Patents

Literature

119results about How to "Uniform modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for dyeing cotton fibers by using natural dye

The invention relates to a method for dyeing cotton fibers by using a natural dye, comprising the following steps of: 1) boiling the cotton fibers and drying the cotton fibers for later use; 2) modifying the cotton fibers; 3) dyeing the cotton fibers; and 4) fixing the color of the cotton fibers, wherein the dosage of a color fixing agent is 1-5% of the mass of the cotton fibers, the temperature of color fixation is 50-85 DEG C, the color fixing agent is added to the cotton fibers obtained in step 3), the time of color fixation is 20-50 min, drying is performed after water washing, and the color fixing agent can be one or two of sodium chloride, sodium sulfite, citric acid and aluminum potassium sulfate dodecahydrate. The food-grade fixing agent is selected in the method; therefore, the troubles caused by synthetic dyes and heavy metals for the health of human are solved, and the fastness of the cotton fibers can be enhanced; as a result, the dyed cotton fibers are natural and soft in color and have no harm to the human body and the environment.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

Inorganic material surface biological method

InactiveCN101214395AExcellent anticoagulant propertiesGuaranteed mechanical propertiesSurgeryPharmaceutical containersBio moleculesEngineering

A method of biolization to the surface of inorganic material includes the following steps: the surface is spattered to form a tantalum oxide or a titanium oxide thin film; and then the inorganic material is put in a plasma immersion ion implantation device; after vacuumization, hydrogen, water vapour or ammonia is fed in, with gas pressure 0.05 to 50 Pa; the radio frequency discharge power is 200 to 1200W; the range value of the loaded pulse high-voltage power is 1KV to 100KV, the frequency is 50 to 40000HZ, and the duty ratio is 3 percent to 80 percent; the heating temperature is 20 to 500 DEG C; the treatment time is 0.1 to 5 hours; finally, the inorganic material is put into 10 to 100mg / mL albumin or heparin solution to be soaked for 2 to 48 hours under 20 to 40 DEG C soaking temperature. The method does not damage the activity of the biomolecule and the protein; the prepared inorganic material with biolized surface has good anti-coagulability, is used for medical blood vessel scaffolds and artificial heart valves, and can greatly improve the product performance.

Owner:SOUTHWEST JIAOTONG UNIV

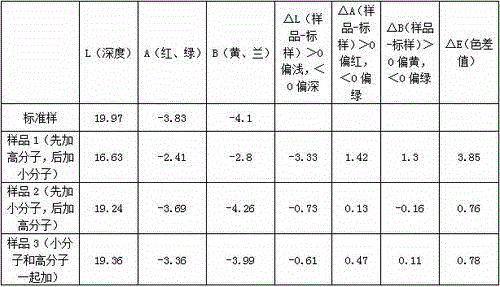

Method for cation modification and salt-free dyeing of cellulose fiber fabric

ActiveCN104233866AImprove permeabilityImprove uniformityDyeing processVegetal fibresRing dyeingSalt free

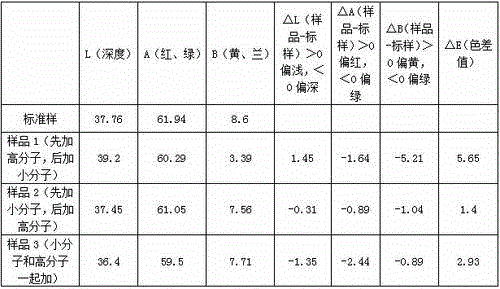

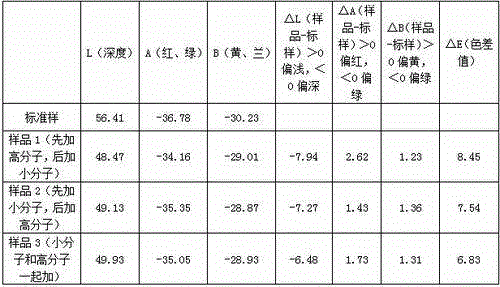

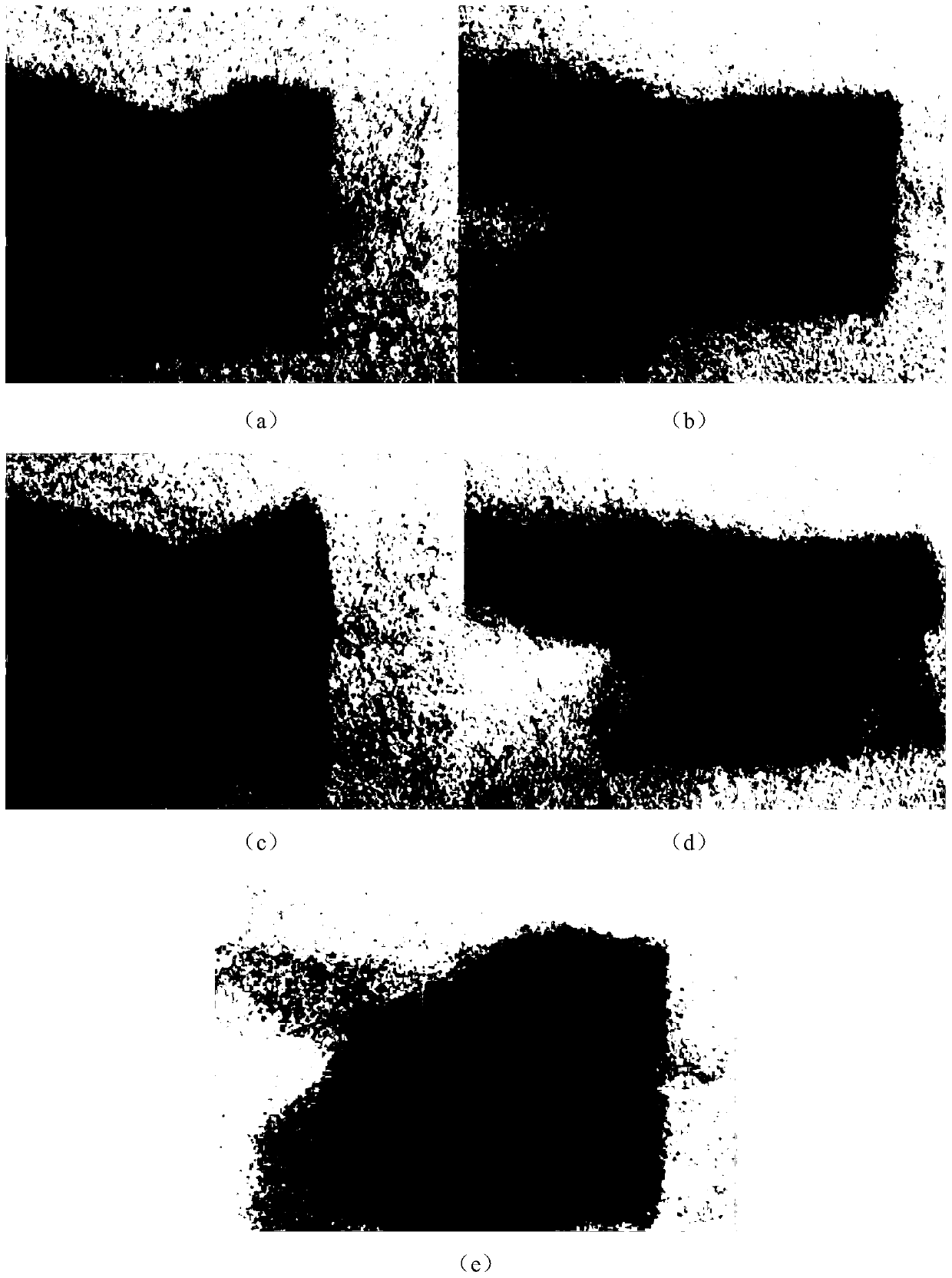

The invention discloses a method for cation modification and salt-free dyeing of a cellulose fiber fabric. The method comprises the steps as follows: preparing a high-polymer cation modifier aqueous solution with soft water, adding the cellulose fiber fabric, then adding NaOH, exerting pressure, heating the solution for a thermostatic reaction, performing cooling and pressure relief, discharging the modifying solution, and performing washing to obtain a cation-modified fabric; placing the cation-modified fabric in a dyeing machine, adding the soft water, sequentially dissolving reactive dye and sodium carbonate with return water, injecting the reactive dye and the sodium carbonate into the dyeing machine, heating the dyeing machine to the dyeing temperature, keeping the temperature, discharging a residual dyeing solution, and dehydrating and drying the fabric after a washing-soaping-washing process to obtain the salt-free low-alkaline dyed fabric. With the adoption of the method, salt-free low-alkali dyeing is realized, the problems of dyeing defects, color sinking and ring dyeing as well as reduction of the color fastness when cellulose fiber fabrics modified by high-polymer cation modifiers are dyed with reactive dyes are solved, a leveling agent is not required to be added during dyeing, the sodium carbonate and the dye can be added into a dyeing vat simultaneously, the sodium carbonate is not required to be added repeatedly during dyeing, and the dyeing operation is simple and easy to control.

Owner:SOUTH CHINA UNIV OF TECH +1

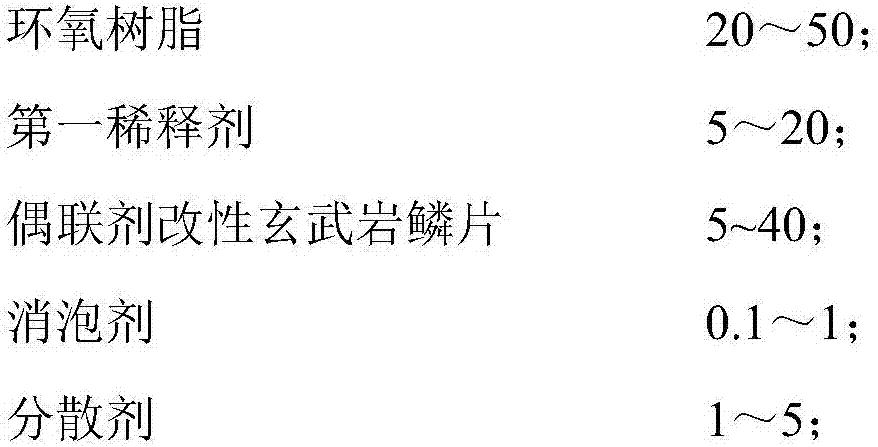

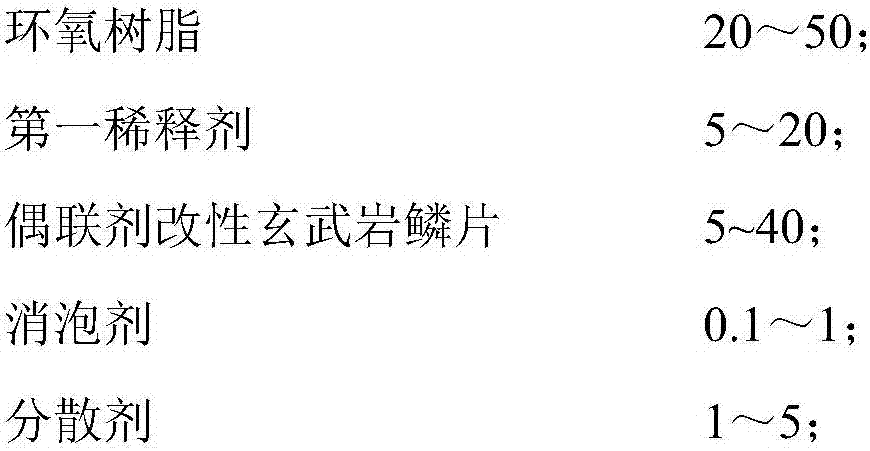

Modified basalt flake solvent-free epoxy resin anticorrosion coating and preparation method thereof

InactiveCN107384118AGood modification effectUniform modificationAnti-corrosive paintsEpoxy resin coatingsSolventPre treatment

The invention provides a modified basalt flake solvent-free epoxy resin anticorrosion coating and a preparation method thereof. The modified basalt flake solvent-free epoxy resin anticorrosion coating comprises a coupling agent modified basalt flake, namely a coupling agent is diluted or hydrolyzed with a solvent, and a basalt flake is immersed in a coupling agent diluent or hydrolysate for 10 to 120 minutes; then an obtained product is baked at 100 to 200 DEG C for 10 to 120 minutes. According to the coating disclosed by the invention, the basalt flake is pretreated; the hydrophilic end of a hydrolyzed coupling agent molecule is chemically combined with the surface of the flake, and the hydrophobic end of the hydrolyzed coupling agent molecule forms well combination with resin in a use process. Therefore, compared with a conventional mode of directly adding the coupling agent into resin, the pretreatment can uniformly modify the flake, the flake can be better chemically combined with the resin, is higher in wettability for epoxy resin, and can be better uniformly distributed in the resin; the corrosion resistance and the mechanical property of a coating layer are improved.

Owner:SOUTHEAST UNIV

Reaction liquid for modifying polymer film and modifying method

The present invention provides reaction solution and modification method for modifying polymer film, especially raising the surface hydrophilicity of the polymer film. The reaction solution includes acrylic acid and its derivative, acrylamide and its derivative, acrylate, N-vinyl pyrrolidone, acrylonitrile or other polar monomer; dibenzophenone, thioanthrone and its derivative, anthraquinone and other hydrogen accepting light initiator; and mixed solvent comprising and organic solvent. During ultraviolet grafting treatment, the film to be treated is painted with the prepared reaction solution, irradiated with ultraviolet ray, washed and dried to become polymer film with high hydrophilicity. The said process has the advantages of long modification effect, simple post-treatment, etc.

