Patents

Literature

150results about How to "Reduced flow cross section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

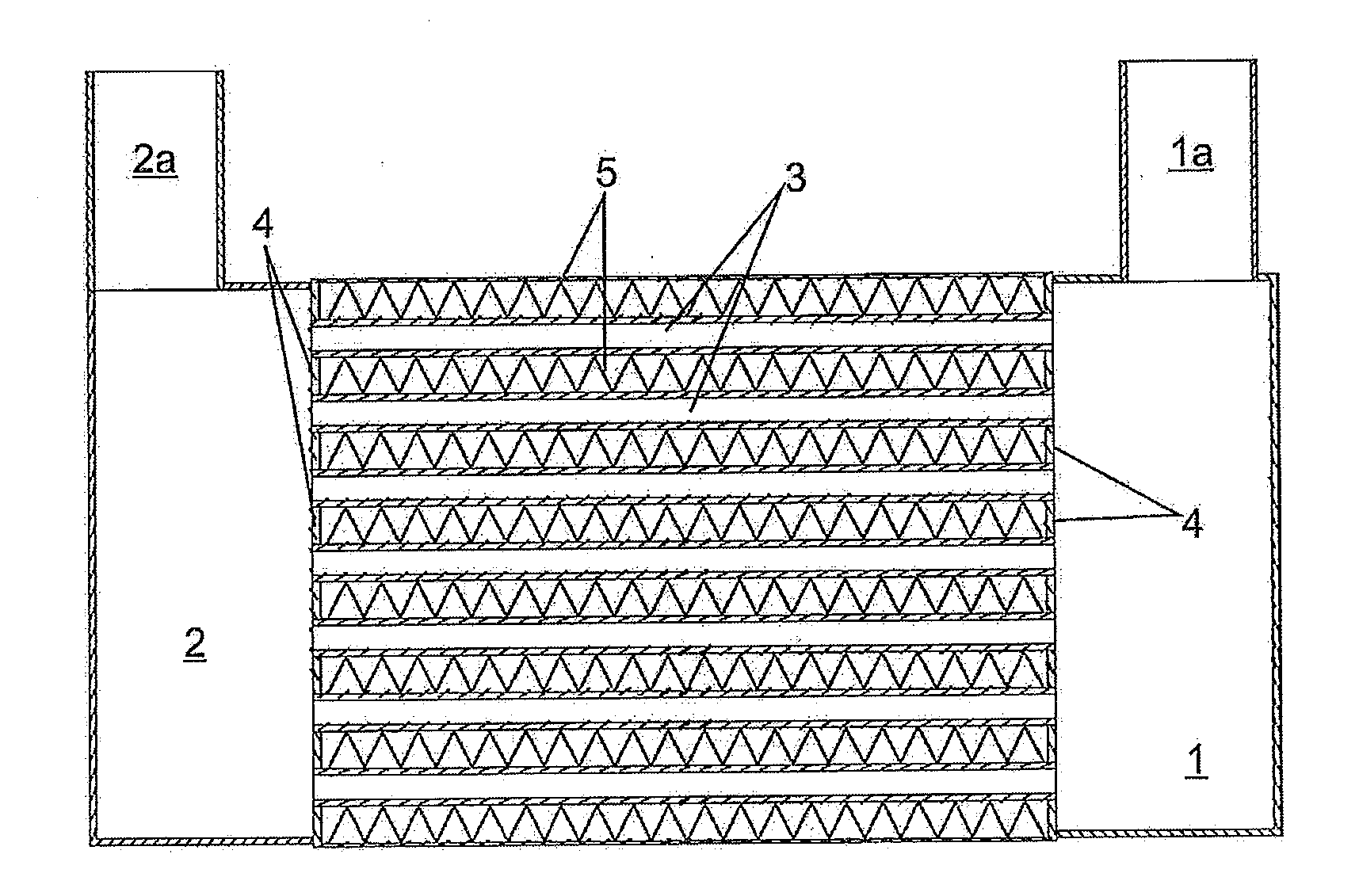

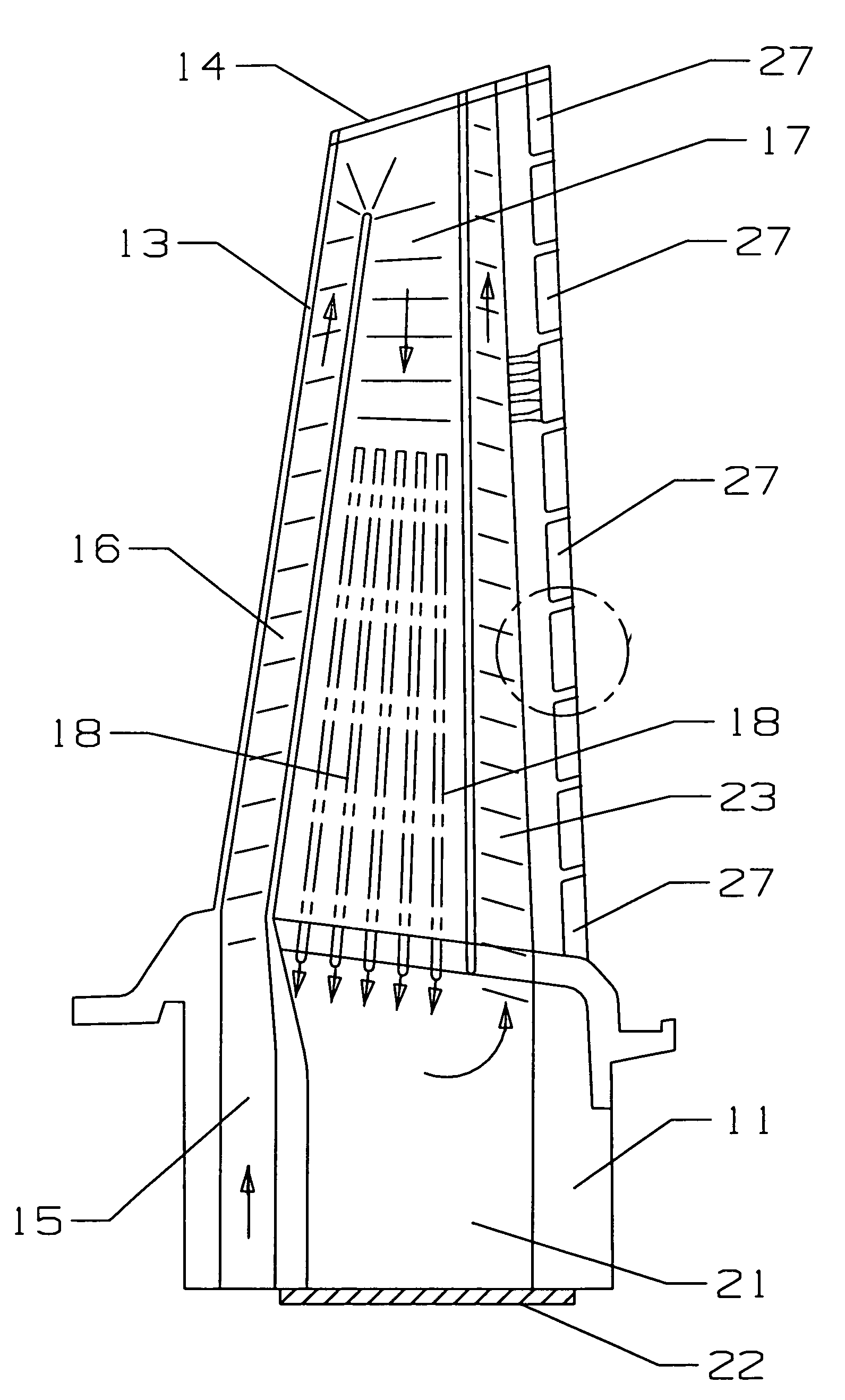

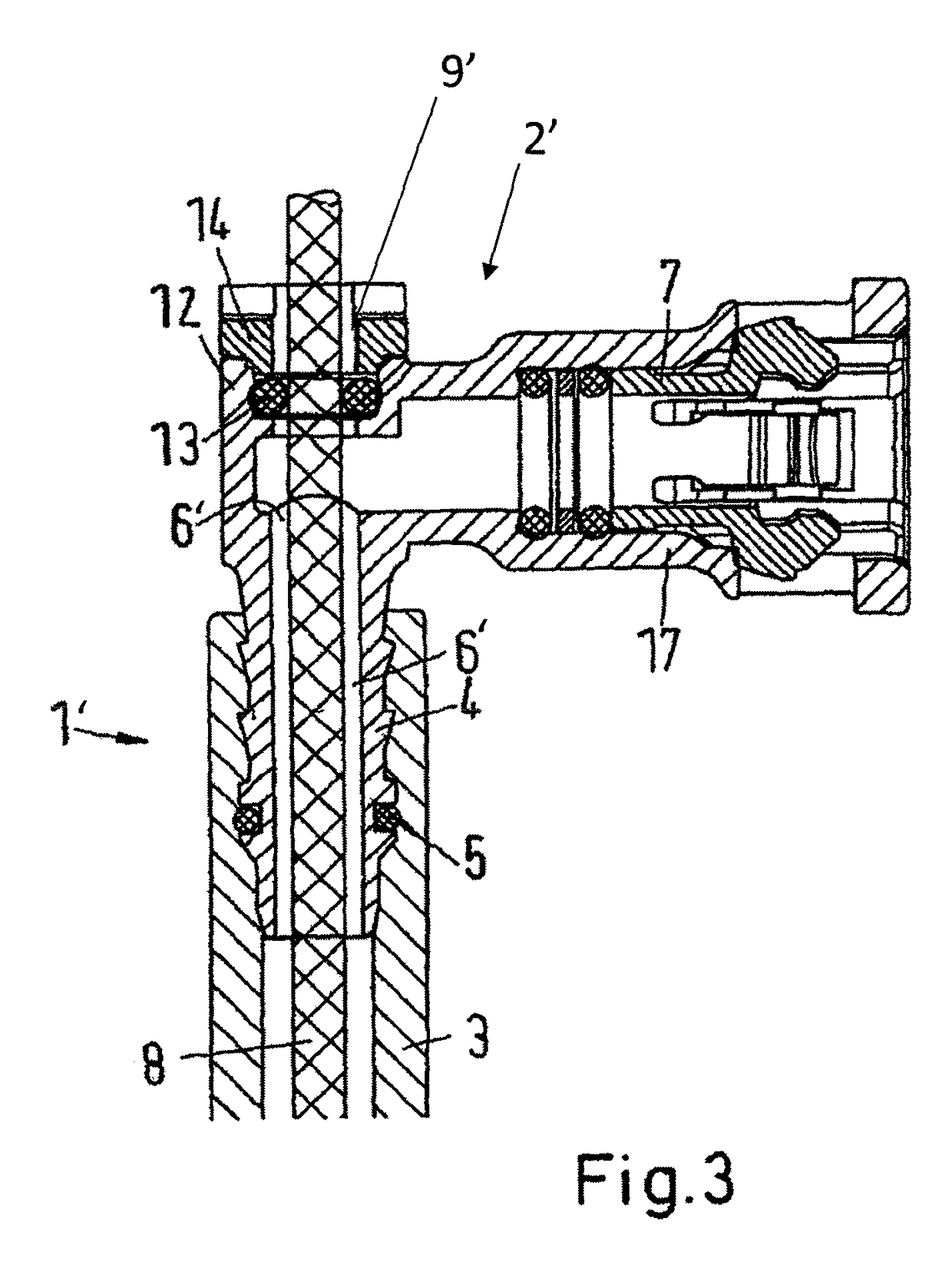

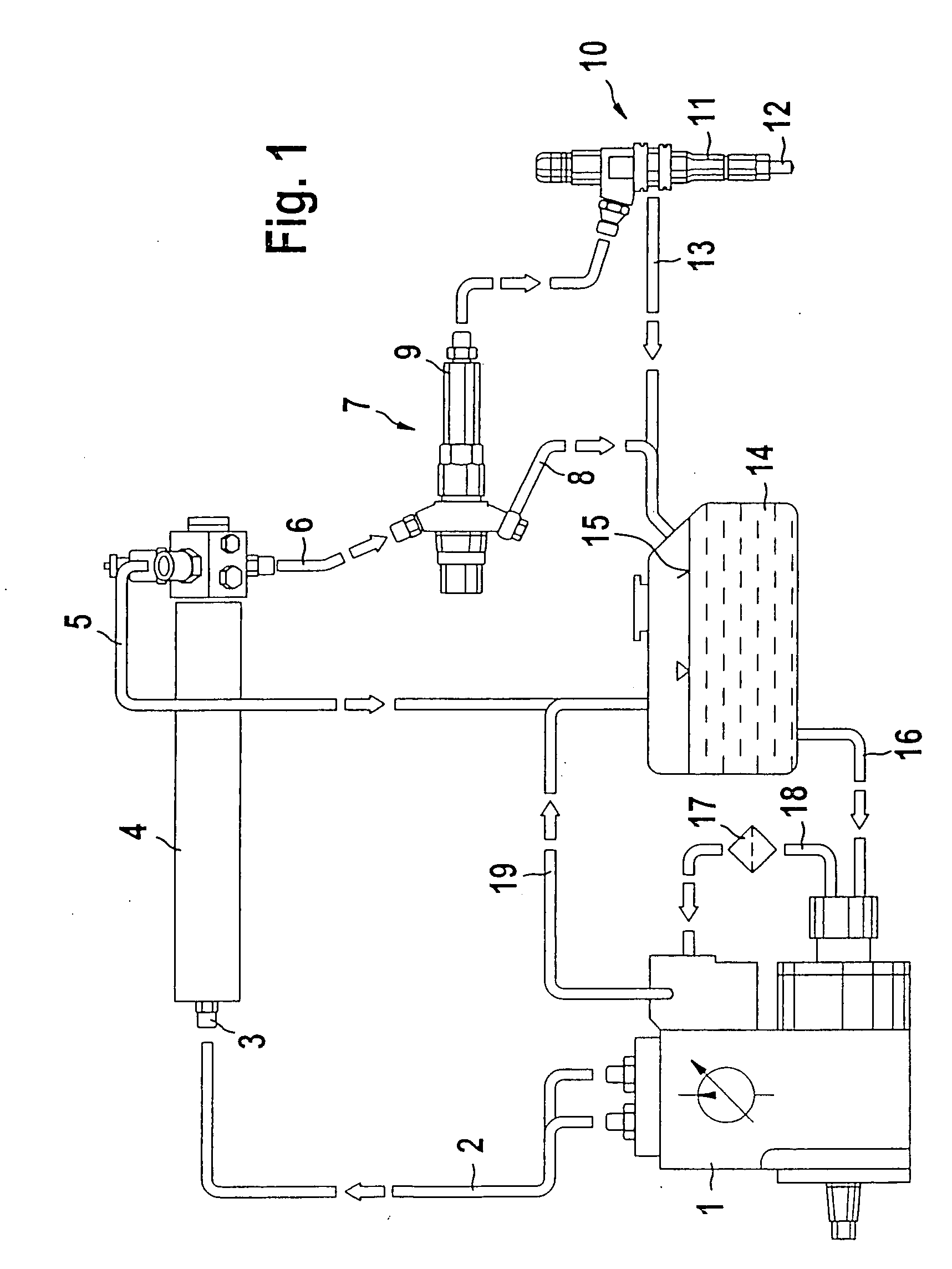

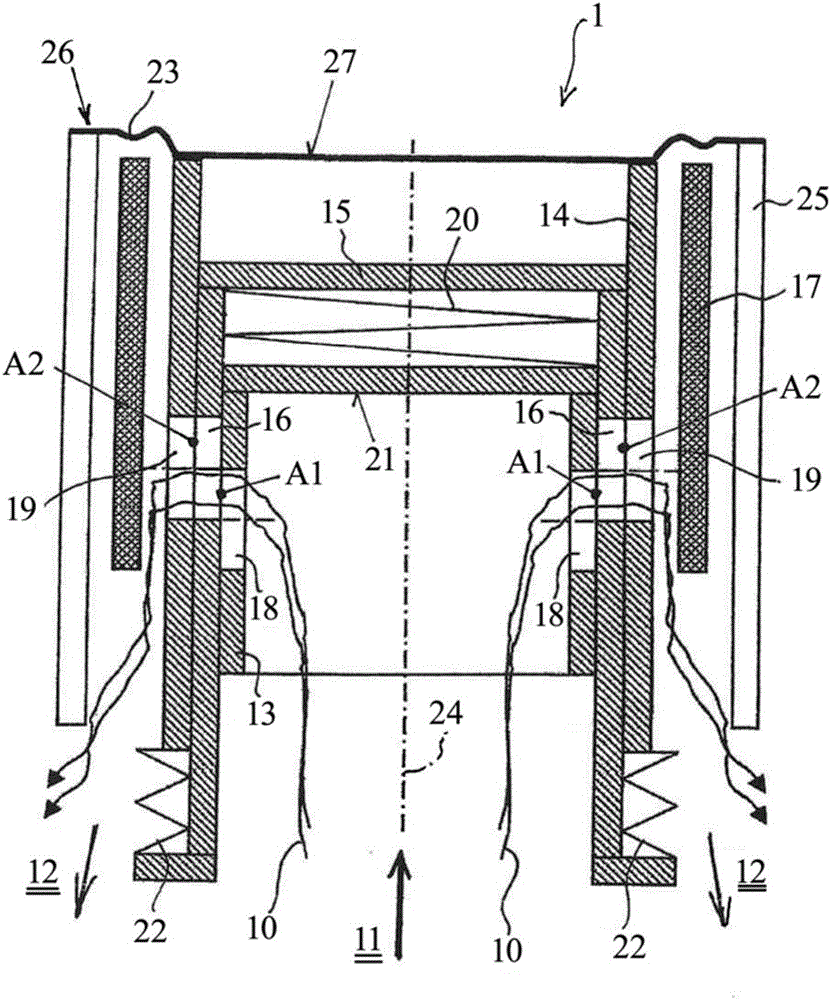

Heat exchanger

InactiveUS20100300647A1Promote atomizationReduce gas flowRecuperative heat exchangersMachines/enginesExternal combustion engineProcess engineering

A heat exchanger, in particular a charge air cooler or an exhaust gas cooler for an internal combustion engine, comprising a plurality of essentially parallel tubes and at least one collector box on the output side, the tubes each emptying into the collector box on the output side, and a gas flow flowing from the tubes into the collector box and from the collector box into an outlet of the collector box, a structure for interacting with the gas flow being provided at least one of the tubes or collector box, a condensation being transported to the outlet with the aid of the structure.

