Patents

Literature

88results about How to "Reduced volume flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

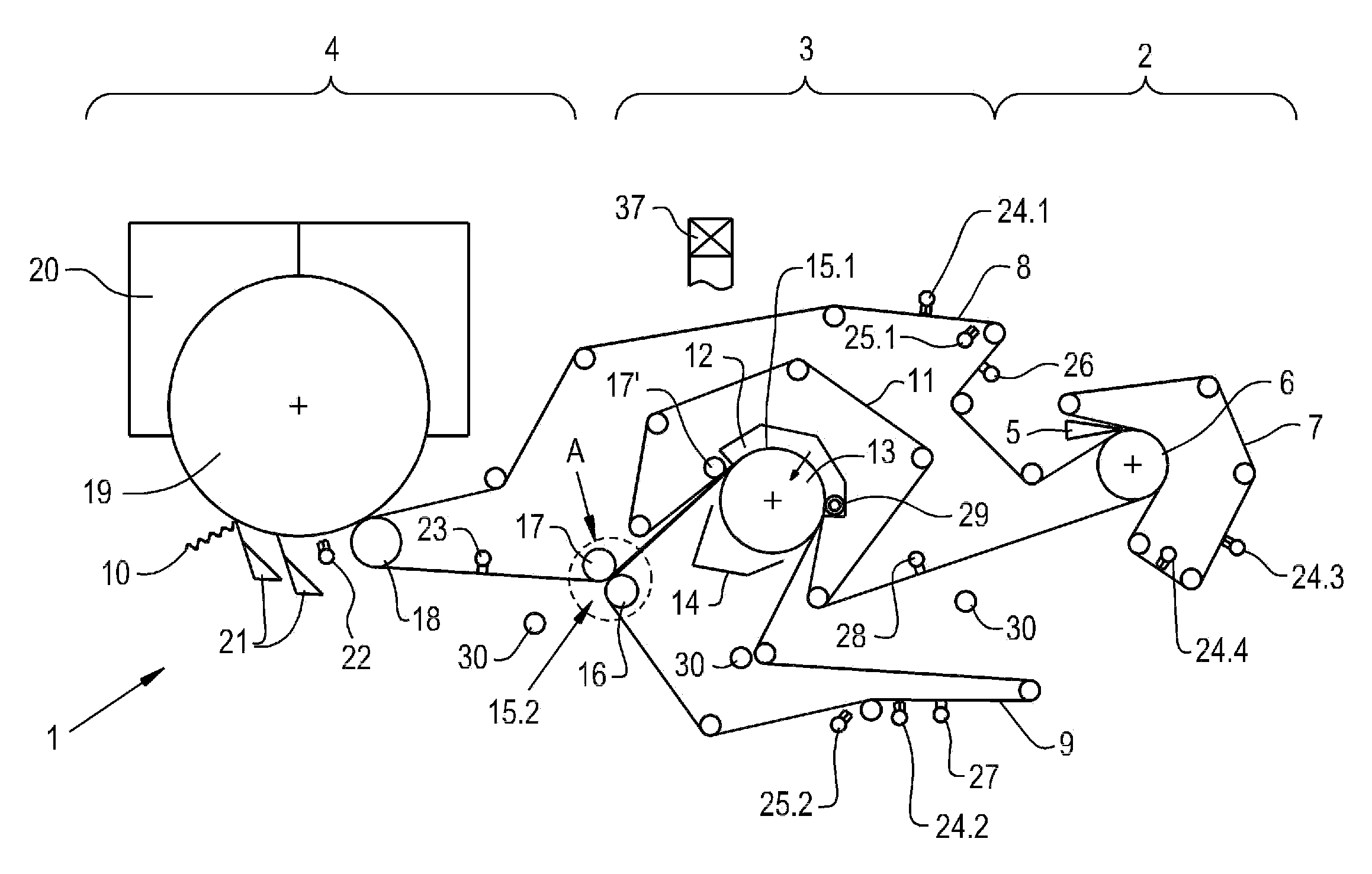

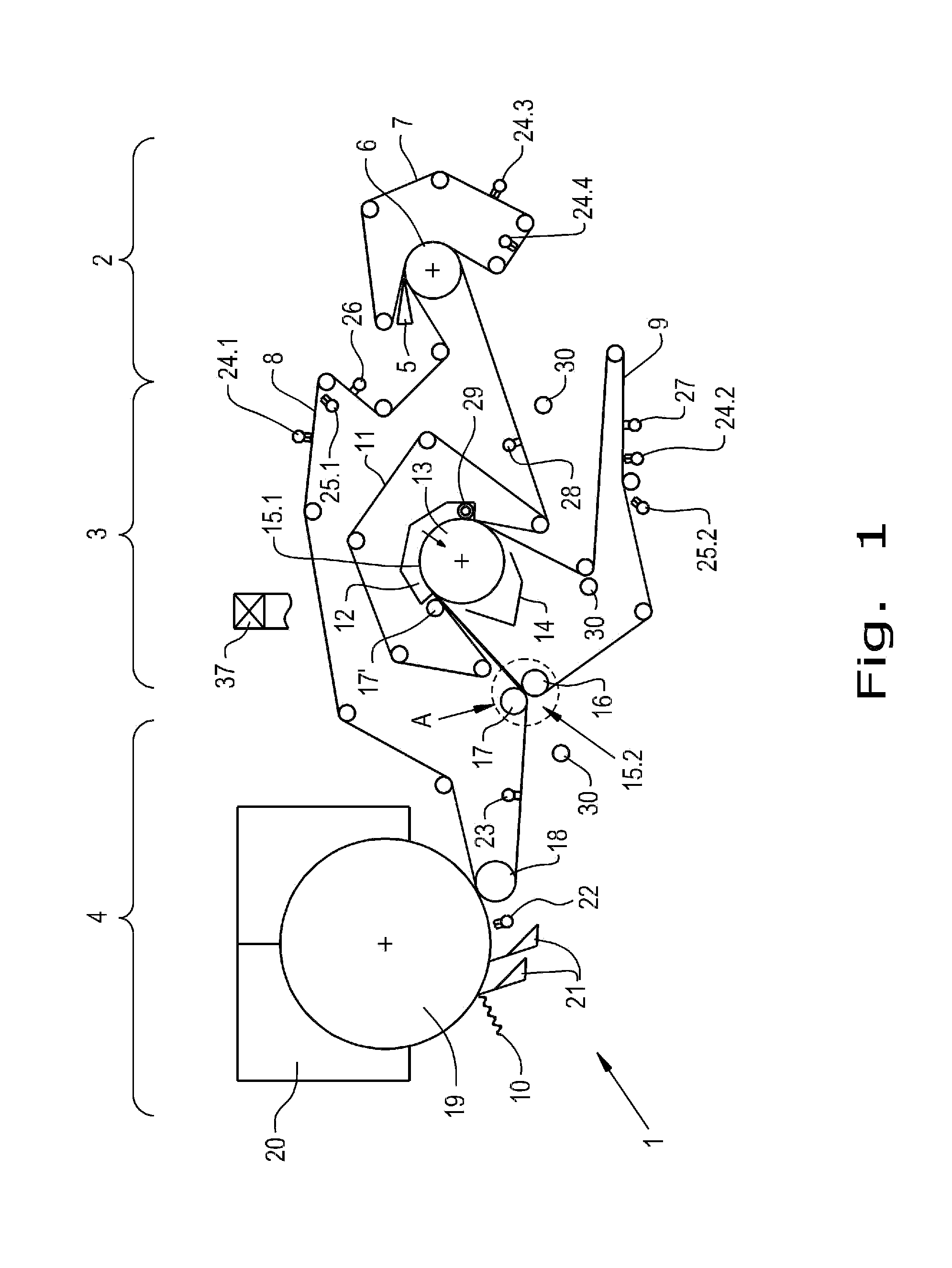

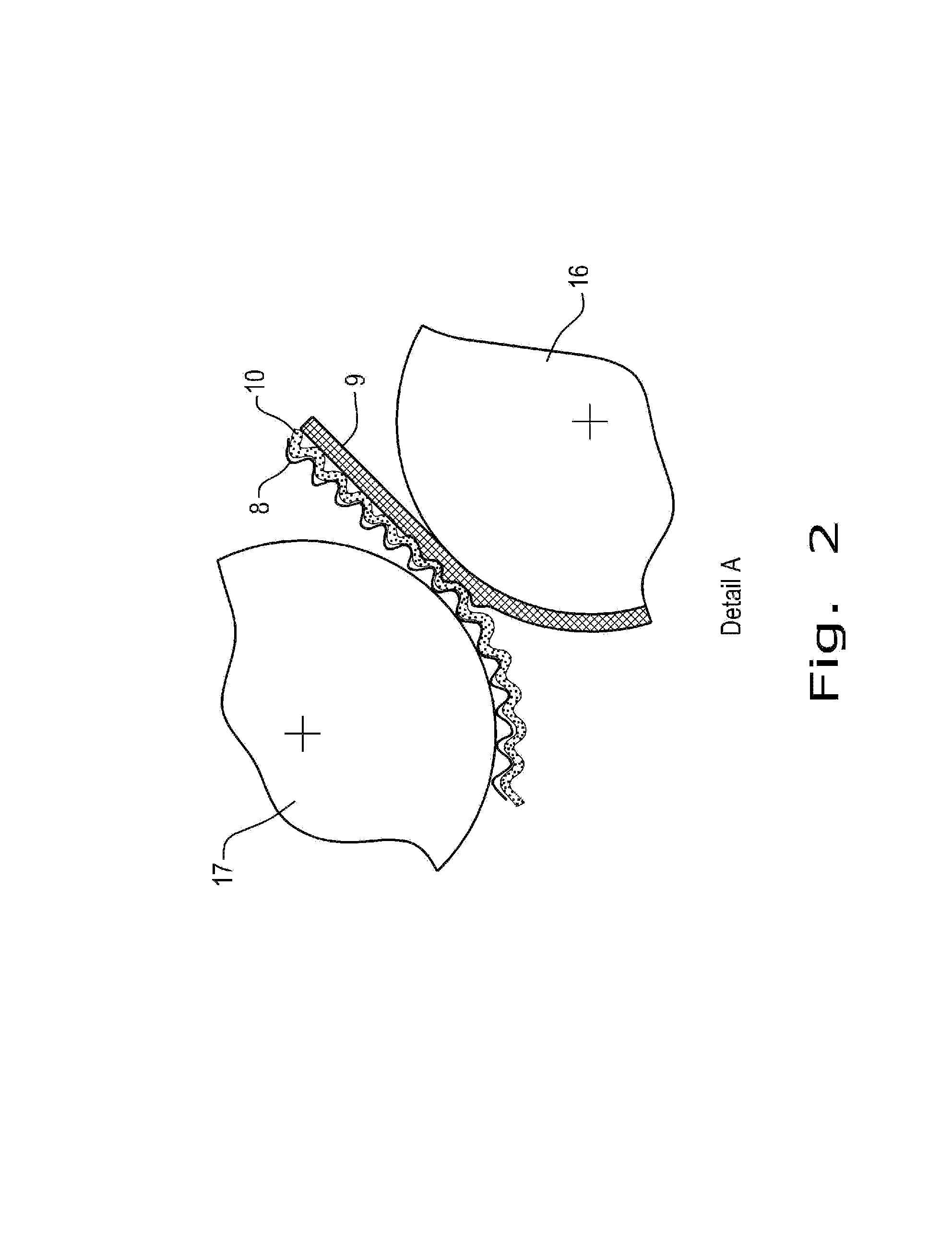

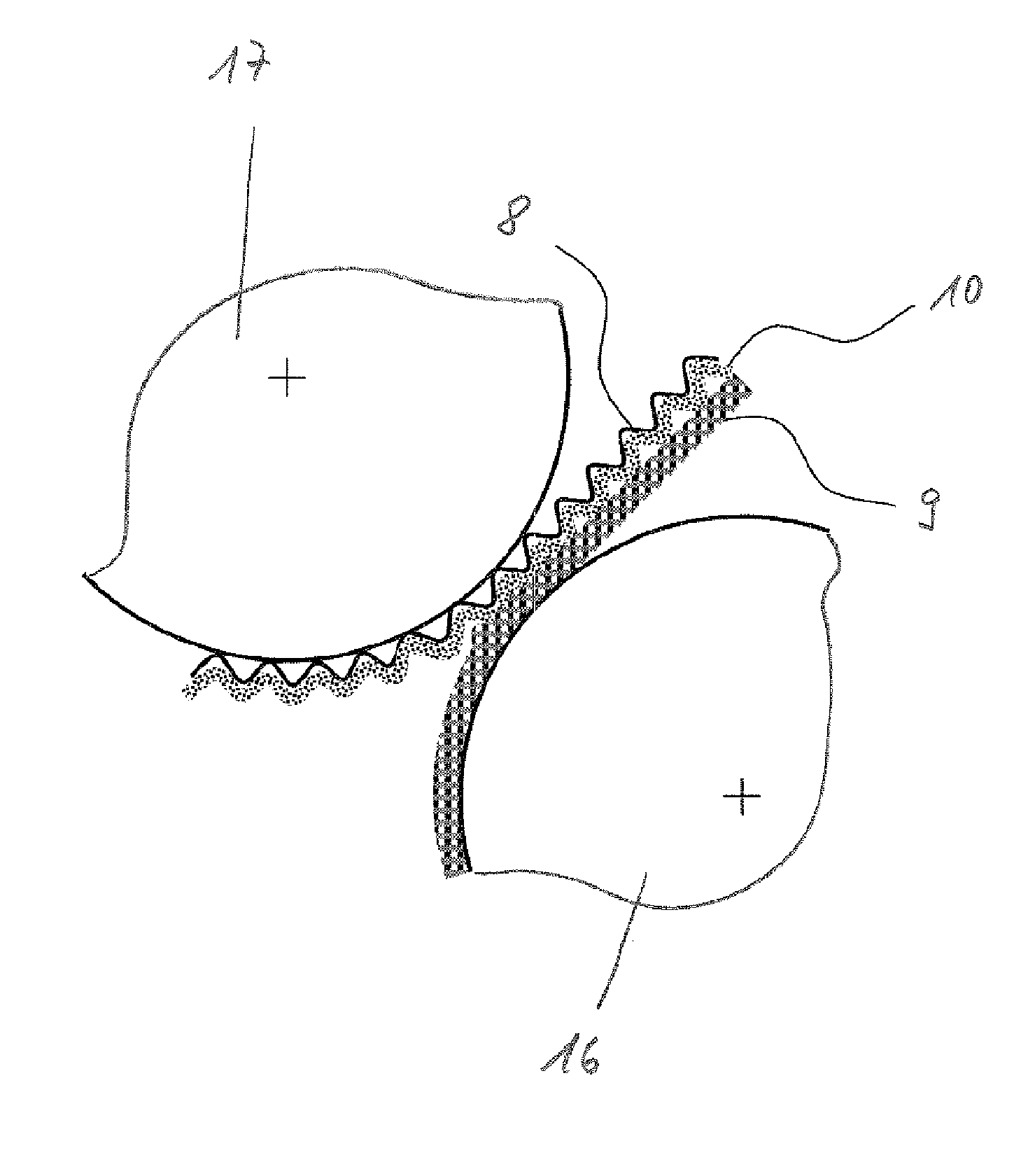

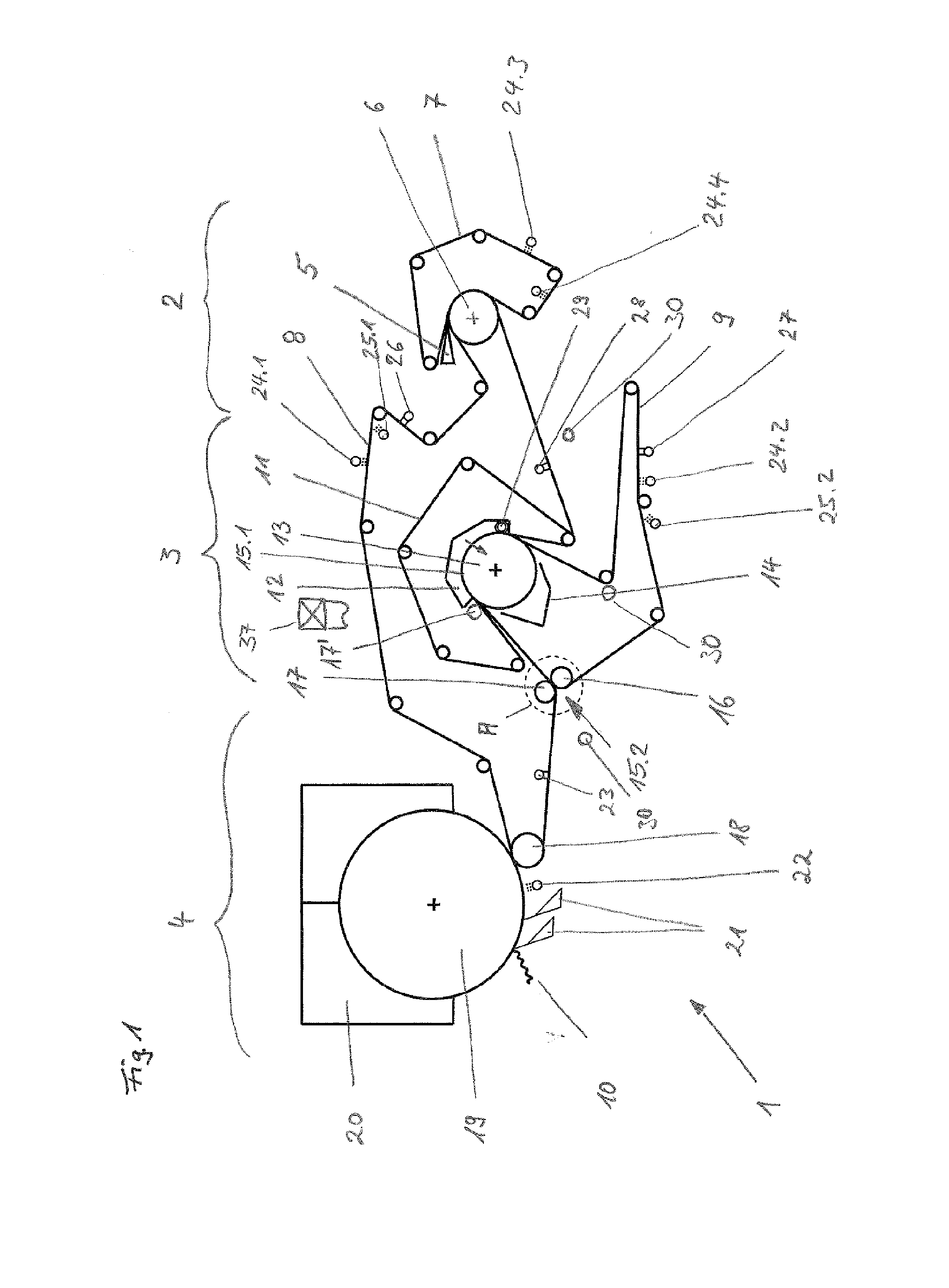

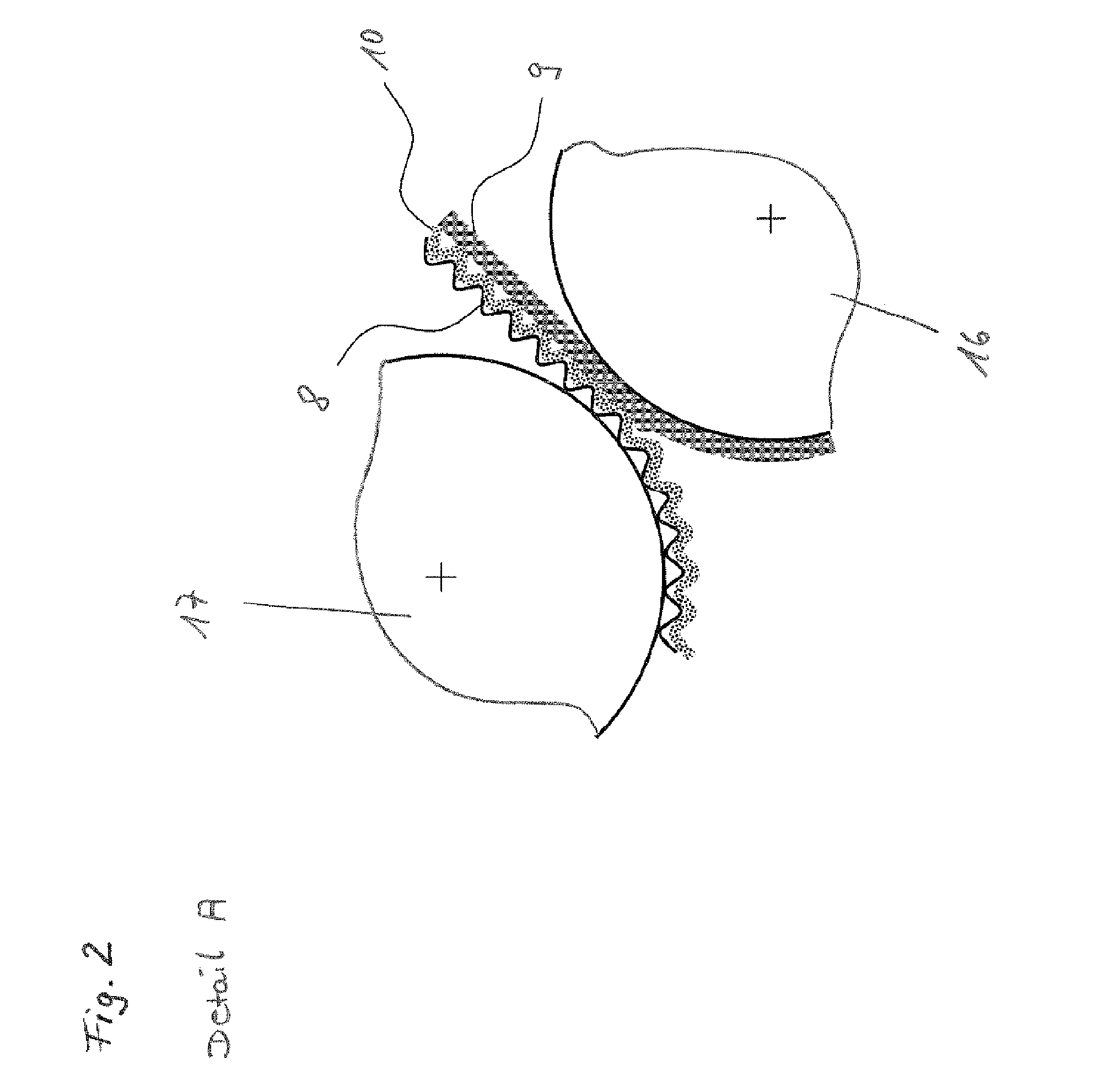

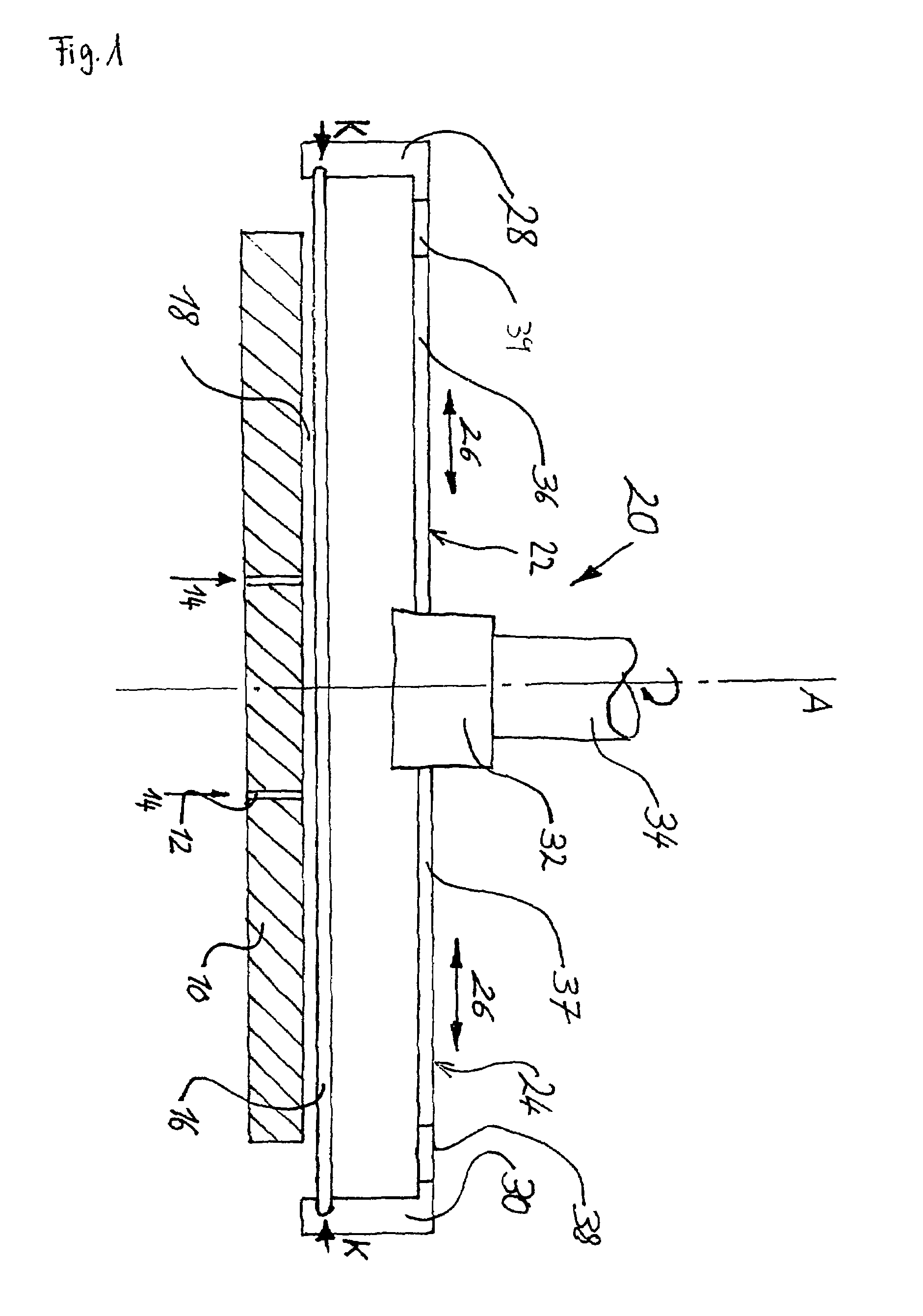

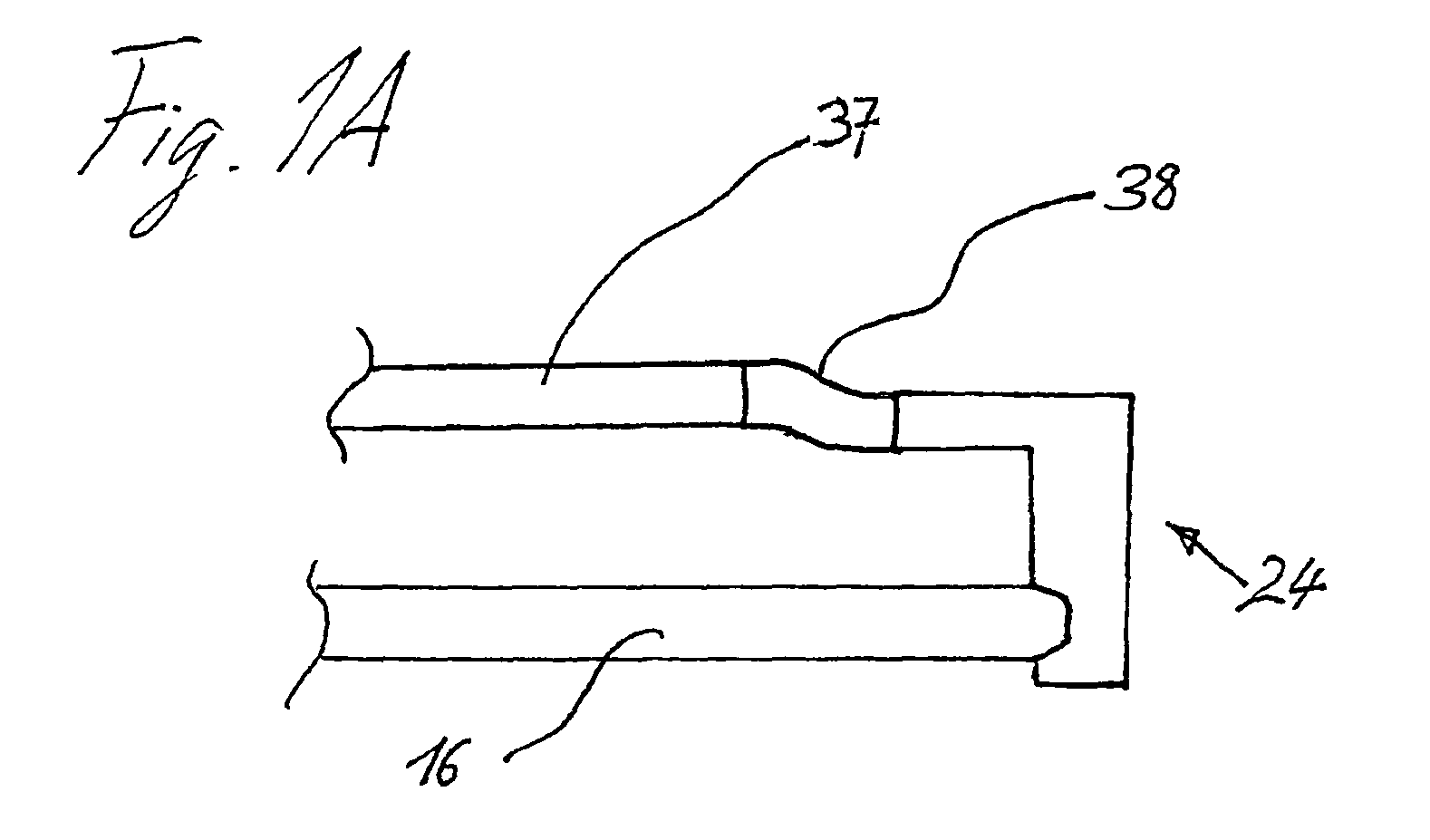

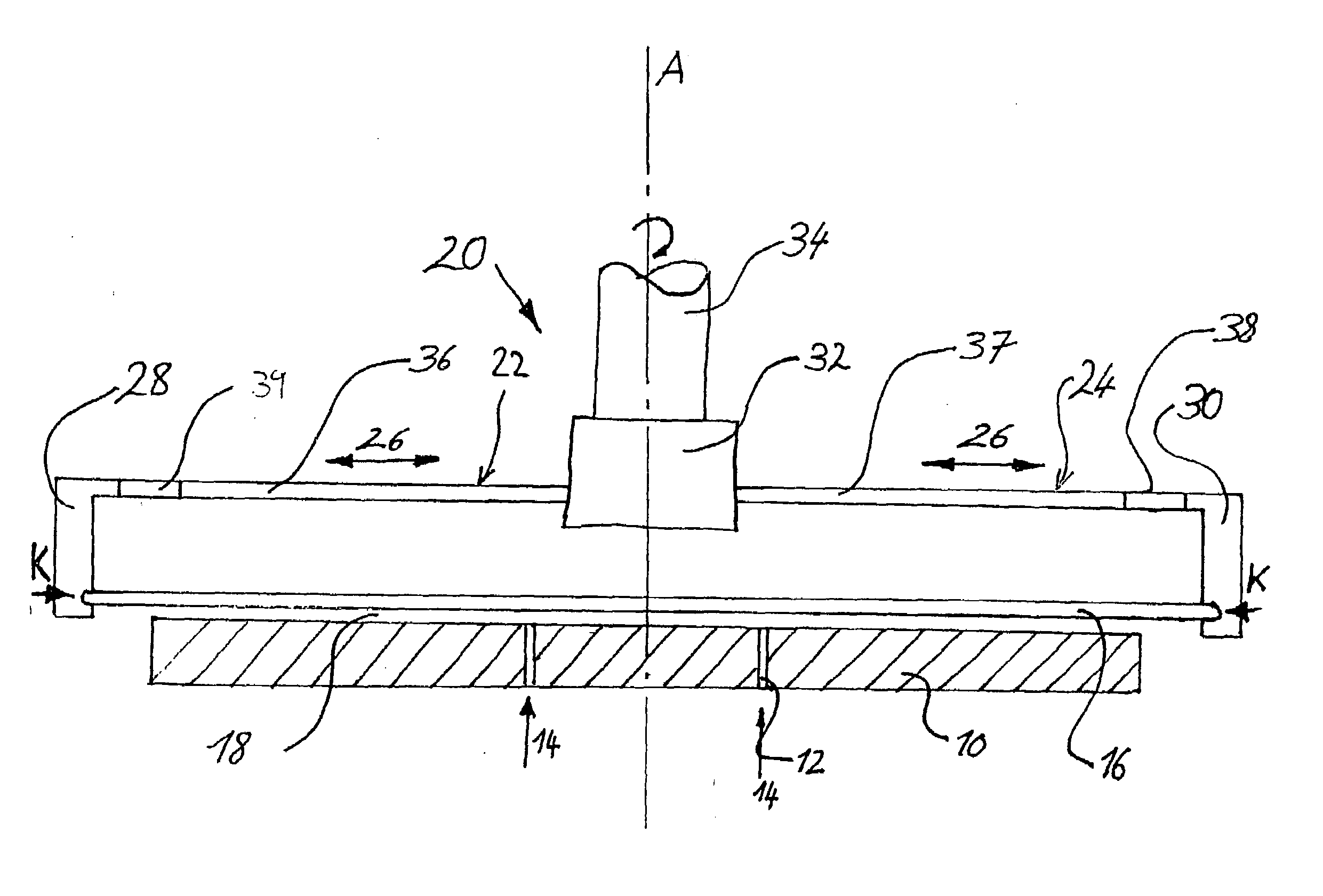

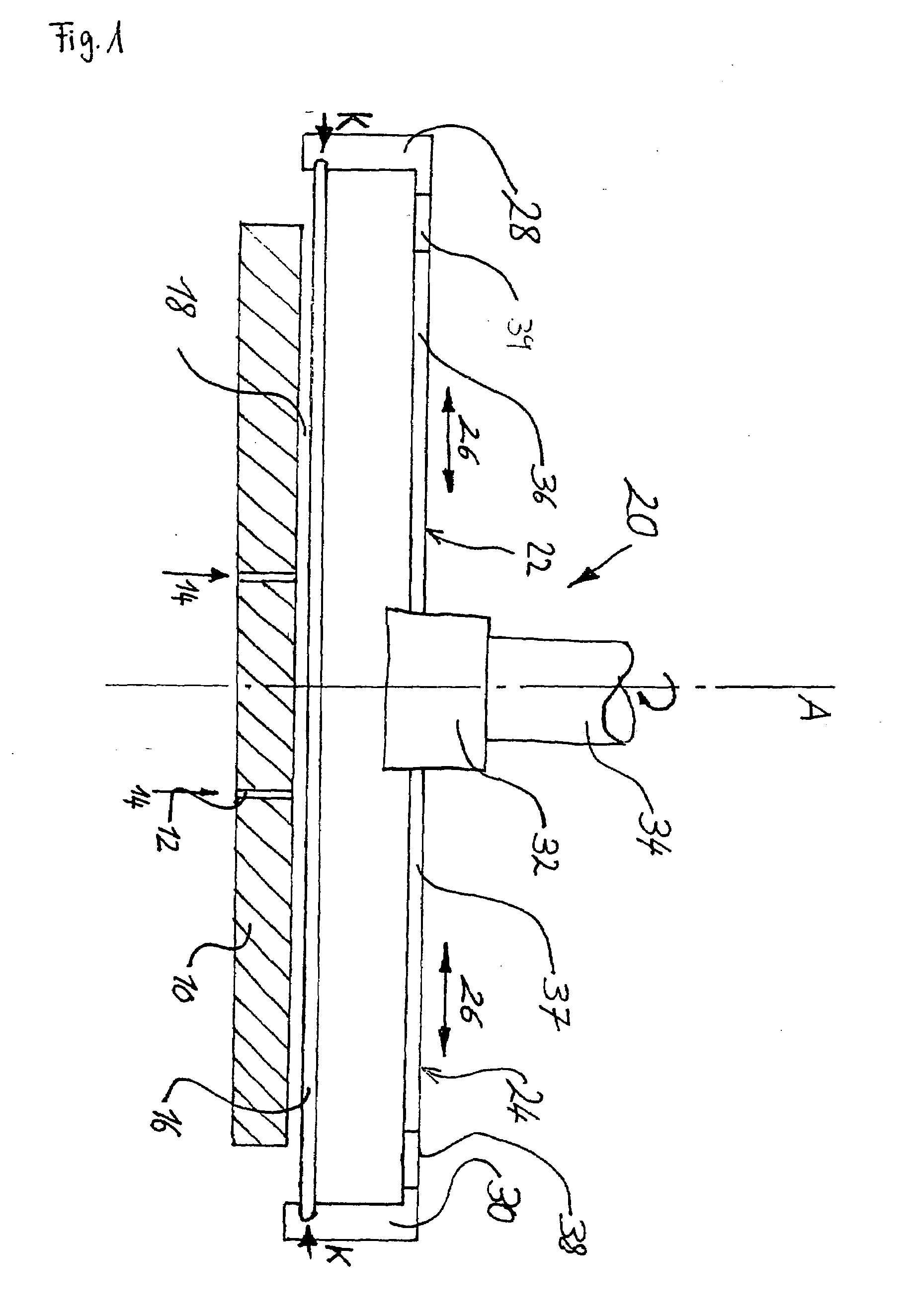

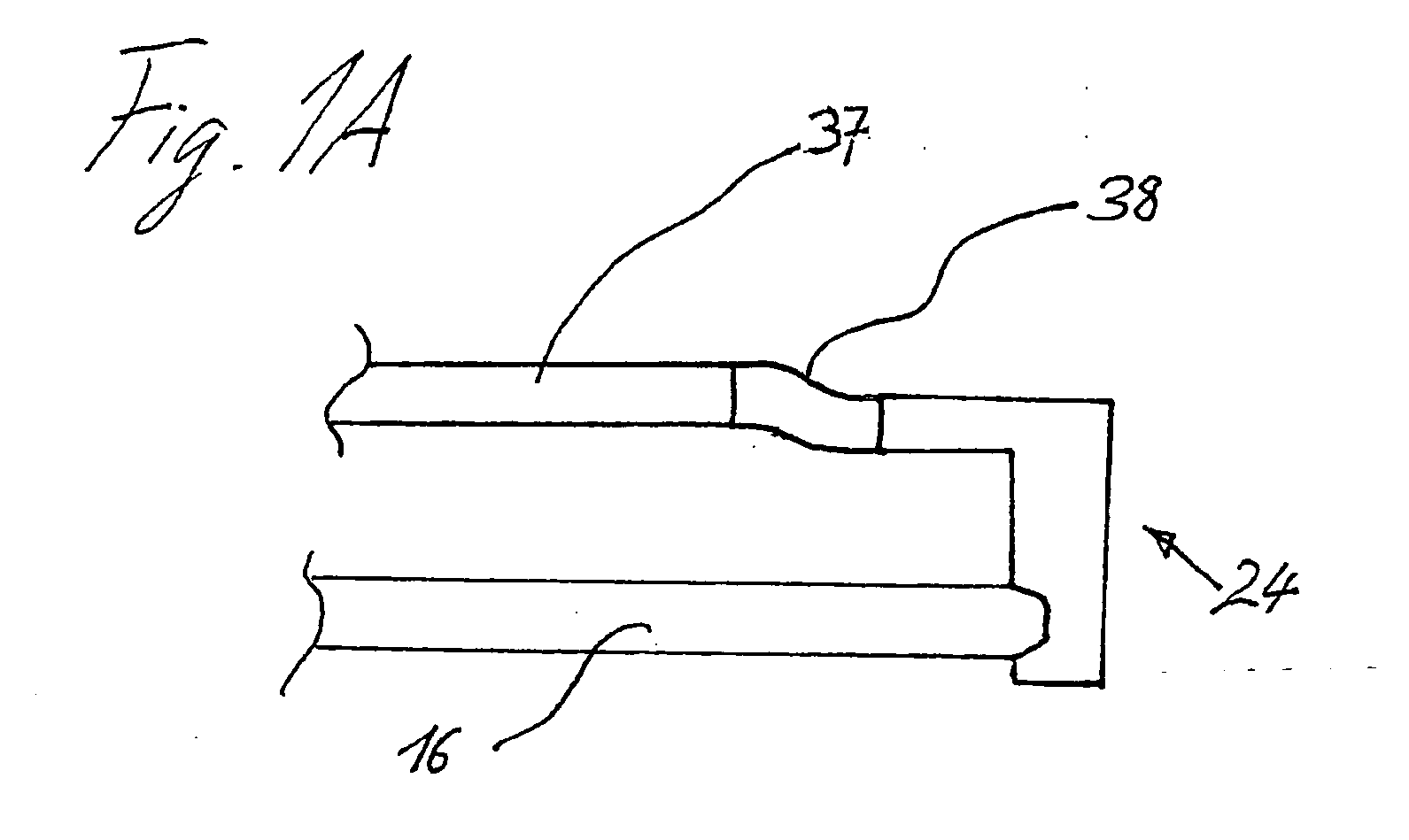

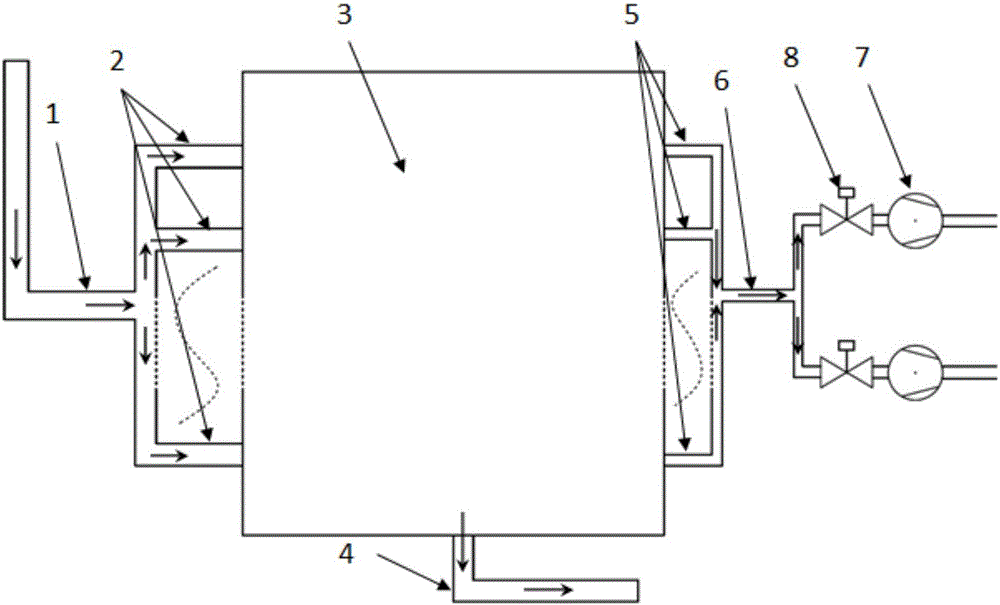

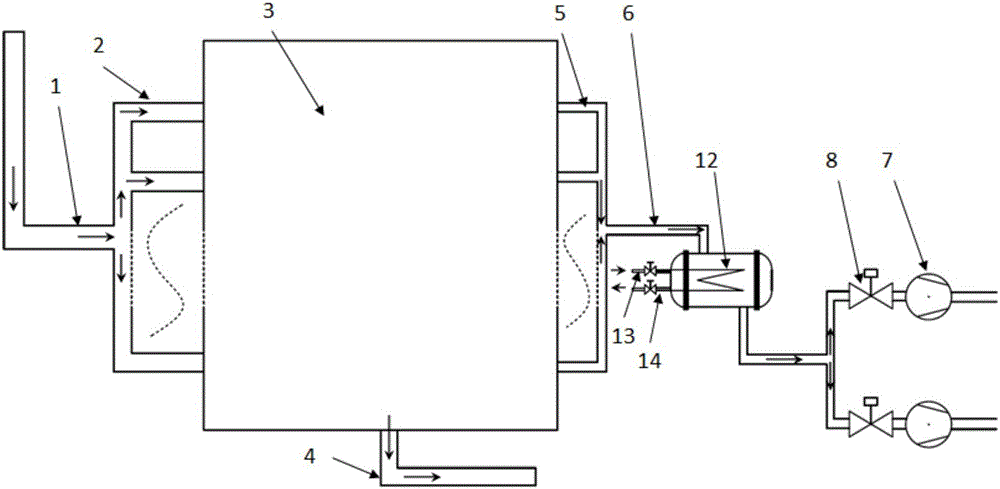

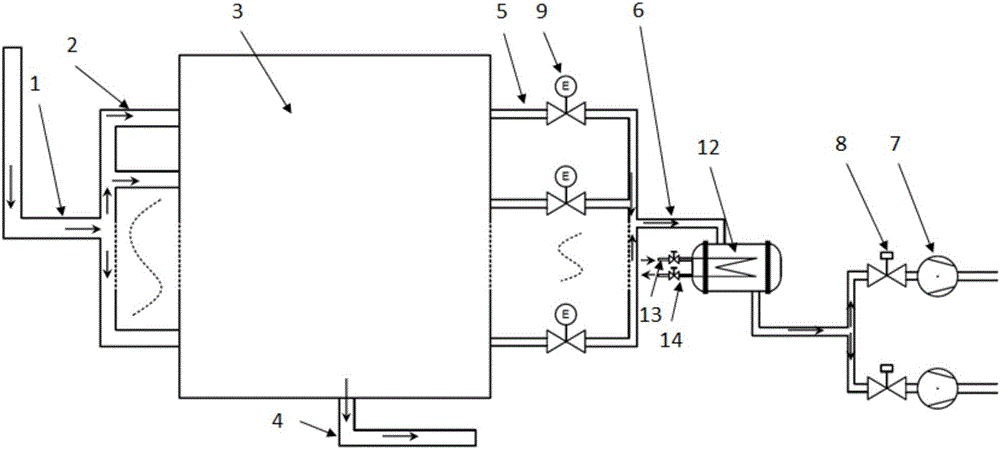

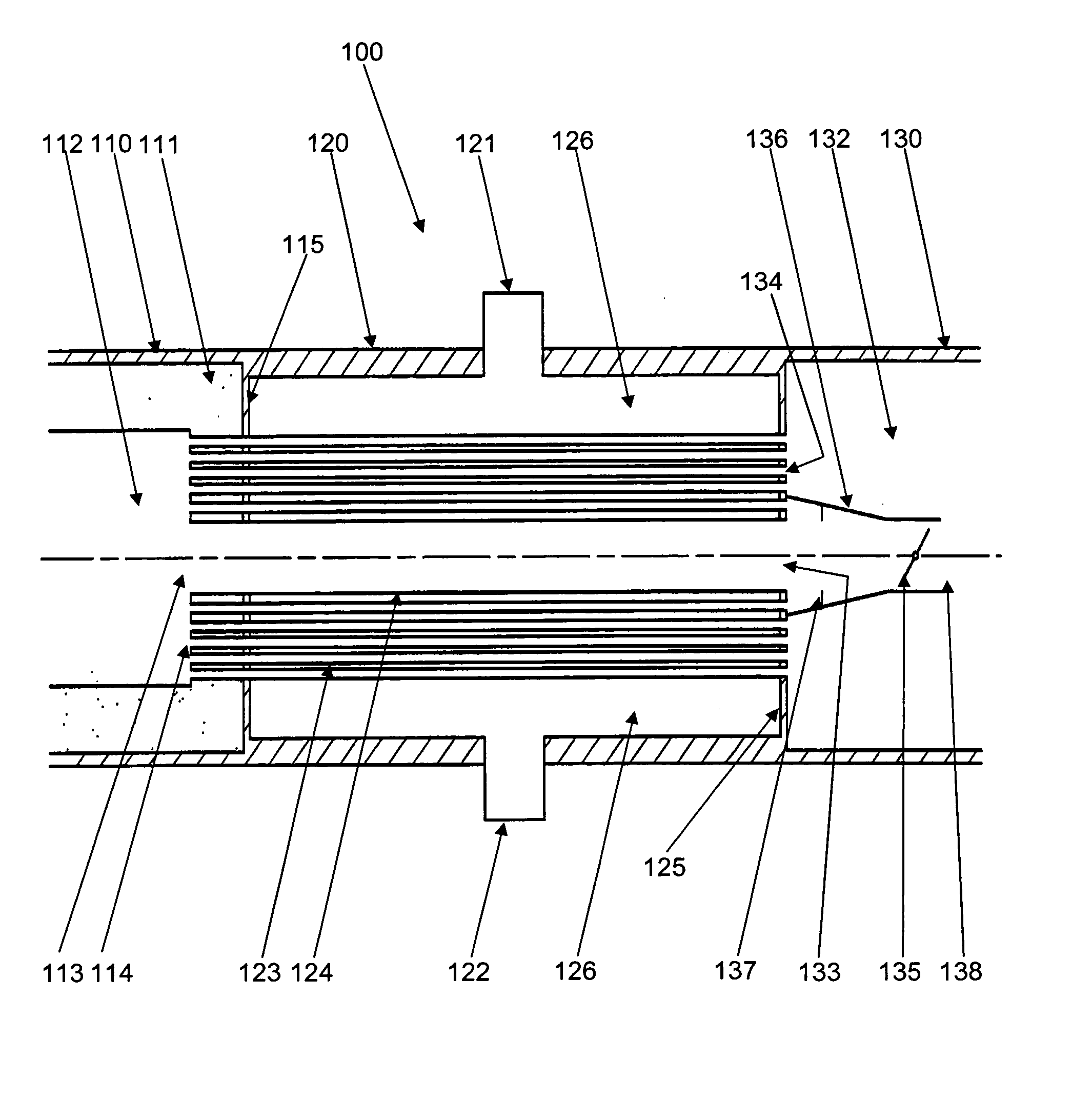

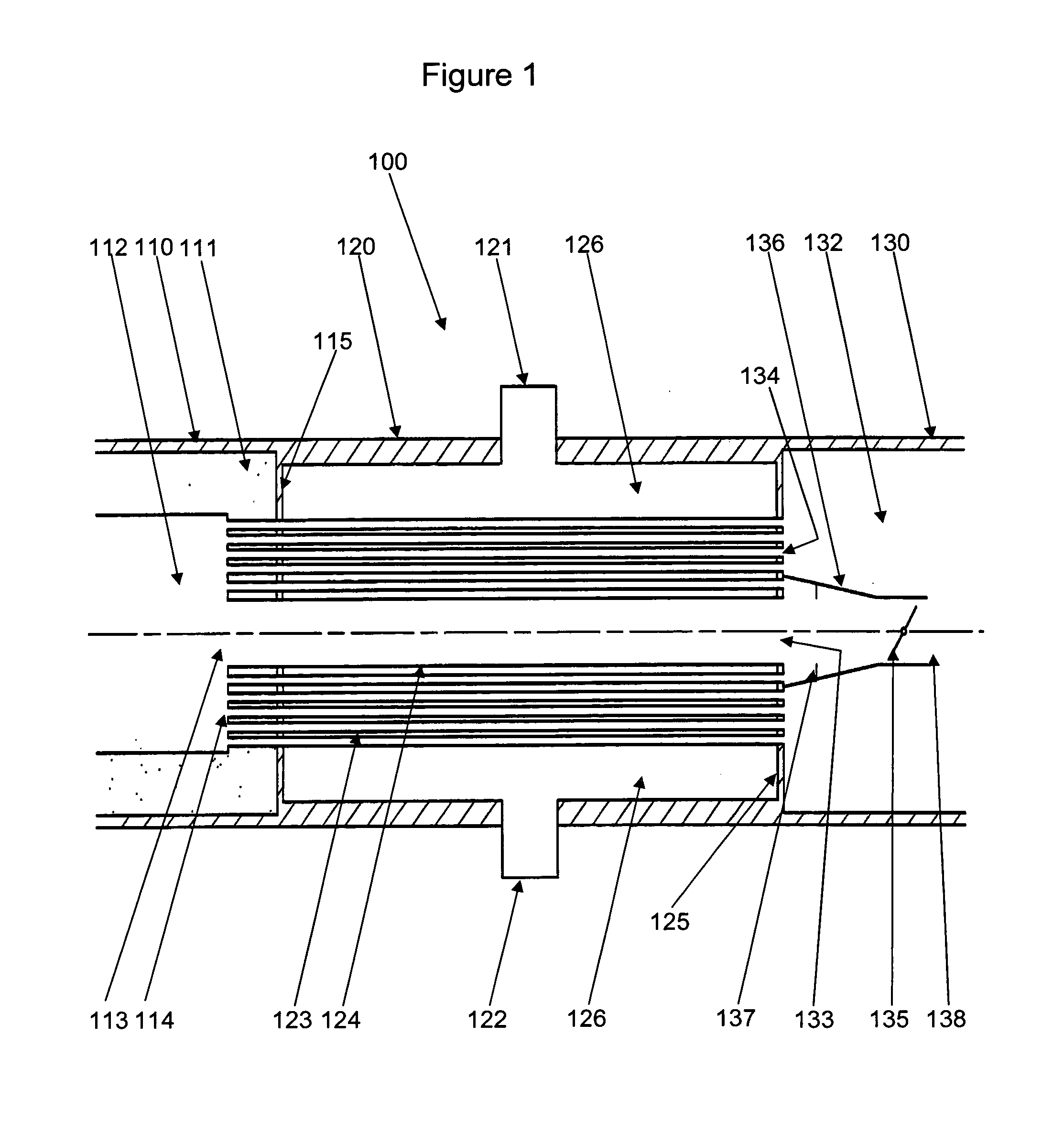

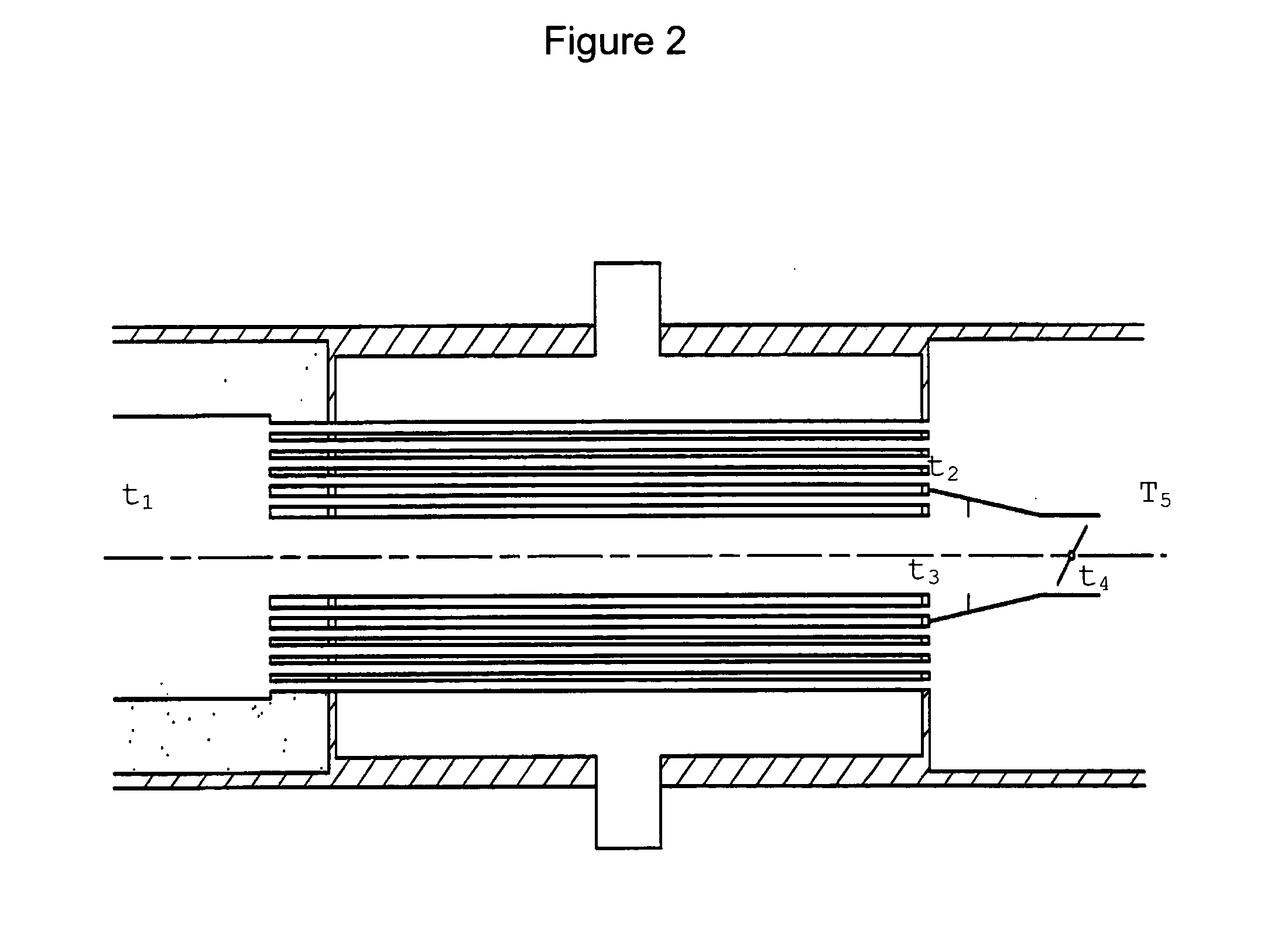

Device and method for producing a material web

InactiveUS8382956B2Increase contentLow compressibilityDrying solid materials with heatDrying solid materials without heatTwo bandPulp and paper industry

A device for drainage of a pulp web, particularly a tissue web, having a first pressing zone having a first pressing zone length through which the pulp web is fed horizontally between a circulating, permeable band and a circulating, permeable support band. The first pressing zone is designed such that a fluid can flow through the band, the pulp web and the support band at least on one part of the first pressing zone length. In addition, the device has a subsequent second pressing zone having a second pressing zone length. The pulp web is guided through the second pressing zone between two bands having differing compressibility.

Owner:VOITH PATENT GMBH

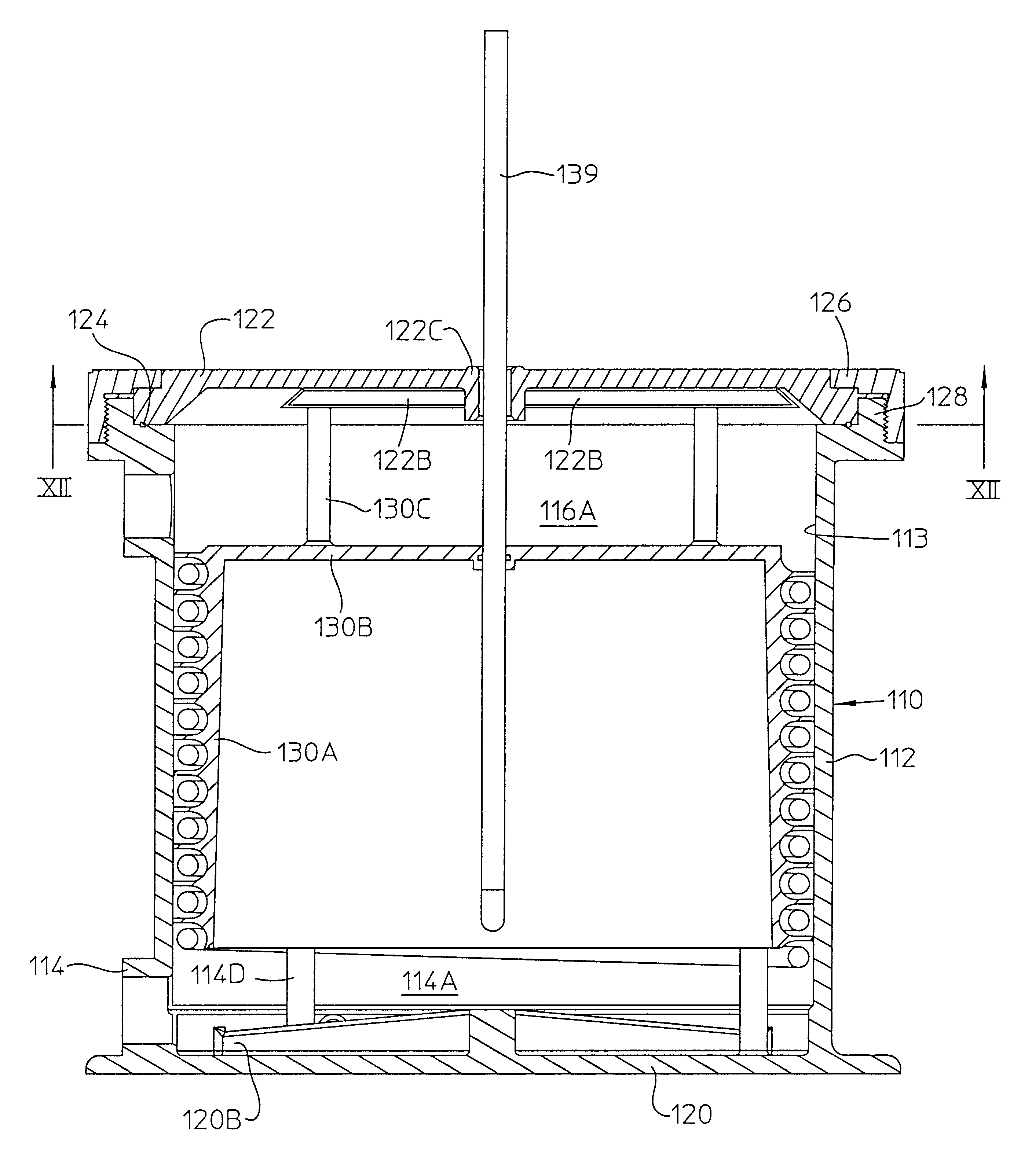

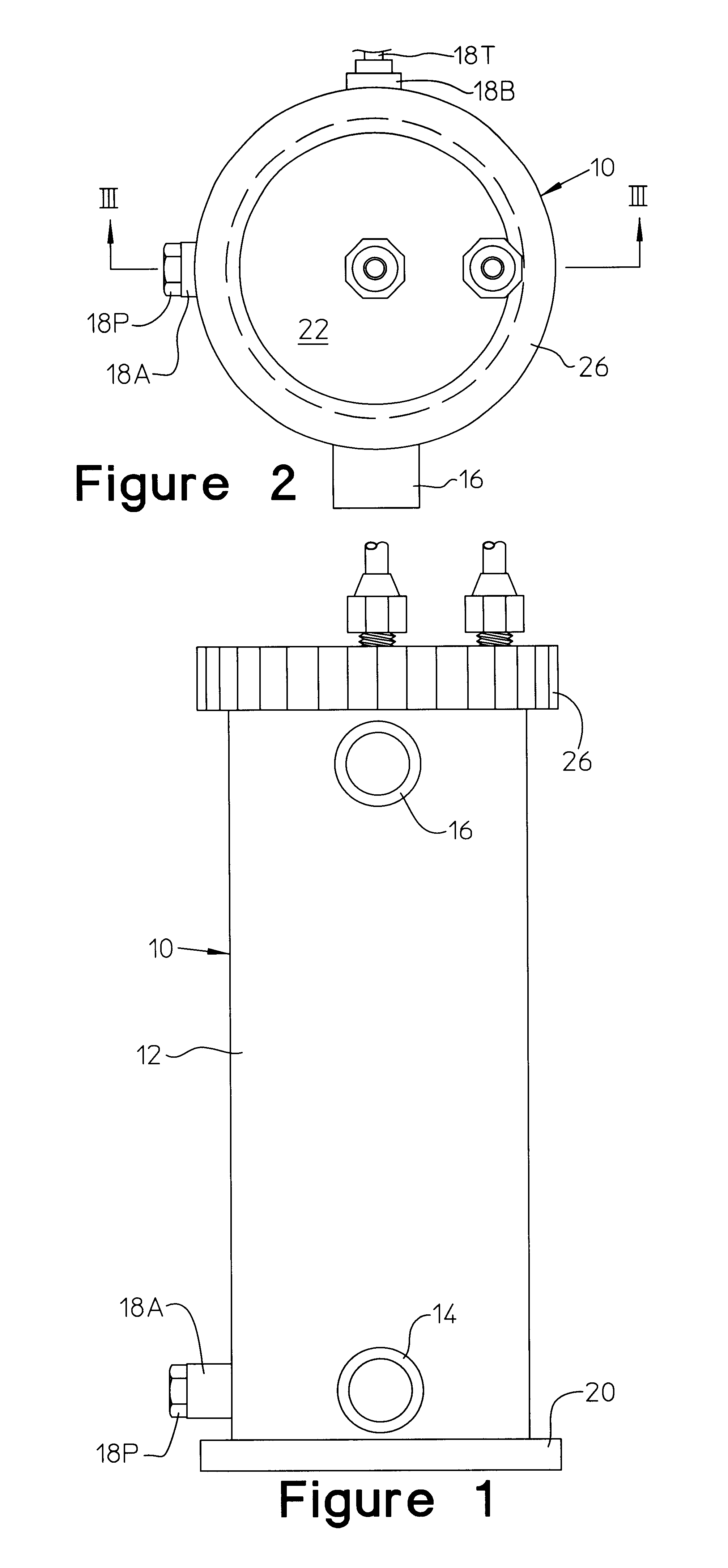

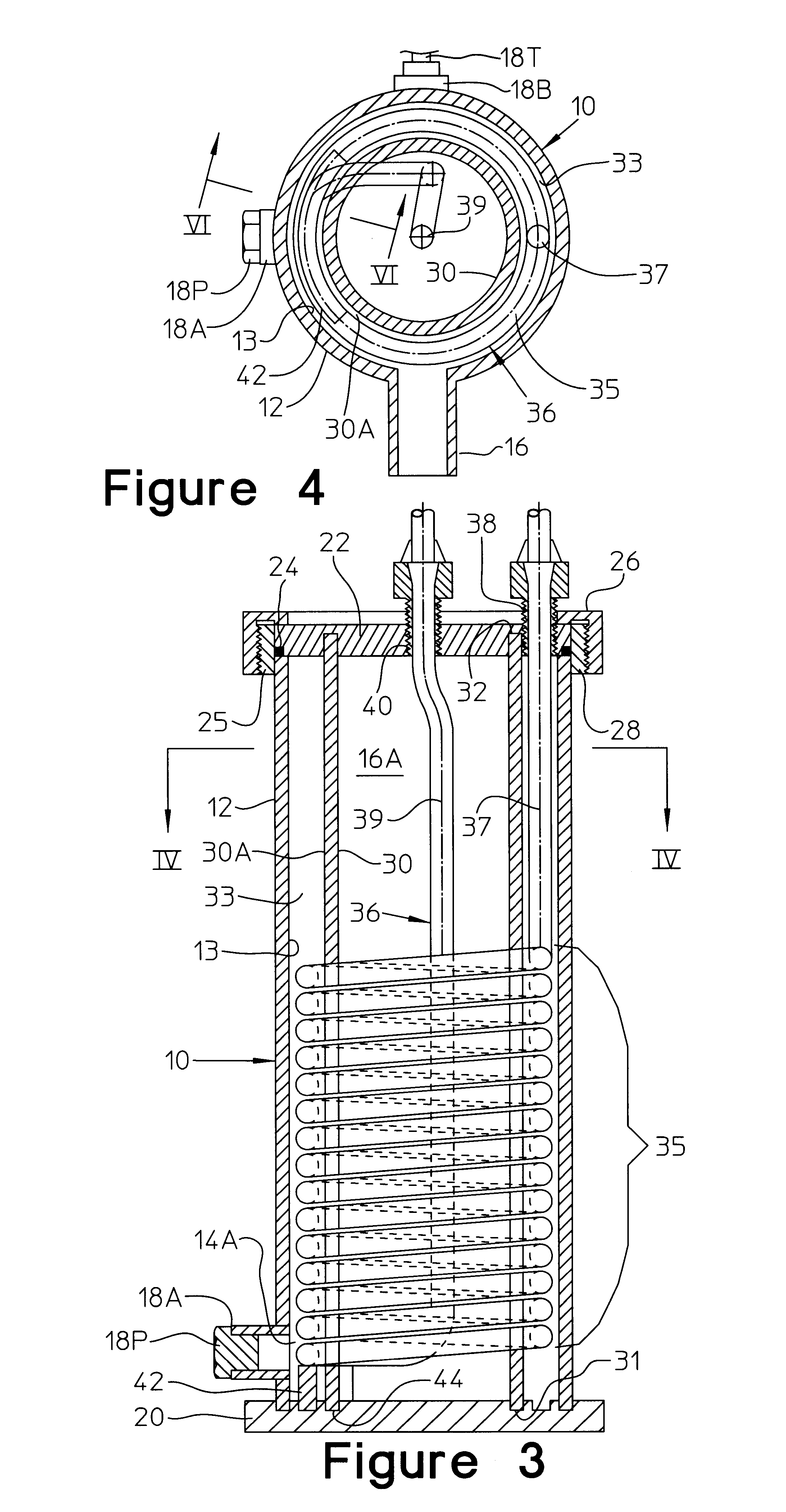

Method and apparatus for optimizing heat transfer in a tube and shell heat exchanger

InactiveUS6293335B1Increased turbulenceMaximize heat transferHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

A tube and shell heat exchanger having a transversely oriented inlet port and a spirally coiled heat transfer tube contained within an arcuate chamber created by an internal baffle in which the water to be conditioned travels along a helical pathway in which the flow has minimized water depth and high turbulence. The tube and shell heat exchanger maximizes heat transfer capability in a relatively easy to assemble design to make feasible the use of a higher cost material for the tubing such as titanium in a wide range of applications.

