Patents

Literature

224results about How to "Spacing adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

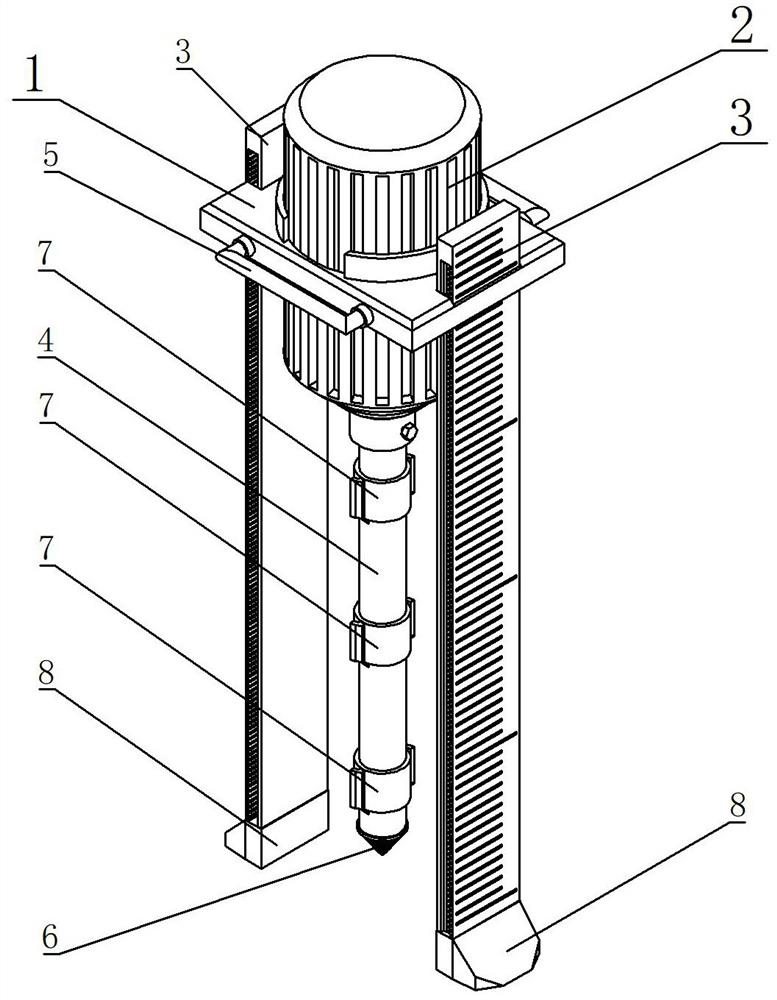

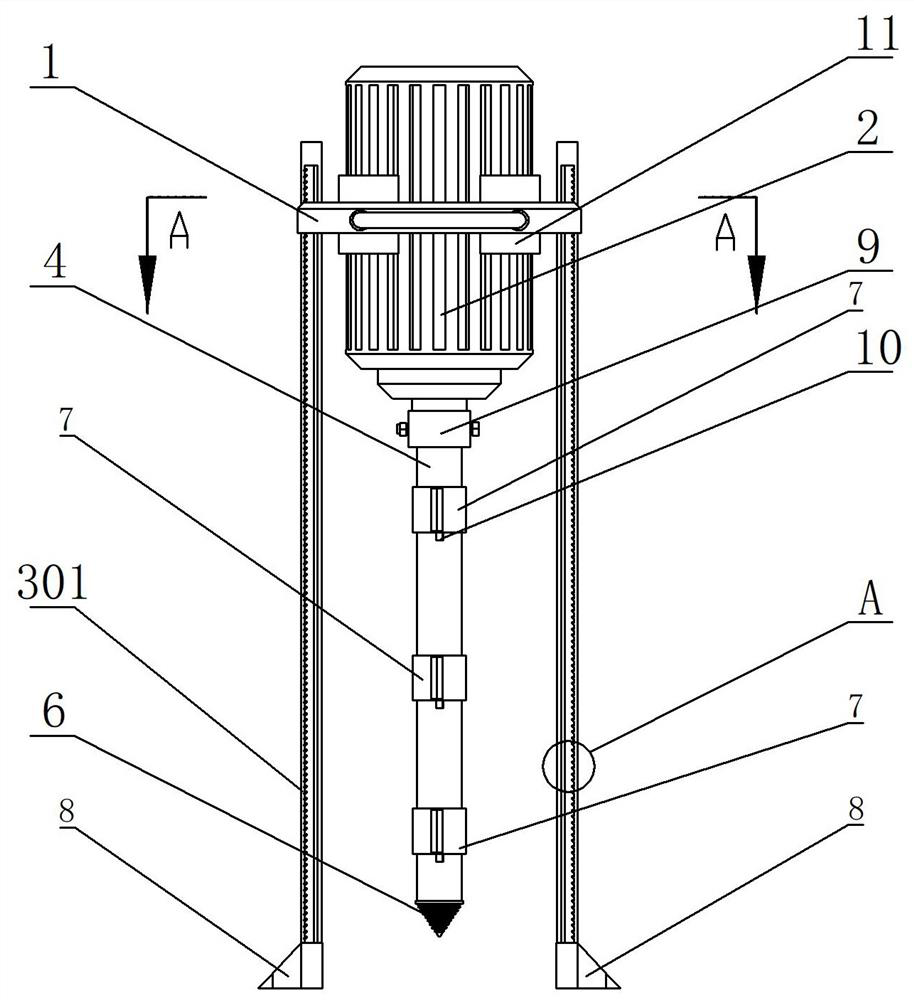

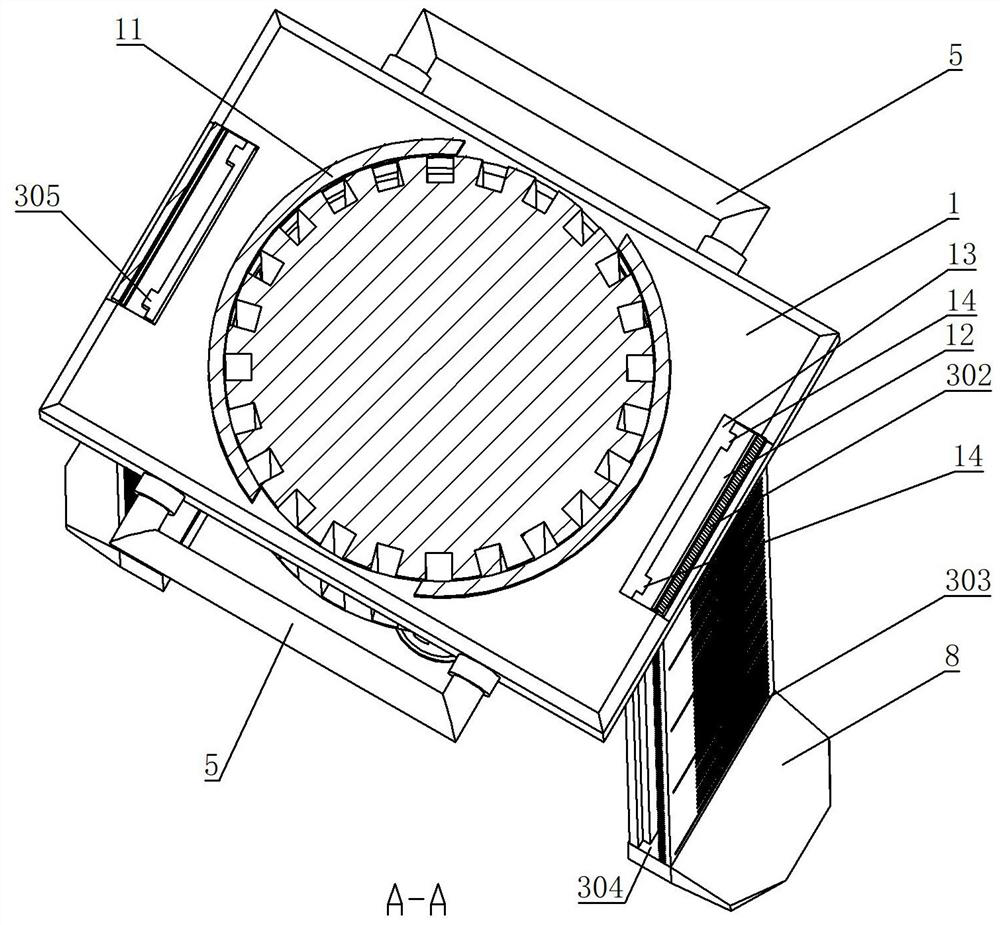

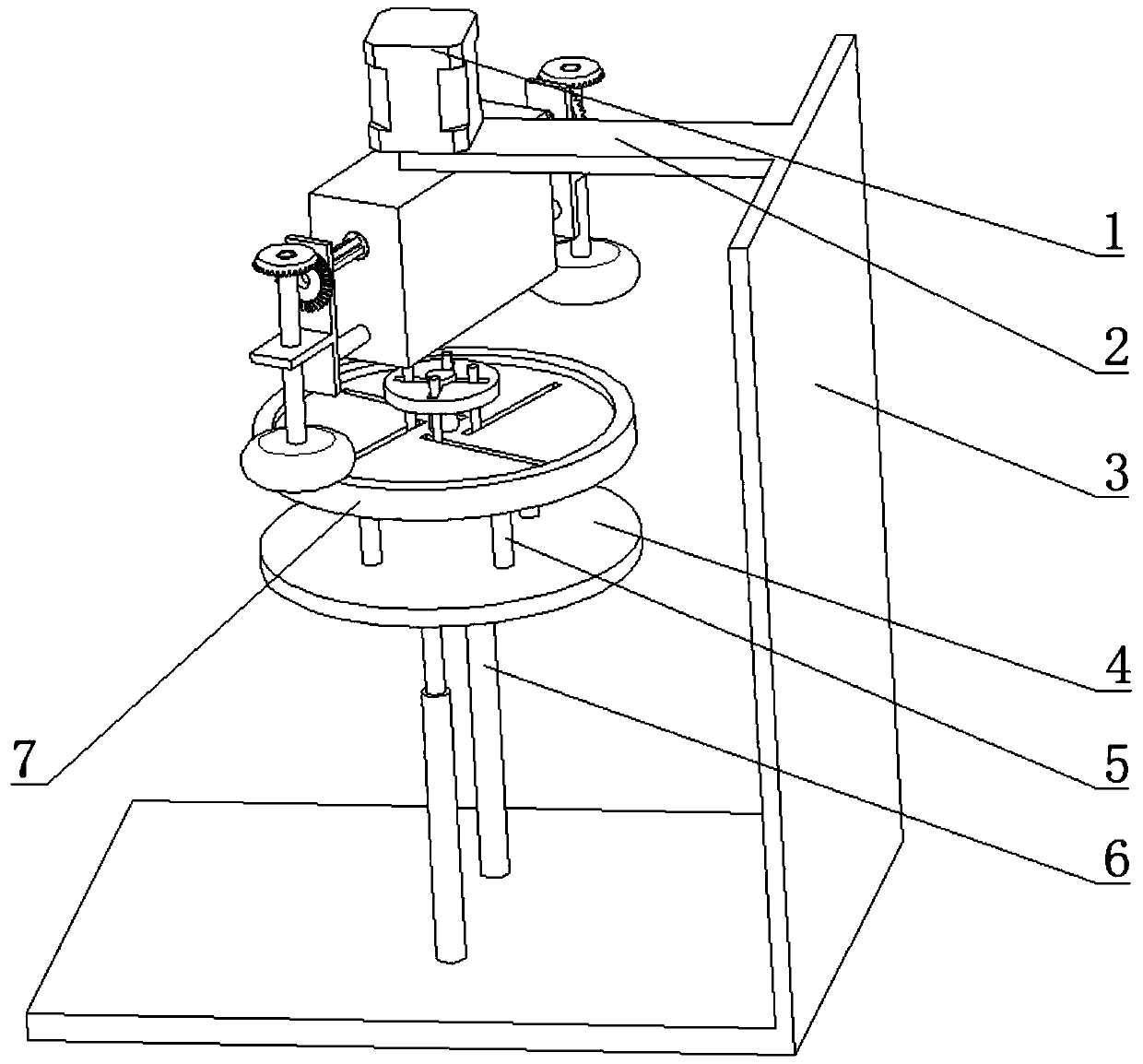

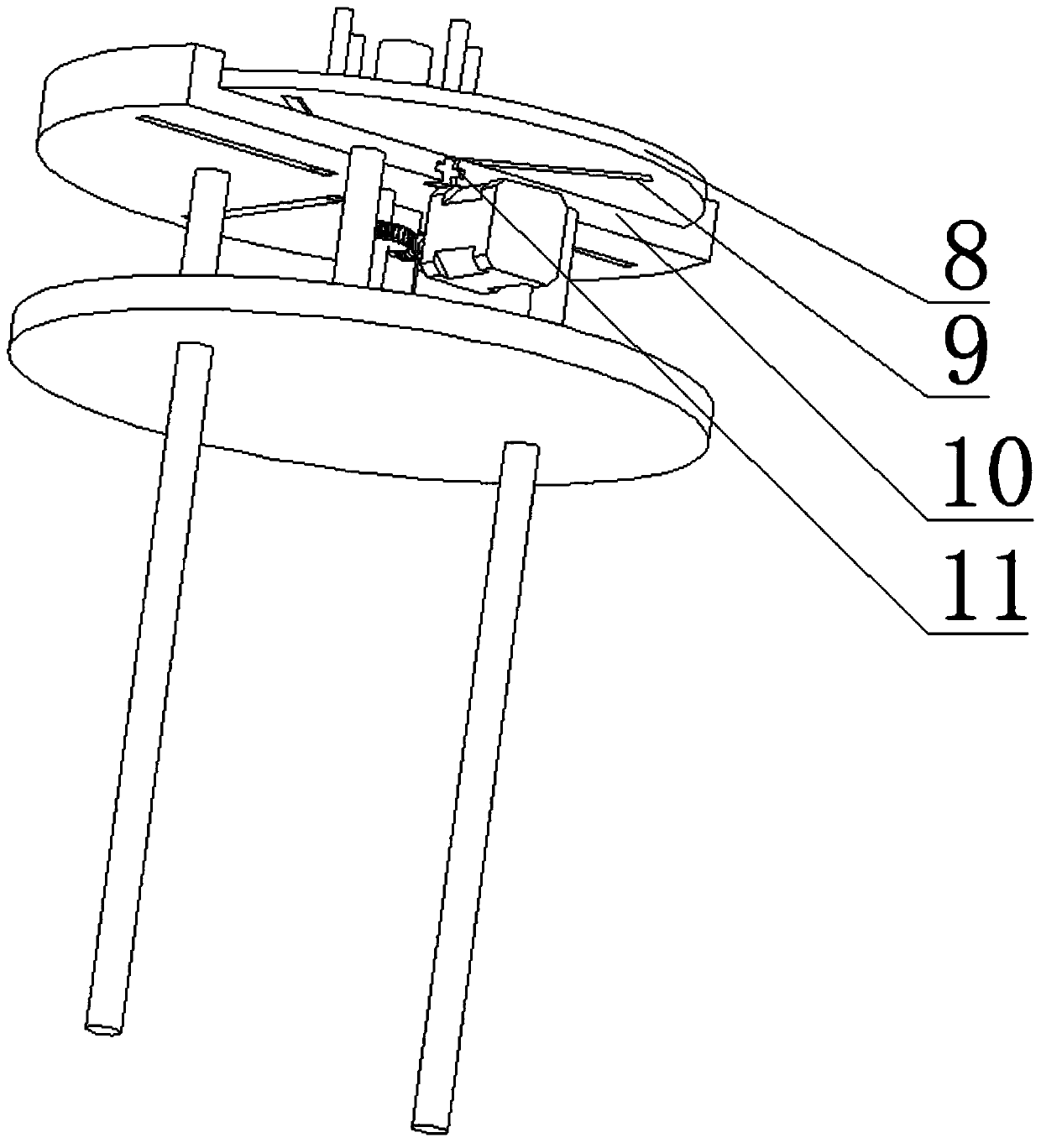

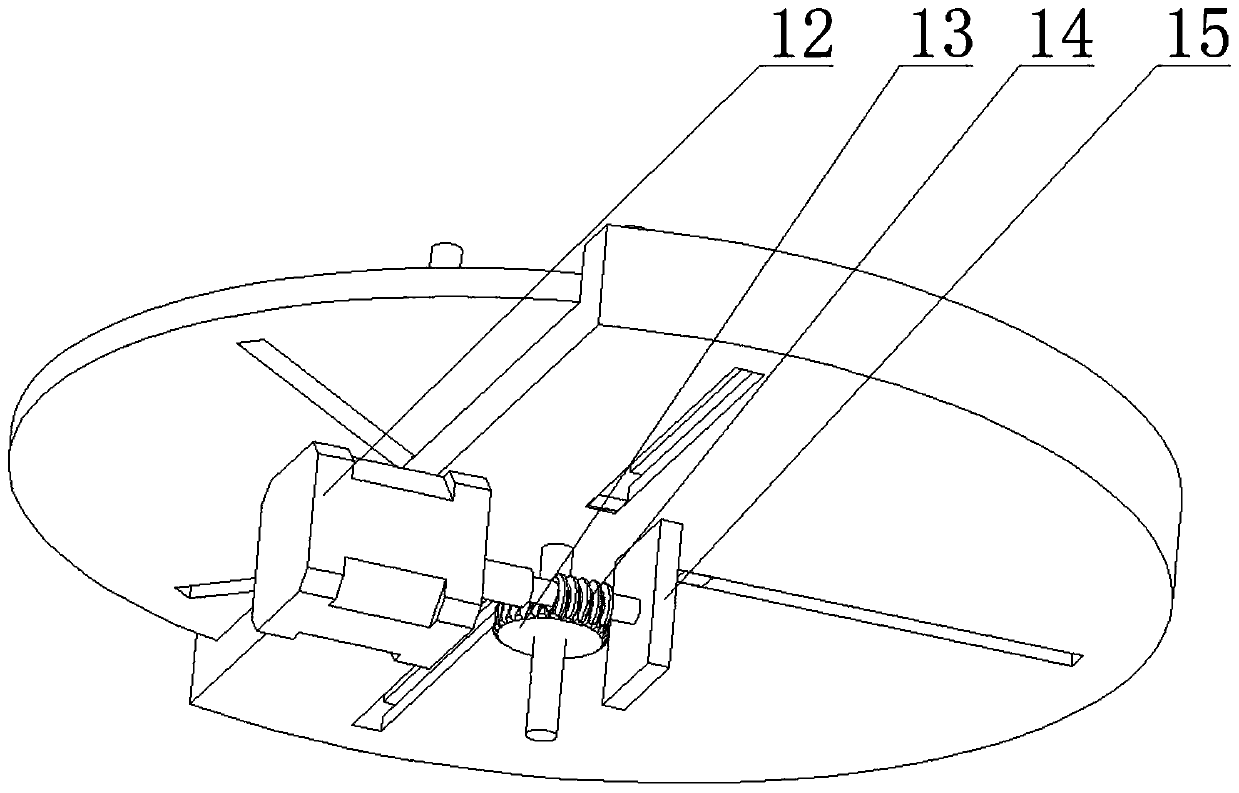

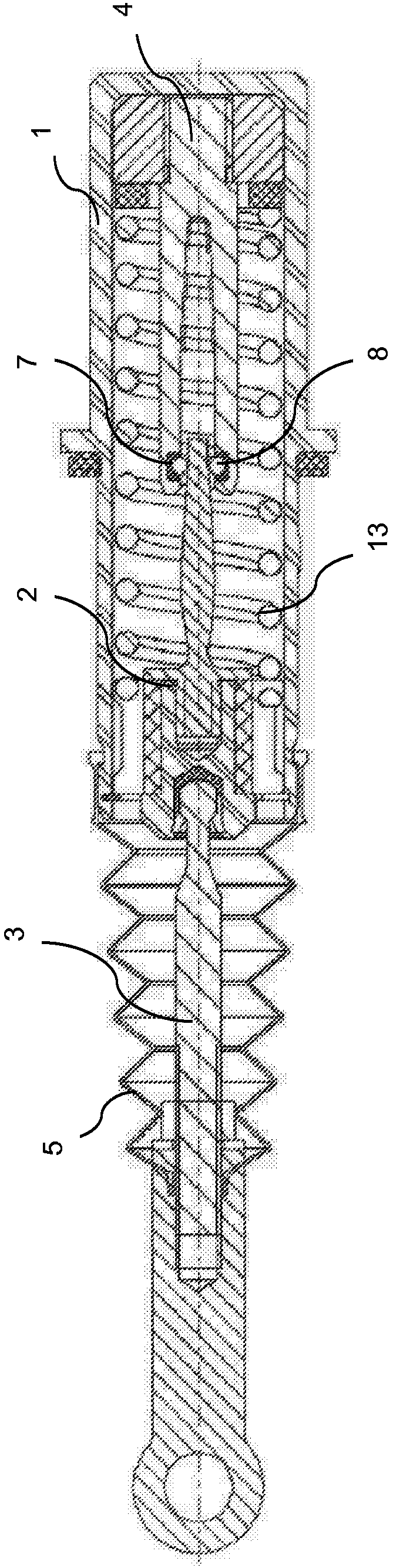

Soil stratified sampling device for hydrogeological survey

ActiveCN113358409AEasy to drill downEasy to controlWithdrawing sample devicesElectric machineAgricultural engineering

The invention provides a soil stratified sampling device for hydrogeological survey which comprises a supporting fixing plate and a motor, the center of the supporting fixing plate is hollow, a motor positioning clamp is integrally mounted in the supporting fixing plate, the motor is fixedly mounted in the motor positioning clamp in a limiting manner, and a sampling mounting pipe is mounted at the output end of the lower end of the motor through a connecting ring; a plurality of sampling assemblies are mounted in the sampling mounting pipe in a penetrating manner. According to the sampling device, soil of different layers can be sampled in a classified mode through the sampling assemblies, and simultaneous collection is achieved. Compared with the prior art, the situation that multiple times of repeated treatment are needed due to the fact that only one kind of soil can be sampled at a time is avoided; and the position of the supporting fixing plate can be slid through a movable assembly, so that personnel can drill soil conveniently, and compared with the prior art, the problem that deviation is caused by position deviation due to the fact that no supports are arranged on the two sides is effectively solved.

Owner:山东省地质矿产勘查开发局第四地质大队

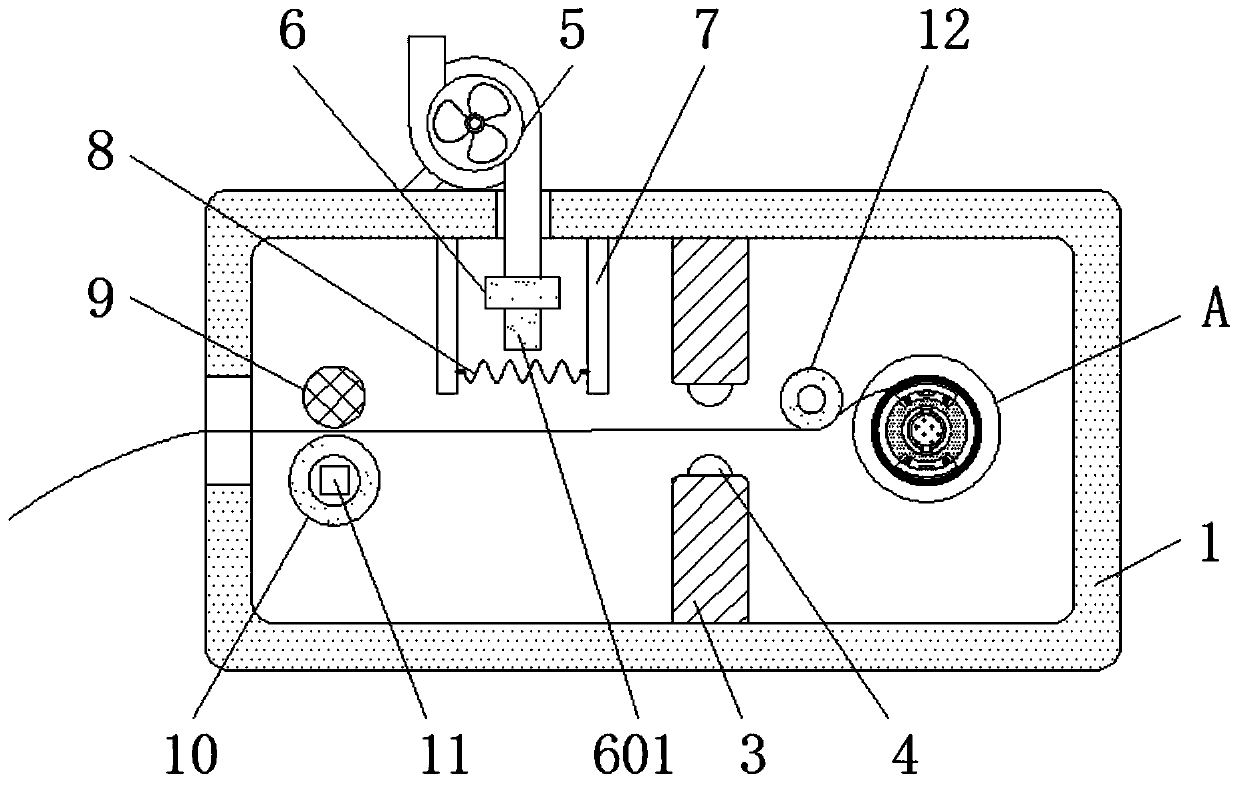

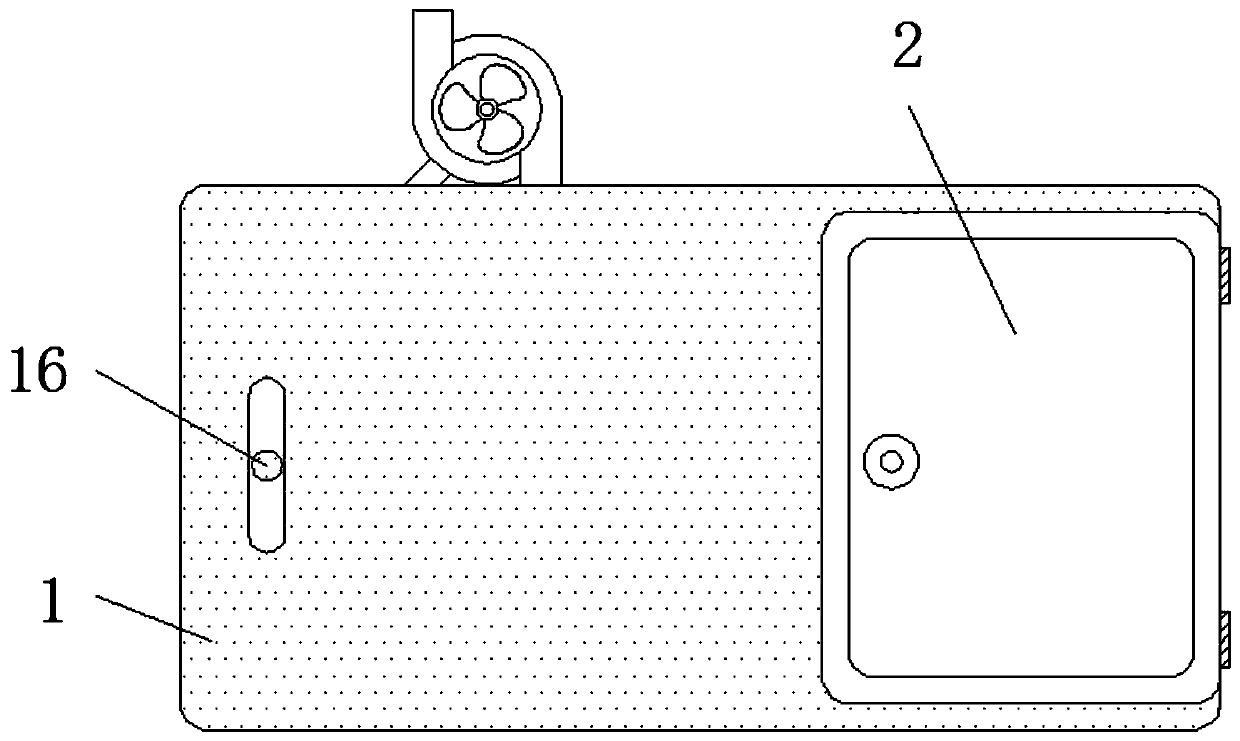

Spinning cloth winding device with drying and sterilizing functions

ActiveCN110589550AQuality improvementImprove functionalityDrying solid materials with heatHearth type furnacesDrive motorElectric heating

The invention discloses a spinning cloth winding device with drying and sterilizing functions. The device comprises a winding box, mounting plates, a fan, an electric heating wire and a driving motor,wherein a box door is mounted on the surface of the front side of the winding box; the mounting plates are arranged in the winding box; ultraviolet lamps are mounted at the outer ends of the mountingplates; the fan is arranged above the left of the winding box; the lower end of the fan is connected with an air guide pipe; the electric heating wire is arranged below the air guide pipe; the two ends of the electric heating wire are connected with fixing plates positioned on the inner wall of the winding box; and an electrostatic elimination rod is arranged below the left of the fixing plates.The spinning cloth winding device with the drying and sterilizing functions is provided with the electrostatic elimination rod, connecting blocks and a movable rod, spinning cloth passing through thesurface of a first rotary drum can be subjected to electrostatic elimination through the electrostatic elimination rod, and meanwhile, the position of the connecting blocks can be controlled through the rotation of the movable rod, so that the distance between the electrostatic elimination rod and the first rotary drum is conveniently adjusted.