Owner:MAHLE INT GMBH

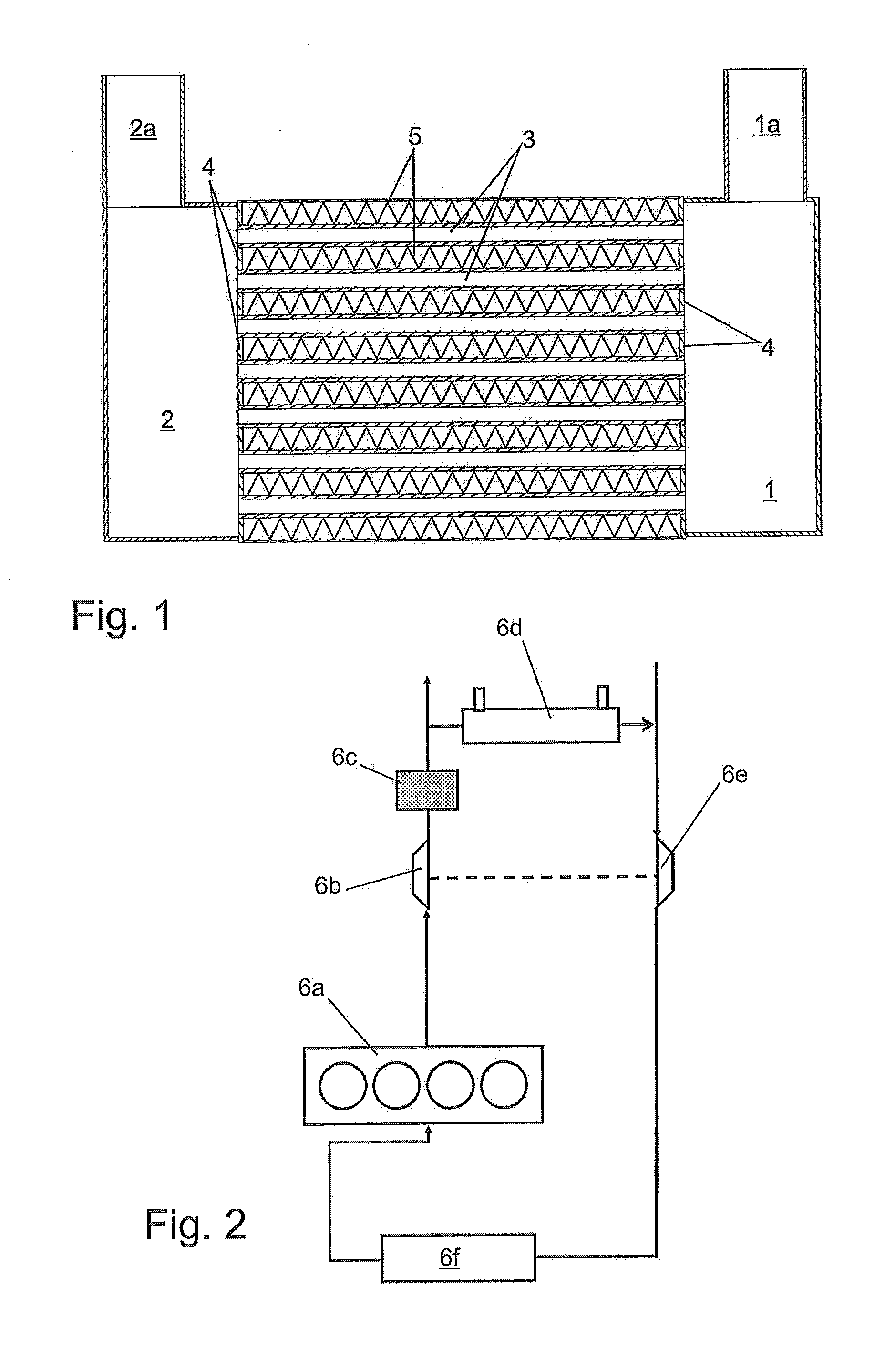

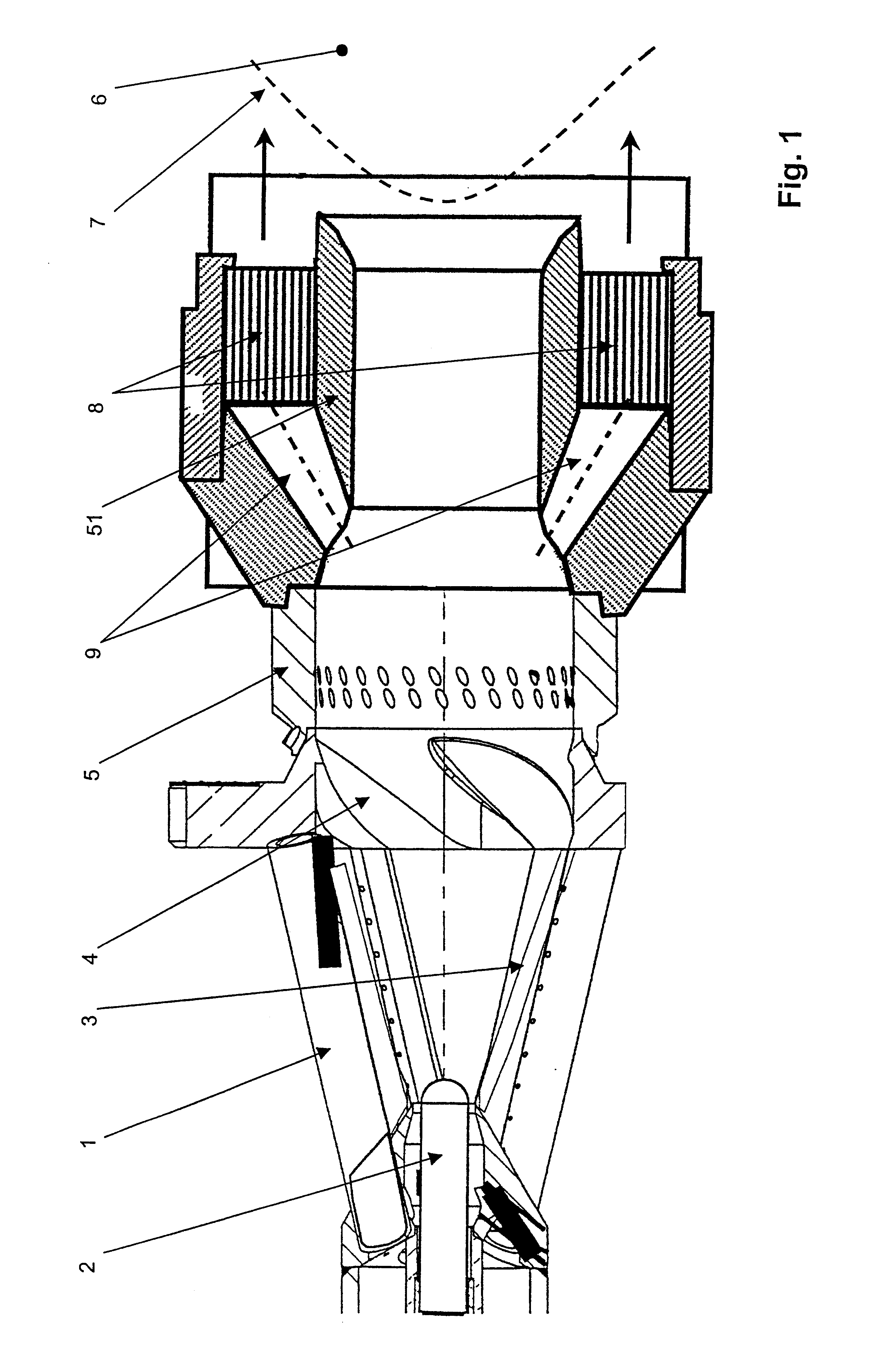

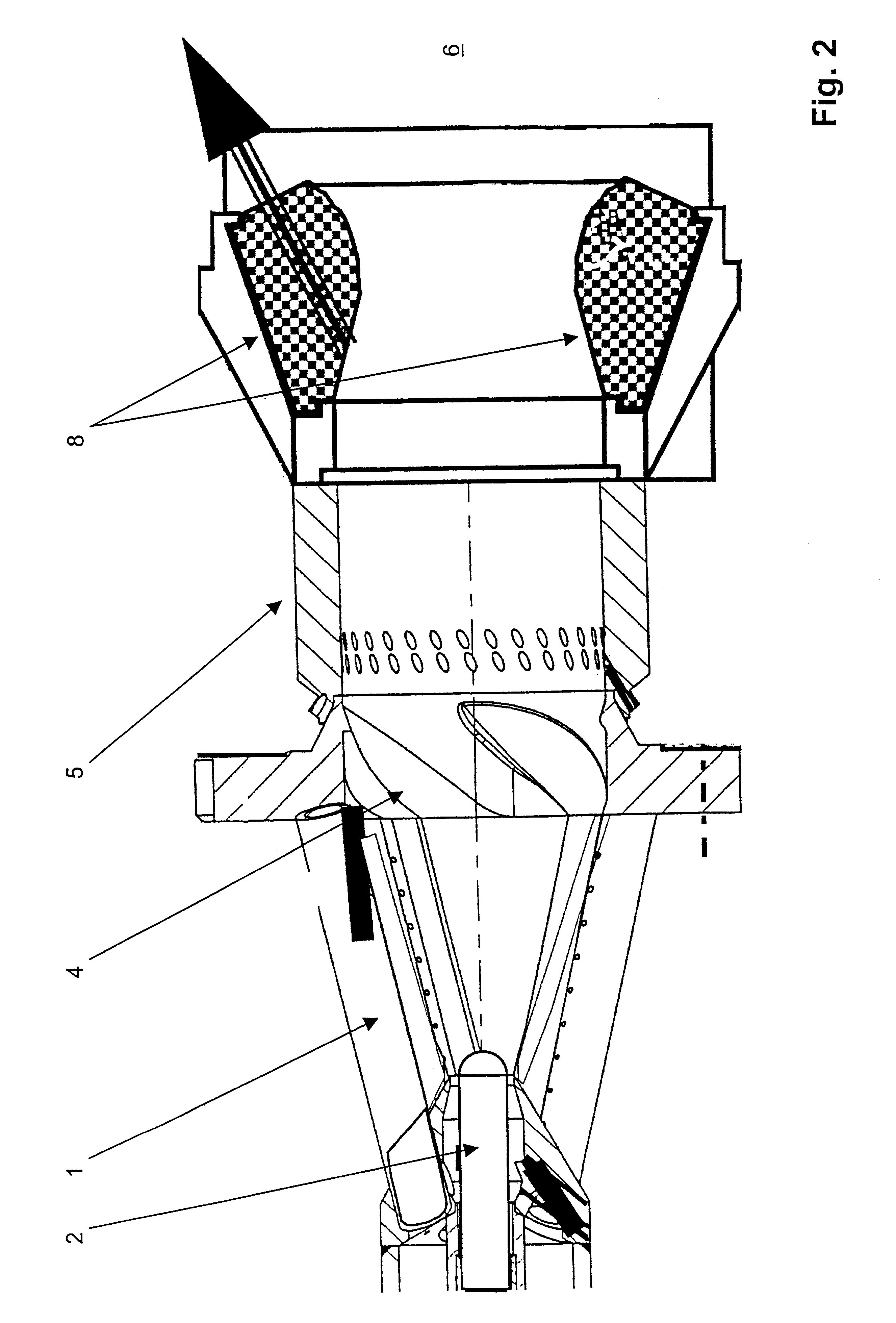

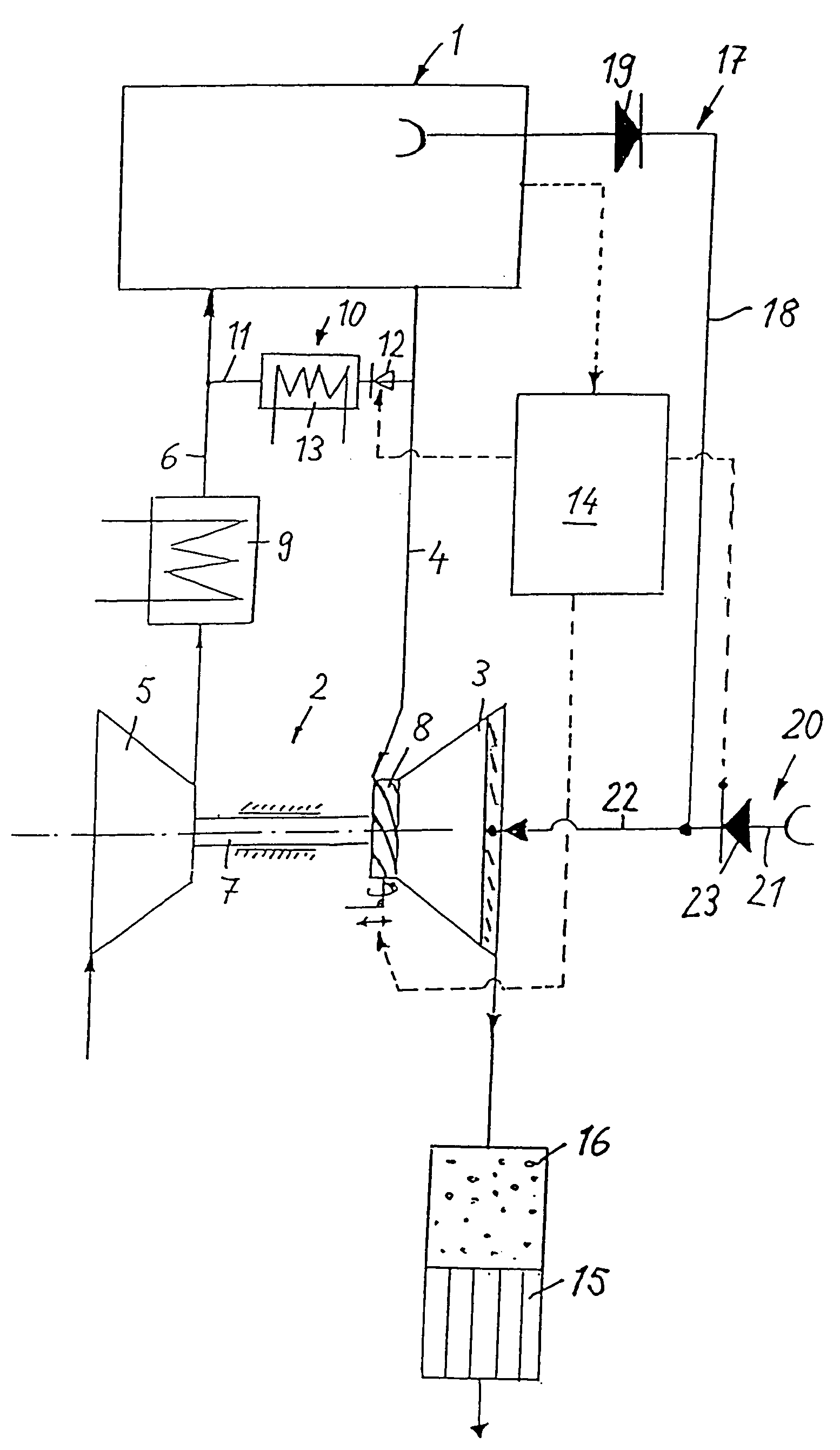

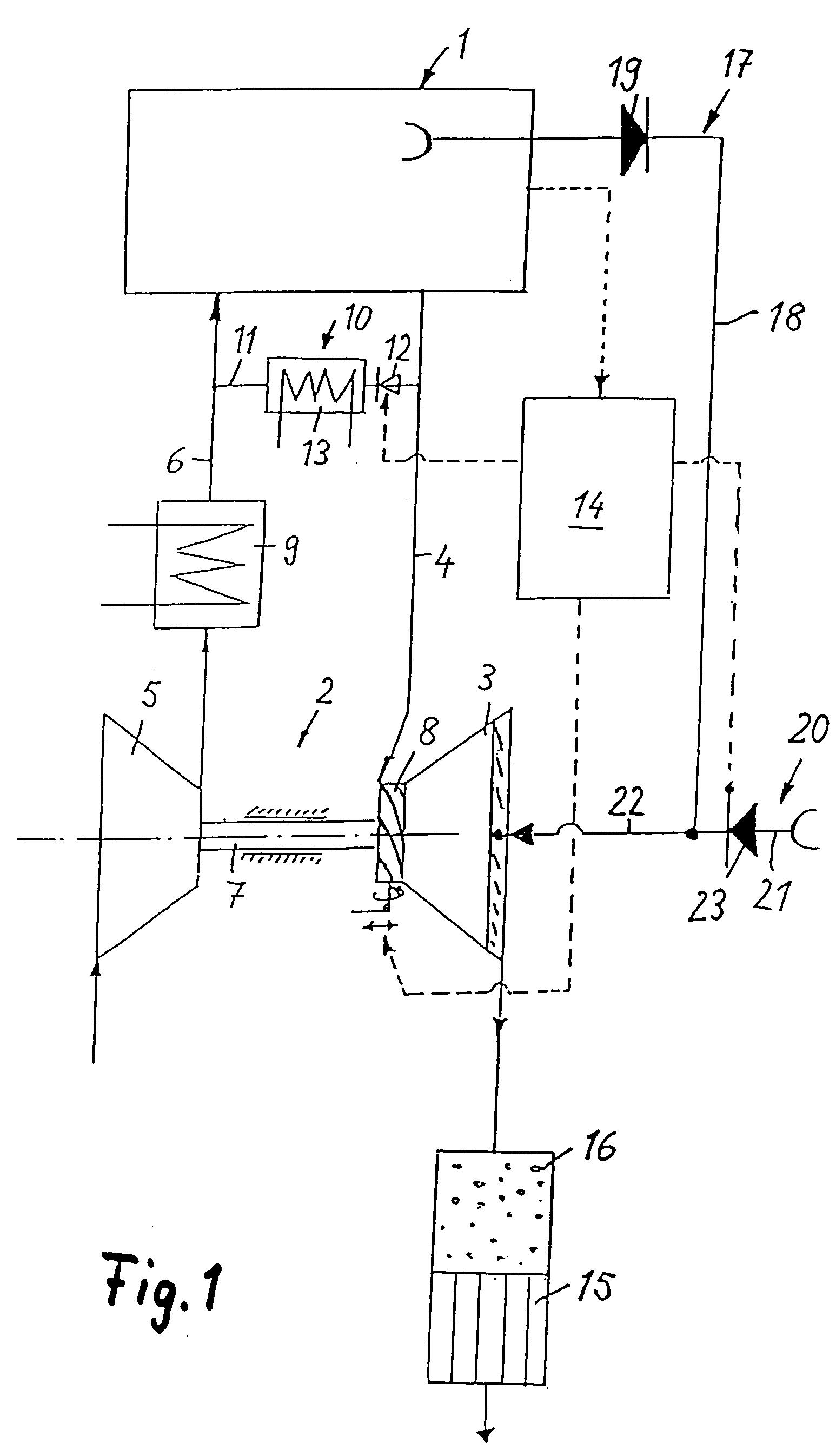

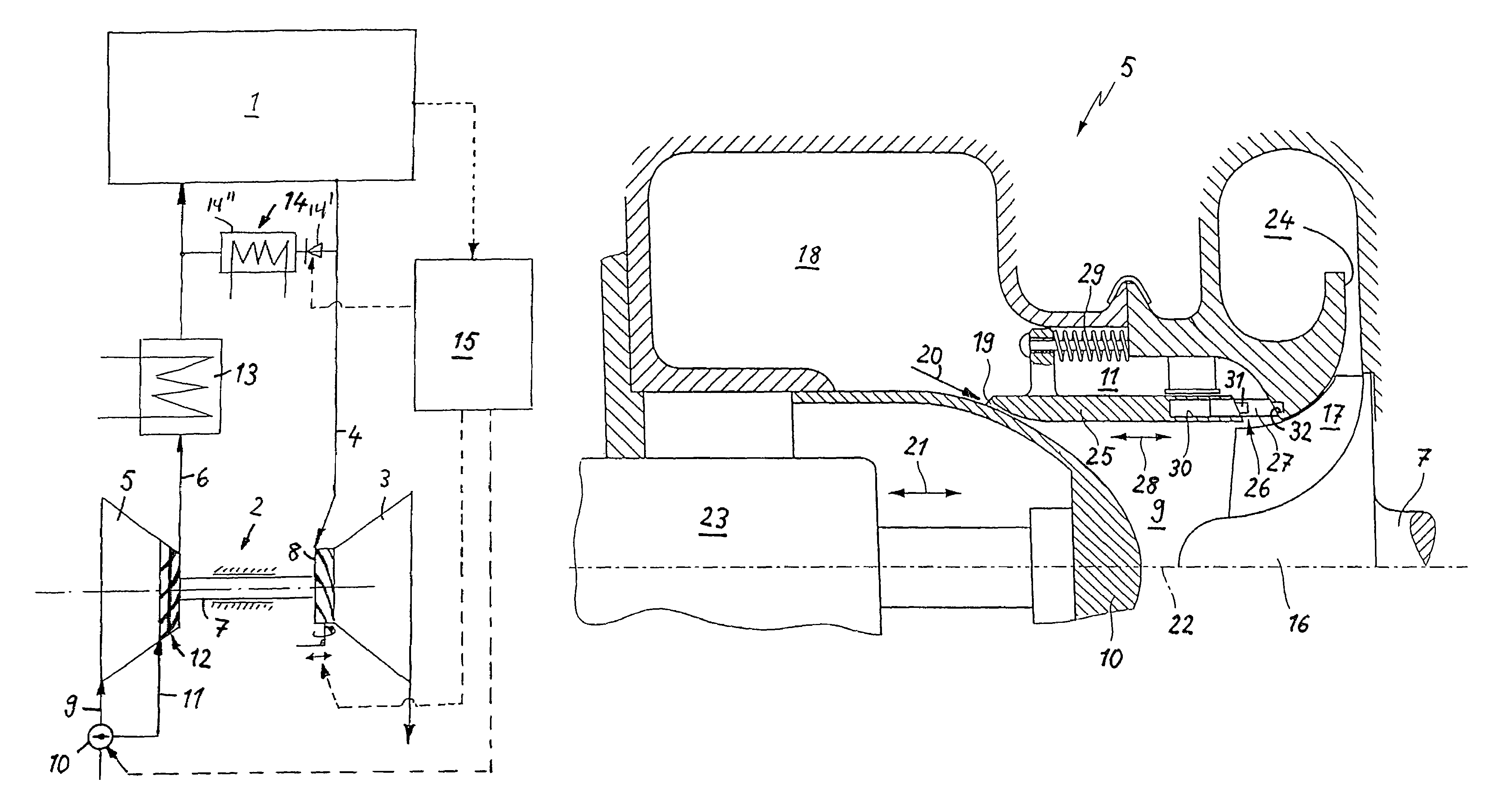

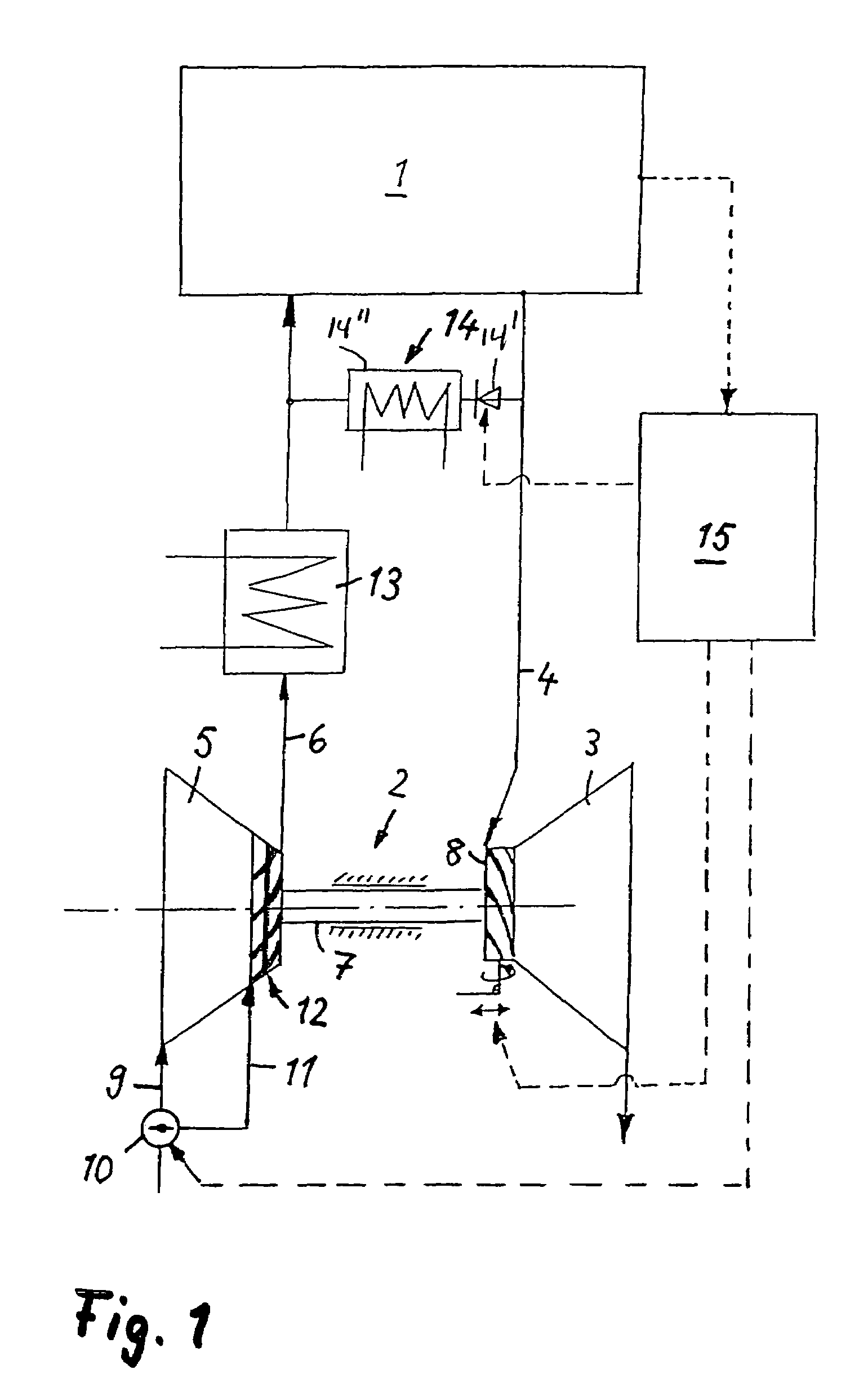

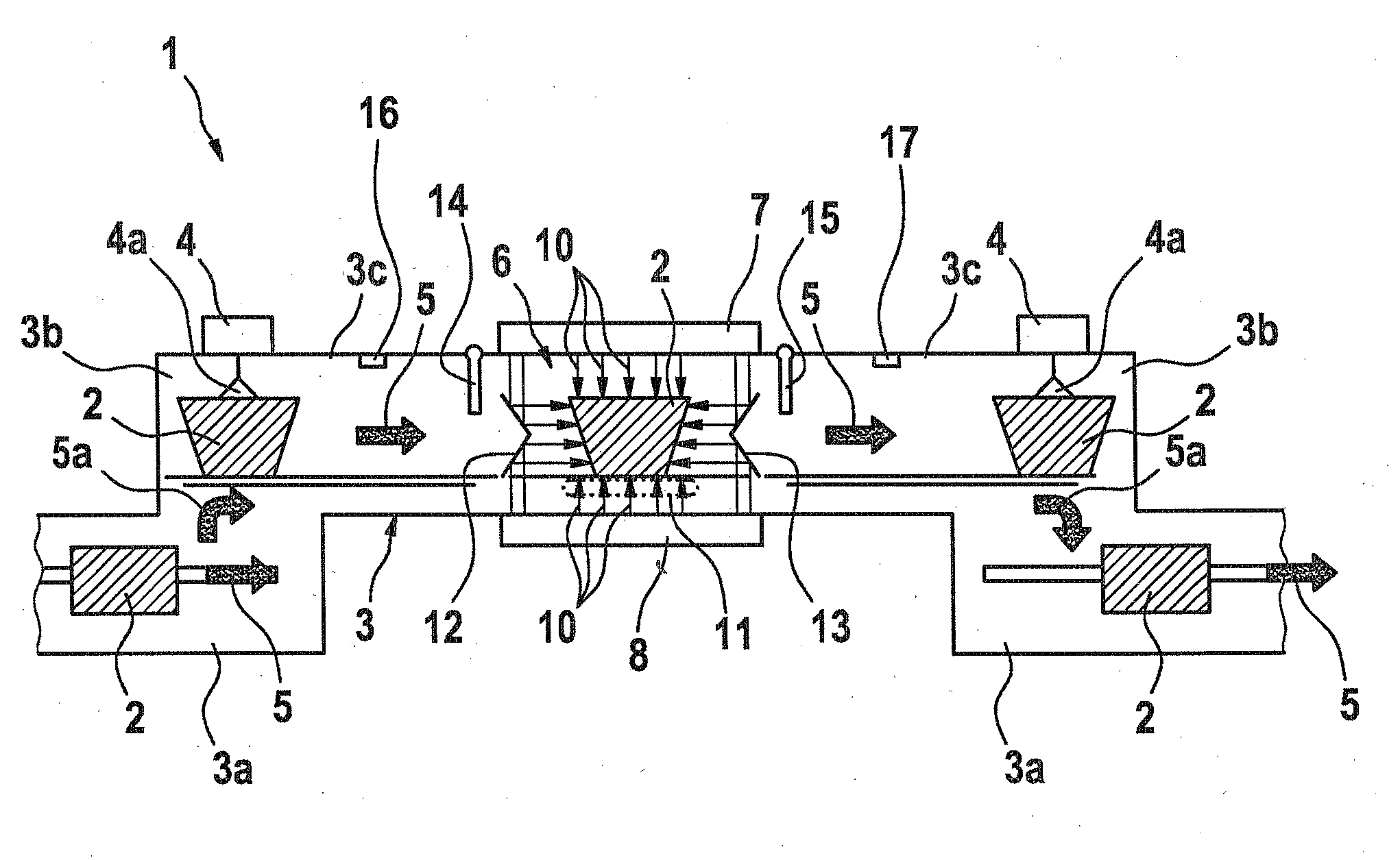

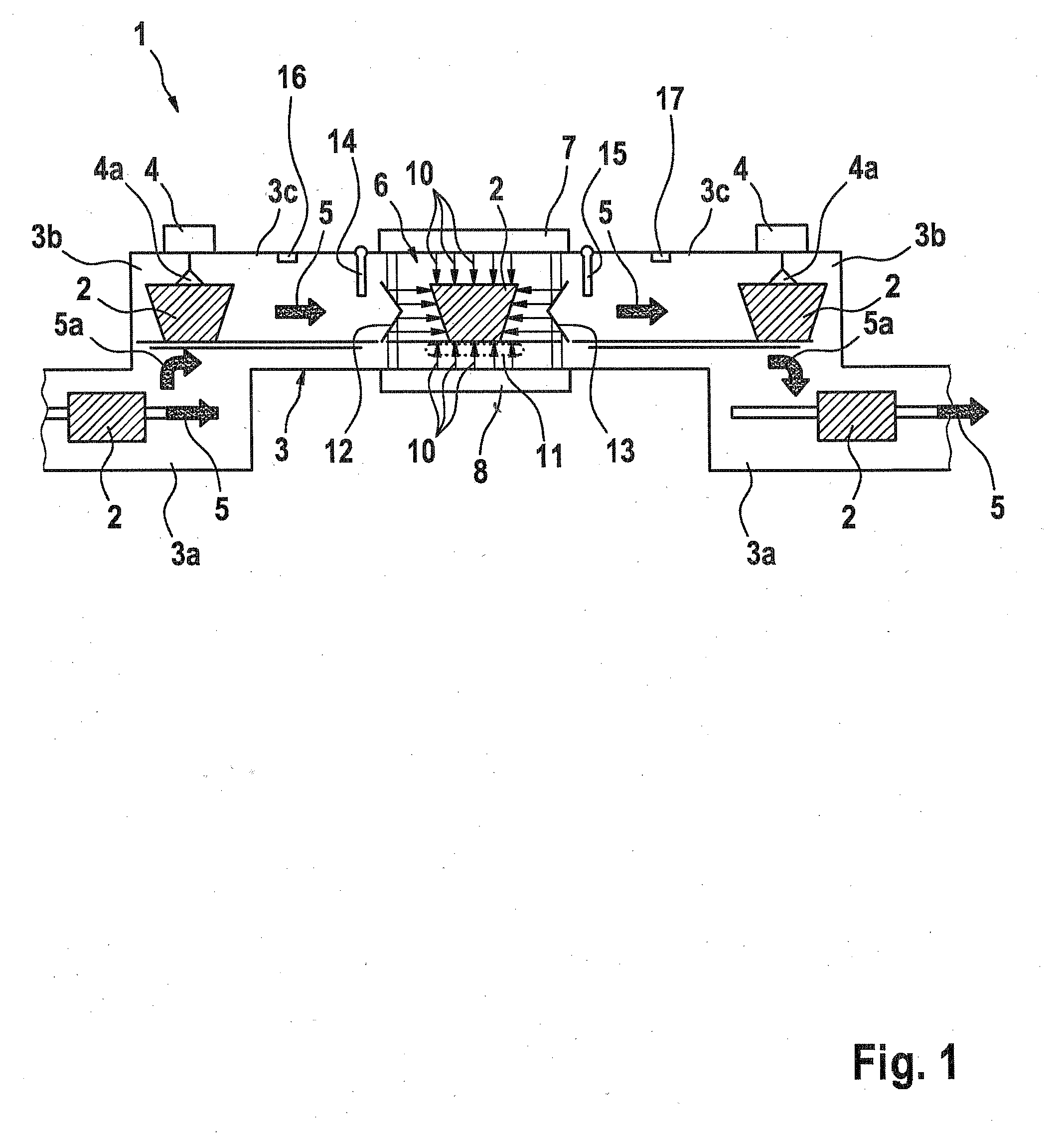

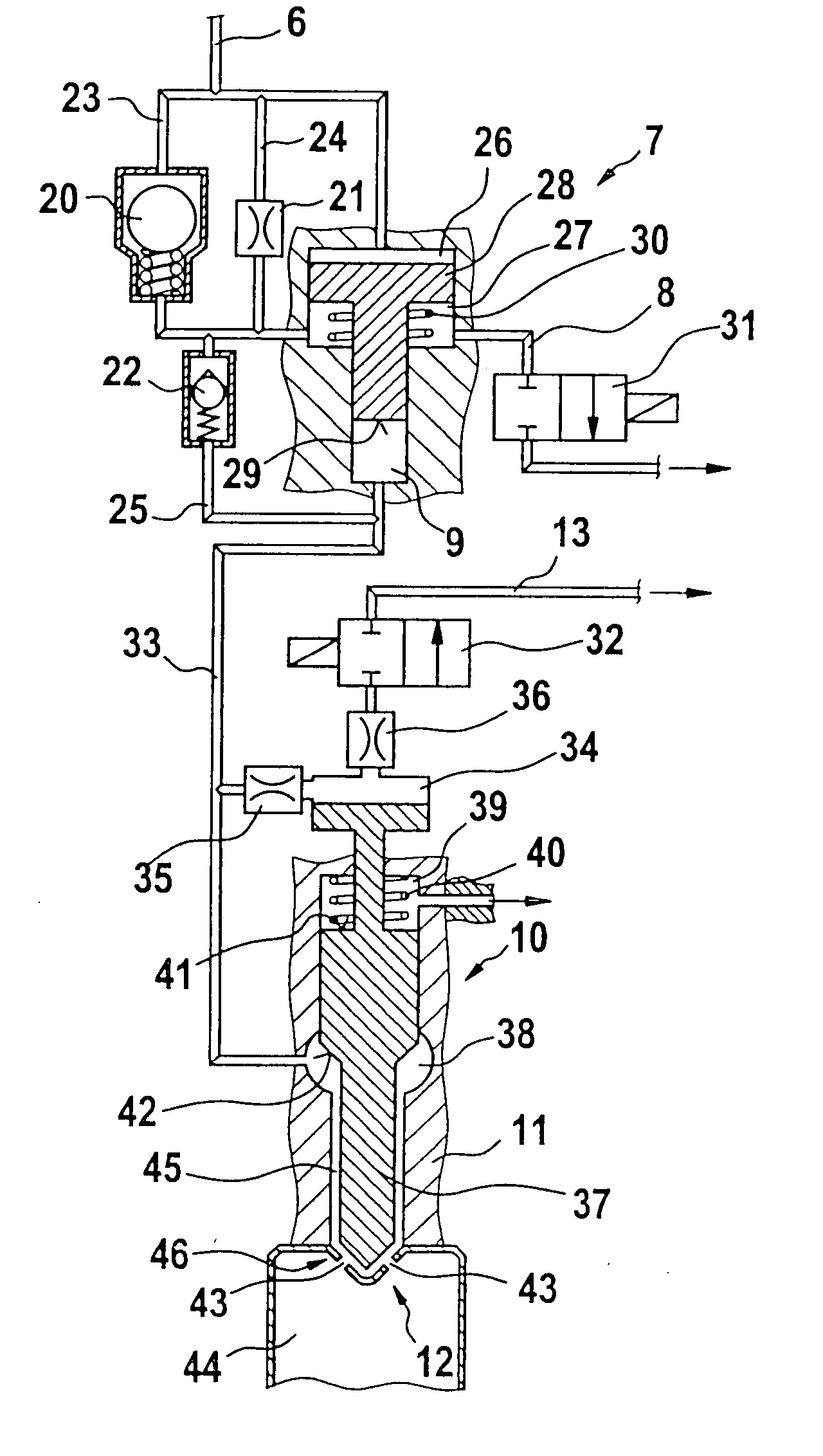

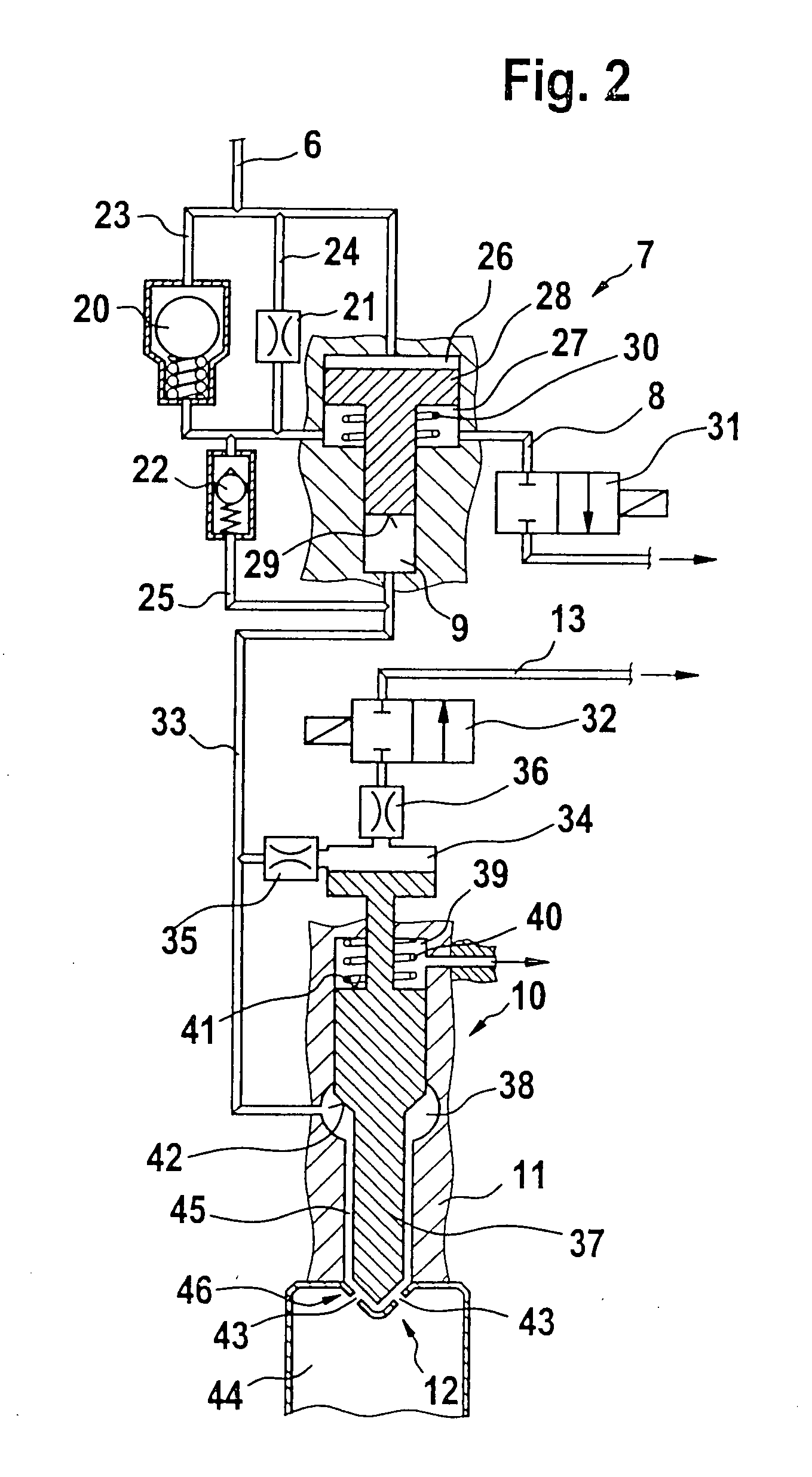

Premix burner arrangement with catalytic combustion and method for its operation

InactiveUS6625988B2Reduced flow cross sectionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustion chamberCombustor

A premix burner arrangement with catalytic combustion provides a fuel / air mixture to a combustion chamber of a gas turbine arrangement. The premix burner arrangement includes a premix burner, at least one fuel addition unit, and air inlet openings arranged in such a way that at least one of gaseous and liquid fuel can be mixed with combustion inlet air inside the premix burner to form a fuel / air mixture. The fuel / air mixture exits from the premix burner downstream in the direction towards a combustion chamber positioned after the premix burner arrangement and can be ignited inside the combustion chamber. A catalyzer unit is provided before the entrance of the fuel / air mixture into the combustion chamber. Part of the fuel / air mixture can be introduced into and passed through the catalyzer unit before the catalyzed part of the fuel / air mixture flows together with the remaining portion of the fuel / air mixture into the combustion chamber.

Owner:GENERAL ELECTRIC TECH GMBH

Device for determining at least one parameter of a medium flowing in a conduit

ActiveUS7162920B2Reduce total pressure lossAvoiding undesirable pulsation in flowElectrical controlVolume/mass flow by thermal effectsInternal combustion engineMechanics

Devices are previously known for determining at least one parameter of a medium flowing in a conduit, in particular for determining the air mass flow in the intake section of an internal combustion engine, having a conduit part and a sensor device that has a bypass part. In order to avoid a flow detachment at the side walls of the bypass part, it is provided that a flow vane, running at least approximately parallel to a side wall, provided with a separation opening, of the bypass part, be provided in a conduit part behind a separation opening, seen in the main flow direction, and that the conduit part be provided, in the area of the bypass part, with at least one projection that protrudes from an inner wall of the conduit part towards the bypass part.

Owner:ROBERT BOSCH GMBH

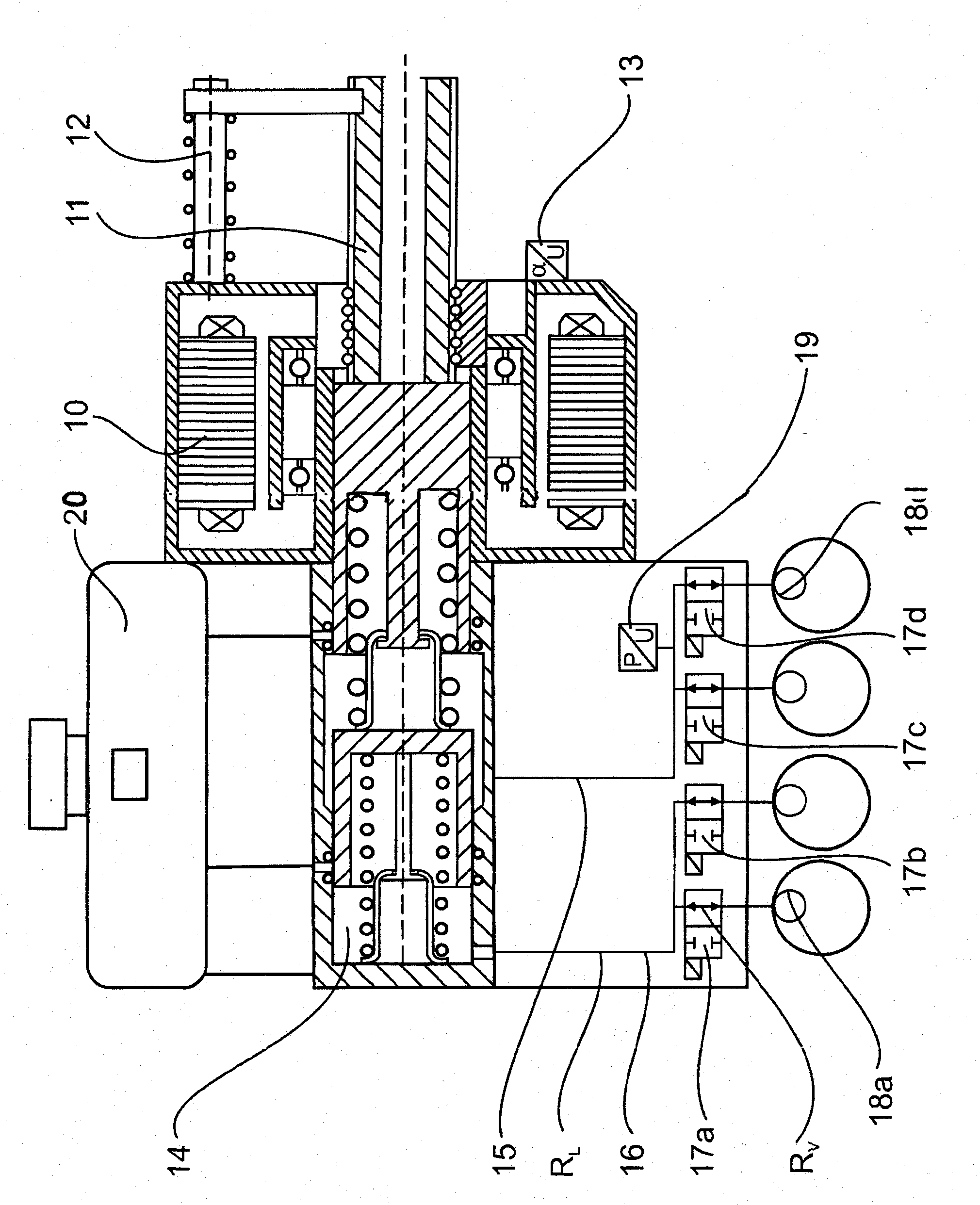

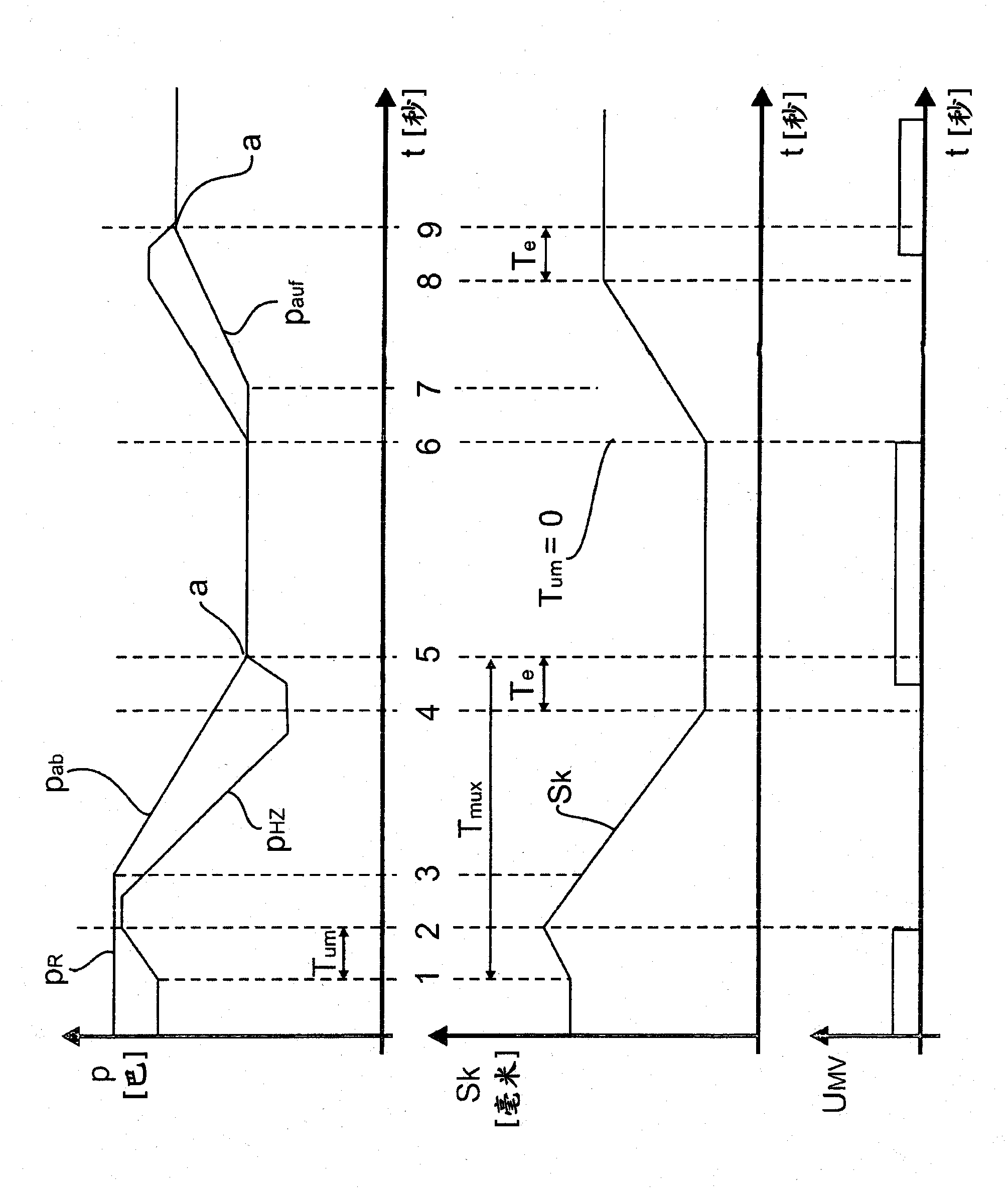

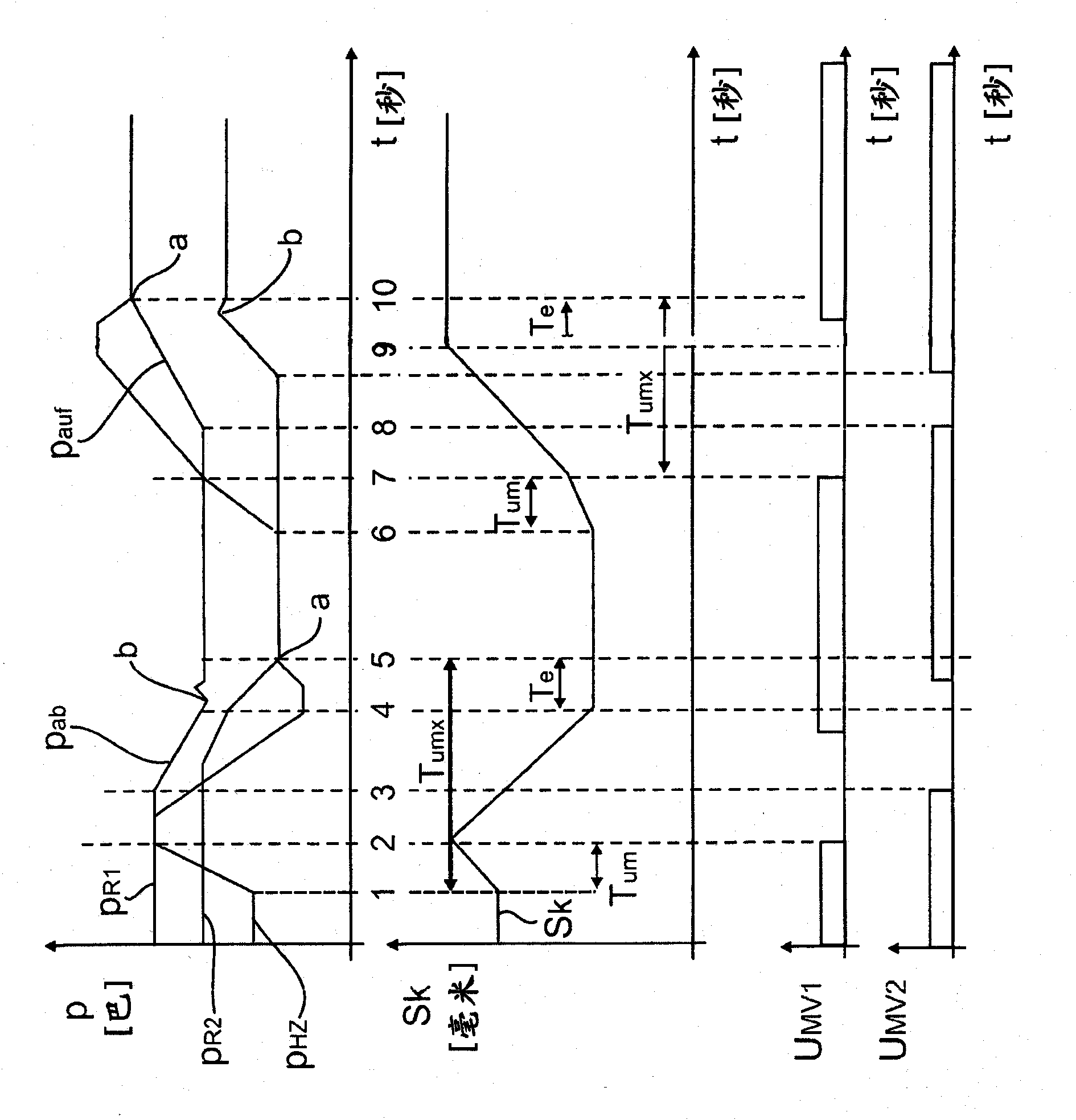

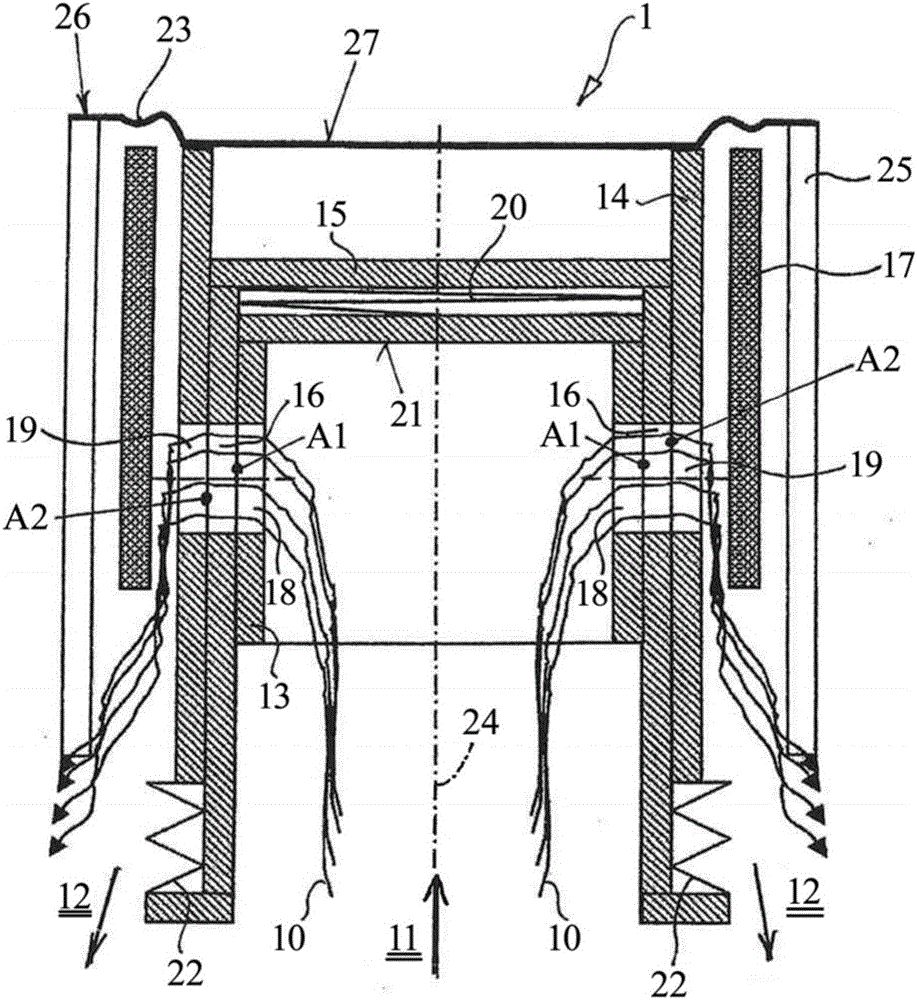

Brake system having simultaneous or partially simultaneous pressure generation and reduction in the wheel brakes from differing wheel cylinder pressure levels

ActiveCN102325676AReduced flow cross sectionIncrease flow resistanceBraking action transmissionPressure generationMultiplexer

The invention relates to a braking system having a brake booster, the piston-cylinder system (14, HZ, THZ) thereof being driven by an electrical motor, wherein at least one working chamber of the piston-cylinder system (14, HZ, THZ) is in connection to at least two wheel brakes via hydraulic lines, wherein a 2 / 2-way switching valve (17a, 17b, 17c, 17d) is allocated to each wheel brake and the hydraulic connection lines between the wheel brakes (18a, 18b, 18c, 18d) and the piston-cylinder system (14, HZ) are separately or commonly closable by means of the 2 / 2-way switching valves (17a, 17b, 17c, 17d), such that a pressure can be adjusted in the wheel brakes (18a, 18b, 18c, 18d) one after another in terms of a multiplexer process and / or simultaneously, wherein the electrical motor and the switching valves (17a, 17b, 17c, 17d); are activated by a control device and the hydraulic connection line from the working chamber of the piston-cylinder system (14, HZ, THZ) to the respective magnetic valve has a flow resistance RLi and each switching valve has a flow resistance RVi together with the hydraulic line to the wheel cylinder (17a, 17b, 17c, 17d), wherein the flow resistances RLi and RVi are small, such that the HZ piston speed determines the pressure reduction gradients and pressure generation gradients in each wheel brake (18a, 18b, 18c, 18d), wherein the flow resistance RLi is smaller than the flow resistance RVi and the control device regulates or activates the piston movement and piston speed during pressure generation and pressure reduction in dependence on the pressure-volume characteristic curve of the wheel brakes (18a, 18b, 18c, 18d).