Owner:AQUACAL

Device and method for producing a material web

InactiveUS20110303379A1Increase contentLow compressibilityDrying solid materials with heatDrying solid materials without heatTwo bandPulp and paper industry

A device for drainage of a pulp web, particularly a tissue web, having a first pressing zone having a first pressing zone length through which the pulp web is fed horizontally between a circulating, permeable band and a circulating, permeable support band. The first pressing zone is designed such that a fluid can flow through the band, the pulp web and the support band at least on one part of the first pressing zone length. In addition, the device has a subsequent second pressing zone having a second pressing zone length. The pulp web is guided through the second pressing zone between two bands having differing compressibility.

Owner:VOITH PATENT GMBH

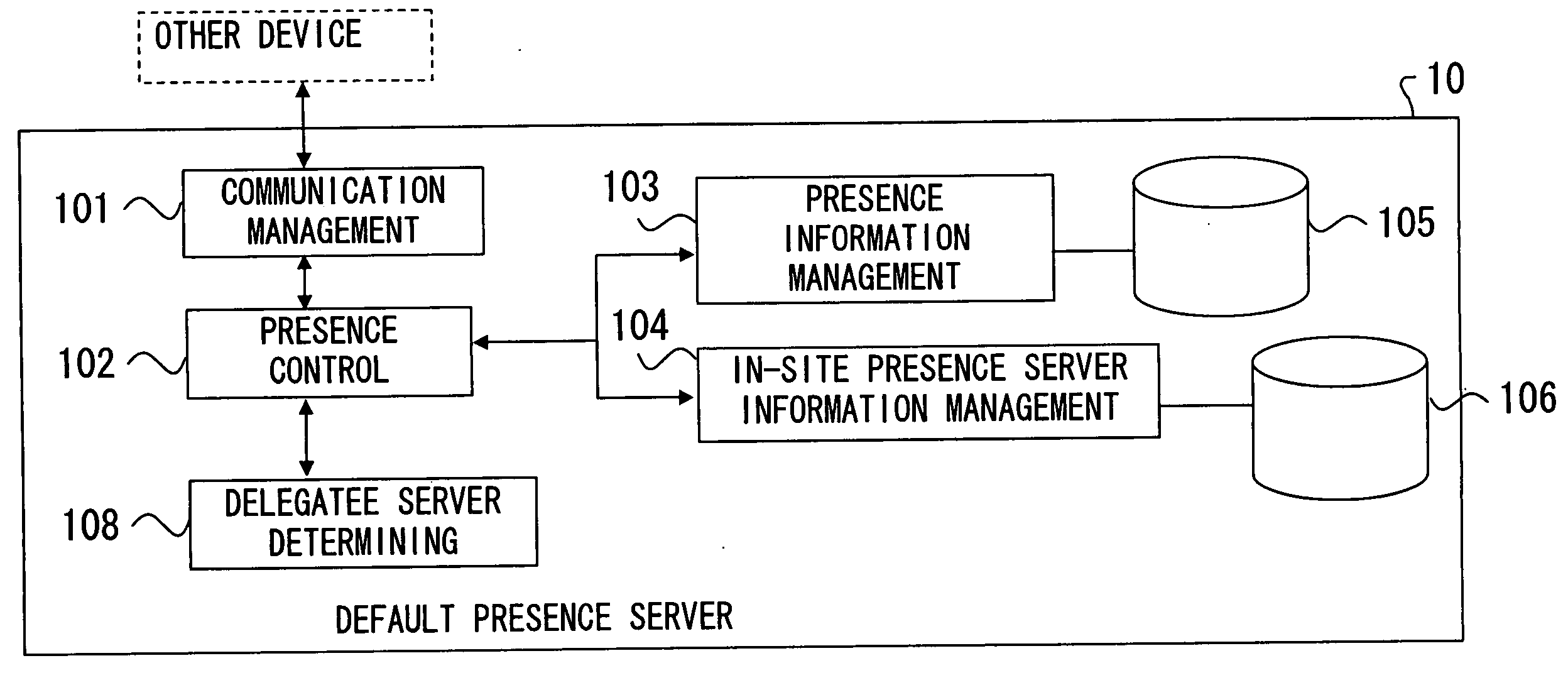

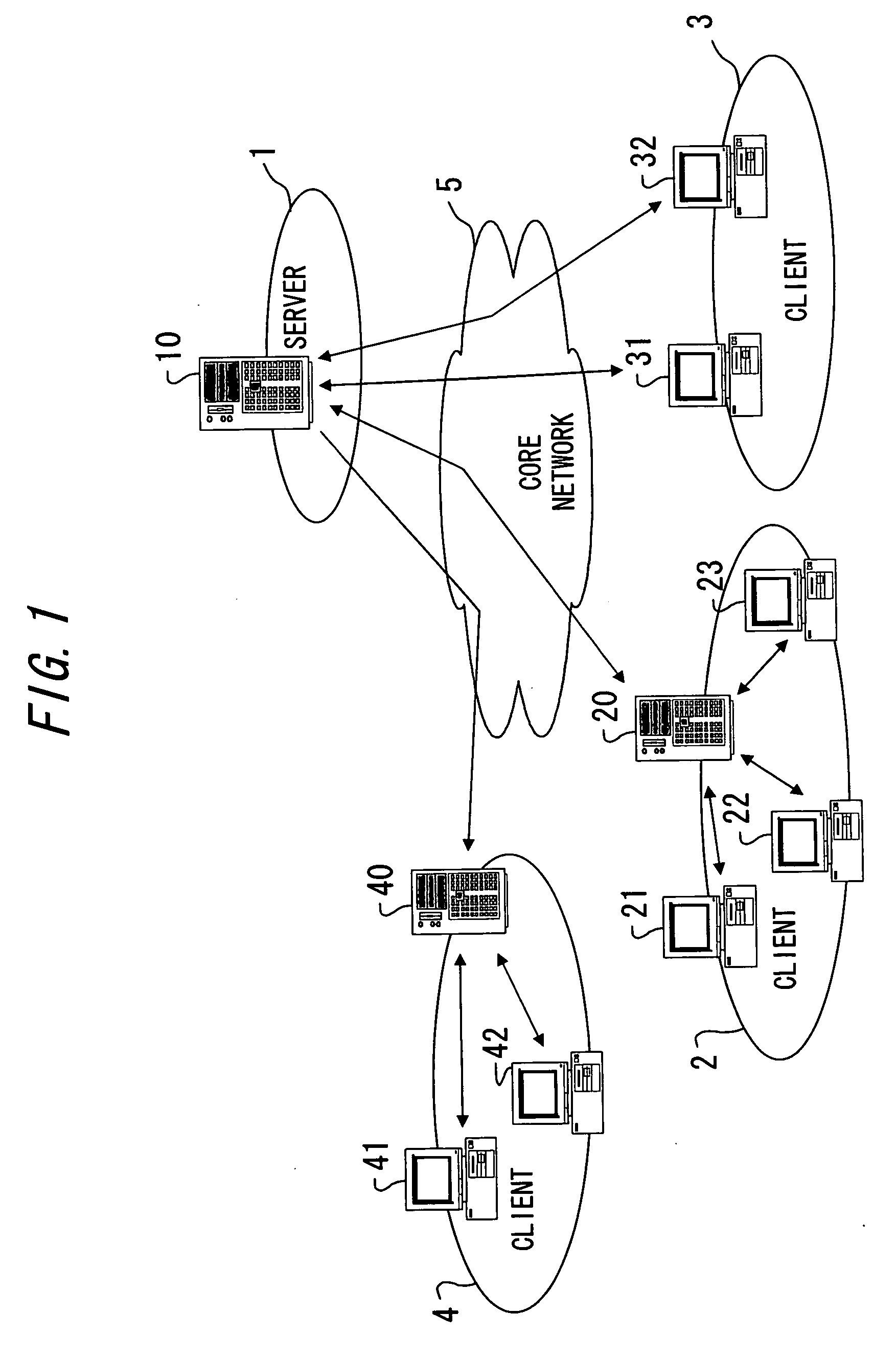

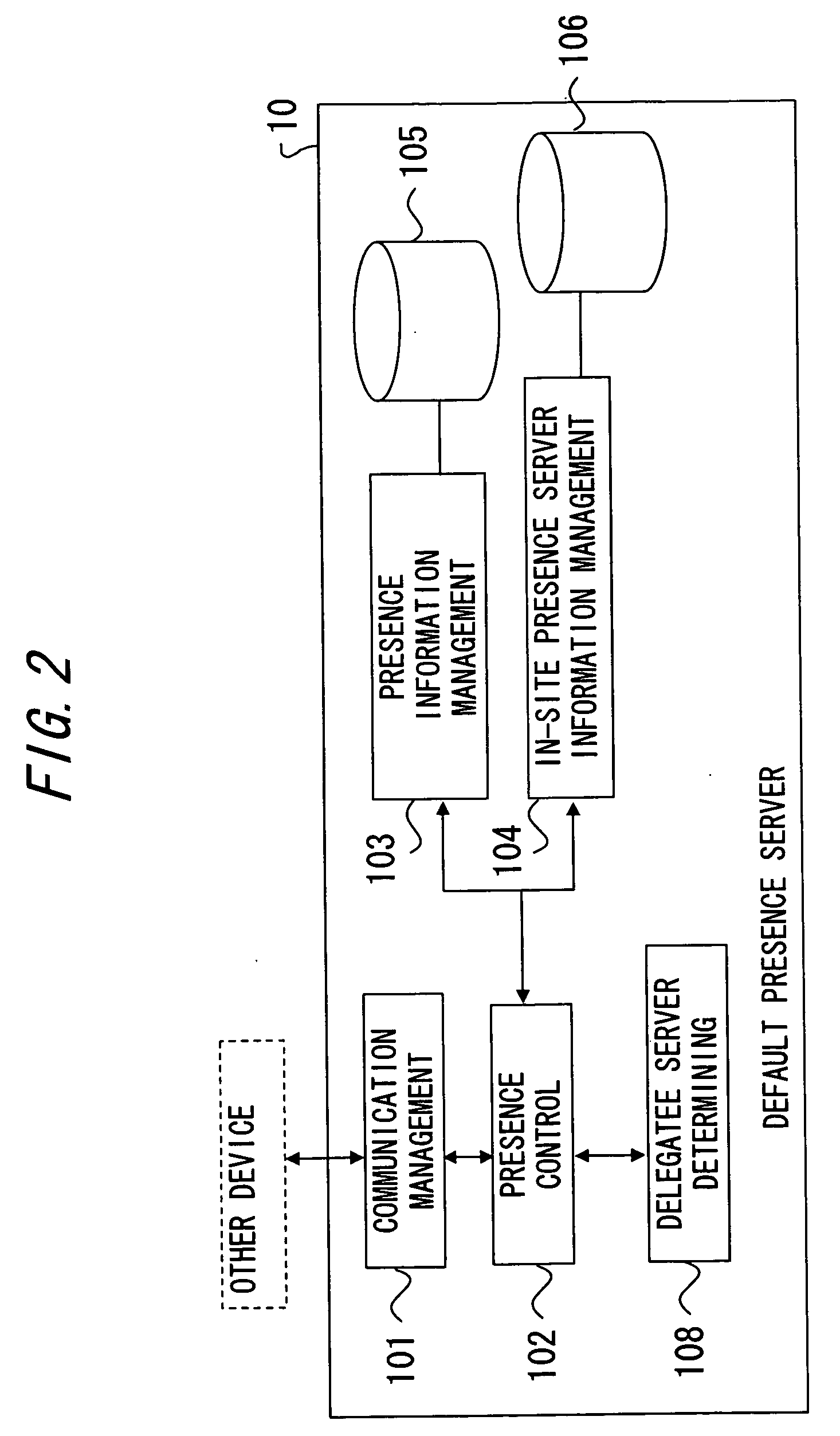

Presence information management system, presence server device, gateway device and client device

InactiveUS20080034078A1Restrain communication trafficAvoid trafficDigital computer detailsTransmissionClient-sideTraffic volume

The present invention provides a presence information management system, a presence server device, a gateway device and a client device, which notify of presence information in realtime while restraining communications traffic. The presence server device managing presence information of a plurality of presentities, comprises a delegating unit sending delegating notification of presence information management function related to at least one of the plurality of presentities, to another device becoming a delegatee of the presence information management function. The gateway device comprises a managing unit managing presence information of a presentity, and a control unit performing control so that, when receiving the delegating notification of the presence information management function about at least one of the plurality of presentities from a presence server, the managing unit is executed with respect to the function-delegated presentity.