Owner:仙桃晨光防护用品有限公司

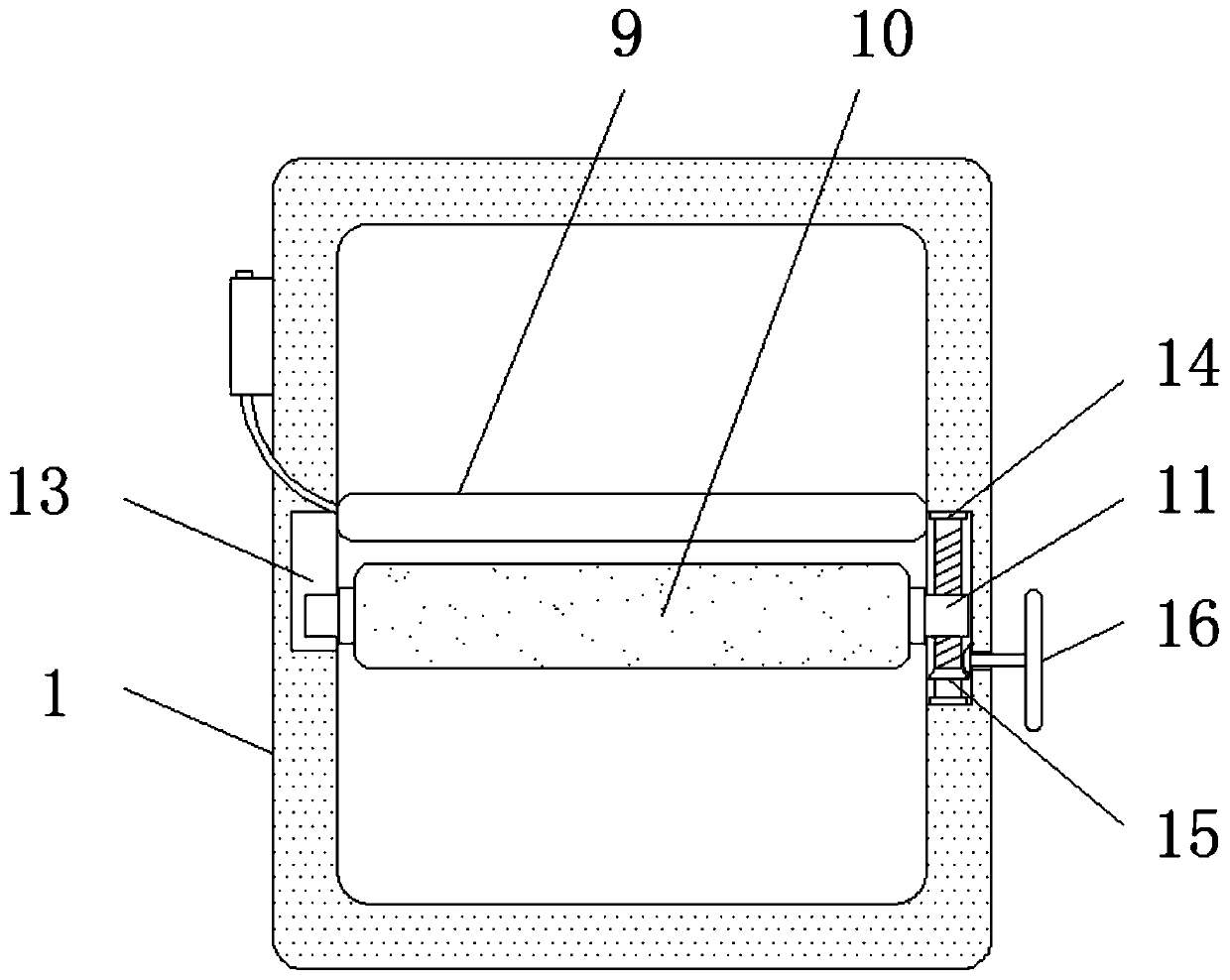

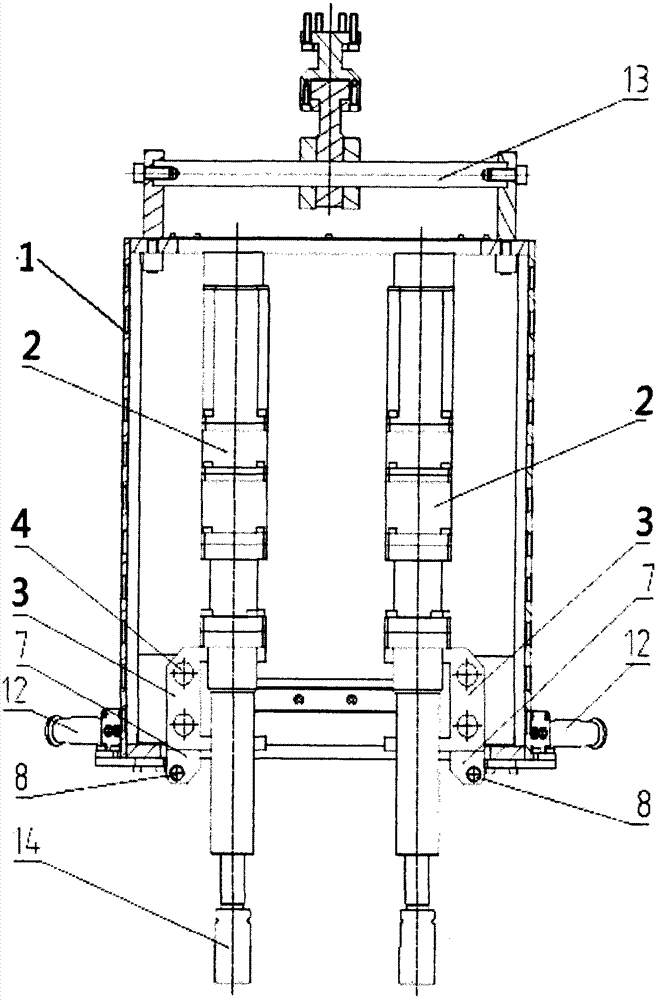

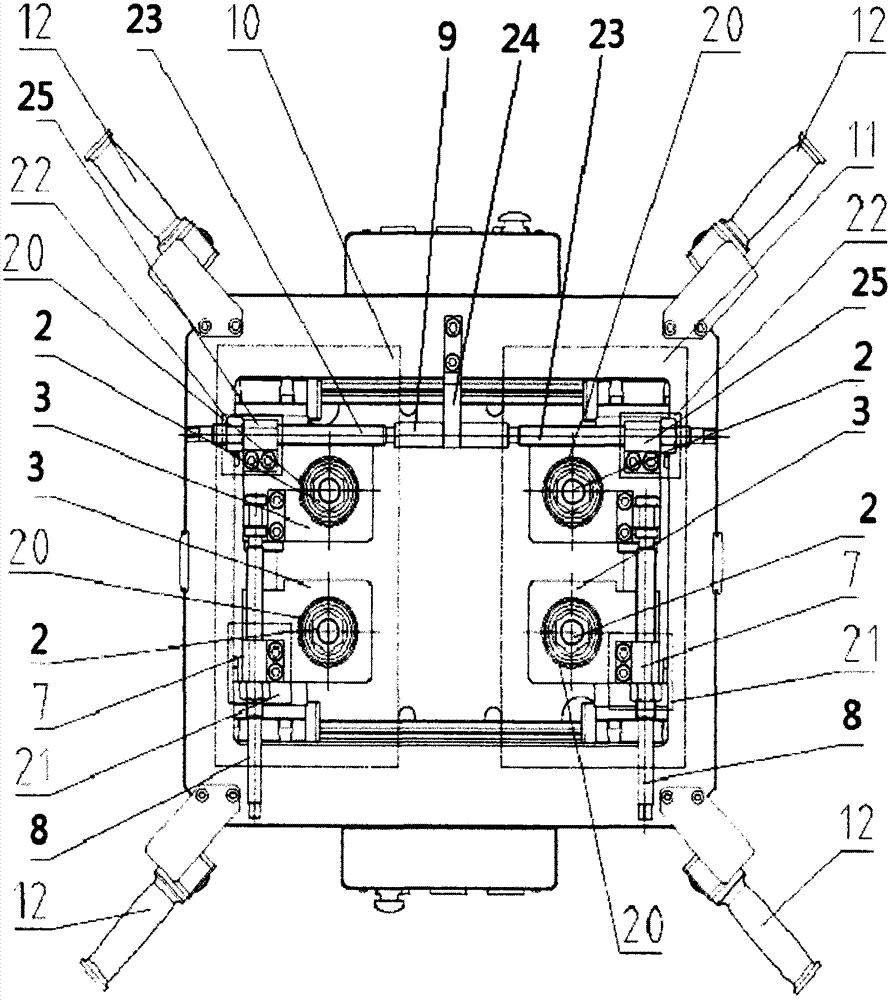

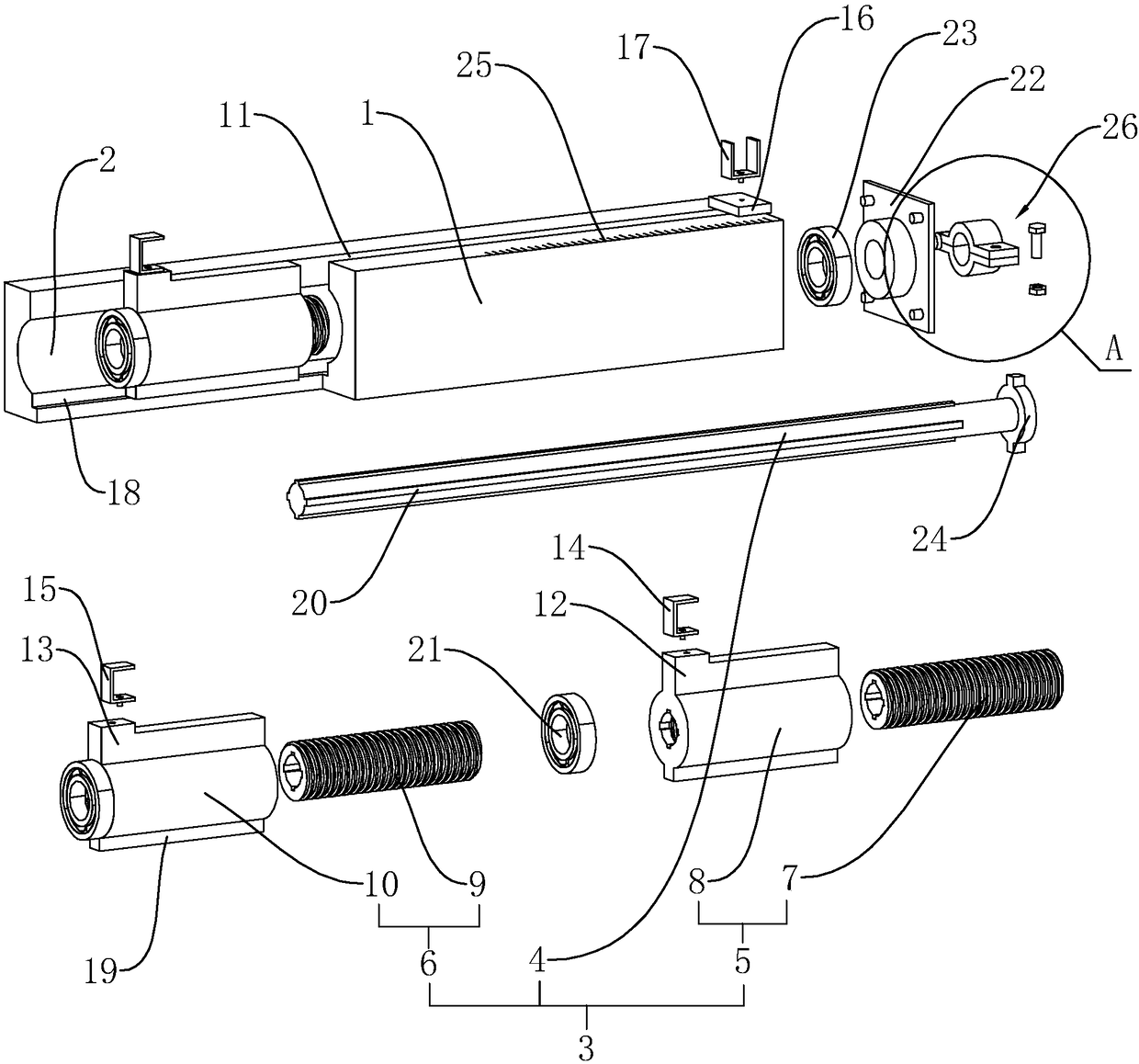

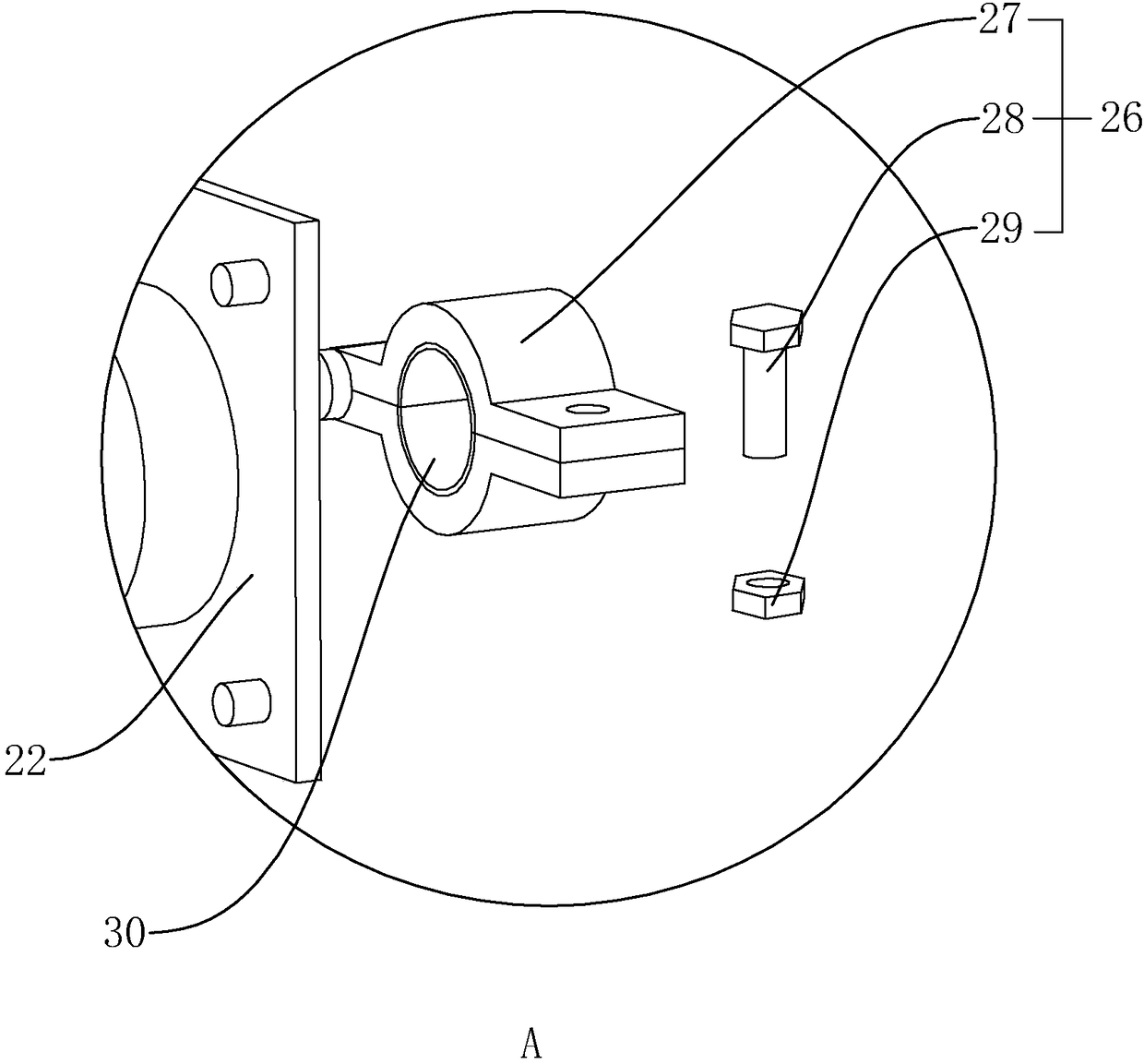

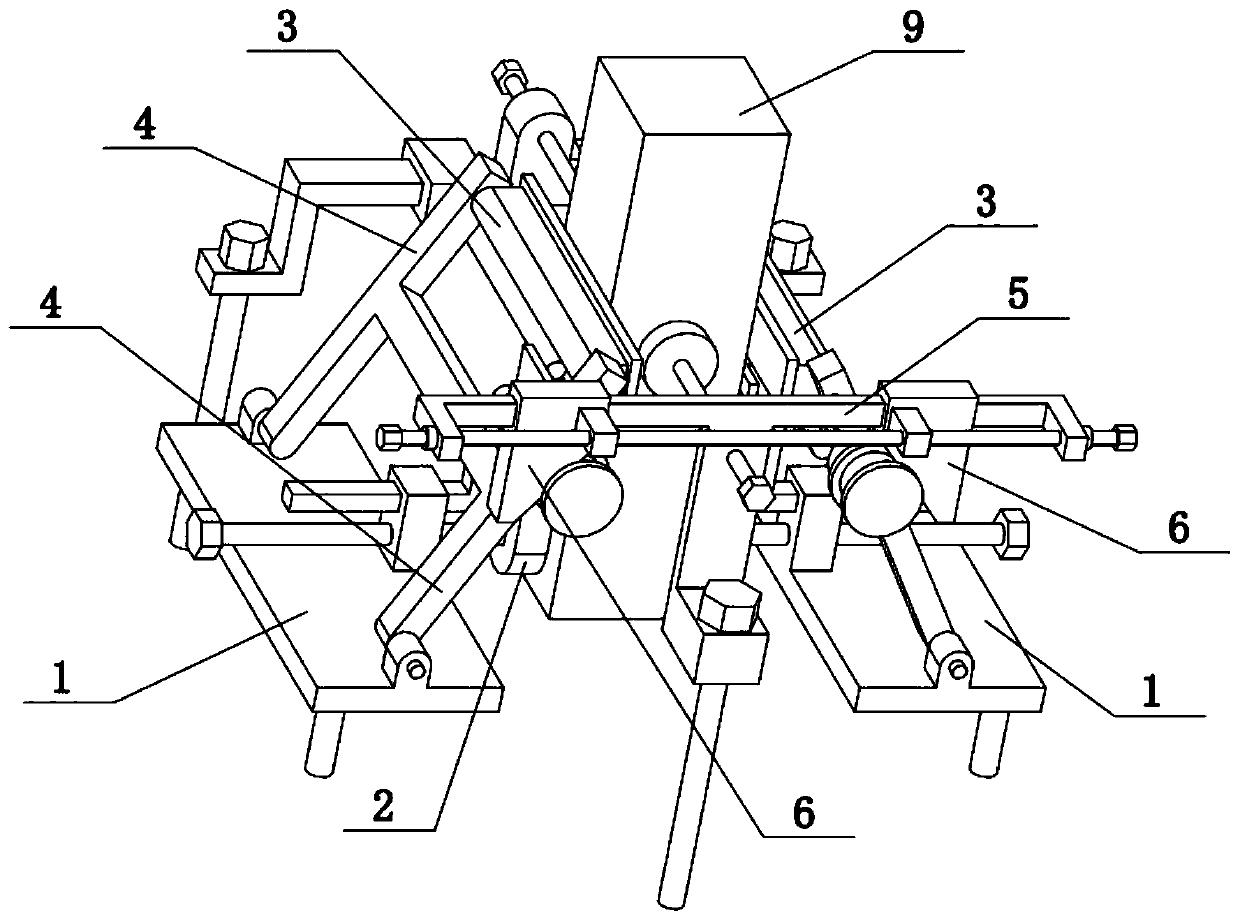

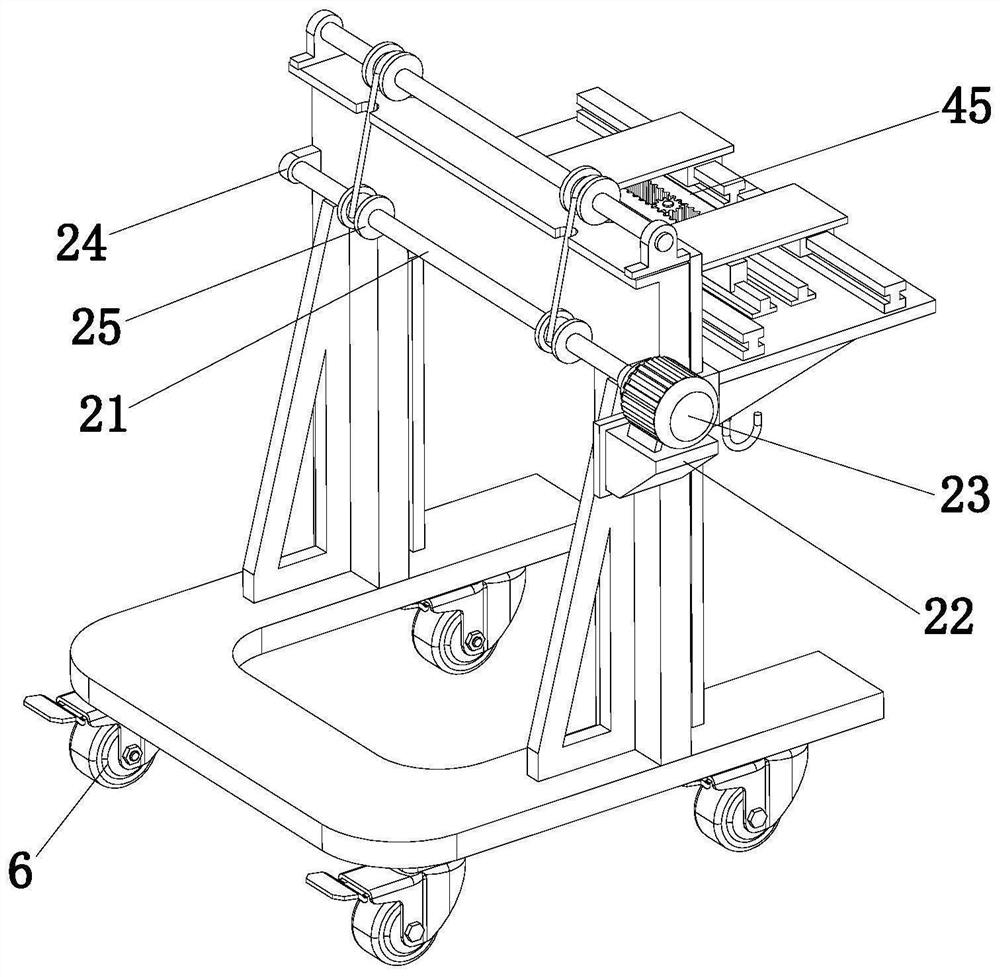

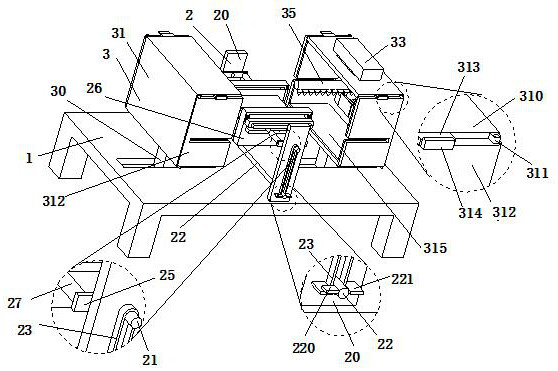

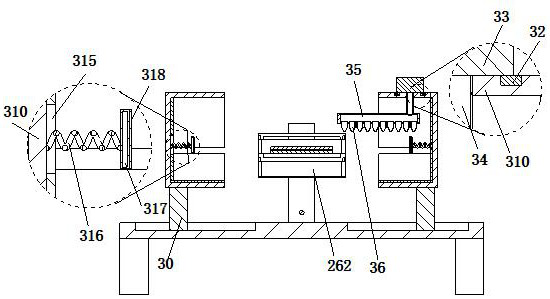

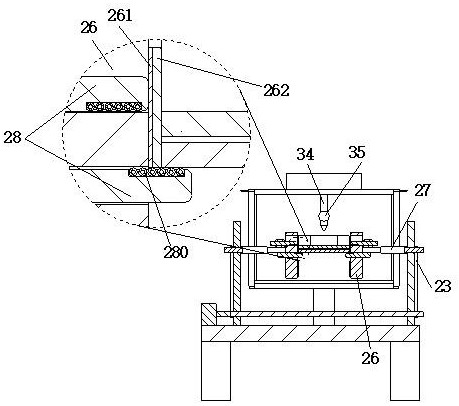

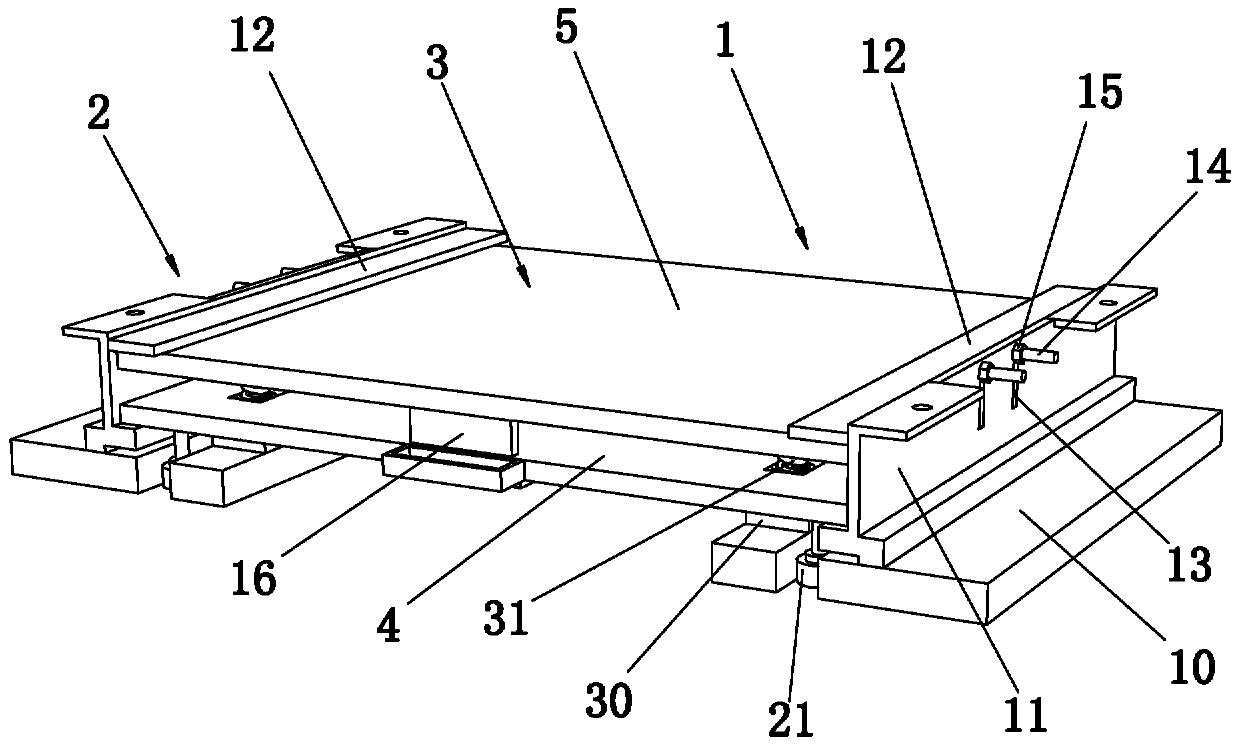

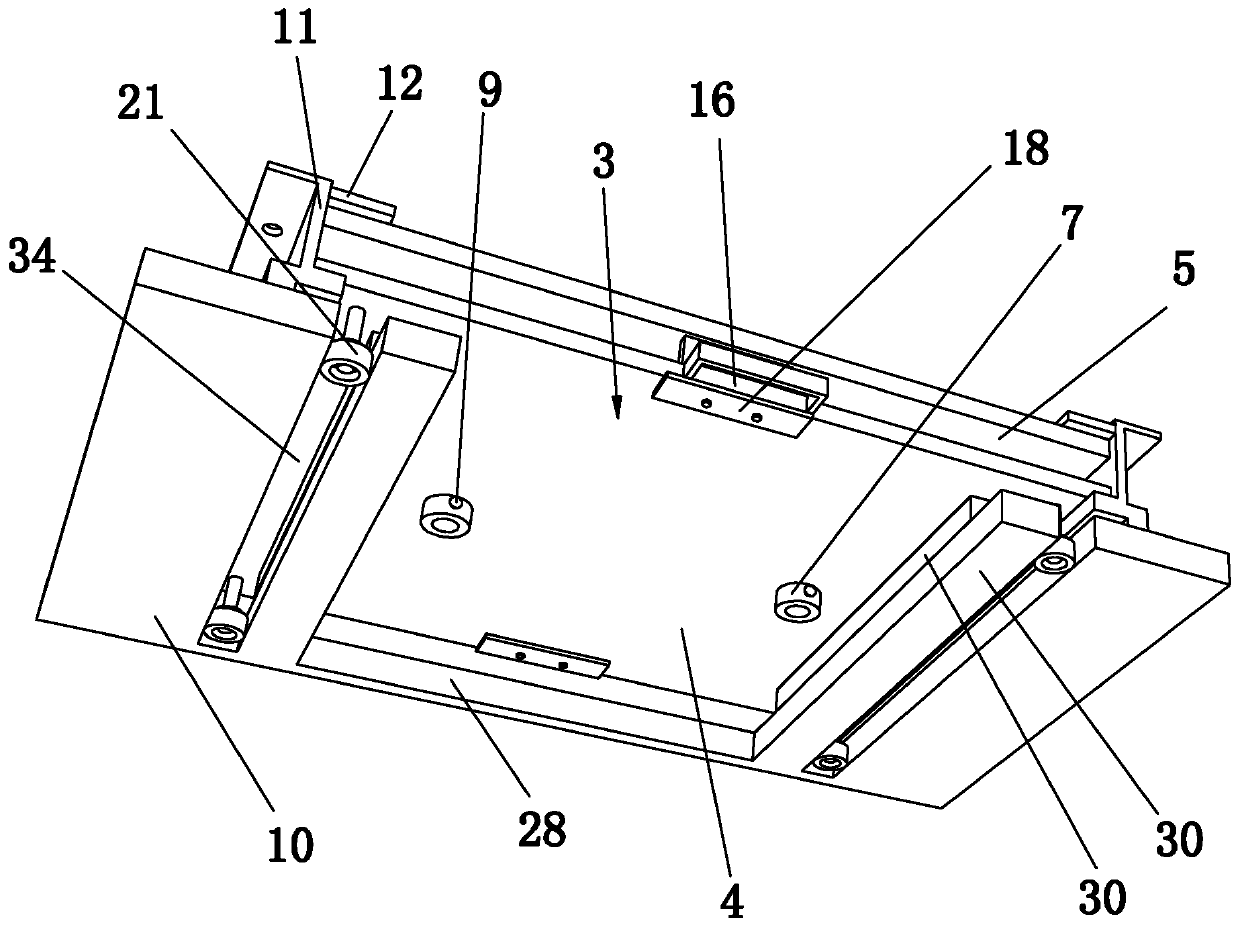

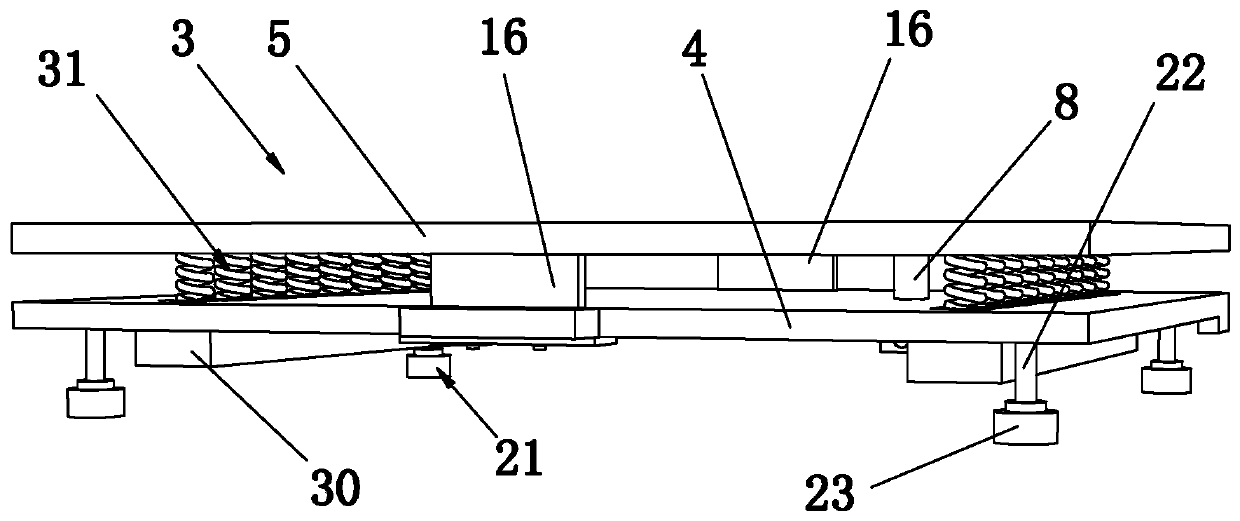

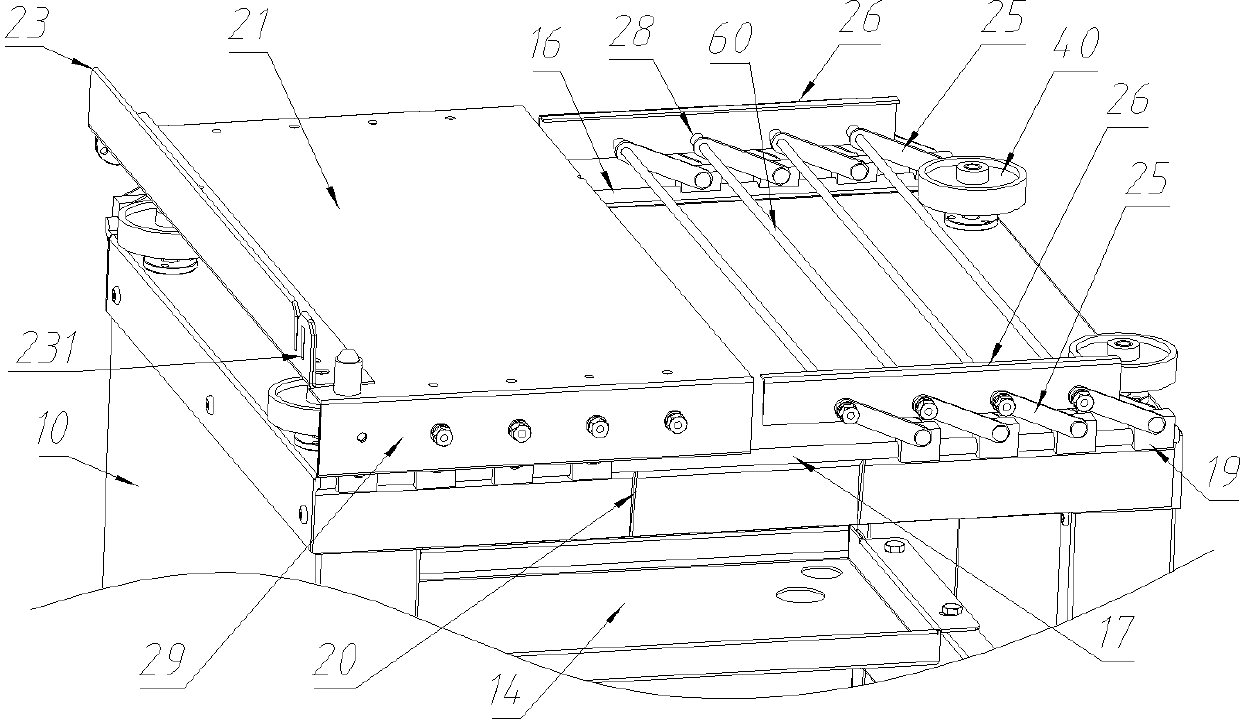

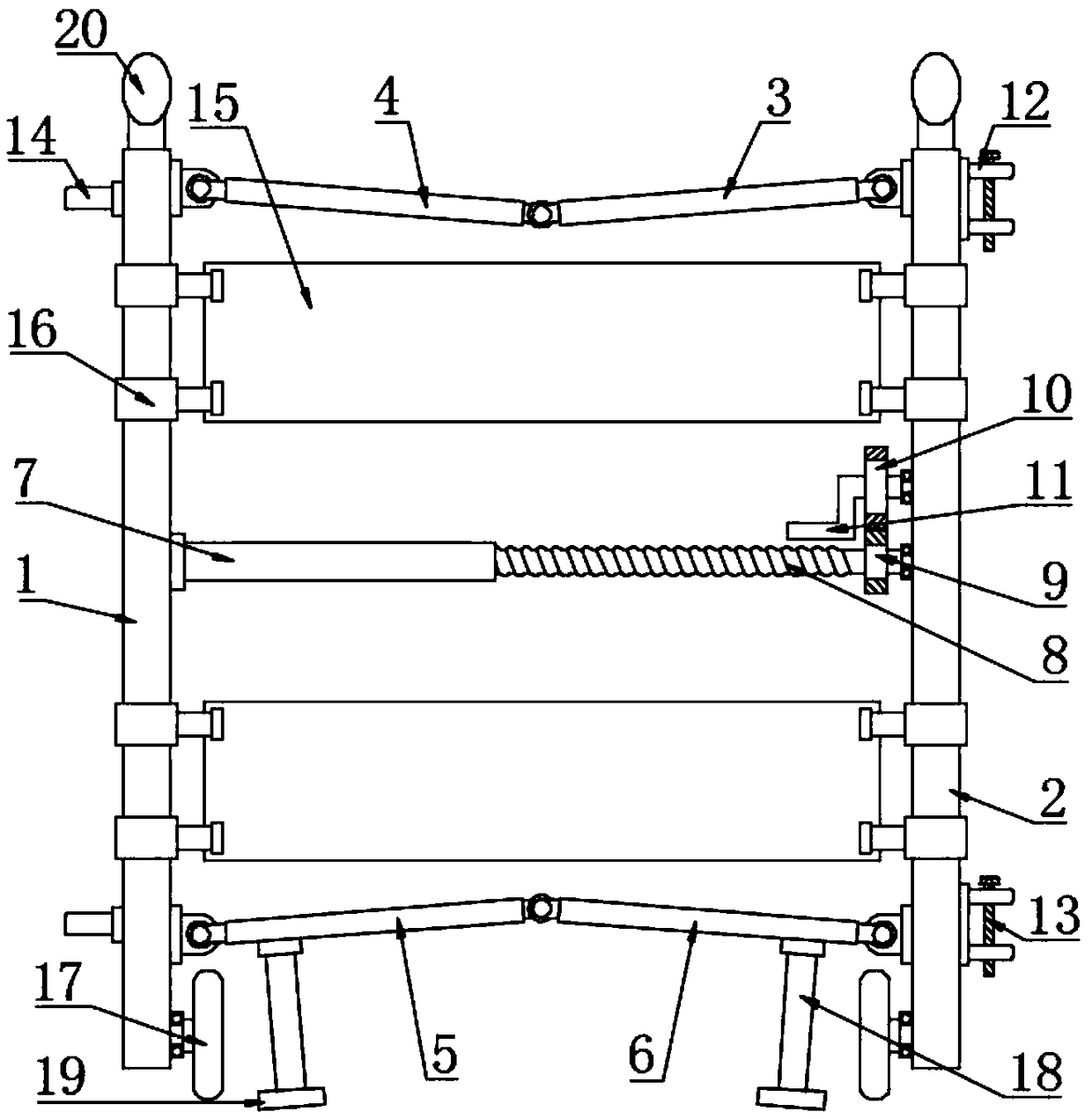

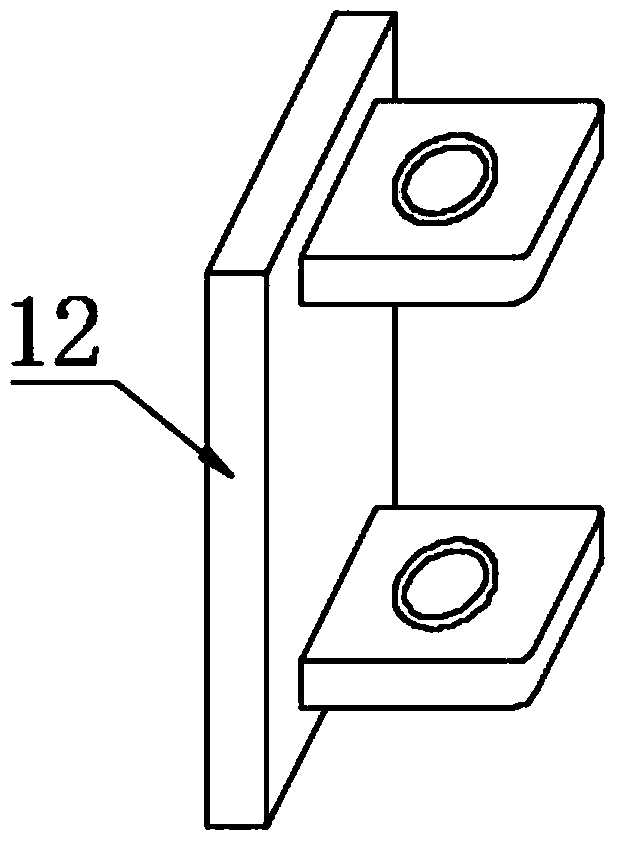

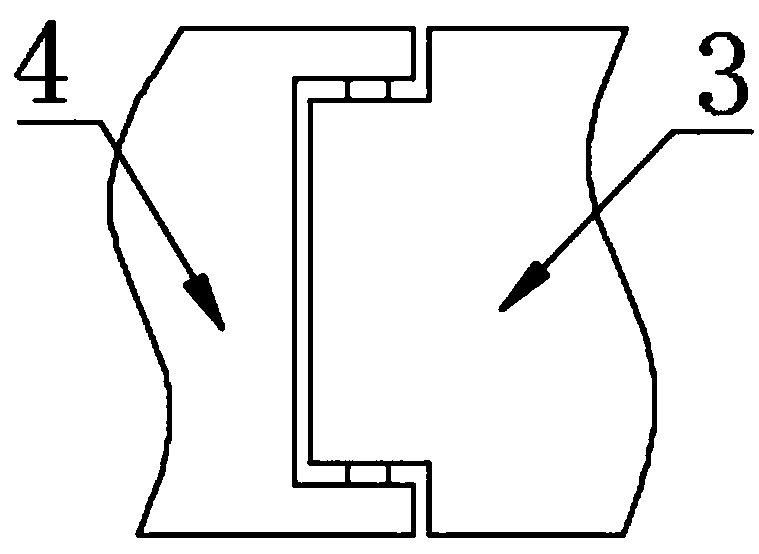

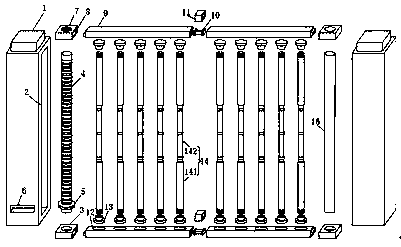

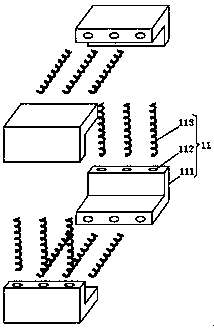

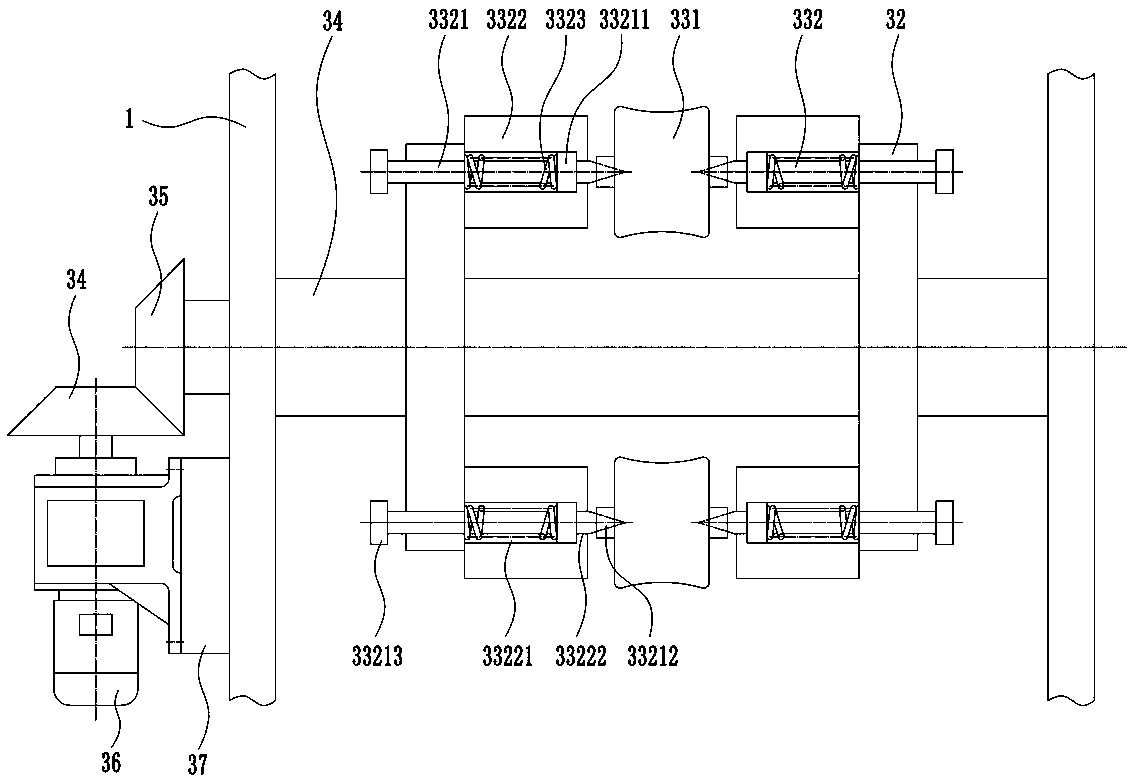

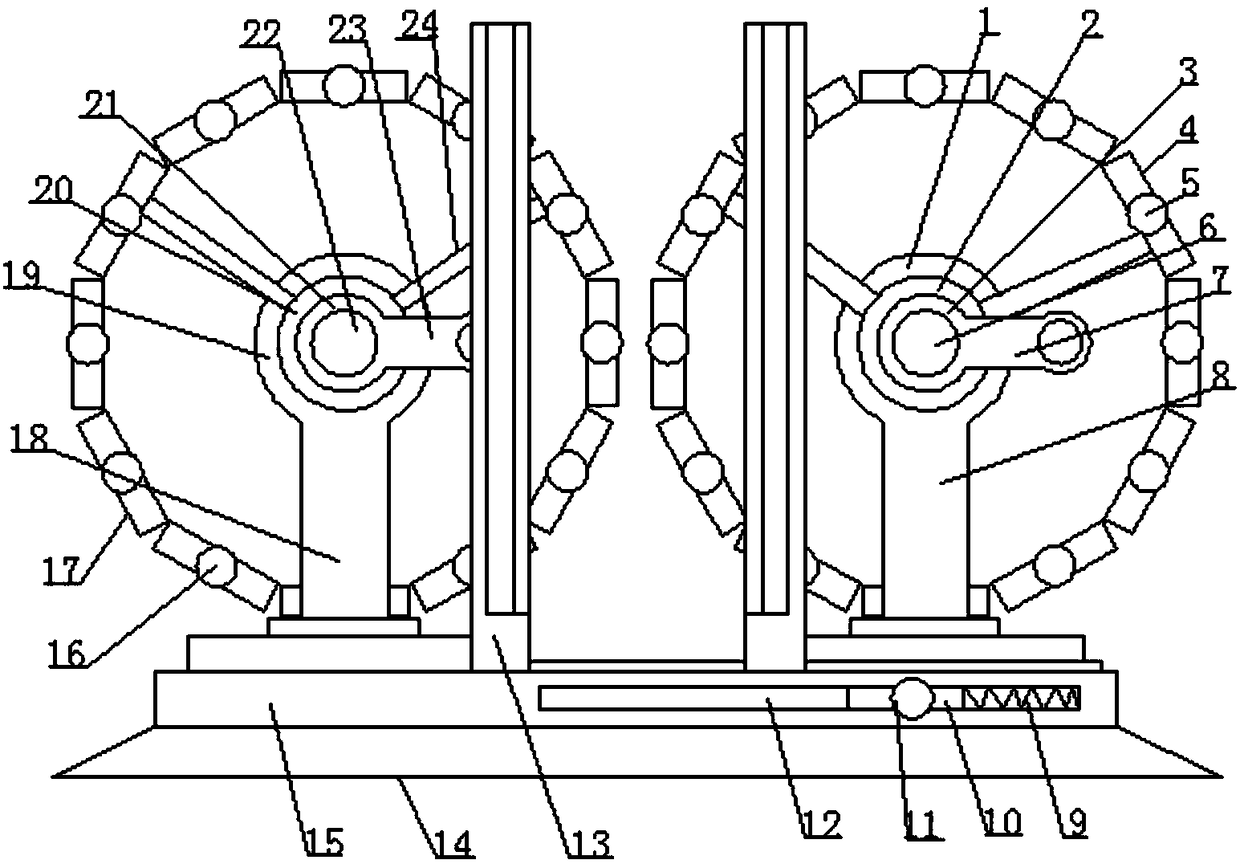

Four-shaft spacing-variable bolt tightening device

ActiveCN102756269ASpacing adjustmentSolve problems that cannot be guaranteedMetal working apparatusEngineeringMechanical engineering

The invention discloses a four-shaft spacing-variable bolt tightening device which comprises a vertical framework, four tightening shafts and fixed blocks, wherein the four tightening shafts are divided into two groups; the two tightening shafts are contained in each group; the two fixed blocks in the same group are connected with each other in series through a guide rod; the guide rods in the two groups are arranged in parallel; a first adjusting mechanism is arranged between the two fixed blocks in the same group of tightening shafts and used for adjusting a spacing between the tightening shafts in the same group; second adjusting mechanisms are arranged at the two ends of each guide rod, and are fixed on the vertical framework and used for adjusting the spacing between the two groups of the tightening shafts; and the adjusting direction of each first adjusting mechanism is vertical to that of each second adjusting mechanism. The four-shaft spacing-variable bolt tightening device has the benefits that the longitudinal and transverse distance adjustment of the four tightening shafts can be realized through the first adjusting mechanisms and the second adjusting mechanisms, the technical problems of large operating force, slow speed and uneasiness in operation in the multi-variety production and spacing adjusting processes are solved, and the tightening quality and the reliability are improved.

Owner:大连嘉禾自控技术有限公司

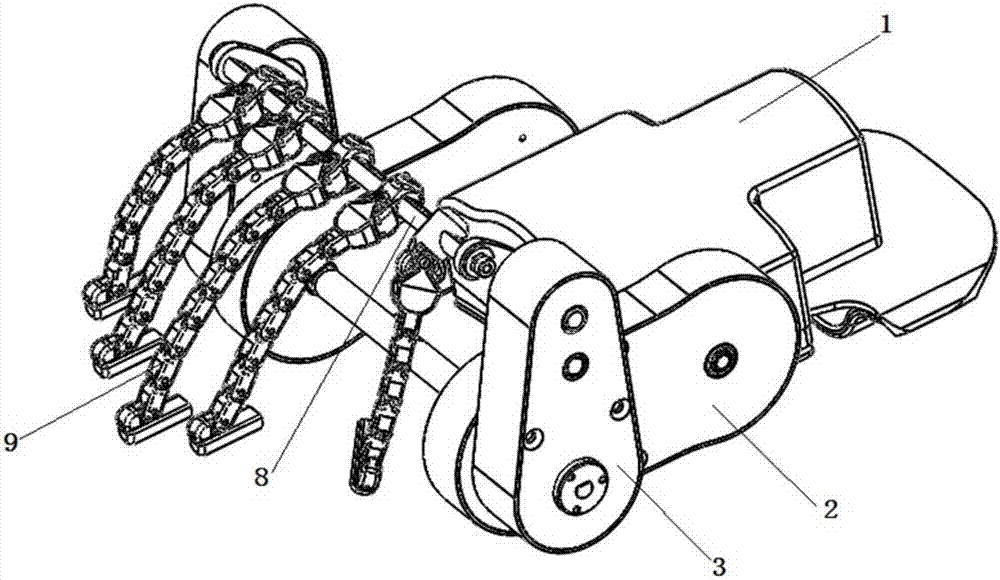

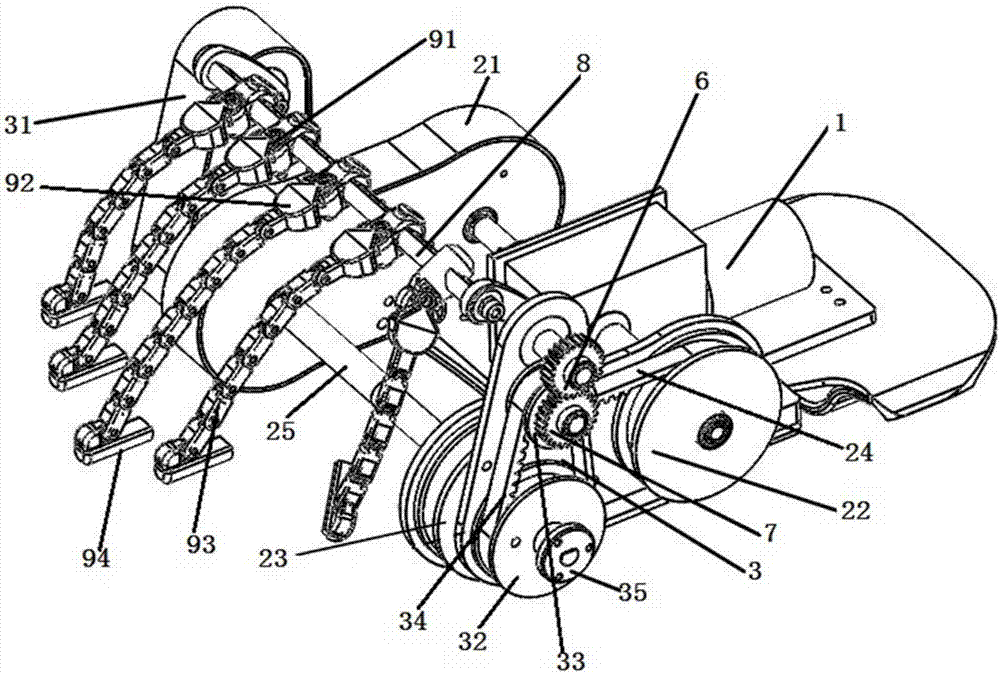

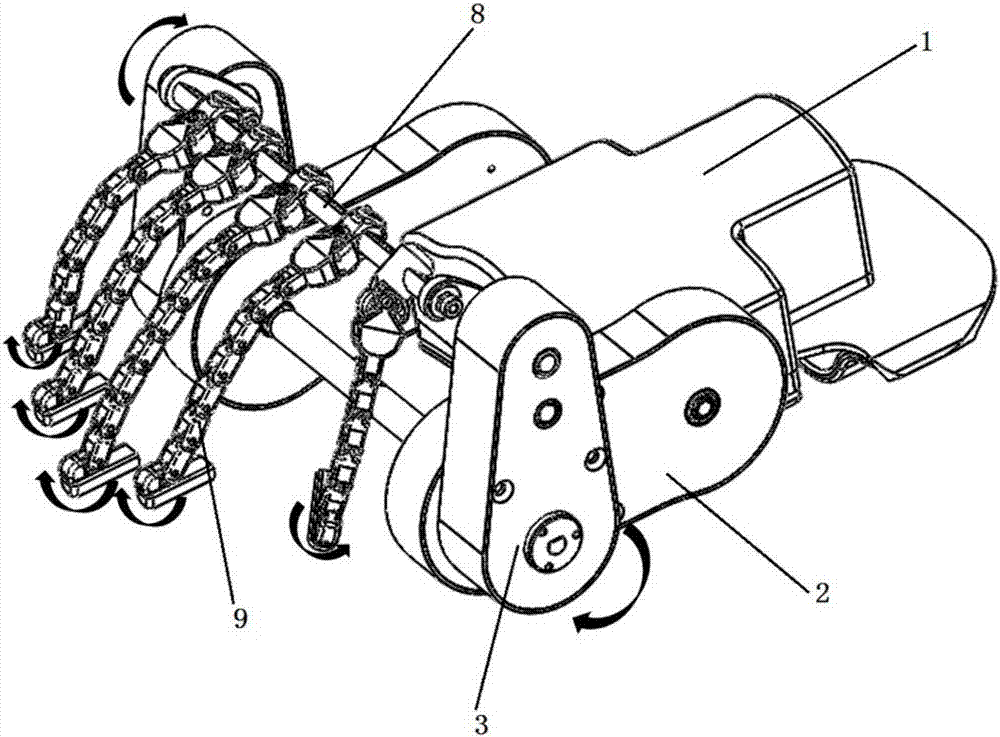

Flexible hand functional rehabilitation training device

ActiveCN107233188ASpacing adjustmentQuickly realize left and right hand interchangeChiropractic devicesIndependent motionHand parts

