Device and method for cleaning and/or operating an ink-jet printer head equipped with an upstream pressure absorber

An inkjet print head and buffer technology, applied in printing and other directions, can solve problems such as damage to buffer capacity and difficulty in generating negative pressure, and achieve the effect of avoiding pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

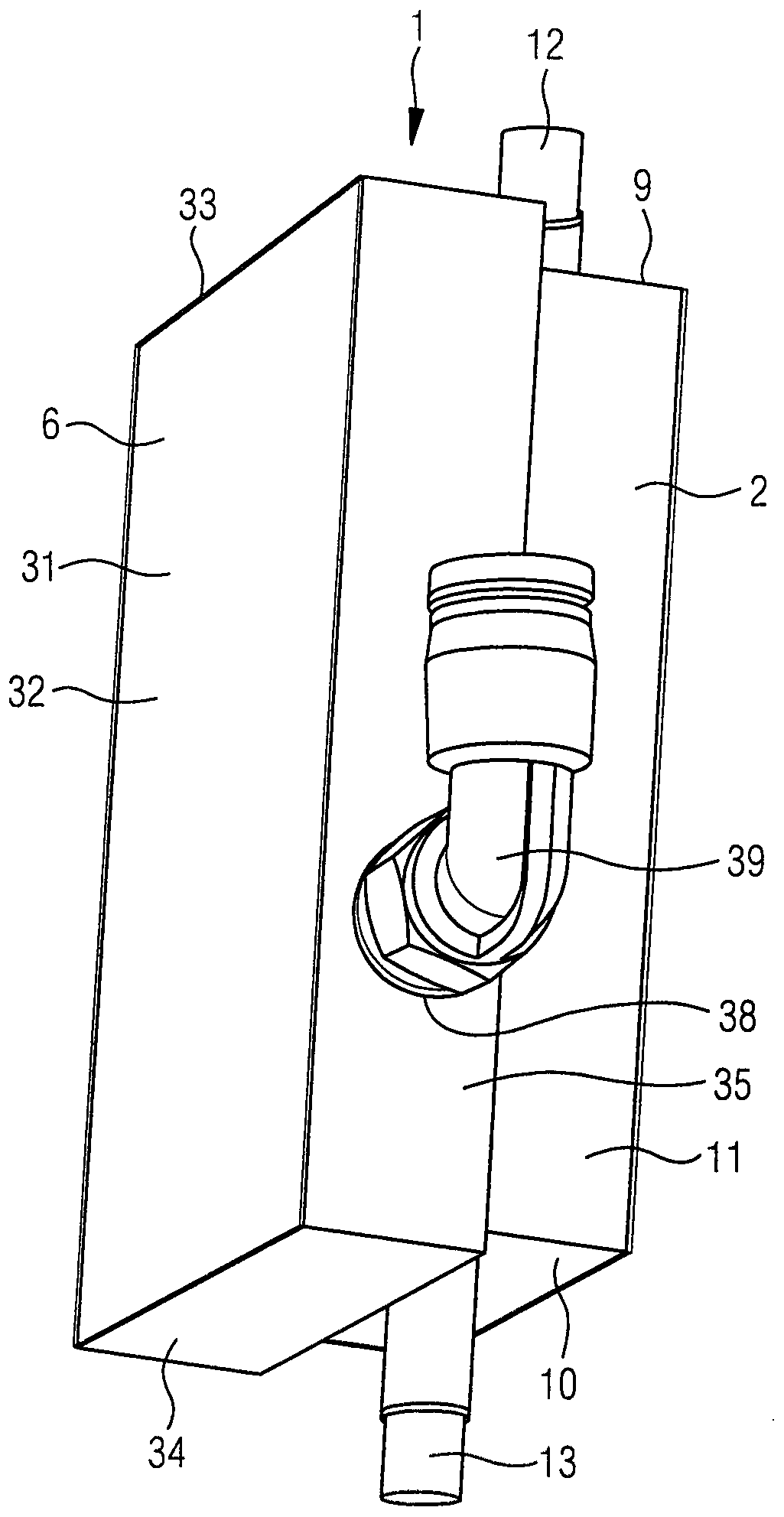

[0035] in the attached figure 1 The device 1 shown in is used for flushing an ink or inkjet print head (not shown) with ink through an upstream pressure buffer 2 .