Owner:FUJITSU LTD

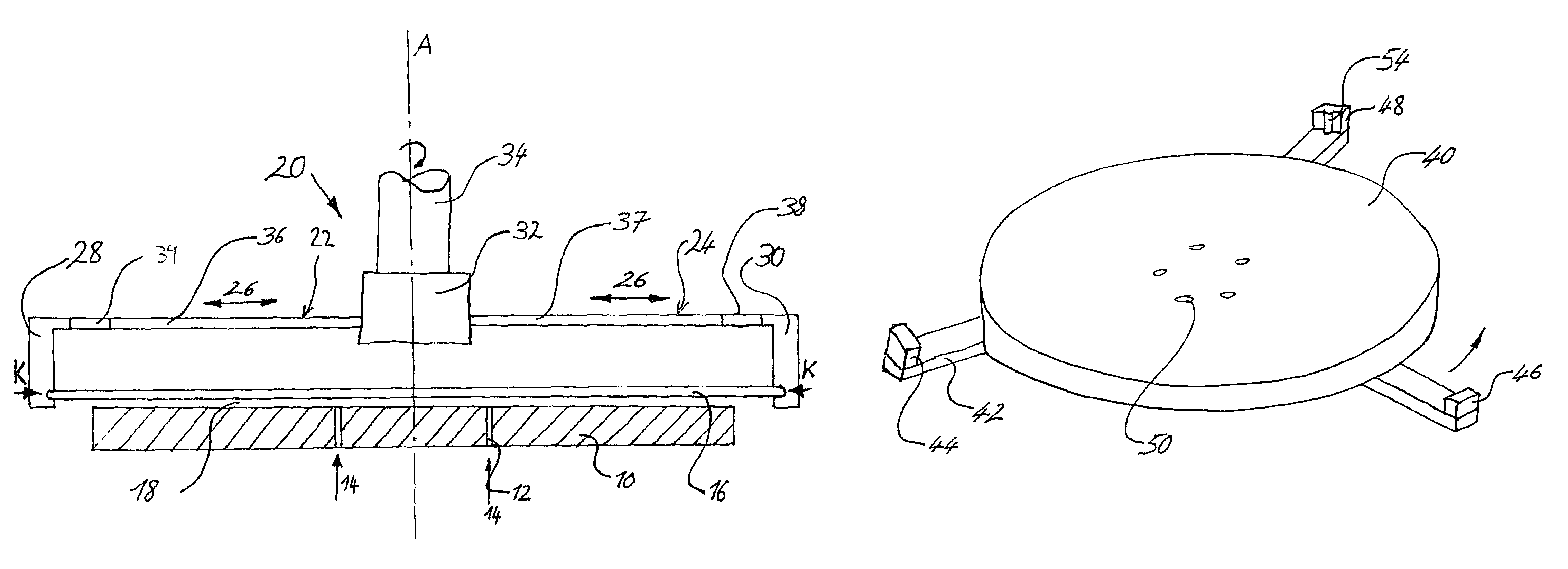

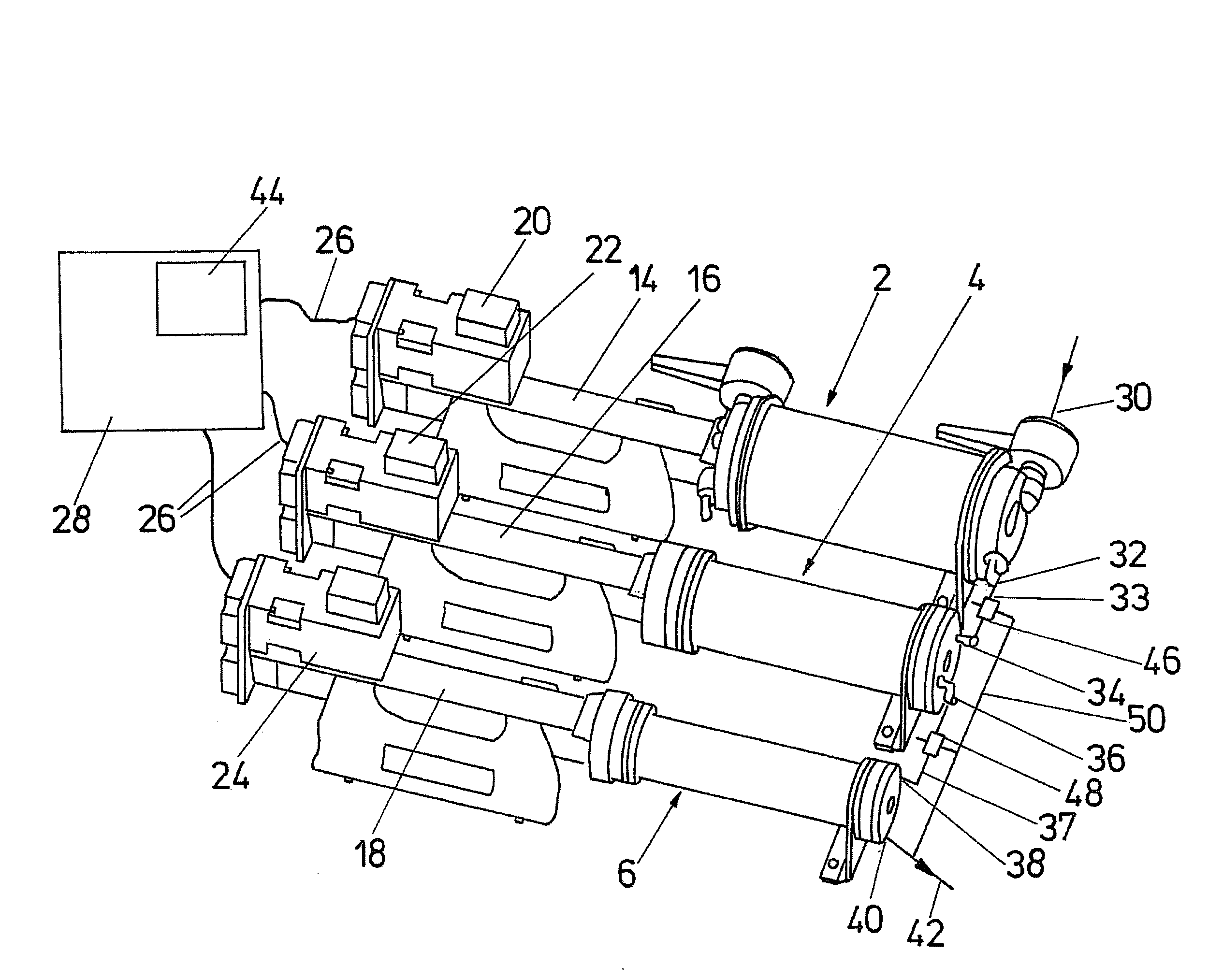

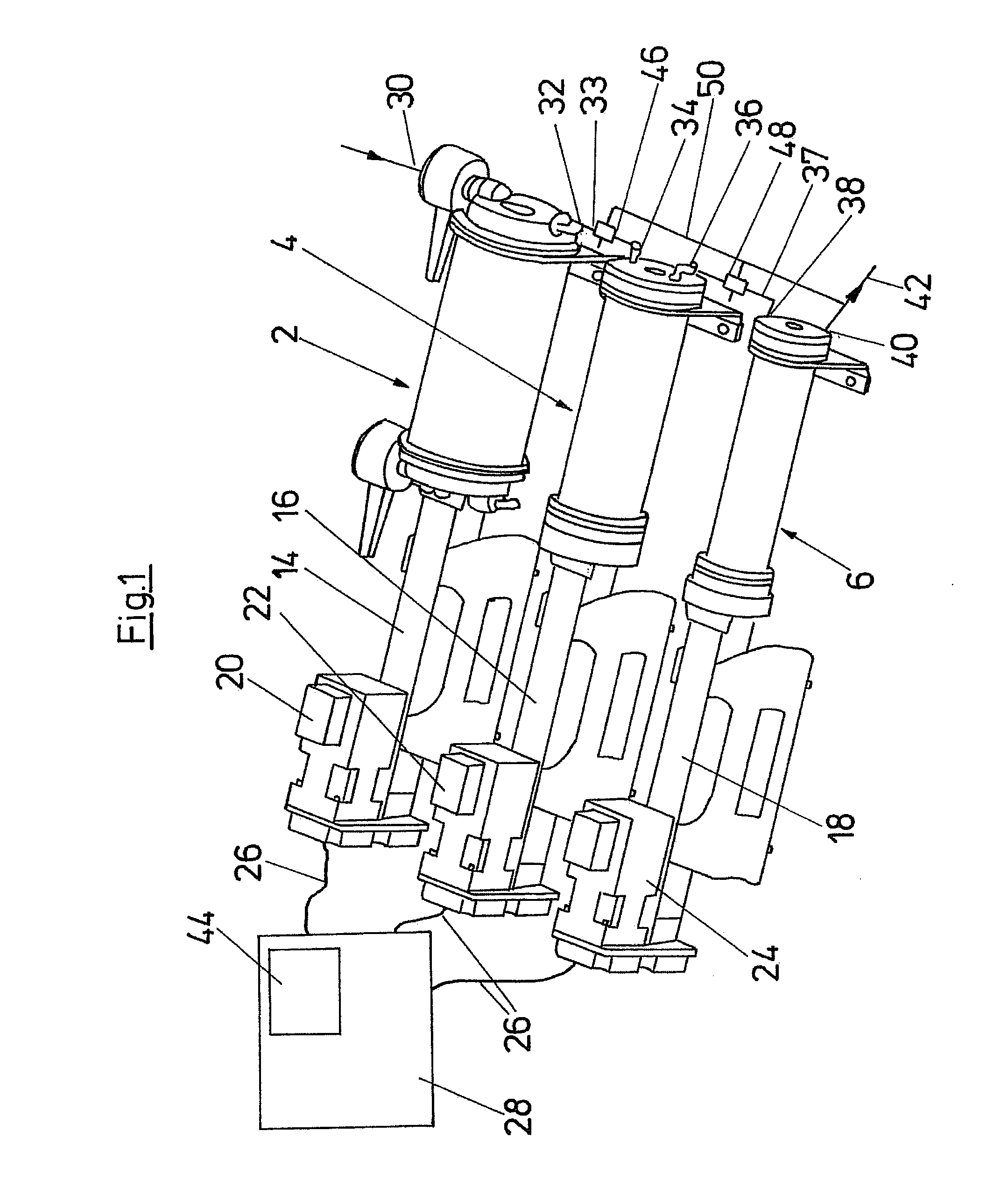

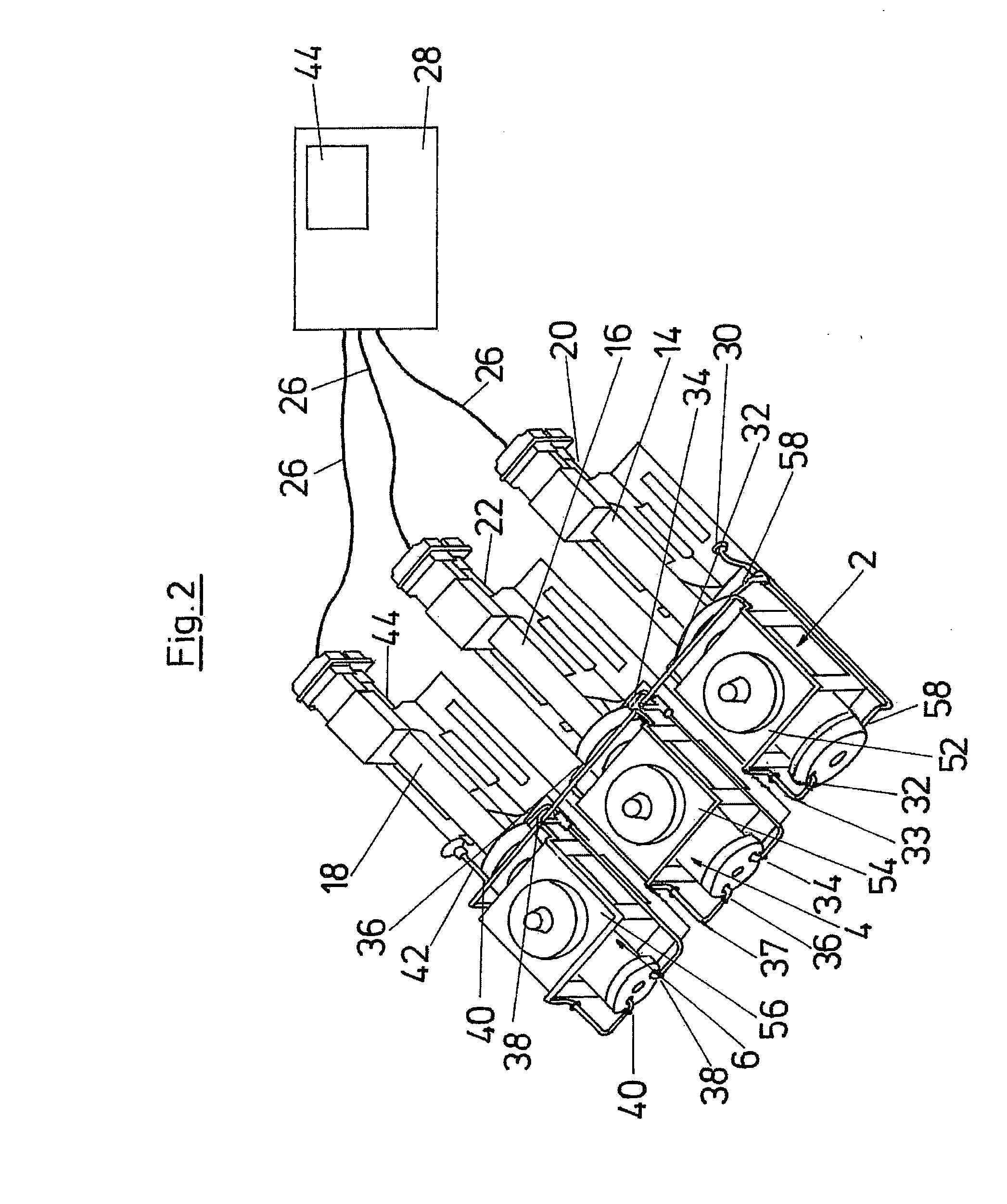

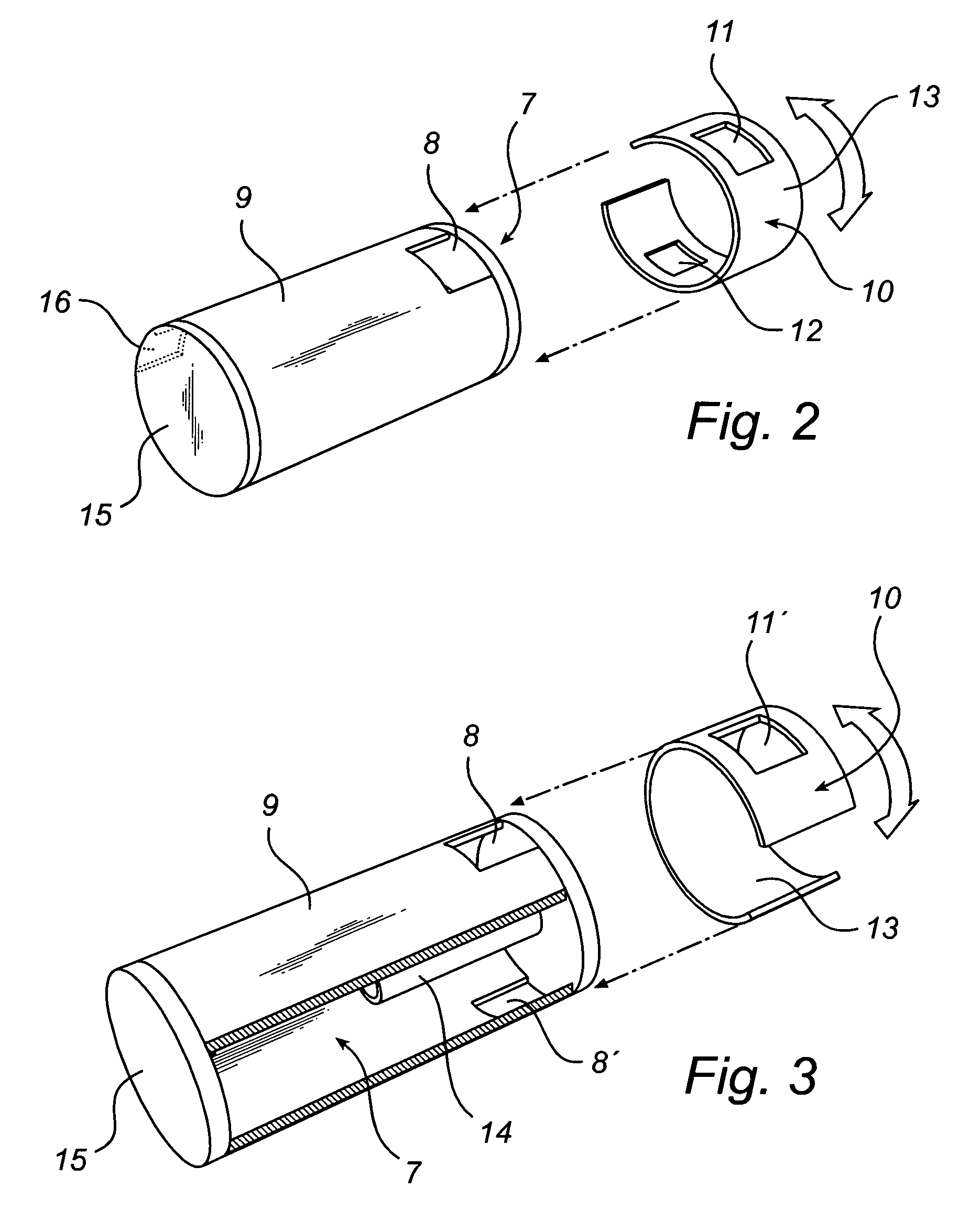

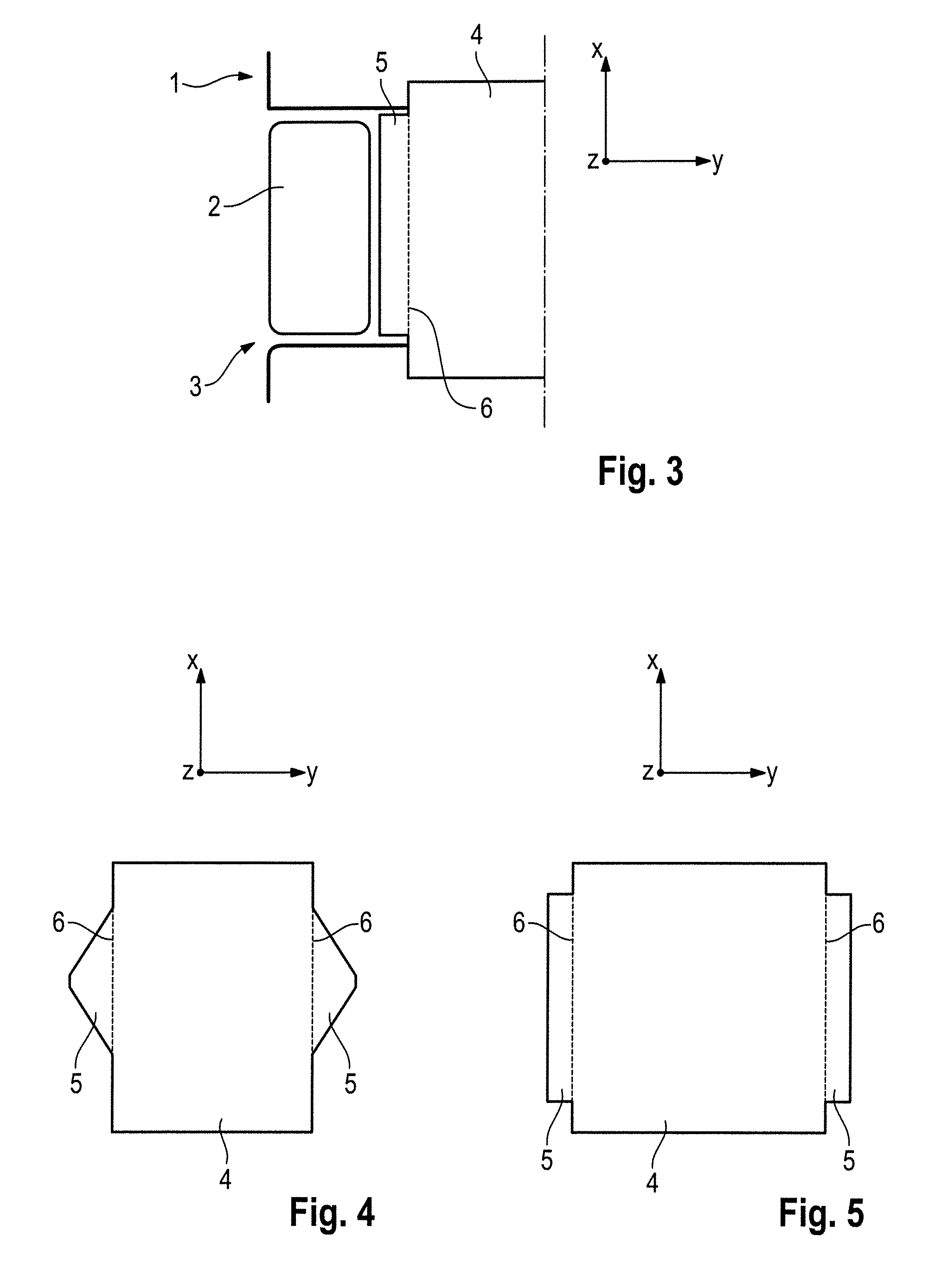

Holding and turning device for touch-sensitive flat objects

ActiveUS8444126B2Simple designReduce quality problemsTravelling carriersHoldersRotational axisClassical mechanics

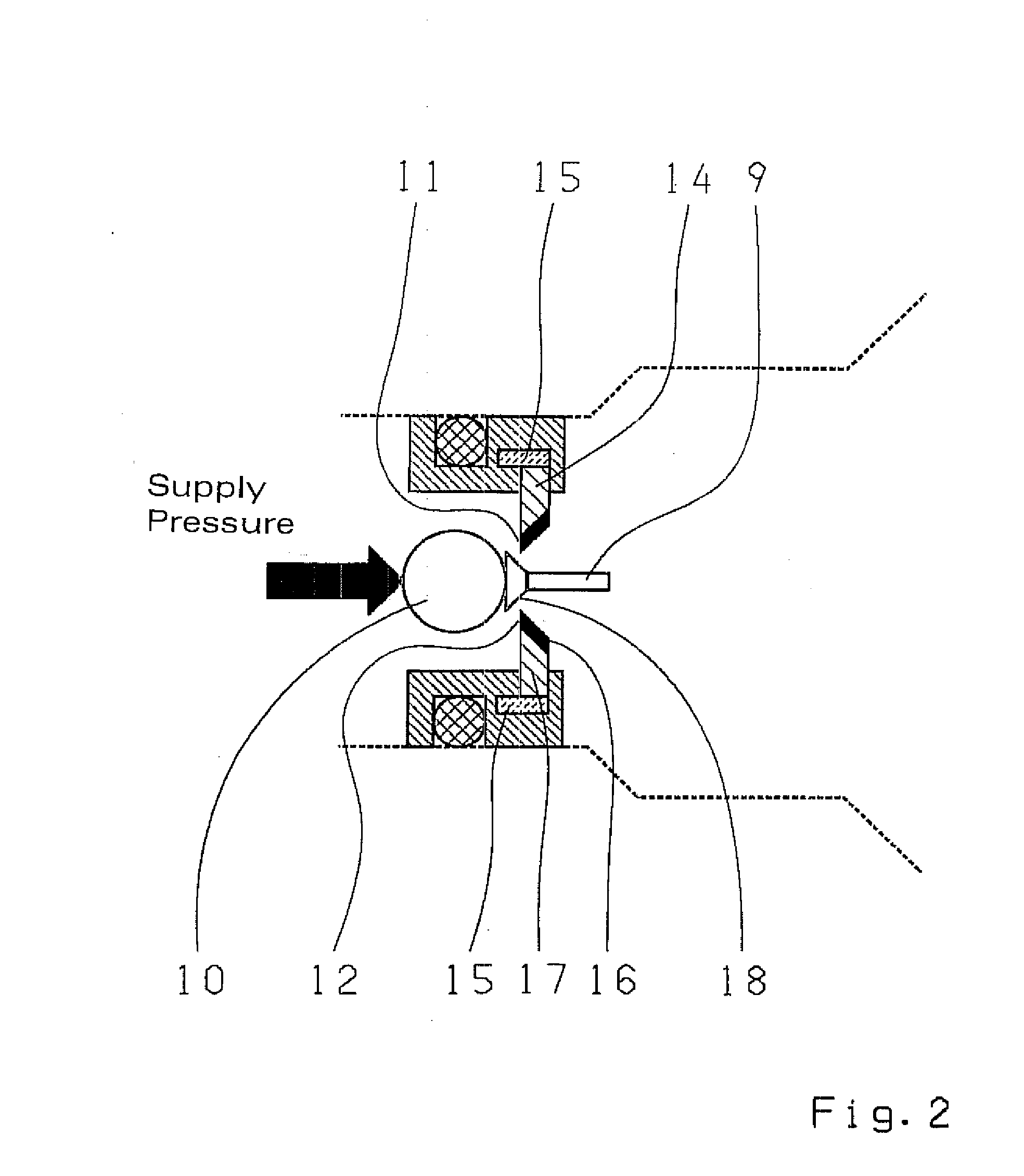

A holding / turning device for touch-sensitive flat objects, in particular wafers, with a distance positioning device which is arranged for holding the object perpendicular to the object plane at a defined distance, a lateral positioning device, arranged for positioning the object in the object plane and for rotating together with the object about a rotational axis perpendicular to the object plane, and with a rotational drive, coupled with the lateral positioning device, providing a driving force for rotating the object about the rotational axis, wherein the driving force can be applied to the object by the lateral positioning device. The distance positioning device is adapted for holding the object without involving contact, and is decoupled from the rotational drive in such a way that the distance positioning device does not rotate together with the object.

Owner:ONTO INNOVATION INC

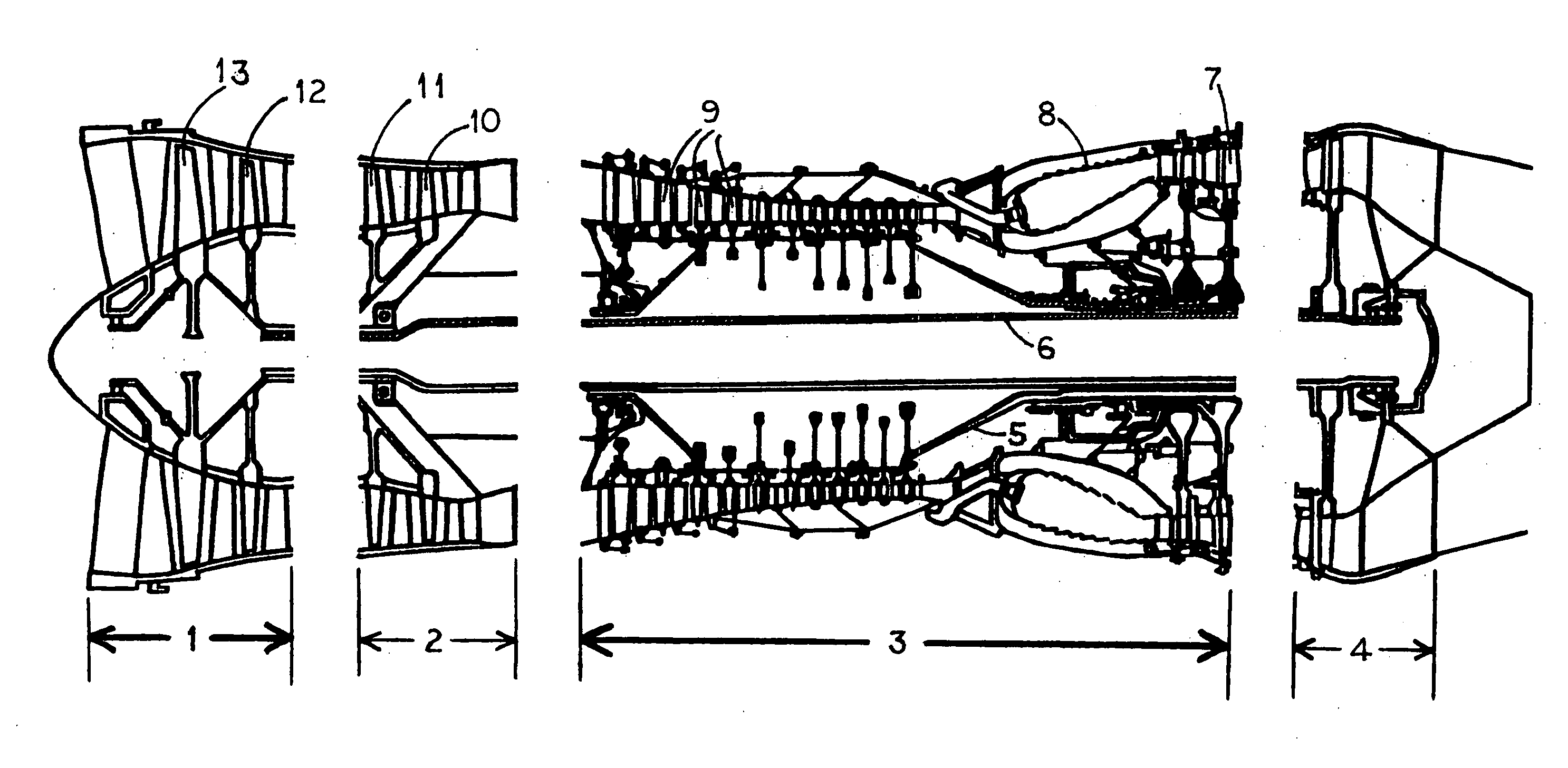

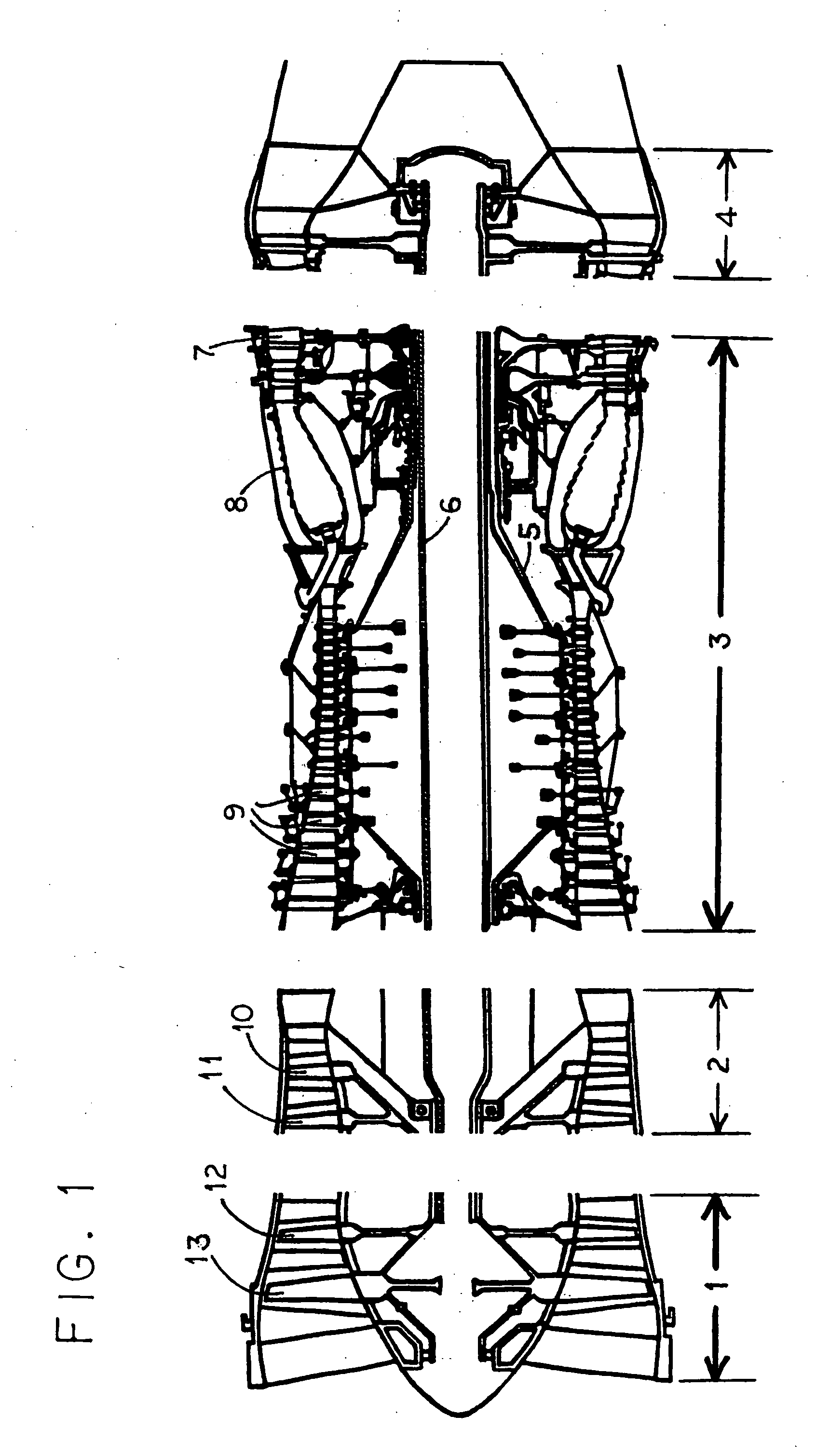

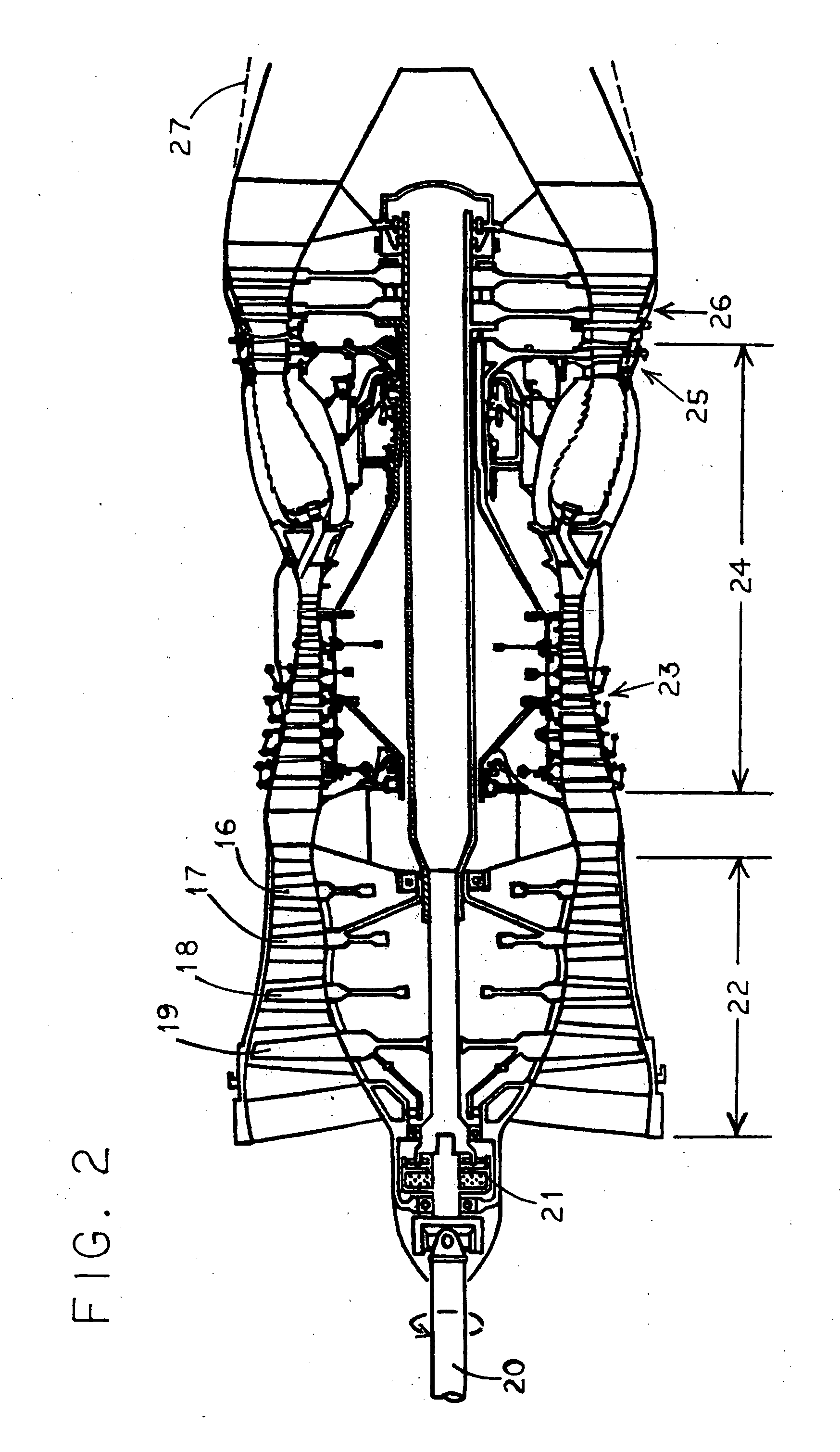

Piecemeal Turbojet

InactiveUS20130186060A1Much of development costMany timesGas turbine plantsRocket engine plantsJet enginePropulsive efficiency

A two-spool turbojet built up of major bladed components first developped for unrelated turbofan engine types. The high pressure (“HP”) spool comes from a turbofan which powered a large airliner carrying 300 or more passengers across a continent or an ocean. The low pressure (“LP”) compressor is the fan from a military aircraft's engine or a smaller airliner turbofan, or both. The object is that all the LP compressor output goes into the HP compressor, making a turbojet from existing turbofan components. This saves development costs, and creates an engine for propelling a large aircraft at supersonic speeds more efficiently than by an afterburning turbofan. In the preferred embodiment, the number of stages in the HP spool is halved, saving weight for the addition of a remote fan (known elsewhere) which doubles the air mass flow. That increases propulsive efficiency during subsonic cruise.

