Patents

Literature

74results about How to "Control inflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

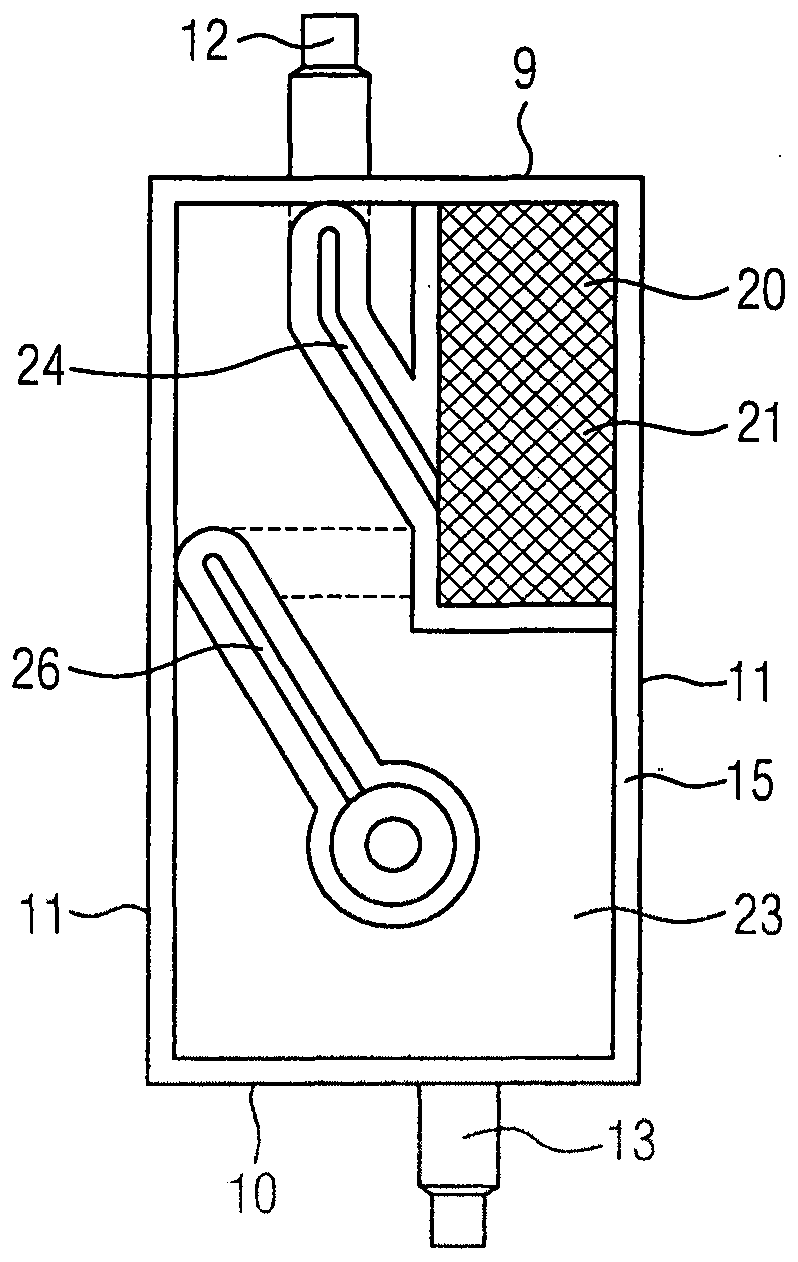

Refrigerator with multipurpose storing box and its controlling method

InactiveCN1421666AControl inflowDomestic refrigeratorsCompression machines with several evaporatorsEngineeringCold store

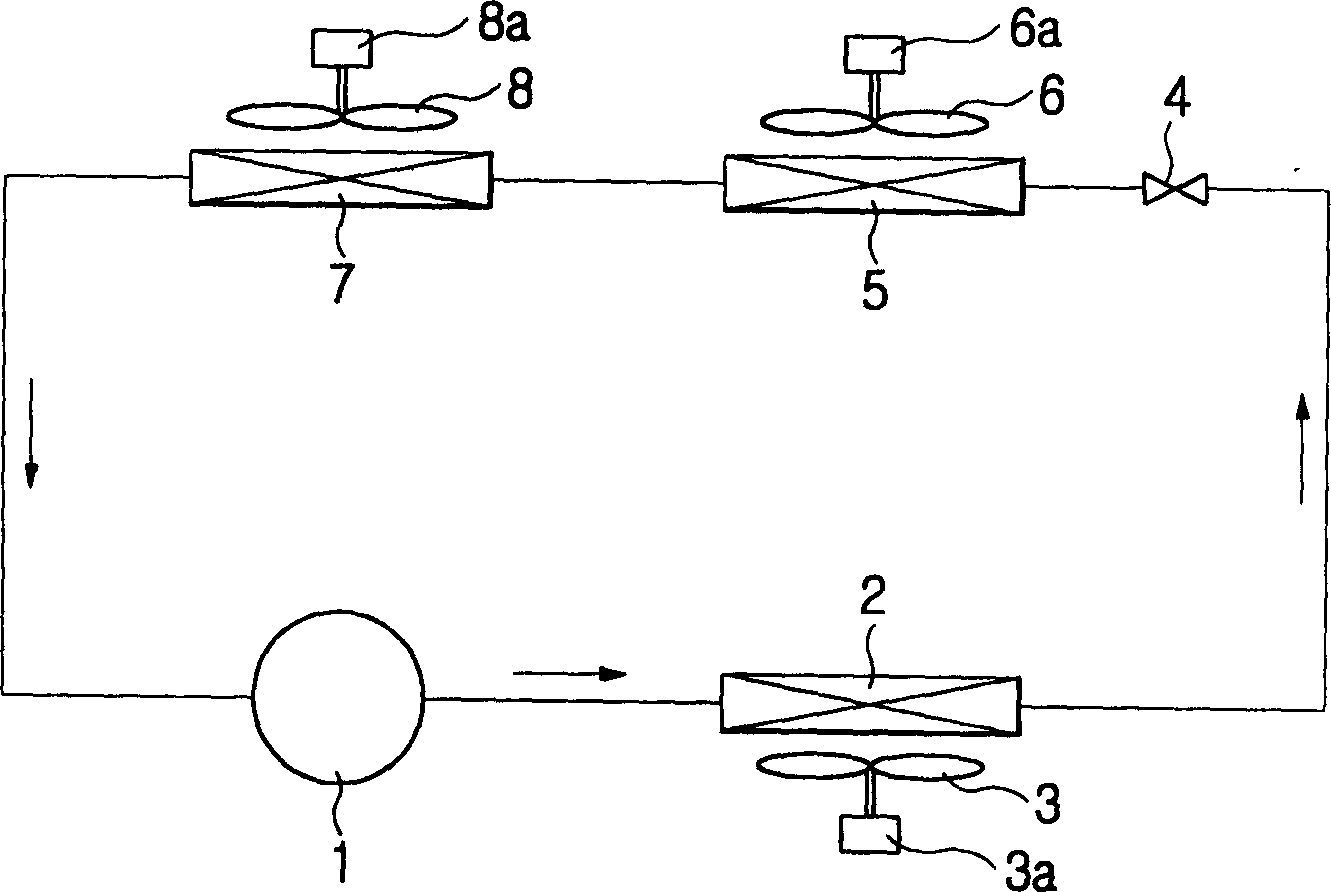

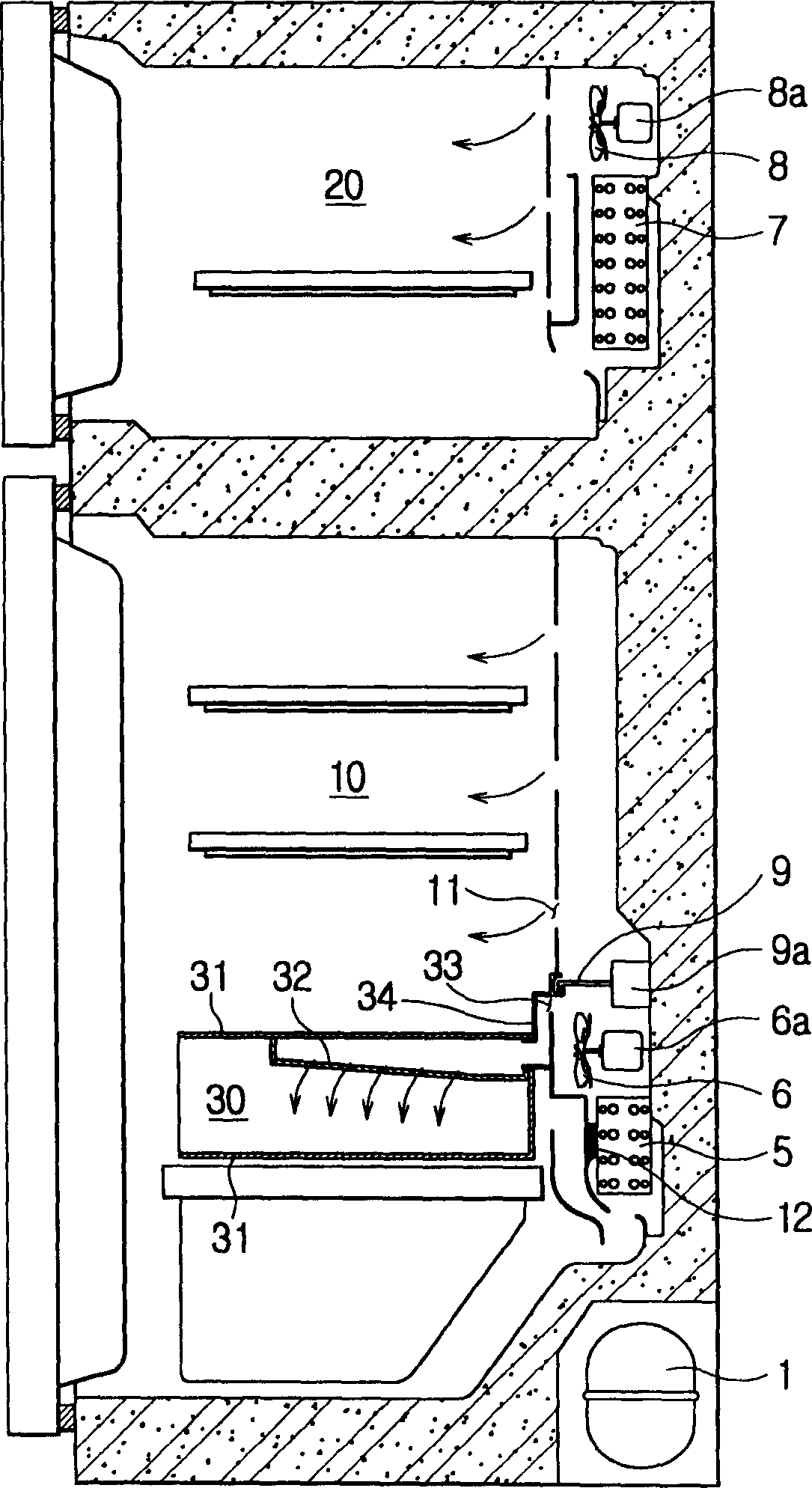

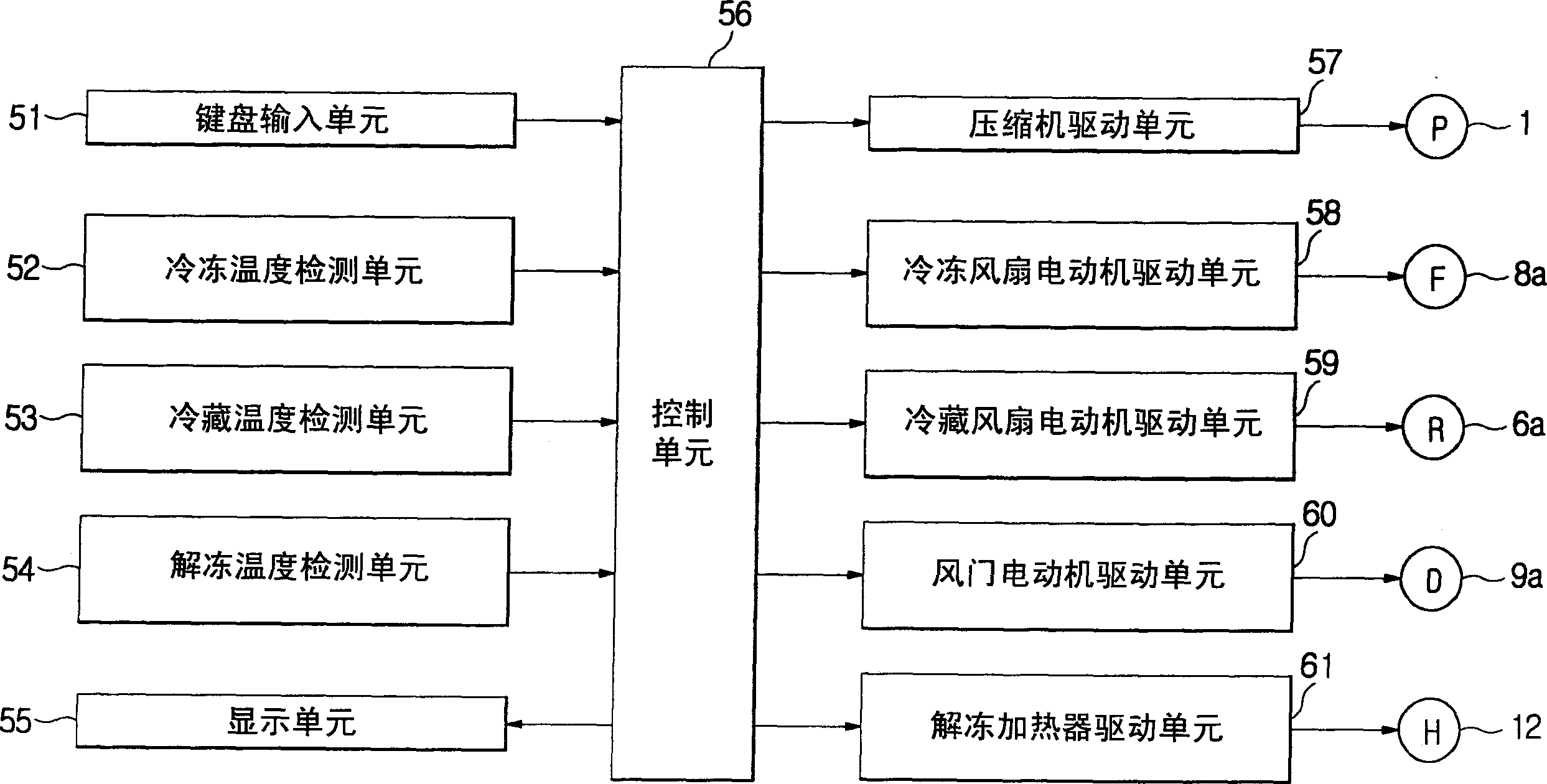

A refrigerator with a multipurpose storage chamber and a control method. In the refrigerator, the flow of cool air to the multipurpose storage chamber is selectively controlled in accordance with a variety of operational modes. In order to accomplish such a cool air flow control, a refrigerating compartment fan and a damper are provided at positions above a refrigerating compartment evaporator. In addition, a flap, controlled at an open angle thereof, is provided at the inlet of an air guide path guiding the cool air to the multipurpose storage chamber. The multipurpose storage chamber of this refrigerator can thus effectively be used to store a variety of foods in accordance with storage characteristics of the foods. In addition, a thawing mode operation of the refrigerator is performed under the condition that it is not necessary to perform a refrigerating compartment cooling operation. It is thus possible to prevent an excessive increase in the temperature of the refrigerating compartment caused by an operation of the defrosting heater during such a thawing mode.

Owner:SAMSUNG ELECTRONICS CO LTD

Composite bacterial agent and method for treating kitchen waste through composite bacterial agent

PendingCN110218680ACreate pollutionControl inflowFungiBacteriaBacillus licheniformisKlebsiella oxytoca

The invention provides a composite bacterial agent and a method for treating kitchen waste through the composite bacterial agent and relates to the technical field of kitchen waste treatment. The technical problem of low degradation efficiency for the kitchen waste in the prior art is solved. The composite bacterial agent comprises IrPex Cacteus, rumen microorganisms, bacillus subtilis, bacillus cereus, bacillus stearothermophilus, klebsiella oxytoca, bacillus licheniformis and aspergillus niger. By means of the composite bacterial agent and a treatment device and method, 90% or above of organic waste in the kitchen waste can be degraded, and the treatment efficiency is high.

Owner:北京瑞斯壮环保设备有限公司

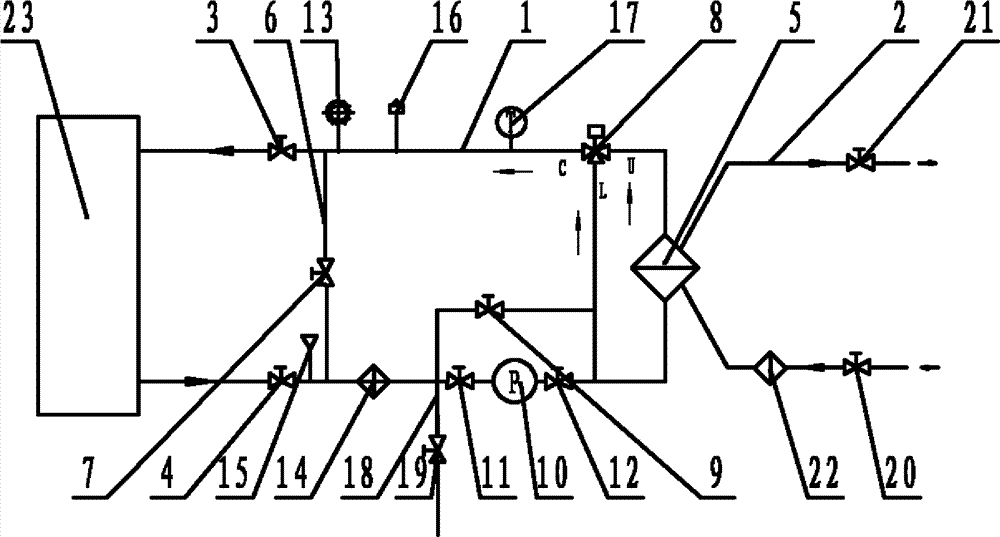

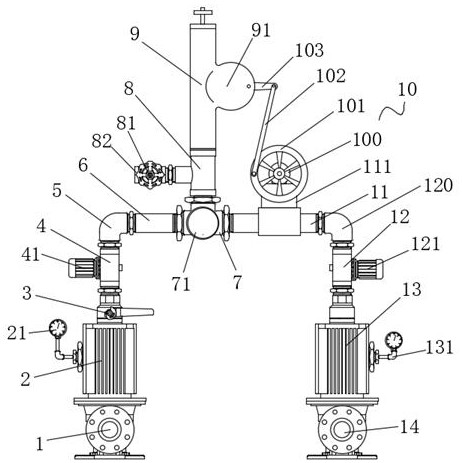

Repairing liquid injection system for cross-linked cable

ActiveCN1780078AGuarantee injection qualityControl pressureApparatus for repairing insulation/armouring cablesCross-linkEngineering

A preparing liquid injecting system for the cross-linked electric cable is composed of a compressed gas tank, repairing liquid tank, connecting pipelines and liquid outlet tube. The pressure limiting valve, electromagnetic valve, pressure sensor, and liquid flow distributing plate are respectively installed to relative connecting pipelines.

Owner:中国华北电力集团公司天津市电力公司

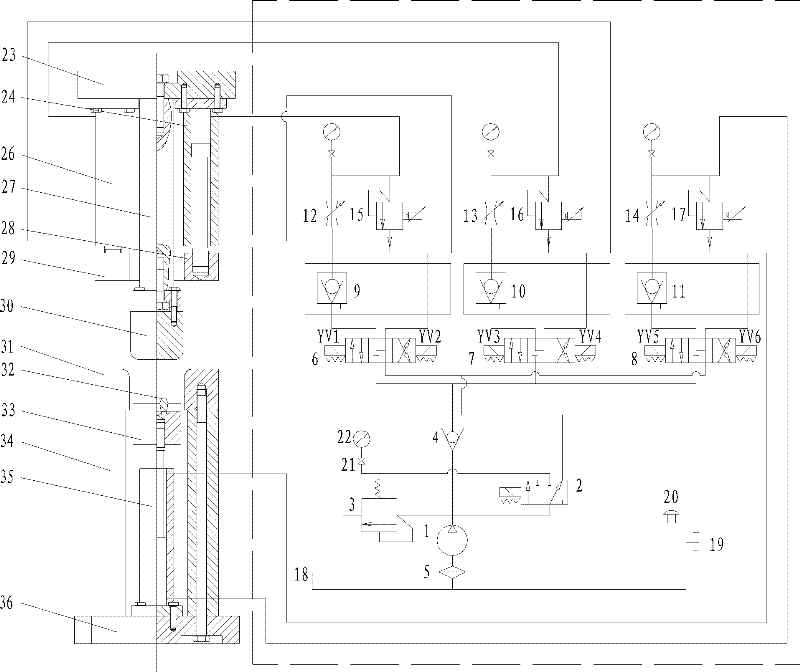

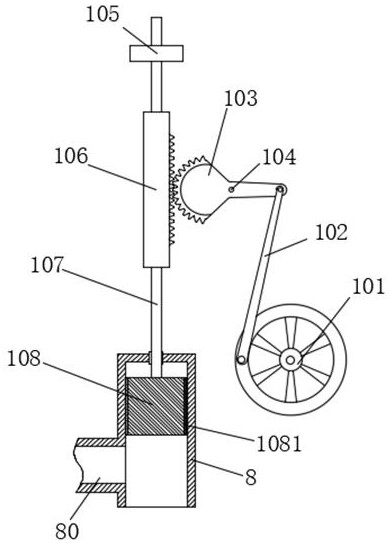

Constant temperature device of engine oil

ActiveCN102819276AControl inflowRealize the sewage emptying functionTemperature control without auxillary powerTemperature controlProportional control

The invention discloses a constant temperature device of engine oil. The constant temperature device comprises a heat exchanger, an external medium circulating pipeline and an engine oil circulating pipeline; the heat exchanger is provided with an engine oil heat exchange pipeline and an external medium heat exchange pipeline respectively communicated with the engine oil circulating pipeline and the external medium circulating pipeline; the engine oil circulating pipeline comprises a main oil inlet path and a main oil return path; an oil inlet temperature sensor is arranged on the engine oil circulating pipeline; a three-way valve for carrying out proportional control and temperature control on the engine oil of an engine is arranged on the main oil return path; the main oil inlet path is divided into a first oil path and a second oil path; the first oil path is connected with an oil inlet of the three-way valve; the second oil path is connected with the oil inlet end of the engine oil heat exchange pipeline; an oil outlet end of the engine oil heat exchange pipeline is connected with another oil inlet of the three-way valve, and the oil outlet of the three-way valve is connected with the main oil return path. According to the invention, the flow of the oil liquid flowing into the heat exchanger is controlled through the three-way valve and mixed with the flow which does not flow into the heat exchanger according to a certain ratio, so that the temperature of the oil flowing into the engine is accurately controlled.