The invention relates to a flexible hand functional rehabilitation training device. The device comprises a double-shaft output speed reducer, a pair of first-stage synchronous belt drive mechanisms symmetrically arranged on the two sides of the speed reducer and in drive connection with the speed reducer, second-stage planet synchronous belt drive mechanisms in drive connection with the first-stage synchronous belt drive mechanisms, an adaptive adjusting bracket in drive connection with the second-stage planet synchronous belt drive mechanisms through gear sets, and finger flexible drive modules arranged on the adaptive adjusting bracket. Compared with the prior art, the overall structure is compact, the problems that hand rehabilitation of a stroke patient is difficult, and hand training can be carried out only by depending on professional doctors can be effectively solved, the current situation that existing hand rehabilitation equipment is poor in adaptability is broken through, left and right interchange can be achieved, rapid adjustment of the lengths of modules and the intervals between the modules is driven, and independent motion of thumb metacarpophalangeal joints, four-finger metacarpophalangeal joints and proximal interphalangeal joints under a lightweight structure can be achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

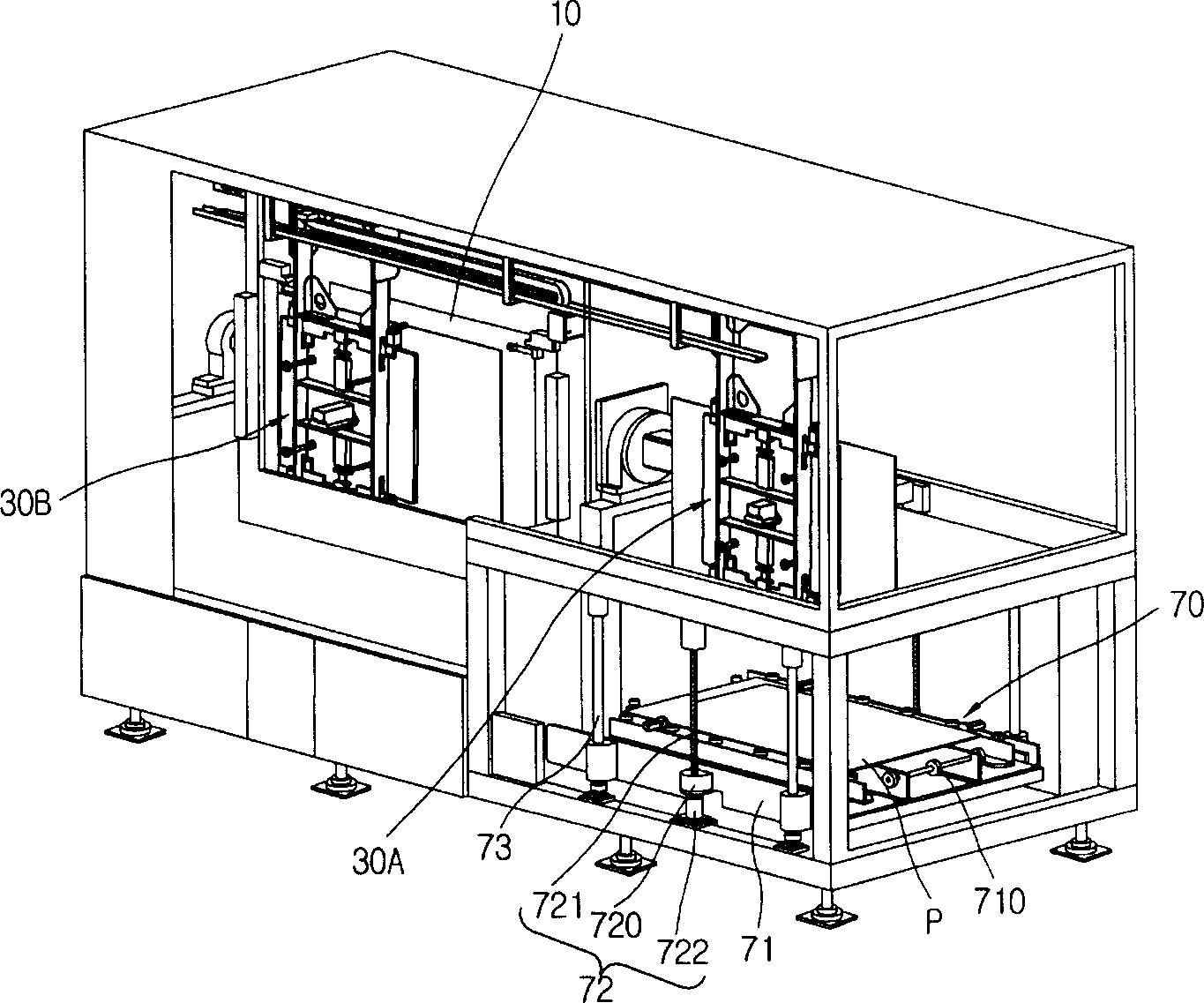

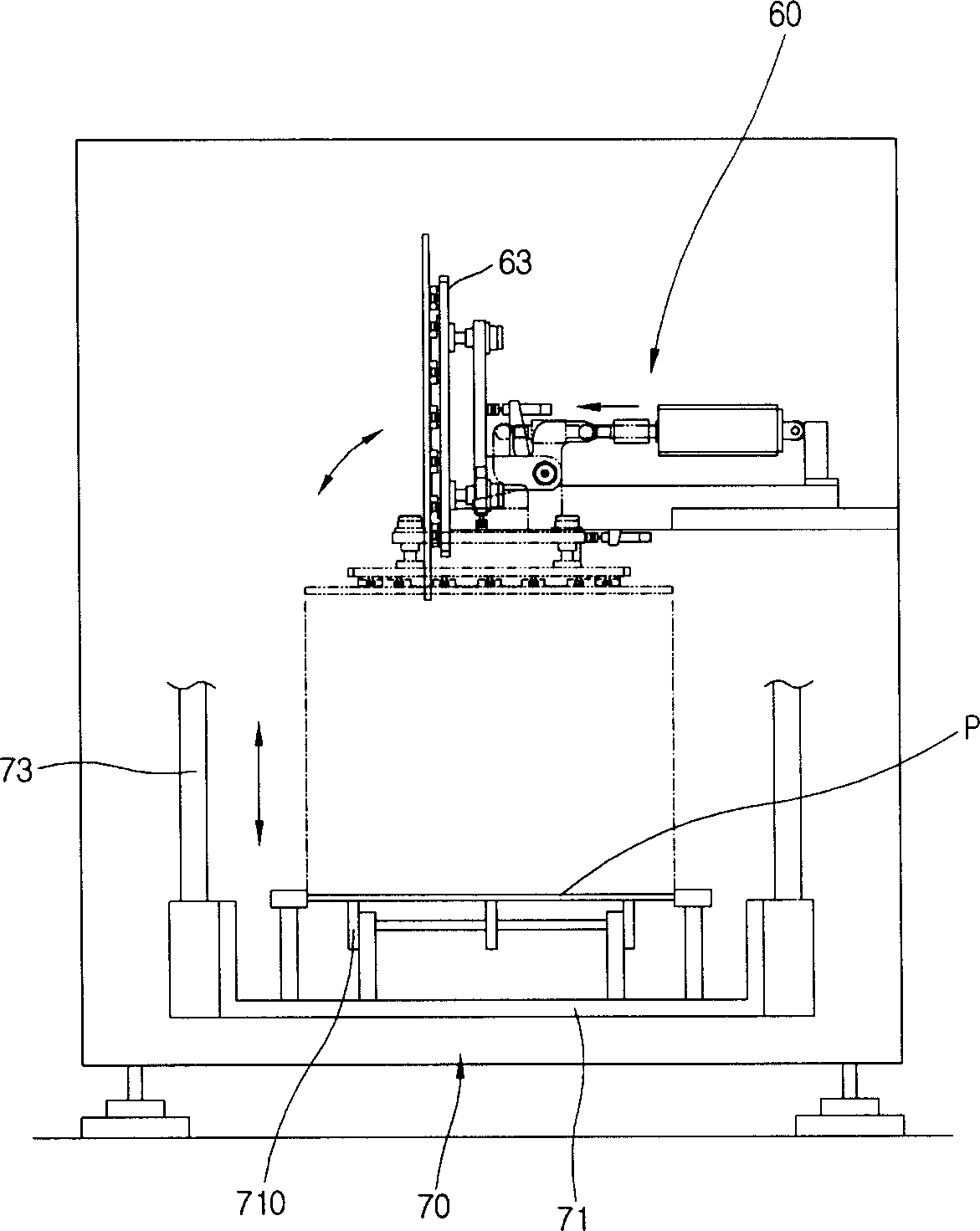

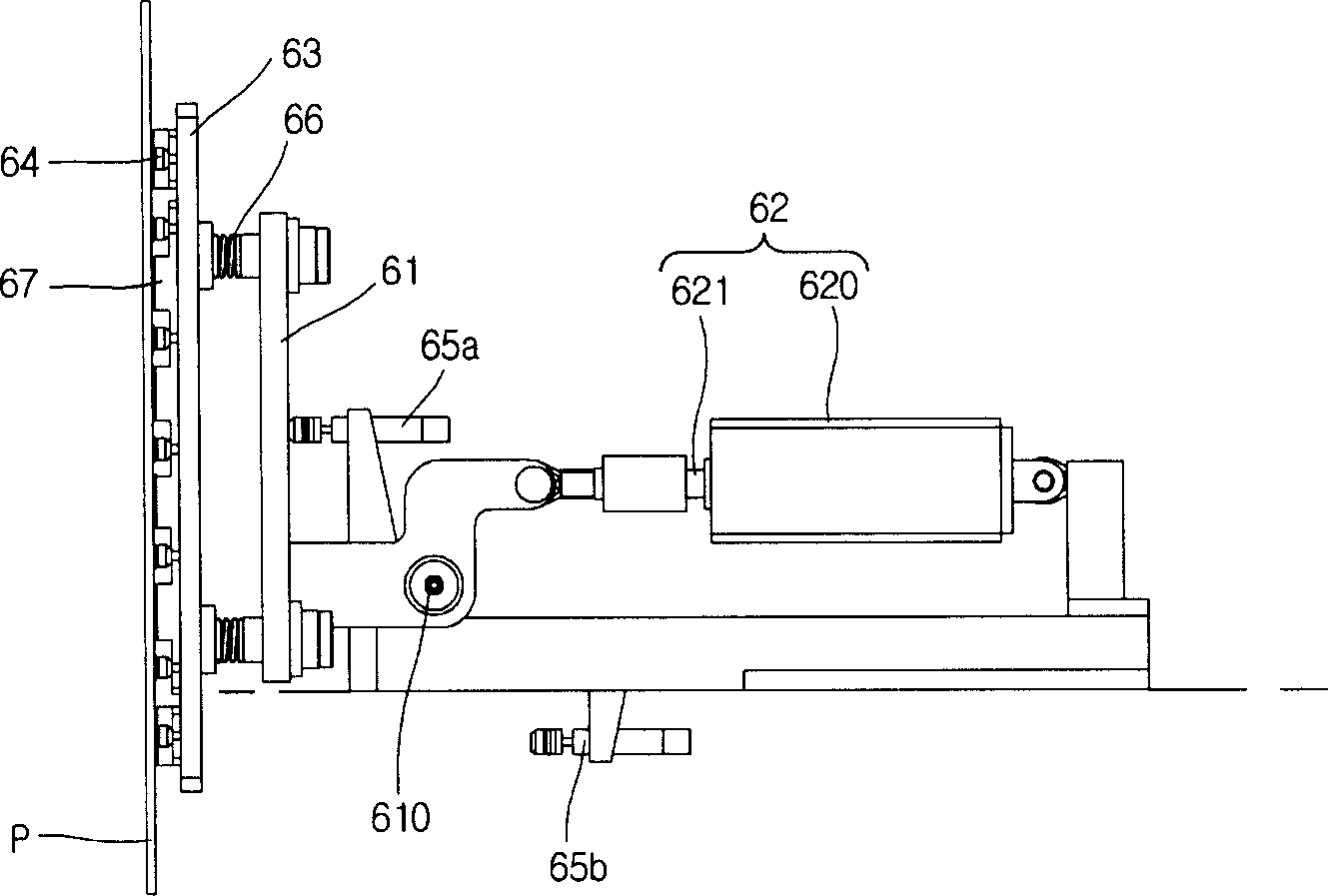

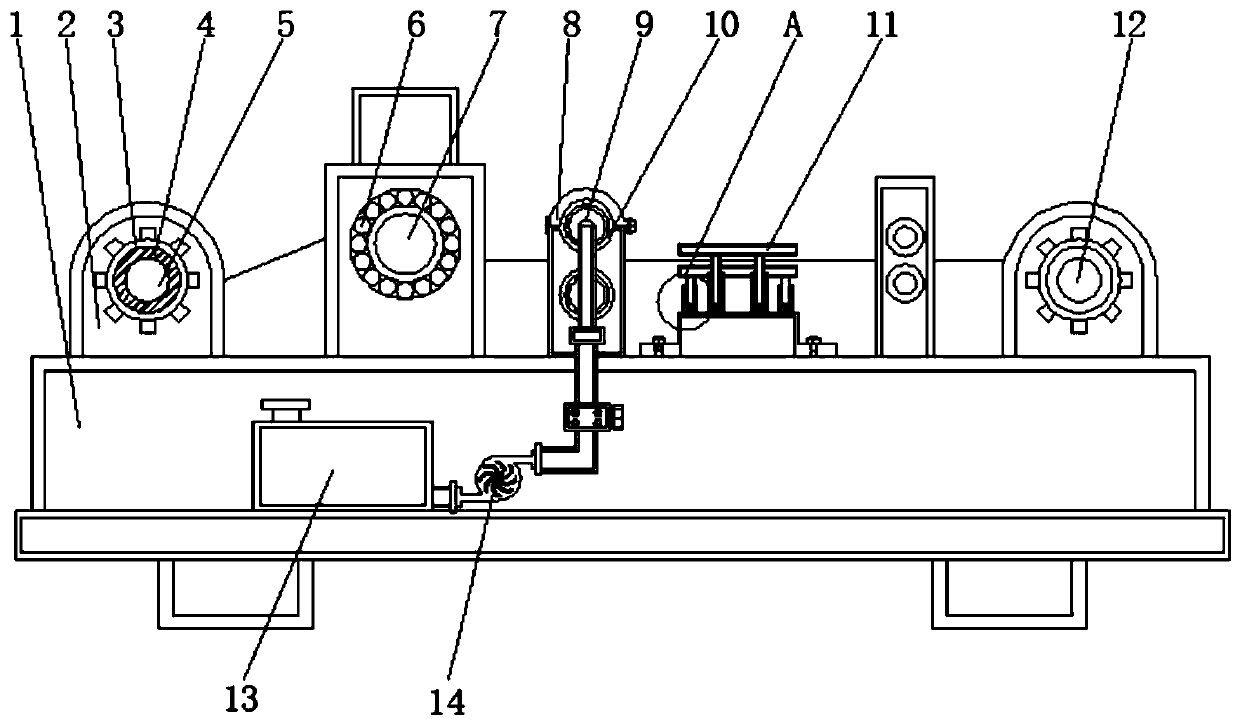

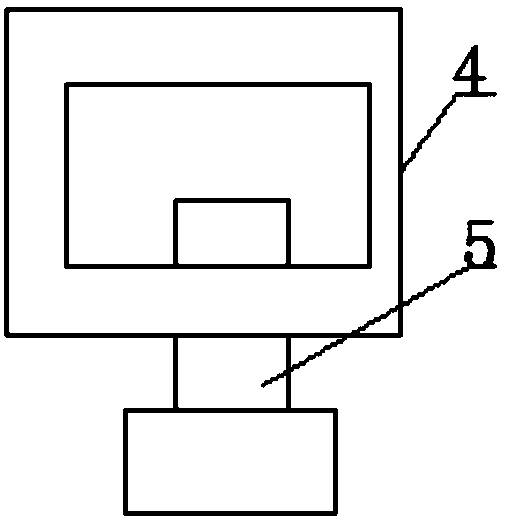

Detector of flat-board display

InactiveCN1677178AReduce impactPrevent disengagementStatic indicating devicesAlternating current plasma display panelsReciprocating motionDisplay device

The present invention provides a flat panel display tester comprising a testing unit including a stage for mounting panels thereon, a panel-conveying unit for separating a tested panel from the stage and simultaneously for feeding an untested panel onto the stage, and a panel-feed unit for discharging the tested panel conveyed by the panel-conveying unit to the outside and for transferring the untested panel to the panel-conveying unit, wherein the panel-conveying unit includes a pair of rails horizontally arranged between the stage and the panel-feed unit; first and second carriers respectively installed on the rails and reciprocating so that panels conveyed along the first and second carriers cross each other; and loaders, respectively provided on the first and second carriers, moving to the stage and the panel-feed unit for directly loading and unloading the panels and then returning to a stand-by state. The flat panel display tester remarkably improves efficiency and productivity of a testing process compared to a conventional flat panel display tester.

