Patents

Literature

405 results about "Damping capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Damping capacity is the ability of a material to absorb energy by converting mechanical energy into heat.

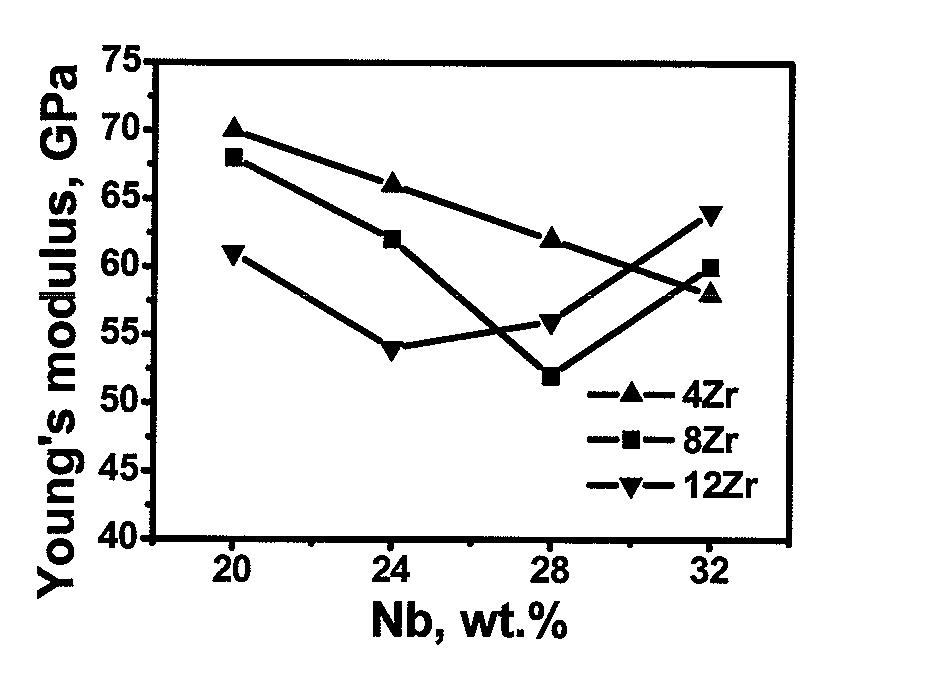

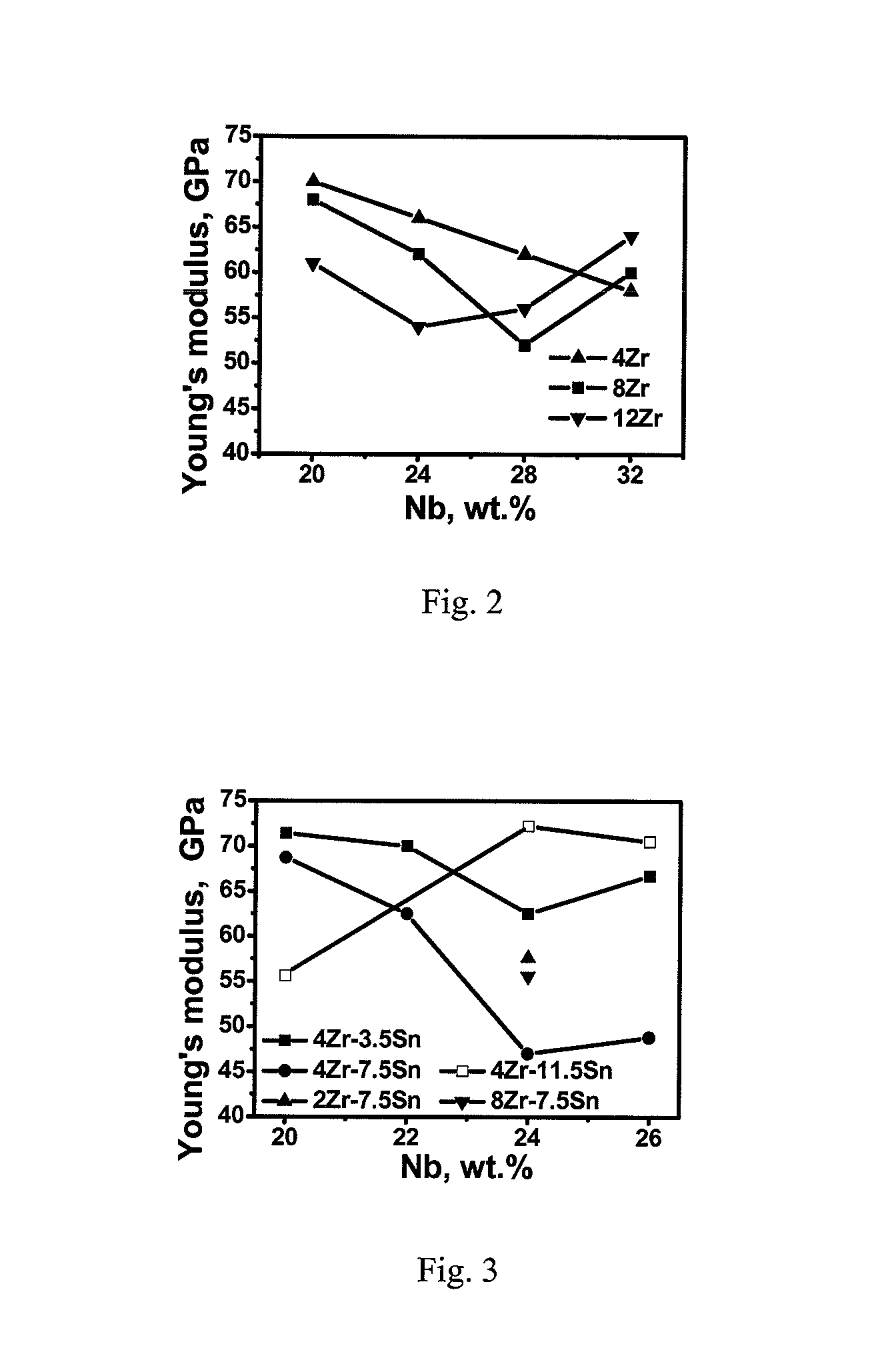

Titanium alloy with extra-low modulus and superelasticity and its producing method and processing thereof

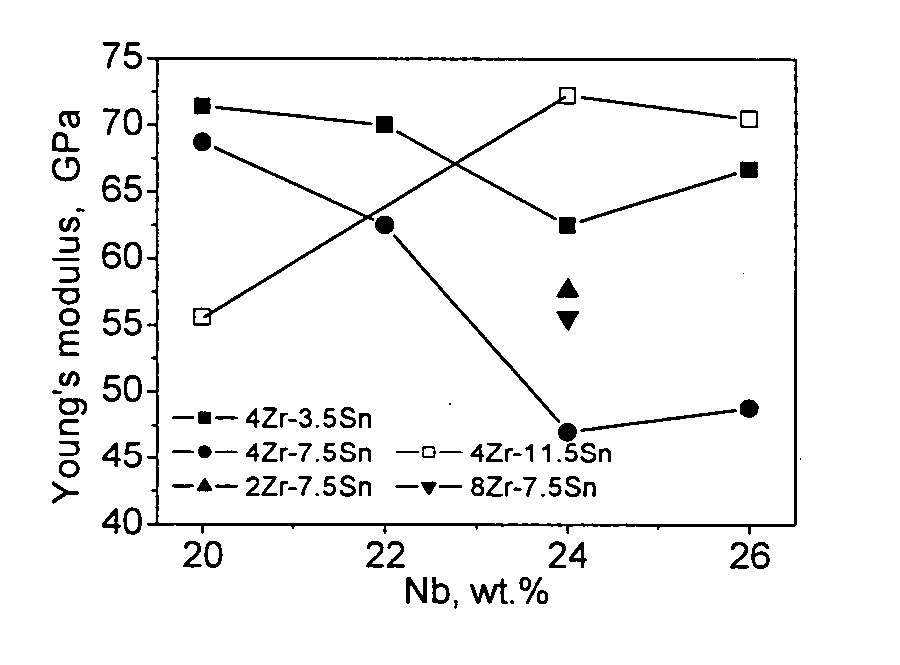

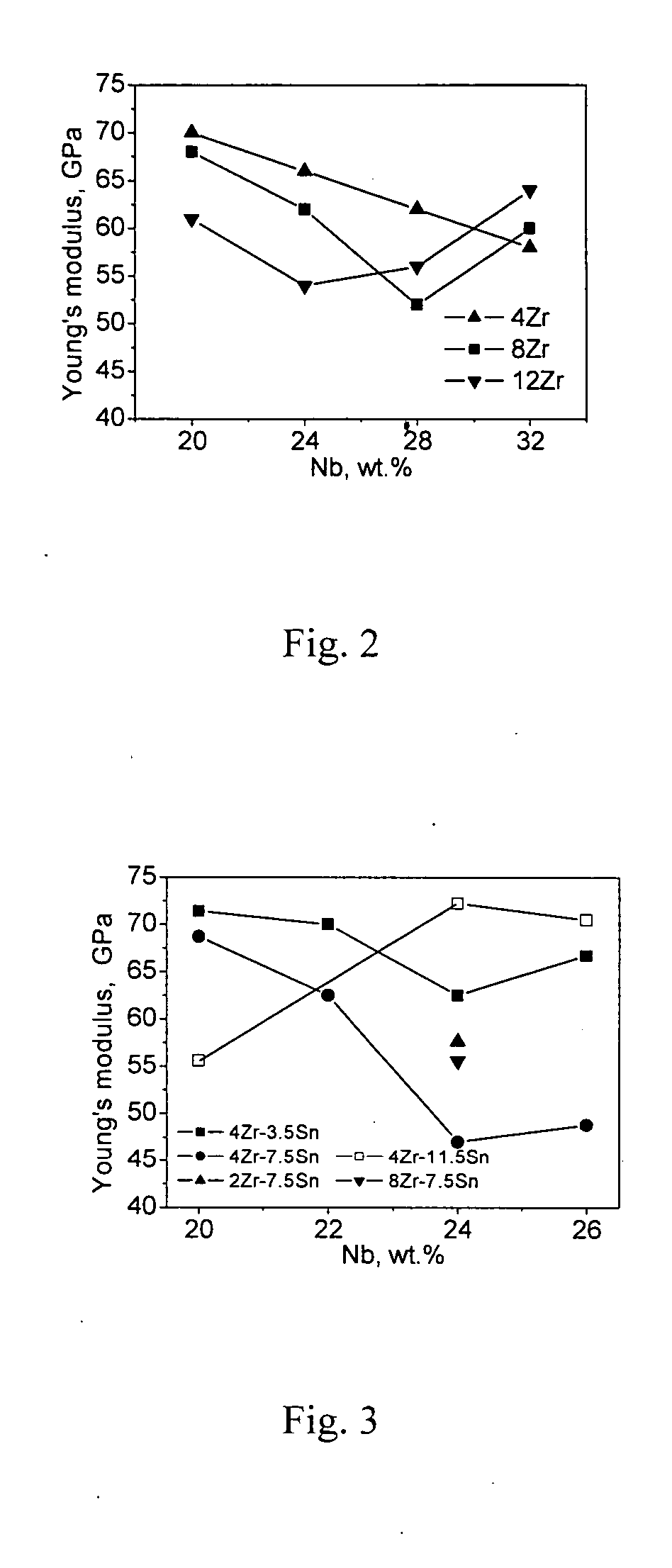

The patent provides the titanium alloy with extra-low modulus and superelasticity containing 20˜35 wt. % niobium, 2˜15 wt. % zirconium, balanced titanium and other unavoidable impurity elements. The advantages of the invention alloy are shown as follows: The invention titanium alloy has superior cold processing capacity and low work hardening rate; It can be severely deformed by cold rolling and cold drawing; It has superelasticity, shape memory effect, damping capacity, low modulus, high strength, good corrosion resistance and high biocompatibility; The invention titanium alloy can be made into nano-size materials by cold deformation and extra high strength can be achieved by heat treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-strength, high-damping metal material and method of making the same

A composite material includes a metallic second phase dispersed in a metallic matrix material. The metallic second phase has a grain structure that is at least partially martensitic. The second phase material is preferably an alloy of nickel and titanium, each present in the range from 48 to 52 atomic %, optionally in combination with further additives. The second phase particles can be present in the form of granular particles, wires, fibers, whiskers, or layers, making up 5 to 60 vol. % of the overall composite material. The matrix material is preferably an aluminum alloy. The composite material has a high damping capacity and a high tensile strength provided by the matrix, and a high damping capacity provided by the second phase. A method of making the composite material involves mixing a powdery matrix material and a powdery second phase material, and then heat and consolidating the mixture at a temperature of 400 to 700 ° C. and a pressure of 100 to 300 MPa.

Owner:DAIMLER AG

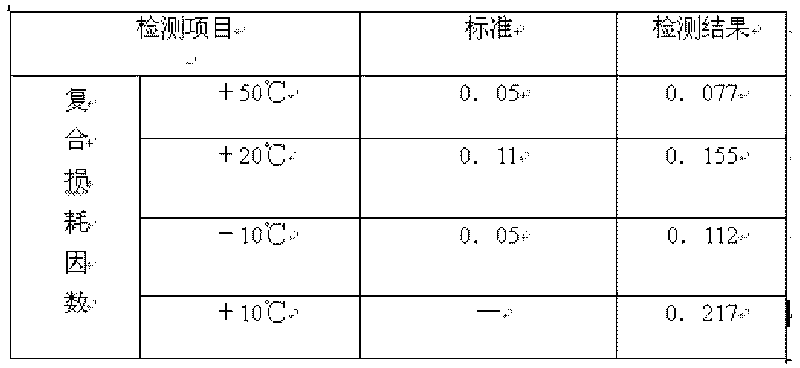

Medium-temperature high-performance water-based damping coating material and preparation method of same

The invention relates to medium-temperature high-performance water-based damping coating material and a preparation method of the medium-temperature high-performance water-based damping coating material. The coating material is made from binding base material, functional filling material, auxiliary agent and the like. The preparation method adopts a low-speed mixing, dispersion and three-roll grinding technology, thereby effectively avoiding cross linked deterioration of ternary polymer emulsion in the binding base material under high temperature because of high-speed mixing and dispersion. The coating material is added with the ternary polymer emulsion, addition agent and the functional filling material, wherein the ternary polymer emulsion belongs to rubber emulsion that is beneficial to improve the damping capacity and the drying of coating films, and the functional filling material has the functions of damping vibration, reducing noises, retarding flame and the like. The coating material can form a network structure through cross linked solidification under low-temperature baking of about 60 degrees, thereby obviously increasing the damping recombination loss factor, the flame-retardant heat-insulation performance and the sound-absorbing noise-reducing property. The water-based damping coating material is widely applied to railway vehicles, has the advantages of high damping recombination loss factor, small specific weight, strong adhesive force, good flame-retardant performance, low toxicity level and easy construction, and is not easy to crack in thick coatings.

Owner:ZHUZHOU HUALIAN HI TECH

Rubber material with damping capacity

The invention relates to a rubber material with damping capacity which is characterized in that the rubber material comprises the following components in parts by weight: 10-50 parts of eucommia ulmoides gum, 10-90 parts of rubber material additive 1, 10-90 parts of rubber material additive 2, 1-4 parts of sulfur-containing promoter, 1-5 parts of zinc oxide, 1-5 parts of stearic acid, 5-50 parts of piezoelectric additive and 1-5 parts of sulfur. The rubber material additive 1 is one or two of natural rubber, chlorobutyl rubber, nitrile-butadiene rubber, styrene-butadiene rubber and ethylene propylene rubber and the rubber material additive 2 is one or two of polyacrylate, polyurethane and polyvinyl chloride. The rubber material with damping capacity is mainly characterized by high dampingcapacity, good wearability, excellent anti-fatigue property and good comprehensive mechanical properties and is the ideal rubber material used for relieving mechanical oscillation caused and reducingnoise.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