Owner:CAMALUOYANGELECTROMECHANIC

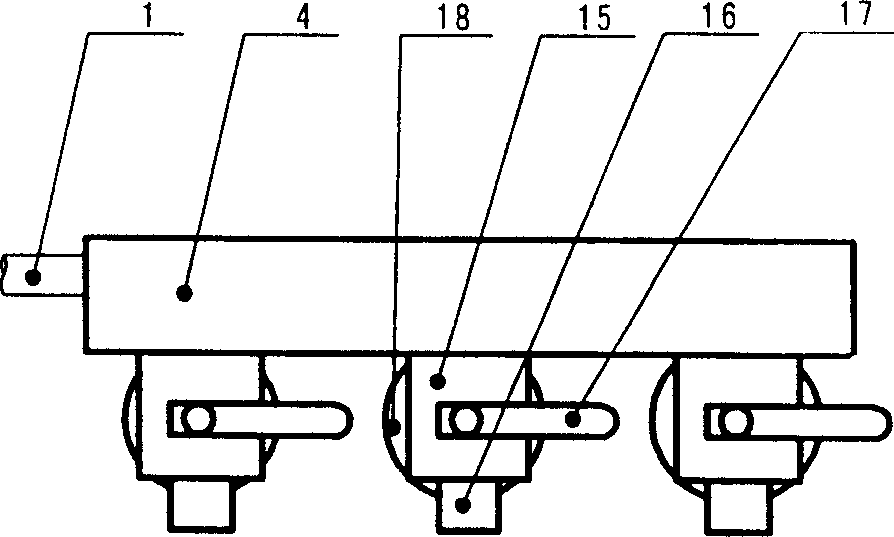

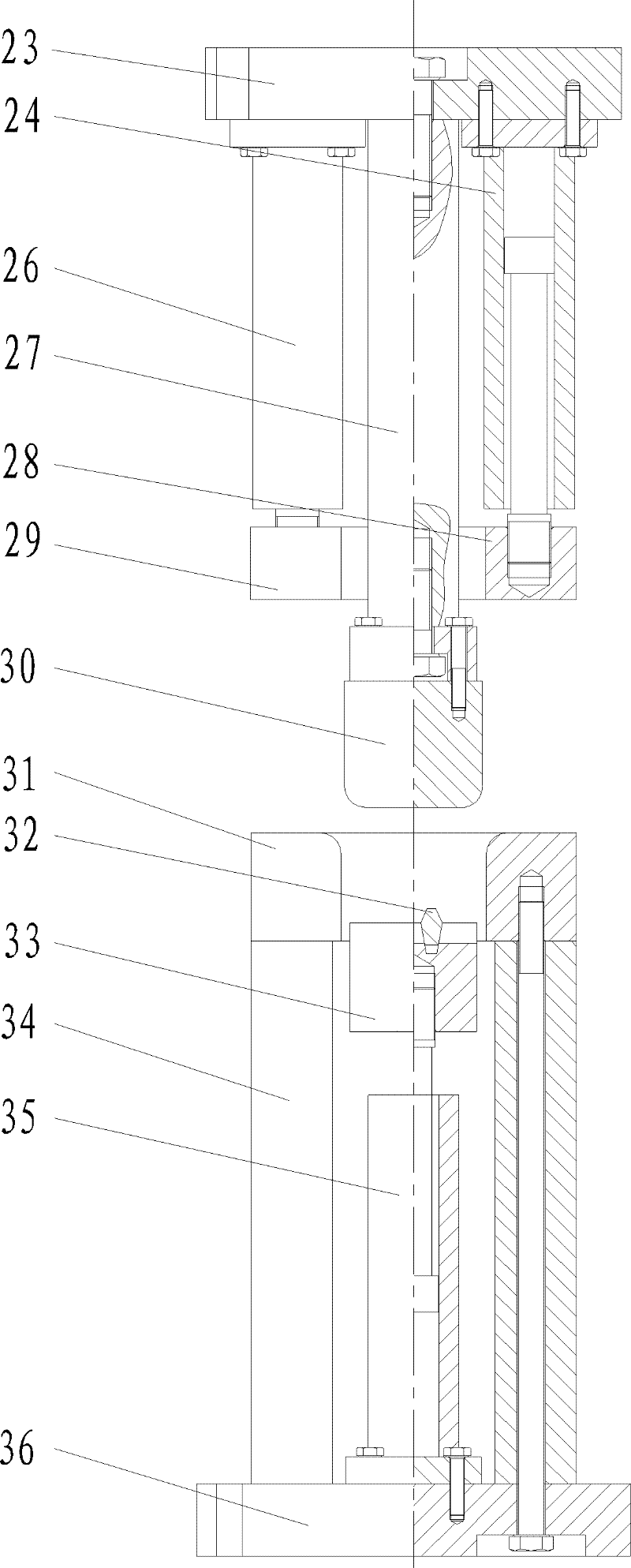

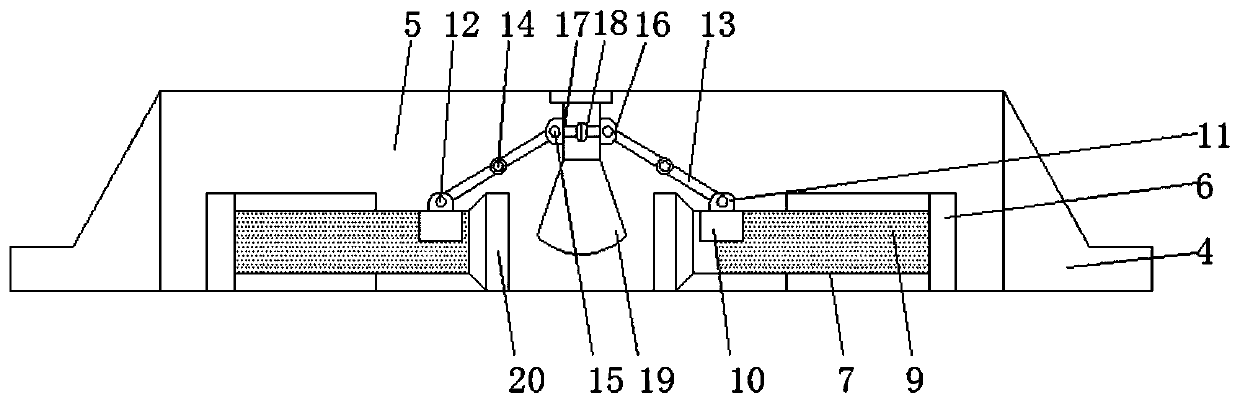

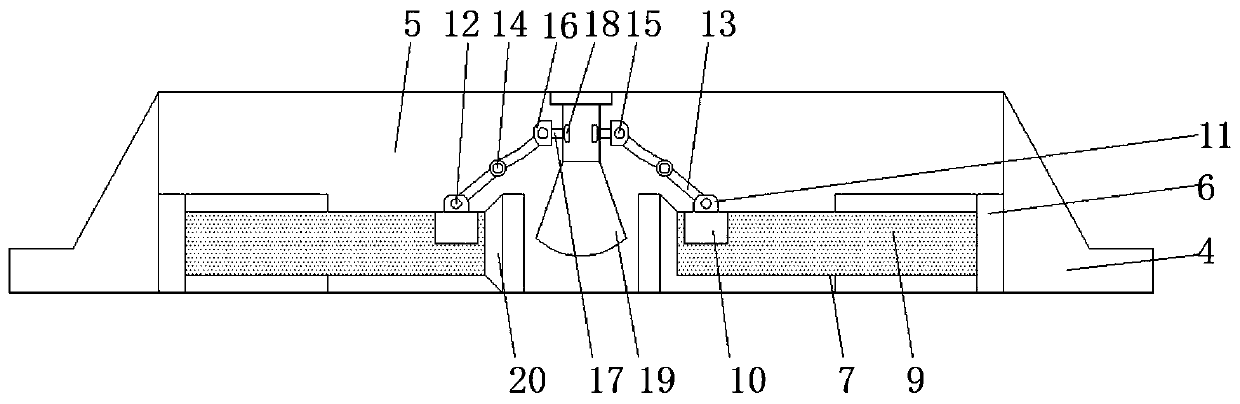

Weld-line movement-controlled tailor-welded blank stamp-forming device

InactiveCN102303063AControl flowFlexible control of blank holder forceServomotorsHydraulic cylinderControl system

The invention discloses a weld-line movement-controlled tailor-welded blank stamp-forming device, relating to tailor-welded blank stamp-forming devices. The weld-line movement-controlled tailor-welded blank stamp-forming device aims at solving the problem that the traditional tailor-welded blank stamp-forming device cannot control a weld line to move to a correct position through regulating a blank-holding force of a blocking blank holder and regulating a holding force of the weld line and cannot flexibly control a blank-holding force on a blank at two sides of the weld line. A female die is mounted on the upper end faces of two female die cushions; a holding block can move up and down along the die cavity of the female die under the driving of a piston rod of a third hydraulic cylinder; a holding pin inserts into one of grooves; a first blank holder and a second blank holder are arranged above the female die and are used for positioning a tailor-welded blank; the upper end face of the first blank holder is connected with a piston of a first hydraulic cylinder; the upper end face of the second blank holder is connected with a piston of a second hydraulic cylinder; and a control system is used for adjusting the motion of the three hydraulic cylinders through controlling the on / off of each hydraulic valve component in a hydraulic system. According to the invention, the inflow volume of blanks at the two sides of the weld line of the tailor-welded blank can be effectively controlled.

Owner:HARBIN INST OF TECH

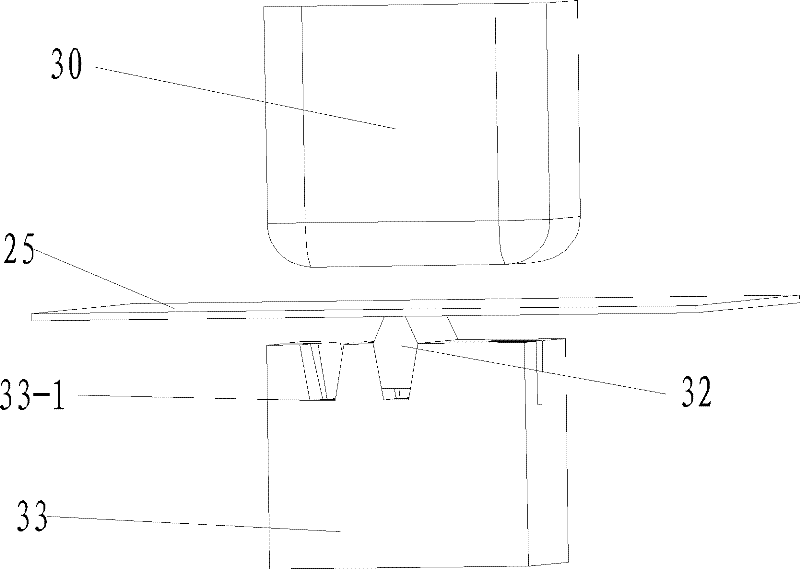

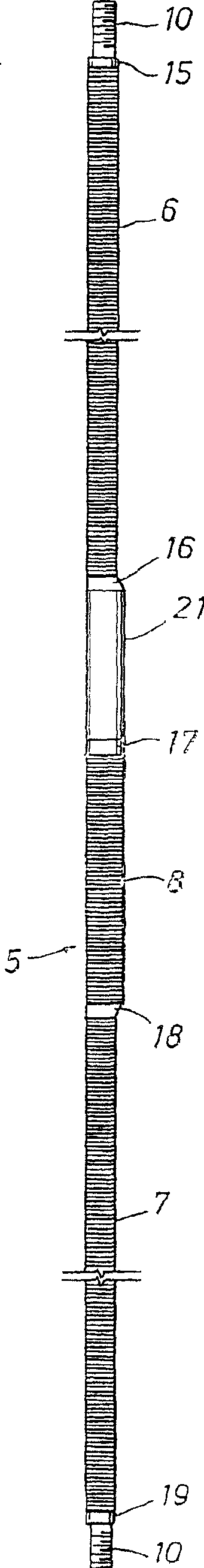

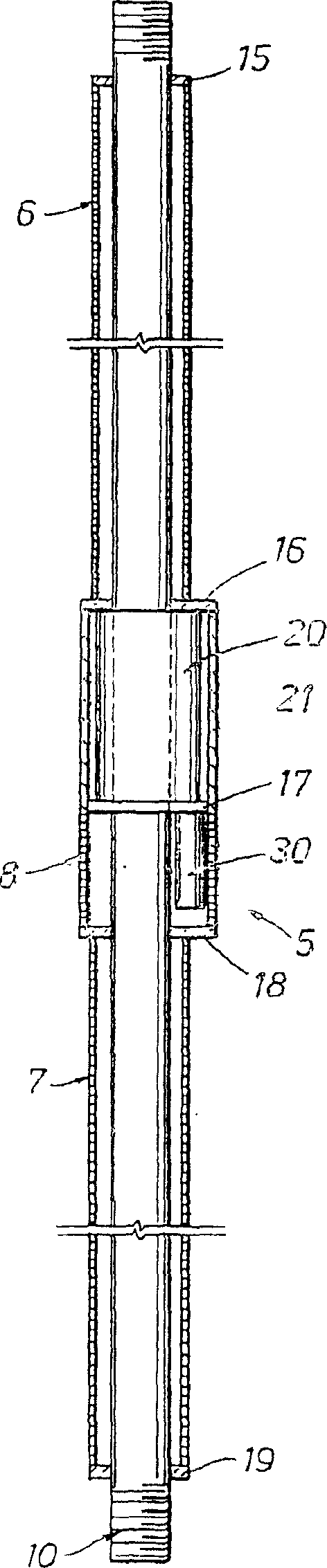

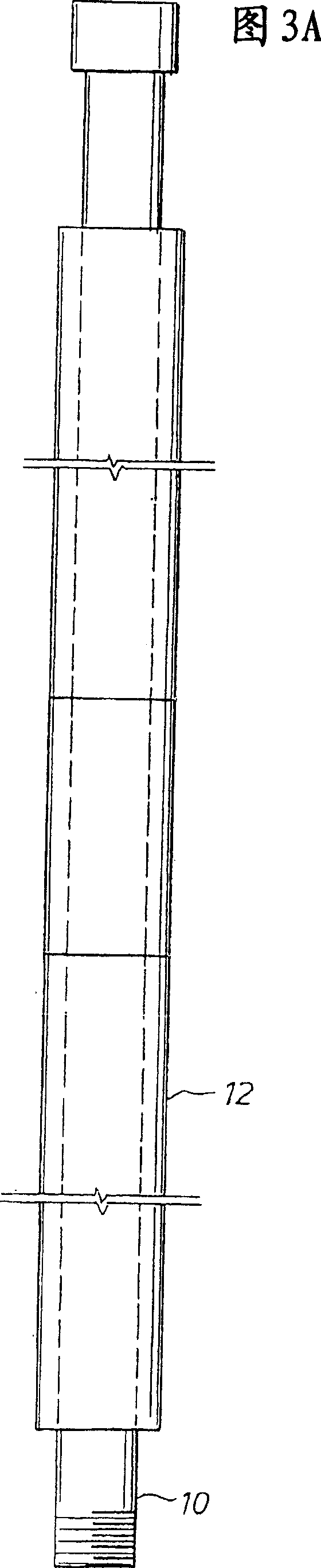

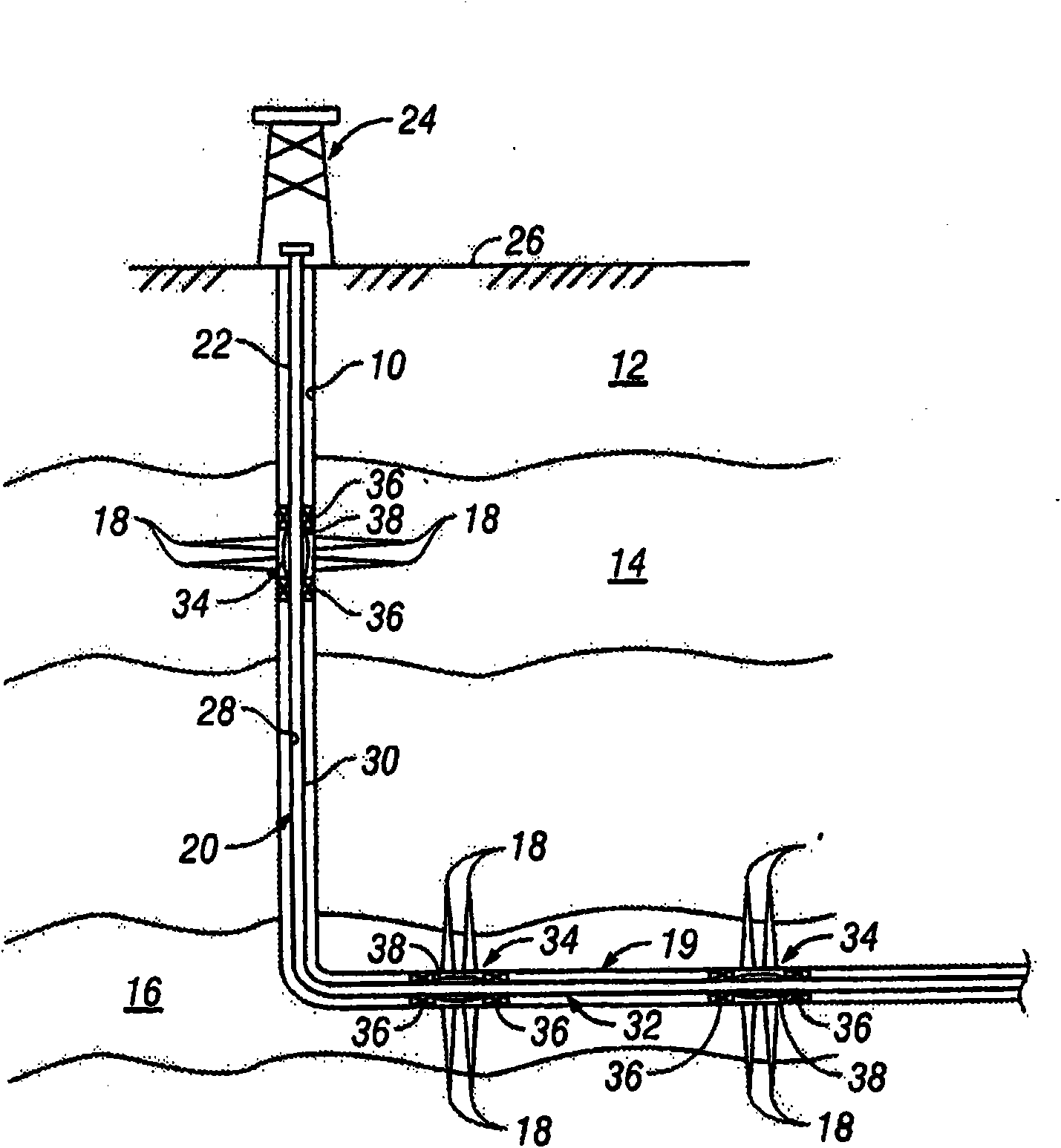

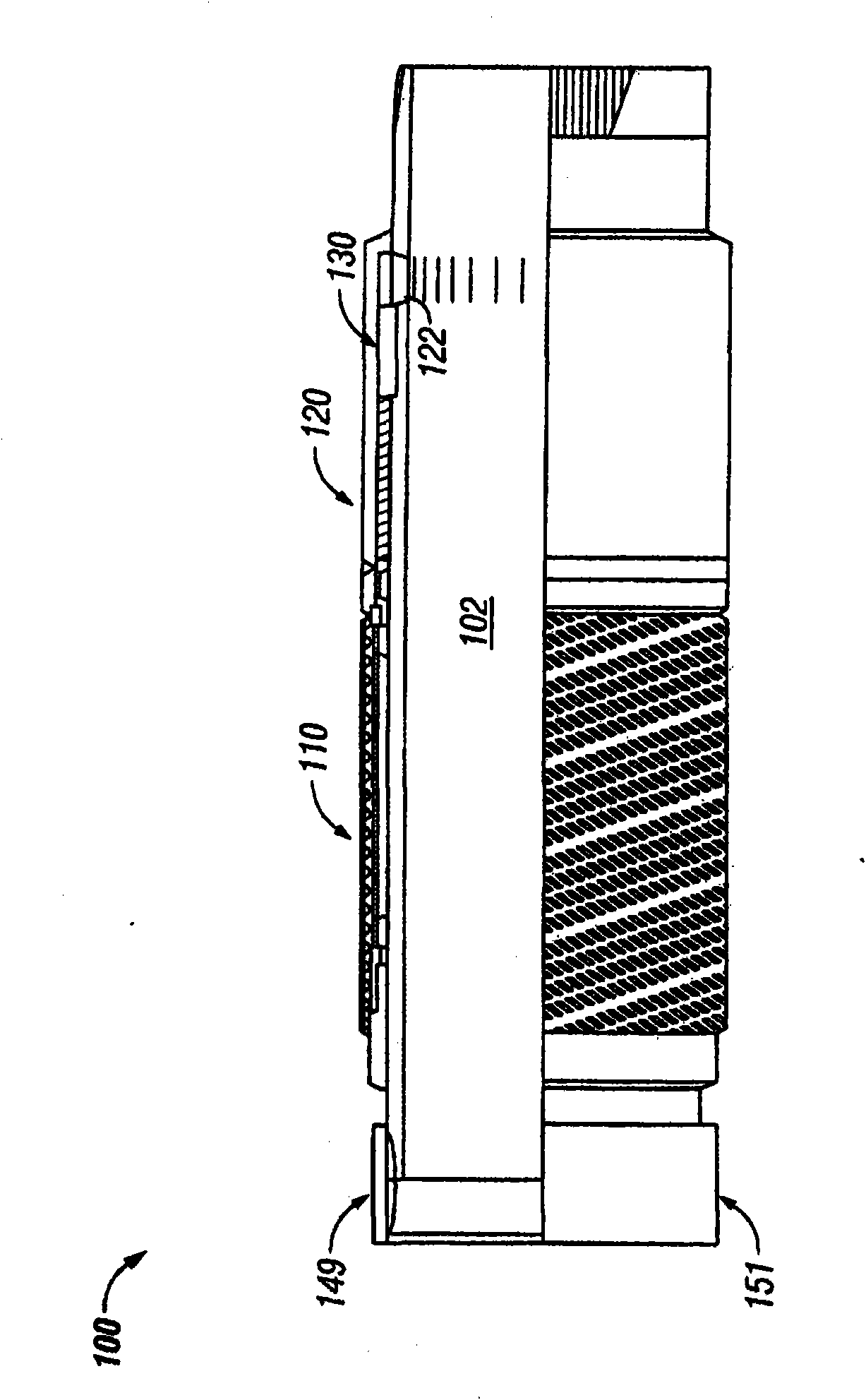

Surface flow controlled valve and screen

InactiveCN1768190AControl inflowReduce or close flowFluid removalWell/borehole valve arrangementsEngineeringControl valves

An adjustable downhole screen assembly (5), which includes: a pipe string (10) connected to a production oil pipe, the pipe string including holes extending from the inner diameter of the pipe string to the outer diameter of the pipe string; connected to the pipe string and a screen adjacent to the string aperture; a valve (31) connected to the string, said valve controlling the flow of fluid through the string aperture; a valve motor mechanically connected to the valve (32), the valve motor opens and closes the valve, and a valve controller communicatively connected to the valve motor, the valve controller instructs the valve motor according to the status of the valve.

