Ventilating die assembling system with external ring cavity

A ring cavity, outer ring technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problem of low material utilization rate, and achieve high material utilization rate, improve utilization rate, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

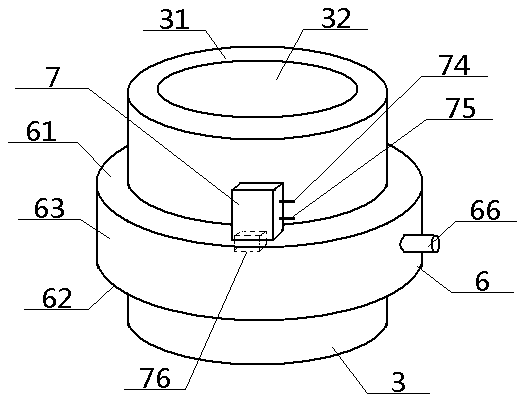

[0058] see Figure 1 to Figure 15 , a peripheral ring-cavity ventilation mold clamping system, including an outer sleeve 4, an upper mold 2 and a lower mold 3, the outer sleeve 4 is a hollow structure, and the upper mold 2 includes an upper mold body 21 and its interior The upper mold cavity 22 opened, the lower mold 3 includes the lower mold body 31 and the lower mold cavity 32 opened inside, the upper mold cavity 22, the lower mold cavity 32 are butted up and down to form a molding cavity 1, and the outer sleeve 4 The width of the inner wall is greater than the width of the upper mold 2 and the lower mold 3; the inside of the upper mold body 21 is provided with a plurality of upper air passages 25 communicating with the upper mold cavity 22, and the outer end of the upper air passage 25 is connected to the upper mold 2. The external environment communicates, and the inside of the lower mold body 31 is provided with a plurality of lower air passages 35 communicating with the ...

Embodiment 2

[0060] Basic content is the same as embodiment 1, the difference is:

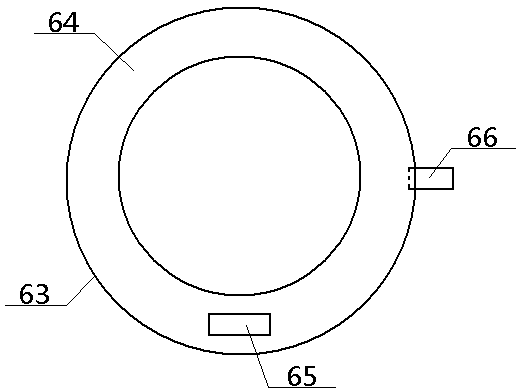

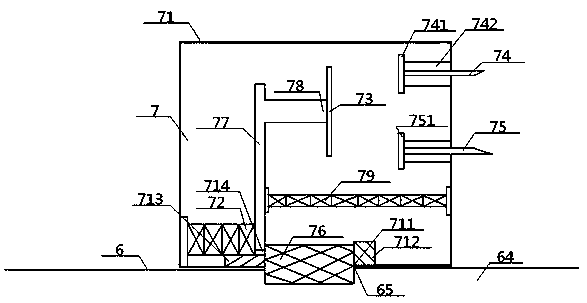

[0061] The temperature monitor 7 includes a monitoring shell 71, a compression spring 72, a movable conductive sheet 73, an upper conductive wire 74, a lower conductive wire 75, and a monitoring wax block 76. A container opening 711 is provided at the bottom of the monitoring shell 71. A monitoring wax block 76 is embedded in the content opening 711. The top surface of the monitoring wax block 76 is located in the monitoring shell 71. The bottom surface of the monitoring wax block 76 passes through the monitoring port 65 and is located inside the outer ring cavity 64. The monitoring wax block The left end of 76 is bonded to one side of the lower part of the insulating vertical bar 77, the other side of the lower part of the insulating vertical bar 77 is fixedly connected to one end of the compression spring 72, and the other end of the compression spring 72 is connected to the left wall of the monitoring hou...

Embodiment 3

[0063] Basic content is the same as embodiment 1, the difference is:

[0064] The top surface of the upper mold body 21 is connected with the lower pressing shaft 20, and the bottom surface of the upper mold body 21 is provided with a concentric upper inner slide rail 23 and an upper outer slide rail 24 around the position of the upper mold cavity 22. The rail 23 and the upper and outer slide rails 24 are all ring structures, and the top surface of the lower mold body 31 is provided with a concentric lower inner chute 33 and a lower outer chute 34 around the lower mold cavity 32. The groove 33 and the lower outer chute 34 are all annular structures, the lower inner chute 33 is slidably matched with the upper inner slide rail 23 inserted into its interior, and the lower outer chute 34 is slidably matched with the upper outer slide rail 24 inserted into its interior . The structures of the upper inner slide rail 23 and the upper outer slide rail 24 are consistent, and both incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com