Owner:KOSHELEFF PATRICK A

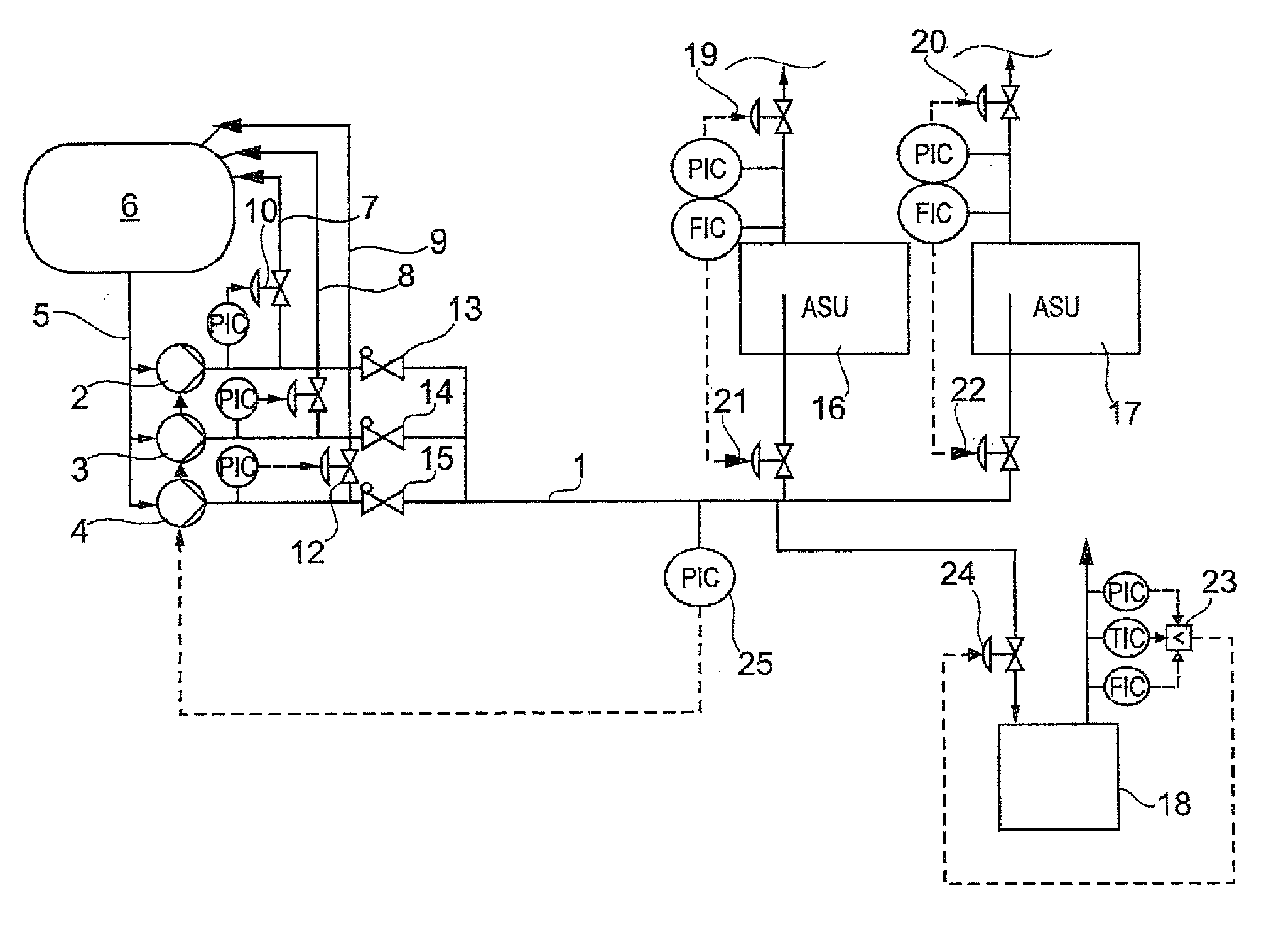

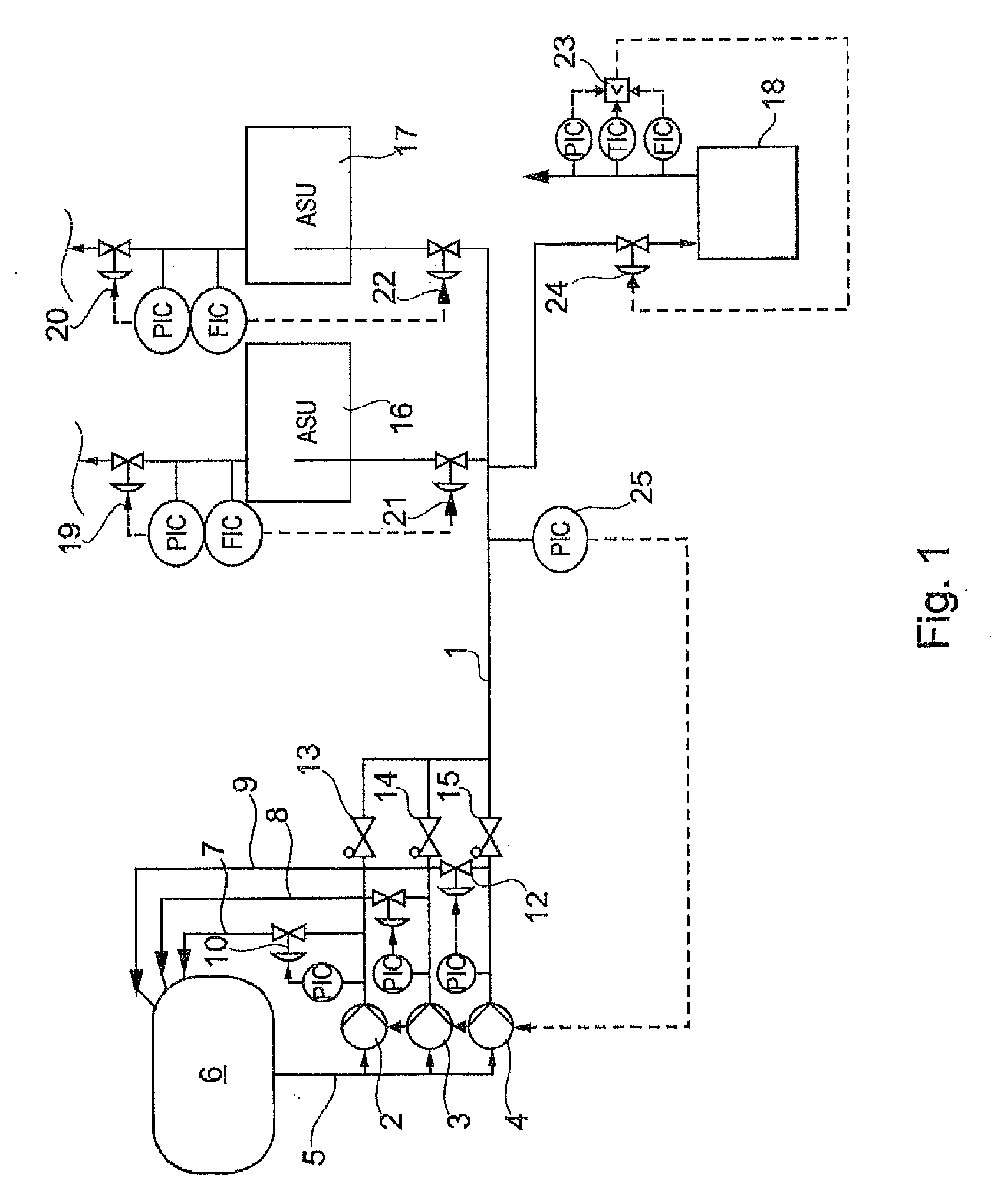

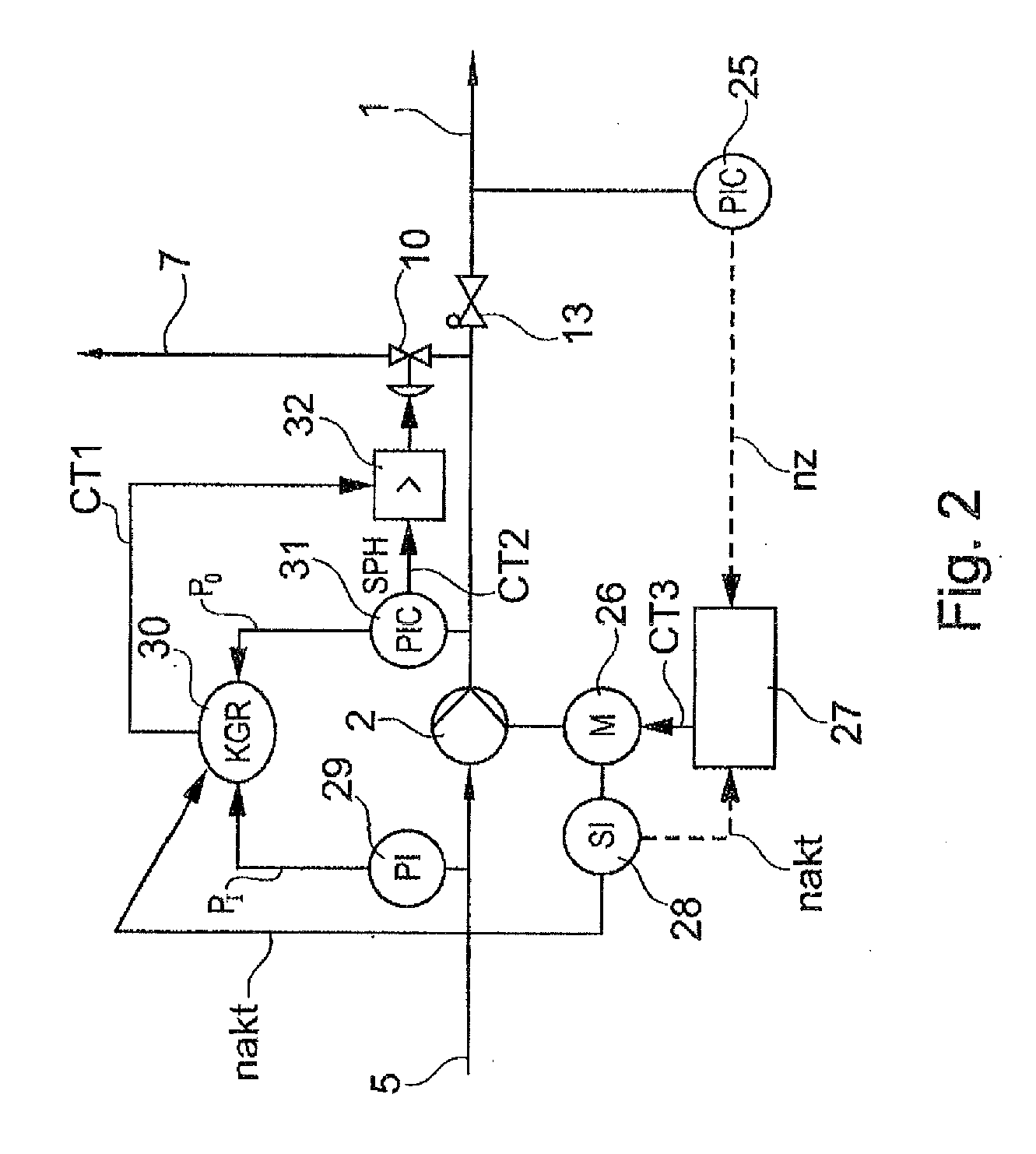

Method for controlling a pump arrangement, and pump arrangement

InactiveUS20090129941A1Great reductionReduced volume flowSolidificationFluid parameterEngineeringMechanical engineering

A method for controlling a pump arrangement comprising a fluid delivering pump having a pump drive, a bypass line having a bypass valve for routing fluid back from an outlet side of the pump to a reservoir is disclosed. During ramping up the pump drive to a predetermined target rotational speed, the bypass valve is controlled to reduce a volume flow through the pump so that the volume flow, at a respective delivery height, lies between a cavitational volume flow and the cavitational volume flow increased by a predetermined maximum volume flow deviation.

Owner:LINDE AG

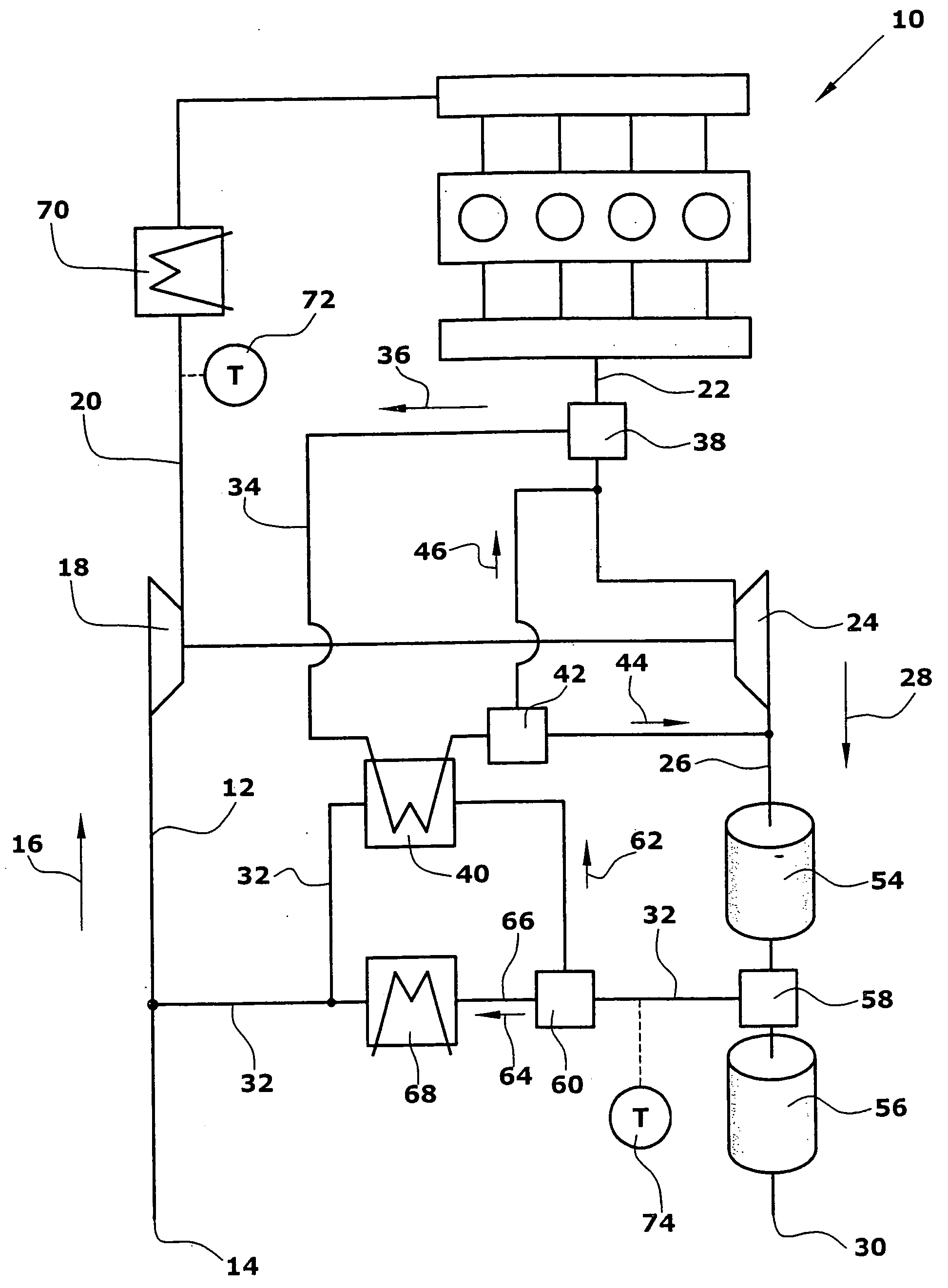

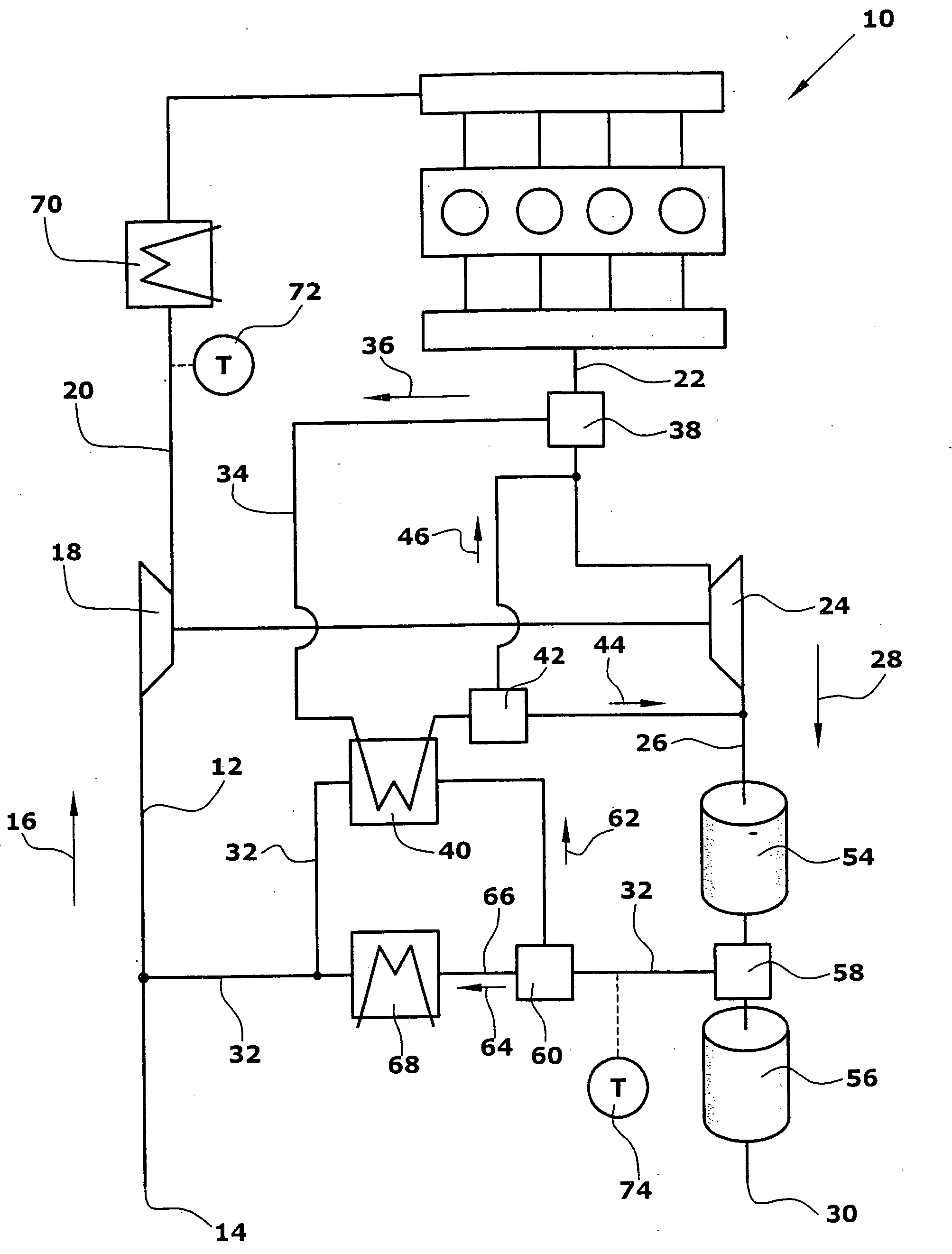

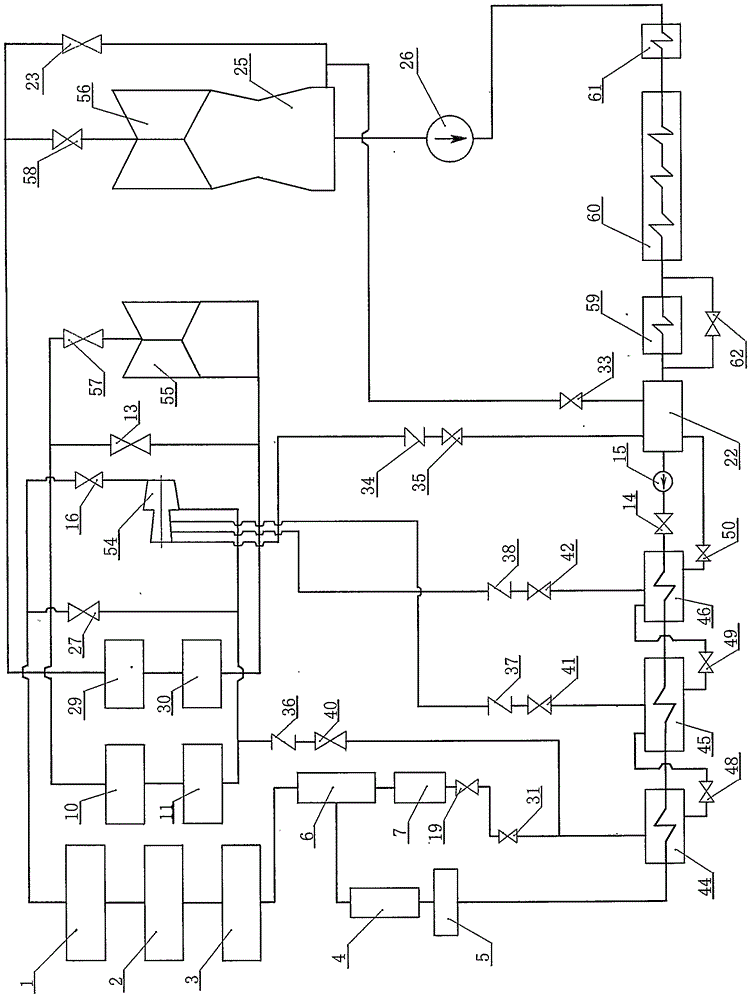

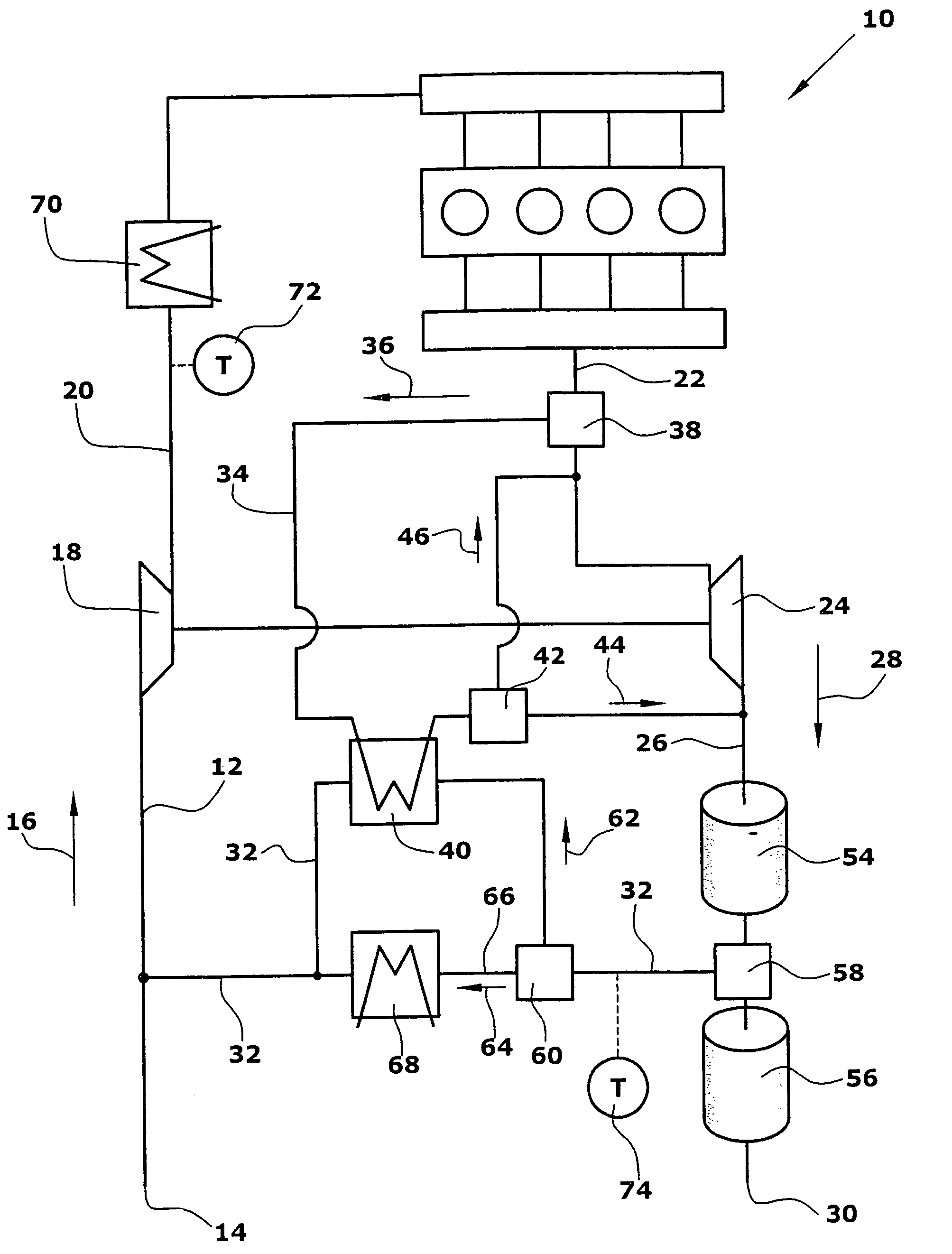

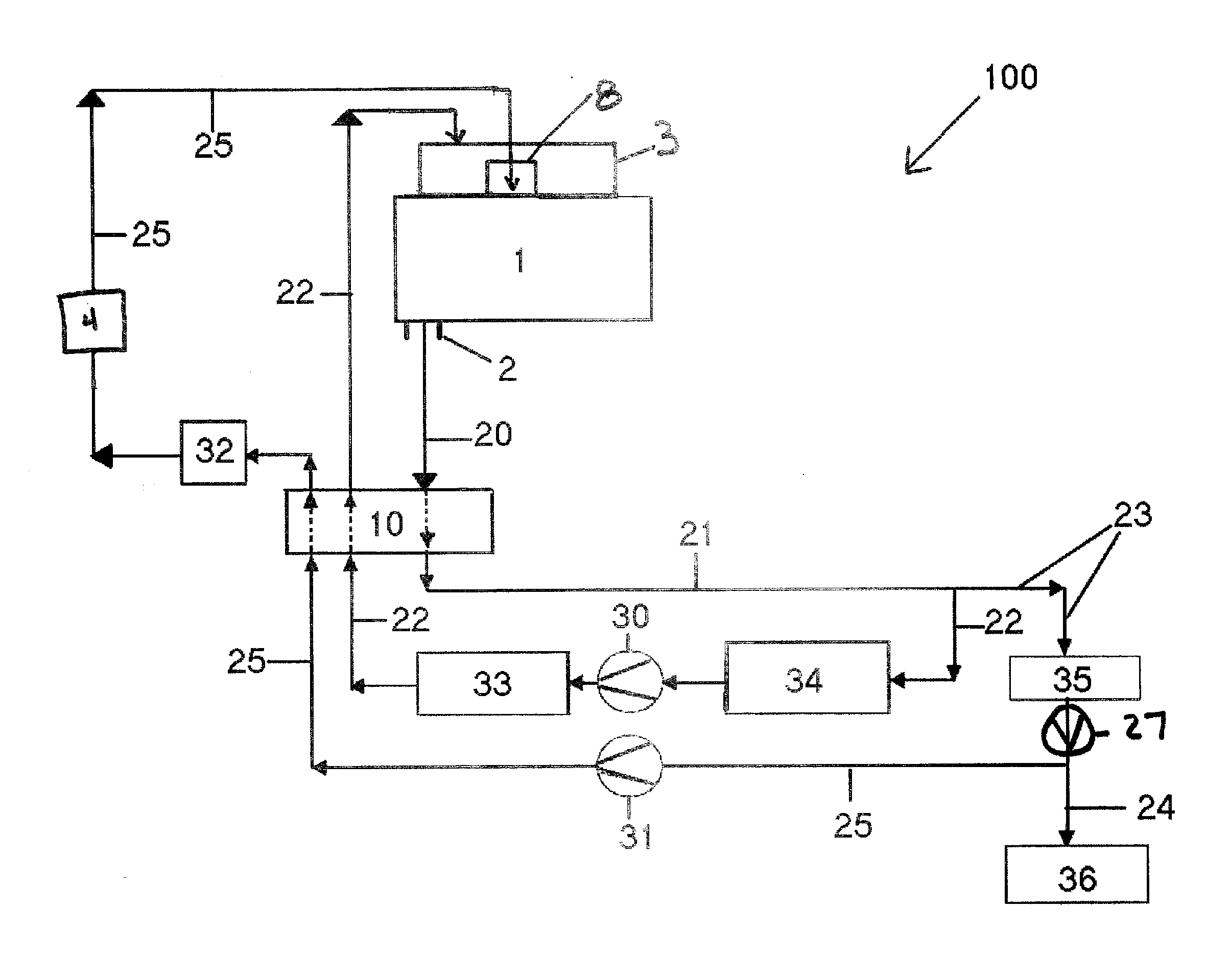

Exhaust-gas return system for an internal-combustion machine and method of returning exhaust gas

InactiveUS20060156724A1Improved cold start behaviourAvoid heatingNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExhaust fumes

An exhaust gas return system for an internal-combustion machine which comprises a low-pressure supply line extending from an inlet to a compressor. From the compressor a high-pressure supply line extends to the internal-combustion machine. From the internal-combustion machine a high-pressure exhaust gas line extends to a turbine. From the turbine a low-pressure exhaust gas line extends to an outlet. The low-pressure exhaust gas line and the low-pressure supply line have connected therewith a low-pressure return line for returning exhaust gas. The high-pressure exhaust gas line has connected therewith a bypass line for utilizing the heat of the exhaust gas produced in the internal-combustion machine for heating the exhaust gas to be returned of the low-pressure return line before the exhaust gas is supplied to the turbine (24), if desired. Thus the cold start phase of the internal-combustion machine can be reduced.

