Surface flow controlled valve and screen

A technology of screen tube and controller, applied in the direction of production fluid, wellbore/well valve device, instrument, etc., can solve problems such as restriction of production well or injection well, and achieve the effect of reducing downhole intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

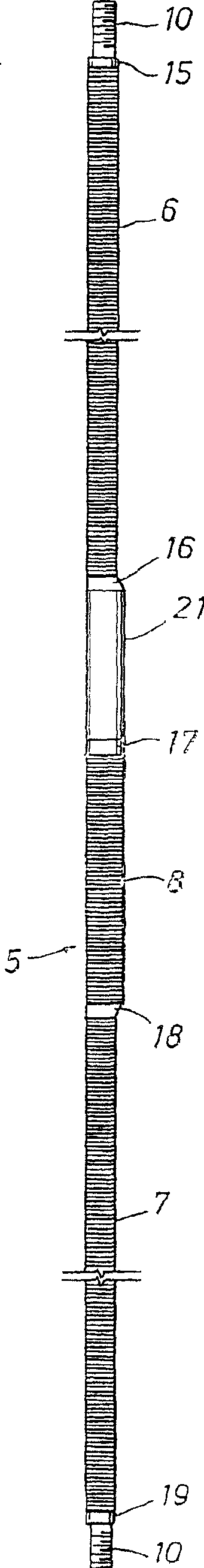

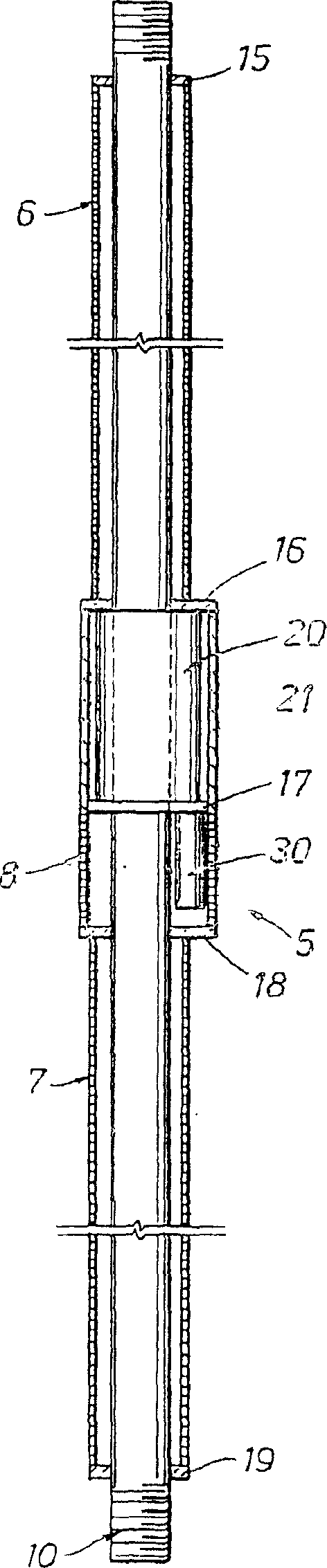

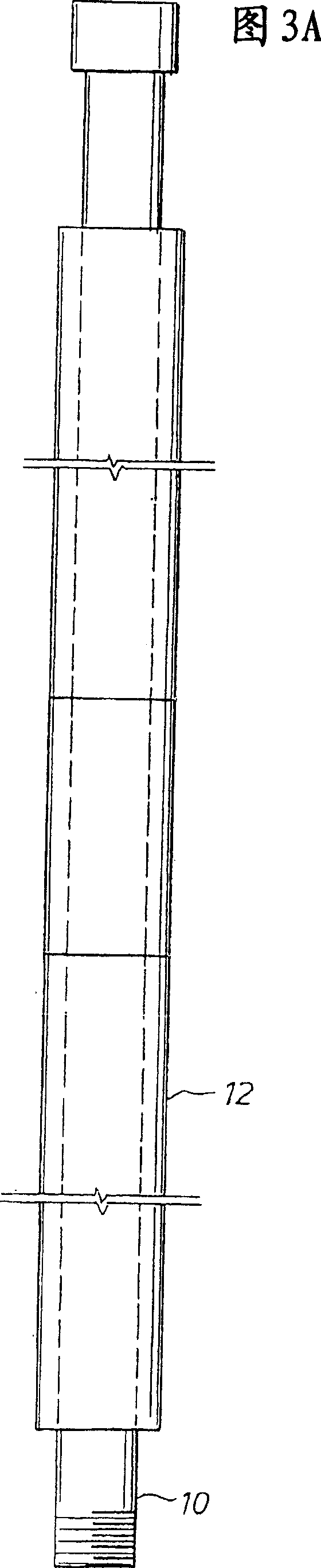

[0053] see figure 1 , which shows a side view of the adjustable downhole sand control screen 5 . The sand control screen 5 is composed of three parts, namely the upper screen 6 , the lower screen 7 and the valve screen 8 . Each of these screens can be constructed in a manner known to those skilled in the art. For example, if Figure 3B As shown, the screen can include a central pipe 10 , longitudinal fins 11 and a screen 12 . In this particular invention, the base tube 10 has no perforations to allow fluid to flow between the outside and the inside of the base tube. In this respect, the base pipe 10 described differs from production screens known in the art. The longitudinal ribs 11 are arranged around the outside of the central pipe 10 in the longitudinal direction. The screens 12 are then wrapped around the longitudinal fins 11 to define channels 13 between the central pipe 10 , adjacent longitudinal fins 11 and the screens 12 . Said channel 13 is the part between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com