyaniline or an addition salt thereof, and the oxidation retarder is a polyhydroxyl phenol oxidation retarder. The oxidized type dyeing composition provided by the invention is applied to hair, of which the ratio of white hair does not exceed 50%, and the color difference between the white hair and black hair after hair dyeing can be reduced while the white hair is excellently covered, so that the dyeing requirement that the hair is uniformly dyed to brown can be met.

Owner:肇庆迪彩日化科技有限公司

Polyester combined-filament yarn and woven or knitted fabric comprising it

InactiveUS7645508B2Good effectMaintain good propertiesWeft knittingSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

Owner:TEIJIN FRONTIER CO LTD

Black dye composition and dyeing application and method thereof on fibers

ActiveCN106433214AReflect the development prospects of energy saving and emission reductionUniform dyeing effectOrganic dyesDyeing processCellulose fiberProtein fiber

The invention provides a black dye composition and dyeing application and method thereof. The black dye composition and the dyeing application and method thereof are used for dyeing of brocade / cotton and brocade / viscose blended fabrics and interlacing fabrics through the one-bath and two-step method. The composition comprises one or more reactive dye compounds shown in the general formula (I), one or more reactive dye compounds shown in the general formula (II) and one or more 1:2 metal complex dye compounds shown in the general formula (III), wherein the dye compounds are mixed in a certain proportion. Fastnesses, especially light fastness and wet treatment fastness, of the dye composition are excellent, and the dye composition can be widely used in coloring of cellulose fibers, polyamide fibers, protein fibers, blended textiles and the like. The dye composition has an unexpected coloring effect during union dyeing of brocade / cotton and brocade / viscose blended fabrics and interlacing fabrics by means of the one-bath and two-step method. Please see the formulas in the description.

Owner:苏州科法曼化学有限公司

Shortened wet steaming pad-dyeing technology of all-cotton fabric vat dye

ActiveCN106065530AUniform aggregationShorten grinding timeSucessive textile treatmentsDyeing processWet steamEngineering

The invention discloses a shortened wet steaming pad-dyeing technology of an all-cotton fabric vat dye. The technology comprises the following steps: 1, padding with the dye: padding an all-cotton fabric with the dye according to a bath ratio of 1:5-10 at 20-40DEG C to make the pickup be 85-95%; 2, adding an assistant: feeding the assistant by using a high-level liquid adding device to make the assistant pickup on the all-cotton fabric be 90-100%; 3, rapidly steaming: rapidly steaming by using saturated steam, wherein the temperature of a steaming box is 90-110DEG C, the humidity of the steaming box is 99-100%, and the steaming time is 1.5-2min; 4, carrying out high-temperature water washing; 5, carrying out oxidation treatment; and 6, soaping. The shortened wet steaming pad-dyeing technology of the all-cotton fabric vat dye has the advantages of good level dyeing property, high color fastness, simple process, environmental protection and healthiness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

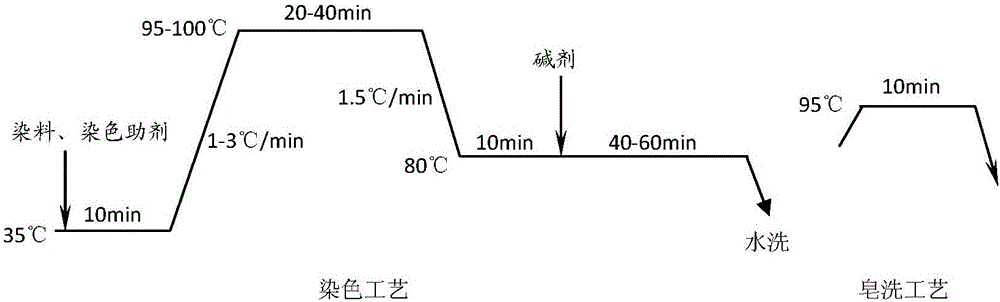

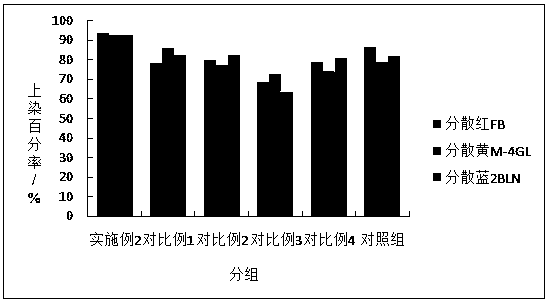

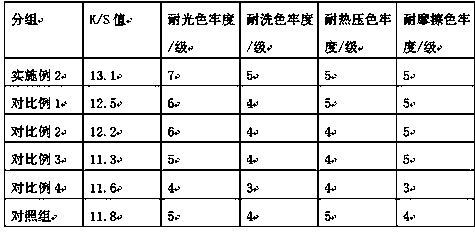

Dyeing method for improving disperse dye color fastness of polyester fabrics

InactiveCN110820368AAdd depthGood dye utilizationFibre typesUltrasonic/sonic fibre treatmentDisperse dyeColour fastness

The invention belongs to the technical field of polyester dyeing and discloses a dyeing method for improving disperse dye color fastness of polyester fabrics. The dyeing method includes steps: (1) polyester fiber pretreatment; (2) dyeing; (3) dyeing aftertreatment. The polyester fabrics dyed according to the dyeing method are high in dyeing depth and dye utilization rate, the dyed fabrics are excellent in color fastness, dyeing effects of different primary color dyestuffs are equalized, and popularization and application are benefited.

Owner:安徽省锦元纺织品科技有限公司

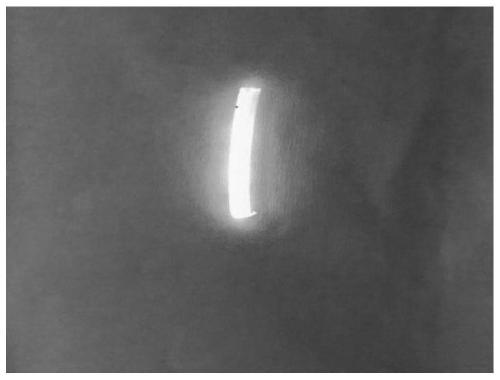

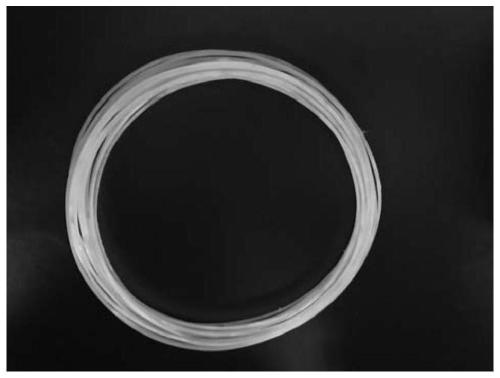

3D printing composite material containing organic fluorescent dye and application thereof

InactiveCN109880323AWith fluorescent effectImprove performanceAdditive manufacturing apparatusOrganic solventFluorescence

The invention discloses a 3D printing composite material containing an organic fluorescent dye and application thereof. The preparation method comprises the following steps: dissolving the organic fluorescent dye in an organic solvent, and then coating a printing piece with the organic fluorescent dye so as to obtain a PLA printing wire material dyed by the organic fluorescent dye. A 3D printer isused for printing the printing piece to obtain the 3D printing piece containing the organic fluorescent dye. Compared with an original PLA wire, the PLA wire with the organic fluorescent dye has thefluorescent effect, a product still has the fluorescent effect after being subjected to hot-melt printing through a 3D printer, a printing work containing the fluorescent dye can be self-luminous under the irradiation of an ultraviolet lamp, and the artistic performance of the 3D printing work is improved. The preparation method is simple, the operation is simple and convenient, the practicabilityis high, the performance of the dyed PLA wire is stable, the dyeing effect is uniform, the diameter of the wire is not increased, adverse effects on a 3D printer nozzle cannot be caused, and the 3D printing composite material is suitable for being used by an FDM (frequency division multiplexing) printer.