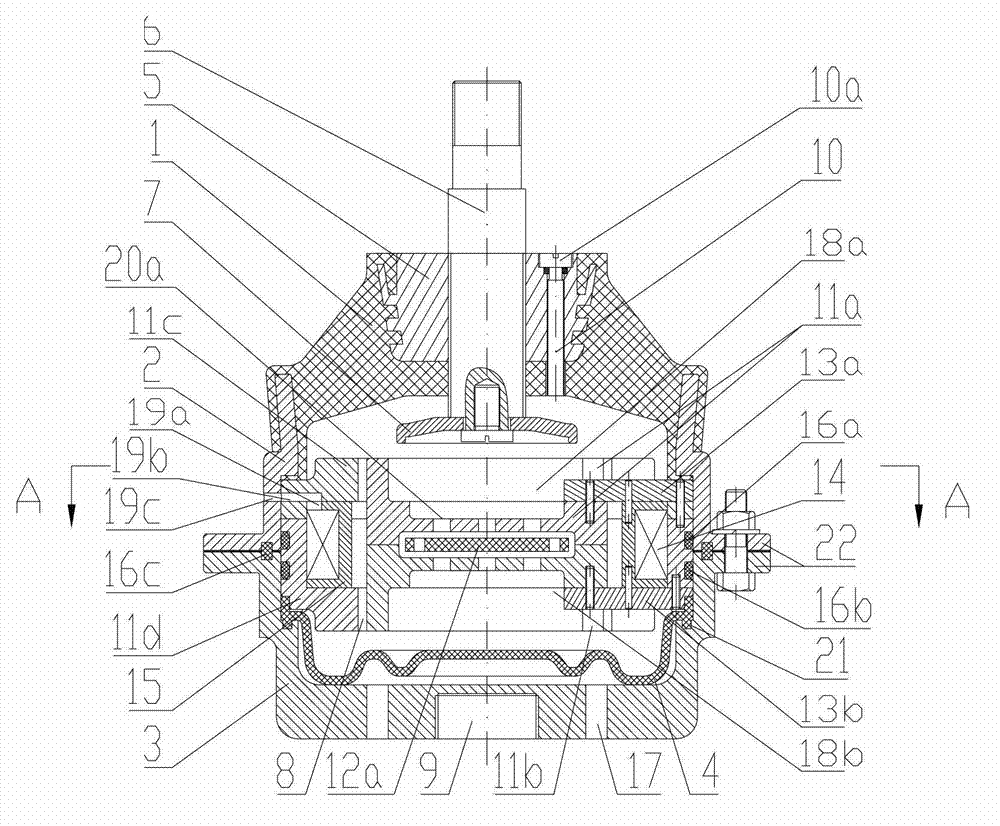

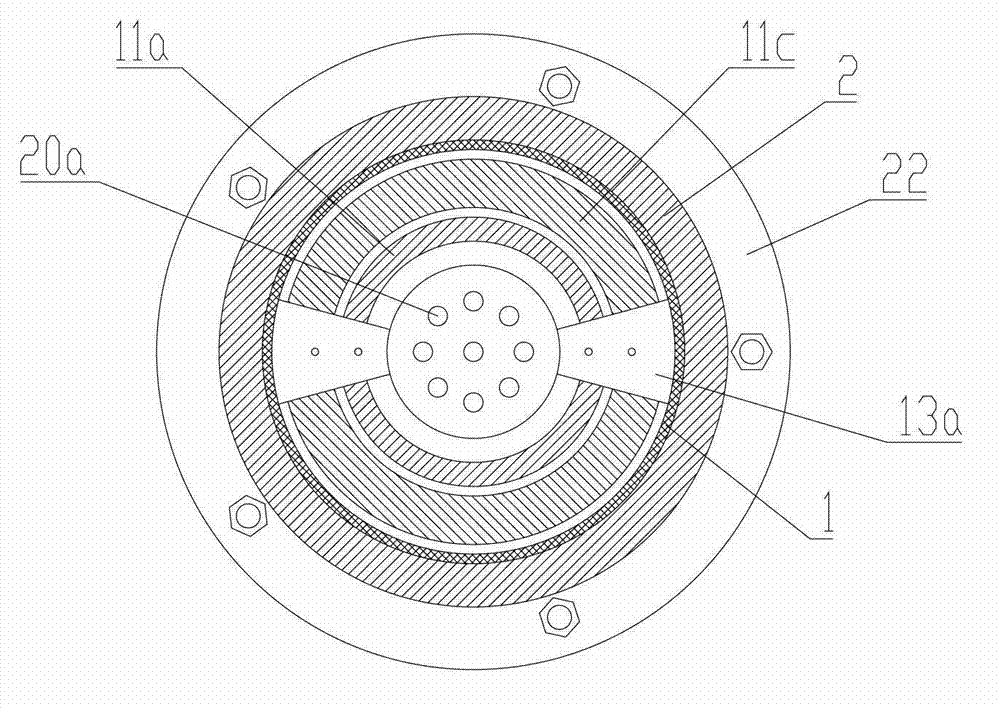

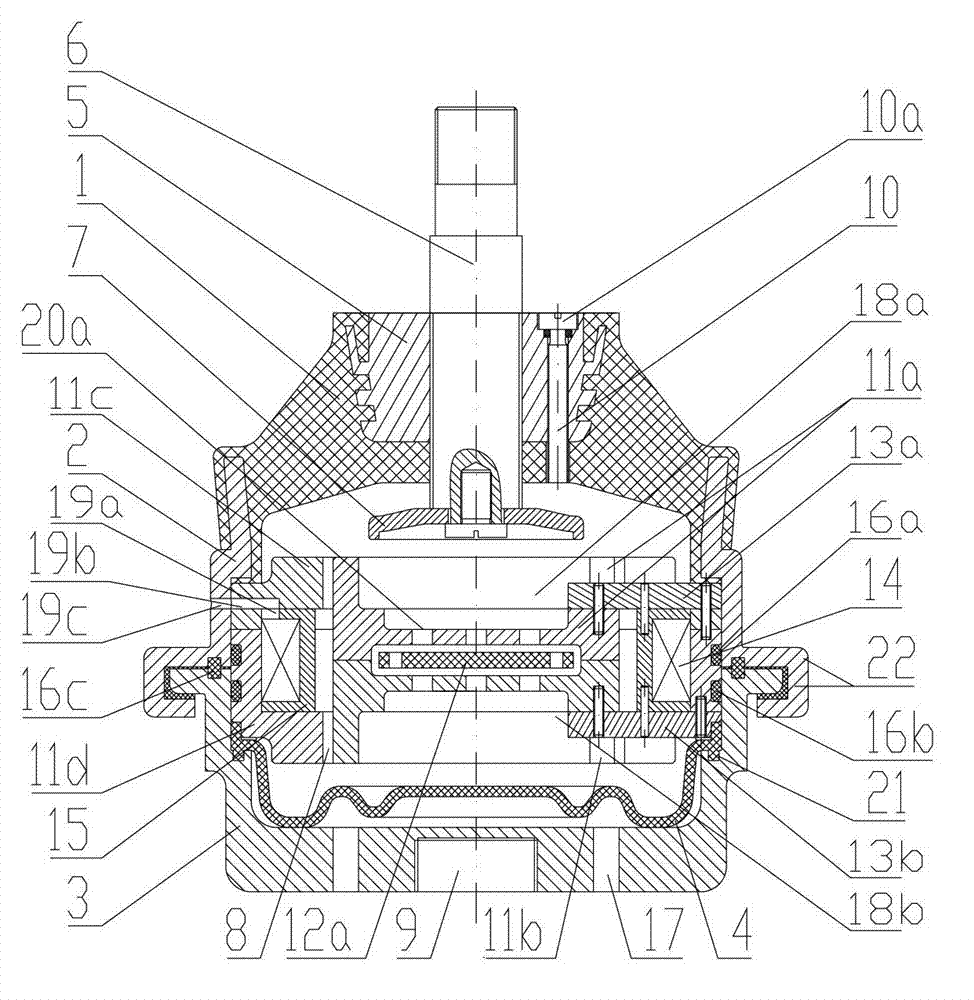

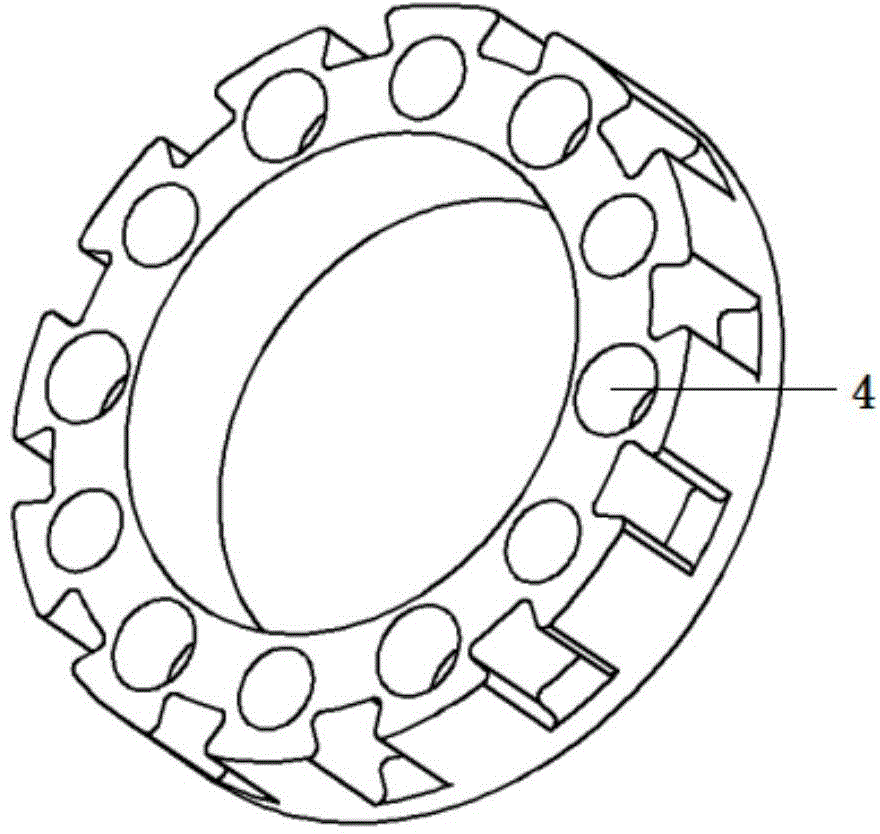

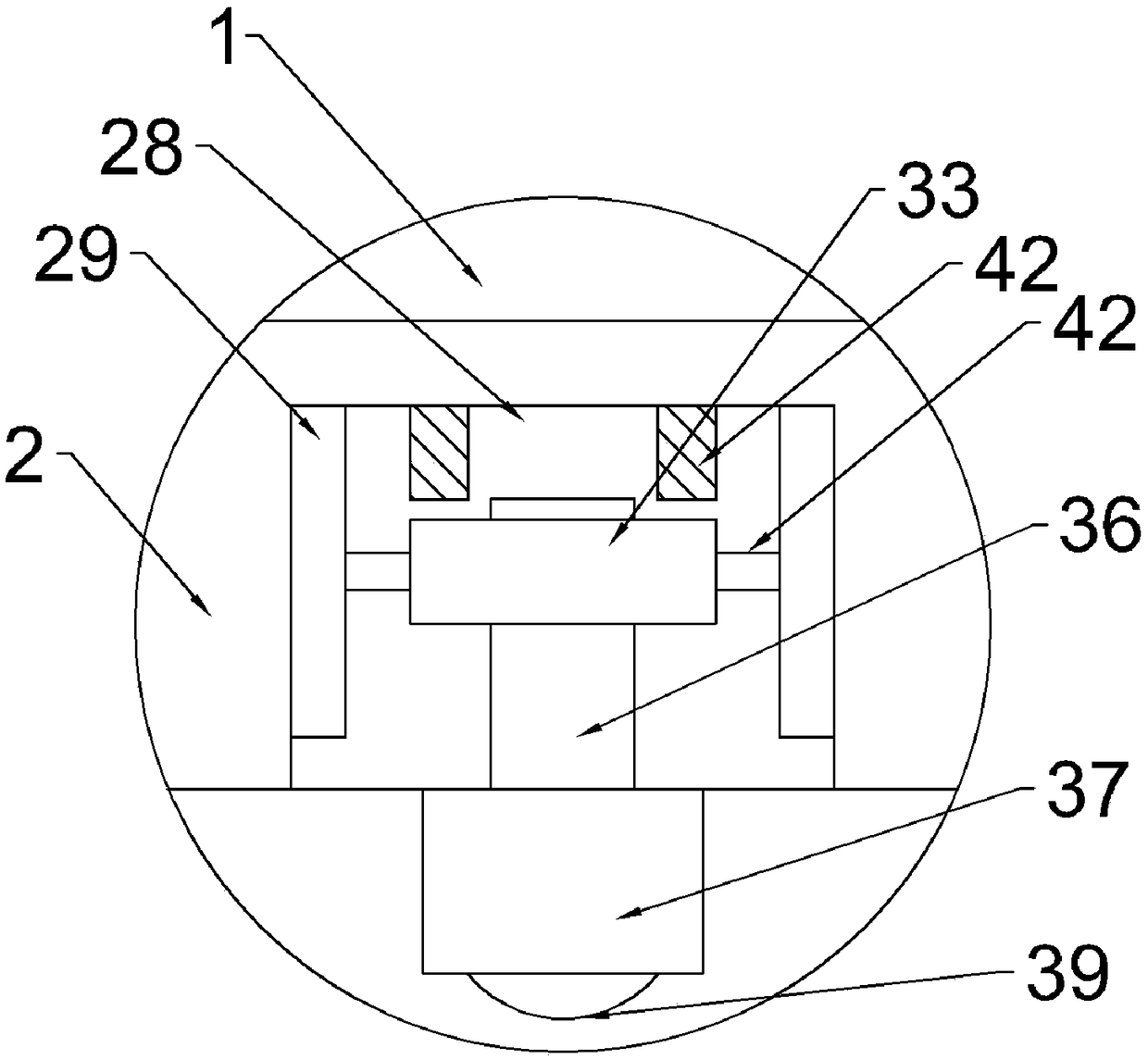

Magneto-rheological damper of automobile engine suspension system

InactiveCN102829127ASuppression of high frequency dynamic hardeningImprove the vibration isolation effectNon-rotating vibration suppressionPower flowExcitation current

The invention discloses a magneto-rheological damper of an automobile engine suspension system, comprising a main rubber spring, a throttling disk, a magnetic core assembly and a decoupling film, wherein the damper is used for regulating the magnetic induction intensity at a magneto-rheological liquid channel in the magnetic core assembly through controlling the excitation current of an electromagnetic coil and then regulating the viscosity of magneto-rheological liquid at the magneto-rheological liquid channel to achieve the optimal damping effect. When the magneto-rheological damper is used, the turbulence level of the magneto-rheological liquid in a liquid feeding chamber can be increased through the throttling disk, the high-frequency dynamic hardening of the damper can be effectively inhibited, and the effectively damping frequency range can be widened. The damper has a more ideal dynamic characteristic and meets the use requirement for damping the automobile engine suspension system with high rotating speed; in addition, the damping capacity, the work stability and the convenience in assembly of the damper are improved through improving a floating decoupling film type decoupler, a sealing structure of the magnetic core assembly, a liquid injection hole structure and the like.

Owner:CHONGQING UNIV

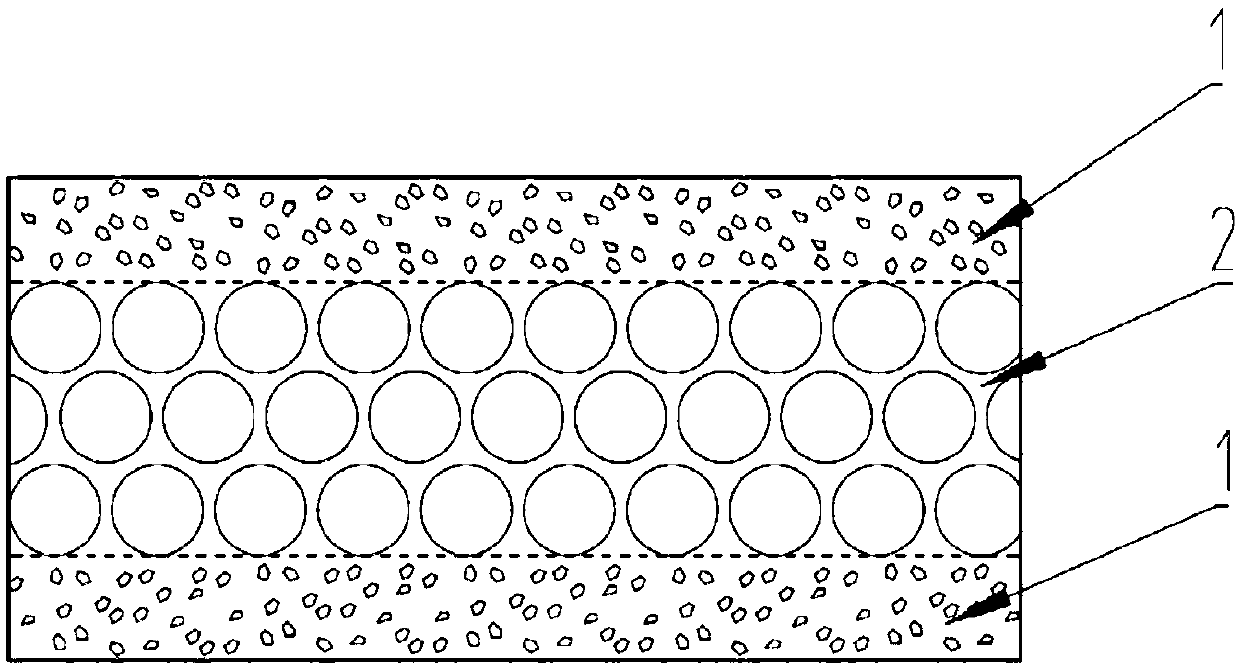

Lattice metal-foamed aluminium composite material and preparation method thereof

InactiveCN102416714AGood mechanical propertiesImprove performanceMetal layered productsMetallic materialsHigh intensity

The invention discloses a preparation method of a lattice metal-foamed aluminium composite material, characterized by cementing a lattice metal material (including ripple structure and pyramid structure) and cut foamed aluminium to obtain a multifunctional composite porous material. The lattice metal-foamed aluminium composite sandwich panel disclosed herein has a wide application prospect in the fields of transportation, mechanical manufacturing, and military, can effectively reduce the structure weight, improves the performances of impact deformation and magnetic shield, especially brings the performances of high intensity, high rigidity and excellent damping capacity into play in the field of mechanical manufacturing, and has the advantage of low production cost.

Owner:XI AN JIAOTONG UNIV

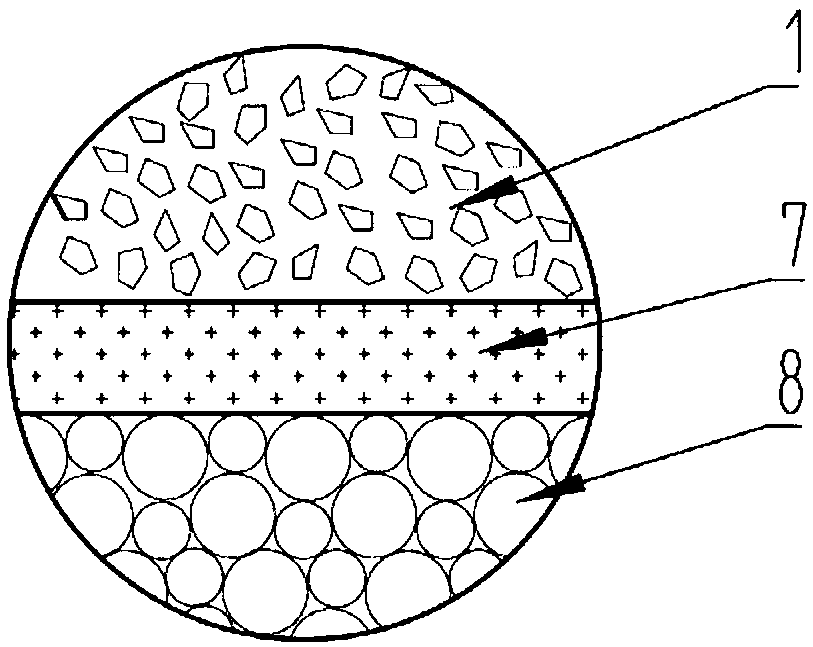

Rubber elastic self-compaction concrete for plate-type ballastless tracks

InactiveCN104030638AHigh compressive strengthImprove impact resistancePolyvinyl alcoholUltimate tensile strength

The invention relates to a rubber elastic self-compaction concrete for plate-type ballastless tracks, which is used for obviously enhancing the compression strength of the self-compaction concrete and enabling the self-compaction concrete to have favorable shock absorption and damping capacities. The rubber elastic self-compaction concrete for plate-type ballastless tracks can be used as a filler between the track plate and the bottom plate in a CRTS III plate-type ballastless track structure, and can also be used as a filler between a switch plate and the bottom plate in a switch structure. The self-compaction concrete is composed of the following components in parts by weight: 100 parts of cement, 4-10 parts of rubber powder, 30-60 parts of mineral admixture, 250-300 parts of fine aggregate, 250-300 parts of coarse aggregate, 1-2 parts of basalt fiber, 5-15 parts of expanding agent, 1.0-2.0 parts of water reducing agent, 0.01-0.05 part of rheologic assistant, 0.001 part of defoaming agent and 40-60 parts of water. The grain fineness of the rubber is 30-50 meshes, and the surface of the rubber is previously treated with polyvinyl alcohol and a silane coupling agent.