Owner:PIERBURG GMBH & CO KG NEUSS

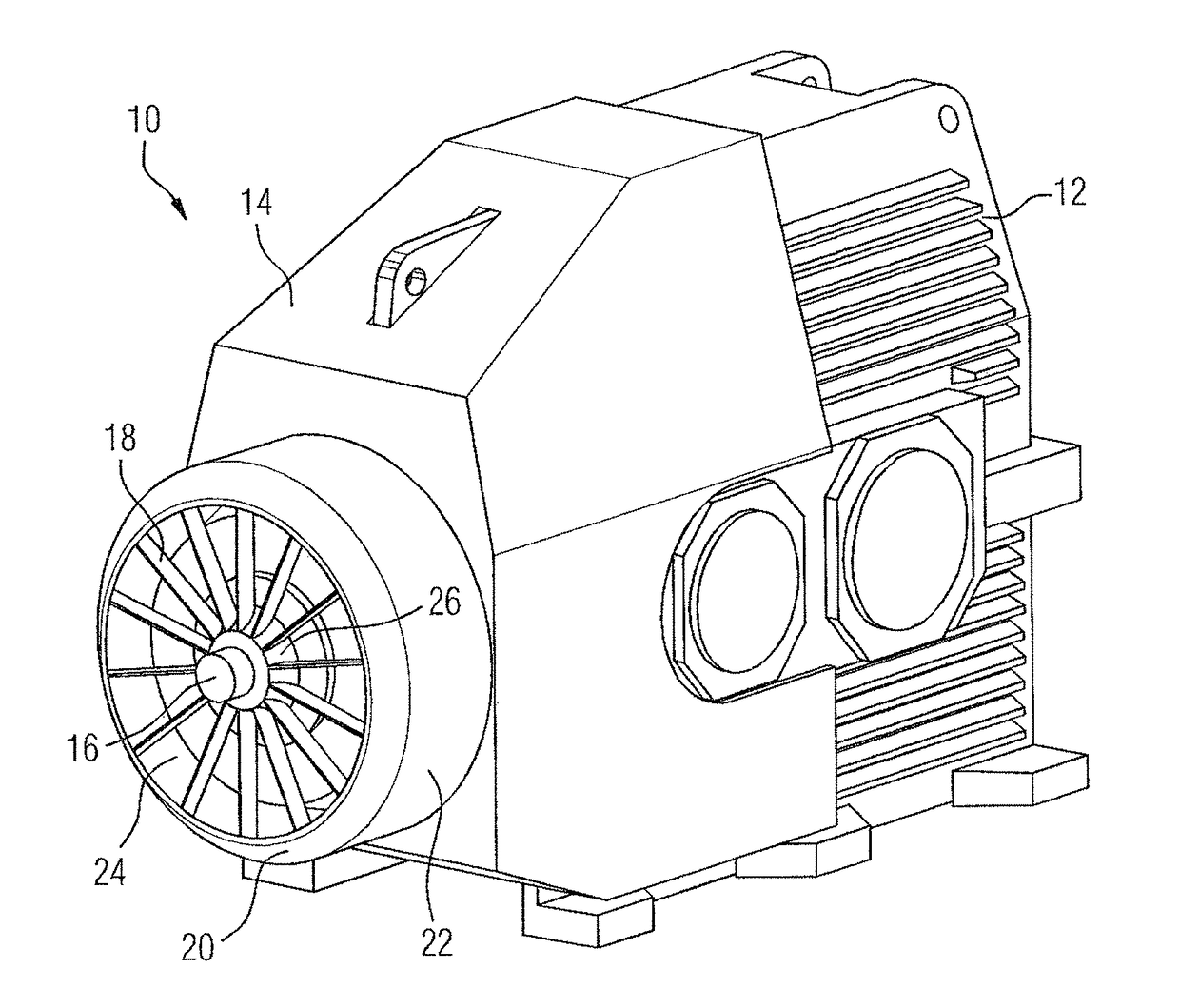

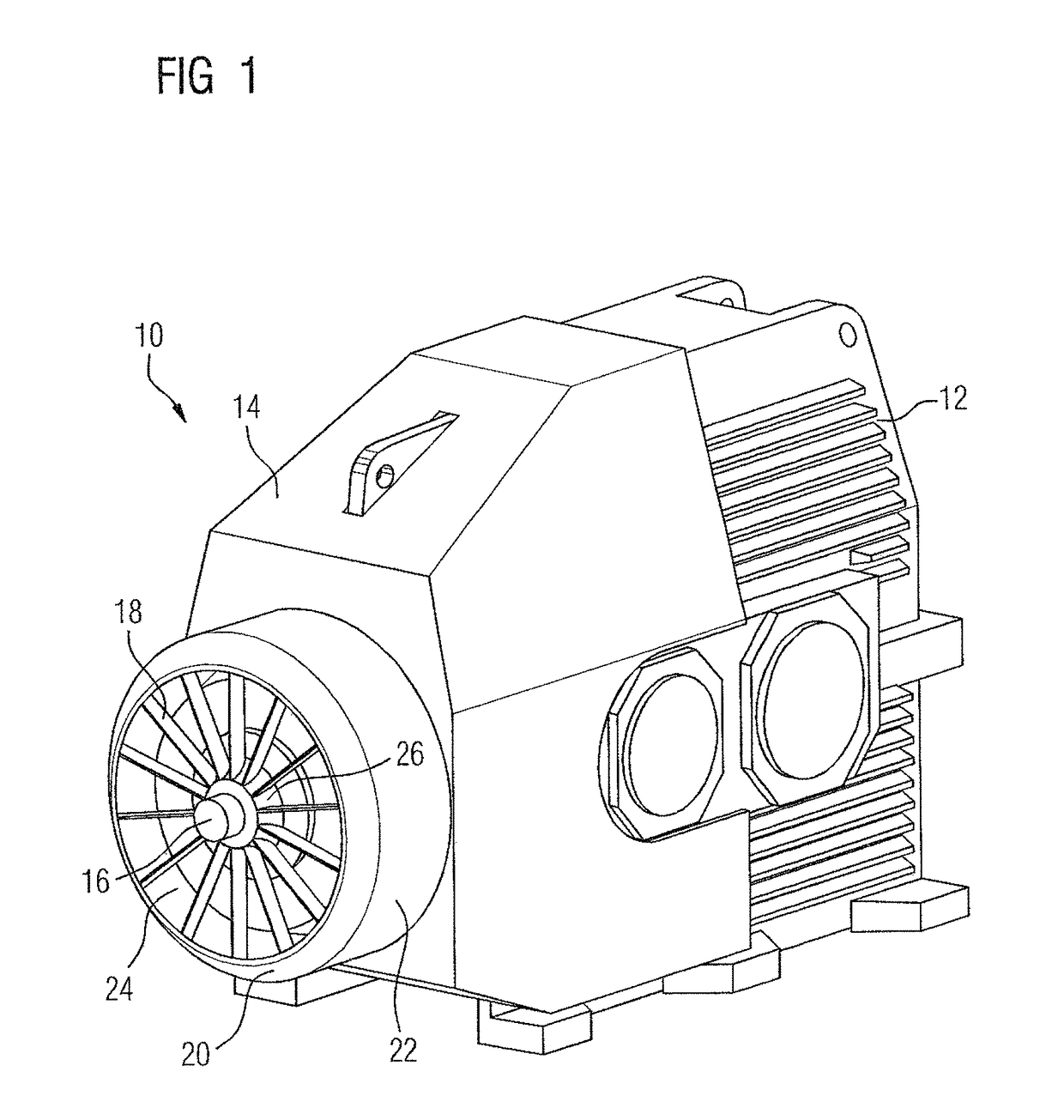

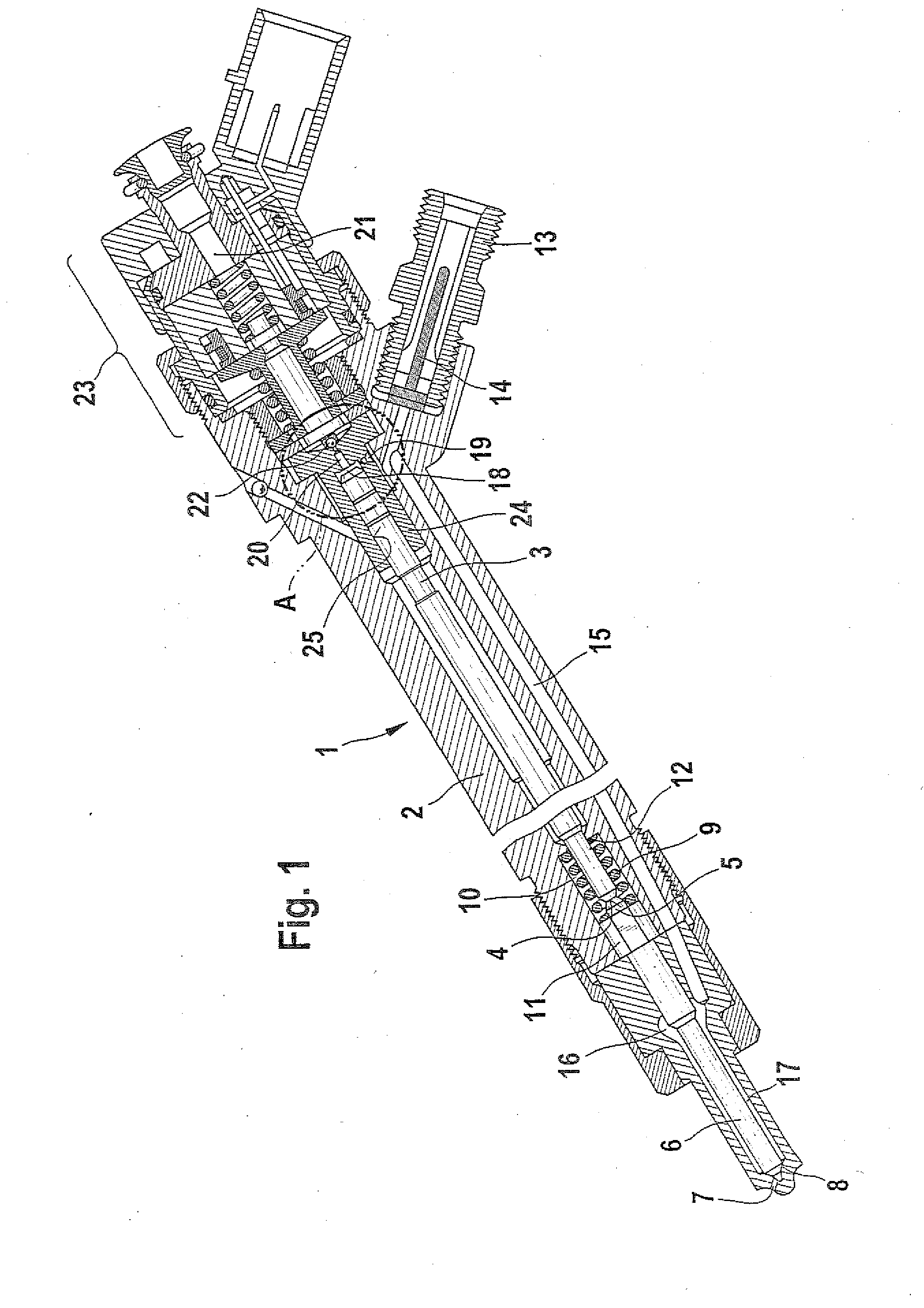

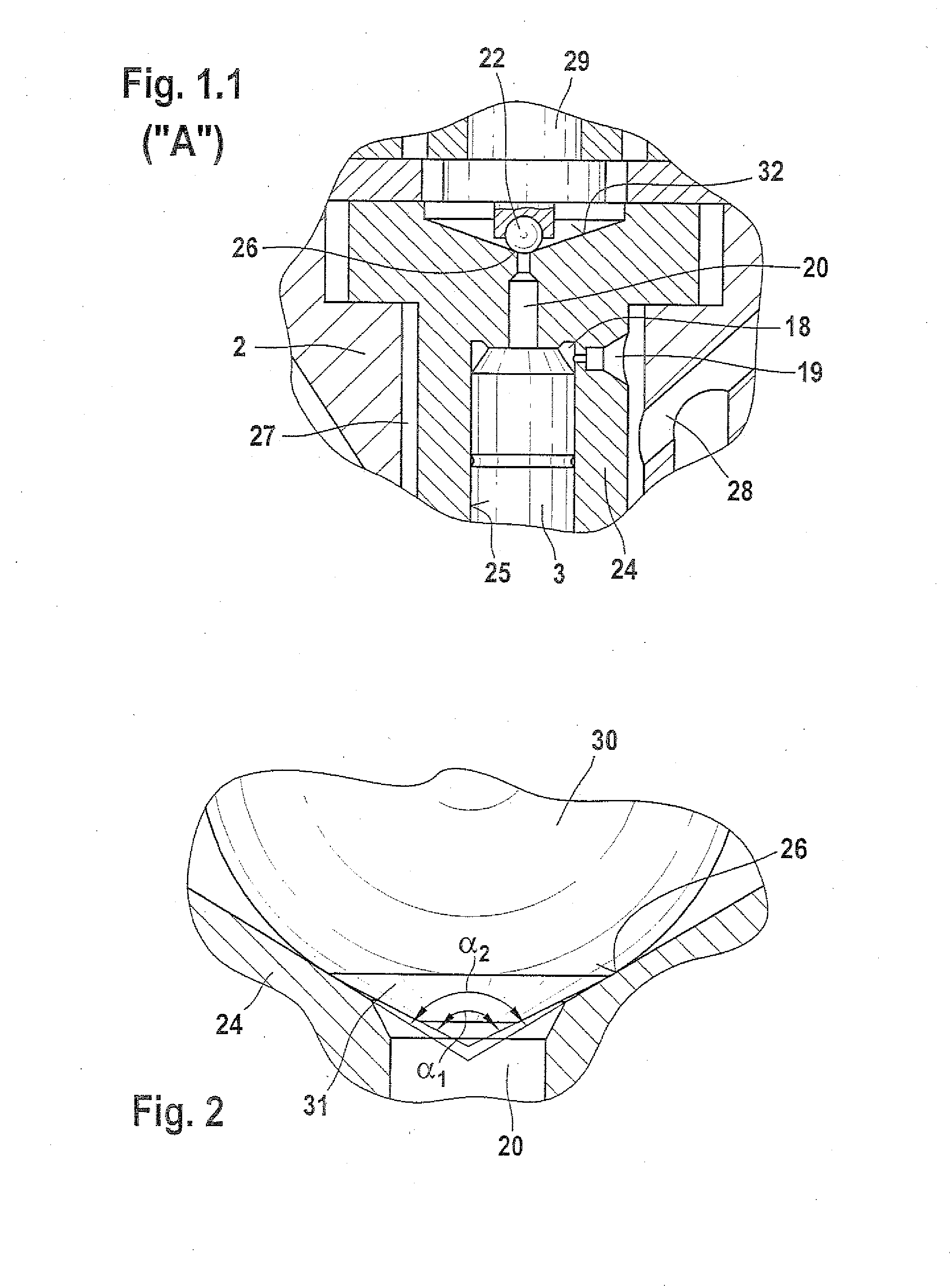

Multi-stage piston compressor

InactiveUS20090311114A1Reduced volume flowSpeed of can varyPiston pumpsMulti-stage pumpsEngineeringPiston

A multi-stage piston compressor is provided with at least two piston-cylinder units, which respectively comprise a separate linear drive for moving the piston. A control device is also provided, which is designed in a manner such that the linear drives may be controlled individually with regard to speed and stroke.

Owner:BORSIG COMPRESSOR PARTS GMBH

Well kill additive, well kill treatment fluid made therefrom, and method of killing a well

InactiveUS20060011343A1Well mixedReduced volume flowDrilling compositionSealing/packingFiberWell kill

Owner:BURTS BOYCE DONALD III

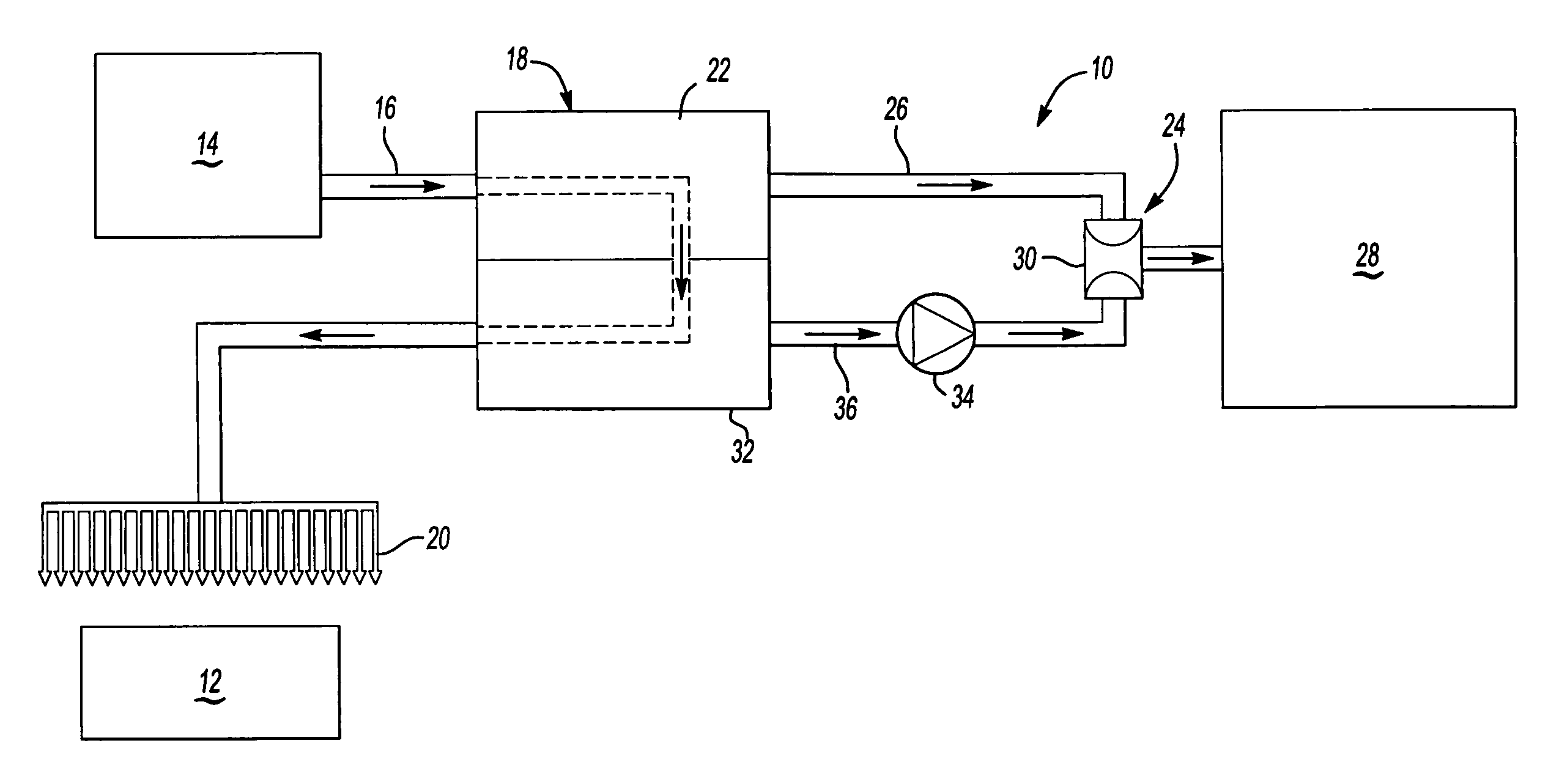

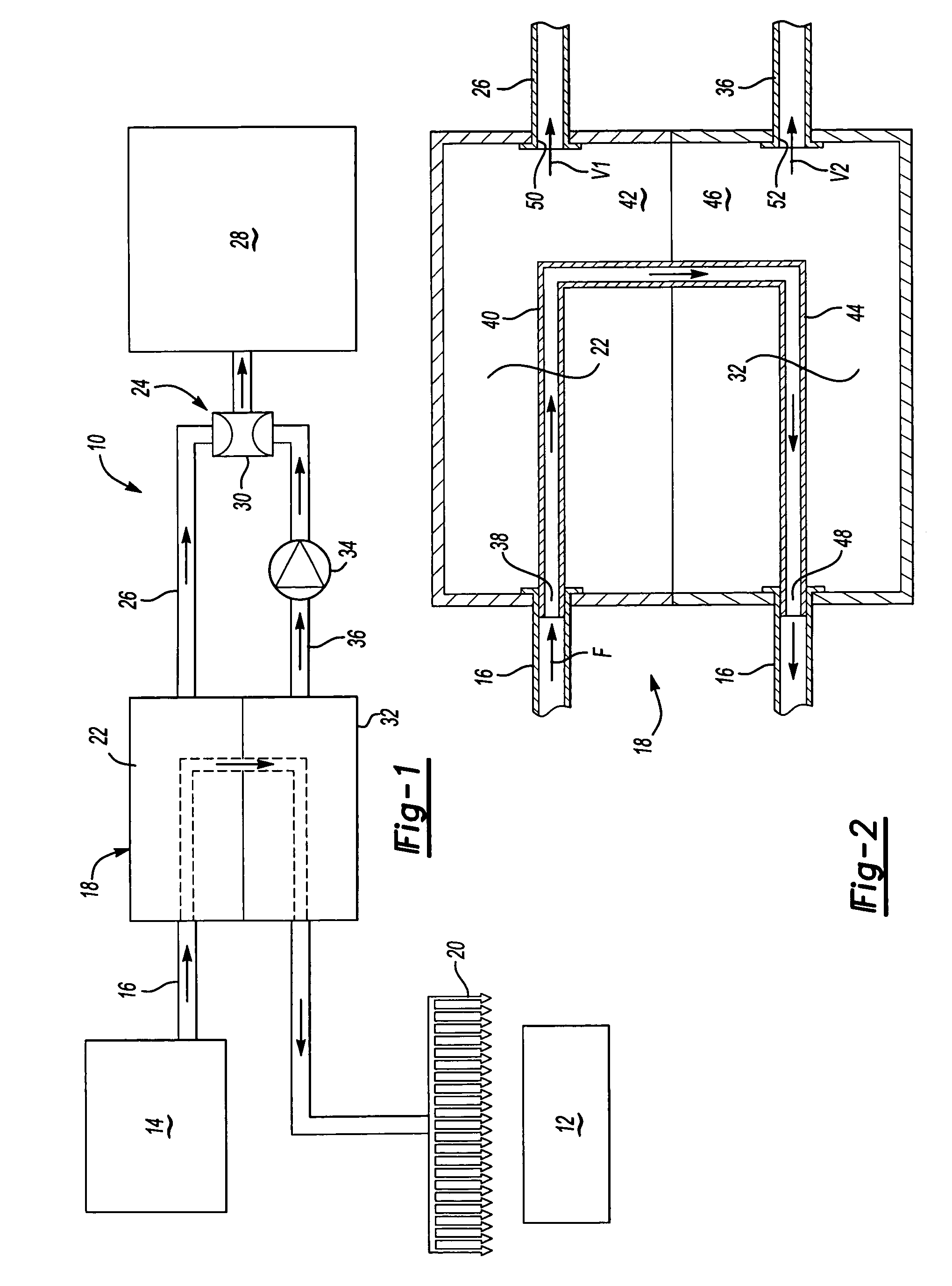

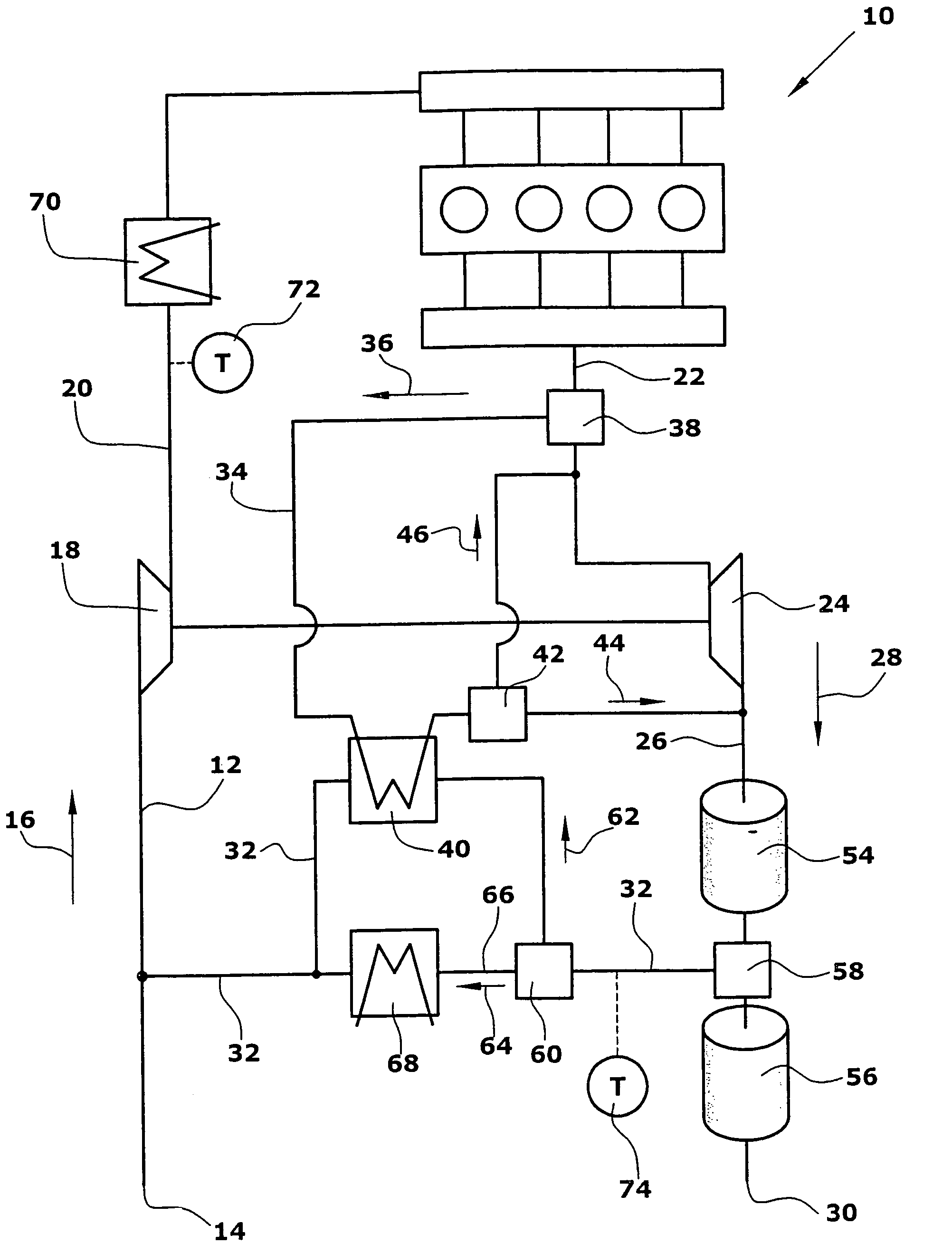

Hybrid vacuum system for fuel deoxygenation

ActiveUS7601203B2Reduced volume flowSemi-permeable membranesSolid sorbent liquid separationVacuum pressureOxygen

A fuel system for a gas turbine engine removes oxygen from fuel with a fuel stabilization unit (FSU). The FSU includes a first vacuum stage, where vacuum pressure is created by an ejector and a second vacuum stage where vacuum pressure is created by the ejector and a vacuum pump. The vacuum stream from the first vacuum stage and the second vacuum stage flow through the ejector. The vacuum stream from the second vacuum stage is all that passes through the vacuum pump.

Owner:RTX CORP

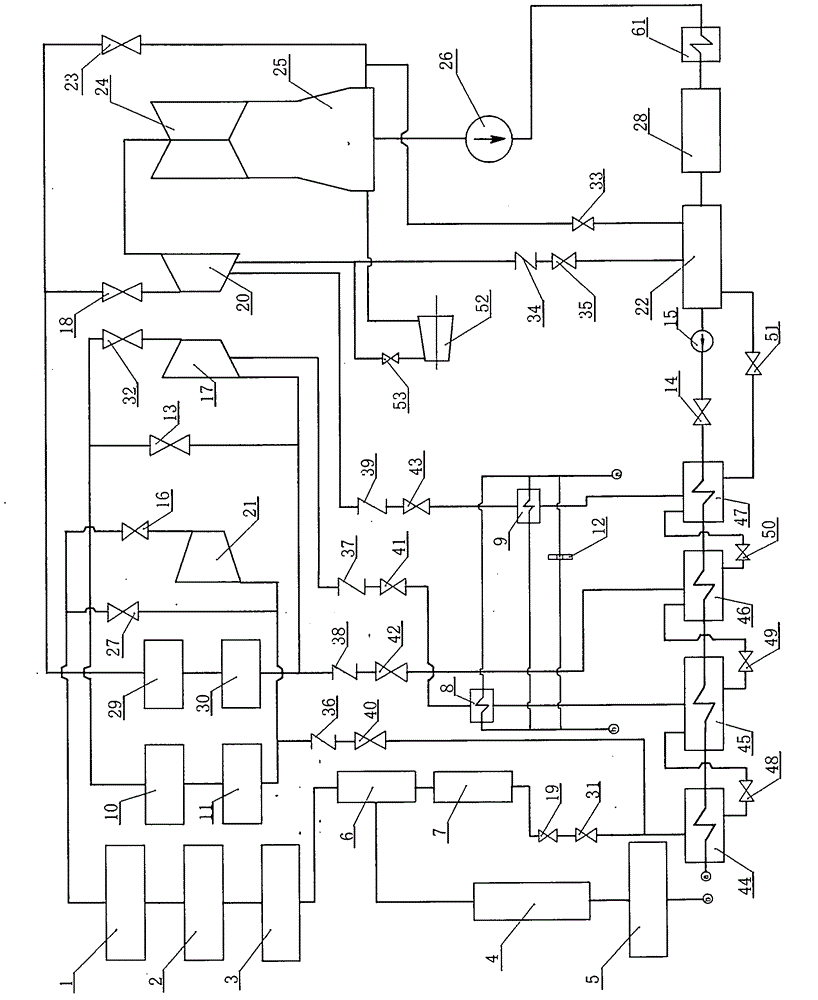

Optimum scheme of ultra-supercritical secondary reheating unit

ActiveCN104806308AIncrease output powerReduce heat consumptionSteam engine plantsUltra high pressureEngineering

The invention discloses an optimum scheme of an ultra-supercritical secondary reheating unit, and refers to a secondary reheating unit of a coal-fired power plant after optimization of a back heating system, parameter optimization of main steam, primary reheating steam, and secondary reheating steam, and structural optimization of a turbine body. The optimum scheme of the ultra-supercritical secondary reheating unit can obviously reduce the heat loss of the secondary reheating unit, and significantly decrease greenhouse gas emission and decreases cost of the ultra-supercritical secondary reheating unit obviously. By taking a 1200 MW grade unit as an example, four mono-axial cylinders are used for gas exhausting, the ultra-supercritical secondary reheating unit is composed of a single-flow ultra-high pressure cylinder capable of completely supplying water, back-heating and pumping gas, a dual-flow high and medium pressure cylinder, and two dual-flow middle and low pressure cylinders; there is no middle pressure cylinder and a middle low pressure linking pipe; no gas pumping opening is arranged on the high middle pressure cylinder and the middle low pressure cylinder; the water supply and back heating are provided by a first pump, a new second pump, a new third pump, and a new fourth pump; a ultra-low temperature coal economizer, and a heat primary wind condensing water heater replace a seventh pump, an eighth pump, a ninth pump, and a tenth pump to heat the condensed water; all low-pressure heaters are canceled.

Owner:章礼道

Exhaust-gas return system for an internal-combustion machine and method of returning exhaust gas

InactiveUS7343743B2Improved cold start behaviourAvoid heatingNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExhaust fumes

An exhaust gas return system for an internal-combustion machine which comprises a low-pressure supply line extending from an inlet From the compressor. a high-pressure supply line extends to the internal-combustion machine. From the internal-combustion machine a high-pressure exhaust gas line extends to a turbine. From the turbine a low-pressure exhaust gas line extends to an outlet. The low-pressure exhaust gas line and the low-pressure supply line have connected therewith a low-pressure return line for returning exhaust gas. The high-pressure exhaust gas line has connected therewith a bypass line for utilizing the heat of the exhaust gas produced in the internal-combustion machine for heating the exhaust gas to be returned of the low-pressure return line before the exhaust gas is supplied to the turbine (24), if desired. Thus the cold start phase of the internal-combustion machine can be reduced.

Owner:PIERBURG GMBH & CO KG NEUSS

Holding and turning device for touch-sensitive flat objects

ActiveUS20100001449A1Simple designReduce quality problemsTravelling carriersHoldersRotational axisClassical mechanics

A holding / turning device for touch-sensitive flat objects, in particular wafers, with a distance positioning device which is arranged for holding the object perpendicular to the object plane at a defined distance, a lateral positioning device, arranged for positioning the object in the object plane and for rotating together with the object about a rotational axis perpendicular to the object plane, and with a rotational drive, coupled with the lateral positioning device, providing a driving force for rotating the object about the rotational axis, wherein the driving force can be applied to the object by means of the lateral positioning device. The distance positioning device has means for holding the object without involving contact, and is decoupled from the rotational drive in such a way that the distance positioning device does not rotate together with the object.

Owner:ONTO INNOVATION INC

Gearset with an air-guiding cover

ActiveUS9951859B2Improve cooling effectEfficiently deflectedGearboxesGear lubrication/coolingDrive shaftGear wheel

A gearset includes a gearset housing, a drive shaft, and a radial fan fixed to the drive shaft. Disposed in surrounding relationship to the radial fan is an air-guiding cover which includes a gearset housing section to at least partially cover the gearset housing, a cylindrical section adjoining the gearset housing section and configured to receive an attachment for securement to the drive shaft, and a conical section adjoining the cylindrical section. The conical section of the air-guiding cover is disposed in surrounding relationship to the radial fan directly and without any dead space.