Owner:IPGATE

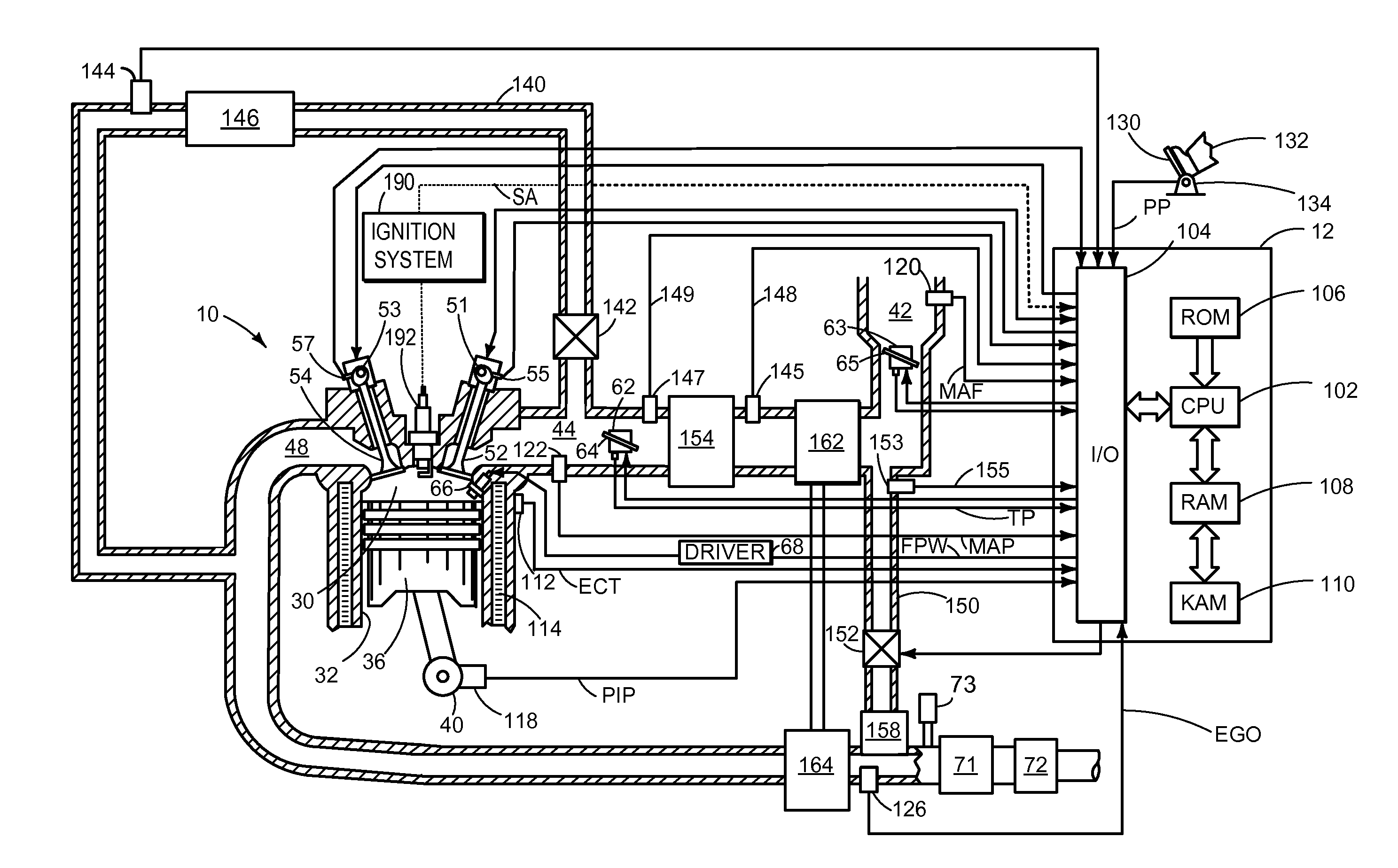

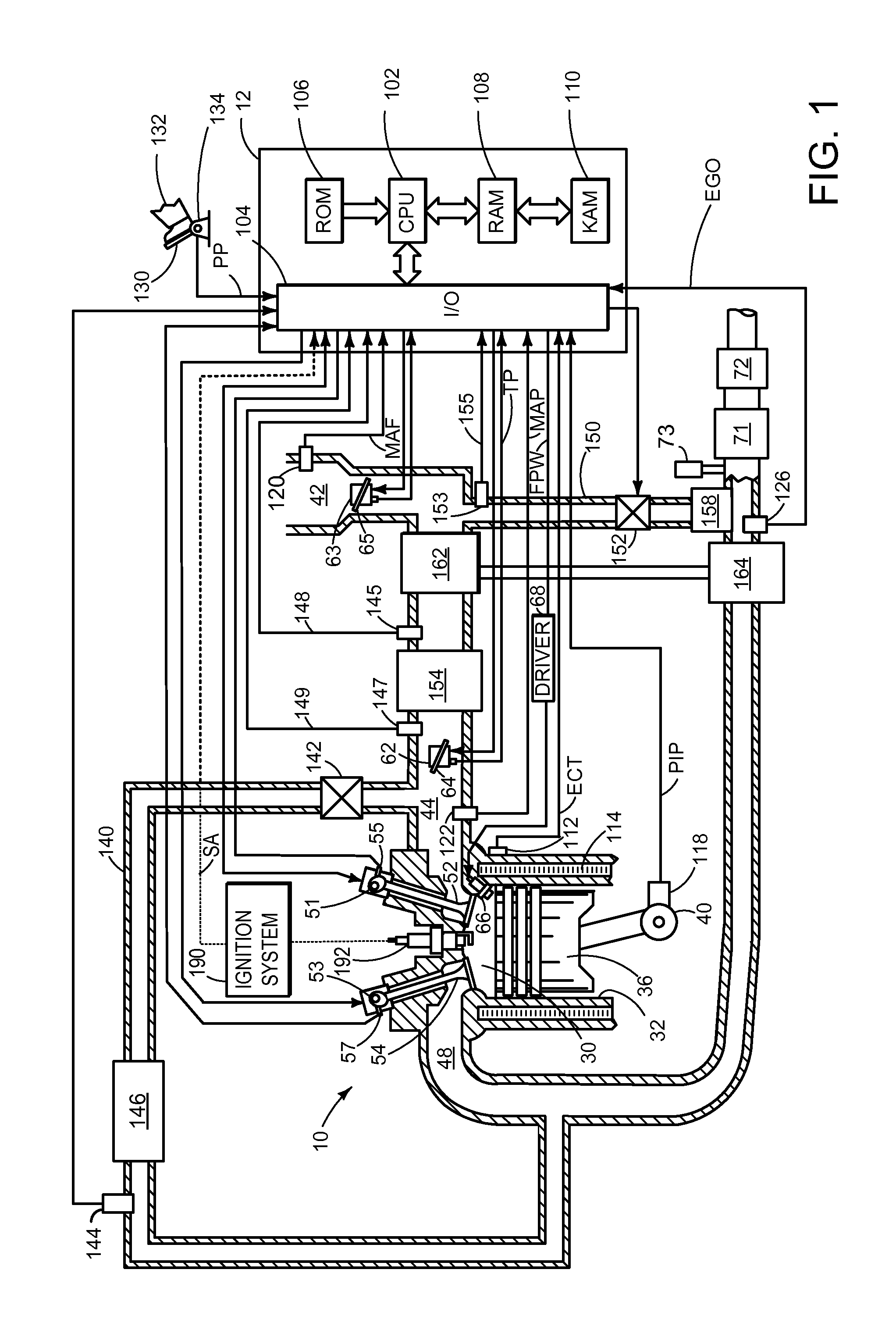

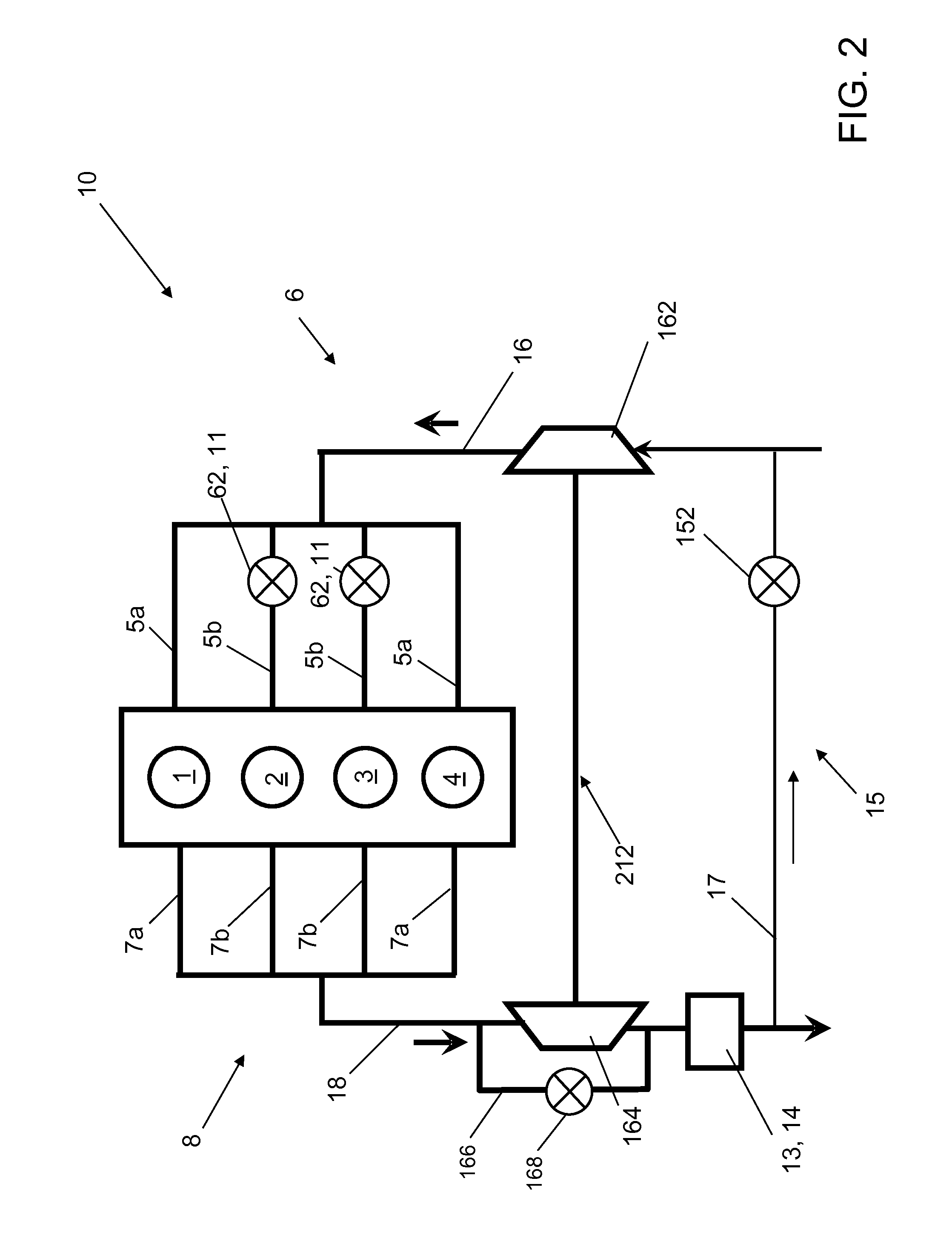

Internal combustion engine featuring partial shutdown and method for operating an internal combustion engine of this kind

ActiveUS20130333663A1Reduce the total massBoost pressure ratio likewise decreasesElectrical controlOutput powerEngine efficiencyExternal combustion engine

Systems and methods are provided for an engine wherein one group of cylinders is active and a second group of cylinders is switchable, such that under low loads the second group of cylinders is deactivated, and under high loads the second group of cylinders is activated. Following deactivation of the second group of cylinders a throttling element in an intake line for the second group of cylinders is gradually closed. The closing of the throttling element may reduce pumping losses and thus increase engine efficiency.

Owner:FORD GLOBAL TECH LLC

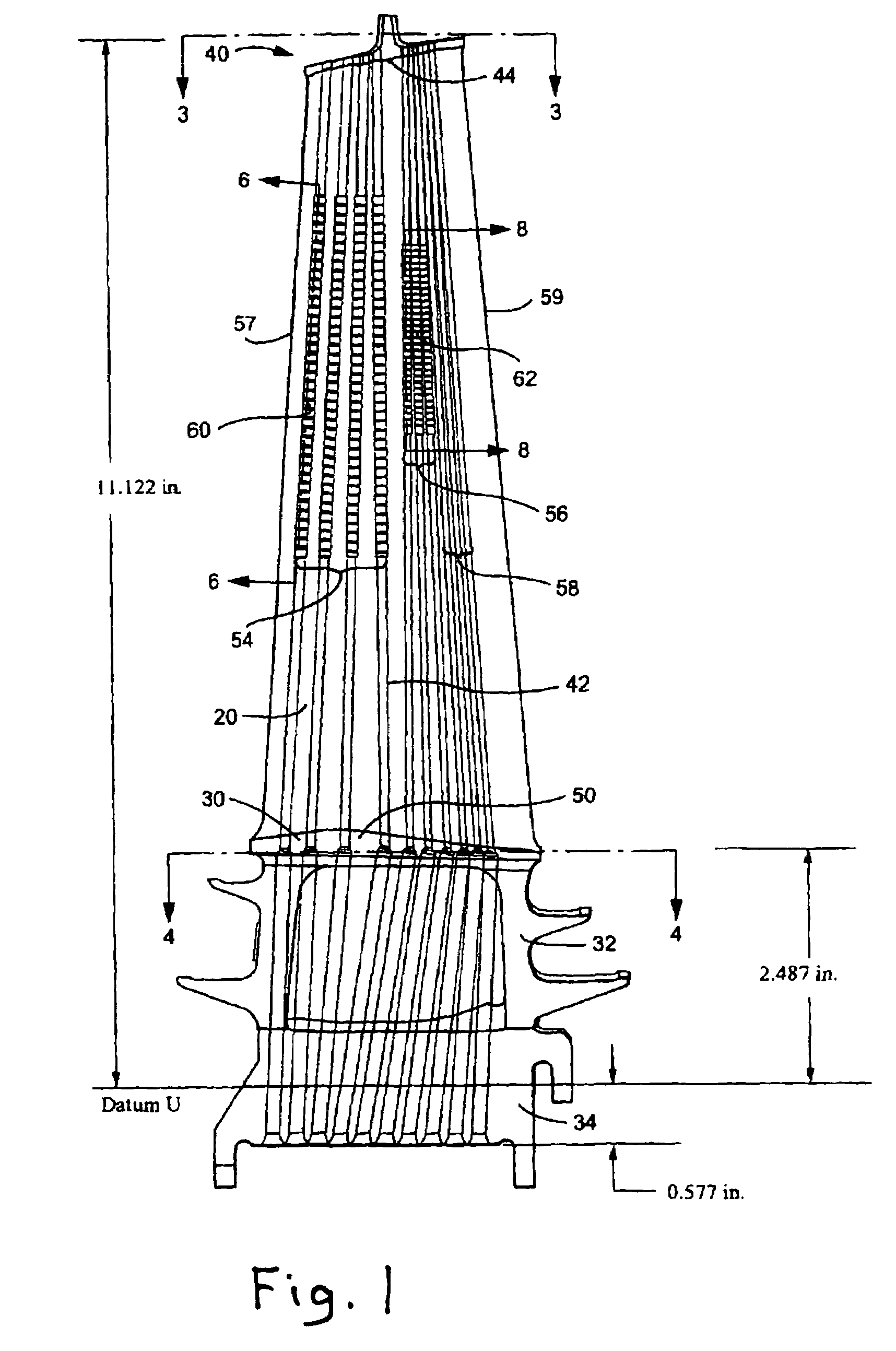

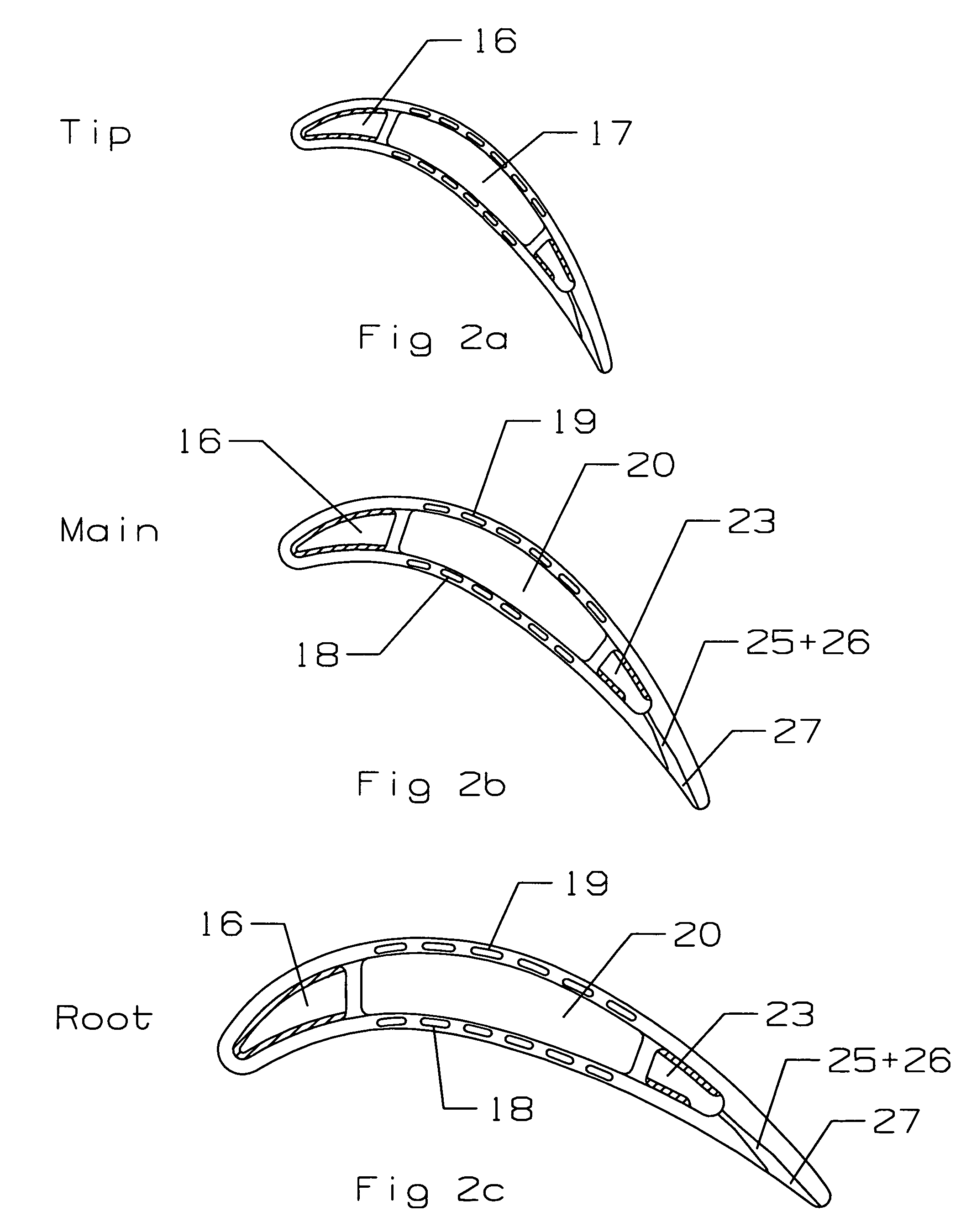

Large tapered rotor blade with near wall cooling

InactiveUS7641445B1Lighten bladeReduction of cooling flow cross sectional areaEngine manufactureEngine fuctionsLeading edgeTrailing edge

A turbine rotor blade for use in a gas turbine engine, the blade including a serpentine flow cooling circuit that includes a first leg forming a leading edge cooling channel, a second leg that includes an upper channel with trip strips and a lower portion with near wall cooling channels that split off from the upper portion of the second leg to form near wall cooling channels extending along the pressure side and the suction side of the blade, the near wall cooling channels being separated by a dead cavity, and a third leg formed along the trailing edge of the blade with a collecting cavity formed in the blade root and providing the fluid communication between the trailing edge third leg and the near wall cooling channels. The trailing edge channel is connected to a plurality of metering and diffusion holes spaced along the trailing edge. These exit holes include a metering hole, a first diffusion hole, and a diffusion slot located on the pressure side of the trailing edge of the blade. A plurality of the metering and diffusion holes opens into a single diffusion slot. The diffusion slots each include a second diffusion hole and a third diffuser arranged in series.

Owner:SIEMENS ENERGY INC

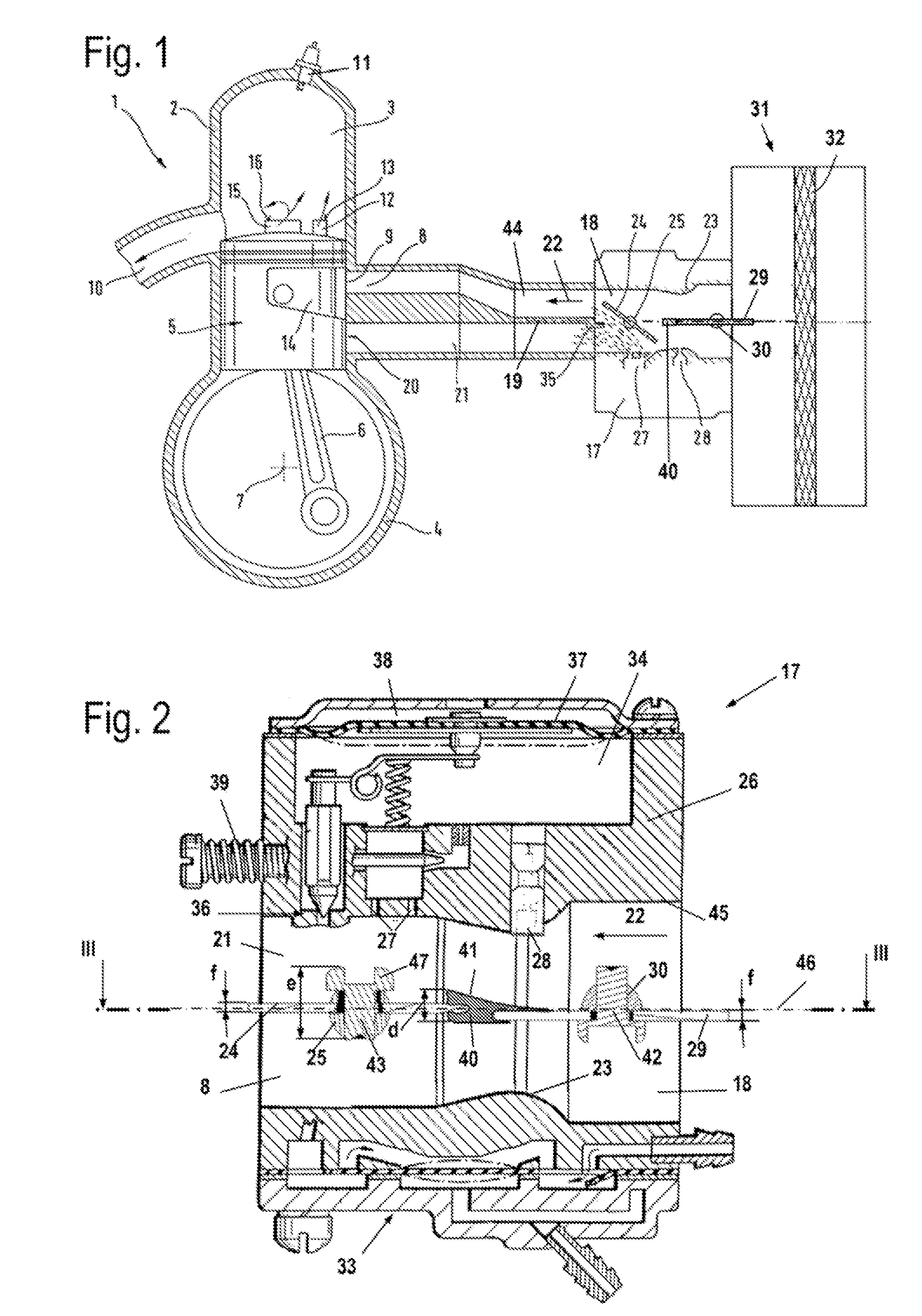

Carburetor

ActiveUS7494113B2Easy to makeEasy to processLighting and heating apparatusMixing methodsCombustionEngineering

A carburetor having a carburetor body in which an intake channel portion is formed. At least one fuel opening opens out into the intake channel portion. Pivotably mounted in the intake channel portion is a butterfly valve that in a completely opened position divides the intake channel, in the region of the butterfly valve, into a mixture channel and a feed channel, so that in the completely opened position of the butterfly valve, flowing into the feed channel is combustion air having a fuel content that is less than the fuel content in the mixture channel. Provided in the intake channel portion is at least one partition section that extends between the feed channel and the mixture channel. The partition section is formed on the carburetor body.

Owner:ANDREAS STIHL AG & CO KG

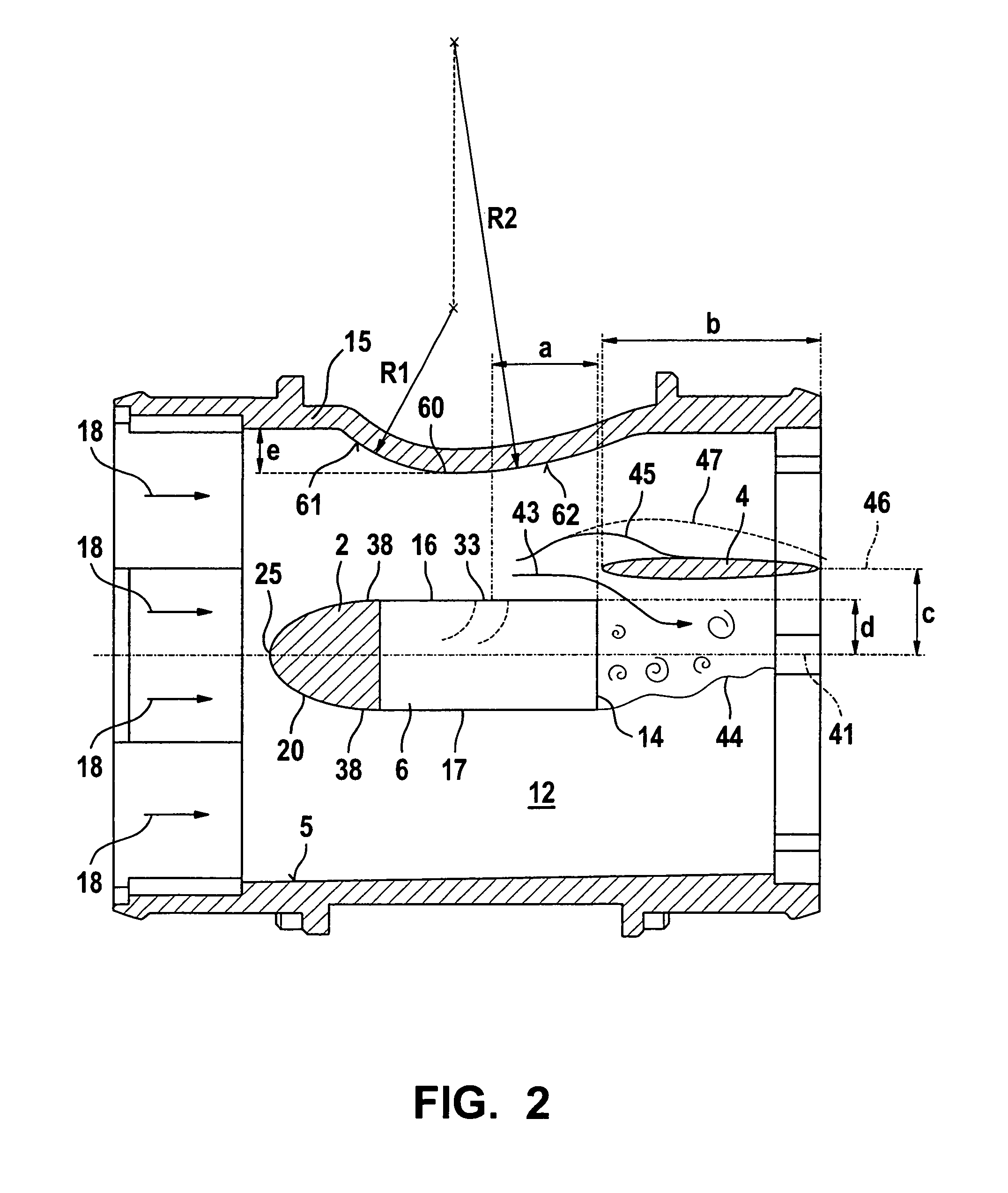

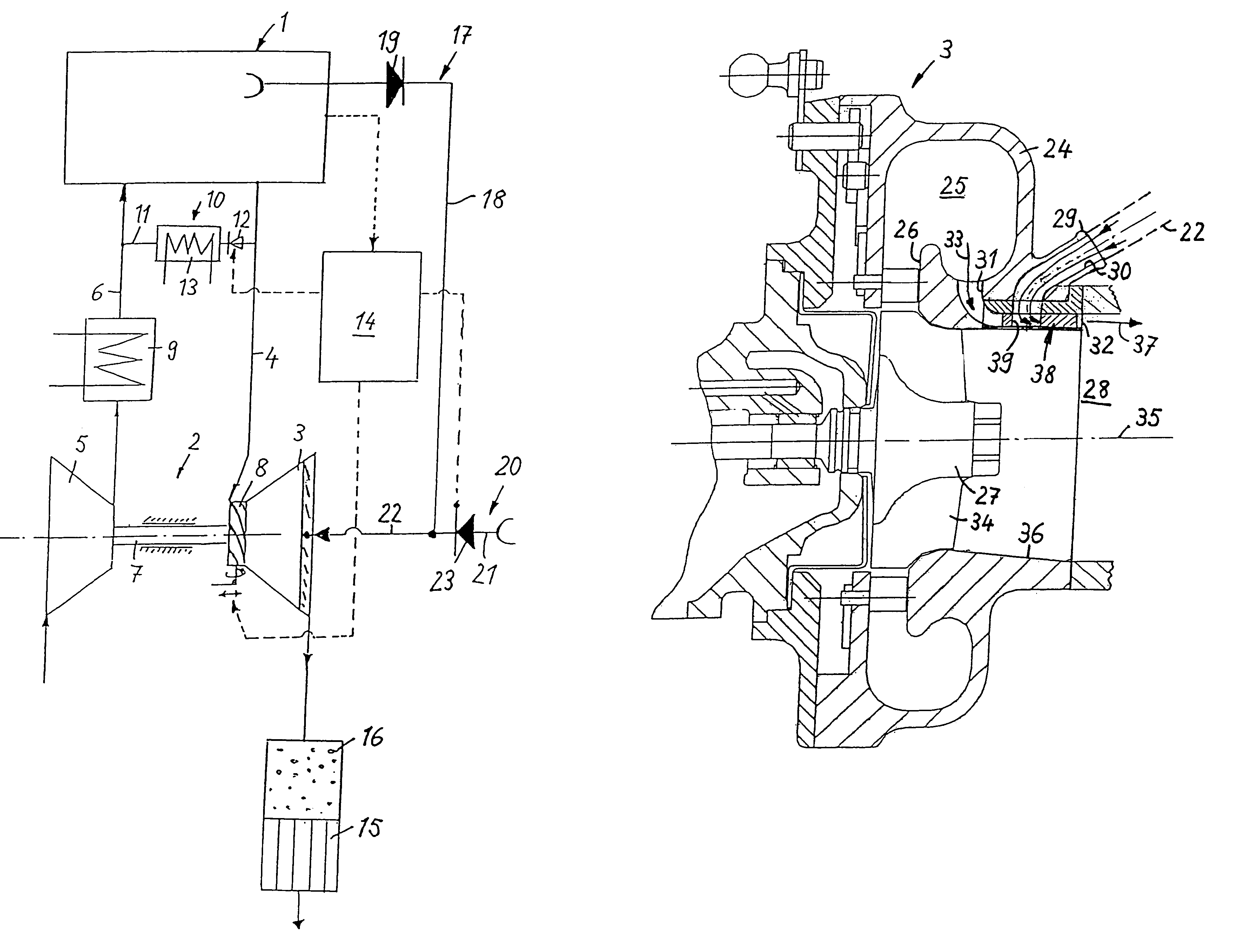

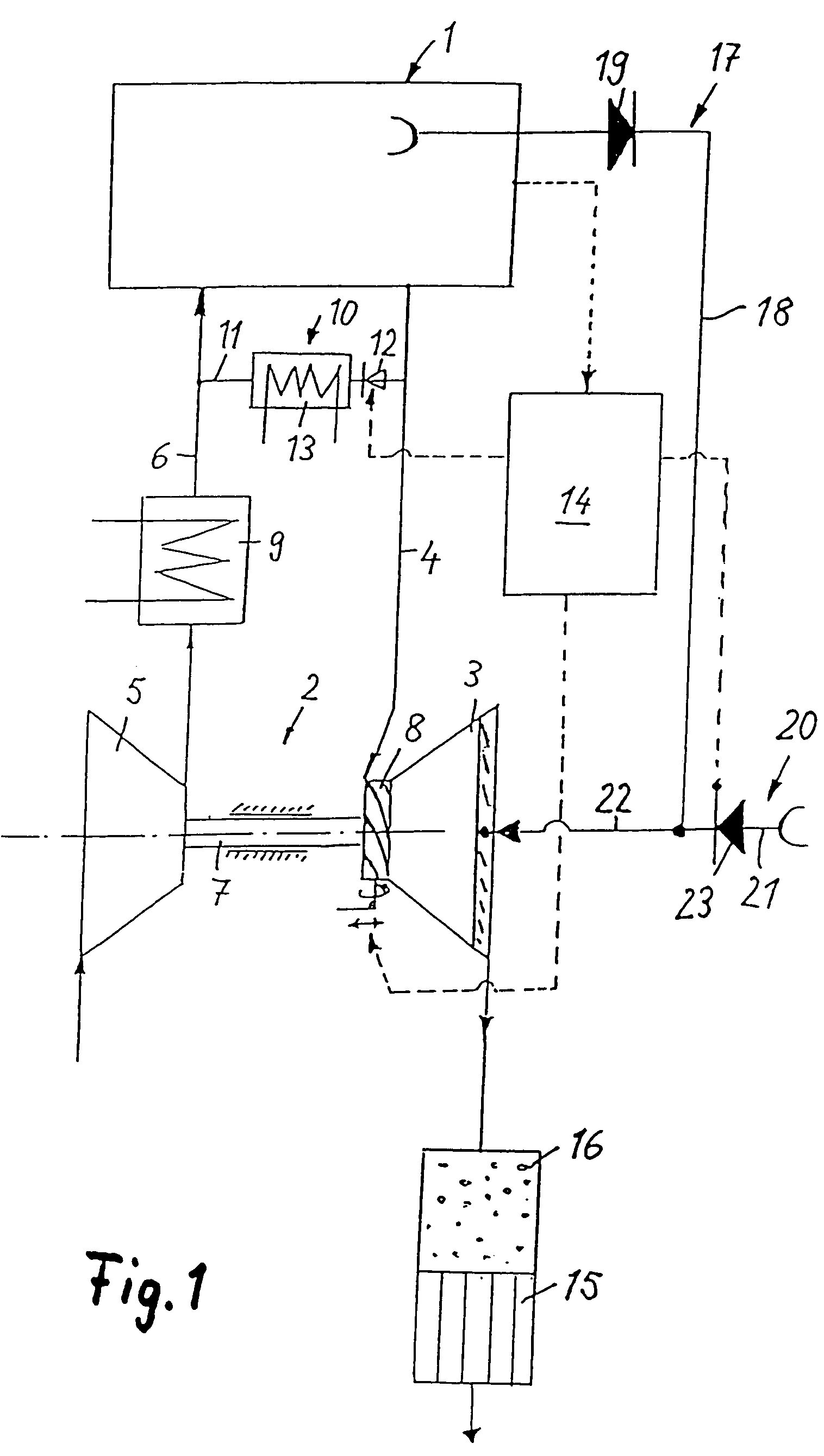

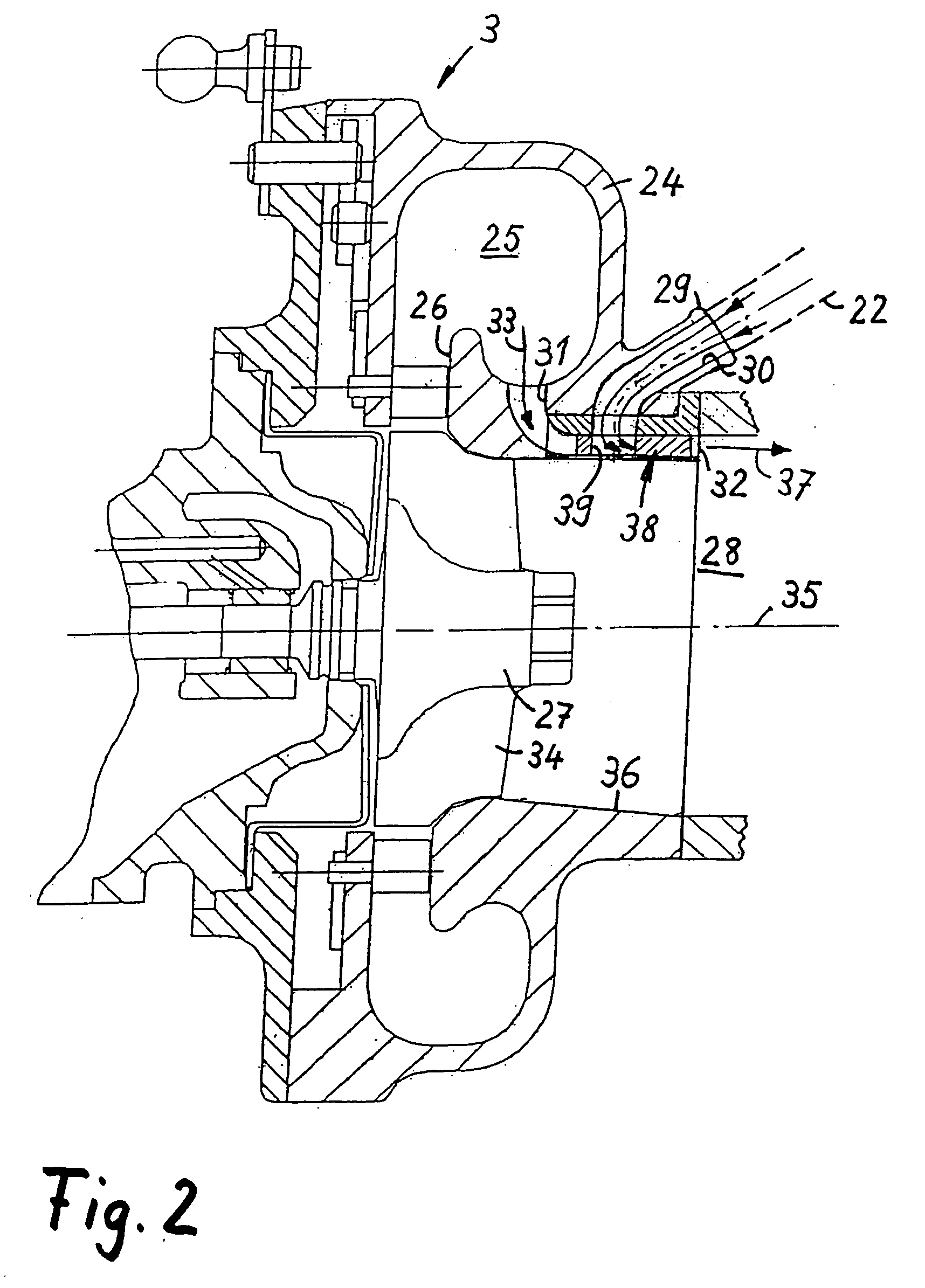

Exhaust gas turbocharger for an internal combustion engine

InactiveUS7162872B2Function increaseReduced flow cross sectionInternal combustion piston enginesWind motor controlImpellerTurbine wheel

Owner:DAIMLER AG

Device for determining at least one parameter of a medium flowing in a conduit

ActiveUS20060021429A1Inhibition of flow separationReduce total pressure lossElectrical controlVolume/mass flow by thermal effectsEngineeringInternal combustion engine

Devices are previously known for determining at least one parameter of a medium flowing in a conduit, in particular for determining the air mass flow in the intake section of an internal combustion engine, having a conduit part and a sensor device that has a bypass part. In order to avoid a flow detachment at the side walls of the bypass part, it is provided that a flow vane, running at least approximately parallel to a side wall, provided with a separation opening, of the bypass part, be provided in a conduit part behind a separation opening, seen in the main flow direction, and that the conduit part be provided, in the area of the bypass part, with at least one projection that protrudes from an inner wall of the conduit part towards the bypass part.