Owner:BEIJING UNIV OF CHEM TECH

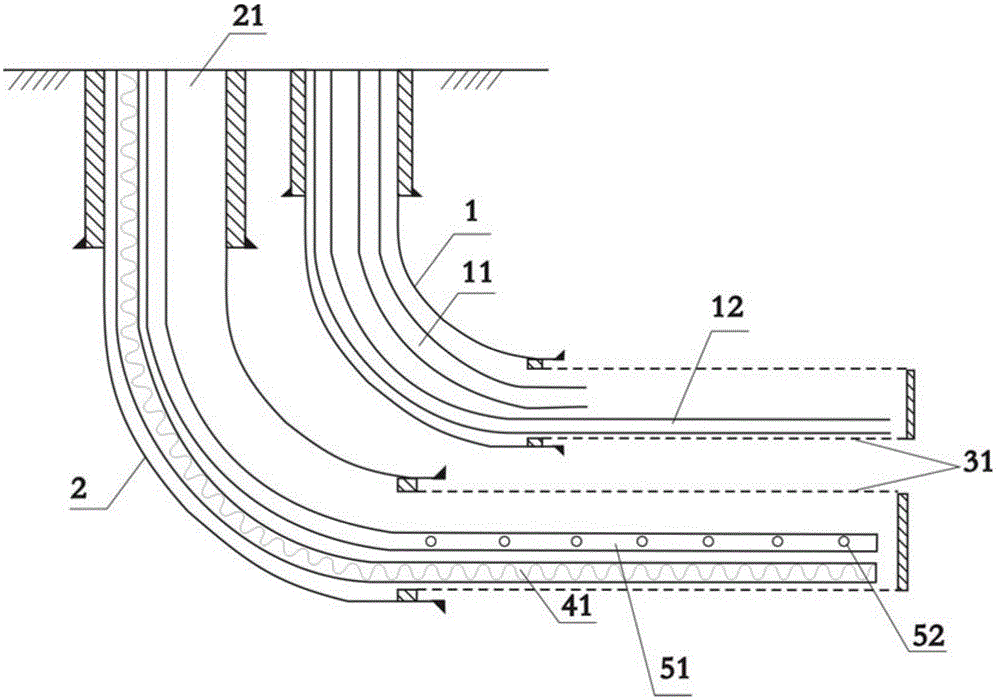

Well structure and method for underground modified mining of heavy oil and super heavy oil reservoir

ActiveCN104563981AFully exposed to the effect of modificationAchieve high temperature in-situ modificationFluid removalDrilling compositionElectrical resistance and conductanceMicrowave

The invention provides a well structure and a method for underground modified mining of a heavy oil and super heavy oil reservoir. The well structure comprises oil tubes, a catalyst injection tube and a heating device; injection holes unevenly distributed are formed in the horizontal section of the catalyst injection tube; the heating device comprises a high-energy fused salt heating tube, an electric heating tube, an electric resistance wire heating device, an electromagnetic heating device, a radio-frequency heating device or a microwave heating device; the oil tubes comprise parallel dual oil tubes, concentric dual oil tubes or single continuous punched oil tubes; the invention also provides the method for performing the modified mining on the heavy oil reservoir by utilizing the well structure. According to the well structure and the method for the underground modified mining of the heavy oil and super heavy oil reservoir, provided by the invention, oil can be rapidly dissolved and the viscosity of crude oil is greatly reduced, so the fluidity of mined fluid is further increased, and long-time continuous modification of the oil reservoir can be realized.

Owner:PETROCHINA CO LTD

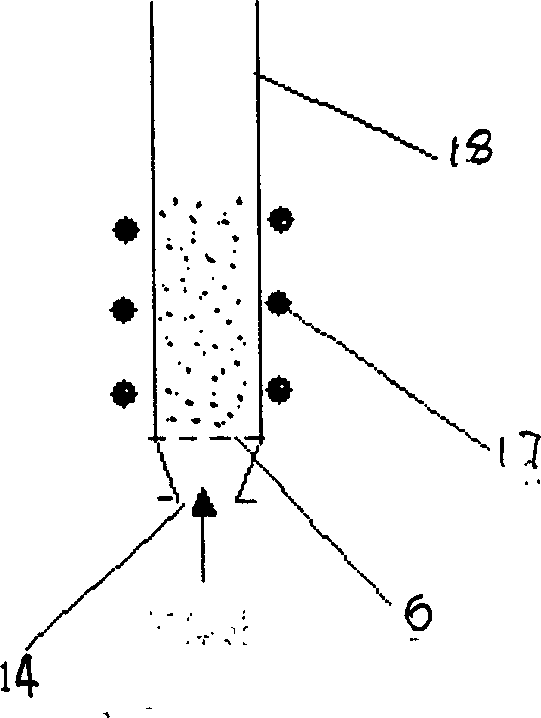

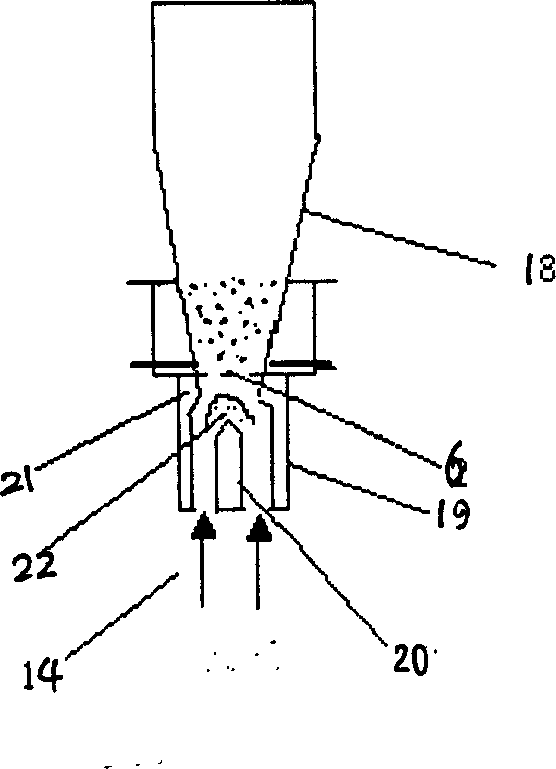

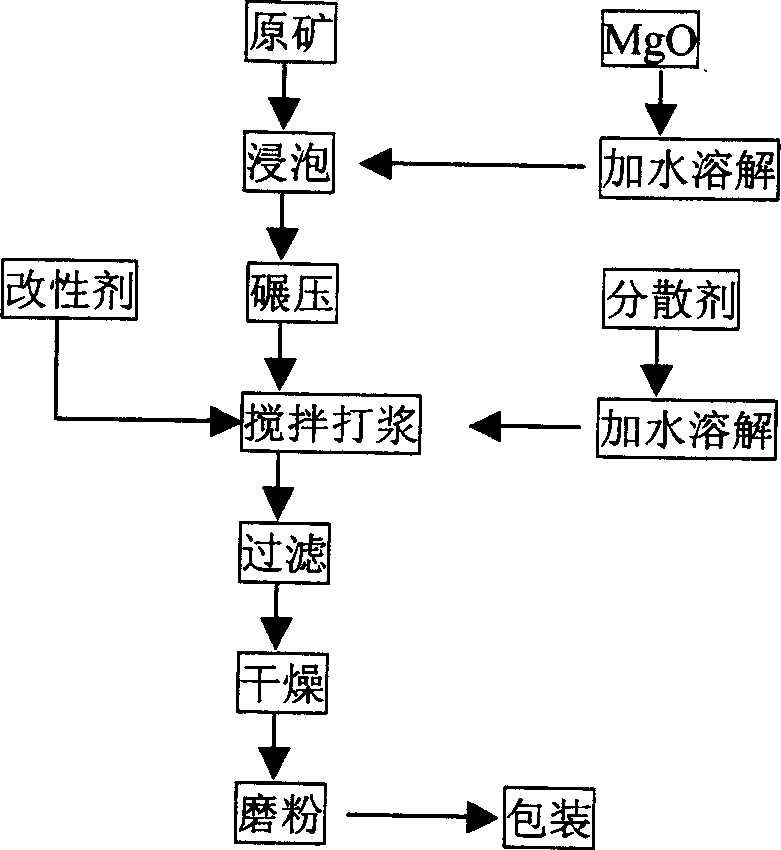

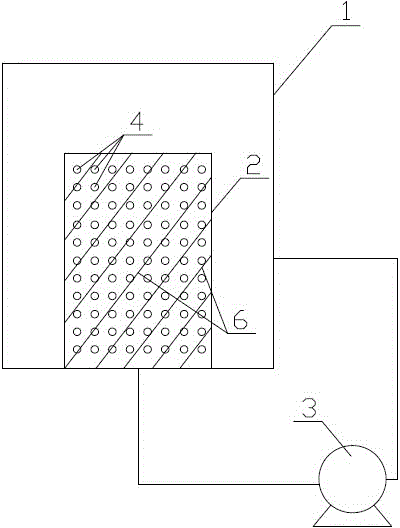

Plasma fluidized bed for treating material under normal temperature atmosphere and method thereof

The invention relates to a kind of plasma sulfurization bed processing materials at room temperature atmospheric pressure. It includes: the bed body produced by insulating material, the downer port of which equips a gas divider, and under the gas divider equips an infundibular gas inlet, which is connected to the gas source to the conduit with gas flowmeter; the side surface of the upper bed body has gas exit, leave a hole above the position of the gas exit of the bed body; the hole equips a conduit with valve, which is linked through a feed-in tundish; set a outer electrode below the gas exit of the bed body to a segment of the outer surface of the gas divider, and the outer electrode is connected to one end of the high voltage alternating current supply; the inner electrode is inserted into the bed body, sealed and fixed at the upper port of the bed body through a insulating board; the inner electrode reaching outside the upper port of the bed body is connected to the other end of the high voltage alternating current supply. The processing method of the invention can operate at room temperature atmospheric pressure without needing vacuum equipment, so its operating cost is low. It won't damage the powdered material, and is suitable to wide area of modified materials.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for depositing, crosslinking and modifying chitosan on surface of polypropylene porous membrane

InactiveCN104437144AExtended service lifeImprove effluent qualitySemi-permeable membranesPorous membraneIndustrial scale

The invention relates to a method for modifying surface of a polypropylene porous membrane, and concretely relates to a method for depositing, crosslinking and modifying chitosan on surface of the polypropylene porous membrane. The method takes chitosan or a chitosan derivative as a modifier, the polypropylene porous membrane is immersed in a cross-linking agent solution 1 for pretreatment, then placed in a chitosan or chitosan derivative solution , the chitosan or the chitosan derivative are uniformly deposed on the surface and in the membrane pore of the polypropylene porous membrane, under existence of a catalyst, a crosslinking reaction is carried out in a cross-linking agent solution 2, immersion is carried out in an alkaline aqueous solution, and steps of washing and drying are carried out to obtain the modified polypropylene porous membrane having dual performance of hydrophillicity and antibiosis. According to the invention, modification technology is simple, processing effect is reliable, complex equipment is not required, and the method is suitable for industrial large-scale application.