Owner:SOUTHWEST JIAOTONG UNIV +1

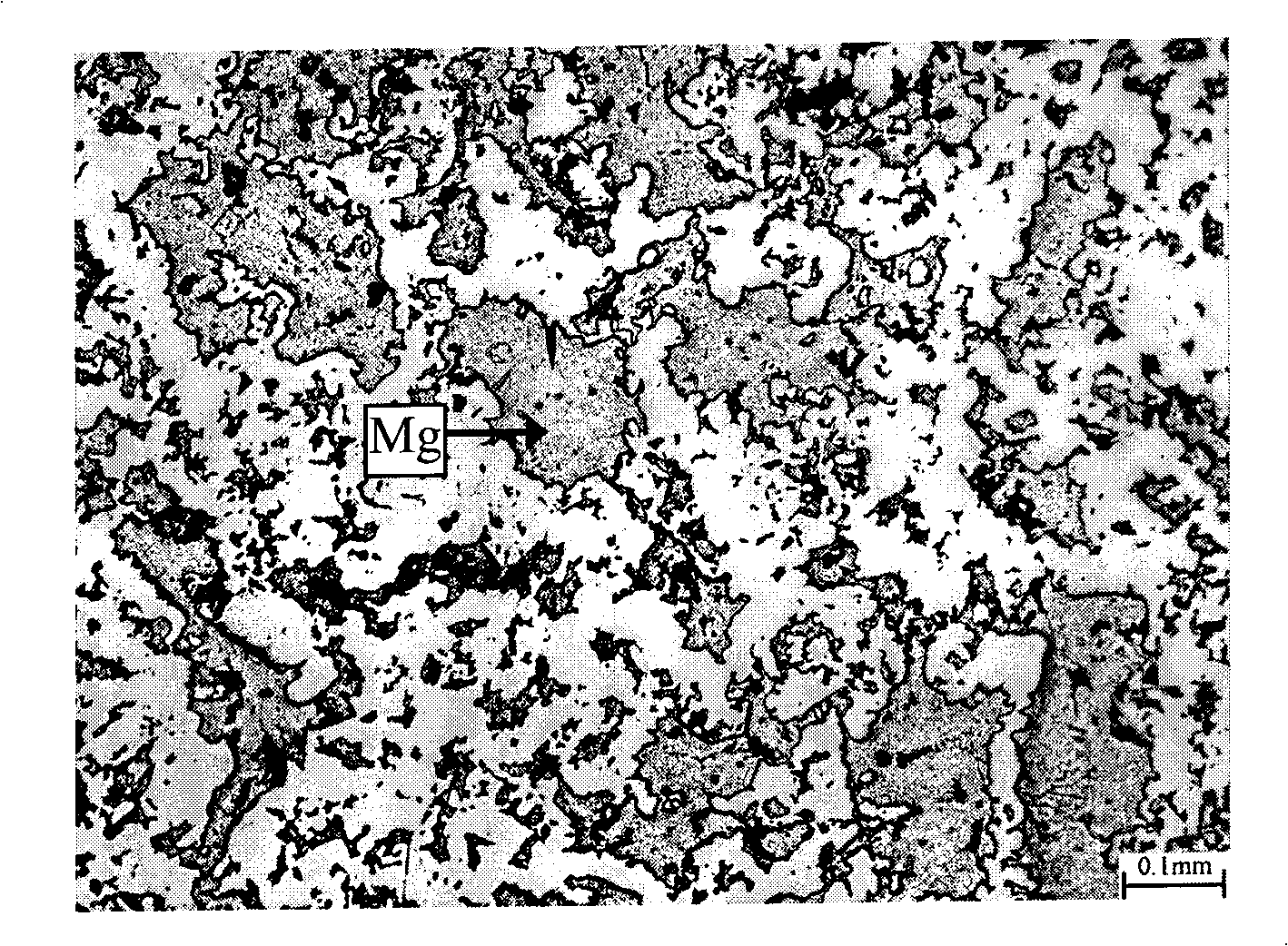

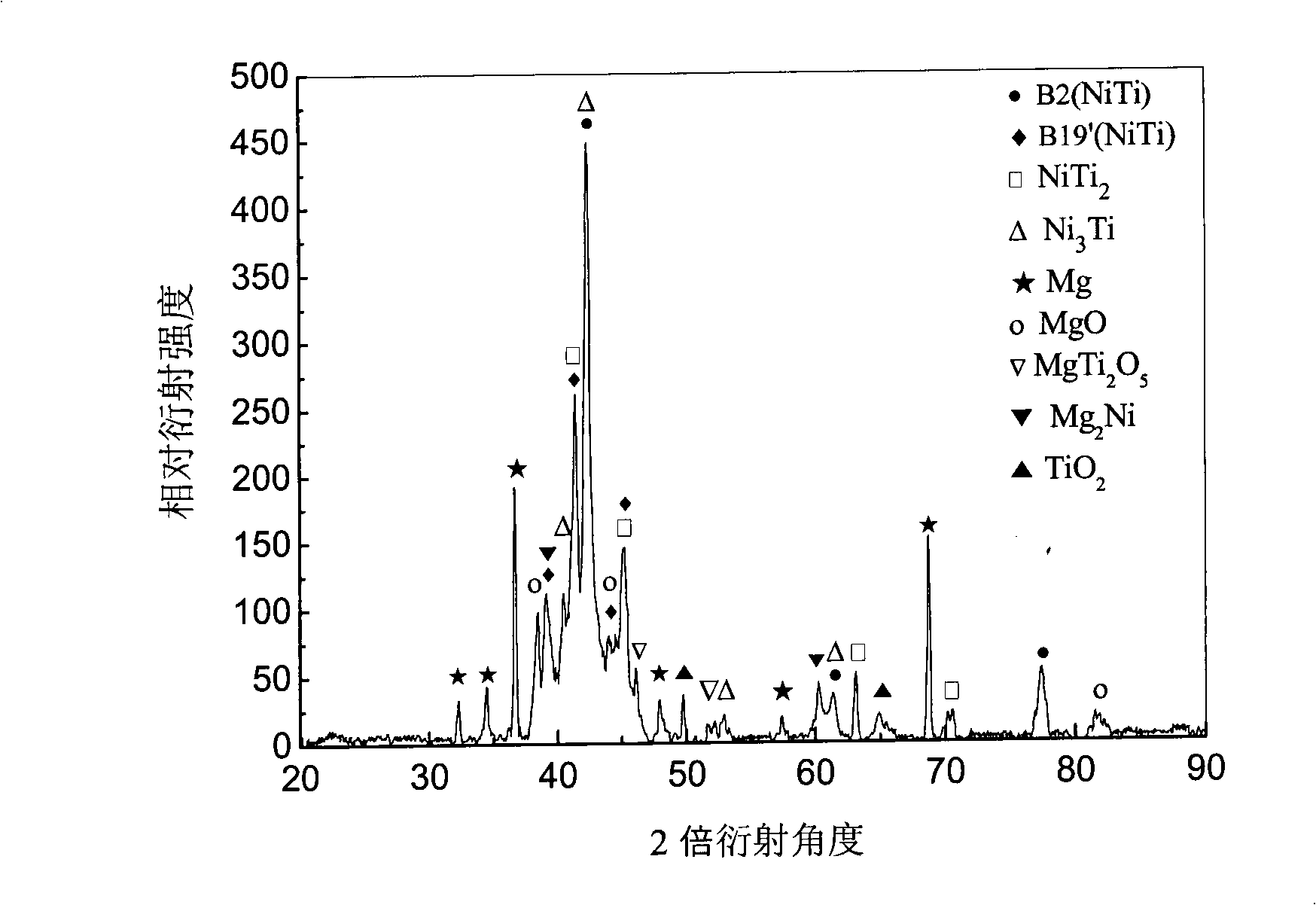

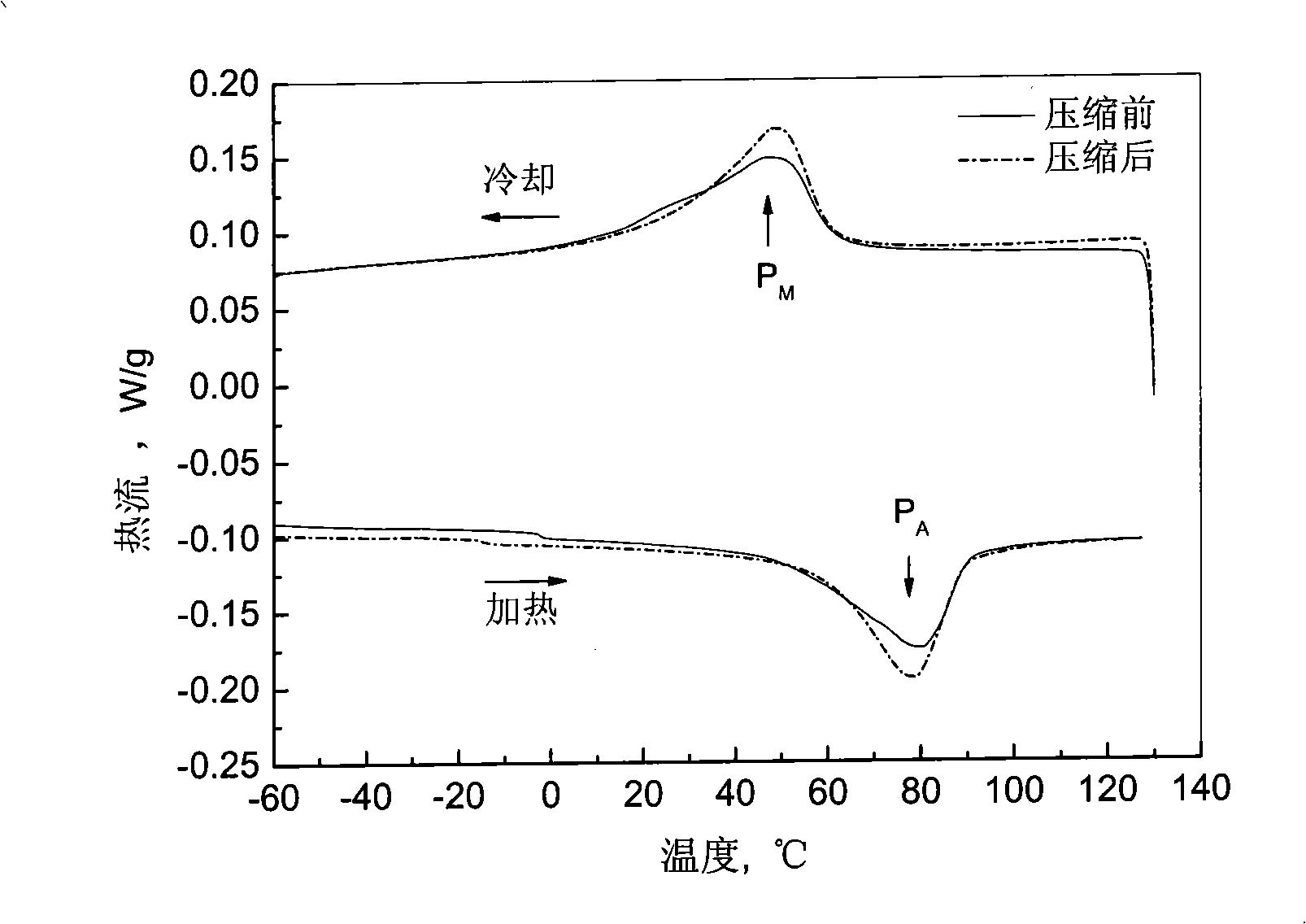

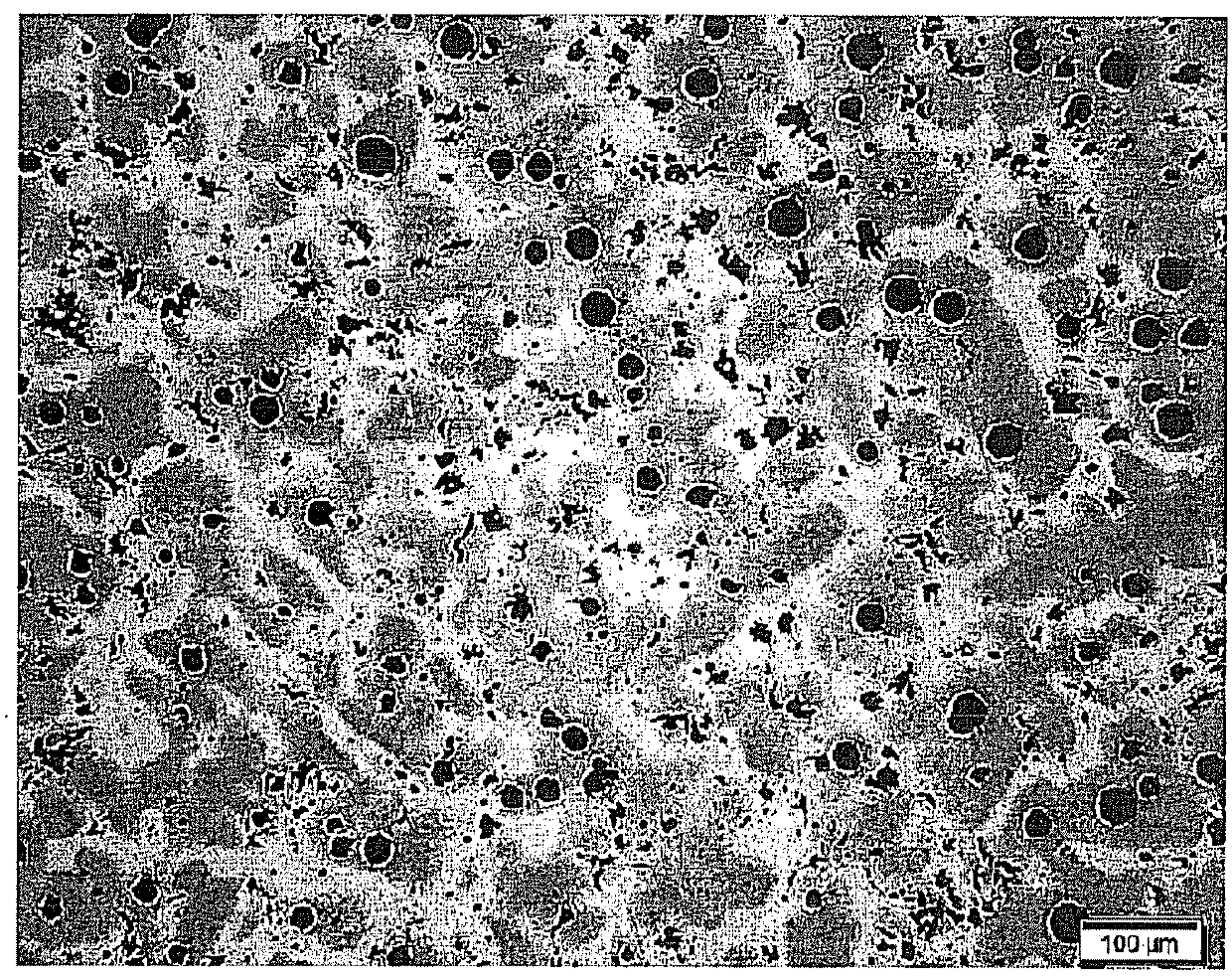

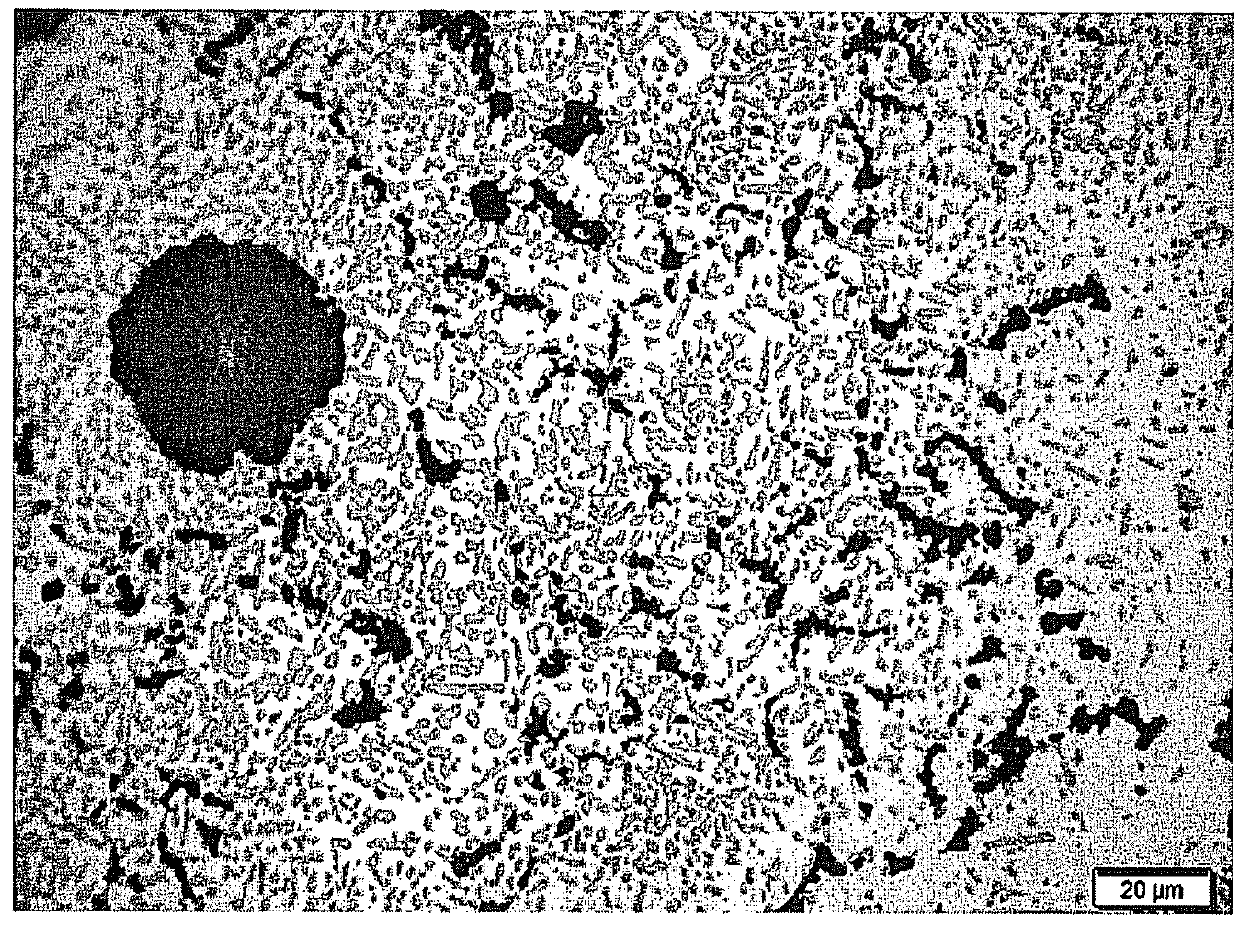

Preparation of composite type light high-strength nickel-titanium memory alloy-based high damping material

The invention discloses a preparation method of a compound type light-weight high-intensity nickel-titanium memorial alloy base high damping material. In the method, a powder sintering method is mainly used as a foundation and a pressureless infiltration technology is used as assistance; a pore-creating technology is firstly adopted; and a unit metal powder cascade sintering method is used for preparing a porous nickel-titanium alloy the holes of which are uniformly distributed; and then the pressureless infiltration technology is adopted for inducing the pure magnesium or magnesium alloy phase with high intrinsic damping, low density and micron scale into the porous nickel-titanium alloy, thereby preparing the high-damping magnesium(or magnesium alloy) / nickel-titanium memorial alloy base compound material the damping control phase of which is magnesium or the magnesium alloy. The compound nickel-titanium memorial alloy prepared by the invention still has the shape memory effect and the superelasticity action as well as has weight lighter than that of the compact nickel-titanium memorial alloy and intensity and damping capacity more excellent than that of the common porous nickel-titanium memorial alloy. The preparation method has good technical suitability, simple preparation process and low cost, and can be used for manufacturing the light-weight high-intensity compound damping materials, damping structures and apparatuses.

Owner:SOUTH CHINA UNIV OF TECH

Titanium alloy with extra-low modulus and superelasticity and its producing method and processing thereof

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

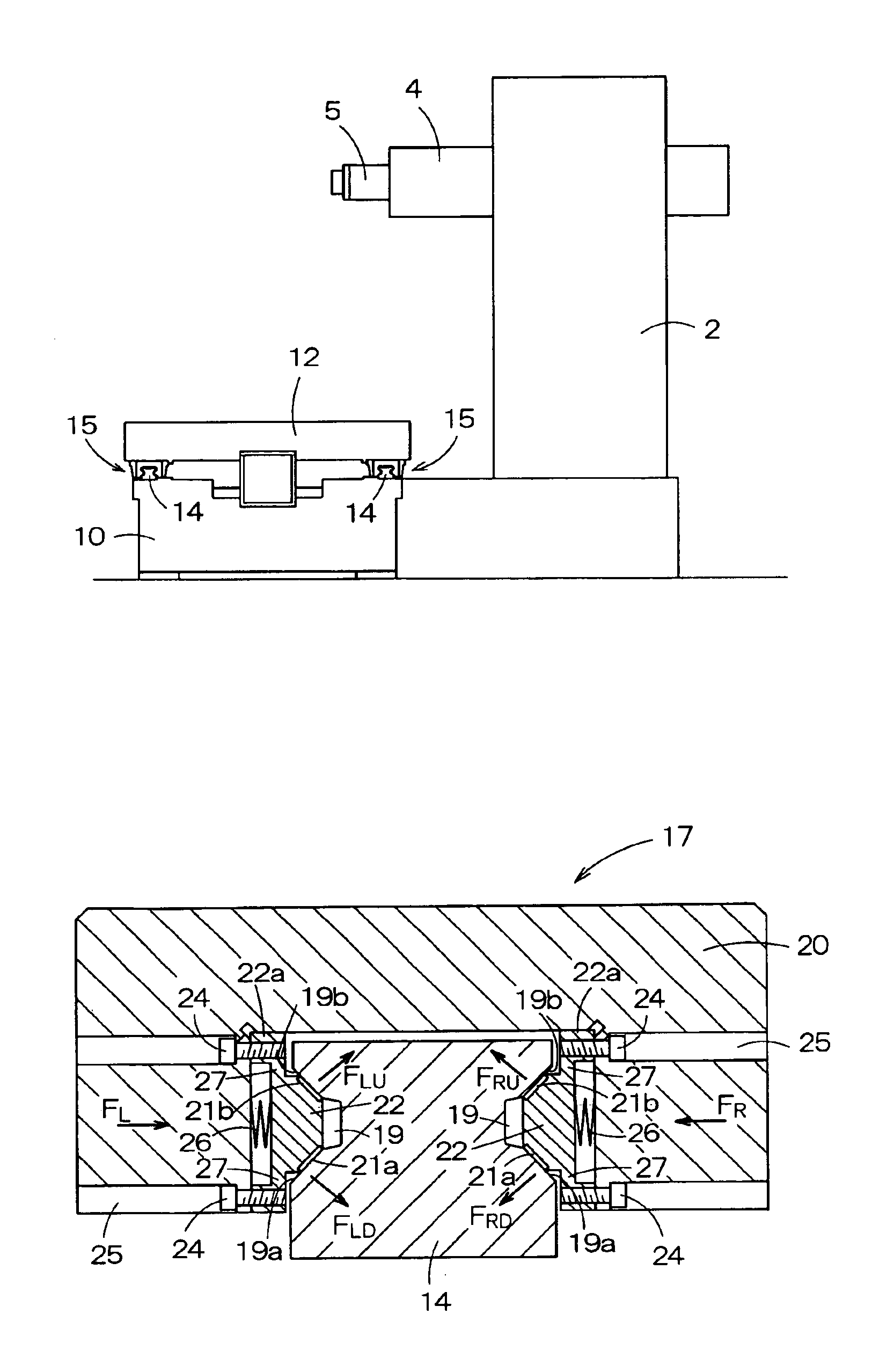

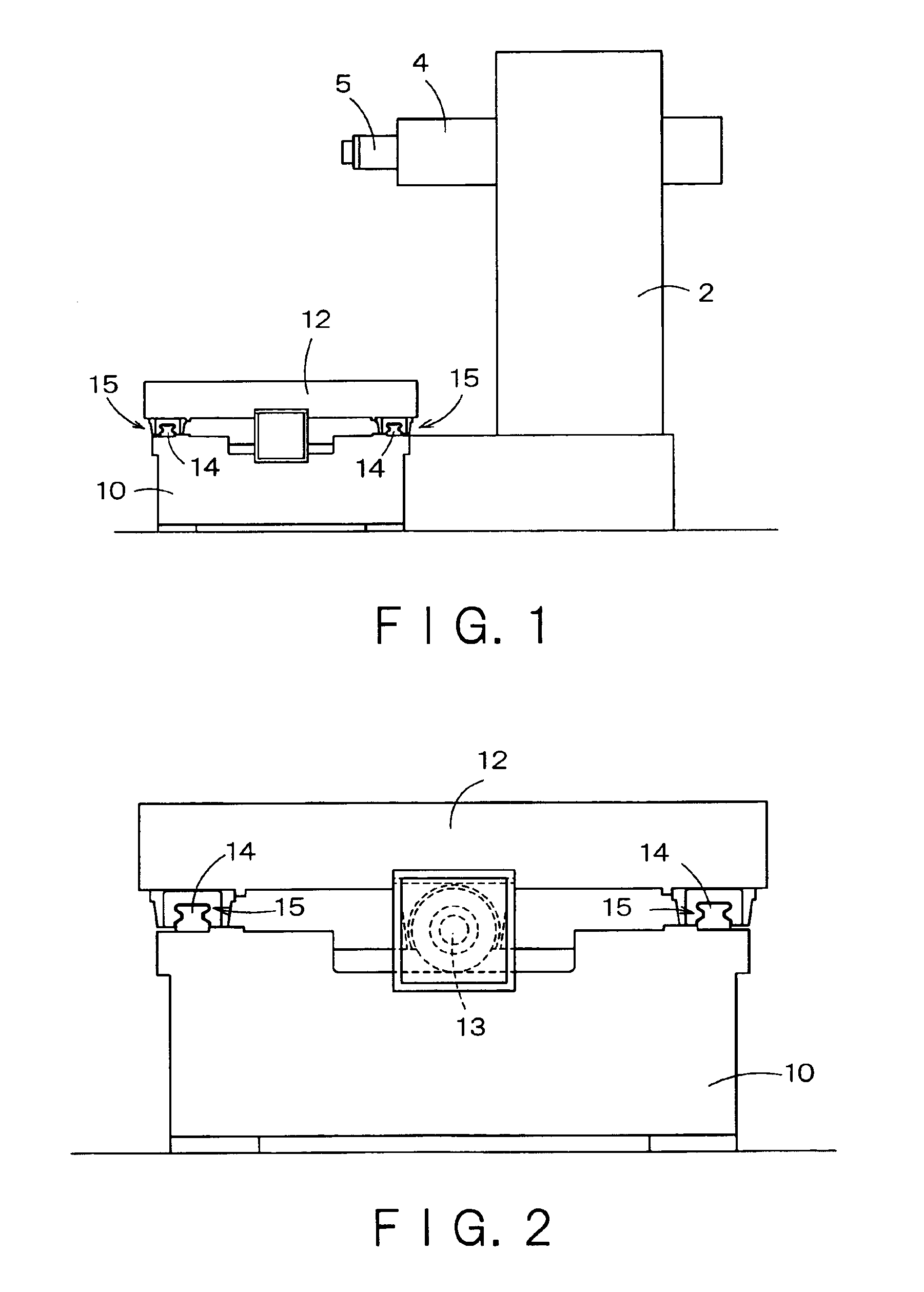

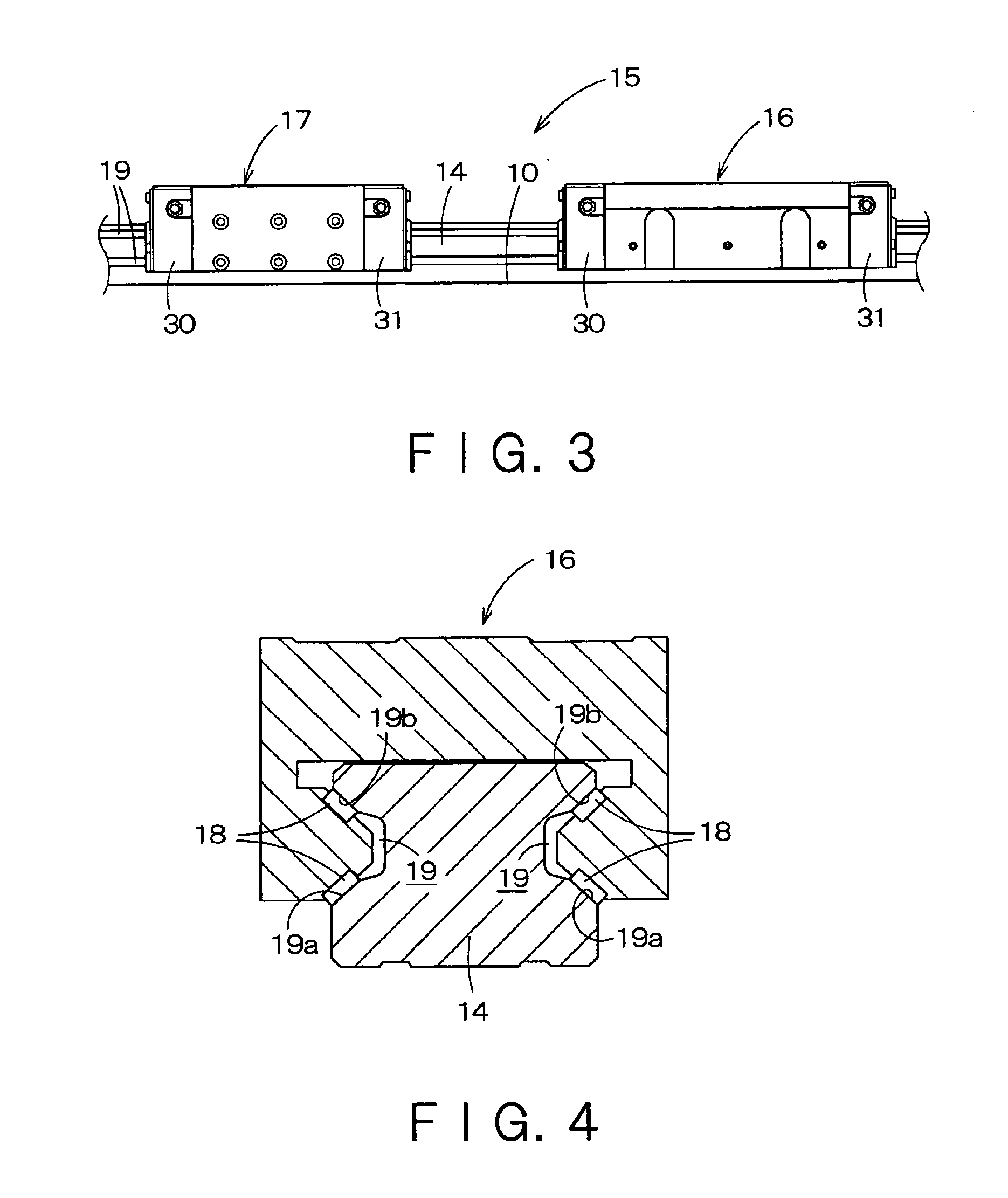

Linear guide apparatus

InactiveUS7029214B2Improve damping performanceHard structureLinear bearingsBraking action transmissionLinear motionEngineering

There is provided a linear guide apparatus which, owing to the use of a gap-free braking device in a rolling guide, has a sufficiently high damping capacity. The linear guide apparatus for guiding a linear motion of a movable body along a guide rail on a fixed structure in a machine tool, includes: a rolling guide section including a rolling element for rolling on a rolling element-rolling surface of the guide rail; and a brake section for enhancing the damping capacity of the rolling guide section, the brake section including a pair of brake shoes, having a flexible structure, for sliding on the rolling element-rolling surface of the guide rail.