Owner:ROBERT BOSCH GMBH

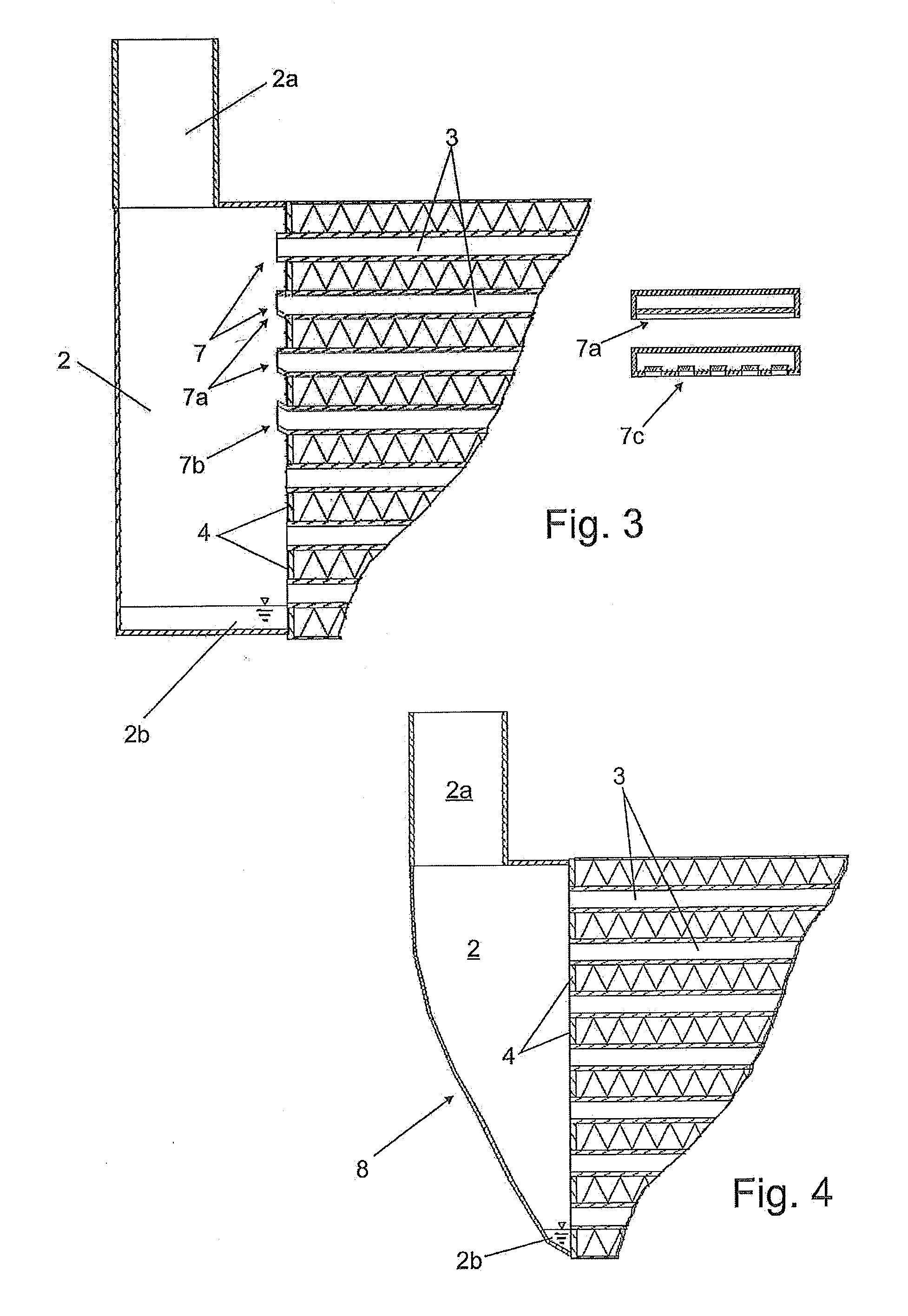

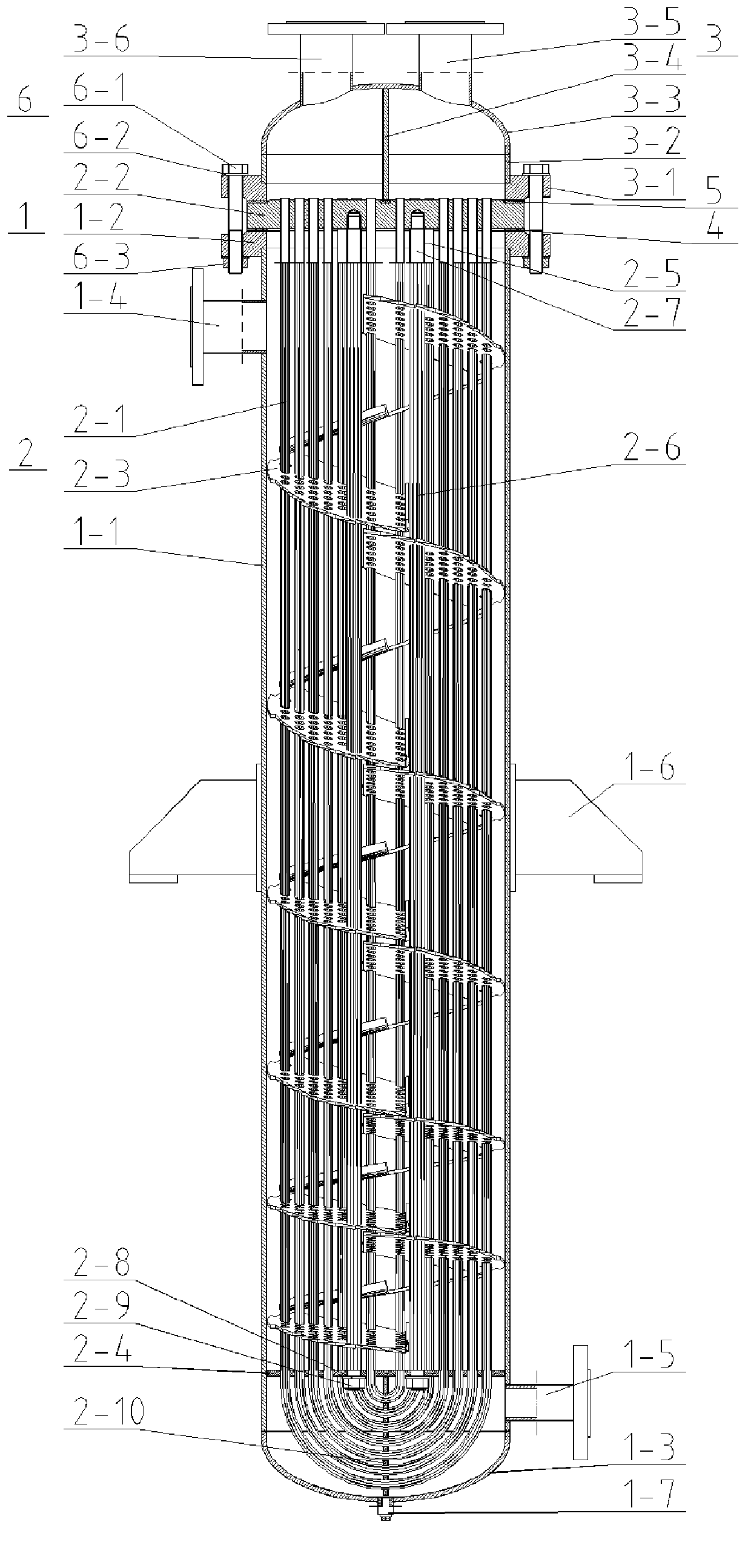

U-shaped tubular condenser of vertical type spiral baffle plate

InactiveCN103105075AIncreased condensation heat transfer coefficientAvoid gatheringSteam/vapor condensersHeat exchanger casingsCondensation heat transferMechanical engineering

A U-shaped tubular condenser of a vertical type spiral baffle plate comprises a shell body component, a tube bundle component, an upper head component and the like. A downstream edge of a fan-shaped baffle plate of a spiral baffle plate set of the tube bundle component is bent upwards to form a liquid blocking weir which is arranged among rows of tubes. An upstream liquid dredging opening and a downstream liquid dredging opening are formed in an arc-shaped edge of the fan-shaped baffle plate. An inclination angle of the fan-shaped baffle plate is reduced in sections from top to bottom. The spiral baffle plate set can be a two-head spiral or a three-head spiral. The fan-shaped baffle plate not only supports the tube bundle, but also is in favor of drying the surface of the tube bundle by scraping, guides condensing liquid to the inner wall of the shell body, discharges the condensing liquid to the bottom portion along the wall surface, enables a tube which is arranged under the baffle plate to directly contact steam through the dry surface and improves condensation heat transfer coefficient. The U-shaped tubular condenser of the vertical type spiral baffle plate enables the heat transfer coefficient of the vertical type shell-and-tube condenser which has the advantages of being small in occupied area, enabling the tube bundle to be conveniently taken out and being convenient to repair to be improved.

Owner:SOUTHEAST UNIV

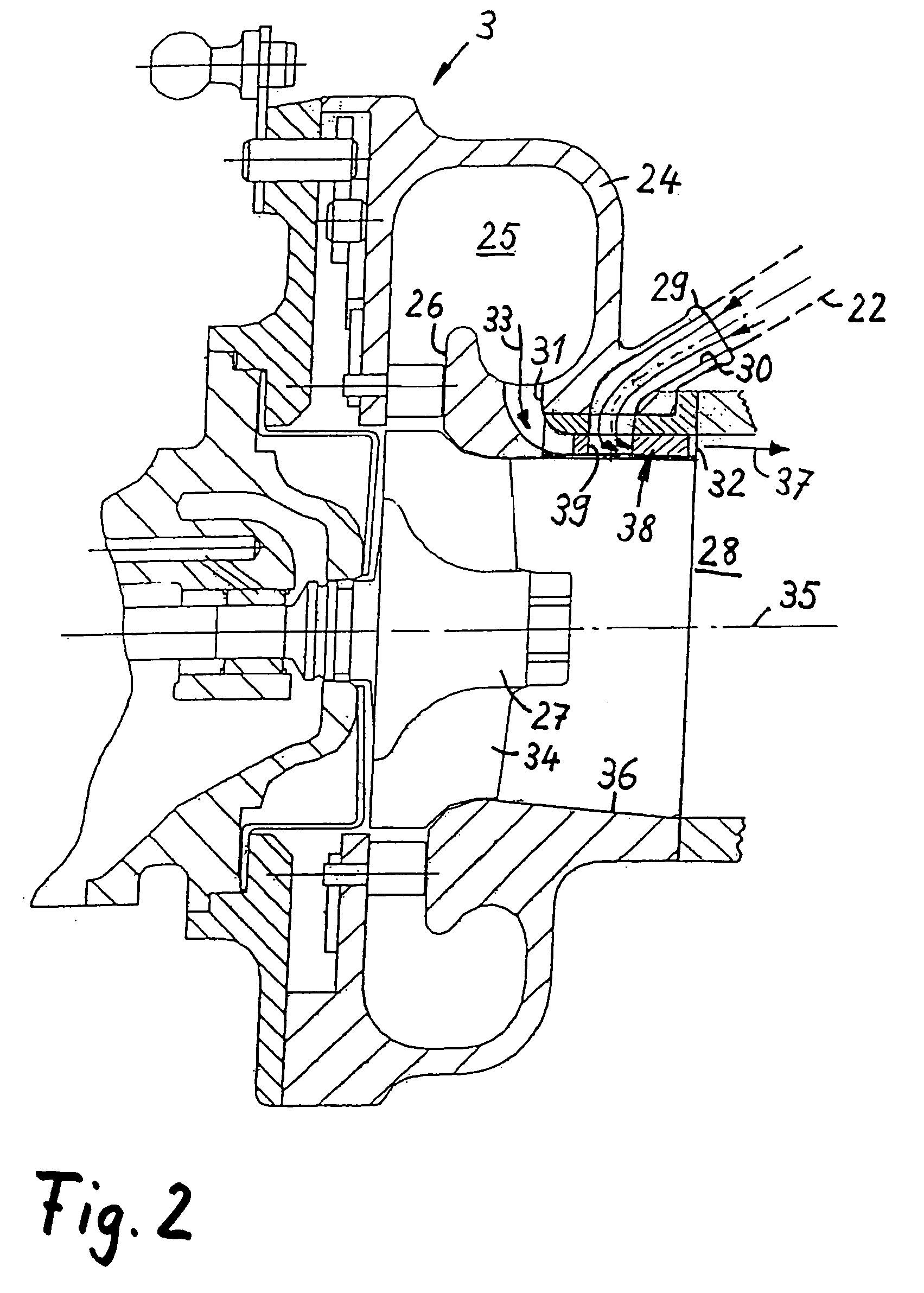

Exhaust gas turbocharger for an internal combustion engine

InactiveUS20050252211A1Simple constructive meanFunction increaseInternal combustion piston enginesCombination enginesImpellerTurbine wheel

In an exhaust gas turbocharger of an internal combustion engine including a compressor arranged in the intake duct and a turbine arranged in the exhaust duct of the engine, wherein the turbine includes in its housing an exhaust collection chamber from which the exhaust gas is directed via turbine inlet passage to the turbine wheel, the housing also includes a bypass arrangement for conducting part of the exhaust gas to the turbine exhaust structure in a turbine wheel bypass line which includes an ejector structure forming a gas pumping device.