Owner:SHELL INT RES MAATSCHAPPIJ BV

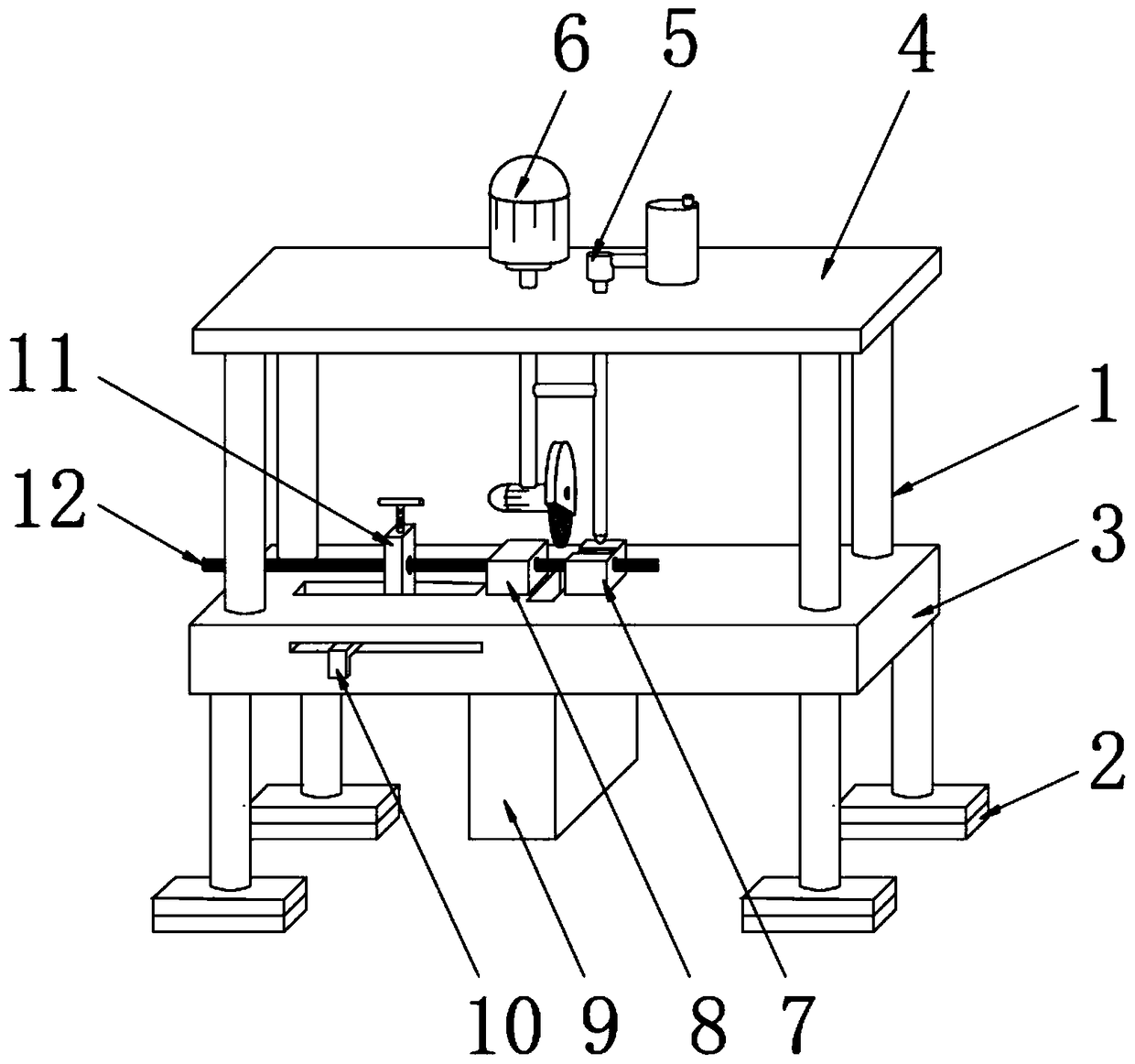

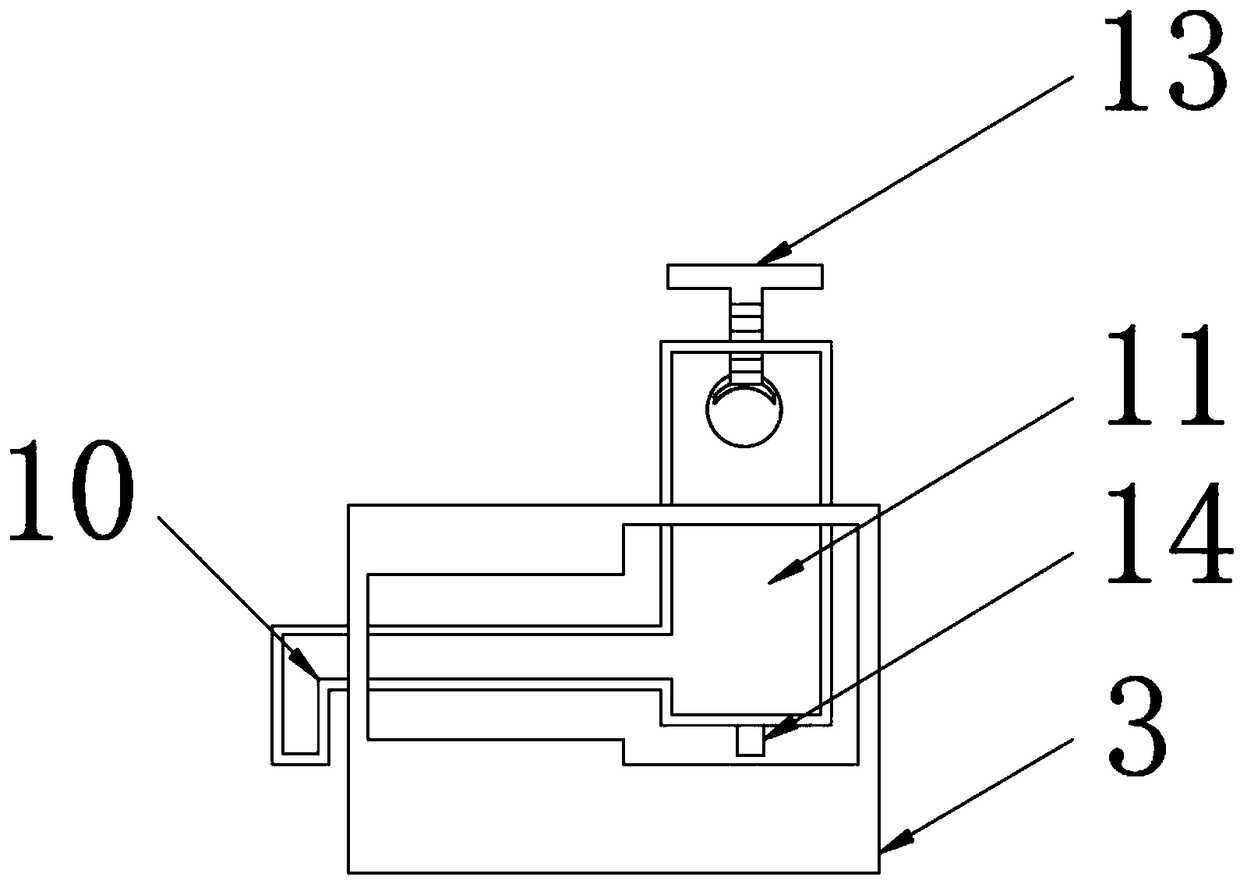

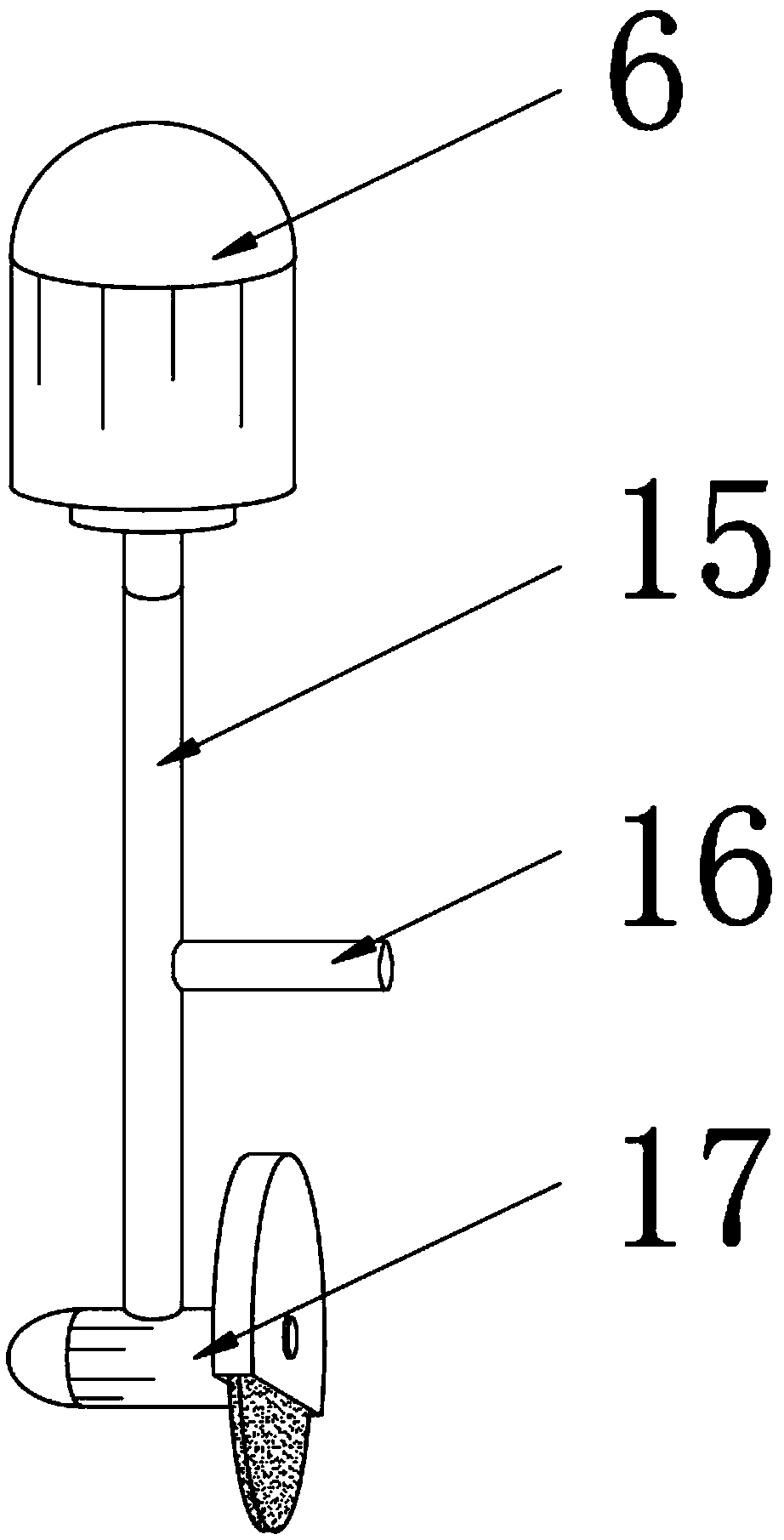

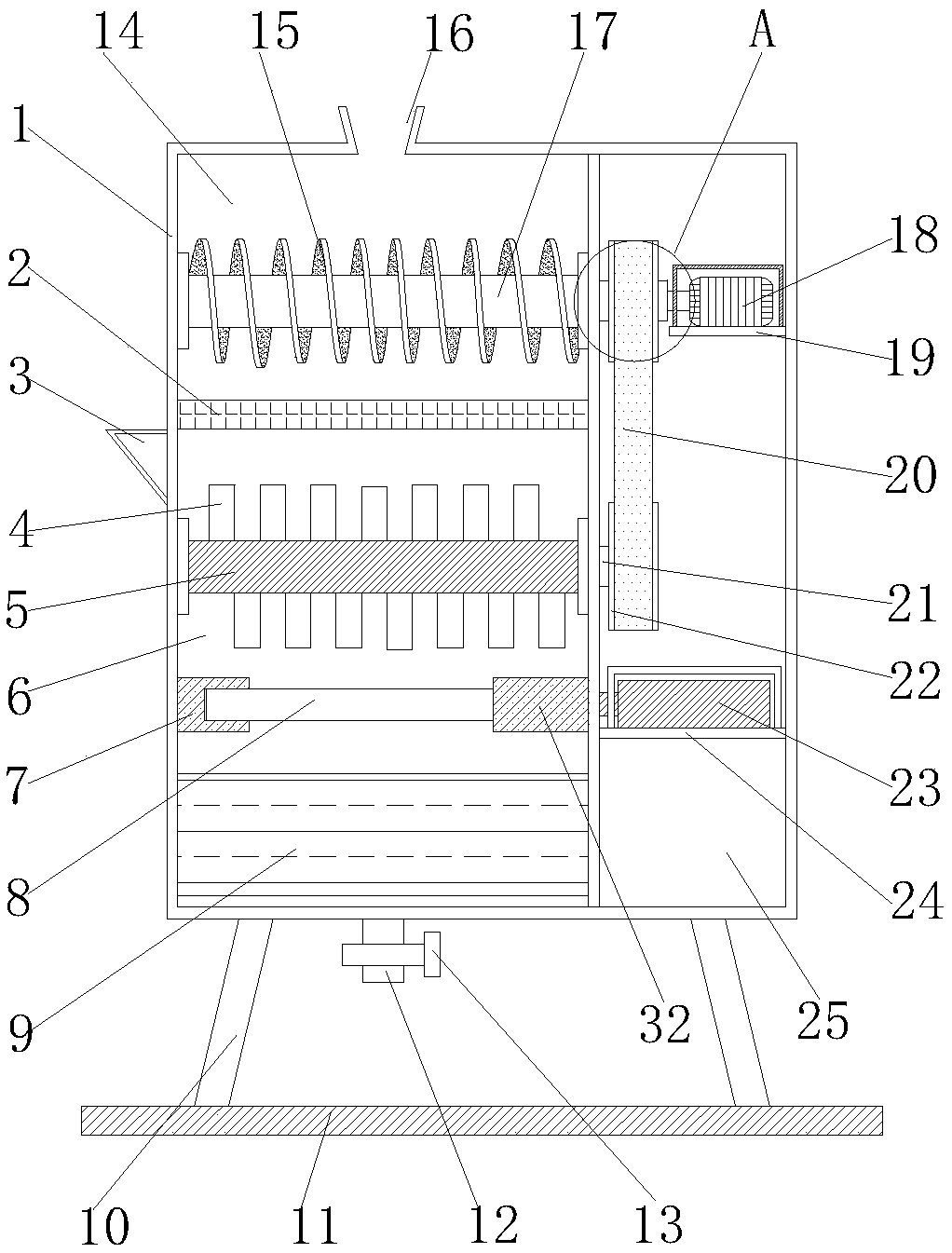

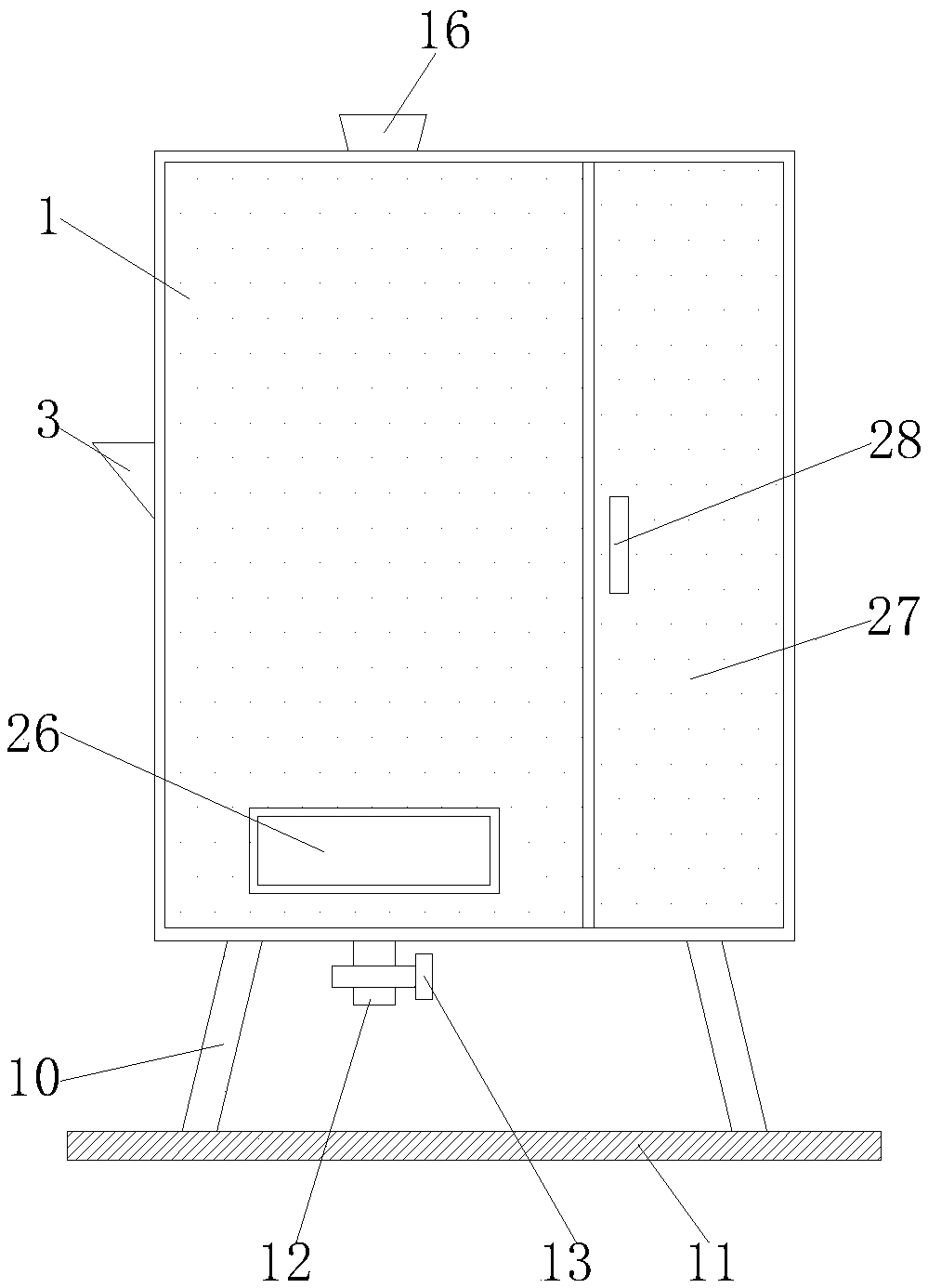

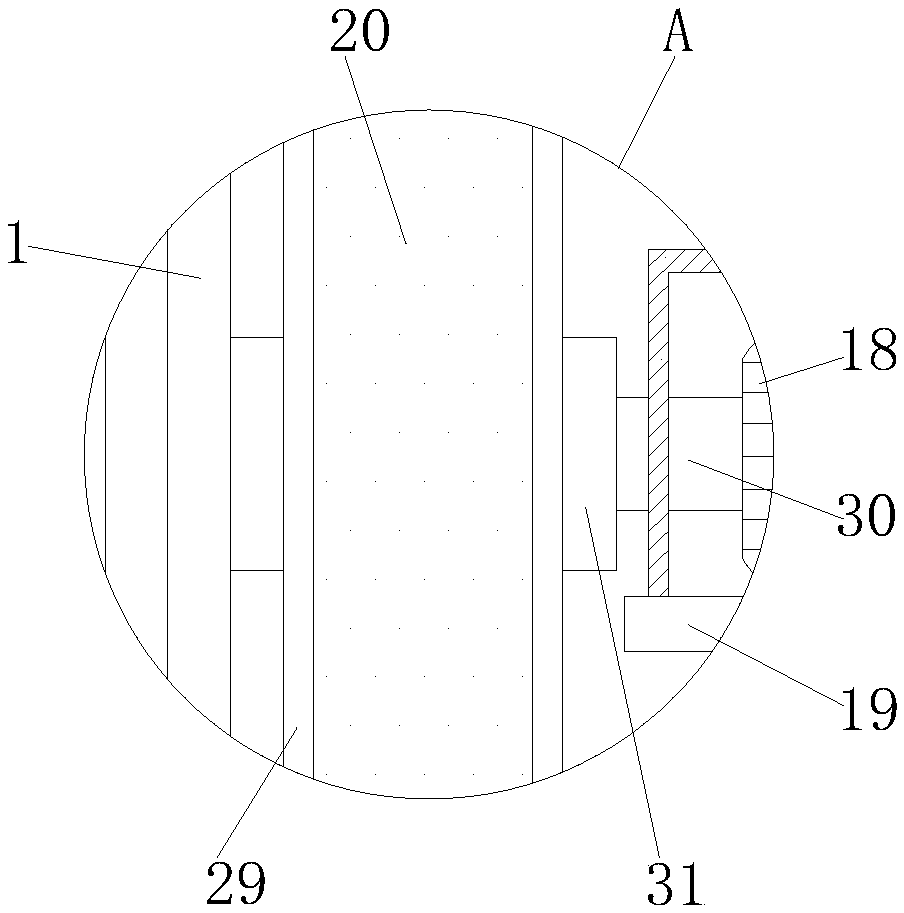

Novel workbench for steel bar cutting machine

The invention discloses a novel workbench for a steel bar cutting machine, comprising a support column. A lower end of the support column is fixedly connected with a shock absorber, and an outer surface of the support column is sleeved and mounted with a cutting table. A top platform is fixedly mounted on a top end of the support column. A water injector is mounted on an upper surface of the top platform in an embedded mode, and a cylinder is mounted at one side of the upper surface, close to the water injector, of the top platform in the embedded mode. The upper surface of the cutting table is fixedly provided with a first fixing block, and a second fixing block is fixedly disposed at one side of the upper surface, close to the first fixing block, of the cutting table. According to the novel workbench for the steel bar cutting machine, the cutting machine can be driven to reciprocate up and down by arranging an air cylinder, so that cutting of steel bars is achieved automatically, theuse of a handheld cutting machine is avoided, the labor intensity is reduced, and the steel bar swarf generated during cutting can fall into a collecting box by arranging the collecting box, therebyavoiding soiling the cutting table.