Owner:CHINA PETROLEUM & CHEM CORP +1

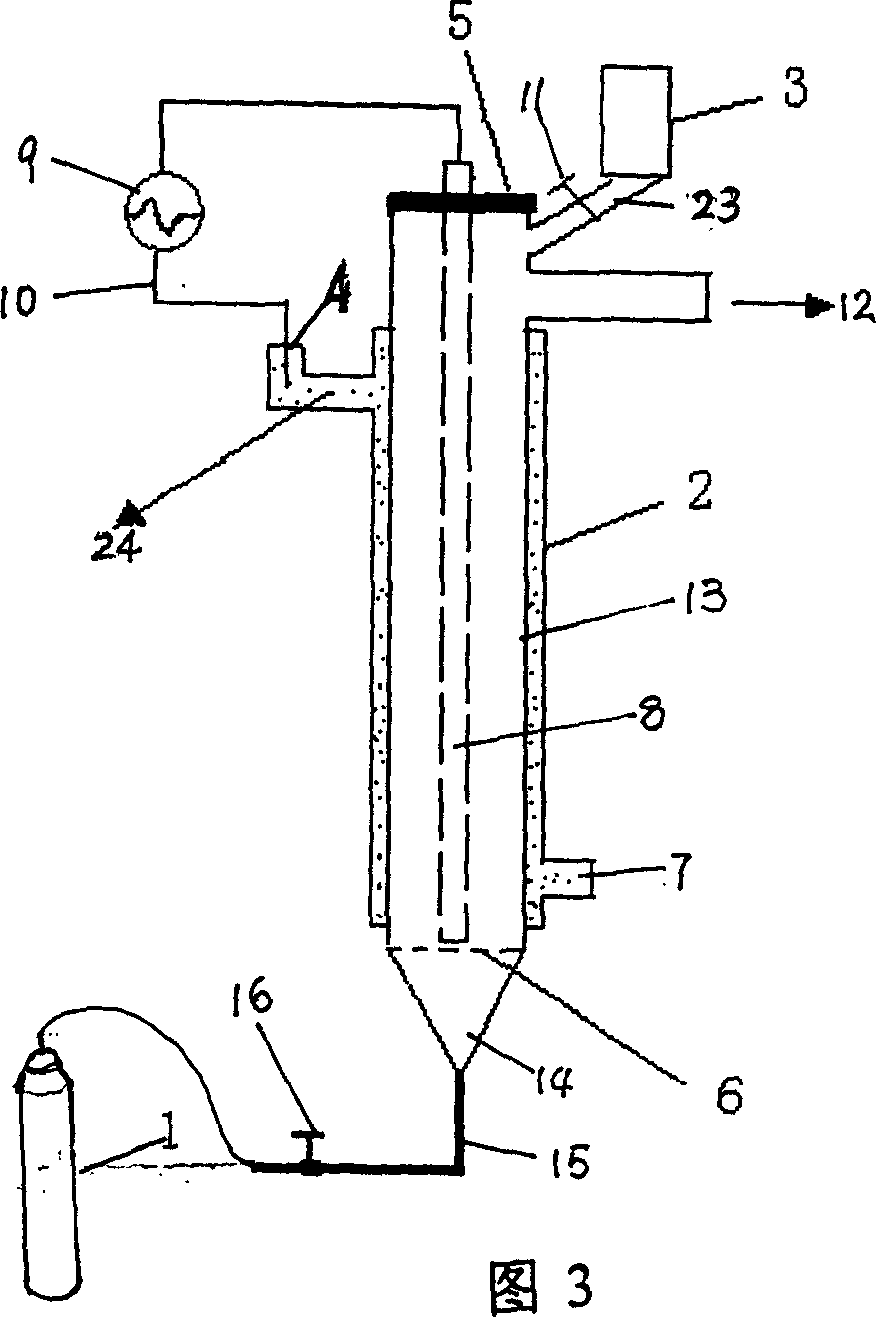

Production method of attapulgite gelatin for coating thickener

This invention discloses a method for producing attapulgite gel used in paint thickening agent, comprising: first, soak the attapulgite ore concentrate with water and additive for 5-7d, wherein the additive MgO is 2-4% of the ore concentrate weight, and the ratio of the ore concentrate and water is 1:9; then roll the mixture at pressure of 50-70 kilogram / cm2 to be wet material with 40-55% water content, soak the wet material for another 2-3 days, and continuously roll 2-3 more times to obtain the finished wet material; second, filtrate the wet material, and dry it at below 120Deg C to obtain the dry material with 8-12% water content; finally, grind the dry material to 500 order to obtain the attapulgite gel. This invented attapulgite thickening agent used in water paint and solvent paint is characterized of high viscosity coefficient and thixotropy index, thorough dispersion, and no agglomeration.

Owner:JIANGSU PROVINCE HUAIYUAN MINING

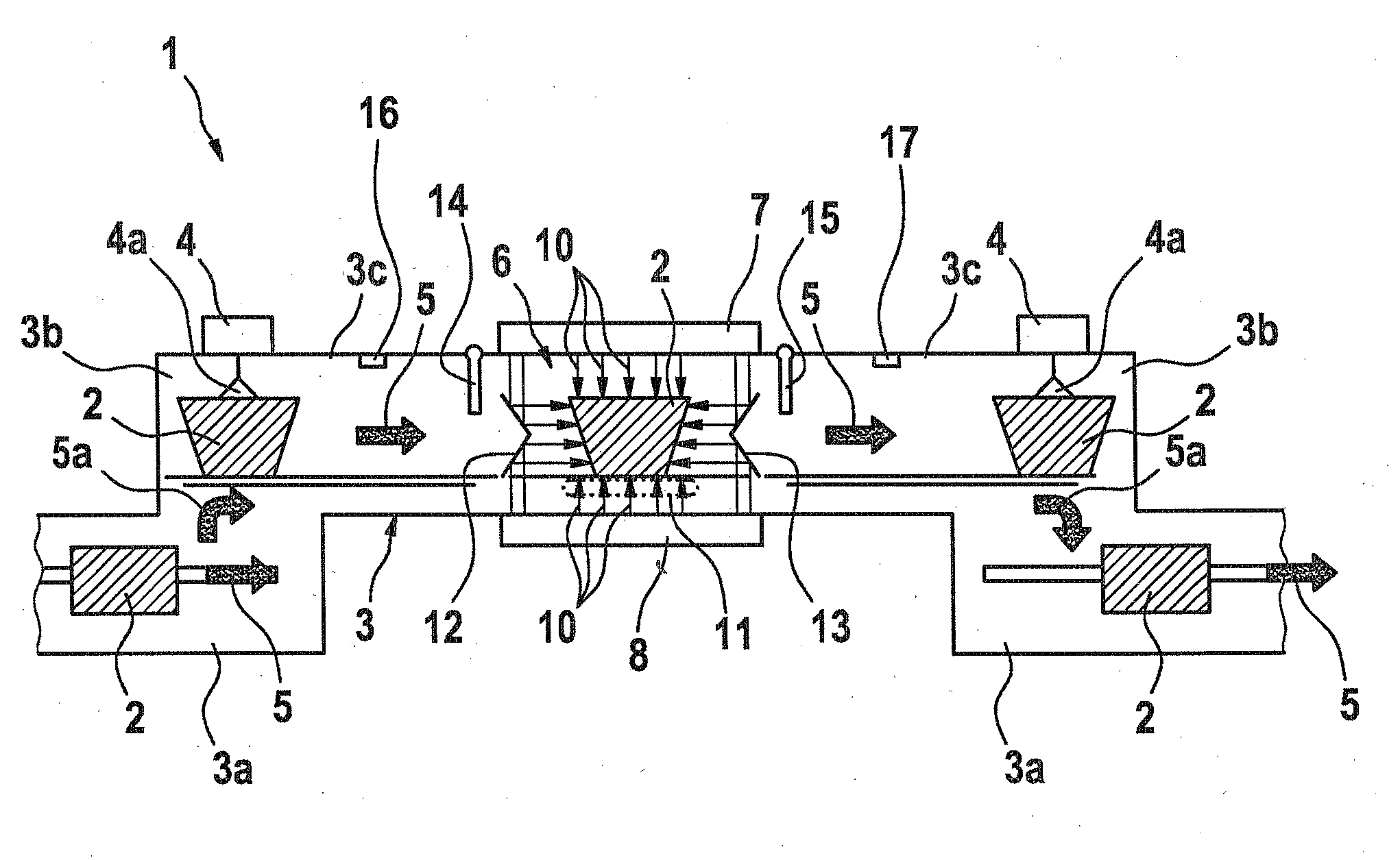

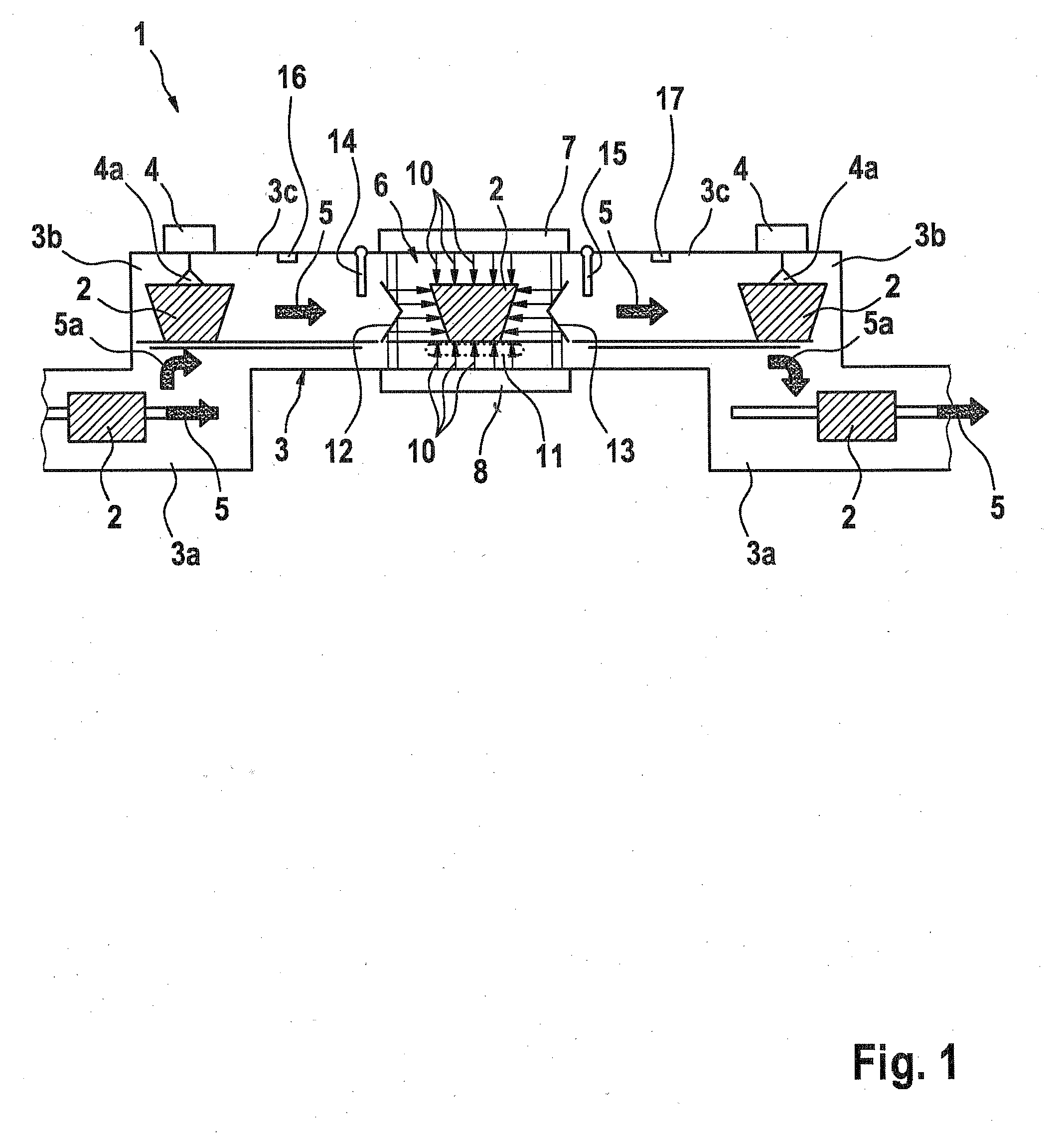

Apparatus and method for treating formed parts by means of high-energy electron beams

InactiveUS20110020174A1Complicated constructionReduced flow cross sectionElectric discharge tubesMaterial analysis by optical meansHigh energyX-ray

The invention relates to a device for treating formed parts with high-energy electron beams. The electron beams are guided by two opposite stationary or displaceable electron discharge windows onto the formed part and bounding a process space for the formed part. A transport device is present for the formed part, by which the formed part can be guided through the process space to the electron discharge windows disposed substantially vertically perpendicular to the transport direction. A channel is disposed in the process space for transporting the formed part and largely shielded against the X-ray radiation.

Owner:ROBERT BOSCH GMBH

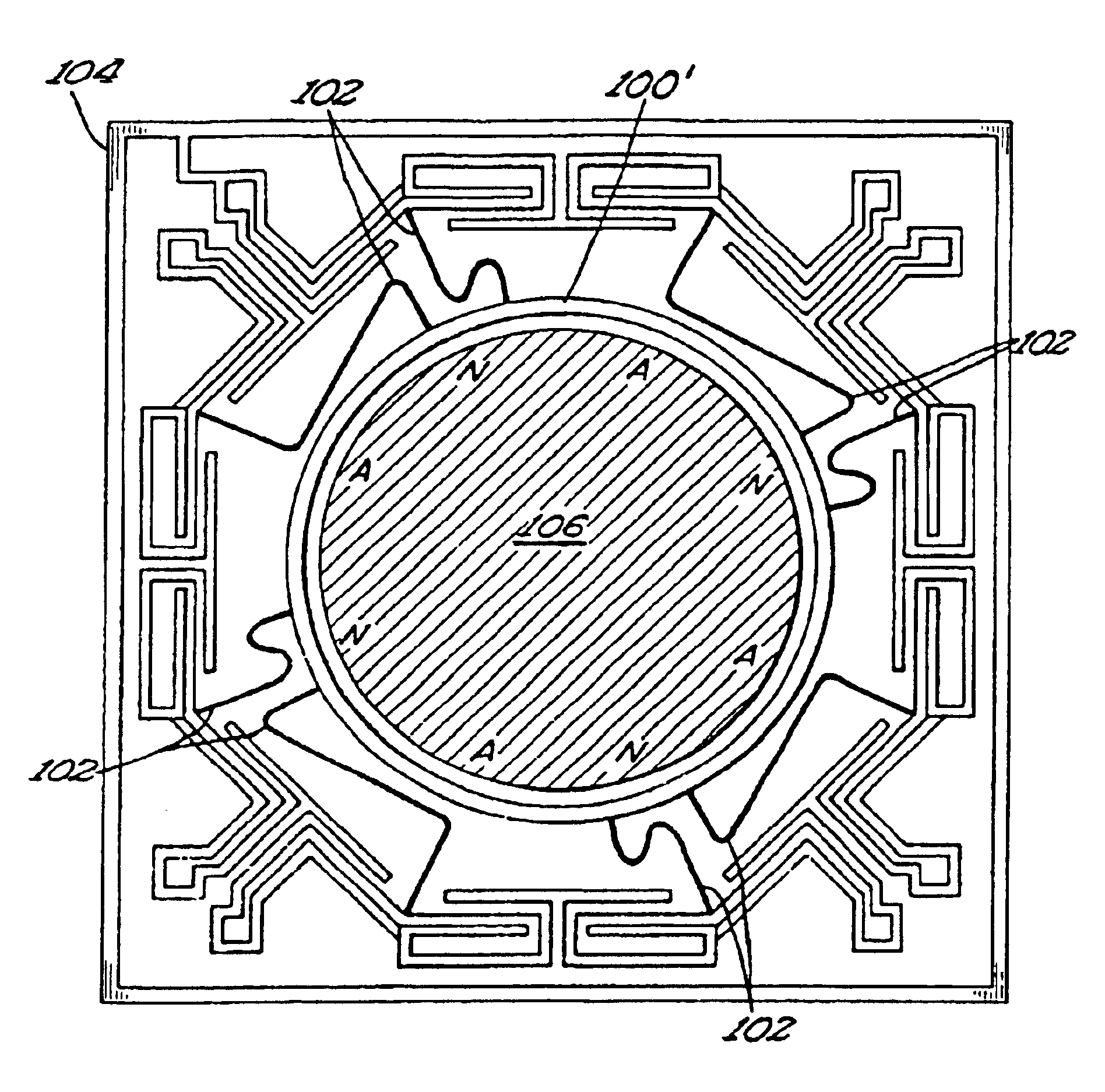

High Q angular rate sensing gyroscope

InactiveUS6845667B1Improve accuracy and Q valueMaximize flexureAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsElectrical conductorGyroscope

A structure and arrangement for improving the accuracy and efficiency of an angular rate sensing gyroscope is herein disclosed. Voltage pick-off conductors are applied to an area of the surface of a resonating element of an angular rate sensing gyroscope that is subject to substantially zero stress when the gyroscope is rotationally stationary. Actuator conductors are similarly applied to a resonating element at a location bounded by areas of the resonating element subject to substantially uniform levels of stress when the gyroscope is rotationally stationary. A method for improving the voltage response of a piezoelectric resonating element is also disclosed.