Owner:DAIMLER AG

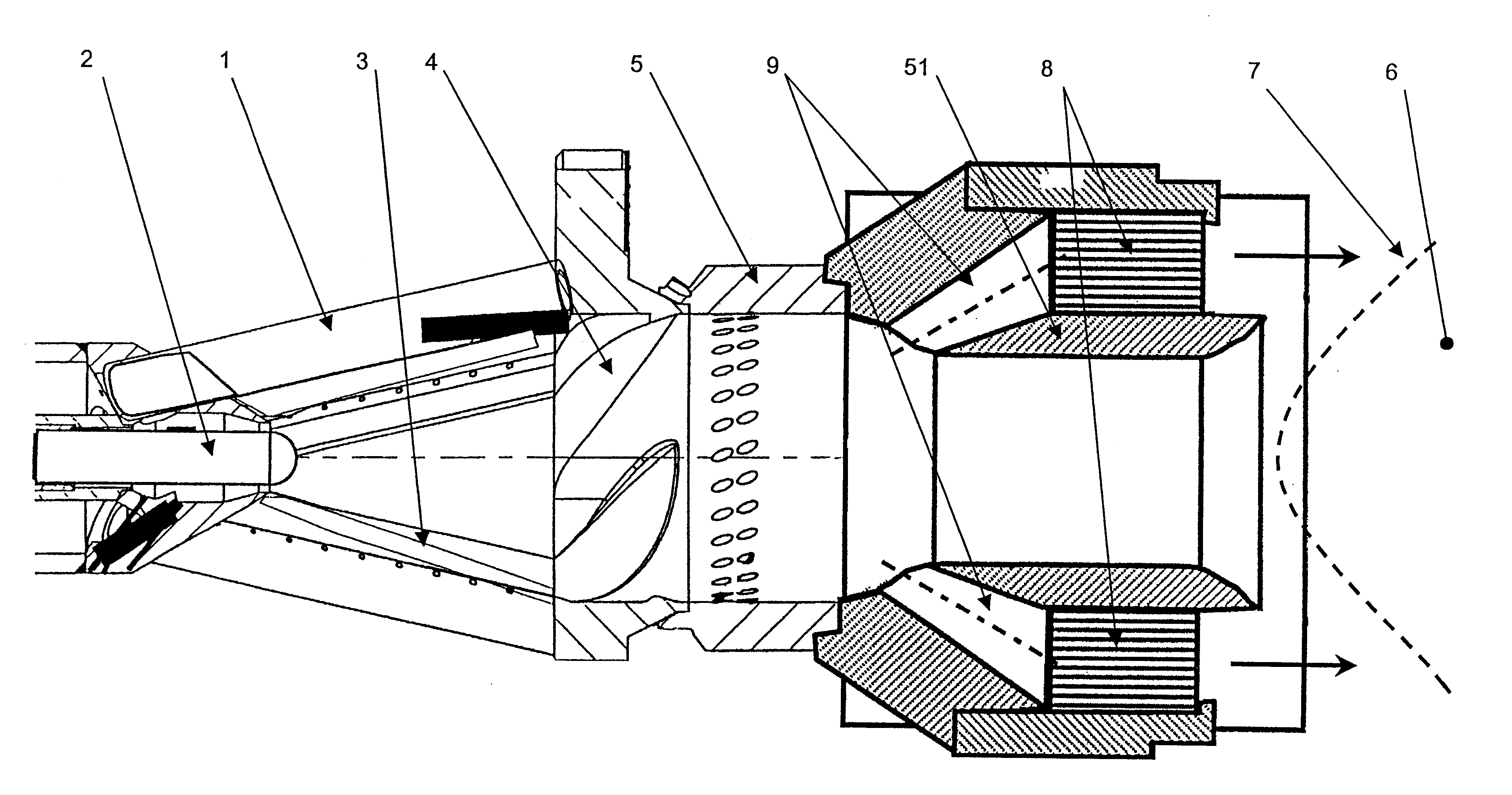

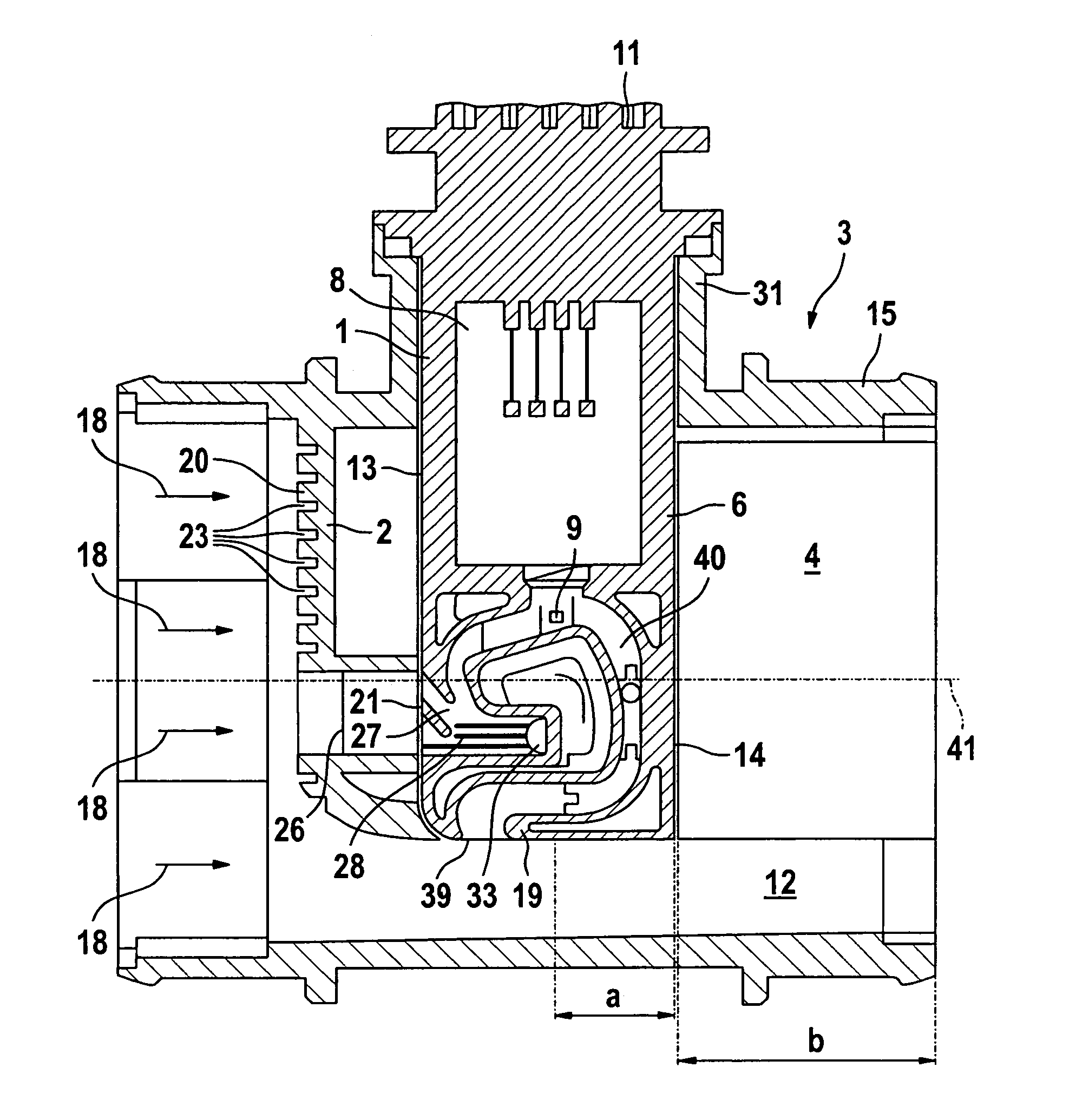

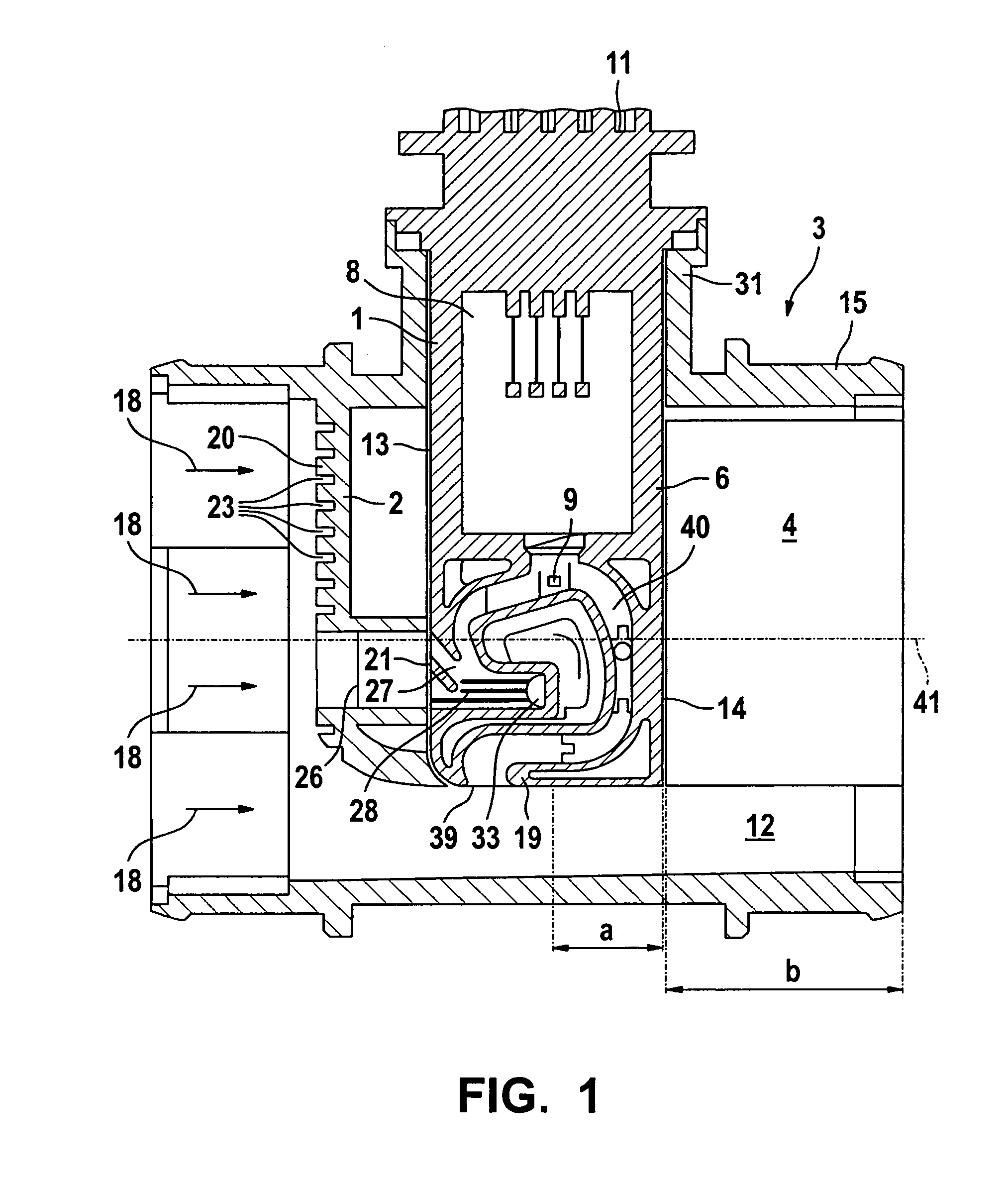

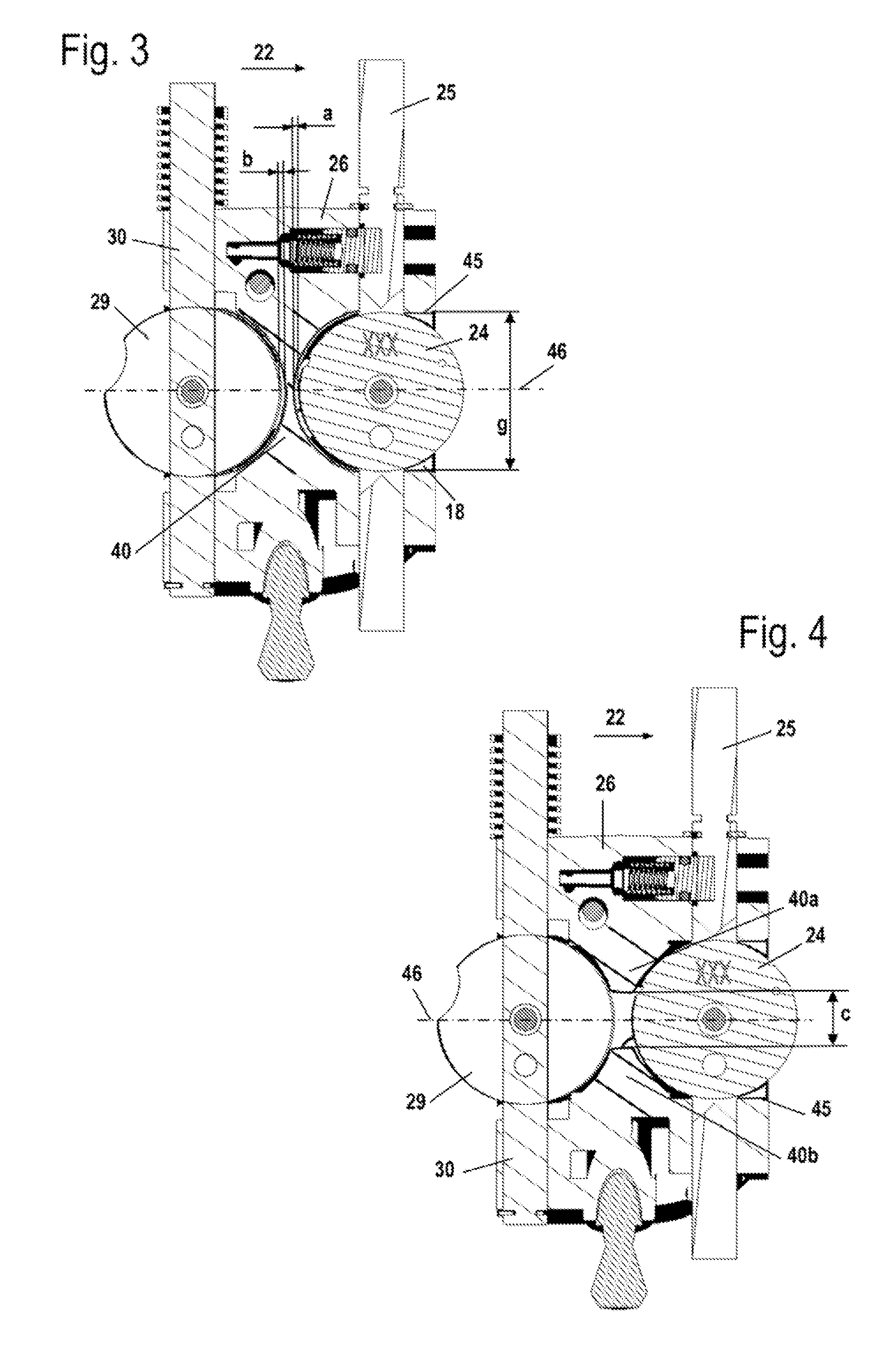

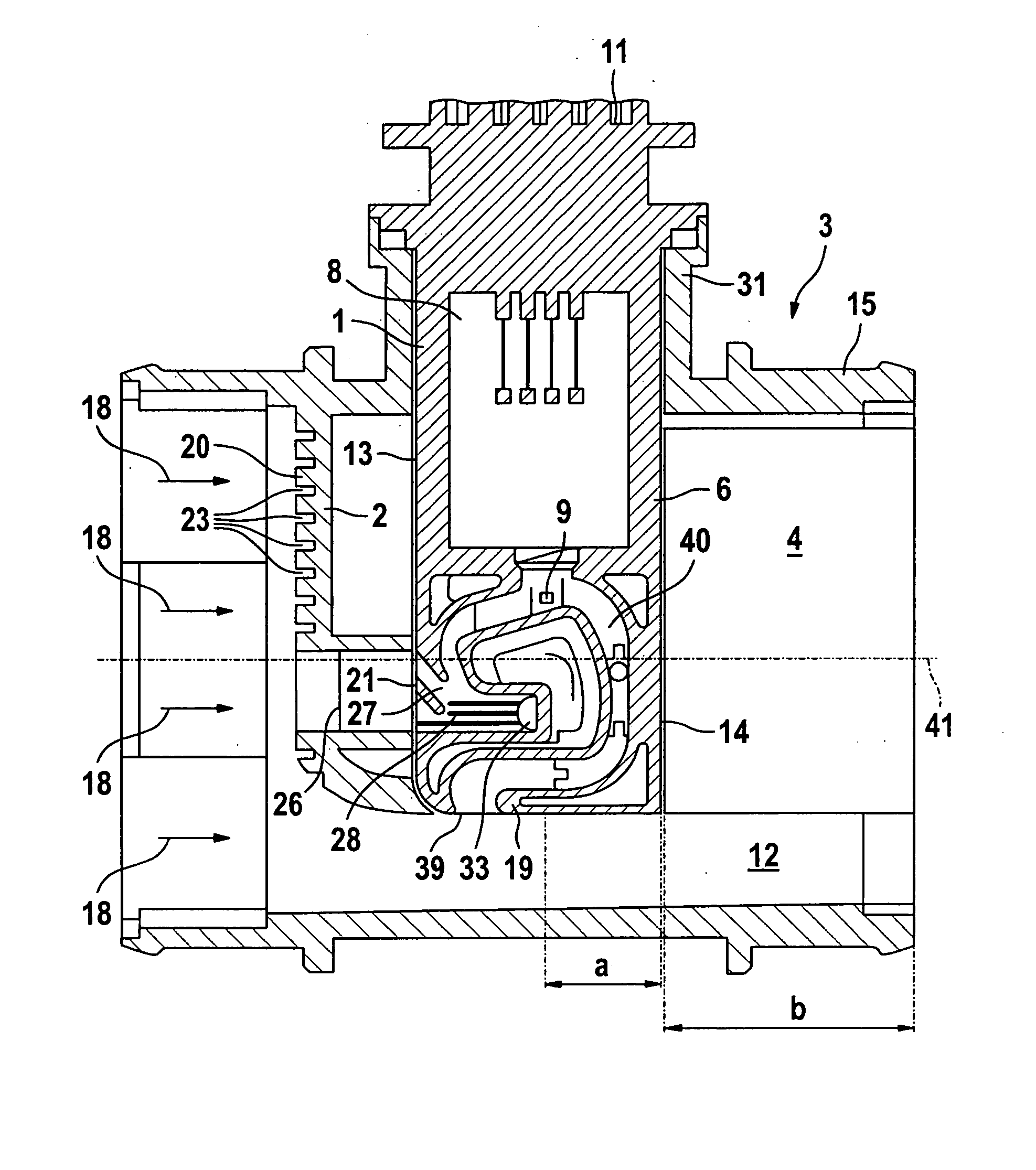

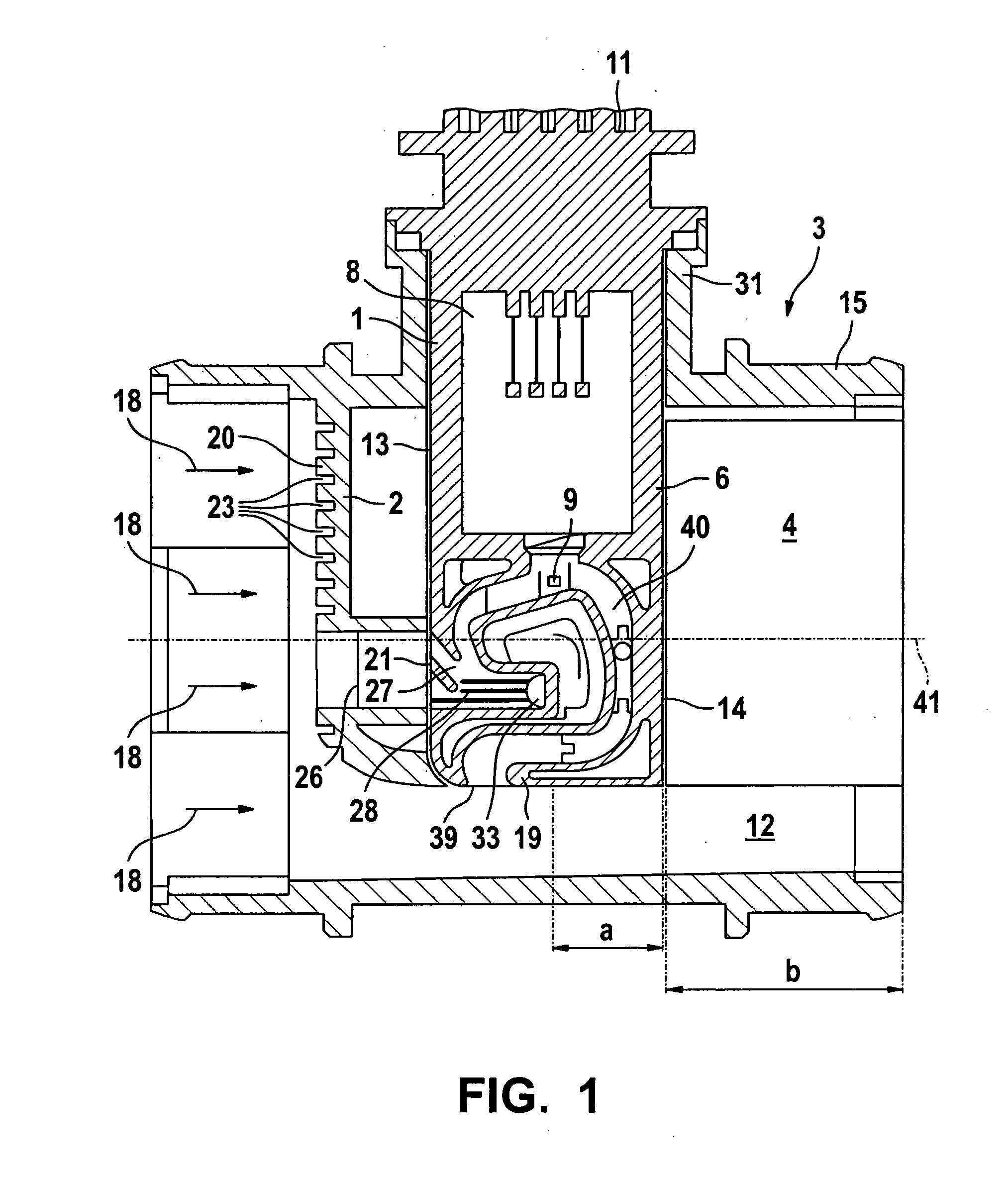

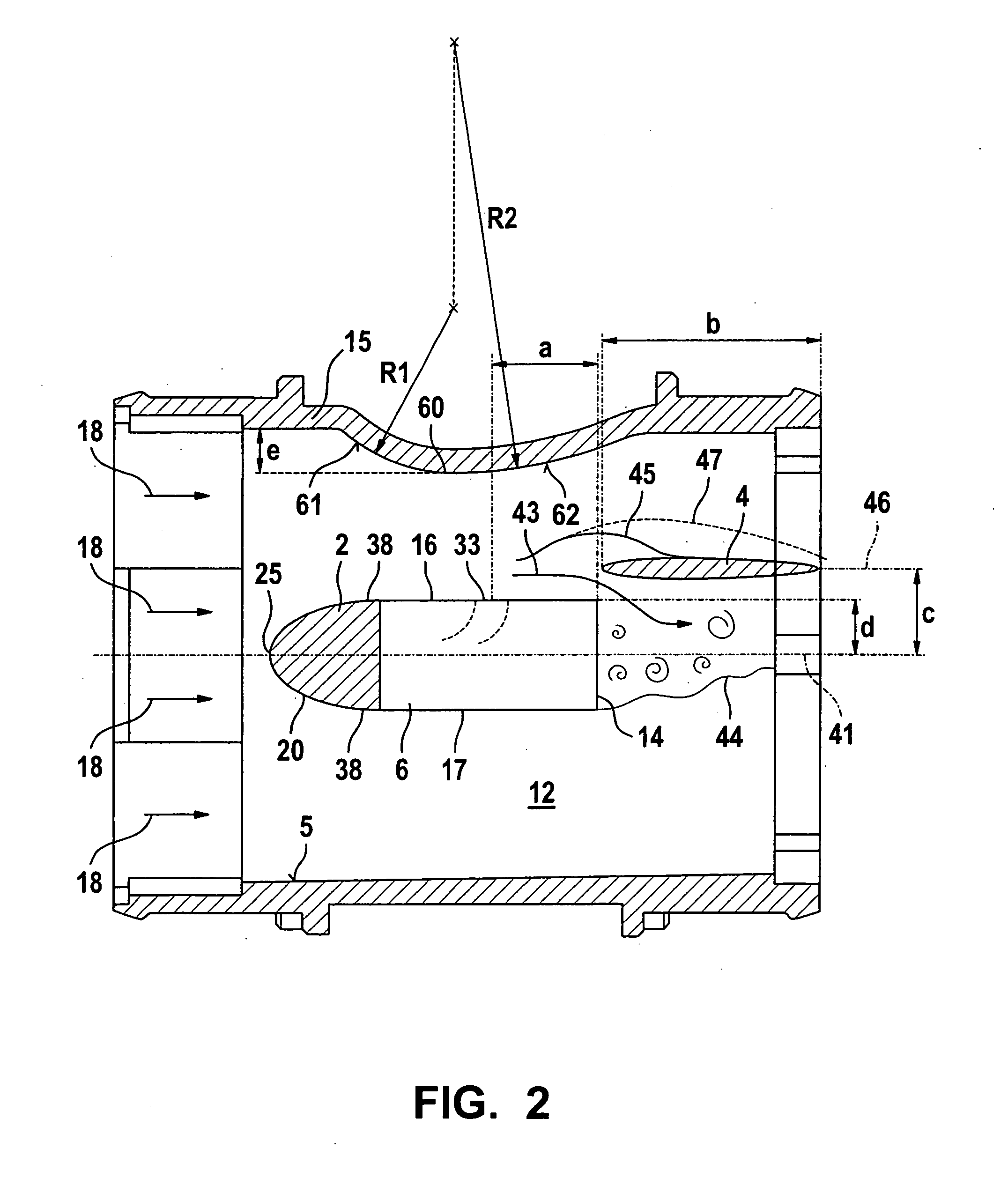

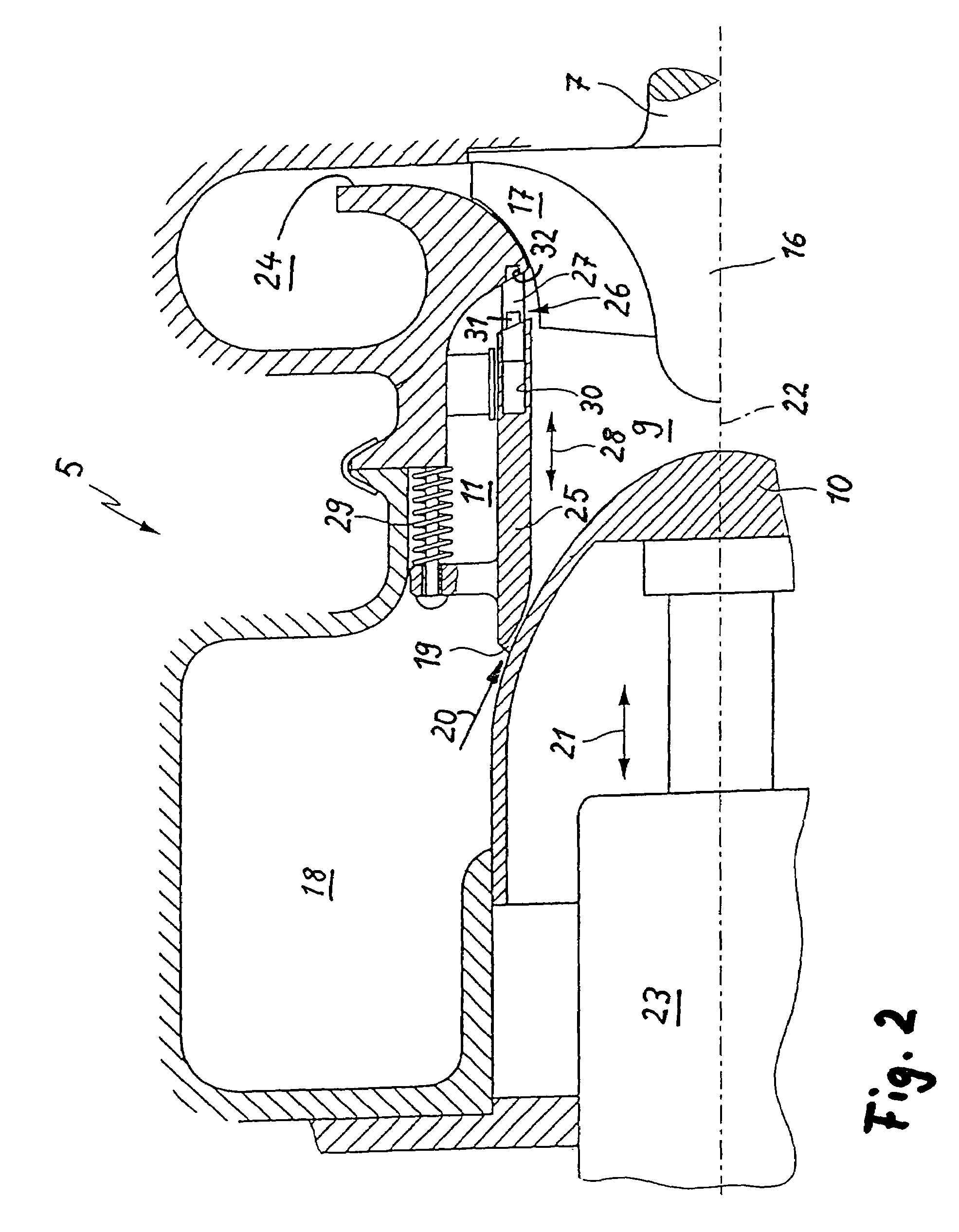

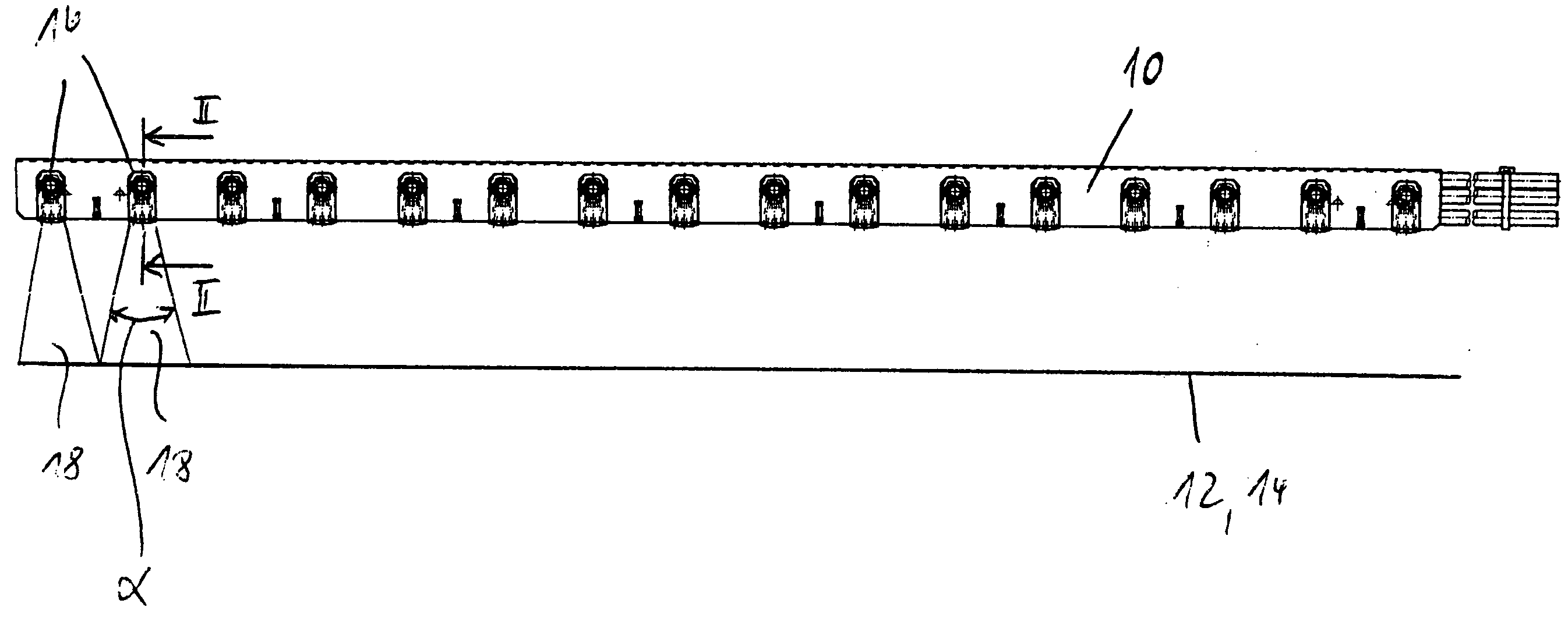

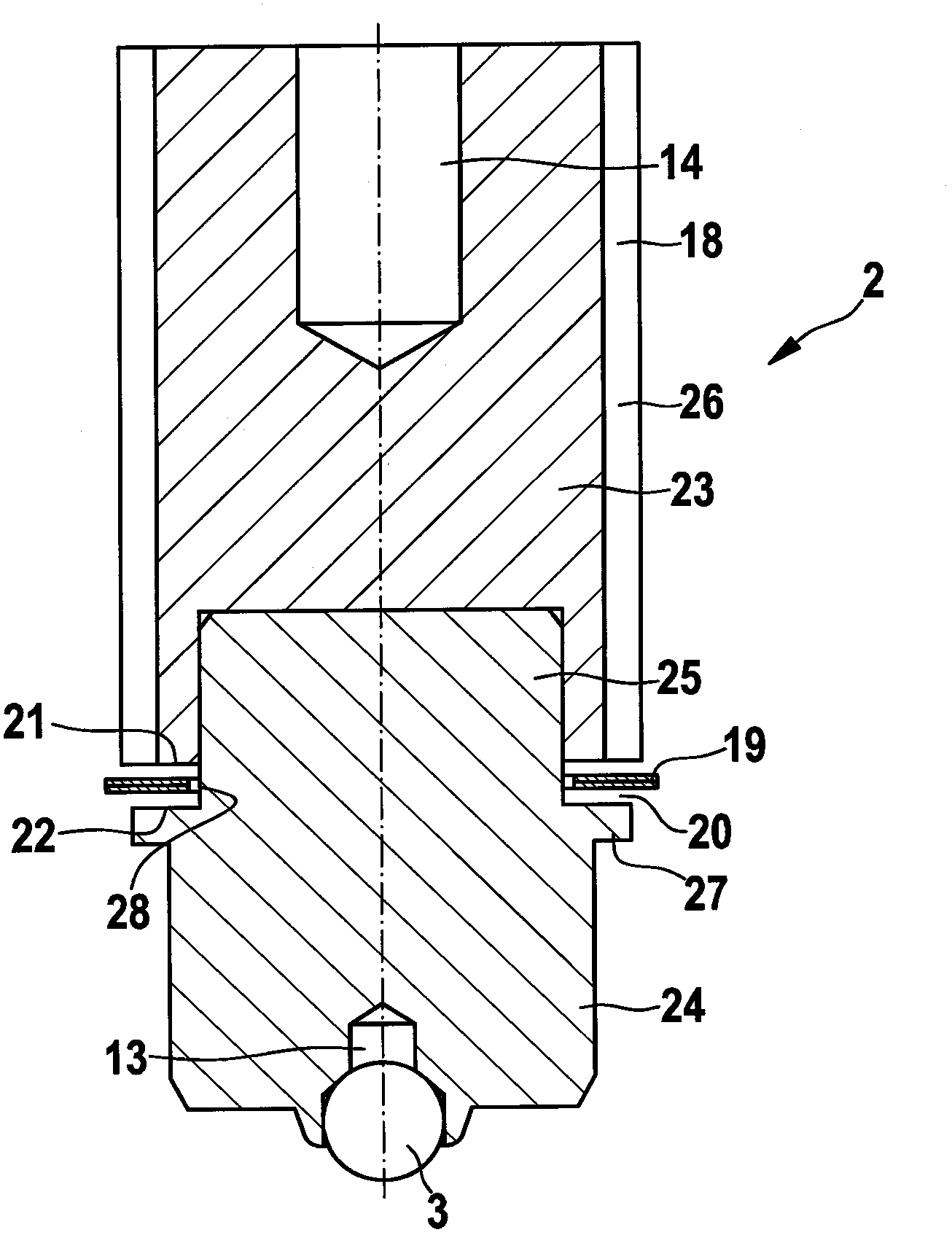

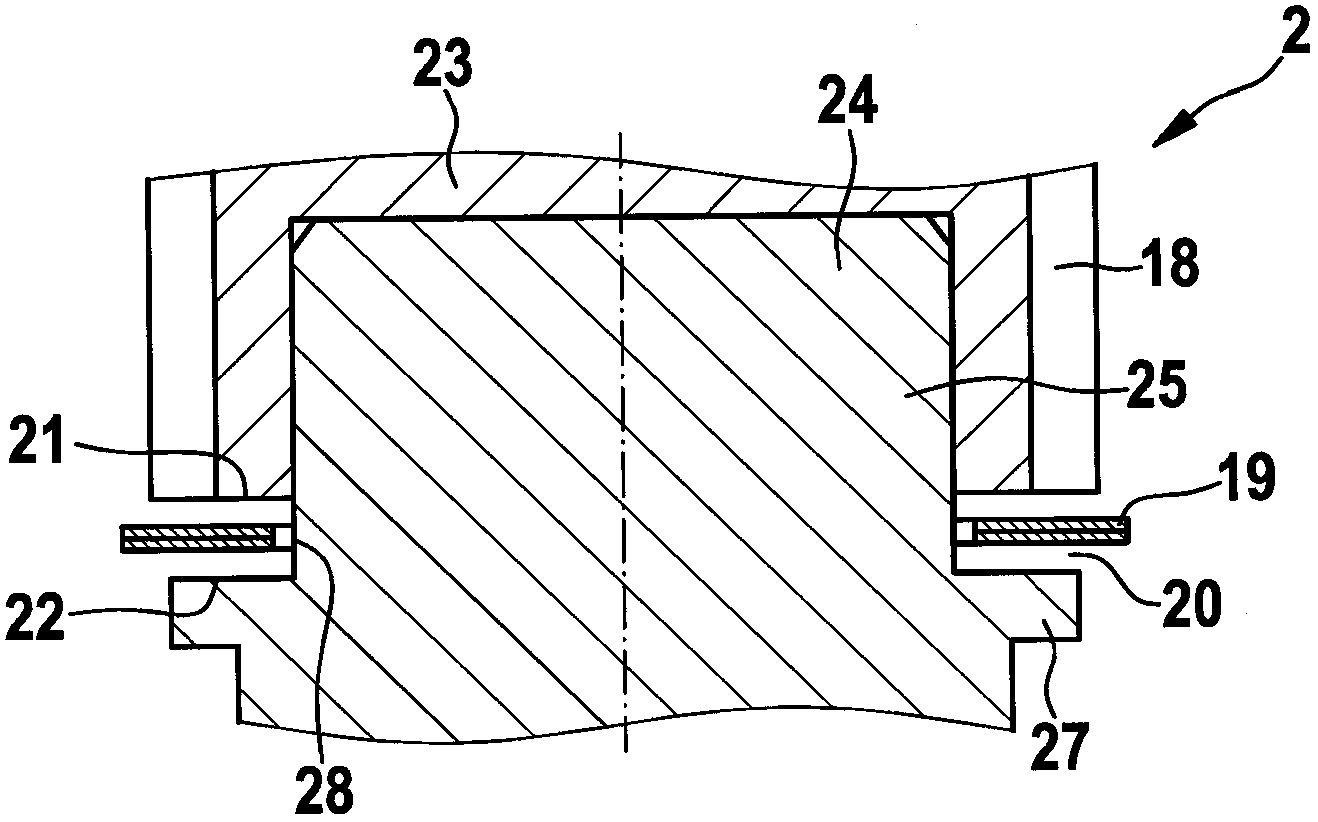

Compressor in the induction tract of an internal combustion engine

InactiveUS7412830B2Increased rotational speed levelReduced flow cross sectionInternal combustion piston enginesWind motor controlImpellerCombustion

In a compressor in the induction tract of an internal combustion engine with a compressor by which combustion air can be compressed to an increased boost pressure and which includes a compressor wheel rotatably mounted in a compressor housing with a main inlet duct in the flow path to the compressor wheel, and an auxiliary inlet duct joining the main inlet duct in the area of the compressor wheel, an adjustable swirl device is provided in the auxiliary intake duct, which comprises two separate, interacting swirl structures with a plurality of guide vanes distributed over the periphery and arranged so that the flow cross-section between the guide vanes of the two swirl structures can be changed by an adjusting motion of at least one swirl structure, the vane height of the guide vanes of the smaller swirl structure being 5% to 35% of the vane height of the guide vanes of the larger swirl structure.

Owner:DAIMLER AG

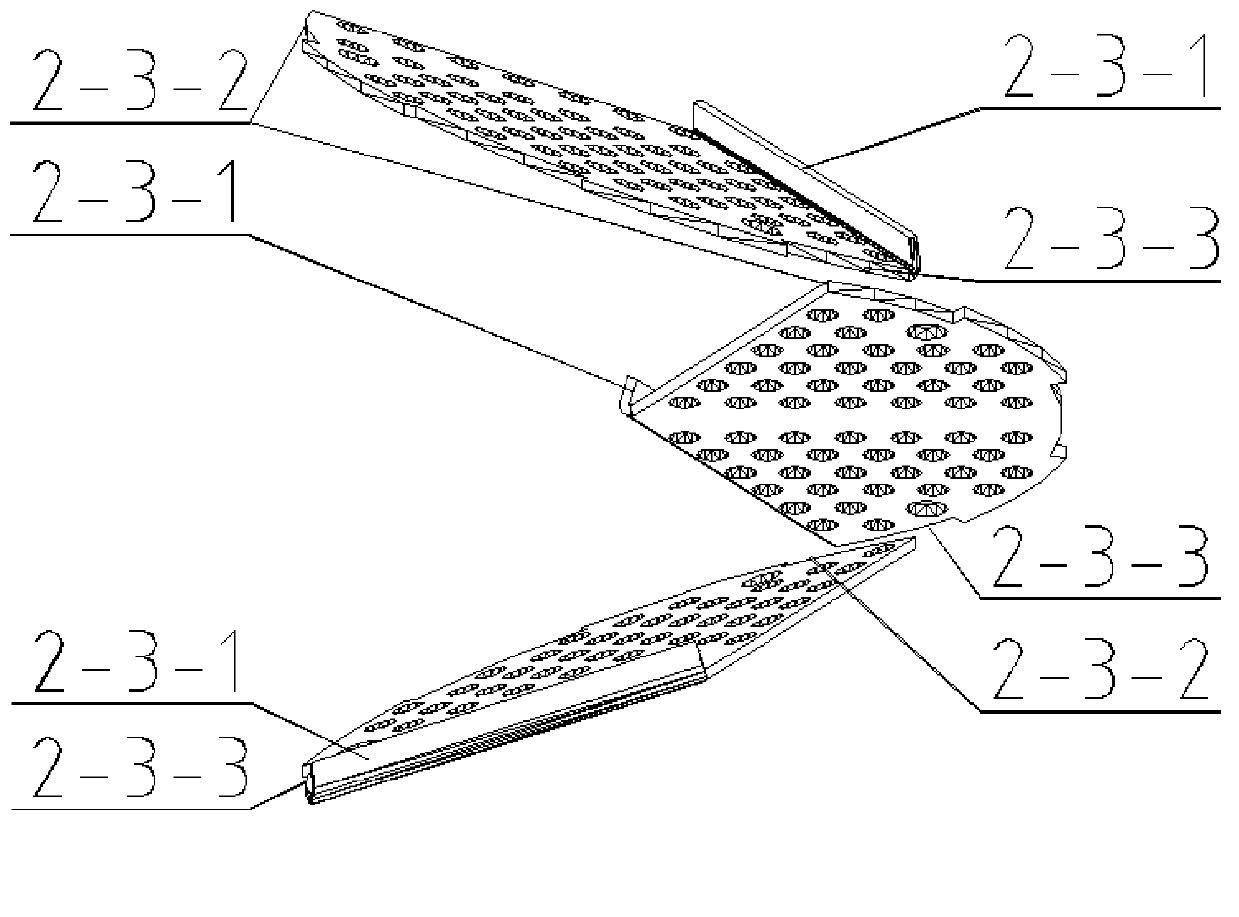

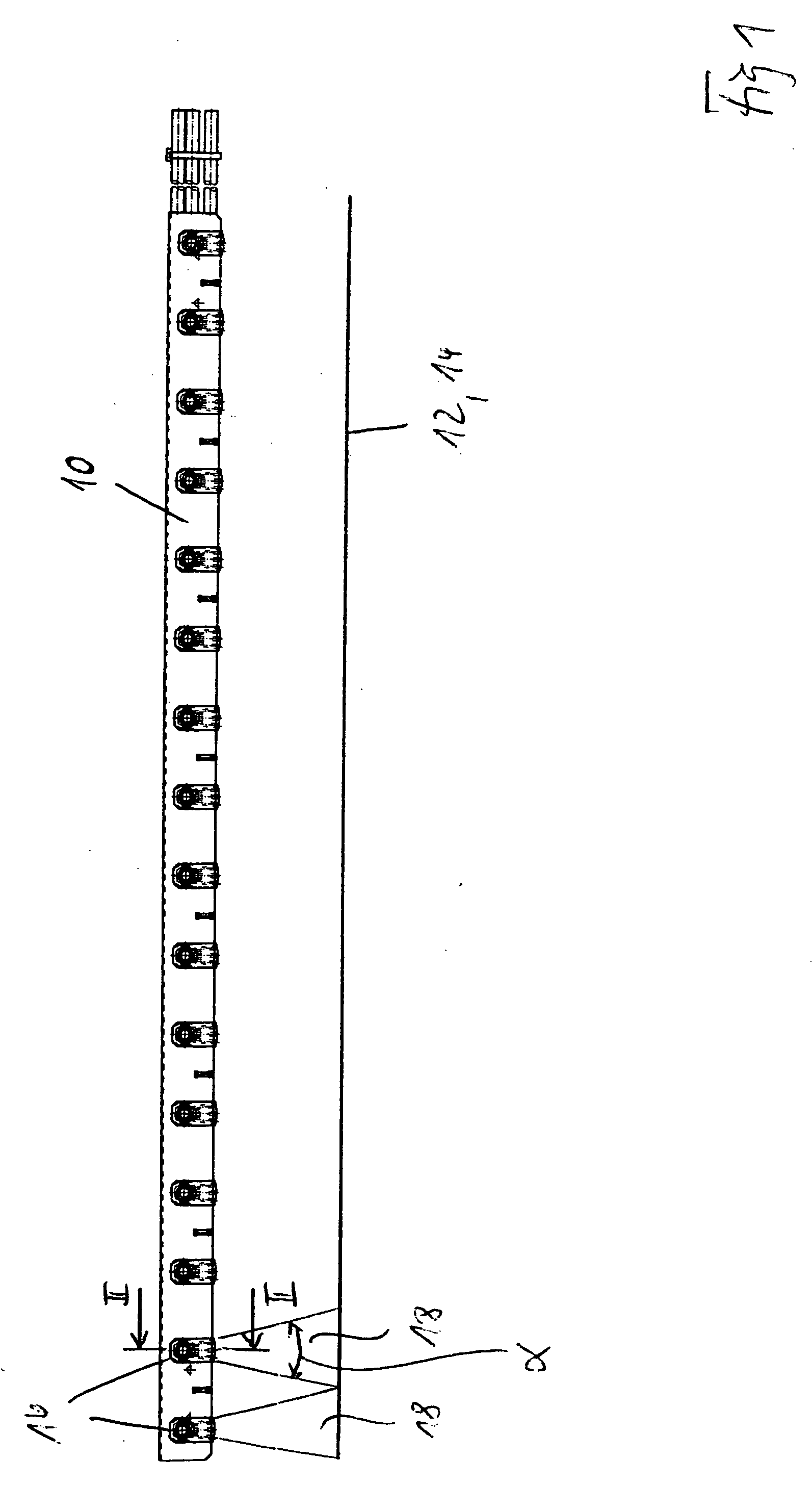

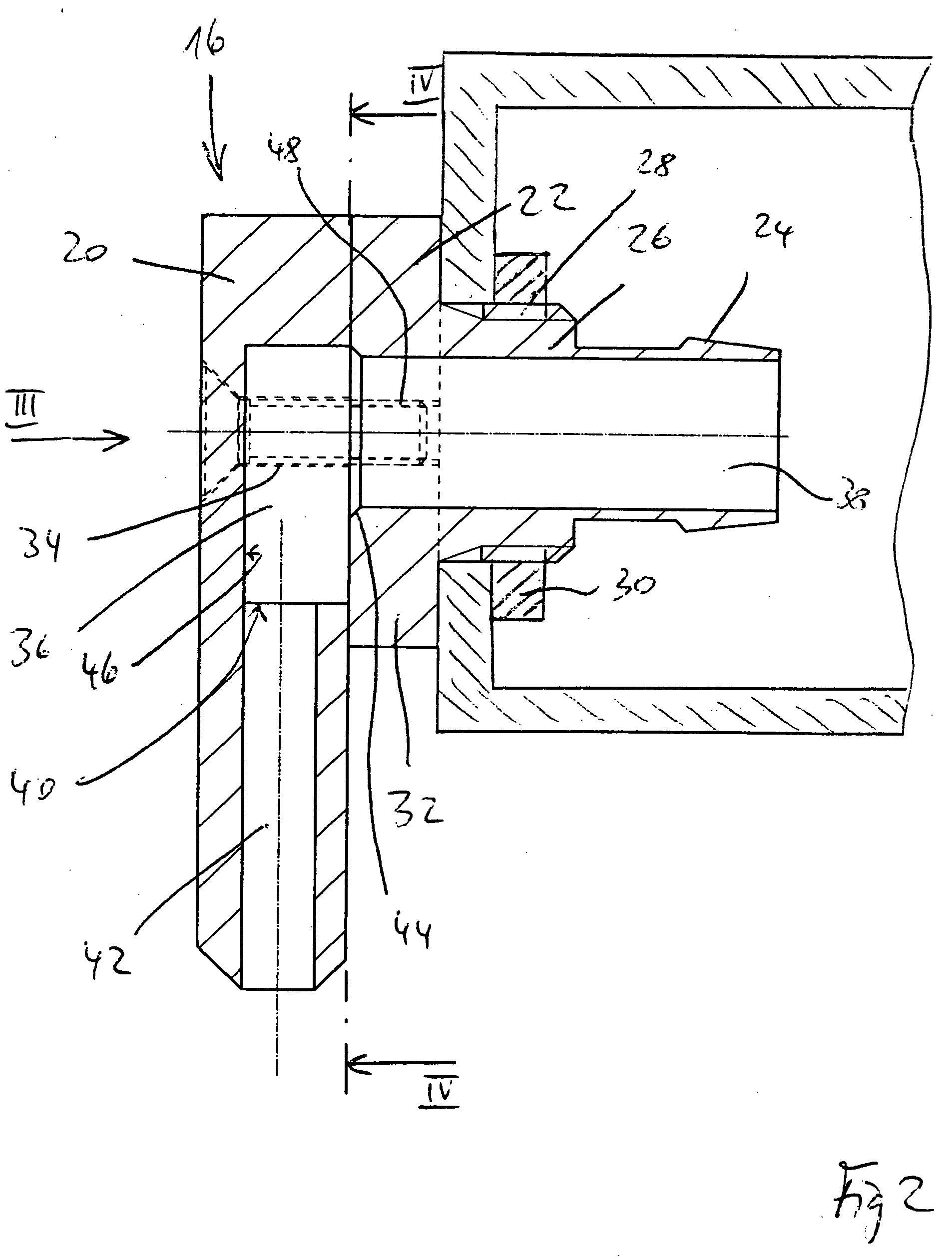

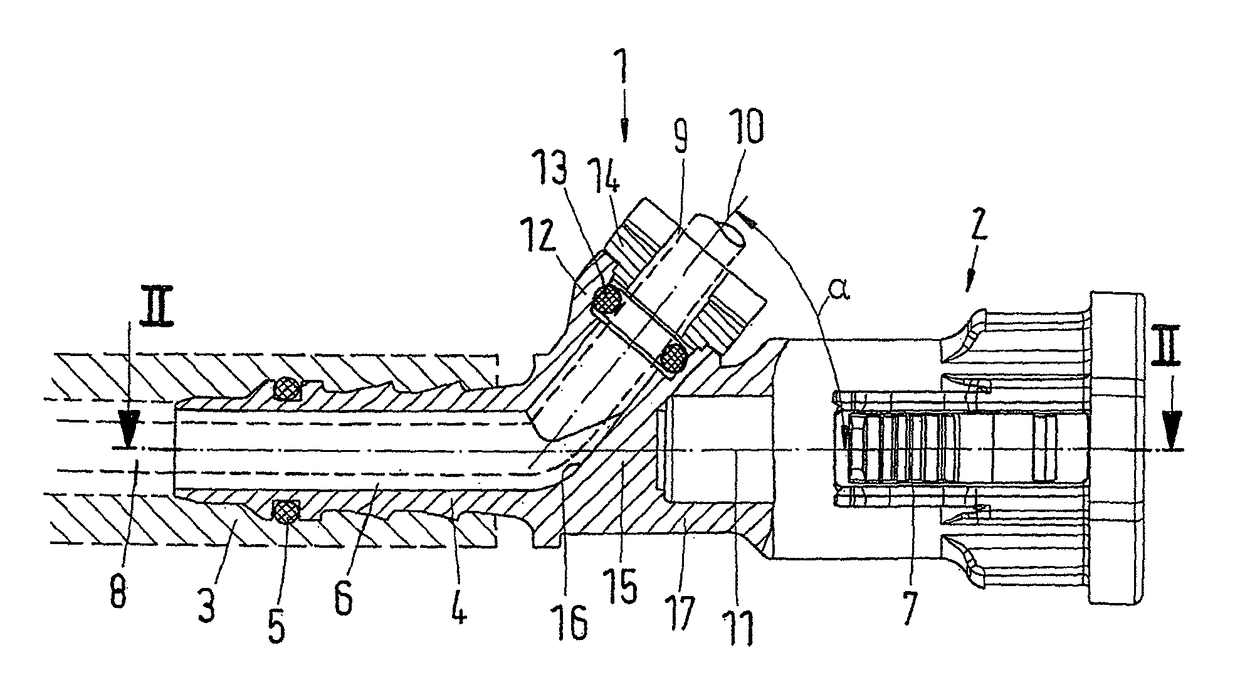

Spray nozzle and method for dusting freshly printed products

ActiveUS20060107857A1Smooth connectionAvoid distributingLiquid surface applicatorsLiquid spraying apparatusEngineeringMechanical engineering

The invention concerns a spray nozzle for a powder duster for dusting freshly printed products with a connection for a tube for supplying a powder-air mixture, a distribution chamber and at least two nozzle channels which branch off from the distribution chamber like a fan, wherein the opening angle of the outer nozzle channels limiting the fan subtends an angular range of 5° to 20°, in particular an angular range of 8° to 15°, and preferably 12°. The invention also concerns a spray bar with spray nozzles of this type, a powder duster comprising spray nozzles of this type, and a method for dusting freshly printed products.

Owner:WEITMANN & KONRAD

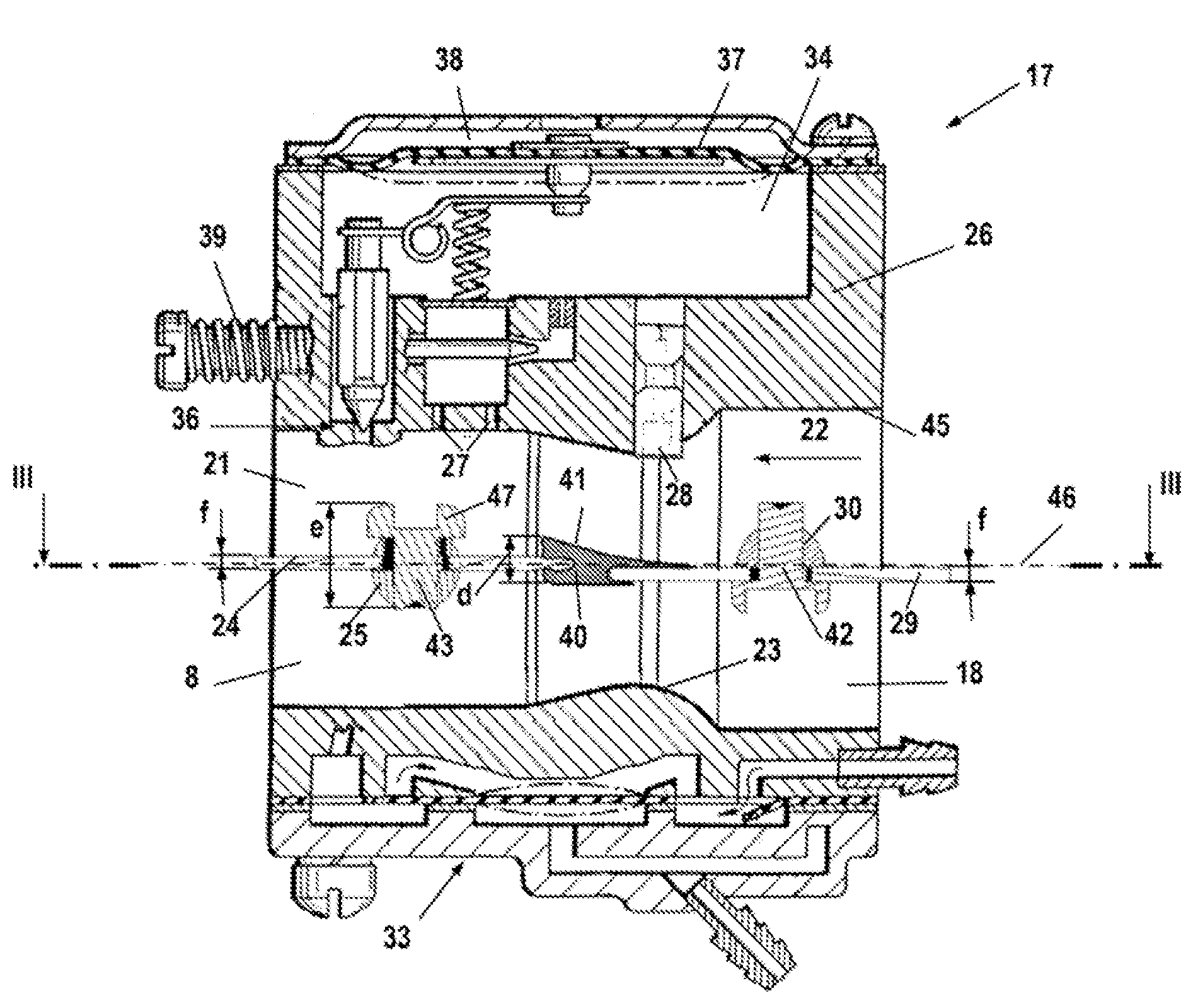

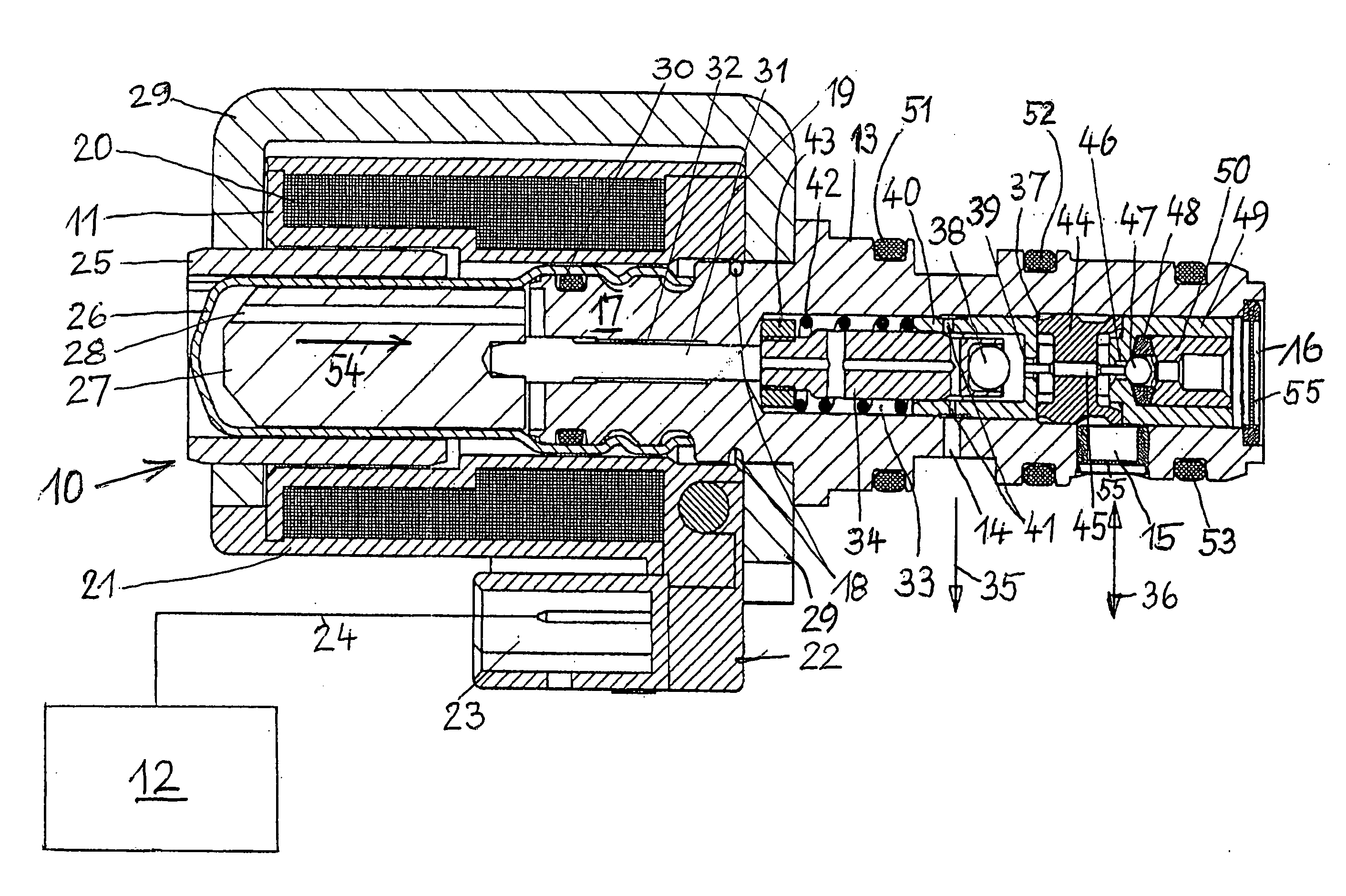

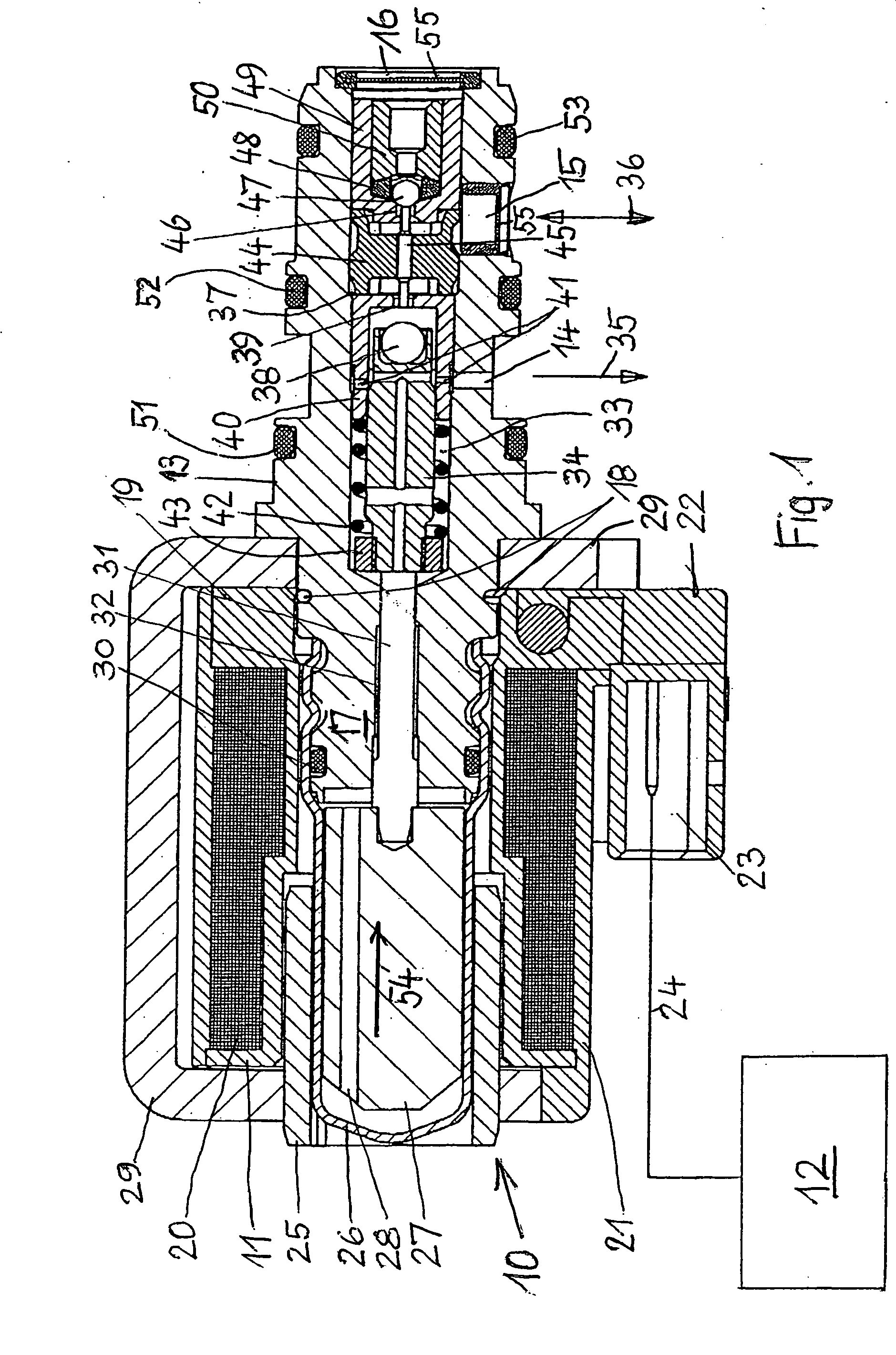

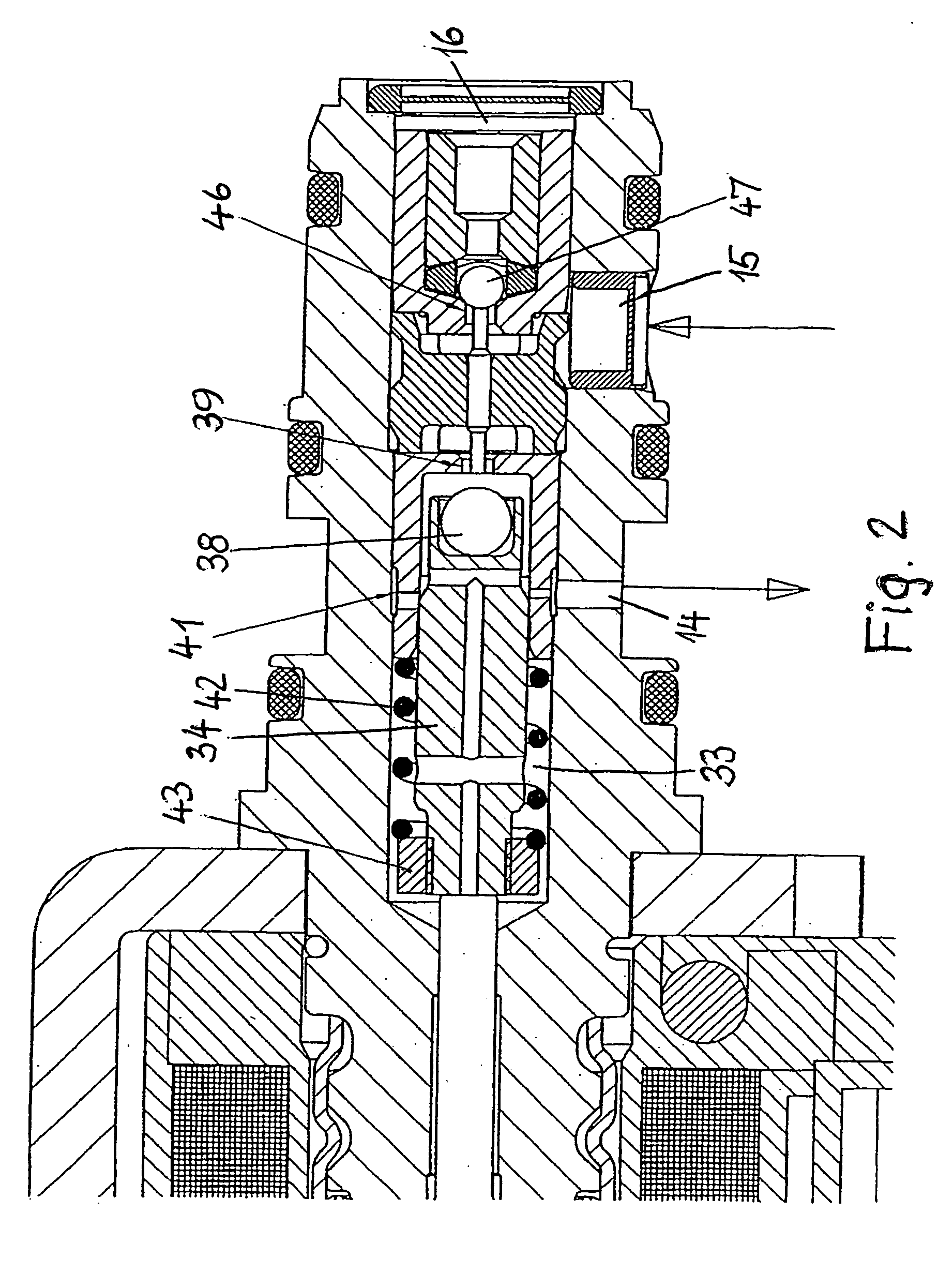

Controllable solenoid valve

ActiveUS20060048824A1Flow cross sectionReduced flow cross sectionOperating means/releasing devices for valvesServomotor componentsSolenoid valveSpring force

Controllable solenoid valve in which, due to the interaction between a magnetic force caused by an electrical flow and a spring force acting against the magnetic force, at least one first sealing body in the interior of a valve housing is displaced in axial direction between two final positions whereby moving relative to its first sealing seat. The interior extends from one electromagnet to a connection. To enable, in a simple manner, a specific reproducible influencing of the sequence speed of cylinder controls in hydraulic drives and to prevent uncontrolled movements by these drives, the first sealing seat up to the first sealing body is provided with an axially extending cylindrical housing inside of which a slide is axially displaced according to the electrical flow. The cylindrical housing comprises radially oriented passages, whereby these passages are closed if the first sealing body is located in a final position in its first sealing seat or in the immediate vicinity of the first sealing seat, and the passages are opened if the first sealing body is located in the opposite final position.