Owner:GUIZHOU UNIV

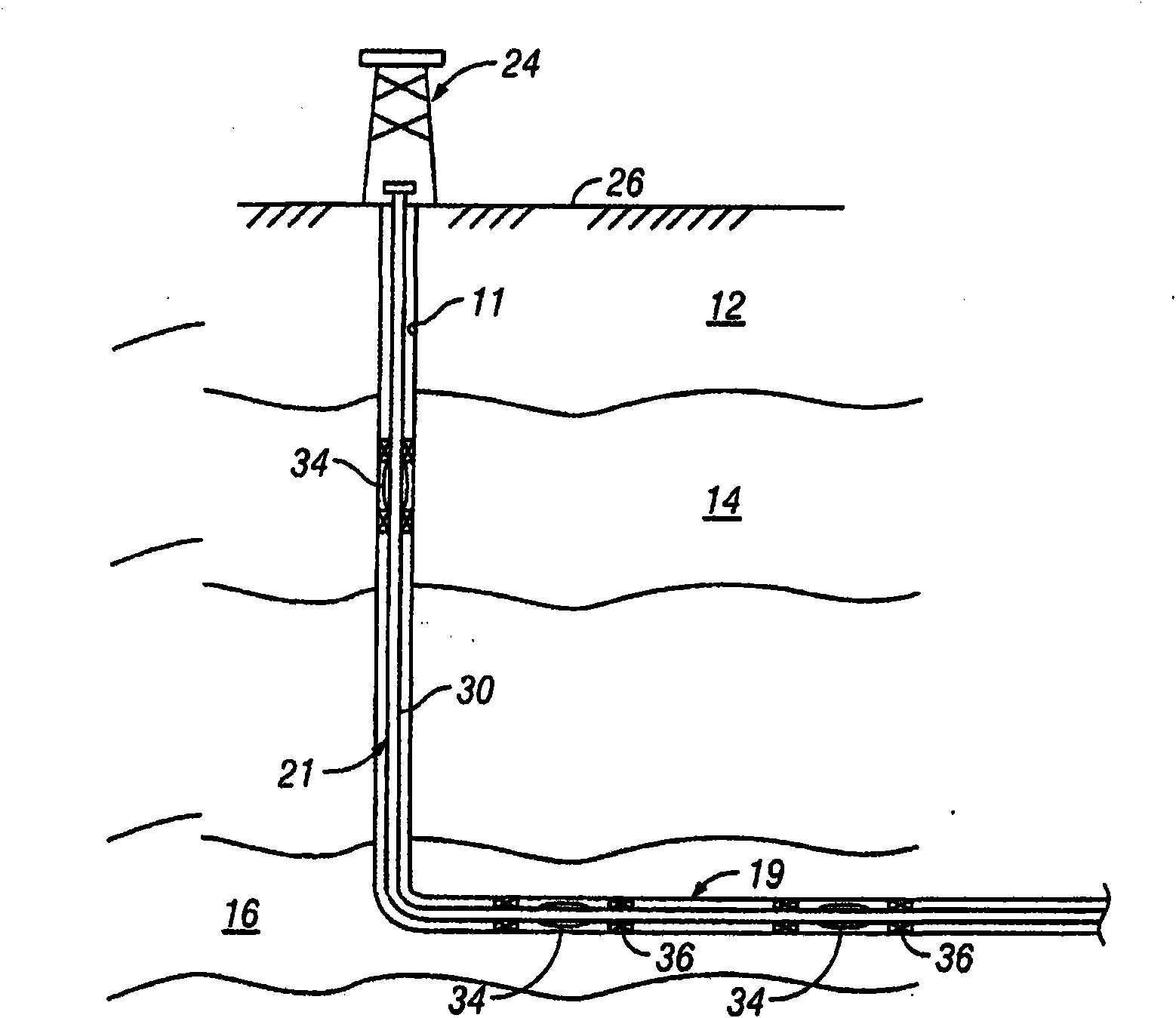

Water sensing devices and methods utilizing same to control flow of subsurface fluids

InactiveCN101828001AControl inflowEasy to understandFluid removalWell/borehole valve arrangementsControl flowEngineering

An apparatus for controlling fluid flow in a wellbore includes a reactive element that reacts when exposed to a fluid and a flow control device configured to control a flow of the fluid. The flow control device may be actuated by a reaction of the reactive element to the fluid. In embodiments, the reactive element reacts by exhibiting a change in a material property. The reaction of the reactive element may be reversible. In embodiments, the reactive element may be a shape memory polymer. The flow control device may include an actuating element operably coupled to the reactive element. The reaction of the reactive element to a given fluid releases the actuating element to actuate the flow control device.

Owner:BAKER HUGHES INC

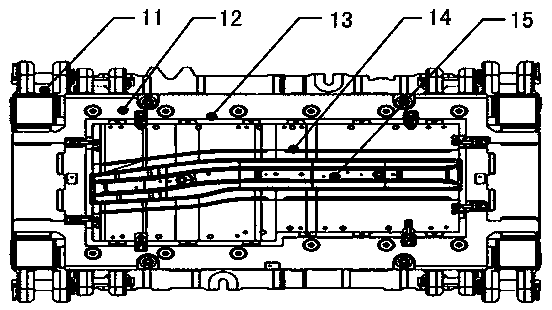

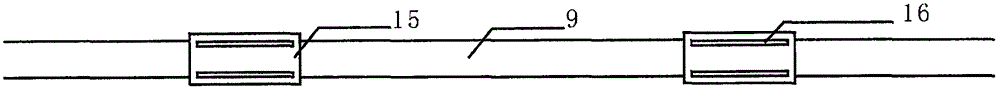

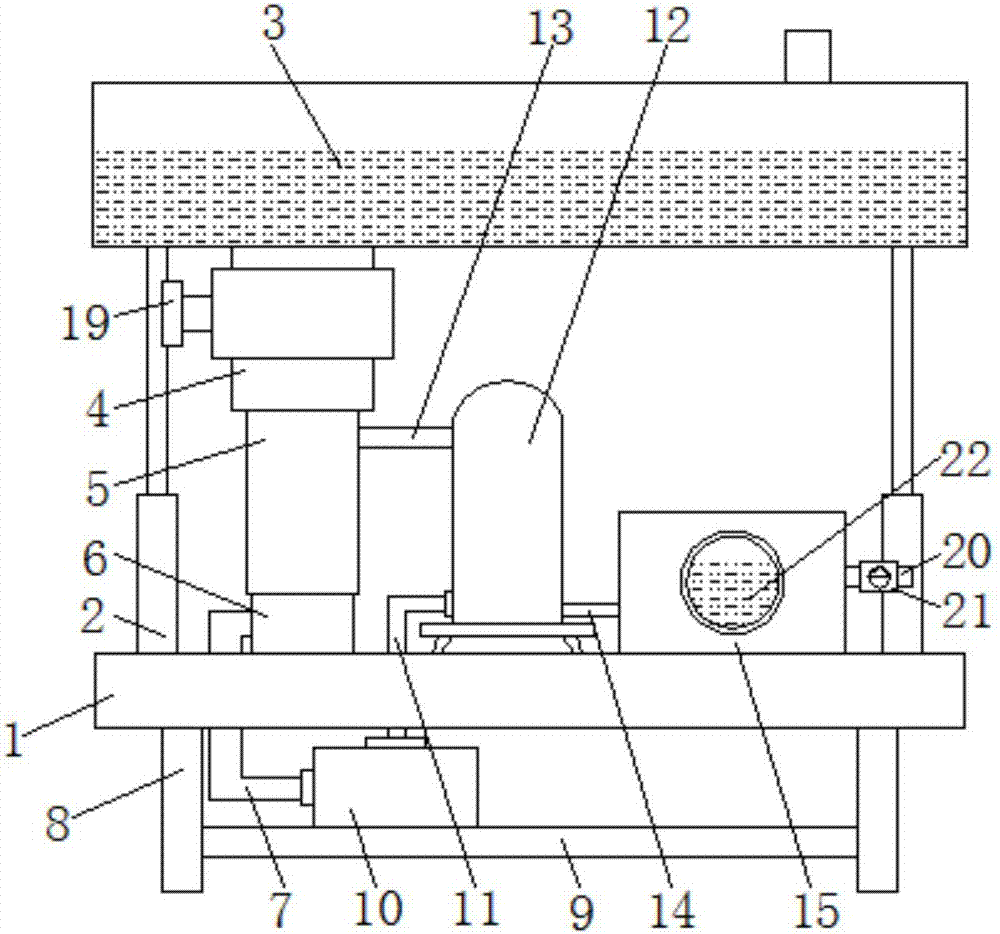

Linear straight-rail-type production system for textile bodies

ActiveCN109898237AGood equipment connectivityIncrease productivityNon-woven fabricsEngineeringInjection air

A linear straight-rail-type production system for textile bodies comprises an upper mold, a lower mold, an outer sleeve, an air injection device, linear guide rails and a conveying device. Each of theupper mold and the lower mold comprises an external mold body, a mold cavity and an air passage, and the mold cavities and the air passages are formed in the mold bodies and communicated with each other. The outer sleeve is higher than the upper mold. The linear guide rails include a first guide rail, and a second guide rail parallel to the first guide rail. The top ends of the first guide rail and the second guide rail are in sliding fit with the bottom surfaces of first and second sliding seats respectively. The top surfaces of the first sliding seat and the second sliding seat are connected with bottoms of mold lifting cylinders respectively. The output ends of the mold lifting cylinders are connected with the lateral portion of the lower mold through support shafts. An air outlet corresponding to an air inlet region is arranged at the top of the air injection device, and is clamped between the middle portions of the first guide rail and the second guide rail. The conveying deviceis arranged between the tail ends of the first guide rail and the second guide rail. The linear straight-rail-type production system has the advantages that streamline operation can be realized, and the production efficiency is high; the shapes of the textile bodies are not limited, and the utilization rate of materials can be increased.

Owner:武汉博瑞智信科技有限公司

Auxiliary runner structure for preventing deformation of injection product

The invention discloses an auxiliary runner structure for preventing deformation of an injection product. The auxiliary runner structure comprises a mold cavity channel, a main injection nozzle and a plurality of injection nozzles. Plastic melt passes through the mold cavity channel, the main injection nozzle and the injection nozzles communicate with the mold cavity channel through pouring gates, and control valve needles are arranged in the main injection nozzle and the injection nozzles. The auxiliary runner structure is arranged at the broken plastic melt flowing tail end of the mold cavity channel, is connected to the bottom of the product, and comprises a first auxiliary pouring gate, a second auxiliary pouring gate, a third auxiliary pouring gate, a fourth auxiliary pouring gate and a flowing channel. The first auxiliary pouring gate and the third auxiliary pouring gate are located on the same horizontal plane, and the second auxiliary pouring gate is opposite to the first auxiliary pouring gate. The structural strength and rigidity of the injection product before electroplating are improved, and the product cannot be distorted or deformed in the whole electroplating process.

