Four-shaft spacing-variable bolt tightening device

A variable axis spacing technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that the position accuracy cannot be well maintained, the position of the tightening shaft is fixed and cannot be changed, and the tightening accuracy is affected. The spacing cannot be guaranteed, the effect of solving multi-variety production and improving the tightening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

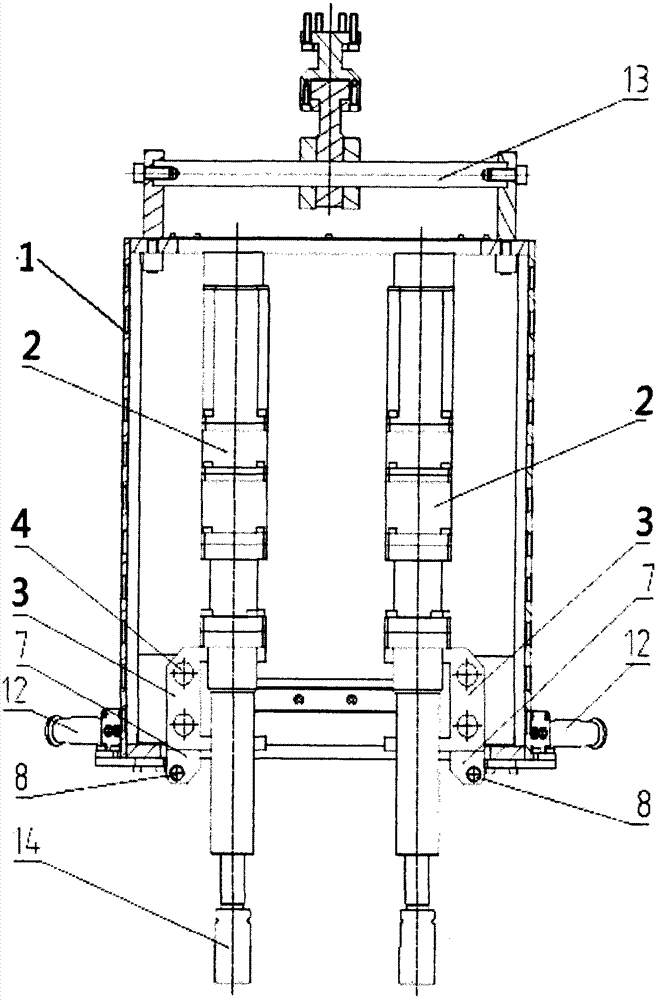

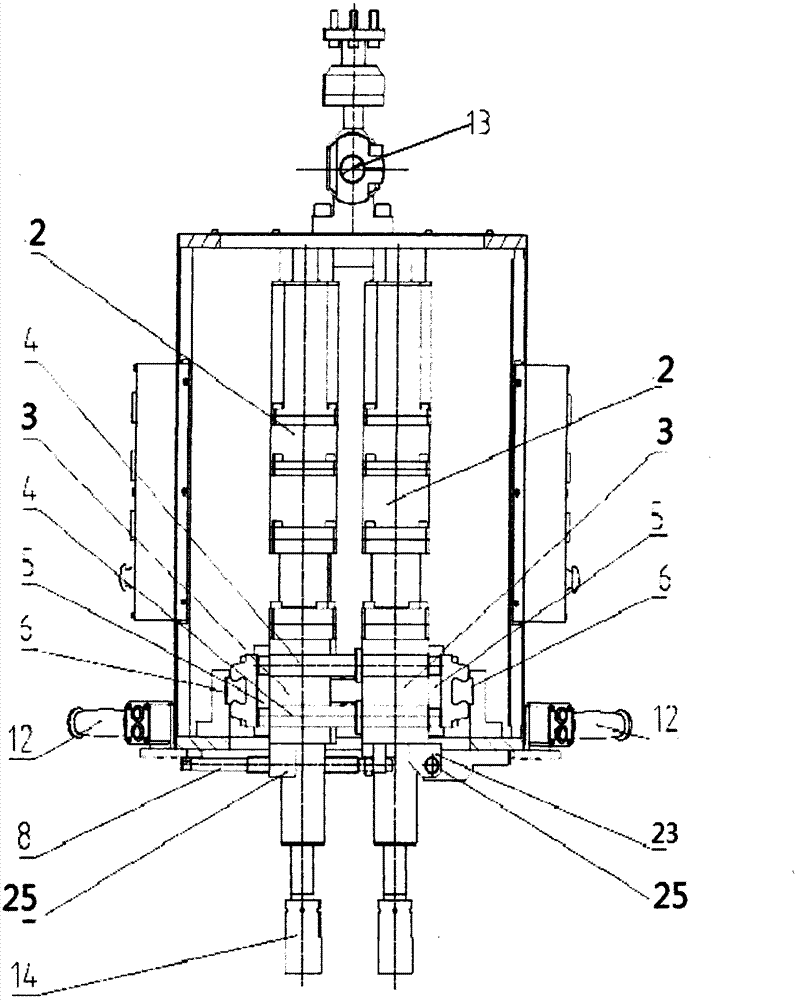

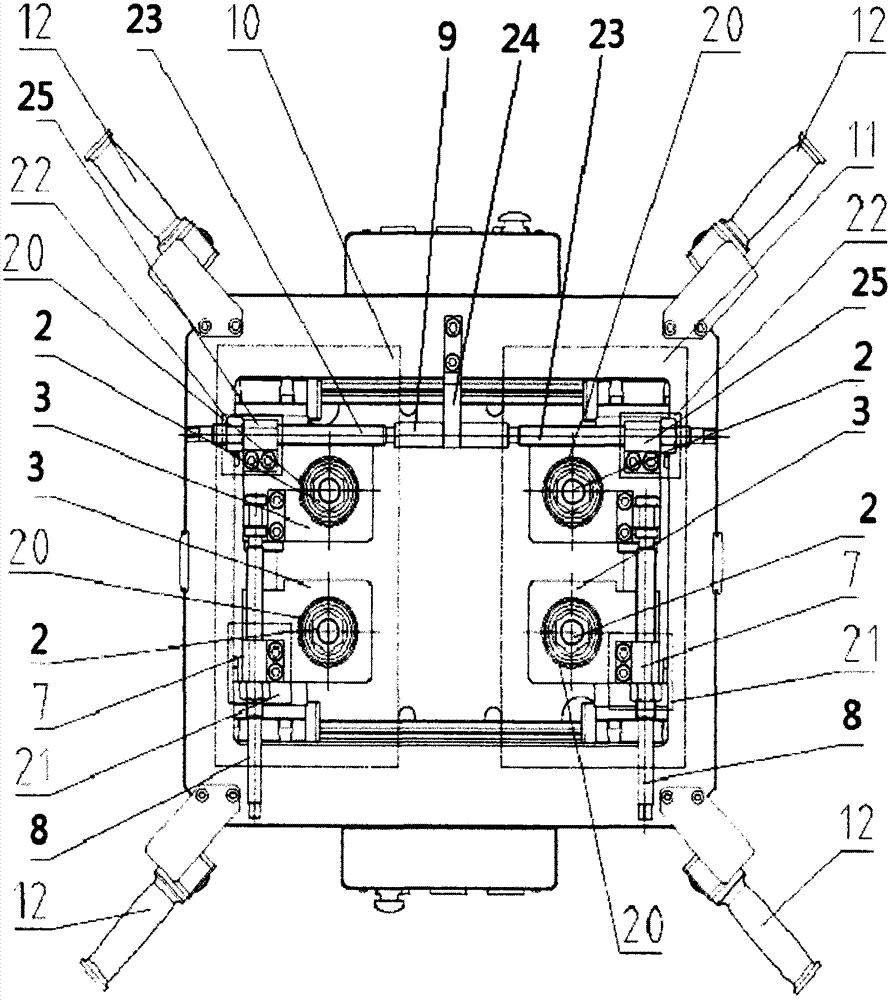

[0036] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a four-axis spacing variable bolt tightening device, comprising:

[0037] A vertical frame 1, the upper end of which is connected with the pneumatic suspension device 15;

[0038] There are four tightening shafts 2, which are arranged in the vertical frame 1, and are used to realize the tightening connection between the car and the leaf spring;

[0039] There are four fixed blocks 3, which are relatively fixed on the vertical frame 1. The tightening shaft 2 runs through the fixed block 3 vertically and is connected with the fixed block 3 in rotation; the four tightening shafts 2 and the four fixed blocks 3 are fixed by Mounting hole 20 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com