Adjustable wellhead Christmas tree device

A Christmas tree, adjustable technology, applied in the direction of wellbore/well valve device, earthwork drilling, wellbore/well components, etc., can solve the problems of staff injury, shut down, increase the maintenance cost of the Christmas tree, etc., and achieve improvement Improve mining efficiency and improve maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

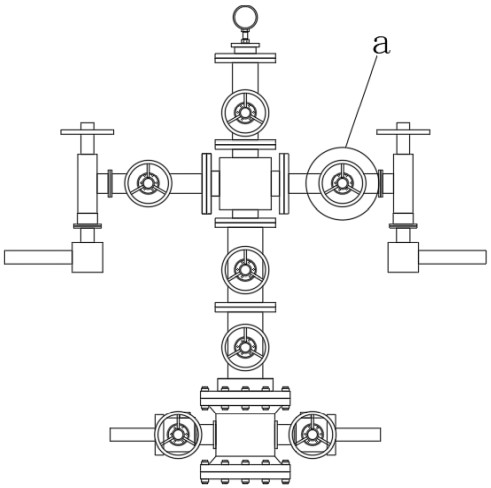

[0038] like figure 1The marked position a shown is at the connection position between the wing valve and the three-way pipe. Since the throttle valve 7 is connected to one end of the wing valve, the oil flows in the pipeline for a long time, which will cause the inner clamp at the connection position of the wing valve and the three-way pipe. Steel ring piercing, because steel rings are installed on the left and right sides of the wing valve, the sealing performance of the valve is improved by the steel rings;

[0039] For this purpose, pierce the right steel ring at the position marked a: for the well with no production pipeline connection on the right side, the piercing of the outer clamp steel ring can directly close the right wing valve, and then remove the clamp and replace the steel ring;

[0040] For the piercing of the steel ring on the left side at the position marked a: For the well with the production pipeline connection on the left side, the production valve, the ba...

Embodiment 2

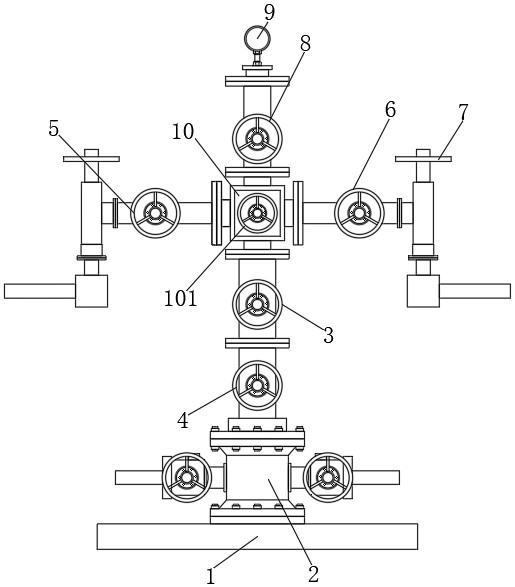

[0047] The top of the bottom plate 1 is communicated with an oil production pipe body 2, and one end of the oil production pipe body 2 is installed with a pressure test gauge 9, an oil drain valve 8, an upper main valve 3 and a lower main valve 4 from top to bottom, and the oil production pipe body 2 The side wall of the main wing valve 6 and the sub-wing valve 5 are symmetrically installed on the opposite plane of the oil-draining valve 8 and the upper-end main valve 3, and the main wing valve 6 and the end of the sub-wing valve 5 are connected with a throttle valve 7;

[0048] The vertical spine 11 is installed on the bottom plate 1, and the card slots 13 are evenly installed on the vertical spine 11. The installation position of the entire vertical spine 11 needs to be measured between fixing, and the clamping block 178 in the clamping mechanism 17 on the vertical spine 11 needs to be measured. The distance between the production pipe bodies 2 on the Christmas tree is reache...

Embodiment 3

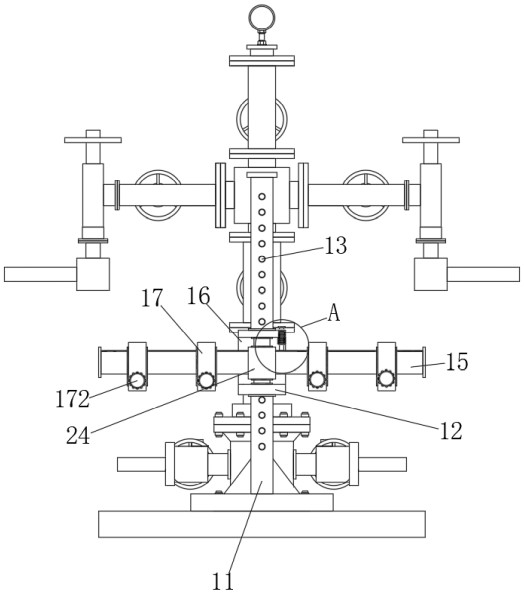

[0051] Four clamping mechanisms 17 are installed on the entire beam 15, such as Figure 4 and Image 6 As shown, a second sliding sleeve 171 is slidably connected to the entire clamping mechanism 17, and a knob 172 is installed on one side of the second sliding sleeve 171. The installation of the knob 172 does not pass through the beam 15 to prevent the second sliding sleeve 171 from being affected. Moving left and right on the beam 15, the other end of the knob 172 is connected with a fixed rod 174, and at the same time, a second movable rod 177 and a load-bearing rod 175 are installed on the fixed rod 174, and the other end of the load-bearing rod 175 is connected with a first movable rod 176 One end is connected with one end of the knob 172, and the other end of the knob 172 penetrates the turntable 173. When the knob 172 rotates, it will drive the turntable 173 to rotate, and the fixing rod 174 is installed on the turntable 173. When the limit pin 19 is installed, the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com