Owner:TOSHIBA MASCH CO LTD

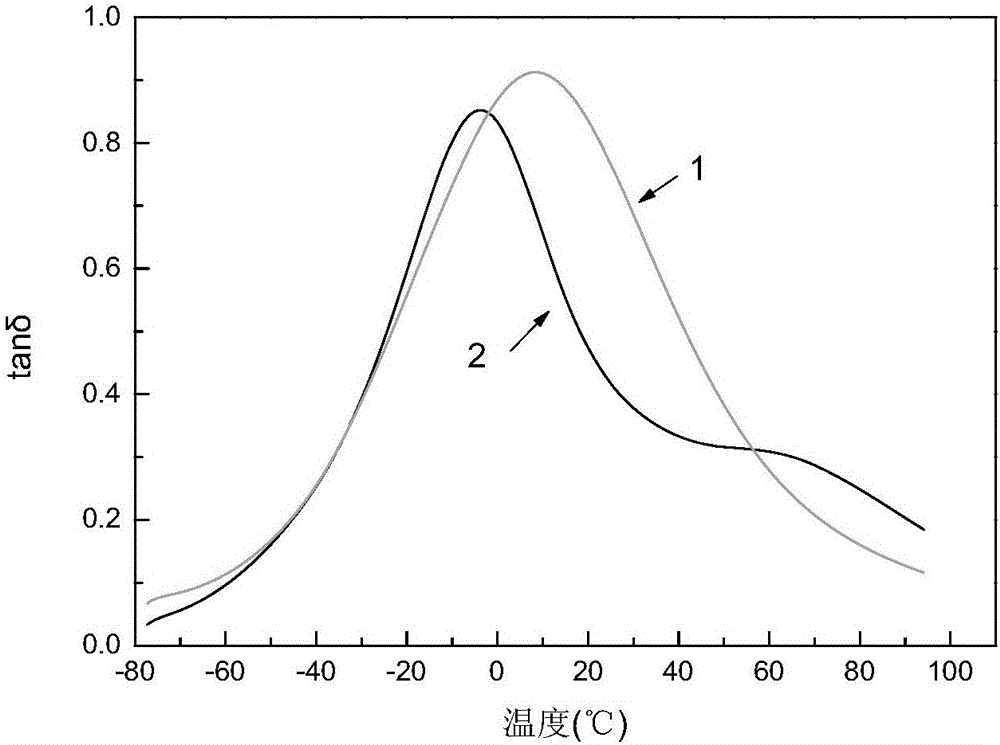

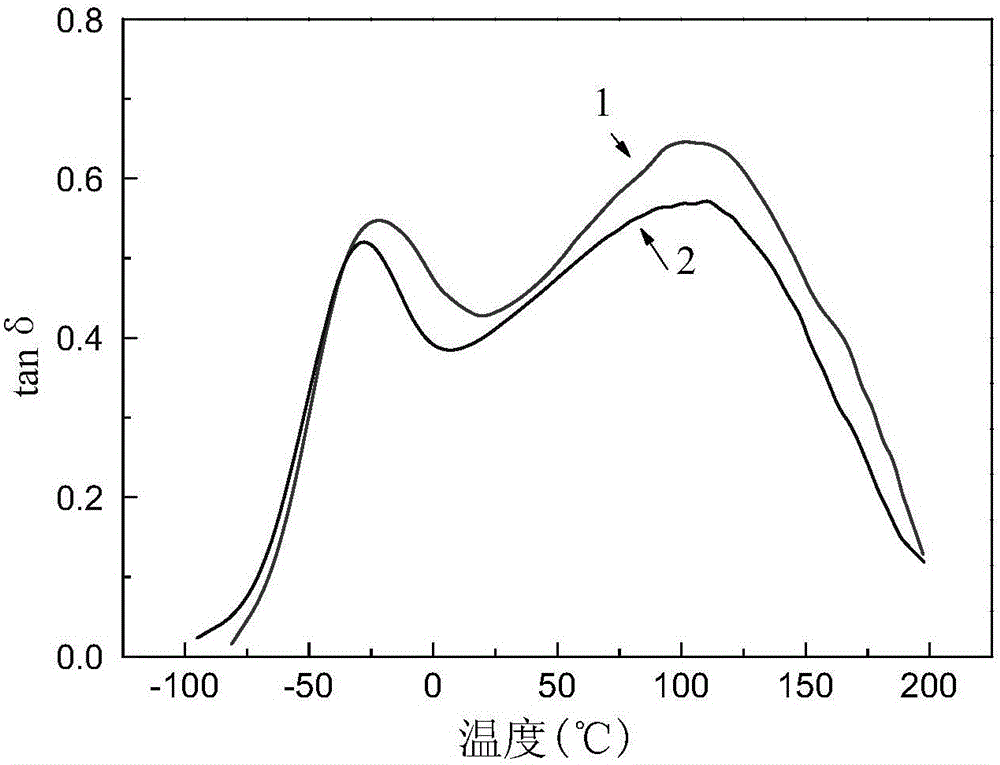

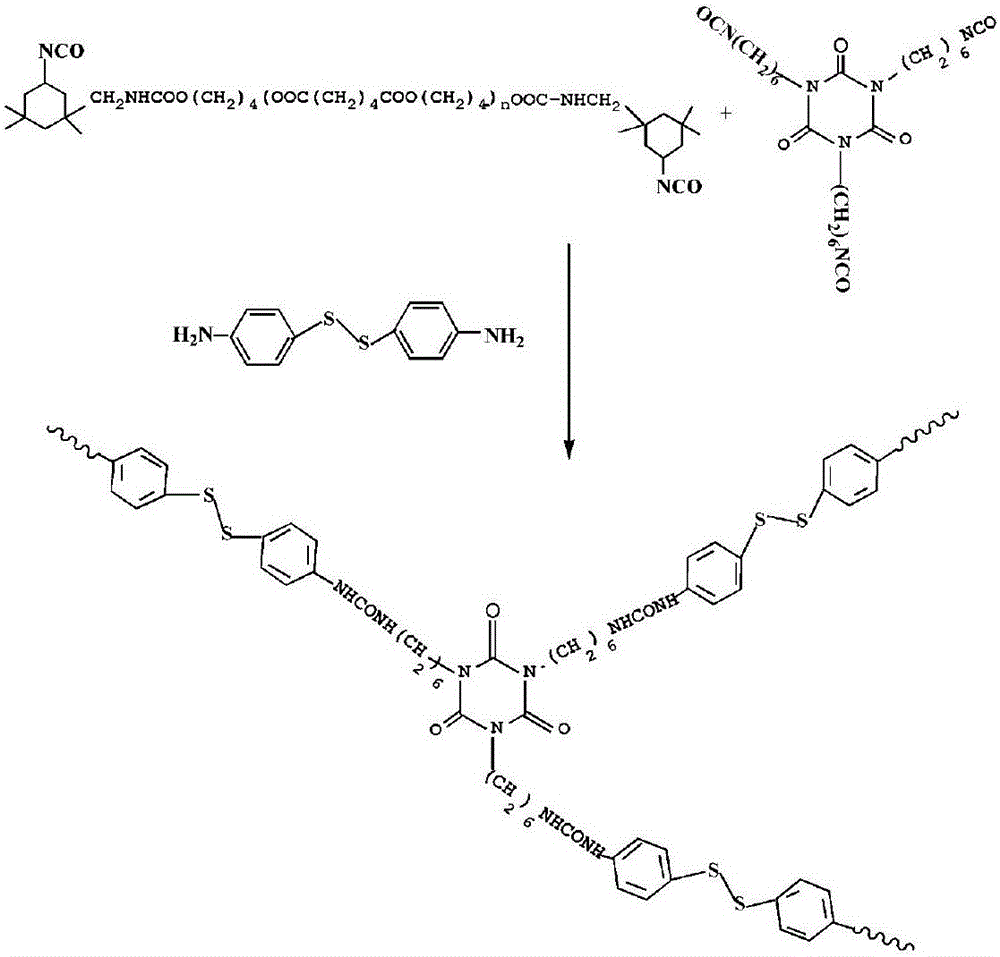

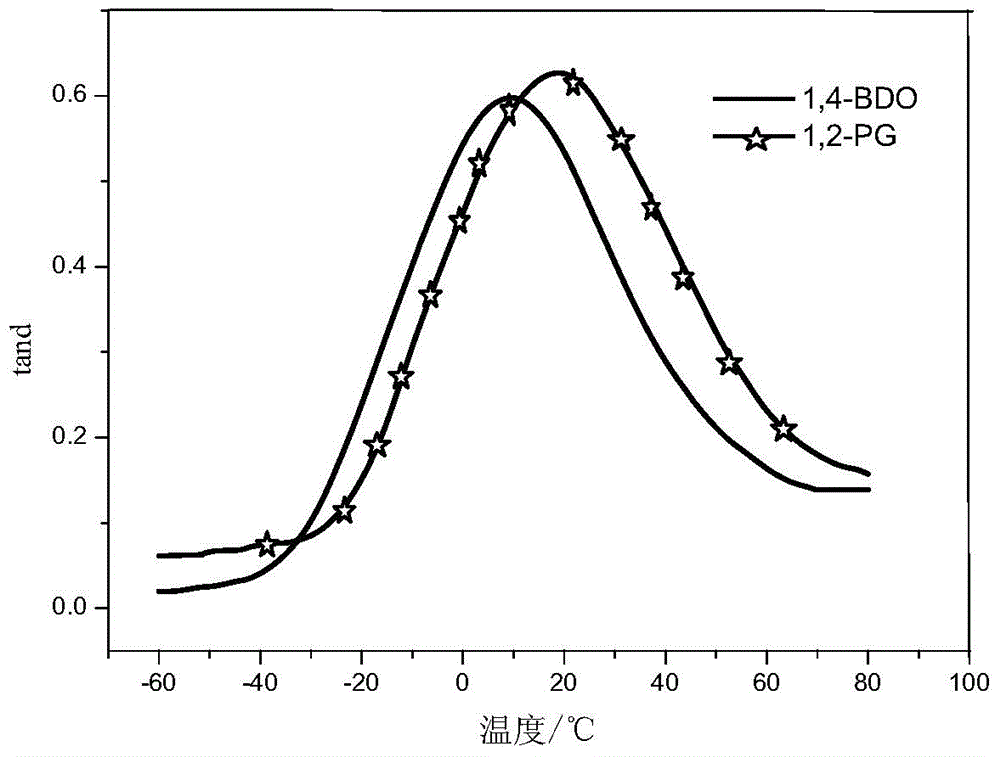

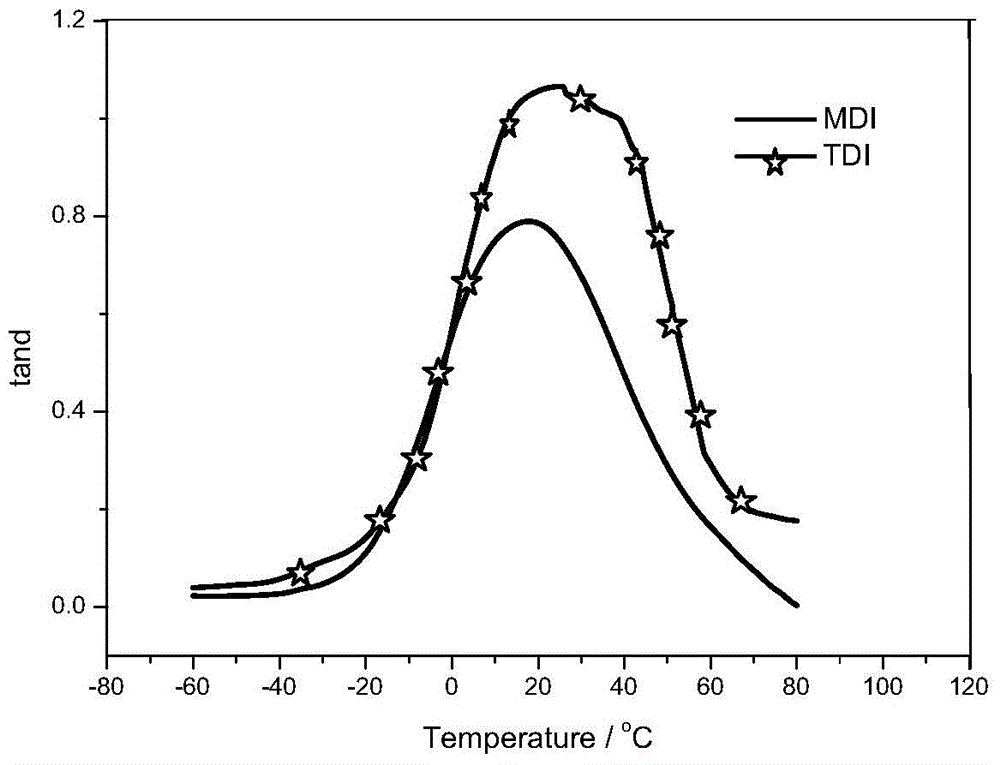

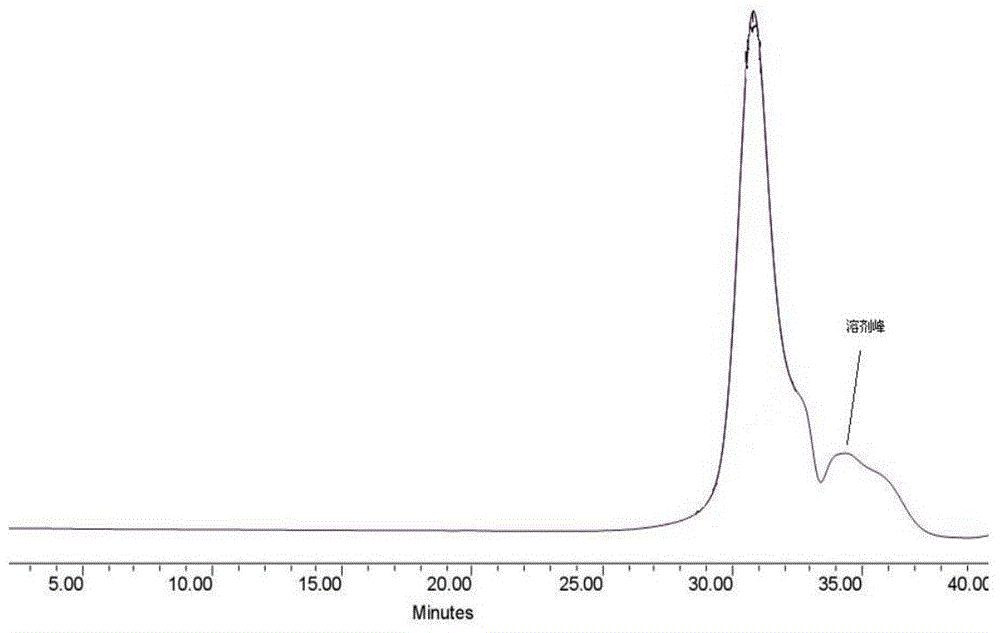

Polyurethane elastomer material with wide temperature range and high damping capacity and preparation method thereof

InactiveCN106146799AIncrease dampingExcellent high and low temperature dampingPolyesterDamping factor

The invention discloses a polyurethane elastomer material with the wide temperature range and the high damping capacity and a preparation method thereof. The preparation method comprises the steps that polyester diol and a diisocyanato raw material are adopted to react with each other to prepare a polyurethane prepolymer, the polyurethane prepolymer is poured into a polytetrafluoroethylene plate mold by taking an HDI trimer as a cross-linking agent and taking a raw material containing dynamic reversible disulfide bonds as a chain extender to remove bubbles, and heat preservation and curing molding are conducted. According to the polyurethane elastomer designed and synthesized based on the molecular structure, the damping factor tan<delta> is larger than 0.3 when the temperature of the damping material exceeds the temperature range of 220 DEG C (minus 50 DEG C-178 DEG C), and the damping factor tan<delta> is larger than 0.4 when the temperature of the damping material exceeds the temperature range of 200 DEG C (minus 44 DEG C-165 DEG C); the polyurethane elastomer material has the good high-low temperature damping property and can be expected to be widely applied to the damping and noise reducing aspects in the fields of building materials, automobiles, national defense, aerospace and the like.

Owner:SOUTH CHINA UNIV OF TECH

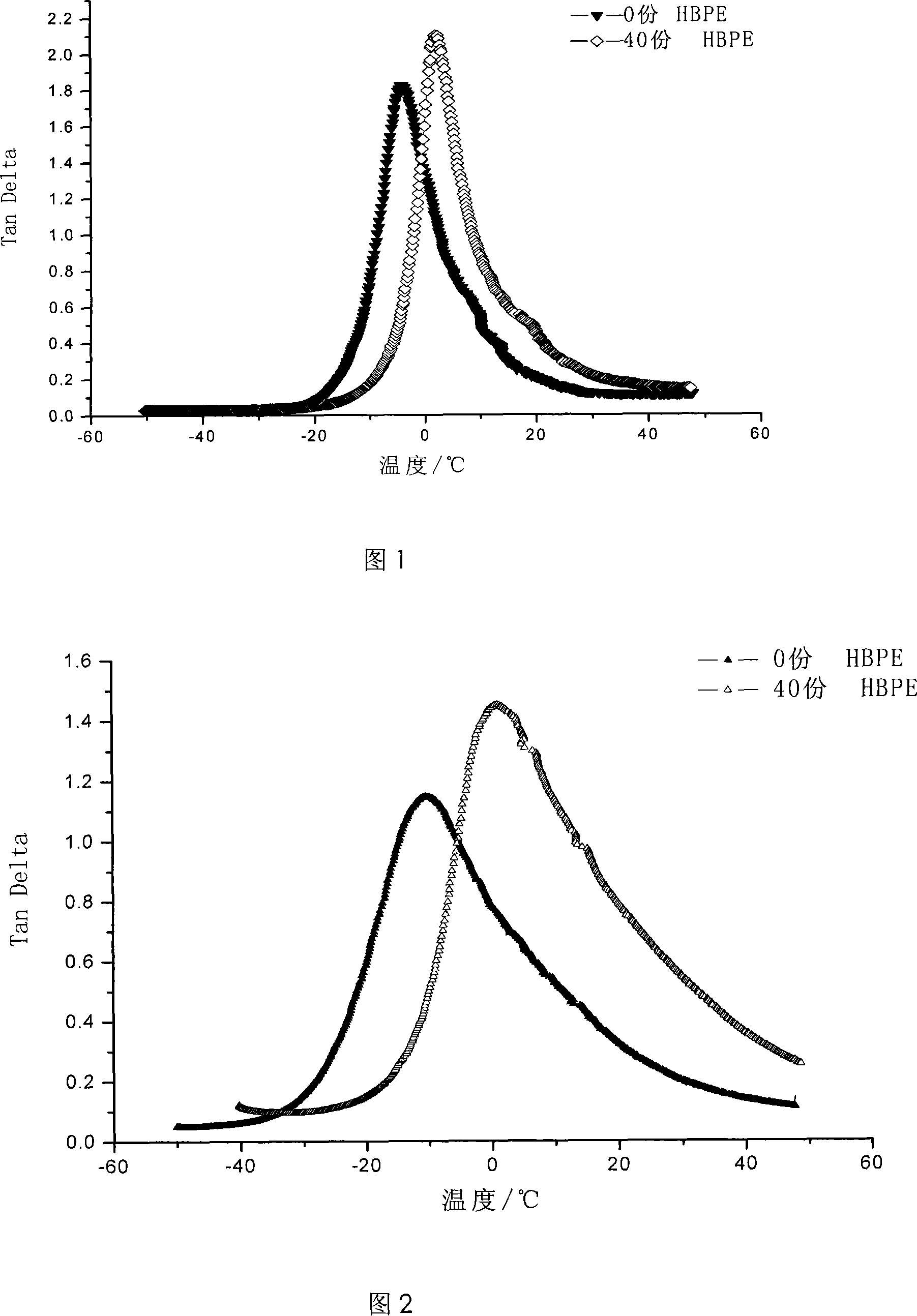

Preparation of high-damping rubber containing hindered phenol terminated hyper branched polymer

The invention belongs to the field of functional polymer materials. Aiming at the defect that the small organic molecules are easy to be moved and are easy to low the mechanical properties of a rubber, a hyperbranched polymer promoter capable of effectively enhancing the damping capacity of the rubber is designed. The invention is calcualted in mass percentage: 100 shares of raw rubbers, 10 to 40 shares of terminated hyperbranched polymers of hindered phenol, 0.5 to 1 share of potassium stearates, 3 to 5 shares of stearic acids, 5 to 8 shares of zinc oxides, 1 to 2 shares of sulfurs and 20 to 30 shares of carbon blacks are selected and the raw materials are mixed with each other uniformly on an open mill; the mixtures are subject to the packing mixing for 8 to 12 times; the mixtures are driven to rest for 10 to 16 hours with ventilation and the vulcanization time of the mixtures is tested on a rotor-free curometer at a temperature ranging from 150 DEG C to 170 DEG C; the curing time is recorded after the vulcanization curve flattens out; then the vulcanization is carried out utilizing a platten curometer, the temperature is set to range from 150 DEG C to 170 DEG C corresponding to the rotor-free curometer and the pressure is 15MPa and the strips are taken out. The invention can enhance the damping capacity of the rubber, overcome the defect of a small organic molecular promoter without lowering the mechanical properties of the rubber and maintain the stable performances for a long time.

Owner:BEIJING UNIV OF CHEM TECH

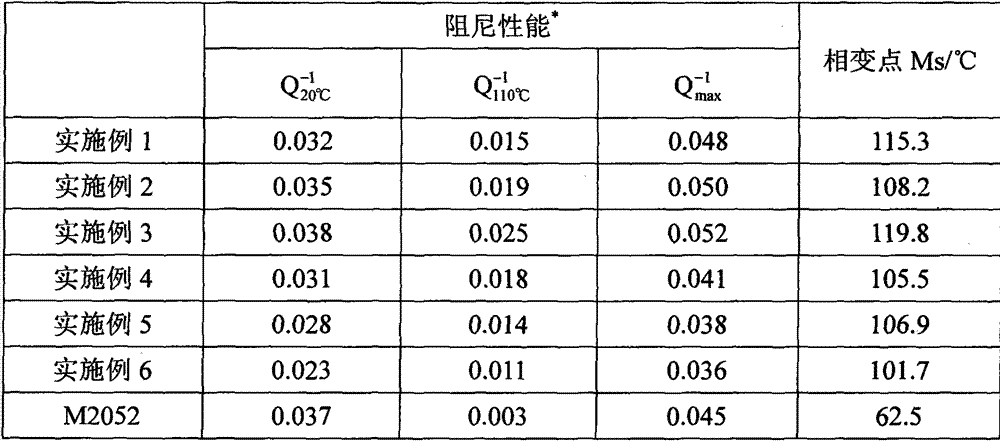

High-damping Mn-Cu damping alloy and manufacturing method thereof

ActiveCN104762540AIncrease temperatureImprove hot and cold working performanceRare earthNoise reduction

The invention provides a high-damping Mn-Cu damping alloy and a manufacturing method thereof. The alloy comprises chemical components of: 60.00-75.00 wt% of 2.00-5.00 wt% of Ni, 0.50-3.00 wt% of Al, 1.50-2.50 wt% of Fe, no more than 0.01 wt% of C, no more than 0.10 wt% of Si, less than 0.020 wt% of P, less than 0.020 wt% of S, no more than 0.050 wt% of N, no more than 0.010 wt% of O, one or more selected from Zr, Ti, La, Ce, Y and mixed rare earth (Mm), and the balance of Cu and inevitable impurities. After heat treatment, the alloy has damping performances as follows: Q<-1><max> of 0.035-0.055, Q<20 DEG C> <-1> of 0.020-0.040, and Q<110 DEG C> <-1> of 0.010-0.030. The alloy has high damping capacity, good temperature stability, wide temperature range, high strength and good processability, can be processed into sectional material and strips, is applicable to the parts requiring vibration and noise reduction in the fields of aviation and space flight, navigation, nuclear industry, automobile manufacturing, electrical equipment and precision instruments and instrumentation, and can play the roles of reducing the vibration transmission, reducing noise and prolonging the service life of structural components.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

High temperature and high damping high entropy alloy and preparation method thereof

ActiveCN109338200AThe scope of application of large ingredientsBroad preparation conditionsElectric arc furnaceHigh entropy alloys

The invention relates to a high temperature and high damping high entropy alloy and a preparation method thereof. Due to the microalloying oxygen or nitrogen elements of a refractory high-entropy alloy matrix and utilizing high thermal stability of a high-entropy alloy matrix, the high temperature and damping capacity of the high entropy alloy is achieved. The process is as follows: the metal materials Ta, Nb, Hf, Zr, Ti, Mo, V, W, Al, etc. are subjected to mechanical removal of oxidized scale, and are weighted by the molar ratio; other added elements are mechanically scaled, ultrasonically cleaned or pickled, and weighted by the molar ratio; the oxygen element is added in the form of an oxide, and the nitrogen element is added in the form of a nitride; and the alloy is obtained by vacuumcasting or casting equipment through smelting in a non-consumable vacuum electric arc furnace or a cold crucible suspension furnace. The high temperature and high damping high entropy alloy and the preparation method thereof utilize the high structural stability of the high-entropy alloy, and significantly improves the high temperature damping performance and mechanical property of the alloy by small atom microalloying.

Owner:UNIV OF SCI & TECH BEIJING

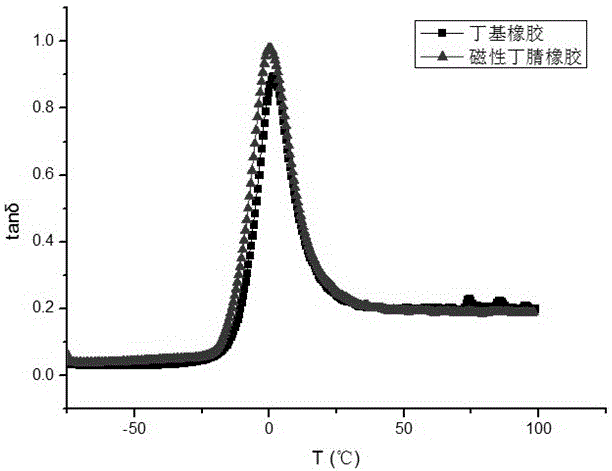

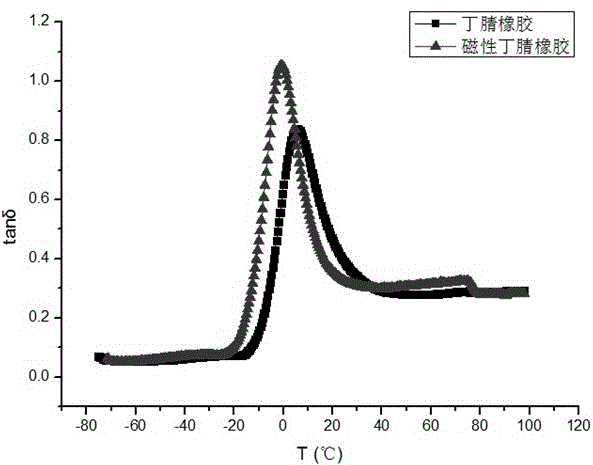

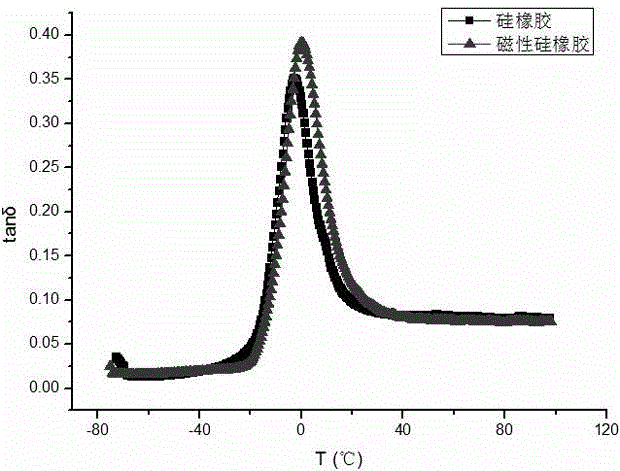

Method for enhancing damping capacity of rubber by adding neodymium-iron-boron magnetic powder

ActiveCN102875909AIncreased maximum damping factorImprove energy conversionMagnetic materialsPolymer scienceSulfur

The invention discloses a method for enhancing damping capacity of rubber by adding neodymium-iron-boron magnetic powder, which comprises the following steps: 1) plasticizing 100 parts by mass of rubber on milling equipment, sequentially adding 1-50 parts by mass of reinforcing agent, 20-120 parts by mass of neodymium-iron-boron magnetic powder, 0.1-5 parts by mass of sulfur, 0.1-5 parts by mass of zinc oxide and 0.1-5 parts by mass of stearic acid, and milling for 5-20 minutes to obtain a mixture; 2) putting the mixture in a mold, applying a pressure of 5-50Pa onto the mold, and vulcanizing at 120-200 DEG C for 5-30 minutes to obtain vulcanized rubber; and 3) putting the vulcanized rubber in a 0.5-5T magnetic field to carry out magnetization for 1-60 seconds, thereby obtaining the high-damping neodymium-iron-boron magnetic rubber. The damping capacity of the rubber obtained by adding the neodymium-iron-boron magnetic powder can be maximally enhanced by more than 25% within a wide frequency range and a wide temperature range.