Owner:WATSON INDUSRIES

Preparation method of stratified-structure mineral reinforced rubber composite material

The invention relates to a preparation method of a stratified-structure mineral reinforced rubber composite material. The preparation method comprises the following steps: (1) carrying out nano-organic modification on a stratified-structure mineral; (2) preparing an organic modified nano-stratified-structure mineral inserted rubber master batch; (3) preparing the raw materials of an organic modified nano-stratified-structure mineral reinforced rubber composite material; and (4) preparing the organic modified nano-stratified-structure mineral reinforced rubber composite material, wherein the stratified-structure mineral is one or mixture of two of black talc, montmorillonite, kaolin and illite in the same mass ratio. According to the preparation method, the functional rubber composite material with excellent mechanical property, stable weather resistance and good warping strength and humidity resistance is prepared.

Owner:HEBEI UNIV OF TECH

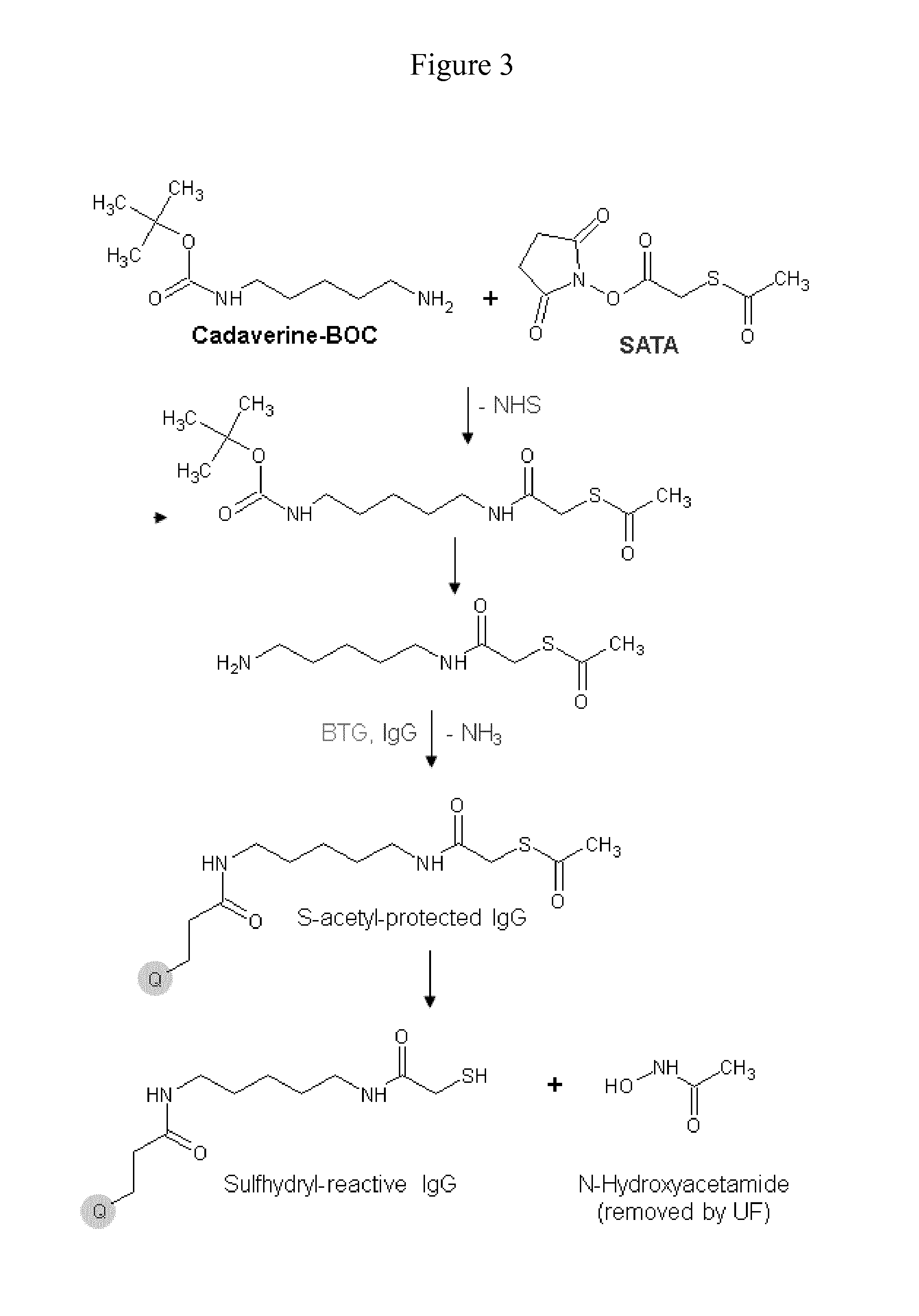

Screening of conjugated antibodies

ActiveUS20150346195A1Uniform modificationImprove stabilityMicrobiological testing/measurementImmunoglobulinsAntiendomysial antibodiesIntravenous gammaglobulin

Provided is a method for the functionalization of immunoglobulins through the use of transglutaminase, including methods for screening functionalized antibodies for characteristics of interest, antibody compositions comprising a plurality of functionalized antibodies, and functionalized antibodies with rodent constant regions.

Owner:PAUL SCHERRER INSTITUT +1

Method for improving crushing strength of asphalt-based spherical activated carbon

ActiveCN104276569AUniform modificationHigh strengthCarbon compoundsActivated carbonPolyvinyl alcohol

The invention discloses a method for improving crushing strength of asphalt-based spherical activated carbon. The method comprises the following steps: evenly mixing high-softening-point asphalt, naphthalene and iodide, and reacting at 230-350DEG C to obtain modified asphalt; then adding into an autoclave containing 1-5wt% polyvinyl alcohol water solution, and stirring for 0.5-3h at 85-150DEG C, to obtain asphalt spheres; and oxidizing the asphalt spheres without melting, and performing carbonization and activation treatment to the asphalt spheres to obtain the asphalt-based spherical activated carbon product. The asphalt-based spherical activated carbon has the advantages of being capable of performing large-scale production and high in crushing strength.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

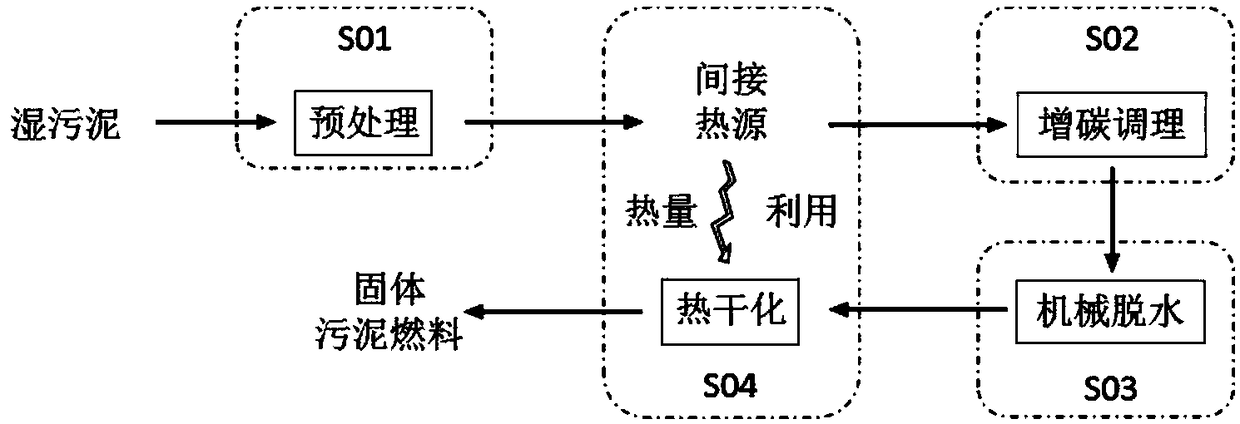

Method simultaneously for moisture removal and solid fuel preparation from sludge and products

ActiveCN108358421AChange fuel propertiesLower ignition pointSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningBound waterSludge

The invention provides a method simultaneously for moisture removal and solid fuel preparation from sludge. The method comprises the following steps: step S01: subjecting wet sludge to pretreatment under heating so as to obtain heat conditioned sludge; step S02: cooling the heat conditioned sludge so as to obtain cold sludge, adding a carburetting conditioning agent into the cold sludge, and carrying out uniform mixing so as to obtain carburetted conditioned sludge; step S03: subjecting the carburetted conditioned sludge to dehydration treatment; and step S04: subjecting the dehydrated carburetted conditioned sludge to heat drying so as to obtain a solid sludge fuel. Through combined application of a heat conditioning process and a conditioned sludge sensible heat direct utilization systemin pretreatment of the sludge, the method provided by the invention avoids the problem of excessively high energy consumption, and integrates advantages like improvement of sulfur-fixing, chlorine-fixing, nitrogen-fixing and phosphorus-fixing abilities of modified heat-conditioned sludge and reduction of the content of bound water in a reasonable energy consumption range.

Owner:HUAZHONG UNIV OF SCI & TECH

Filler capable of enhancing low-temperature resistance of plastic and preparation method thereof

InactiveCN104592551AUniform modificationImprove lipophilicityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolyesterSlag

The invention relates to filler capable of enhancing the low-temperature resistance of plastic. The filler is prepared from the following raw materials in parts by weight: 0.5-0.7 part of mineral oil, 2-3 parts of aluminum oxide, 0.4-0.7 part of rosin, 0.5-0.8 part of polyamide wax micropowder, 0.7-1 part of polyester acrylate, 0.1-0.2 part of ammonium persulfate, 1-2 parts of 2-mercaptobenzimidazole, 1-1.5 parts of tetraethylortho silicate, 0.4-0.6 part of ammonia water, 1-2 parts of triphenyl phosphate, 2-3 parts of nanometer iron slag, 200-220 parts of light calcium carbonate, 5-9 parts of an additive and 20-30 parts of water. Since calcium carbonate is uniform in surface modification and good in lipophilicity and has good compatibility with the plastic, the strength and impact resistance of the plastic can be increased; by adding polyamide wax micropowder, the self-lubricating property of the filler is increased, the filler is easily and uniformly dispersed in the plastic and good low temperature resistance is achieved.

