Waterborne polyurethane emulsified asphalt concrete as well as preparation method and application thereof

A technology of water-based polyurethane and emulsified asphalt, which is applied in the field of road engineering, can solve the problems of low content of water-based polyurethane, no application performance evaluation, insufficient contribution of strength, etc., and achieve easy modification, excellent mechanical properties, stability and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

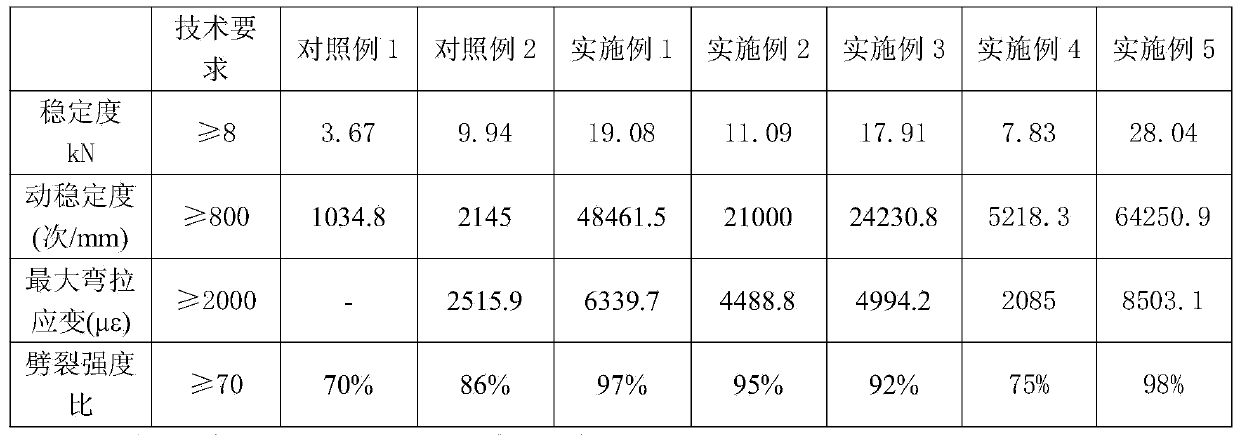

Examples

Embodiment 1

[0035] 1) Preparation of emulsified asphalt

[0036] Prepare materials according to the following weight ratio:

[0037] Bitumen 110g

[0038] water 90g

[0039] Sodium Lauryl Sulfate 4g

[0040] Mix water and sodium dodecylsulfonate, and stir at 60°C to fully dissolve into a uniform emulsion, and use sodium hydroxide buffer to control the pH of the emulsion at 12; heat the asphalt to 140°C, pour Emulsification was carried out in the prepared homogeneous emulsion, and the emulsification time was 4 minutes; the solid content of the prepared emulsified asphalt was 54%.

[0041] 2) Preparation of waterborne polyurethane emulsified asphalt concrete

[0042] Mix 100g of emulsified asphalt with 40g of water-based polyurethane emulsion, and use a low-speed stirrer to fully stir for 5 minutes to obtain a uniform, non-sticky brown mixture, which is the water-based polyurethane emulsified asphalt emulsion;

[0043] Put the water-based polyurethane emulsified asphalt emulsion in a m...

Embodiment 2

[0047] 1) Preparation of emulsified asphalt

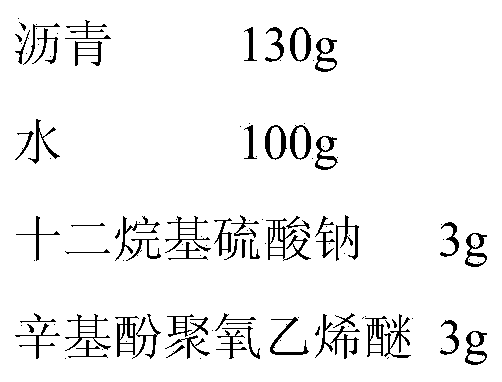

[0048] Prepare materials according to the following weight ratio:

[0049] Bitumen 160g

[0050] water 50g

[0051] Octylphenol ethoxylate 2g

[0052] Mix water and octylphenol polyoxyethylene ether, and stir at 55°C to fully dissolve into a homogeneous emulsion; heat the asphalt to 120°C, pour it into the prepared homogeneous emulsion for emulsification, and the emulsification time is 5 minutes; The solid content of emulsified bitumen is 75%.

[0053] 2) Preparation of waterborne polyurethane emulsified asphalt concrete

[0054] Mix 200g of nonionic emulsified asphalt with 10g of water-based polyurethane emulsion, and use a low-speed stirrer to fully stir for 10 minutes to obtain a uniform, non-sticky brown mixture, which is the water-based polyurethane emulsified asphalt emulsion;

[0055] Put the water-based polyurethane emulsified asphalt emulsion in a mixing pot, add 1000g of mineral material, stir at room temperature for...

Embodiment 3

[0059] 1) Preparation of emulsified asphalt

[0060] Prepare materials according to the following weight ratio:

[0061] Bitumen 40g

[0062] water 60g

[0063] Cetyltrimethylammonium Chloride 1g

[0064] Mix water and cetyltrimethylammonium chloride, and stir at 65°C to fully dissolve into a uniform emulsion, and use hydrochloric acid buffer to control the pH of the emulsion at 3; heat the asphalt to 160°C; The heated asphalt is poured into the prepared emulsion for emulsification, and the emulsification time is 3 minutes; the solid content of the prepared emulsified asphalt is 40%.

[0065] 2) Preparation of waterborne polyurethane emulsified asphalt concrete

[0066] Mix 70g of cationic emulsified asphalt with 200g of water-based polyurethane emulsion, and use a low-speed stirrer to fully stir for 2 minutes to obtain a uniform, non-sticky brown mixture, which is the water-based polyurethane emulsified asphalt emulsion;

[0067] Put the water-based polyurethane emulsifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com