Owner:SOUTH CHINA UNIV OF TECH +1

Technology for dyeing silk fabric by using indigo pigment

InactiveCN106811995AUniform dyeing effectImprove working environmentDyeing processWorking environmentHue

The invention relates to a dyeing process of indigo dyed silk fabrics, which comprises the following steps: (1) placing the silk fabrics in an aqueous solution in which an alkali agent is dissolved for pretreatment. (2) placing the pretreated silk fabric in a protease solution for enzyme treatment. (3) Soak the silk fabric after the enzyme treatment in the dye material liquid that is configured with dispersant, dye cosolvent, alkali agent, reducing agent, acid agent, antioxidant, anti-over-reducing agent, leveling agent and dye it. The dyed silk fabric is washed and dried to obtain the dyed silk fabric. The invention adopts pretreatment and enzyme treatment for dyeing, which can make the dyeing effect uniform, and endow the fabric with better dyeing rate, abrasion fastness and washing fastness. The indigo dyeing method of the invention is convenient for automatic operation, has a good working environment and stable hue, and improves the competitiveness of products in the market.

Owner:苑少纯

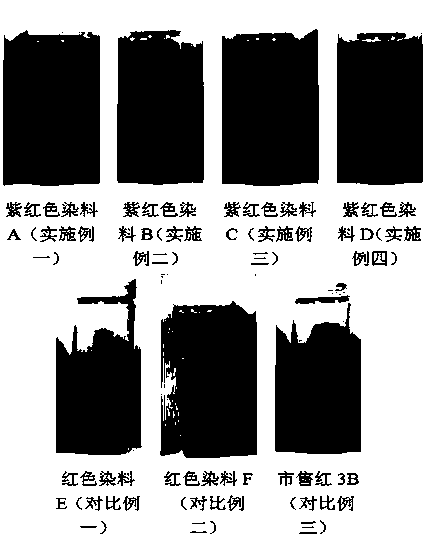

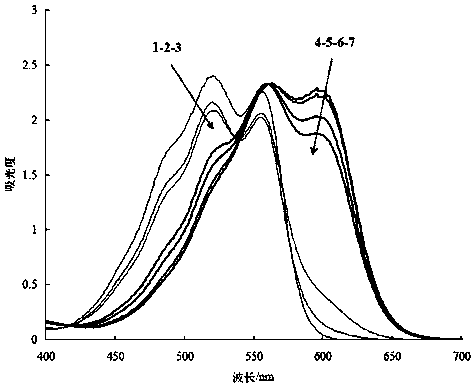

Aubergine liquid disperse dye as well as preparation method and application of dye

ActiveCN107761409AWide pH requirementStrong process adaptabilityOrganic dyesDyeing processDisperse dyePurplish red

The invention discloses an aubergine liquid disperse dye as well as a preparation method and application of the dye. The aubergine liquid disperse dye is prepared from 1-amino-4-hydroxy-9,10 anthraquinone and CNF, 1815, alkali, ethanol, sodium polyacrylate, water soluble polyester and water soluble polyether; by adding water soluble polyester and polyether as well as sodium polyacrylate, an aubergine dyeing product is obtained for the first time, thus solving the problem that aubergine needs to be formed by color matching of the prior art, and widening the hue of 1-amino-4-hydroxy-9,10 anthraquinone dye.

Owner:SUZHOU UNIV

Preparation method of knitted Roman cloth

InactiveCN109610082AClear textureTight weaveWeft knittingHeating/cooling textile fabricsPolyesterYarn

The invention relates to a preparation method of knitted Roman cloth. The preparation method comprises the following steps: weaving by taking an all-cotton strong twist 40s combed cotton yarn combinedwith a 2075 polyester coated ammonia-coated wire as a raw material; then scutching, pre-streaming, pre-setting, scouring and bleaching, enzyme-washing, dyeing, after-finishing, drying, setting and forming to obtain the knitted Roman cloth. The preparation method provided by the invention has the benefits that through the reasonable selection on the twist degree and the twist direction of the yarn, the polyester coated ammonia-coated wire is combined; the knitted Roman cloth produced by adopting a suitable dyeing and finishing process is suitable in gram weight, elastic in cloth face and delicate, thereby being a material for making high fashions.