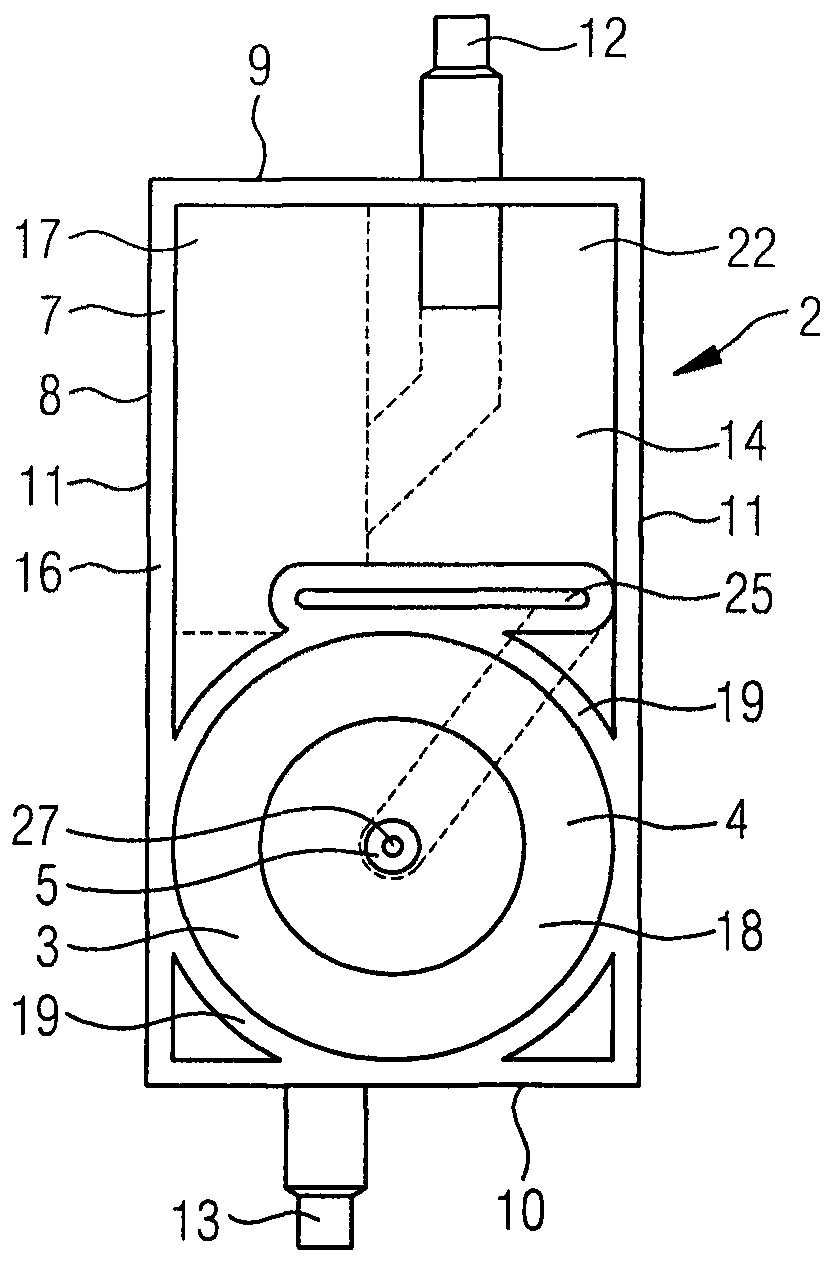

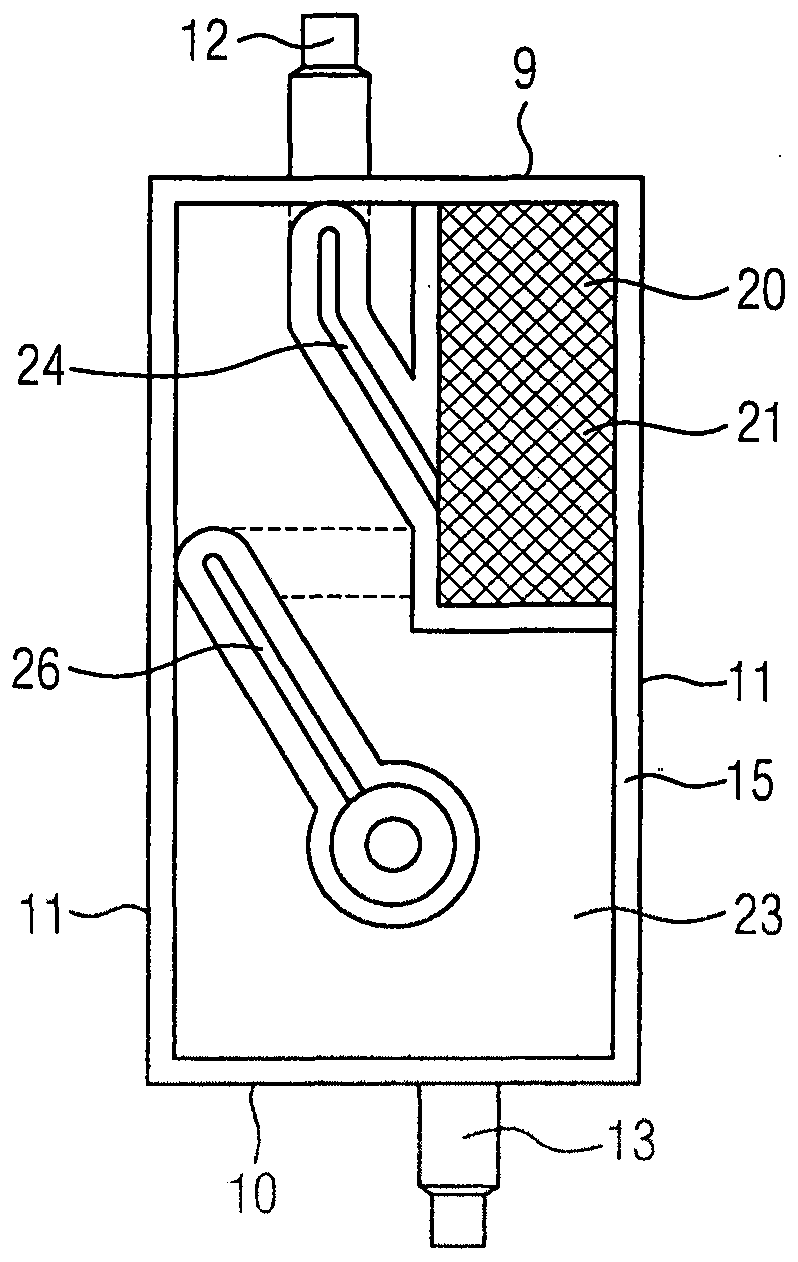

[0036] The internal structure of pressure buffer 2 is in Figures 2 to 5 It can be seen in:

[0037] The pressure damper 2 is provided with a closed damping chamber 4 at least partially delimited by a damping membrane 3, in which is arranged a refill valve 5 which arches the damping membrane 3 inwards into the damping chamber 4 The refilling of the buffer chamber 4 with ink is controlled in a reactive manner.

[0038] The entire pressure damper module 2 has a square shape, while the damping chamber 4 itself accommodated therein is approximately disc-shaped. However, the housing 7 of the pressure damper 2 has the shape of a frame 8 open on two flat sides, which has four interconnected walls, namely an upper side 9, a lower side 10 and an upper side and a lower side to each other. The two longitudinal sides 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com