Owner:FLENDER GMBH

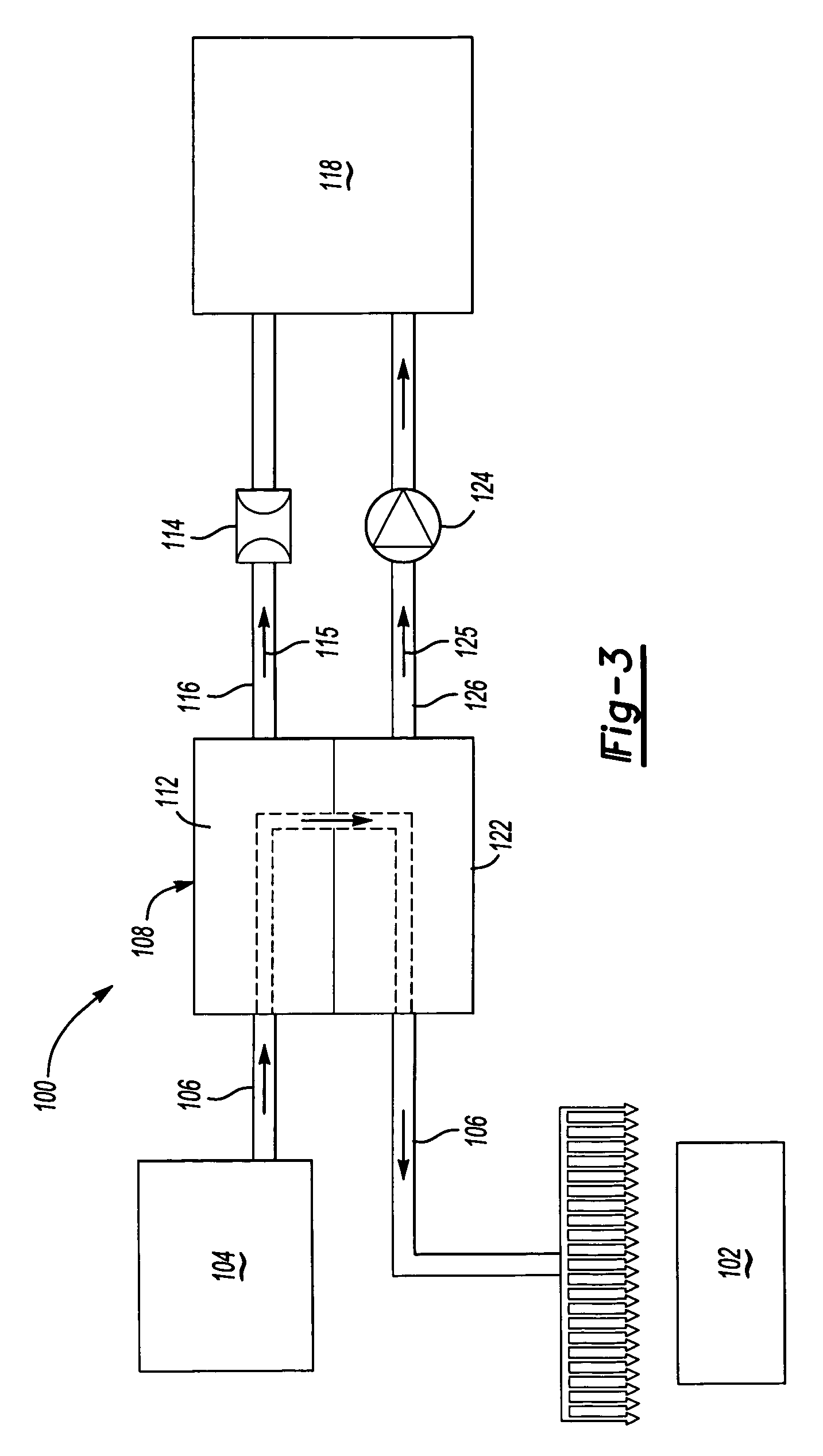

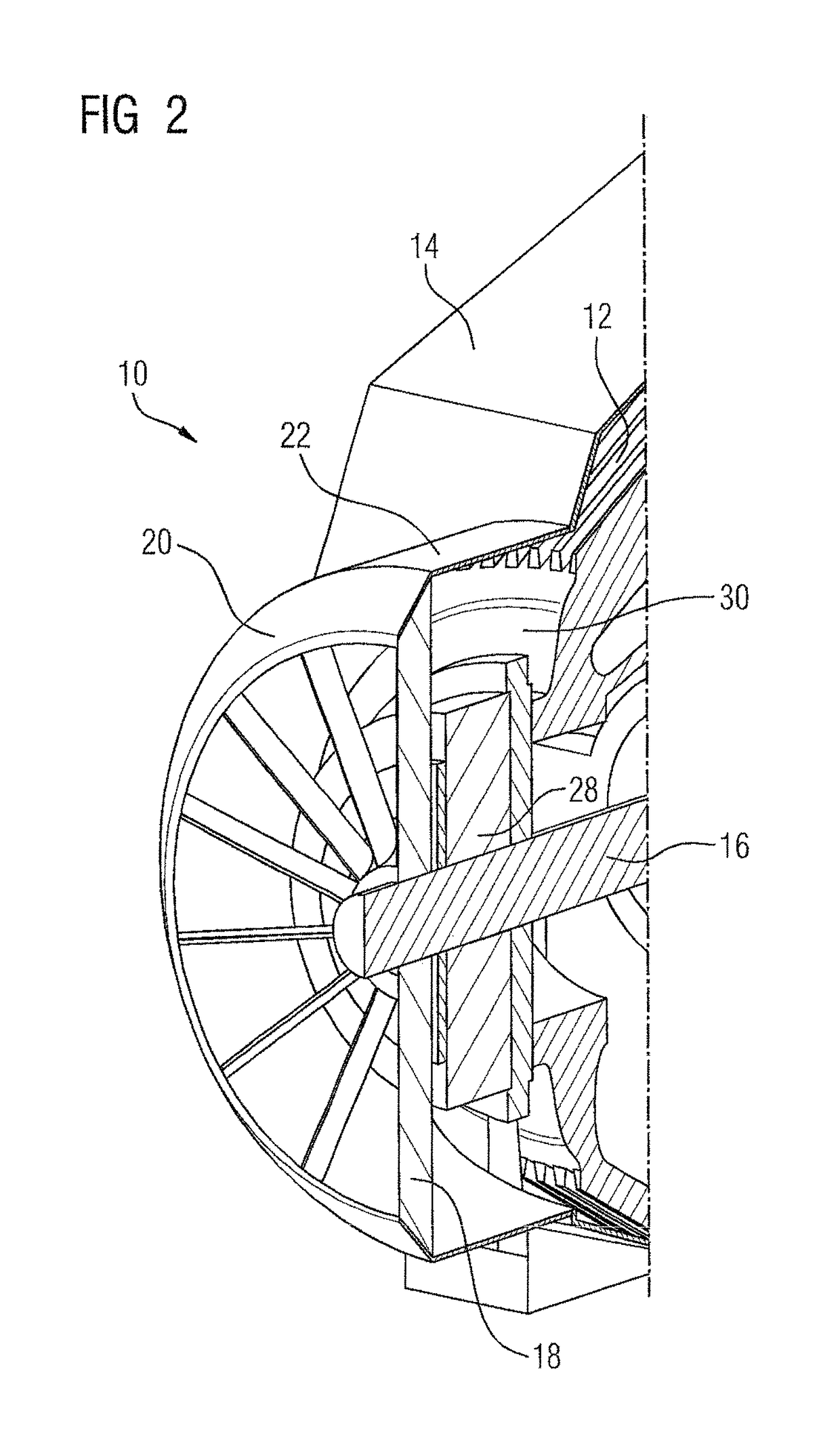

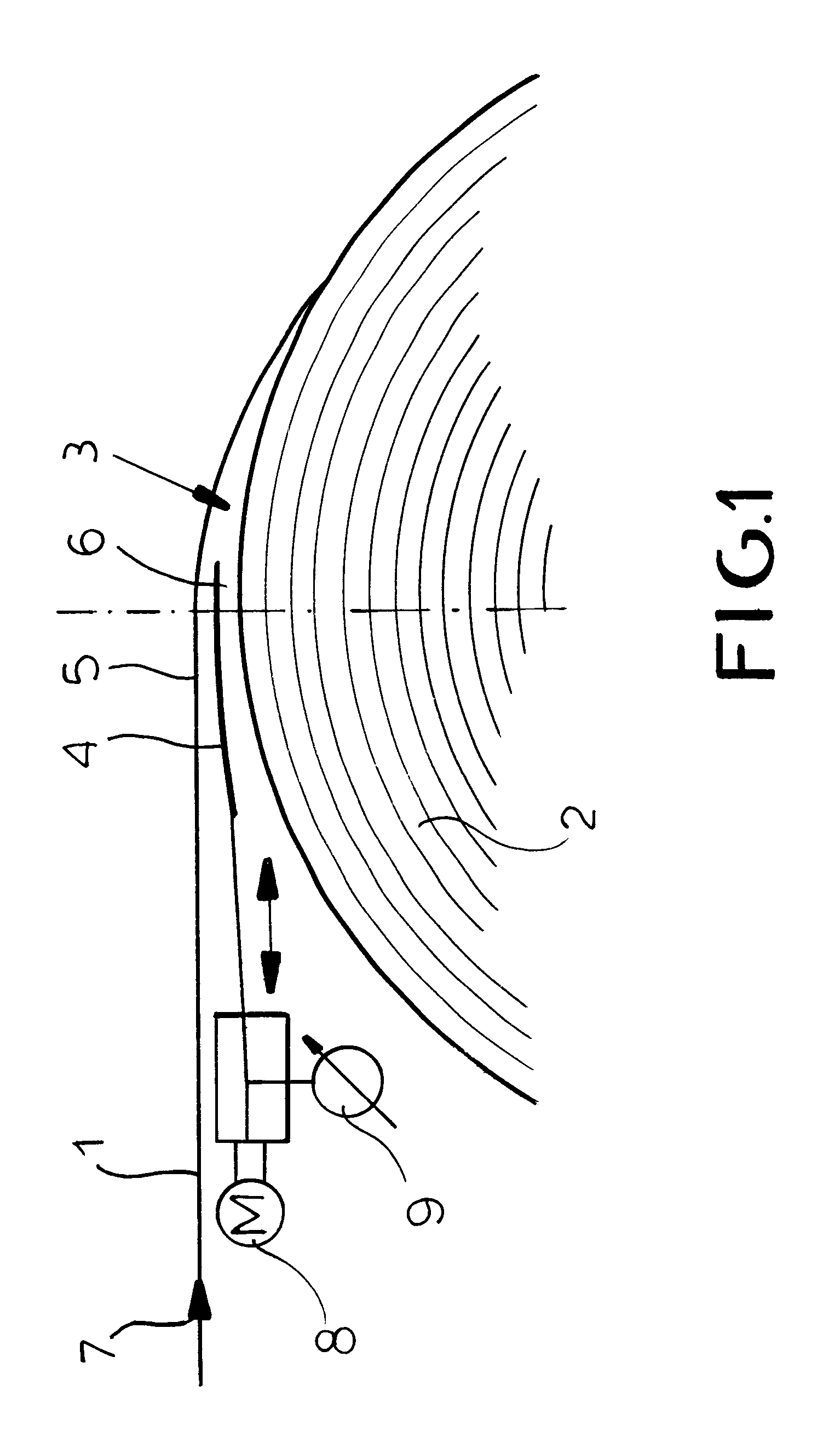

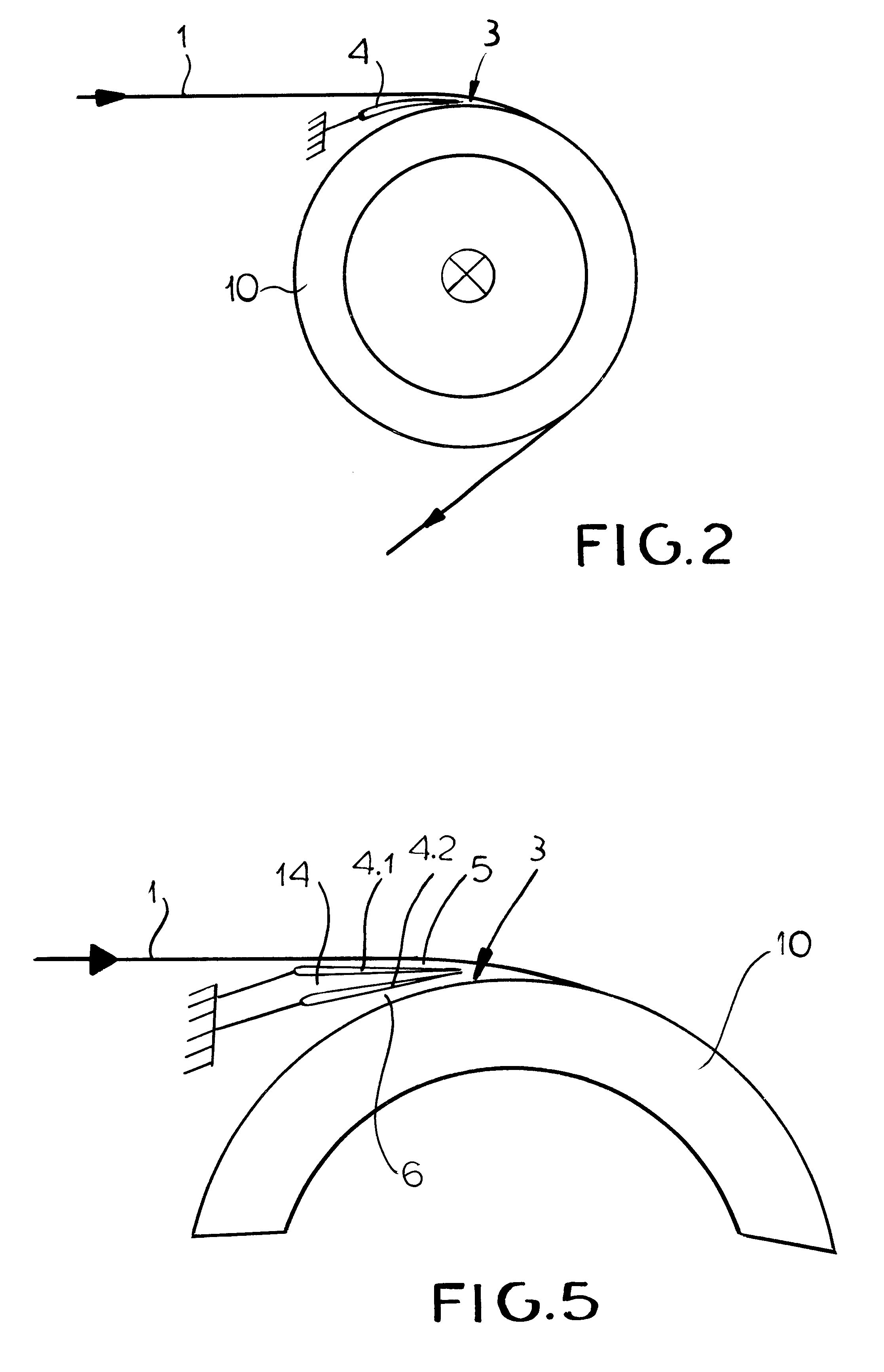

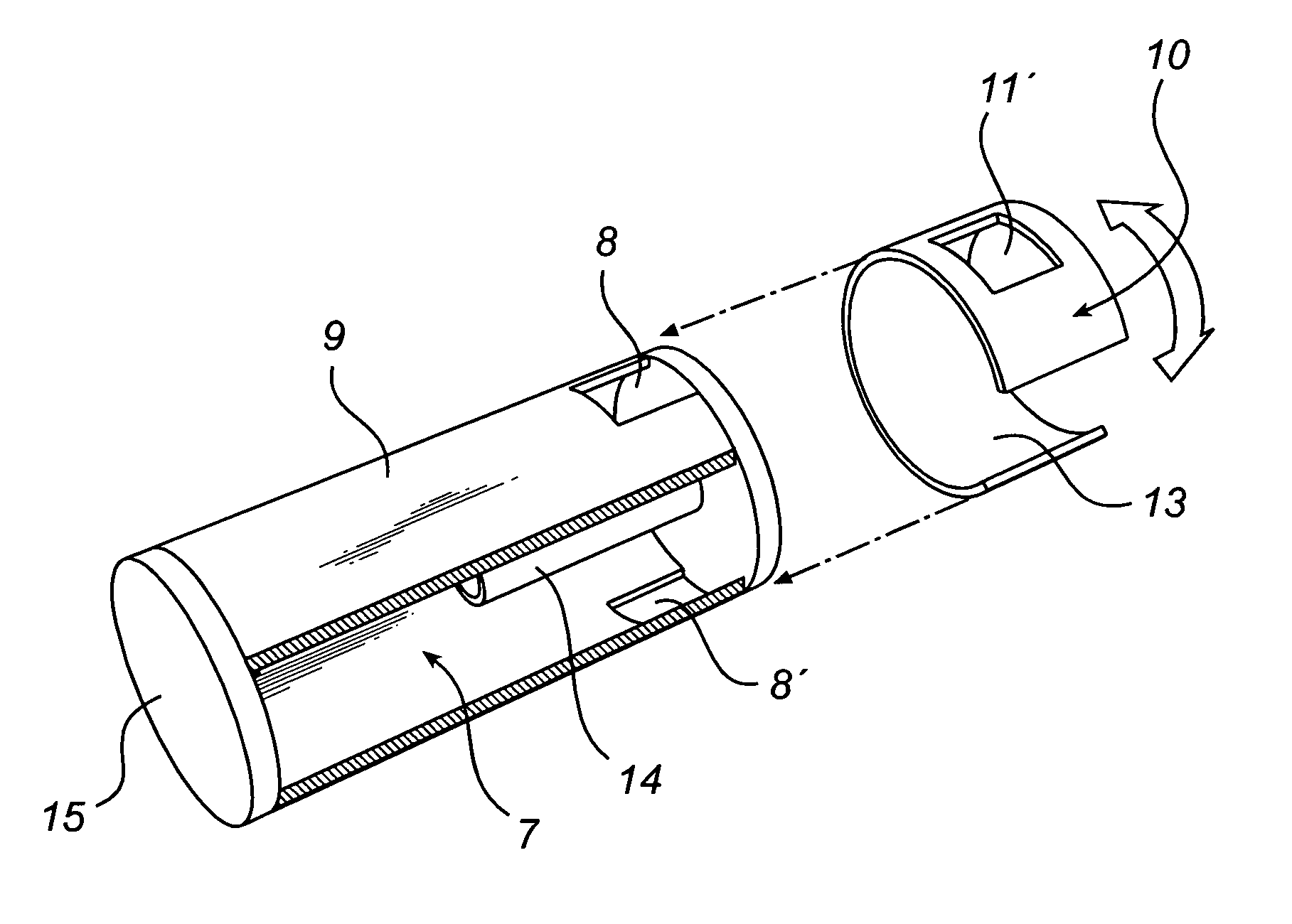

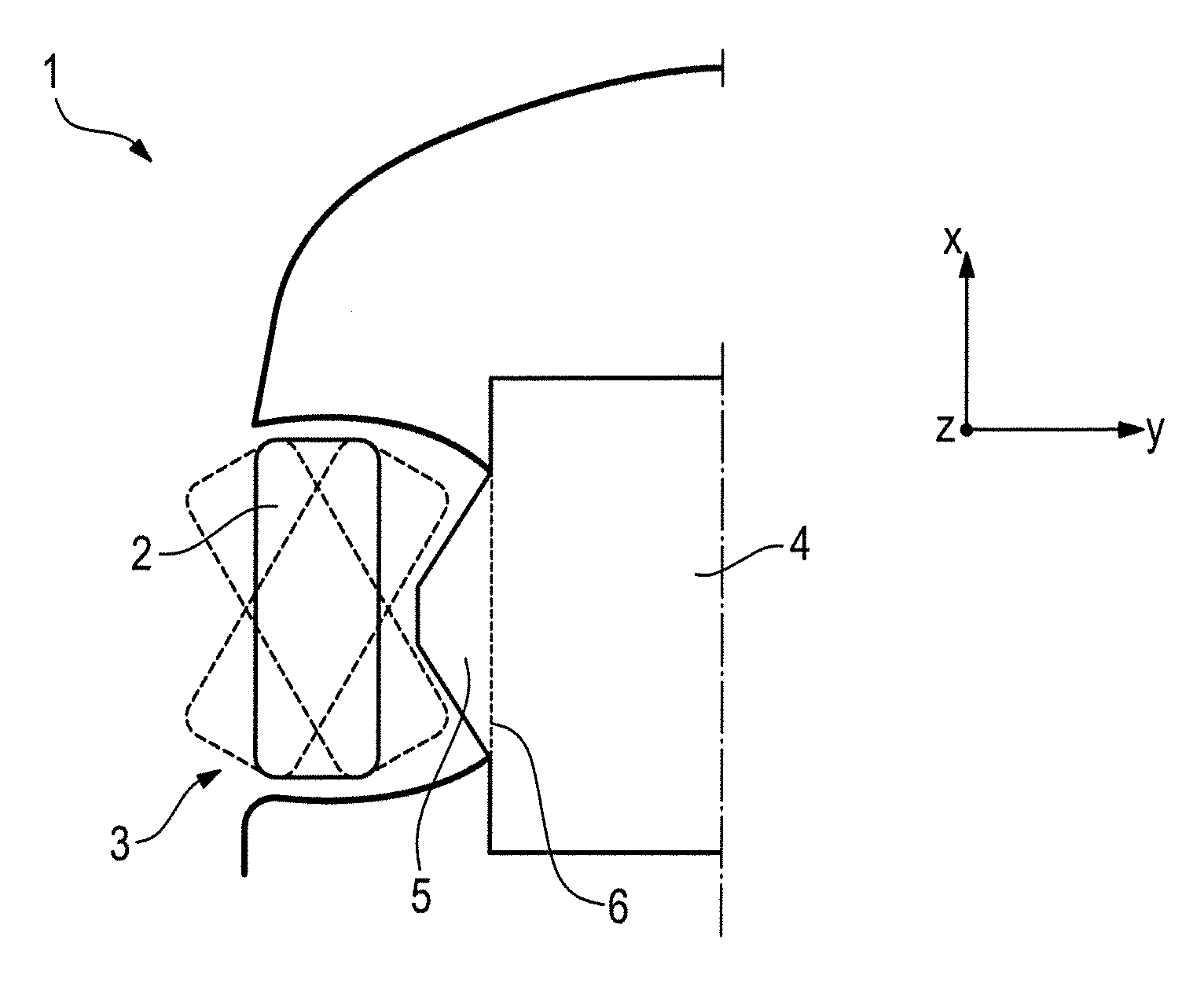

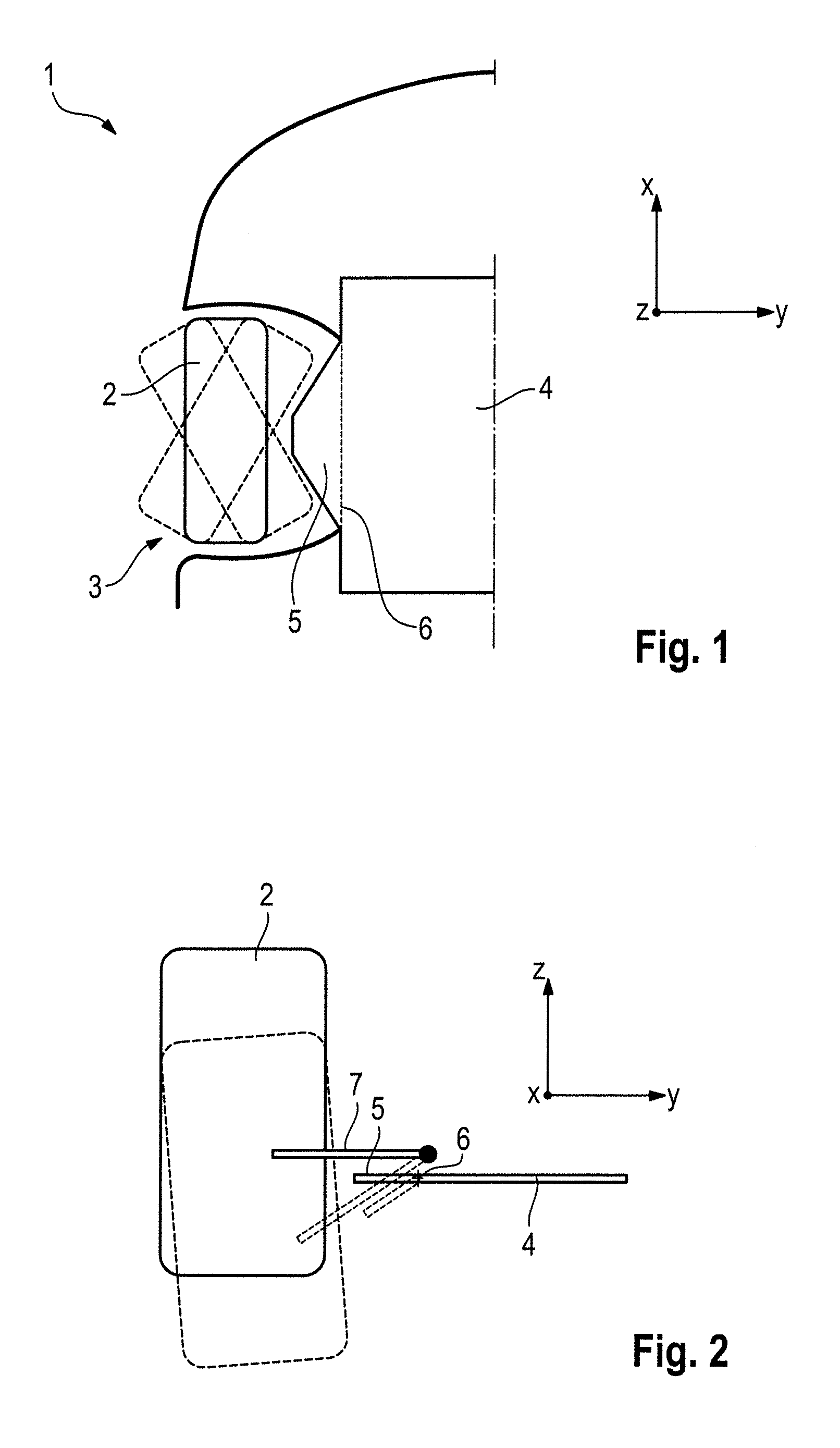

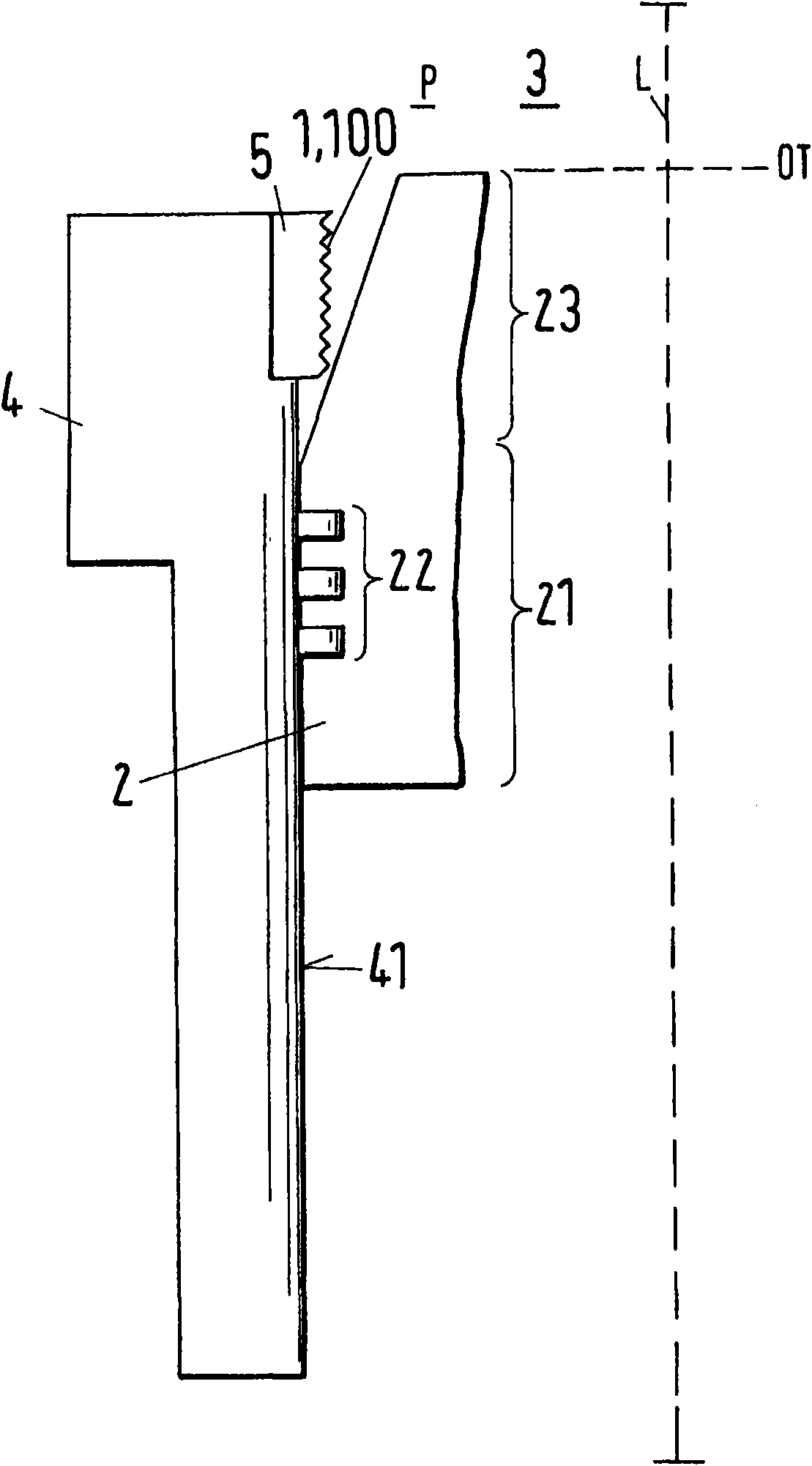

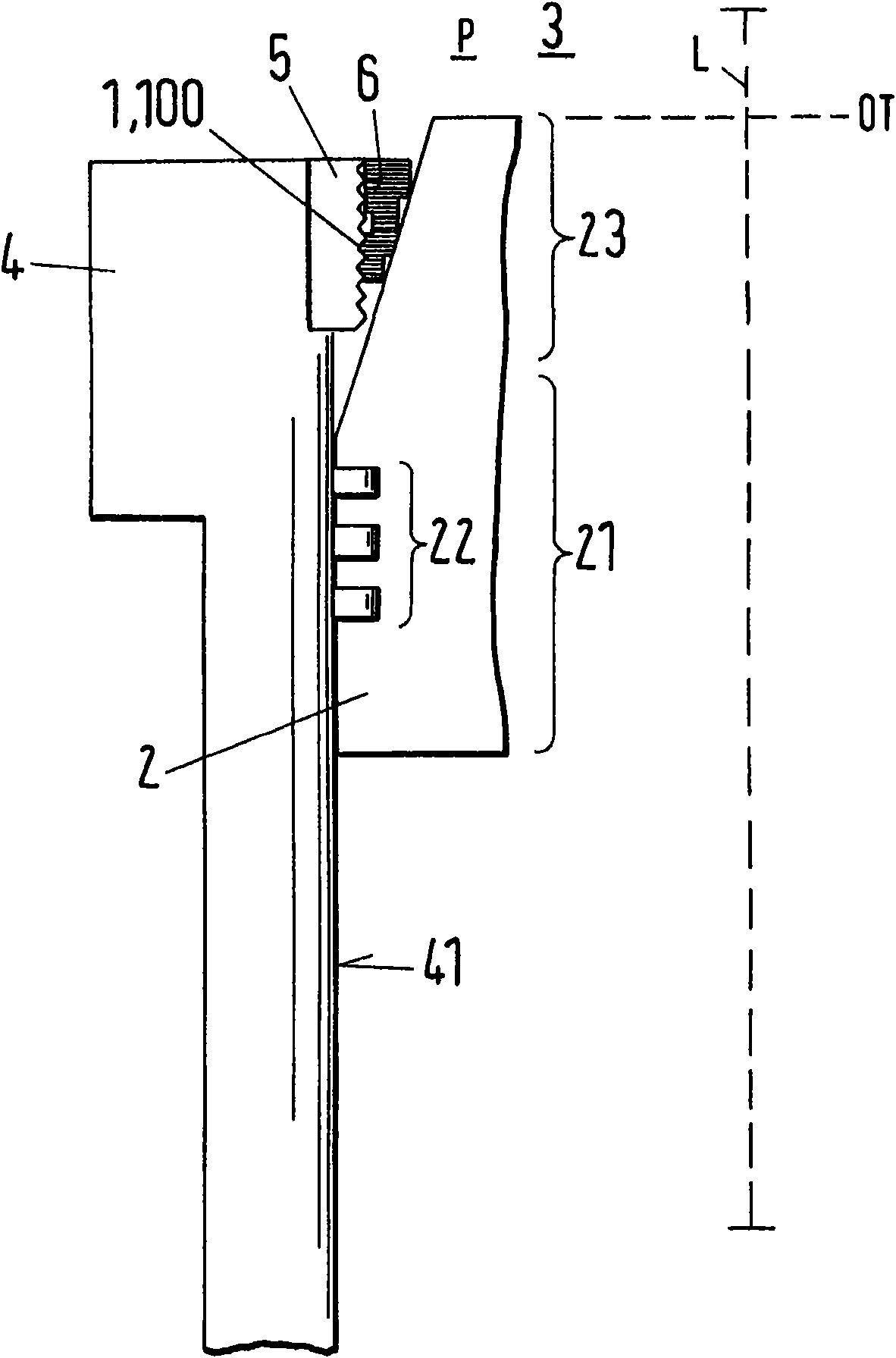

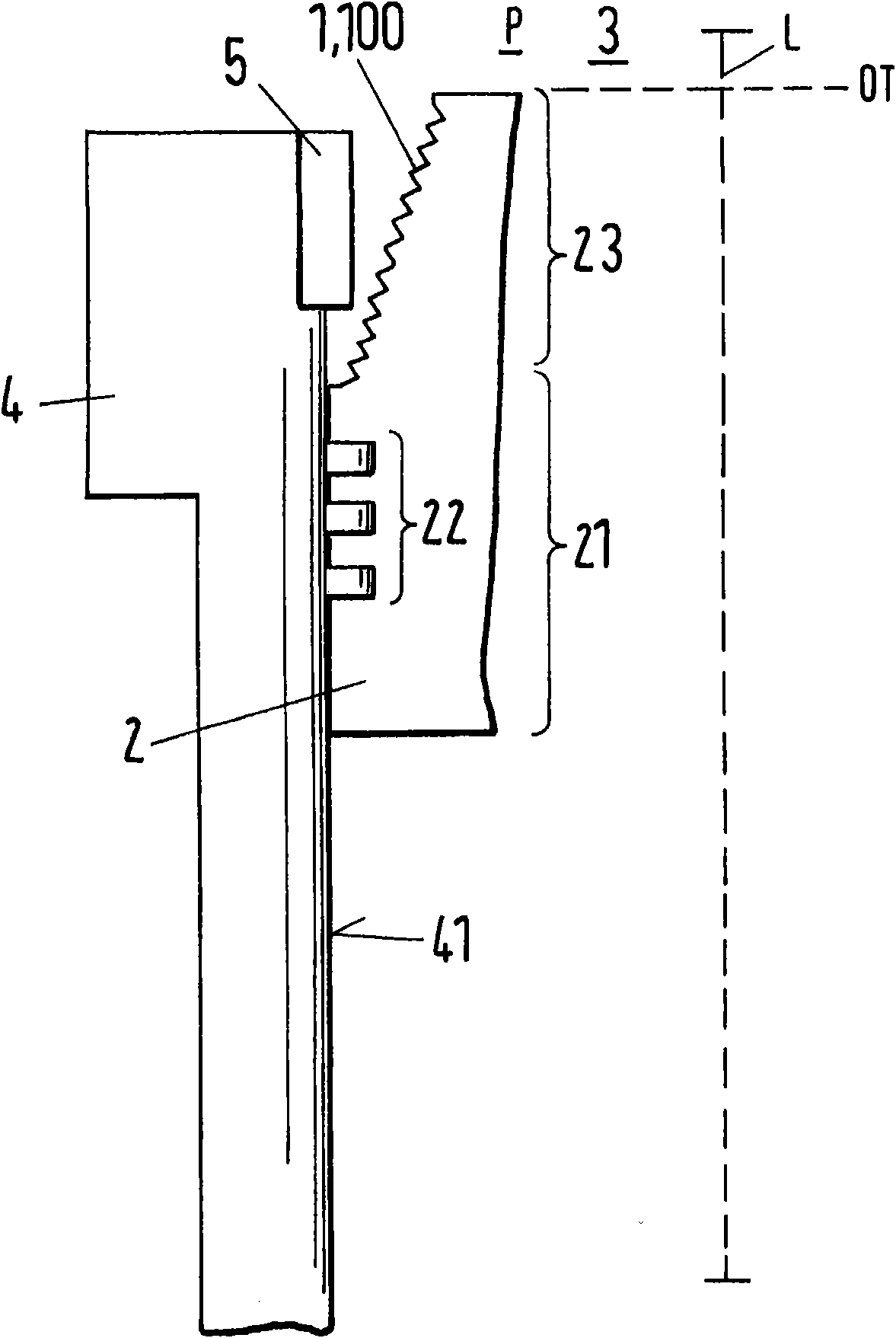

Method and device for reducing the volume or pressure of a fluid which is driven through an opening by moving surfaces

InactiveUS6557269B1Reduced volume flowDrying solid materials with heatDrying machines with progressive movementsCardboardPlastic materials

The invention relates to a method and device for reducing the volume or pressure of a fluid which is driven through an opening (3, 17) by moving surfaces. According to said method, the opening (3, 17) is divided in at least two flow channels (5, 6, 14) by means of one or more flexible separation members (4). Each separation member (4) is attached at its rear end relatively to the direction of displacement of said surfaces, and its front finishing end extends inside said opening (3, 17). The inventive method can be advantageously implemented during production and further transformation of strip-shaped materials (paper, cardboard strips, plastic material sheets) for bringing the strip which moves on an element (cylinder, roll, rigid guiding element, winding reel) into close contact with said element.

Owner:JAGENBERG PAPIERTECHN

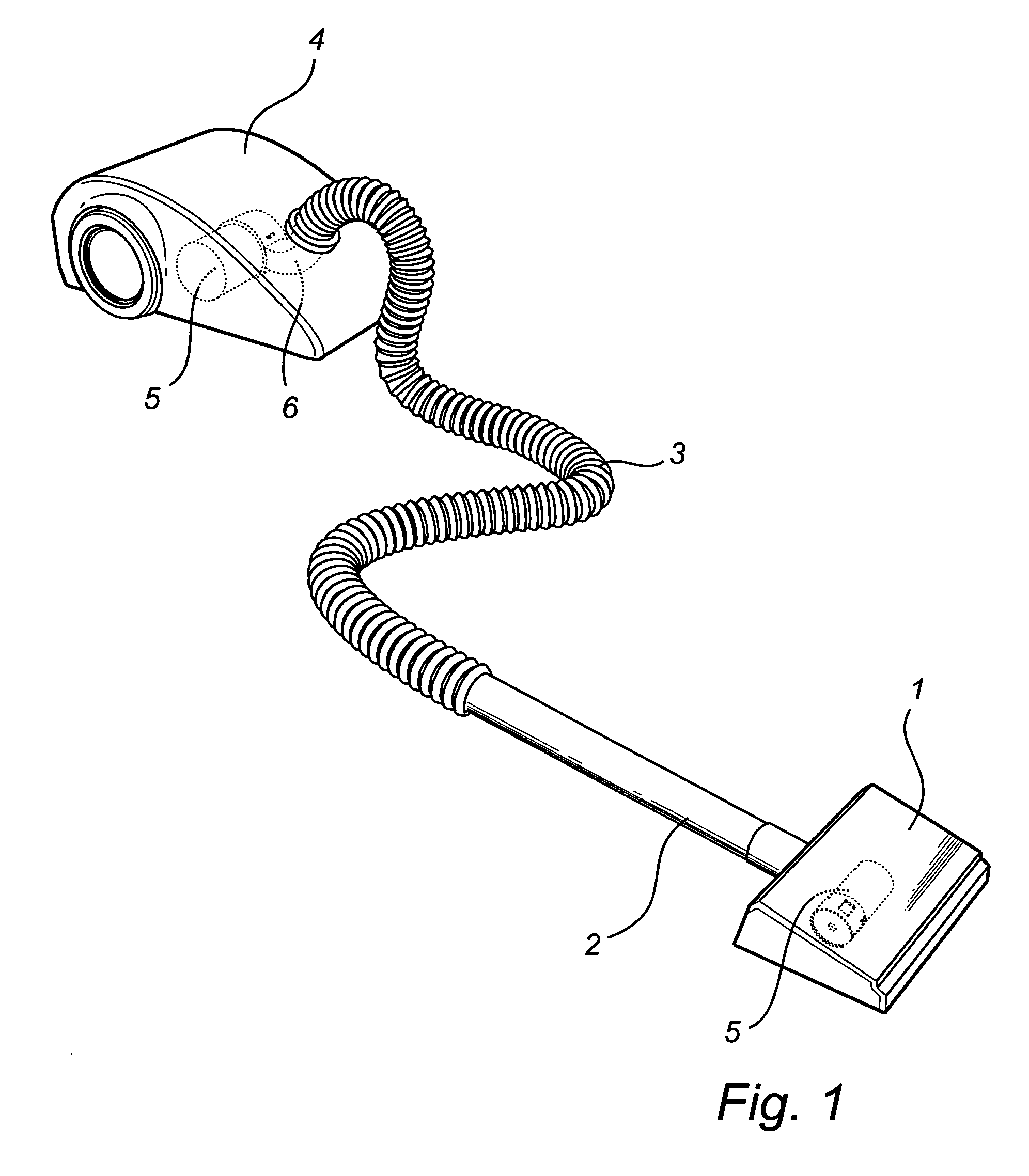

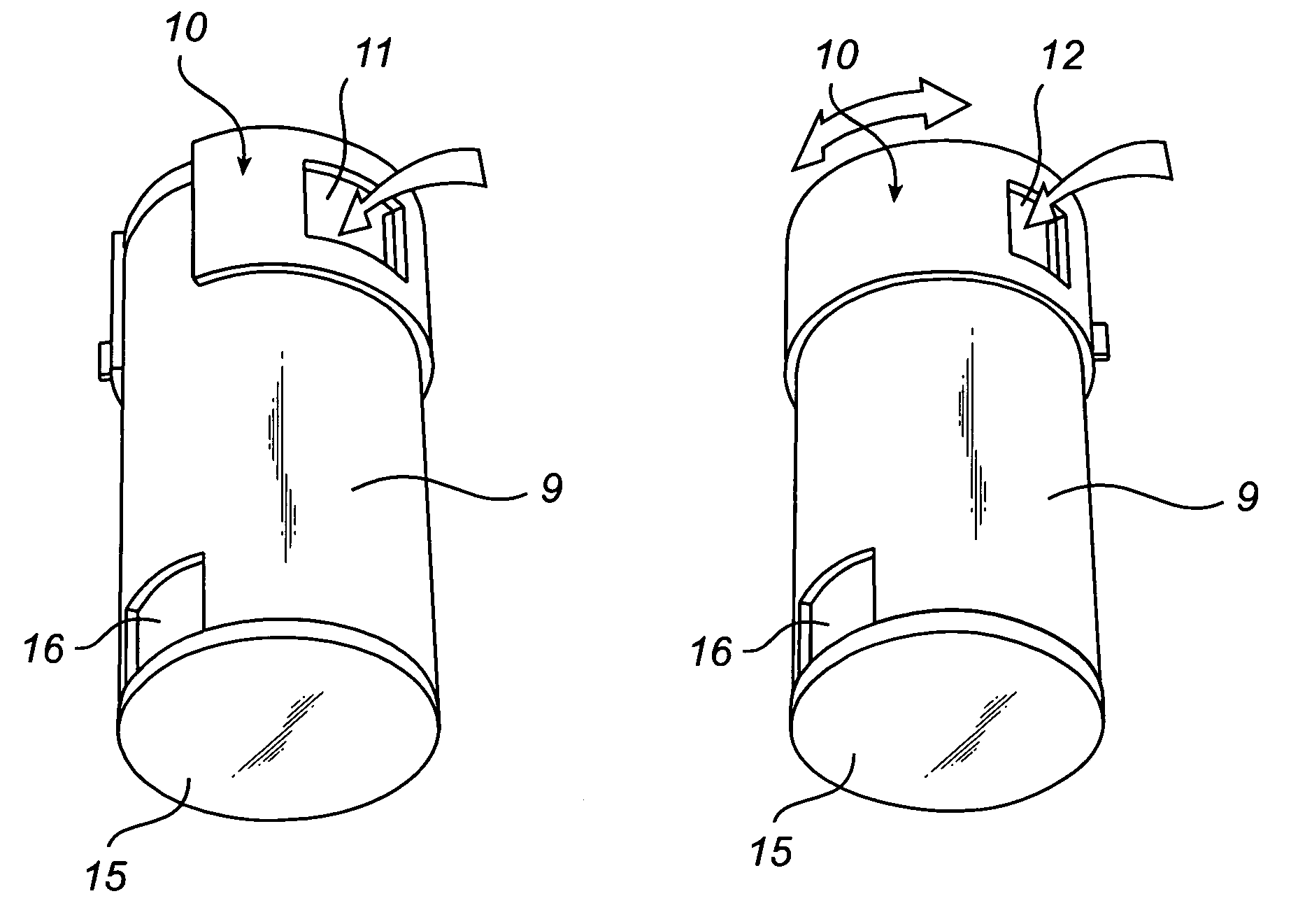

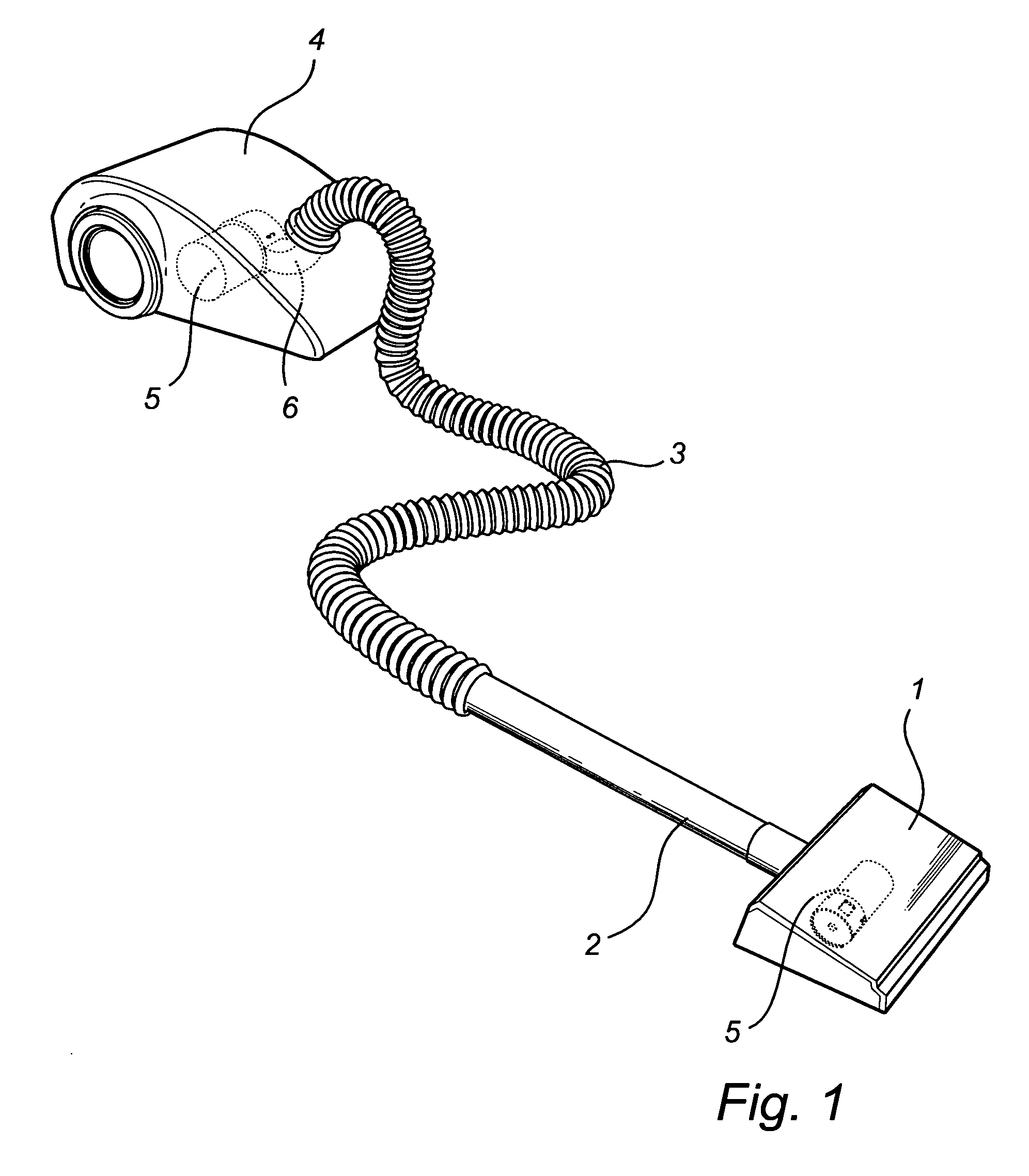

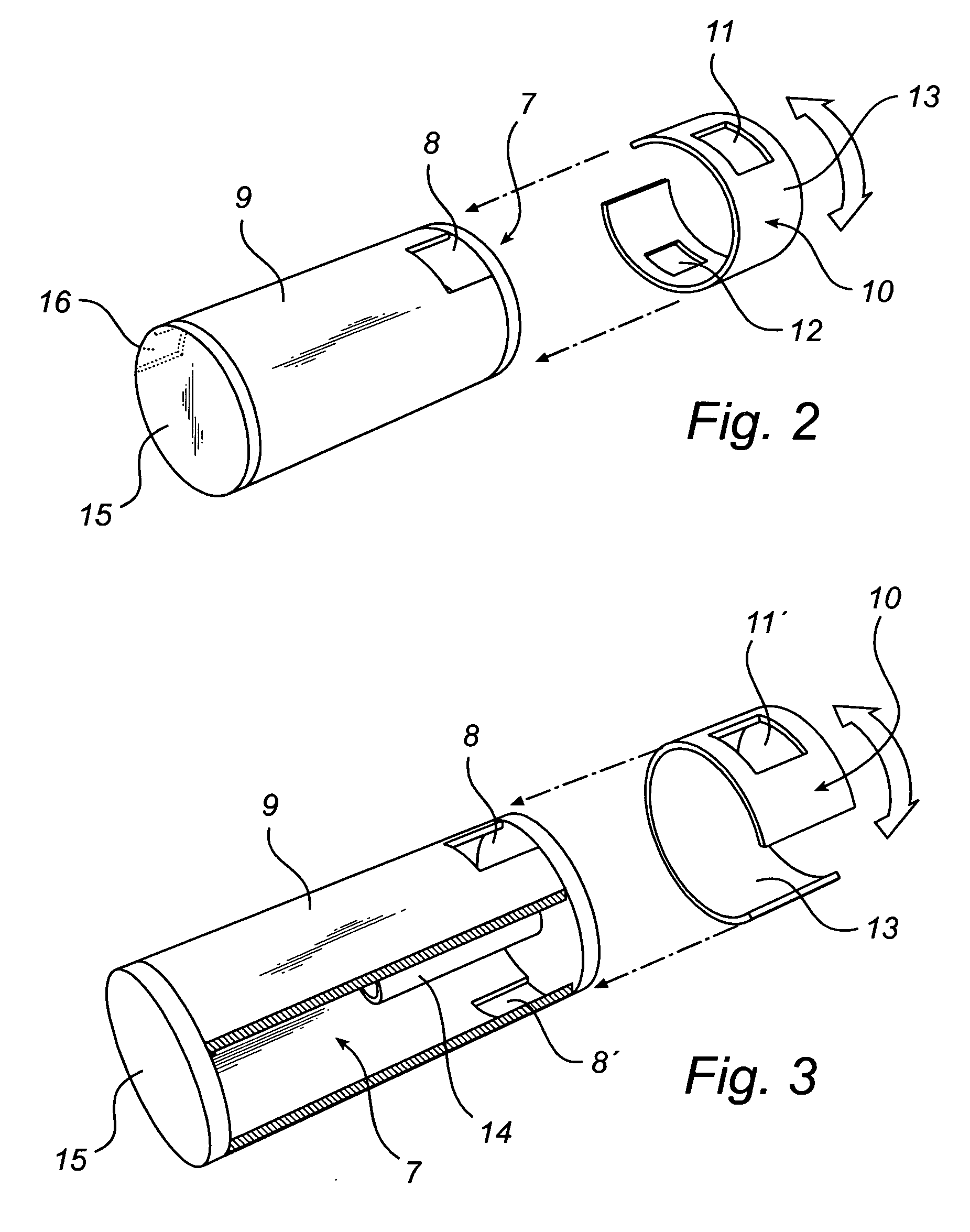

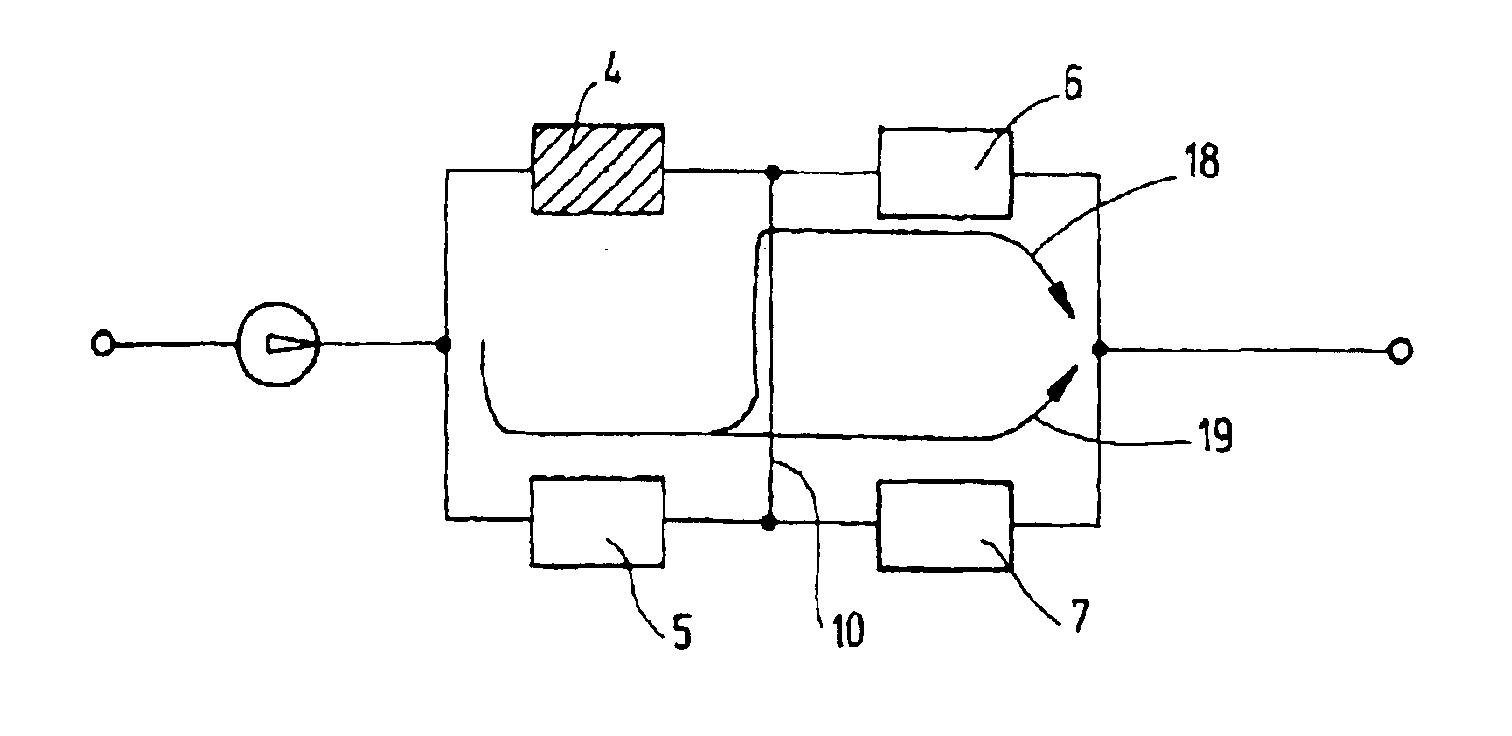

Cyclone-like separator for a vacuum cleaner

InactiveUS8448292B2Lose weightEasy to separateCleaning filter meansSuction filtersVacuum cleanerAirflow

A cyclone separator for a vacuum cleaner. The separator has a cyclone chamber, an air entrance device having a flow passage arrangement therethrough for introducing an air stream into the cyclone chamber in a manner that causes the air stream to swirl in the cyclone chamber to remove dust from the air stream, and an air outlet for emitting the air stream from the cyclone chamber. The entrance device has a control member that is operable to alter the flow passage arrangement such that one or more properties of the air stream in the cyclone chamber are affected by the alteration. The flow passage arrangement has a first path and a second path, and the control member is operable to alter the flow passage arrangement by redirecting the air stream from the first path to the second path.

