Online monitoring and fault diagnosis system of mine fan

A fault diagnosis system and fan technology, applied in mechanical equipment, machine/engine, pump control, etc., can solve problems such as increasing the overall failure rate of equipment, single diagnosis results, and reducing equipment utilization, reducing equipment maintenance costs and improving equipment. Human-computer interaction ability and the effect of improving the fault recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above purpose and features of the present invention more comprehensible, the present invention will be described in detail below through specific embodiments and accompanying drawings.

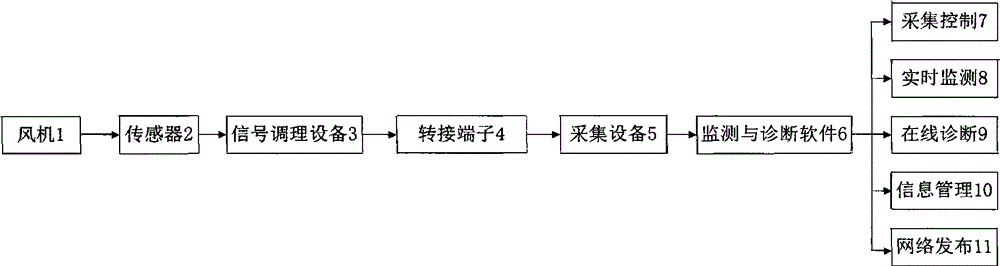

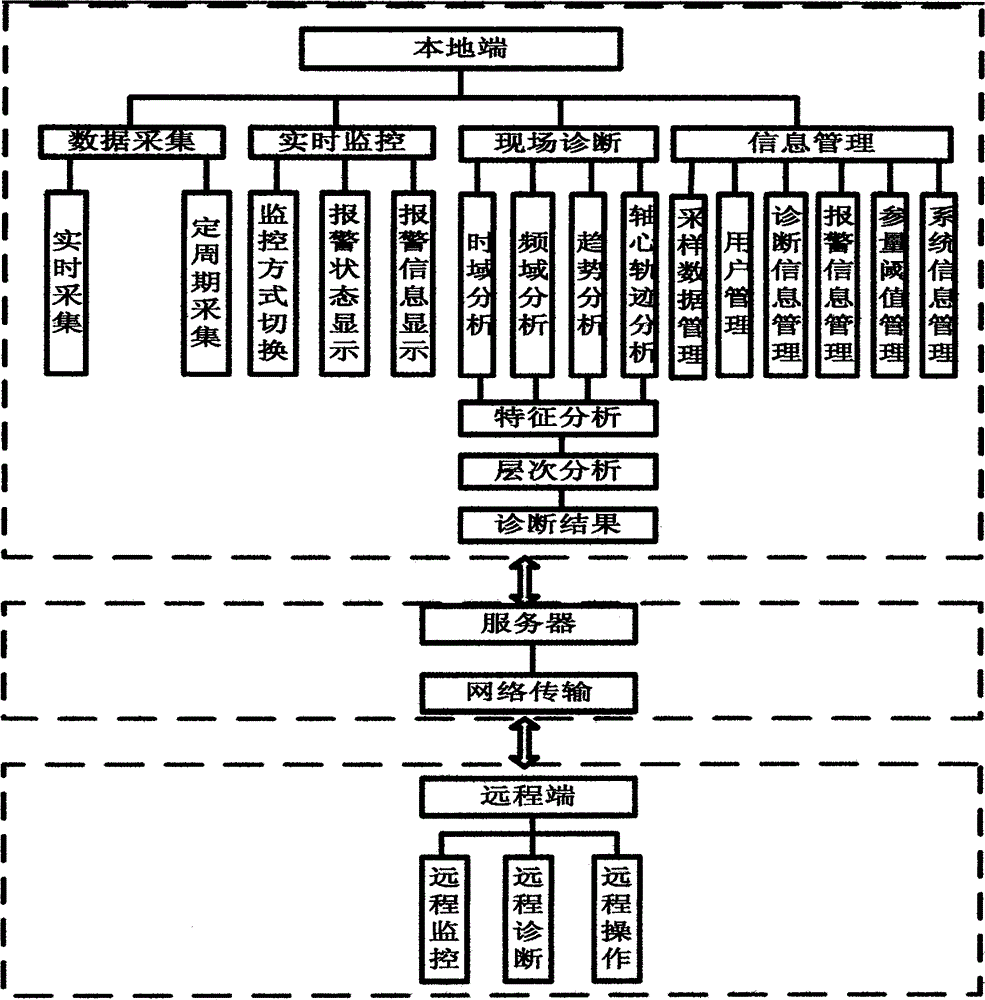

[0023] The invention provides a mine fan online monitoring and fault diagnosis system, such as figure 1 As shown, the system is composed of a hardware system and a software system. The hardware system includes a sensor 2, a signal conditioning device 3, an adapter terminal 4, an acquisition device 5, and monitoring and diagnosis software (computer) 6; the software system includes an acquisition control module 7, Real-time monitoring module 8, online diagnosis module 9, information management module 10, network publishing module 11. The specific structure of this system is as follows:

[0024] The sensor 2 that communicates with the fan 1 is used to obtain the analog data of each monitoring part during the operation of the fan; specifically, the sensor can obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com