Owner:DE&T

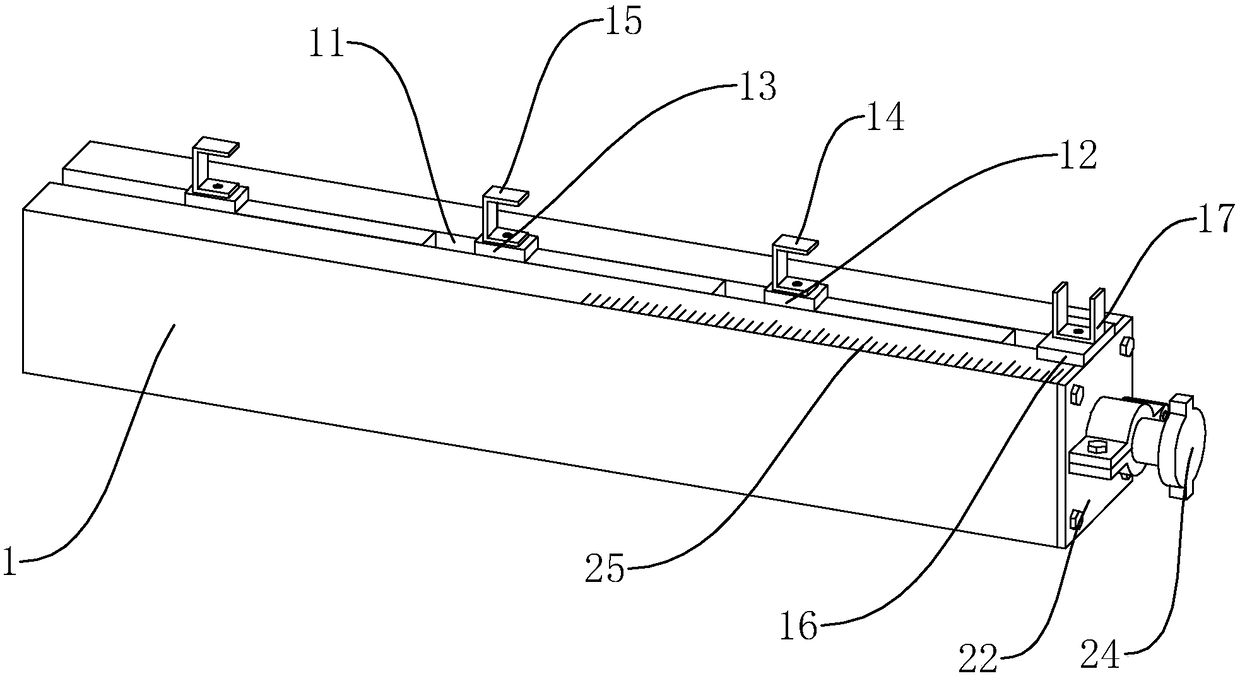

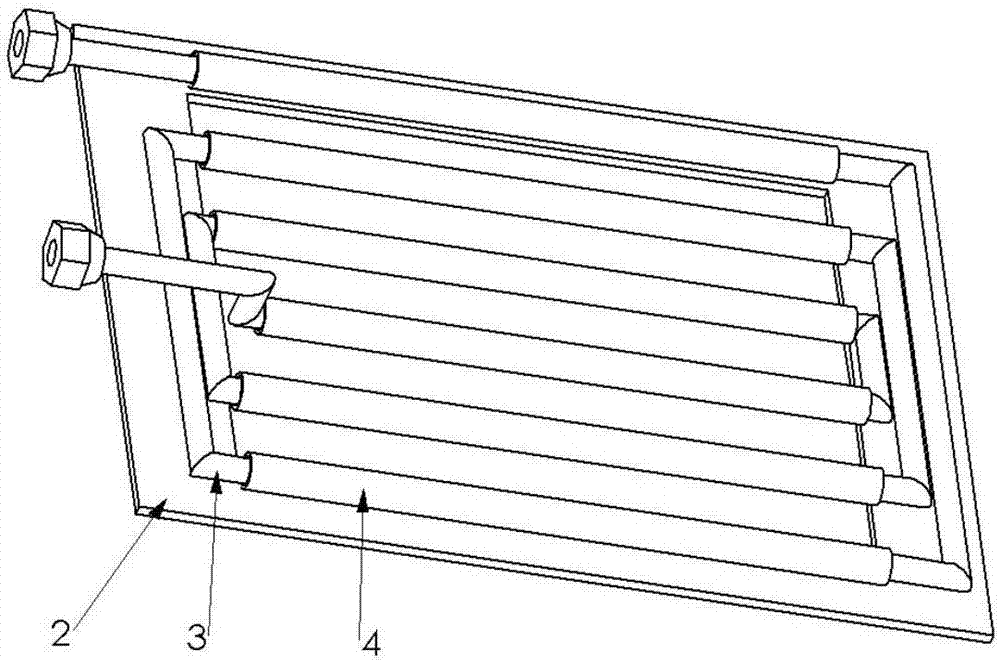

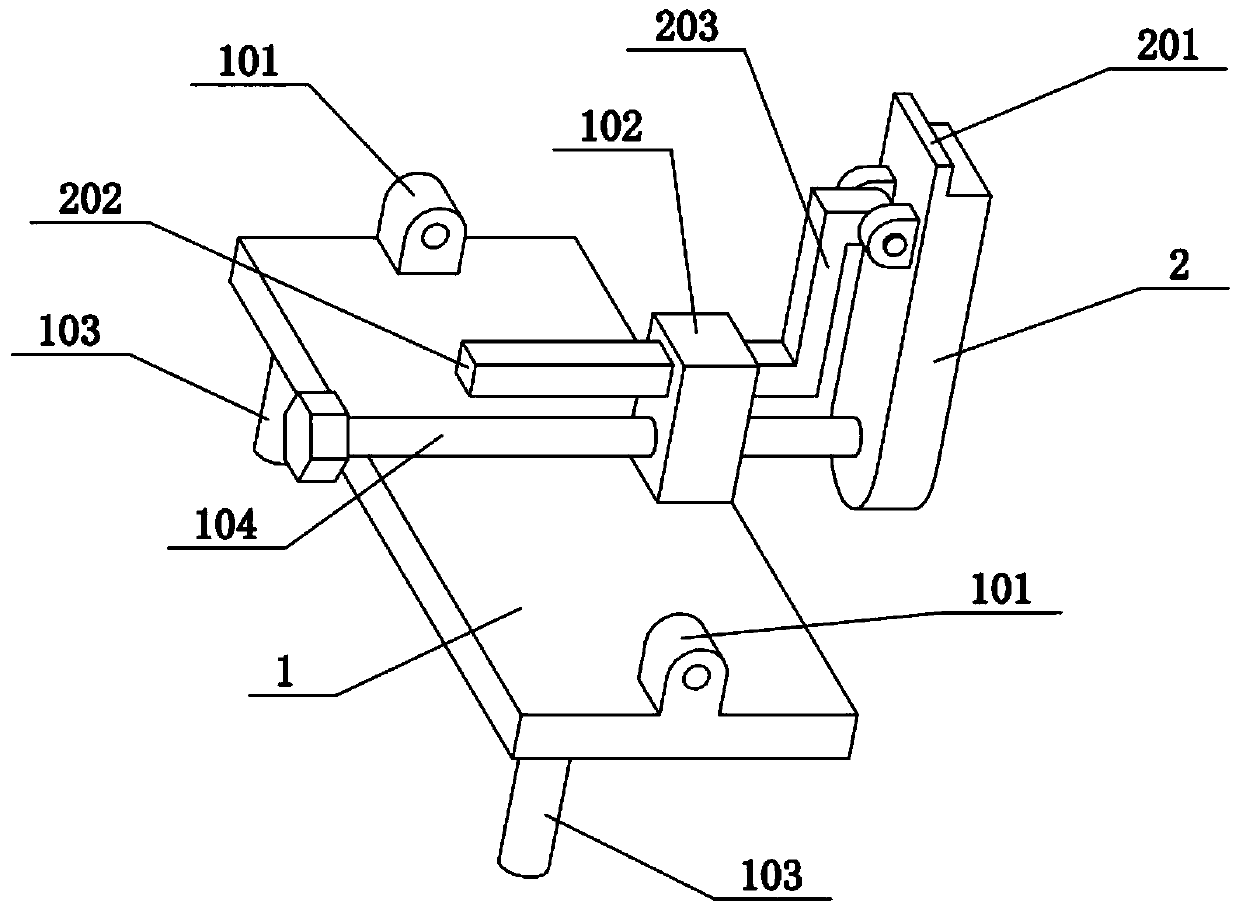

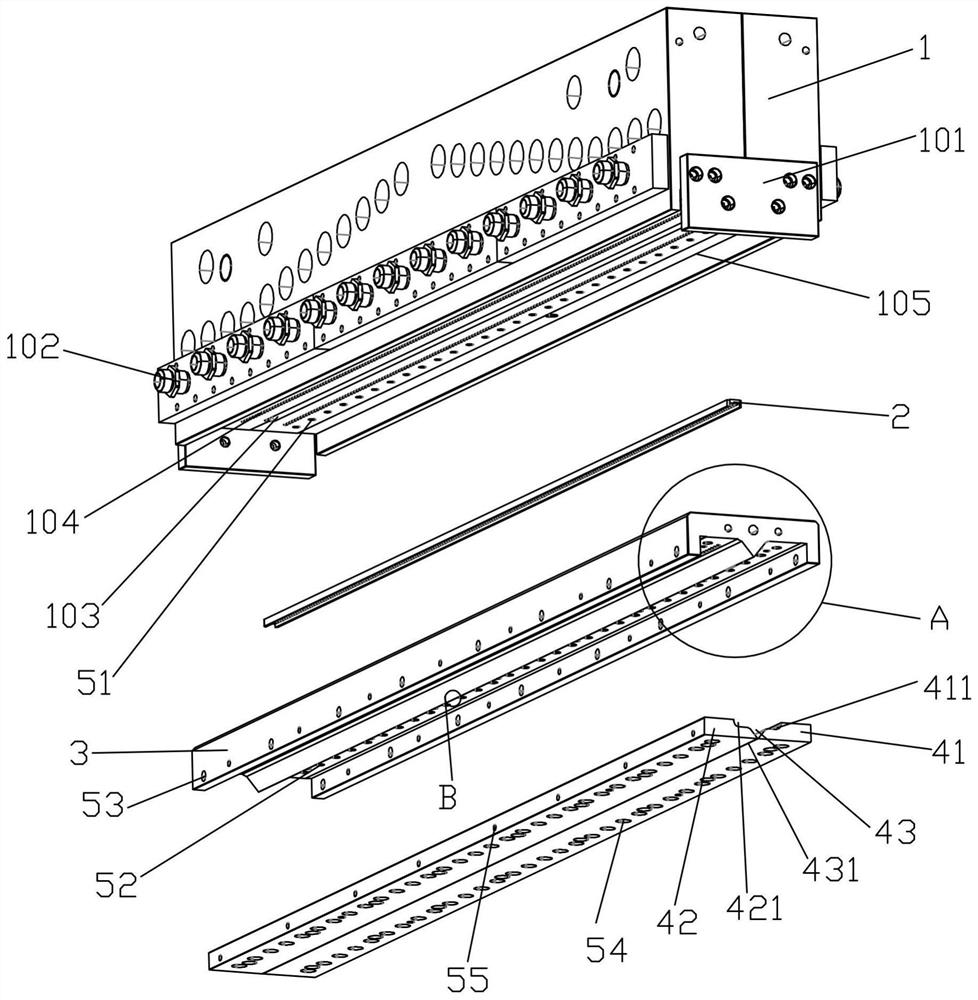

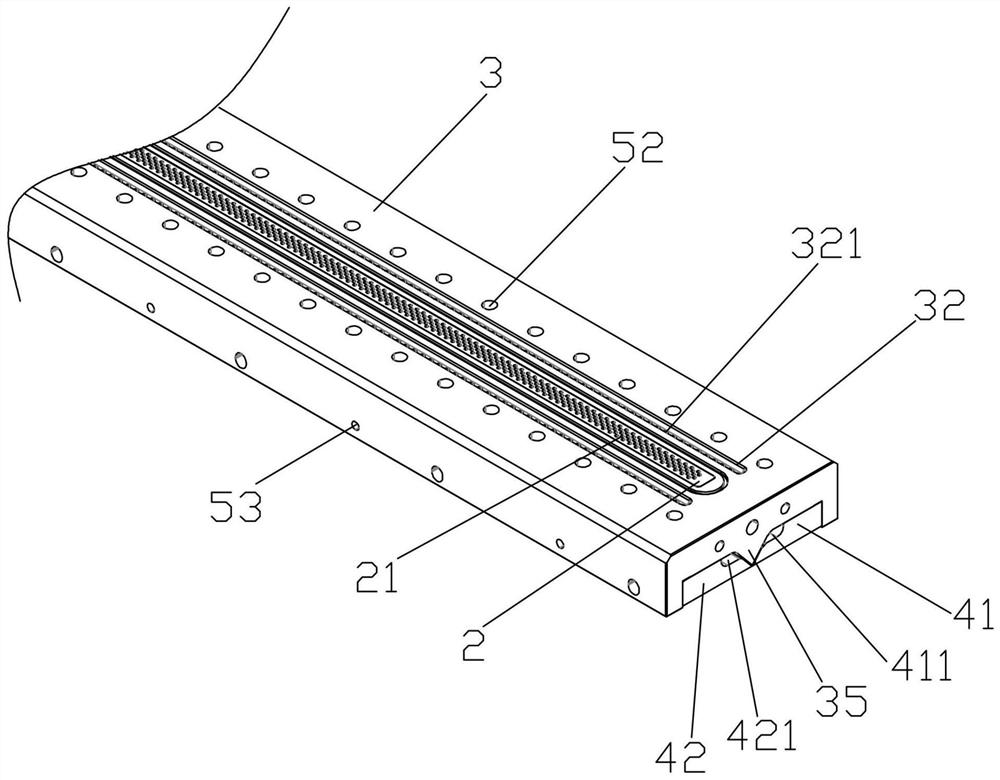

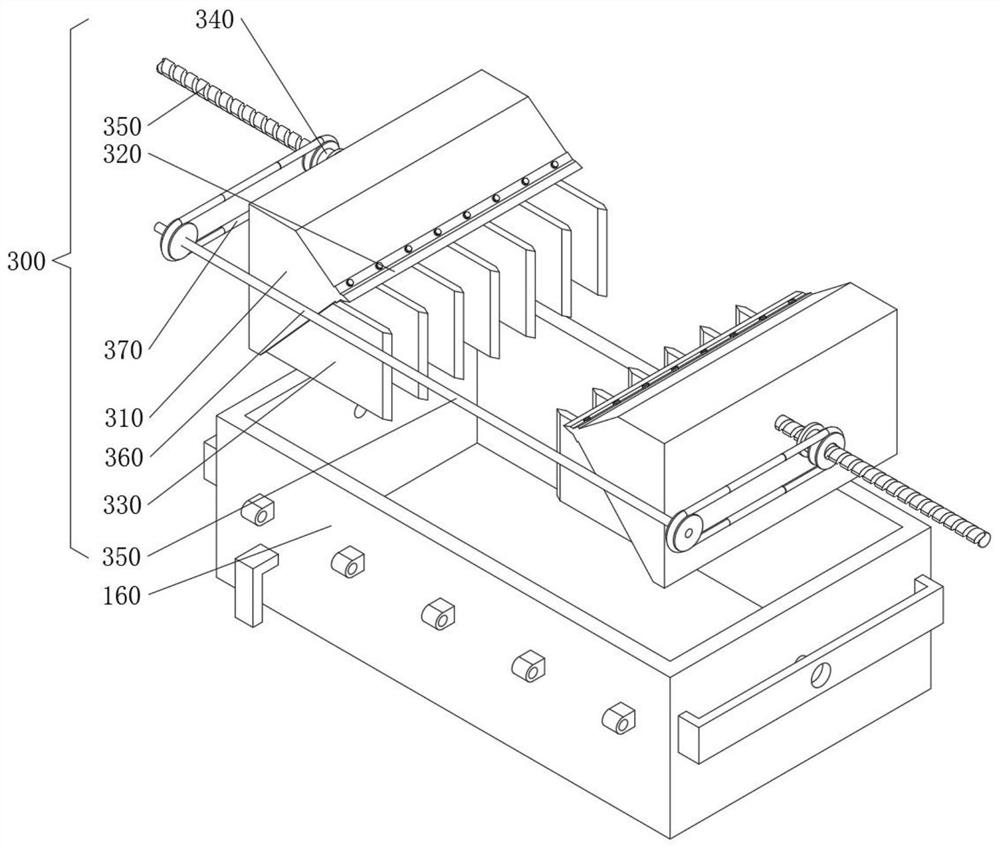

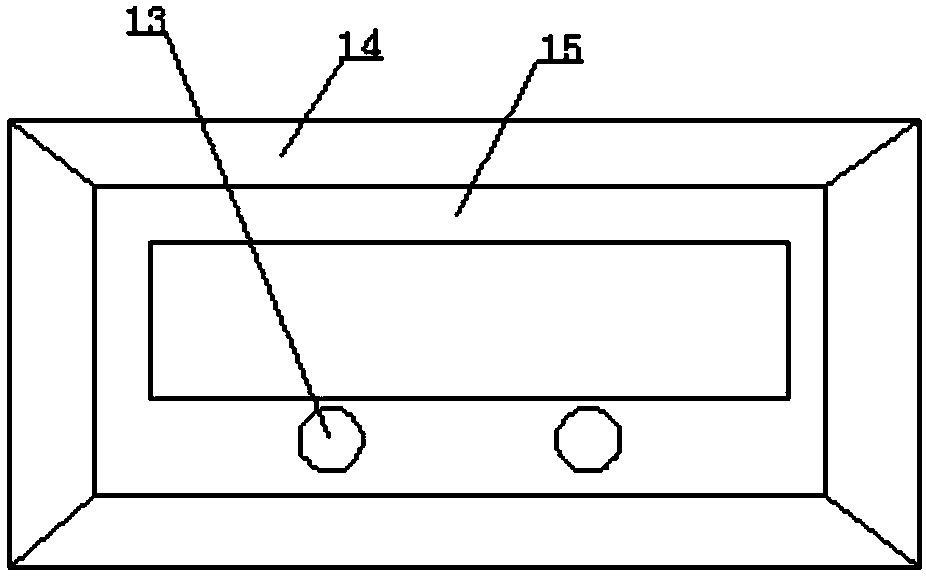

Steel bar interval adjusting device

The invention discloses a steel bar interval adjusting device. The steel bar interval adjusting device comprises an adjusting seat and a displacement adjusting device arranged on the adjusting seat. The displacement adjusting device comprises a center shaft arranged in the length direction of the adjusting seat and further comprises a main lead screw and an auxiliary lead screw which are arrangedon the center shaft in a penetrating mode side by side, the main lead screw and the auxiliary screw are provided with a main rod sleeve and an auxiliary rod sleeve correspondingly, and a connecting bearing is arranged between the main rod sleeve and the auxiliary lead screw. Steel bars are limited on the adjusting seat, the main rod sleeve and the auxiliary rod sleeve correspondingly, when rotating, the center shaft drives the main lead screw and the auxiliary lead screw to jointly rotate, and thus the main rod sleeve and the auxiliary rod sleeve move in the same direction relative to the mainlead screw and the auxiliary lead screw. When moving, the main rod sleeve drives the auxiliary lead screw to move in the same direction, thus the auxiliary rod sleeve moves by the same distance relative to the main rod sleeve while the main rod sleeve moves relative to the adjusting seat, and the effects that the intervals between the adjacent steel bars are the same while the intervals between the steel bars are adjusted are achieved.

Owner:SANJIAN CONSTR ENG GROUP

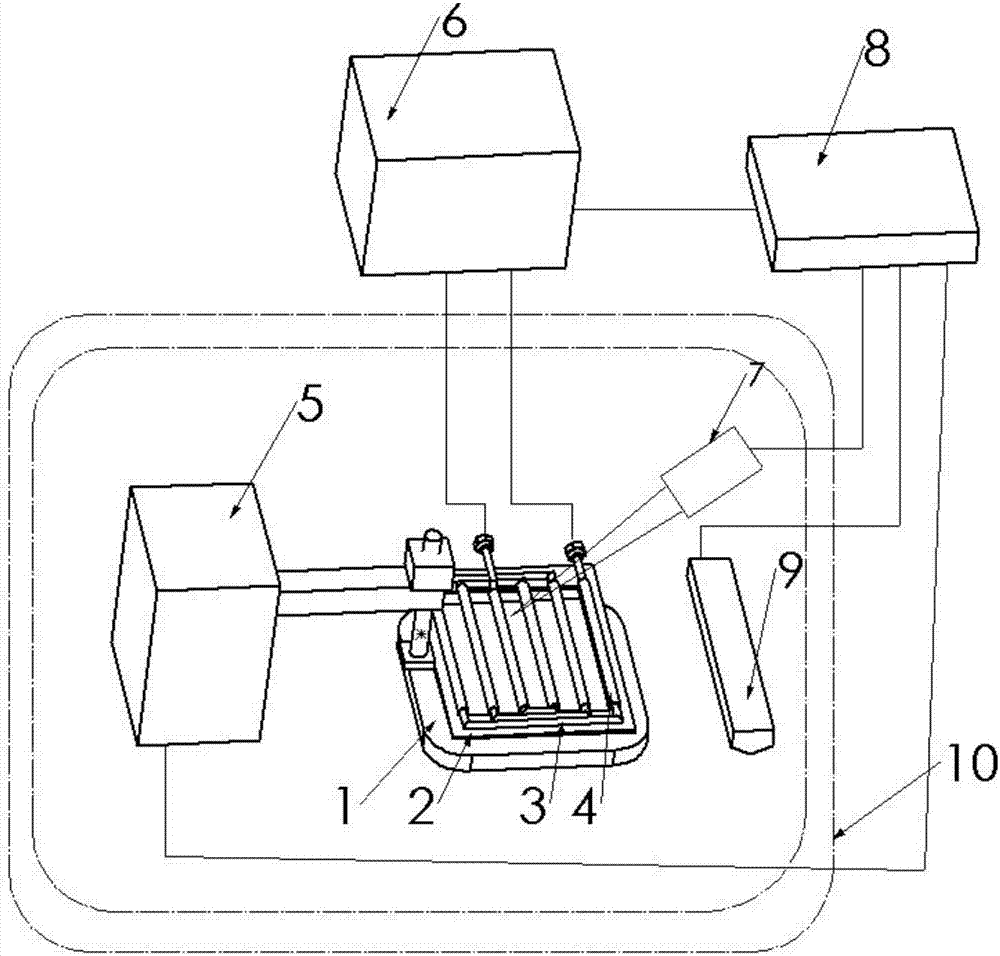

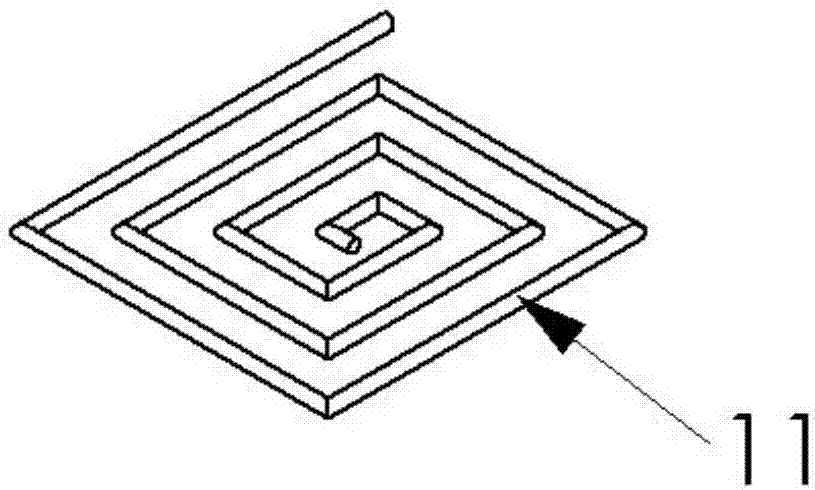

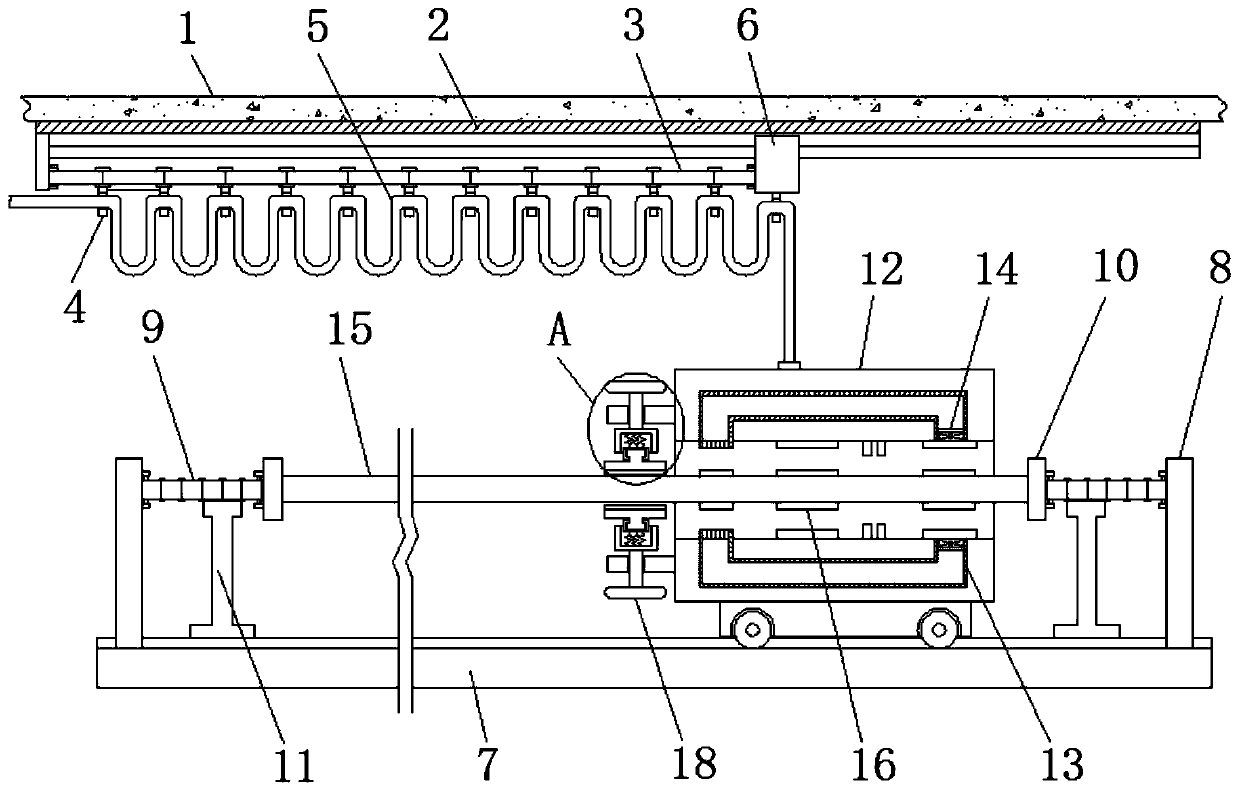

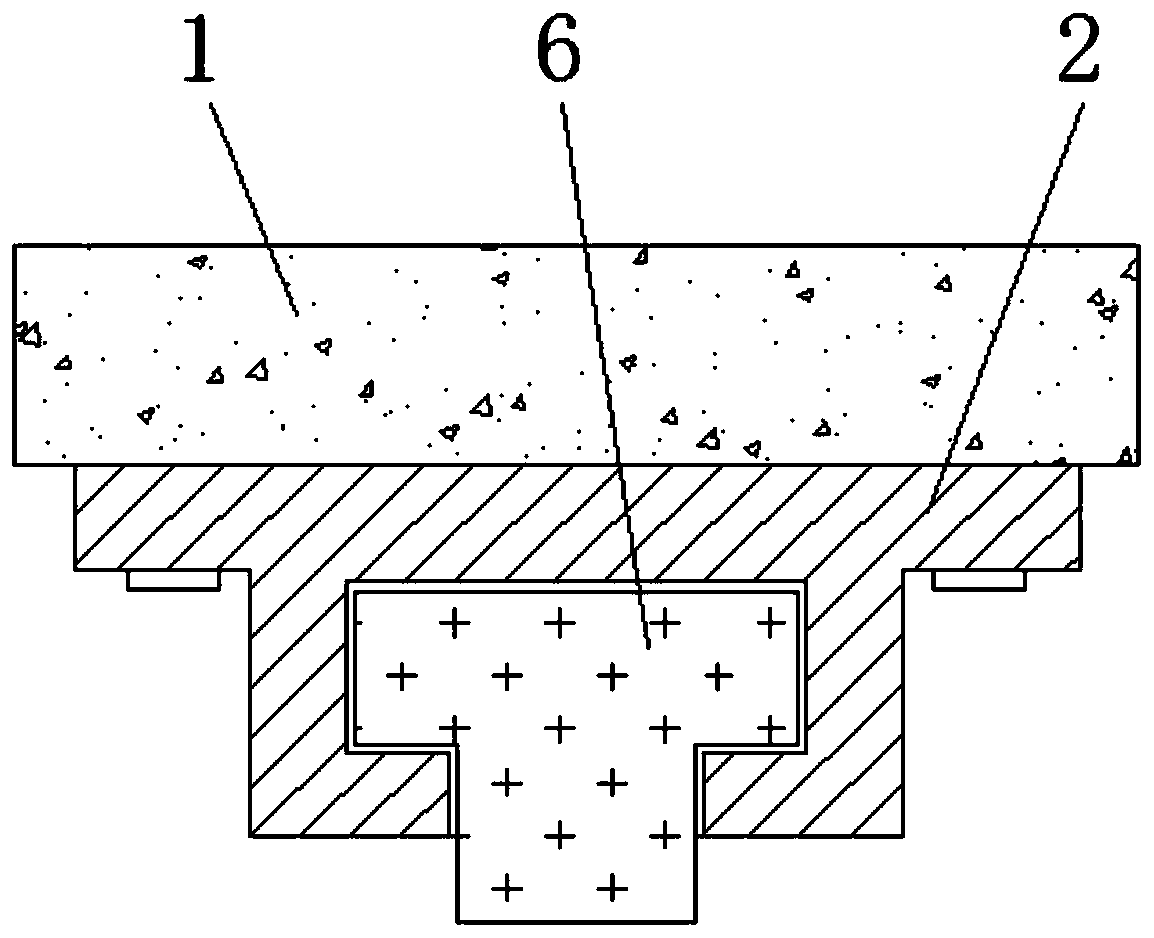

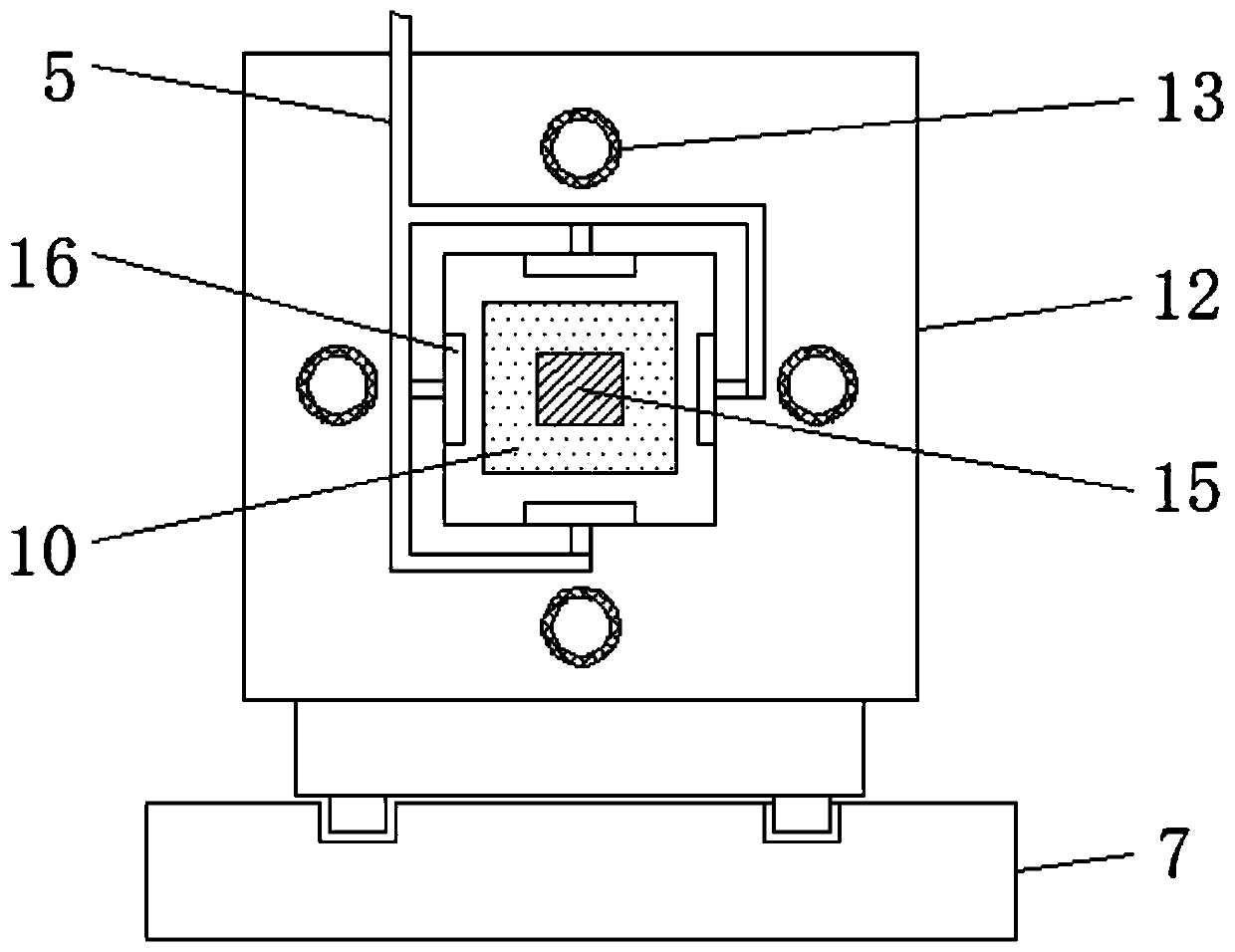

Electromagnetic induction selective laser melting powder bed on-line heating system and method

InactiveCN106903311AGuaranteed continuous heatingRealize online annealingManufacturing heating elementsIncreasing energy efficiencySelective laser meltingIntermediate frequency

The invention discloses an electromagnetic induction selective laser melting powder bed on-line heating system and an electromagnetic induction selective laser melting powder bed on-line heating method. The system comprises a powder bed in a selective laser melting forming chamber; a metal electromagnetic induction coil is arranged above the powder bed, and is connected with an intermediate-frequency or high-frequency heating power supply; the intermediate-frequency or high-frequency heating power supply is connected with a central control unit through a control circuit; the metal electromagnetic induction coil is fixed to a nonmetal high-temperature resistant bracket; the nonmetal high-temperature resistant bracket is connected with a three-dimensional moving bracket; the three-dimensional moving bracket is fixed in the selective laser melting forming chamber; an infrared thermometer is arranged above the metal electromagnetic induction coil; the powder bed is provided with a moving powder spraying device matched with the powder bed to move; and the three-dimensional moving bracket, the infrared thermometer and the moving powder spraying device are connected with the central control unit through the control circuit. With the adoption of the method, on-line heating on the surface of the powder bed can be realized, so a temperature gradient of a forming area is reduced, when the heating temperature is high enough, and on-line annealing on a manufactured part can be realized in an SLM forming process when a heating temperature is high enough.