Owner:ZHEJIANG UNIV +1

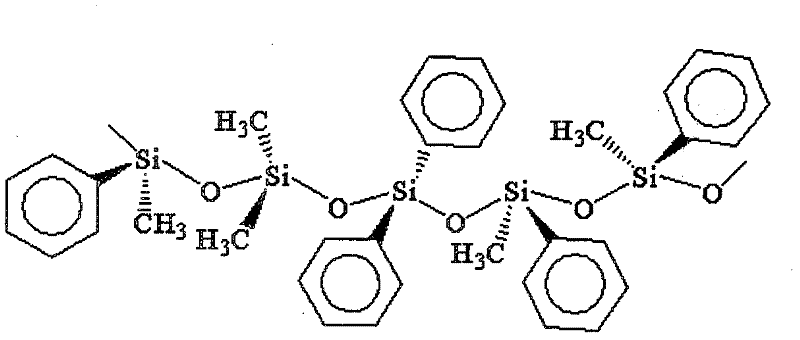

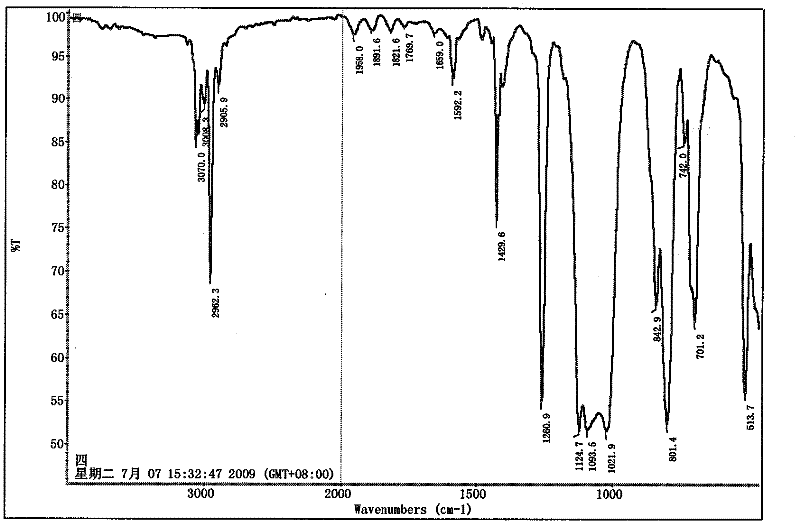

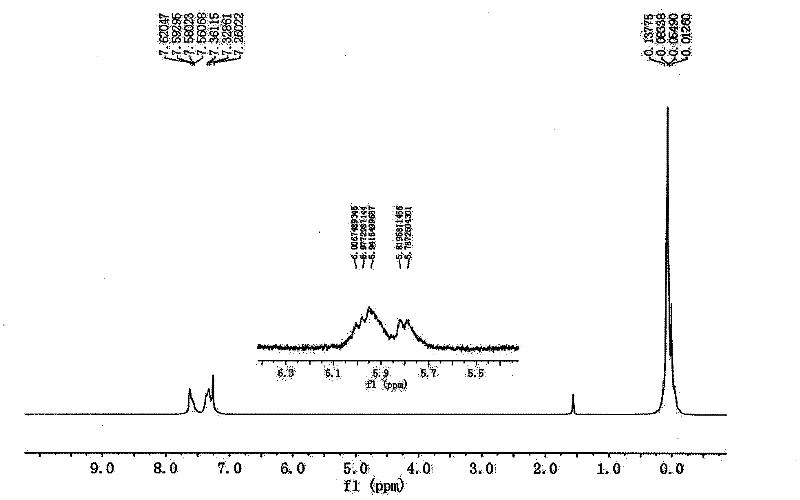

Copolymerized high-performance damping silicon rubber and preparation method thereof

The invention discloses copolymerized high-performance damping silicon rubber and a preparation method thereof. The preparation method is characterized by comprising the following steps of: adding 100 parts by mole of octamethylcy-clotetrasiloxane, 0.001-1 part by mole of tetram-ethy1tetravinylcyclotetrasiloxane, 1-50 parts by mole of octaphenyl cyclotetrasiloxane and 1-500 parts by mole of hybrid ring containing methylphenyl siloxane chain links into a reactor; dehydrating by forming nitrogen bubbles at the temperature of between 55 DEG C and 65 DEG C under the protection of nitrogen gas for 1-3 hours; adding 0.01-5 percent by weight of catalyst; continually drying nitrogen bubbles; adding 0.00001-1 part by millimole of end-capping reagent when the viscosity rises; undergoing a balanced reaction at the temperature of between 90 DEG C and 110 DEG C for 7-8 hours; raising the temperature to 145-165 DEG C after the reaction; preserving heat for 1-2 hours; decomposing and breaking the catalyst; raising the temperature to 180-200 DEG C finally; separating low molecular substances out at reduced pressure under the vacuum degree of 6-12 Mpa until distillate is eliminated fully; cooling to room temperature and discharging; and stopping reducing pressure to obtain polymethyl phenyl ethylene siloxane. Phenyl siloxane rubber further prepared from the copolymer has superior damping capacity and mechanical property.

Owner:SICHUAN UNIV

High-stength, high-damping-capacity cast iron

A high-strength, high-damping-capacity cast iron having both a high strength and high vibration damping capacity is provided.The high-strength, high-damping-capacity cast iron is obtained by a method including performing a graphite spheroidizing treatment on a molten metal, and consists of 2% to 4% of C, 1% to 5% of Si, 0.2% to 0.9% of Mn, 0.1% or less of P, 0.1% or less of S, 3% to 7% of Al, 0% to 1% of Sb, 0% to 0.5% of Sn, 0.02% to 0.10% of Mg, 01% to 0.5% of RE (Ce, La), Fe as balance, and unavoidable impurity.

Owner:TOSHIBA MASCH CO LTD

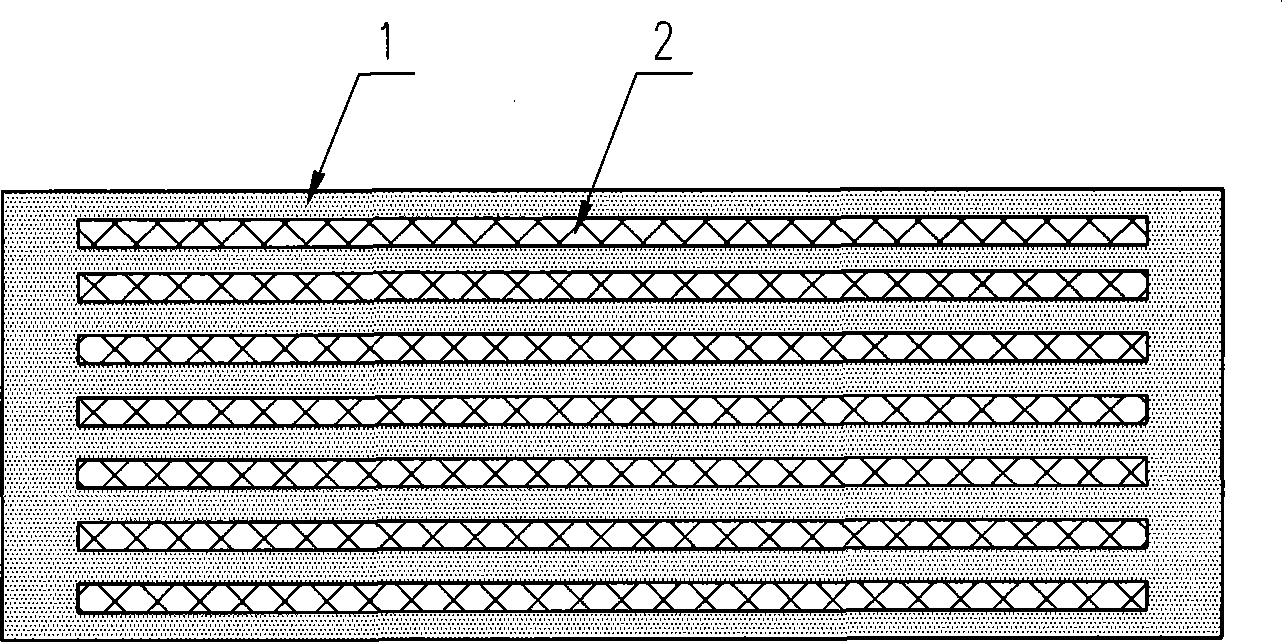

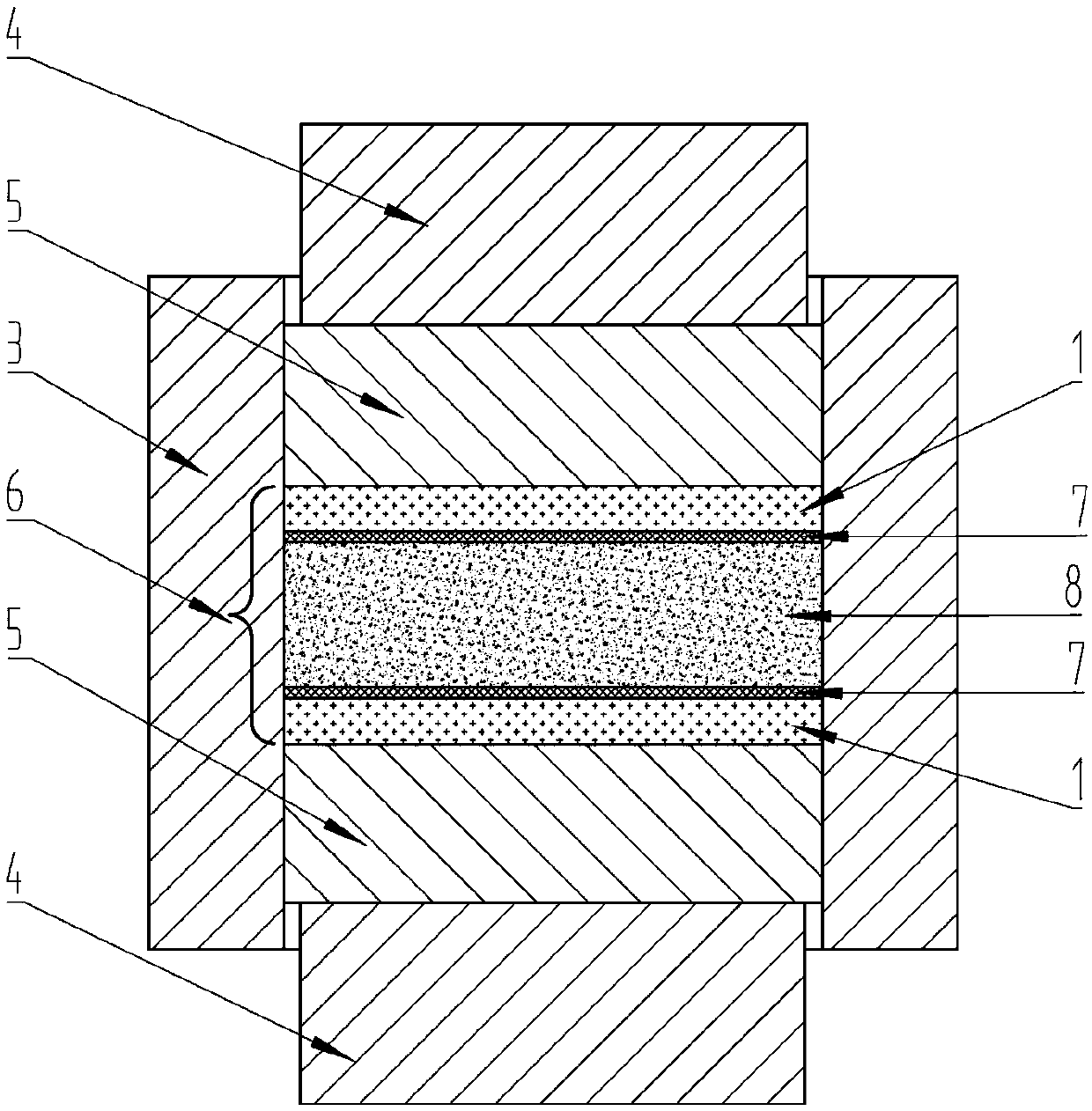

Fiber reinforced rubber vibration isolator and method of producing the same

ActiveCN101469759AWith carrying capacityGuaranteed flexibilityNon-rotating vibration suppressionVulcanizationHigh energy

A FRP reinforced rubber vibration isolator and manufacturing method thereof, relate to a vibration isolator and a manufacturing method thereof. The vibration isolator is formed by a rubber layer and a stiffening layer which are staggeredly superposed, vulcanized and bonded in the thickness direction, wherein the stiffening layer is a fiber layer formed by fiber reinforced material, or a fiber reinforced rubber layer formed by rubber layers on the upper and lower surfaces and fiber reinforced material arranged therebetween through co-vulcanization; the fiber reinforced material for forming thefiber layer or the fiber reinforced rubber layer is the fiber material after RFL resin surface treatment before vulcanization with rubber or combination with rubber. The manufacturing method comprises surface treatment, preparation of the fiber reinforced rubber layer, superposition, vulcanization molding. The fiber reinforced vibration isolator has a certain bearing capacity and high energy damping capacity, good durability and corrosion resistance, and high designability, and has simple and applicable manufacturing method.

Owner:LIUZHOU OVM MASCH CO LTD +2

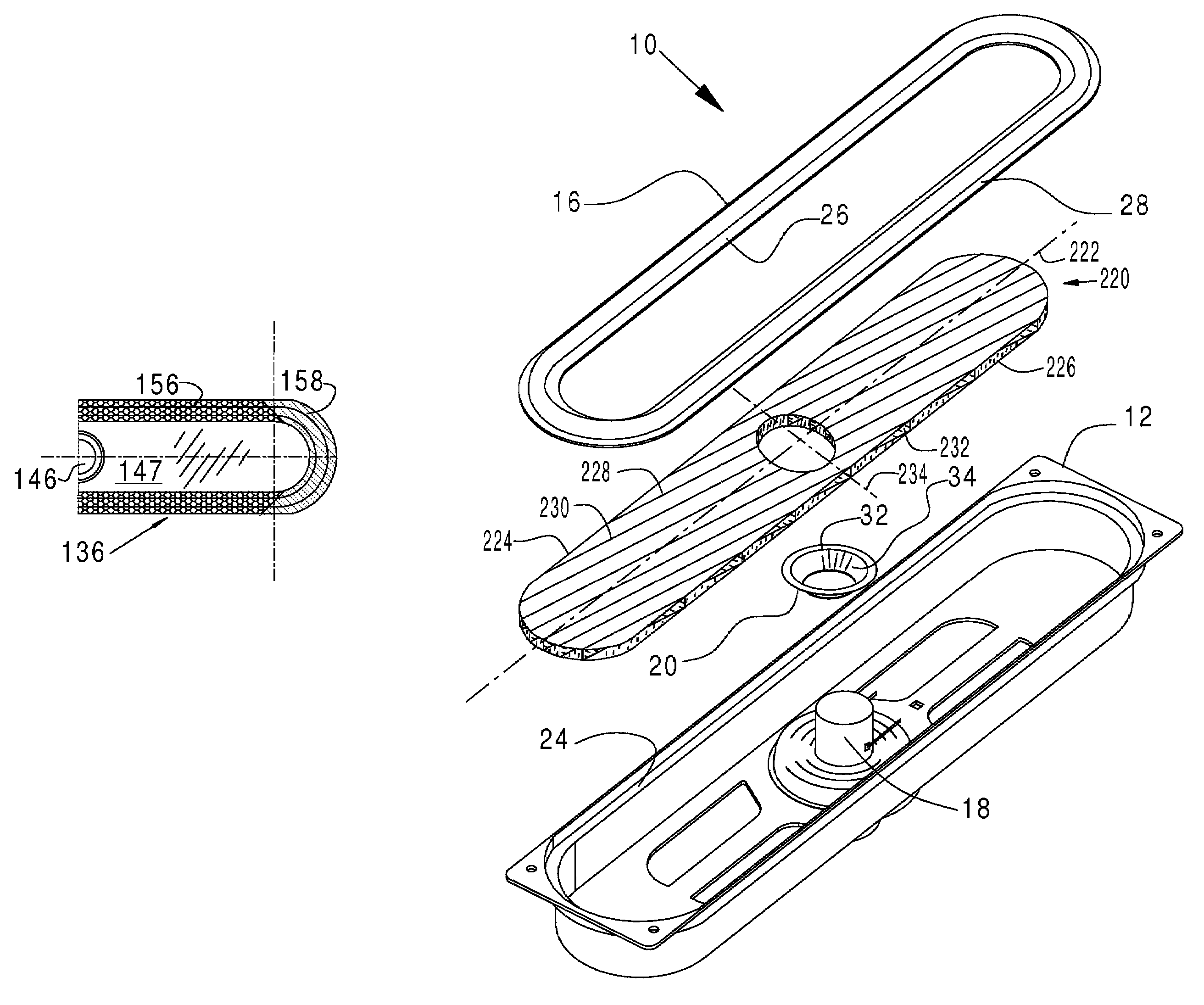

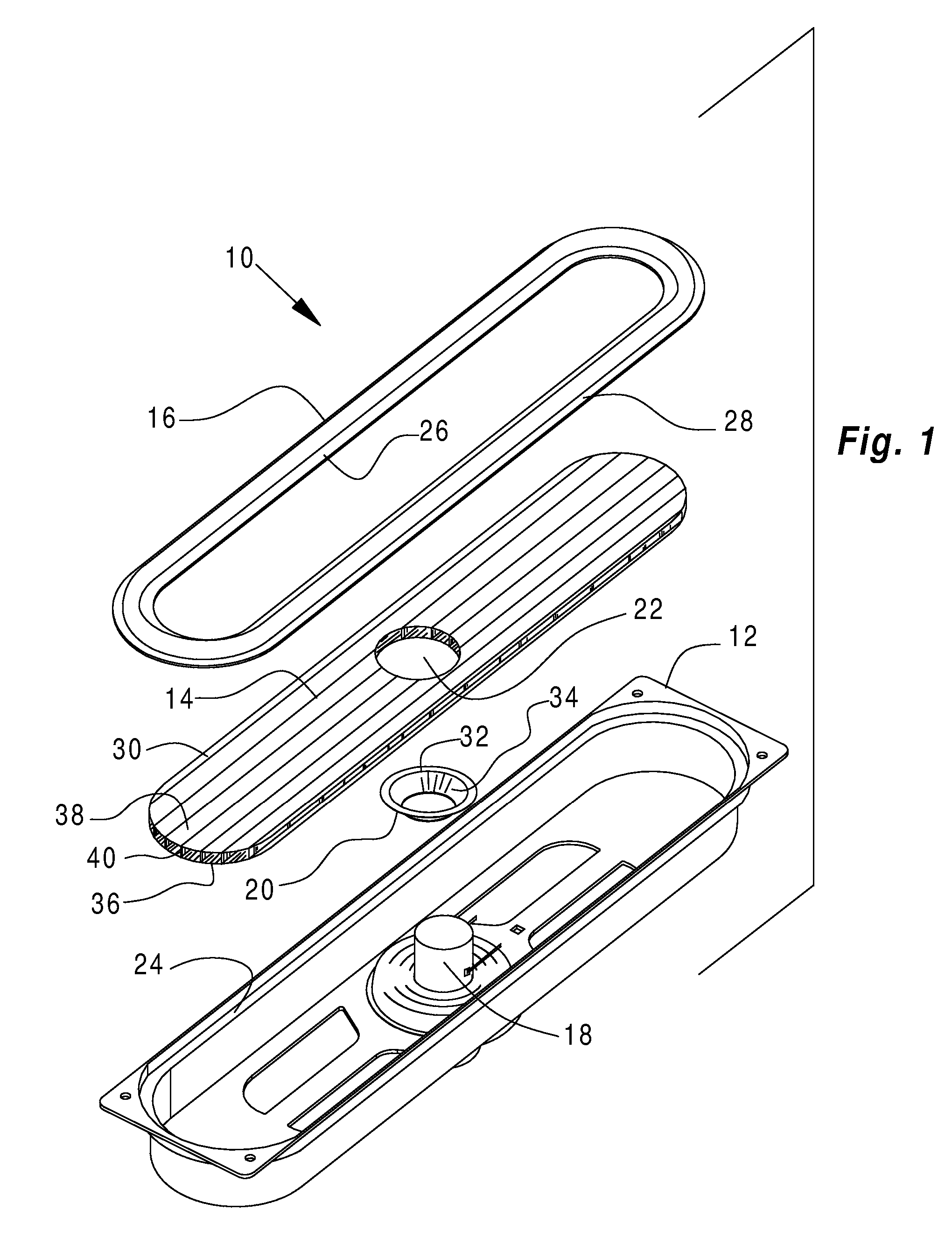

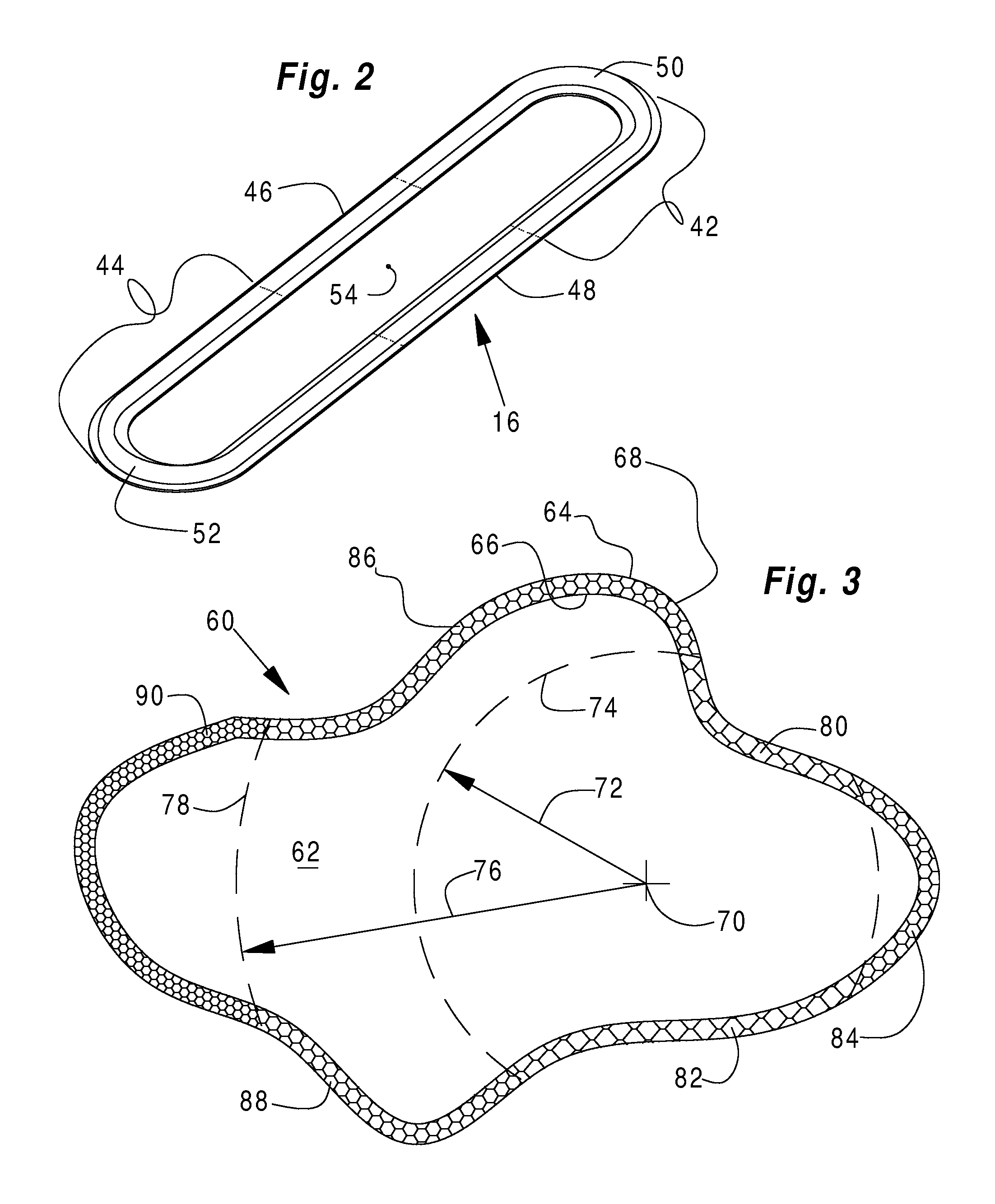

Speaker edge and resonator panel assembly

InactiveUS7510047B2Quality improvementImprove low frequency sound qualitySound producing devicesPlane diaphragmsSound qualityEngineering