Owner:NINGBO BETTER TEXTILE&GARMENTS

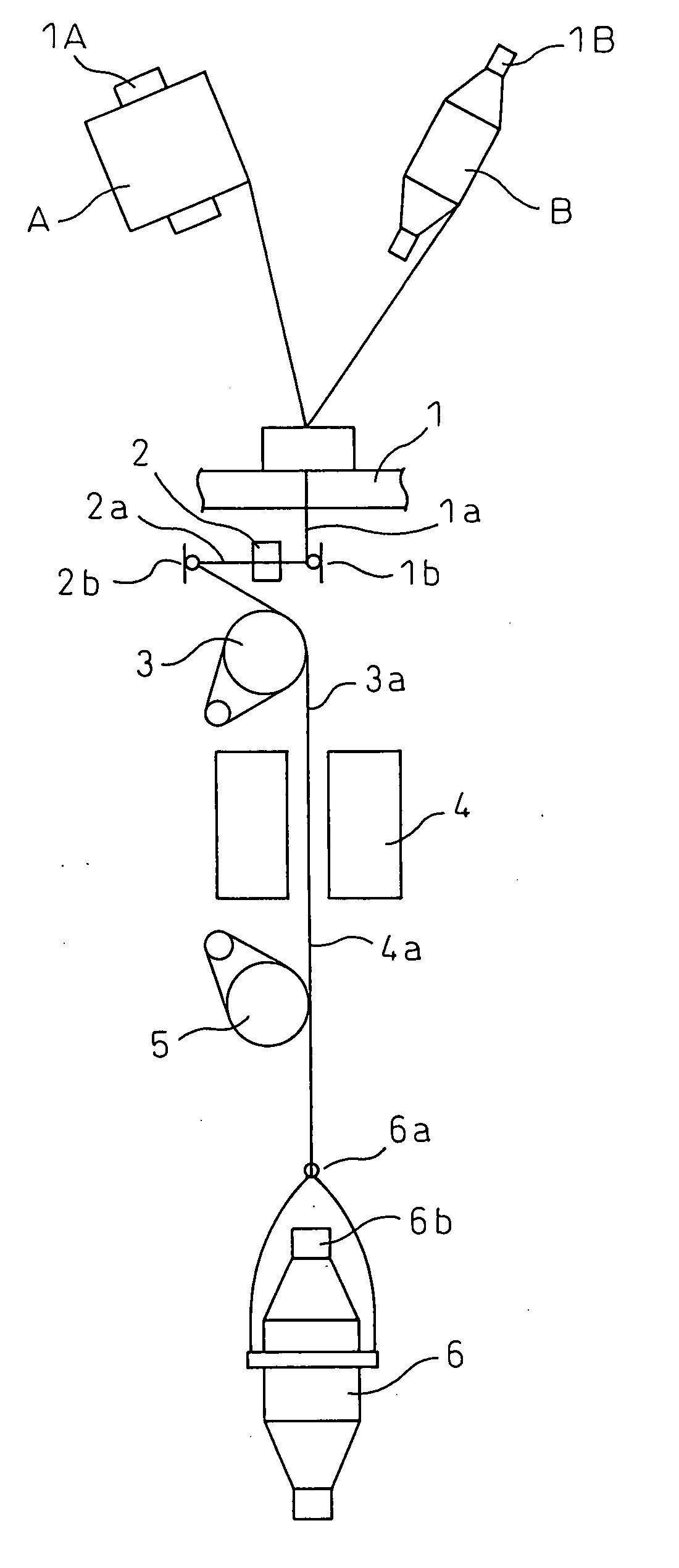

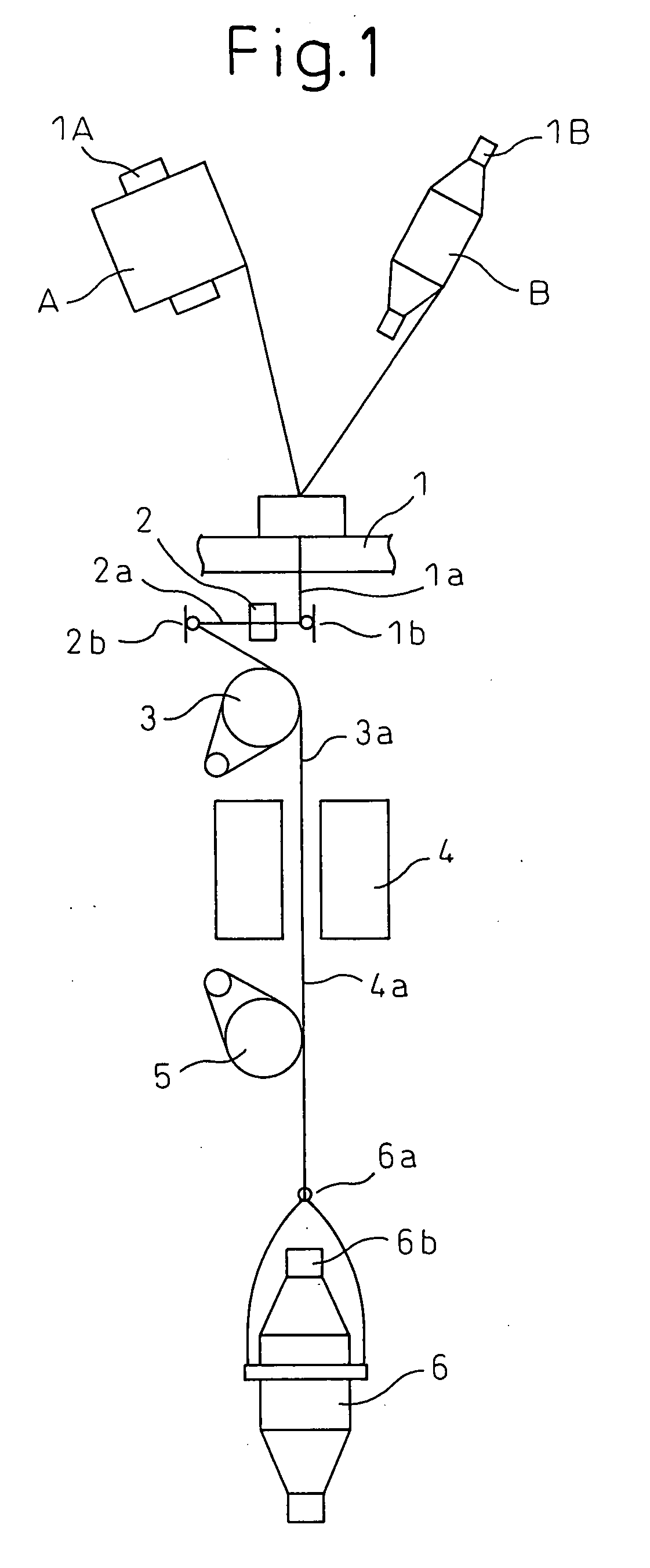

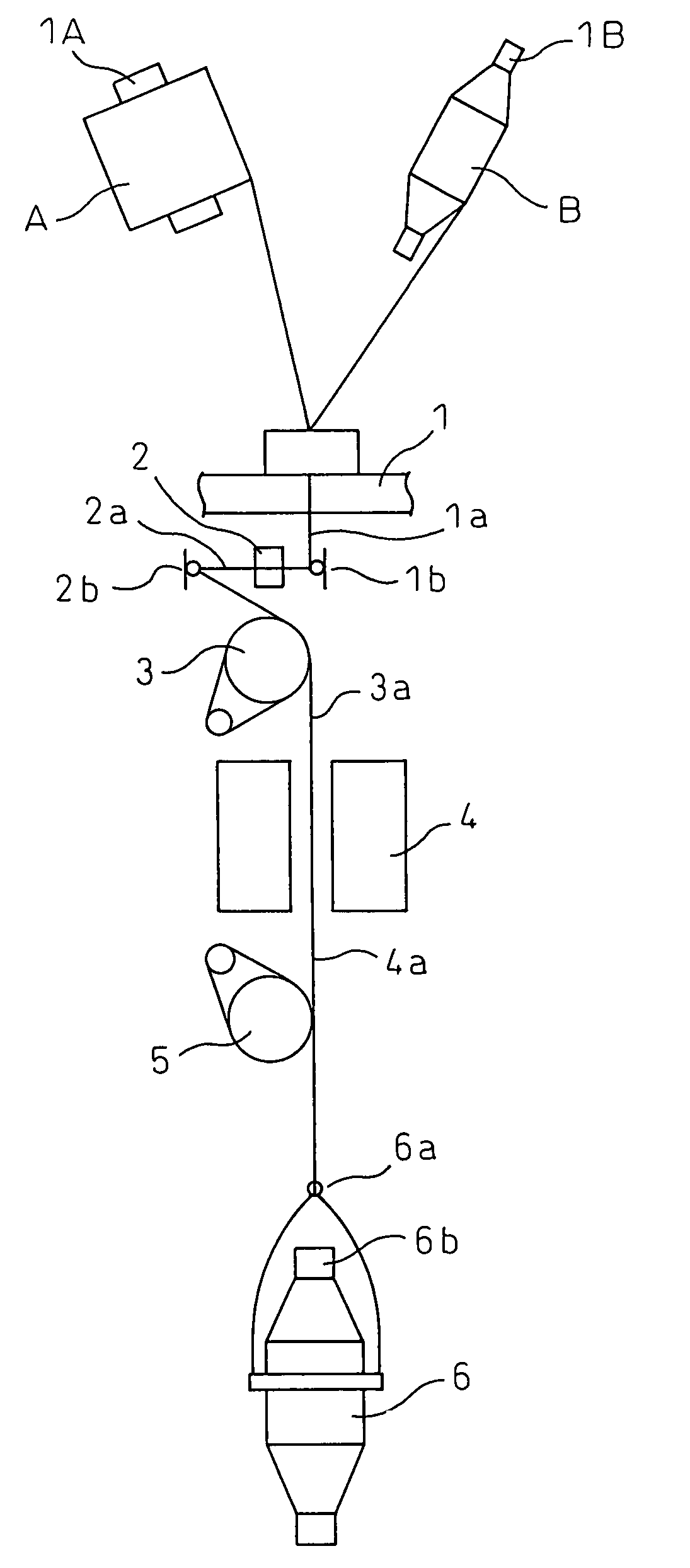

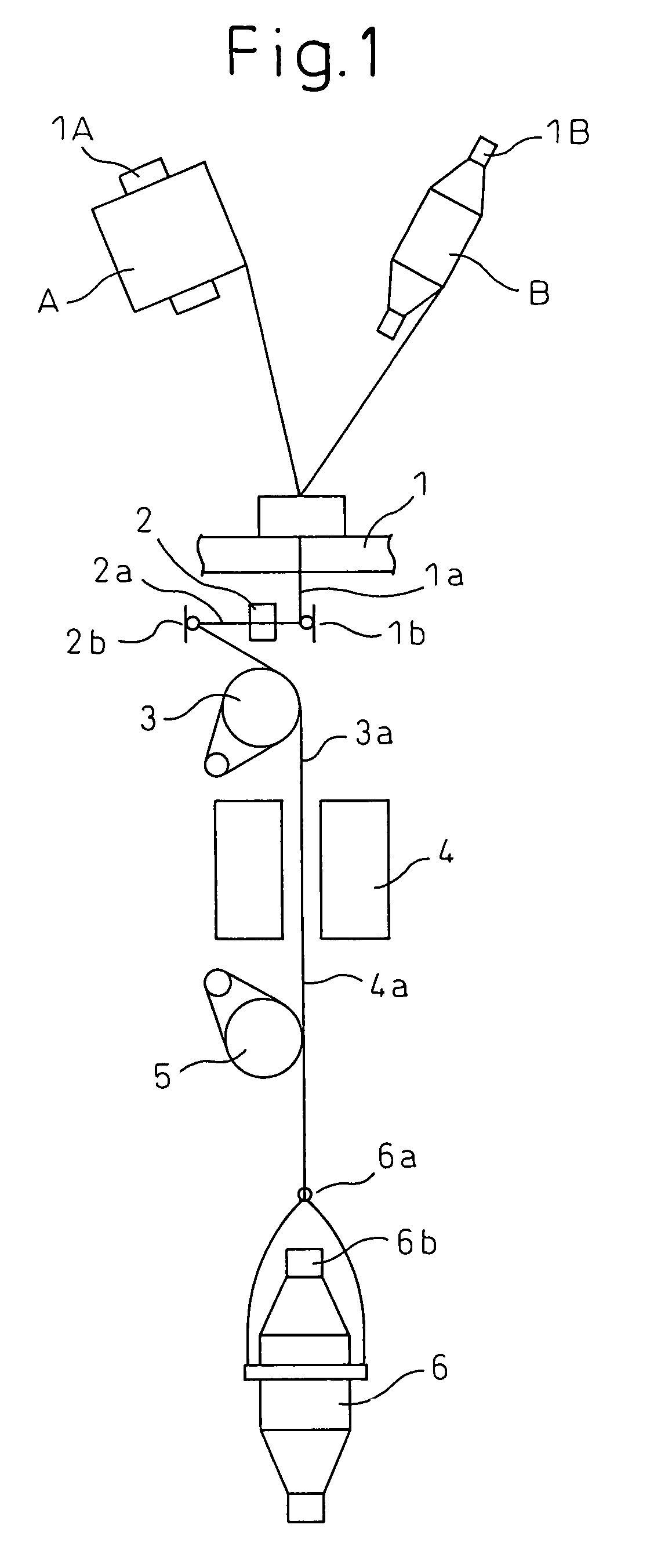

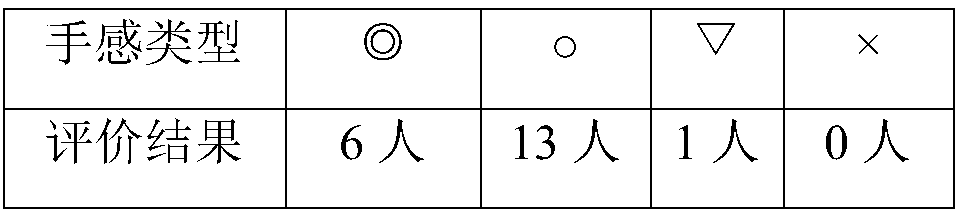

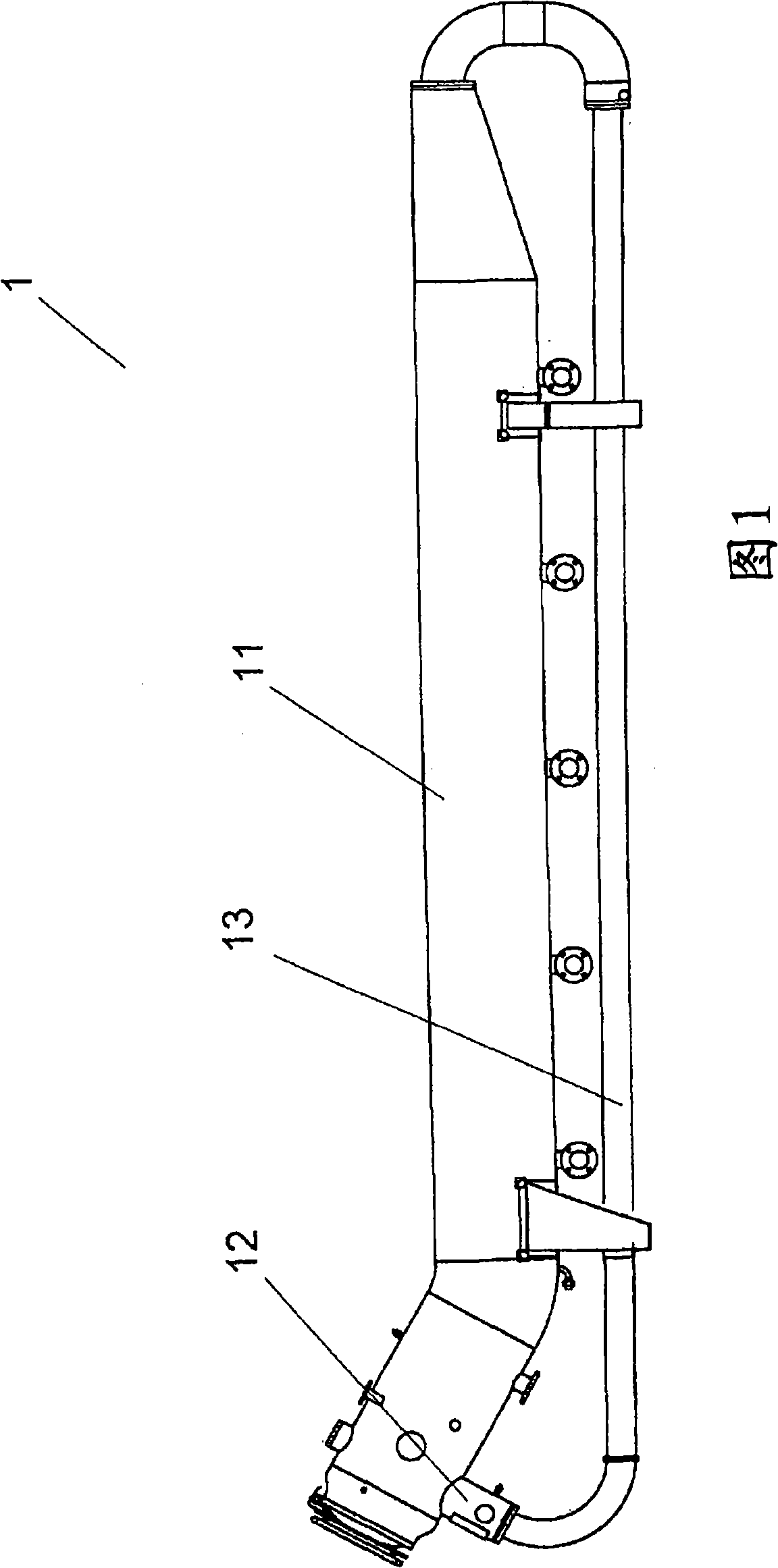

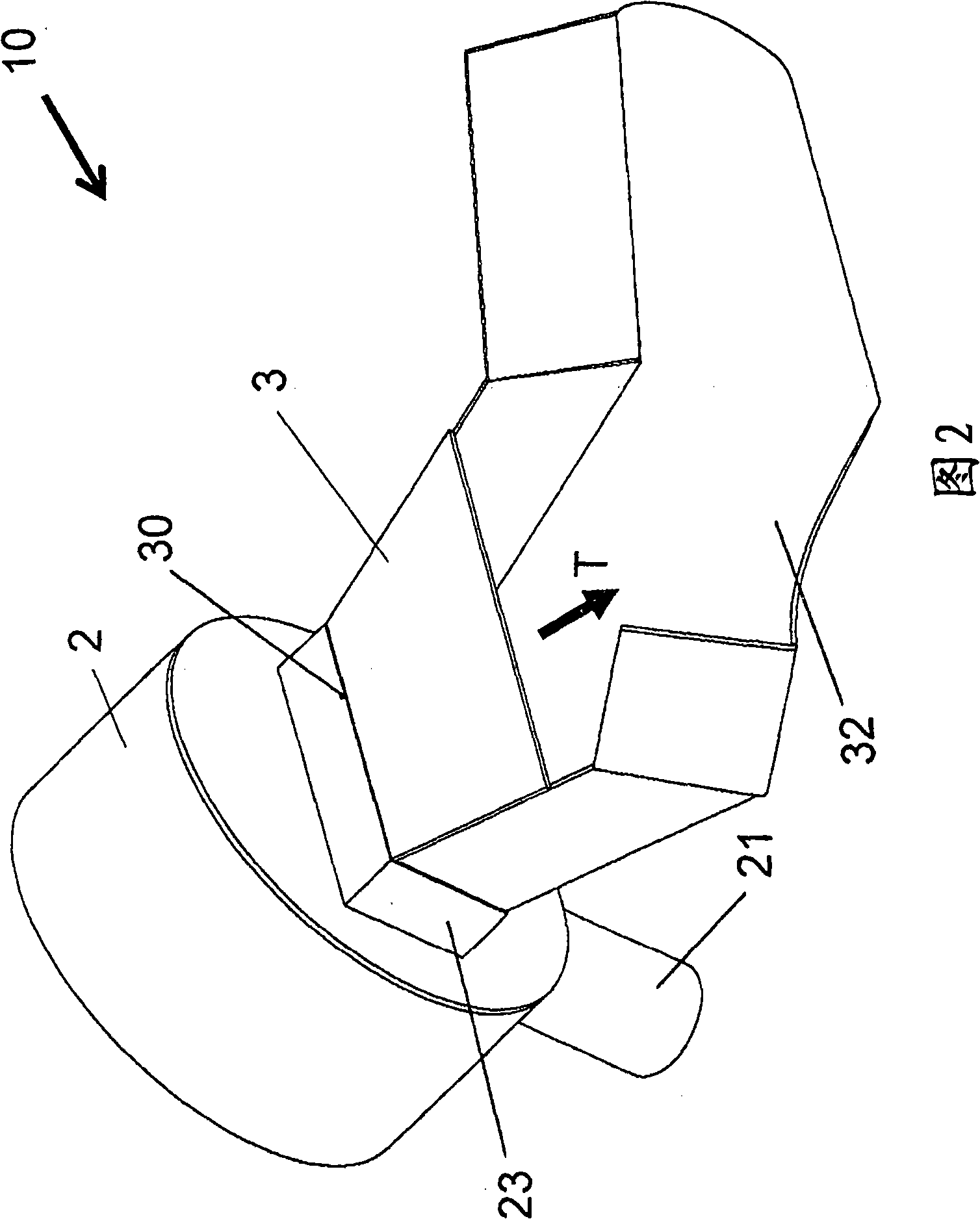

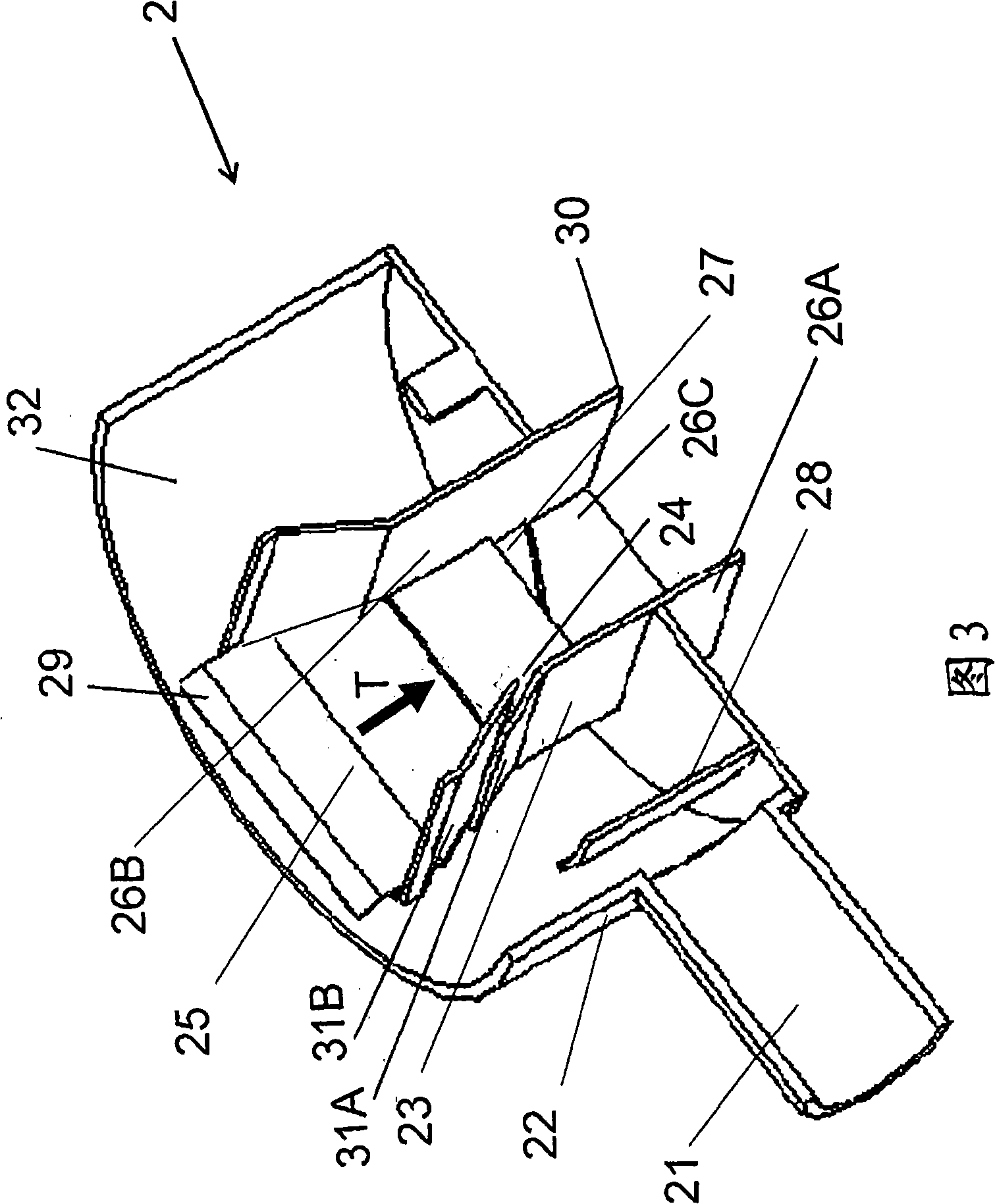

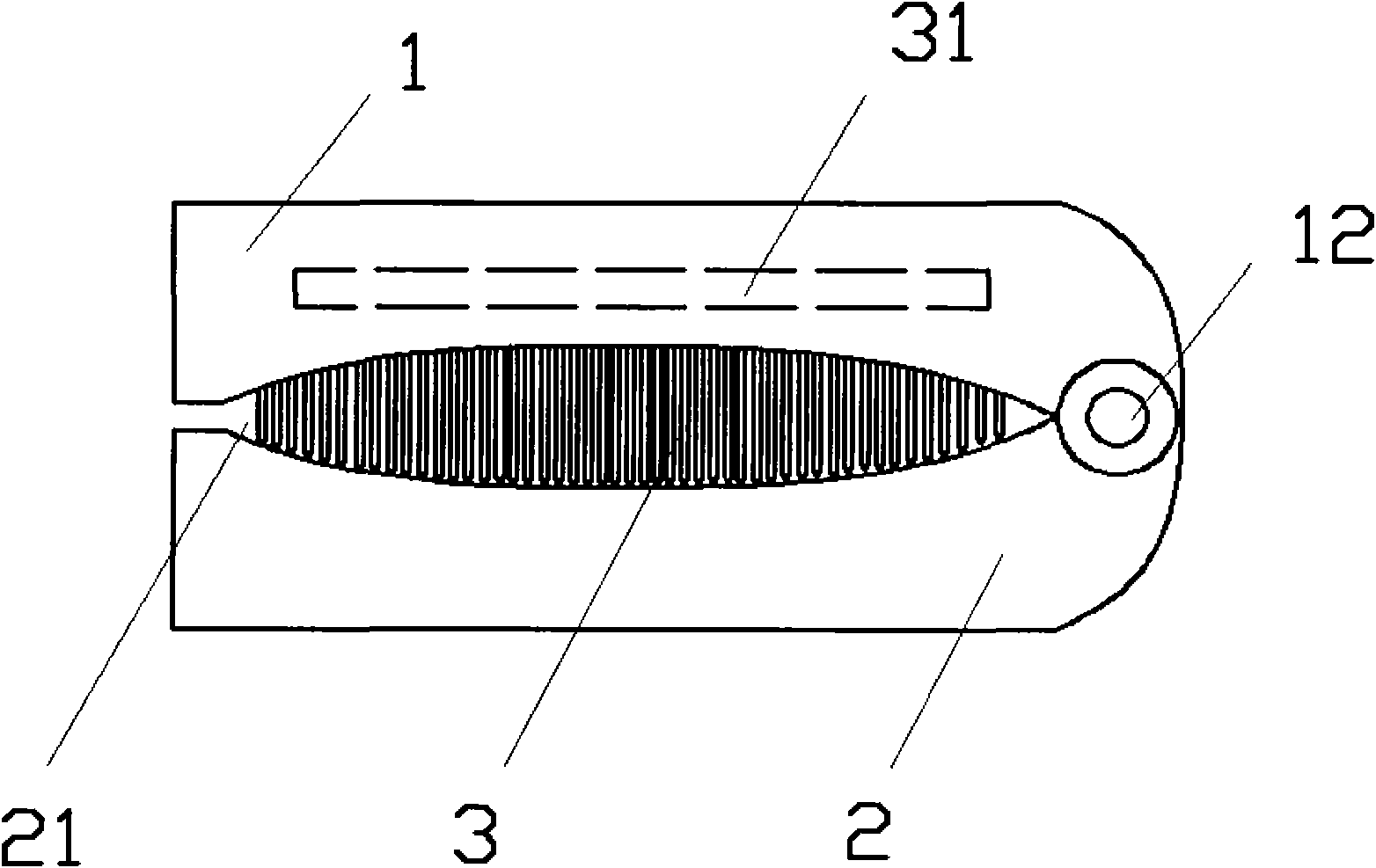

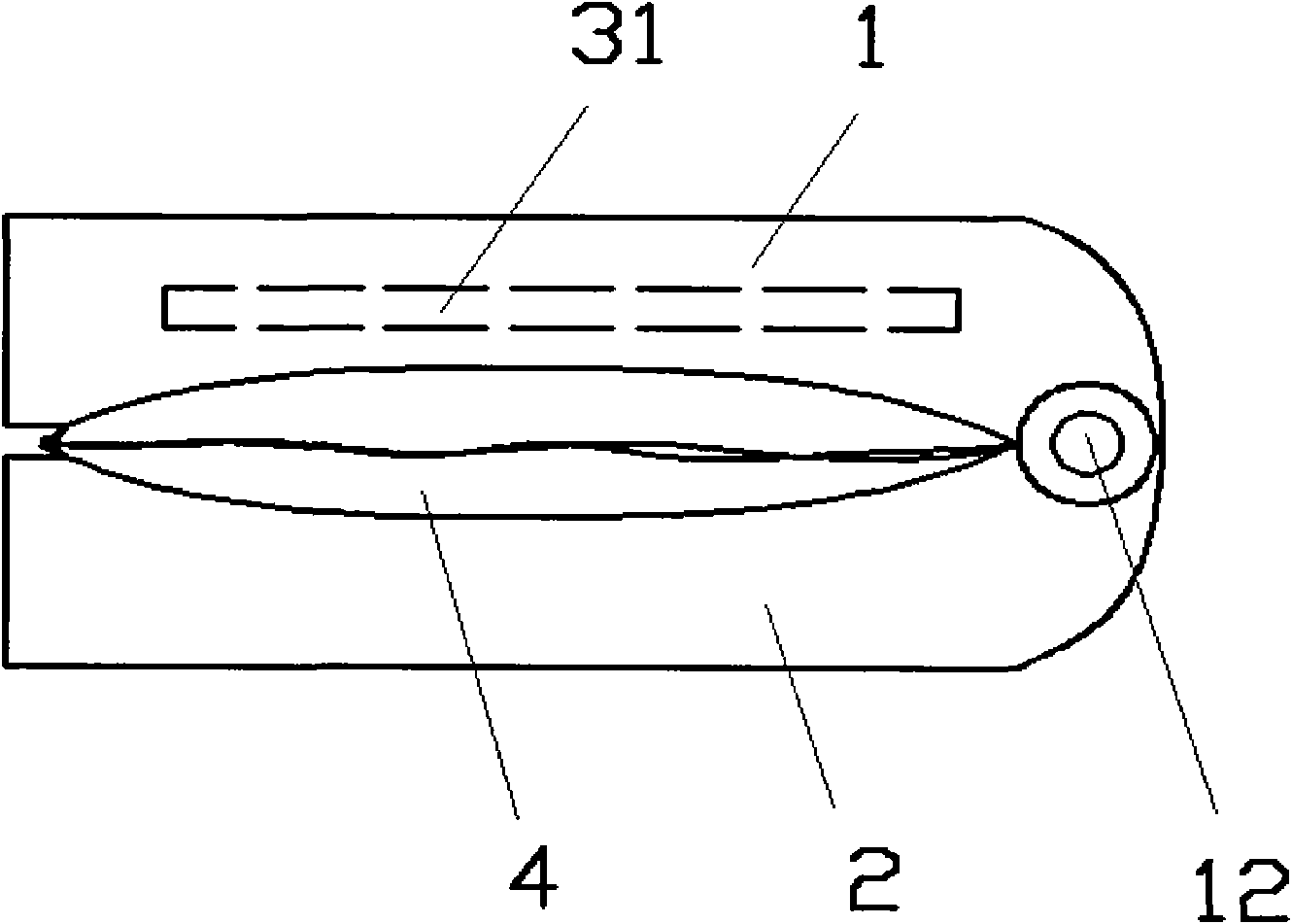

Nozzle for jet fabric dyeing machine

ActiveCN101298726AUniform dyeing effectReduce compactionLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsGuide tubeNozzle