Owner:DONGFENG MOTOR CORP HUBEI

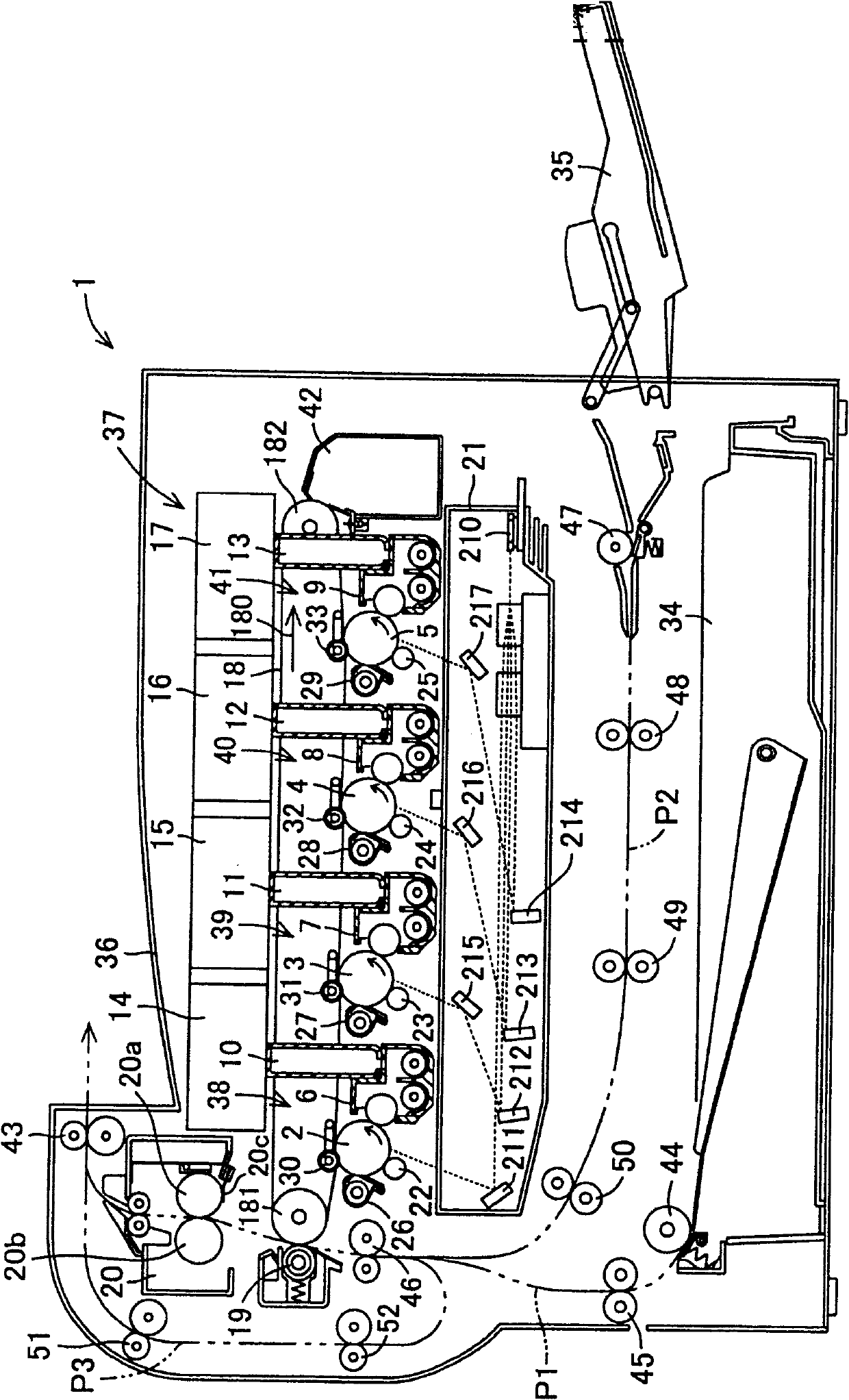

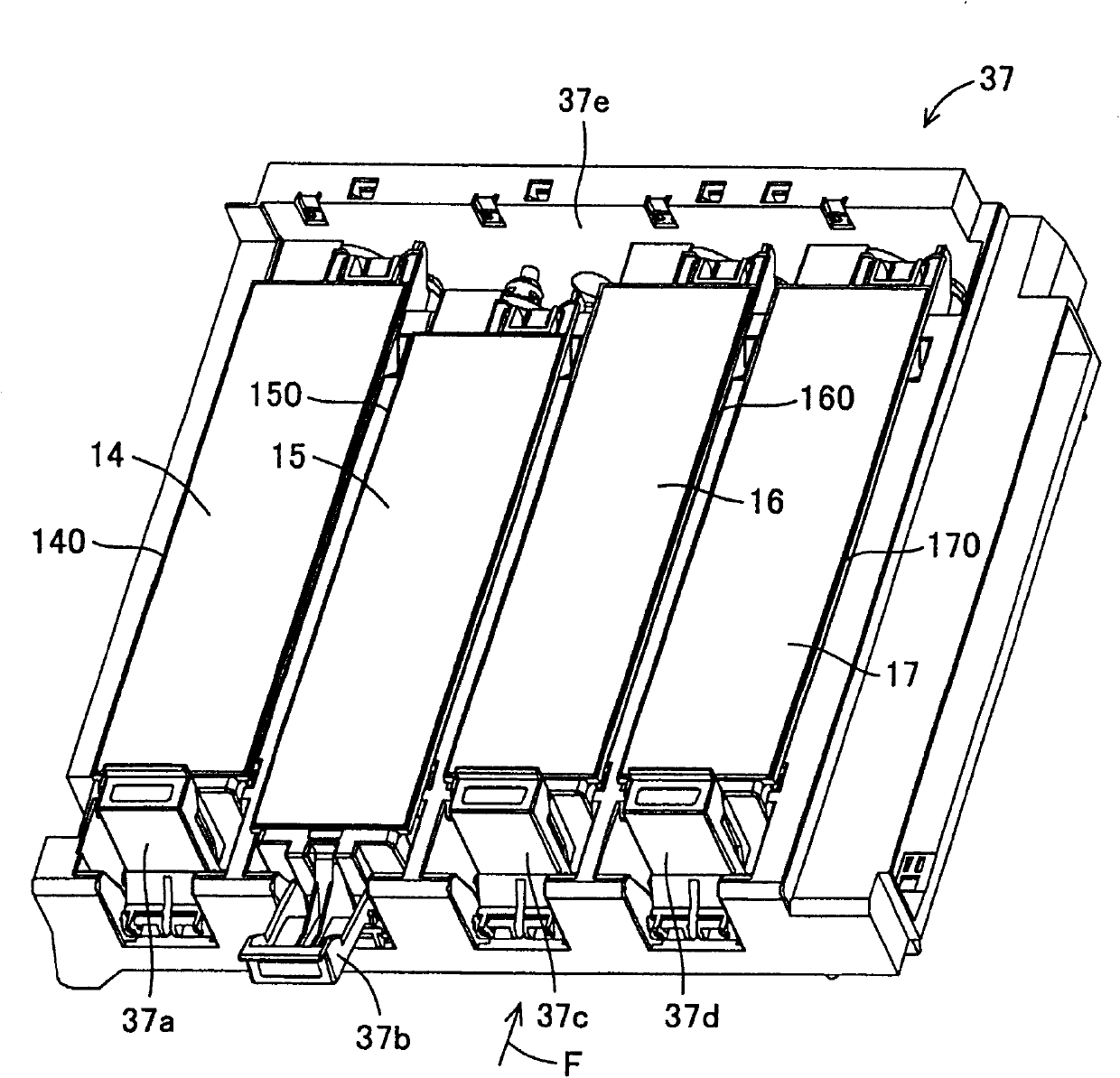

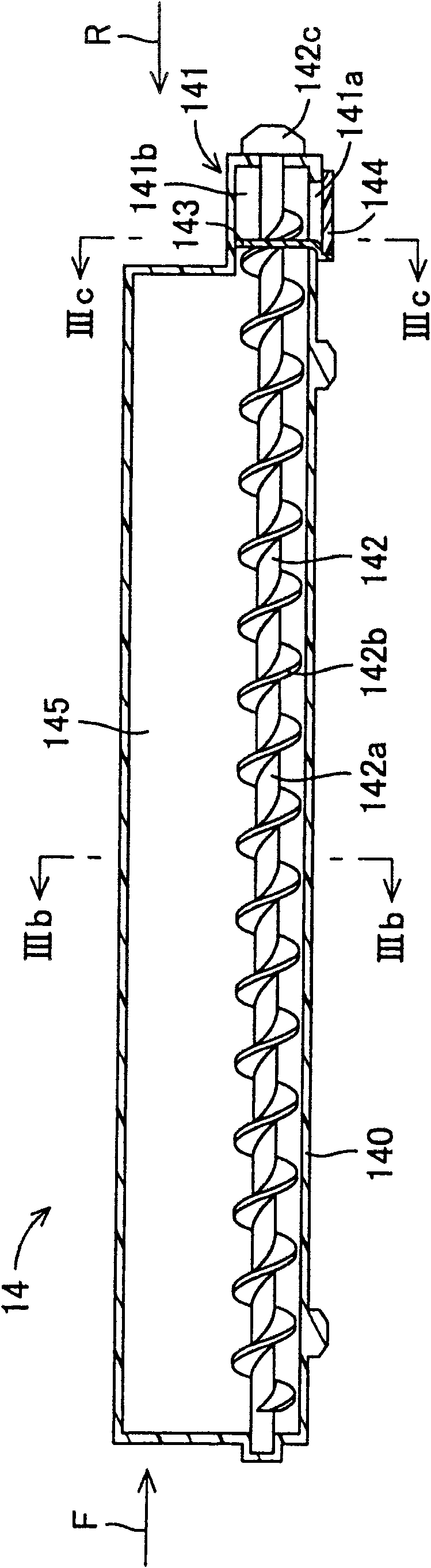

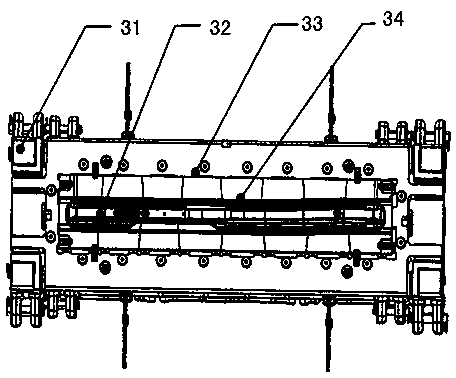

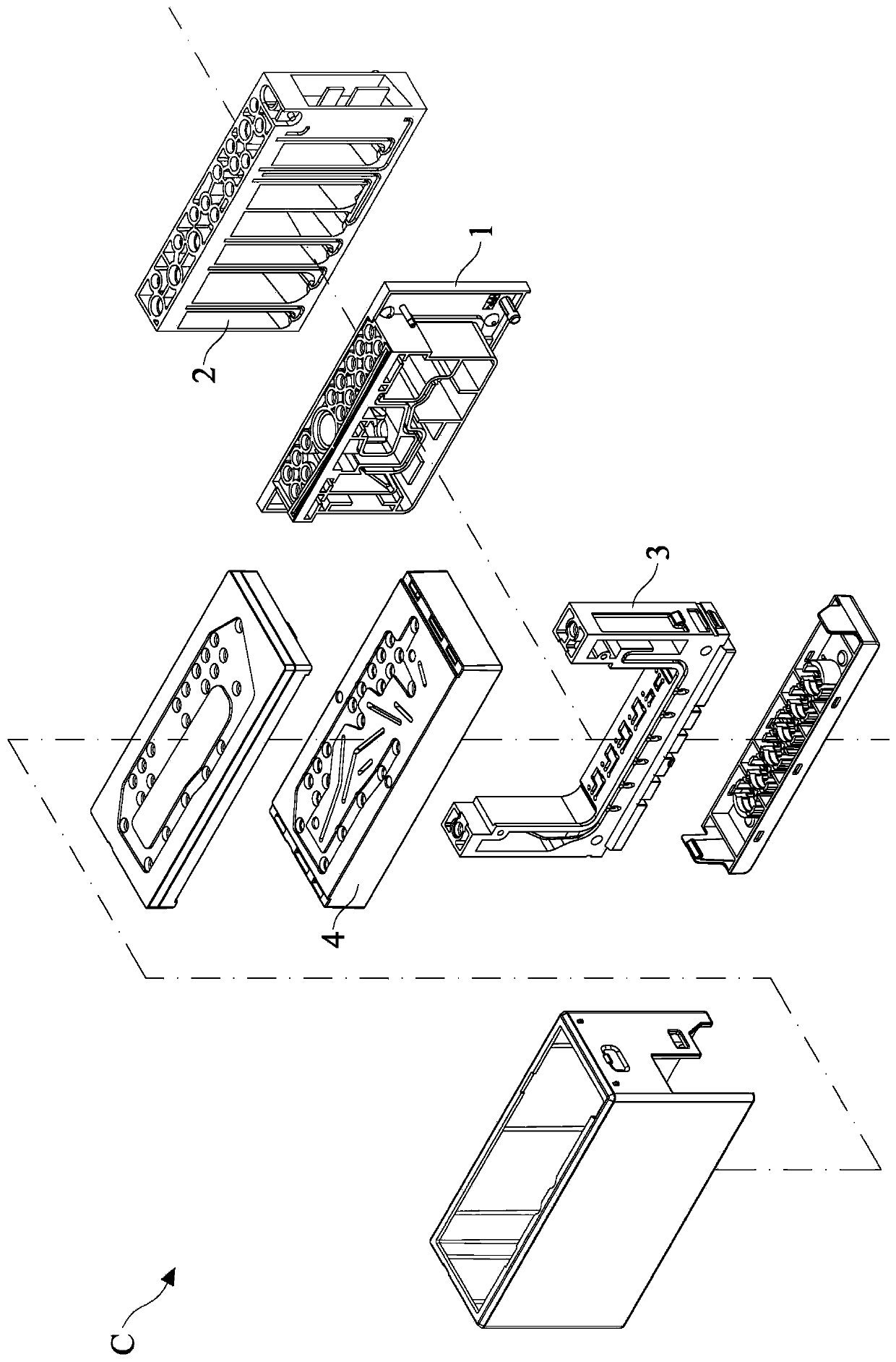

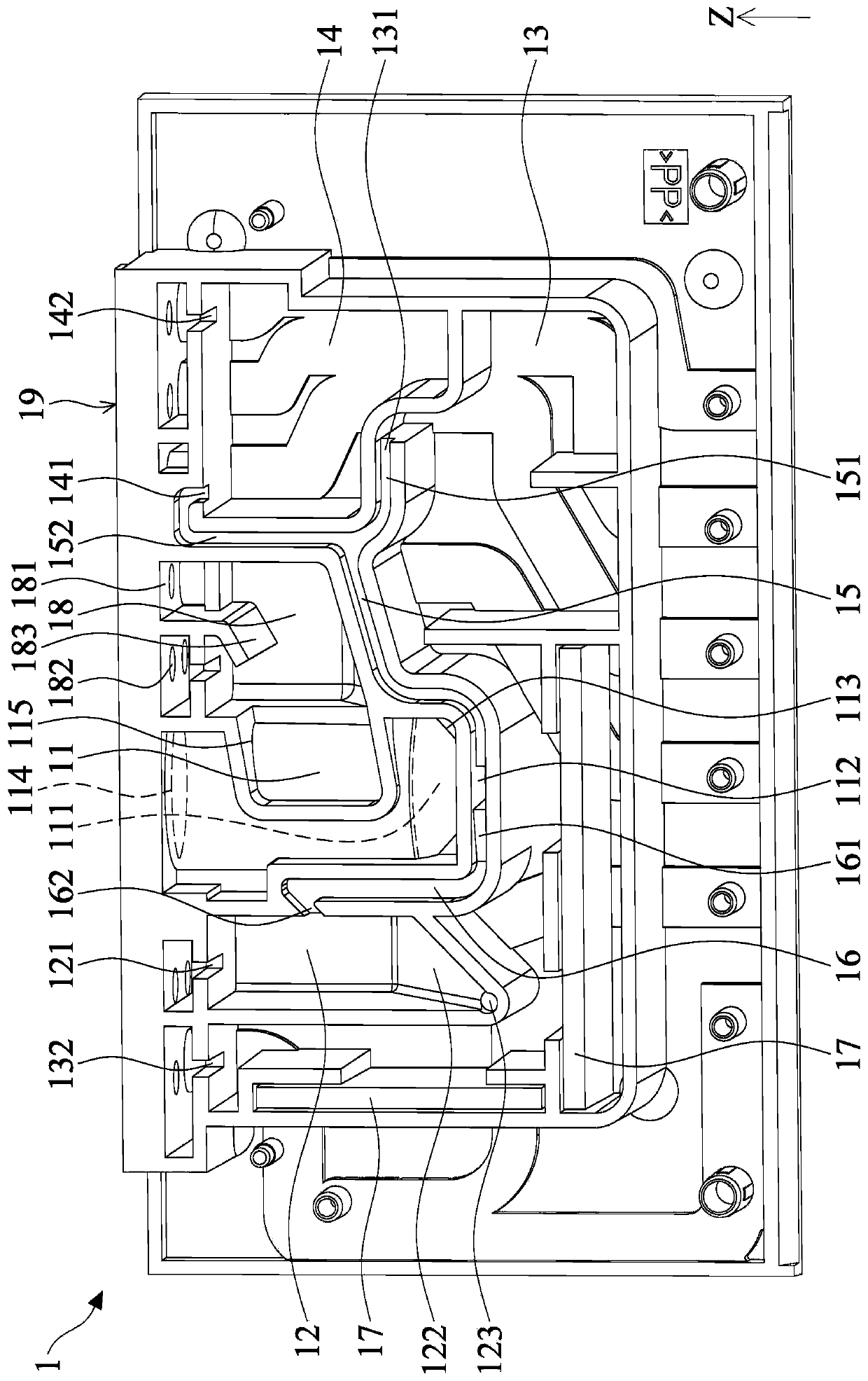

Toner cartridge and image forming apparatus using the same

InactiveCN102023527AControl inflowPrevent outflowElectrographic process apparatusElectrical and Electronics engineering

A toner cartridge includes a container (140) for containing toner, a toner discharge section (141) having a toner discharge port (141a), an auger screw (142) provided in the container (140), for conveying toner in the container (140) to the toner discharge section (141), a shutter (144) for opening and closing the toner discharge port (141a), and a toner flowing-out preventing member (143) provided in a communicating part between the container (140) and the toner discharge section (141), for preventing flowing out of toner by closing an opening of the communicating part. The toner flowing-outpreventing member (143) is configured so as to open the opening in conjunction with an opening operation of the shutter (144).

Owner:SHARP KK

Stretching mould with rib resistance capable of being adjusted

PendingCN104209405AControl wellReduce wrinkle deformationShaping toolsMaterial flowMaterials science

The invention relates to a stretching mould with rib resistance capable of being adjusted. The stretching mould with the rib resistance capable of being adjusted comprises an upper mould body and a lower mould body, and the upper mould body comprises an upper mould seat, a female mould arranged on the upper mould seat and a concave rib arranged on the upper mould seat. The lower mould body comprises a lower mould seat, an edge pressing ring arranged on the lower mould seat, an edge pressing ring protruding rib arranged on the lower mould seat and a male mould arranged on the lower mould seat. Protruding rib supporting rods for controlling the protruding stroke of the edge pressing ring protruding rib are arranged on the lower mould seat, the concave rib is matched with the edge pressing ring protruding rib, and the female mould is matched with the male mould. The stretching mould has the advantages that the protruding stroke of the edge pressing ring protruding rib can be controlled through the protruding rib supporting rods, the time for generating stretching resistance can be controlled, the strength of the stretching resistance can be controlled by controlling the height of the edge pressing ring protruding rib, and therefore the material flow-in quantity can be controlled better, and the phenomenon of wrinkling and deforming caused by later too fast feeding is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

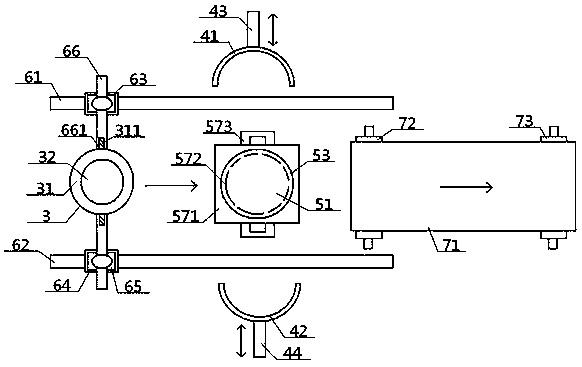

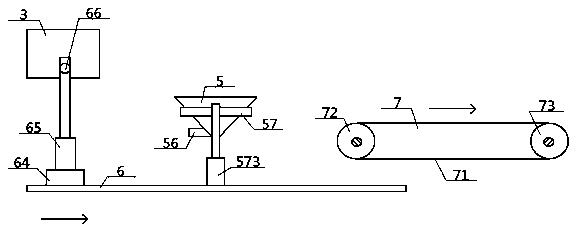

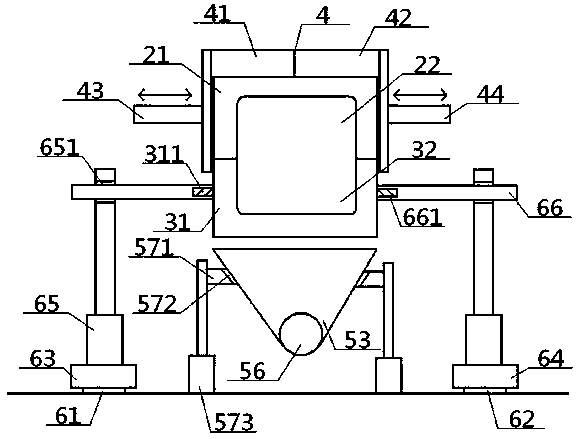

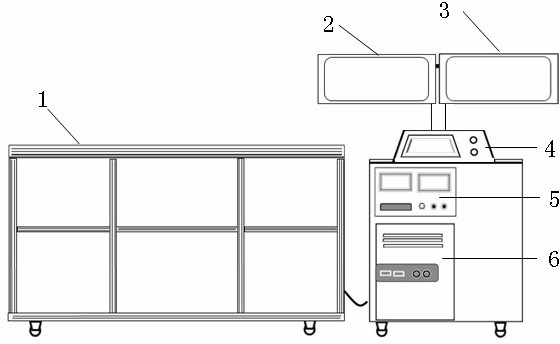

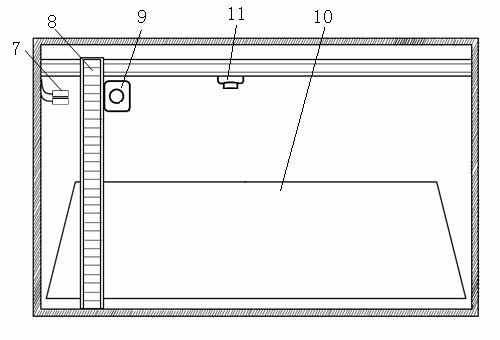

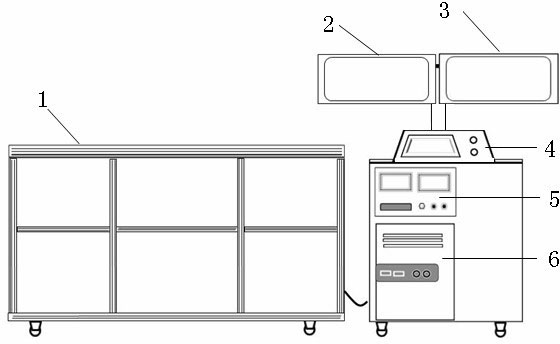

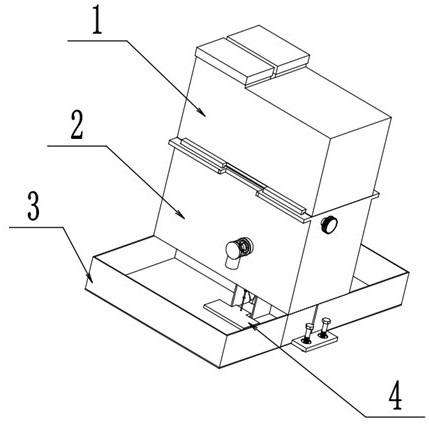

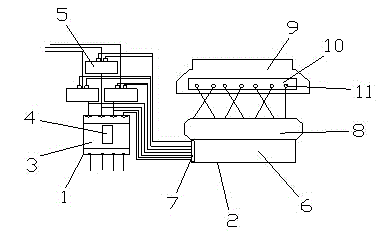

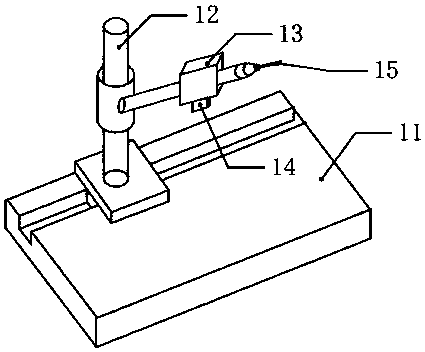

Electroluminescence automatic imaging apparatus

InactiveCN102435611ACost reduction sectionControl inflowAnalysis by electrical excitationOptically investigating flaws/contaminationPower flowDisplay device

The invention relates to an electroluminescence automatic imaging apparatus comprising two main parts, which are a controlling platform (4) and a measuring platform (1). The controlling platform (4) and the measuring platform (1) are connected by using an optical fiber / data line. A current source (5) and a computer (6) are arranged in the controlling platform (4). A display I (2) and a display II (3) are arranged on the controlling platform (4). A current joint (7), an XY high-speed locating system (8), a camera I (9), a mirror (10) and a camera II (11) are arranged in the measuring platform (1). The current joint (7) and the current source (5) are electrically connected. The camera I (9) is arranged on the XY high-speed locating system (8). The mirror (10) is arranged with a certain angle on the bottom of the measuring platform (1). The camera II (11) is arranged on one side of the bottom of the measuring platform (1). The apparatus provided by the invention can be used for testing cell slices, cell slices singly welded or welded in series, components, and all or specified one or a plurality of cell slices in a component.

Owner:JIANGYIN XINHUI SOLAR ENERGY

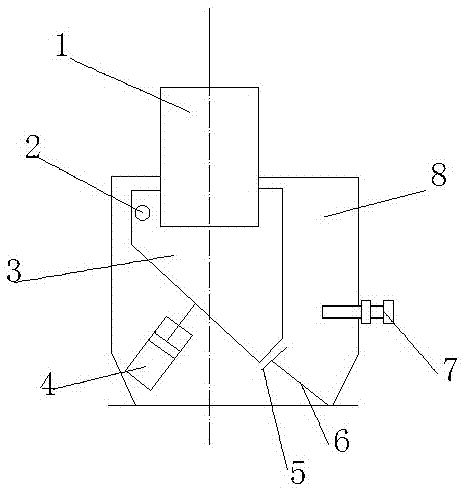

Pneumatic feeding device

InactiveCN105438811AControl inflowEasy to gatherConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to the field of discharge hoppers, in particular to a pneumatic feeding device. The pneumatic feeding device comprises a feeding box body, wherein a hinge shaft is arranged in the feeding box body; an observing barrel is arranged at the upper end of the feeding box body; a rotary hopper is arranged at a position parallel to the observing barrel, is hinged to the feeding box body through the hinge shaft, is positioned in the feeding box body and is conical; a feeding opening and a discharging opening are formed in the rotary hopper; the aperture of the feeding opening is greater than that of the discharging opening; a cylinder is arranged on the left side of the bottom of the feeding box body and comprises a piston and a piston rod; the piston rod is fixedly connected with the rotary hopper; a supporting mechanism is arranged on the right side of the bottom of the feeding box body and comprises a baffle and a supporting shaft; one end of the supporting shaft is fixedly connected with the bottom of the feeding box body; the other end of the supporting shaft is fixedly connected with the baffle; a through hole is formed in the right side of the feeding box body; and a limiting bolt penetrates through the through hole and is in threaded connection with the feeding box body. According to the scheme, fruits can be quantitatively conveyed, the conveying amount of the fruits can be adjusted flexibly, and meanwhile, the pneumatic feeding device is long in service life.

Owner:CHONGQING XIUCAI BAY FRUIT & VEGETABLE PROFESSIONAL COOP

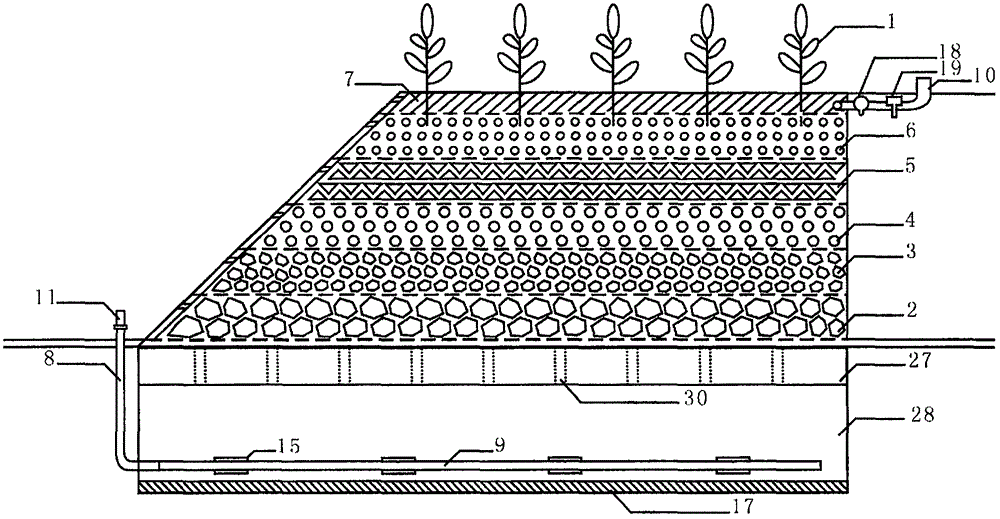

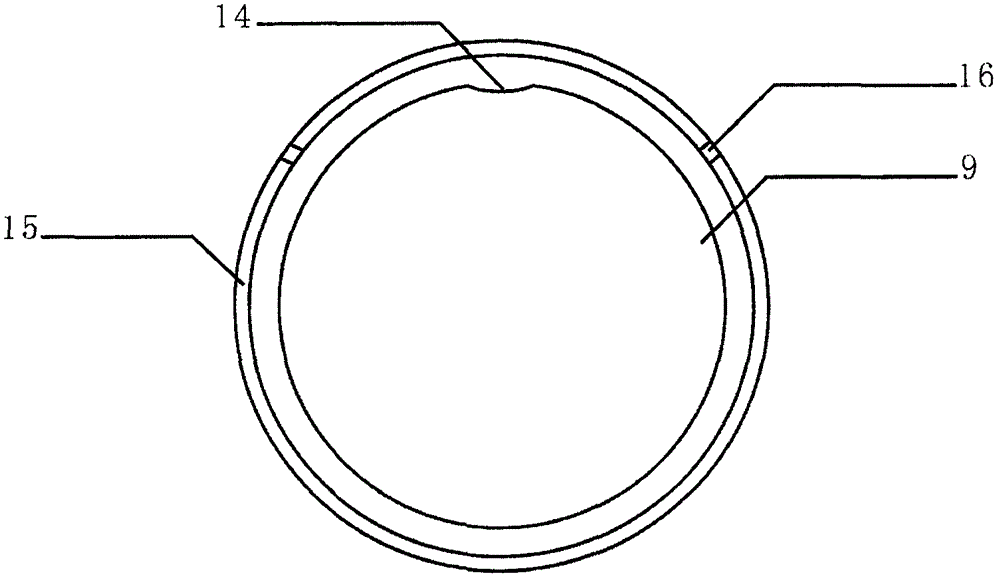

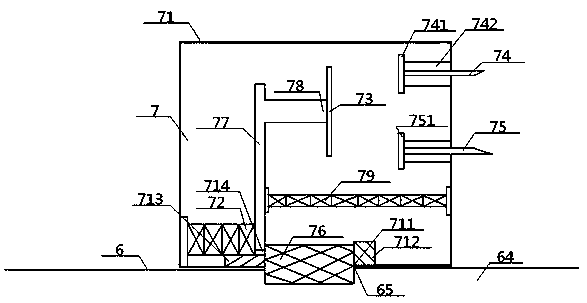

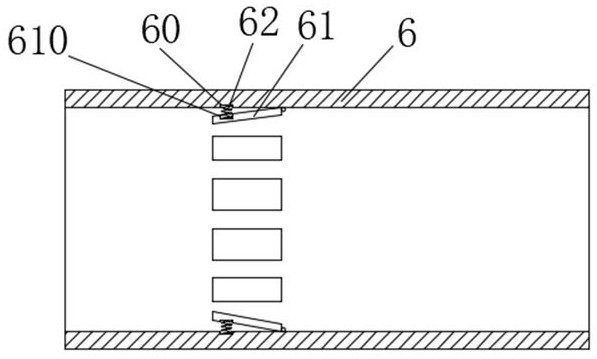

Wastewater treatment system based on constructed wetlands

ActiveCN106348537AImprove adsorption capacityImprove photocatalytic abilityWater treatment compoundsWater contaminantsConstructed wetlandWater treatment system

The invention discloses a wastewater treatment system based on constructed wetlands. The wastewater treatment system based on constructed wetlands comprises wetland plants, a sealed wetland tank and a water inlet pipe, wherein multiple filtration matrixes are laid in the sealed wetland tank; wastewater flows through each layer of filtration matrixes in the wetland tank so as to be purified; the water inlet pipe is used for injecting the wastewater into the wetland tank; a water seepage mechanism which is communicated with the water inlet pipe and is used for conveying the wastewater into each layer of filtration matrixes in the wetland tank in sequence is arranged at the bottom of the wetland tank; and a water outlet pipe, through which water obtained after treating wastewater which flows through the filtration matrixes at the bottom layer in sequence, permeates through and is filtered to the filtration matrixes on the top layer flows out of the wetland tank, is arranged on the top of the wetland tank. The wastewater treatment system based on constructed wetlands has the beneficial effects that the nitrogen and phosphorous removal efficiency of a constructed wetland wastewater treatment technology is intensified, the problem that the traditional constructed wetland wastewater treatment technology is less likely to eliminate heavy metal pollution is solved, and meanwhile, the workload of later period maintenance of the wastewater treatment system is reduced.

Owner:QINGDAO UNIV

High-efficiency circulating domestic water purifier

InactiveCN107879494APrevent outflowControl inflowSpecific water treatment objectivesTreatment involving filtrationEngineeringFilter effect

The invention discloses a high-efficiency circulating domestic water purifier, which comprises a base, a symmetrical electric push rod is fixedly connected to the top of the base, a water collection tank is fixedly connected to the top of the electric push rod, and an end of the water collection tank close to the electric push rod is provided with a A spiral tube, one end of the spiral tube communicates with the through hole opened at the bottom of the sump, the bottom of the spiral tube is provided with a filter tube, the bottom of the filter tube is provided with a water storage tank, and one side of the water storage tank is provided with a first diversion tube, the first One end of the diversion pipe runs through the base and extends to the outside of the base. The bottom of the base is fixedly connected with symmetrical support legs. A connecting plate is arranged between the two supporting legs. The top of the connecting plate is fixedly connected with a water pump. The water suction port communicates with one end of the first diversion pipe running through the base, and the top of the water pump discharge port is provided with a second diversion pipe. The invention improves the overall filtering effect, improves the practical value of the purifier, and is convenient for market promotion.

Owner:吕杨丽

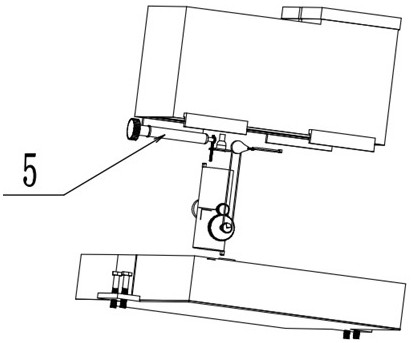

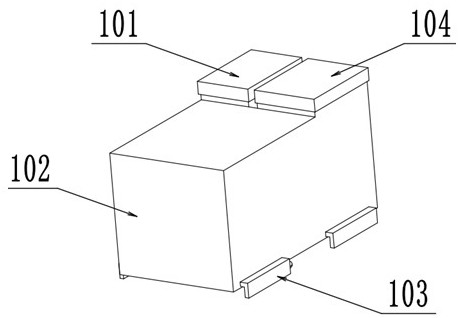

Water and feed supplying machine for outdoor breeding

ActiveCN111802280AReduce consumptionControl inflowClimate change adaptationAvicultureFisheryEngineering

A water and feed supplying machine for outdoor breeding comprises a drinking water and feed box part, a power part, a water tank and feed trough part, an anti-overflow part and a flow adjusting part,wherein the water tank and feed trough part is fixedly installed on the ground through screws, the power part is installed on the water tank and feed trough part in a sliding mode, the drinking waterfeed box part is installed on the power part, a round hole of the anti-overflow part is rotationally installed on a clamping column of the water tank and feed trough part, and the flow adjusting partis rotationally installed in a round hole in the power part; according to the outdoor water and feed supplying machine, drinking water and feed are simultaneously put in one machine, so that the drinking water and the feed are simultaneously put in the same machine; and the feeding interval between drinking water and feed of the machine can be controlled through the flow adjusting part, so that manpower input and electric energy loss are reduced.