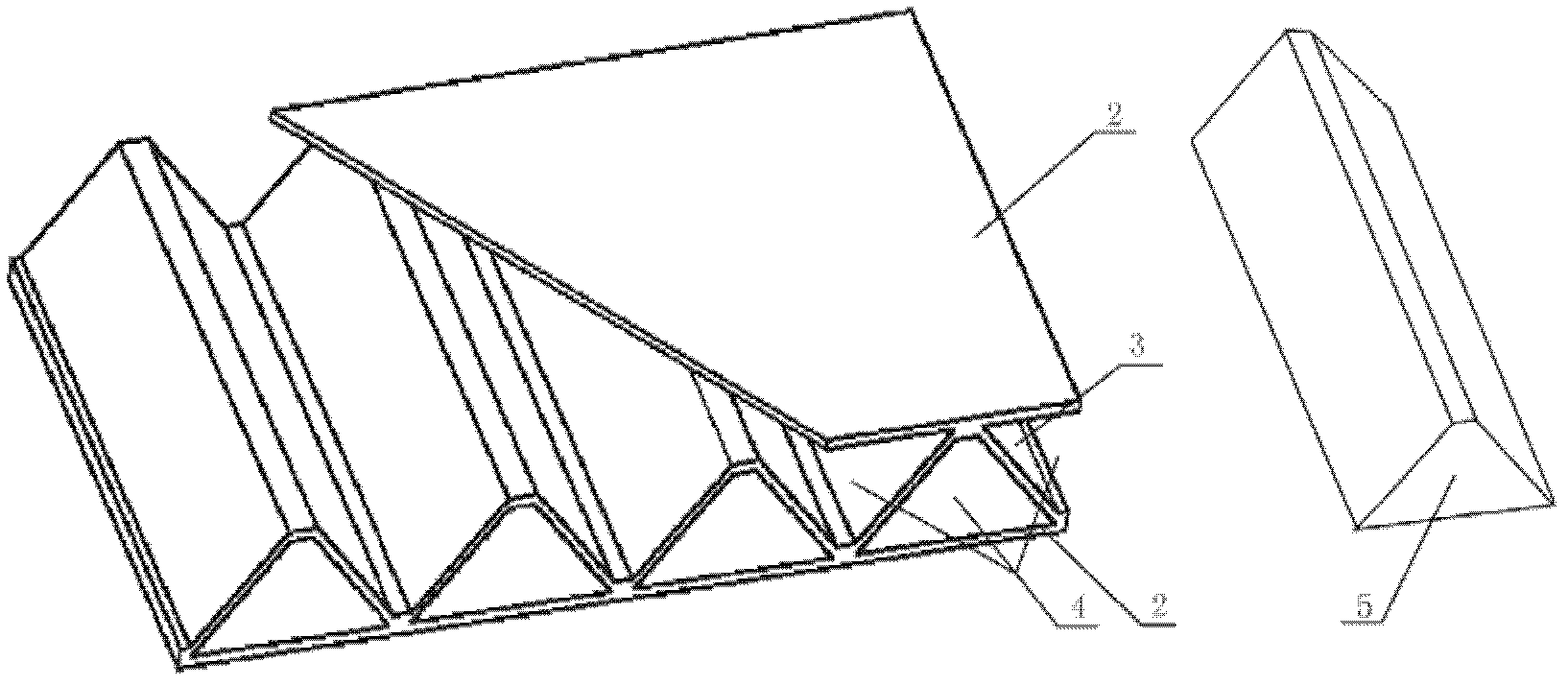

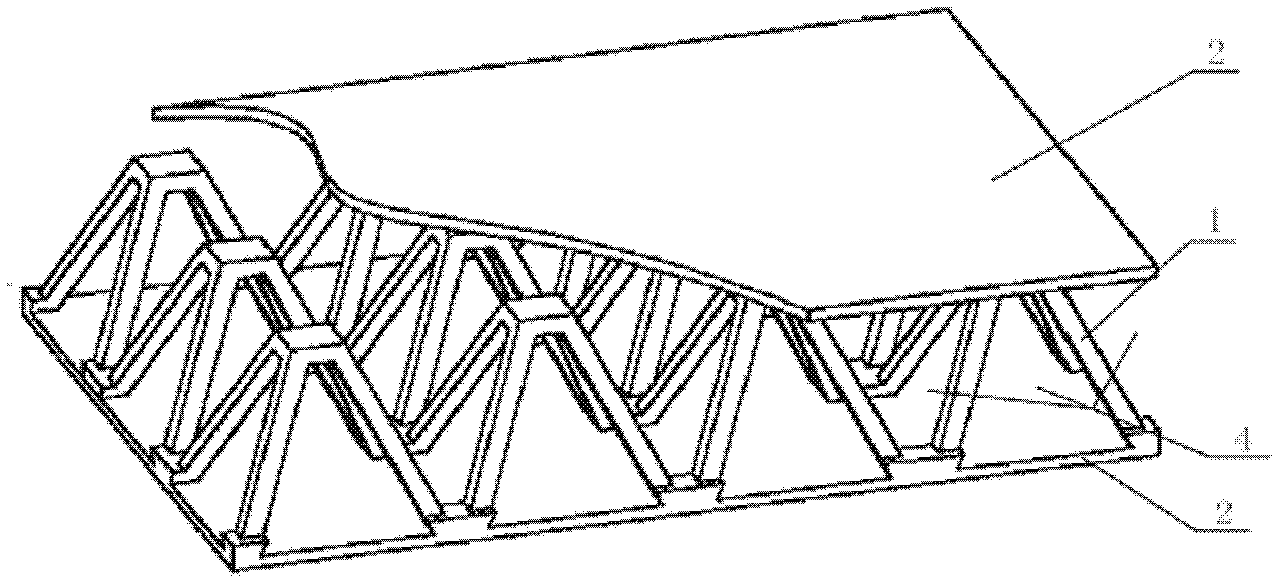

A complex speaker edge and asymmetric resonator panel in which the acoustic vibration damping capacity of the speaker edge varies longitudinally around the speaker edge. The resonator panel has an aspect ratio of approximately 1.3:1 or more, and is composed of top and bottom panels held in spaced apart relationship by a plurality of longitudinally extending ribs extending therebetween. The ribs extend at an angle of from approximately 5 to 35 degrees to the longitudinal axis of the panel. The angle is acoustically matched to the complex speaker edge to improve the accuracy with which said acoustic vibration is reproduced. The effectiveness of the differential damping capacity of the edge in improving the quality of sound output from a speaker assembly is determined by observing the average magnitude of the excursions of the sound level pressure versus frequency curves for comparable complex and single speaker edges, particularly in the 200 to 10,000 Hertz range. The speaker edge and the angle of the ribs are acoustically matched by iteratively adjusting the edge and / or the angle in response to the quality of the sound that is perceived by a trained human ear.

Owner:MUTO KEIKO +1

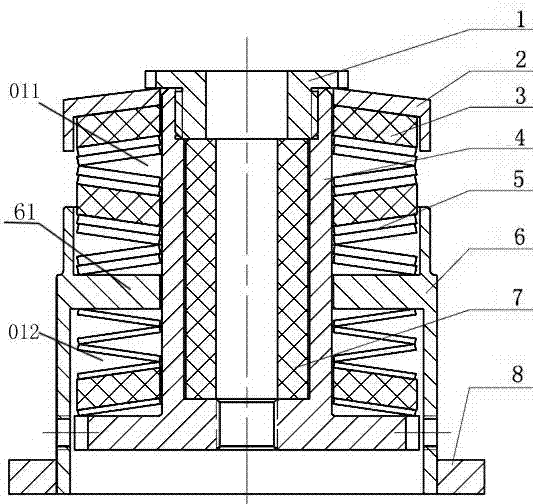

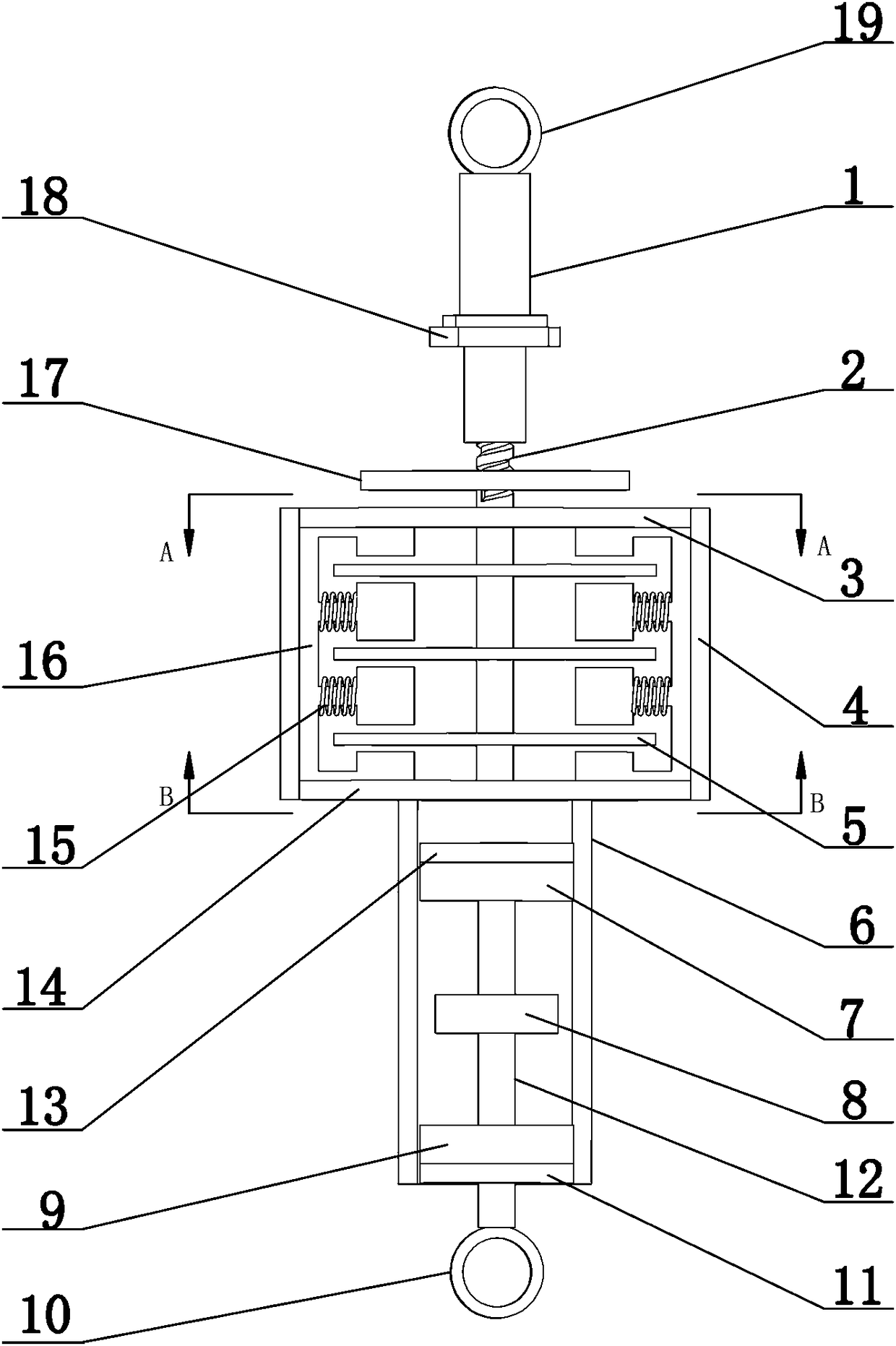

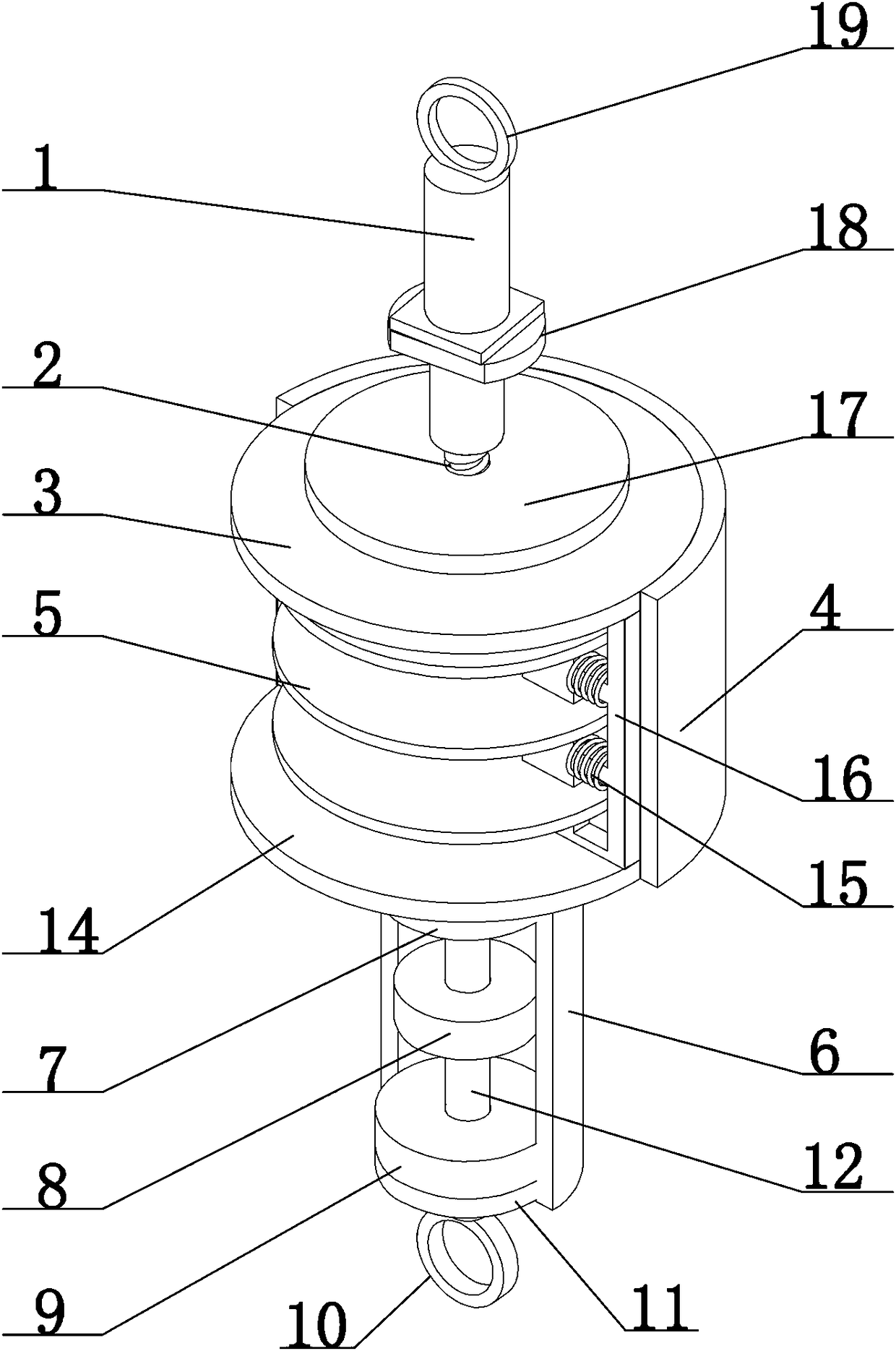

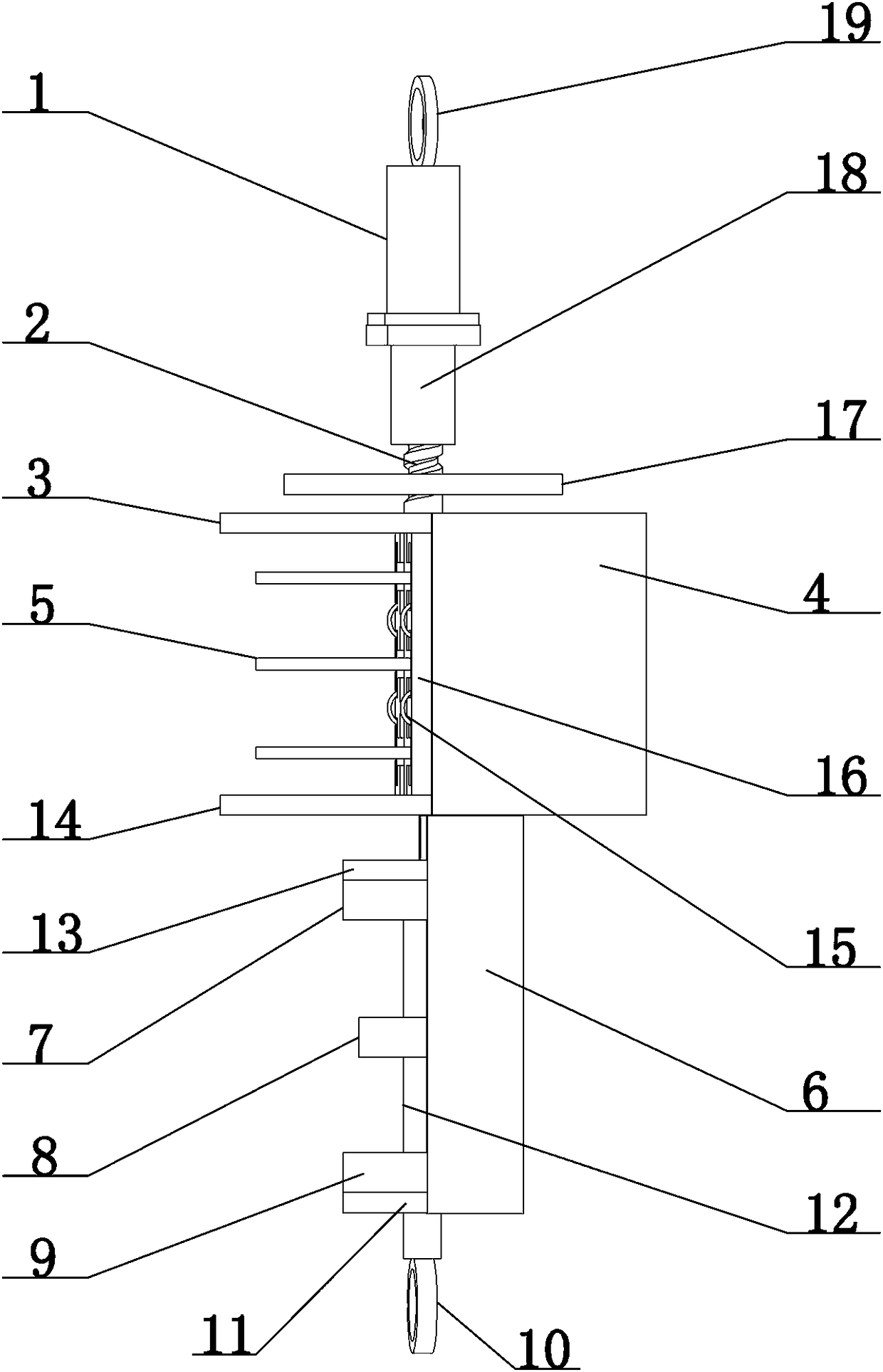

Metal rubber-disc spring all-metal three-way composite support for piping vibration isolation and impact resistance

ActiveCN103711990AIncrease dampingDifferent dampingPipe supportsNon-rotating vibration suppressionVertical vibrationMetal rubber

The invention provides a metal rubber-disc spring all-metal three-way composite support for piping vibration isolation and impact resistance. The metal rubber-disc spring all-metal three-way composite support comprises metal rubber mats and disc springs, a center net, a locking nut, a pressure cover, a guide holder, a mounting base and a base plate, wherein the metal rubber mats and the disc springs are used for bearing vertical vibration and impact load, the center net is used for bearing horizontal vibration and impact load, the locking nut, the pressure cover, the guide holder, the mounting base and the base plate are used for supporting and fixing an elastic component. By the aid of large bearing capacity and flexible rigidity characteristic, Coulomb damping among the disc springs, and the Coulomb damping between hard rigidity characteristic of the metal rubber mats and the disc springs, the flexible and hard rigidity complex characteristics and larger damping on the vertical bearing direction can be realized. The metal rubber-disc spring all-metal three-way composite support is compact in structure, light in weight, high in high-temperature environment adaptability, good in damping capacity, and lower in vibration isolation frequency, and vertical rigidity has higher static rigidity and lower dynamic rigidity; besides, considerations are also given to shock isolation and a limiting function, so that three-way impact acceleration responses and impact displacement responses can be kept within a reasonable range.

Owner:SHANGHAI JIAO TONG UNIV

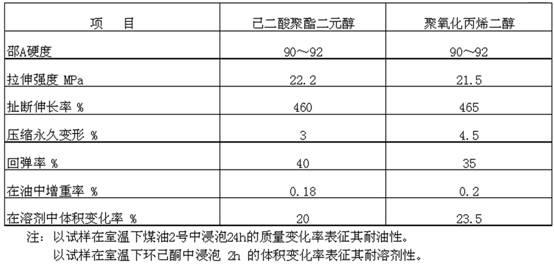

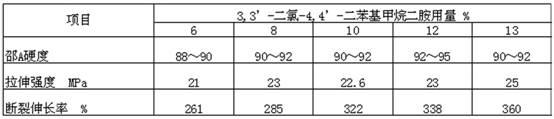

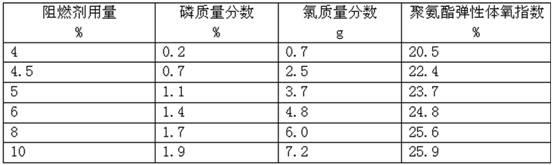

Organic polymer polyurethane elastomer and preparation method thereof

InactiveCN102161742AEliminate static electricityEliminate burning phenomenonPolymer scienceToluene diisocyanate

The invention relates to an organic polymer polyurethane elastomer and a preparation method thereof. The organic polymer polyurethane elastomer mainly comprises the following components in percentage by weight: 40-65% of low-polymer polybasic alcohol, 20-38% of toluene diisocyanate, 6-13% of 3,3'-dichloro-4,4'-diphenylmethane diamine and 8-12% of compounding ingredient. The low-polymer polybasic alcohol is one of adipic polyesterglycol and polyoxypropylene diol; and the accessory ingredient is a flame retardant, or an antistatic agent or the combination thereof. The organic polymer polyurethane elastomer has the advantages of high wear resistance and wide hardness range, the Shore hardness of the organic polymer polyurethane elastomer is A10-D80, and the organic polymer polyurethane elastomer with high hardness stills has a percentage of elongation of 400-800%, which is 2-3 times of natural rubber and synthetic rubber; and the organic polymer polyurethane elastomer also has the advantages of high load bearing capacity, favorable shock resistance and damping capacity, and excellent oil resistance, can not be easily damaged by throwing or knocking, and can effectively eliminate noise and vibration.