A nozzle assembly (10) for a jet fabric dyeing machine (1) comprises a tubular nozzle member through which fabric travels, the nozzle member defined by four side walls (26) and having a rectangular cross-section, and a nozzle gap (24) in a side wall (26A) of the nozzle member through which a jet of fluid can be applied to fabric in the nozzle member to propel the fabric along a travel path (T). An entry end (29) of the nozzle member has a decreasing cross-section to funnel fabric into the nozzle member, and an exit end (30) of the nozzle member has a rectangular guide tube (3) of expanding cross-section terminating in a fan-shaped trough (32). A fluid diverter (25, 27) intercepts part of the fluid jet and delivers it to a different side of the fabric.

Owner:FONGS NAT ENG

Hair dyeing box

The invention provides a hair dyeing box. The hair dyeing box comprises an upper cover, a lower cover, card wires and leather wings, wherein the upper cover and the lower cover are connected through a rotation shaft; notches for accommodating hairs are formed on the two sides of the upper cover and the two sides of the lower cover; the leather wings are adhered to a notch on one side; when the upper cover and the lower cover are folded, the leather wings shield the notches; the card wires are arranged on the inner surface of the upper cover and are densely distributed; and a cavity is reserved in the middle of the distributed surface. When the hair dyeing box is used for dyeing the hairs, extremely uniform dyeing effect can be achieved on the promise of saving a large number of hair dyes; head skin can be protected; and healthy hair dyeing is realized.

