Reduction device for reducing gas pressure in piston ring group of reciprocating piston type internal combustion engine

A decompression device and reciprocating piston technology, applied to piston rings, pistons, mechanical equipment, etc., can solve problems such as damage and pollution of cylinder lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

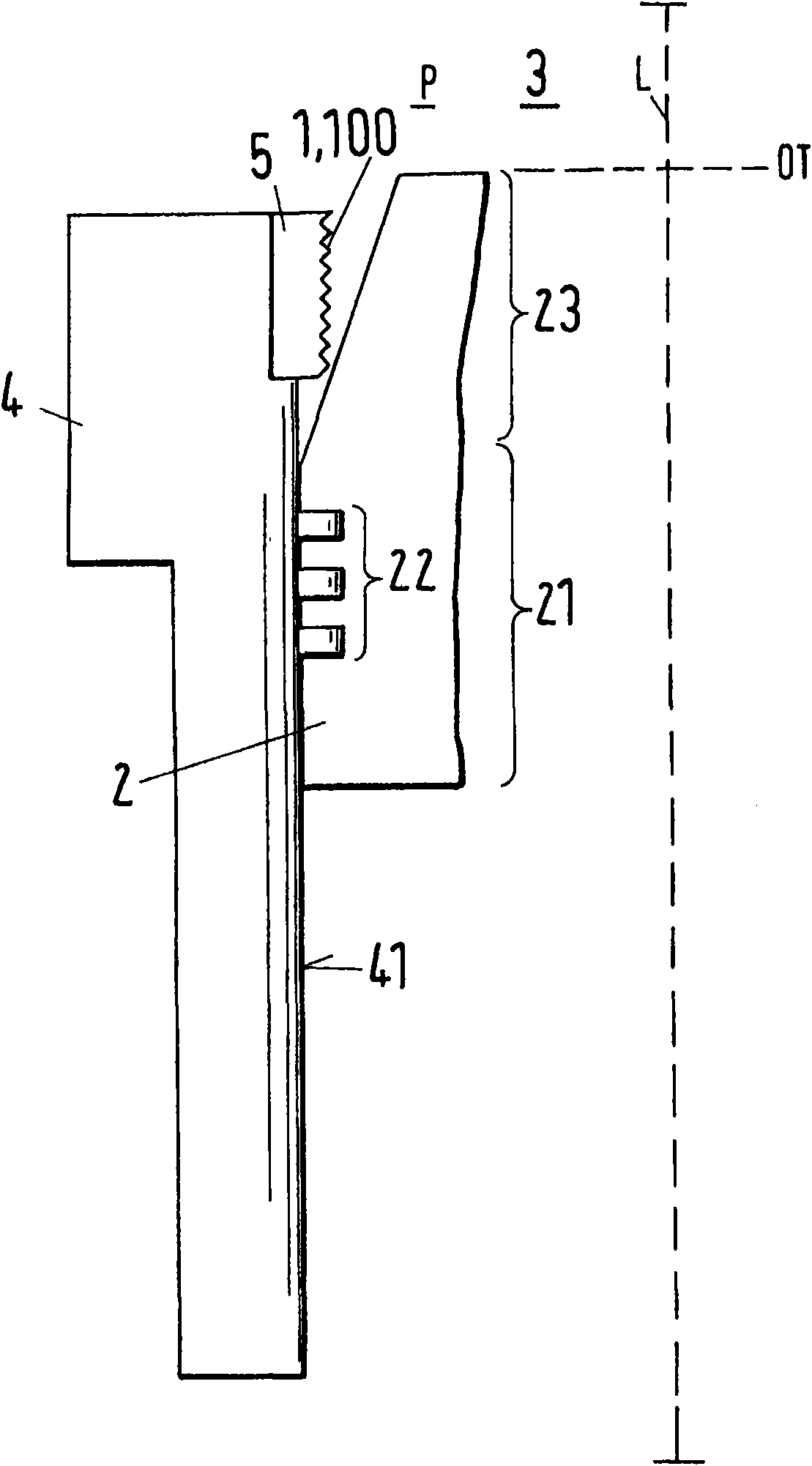

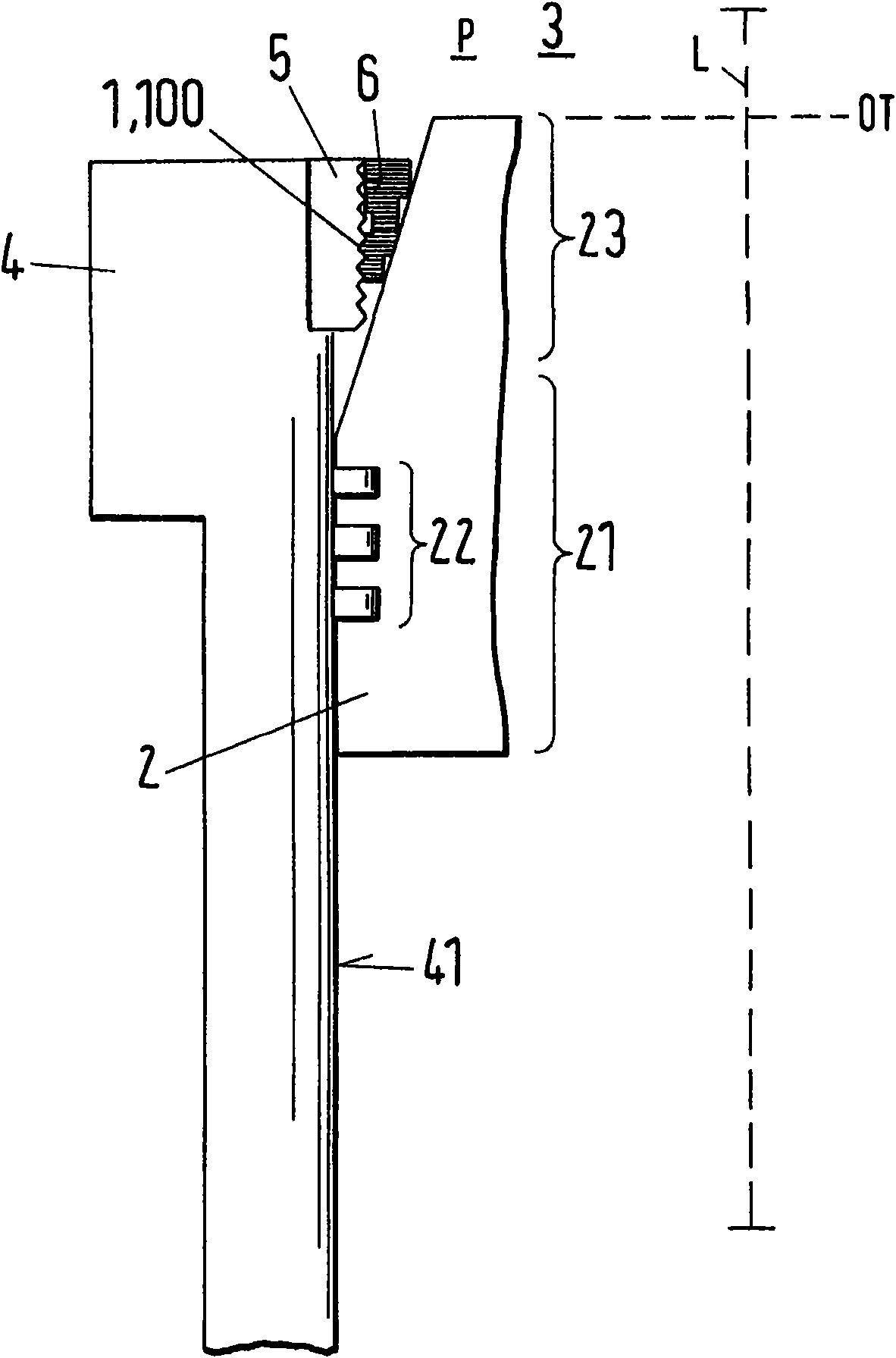

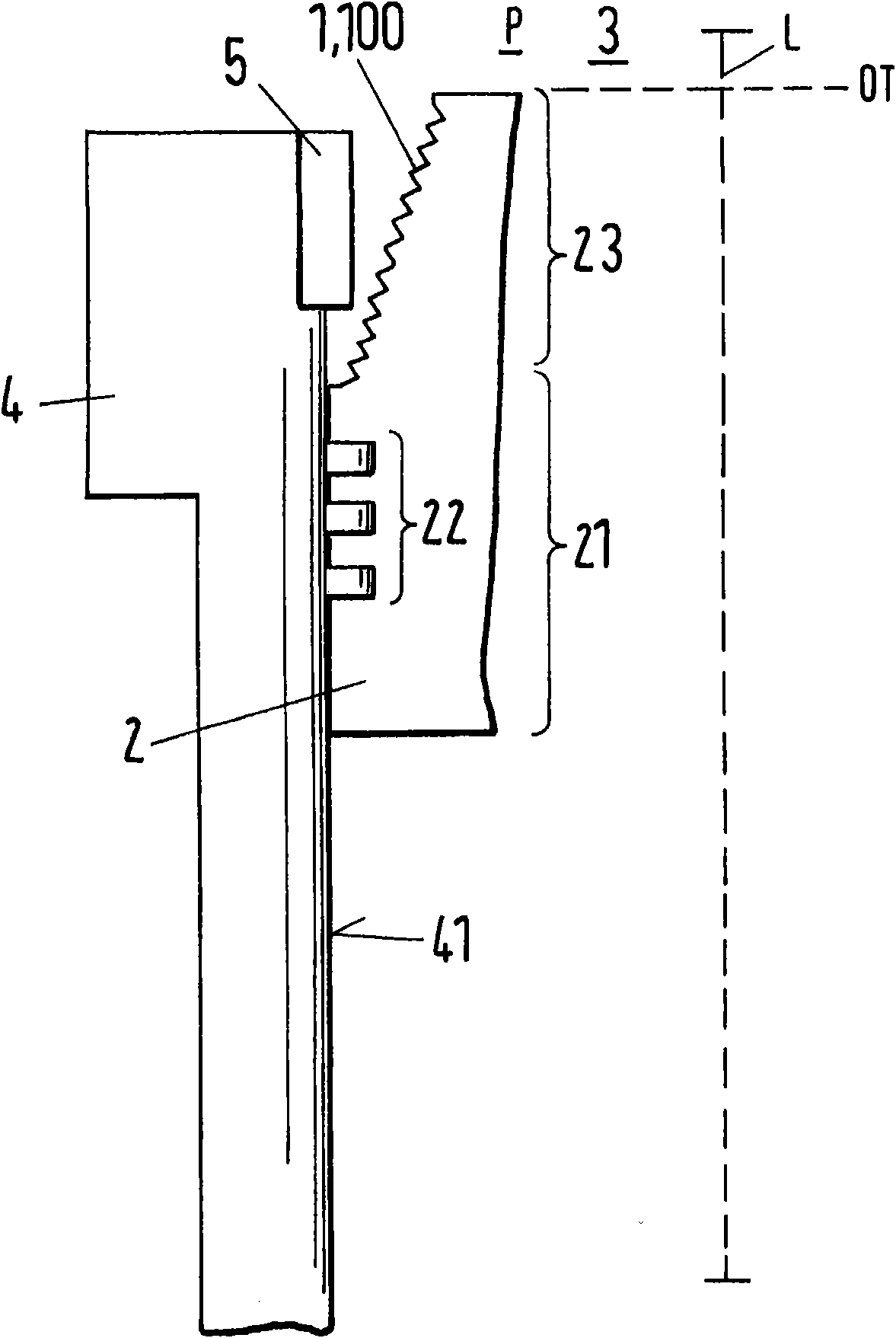

[0045] Figure 1a to Figure 3 The schematic illustrations each show a part and a section of a cylinder assembly with a pressure relief device according to the invention, which is designated as a whole below with the reference numeral 1 .

[0046] In addition to the pressure reducing device 1,100 according to the present invention, Figure 1a to Figure 3 All of the embodiments shown show a known cylinder assembly of a reciprocating piston internal combustion engine, in this particular example a two-stroke crosshead large diesel engine, with a cylinder 4 in which a piston 2 is arranged, in which In the ring region 21 , the piston 2 is provided with a piston ring pack 22 with three piston rings. Obviously, the ring set 22 can also comprise more or less than three piston rings. The air pressure P built up in the combustion chamber 3 during the compression stroke of the piston 2 or by ignition of the combustion mixture in the combustion chamber 3 acts in the operating state on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com