Owner:AB ELECTROLUX

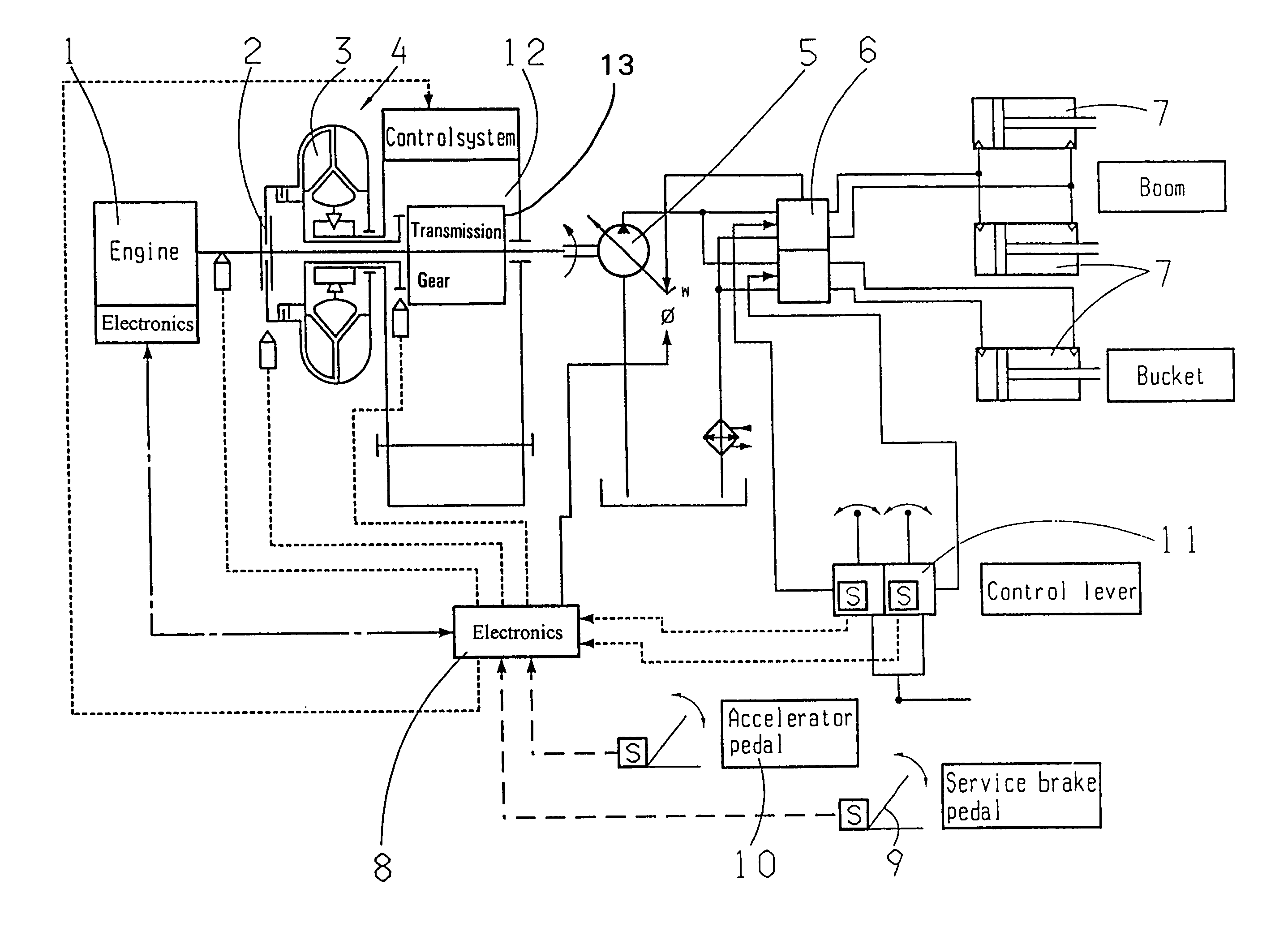

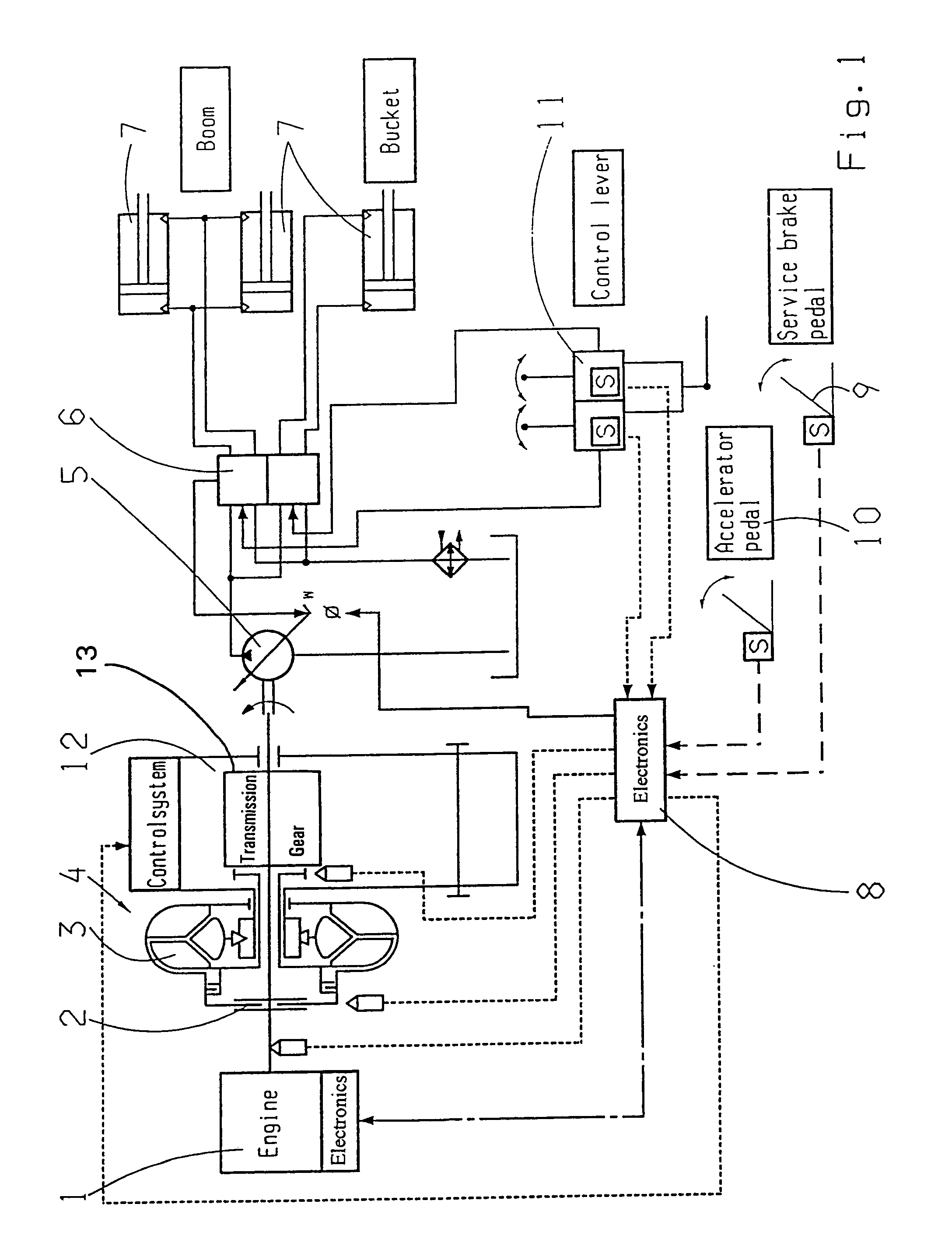

Drive train for powering a mobile vehicle

InactiveUS7022044B2Large volumeIncrease gear ratioGearing controlMotor parameterMobile vehicleHydraulic pump

To reduce the structural volume of a drive engine (1) in a drive train of a mobile vehicle, in particular a working machine such as a wheel loader, a continuously adjustable transmission gear is arranged between the drive engine (1) and a hydraulic pump (5) for the working hydraulic system, which can be adjusted as a function of the load condition of the drive engine (1).

Owner:ZF FRIEDRICHSHAFEN AG

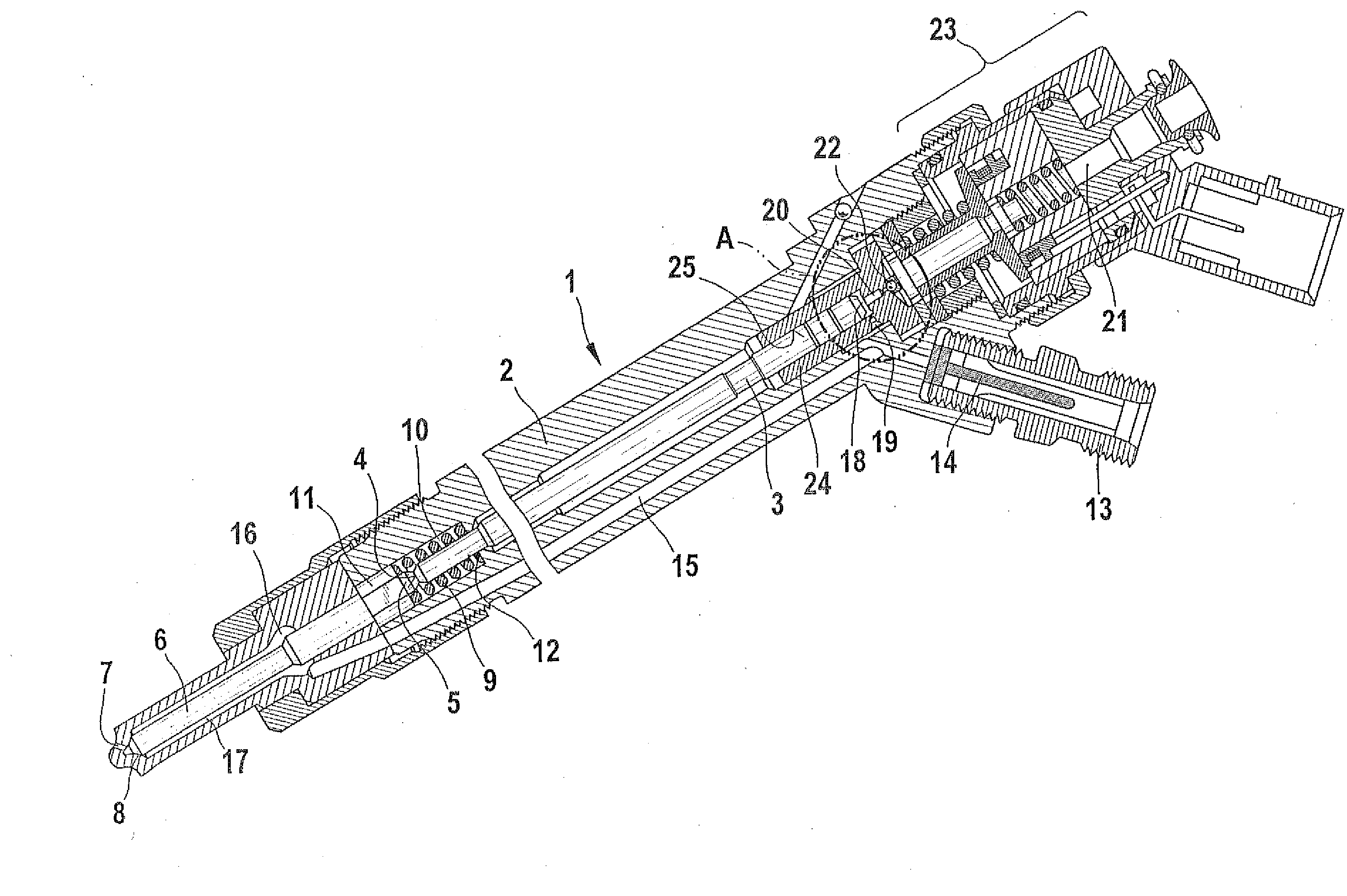

Fuel Injector with Punch-Formed Valve Seat for Reducing Armature Stroke Drift

InactiveUS20070261673A1Powerful of fuel flowControl flowLow-pressure fuel injectionMachines/enginesEngineeringInternal combustion engine

The invention relates to a method for manufacturing a fuel injector for an internal combustion engine that has a control valve, which opens or closes an outlet throttle from a control chamber and in which a closing element is moved into a valve seat in order to close the outlet throttle. The valve seat is produced by punch-forming using a forming punch. The invention also relates to a fuel injector that is manufactured in accordance with this method.

Owner:ROBERT BOSCH GMBH

Motor vehicle with a device for reducing an air stream flow into a wheel house

ActiveUS20150048648A1Reduced flow cross sectionReduced volume flowVehicle seatsWindowsAirflowAutomotive engineering

A motor vehicle (1) has a device (5) that projects into the wheel house (3) to reduce the flow of air into the wheel house (3) while the motor vehicle (1) is moving. The device (5) may extend from an underbody panel (4) of the motor vehicle (1) and may be pivotable about a longitudinal axis (6) of the motor vehicle (1) on a side of the underbody panel (4) that faces the wheel house (3). Alternatively, the device (5) is connected to a chassis component (7) of a wheel (2) arranged within the wheel house (3).

Owner:DR ING H C F PORSCHE AG

Cooling compensation type air cooling island system

The invention provides a cooling compensation type air cooling island system and belongs to the technical field of steam exhaust cooling of steam turbine generator units. According to the cooling compensation type air cooling island system, a compensation cooler is additionally arranged based on an existing air cooling island system; the compensation cooler is installed on a primary pipe of an air extraction pipeline; and meanwhile, each air extraction branch pipeline is provided with a regulating valve, a regulating valve bypass and a compensation cooler bypass. By arranging the compensation cooler on the air extraction pipeline, the volume flow of the air extraction pipeline can be substantially reduced, and accordingly the efficiency of a vacuumizing system is remarkably improved. Through the regulating valves on the vacuumizing pipelines, resistance compensation measures are provided for the resistance characteristics of each row of air cooling radiators, the steam flow of the different rows of air cooling radiators is distributed evenly, thus, the overall cooling capacity of the air cooling island is improved, and the average coal consumption of the units is reduced. Through the composite action of cooling compensation and resistance compensation, aggregation of non-condensable gases of the air cooling radiators can be greatly relieved, and the anti-freezing performance of the air cooling radiators is improved.

Owner:北京中电云汇技术有限公司

Cyclone-like separator for a vacuum cleaner

InactiveUS20100325834A1Lose weightEasy to separateCleaning filter meansSuction filtersAirflowEngineering

A cyclone separator for a vacuum cleaner. The separator has a cyclone chamber, an air entrance device having a flow passage arrangement therethrough for introducing an air stream into the cyclone chamber in a manner that causes the air stream to swirl in the cyclone chamber to remove dust from the air stream, and an air outlet for emitting the air stream from the cyclone chamber. The entrance device has a control member that is operable to alter the flow passage arrangement such that one or more properties of the air stream in the cyclone chamber are affected by the alteration. The flow passage arrangement has a first path and a second path, and the control member is operable to alter the flow passage arrangement by redirecting the air stream from the first path to the second path.

Owner:AB ELECTROLUX

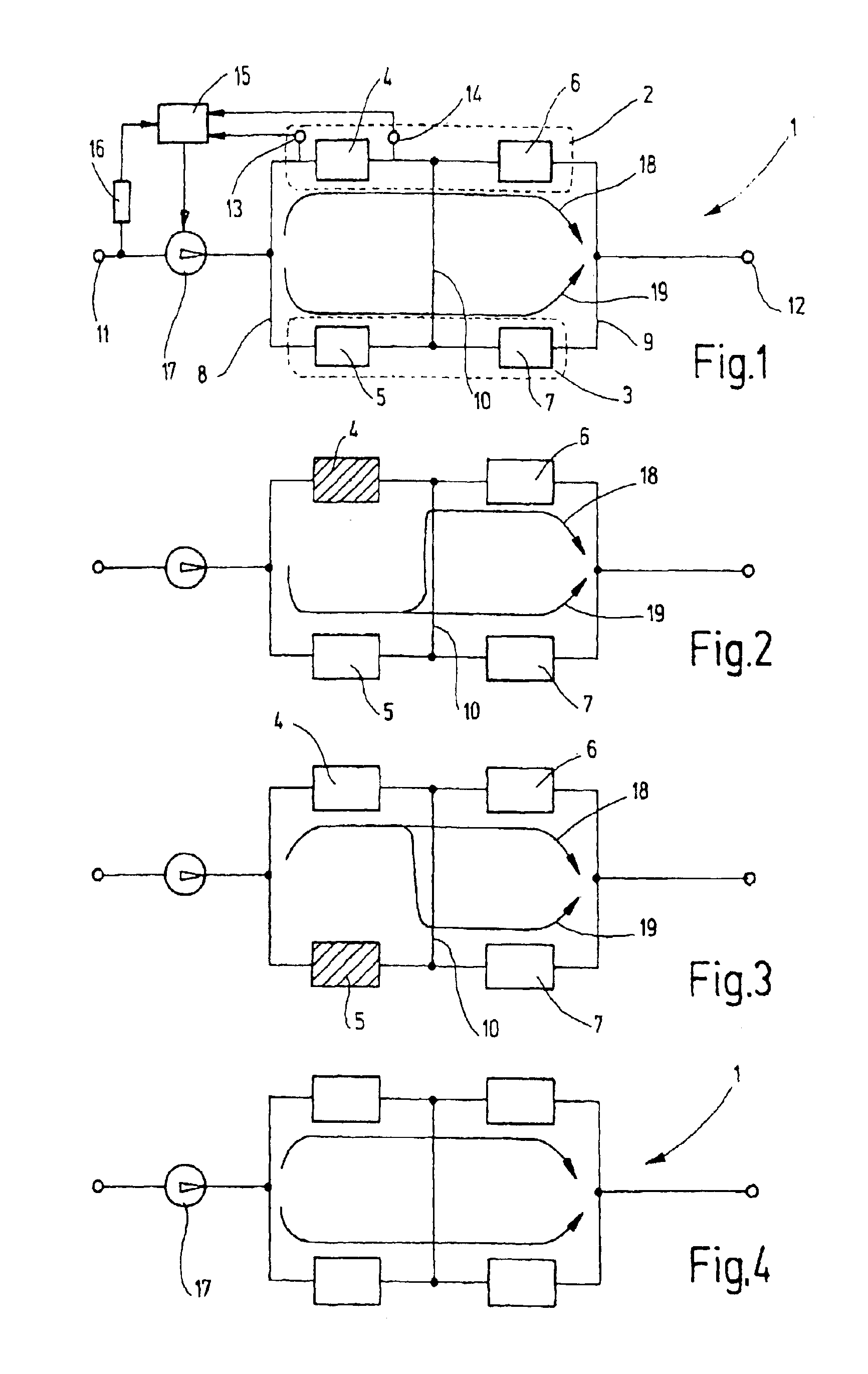

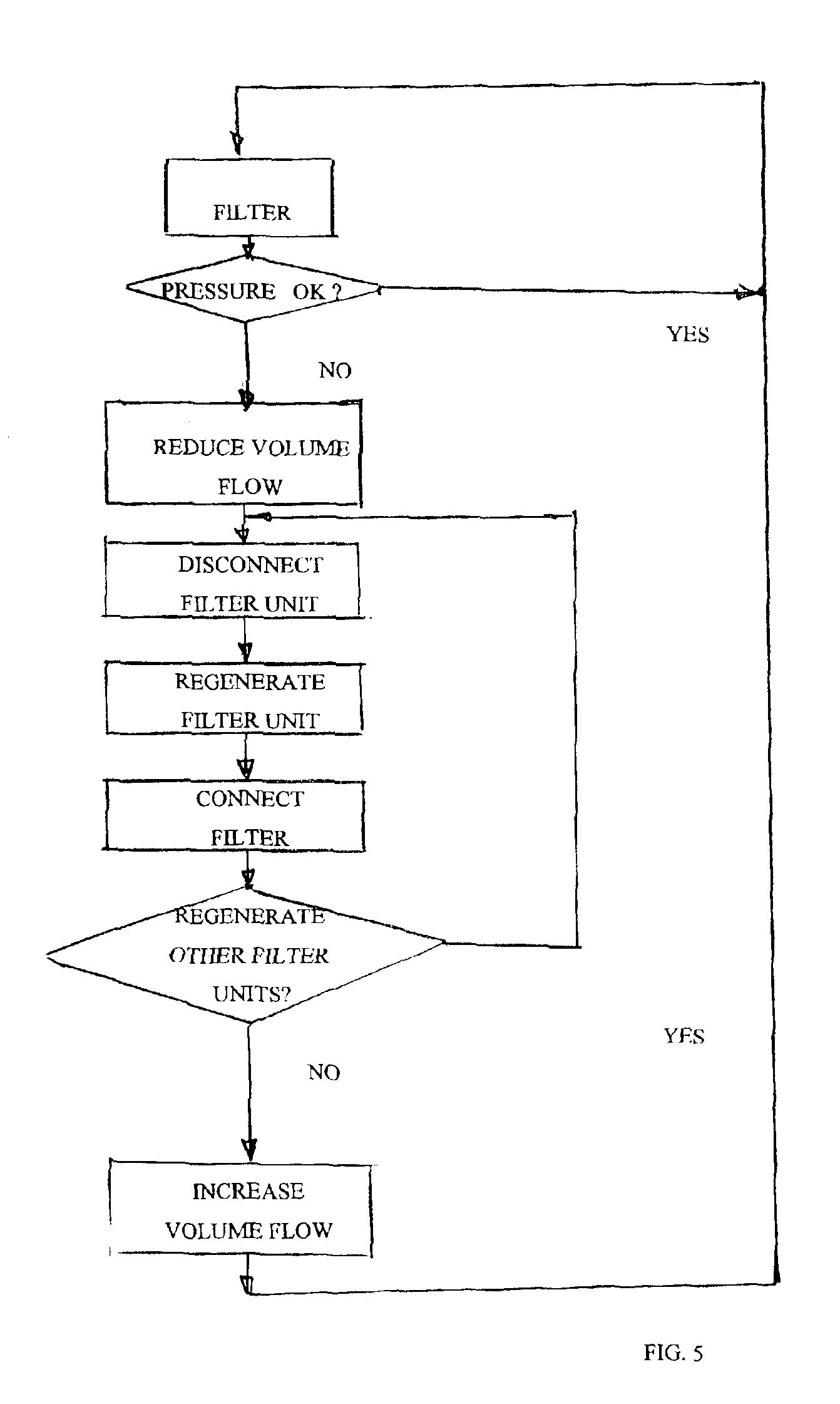

Method and device for filtering liquids, especially drinks

InactiveUS6951614B2Improve qualityLow investment costIsotope separationWater/sewage treatmentEngineeringPressure difference

Owner:E BEGEROW GMBH

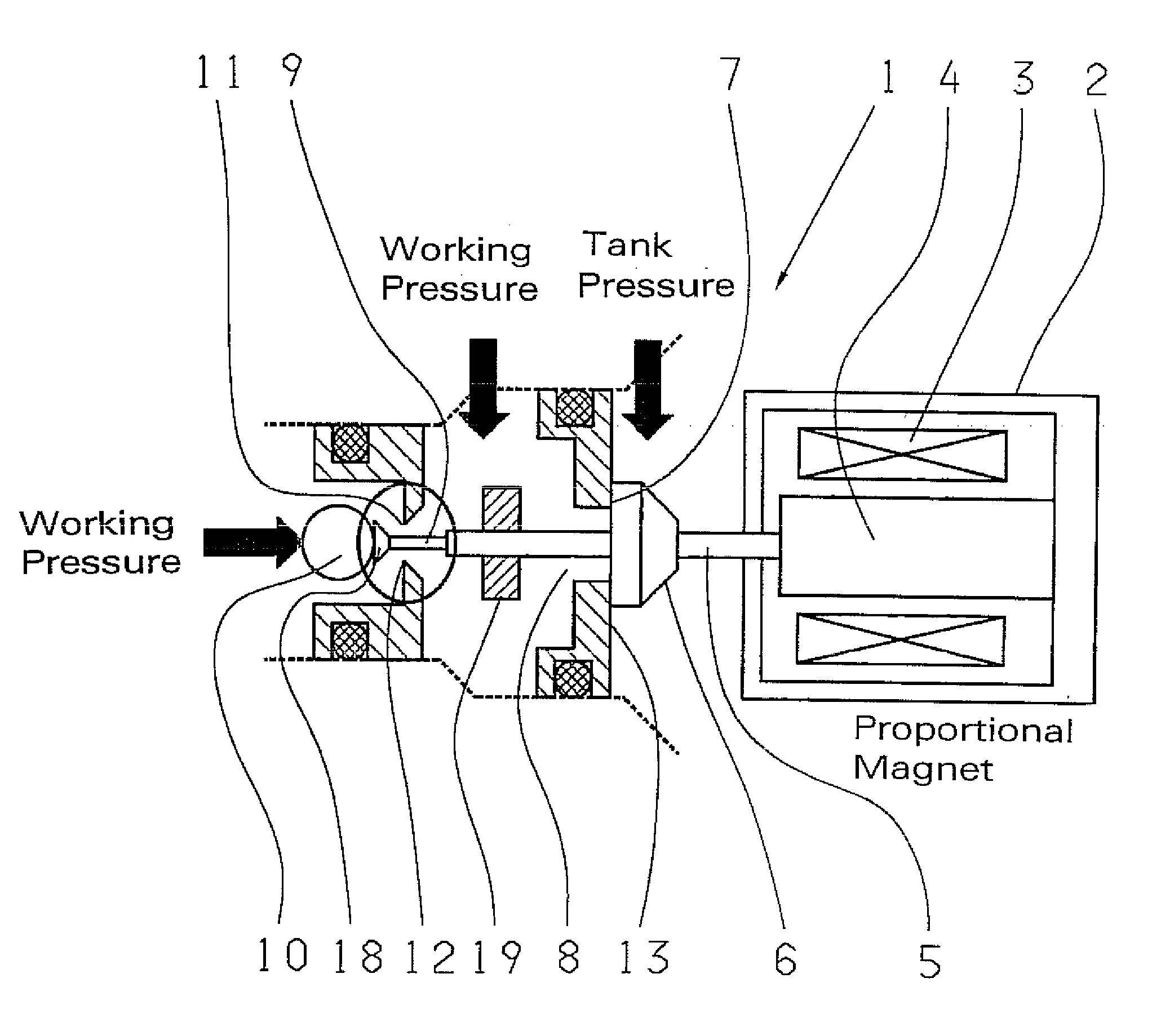

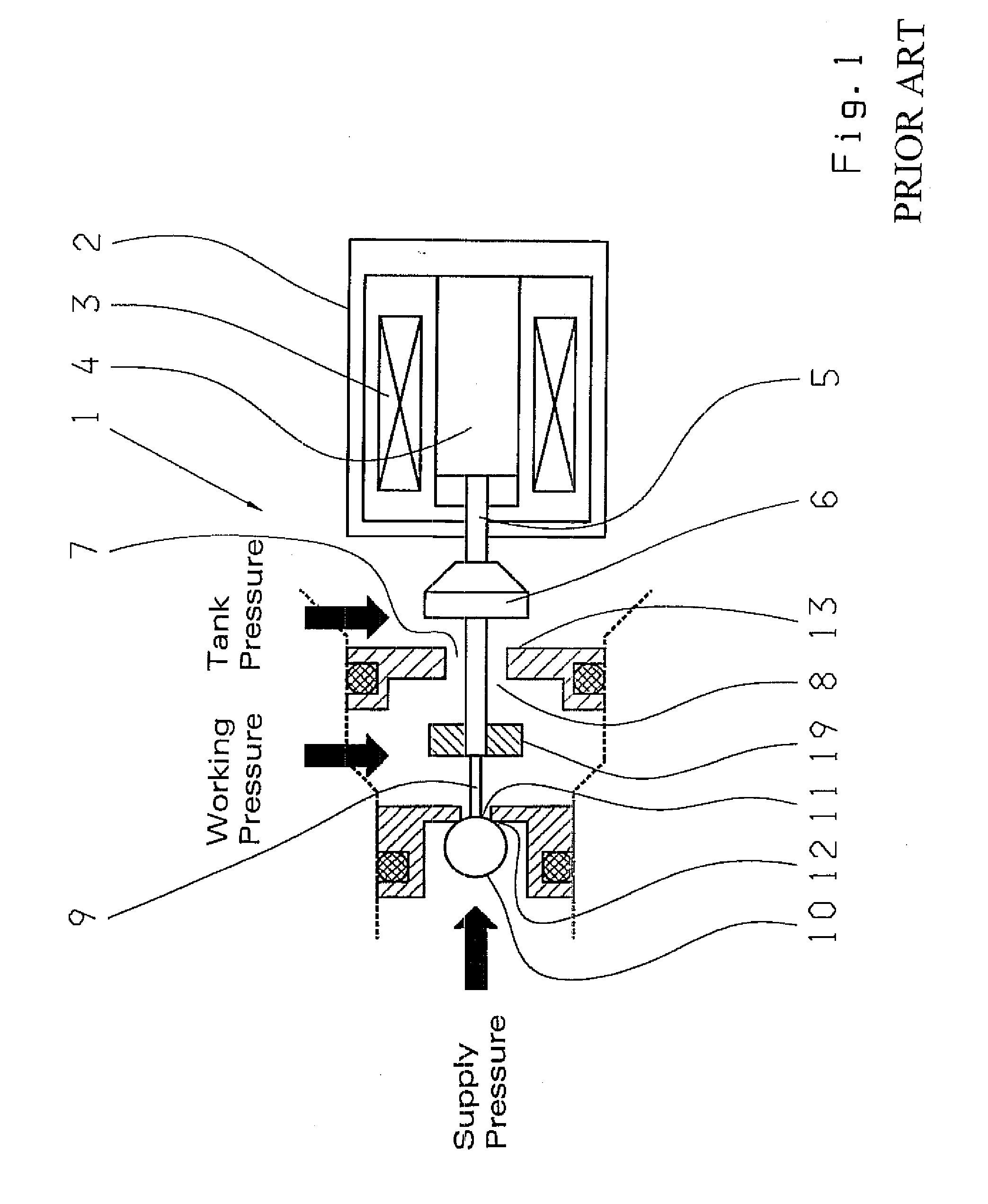

Pressure control valve

InactiveUS20090065075A1Easy to produceCross-section is reducedOperating means/releasing devices for valvesServomotor componentsEngineeringControl valves

A pressure control valve (1) designed as a closed-end pressure regulator is proposed, which comprises two valve seats (7, 11) arranged in a hydraulic half-bridge circuit, with an electromagnet (2) having a magnetic core, a magnetic coil (3), and a displaceable armature (4), with an anchor rod (5) displaceable by the armature (4) for a closing part (6), which can be made to strike against a first valve seat (7) of the tank edge, and with a push rod (9), which is connected to the anchor rod (5) or is designed as a single piece with the anchor rod (5), which can move a locking element (10) designed as a ball out of a ball seat (11) of the inlet control edge, in which the push rod (9) is configured in such a way at its end facing the ball seat (11) that the opening cross-section of the inlet control edge (12), that is, the ball seat (11), can be modified depending on the axial position of the push rod (9) in such a way that the cross-section is reduced when the target pressure is low, in order to reduce the inlet volume flow, while the total cross-section of the inlet edge (12) is made available when the target pressure is high and / or in which the valve seat (11) is designed in such a way that its diameter on the side facing the ball (10) is smaller than the diameter on the side facing away from the ball (10).

Owner:ZF FRIEDRICHSHAFEN AG

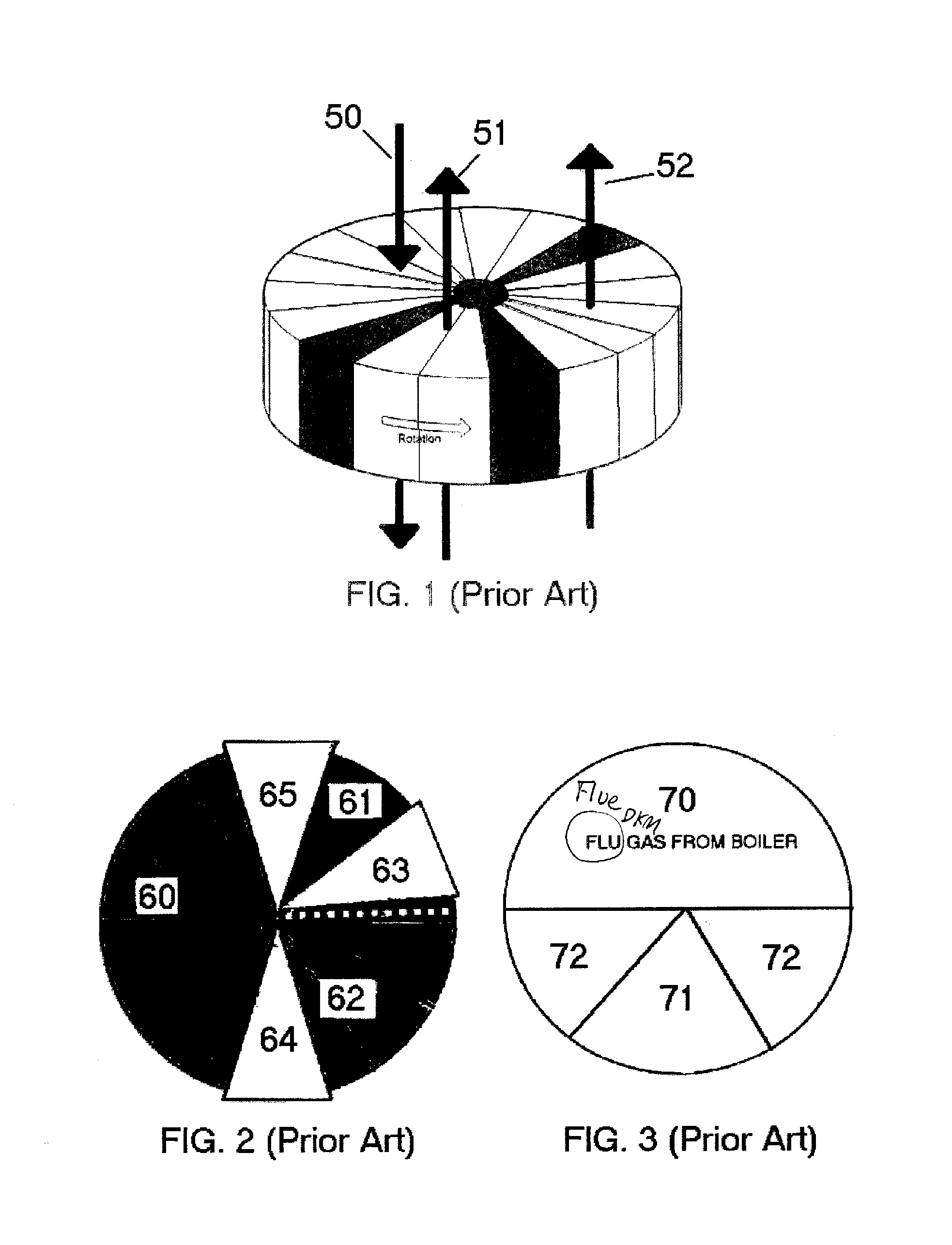

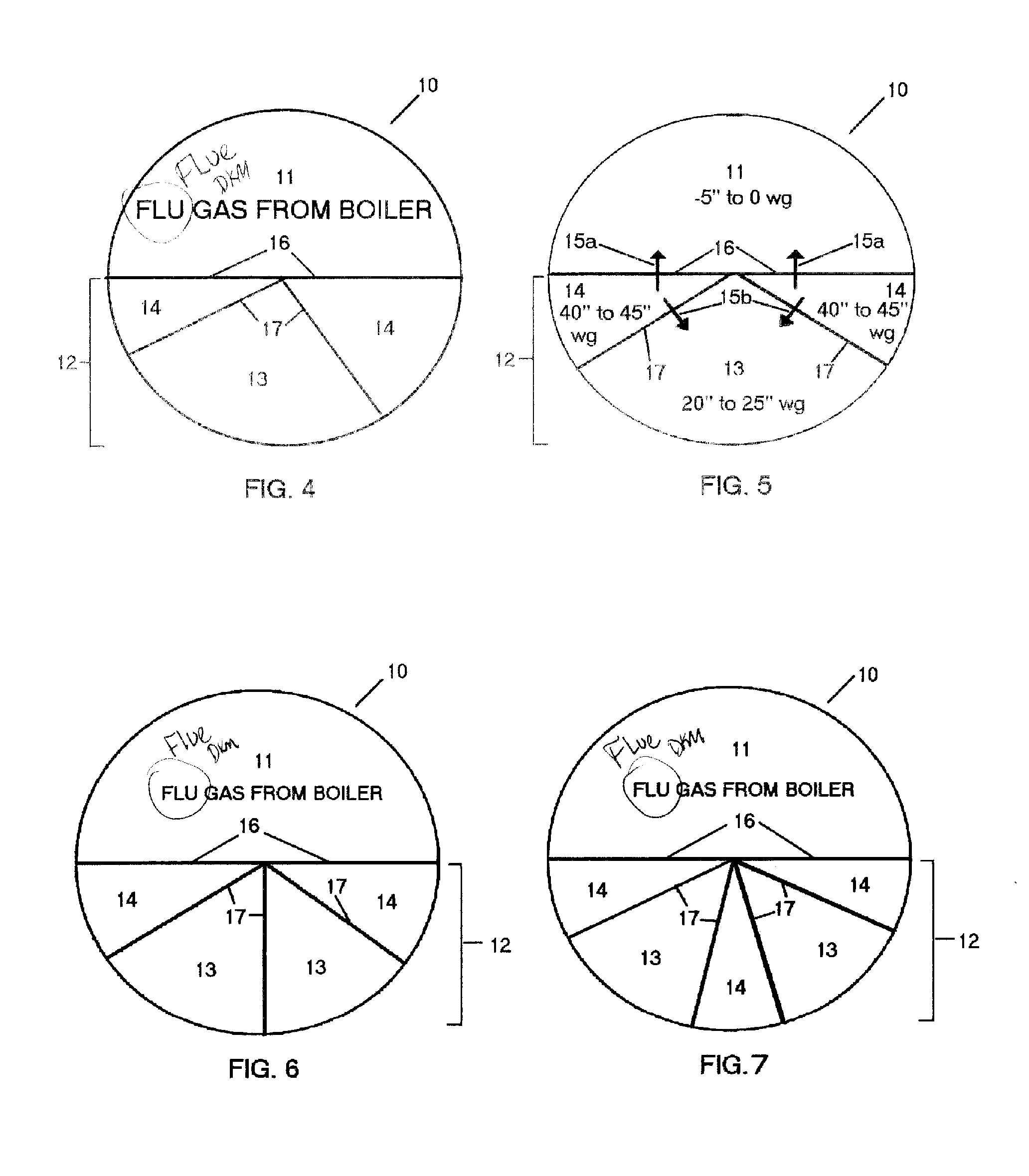

Oxy-fuel combustion oxidant heater internal arrangement

InactiveUS20110250551A1Reduce lossesSimple compositionBurnersIndirect carbon-dioxide mitigationFlue gasEngineering

A regenerative oxidant heater internal arrangement, including a system and method for use thereof, utilizing a unique recycle oxy-combustion methodology which includes at least two primary combustion oxidant sectors placed adjacent to both the flue gas side as well as a secondary oxidant sector positioned between the two primary sectors.

