Cooling compensation type air cooling island system

An air-cooled island, compensation technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as insufficient vacuuming capacity, and achieve the effects of improving antifreeze performance, reducing back pressure and reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, working principle, concrete structure and implementation method of the present invention are further described:

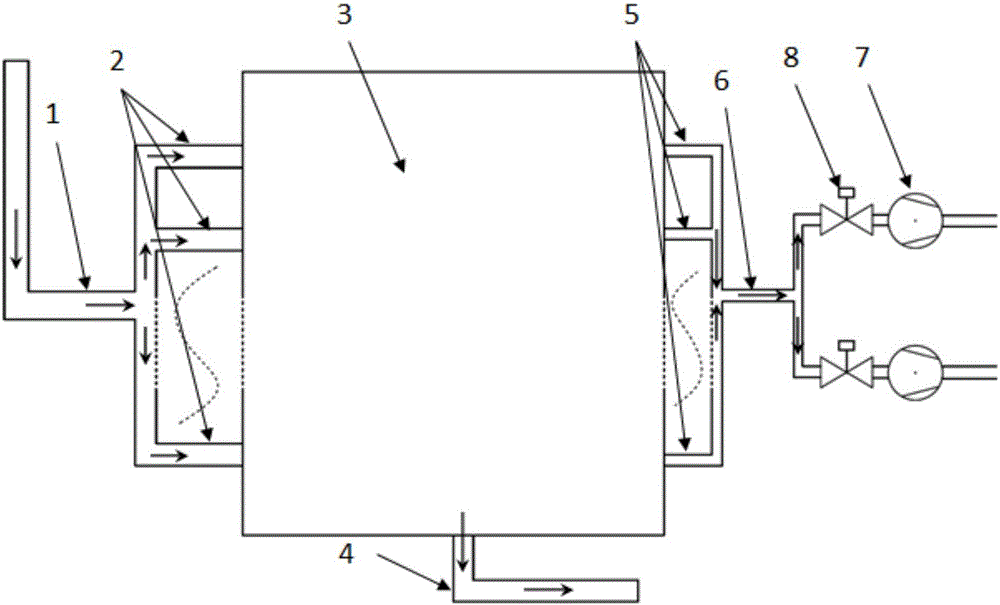

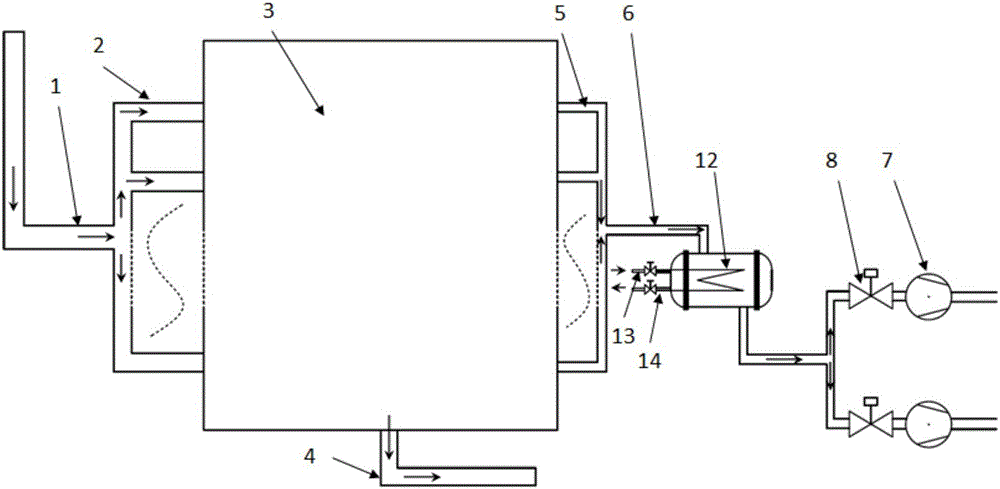

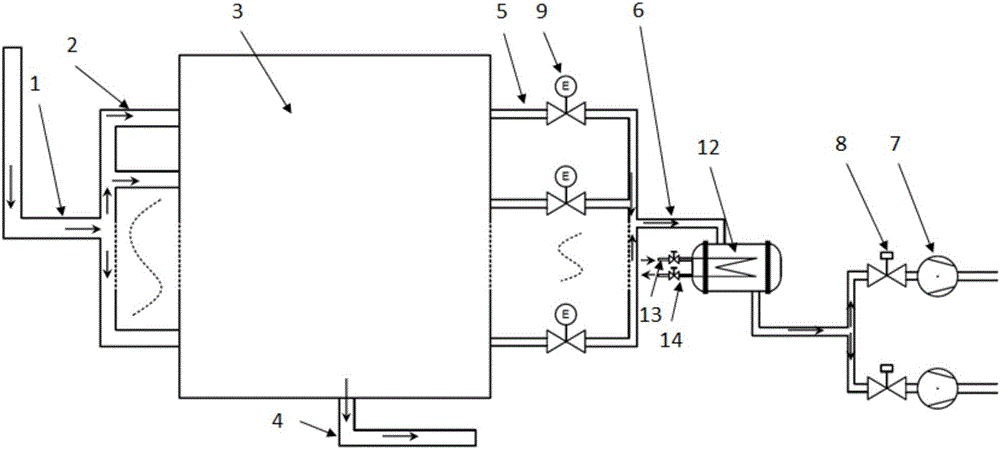

[0021] figure 1 It is a schematic diagram of the structure and principle of a conventional air-cooled island system, figure 2 A schematic diagram of the structural principle of a cooling compensation type air-cooled island system provided by the present invention, the system includes a steam turbine exhaust pipe 1, an exhaust steam distribution pipe 2, an air-cooled radiator 3, a condensed water collection pipe 4, an air extraction branch pipe 5, an air extraction pipe Air pipeline main pipe 6, vacuum equipment 7, vacuum equipment isolation valve 8 and compensation cooler 12, the compensation cooler 12 is installed on the air extraction pipeline main pipe 6, and a cooling medium supply is provided on the compensation cooler pipe 13 and cooling medium discharge pipe 14 .

[0022] Under normal circumstances, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com