Owner:RAUSCH & PAUSCH

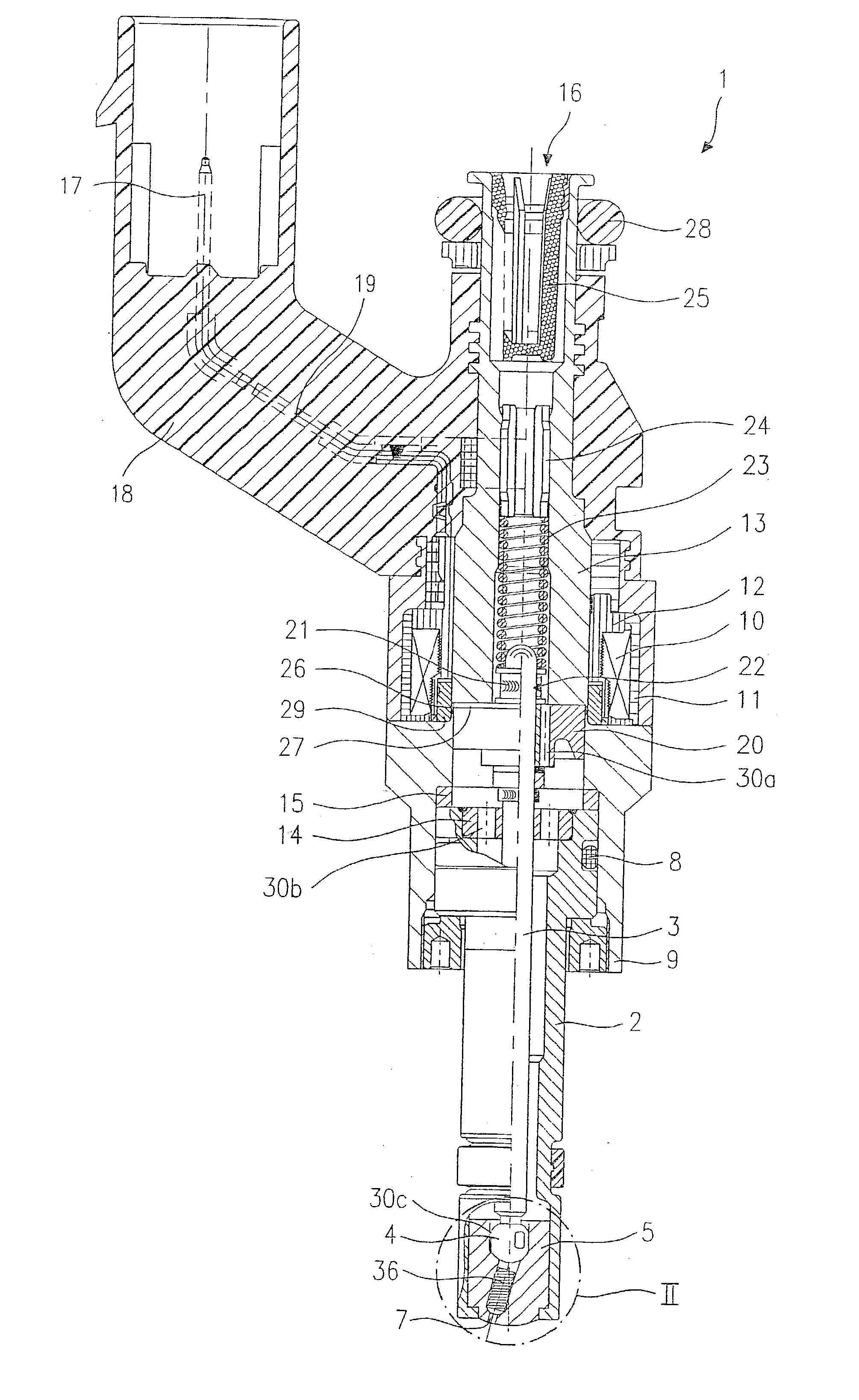

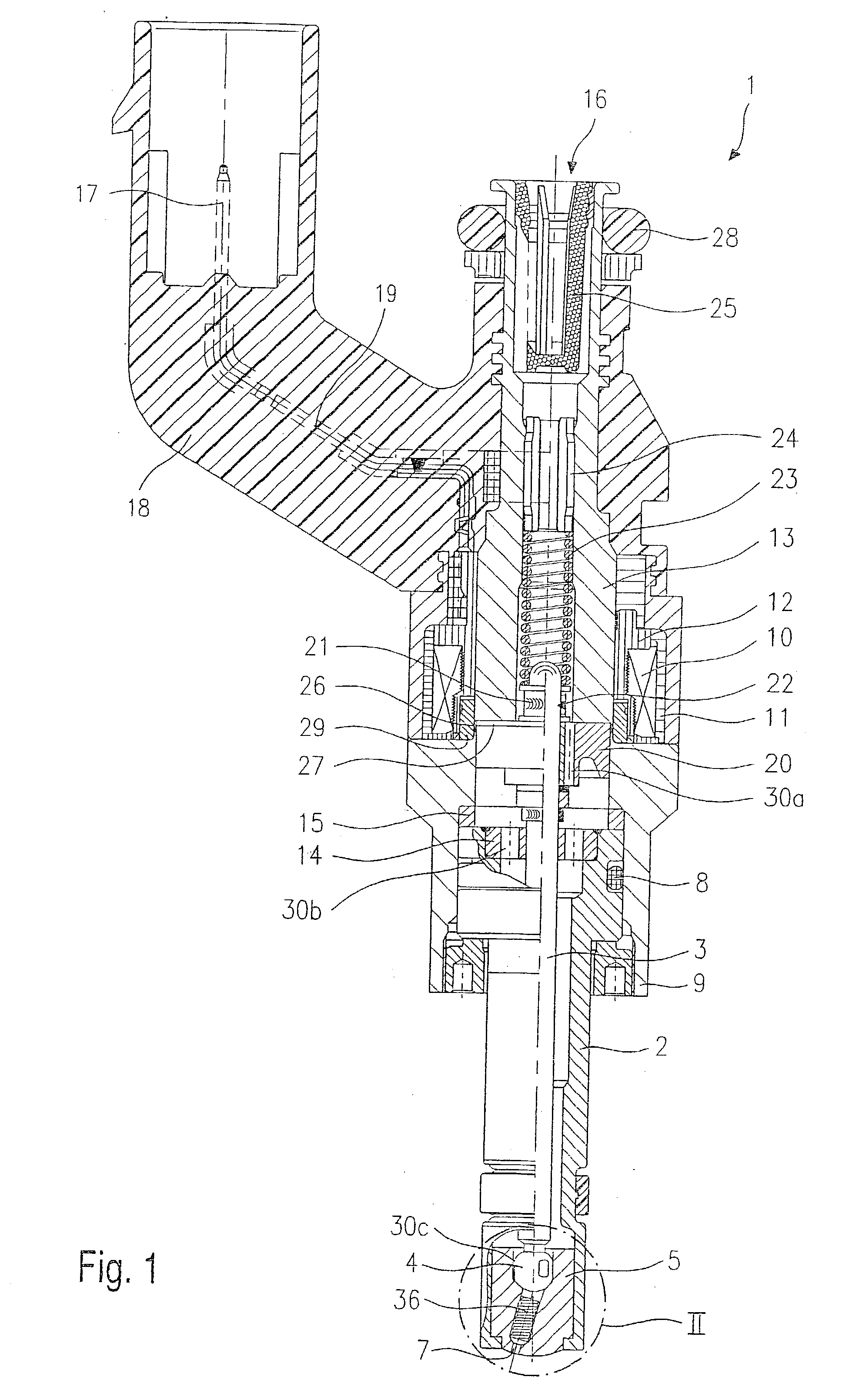

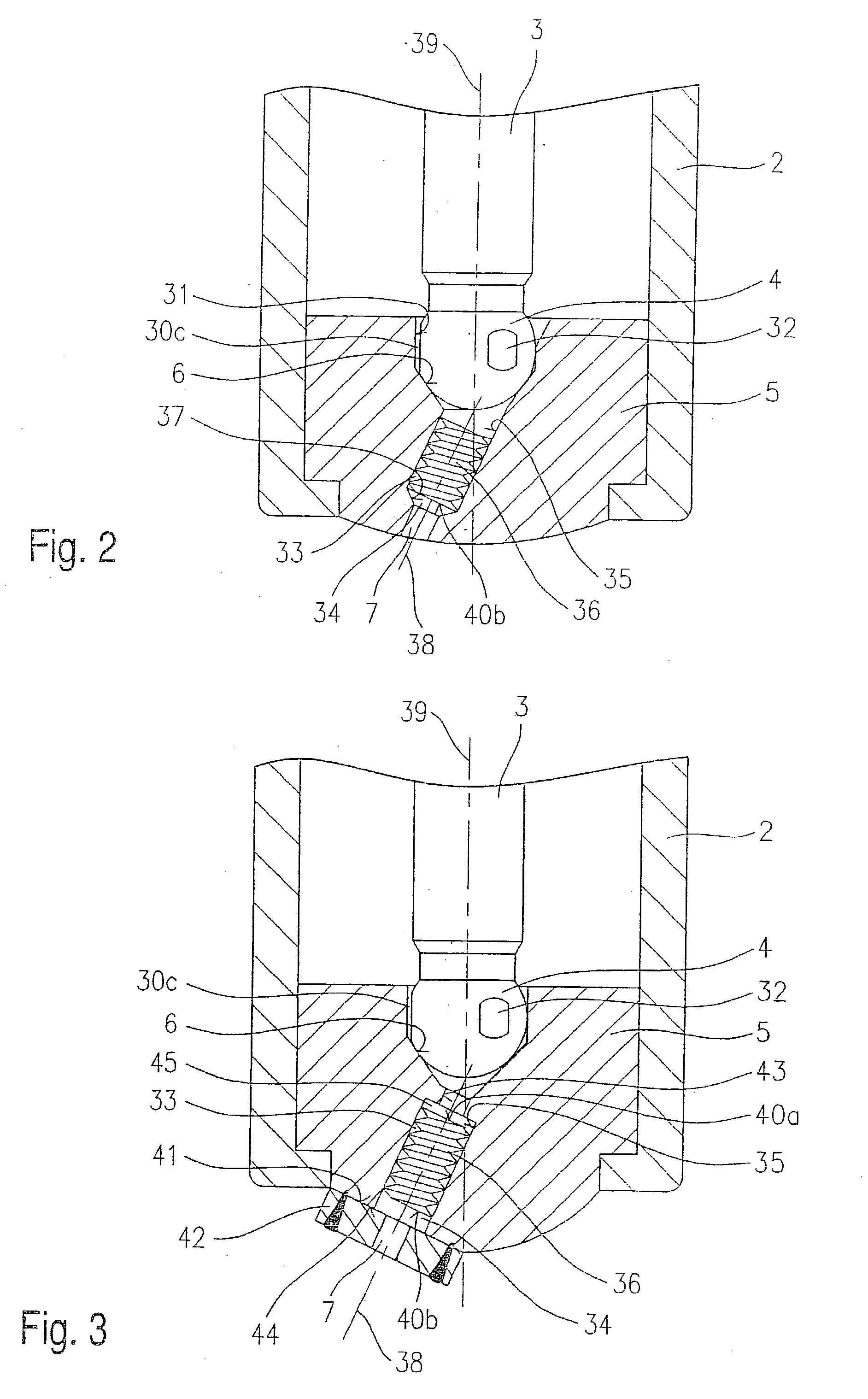

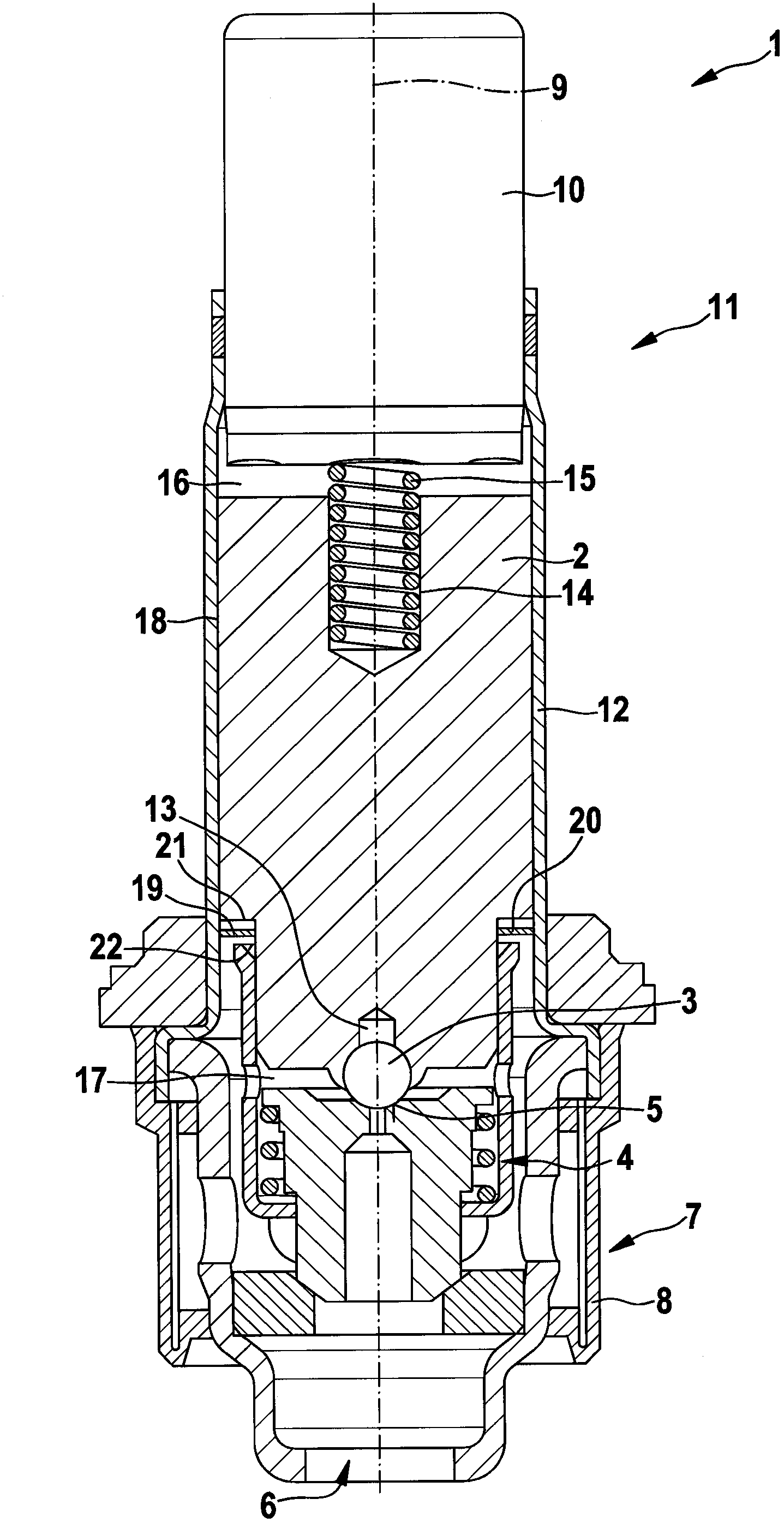

Fuel injection valve

InactiveUS20030111562A1Eliminate deflectionEliminates complicated remachining of the swirl insertSpray nozzlesMachines/enginesCombustionEngineering

A fuel injector (1) for fuel injector systems of internal combustion engines has a valve-closure member (4) which is mechanically linked to a valve needle (3) and cooperates with a valve-seat surface (6) of a valve-seat member (5) to form a sealing seat. A turbulence-producing element is provided in the valve-seat member (5), situated downstream from the sealing seat, and its center line (38) preferably forms an angle different from zero with the center line (39) of the fuel injector (1), a threaded rod (36) being pressed into the valve-seat member (5) as the turbulence-producing element.

Owner:ROBERT BOSCH GMBH

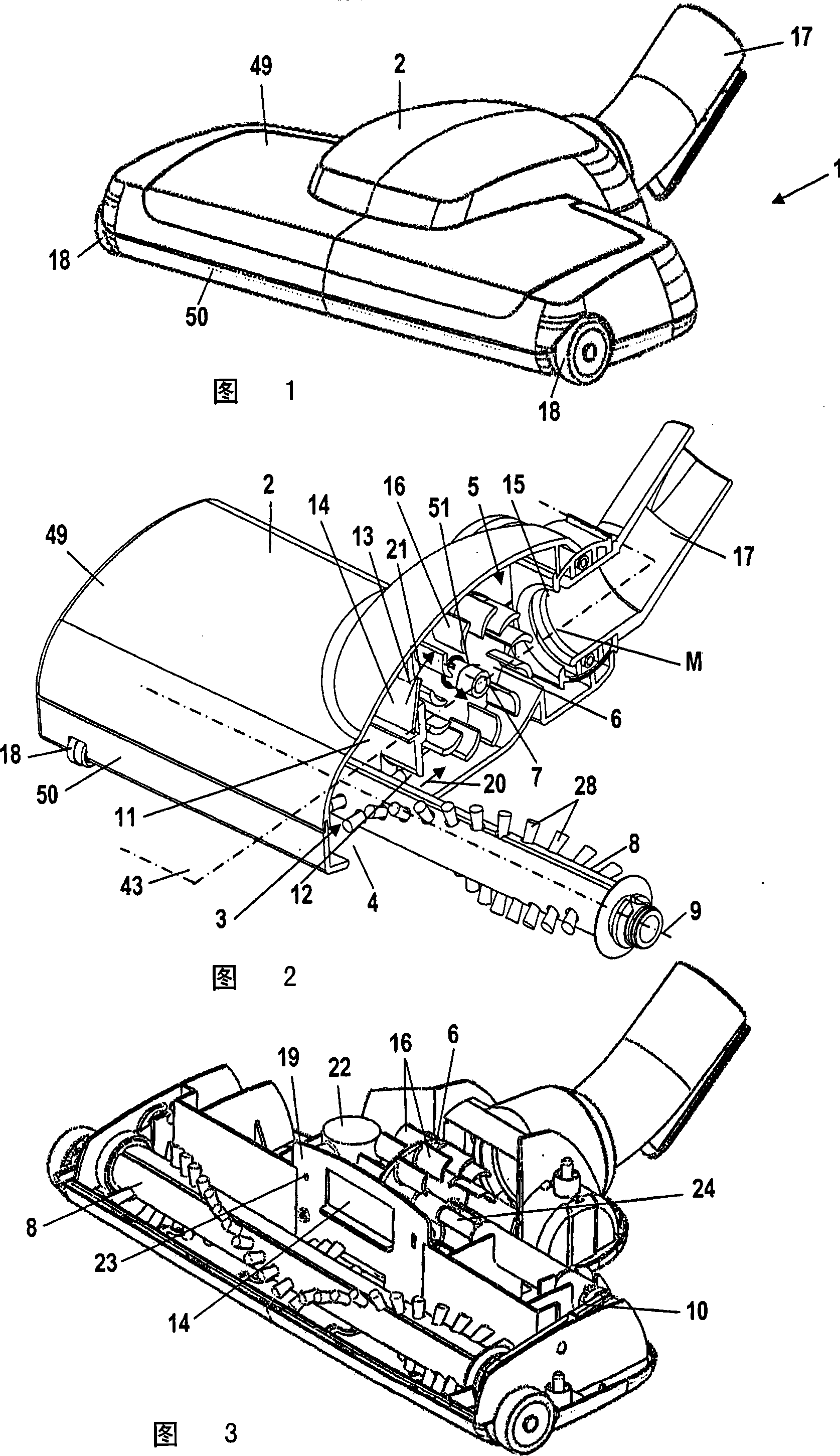

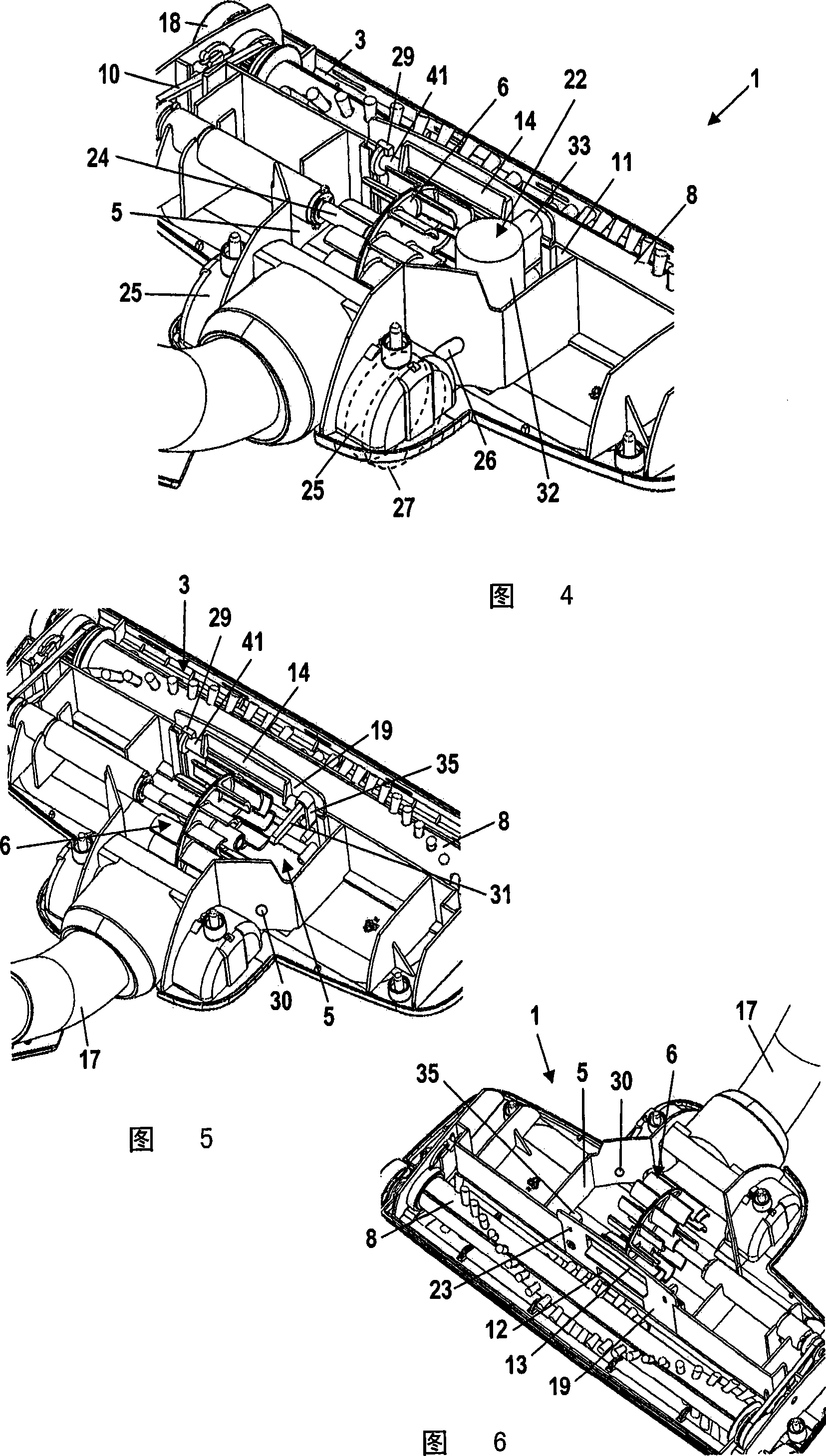

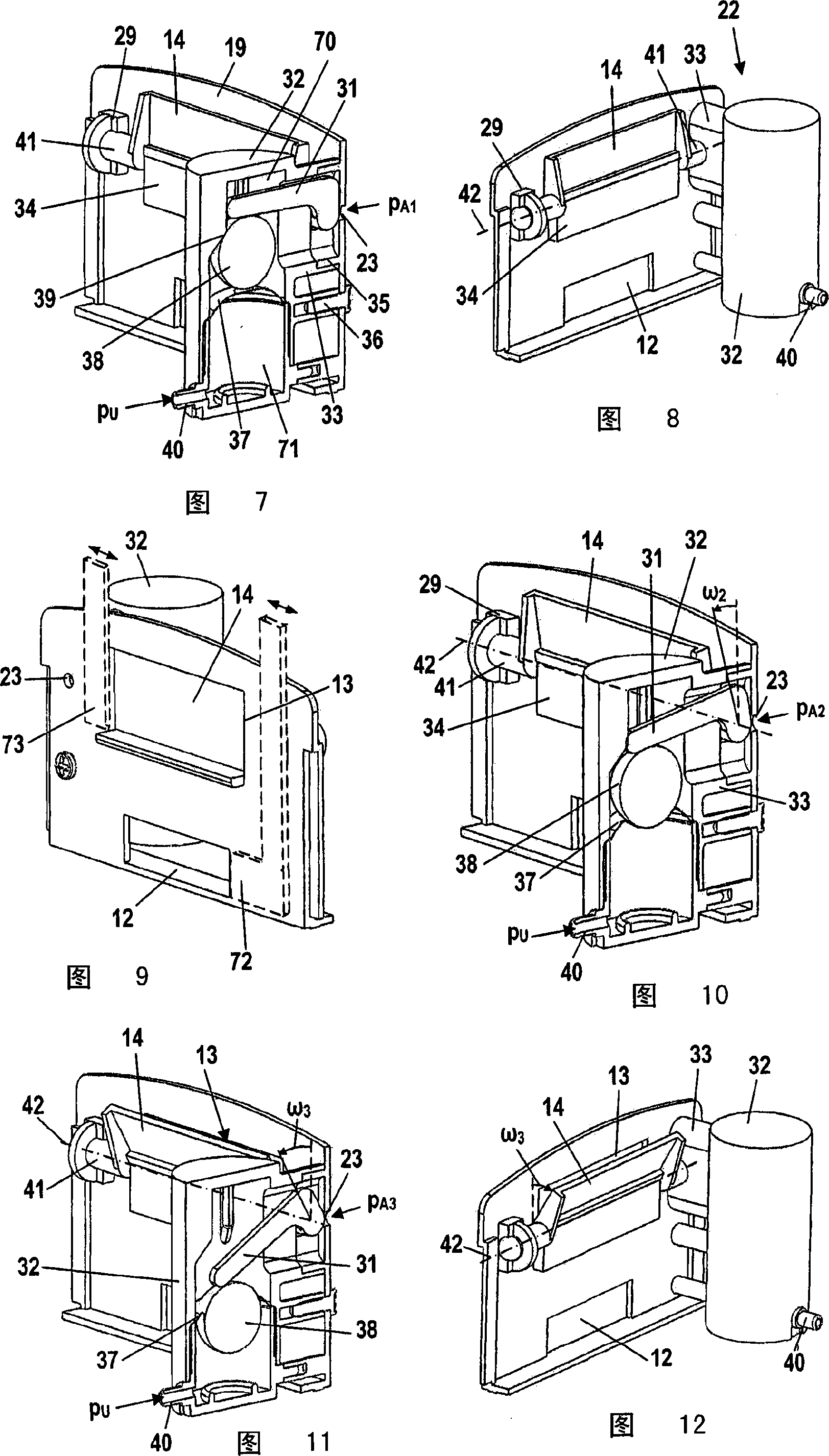

Vacuum cleaning tool and method for its operation

InactiveCN101133931AAdjustable maximum flow cross-sectionSimple structureMechanical suction controlSuction nozzlesEngineeringAirflow

The suction cleaner has a housing (2) with a connecting piece (17) for connection to a suction device of the suction cleaning device. The suction cleaner has a suction hole (4) through which the working airflow flows into the housing (2); and a discharge hole (15) through which the working airflow leaves the housing (2) . The suction cleaner has a cleaner which is rotatably supported in the casing (2) and has a drive device for driving the cleaner to rotate. Good cleaning results and up to turbine power Good fit to different floor conditions. The method for operating the suction cleaner provides that the drive power of the cleaner is controlled as a function of the pressure (p) in the suction cleaner.