Owner:ANHUI YUTANG RAIN GEAR

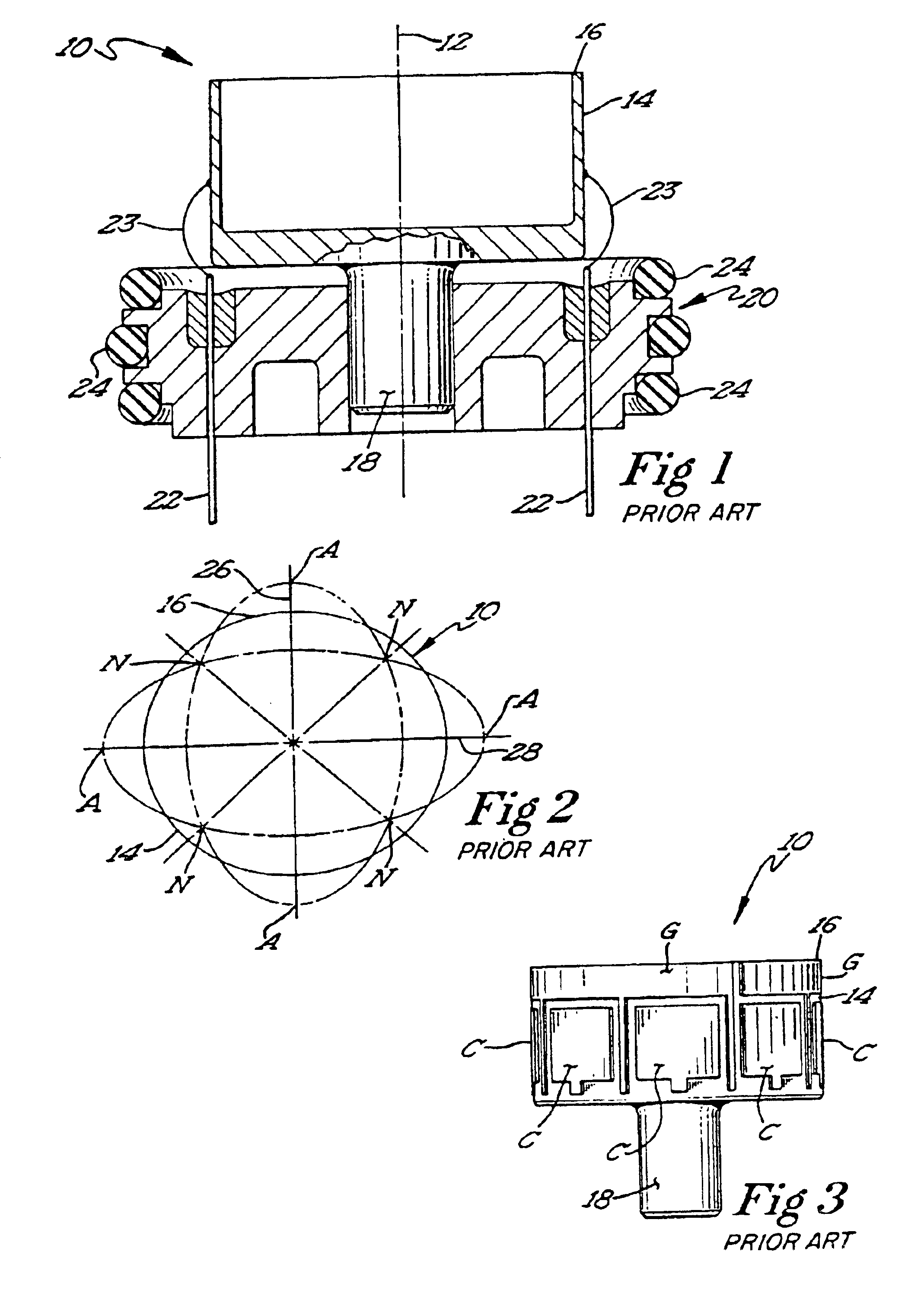

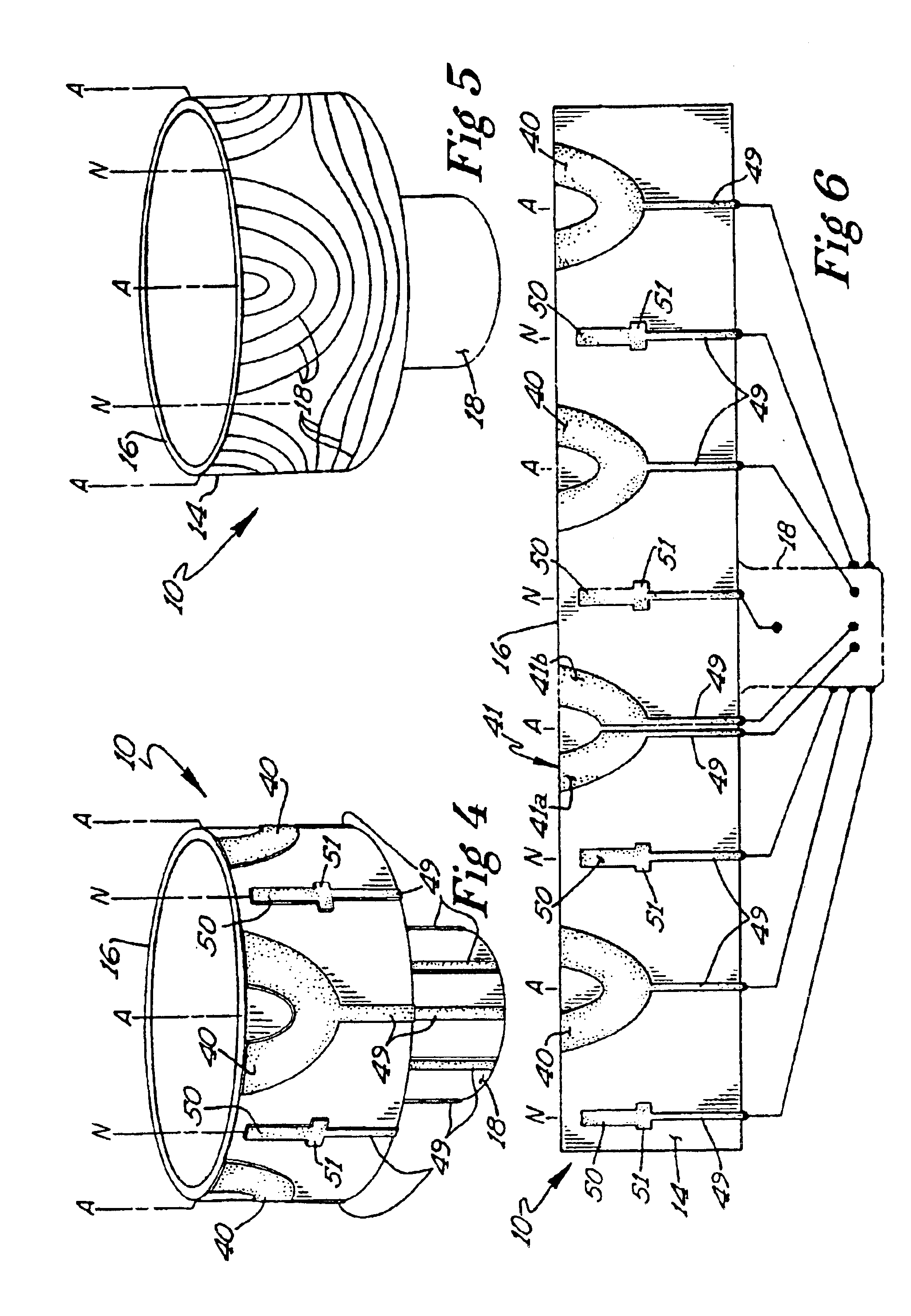

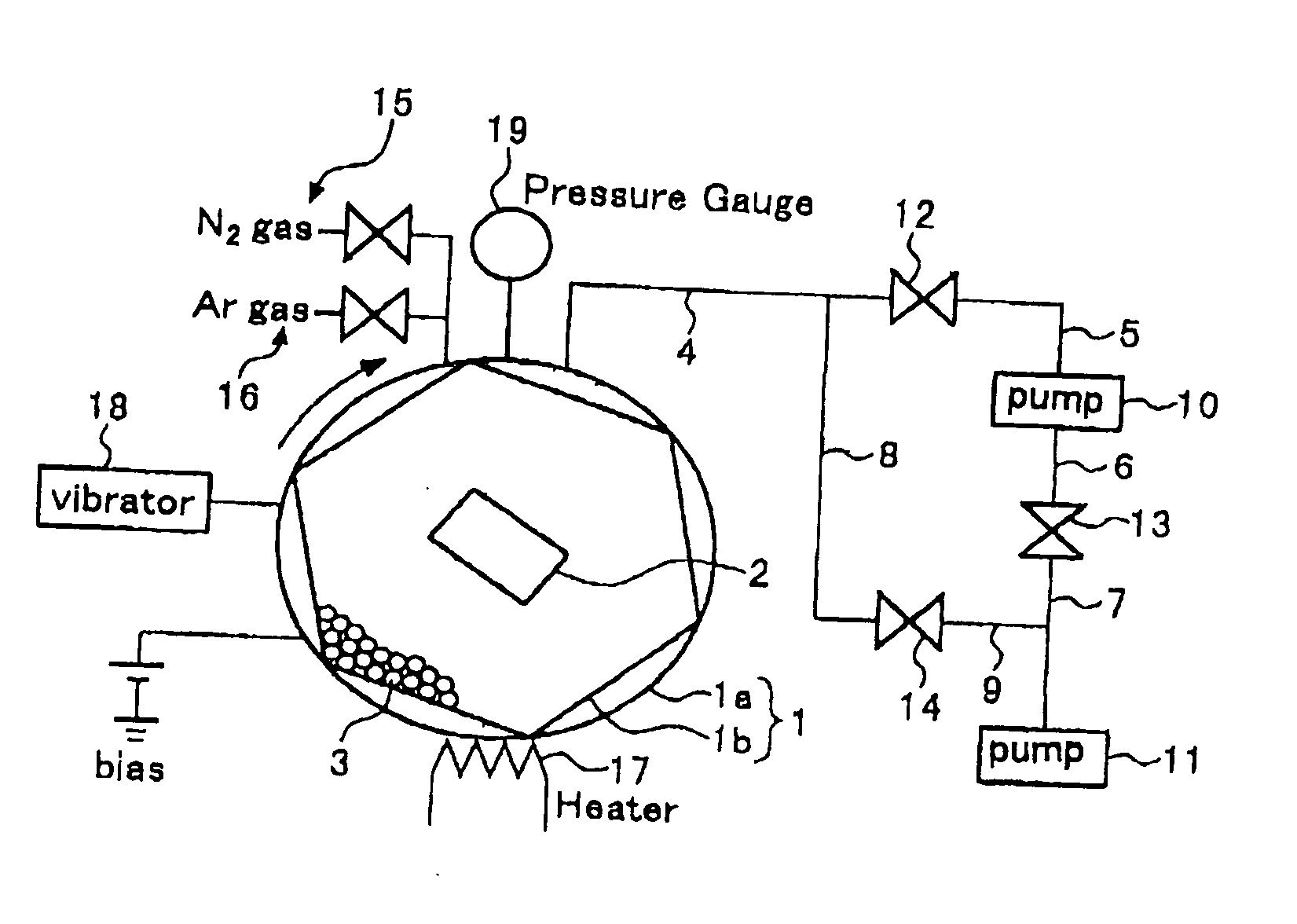

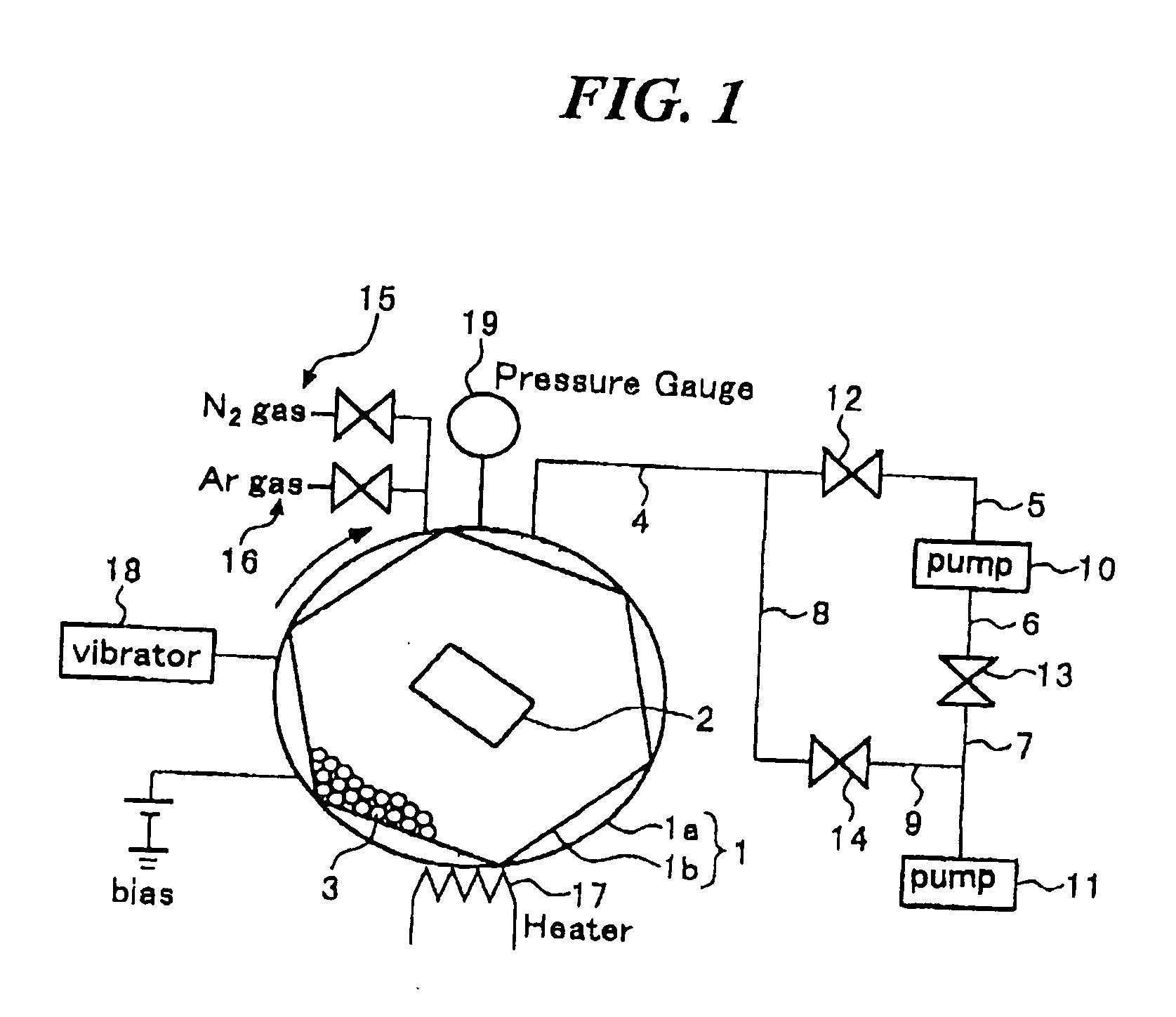

Polygonal barrel spattering device, polygonal, barrel spattering method, coated particle formed by the device and method, microcapsule, and method of manufacturing the micro- capsule

InactiveUS20060254903A1Avoid damageImprove versatilityCellsPressurized chemical processSputteringUltra fine

The present invention relates to a polygonal barrel sputtering device and a polygonal barrel sputtering method for coating surfaces of fine particles with ultra-fine particles having a grain diameter smaller than the particles or thin films, a coated fine particle formed by the device and method, a micro capsule and a method for producing the micro capsule. The polygonal barrel sputtering method according to the present invention comprises a step for containing fine particles 3 in a vacuum container 1 having a polygonal internal shape on a cross section, which is substantially parallel with a gravitational direction, and a step for performing sputtering while stirring or rolling the fine particles 3 contained in the vacuum container 1 by rotating the vacuum container 1 about a rotating axis, which is substantially perpendicular to the cross section, whereby surface of the fine particle 3 is coated with ultra-fine particles having a grain diameter smaller than the fine particle or thin films.

