Comprehensive utilization method of coal water slurry gasified waste residue on Texaco gasifier

A technology of coal water slurry and waste residue, which is applied in the direction of cement production, solid waste management, climate sustainability, etc., can solve the problems that rarely involve the utilization of waste residue, and achieve the effect of large consumption, low modification cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

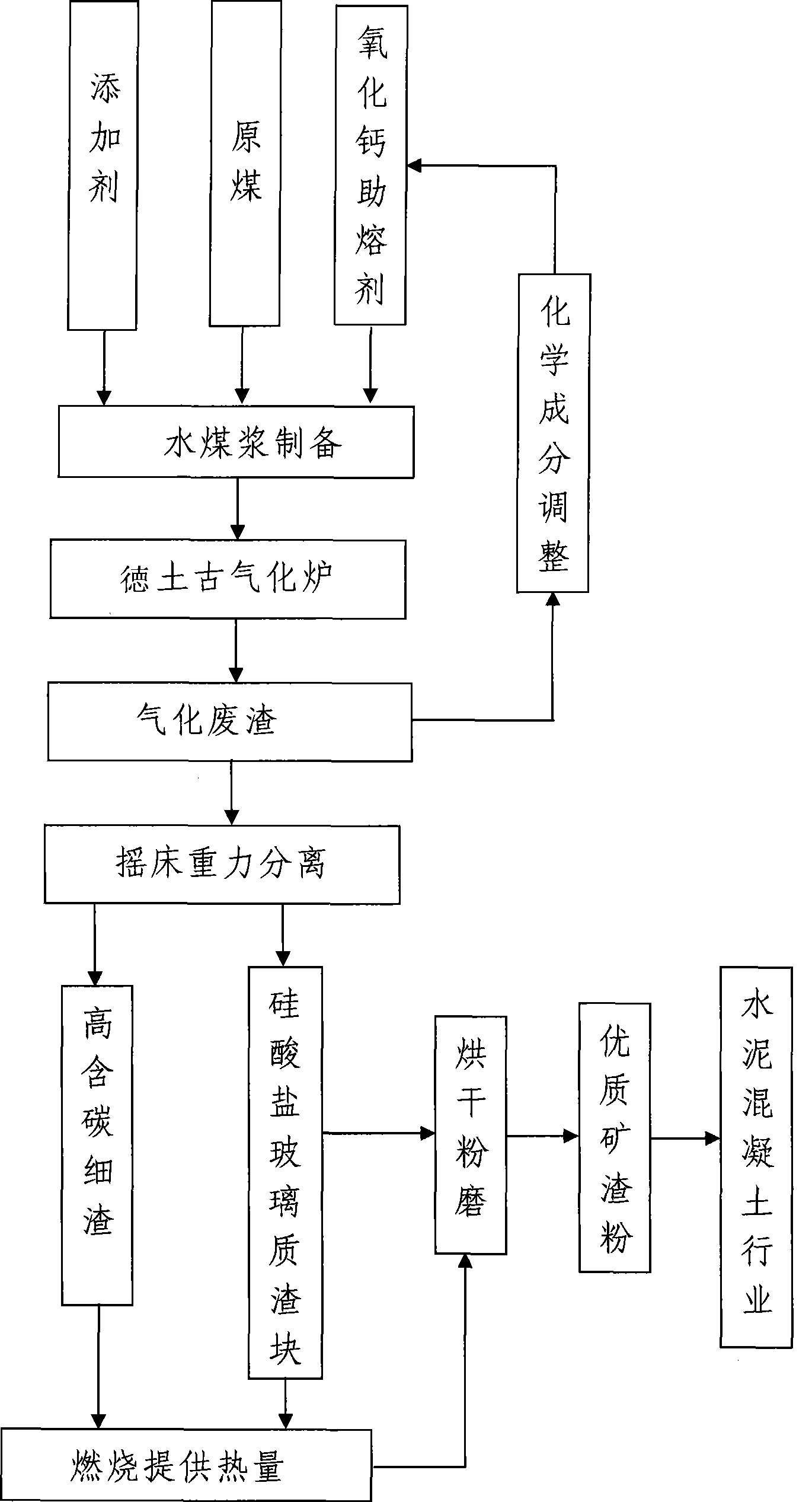

Method used

Image

Examples

Embodiment 1

[0024] Add 10% lime by weight of high-calcium coal to Shenfu high-calcium coal for gasification, prepare coal-water slurry, gasify in Texaco gasifier, and obtain gasification waste residue, which is separated by gravity on a shaking table. After separation, the waste residue contains The amount of water is 35.58% (WT); the obtained silicate vitreous slag block after waste slag separation accounts for 75% (WT) of the total waste slag; black coke powder accounts for 25% (WT); the alkalinity coefficient of the silicate vitreous slag is 1.15, passed The vertical mill or ball mill with drying function will grind and dry the silicate glassy waste residue, and after grinding and drying, the specific surface area will be 370m 2 Silicate vitreous waste slag powder per kg, according to the national standard (GB / T18046-2000) "Granulated blast furnace slag powder used in cement and concrete" test, each age (3 days, 7 days, 28 days) , 90 days) activity coefficient A3=69%, A7=74.1%, A28=98%...

Embodiment 2

[0026] Process is the same as the waste slag of embodiment 1, obtains specific surface area 500m after grinding and drying 2 / kg, according to the national standard (GB / T18046-2000) "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" test, the activity coefficients of each age are A3=72%, A7=83%, A28=112%, A90 = 128%.

Embodiment 3

[0028] Process is the same as the waste slag of embodiment 1, obtains specific surface area 700m after grinding and drying 2 / kg, according to the national standard (GB / T18046-2000) "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" test, the activity coefficient of each age is A3=98%, A7=110%, A28=123%, A90 = 141%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com