Owner:山东华牧天元农牧股份有限公司

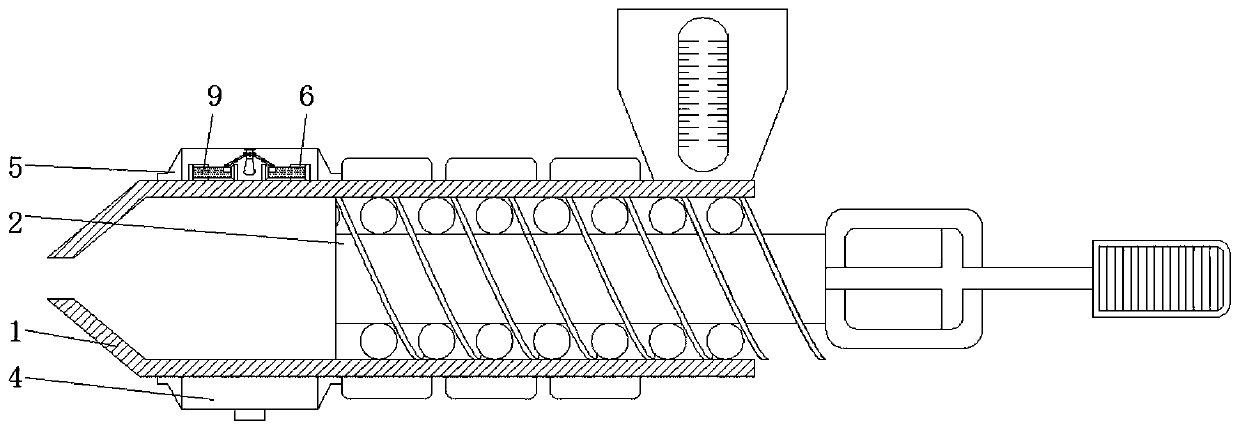

Preparation process and device of polyamide

The invention relates to the technical field of polyamide preparation, and discloses a preparation device of polyamide. The device comprises an injection molding machine, a screw rod and a drill bit,wherein the screw rod and the drill bit form a transmission device to extrude a polyamide liquid, a sleeve is arranged on the outer wall of the injection molding machine in a sleeve mode, a copper pipe is arranged in the sleeve, a threaded pipe is arranged in the copper pipe, the end part of the threaded pipe is connected with a supporting block, and an expansion body is arranged in the threaded pipe. The expansion body is automatically expanded according to the temperature of the injection molding machine, so that a cooling tube is opened, a cooling liquid is injected into the sleeve, the temperature of the injection molding machine is reduced, so that in the using process of the injection molding machine, the injection molding machine can be kept at a normal temperature all the time, theinjection molding machine can keep a good state in the injection molding process, the service life of a hydraulic element and an air cylinder in the injection molding machine is prolonged at the sametime, the abrasion degree of the drill bit and the injection molding machine can be reduced when the temperature of the injection molding machine is normal, so that the injection molding machine is always in a sealed state in the use process, the service life of the injection molding machine is prolonged, and the injection molding effect of the injection molding machine is improved.

