Modified basalt flake solvent-free epoxy resin anticorrosion coating and preparation method thereof

A technology of epoxy resin and anti-corrosion coating, applied in the field of coatings, can solve the problems of reducing coating anti-corrosion performance, poor wetting performance, and easy agglomeration of scales, so as to improve anti-corrosion performance and mechanical properties, improve coating performance, and excellent coating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

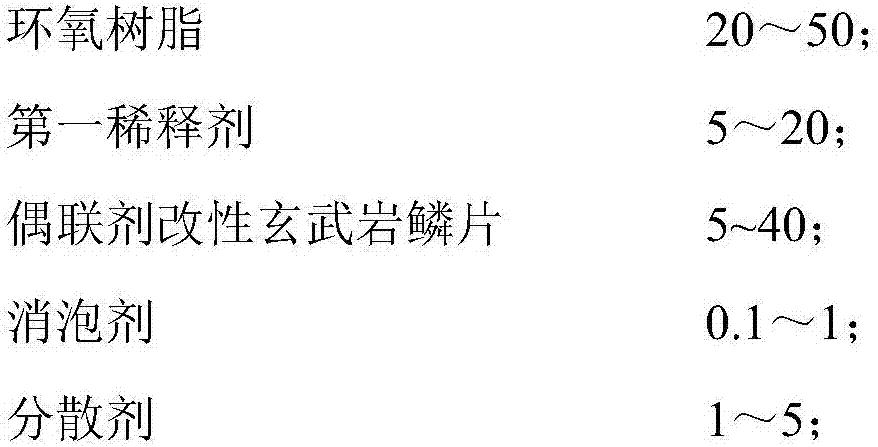

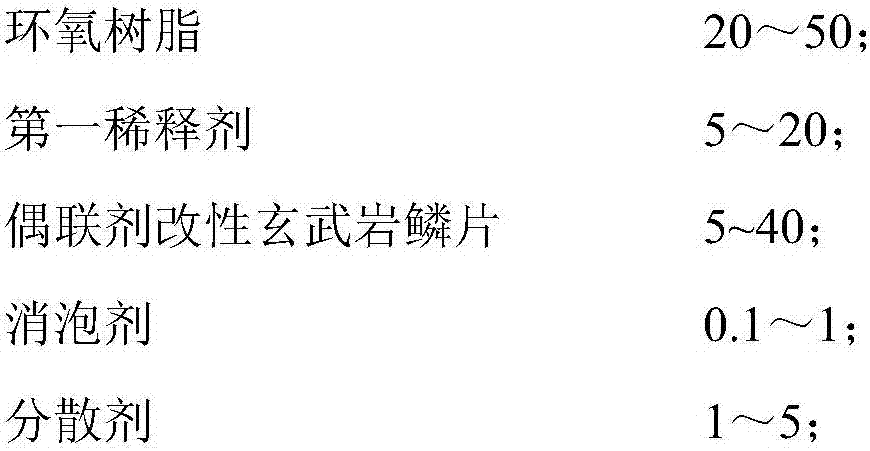

[0035] Embodiment 1: A kind of modified basalt flake solvent-free epoxy resin anticorrosion coating, including A component and B component mixed according to the mass fraction of 10:1; Wherein:

[0036] Component A contains: bisphenol A epoxy resin E-51, 20 parts by mass; BYK-A530 defoamer produced by BYK, 0.1 parts by mass; Disperbyk163 dispersant produced by BYK, 1 part by mass; 80 Mesh basalt scales, 5 parts by mass; 5 parts by mass of 1,4-butanediol diglycidyl ether diluent;

[0037] Component B includes: phenalkamine curing agent, 5 parts by mass; 1,4-butanediol diglycidyl ether diluent, 1 part by mass.

[0038] The preparation process is as follows:

[0039] 1) The basalt scales are ultrasonically cleaned with deionized water and absolute alcohol, and dried;

[0040] 2) Titanate coupling agent TMC-931 and deionized water are diluted 1:1;

[0041] 3) Soak the basalt scales in the dilution of the coupling agent, filter after soaking for 10 minutes, and bake at 100°C for...

Embodiment 2

[0046] Embodiment 2: A modified basalt flake solvent-free epoxy resin anticorrosion coating, including component A and component B mixed according to the mass fraction of 5:1; wherein:

[0047] Component A contains: bisphenol F epoxy resin, 50 parts by mass; BYK-A088 defoamer produced by BYK, 0.5 parts by mass; Disperbyk162 dispersant produced by BYK, 5 parts by mass; benzyl glycidyl ether diluted Agent, 20 mass parts; 500 order modified order basalt scales, 20 mass parts;

[0048] Component B includes: polyamide curing agent, 10 parts by mass; benzyl glycidyl ether diluent, 5 parts by mass.

[0049] The preparation process is as follows:

[0050] 1) The basalt scales are ultrasonically cleaned with deionized water and absolute alcohol, and dried;

[0051] 2) KH-560: water: methanol is prepared according to the mass ratio of 0.5:9:1, adjust the pH to 5 with acetic acid, add glycerol with 1% volume of the solution, and stir evenly;

[0052] 3) Hydrolysis reaction in constant...

Embodiment 3

[0058] Embodiment 3: A modified basalt flake solvent-free epoxy resin anticorrosion coating, including component A and component B mixed according to the mass fraction of 1:1; wherein:

[0059] Component A contains: bisphenol A epoxy resin E-44, 45 parts by mass; Defom5300 defoamer produced by Deqian Chemical Company, 0.3 parts by mass; Disperbyk164 dispersant produced by BYK, 4 parts by mass; 1,6 -diol diglycidyl ether diluent, 8 parts by mass; 1000 mesh basalt scales, 40 parts by mass;

[0060] Component B includes: phenalkamine curing agent, 25 parts by mass; 1,6-hexanediol diglycidyl ether diluent, 10 parts by mass.

[0061] The preparation process is as follows:

[0062]1) The basalt scales are ultrasonically cleaned with deionized water and absolute alcohol, and dried;

[0063] 2) KH-550: water: methanol is hydrolyzed according to the mass ratio of 20:72:8;

[0064] 3) Soak the basalt scales in the hydrolyzate of KH-550 for 120 minutes, filter and bake at 200°C for 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com