Owner:THE BABCOCK & WILCOX CO

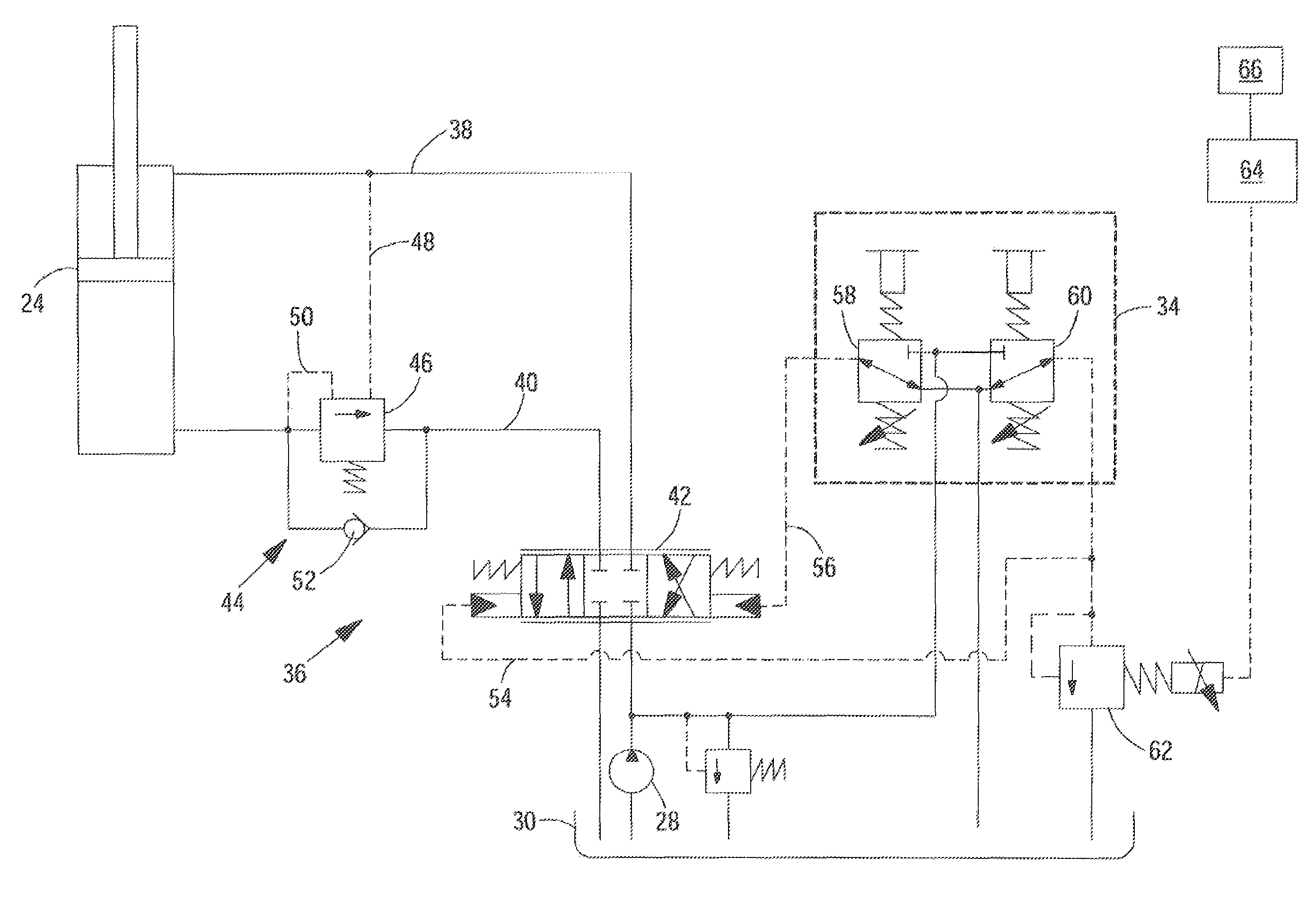

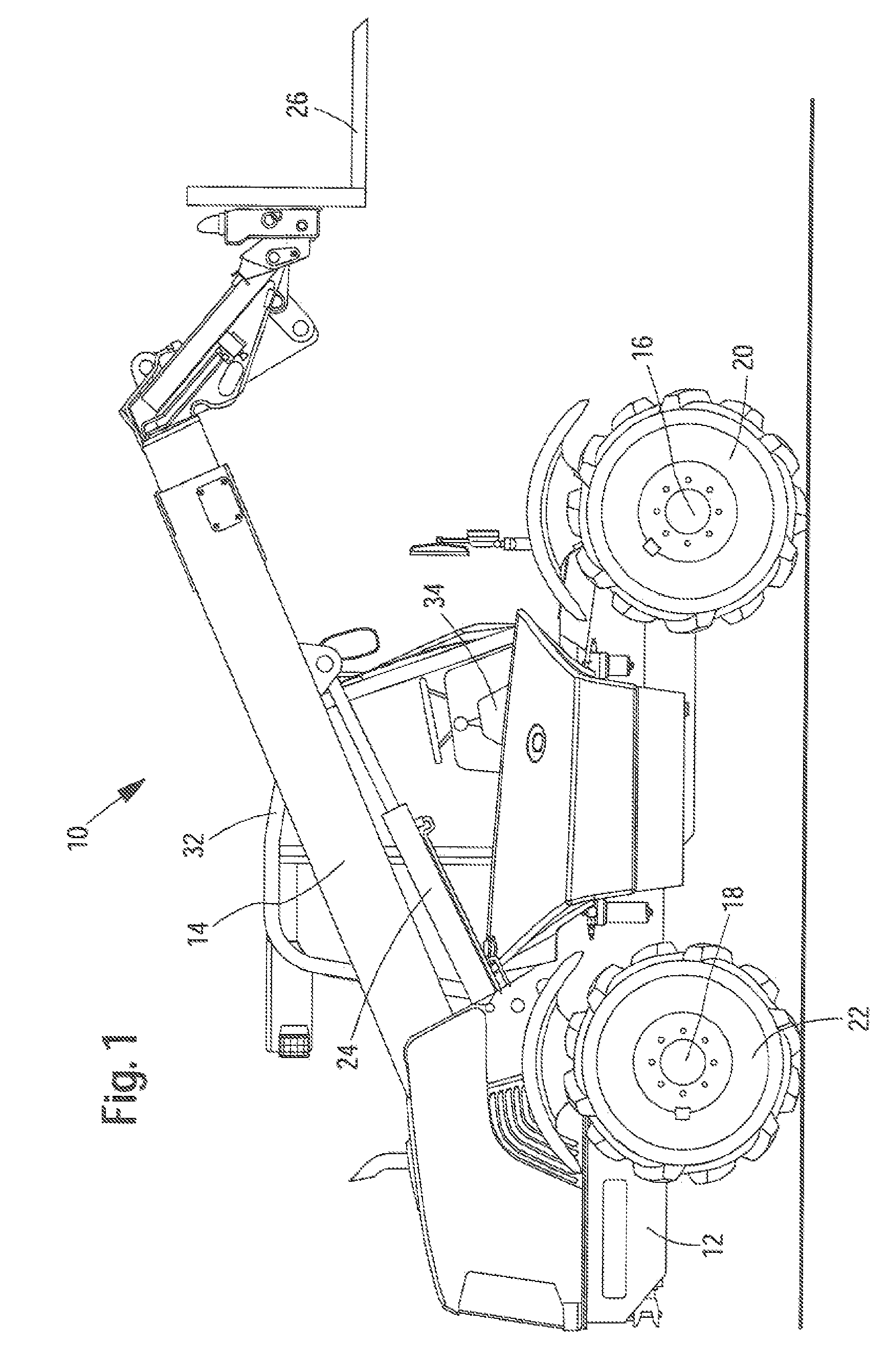

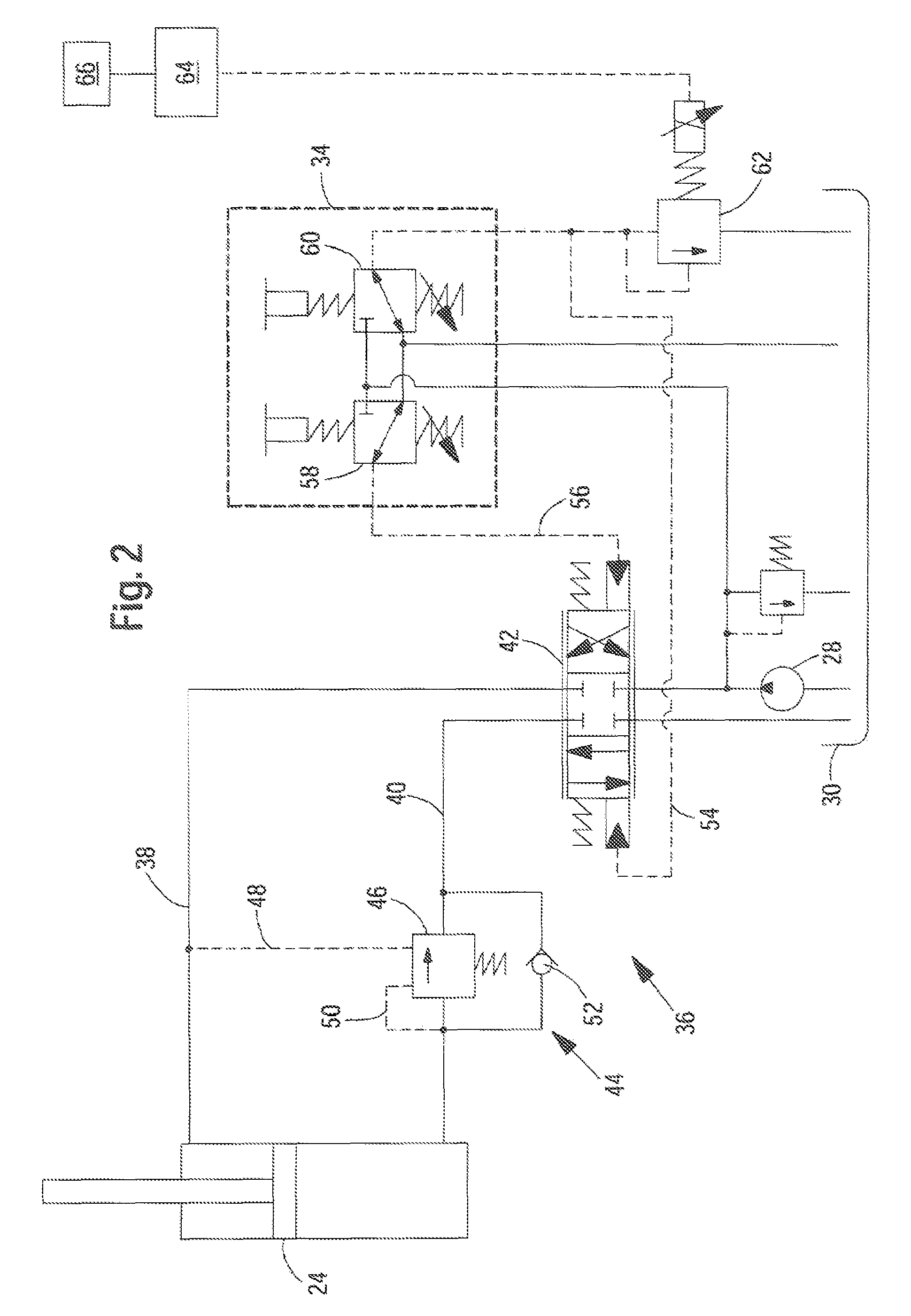

Loader

ActiveUS7717664B2Low control pressureReduced volume flowSafety devices for lifting equipmentsFluid couplingsHydraulic cylinderPressure transmission

Owner:DEERE & CO

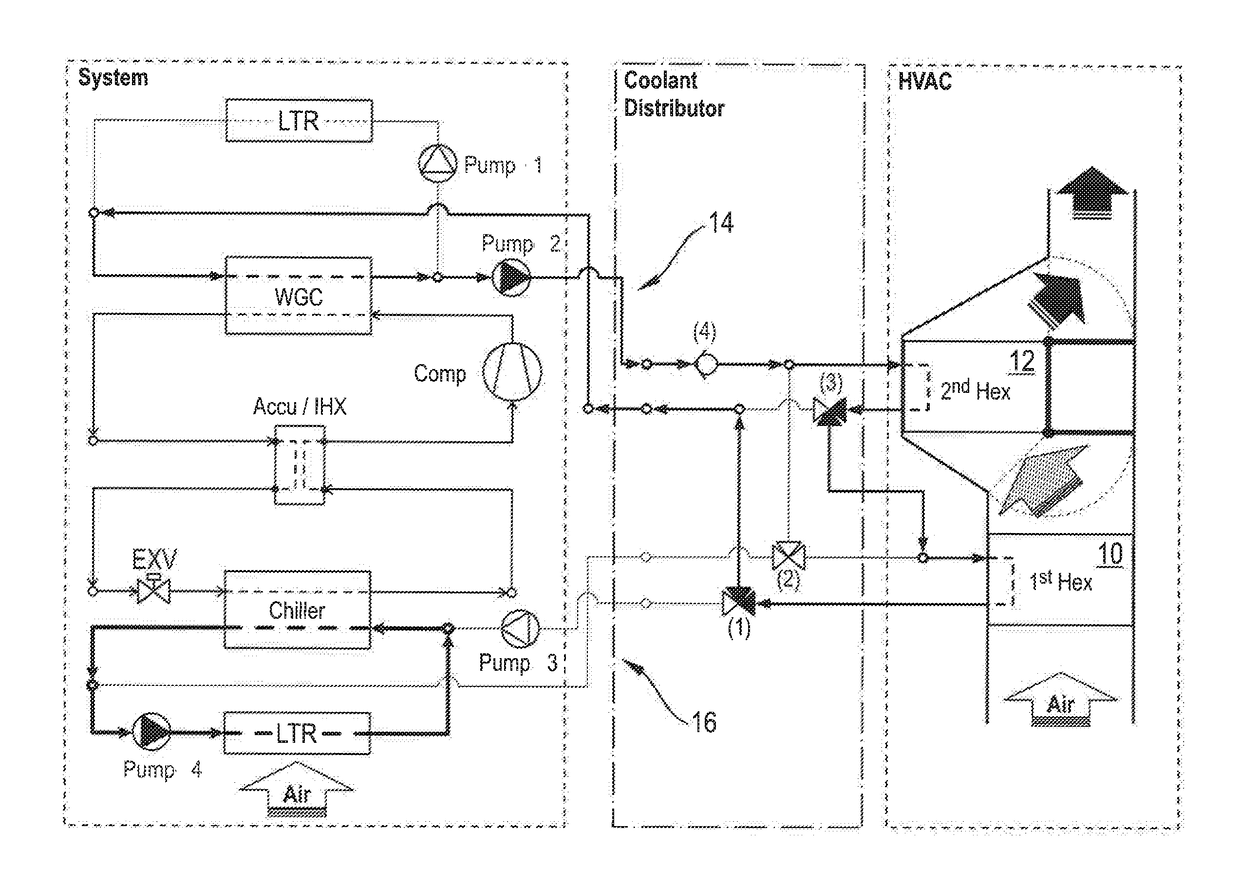

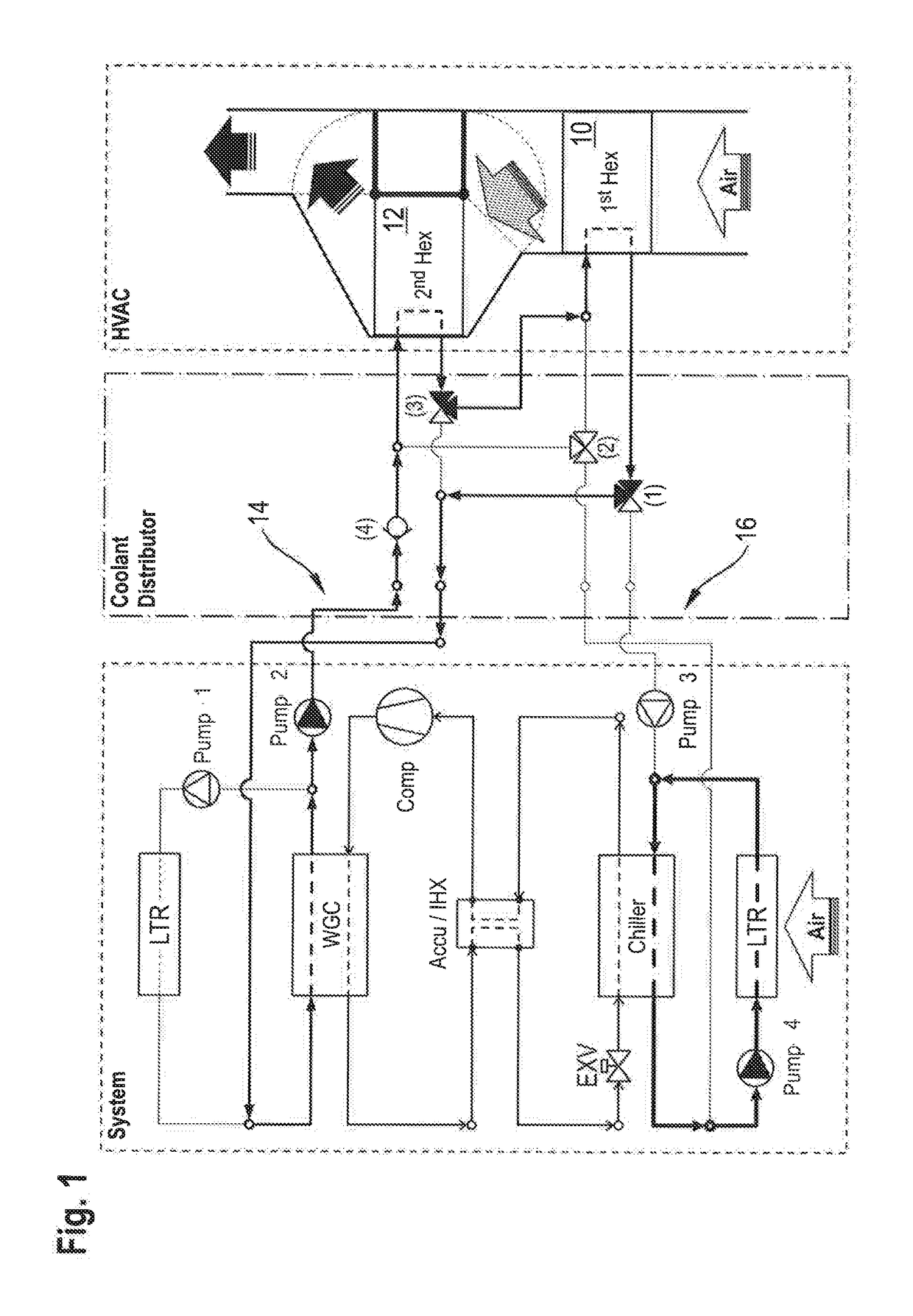

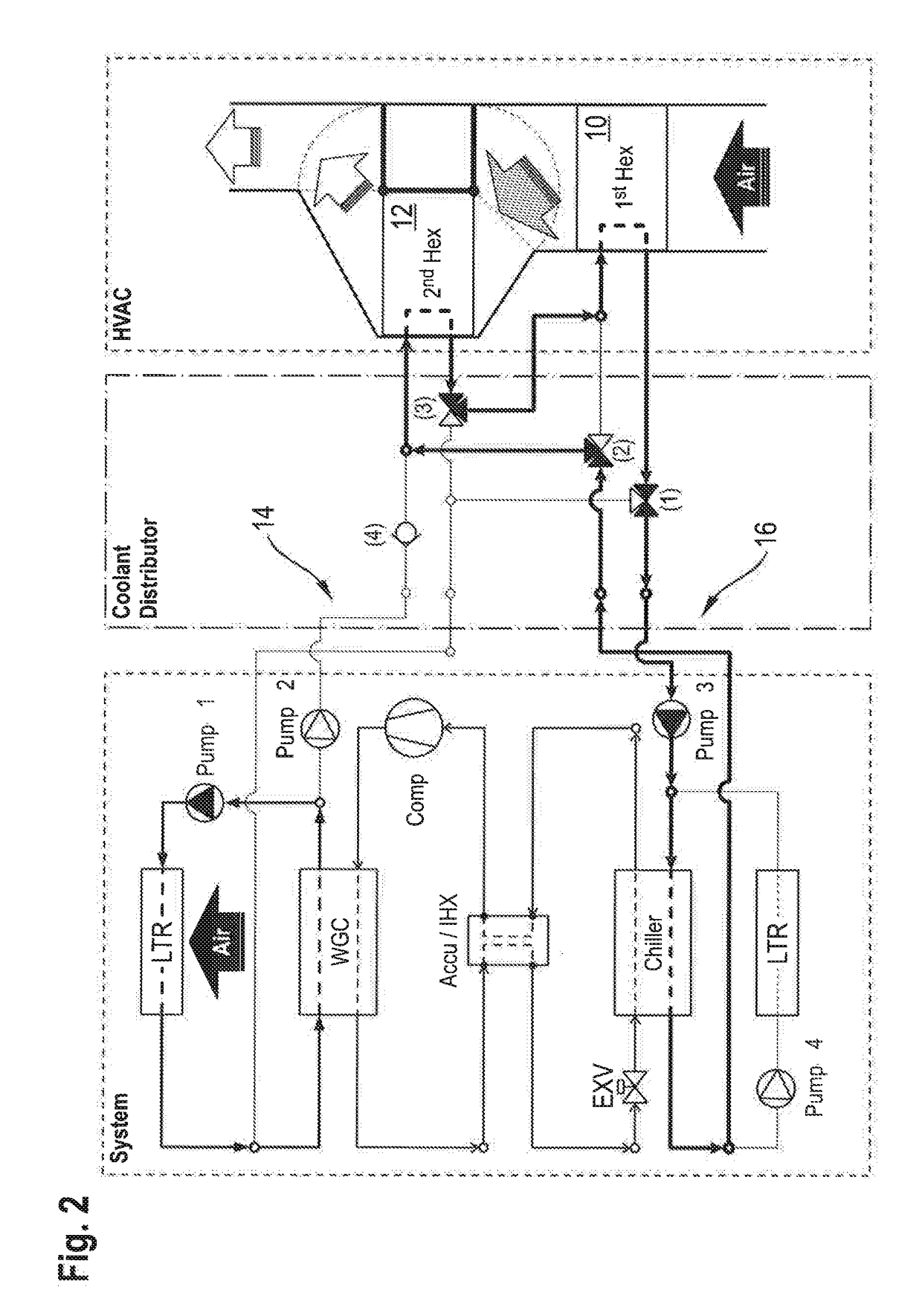

Device for distributing the coolant in an air-conditioning system of a motor vehicle

ActiveUS20180281562A1Reduced volume flowAir-treating devicesCompression machinesEngineeringAir conditioning

A heat pump system for a motor vehicle comprises at least two heat exchangers 10, 12, through which, for heating and / or cooling the motor vehicle interior, a flow is conducted, and at least two coolant circulations 14, 16 separable from one another, of which at least one is connectable, independently of the other coolant circulation, with one, two or more heat exchangers 10, 12 such that through these, in the presence of a connection with two or more heat exchangers 10, 12, a flow is successively conducted and the other coolant circulation is connectable with at least one heat exchanger 10, 12.

Owner:HANON SYST

Waste heat boiler

InactiveUS20130180475A1Improve heat transfer and temperature controlEasy to controlSafety devices for heat exchange apparatusFurnace-tube steam boilersProcess engineeringCooling medium

Owner:HALDOR TOPSOE AS

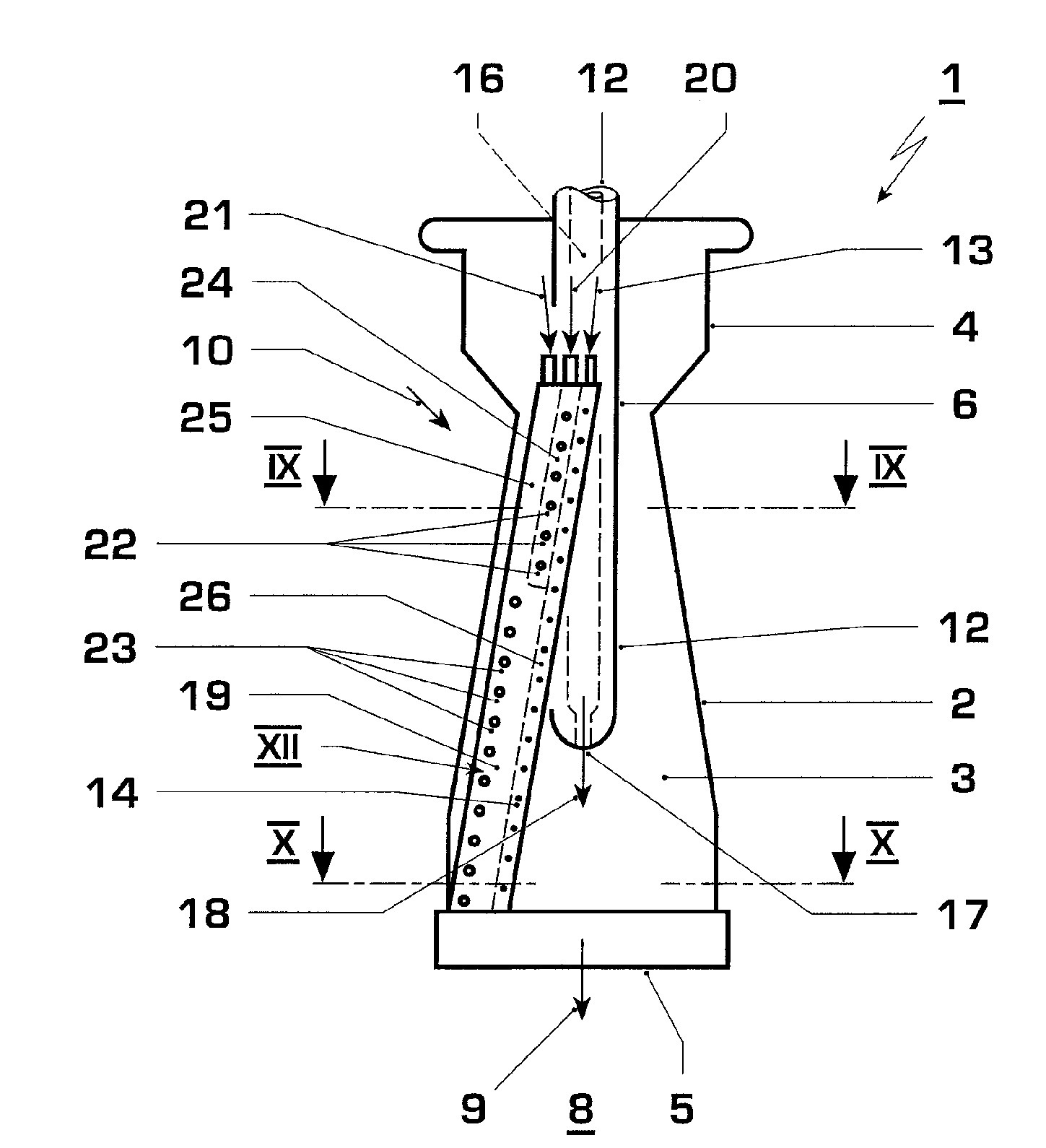

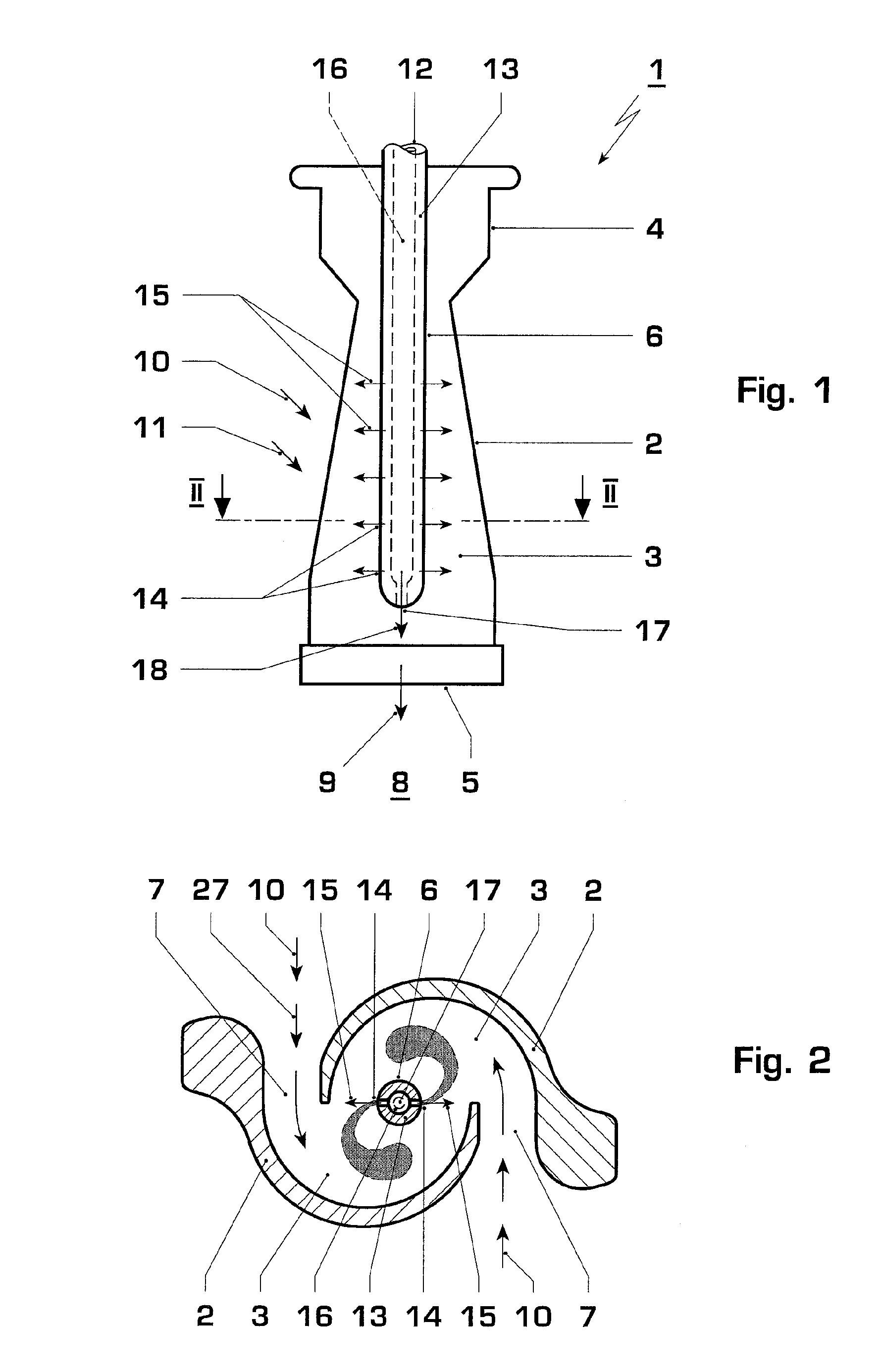

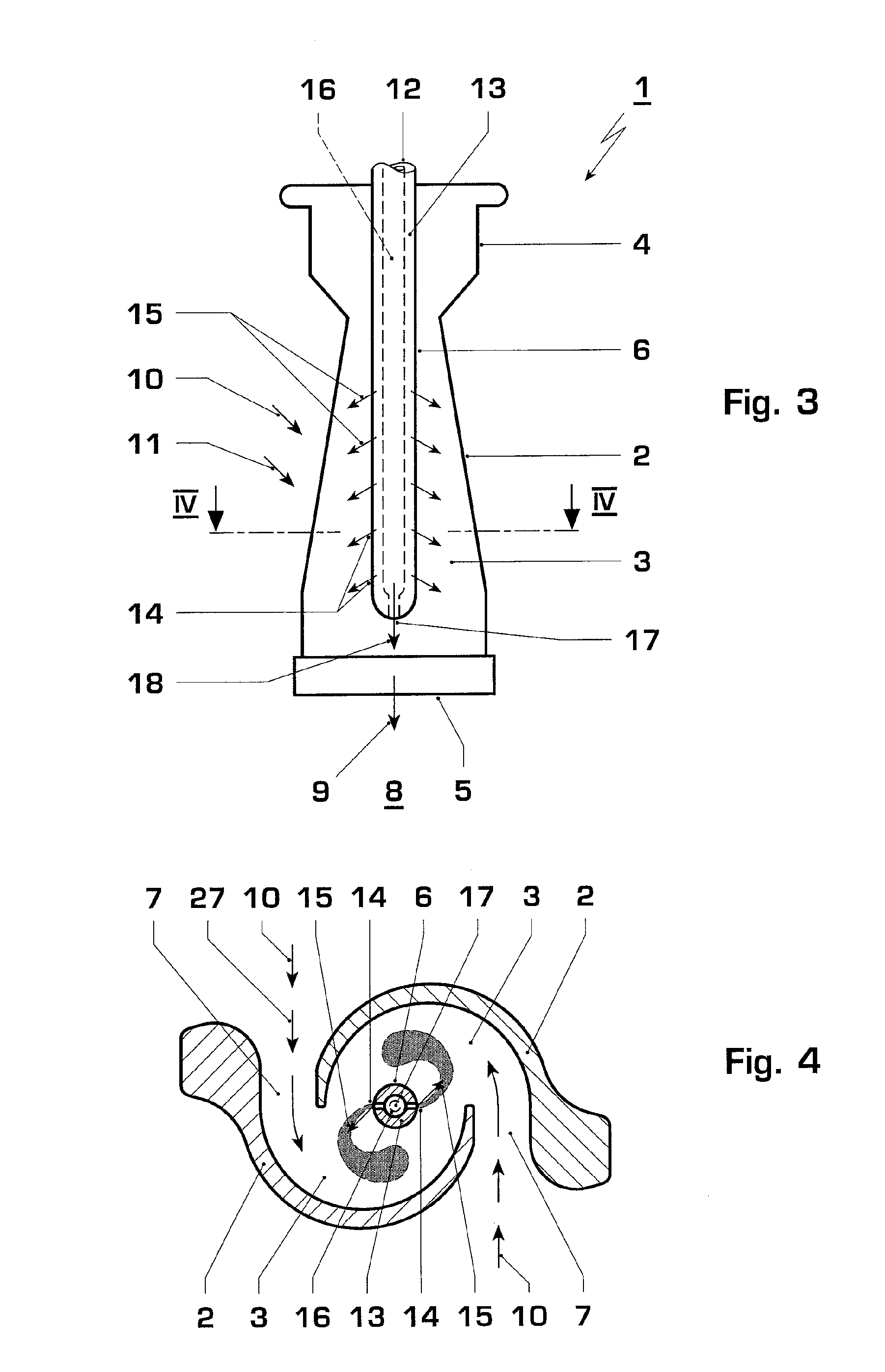

Premix burner for a gas turbine combustion chamber

ActiveUS7565794B2Reduce impactRaise the ratioCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustion chamberPower station

A burner (1) for a combustion chamber of a gas turbine, especially in a power plant, includes an oxidizer feed device (10) for feeding a gaseous oxidizer into a mixer chamber (3) of the burner (1), a gaseous fuel feed device (11) for feeding a gaseous fuel into the mixer chamber (3), and a liquid fuel feed device (12) for feeding a liquid fuel into the mixer chamber (3). In order to improve the operation of the burner (1) with liquid fuel, the liquid fuel feed device (12) has a main feed line (13) which feeds liquid fuel to a plurality of injection orifices (14). Some of these injection orifices (14), with regard to a main outflow direction (9) of the burner (1), which has an oxidizer-fuel mixture, which flows from the mixer chamber (3), at an outlet opening (5) of the mixer chamber (3), are arranged in series. Some or all of these injection orifices (14) are designed so that a main injection direction (15) of the respective injection orifice (14) has a radial component which extends radially to the main outflow direction (9).

Owner:ANSALDO ENERGIA SWITZERLAND AG

Reduction device for reducing gas pressure in piston ring group of reciprocating piston type internal combustion engine

InactiveCN101858276AReduced volume flowRelieve pressurePiston ringsCylinder headsCombustion chamberPiston ring

The present invention relates to a reduction device for reducing gas pressure in piston ring group of reciprocating piston type internal combustion engine. The piston comprises a piston crown which is adjacent to a ring area, and the piston crown faces a combustion chamber in a mounting state. The piston is arranged in the operation state with a mode that the reciprocation along a longitudinal axis of the cylinder is allowed, namely, the piston crown of the piston functions together with a scraping device provided at the cylinder wall of the cylinder next to an upper dead center of the motion in the cylinder for controllably scraping the combustion residue, wherein, the reduction device is designed to a dent shape thereby realizing controllable deposit of the combustion residue at the reduction device. According to the invention, the scraping device and the piston crown are designed and arranged relatively with each other, namely, the scraping device and the piston crown at least partially at a stop state temperature at an angle which can be preset, thereby causing the reduction of gas pressure acting on the piston ring group to be automatically adjusted under the cooperation of the piston crown and the scrapping device.

Owner:WAERTSILAE SCHWEIZ AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com