Owner:李素琴

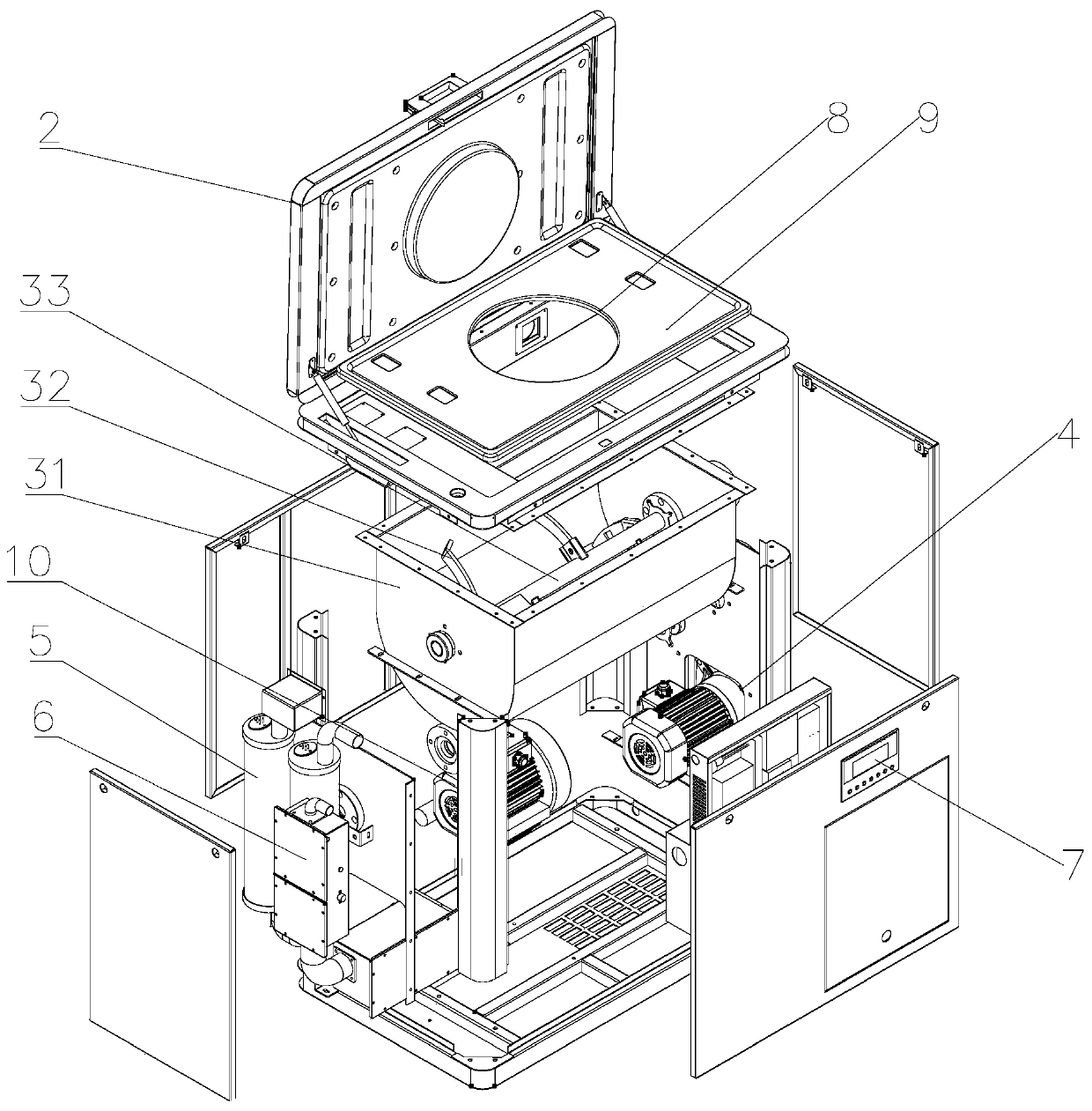

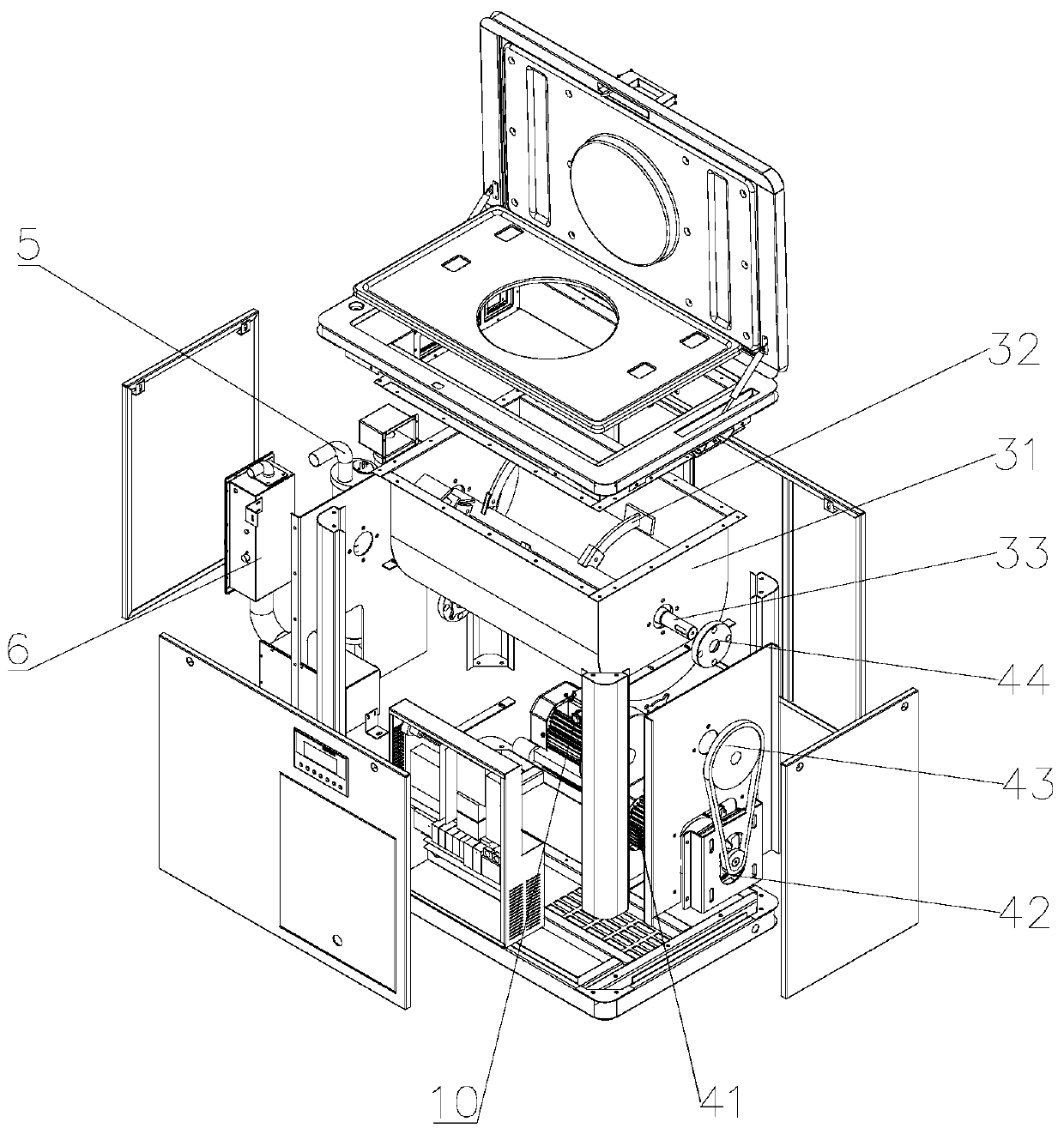

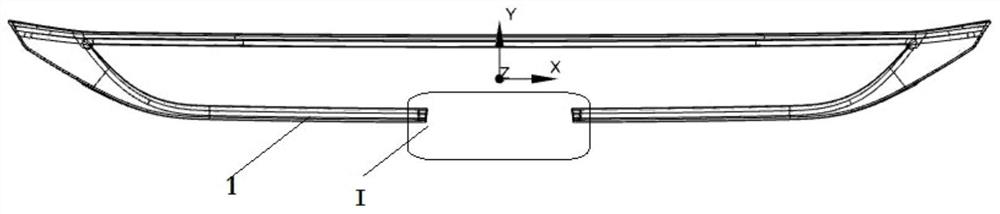

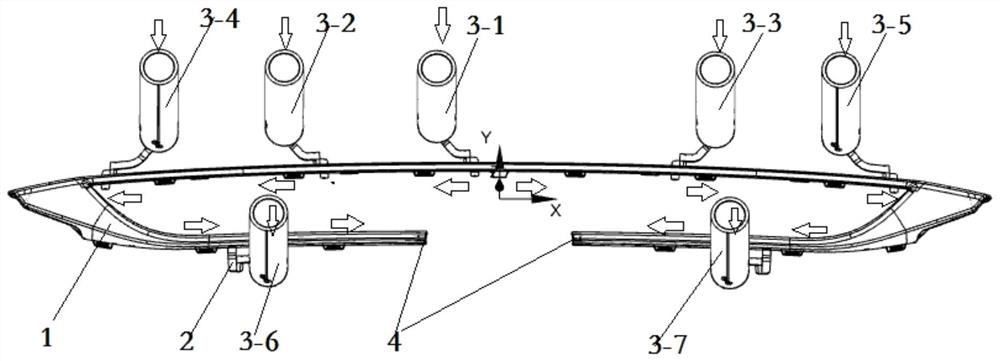

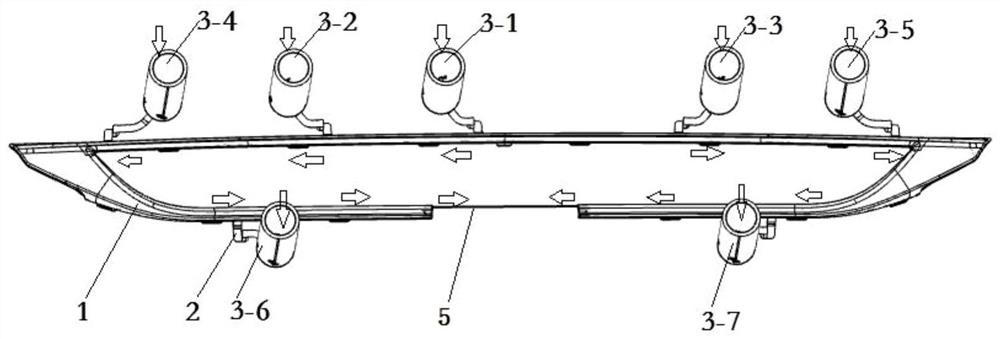

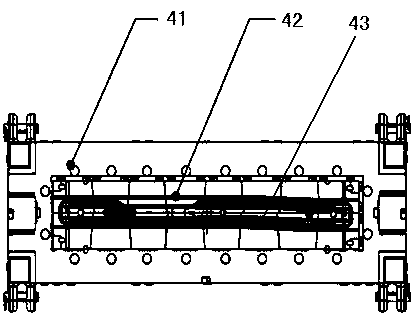

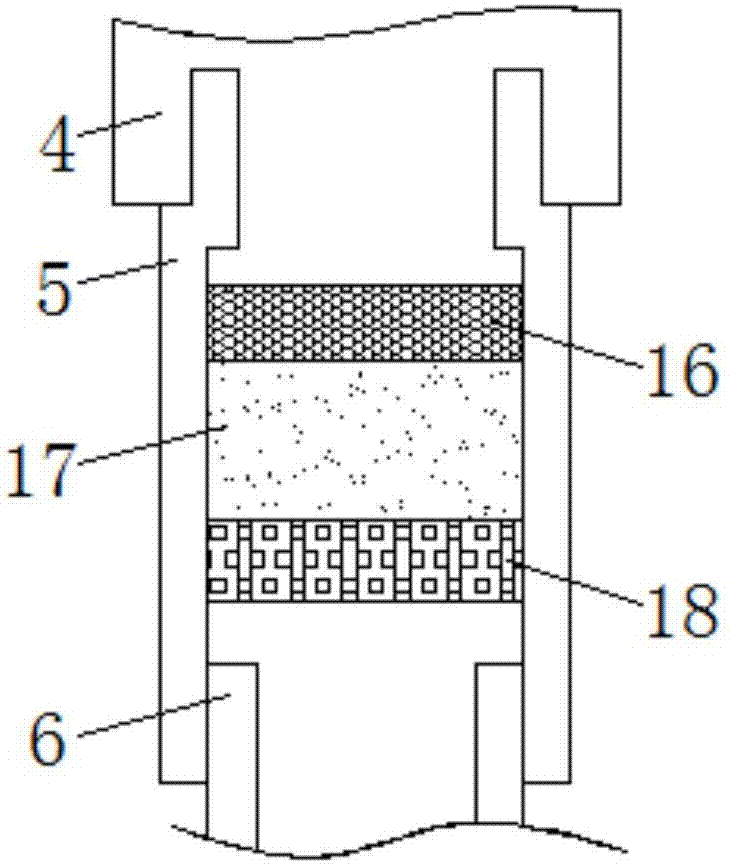

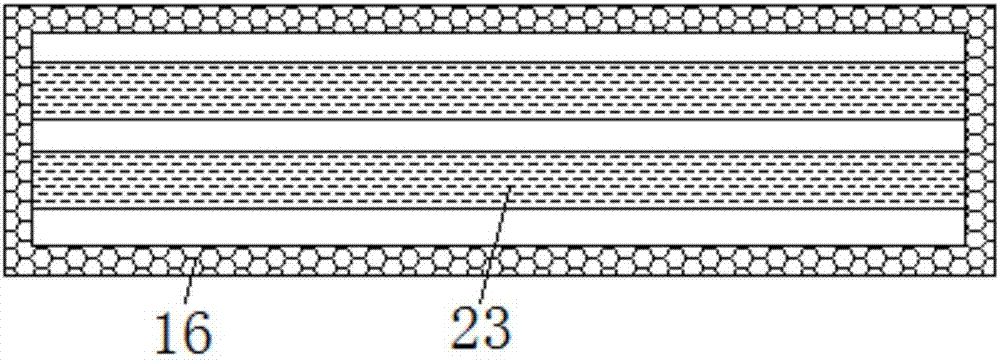

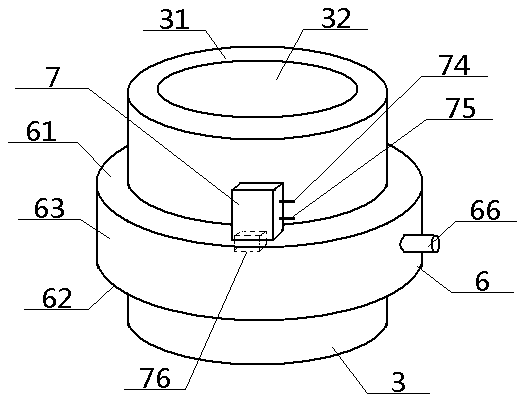

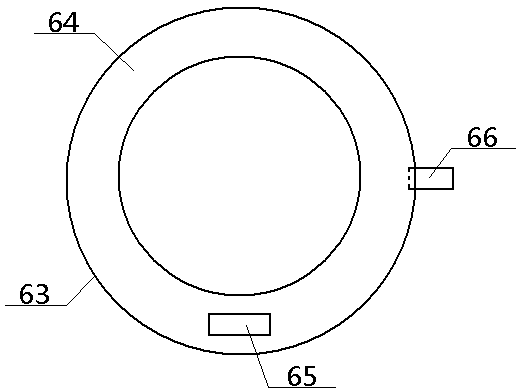

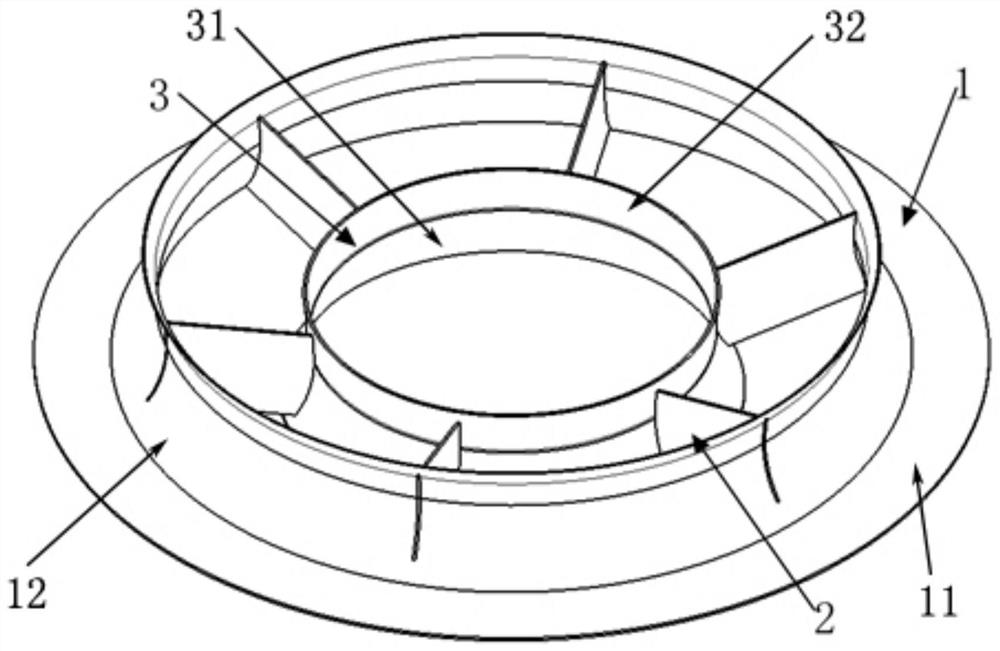

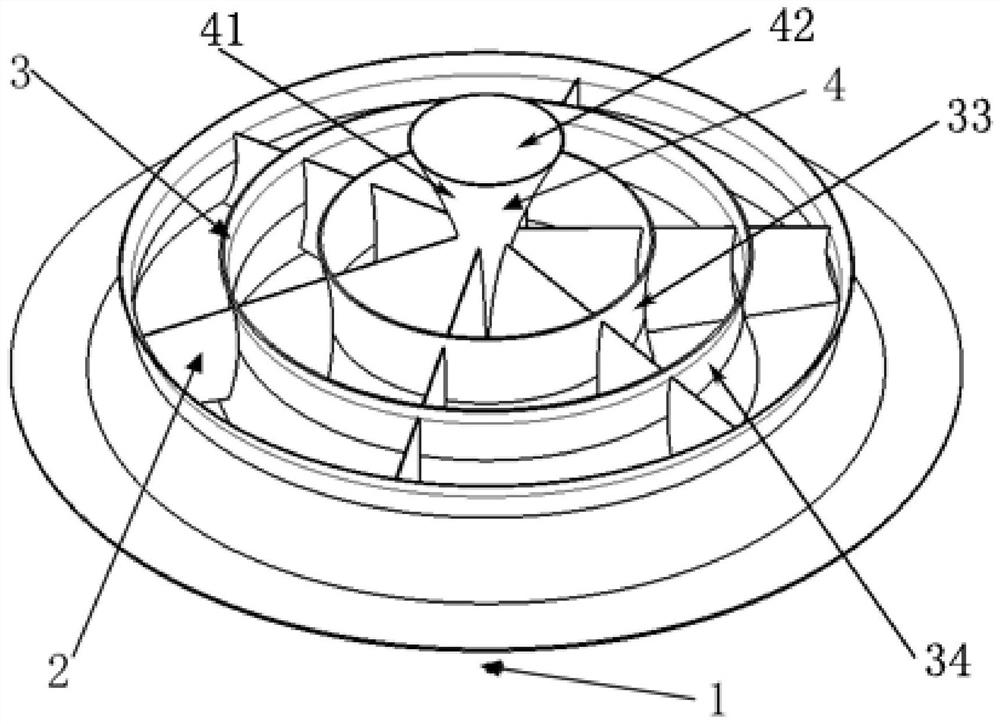

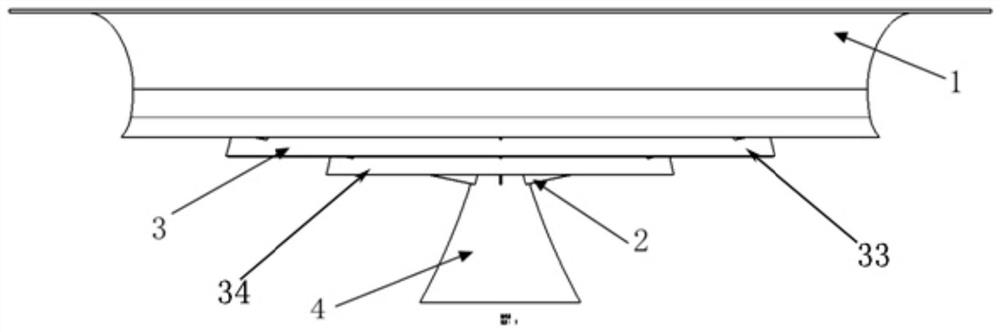

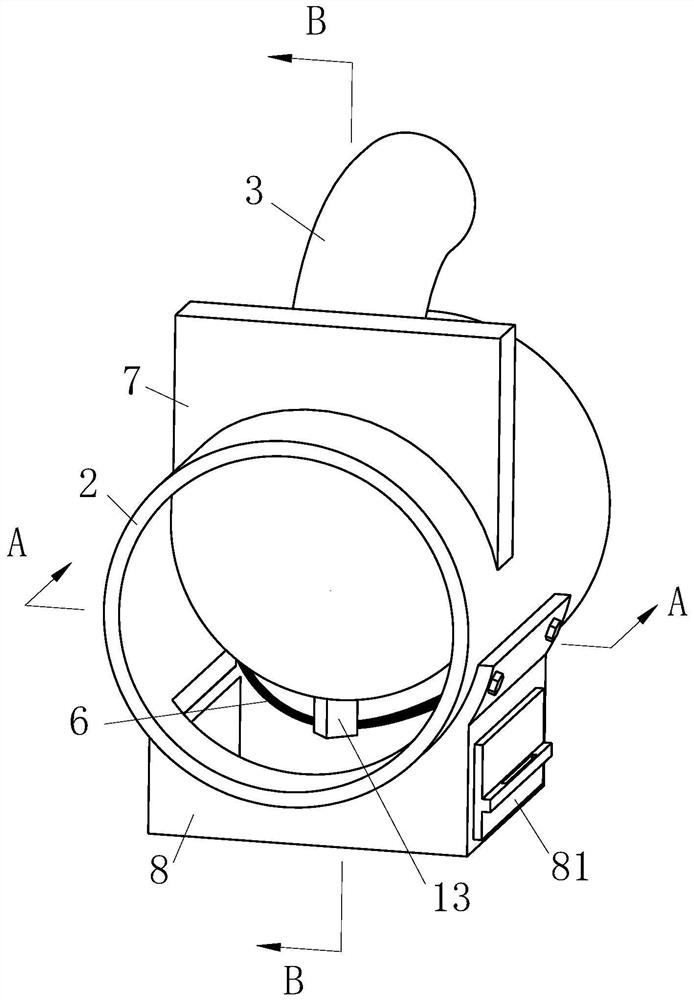

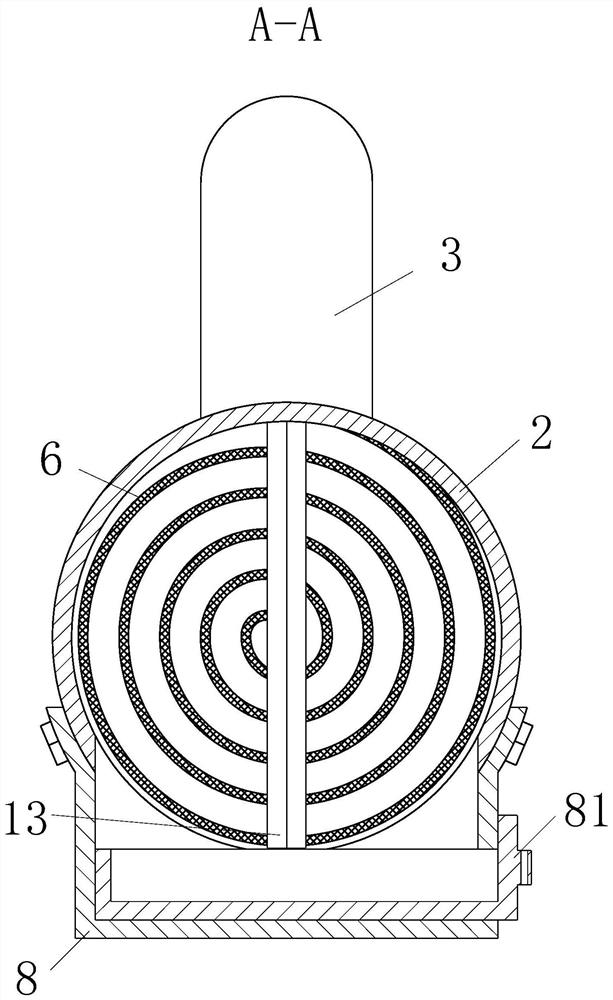

Ventilating die assembling system with external ring cavity

ActiveCN110067083AIncrease profitAvoid shape clippingHeating/cooling textile fabricsNon-woven fabricsControllabilityMechanical engineering

The invention discloses a ventilating die assembling system with an external ring cavity. The ventilating die assembling system comprises an outer sleeve, an upper die and a lower die, wherein the height of the outer sleeve is greater than that of the upper die; the bottom end of the outer sleeve is located between the top surface of a lower die body and an outer ring body; each of the upper and lower dies comprises an external die body and an internal die cavity; a plurality of upper ventilating passages communicated with the upper die cavity are formed in the upper die body; a plurality of lower ventilating passages communicated with the lower die cavity are formed in the lower die body; the outer ends of the lower ventilating passages pass through an air inlet region arranged on the bottom surface of the lower die and then are communicated with an air outlet of an air jet device; the outer ring body of the hollow structure is arranged on the outer side wall of the lower die; the outer ring body comprises an outer ring top surface, an outer ring bottom surface and an outer ring side wall; the outer ring top surface, the outer ring side wall, the outer ring bottom surface and theouter wall of the lower die body jointly form one outer ring cavity in an encircling manner; a monitoring port connected with a temperature monitor is formed in the top surface of the outer ring. Thedesign does not limit the shape of formed cotton, can increase the material utilization rate and is relatively high in controllability.

Owner:WUHAN TEXTILE UNIV

Oil field wellhead device with multi-stage coupling viscosity reduction function

The invention discloses an oil field wellhead device with a multi-stage coupling viscosity reduction function, and relates to the technical field of oil field exploitation. The oil field wellhead device comprises an access pipe, wherein one end of the access pipe is connected with a first flow measuring box; one end of the first flow measuring box is provided with an opening valve; one end of the opening valve is provided with a pump pipe; one end of the pump pipe is provided with a first steering pipe; one end of the first steering pipe is provided with a flow limiting pipe; one end of the flow limiting pipe is provided with a porous connecting pipe; a viscosity reduction pipe is arranged above the porous connecting pipe; a limiting pipe is arranged above the viscosity reduction pipe; one side of the limiting pipe is provided with a limiting disc; the limiting disc is rotationally provided with a swing disc; one end of the porous connecting pipe is provided with a limiting cylinder; and the outer part of the limiting cylinder is sleeved with a fixing block. The oil field wellhead device has the advantages that the rotation of a motor is adjusted, the two ends of the swing disc are controlled to swing up and down through an adjusting rod, a flow limiting block slides up and down in the limiting pipe to control the amount of a viscosity reducer flowing into the viscosity reduction pipe, and the viscosity of petroleum is reduced to different degrees.

Owner:大庆汇丰达石油科技开发有限公司

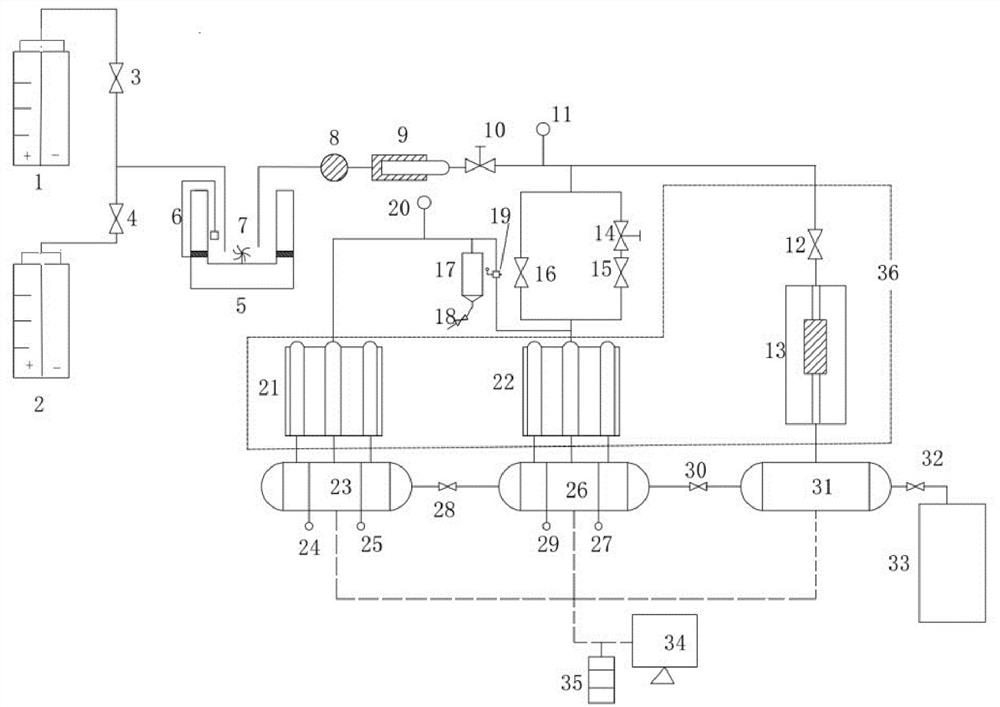

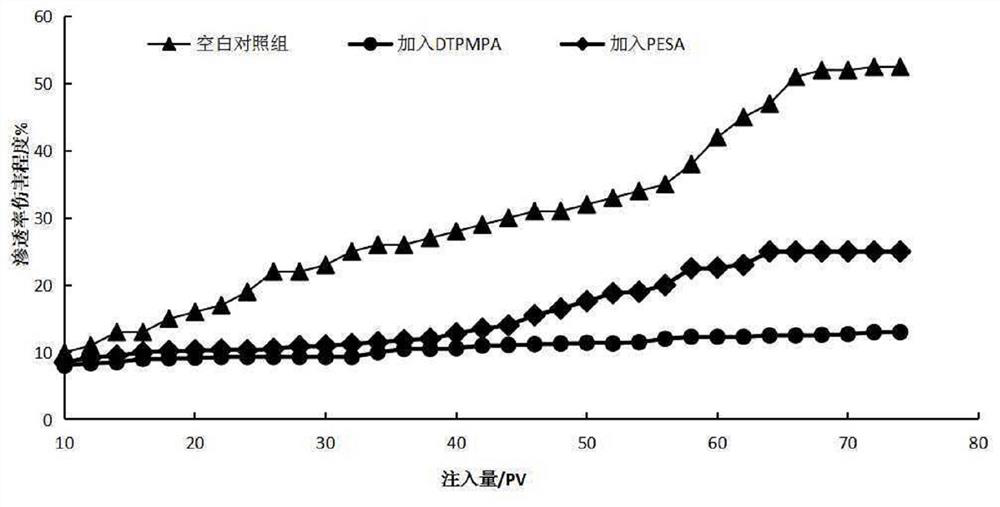

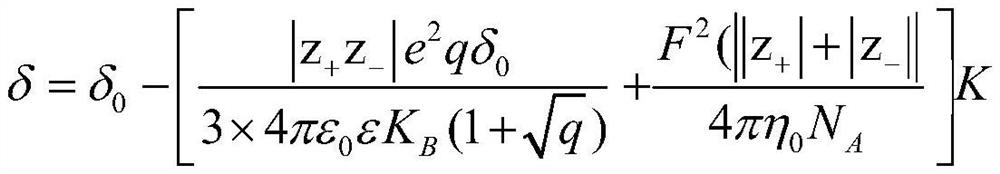

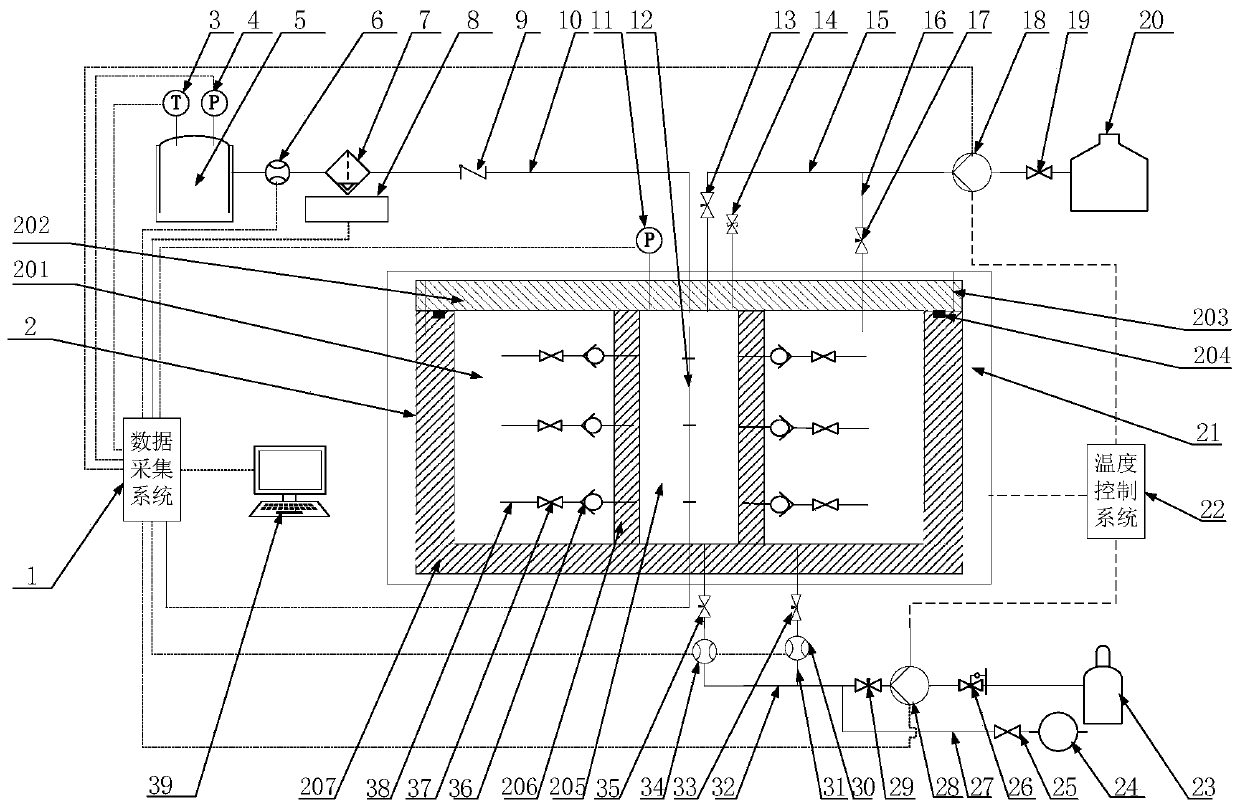

Dynamic experimental device and method for evaluating performance of scale inhibitor on oil field

PendingCN114112852AEasy to replaceSmall pressure fluctuationsPermeability/surface area analysisRock coreOil field

The invention aims to provide a device and a method for dynamically evaluating the performance of an oil field scale inhibitor. According to the experimental device, the scaling and scale inhibition conditions of a pipeline in a field high-temperature and high-pressure environment are simulated, the scaling and scale inhibition conditions under the condition of different fluid flow patterns are simulated by adjusting the flow and the flow speed through the flow adjusting valve, and two groups of high-pressure and low-pressure pipeline testing devices which are connected in parallel are designed; test pipelines made of different materials can be replaced on the test device through detachable joints, dynamic scaling and scale inhibition experiments can be carried out on multiple groups of pipelines made of different materials at the same time, finally, reaction liquid is collected through a collecting tank, the conductivity reading of the reaction liquid of each pipeline is recorded at the same time, and the conductivity reading is compared with the conductivity of a blank control group. The scale inhibition performance of the scale inhibitor and the scaling condition of the pipeline are represented by comparing the residual concentration of scaling ions fitted by the conductivity with the initial scaling ion concentration, and meanwhile, a rock core dynamic displacement experiment device is arranged, so that the improvement degree of the scale inhibitor on the permeability damage of the rock core is further evaluated; and a foundation is laid for screening of the oil field scale inhibitor and evaluation and development of the scale inhibition performance of the scale inhibitor.

Owner:SOUTHWEST PETROLEUM UNIV

Garden fallen leaf smashing and fertilizing device

InactiveCN111196742AMaximize utilizationControl inflowBio-organic fraction processingOrganic fertiliser apparatusMechanical engineeringFermentation

The invention discloses a garden fallen leaf smashing and fertilizing device, and belongs to the field of garden technologies. The device comprises a box body; supporting legs are arranged at the fourcorners of the bottom of the box body correspondingly; a discharge hole is formed in the bottom of the box body; a feeding hole is formed in the top of the box body; a crushing cavity is formed in the position, located below the feeding hole, of the top of the interior of the box body; a filter screen is arranged below the crushing cavity; a first rotating shaft is arranged in the crushing cavity; a blade is arranged outside the first rotating shaft; and one end of the first rotating shaft is connected with one side of the inner wall of the box body through a bearing. The device is provided with the crushing cavity, a stirring cavity and a fermentation cavity. By arranging the crushing cavity, collected fallen leaves can be smashed; the smashed leaf residues enter the stirring cavity through the filter screen, and the leaf residues, water and ferment powder are stirred and mixed through stirring blades in the stirring cavity; and the leaf residues enter the fermentation cavity after being fully mixed to be subjected to final fermentation treatment.

Owner:黄石市禾呈林业有限公司

Two-phase four-wire power saving system

InactiveCN104979832AControl inflowReduce power consumptionAc network voltage adjustmentCurrent distributionElectric power

The invention discloses a two-phase four-wire power saving system. The two-phase four-wire power saving system comprises an electric brake device and a power device, wherein the electric brake device is located on the left side of a connection block; the electric brake device comprises a brake body and a connection block; the brake body is located in the middle of the electric brake device; the brake body is internally provided with a switch; the connection block is located above the power device; more than one connector is arranged; the power device is connected with the electric brake device; the power device comprises a main board, a current distribution board and a top board; the main board is located under the current distribution board and the current distribution board is provided with a connection wire; the current distribution board is connected with the top board; the top board is provided with an electrified board; and the electrified board is provided with a wiring hole. The two-phase four-wire power saving system has the advantages that power consumption is reduced and the utilization rate of power is improved.

Owner:ZHONGSHAN SHUNFU ENERGY SAVING TECH

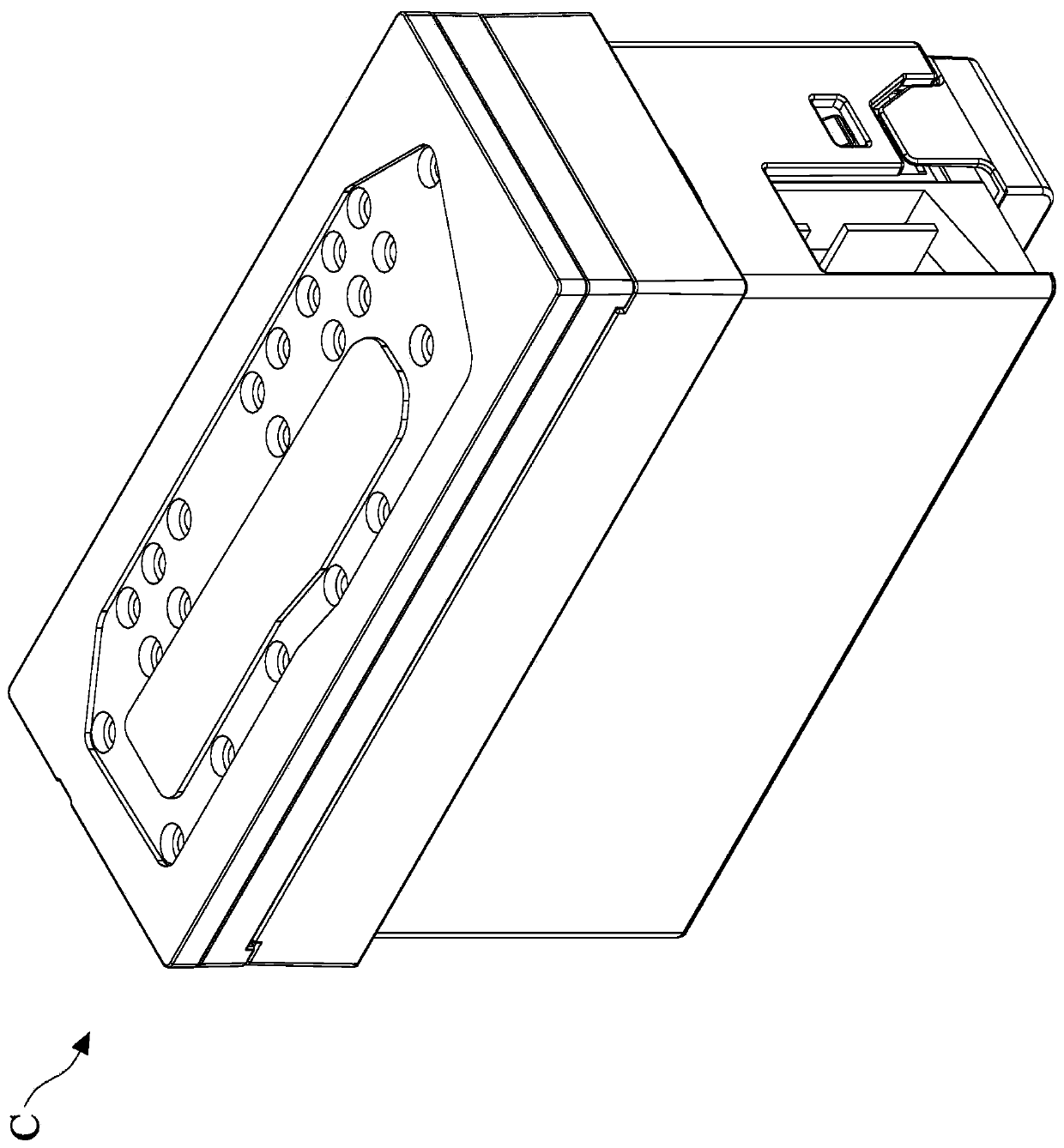

Method for extracting nucleic acid and extraction cassette thereof

PendingCN110004141AControl inflowReduce volumeLiquid solutions solvent extractionDNA preparationMechanical engineeringReaction chamber

Owner:DELTA ELECTRONICS INC

Efficient and low-noise multi-layer flow collector and centrifugal fan

The invention discloses an efficient and low-noise multi-layer flow collector and a centrifugal fan. Flow collecting barrels, blade grids and a flow guide cone are arranged on a flow collector body, so that the blade grids can achieve the effects of a front guide blade and supporting the flow collecting barrels and the flow guide cone. Meanwhile, the flow collecting barrels play a role in layering gas entering the flow collector, so that the gas enters an impeller more smoothly, and the flow guide cone plays a role in guiding the gas. Meanwhile, after the flow collector combining the multiple layers of flow collecting barrels and the flow guide cone is used for being axially inserted into the impeller, gas enters the impeller more smoothly through mutual cooperation of the blade grids, the flow collecting barrels and the flow guide cone, and then the inflow situation of each small unit gas on the inlet section of the flow collector is controlled, and the impeller inlet eddy current loss and the blade inlet impact loss are reduced, so that the purposes of efficiency improvement and noise reduction are achieved.