Owner:XI AN JIAOTONG UNIV +1

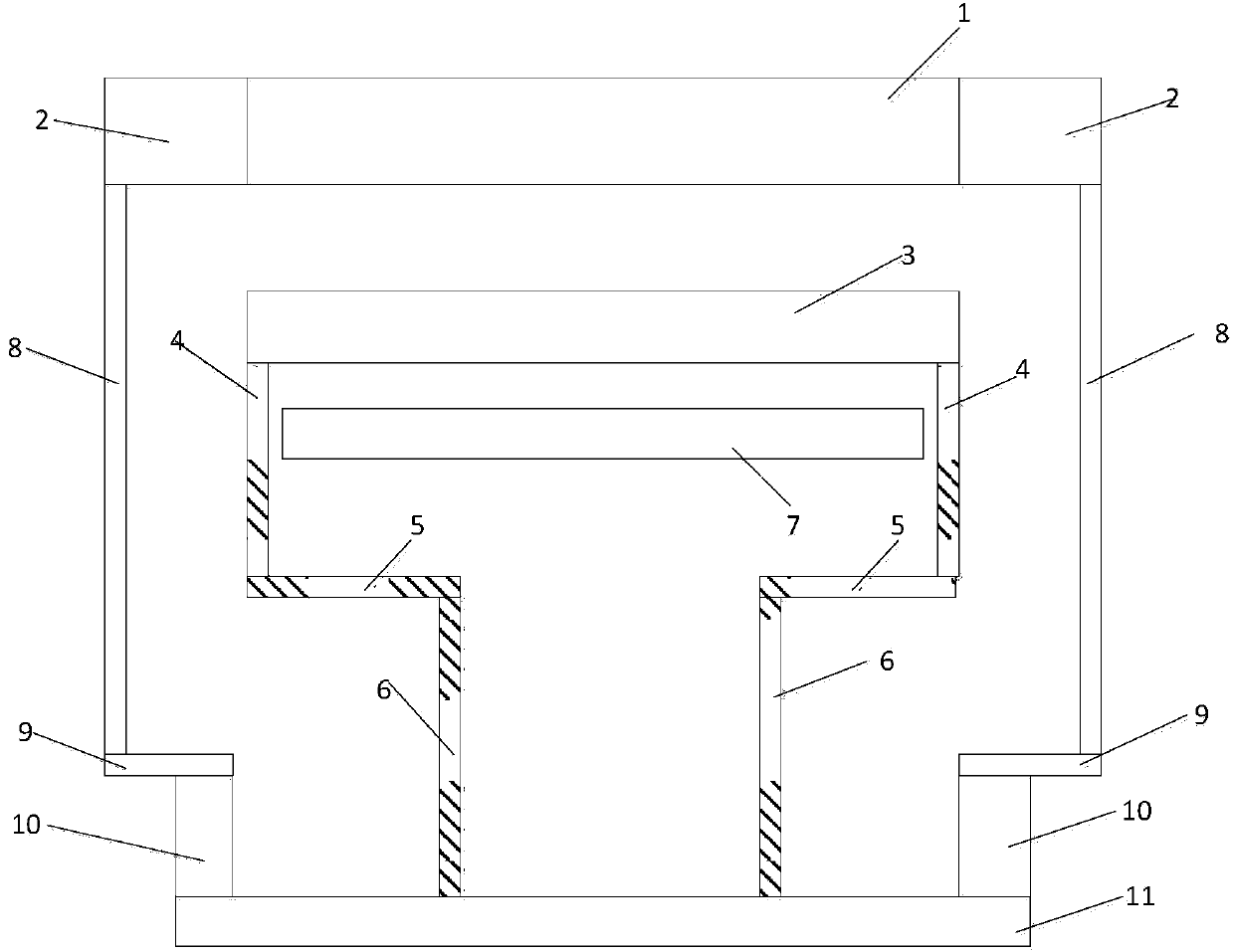

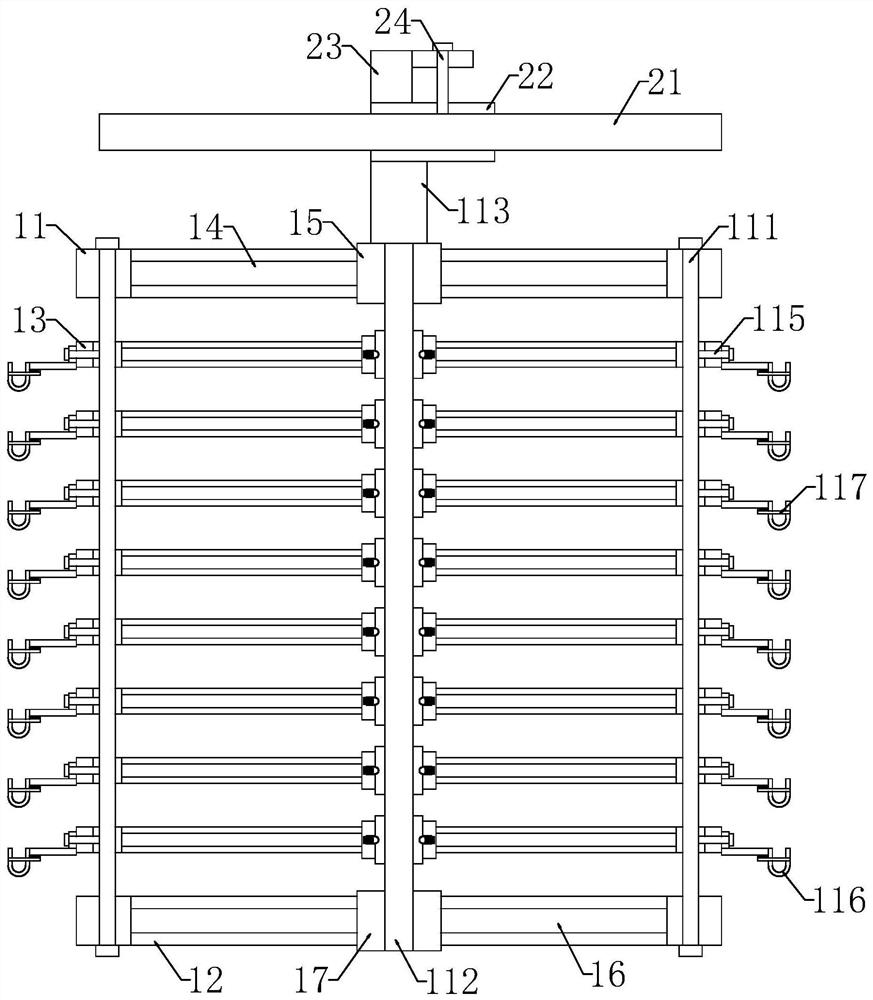

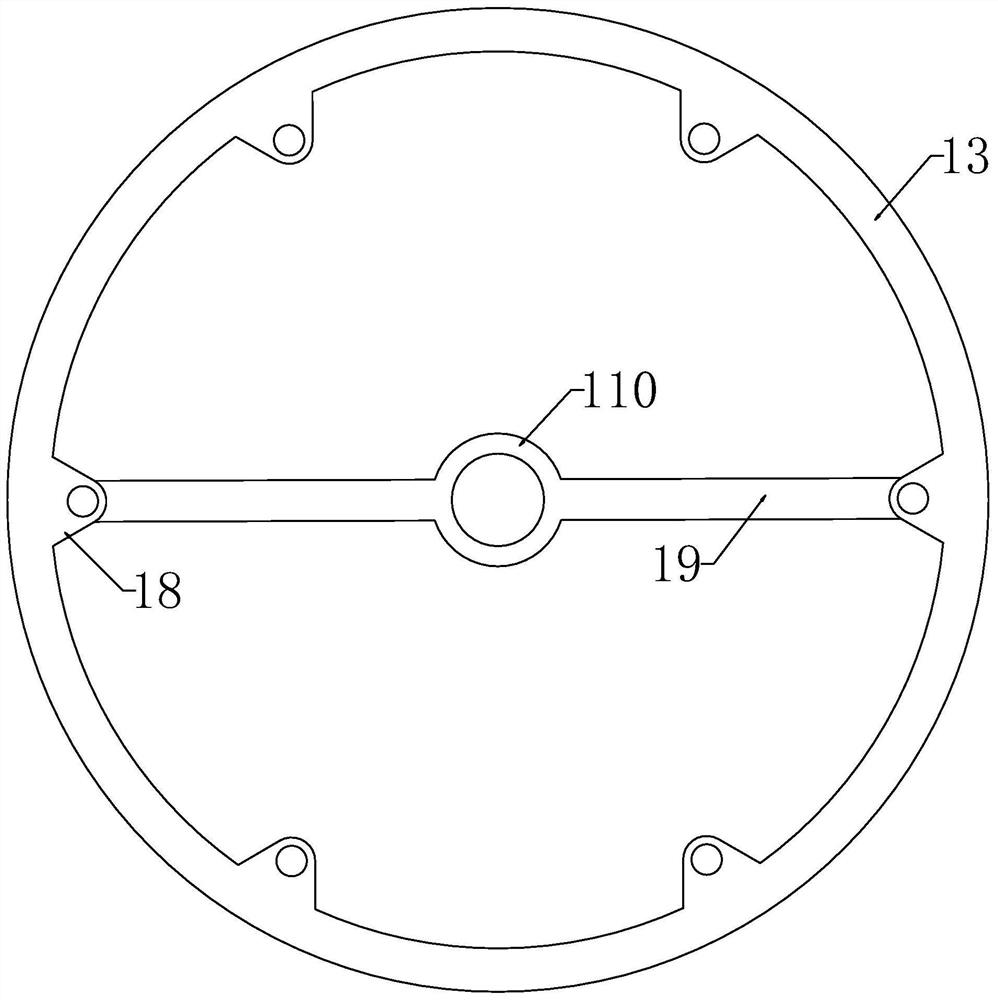

MOCVD (Metal-organic Chemical Vapor Deposition) equipment and adjustment method for interval between tray and spray header of equipment

InactiveCN103388133ASpacing adjustmentConvenient spacingChemical vapor deposition coatingCouplingReaction zone

The invention provides MOCVD (Metal-organic Chemical Vapor Deposition) equipment and an adjustment method for the interval between a tray and a spray header of the equipment. The MOCVD equipment comprises a reaction cavity, the spray header, the tray, a spray header lifting device and a cavity sealing element, wherein the reaction cavity comprises a cavity side wall and a cavity bottom plate below the cavity side wall; the spray header is arranged at the top of the reaction cavity and is provided with a gas venting surface; the tray is arranged below the spray header and a reaction zone; the spray header lifting device is connected with the spray header and is used for lifting or lowering the spray header in the reaction cavity so as to adjust the interval between the spray header and the tray; the cavity sealing element is arranged at the top of the reaction cavity and is used for ensuring that tight coupling is formed between the spray header and the cavity side wall when the spray header in the reaction cavity is lifted and lowered. The MOCVD equipment has the advantages that the distance between the tray and the spray header is adjusted by adjusting the height of the tray in the reaction cavity in a sealed environment, and that the equipment structure is simplified. The adjustment method for the interval between the tray and the spray header is simplified.

Owner:光垒光电科技(上海)有限公司

Building pillar clamping and supporting device

Owner:江苏静远建设工程有限公司

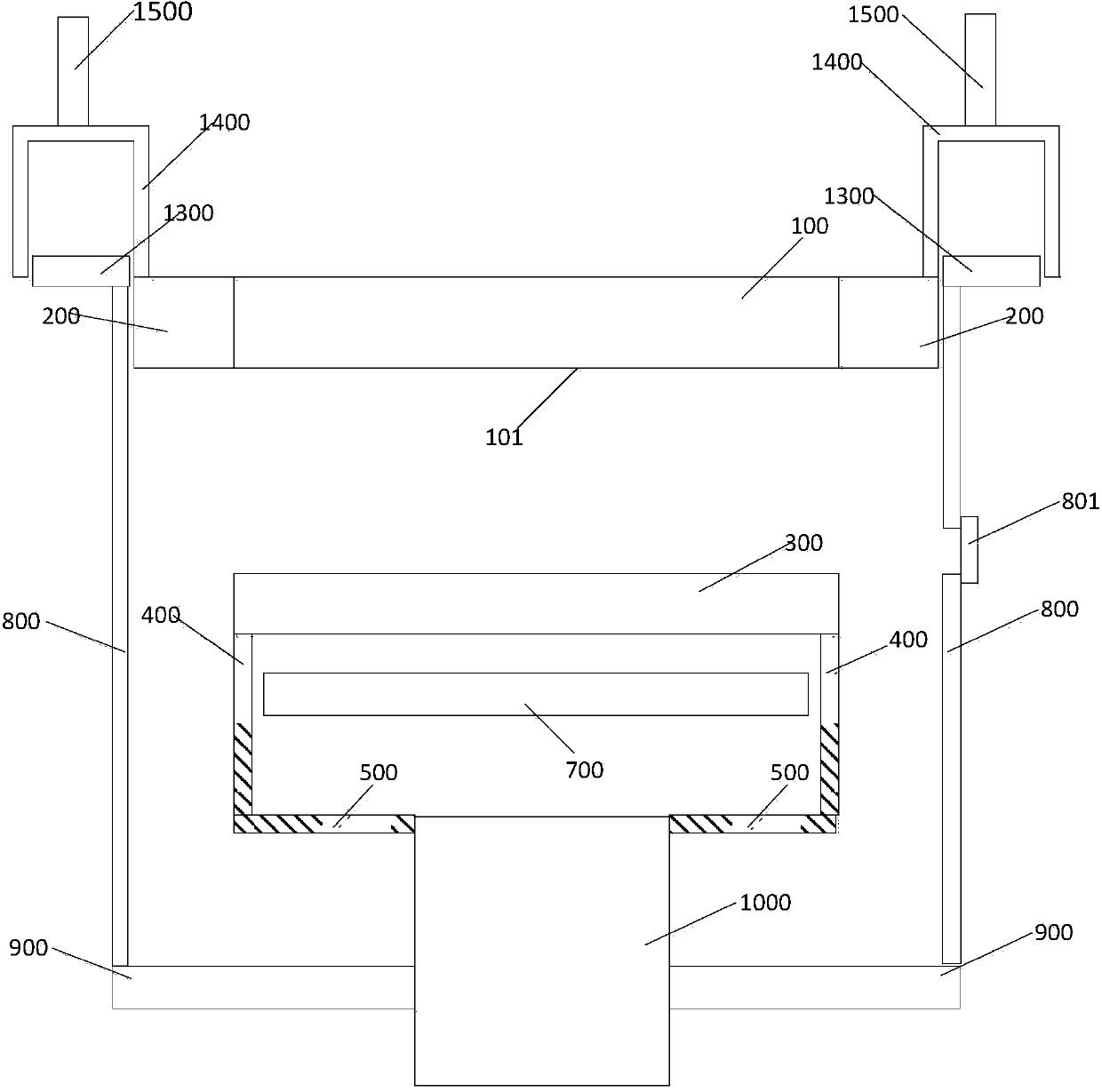

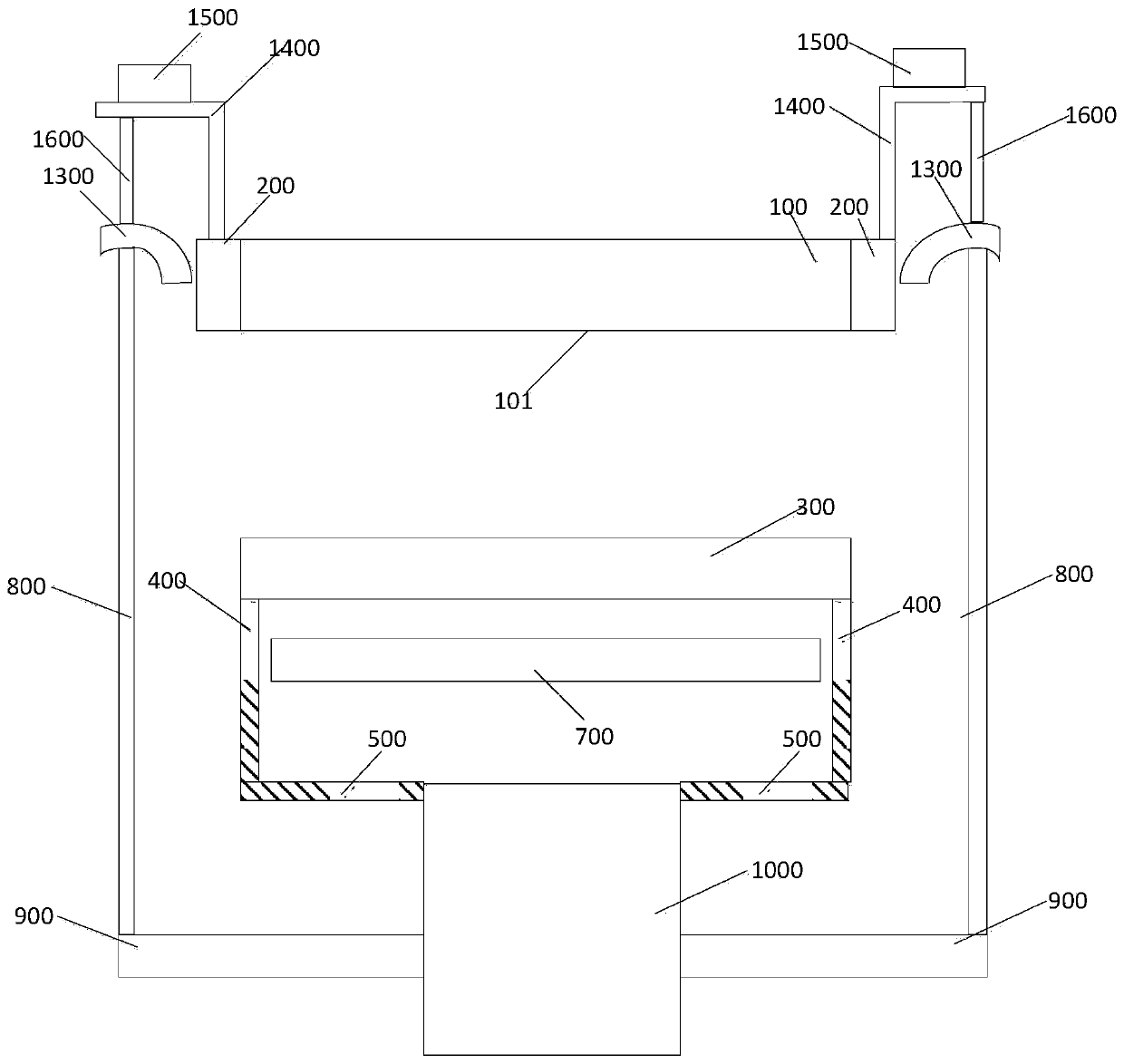

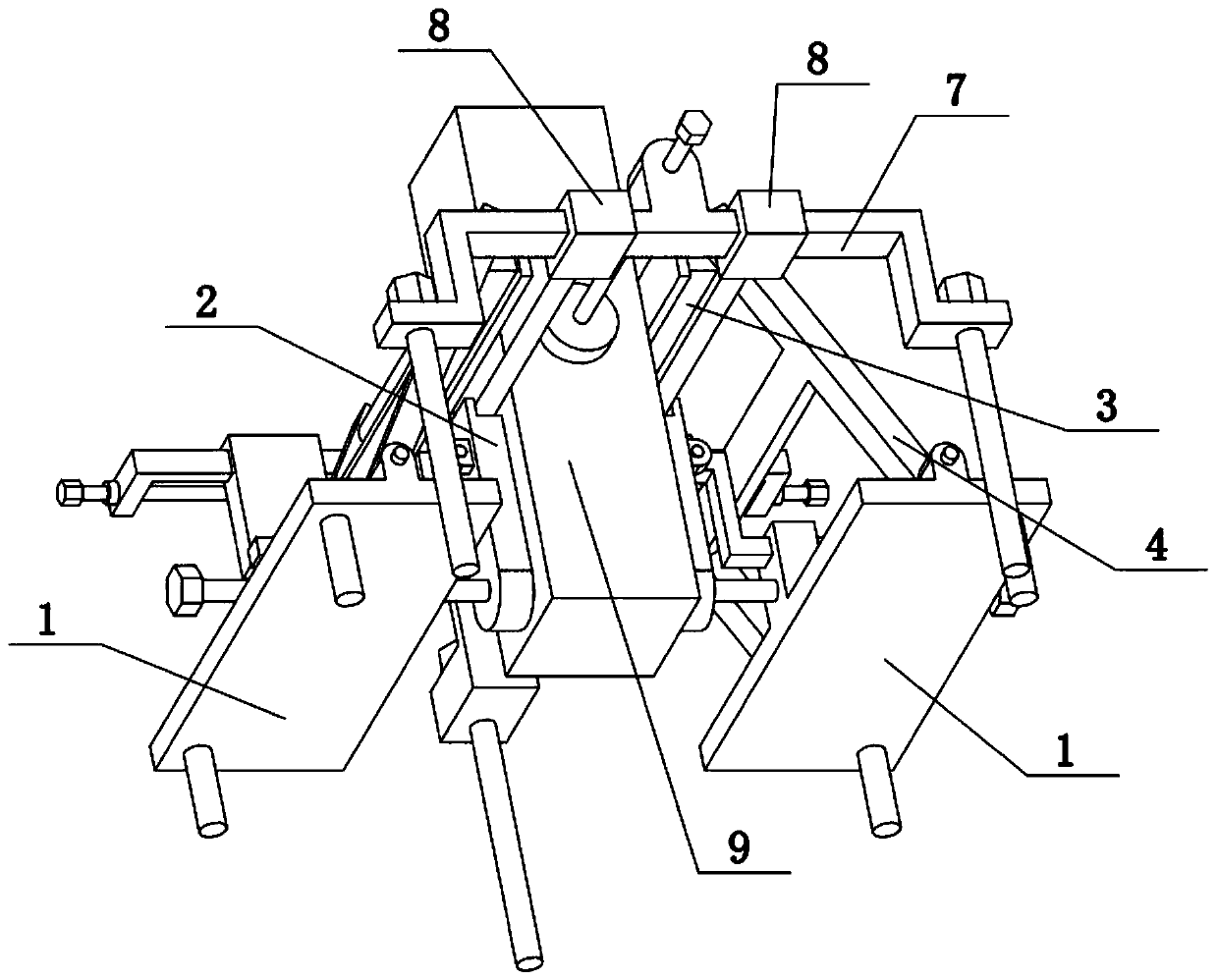

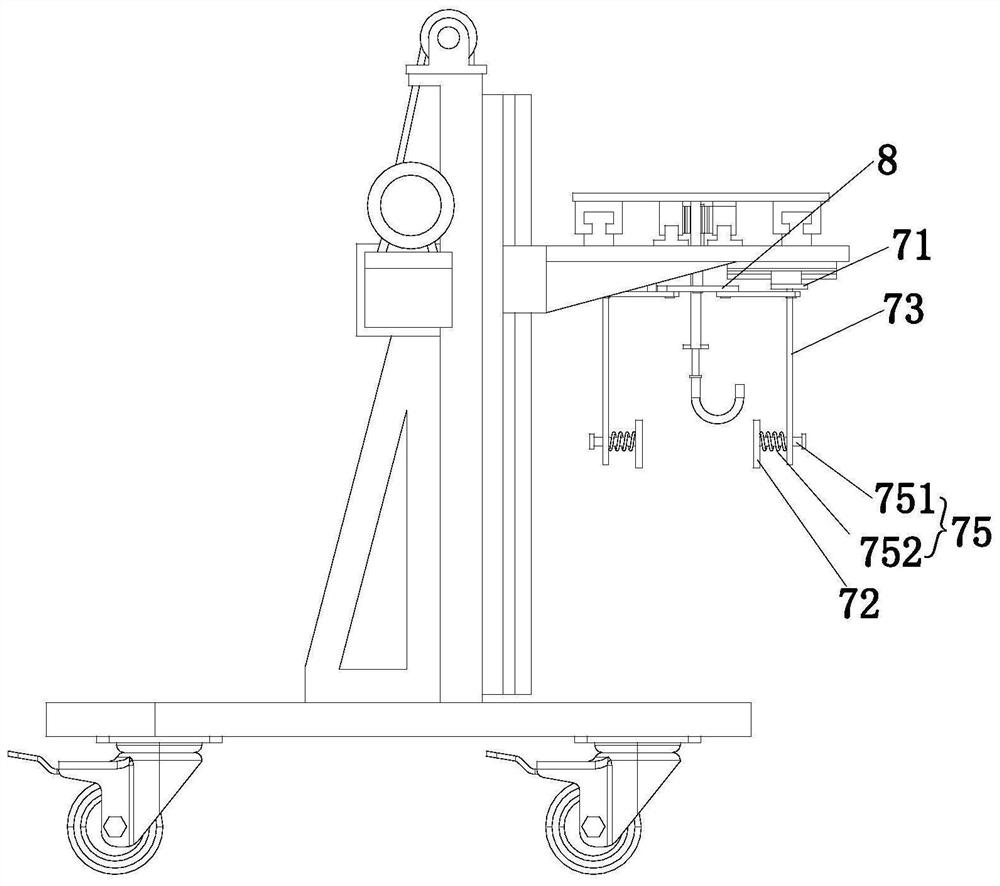

Intelligent hoisting equipment used for motor shells

PendingCN111606190AAvoid shakingTroubleshoot flat technical issuesWinding mechanismsCranesControl engineeringElectric machinery

The invention discloses intelligent hoisting equipment used for motor shells, and belongs to the technical field of auxiliary lifting equipment. The intelligent hoisting equipment comprises a U-shapedbase, an automatic lifting assembly, a lifting platform, a spacing adjusting assembly, a centralizing and shake-prevention assembly and a portal frame arranged at the top of the U-shaped base. Vertical slide rails are arranged at the two sides of the front end of the portal frame, each slide rail is provided with a lifting block which is in sliding fit with the slide rail, the spacing adjusting assembly comprises a moving part and two moving platforms arranged at an interval, the portion, corresponding to each moving platform, of the lifting platform is provided with two guide rails, a hoisting rope is arranged at the bottom of each moving platform, and a hook is arranged at the bottom end of each hoisting rope. The intelligent hoisting equipment has the advantages that under the effect of the spacing adjusting assembly, the spacing of the two hoisting ropes can be adjusted to hoist the motor shells with different specifications, and by adoption of the centralizing and shake-prevention assembly, the motor shells can be centralized, so that the motor shells are unlikely to deviate in the hoisting process.