Owner:DUPRO AG

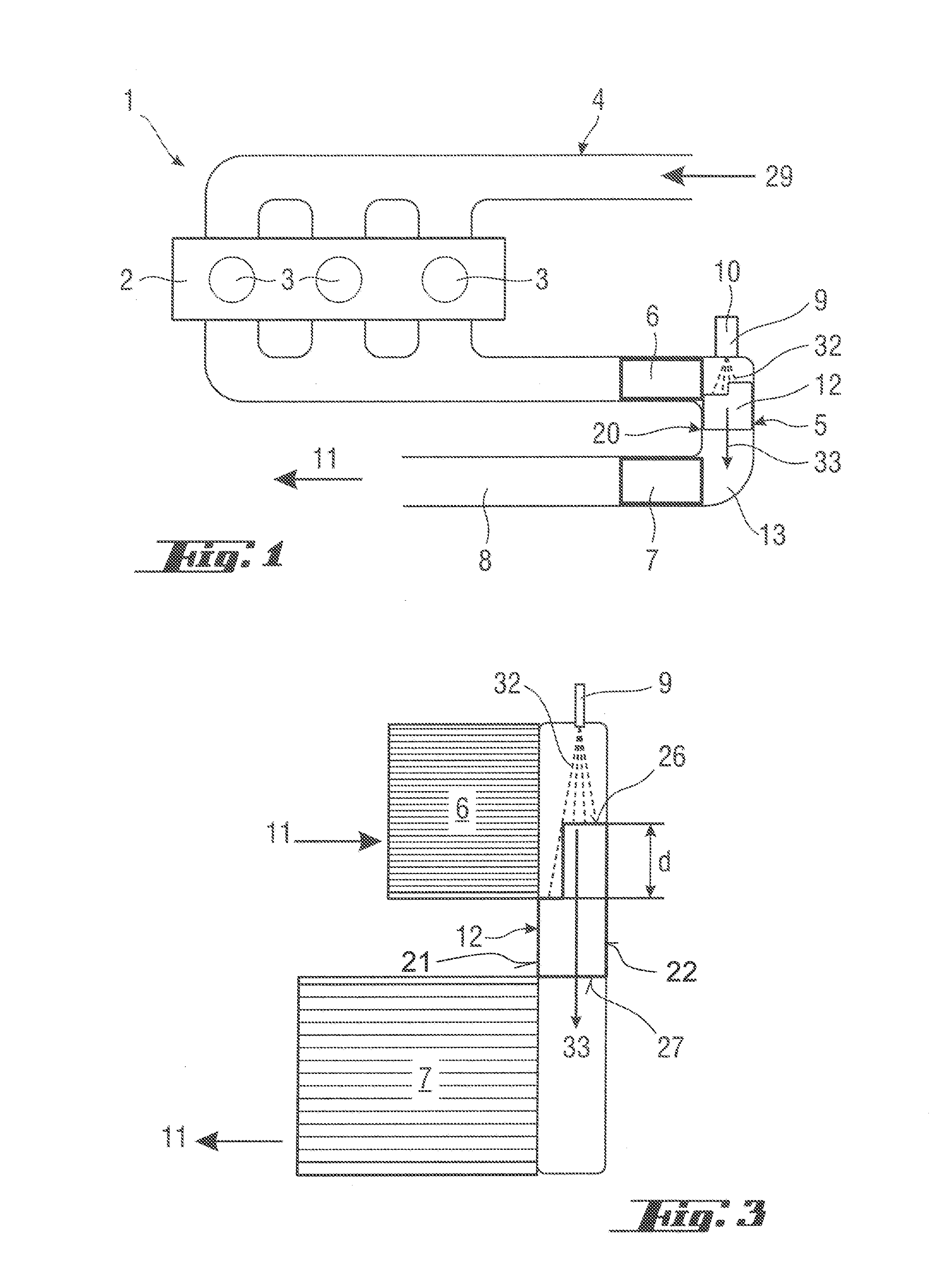

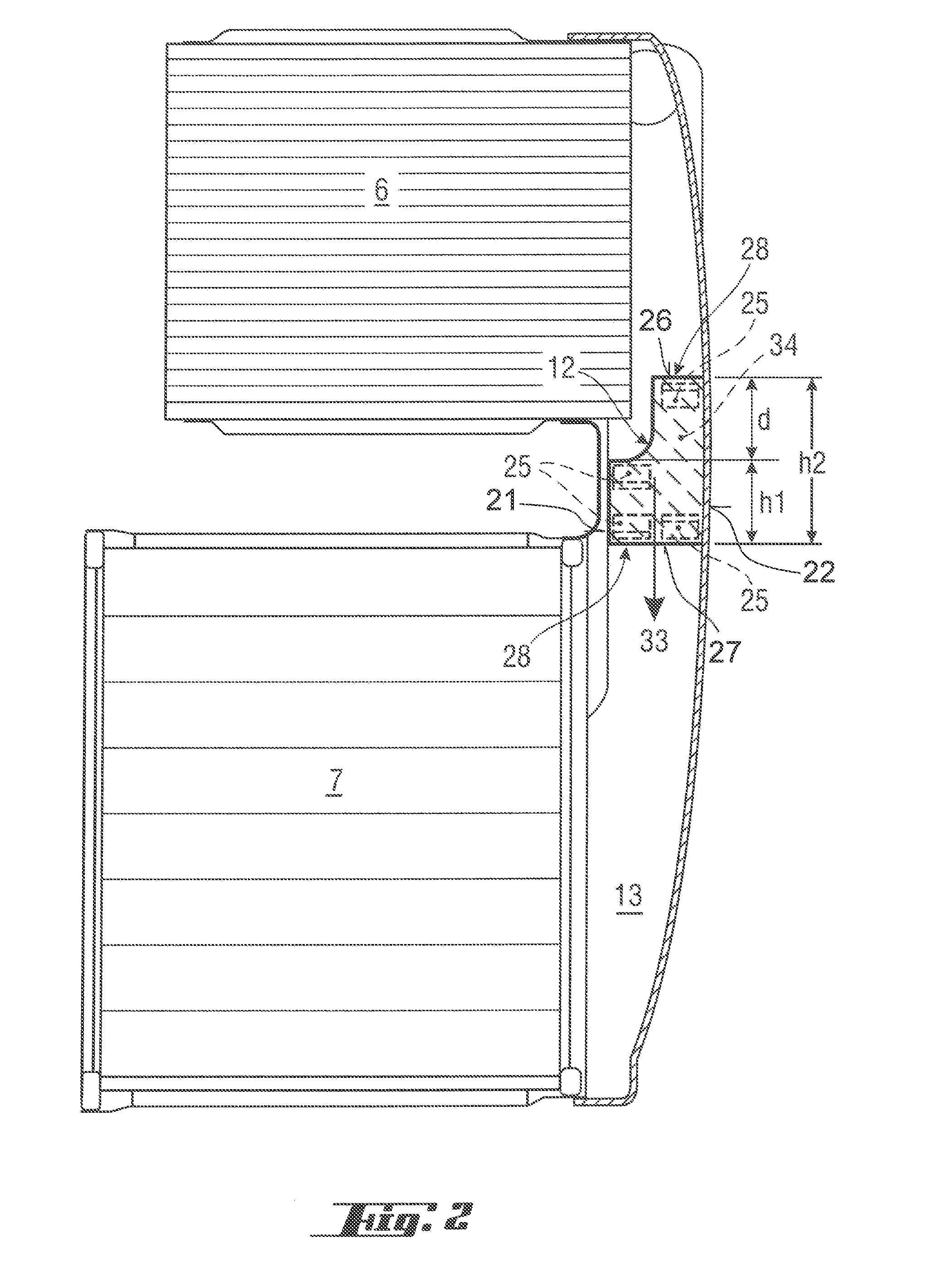

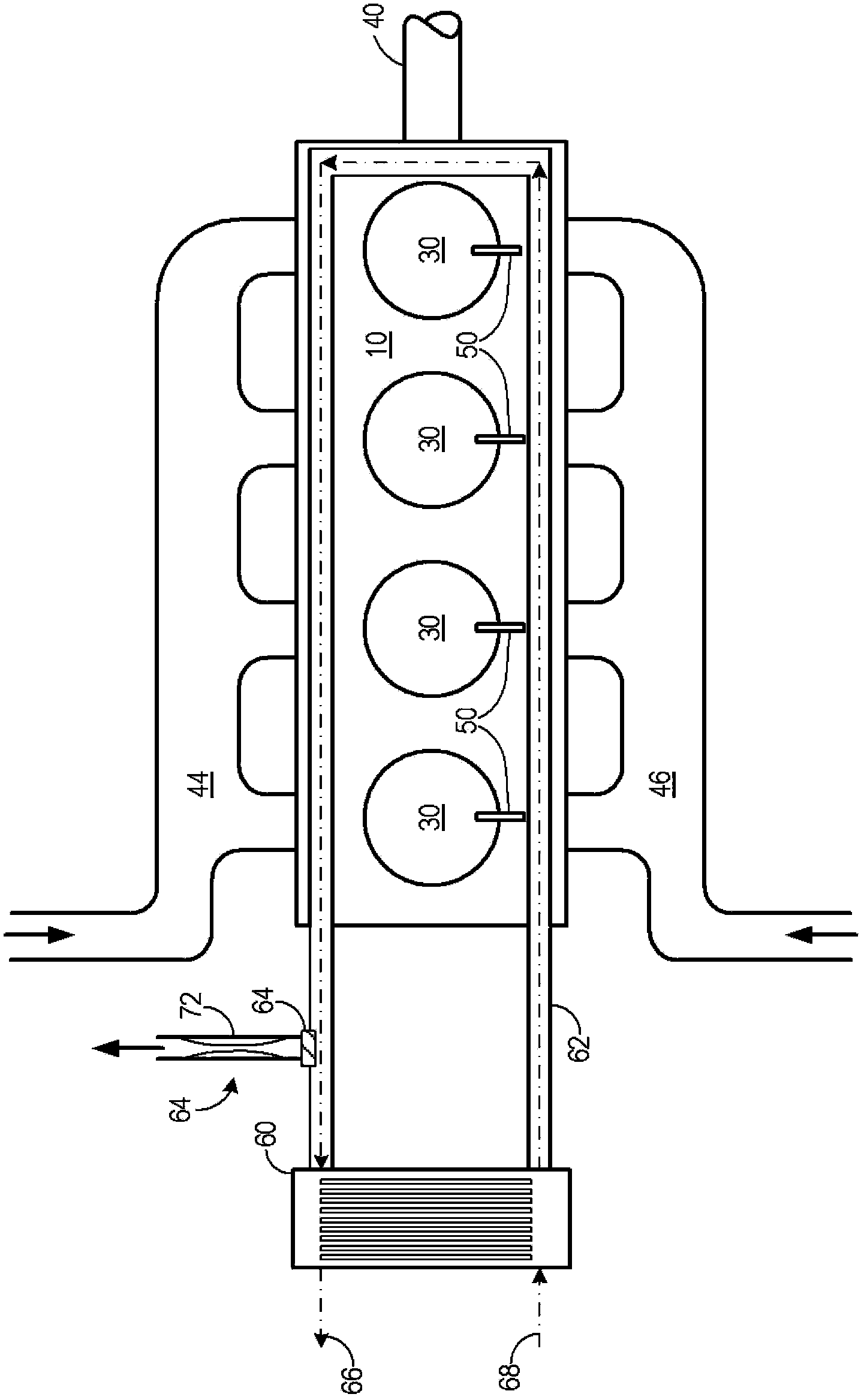

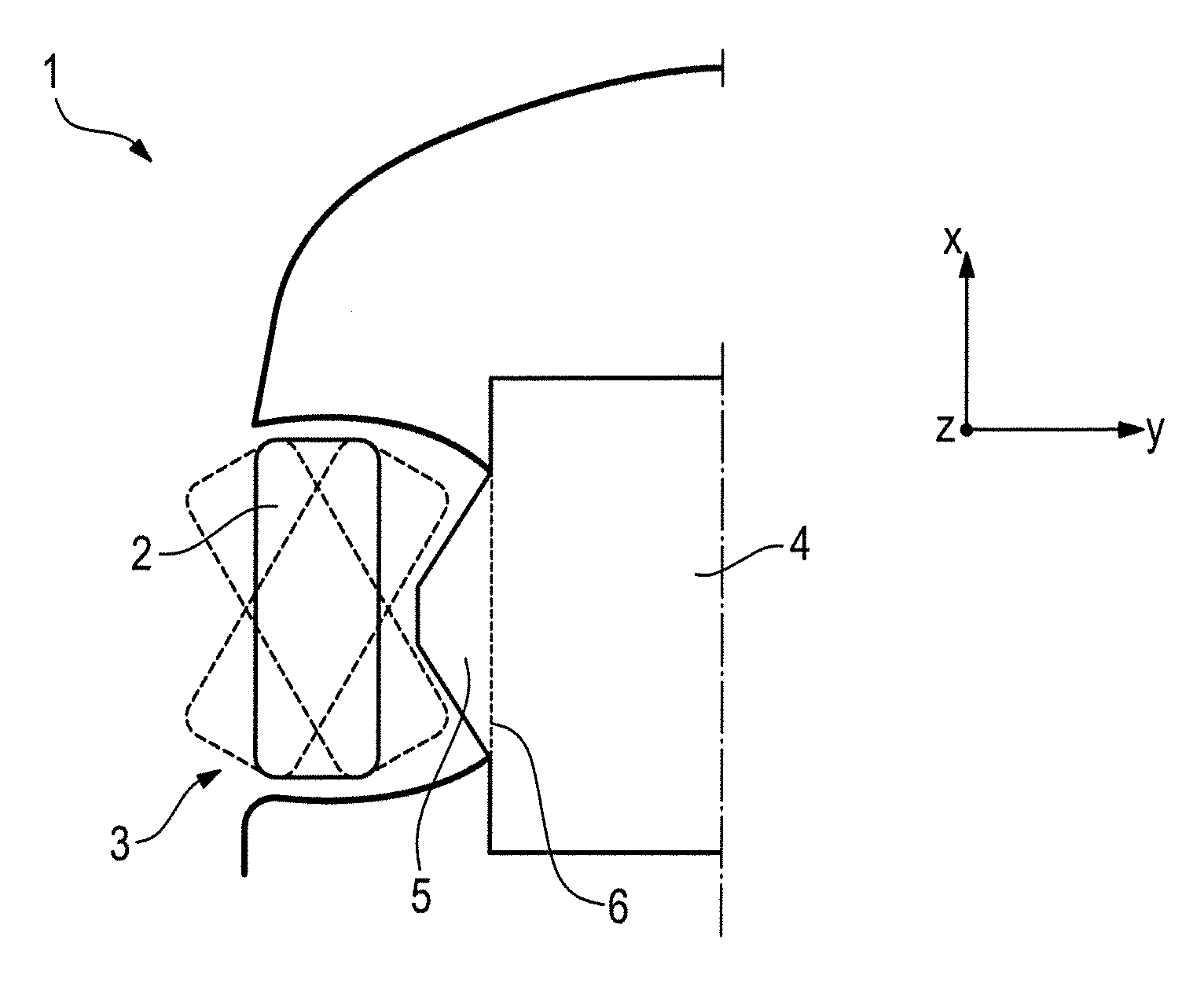

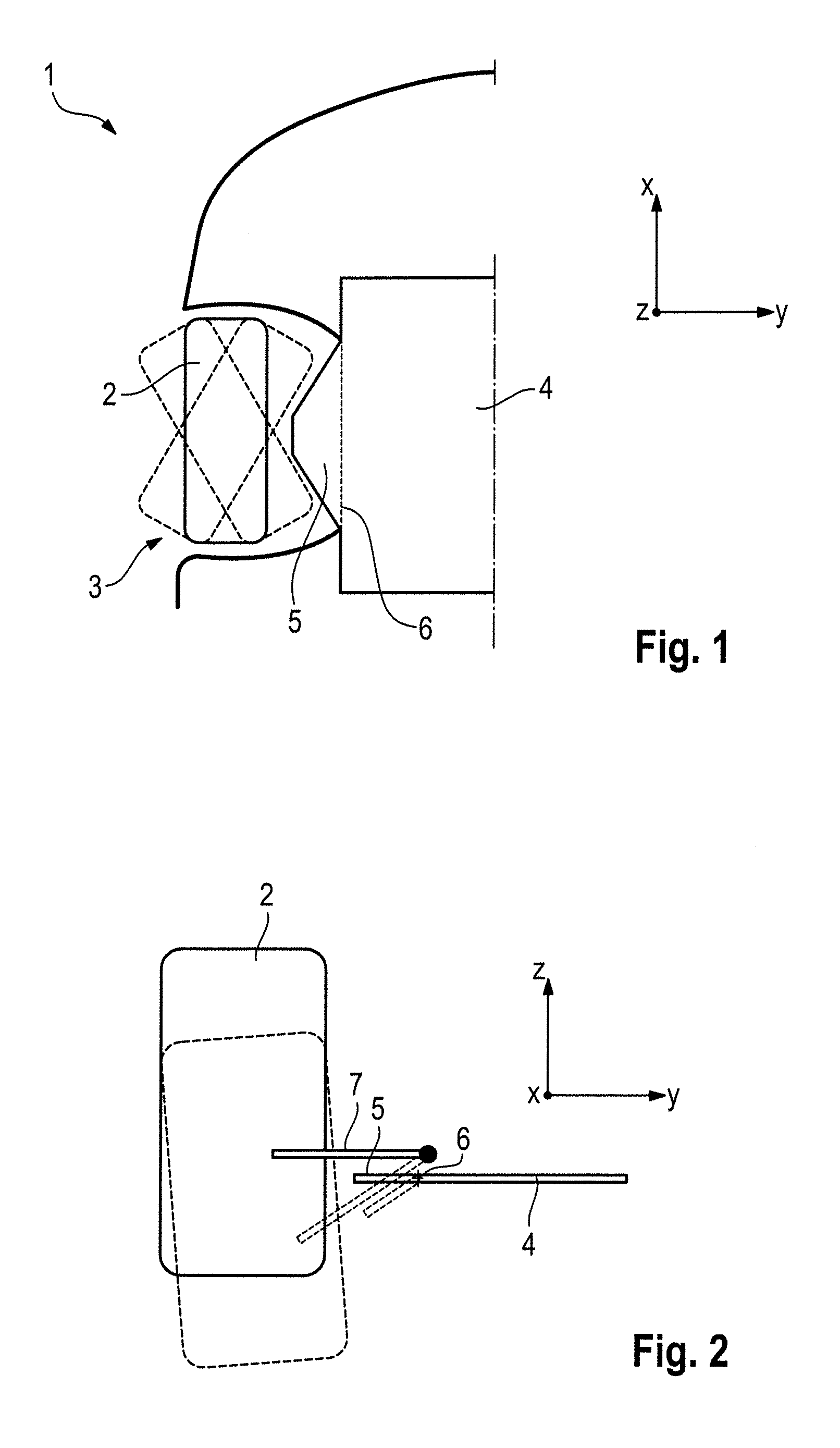

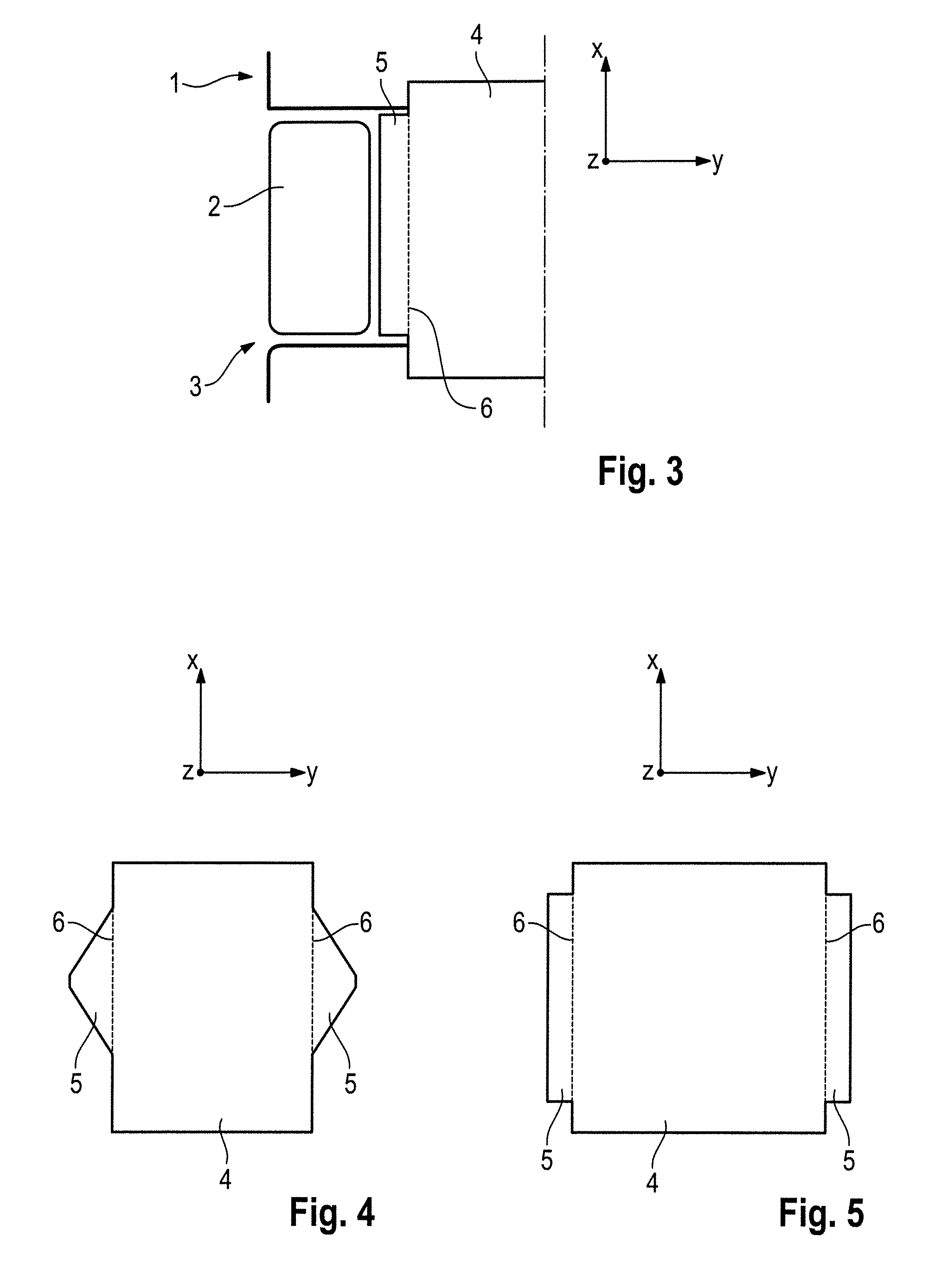

Exhaust system with mixing and/or evaporating device

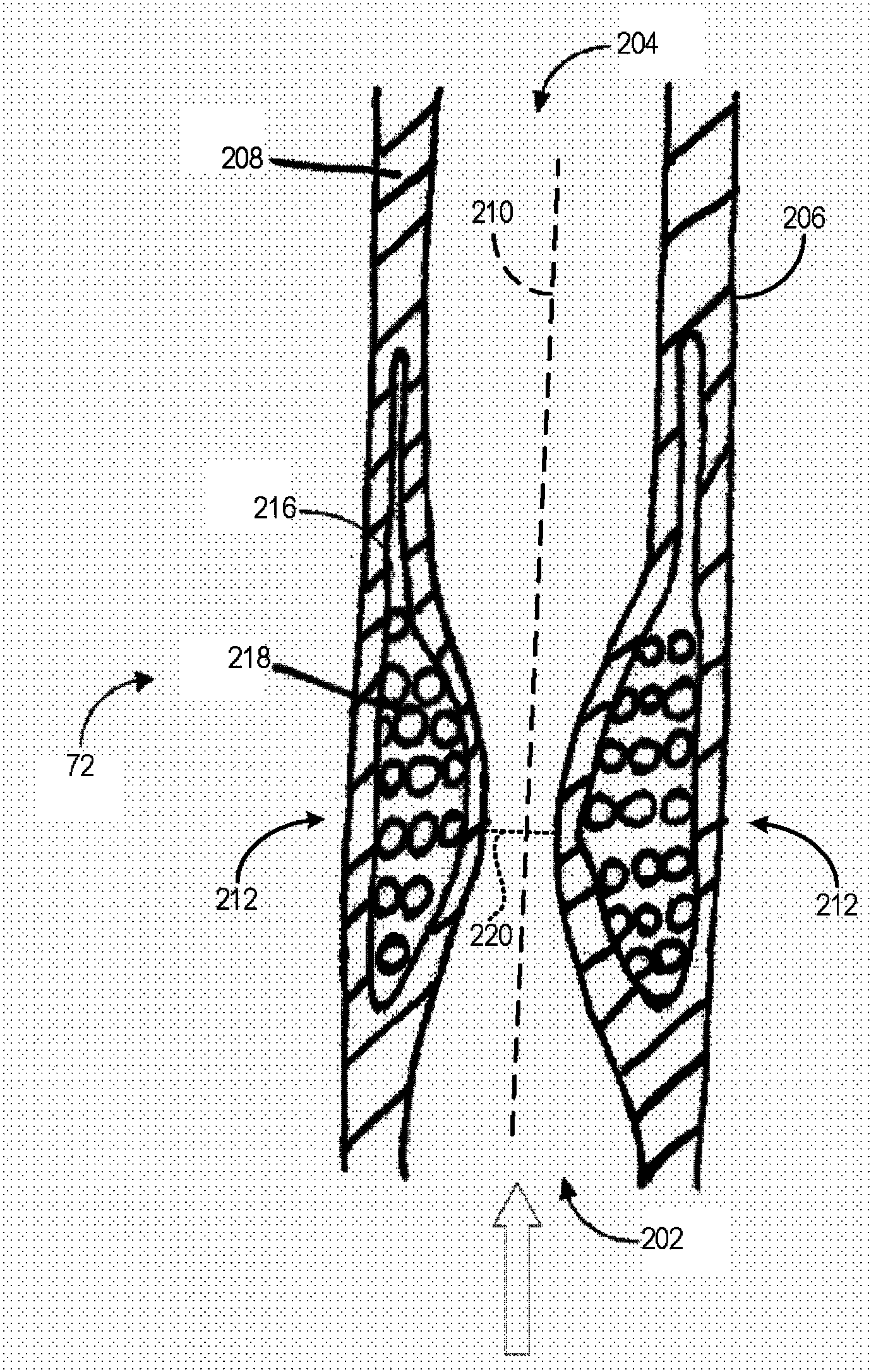

ActiveUS20140109557A1Well mixedInhibition formationFlow mixersExhaust apparatusEngineeringInternal combustion engine

A mixer / evaporator or an exhaust system (5) of an internal combustion engine (1), includes a carrier (20) surrounding, in a circumferential direction, a flat cross section of a mixing / evaporating device (12), through which exhaust gases flow and which extends at a right angle to the axial direction (17). The carrier has opposite side walls, wherein short side walls (23, 24) connect each long side walls (21, 22) to one another. Guide blades (25) project in a direction of the respective opposite long side wall, are set at an angle in relation to the axial direction and are arranged at one of the long side walls at at least one axial end (26, 27). An axial end of the first long side walls is offset in the axial direction in relation to the axial end of the second long side wall on the same side of the mixing / evaporating device.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

Apparatus and method for treating formed parts by means of high-energy electron beams

InactiveUS20110020174A1Complicated constructionReduced flow cross sectionElectric discharge tubesMaterial analysis by optical meansHigh energyX-ray

The invention relates to a device for treating formed parts with high-energy electron beams. The electron beams are guided by two opposite stationary or displaceable electron discharge windows onto the formed part and bounding a process space for the formed part. A transport device is present for the formed part, by which the formed part can be guided through the process space to the electron discharge windows disposed substantially vertically perpendicular to the transport direction. A channel is disposed in the process space for transporting the formed part and largely shielded against the X-ray radiation.

Owner:ROBERT BOSCH GMBH

Method for the treatment and prevention of asphaltene-paraffin-vax precipitates in oil-wells, wellheads and pipelines by the use of biocolloid suspensions

InactiveUS20060060350A1Low viscosityHigh viscosityContaminated soil reclamationFluid removalMicroorganismDecomposition

The method for the prevention, reduction and / or removal of asphaltene-paraffin-vax precipitates on surfaces in contact with crude oil within oil-wells from bottom hole to well head, in flow lines and pipelines by the use of biocolloid suspensions comprises the steps of: adding together (a) microorganism(s) capable of reacting with, solubilizing of and / or resistant to the components of crude oil, (b) organic or inorganic additives, or (c) a mixture thereof into the pipes; and allowing the so formed suspension containing the microorganisms to act for a desired time. The suspension is used for the decomposition, washing-off and removal of solid hydrocarbons and mixtures of long chain hydrocarbons, as well as for the prevention of formation thereof.

Owner:MOL HUNGARIAN OIL & GAS

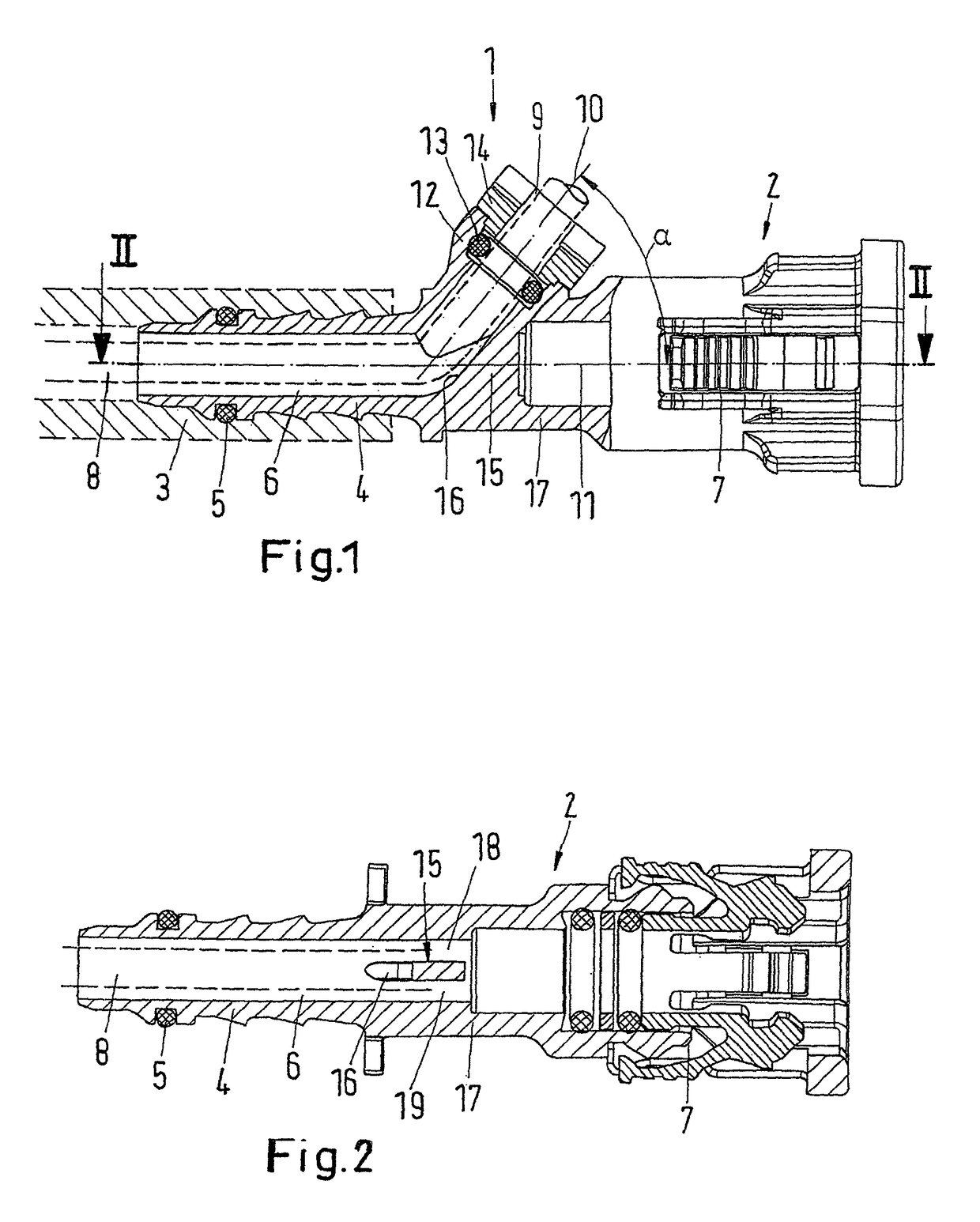

Fluid line

A fluid line includes a pipe, a connector having a pipe connection arranged at one end of the pipe, and a through-channel through the connector, wherein the pipe connection surrounds a portion of the through-channel, and a heater structured and arranged within the pipe and the connector to heat at least a portion of the pipe and at least a portion of the connector. A flow cross section of the through-channel section at least on a part of its length is no more than 60% of a flow cross section of the pipe.

Owner:NORMA GERMANY GMBH

Variable flow resistance

InactiveCN103363148AReduced flow cross sectionDiaphragm valvesOperating means/releasing devices for valvesShear rateEngineering

A fluid-carrying conduit achieves variable resistance to flow. An elongate, hollow body casing has at least one chamber containing either a dilatant fluid or an electroactive polymer. In the case of the dilatant fluid, a reduction in an effective flow cross section of the fluid line occurs in reaction to an increase in the shear rate of a fluid flowing through the fluid line. In the case of the electroactive polymer, a reduction in an effective flow cross section of the fluid line occurs in reaction to an electric current being applied to the body casing. The conduit may be configured for use as a degassing line in a cooling system of an internal combustion engine. The conduit may have a reinforcement encircling the electroactive polymer. The conduit may have an electrically conductive connecting surface adjacent to the electroactive polymer. The electroactive polymer may be an ionic electroactive polymer.

Owner:FORD GLOBAL TECH LLC

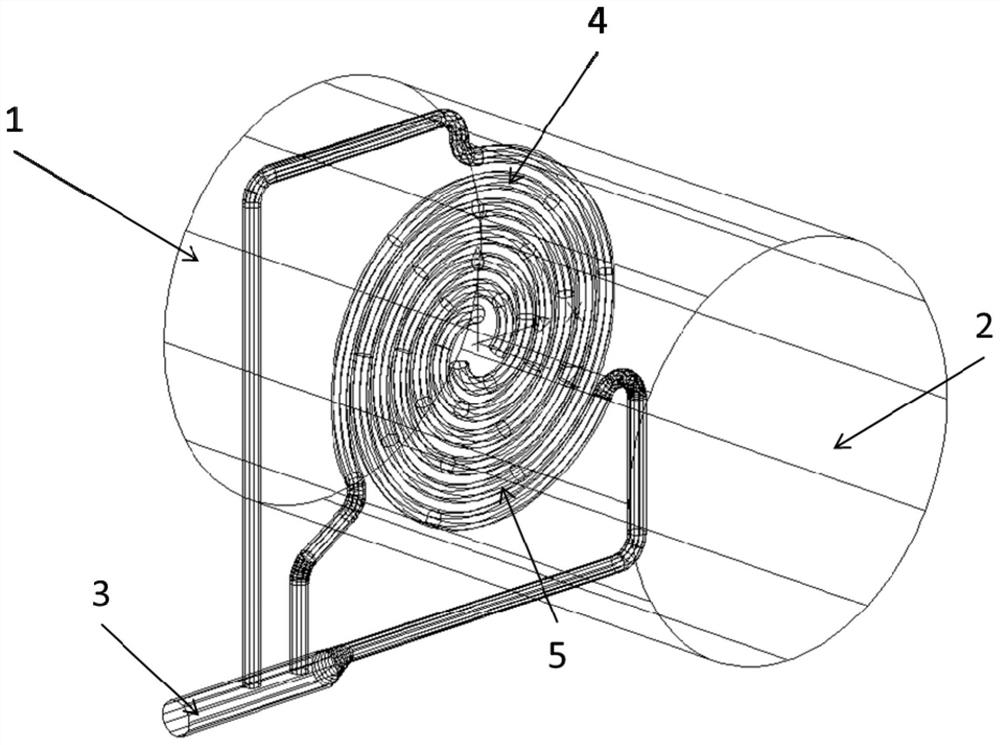

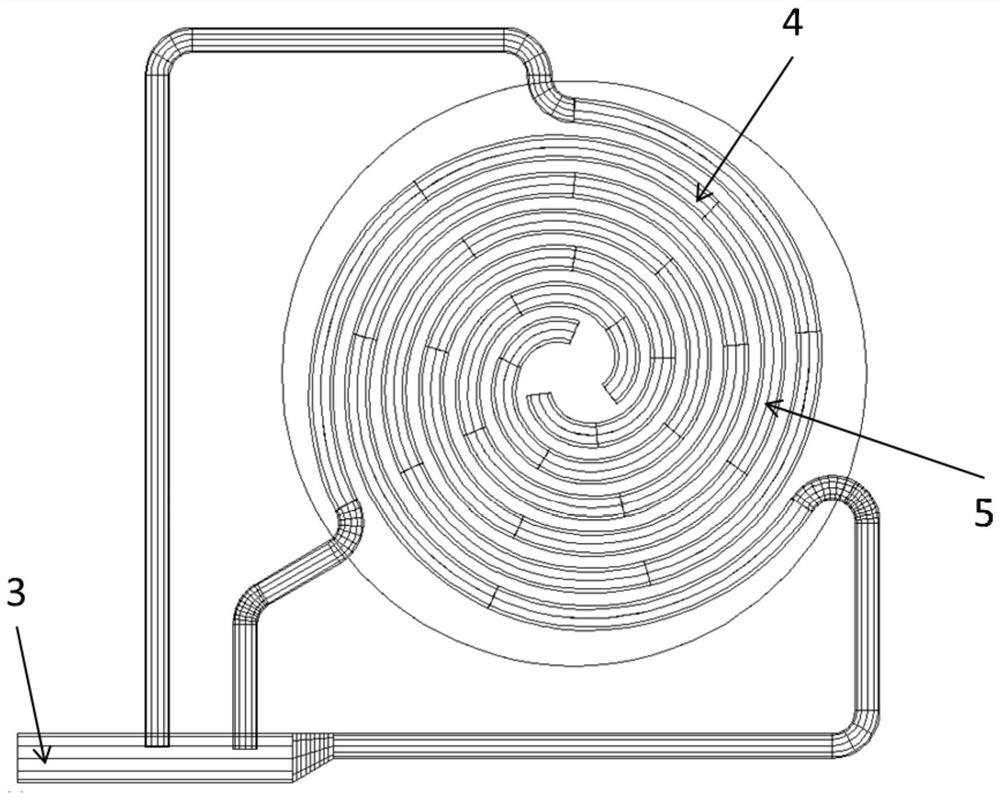

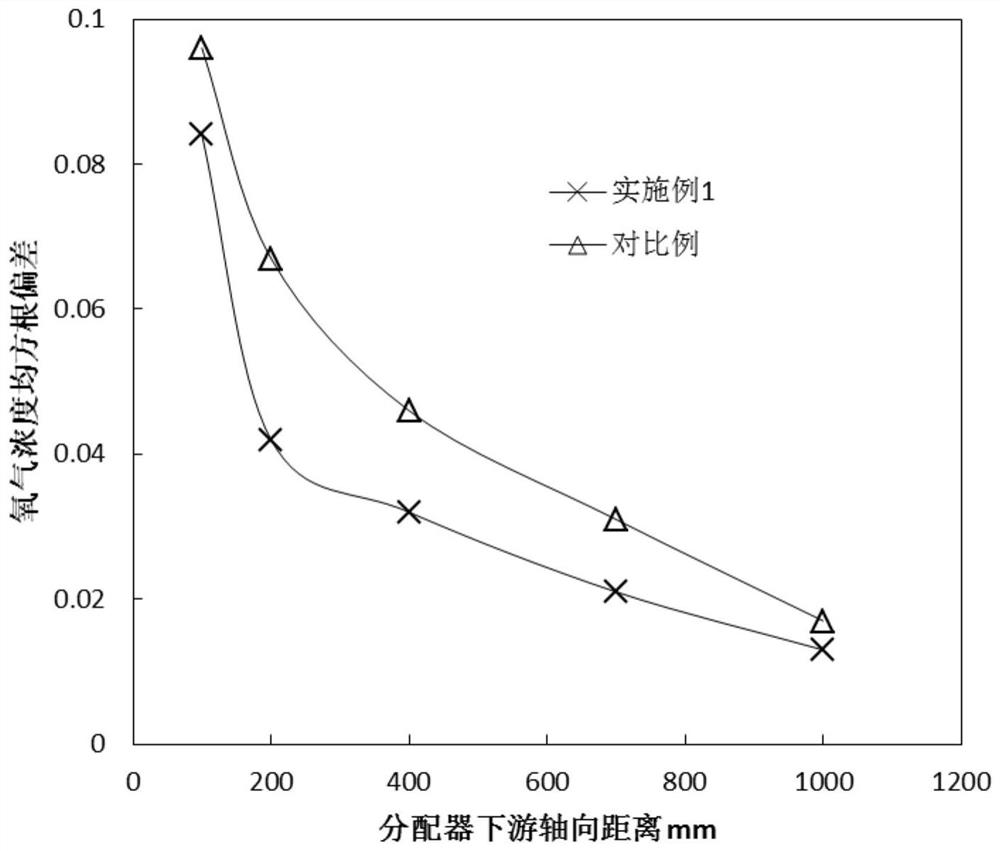

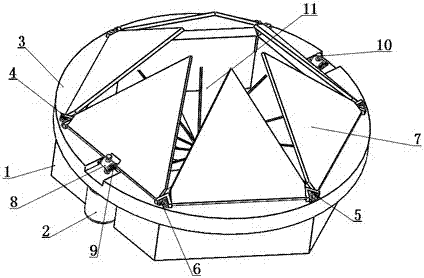

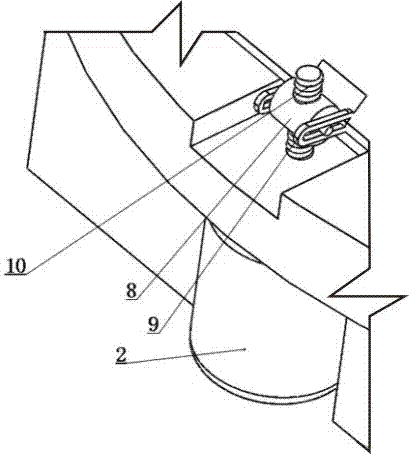

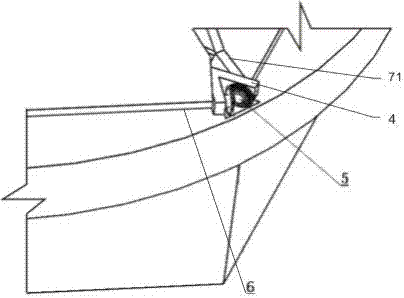

Rapid mixing equipment for ethylene and oxygen

ActiveCN108310989BFlexible structureSimple structureFlow mixersTransportation and packagingAlkeneMaterials science

The invention relates to a rapid mixing device for ethylene and oxygen, which mainly solves the problem of unsatisfactory mixing effect of olefin and oxygen in the prior art. The present invention adopts a kind of rapid mixing equipment of ethylene and oxygen, comprising ethylene main pipe and mixing chamber, the end of ethylene main pipe is connected to the mixing chamber, a number of oxygen spiral distribution pipes are arranged in the mixing chamber, the plane of the spiral distribution pipe is perpendicular to the flow direction of ethylene, A number of oxygen nozzles are evenly distributed on each spiral distribution pipe. The direction of the nozzles is consistent with the flow direction of ethylene. The oxygen feed pipe is divided into several branch distribution pipes in the main pipe and enters the main pipe of ethylene, so that the ethylene entering from the main channel and the nozzle of the spiral distribution pipe are sprayed. The technical scheme of rapid mixing of the oxygen produced in the mixing zone solves the above problems well, and can be used in the mixing of ethylene and oxygen.