Owner:FANS TECH ELECTRIC CO LTD

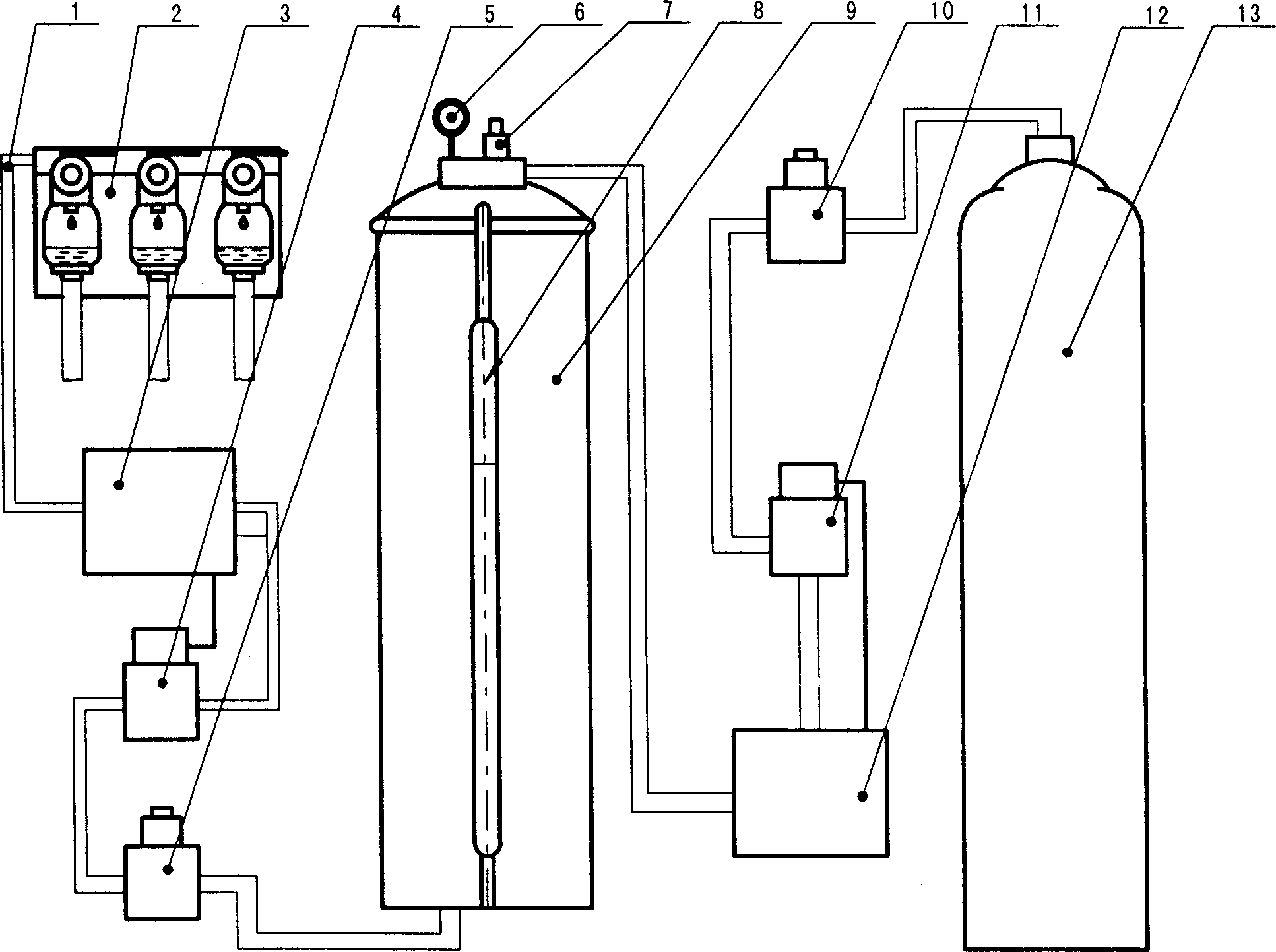

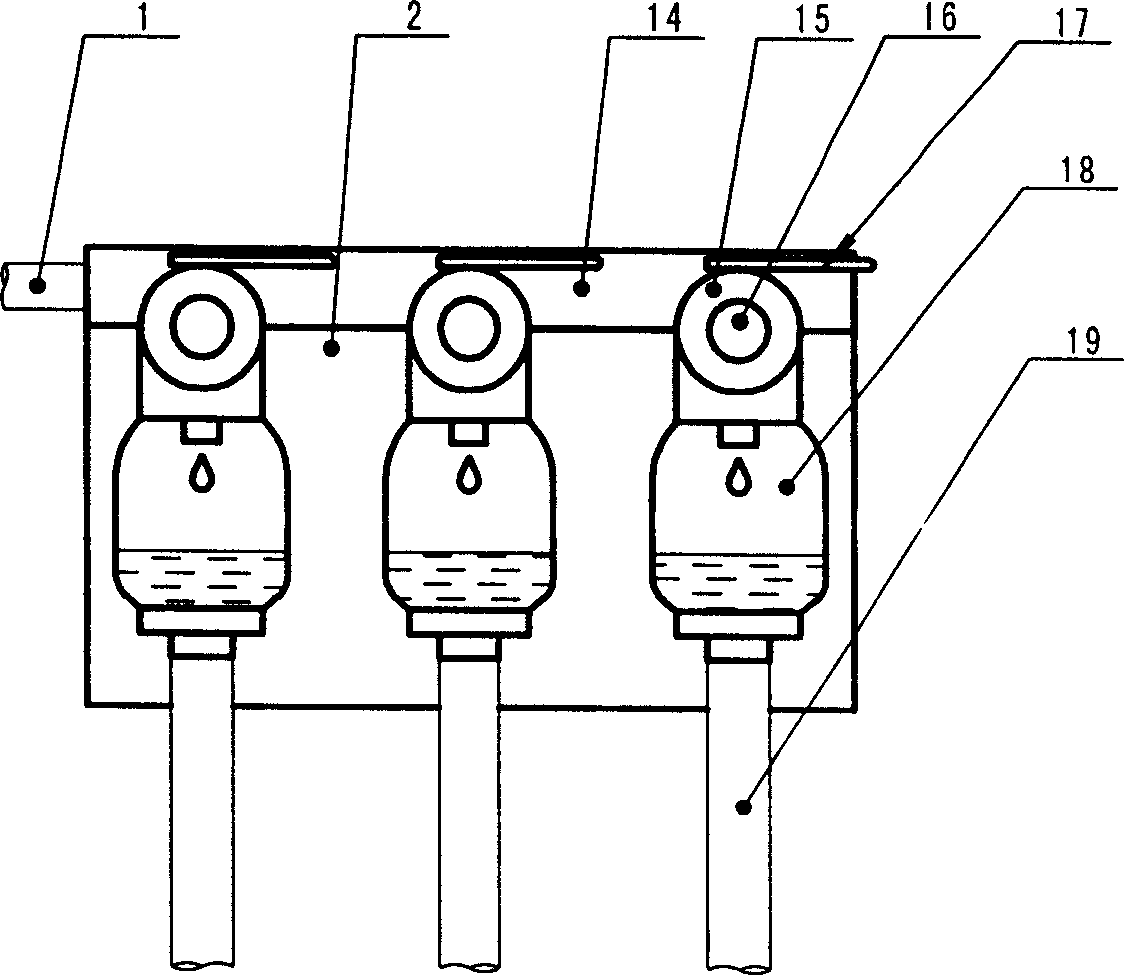

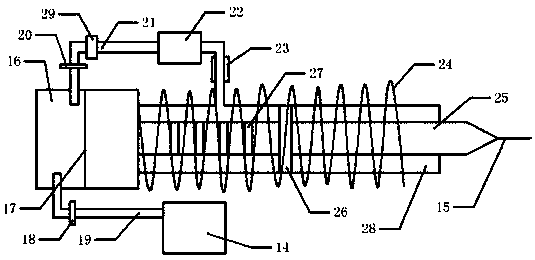

Natural gas hydrate mining device with reservoir multi-position pressure compensation function

The invention belongs to the technical field of natural gas hydrate simulation, and relates to a natural gas hydrate mining device with a reservoir multi-position pressure compensation function. The device mainly comprises a hydrate generation device, a hydrate decomposing device, a gas supply device, a water supply device, an air water compensating device, a temperature control system, a data acquiring system and a computer. An inner sleeve is arranged in a reaction kettle forming the hydrate generation device; internal space of the reaction sleeve is divided into a sample cavity and a confining pressure cavity, which are connected through multiple layers of fluid feeding pipes provided with valves and one-way valves; the one-way valves can guarantee fluids in the confining pressure cavity to flow into the sample cavity in one direction; and through opening and closing of valves arranged in different positions, the flowing quantity of surrounding fluids in the different positions to adecomposing area can be controlled. The device can simulate the pressure compensation of the surrounding fluids to the hydrate decomposing area in multiple positions during mining of hydrates under air-enriched and water-enriched environments, and provides a new thought to a natural gas hydrate simulation technology.

Owner:DALIAN UNIV OF TECH

A kind of clay model drilling device

ActiveCN106626113BControl inflowControl the flow rate into the cylinderWorking accessoriesStone-like material working toolsExhaust pipeSpiral coil

The invention belongs to mechanical devices for automobile shape modelling, and particularly relates to a drilling device for a clay model. A groove is formed in a workbench; a coordinate locator is slidably connected in the groove; the drilling device is installed on the coordinate locator; a liquid storage box is connected to the drilling device; a metal pipe is arranged in the drilling device in a penetrating manner; a sleeve is arranged outside the metal pipe; a spiral coil is wound outside the sleeve; a drill bit is installed at one end away from the coordinate locator, of the metal pipe; a cylinder is connected with a piston; an insulation partition is arranged in the drilling device; the sleeve is partitioned by the insulation partition; the insulation partition is movably inserted in the sleeve; a plurality of superconductors are fixed in the metal pipe between the insulation partition and the piston; an intake pipe and an exhaust pipe are connected to the cylinder; the intake pipe is connected to the liquid storage box; and the exhaust pipe is connected in the sleeve between the insulation partition and the cylinder. The problems of rough drilling of the drill bit on the clay model and uneven curved surface of the clay model formed through drilling connection due to reciprocating shake of the drill bit during the drilling of the drill bit for the clay model are solved.

Owner:CHONGQING BIYANG PROD DESIGN

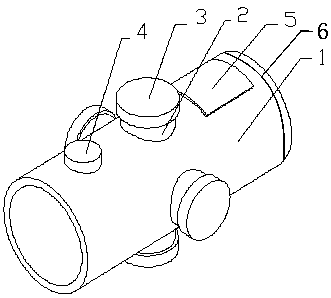

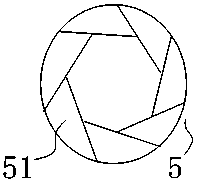

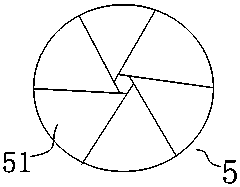

Filtering and flow dividing device

The invention discloses a filtering and flow dividing device, and belongs to the field of pipe fittings. The filtering and flow dividing device comprises a main body pipe, and flow dividing short pipes are arranged on the main body pipe and provided with sealing covers. The filtering and flow dividing device further comprises a filtering net and a flow limiting device, the filtering net is a polyester fiber thermal compounding nanometer film, and the flow limiting device is composed of a motor and similar aperture blades driven by the motor. The filtering and flow dividing device hast the beneficial effects that the filtering and flow dividing device can effectively divide the flow, the flow dividing short pipes of the filtering and flow dividing device can be connected with any pipes matched with the flow dividing short pipes, meanwhile, the quite good filtering effect is achieved, and the inflow amount of the main body pipe and the inflow amount of the flow dividing short pipes can be controlled through the flow limiting device.

Owner:罗弟容

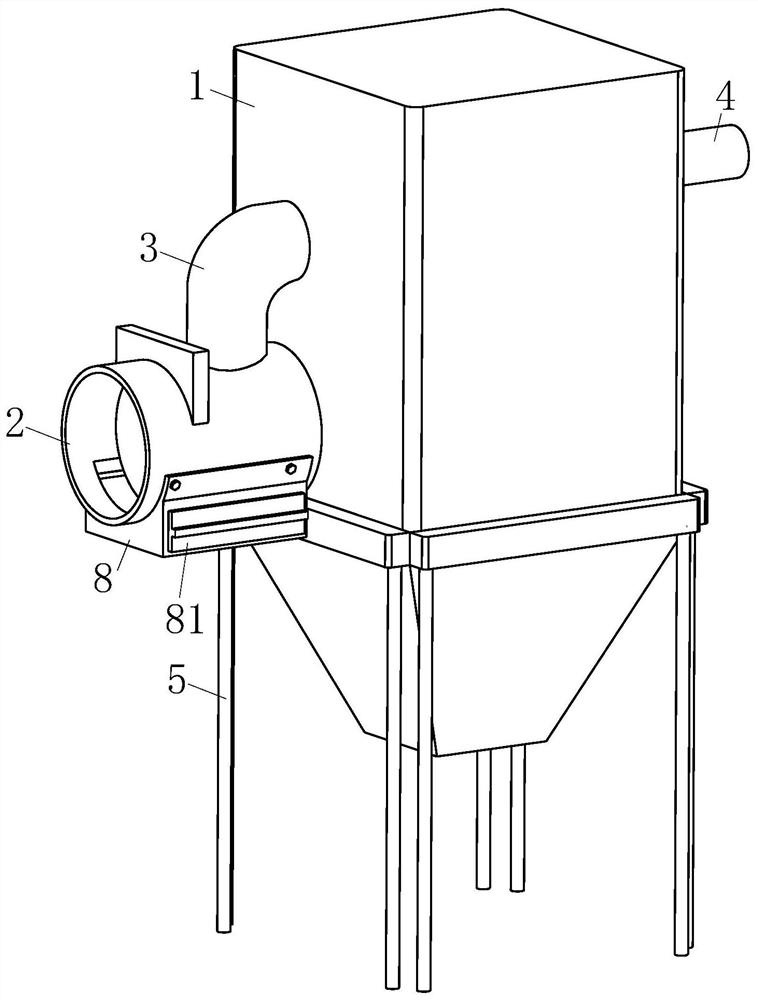

High-concentration superfine dust collector

ActiveCN113476980AImplement hierarchical filteringEasy to cleanHuman health protectionGas treatmentDust controlEnvironmental engineering

The invention relates to the technical field of air dust removal, in particular to a high-concentration superfine dust collector, which comprises a dust collector main body, wherein an air inlet pipe is arranged on the left side of the dust collector main body, an air guide pipe is fixedly mounted above the air inlet pipe, an air outlet pipe is fixedly connected to the right side of the dust collector body, the dust collector main body, the air inlet pipe and the air guide pipe are fixedly connected, four groups of brackets are fixedly mounted at the lower end of the dust collector main body, the air guide pipe is positioned above the air inlet pipe, a filter screen and a mounting pipe are arranged in the air inlet pipe, a collecting box is fixedly mounted at the lower end of the air inlet pipe, and a cleaning device is arranged on the surface of the filter screen. According to the invention, the high-concentration superfine dust collector is simple in structure and practical, can effectively filter dust particles in waste gas, can clean the dust particles on the surface of a filter screen through a cleaning device, achieves the function of filtering and cleaning at the same time, and improves the use efficiency of the dust collector.

Owner:黑龙江省宝泉岭农垦溢祥新能源材料有限公司

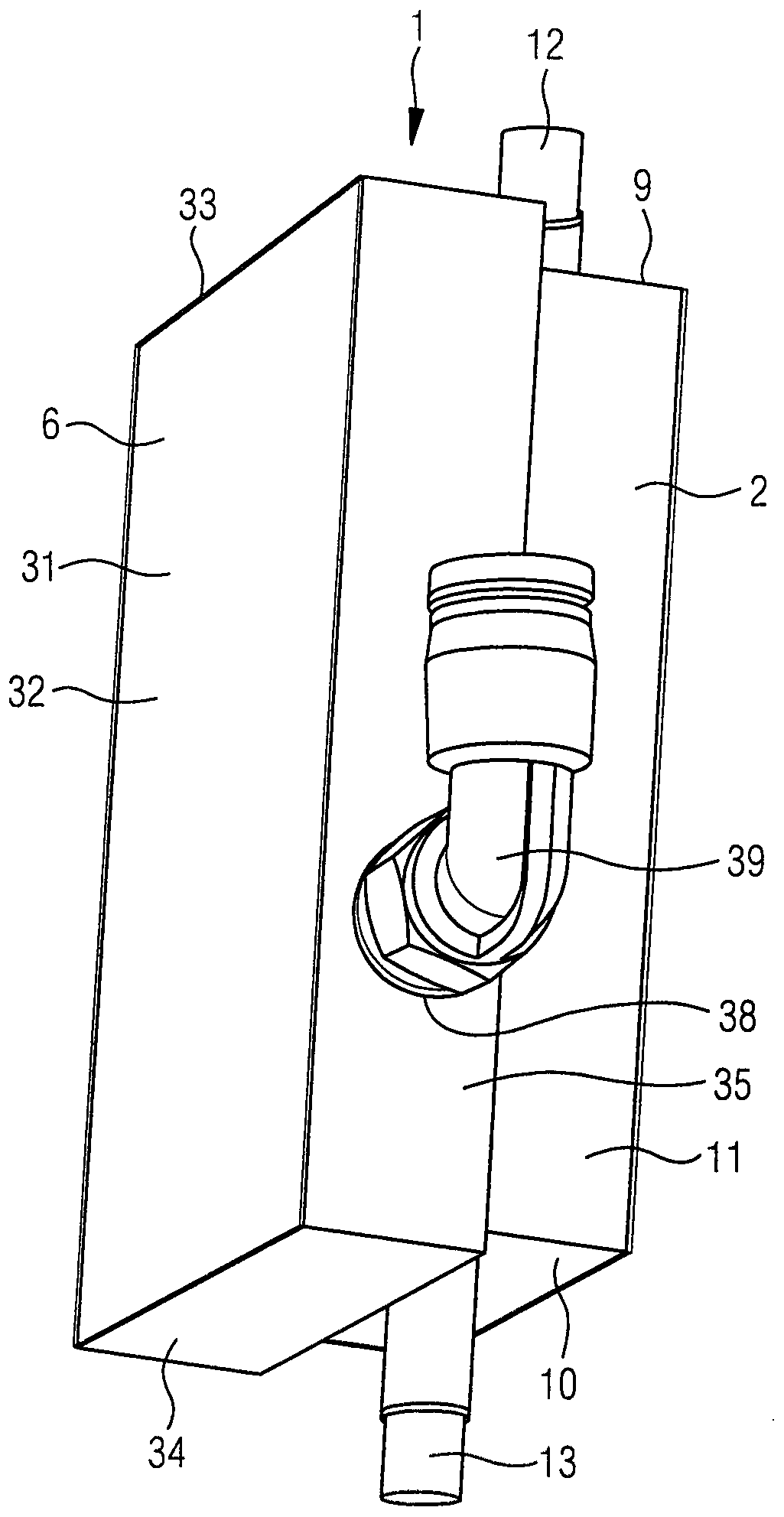

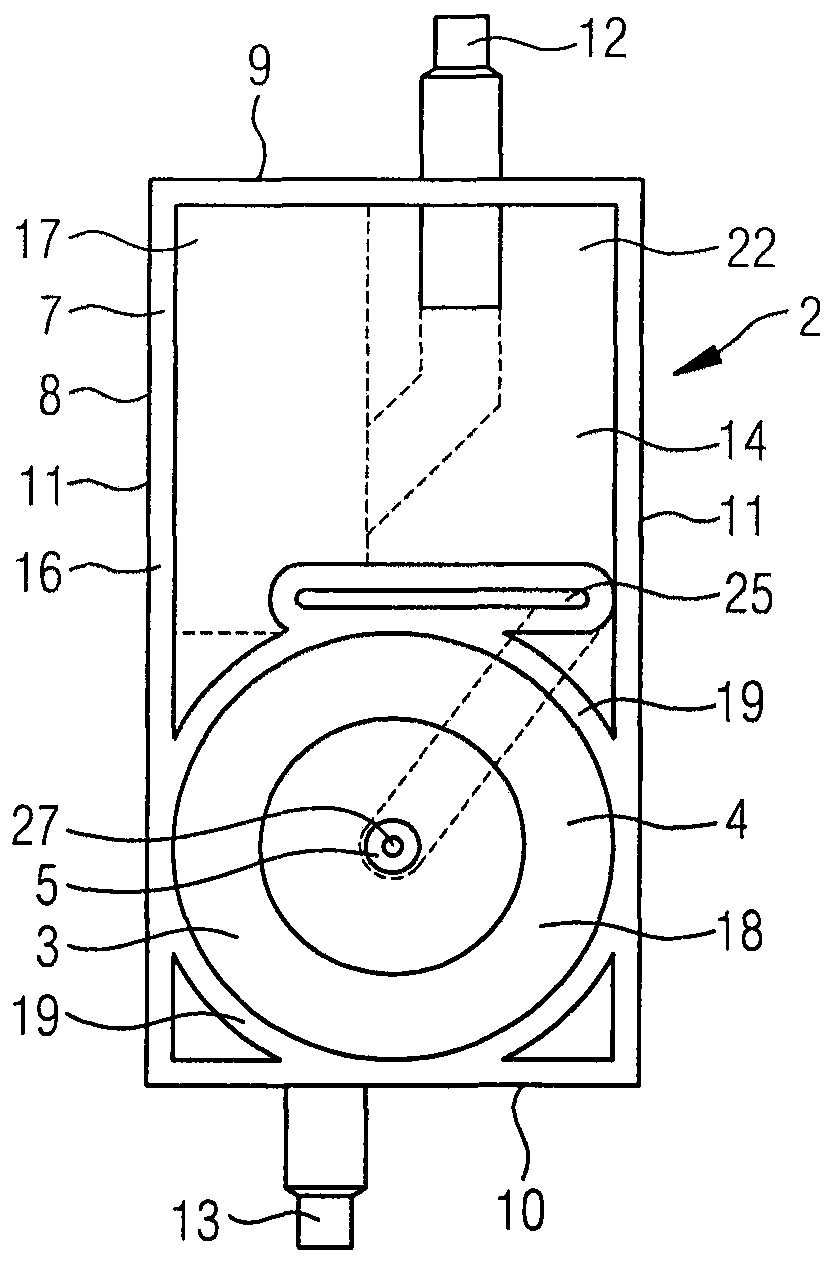

Device and method for cleaning and/or operating an ink-jet printer head equipped with an upstream pressure absorber

ActiveCN110881272ADoes not affect switching characteristicsImplement control inflowPrintingEngineeringDamper

The invention relates to a device (1) for operating and / or cleaning an ink or ink-jet printer head equipped with an upstream pressure absorber (2), the pressure absorber (2) comprises a closed damperchamber (4) that is at least partially limited by a damper film (3). A refill valve (5) is arranged in the damper chamber (4) and is designed to refill the damper chamber (4) with ink in response to acurvature of the damper film (3) in the damper chamber (4). A controllable device (6) is arranged outside of the damper chamber (4) for exerting an external pressure on at least one area of the damper film (3) limiting the damper chamber (4) in order to open the refill valve (5) arranged in the damper chamber (4) and also to create a continuously open channel through the pressure absorber for cleaning the ink-jet printer head and / or to exert an adjustable pressure on the refill valve arranged in the damper chamber (4).

Owner:扬弗兰克

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com