Owner:安徽杰特电气有限公司

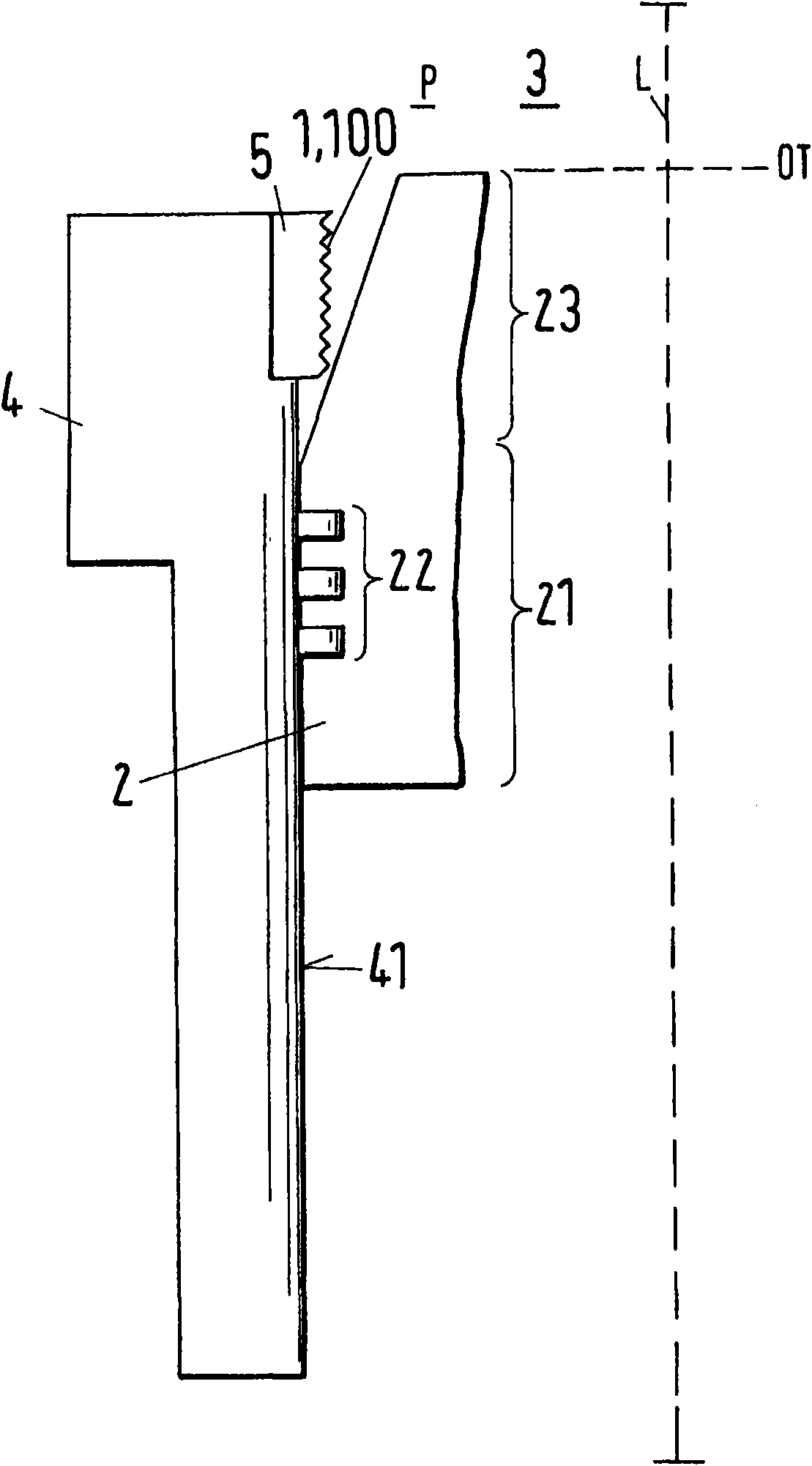

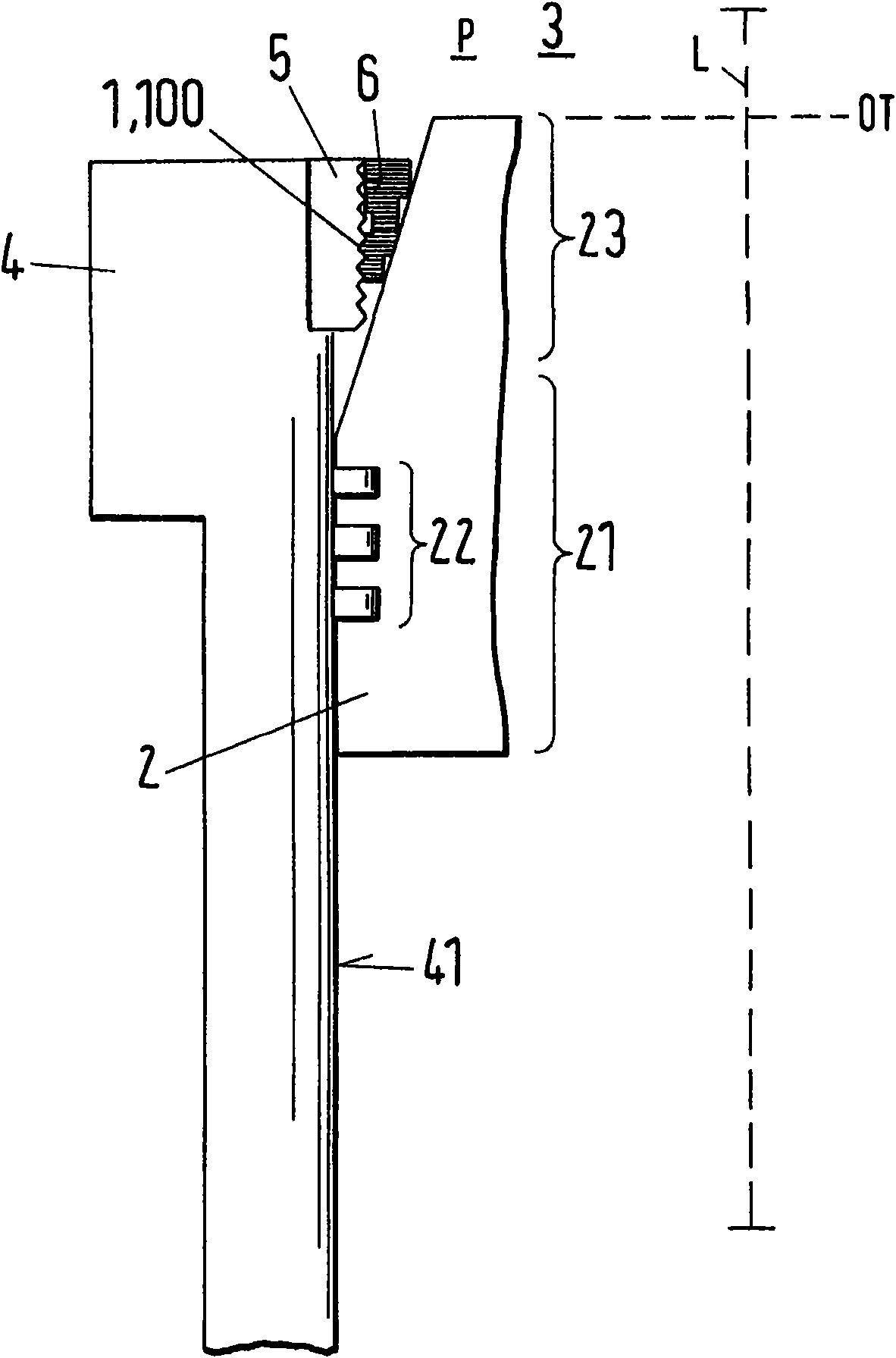

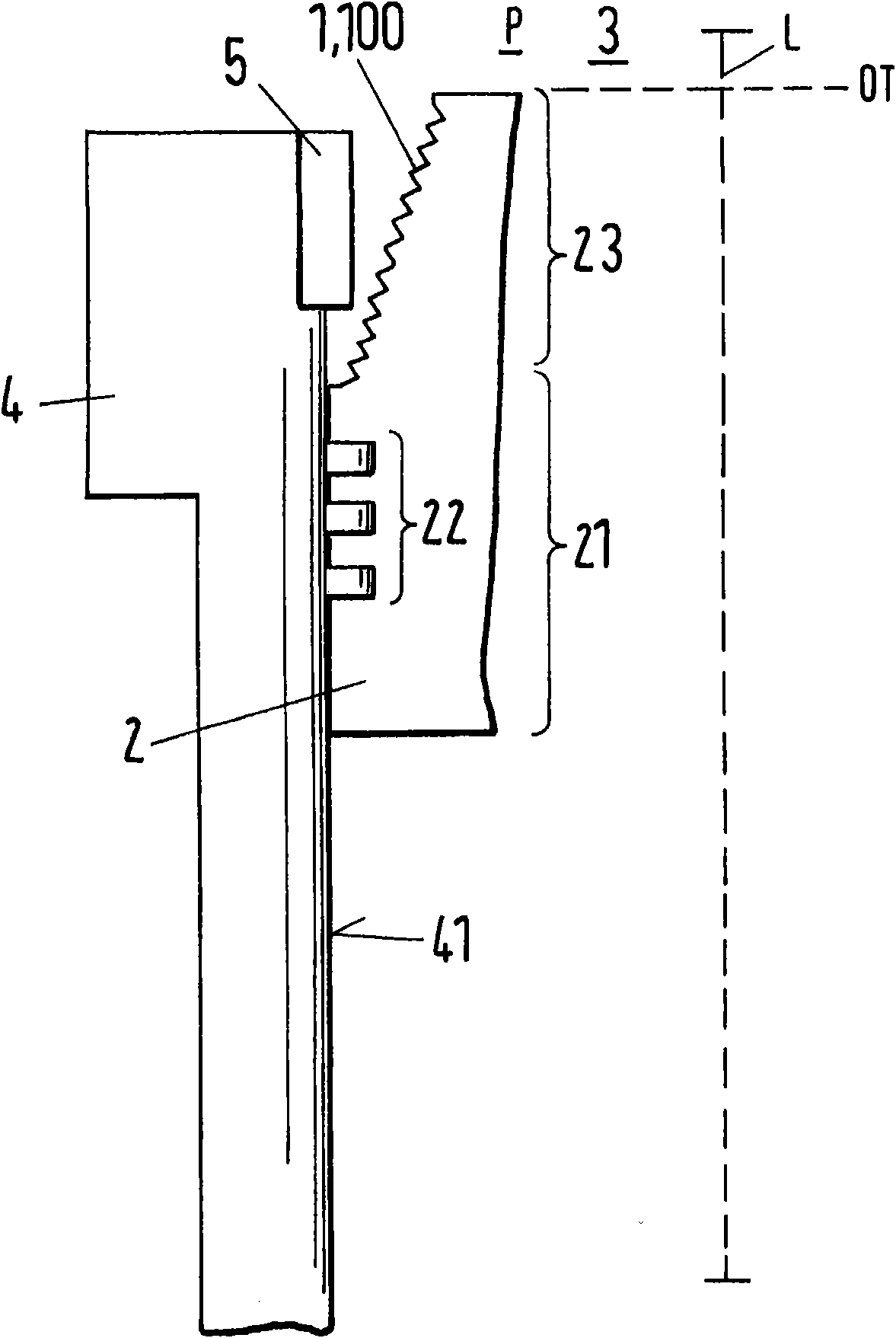

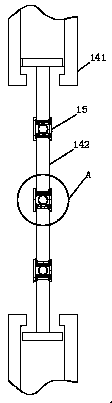

Reduction device for reducing gas pressure in piston ring group of reciprocating piston type internal combustion engine

InactiveCN101858276AReduced volume flowRelieve pressurePiston ringsCylinder headsCombustion chamberPiston ring

The present invention relates to a reduction device for reducing gas pressure in piston ring group of reciprocating piston type internal combustion engine. The piston comprises a piston crown which is adjacent to a ring area, and the piston crown faces a combustion chamber in a mounting state. The piston is arranged in the operation state with a mode that the reciprocation along a longitudinal axis of the cylinder is allowed, namely, the piston crown of the piston functions together with a scraping device provided at the cylinder wall of the cylinder next to an upper dead center of the motion in the cylinder for controllably scraping the combustion residue, wherein, the reduction device is designed to a dent shape thereby realizing controllable deposit of the combustion residue at the reduction device. According to the invention, the scraping device and the piston crown are designed and arranged relatively with each other, namely, the scraping device and the piston crown at least partially at a stop state temperature at an angle which can be preset, thereby causing the reduction of gas pressure acting on the piston ring group to be automatically adjusted under the cooperation of the piston crown and the scrapping device.

Owner:WAERTSILAE SCHWEIZ AG

Liquid crystal screen glass coating automatic processing device and coating process

ActiveCN113385328AImplement automatic conversionAvoid pollutionSpraying apparatusPhysical chemistryWorking environment

The invention provides a liquid crystal screen glass coating automatic processing device and a coating process, an adopted clamping and fixing mechanism can adaptively clamp and fix a screen plate according to the size of the screen plate, meanwhile, automatic switching of the spraying face of the screen plate can be achieved, so that fingerprints, oil stains and the like are prevented from being left on the surface of the screen plate due to the fact that workers make contact with the screen plate many times, and the forming effect of a coating agent on the surface of the screen plate is further improved. A relatively closed space formed by a spraying mechanism can play a role in blocking the splashed coating agent in the coating period of the screen plate, so that the situation that the working environment is polluted and the body of a worker is injured due to the fact that the coating agent is scattered all around is avoided.

Owner:江苏二五七特显科技集团有限公司

Steam oven door anti-deformation supporting structure and mounting method thereof

PendingCN111101794AEnsure the firmness of the installationEasy to installWing accessoriesSteam cooking vesselsThermodynamicsSupport plane

The invention discloses a steam oven door anti-deformation supporting structure. The steam oven door anti-deformation supporting structure comprises a supporting structure body. The supporting structure body is located at the bottom of a steam oven. The supporting structure body comprises a supporting frame and an adjustable supporting plate assembly. The adjustable supporting plate assembly is movably clamped on the supporting frame. The adjustable supporting plate assembly comprises a supporting plate and an adjusting plate. The supporting plate is located below the adjusting plate, and theadjusting plate and the supporting plate are adjustably connected. A mounting method includes the steps that a, the supporting frame is assembled; b, the adjustable supporting plate assembly is assembled; c, the adjustable supporting plate assembly and the supporting frame are spliced; and d, the anti-deformation supporting structure and the steam oven are mounted. The bottom face of an oven dooris supported and lifted through the supporting structure when the oven door is in an opened state, thus, bending deformation and the like of the joint of the oven door and an oven body are effectivelyavoided, meanwhile, the supporting structure can be adjusted according to the actual thicknesses of different oven doors, it is guaranteed that the oven door is stably supported, and the applicationrange of the supporting structure is widened.

Owner:浙江蓝炬星电器有限公司

Fabric fast-carding device for textile production

ActiveCN110318244AEasy to installEasy to disassemble and replaceMechanical cleaningPressure cleaningCorrosionMoisture

The invention discloses a fabric fast-carding device for textile production. The device includes a fixing support, a heating plate and a dust sucking head; the upper ends of the fixing support are provided with a support frame, an unreeling shaft is fixed to the interior of the support frame, the two ends of the unreeling shaft are provided with thread blocks, rotating blocks are fixed to the outer surfaces of the thread blocks, the unreeling shaft is provided with a roll shaft, and the outer surfaces of the two ends of the roll shaft are provided with balls. Compared with an existing common fabric fast-carding device for textile production, the fabric fast-carding device for textile production can remove dust, cotton fibers and other impurities adhering to fabrics, the carding effect of the carding device is improved, water is prevented from overflowing during the use of the device so as to avoid parts from moisture and corrosion, centralized treatment of waste liquid is convenient, waste of water resources is avoided, meanwhile, the fabrics with different thicknesses can be flattened, and the applicability of the device is improved.

Owner:YUHUAN ZITI COSMETICS CO LTD

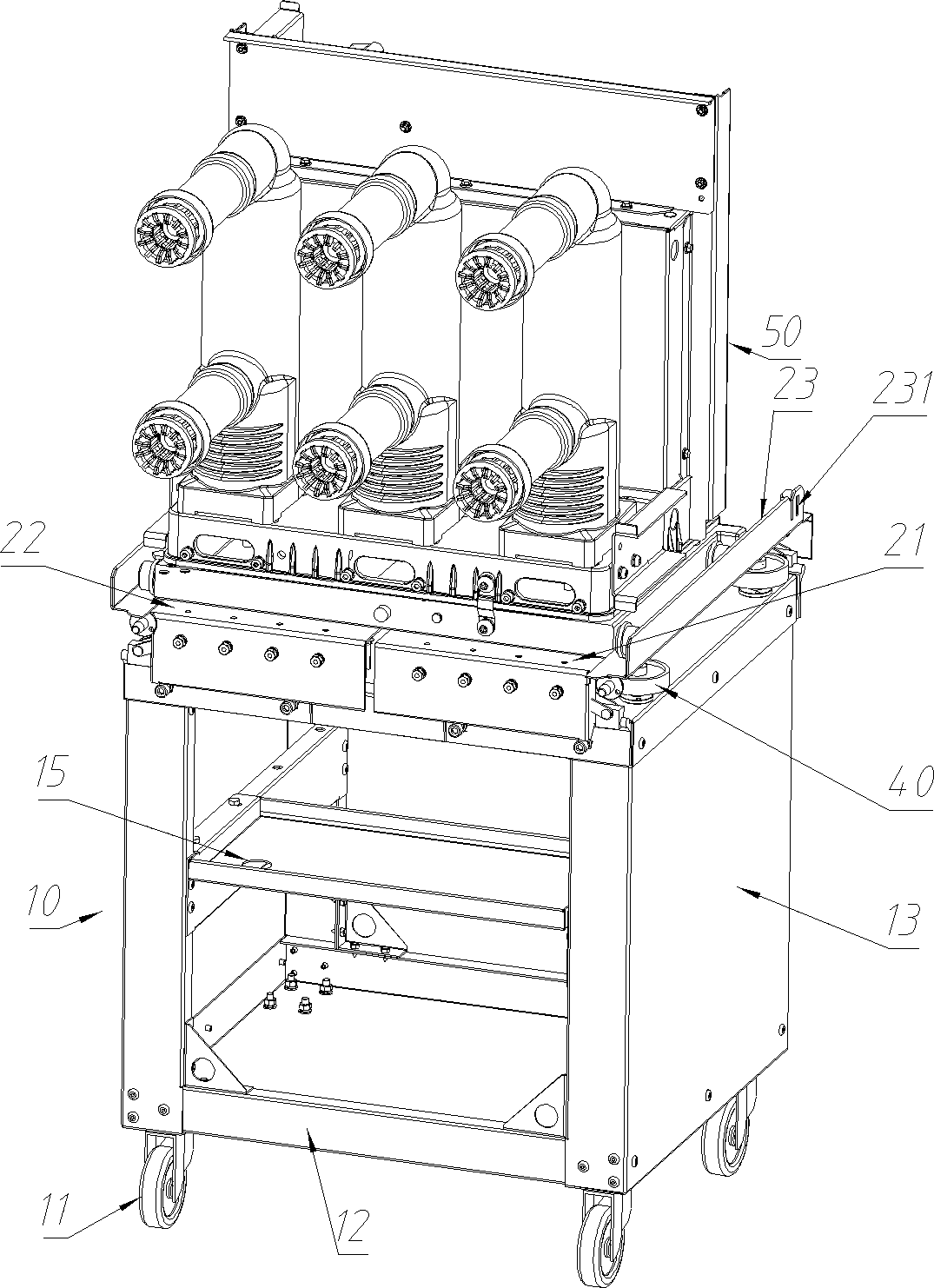

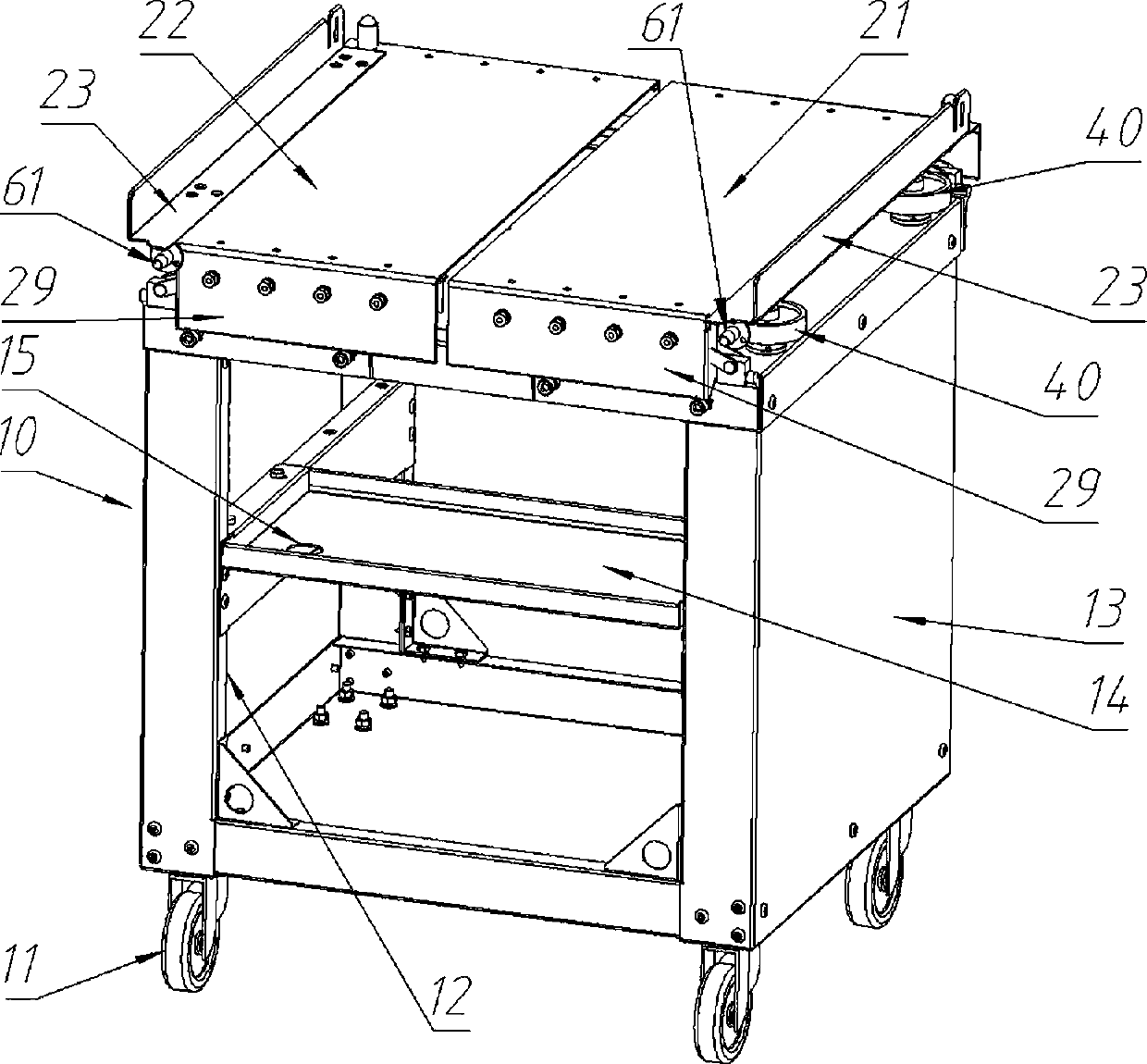

Circuit breaker transfer trolley

ActiveCN109747694ASpacing adjustmentGuaranteed spacingHand carts with multiple axesArchitectural engineeringCircuit breaker

The invention relates to a circuit breaker transfer trolley, which comprises a trolley frame and a bearing table arranged on the trolley frame. Handcart guide rails used for supporting and guiding a circuit breaker handcart are arranged on the bearing table in a left-right spaced mode, the bearing table comprises a left bearing table and a right bearing table, and the left bearing table and the right bearing table are mutually independent and are hinged to the trolley frame through corresponding left connecting rods and corresponding right connecting rods. The trolley frame and the bearing tables and the connecting rods on the corresponding sides form parallelogram mechanisms, and the left bearing table and the right bearing table have narrow bearing positions and wide bearing positions along with swing of the corresponding connecting rods, wherein at the narrow bearing positions, the left bearing table and the right bearing table are close to each other, and at the wide bearing positions, the left bearing table and the right bearing table are away from each other. The left bearing table and the right bearing table can swing left and right through the parallelogram mechanisms, andthe distance between the handcart guide rails can be conveniently guaranteed while width requirements of different switch cabinets are met. Compared with the prior art, operation is convenient, the structure is simple and the cost is low.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

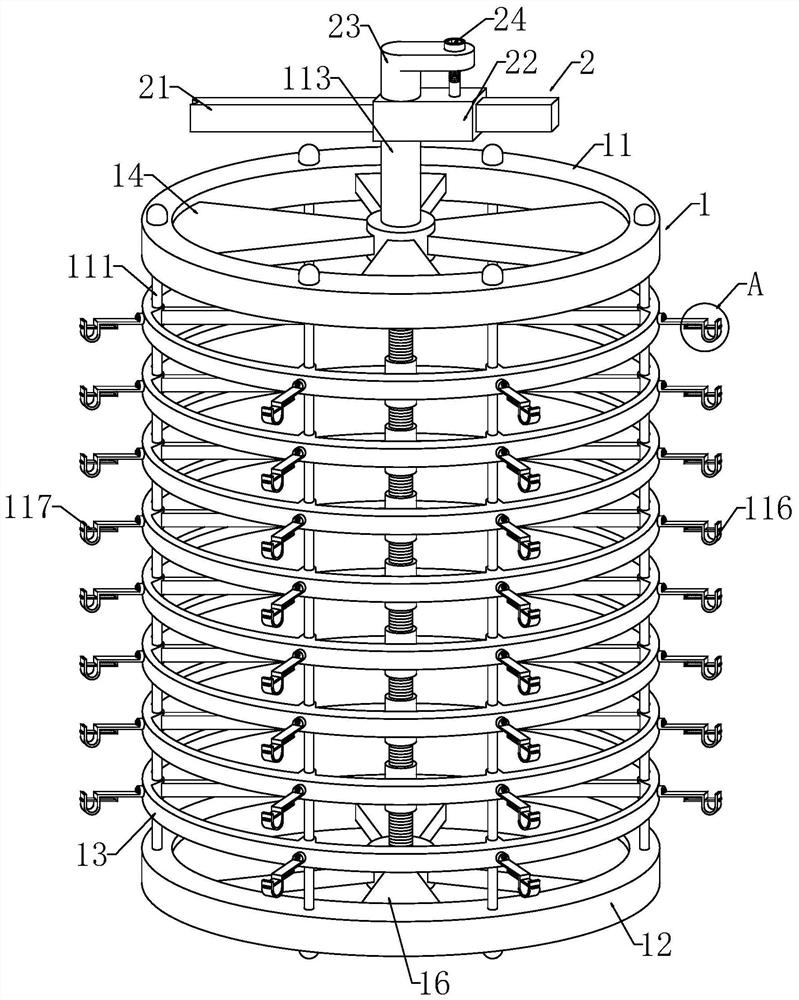

Electroplating hanger

The invention relates to the field of electroplating hangers, in particular to an electroplating hanger. The electroplating hanger comprises a hanger assembly, a moving assembly and a locking assembly, the moving assembly is arranged above the hanger assembly, and the locking assembly is arranged in the hanger assembly. A sliding sleeve sliding along a guide rail and the guide rail can be limitedthrough a second locking bolt penetrating through a through hole, due to the fact that limiting of the sliding sleeve can be achieved only by rotating the second locking bolt, the hanger is quite convenient to move, and when workpieces of different sizes need to be hung, only a servo motor needs to be started, the output end of the servo motor drives a lead screw to rotate through a coupler, the lead screw can drive an internal thread sleeve connected to the rod wall in a threaded and sleeving mode to ascend and descend when rotating, a third rotating sleeve on the outer sleeve wall of the internal thread sleeve can be connected with an inserting block to enable the third rotating sleeve to ascend and descend along with ascending and descending of the internal thread sleeve, and the thirdrotating sleeve can drive a supporting ring to ascend and descend during ascending and descending.

Owner:黄冬冬

Device for treating residual rubber of bicycle hub

ActiveCN111531447APrevent rotationAchieve movementGrinding drivesPlastic recyclingEngineeringStructural engineering

The invention discloses a device for treating residual rubber of a bicycle hub, and relates to the field of environmental protection equipment. The device comprises an L-shaped plate and is characterized in that the L-shaped plate is fixedly connected with a transverse plate and symmetric first electric push rods; push rod ends of the symmetric first electric push rods are respectively fixedly connected to a first circular plate; the first circular plate is fixedly connected with one ends of a group of circular rods uniformly arranged along the circumferential direction; the other end of eachcircular rod is separately fixedly connected to a third circular plate; the third circular plate is fixedly connected with a circular ring and is provided with a group of cross grooves uniformly arranged along the circumferential direction; a second circular plate is arranged in the circular ring; the second circular plate is provided with a group of first straight grooves uniformly arranged alongthe circumferential direction; the transverse plate is fixedly connected with a polishing mechanism; and the third circular plate is fixedly connected with a fixing mechanism. The device for treatingthe residual rubber of the bicycle hub can conveniently remove the residual rubber of the bicycle hub.

Owner:许钦领

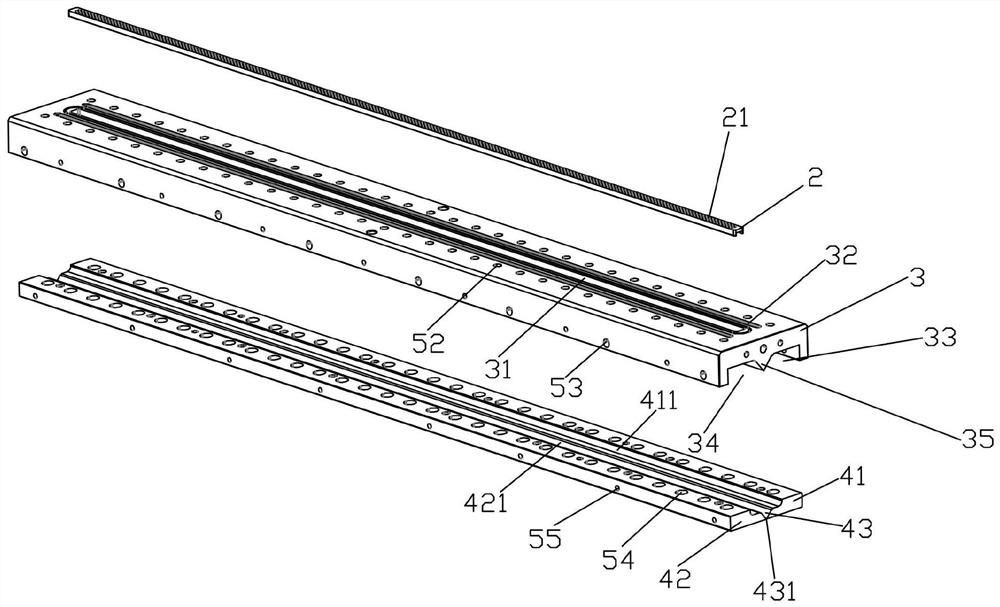

Spinneret plate of melt-blowing mold

InactiveCN112877791AIncrease the number ofIncrease the gapSpinnerette packsSpinningManufacturing engineering

The invention discloses a spinneret plate of a melt-blown mold, and belongs to the technical field of melt-blown cloth processing equipment. The spinneret plate comprises a spraying and melting mold, air pressure injection devices and fixing plates, wherein the fixing plates are connected to the front side and the rear side of the spraying and melting mold, and the air pressure injection devices are arranged at the bottoms of the left side and the right side of the spraying and melting mold. The spinneret plate is characterized in that a discharge hole and a plurality of top air outlets are formed in the bottom surface of the spraying and melting mold, and the plurality of top air outlets are formed in the left side and the right side of the discharge hole correspondingly. Left spinneret orifices and right spinneret orifices are formed in the side edges of convex corners of the bottoms of convex strips correspondingly, and the distance between individual orifices of the left spinneret orifices and the right spinneret orifices in each row is 0.65 mm, so that during spinning, the single row of orifices cannot influence one another, the gap of a discharging groove is increased through cooperation of the left spinneret orifices and the right spinneret orifices, the number of sprayed filaments can be effectively increased while the gas is increased, thus the input cost is effectively controlled, and meanwhile, the yield of melt-blown cloth is greatly increased.

Owner:浙江精功机器人智能装备有限公司

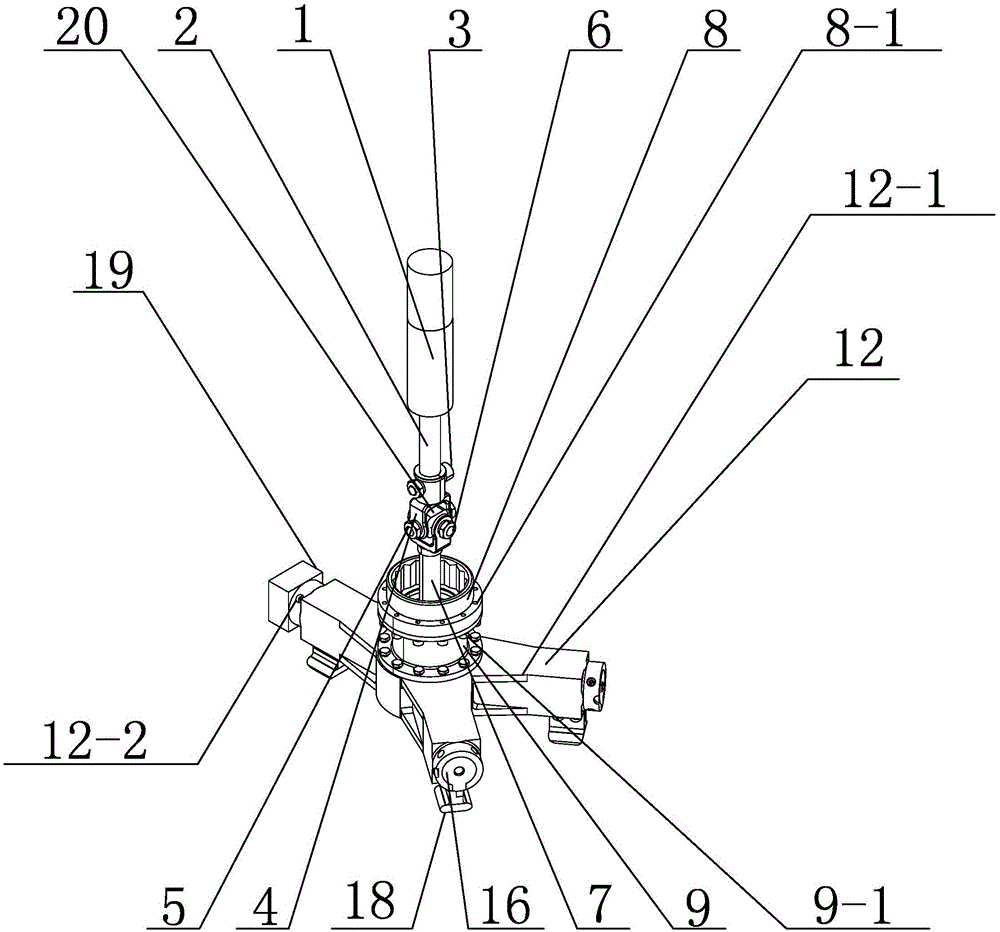

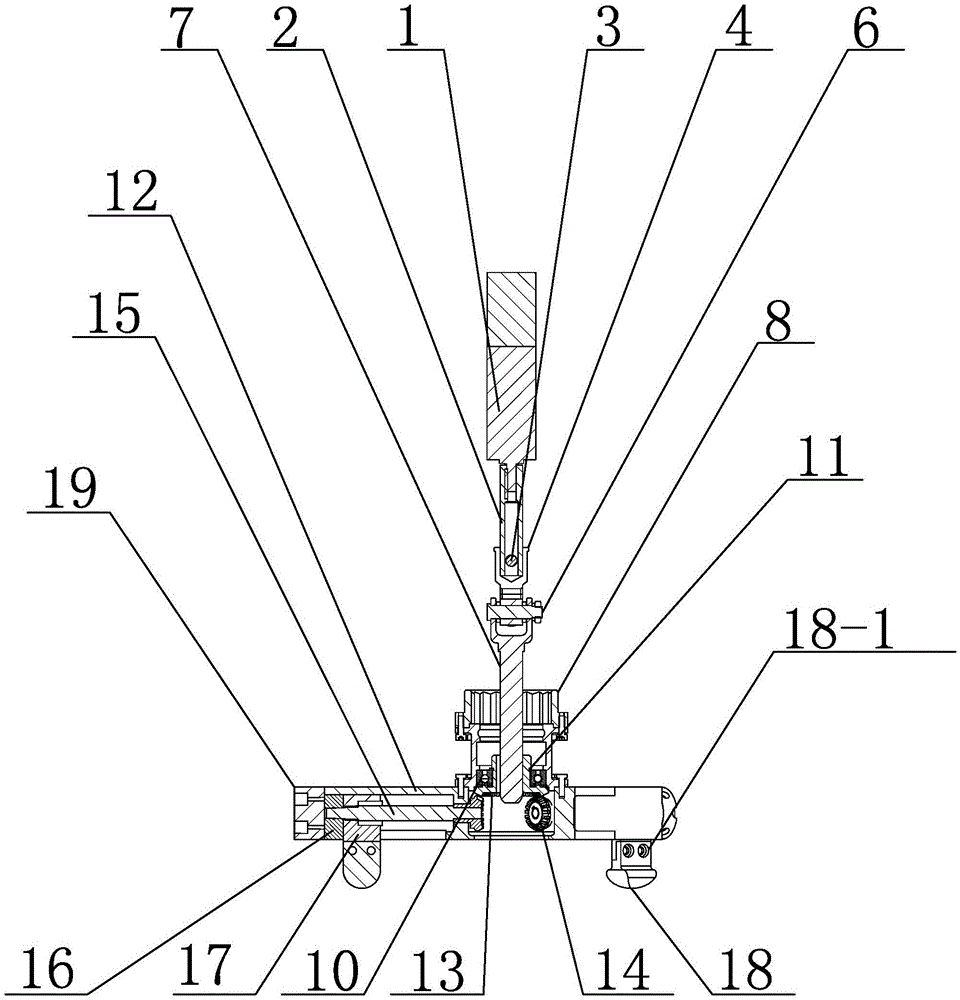

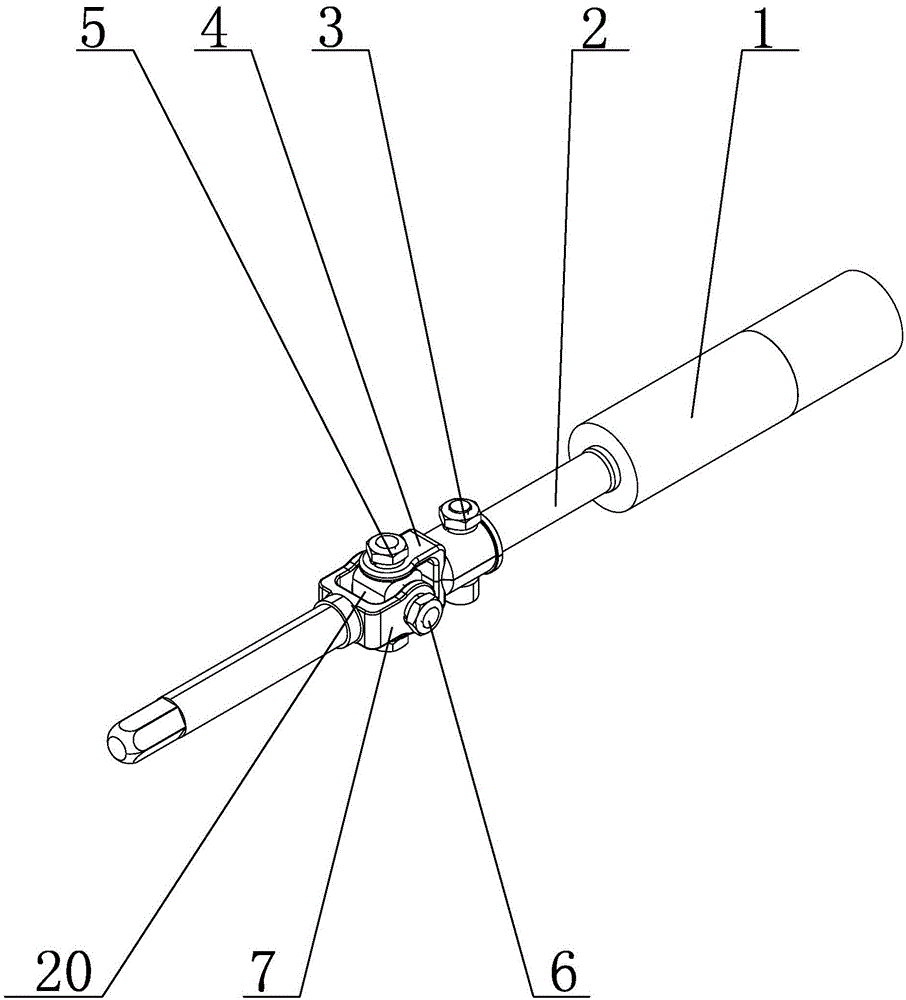

Smooth and self-adaptive valve screwing mechanical arm mechanism

ActiveCN105082115AReduced butt contact forceProtective devices and objects of actionProgramme-controlled manipulatorGripping headsSelf adaptiveManipulator

The invention relates to a valve screwing mechanical arm mechanism, in particular to a smooth and self-adaptive valve screwing mechanical arm mechanism which aims at solving the problems that an existing disaster relief robot cannot be in butt joint with a valve hand wheel with tolerance, and a tail end executer for screwing a valve cannot be achieved, so that the disaster relief operating efficiency is low, and the operating cost is high. The output end of a servo motor is connected with a core shaft. The core shaft is provided with a hook joint mechanism. A tool connector piece is installed on a three-pawl mechanical arm. Three bevel pinions are installed in a center pawl base in a mechanical arm base. A large bevel gear is installed at the upper end of the middle of the mechanical arm base. The core shaft is inserted in the large bevel gear. A lead screw base is arranged in each pawl base. One end of each lead screw is connected with the corresponding lead screw base. The other end of each lead screw is connected with the corresponding bevel pinion. A mechanical finger is installed on one lead screw and is in sliding connection with one pawl base, and two fingers are installed on the other two lead screws respectively. The valve screwing mechanical arm mechanism is suitable for a screw screwing mechanism capable of being in smooth butt joint with the valve hand wheel.