Owner:方郎

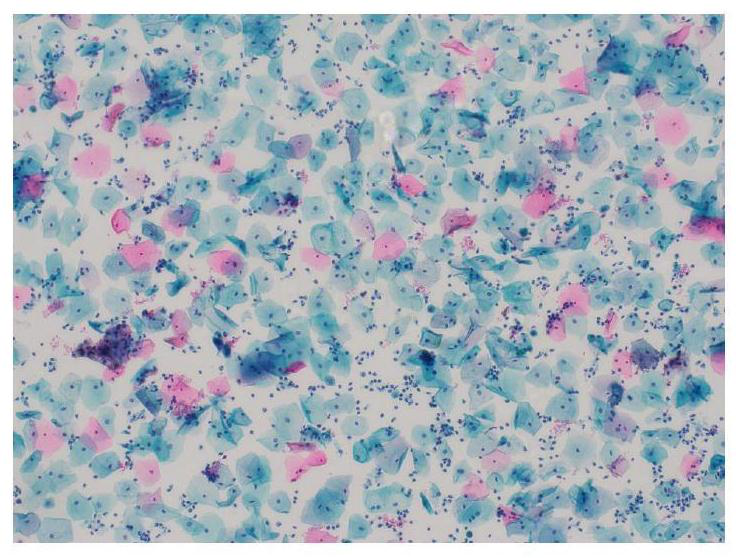

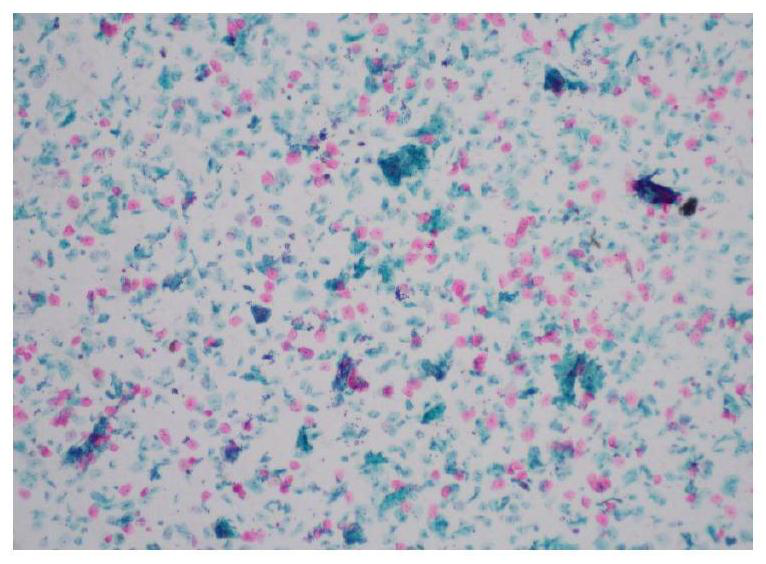

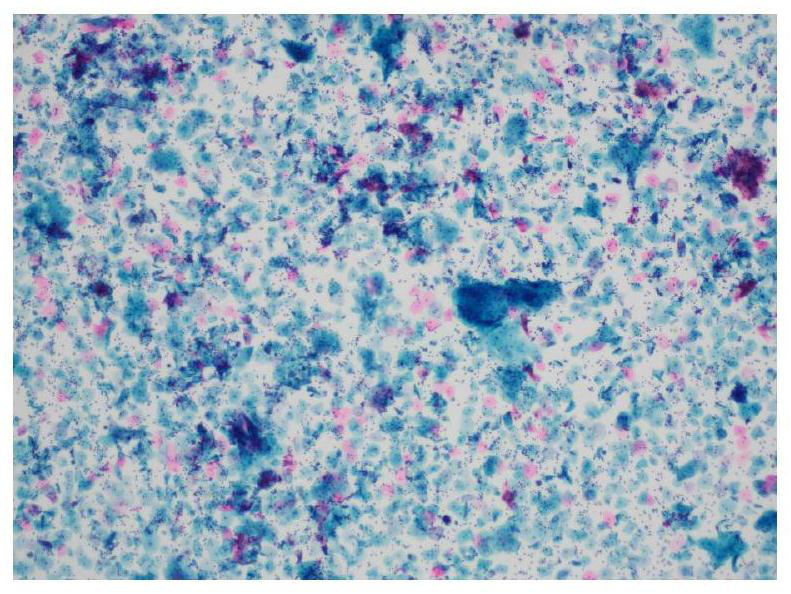

PAP staining kit as well as preparation method and staining method thereof

The invention relates to the technical field of biology, in particular to a PAP staining kit as well as a preparation method and a staining method thereof. The kit comprises a hematoxylin staining solution, an EA / OG staining solution, a buffer solution and a cleaning solution, wherein the hematoxylin staining solution comprises hematoxylin, sodium iodate, aluminum sulfate, sodium sulfite, ethanol, ethylene glycol, glycerol, acetic acid and water; the pH value of the hematoxylin staining solution is 2.0-3.0; the EA / OG staining solution comprises orange G, phosphotungstic acid, bright green SF light yellow, water-soluble eosin, sodium sulfite, ethanol, ethylene glycol, methanol, isopropanol, acetic acid and water; the pH value of the EA / OG staining solution is 5.0-6.0; and the pH value of the buffer solution is 6.8-7.2. The PAP staining solution is uniform in staining effect, clear in cell structure, bright in cell coloring, easy to clinically observe and diagnose, convenient to prepare, simple in staining step, stable in effect, clear in cell contrast and long in service life.

Owner:山东高创医疗器械国家研究院有限公司

Method for cationic modification and salt-free dyeing of cellulose fiber fabric

ActiveCN104233866BImprove permeabilityImprove uniformityDyeing processVegetal fibresPolymer scienceSalt free

The invention discloses a method for cationic modification and salt-free dyeing of cellulose fiber fabrics. The method is as follows: prepare an aqueous solution of a polymer cationic modifier with soft water, add cellulose fiber fabrics, add NaOH, apply pressure, heat up, and react at a constant temperature , lower the temperature and relieve the pressure, discharge the modified liquid, wash with water, and obtain the cationic modified fabric; place the cationic modified fabric in the dyeing machine, add soft water, dissolve reactive dyes and soda ash in turn with backflow water, inject the dyeing machine, and raise the temperature to The dyeing temperature is constant, and the dyeing residue is discharged. The fabric is washed-soaped-washed, dehydrated, and dried to obtain a salt-free and low-alkali dyed fabric. The invention realizes salt-free and low-alkali dyeing, solves the disadvantages of color flower, color sinking, ring dyeing, and reduced color fastness in the dyeing of reactive dyes of cellulose fiber fabrics modified by polymer cationic agents, and does not need to add leveling agent and soda ash during dyeing. It can be added to the dye vat at the same time as the dye, so there is no need to add soda ash several times during the dyeing process, and the dyeing operation is simple and easy to control.

Owner:SOUTH CHINA UNIV OF TECH +1

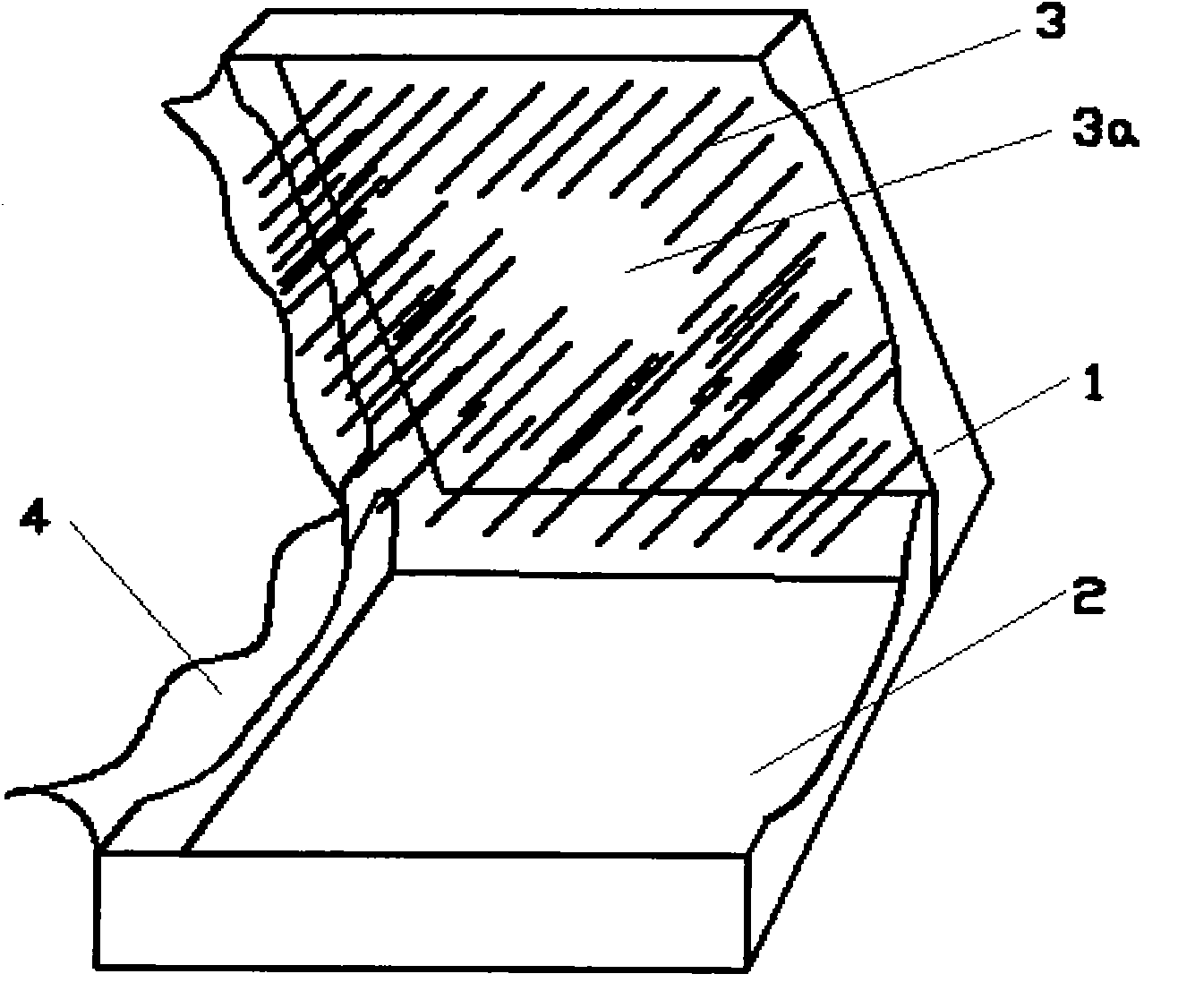

Method for splitting polyester/polyamide compound fibre and ultrafine fabric fabric made from same

InactiveCN1179087CUniform dyeingImprove dyeing effectFibre treatmentConjugated synthetic polymer artificial filamentsPolyesterPolyamide