Owner:SINOPEC SHANGHAI ENG +1

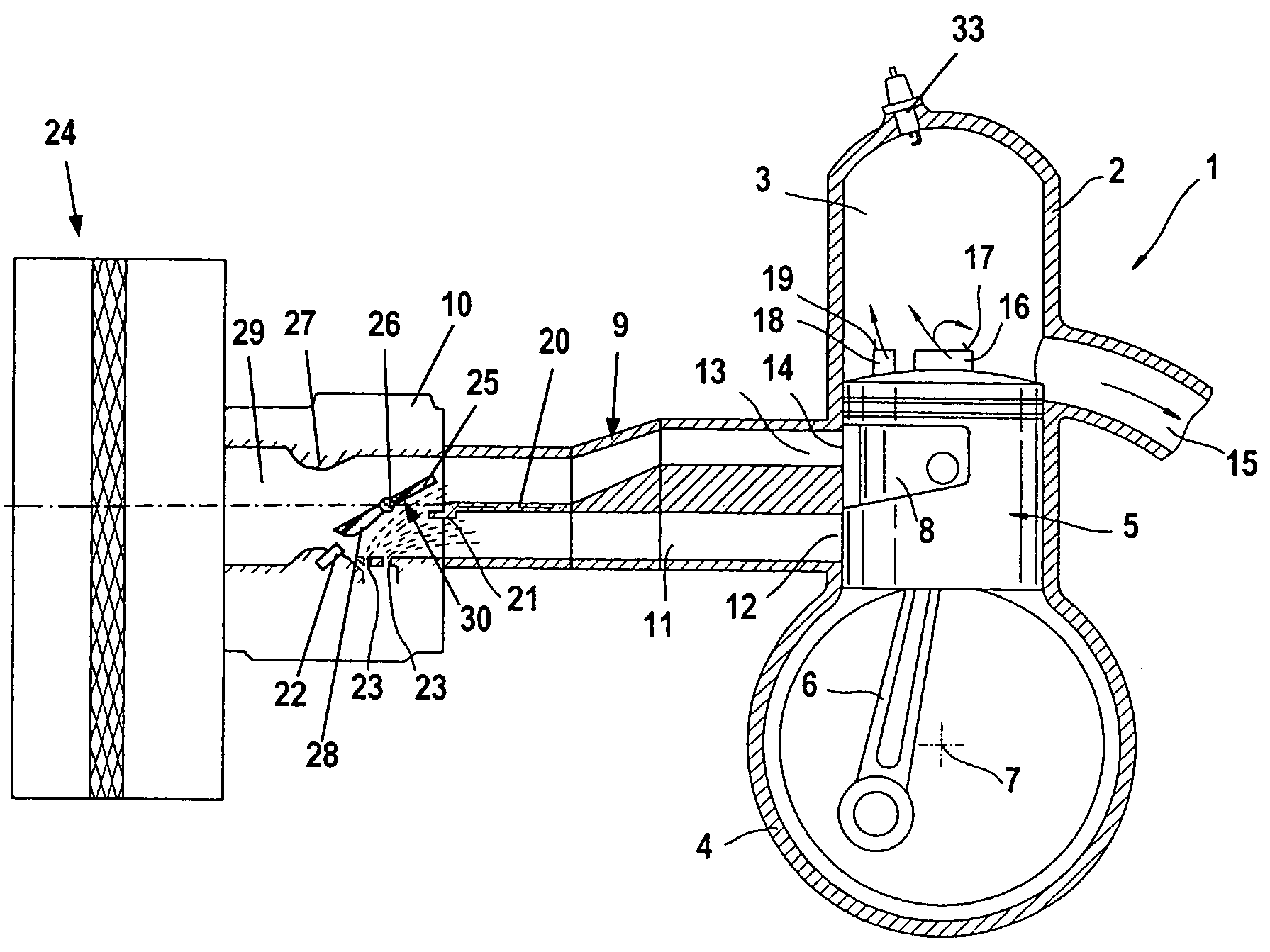

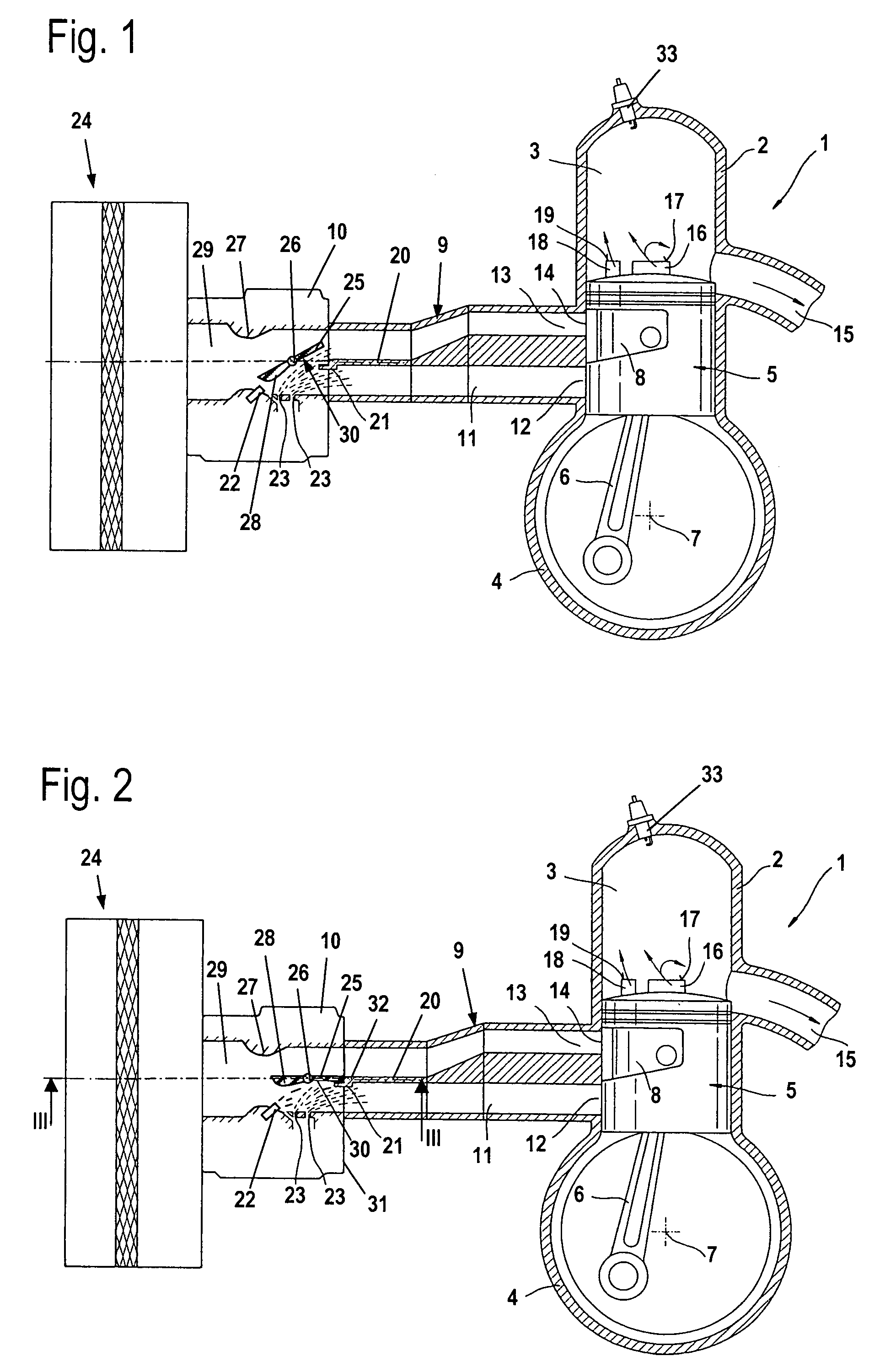

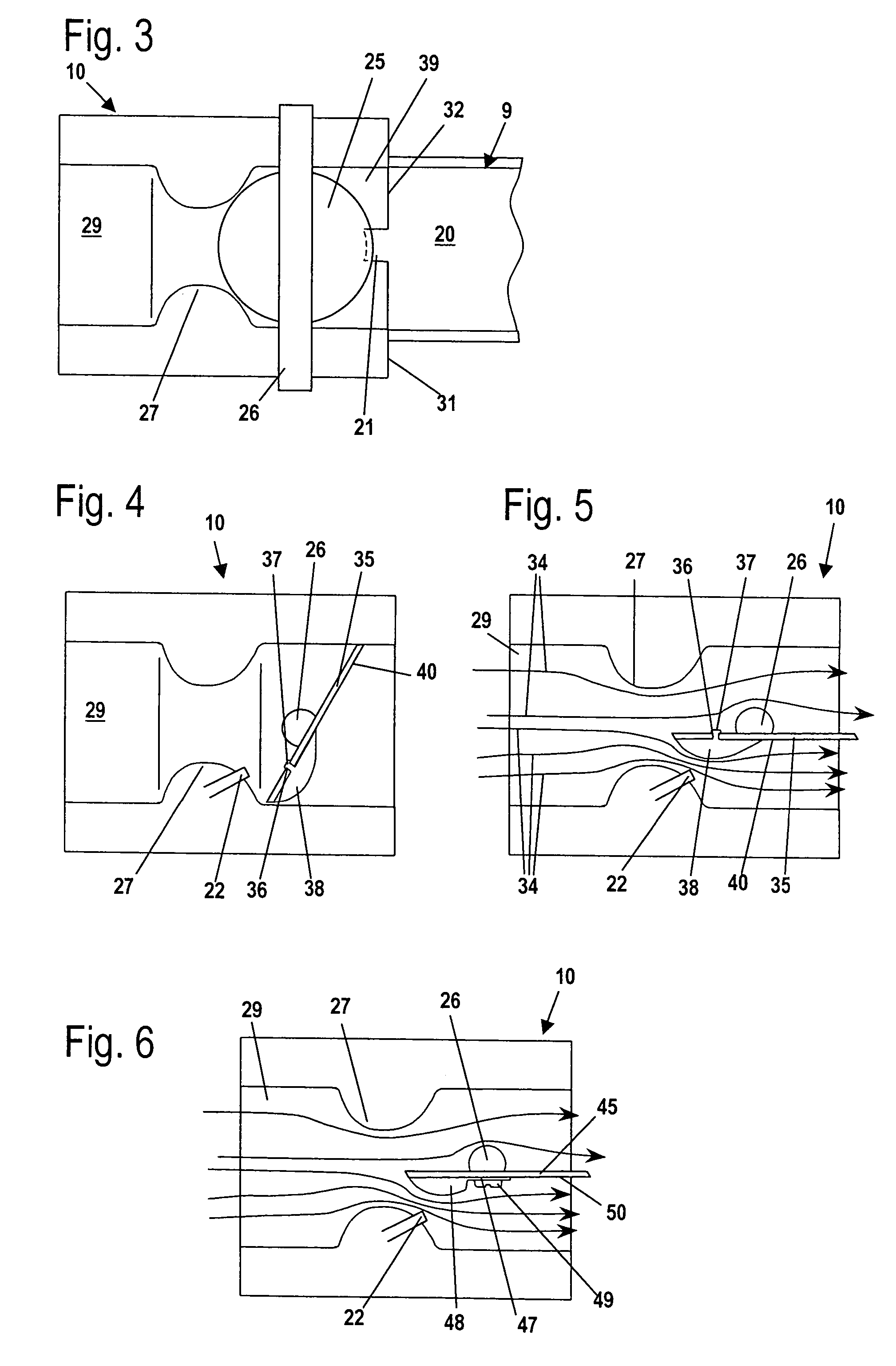

Two-cycle engine

InactiveUS7201120B2Increase flow rateSufficient supplyCombustion enginesCarburettorsCombustion chamberCrankcase

Owner:ANDREAS STIHL AG & CO KG

Magnet valve, and driver assistance device comprising such magnet valve

InactiveCN103052547AIncrease dampingConstant dampingOperating means/releasing devices for valvesValve members for absorbing fluid energySolenoid valveEngineering

The invention relates to a magnet valve (1) comprising a magnet armature (2) that is operatively connected to a sealing element (3) of the magnet valve (1) in order to displace said element and comprising at least one flow path (18) via which fluid chambers (16, 17) that lie on opposing faces of the magnet armature (2) can be connected or are connected in a fluidic manner. At least one damping element (19) is arranged in the magnet valve (1) in a displaceable manner in the axial direction, said damping element protruding into the flow path (18) at least in some regions.

Owner:ROBERT BOSCH GMBH

Motor vehicle with a device for reducing an air stream flow into a wheel house

ActiveUS20150048648A1Reduced flow cross sectionReduced volume flowVehicle seatsWindowsAirflowAutomotive engineering

A motor vehicle (1) has a device (5) that projects into the wheel house (3) to reduce the flow of air into the wheel house (3) while the motor vehicle (1) is moving. The device (5) may extend from an underbody panel (4) of the motor vehicle (1) and may be pivotable about a longitudinal axis (6) of the motor vehicle (1) on a side of the underbody panel (4) that faces the wheel house (3). Alternatively, the device (5) is connected to a chassis component (7) of a wheel (2) arranged within the wheel house (3).

Owner:DR ING H C F PORSCHE AG

Fuel injection system comprising a pressure intensifier and a delivery rate-reduced low-pressure circuit

InactiveUS20060042598A1Decrease quantityReduced flow cross sectionMachines/enginesFuel injecting pumpsInjectorFuel tank

A fuel injection system for an internal combustion engine, having a fuel injector supplied with fuel from a high-pressure fuel source and including an injection valve member for opening or closing injection openings and a low-pressure circuit with a prefeed pump which pumps fuel from a fuel tank. Partial return fuel quantities, depressurized to the prefeed pressure of the prefeed pump, are delivered to the low-pressure circuit by pressure boosters or by fuel injectors inside an infeed portion via returns.

Owner:ROBERT BOSCH GMBH

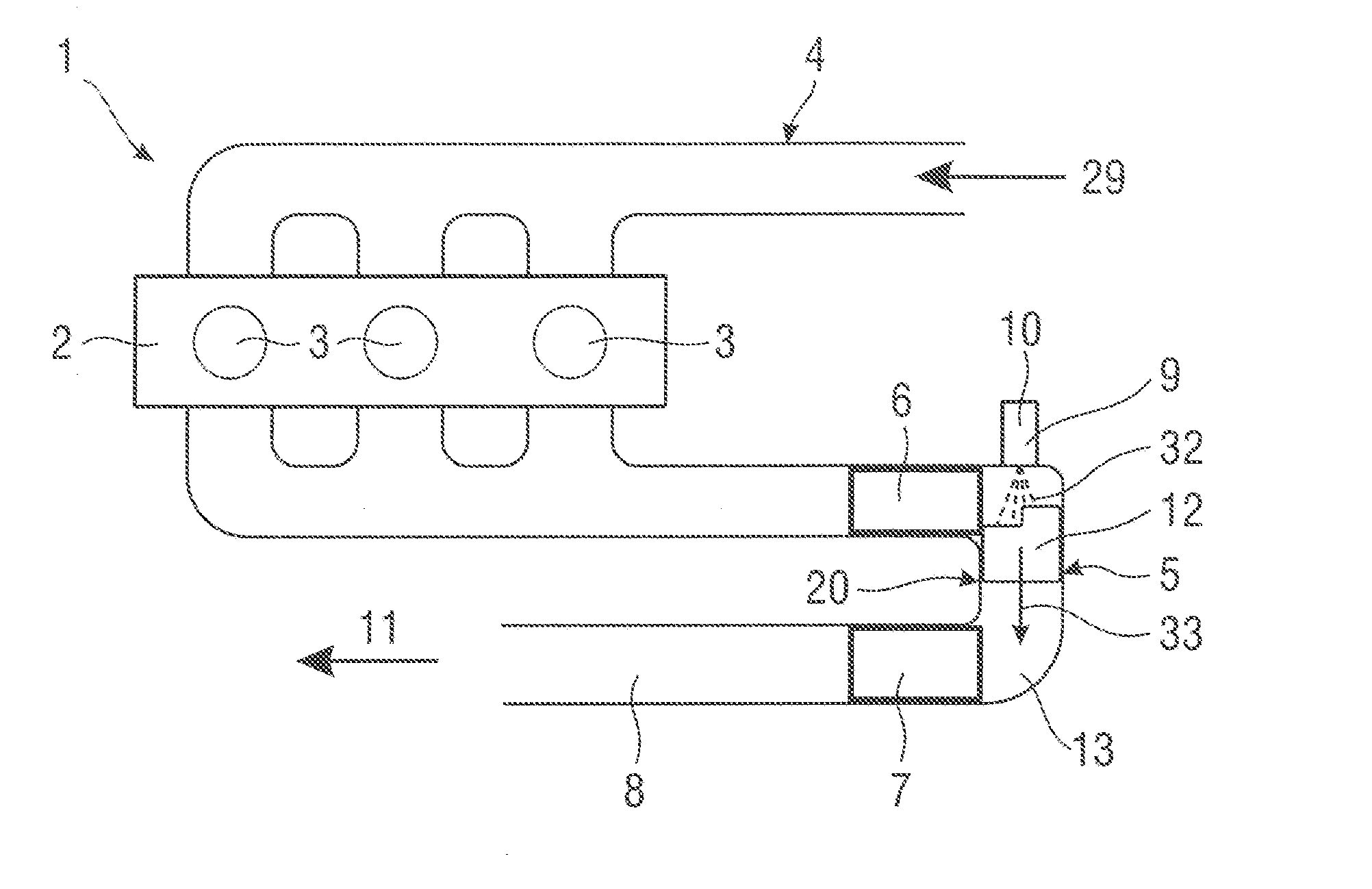

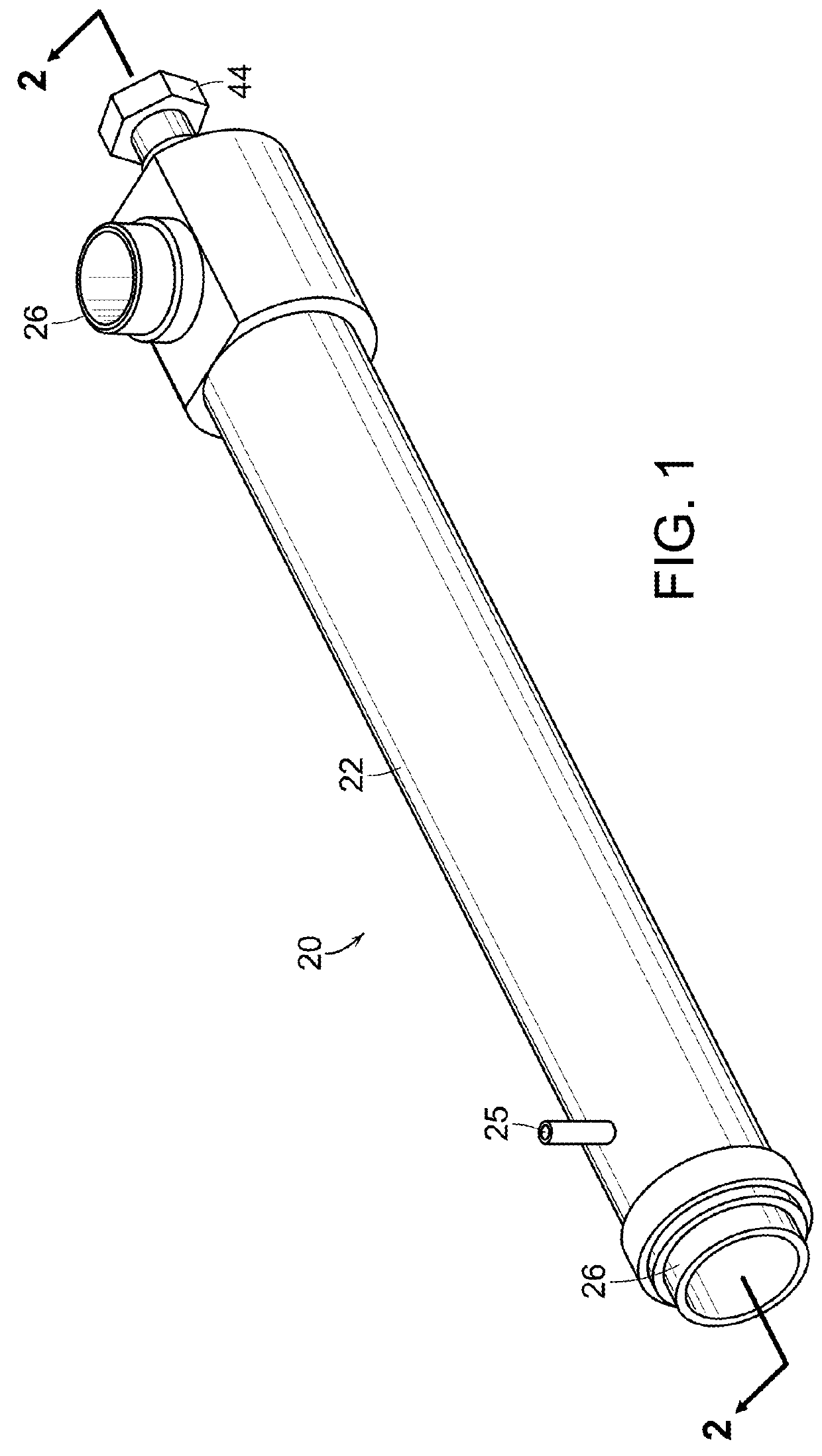

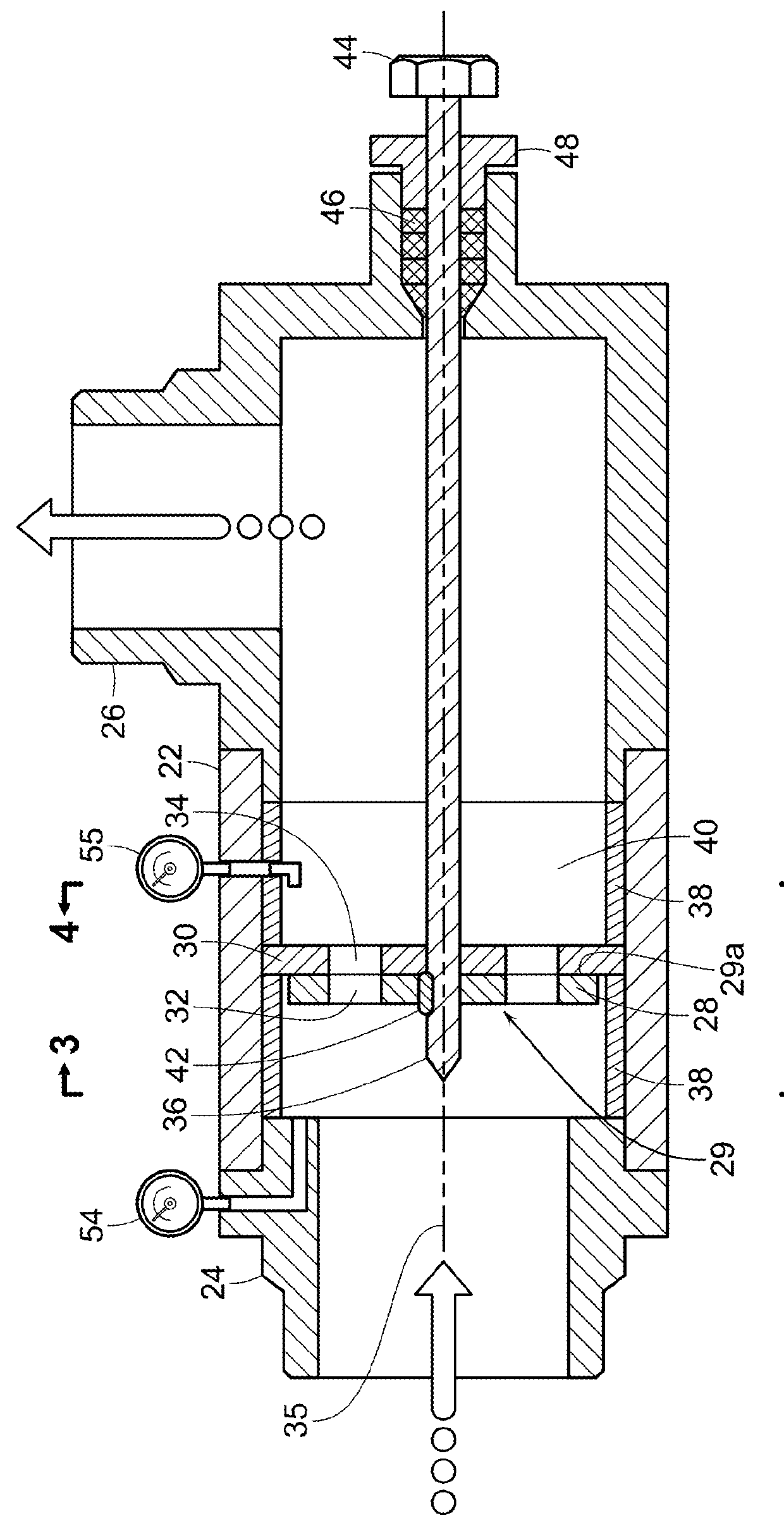

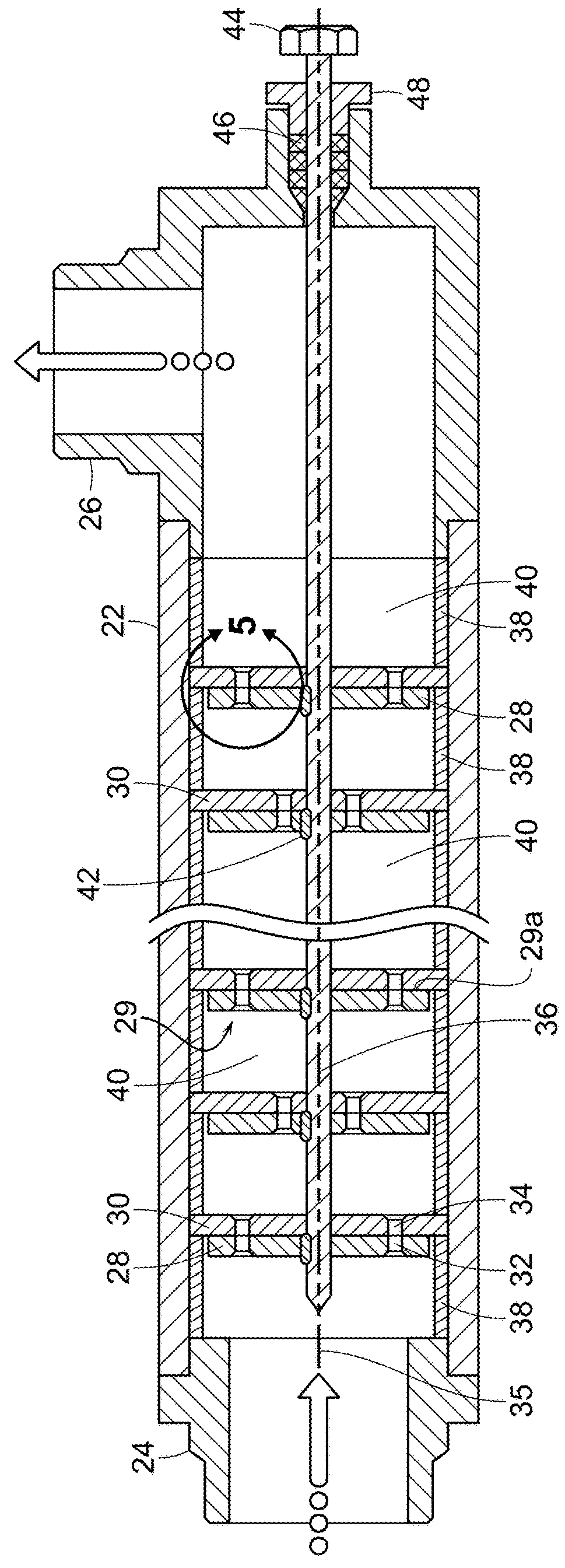

Variable flow-through cavitation device

ActiveUS20180161740A1Fast mass transferImprove treatment efficiencyShaking/oscillating/vibrating mixersFlow mixersCavitationEngineering

A flow-through cavitation device having an elongated housing with an inlet and an outlet. One or more variable multi-jet nozzles are disposed throughout the elongated housing with a working chamber following each variable multi-jet nozzle. Each variable multi-jet nozzle consists of a movable disk fixedly mounted on a central shaft and a stationary disk fixedly mounted on the housing and in contact with the rotating disk. The movable and stationary disks of each variable multi-jet nozzle have through channels. The flow cross-sectional area of the through channels is variable by rotating the movable disk relative to the stationary disk.

Owner:CAVITATION TECH

Controllable oil separation device

ActiveCN105705739AImprove efficiencyEasy to separateDispersed particle separationMachines/enginesCombustionOil separation

Owner:THYSSENKRUPP PRESTA TECCENTER AG

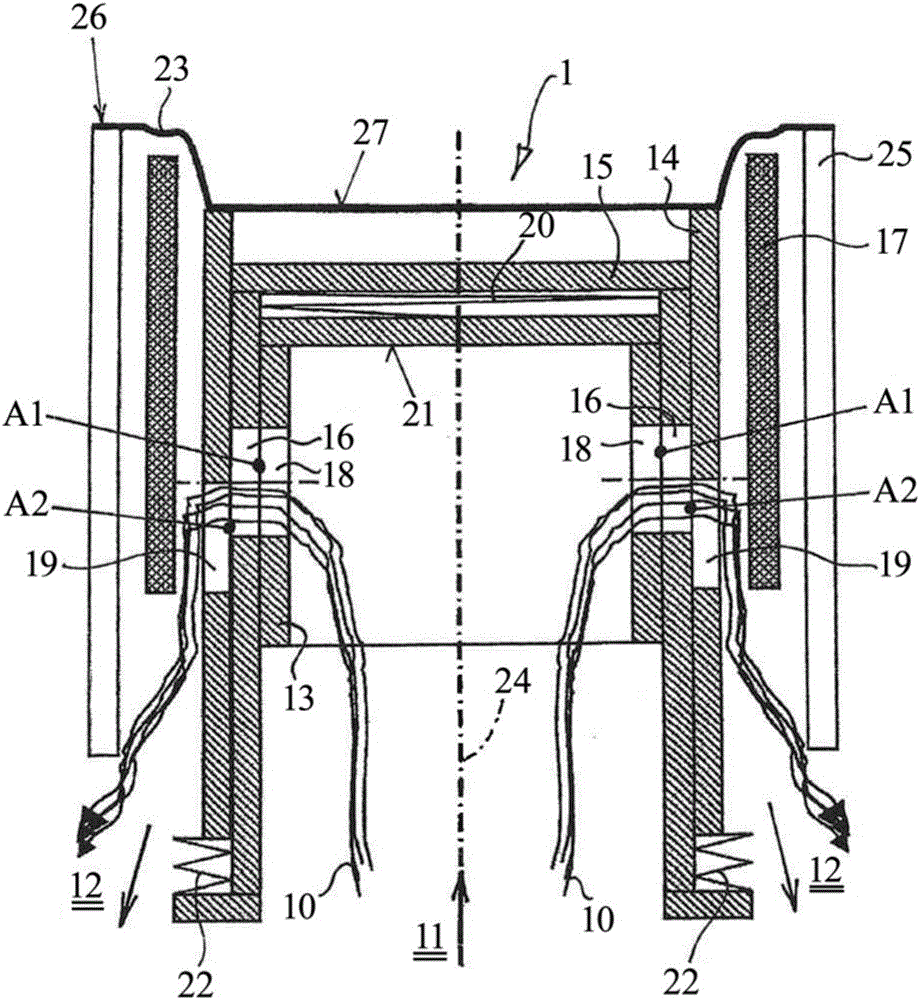

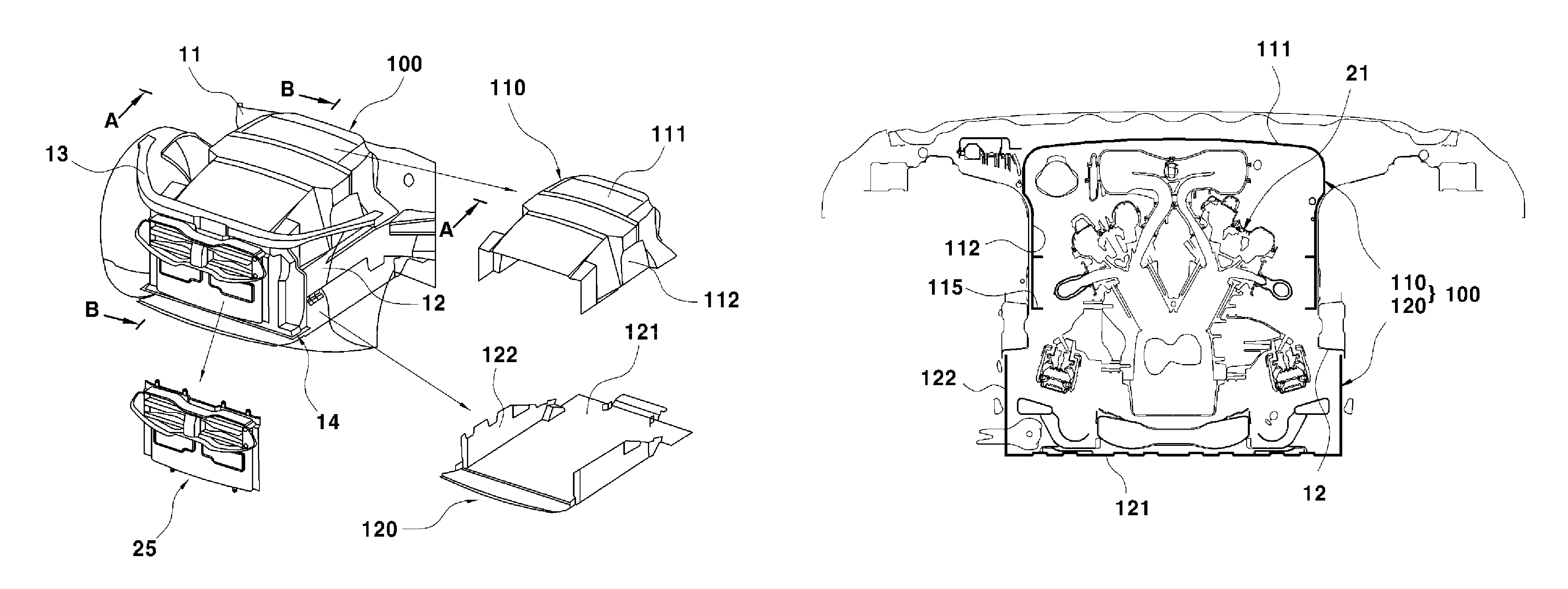

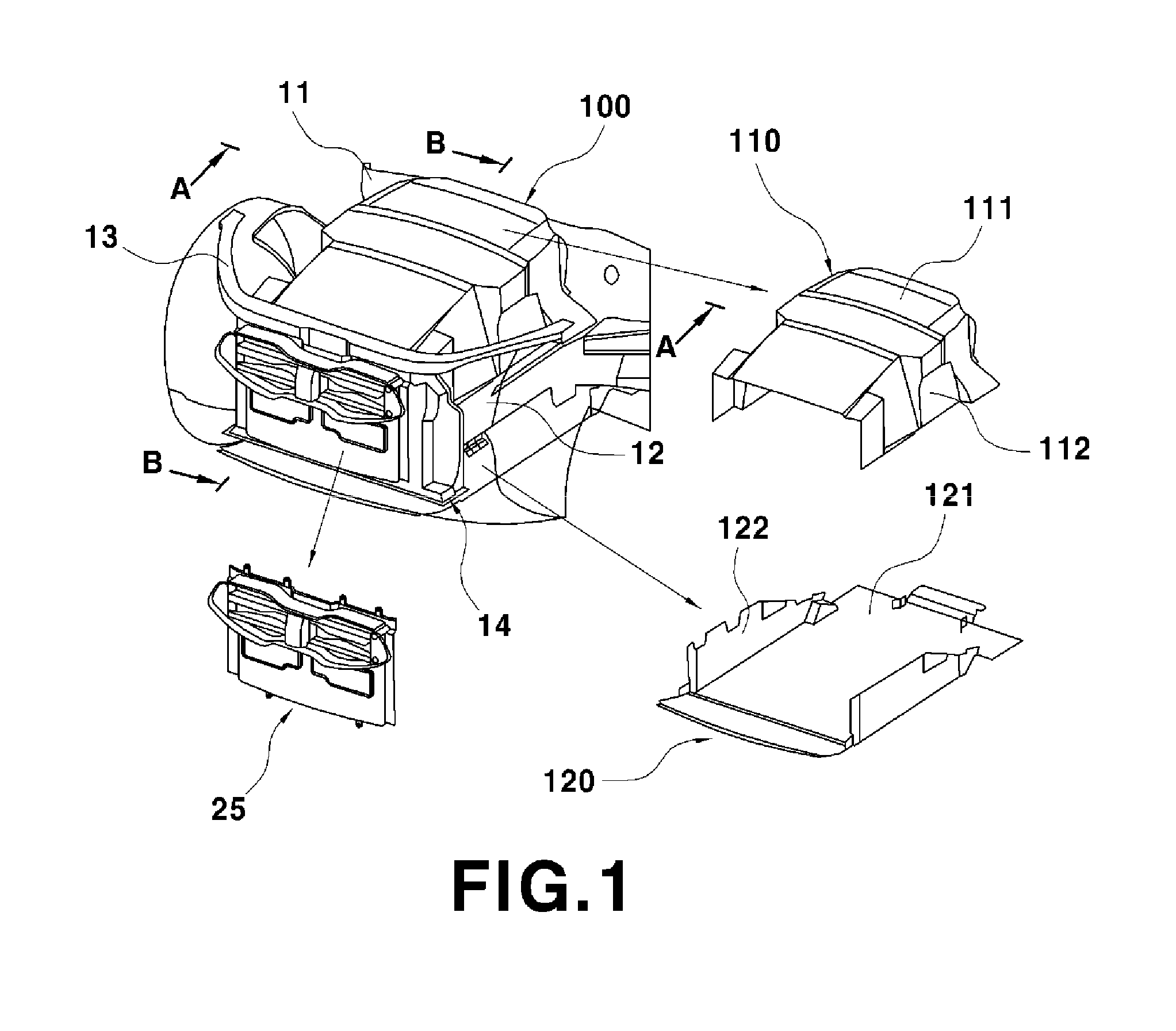

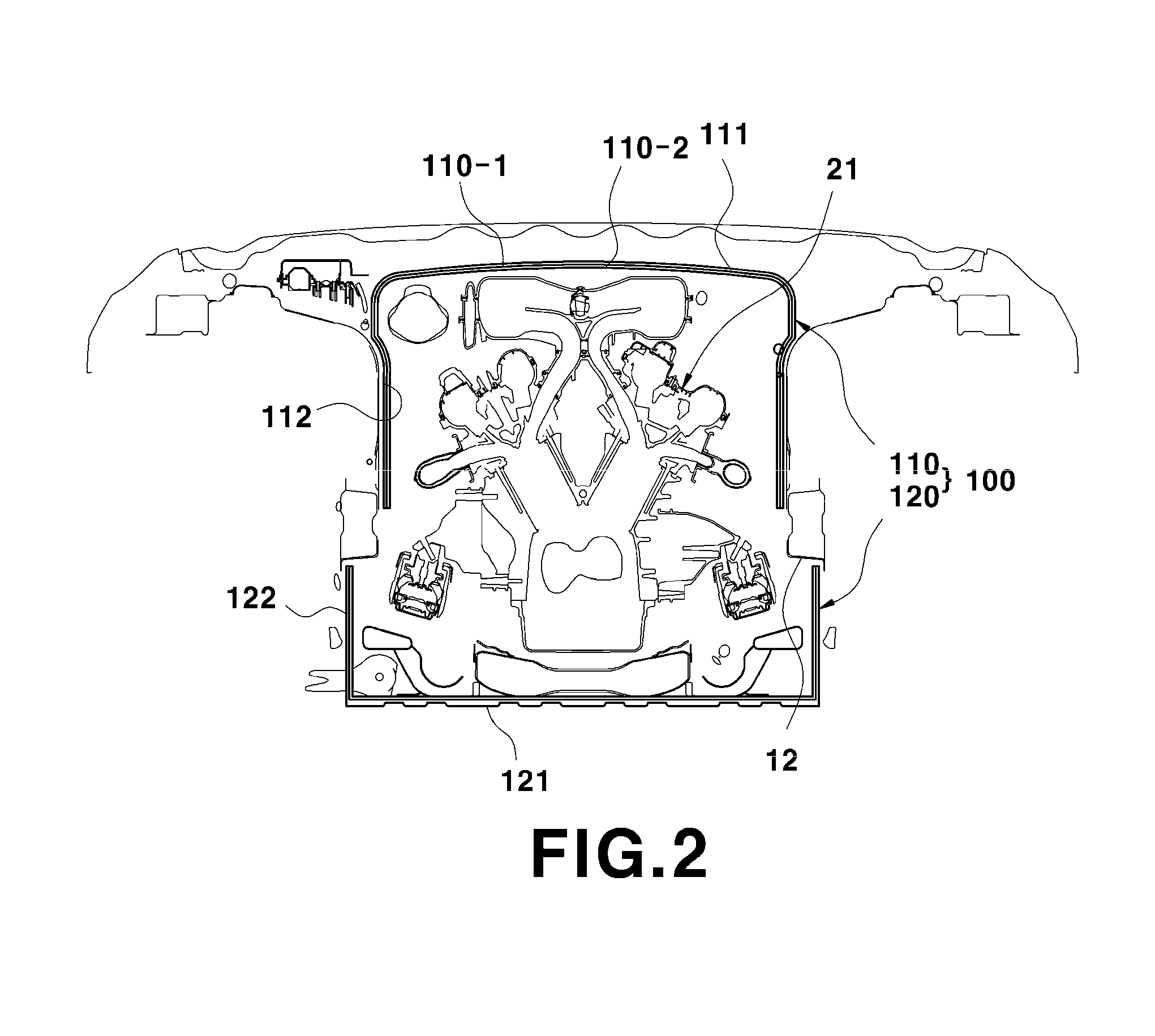

Engine encapsulation structure of vehicle

ActiveUS9016411B2Improve performanceImprove cooling effectAir-treating devicesRailway heating/coolingEngineeringEngine room

An engine encapsulation structure of a vehicle may include an engine room encapsulation member disposed at an upper portion of an engine compartment and covering an upper portion of a power train having an engine and a transmission, an underbody encapsulation member disposed at a lower portion of the engine compartment and covering a lower portion of the power train, wherein the engine room encapsulation member and the underbody encapsulation member form an inner space and enclose the power train in the inner space when being assembled each other, and a front inlet formed at a front portion of the assembly to allow air through the front inlet and to cool the power train while the air passes through the inner space of the assembly, the air being discharged through a rear outlet formed to the assembly.

Owner:HYUNDAI MOTOR CO LTD +1

Ventilating fan provided with linkage type air valve

ActiveCN107237765AAchieve regulationReach regulationPump controlPump installationsIsoetes triquetraEngineering

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com