Owner:HARBIN INST OF TECH

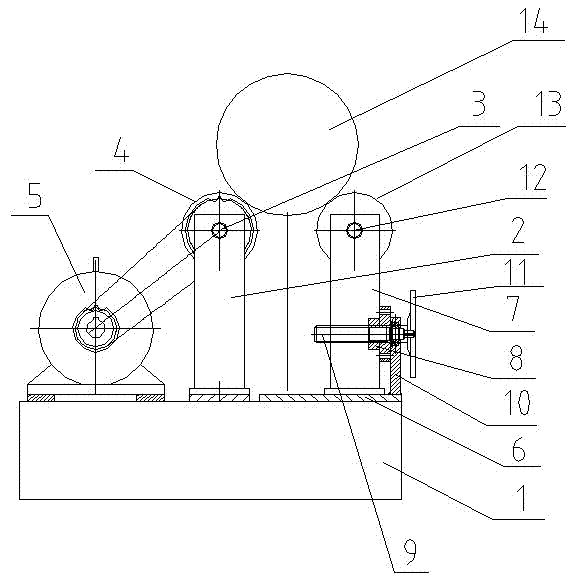

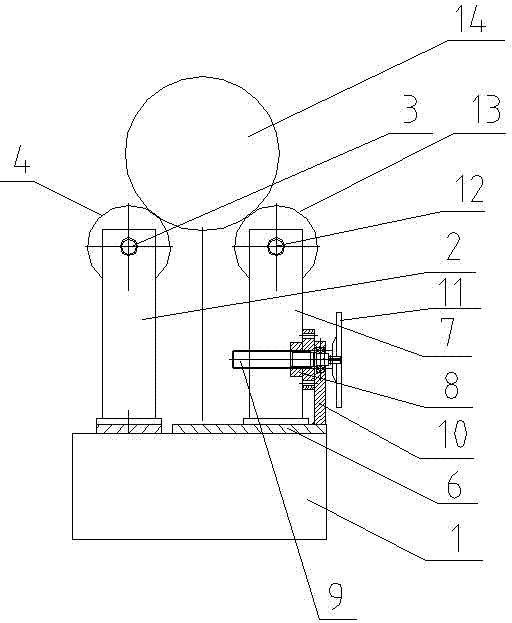

Roller frame for long rod polisher

InactiveCN102756311ASpacing adjustmentAdjustable spacingRevolution surface grinding machinesPulp and paper industryBlock type

A roller frame for a long rod polisher relates to the technical field of circumference polishing in the industry of electric poles and light poles, and comprises a driving roller frame and a driven roller frame, wherein a set of fixed roller bracket is arranged on the base of the driving roller frame, and supports a first roller through a first rotating shaft; a roller driving device is also arranged on the roller base; the output end of the roller driving device is in transmission connection with the axle of the first roller; a slide rail is arranged on the roller base; a sliding block type roller bracket is connected to the slide rail; a nut is connected to the lower part of the sliding block type roller bracket, and in threaded connection with a screw; one end of the screw is connected to a vertical frame through a bearing; the vertical frame is fixedly connected to the roller base; an adjusting hand wheel is connected to the end part of the screw; and the upper end of the sliding block type roller bracket supports the second roller through a second rotating shaft. The roller frame is suitable for polishing and processing of long rods of different diameters and lengths, which provides convenience for improving the production efficiency and the product quality.

Owner:JIANGSU TEWEI MACHINE TOOL MFG

Building construction guardrail

InactiveCN108756448AEasy to move and stableAchieve stabilityFencingArchitectural engineeringBuilding construction

The invention discloses a building construction guardrail. A threaded sleeve is fixedly connected to the middle portion of a first vertical column, the threaded sleeve is in threaded connection with ascrew rod, a second vertical column is connected to the end portion of the screw rod in a bearing rotation mode, the screw rod is fixedly connected with a pinion, the upper portion of the pinion meshes with a big gear wheel, the big gear wheel is fixedly connected with a rocker handle, and the second vertical column is connected to the end portion of the rocker handle in a bearing rotation mode.Connecting inserting plates are fixedly connected to the outer sides of the upper and lower portions of the first vertical column, through holes are formed in the middle portions of the connecting inserting plates, and connecting clamping slots are fixedly connected to the outer sides of the upper and lower portions of the second vertical column. According to the guardrail, the rocker handle is rotated to drive the large gear wheel so as to drive the pinion to rotate at the same time, the pinion drives the screw rod to rotate, the screw rod and the second vertical column are driven to move left and right under the action of the fixed threaded sleeve, adjustment of the spacing between the first vertical column and the second vertical column can be realized, moreover, movable support legs and moving rollers are driven to be in contact with the ground separately while the spacing between the first vertical column and the second vertical column is adjusted, and the effects of convenient and stable movement of the guardrail are achieved.

Owner:何敏

Telescopic fabricated building protective railing

InactiveCN108612272AAdapt to different needsEasy to disassembleBalustersBalustradesArchitectural engineeringBaluster

Owner:穆琳瑛

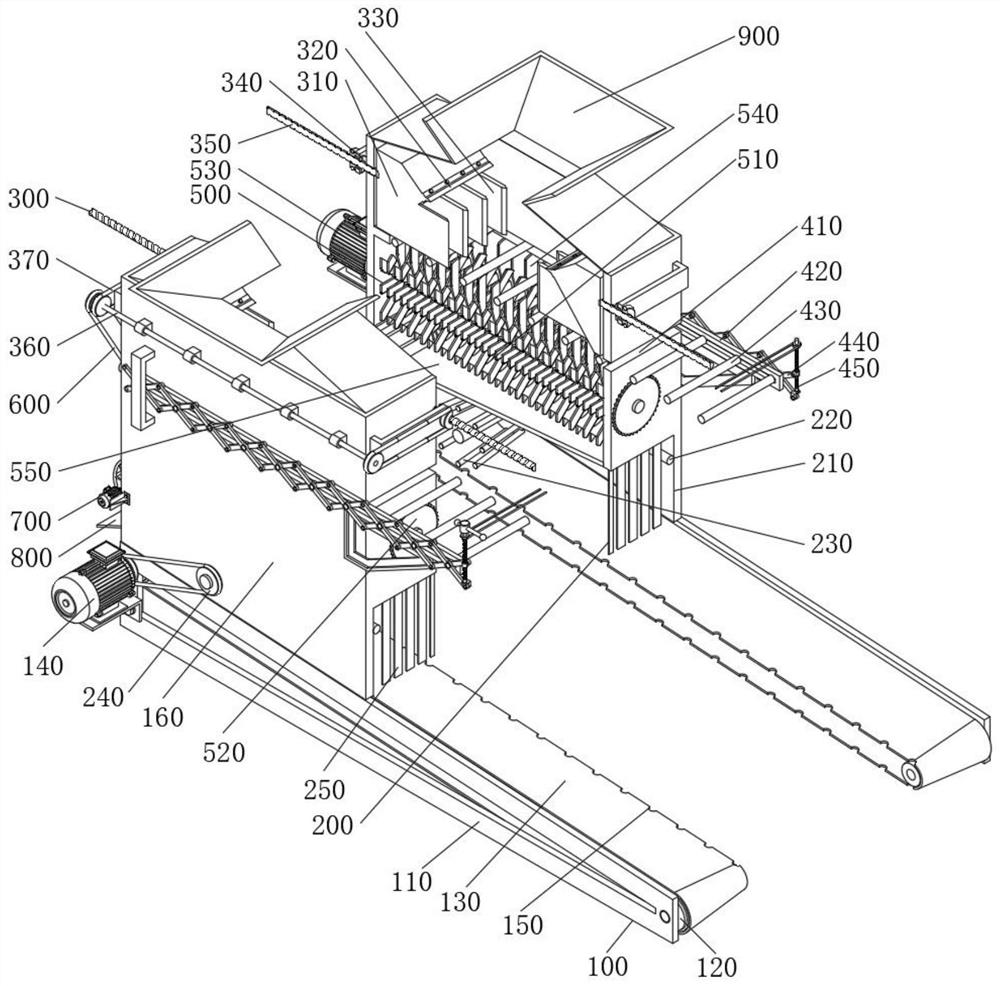

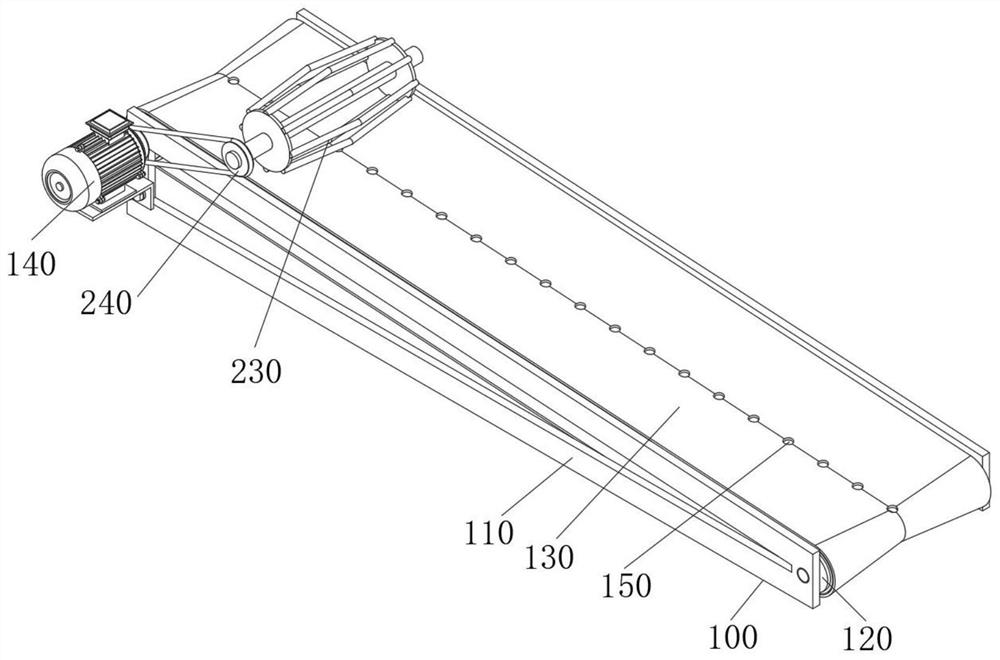

Building solid residue conveying device with separation structure for building construction

InactiveCN113000147AEffective separation and flushingEasy to recycleGrain treatmentsParticulatesArchitectural engineering

The invention relates to the technical field of residue conveying equipment for building construction, in particular to a building solid residue conveying device with a separation structure for building construction. The building solid residue conveying device comprises a conveying part, the conveying part comprises a support frame, the left side and the right side of the support frame are symmetrically and rotatably connected with conveying rollers, and the outer sides of the two sets of conveying rollers are sleeved with a conveying belt; and the two sets of conveying rollers are in transmission connection through a conveying belt, and the outer side of one set of conveying rollers is fixedly connected with a first servo motor. According to the building solid residue conveying device, dust particles in residues and waste are separated and flushed out through water mist flushing, the residues and waste are conveniently recycled, the middle positions of the conveying rollers are arranged to be in a concave shape, the middle position of the conveying belt is made to be concave downwards, water flow is conveniently collected and guided, the water flow is effectively prevented from overflowing at will, and in cooperation with rotary stirring of a wheel cylinder, it is guaranteed that the device comprehensively removes dust particles.

Owner:安徽香蕉传媒有限公司

Natural gas energy supply type sliding rail multi-surface synchronous coating device

ActiveCN110773349AEasy to sync jobsEasy wipe downSpraying apparatusPretreated surfacesThermodynamicsEnergy supply

The invention discloses a natural gas energy supply type sliding rail multi-surface synchronous coating device. The device comprises a workshop top beam, a gas delivery pipe and a support rail, the lower surface of the workshop top beam is fixed with a limiting rail in a bolted mode, a supporting rod placed on the support rail is attached to the lower surface of a hydraulic telescopic frame, a travelling trolley is arranged on the upper surface of the support rail, an air extracting fan is installed at the right end of a guiding pipe, a sliding rail body penetrates through the middle of the travelling trolley, a mounting plate is welded to the surface of the left side of the travelling trolley, an adjusting rod penetrates through the middle of the mounting plate, a connecting block is welded to the inner end of the adjusting rod, and an extrusion block is mounted in the connecting block. According to the natural gas energy supply type sliding rail multi-surface synchronous coating device, various surfaces of a sliding rail are conveniently subjected to synchronous operation, the operation efficiency is improved, dust on the surfaces of the slide rail is conveniently wiped, the spraying effect is guaranteed, the use is convenient, and the surfaces of the sliding rail body can be preheated.

Owner:HAINING JINMAO HARDWARE

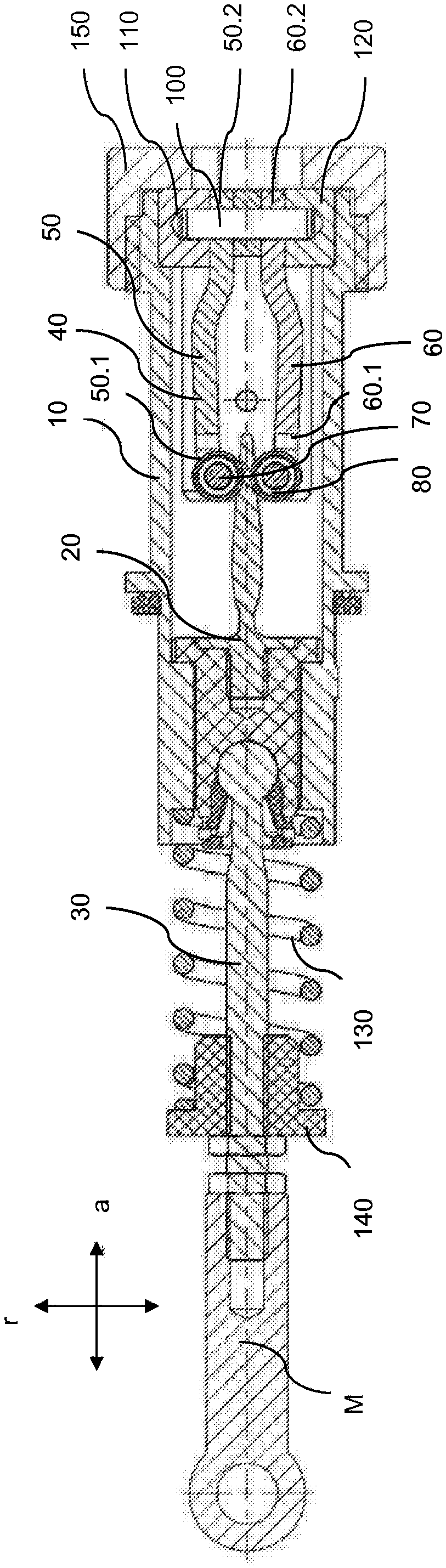

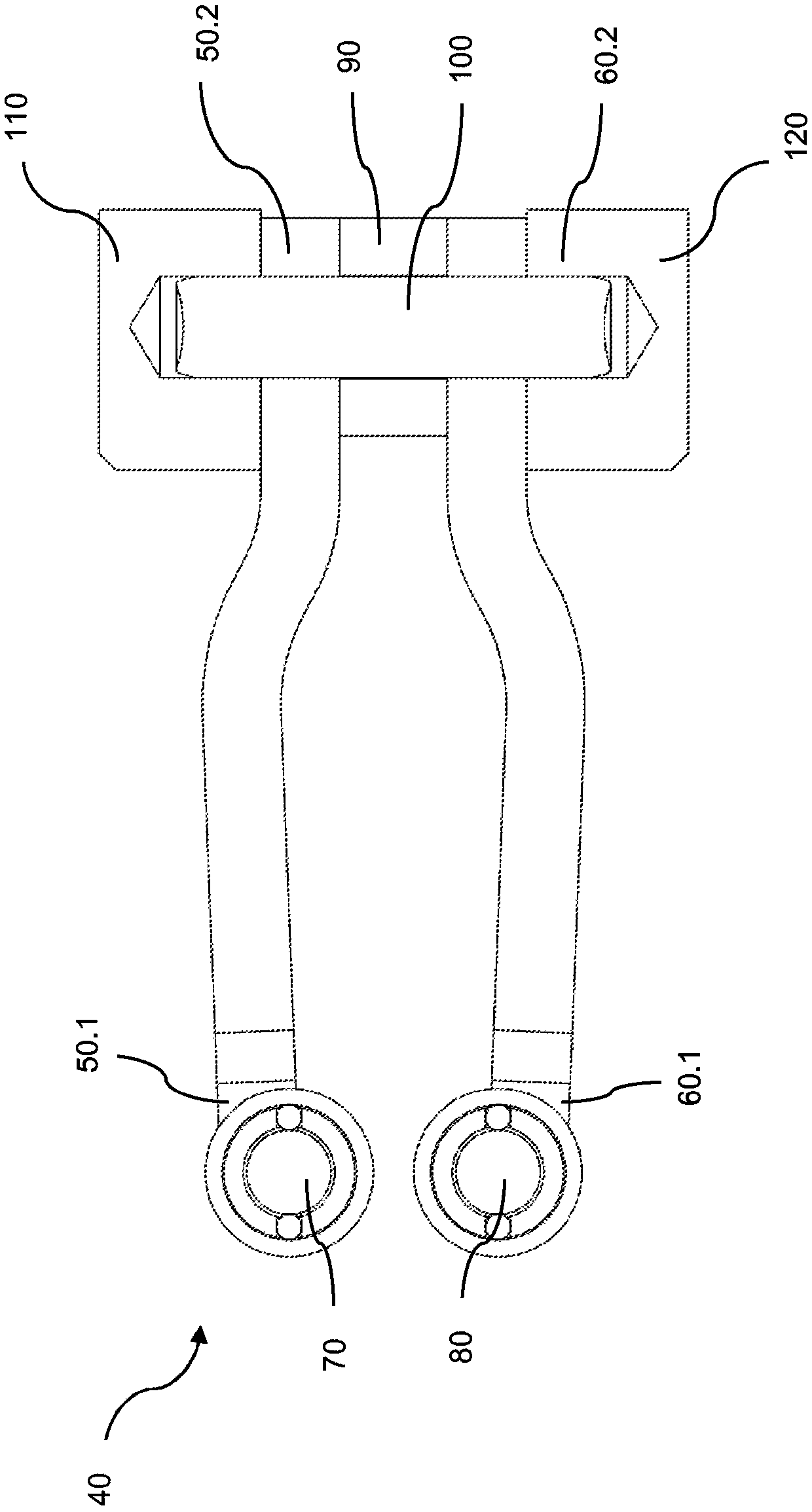

Device for simulating a force on an actuation element of a vehicle, in particular a pedal force simulator

ActiveCN107848511AChange cross sectionEasy to manufactureBraking systemsEngineeringMechanical engineering

The invention relates to a device for simulating a force on an actuation element of a vehicle, in particular a pedal force simulator, comprising a housing (10), a piston (20) which can be moved axially in the housing (10), said piston (20) being connected to the actuation element via a piston rod (30), and a spring element (40) which is arranged at least partly within the housing (10), in particular completely within the housing. According to the invention, the piston (20) has a changing cross-section and engages into the spring element (40) upon being actuated by the actuation element. The spring element (40) is equipped with rolling bodies (70, 80) which are operatively connected to the piston (20), and the spring element (40) consists at least of a first and a second spring part (50, 60) which are connected together.

Owner:SCHAEFFLER TECH AG & CO KG

Yarn drawing hair removal equipment

The invention provides yarn drawing hair removal equipment and belongs to the technical field of textile machinery. The yarn drawing hair removal equipment comprise a guiding device, a waxing device,a drawing device and a hair removal device, wherein he waxing device is arranged between a first guide roller and a second guide roller; the drawing device is arranged between the second guide rollerand a third guide roller; the drawing device comprises a first drawing mechanism, a second drawing mechanism, a drawing driving mechanism and a drawing tensioning mechanism. The drawing tensioning mechanism is arranged between the first drawing mechanism and the second drawing mechanism. The hair removal device is arranged between the third guide roller and a fourth guide roller. The hair removaldevice comprises a first hair removal supporting roller, a second hair removal supporting roller and a hair removal mechanism. According to the yarn drawing hair removal equipment, the first drawing mechanism and the second drawing mechanism can draw and process yarns independently and the first drawing mechanism and the second drawing mechanism can achieve linked drawing of the yarns by mean of adrawing speed difference, so that hairs generated by drawing are reduced effectively.

Owner:桐乡市隆源纺织有限公司

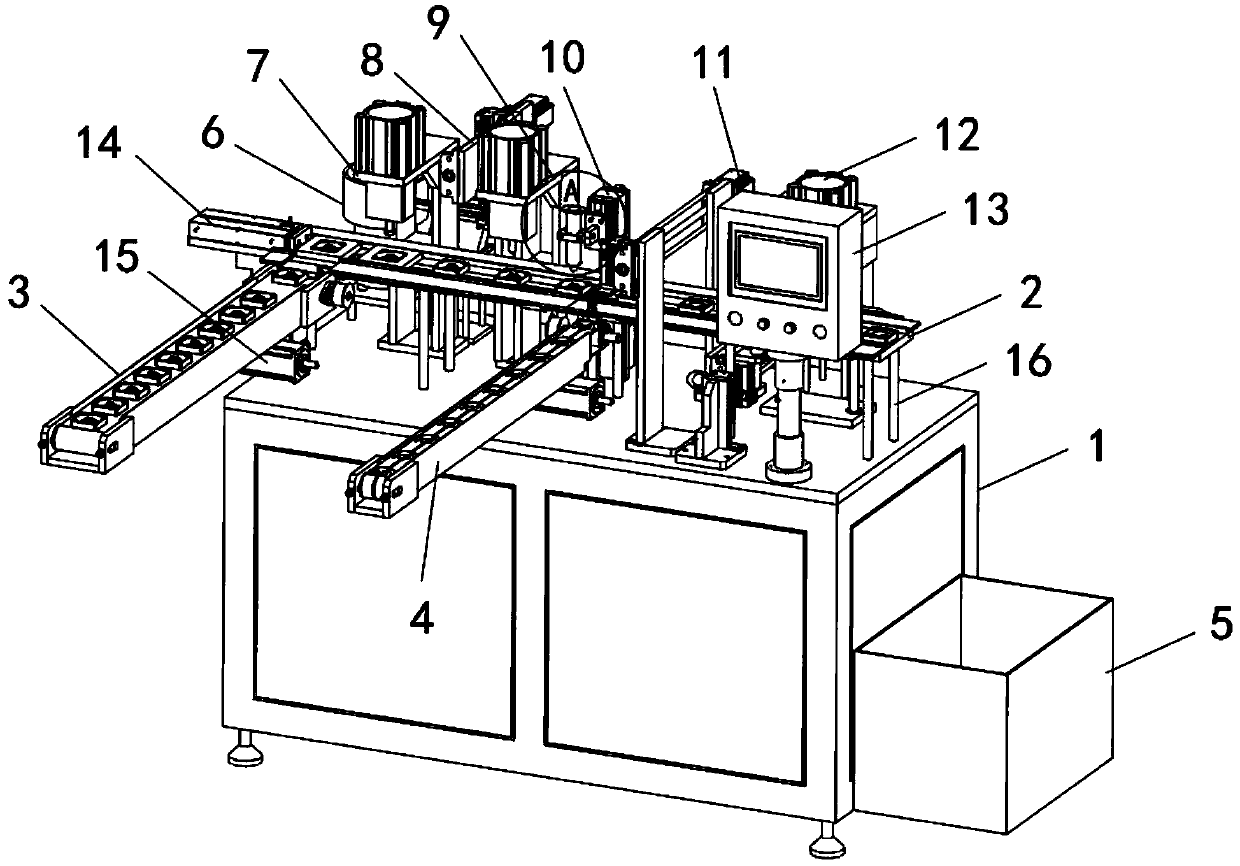

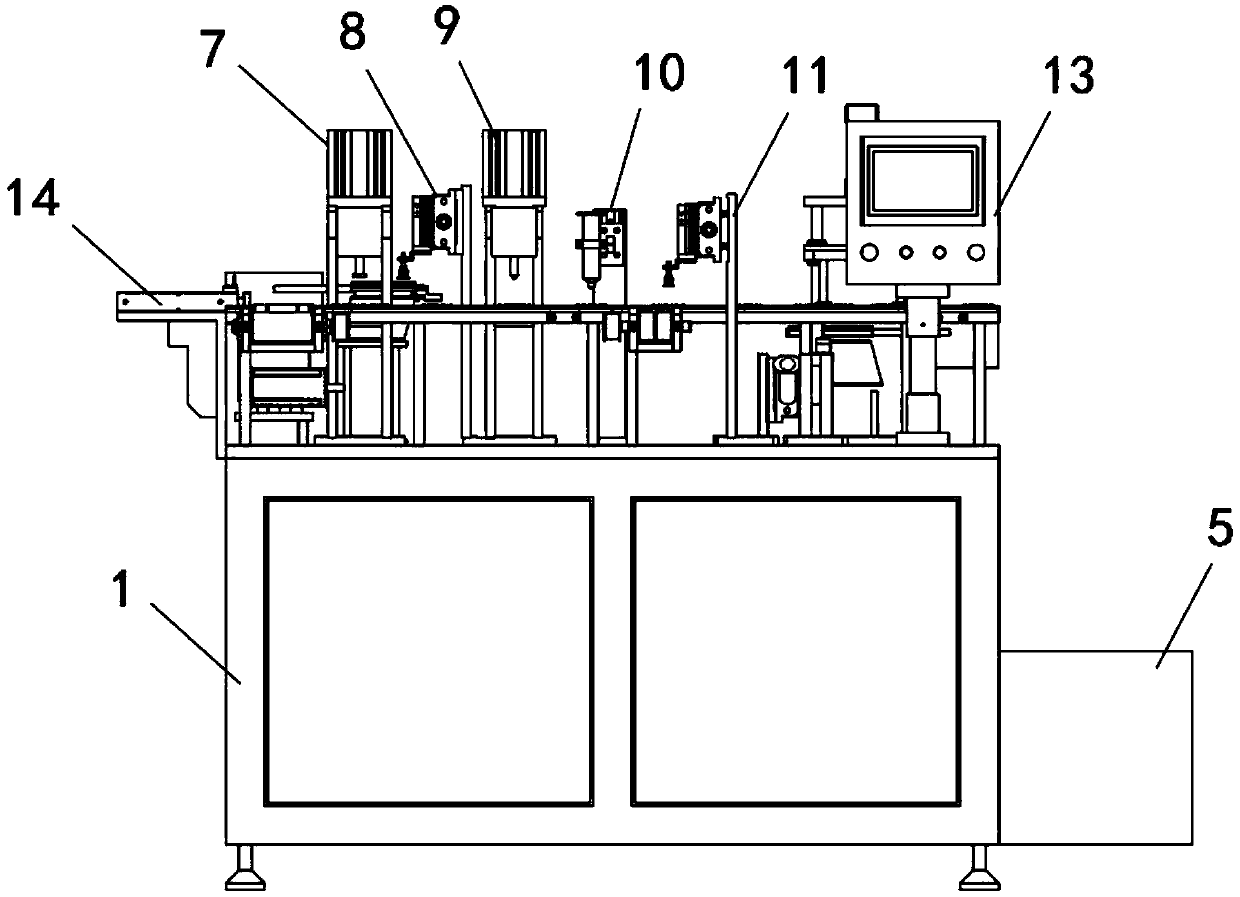

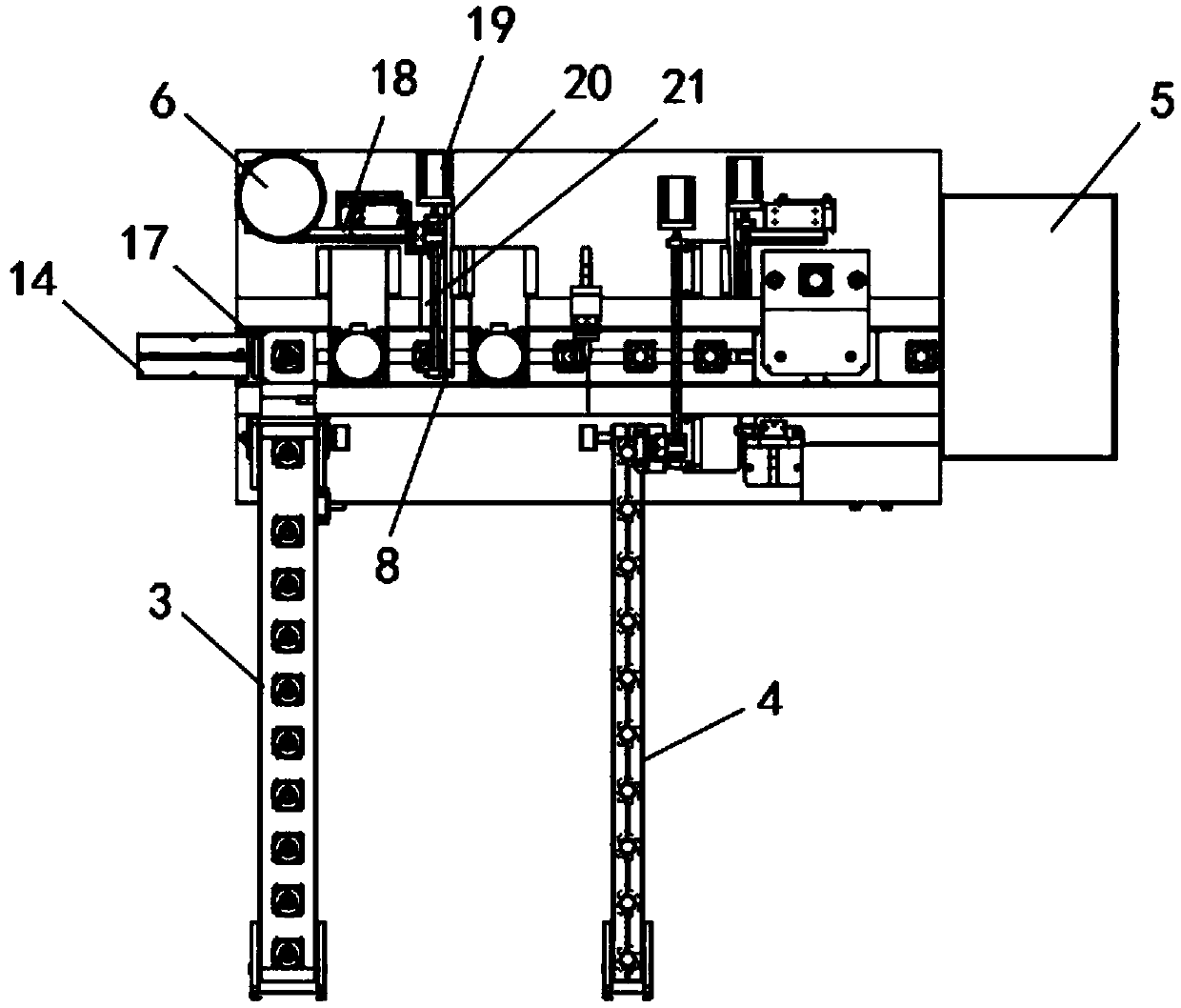

Automatic assembly equipment used for computer accessory production

ActiveCN109623308ASpacing adjustmentDocking degree adjustmentMetal working apparatusAutomatic test equipmentEngineering

The invention discloses automatic assembly equipment used for computer accessory production. The problems that when traditional automatic assembly equipment used for computer accessory production is used, due to the fact that structures used for carrying out angle and direction adjustment on various assembled parts are lacked in the equipment, accuracy cannot be guaranteed when the equipment assembles the parts in the accessories, structures used for extruding and stabilizing the assembled accessories are lacked, consequently, the overall structures of the assembled accessories are not firm and prone to loosening, the parts need to be constantly taken and placed in the assembly process, the existing assembly equipment is low in speed of taking and placing the parts and low in efficiency, and consequently the requirement for high efficiency during use of the automatic equipment cannot met can be solved. The automatic assembly equipment comprises a machine box and a material passing table located at the top of the machine box. A support is arranged at the bottom of the material passing table. A collection box is mounted on the side wall of the bottom of the machine box. A feeding airpump is mounted at one end of the material passing table.