Owner:上海科华聚氨酯制品有限公司

Polyether polyol capable of improving damping capacity of polyurethane, preparation method of polyether polyol and preparation method of damping material prepared from polyether polyol

InactiveCN104448289ASolve complexitySolve the narrow damping temperature rangeDamping factorEnd-group

The invention belongs to the technical field of synthesizing organic macromolecules, and in particular relates to polyether polyol capable of improving the damping capacity of polyurethane, a preparation method of the polyether polyol and a preparation method of a damping material prepared from the polyether polyol. The polyether polyol of which the end group is secondary hydroxy is obtained by using bisphenol a as an initiating agent and adopting a bimetal cyanide complex catalyst to catalyze ring opening polymerization of epoxy chloropropane. The damping material prepared from the polyether polyol disclosed by the invention has the characteristics of high mechanical strength, good corrosion resistance, good hydrolysis resistance and good low temperature resistance, the damping material has higher damping factors, and the using temperature range of the damping material is wider.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

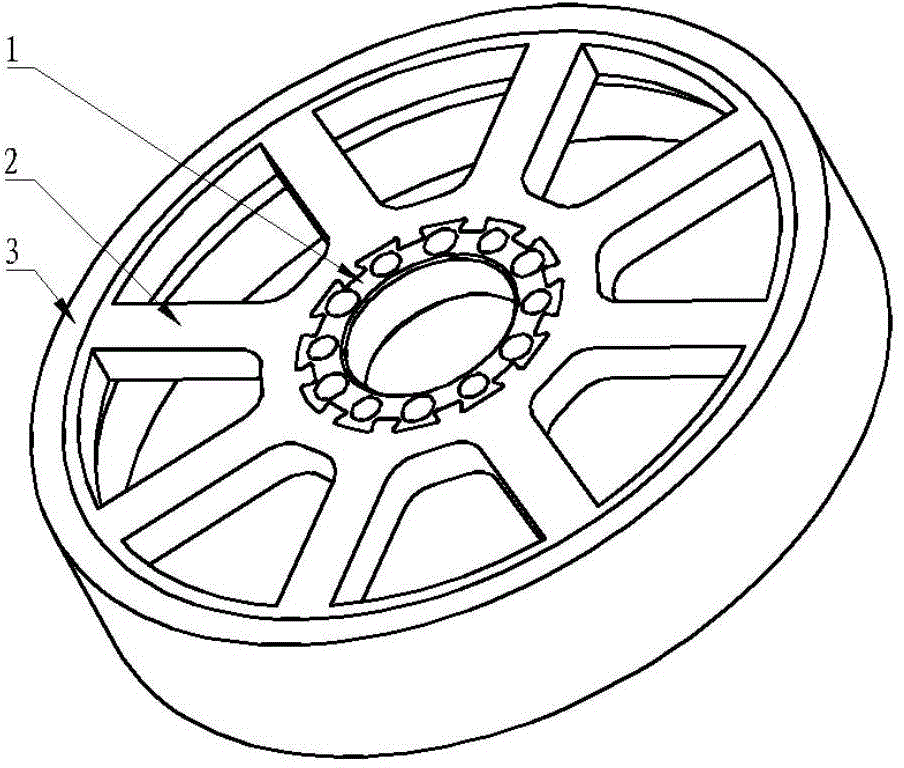

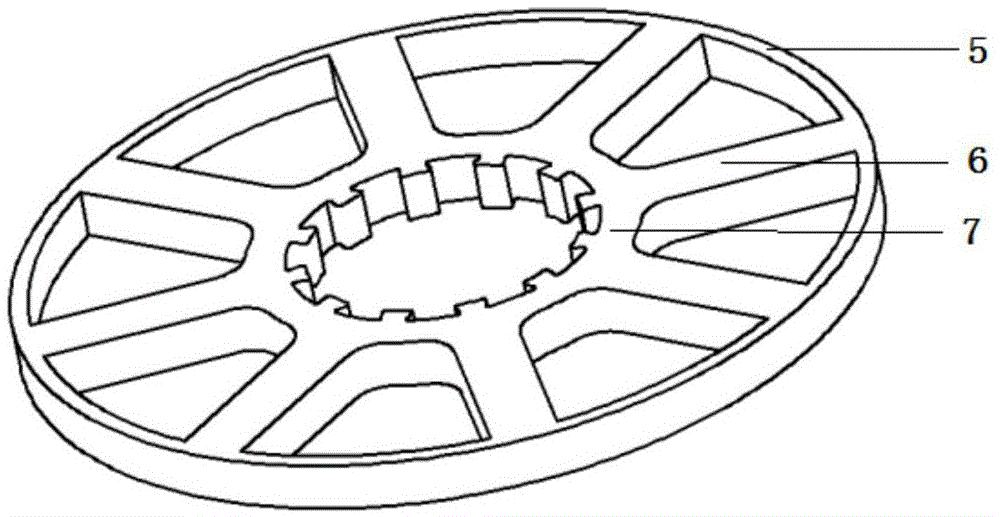

Light-weighted composite momentum flywheel for satellite and manufacture method thereof

The invention provides a light-weighted composite momentum flywheel for satellite and manufacture method thereof. From inside to outside, the flywheel is provided with a hub, spokes and a rim. Connecting grooves are formed in the periphery rim of the juncture of the hub and the spokes, centre holes are formed at the middle of the periphery. A plurality of mounting holes are formed between the groves and the centre holes. The spokes comprises a outer spoke ring, wire spokes and an inner spoke ring. The outer spoke ring is connected with the rim, the wire spokes are multiple, and the inner spoke ring is connected with the hub. Connecting humps are formed in the inner spoke ring. Annular humps are formed in the inside wall of the rim. The hub and the spokes are connected with the grooves and the humps structure in a meshing and co-curing mode. The outer spoke ring is connected with the outer rim in a bonding and close-fitting mode. The bottom of the spokes are arranged on the annular humps in the inside wall of the rim. The light-weighted composite momentum flywheel for satellite and manufacture method thereof have the advantages that the light carbon fiber composite with high strength and good damping property is used. A faster connection mode is replaced by the connection mode of close-fitting and bonding. The passive weight of the flywheel is reduced greatly, the damping capacity of the flywheel is enhanced greatly, and the manufacturing cycle is shortened.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD +1

Movable type heat dissipation high-voltage cabinet

InactiveCN109473887ARealize heat dissipationWith shock absorption abilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsMovable typeOmni directional

The invention discloses a movable type heat dissipation high-voltage cabinet. The cabinet comprises a cabinet body, a base, a circuit switching chamber, an electric control chamber, a current detection device, a bidirectional motor, a screw rod and a screw sleeve, wherein the upper end of the screw rod is fixed to the lower end of a partition plate through a bearing seat; a mounting frame is welded to one side, facing the interior of the cabinet body, of the screw sleeve; a heat dissipation fan arranged towards the center of the cabinet body is mounted on the mounting frame; a sliding groove is formed in the inner side wall of the cabinet body; a sliding rod is arranged in the sliding groove in a sliding mode; and one end of the sliding rod is fixed on the screw sleeve. The bidirectional motor can drive the screw rod to rotate; the screw sleeve can move up and down when the bidirectional motor works, and the heat dissipation fan is driven to move up and down, so that omni-directional heat dissipation in the cabinet body is achieved; and when the cabinet body is pushed, the power cabinet on a bottom plate can be driven to move stably, and under the action of damping springs in sliding rails, roller wheels have a certain damping capacity, so that an excessively serious shaking phenomenon of the power cabinet in the moving process can be avoided.

Owner:海安美物菲斯物联网科技有限公司

High efficiency alkaline organic phosphorus compound fertilizer for acidifying soil

Disclosed is a high efficiency alkaline organic phosphorus compound fertilizer for acidifying soil, characterized in that it comprises 60-95 mass% of alkaline organic phosphorus fertilizer, 0.1-1 mass% of microelement and 5-39 mass% of fertilizer. The advantages of the invention includes: 1 supplying phosphor element in the soil; 2 the alkaline organic phosphorus fertilizer has high pH value, can damp and regulate pH value of soil and eliminate poisoning of Al3+; 3 highly efficient, and hard to be fixed by soil, acidifying major element urgently needed by the soil plant; 4 hard to be washed out by rain; 5 regulating damping capacity and pH value of the soil, and improving soil aggregate structure.

Owner:刘永定

Three-element vibration damping device connecting damper element with inerter in parallel manner, design method of three-element vibration damping device and assembly method of three-element vibration damping device

PendingCN109027090AGive full play to the damping abilityPlay a tuning roleMagnetic springsShock absorbersBall screwHigh energy

The invention belongs to the technical field of structural vibration control, and in particular relates to a three-element vibration damping device connecting a damper element with an inerter in a parallel manner, a design method of the three-element vibration damping device and an assembly method of the three-element vibration damping device. The three-element vibration damping device comprises aspring element, the damper element and the inerter, wherein the damper element is connected in parallel with the inerter and then connected in series with the spring element to form a three-element vibration damping configuration connecting the damper element with the inerter in a parallel manner. The three-element vibration damping device adopts a ball screw system to realize the three-element vibration damping configuration connecting the damper element with the inerter in a parallel manner, and can simultaneously tune the damping force and the inertia force to fully utilize the vibration damping capacity of the damper element and the inerter. In addition, the three-element vibration damping device adopts the assembly technique, and has the advantages of easy adjustment, good durability, high energy dissipation capacity and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

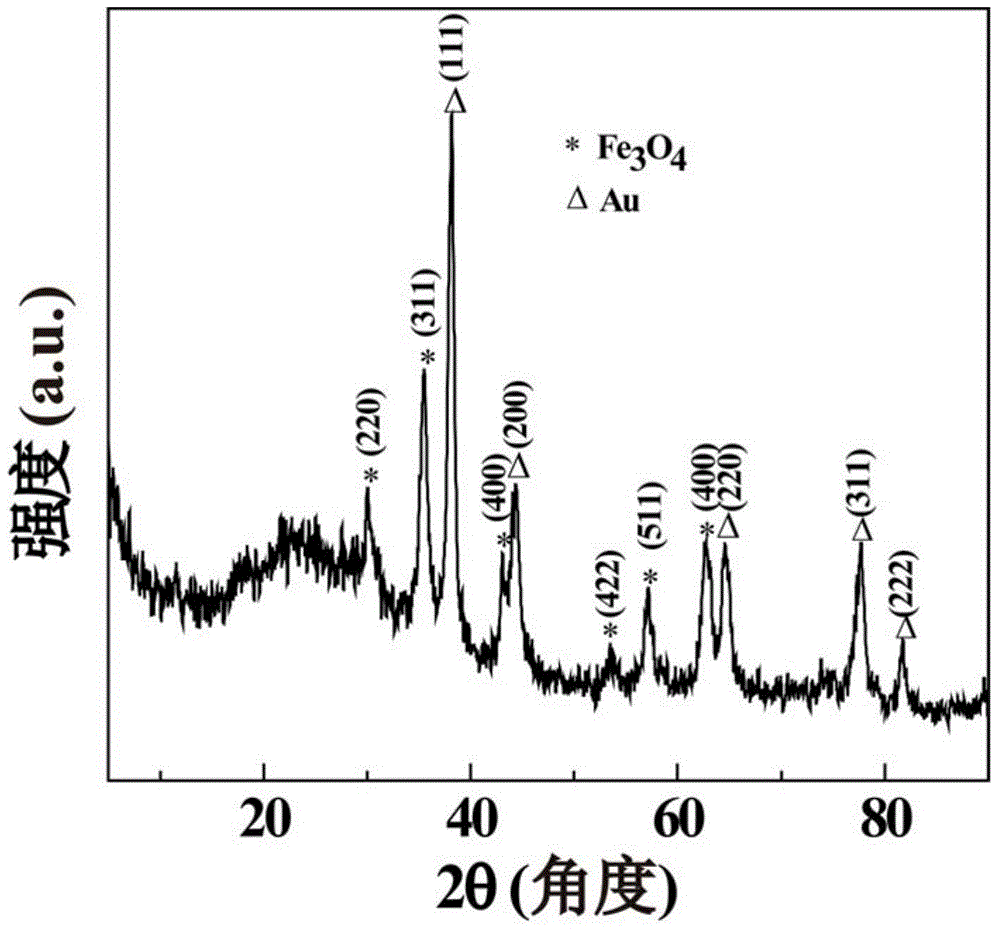

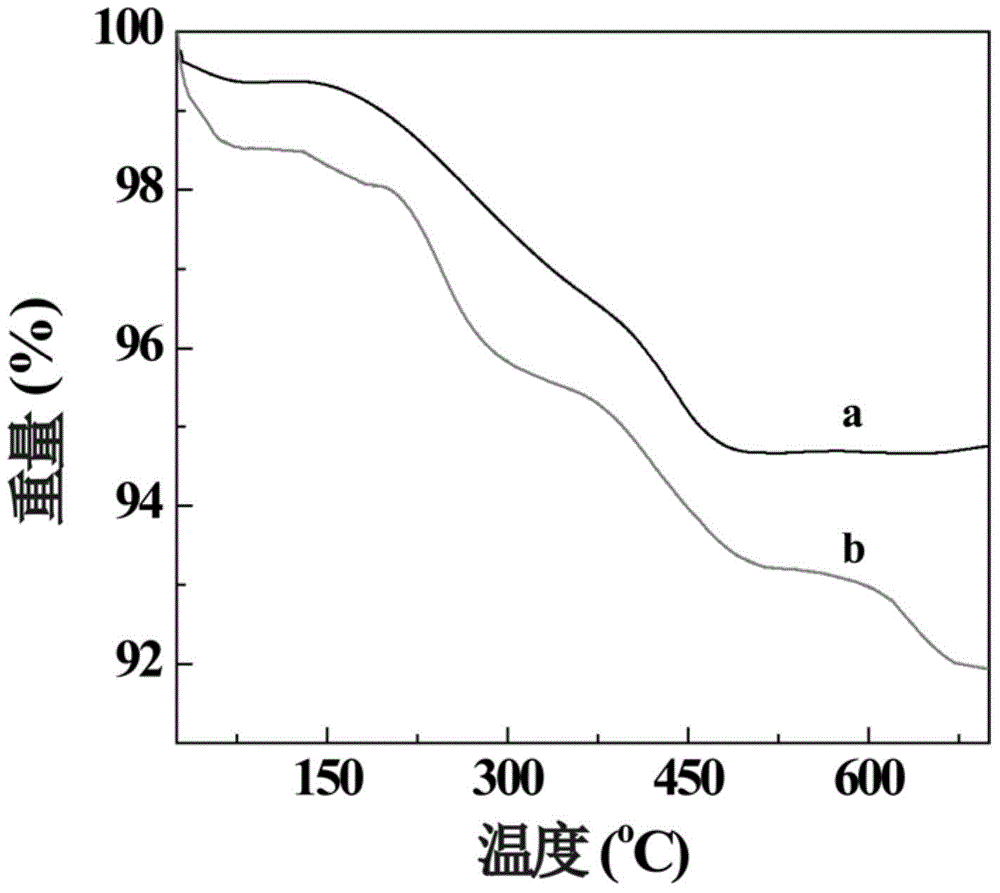

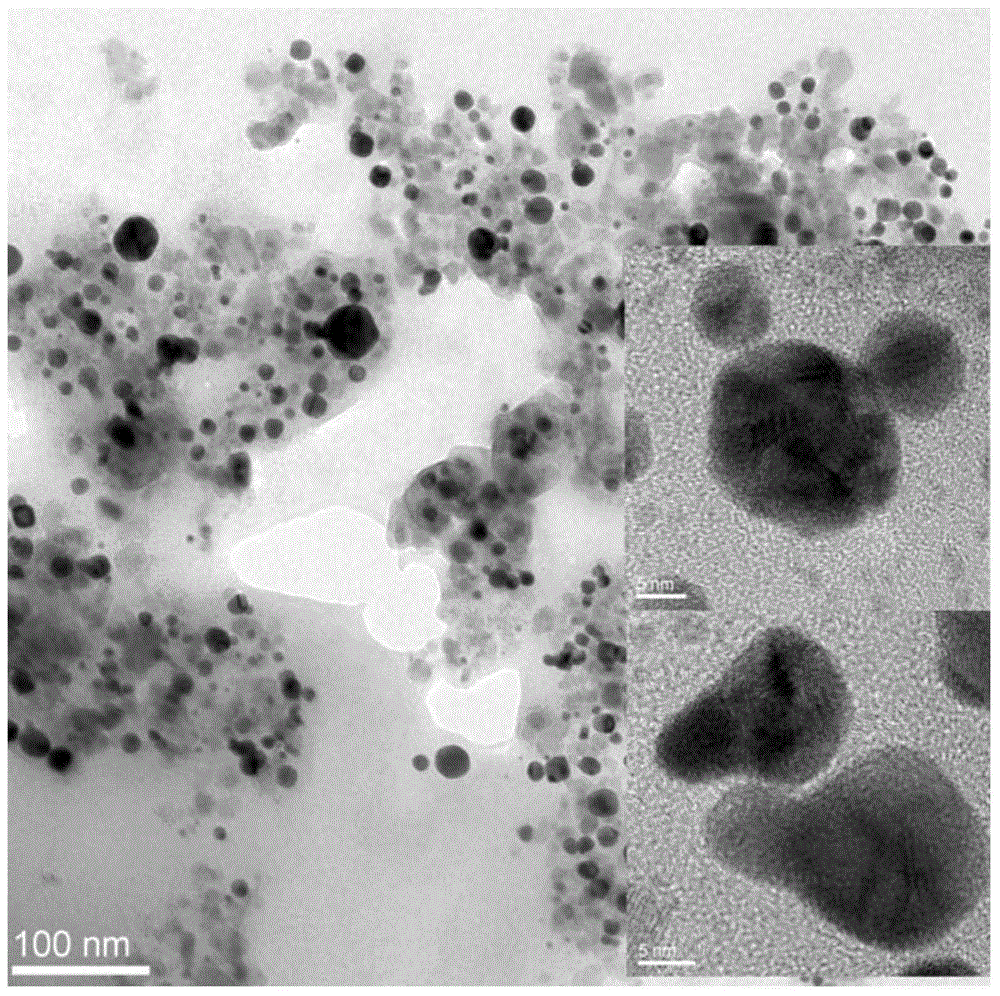

Preparation method of hyaluronic acid modified superparamagnetic iron oxide/gold composite nanoprobe

InactiveCN104548142ASimple operation processMild reaction conditionsX-ray constrast preparationsEmulsion deliveryTumor targetCancer cell

The invention relates to a preparation method of a hyaluronic acid modified superparamagnetic iron oxide / gold composite nanoprobe. A NaBH4 reduction method is used for preparing PEI coated Au nano-particles; Fe3O4 / Au-PEI composite nanoparticles are synthetized in one step through a modified coprecipitation method; then HA is modified on the surface of the Fe3O4 / Au-PEI composite nanoparticles, so as to prepare a Fe3O4 / Au-HA composite nanoprobe. The preparation method provided by the invention is simple in process, mild in reaction conditions, and easy to operate; the prepared Fe3O4 / Au-HA composite nanoprobe has a relatively high relaxation rate, has an excellent X-ray damping capacity, is excellent in colloidal stability and biocompatibility, and has a targeting capability of a high expression cancer cell of a specific CD44 acceptor, and has a potential application value in the field of internal tumor targeted MR / CT bimodal imaging diagnosis.

Owner:DONGHUA UNIV +1

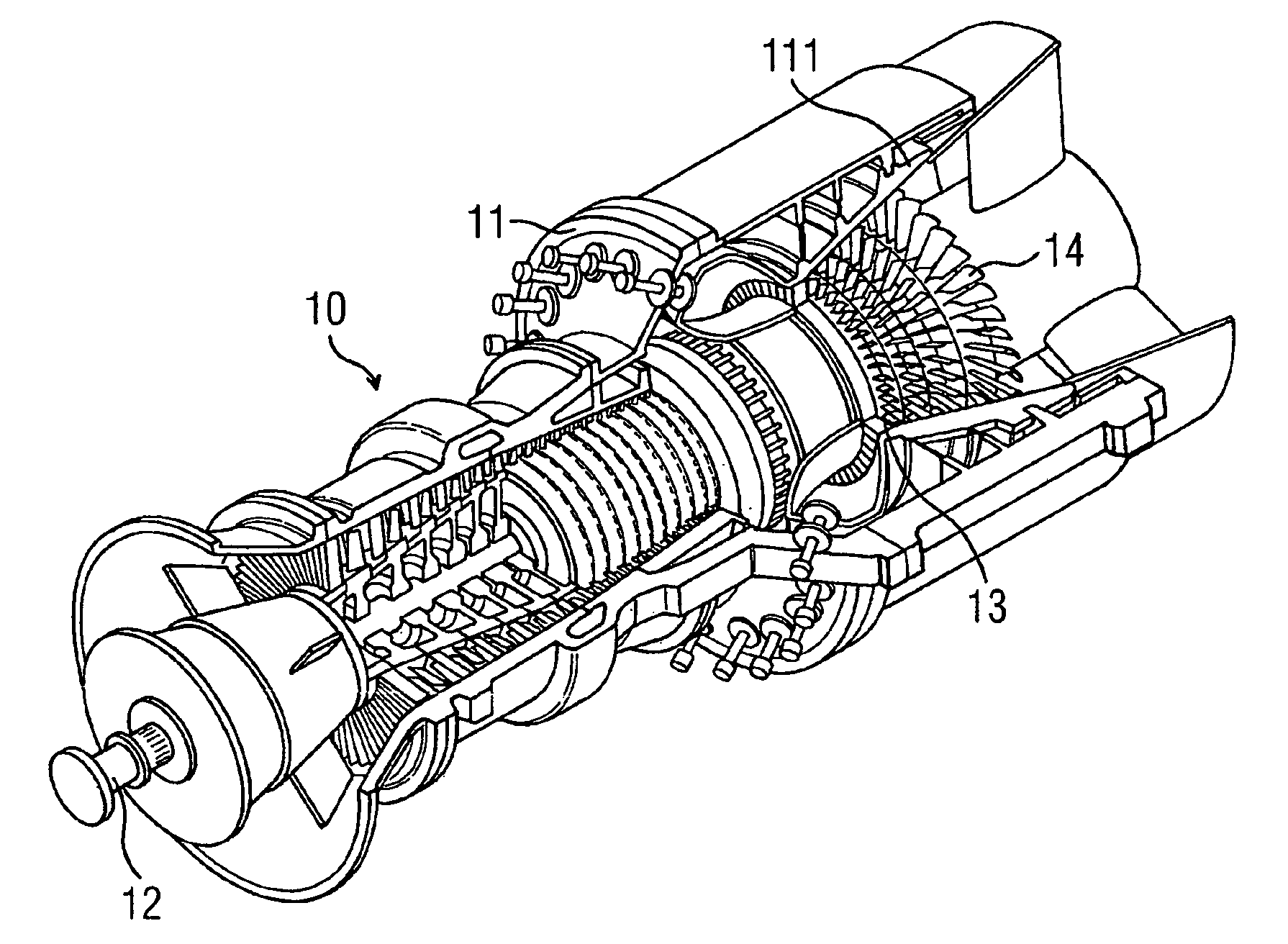

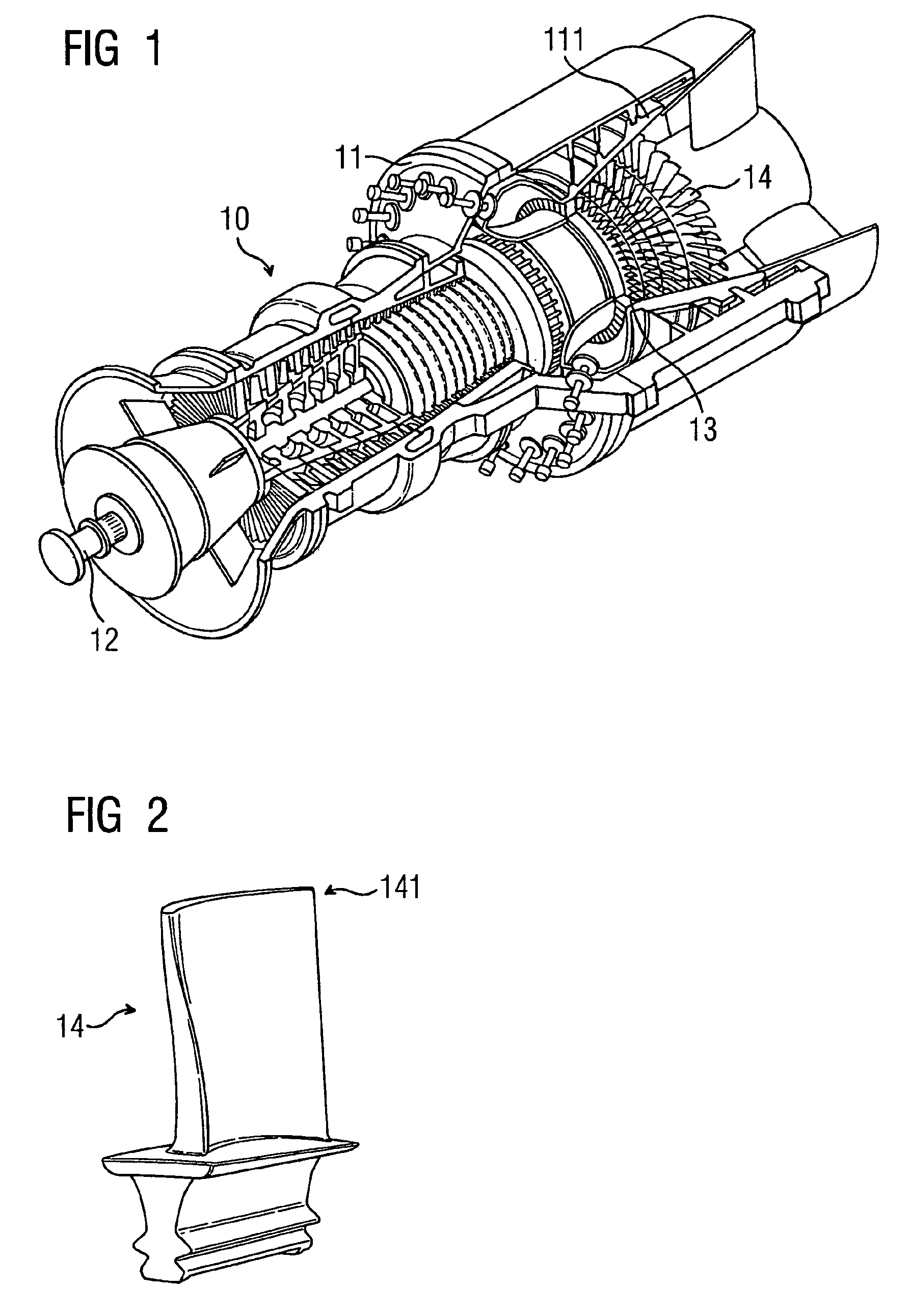

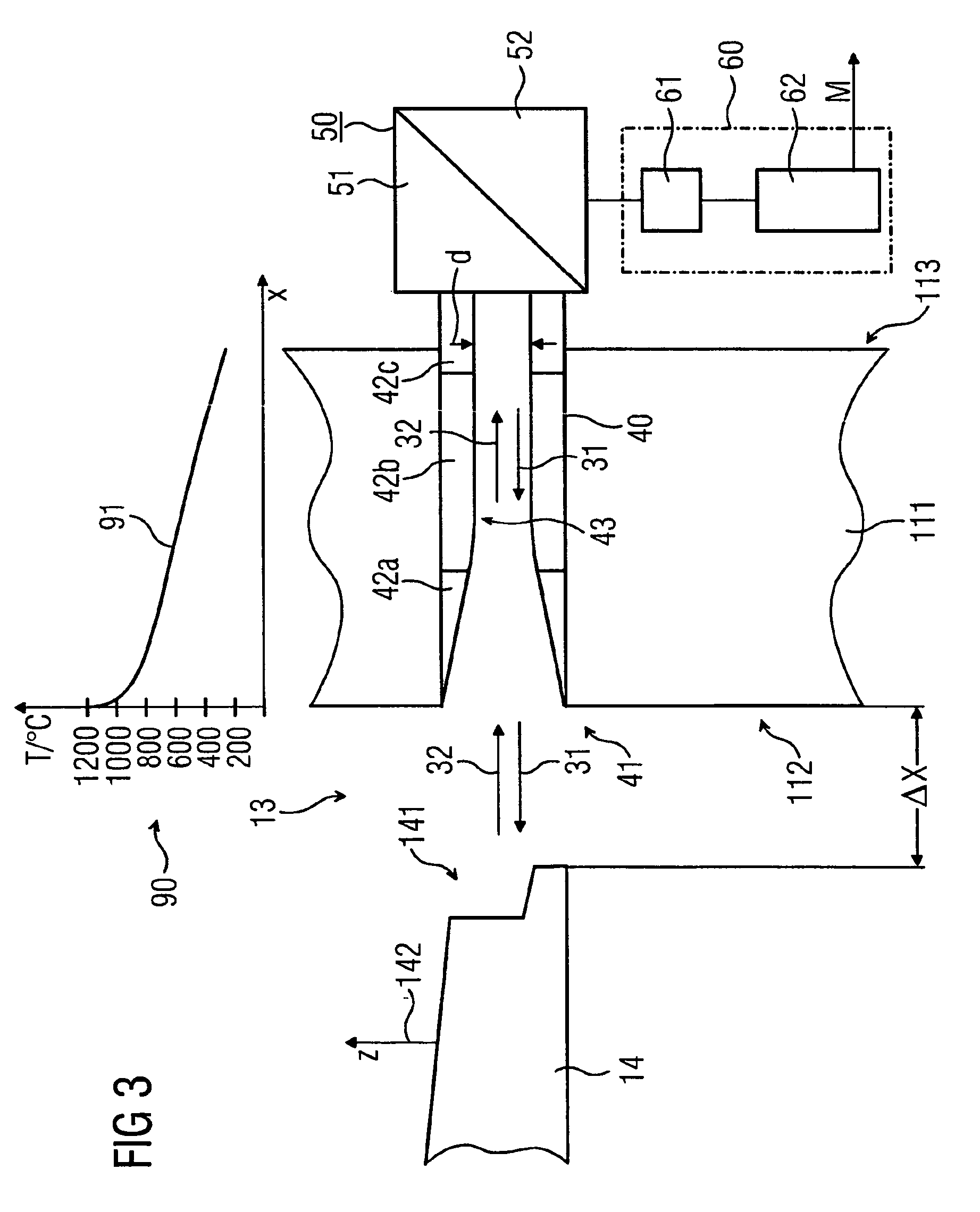

Device for determining the distance between a rotor blade and a wall of a turbine engine surrounding the rotor blade