Owner:YOUTEC CO LTD

Modified cycloolefin copolymer, process for producing the same, and use of the polymer

InactiveUS20060199915A1High transparencyLow moisture permeabilitySemiconductor/solid-state device detailsSolid-state devicesTM compoundChemistry

A modified cycloolefin copolymer is obtained by chemical modification of a base polymer being a cycloolefin copolymer with ethylene chains, through addition of a modifier compound having a functional group and a hydrogen-donating group or having a functional group and an alkyl halide group, wherein: the functional group is added at a stoichiometric percentage of 20 to 90% of all the replaceable hydrogen atoms in ethylene chains and main-chain cycloolefin chains of the base polymer; and the distribution degree of the functional group-modified cycloolefin copolymer in the base polymer is in the range of 0.01 to 0.1 as expressed in distribution correlation coefficient (DR) defined by the relation (1) below. (DR)=[(RI)−(UV)]2 . . . (1) wherein (RI) and (UV) are dispersion indices of molecular weight distributions (=weight-average molecular weight / number-average molecular weight) determined by simultaneous detection based on change of refractive index (RI) and detection based on a UV absorption spectrum characteristic of the functional groups added. Also provided are a process of production and uses of the modified cycloolefin copolypmers.

Owner:SOKEN CHEM & ENG CO LTD

Powdery ardealite filler and preparation thereof

The invention belongs to the field of PVC (Polyvinyl Chloride) production fillers, and particularly relates to powdery ardealite filler. The ardealite is subjected to temperature rise sintering until the surface temperature of the ardealite is 180-190DEG C, the ardealite is grinded until a grain diameter is 60-80mu m, and then, the ardealite is cooled to a room temperature to obtain beta-type hemihydrate gypsum; processing aid and dispersant are added, mixing at a high speed is performed for 5-8min, and the mixture is grinded into powder after the mixture is subjected to constant temperature curing for 30-60min to obtain the powdery ardealite filler. The filler has the advantages of good thermostability and proper foaming property. The method has the advantages of simple technology and low cost.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Cellulose fiber garment anhydrous salt-free dyeing method

A cellulose fiber garment anhydrous salt-free dyeing method includes the steps: 1) preparation of a modification solution, 2) padding and drying, 3) preparation of a dyeing solution, and 4) garment dyeing and padding. Compared with traditional garment dyeing, the cellulose fiber anhydrous salt-free garment dyeing has unique process characteristics, especially preparation of the modification solution in the garment dyeing; in addition, in the knitted fabric anhydrous salt-free garment dyeing process, in fabric padding, the caterpillar band speed and considered reasonable control of the tension, compared with a commonly used dip dyeing process of cotton knitted fabric dyeing, the anhydrous salt-free garment dyeing can substantially reduce the consumption of water, heat and chemicals in the dyeing process, and has huge advantages in energy conservation, emissions reduction, consumption reduction and cost reduction.

Owner:YIWU XIYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

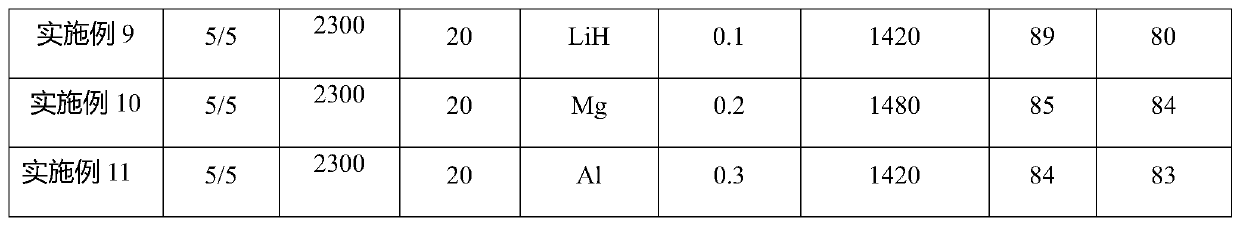

Silicon-based lithium storage material and preparation method thereof

PendingCN111149242AUniform modificationExcellent cycle characteristicsCell electrodesLi-accumulatorsChemical physicsPhysical chemistry

The present application provides a novel silicon-based lithium storage material and a method for manufacturing the same, the silicon-based lithium storage material comprising: a first component comprising Si having a valence of 1 to 4 and a molar number of Si (0) having a valence of 0, and a second component comprising Si having a valence of 0 and a molar number of Si element having a valence of 1to 4; the second component comprises a doping element R, the doping element R at least comprises one of main group elements I, II and III, and CR is the mole number of the doping element R and is themole number of a silicon element with the valence of 0-4. The silicon-based lithium storage material improves the characteristics of the silicon-based lithium storage material as an active substanceof a lithium ion secondary battery under a high-temperature storage condition, and improves the cycle characteristics and initial charge-discharge coulombic efficiency of the battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

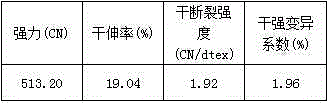

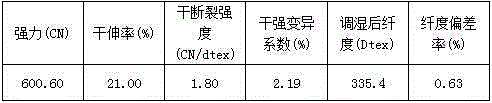

Chemical modification method and chemical modification device for aramid fibers

ActiveCN104894850ASolve the problem of limited modification effectImprove joint forceFibre typesPolymer scienceInterlaminar shear

The invention relates to a chemical modification method and a chemical modification device for aramid fibers and belongs to the technical field of chemical synthetic fiber modification. The method includes preparation of a surface modification treatment agent, modification treatment and washing drying, a specific acyl chloride active reaction reagent or anhydride active reaction reagent is dissolved in an anhydrous strong-polar organic solvent so as to subject the aramid fibers to chemical modification, surface performance of the modified aramid fibers can be improved remarkably, joint force between the aramid fibers and an epoxy resin matrix is enhanced significantly, and interlaminar shear strength of the modified aramid fibers can reach 50-59MPa. In addition, softness and dispersibility of the fibers are improved while the aramid fibers are subjected to surface modification, and application performance of the fibers is improved.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

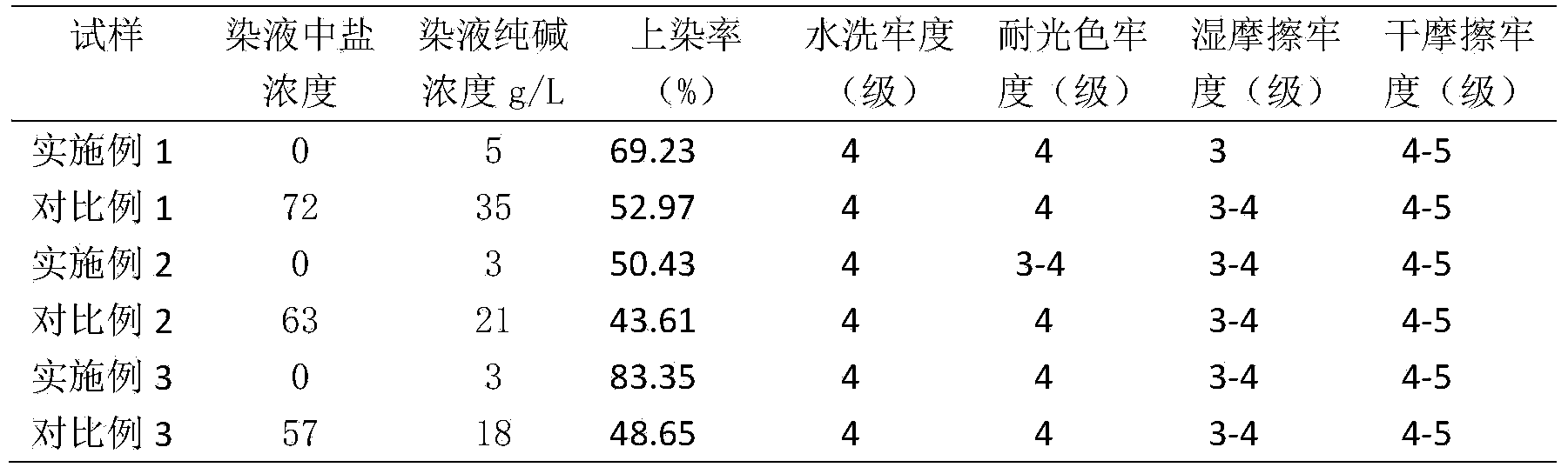

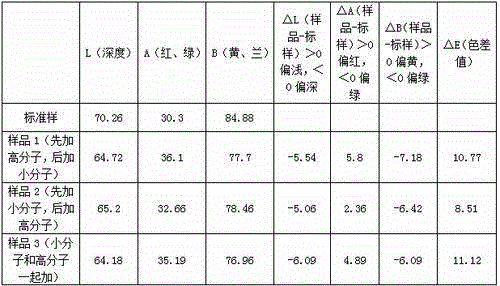

Salt-free low-alkali dyeing method for cellulosic fibers

The invention relates to a salt-free low-alkali dyeing method for cellulosic fibers and belongs to the technical field of textile dyeing. The salt-free low-alkali dyeing method comprises the steps of modification treatment, water processing, dyeing and aftertreatment of the cellulosic fibers, wherein in the modification treatment of the cellulosic fibers, 3-acrylamide-2-hydroxypropyltrimonium and polyamide polyamine epichlorohydrin are adopted for carrying out modification treatment on the cellulosic fibers. According to the salt-free low-alkali dyeing method, two specific modifiers are adopted and the synergistic effect of the two modifiers is used cooperatively with the specific dyeing step, so that salt-free low-alkali dyeing of the cellulosic fibers is realized in the dyeing process, pollution is reduced and the cost is reduced; moreover, the process is simplified; difficulty is reduced; modifying and dyeing effects are good; and the salt-free low-alkali dyeing method is suitable for industrial mass production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

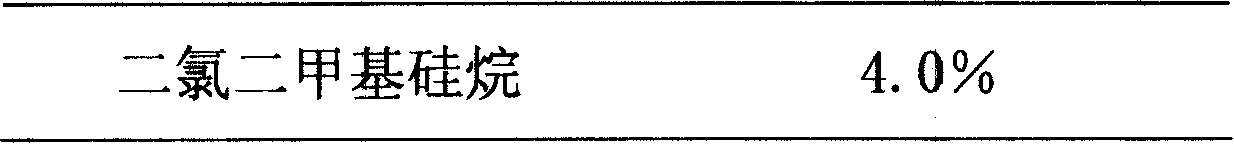

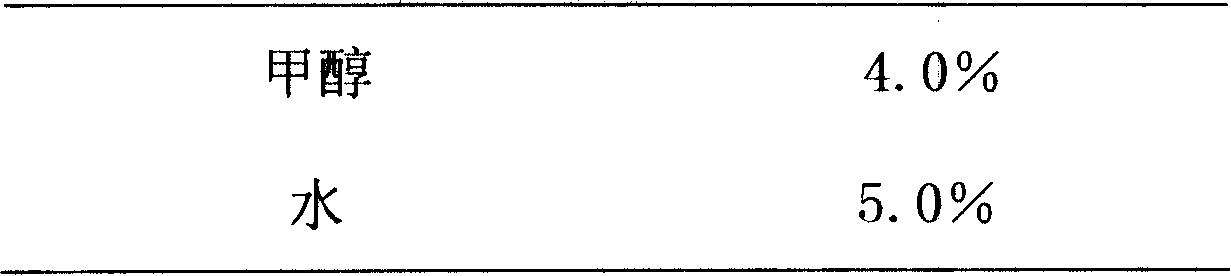

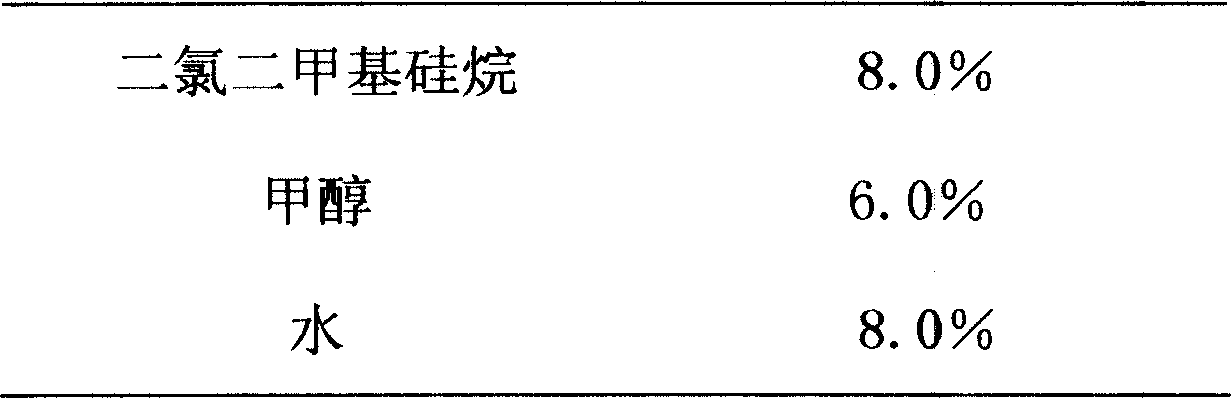

Method for preparing silicane fecula

The present invention relates to a method for preparing a silane starch, especially to a method for preparing the silane starch using dry fluidization method. The invention provides a silane starch with a steady quality and a high efficiency. The invention using the following technical proposal that the feed proportioning is based on the mass of the starch, wherein other raw materials contain from 1.0 percent to 12.0 percent by weight of dimethyldichlorosilane or hexamethyldisiloxane to the mass of the starch, from 0.5 percent to 10.0 percent by weight of methanol to the mass of the starch, and from 5.0 percent to 20.0 percent by weight of water to the mass of the starch.