Owner:宿州市徽腾知识产权咨询有限公司

Adhesive viscosity detecting apparatus for building wood bonding process

ActiveCN109100302AStrong construction glueShorten detection timeUsing mechanical meansMaterial analysisAdhesiveCoil spring

The invention aims to solve the existing problem of the inconvenience of quickly detecting the viscosity of an adhesive, and disclose an adhesive viscosity detecting apparatus for building wood bonding process. The apparatus comprises a first positioning ring, a first rotating ring, a first collar, first mounting frames, first fastening screws, a first rotating shaft, a first rocking handle, a first supporting rod, a spiral spring, a sliding block, a third fastening screw, a guide groove, heating rods, a base, a storage box, second fastening screws, second mounting frames, a second supportingrod, a second positioning ring, a second rotating ring, a second collar, a second rotating shaft, a second rocking handle, and positioning rods. According to the adhesive viscosity detecting apparatusfor the building wood bonding process, various types of wood separately placed can be detected by using the first mounting frames and the second mounting frames, and the woods of different thicknesscan be tightened by the first fastening screws and the second fastening screws; a bonding between the woods is not strengthened during building construction is avoided by detecting the adhesion between various woods, and the requirement is met.

Owner:NANJING INST OF MECHATRONIC TECH

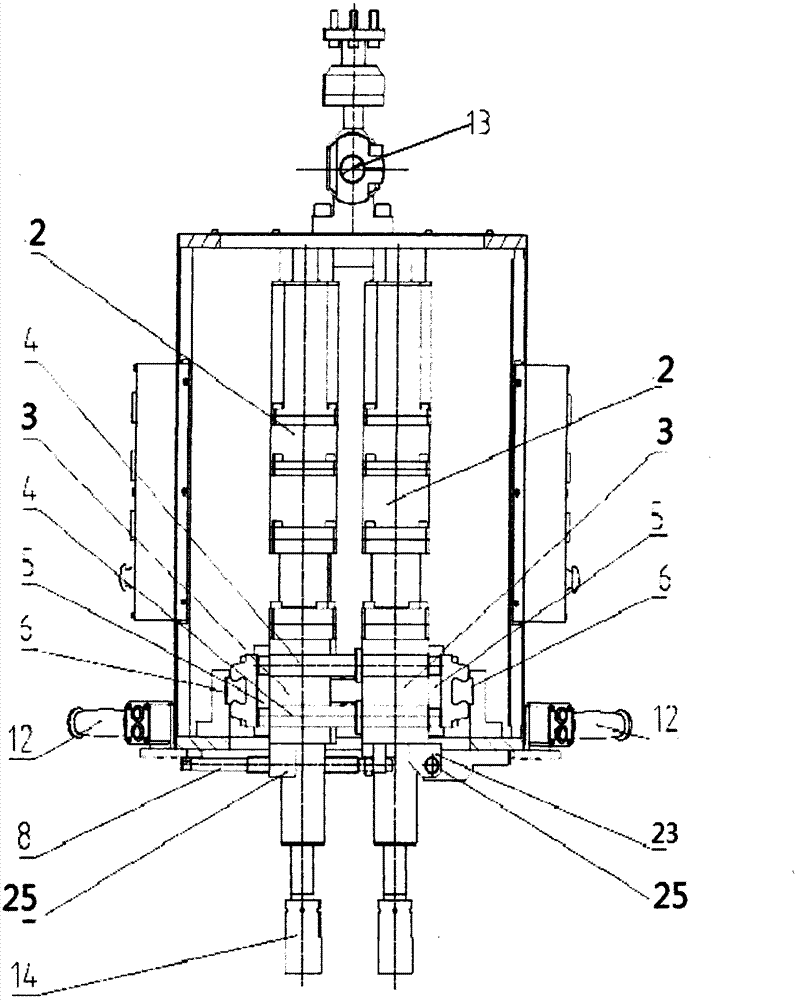

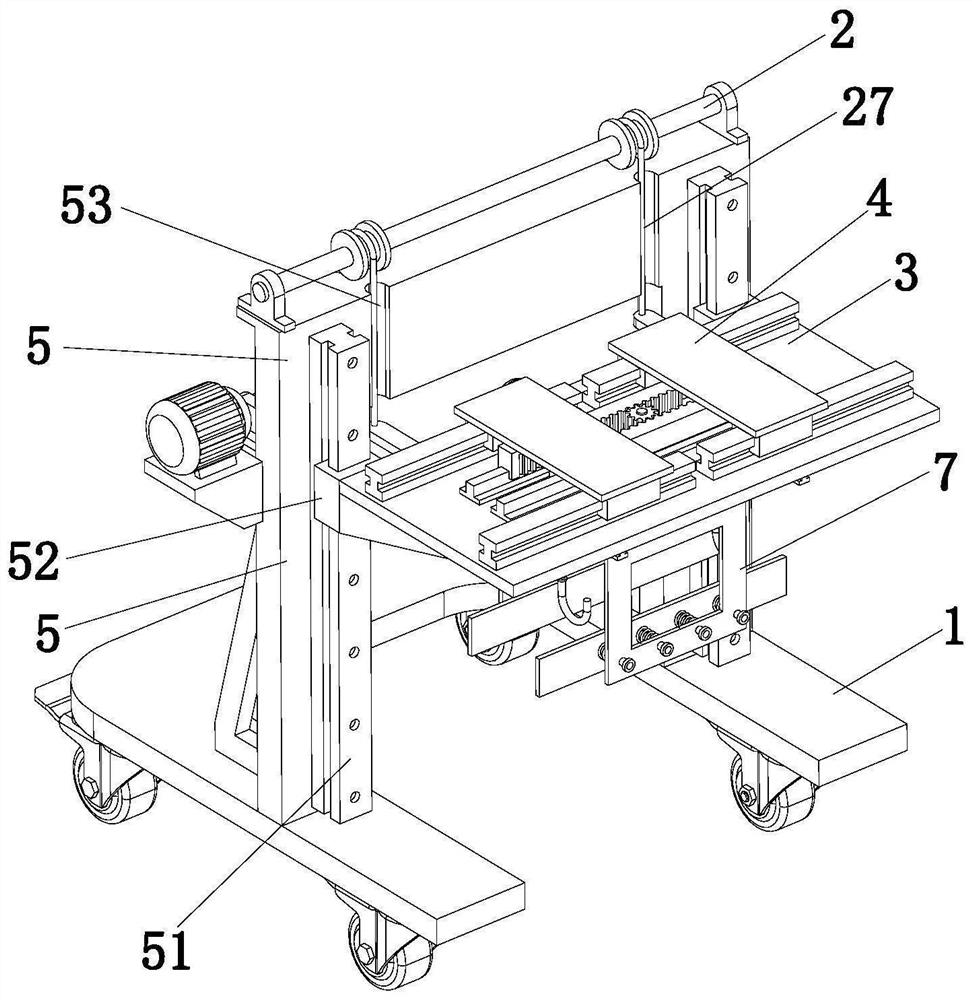

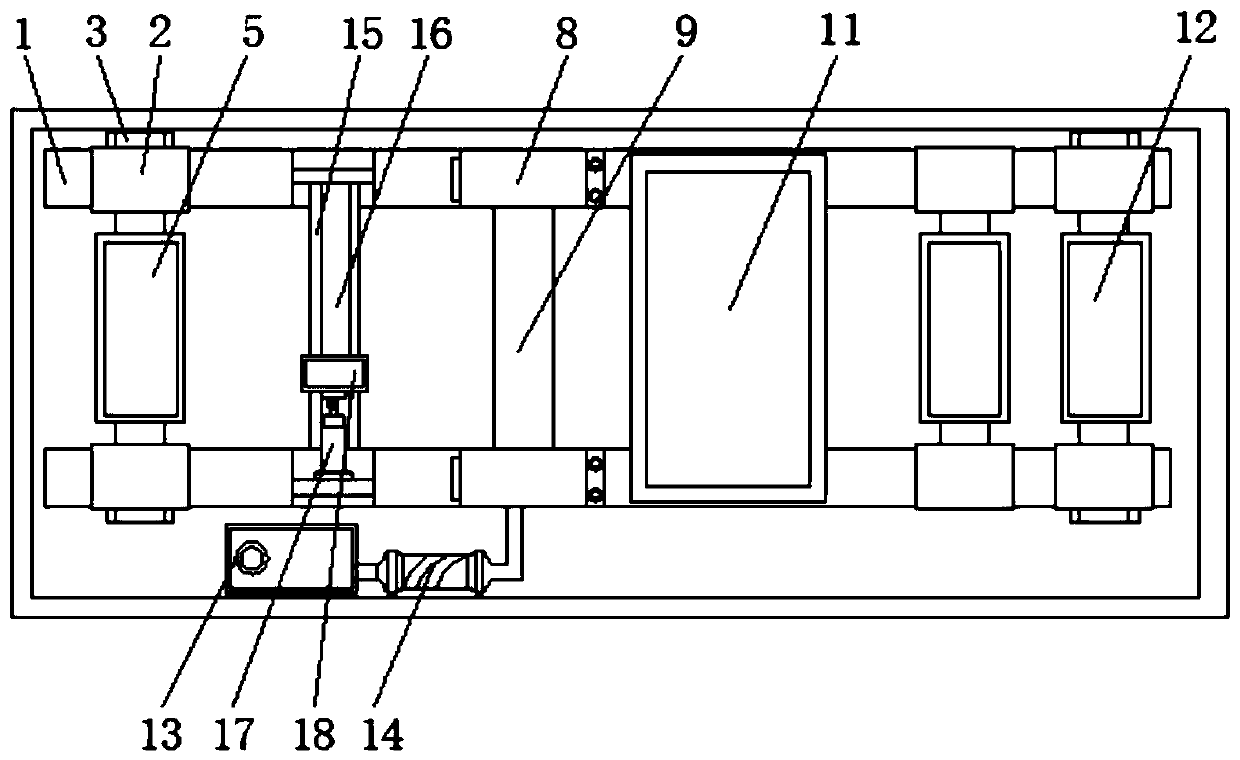

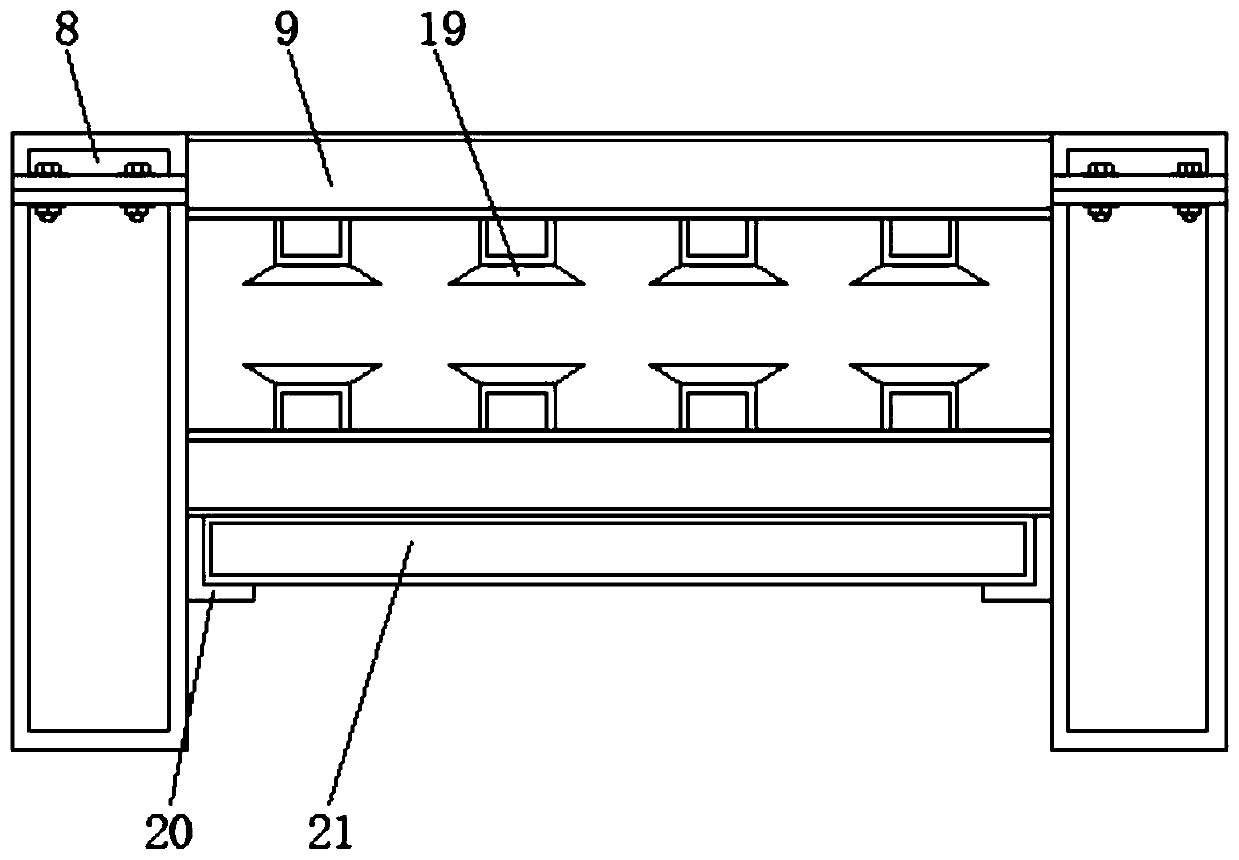

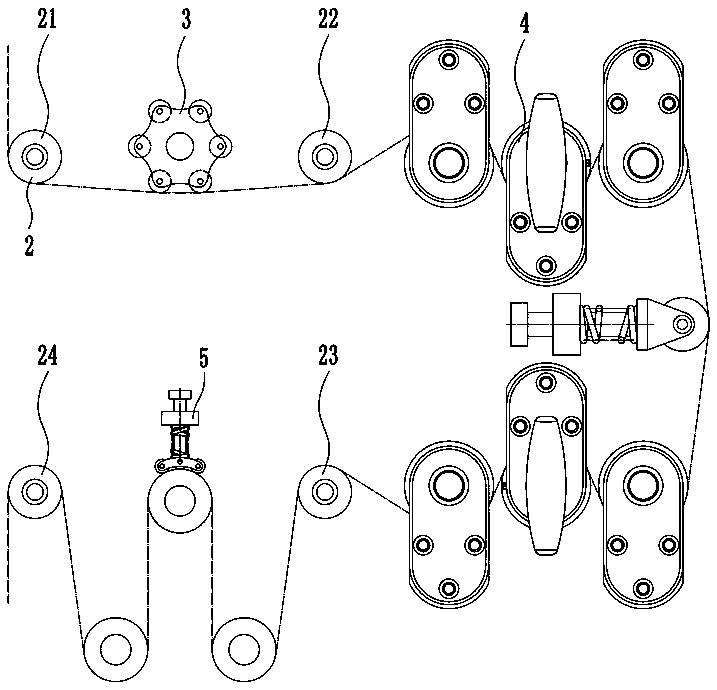

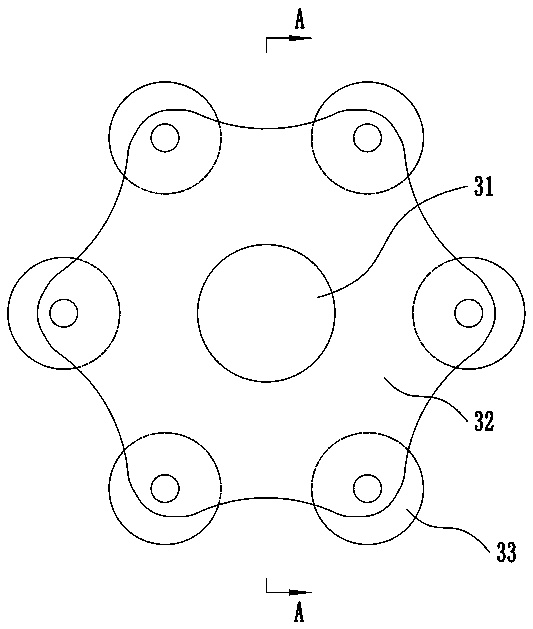

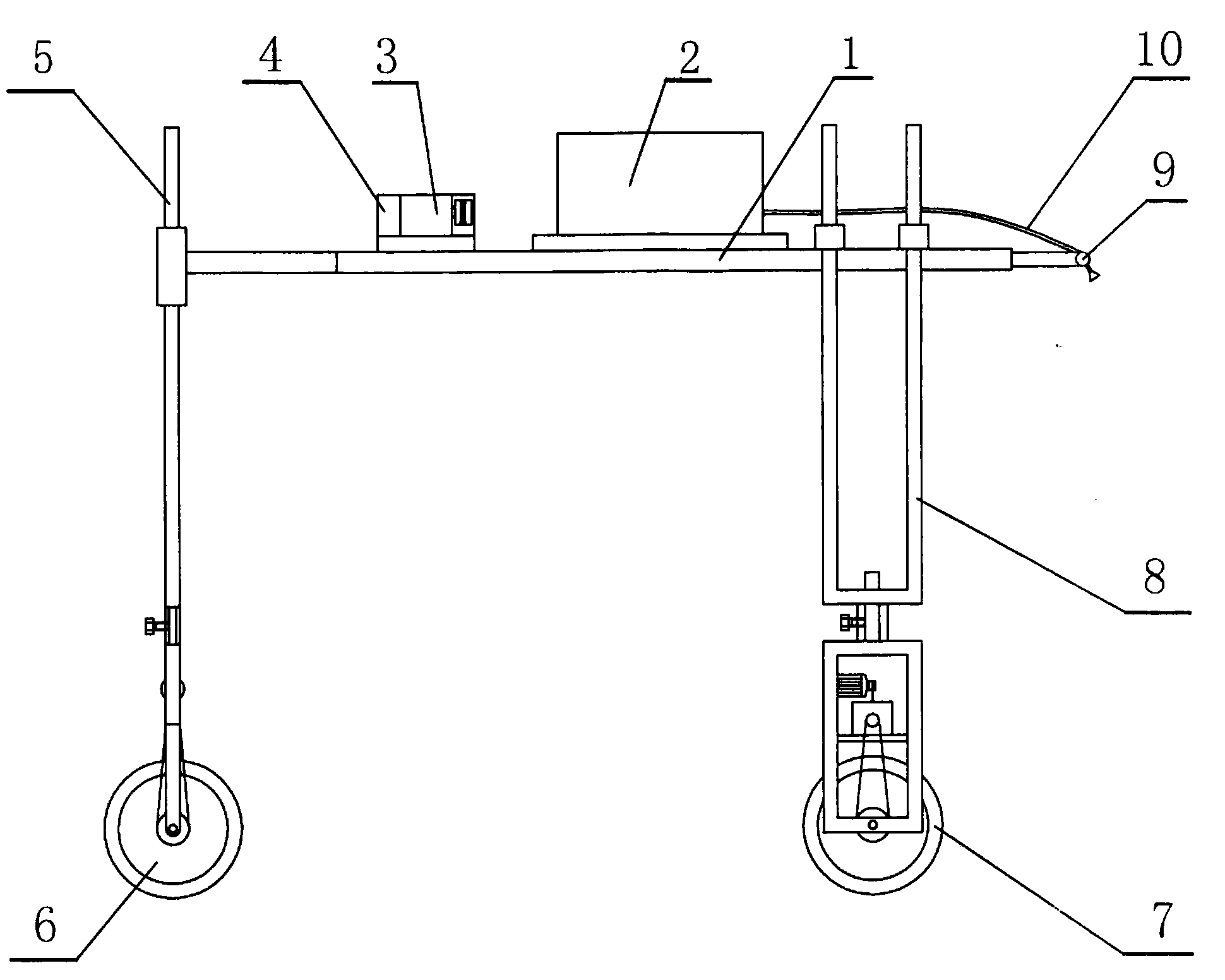

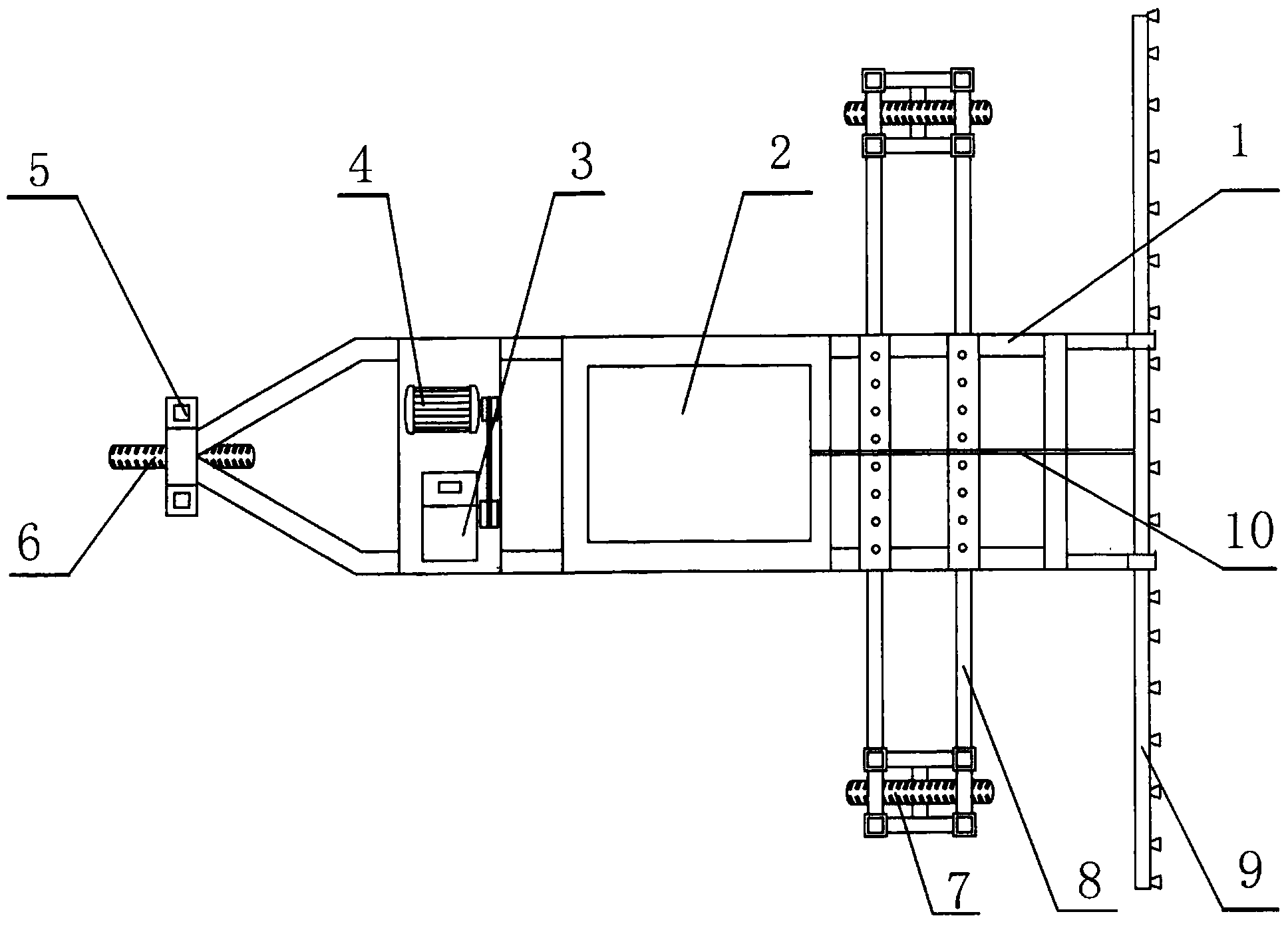

Variable automatically-walking pesticide spraying machine

ActiveCN103798216AAvoid poisoningSpacing adjustmentInsect catchers and killersEngineeringMechanical engineering

The invention relates to a variable automatically-walking pesticide spraying machine. The variable automatically-walking pesticide spraying machine is characterized in that the pesticide spraying machine is provided with a horizontally-arranged loading frame (1), a pesticide box (2) and a pesticide spraying pipe (9) are arranged on the loading frame (1), a front wheel (6) is installed at the front end of the loading frame (1) through a front wheel frame (5), two rear wheels (7) are installed at the two sides of the rear section of the loading frame (1) through rear wheel frames (8) respectively, the height of the front wheel frame (5), the height of the rear wheel frames (8), the direction of the front wheel (6) and the direction of the rear wheels (7) can be adjusted, a power source is arranged on the loading frame (1), the front wheel frame (5) and the rear wheel frames (8) are respectively provided with a motor (19), and the motors are in transmission with the front wheel (6) and the rear wheels (7) respectively. The variable automatically-walking pesticide spraying machine has the advantages that both the height of the loading frame and the interval between the two rear wheels can be adjusted to a large extent, pesticide can be respectively sprayed on crops with high straw and low straw, and the pesticide spraying machine can walk transversely at the edge of a field without turning. If necessary, the pesticide spraying machine can be driven by no man and operated automatically so that personnel can be prevented from being poisoned. The variable automatically-walking pesticide spraying machine has the good killing effect on a large-area destructive plague of insects.

Owner:冯成伟

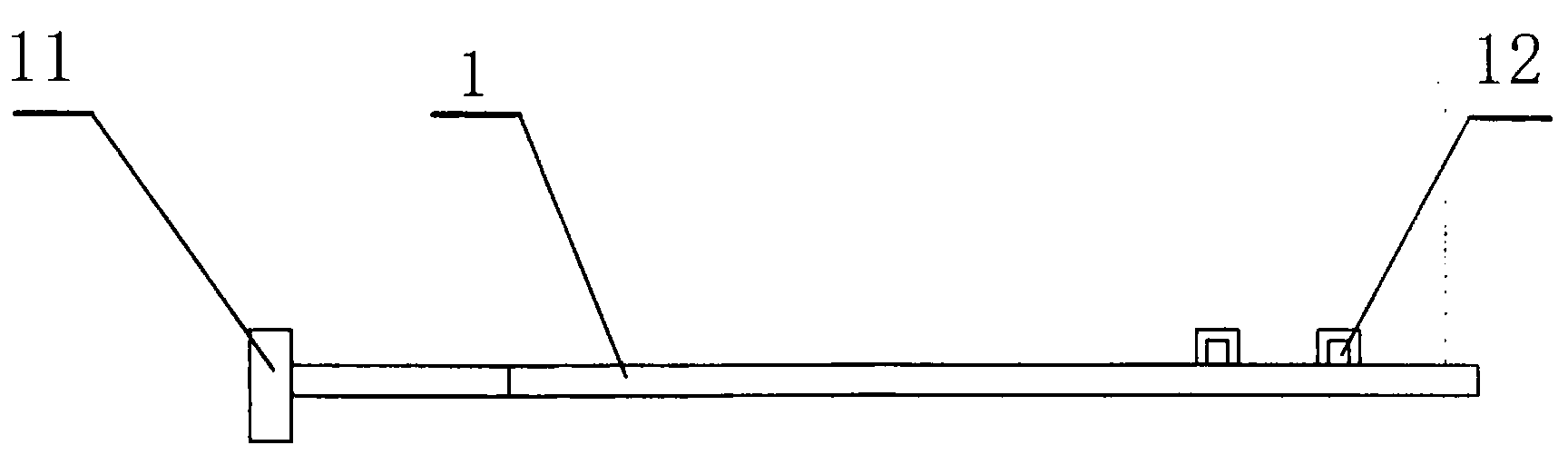

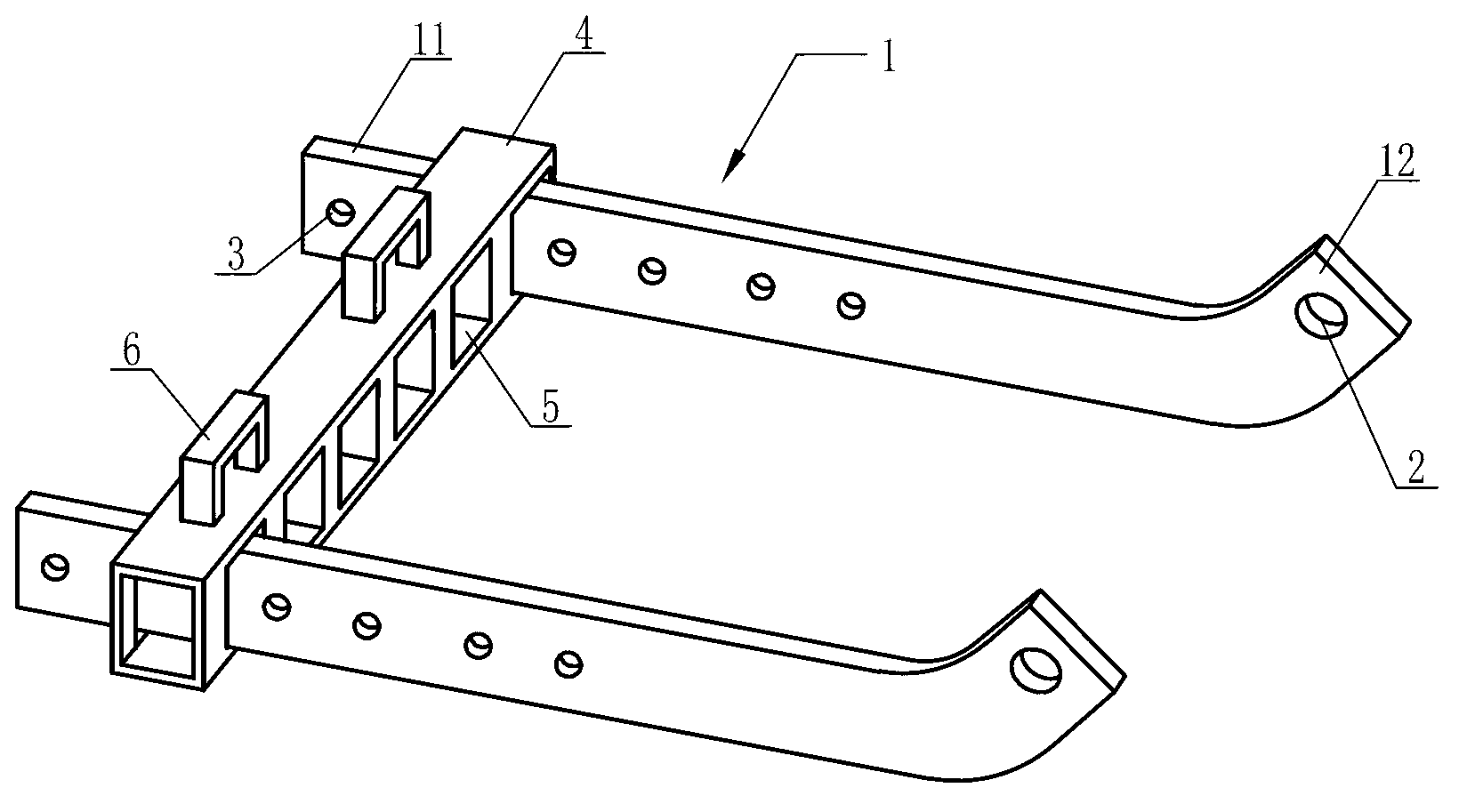

Suspension device for agricultural implements

InactiveCN103190220AEasy to useIncrease profitAgricultural machinesAgricultural engineeringAgricultural plant

The invention discloses a suspension device for agricultural implements. The suspension device comprises two parallel suspension arms. Motor vehicle suspension holes are arranged at front ends of the suspension arms, agricultural implement suspension holes are arranged at rear ends of the suspension arms, a positioning connecting beam is connected between the two suspension arms, distance holes used for adjusting the distance between the two suspension arms are distributed on the positioning connecting beam, and the two suspension arms are respectively sleeved in the distance holes. The suspension device has the advantages that the suspension arms are mounted in the different distance holes, the distance between the two suspension arms can be adjusted, accordingly, the suspension device is widely applicable to multiple agricultural implements or power heads and is convenient to use, and the utilization rate of the suspension device for the agricultural implements is increased advantageously.

Owner:CHANGYI BAOLUDA MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com