The present invention relates to a split-separation method of composite fibre in the dyeing and finishing process of polyester / polyamide composite fibre fabric and the polyester / polyamide composite superfine fibre fabric. In the above mentioned method a weak acid solution whose pH value is 5-6.5 is adopted to treat fabric so as to make polyester and polyamide automatically split and separate, and its split-separation degree is high. Said method does not damage fabric, and the mechanical property, comfortability and colourability of fabric can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

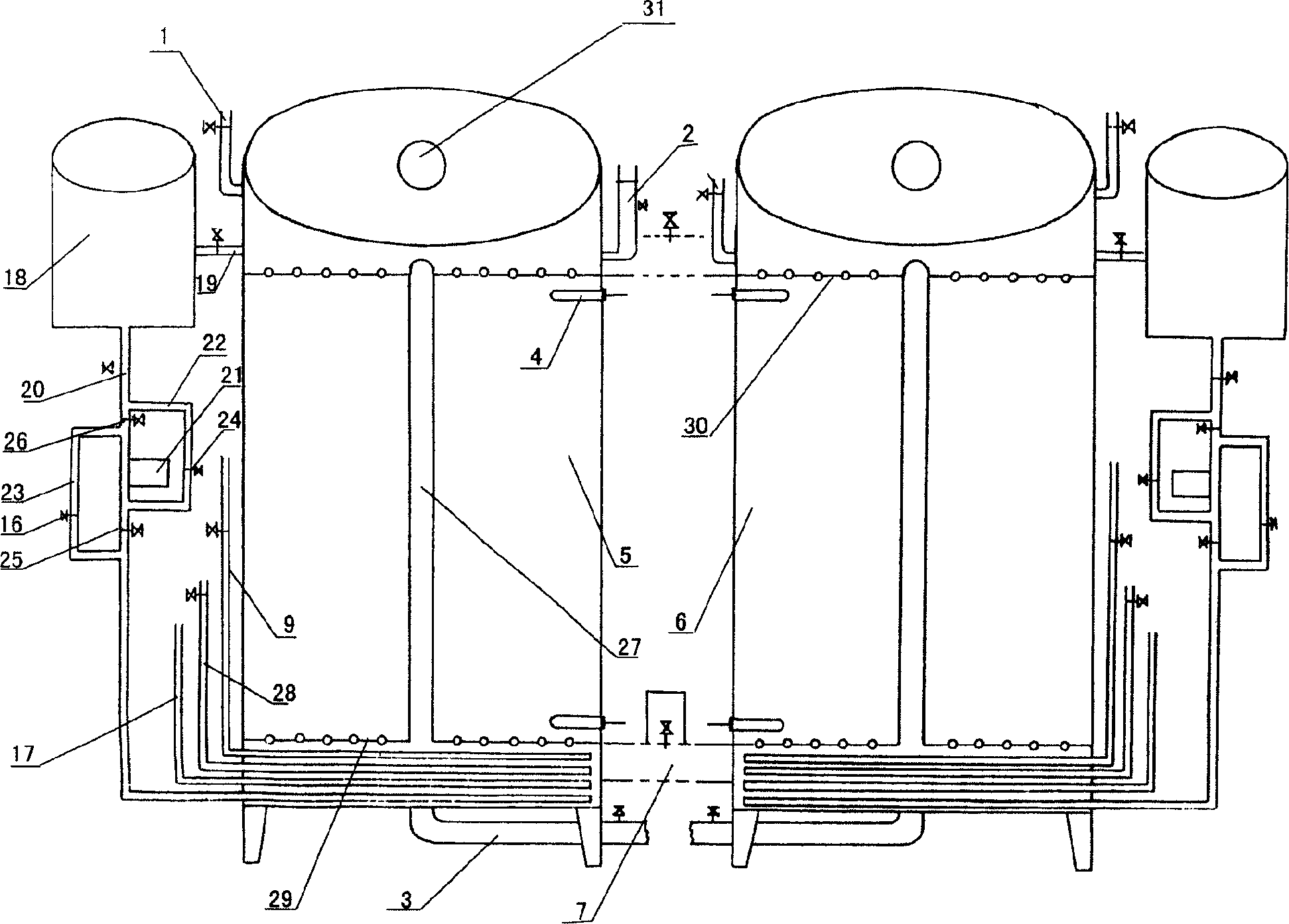

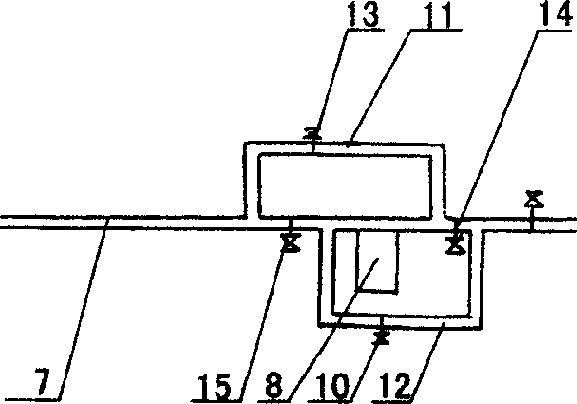

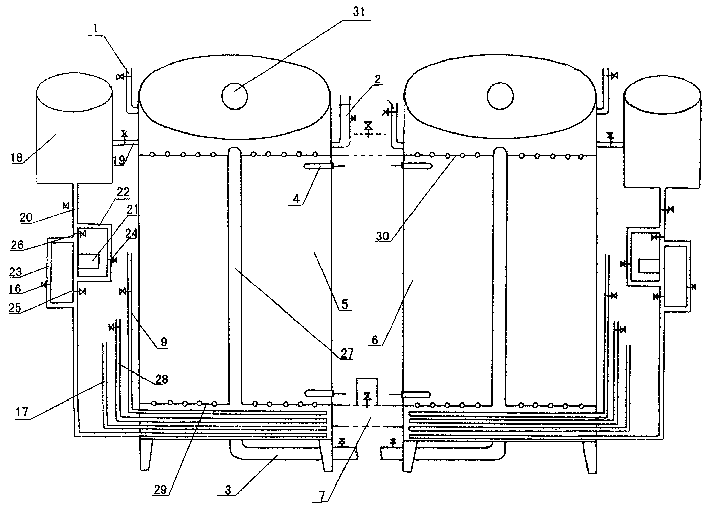

Suspension air vibration twin-cylinder dyeing machine

InactiveCN1218081CUniform dyeingUniform dyeing effectVibration treatmentMaster cylinderWater circulation

The present invention relates to a hanging pneumatic vibration double-cylinder dyeing machine. It includes water inlet tube, air exhaust tube, water outlet tube, thermometer, sample-shearing hole and heating device. It also includes parallelly-arranged first main cylinder and second main cylinder, the described first main cylinder and second main cylinder are formed into water circulation loop by means of circulating water pipe between them, and the bottom portion of the described main cylinder is equipped with air inlet tube on which the air exhaust hole is cut, on the described main cylinder a feeding barrel is communicated, and the interior of the described main cylinder is equipped with cloth-hanging frame, and on the cloth-hanging frame a fabric frame can be removably connected.

Owner:应连根

Acid dye composition

Owner:DALIAN UNIV OF TECH

Dyeing and finishing method for acetate velvet fabric

InactiveCN107675400AGood colorStrong penetrating powerHeating/cooling textile fabricsDry-cleaning apparatus for textilesEngineeringHeat setting

The invention discloses a dyeing and finishing method for an acetate velvet fabric. The method comprises the following steps: inspecting the fabric, conducting heat setting on the fabric, shearing thefabric, pre-shrinking the fabric, putting the fabric on a star frame, refining the fabric, washing the refined fabric for the first time, dyeing the fabric, washing the dyed fabric for the second time, and finishing after dyeing. Through adoption of the dyeing and finishing method, the dyeing rate of the fabric is consistent, the flatness is high, the phenomena of flower gray and dyeing defect are avoided, the dyeing effect of guaranteeing the dye fastness is achieved, the dyeing and finishing method is simple, the process and the dye are simple and easy to control, and green environmental-friendly dyeing and finishing are realized.

Owner:广州弘雅服装科技有限公司

Paint of resin micro-sphere for artificial pearl and its coating

Paint for resin micro-ball of artificial pearl and its coating method are disclosed. The paint consists of celluloid, acetic ether, banana oil, camphor and pigment. The procedure is carried out by surface treating for resin micro-ball by surface curing agent and coating for at least twice. It has short dyeing and drying time, clean surface and good luster,

Owner:QINGDAO MINOA ART CRAFTS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com