Owner:SHENYANG POLYTECHNIC UNIV

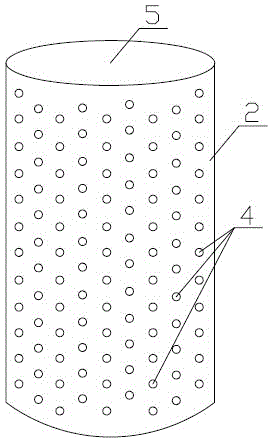

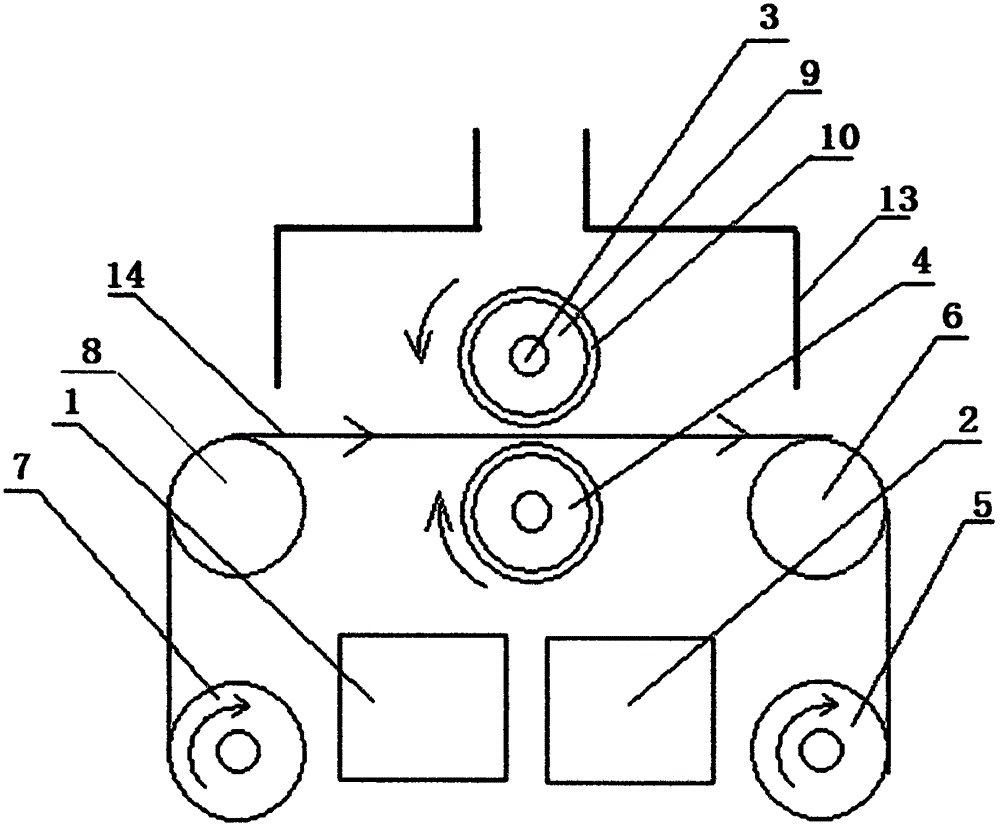

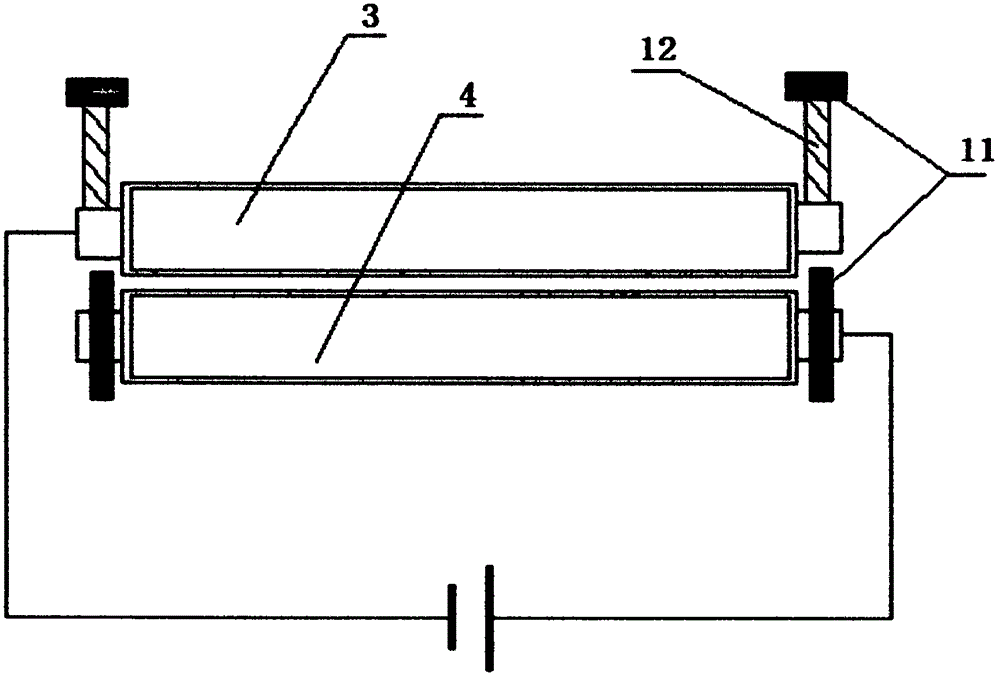

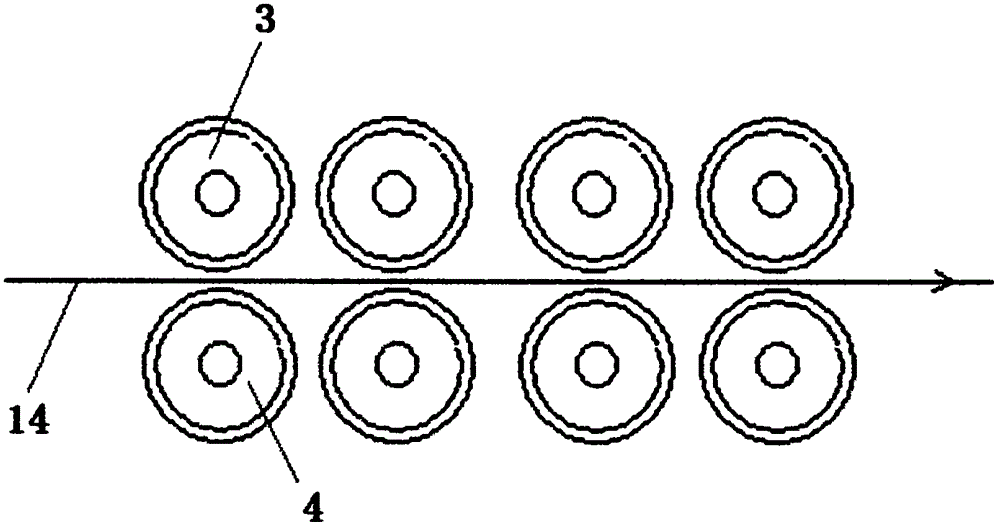

Normal pressure plasma processing device for textile processing

InactiveCN105908484AAchieve surface etchingAchieve hydrophilic modificationUltrasonic/sonic fibre treatmentTextile yarnEngineering

The invention discloses a normal pressure plasma processing device for textile processing. The normal pressure plasma processing device comprises a metal electrode tube assembly, a processed material driving assembly, a power assembly and a power supply. The metal electrode tube assembly comprises at least one set of a first metal electrode tube and a second metal electrode tube opposite and parallel to the first metal electrode tube. The normal pressure plasma processing device for textile processing is simple and reasonable in structure; a textile material is unwound from an unwinding shaft and passes through a transmission shaft, and then the surface of the material is subjected to uniform modification processing with normal pressure plasma when the textile material passes through the upper and lower metal electrode tubes. By means of the normal pressure plasma processing device for textile processing, textile yarns, fabric, thin-film materials and the like can be subjected to wide plasma processing, and surface etching, hydrophilic modification, cleaning processing, function modification and the like of materials can be achieved.

Owner:孙世元

Cationic modified cellulose fibers

The invention relates to cationic modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with a low molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier as cationic modifiers and have Zeta electrode potential values of minus 5-15mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifier is 3-acrylamide-2-hydroxypropyl trimethylammonium chloride; the high molecular quaternary ammonium salt cationic modifier is polyamide polyamine epichlorohydrin. The modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:YIBIN SPARK NEW FIBER CO LTD

Reinforcing and toughening calcium carbonate filler and preparation method thereof

The invention discloses a reinforcing and toughening calcium carbonate filler. The reinforcing and toughening calcium carbonate filler is prepared from the following raw materials in parts by weight: 5-7 parts of calcium sulfate whiskers, 2-3 parts of polyol ester laurate, 2-3 parts of a silane coupling agent KH-550, 1-1.3 parts of molybdenum trioxide, 3-4 parts of iron oxide, 1-1.4 parts of shea butter, 0.3-0.4 part of honey, 0.5-0.8 part of amide propyl glycine betaine, 0.8-1.2 parts of aluminum potassium sulfate, 2-3 parts of morpholine, 0.3-0.5 part of sodium sulfate, 0.3-0.5 part of urea, 0.1-0.2 part of alkanolamide, 3-4 parts of titanium dioxide, 80-85 parts of light calcium carbonate, 13-16 parts of auxiliaries and 120-140 parts of water. The reinforcing and toughening calcium carbonate filler is unique in formula process and uniform in calcium carbonate surface modification and is capable of greatly improving the PVC performance, greatly improving the impact toughness of the PVC and strengthening the rigidity, the heat resistance and the processing performance of the PVC material after being used for a PVC (polyvinyl chloride) filler additive; by adding the calcium sulfate whiskers, the strength and the toughness of PVC are greatly increased. And moreover, the auxiliaries can be used for increasing the wettability of calcium carbonate in PVC, so that the defects of PVC are reduced.

Owner:CHIZHOU RUIXIANG CALCIUM IND

Adsorption type bone apatite and preparation method and application thereof

ActiveCN110841588AWide variety of sourcesHigh specific surface areaOther chemical processesWater contaminantsO-Phosphoric AcidEngineering

The invention belongs to the field of environment-friendly materials, and particularly relates to adsorption type bone apatite and a preparation method and application thereof. The preparation methodcomprises the following steps: removing organic matters in animal bones; calcining the animal bones without the organic matters to obtain bone apatite; and carrying out surface chemical modification on the bone apatite by adopting a phosphoric acid solution to obtain the adsorption type bone apatite. The adsorption type bone apatite can be used for adsorbing heavy metal ions in industrial sewage,and the specific surface area of the adsorption type bone apatite is increased from 47.832 (m<2> / g) to 131.566 (m<2> / g) compared with the specific surface area of the adsorption type bone apatite before modification; when the initial concentration of Pb<2> is 200 mg / L, a removal rate can reach 98.3%; for Zn<2> and Cu<2> ions with an initial concentration of 200 mg / L, the removal rate of the ions can reach 70% or above; so the adsorption type bone apatite has good heavy metal ion removal capacity. The technical problem that bone apatite in the prior art is not high enough in adsorption capacityis solved.

