Device for simulating a force on an actuation element of a vehicle, in particular a pedal force simulator

A technology for manipulating elements and simulators, applied in the direction of brakes, etc., can solve the problems of expensive and laborious manufacturing, and achieve the effects of simplifying manufacturing, reducing costs, and preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

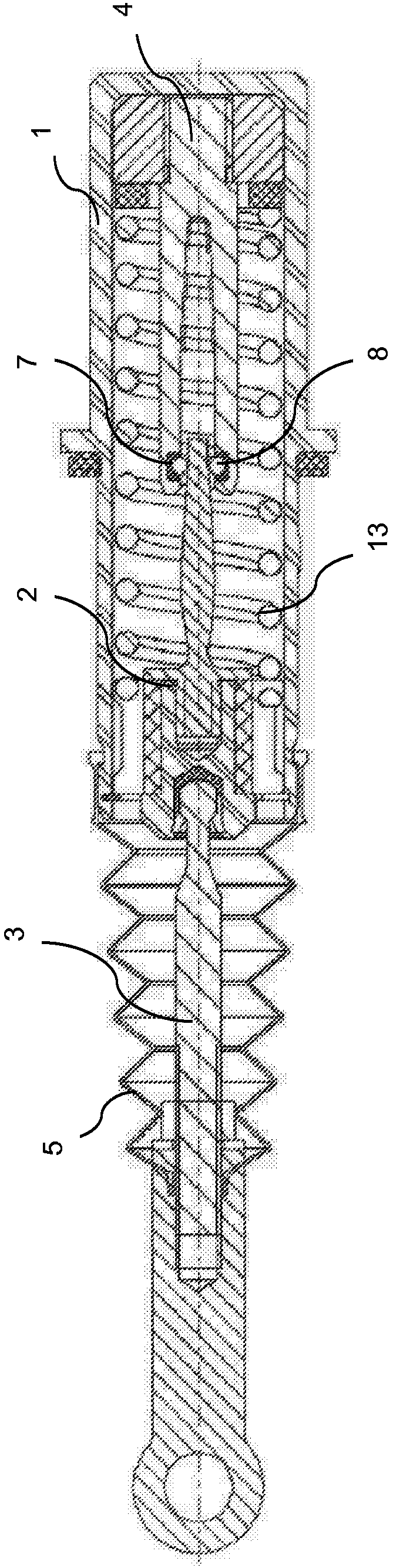

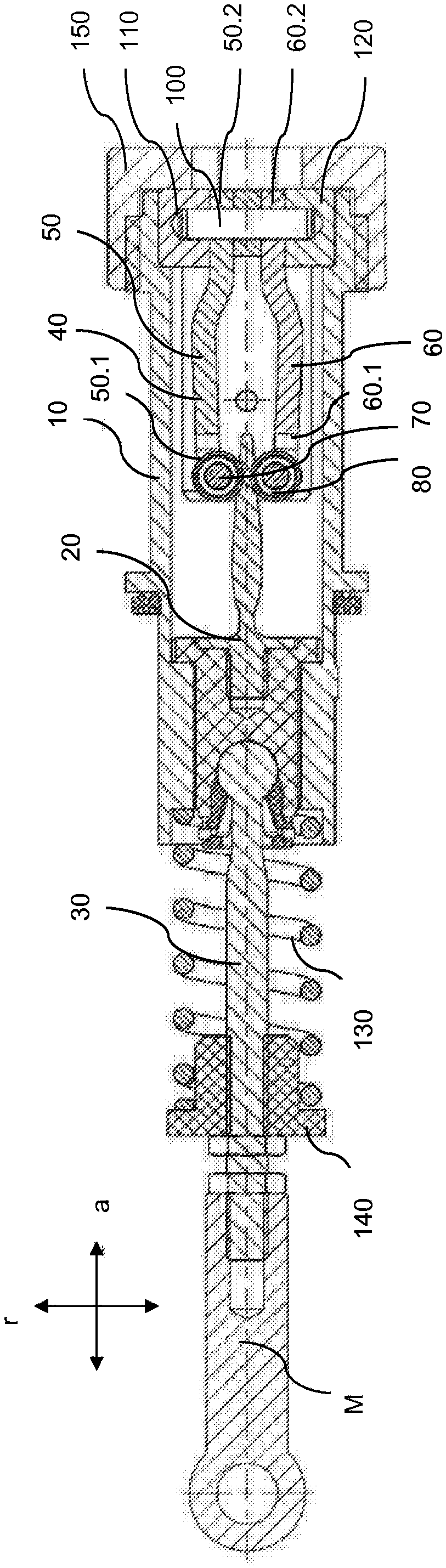

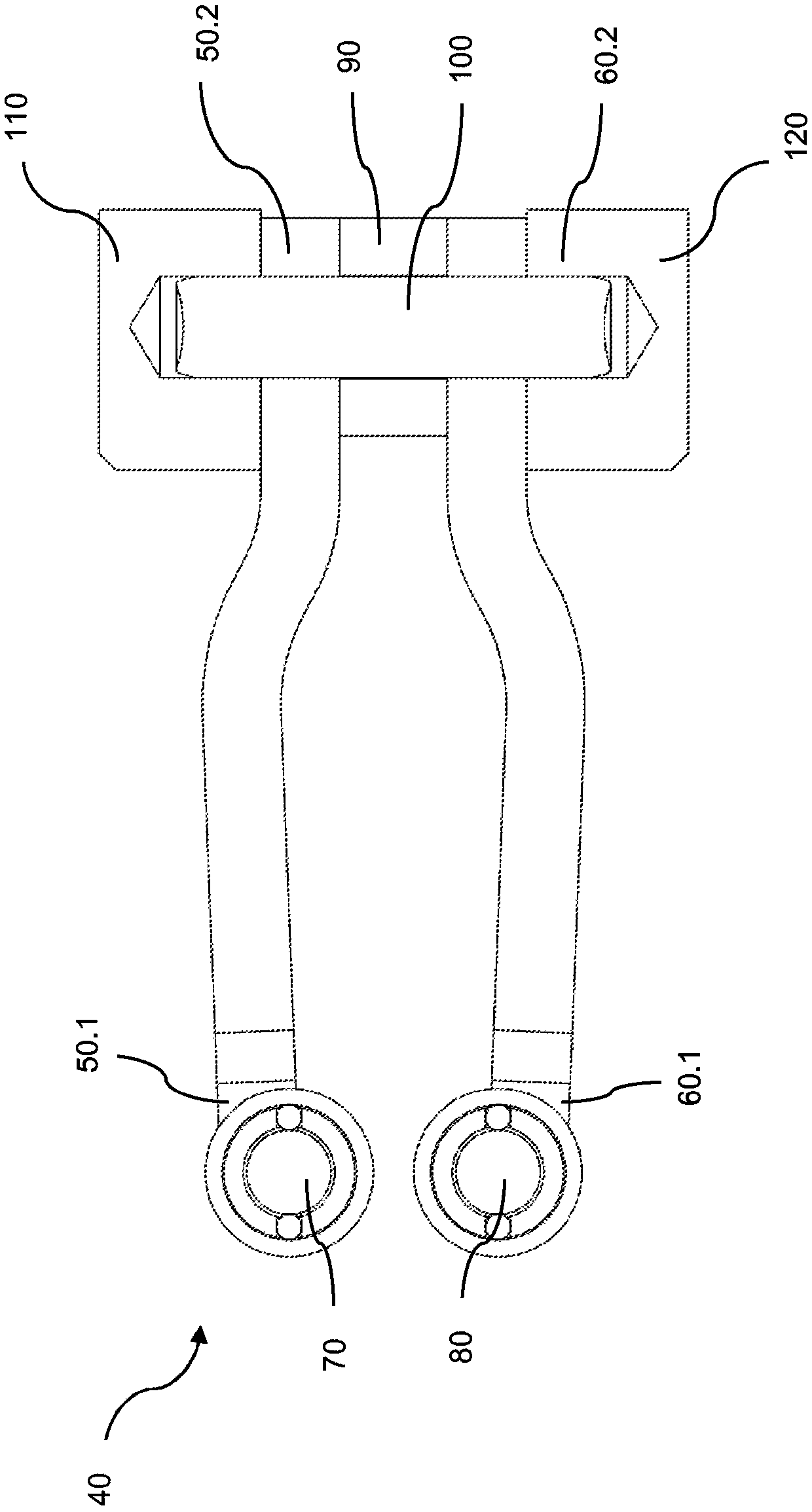

[0025] figure 1 A device for force simulation is shown, as is known from the as yet unpublished prior art. The device has a housing 1 inside which a piston 2 can move axially. Piston 2 is connected via piston rod 2 to an operating element (eg clutch pedal). A dust protection device 5 in the form of a bellows is arranged on the outside of the piston rod in the radial direction. The dust protection device is fixed on the piston rod 3 and on the housing 1 and prevents dirt particles from entering the interior of the cylinder. The piston rod 3 has a piston rod head, not shown in detail, which is supported in the joint socket of the piston 2 . The piston 2 consists of a piston element and a connecting rod member, which are connected to each other. The linkage component has a changing cross section and is pushed axially into the spring element 4 when the actuating element is actuated.

[0026] The spring element 4 is fork-shaped and has two spring arms. as from figure 1 It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com