Owner:SIEMENS AG

High specific rigidity foamed aluminum sandwich board and manufacturing method thereof

The invention relates to a high specific rigidity foamed aluminum sandwich board and a manufacturing method thereof and belongs to the technical field of porous metal materials and metal-based composite materials. The foamed aluminum sandwich board is composed of upper and lower panels and a middle foamed aluminum core layer. The substrate of foamed aluminum is an aluminum alloy, and the panels are particle enhanced aluminum-based composite materials. The manufacturing method comprises the following steps of first, uniformly mixing aluminum powder with a foaming agent titanium hydride powder to prepare mixed powder; adding the particle enhanced aluminum-based composite materials to the upper and lower sides of the mixed powder as the panels, and fully filling a die with the mixed powder for hot pressing densification to prepare a foamable prefabricated member; inserting a zinc belt between the panels and the mixed powder, and carrying out transitional liquid phase diffusion in hot pressing to achieve metallurgical connection of the panels and the core layer; and finally, heating and foaming the prefabricated member to obtain the foamed aluminum sandwich board. The foamed aluminum sandwich board not only has relatively high specific rigidity, but also has comprehensive advantages of high specific strength, high thermal conductivity, low thermal expansion, fatigue resistance, good damping capacity and the like, and the performance can be designed.

Owner:有研金属复材技术有限公司

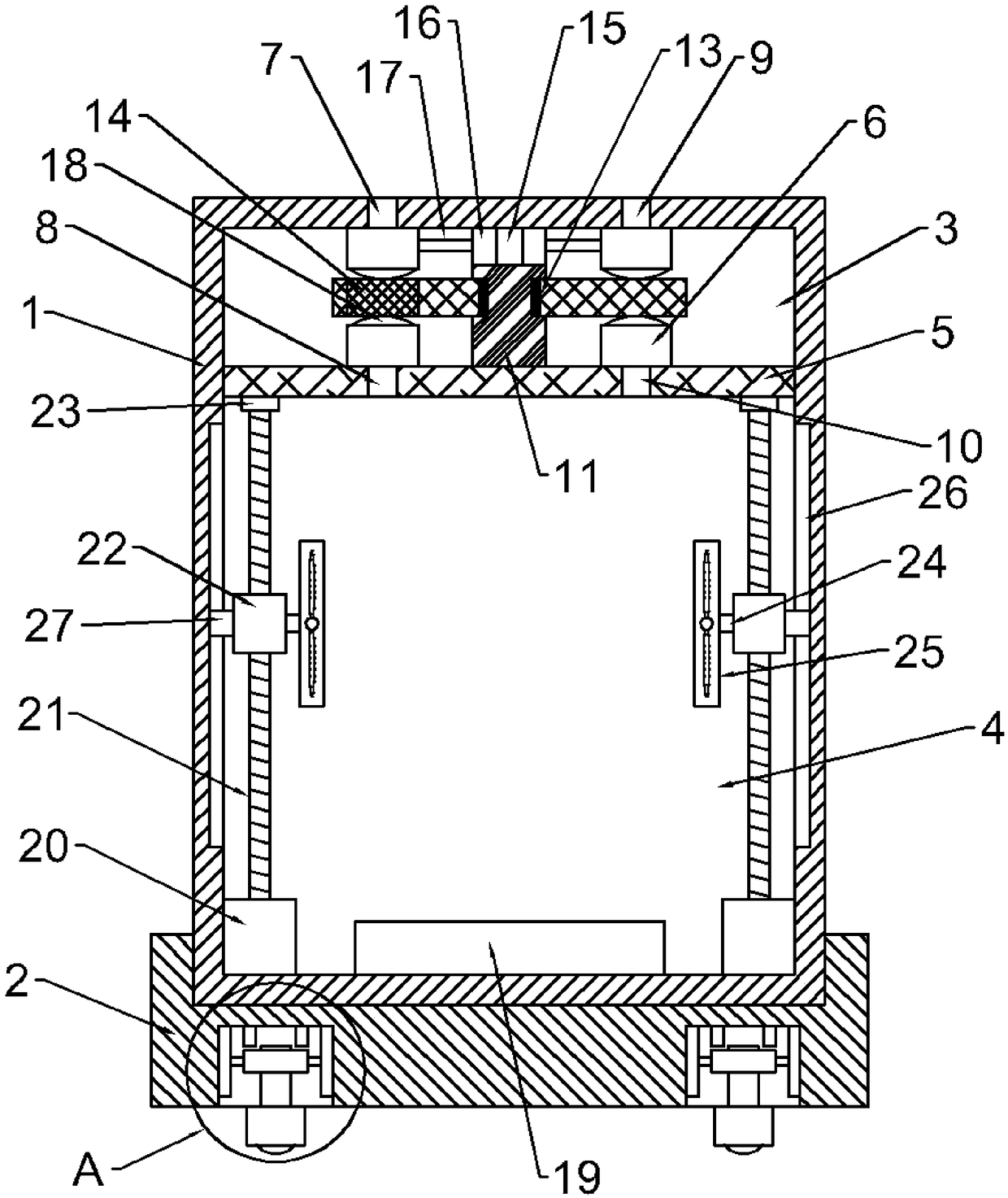

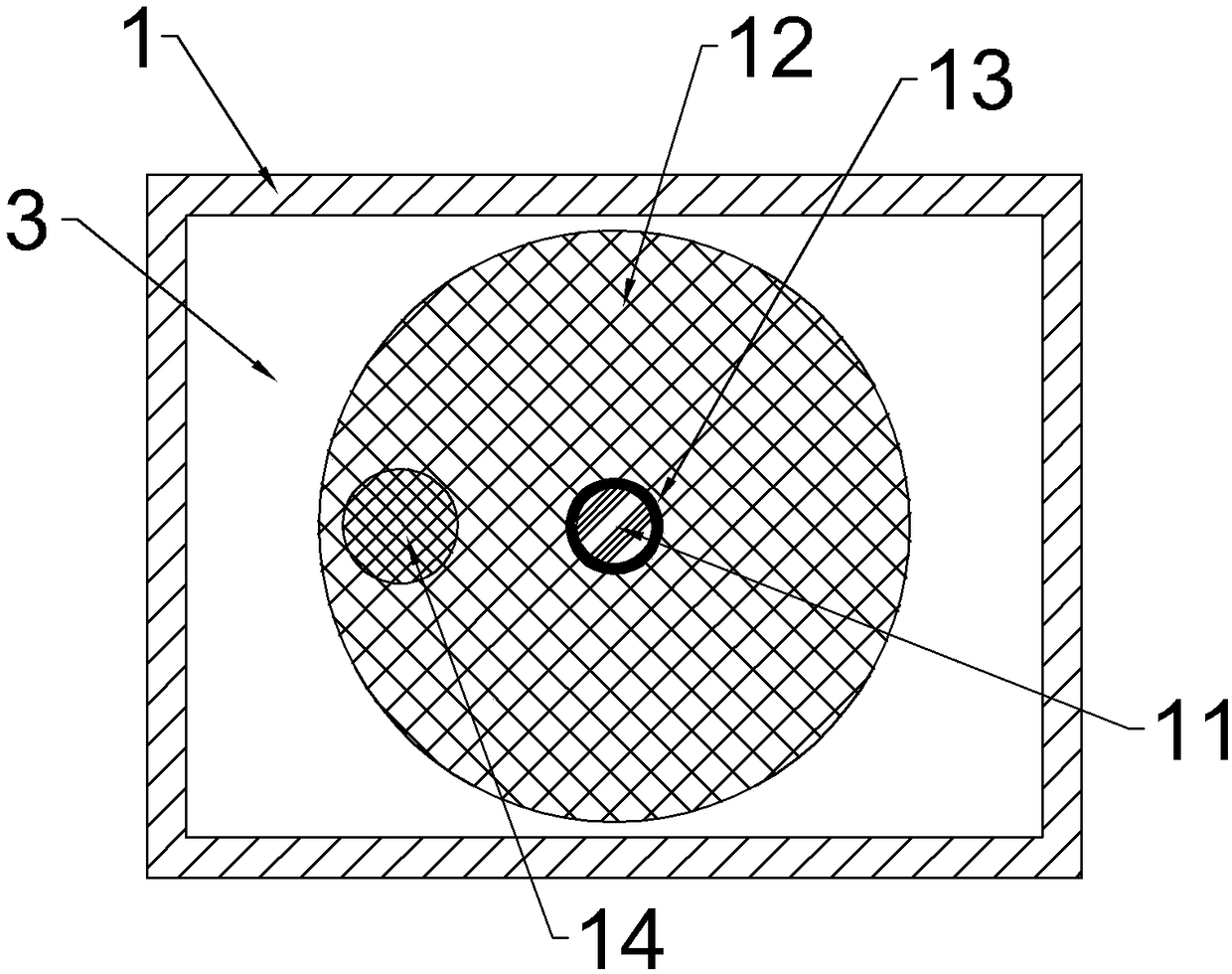

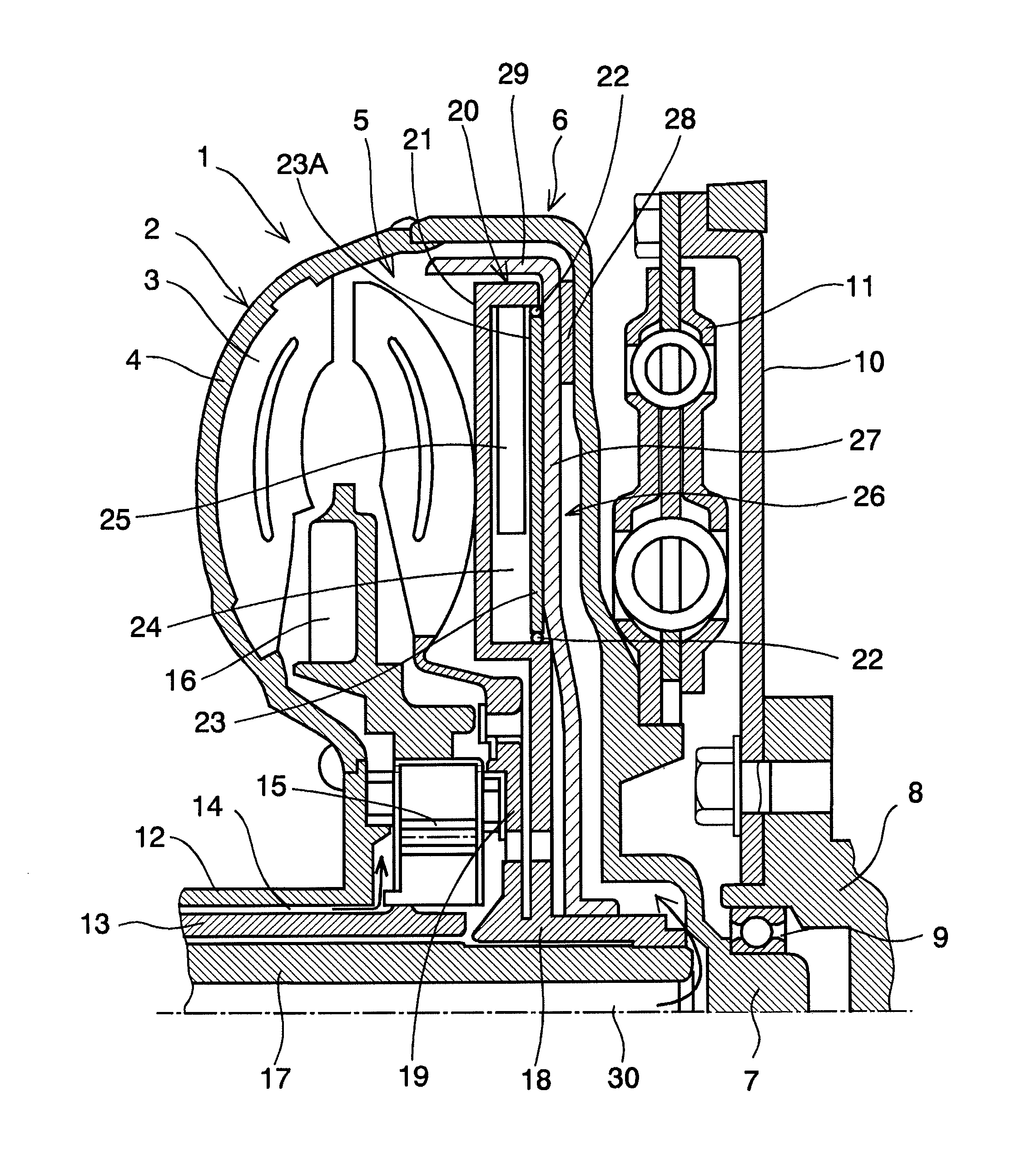

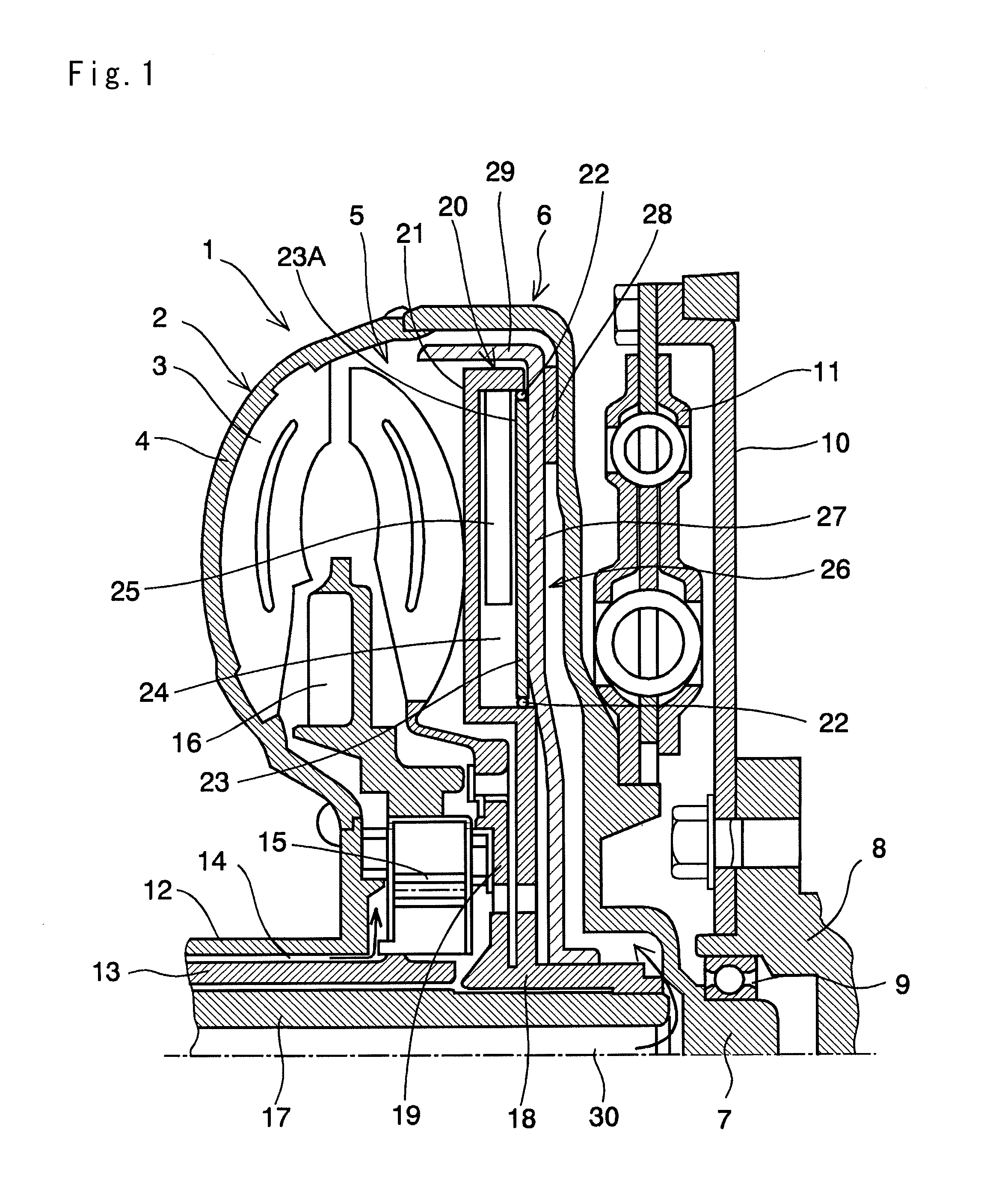

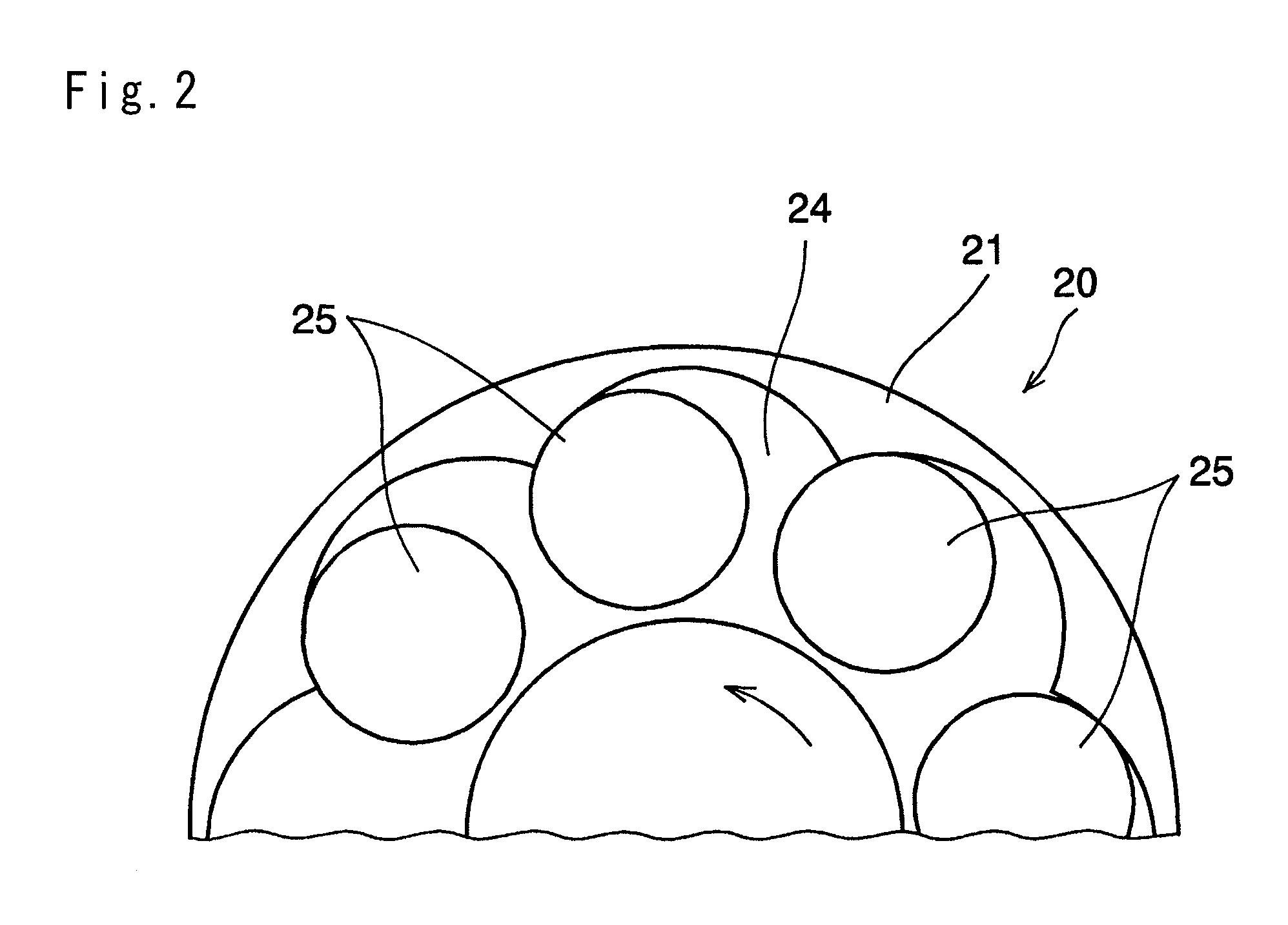

Vibration Damping Device

ActiveUS20130186724A1Reduce vibrationPreventing and suppressing noiseRotating vibration suppressionRotary clutchesImpellerEngineering

To provide a simply-structured vibration damping device having excellent vibration damping capacity.A vibration damping device is configured to damp torsional vibrations of a rotary member of a hydraulic transmission 1, in which the rotary member is rotated integrally with a drive side impeller 2 or with a driven side impeller 5, and in which the drive side impeller 2 and the driven side impeller 5 are connected with a lockup clutch 26 actuated by fluid pressure. The vibration damping device comprises: a holding chamber 24 rotated integrally with the driven side impeller 5; a rolling member 25 held in the holding chamber 24, which is rotated in a rotational direction of the driven side impeller 5 but allowed to rotate relatively with the driven side impeller 5; and a movable member 23 configured to lock the rolling member 25 in the holding chamber 24 when actuated by the fluid pressure for disengaging the lockup clutch 26, and to unlock the rolling member 25 in the holding chamber 24 when actuated by the fluid pressure for engaging the lockup clutch 26.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com