Owner:XI AN JIAOTONG UNIV

Method for improving discharge resistance of epoxy insulator in gas insulation system

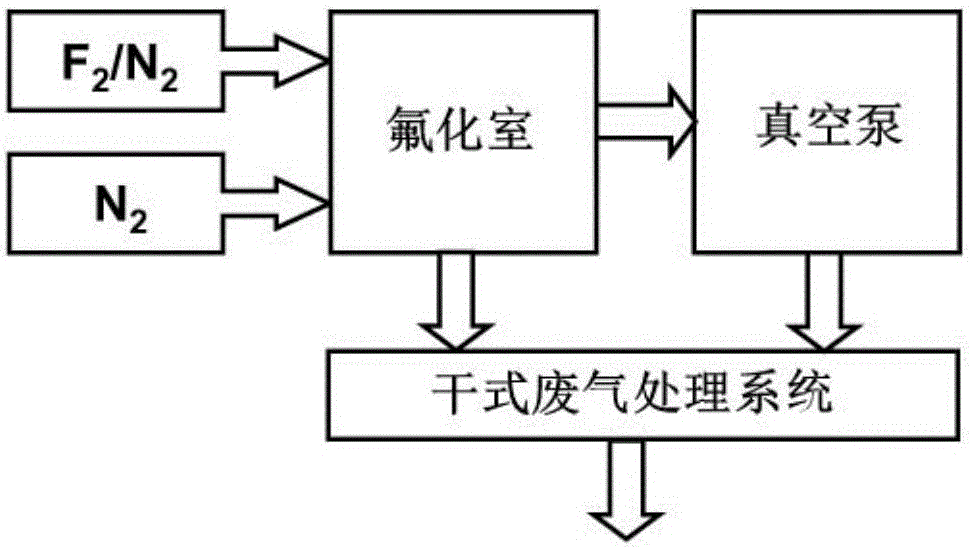

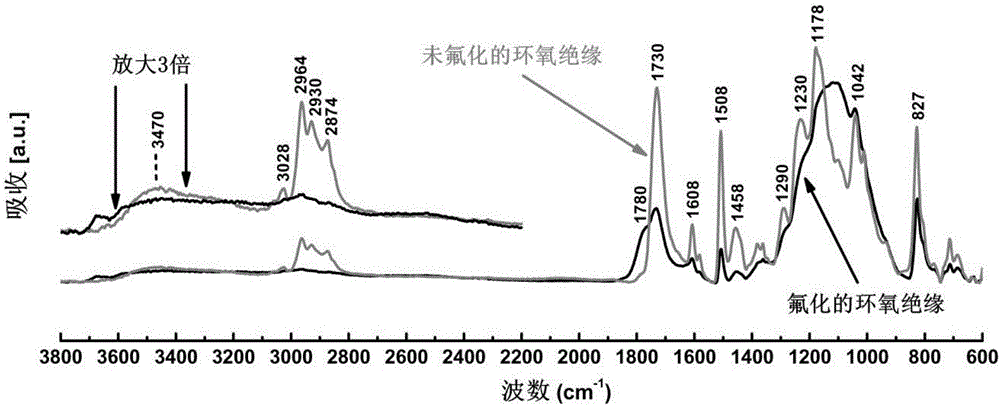

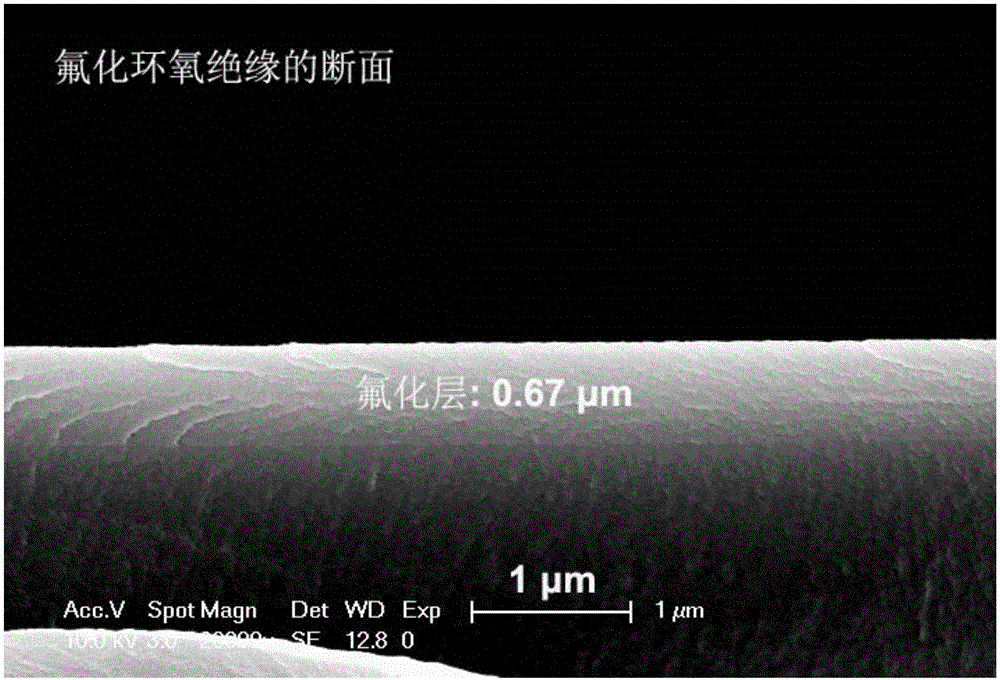

ActiveCN106782941AChange physical and chemical characteristicsSimple processInsulatorsEpoxy insulatorsNitrogen gas

The invention relates to a method for improving the discharge resistance of an epoxy insulator in a gas insulation system. According to the method, fluoridation is carried out on the epoxy insulator by using a gas mixture of fluorine gas and nitrogen gas or a gas mixture of fluorine gas and inert gas under the conditions of appropriate temperature and pressure in a closed reaction chamber, a fluoridation layer containing C-F bonds is formed on the surface of the epoxy insulator, so that the method is used for improving the discharge resistance of the epoxy insulator. Compared with the prior art, the method disclosed by the invention is simple in processing steps, good in controllability and low in economic cost, the epoxy insulators with arbitrary shapes and dimensions can be uniformly modified in batches, and the method is specially applicable for commercial application.

Owner:TONGJI UNIV

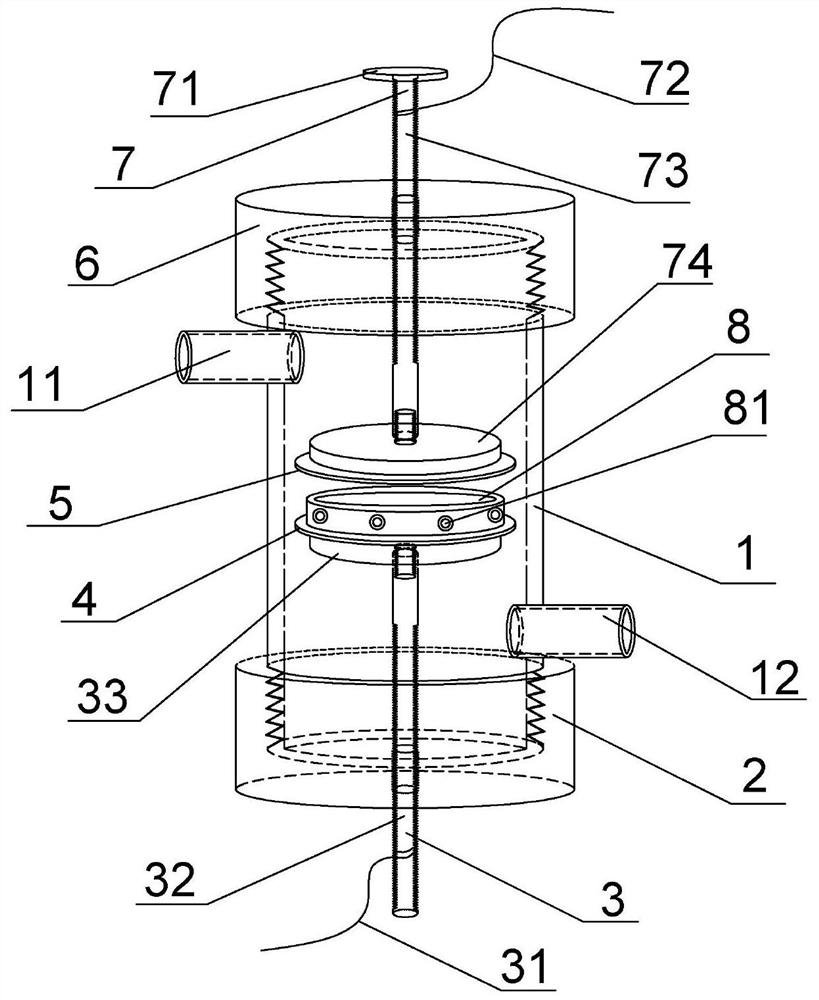

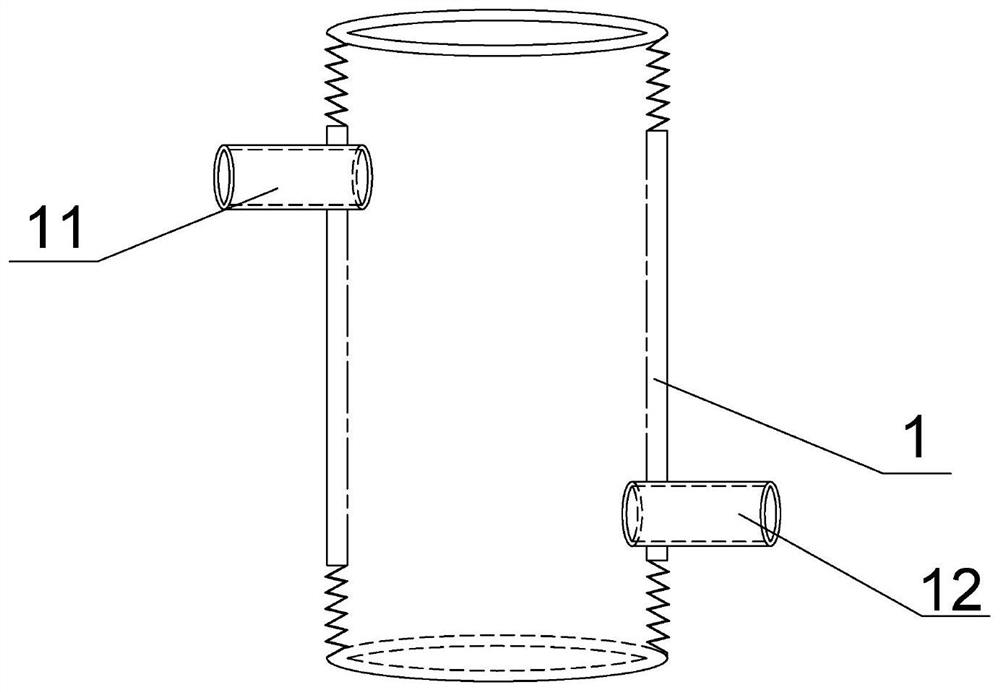

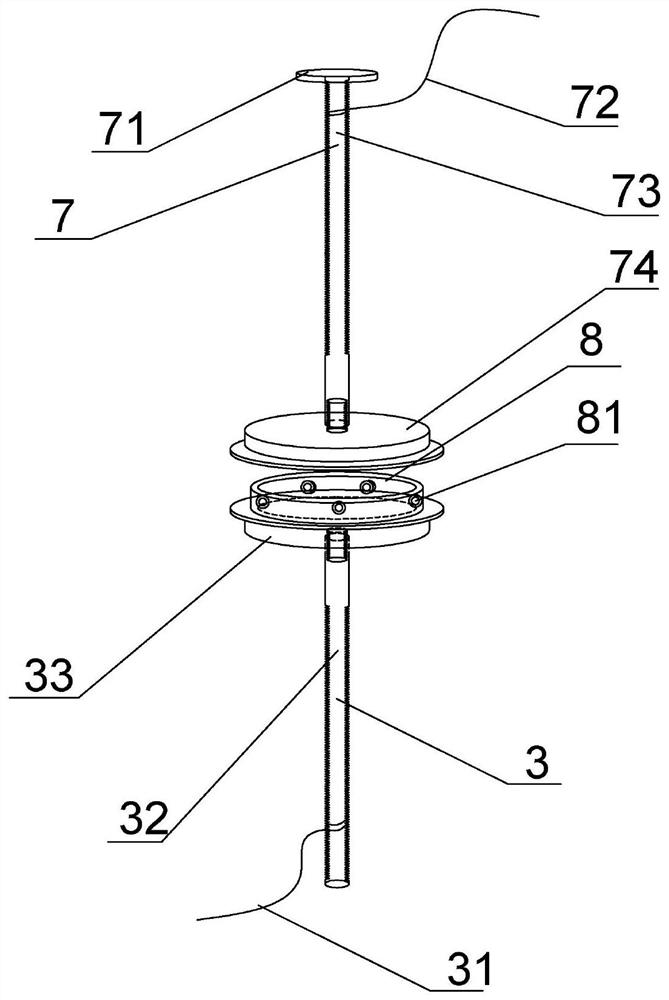

Gas-phase packed bed discharge plasma generating device

InactiveCN111988903AWill not cause uneven dischargeUniform modificationPlasma techniqueLow voltageEngineering

The invention provides a gas-phase packed bed discharge plasma generating device, which comprises a plasma reactor shell body, a lower sealing end cover, an upper sealing end cover, a low-voltage electrode structure, a high-voltage electrode structure and a packed bed, wherein the upper and lower sealing end covers are connected to the upper and lower parts of the plasma reactor shell body; the upper sealing end cover is connected with a high-voltage electrode structure, and the lower sealing end cover is connected with a low-voltage electrode structure; the high-voltage electrode structure comprises a high-voltage screw rod, a high-voltage electrode plate, an adjusting hand wheel, a high-voltage power line and an upper insulating dielectric plate; the low-voltage electrode structure comprises a grounding power line, a low-voltage screw rod, a low-voltage electrode plate and a lower insulating dielectric plate; and the packed bed is fixed on the upper surface of the lower insulating dielectric plate. The gas-phase packed bed discharge plasma generating device disclosed by the invention can realize dielectric barrier discharge of different gas components, is convenient for observinga discharge phenomenon, can measure a spectrum in real time, realizes surface modification experiments of materials such as an adsorbent and the like, and realizes degradation experiments of liquid-phase pollutants in different gas environments.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com